Page 1

EDGE User Manual

Firmware Version 4.5

Ag Leader PN 4002086 Rev. F

Page 2

Page 3

Table of Contents

General

Introduction and Company Profile .........................................................................1

ABOUT US..................................................................................................................1

INNOVATION..............................................................................................................1

COMPATIBILITY.........................................................................................................1

QUALITY AND SUPPORT..........................................................................................1

WE WANT TO HEAR FROM YOU! ............................................................................1

About the Display........................................................................................................1

SERVICE ....................................................................................................................2

SYSTEM USES...........................................................................................................2

SYSTEM FEATURES.................................................................................................2

DATA CARD USAGE..................................................................................................3

COLOR TOUCH SCREEN..........................................................................................3

CAN-BUS TECHNOLOGY..........................................................................................3

TECHNICAL SPECIFICATIONS.................................................................................3

SYSTEM UPGRADES................................................................................................3

Conventions Used in this Manual................................................................................4

Cautions and Warnings .........................................................................................4

Cross-References and Web Links.........................................................................4

Viewing this Manual Online ...................................................................................4

How to Find Information You’re Looking For.........................................................5

Display Hardware ..................................................................................................5

Installation Instructions..........................................................................................5

Mounting the Display........................................................................................6

Mounting Components.....................................................................................6

Fuse Installation and Replacement..................................................................7

Screen Icon Conventions.......................................................................................7

TABLE OF CONTENTS

Setup

System Functionality...................................................................................................9

Home Screen..............................................................................................................9

Setup Screen ............................................................................................................10

Management.............................................................................................................10

Grower Management Tab....................................................................................10

Importing an .MSF File...................................................................................11

Season Management Tab ...................................................................................11

Field Management Tab........................................................................................12

Import and Export Boundaries........................................................................12

Boundary Import .......................................................................................13

Boundary Export.......................................................................................13

Console.....................................................................................................................13

General Tab.........................................................................................................13

Memory Tab.........................................................................................................14

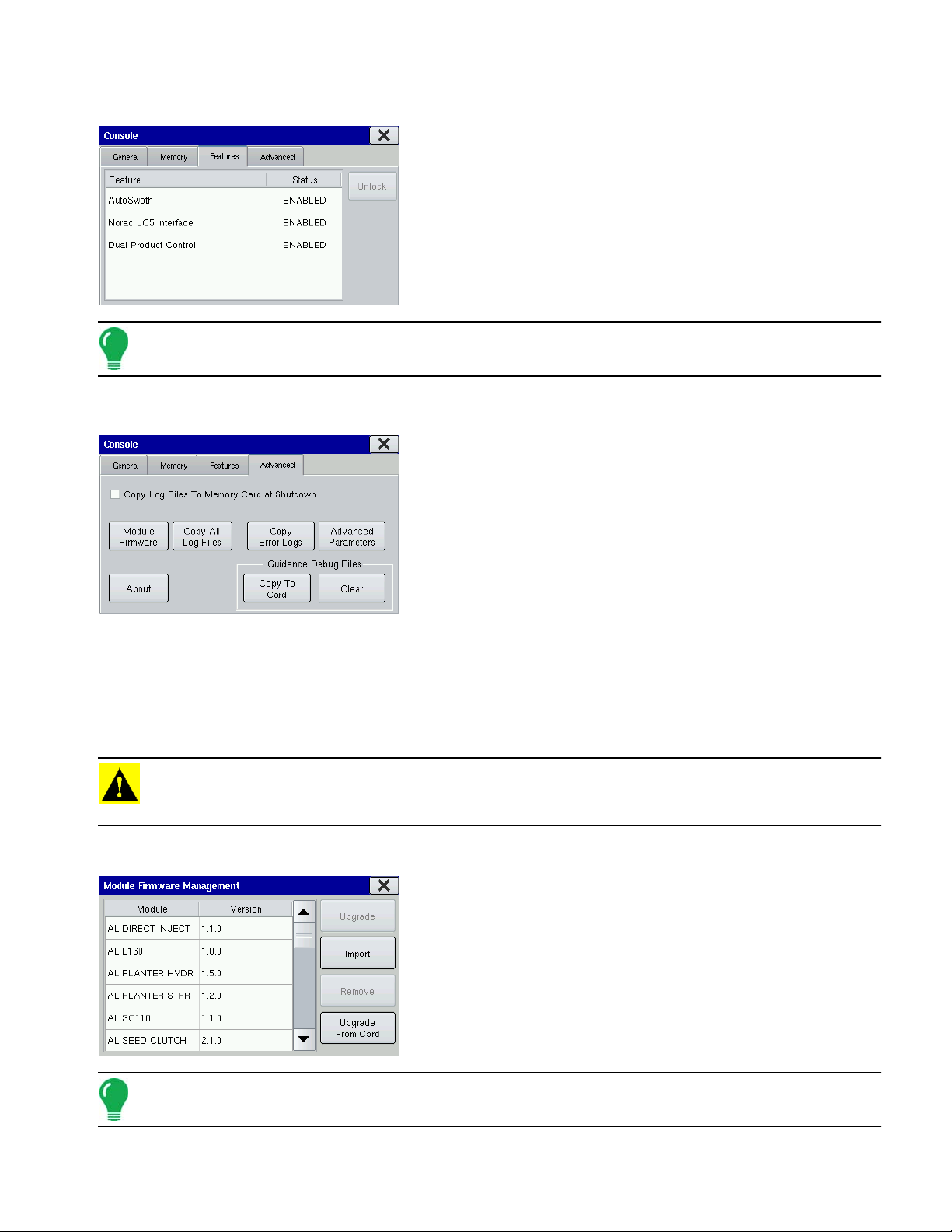

Features Tab .......................................................................................................15

Advanced Tab......................................................................................................15

iii

Page 4

Module Firmware Management..................................................................... 15

Field Notes ............................................................................................................... 16

Start Field Operation ................................................................................................ 17

Run Time Environment: Map Screen.................................................................. 18

Title Bar ......................................................................................................... 18

Task Bar Buttons........................................................................................... 18

Map Screen Icons.......................................................................................... 19

Map Screen Status Items .............................................................................. 21

Edit Legend .............................................................................................................. 21

Create a Boundary ................................................................................................... 22

Start Boundary............................................................................................... 22

Pause Boundary.................................................................................................. 22

View Boundary.................................................................................................... 23

View Map Markers .............................................................................................. 23

Summary.................................................................................................................. 23

Select Summary ............................................................................................ 24

Diagnostics............................................................................................................... 24

Device Information.............................................................................................. 24

Memory............................................................................................................... 24

Display ................................................................................................................ 25

GPS

GPS General Tab..................................................................................................... 27

OmniSTAR Settings ................................................................................................. 28

Serial Port Settings................................................................................................... 28

OmniSTAR Settings — GPS 2500........................................................................... 29

GPS Port Setup - GPS 2500.................................................................................... 30

GPS Diagnostics ...................................................................................................... 31

GPS Information - First Screen........................................................................... 31

GPS Information - Second Screen ..................................................................... 32

GPS Information - Third Screen.......................................................................... 32

OnTrac2 Information........................................................................................... 33

ParaDyme Information........................................................................................ 33

NTRIP Information .............................................................................................. 33

Guidance

GPS Guidance Tab .................................................................................................. 35

Guidance Control........................................................................................... 35

Pattern Files................................................................................................... 35

Lightbar Settings................................................................................................. 36

Guidance Functions.................................................................................................. 36

On-Screen Lightbar............................................................................................. 36

Guidance Screen ................................................................................................ 37

New AB Pattern............................................................................................. 38

SmartPath ..................................................................................................... 40

Creating a SmartPath Pattern.................................................................. 40

SmartPathNotes:...................................................................................................... 41

Select a Previous SmartPath Pass .......................................................... 41

iv

Page 5

Create an AB Line Within a SmartPath Pass............................................41

Choose Existing Lines Within SmartPath .................................................42

SmartPath Guidance Options...................................................................42

Save Pattern...................................................................................................43

Reset Pattern .................................................................................................43

Load Pattern...................................................................................................43

About Guidance Patterns.....................................................................................44

A+ Pattern ......................................................................................................44

Pivot ...............................................................................................................45

Adaptive Curve...............................................................................................46

Identical Curve ...............................................................................................46

Guidance Options................................................................................................47

Pause.............................................................................................................47

Remark A .......................................................................................................47

Shift................................................................................................................47

Adaptive Curve...............................................................................................47

Nudge..................................................................................................................48

OnTrac2....................................................................................................................48

OnTrac2 Setup Tasks..........................................................................................49

Vehicle Configuration...........................................................................................49

Edit Vehicle Settings............................................................................................50

OnTrac2 Tools Tab..............................................................................................51

Calibrating OnTrac2.......................................................................................52

OnTrac2 Steering Diagnostics .......................................................................53

Steering.....................................................................................................53

Drive Unit..................................................................................................54

Status........................................................................................................54

Adjust Disengage Sensitivity..........................................................................54

Minimum Output.............................................................................................54

OnTrac2 Advanced Tab.......................................................................................55

Vehicle Database......................................................................................55

Log Files ...................................................................................................55

OnTrac2 Run Time Environment.........................................................................55

Steering Adjustment.......................................................................................55

Tuning ............................................................................................................56

How the OnTrac2 System works....................................................................57

Steering.....................................................................................................58

Heading.....................................................................................................58

Cross Track...............................................................................................59

TABLE OF CONTENTS

Tillage

Run Time Environment: Map Screen........................................................................61

Create a Tillage Configuration ..................................................................................61

Create a Configuration...................................................................................61

Configuration Notes..................................................................................62

GPS Offsets..............................................................................................................62

Antenna Offsets...................................................................................................62

Hitch Tab Settings ...............................................................................................63

v

Page 6

Implement Offsets .................................................................................................... 63

Planting

Run Time Environment: Map Screen ....................................................................... 65

Map Screen: Zoom to Extent .............................................................................. 65

Map Screen: Zoom Detail ................................................................................... 65

Planting Map Screen Items................................................................................. 66

Planting Setup Tabs................................................................................................. 66

Create a Planting Configuration ............................................................................... 67

Configuration Settings.............................................................................................. 68

Configuration Settings: Equipment Configuration............................................... 69

Equipment Configuration Settings - SeedCommand................................ 69

Speed Input Settings........................................................................................... 69

Calibrate Distance ......................................................................................... 69

Auxiliary Input Settings (Switch Mapping)........................................................... 70

Add Auxiliary Input Settings ..................................................................... 70

AutoSwath........................................................................................................... 71

AutoSwath Notes........................................................................................... 72

Fixing Overplanting and Underplanting in AutoSwath................................... 72

Vehicle Tab............................................................................................................... 72

GPS Offsets........................................................................................................ 72

Antenna Tab.................................................................................................. 73

Hitch Tab ....................................................................................................... 73

Implement Tab.......................................................................................................... 74

Implement Offsets............................................................................................... 74

Section Offsets .............................................................................................. 74

Controller Tab........................................................................................................... 74

Controller Settings (SeedCommand).................................................................. 75

Product Tab.............................................................................................................. 75

Product Options .................................................................................................. 76

Add Product................................................................................................... 76

Import Product............................................................................................... 76

Product Settings.................................................................................................. 77

Planting: SeedCommand™ Machine-Specific Setup............................................... 77

Map Screen: Zoom to Extent .............................................................................. 78

Map Screen: Zoom Detail ................................................................................... 78

Planting Map Screen Items................................................................................. 79

Run Time Environment: Rate Screen....................................................................... 79

Planting Rate Control Configuration Screen....................................................... 80

Loading Prescriptions.................................................................................... 80

Row Shutoff.............................................................................................................. 81

Row Shutoff Configuration.................................................................................. 81

Row Shutoff Look-Ahead Numbers..................................................................... 83

Checking AutoSwath Performance for Row Shutoff ........................................... 83

Hydraulic Seed Rate Control.................................................................................... 84

Hydraulic Seed Rate Control Configuration........................................................ 84

Controller Settings for Hydraulic Seed Rate Motor Drives.................................. 85

Channel Tabs ................................................................................................ 85

vi

Page 7

Control Valve Settings - PWM ..................................................................86

Control Valve Settings - Servo..................................................................86

Auxiliary Tab...................................................................................................86

Hydraulic Seed Controller Settings for Specific Planter.................................87

John Deere Planters.................................................................................87

White Planters...........................................................................................87

Case IH Planters.......................................................................................87

Hydraulic Seed Meter Calibration Numbers...................................................87

Stepper Seed Rate Control.......................................................................................89

Stepper Seed Rate Control Configuration...........................................................89

Controller Settings for Stepper Seed Rate Motor Drives.....................................90

Channel Tabs.................................................................................................90

Auxiliary Tab...................................................................................................90

Gear Ratio Calculations for Seed Rate Motors....................................................91

Gear Ratio Drawing - For Single Motor Drive.................................................91

Gear Ratio Drawing - For Multiple Drive Combinations .................................92

Seed Ratio Calculation Example Procedure..................................................92

Gear Ratio Drawing - For John Deere Pro-Shaft™ Drives.............................93

Priming Seed Rate Meters...................................................................................94

Calibrating Seed Rate Meters..............................................................................94

Troubleshooting ........................................................................................................95

Zero Flow Offset Variation...................................................................................95

Hydraulic Seed Control: Zero Flow Offset Variation............................................96

Stepper Seed Control Meter Alarms....................................................................96

Diagnostics................................................................................................................97

Clutch Diagnostics (for Row Shutoff)...................................................................97

Input Diagnostics.................................................................................................97

TABLE OF CONTENTS

Application

Run Time Environment: Map Screen........................................................................99

Map Screen - Zoom to Extent..............................................................................99

Map Screen: Zoom Detail....................................................................................99

Application Map Screen Items...........................................................................100

Application Setup Tabs...........................................................................................100

Create an Application Configuration .......................................................................101

Configuration Settings.............................................................................................103

Configuration Settings: Equipment Configuration..............................................103

Configuration Settings - Area Logging....................................................103

Edit Configuration Settings - Area Logging.............................................103

Configuration Settings - DirectCommand.....................................................104

Configuration Settings - DirectCommand ...............................................104

Speed Input Settings .........................................................................................104

Calibrate Distance........................................................................................104

Auxiliary Input Settings......................................................................................105

Add Auxiliary Input Settings....................................................................106

Fence Row Nozzle Indicators.................................................................106

AutoSwath .........................................................................................................107

AutoSwath Notes..........................................................................................108

vii

Page 8

Vehicle Tab............................................................................................................. 108

GPS Offsets...................................................................................................... 109

Antenna Tab................................................................................................ 109

Mount Tab.................................................................................................... 109

Hitch Tab ..................................................................................................... 109

Implement Tab........................................................................................................ 110

Implement Offsets............................................................................................. 110

Section Offsets ............................................................................................ 110

Controller Tab......................................................................................................... 111

Controller Settings (DirectCommand)............................................................... 111

Product Tab............................................................................................................ 112

Product Screen ................................................................................................. 112

Product Settings .......................................................................................... 113

Product Options ................................................................................................ 113

Tank Mix Setup................................................................................................. 114

Dry (Granular) Fertilizer Blend Setup................................................................ 114

Miscellaneous Items............................................................................................... 115

Fertilizer Default Product Settings..................................................................... 115

John Deere Specific Instructions....................................................................... 116

MASTER SWITCH INPUT...................................................................................... 116

MASTER SWITCH USAGE.................................................................................... 116

TARGET RATE ...................................................................................................... 117

DATA COLLECTION.............................................................................................. 117

AUTOSWATH BOOM SECTION CONTROL......................................................... 117

SPRAY STAR APPLICATION RATE ..................................................................... 117

SPRAY STAR RINSE CYCLE................................................................................ 117

Control Valve Settings............................................................................................ 117

Liquid Product Control Valve Configuration...................................................... 117

Servo Control Valve Settings (By Manufacturer) .............................................. 119

Control Valve Settings for Self-Propelled Sprayers .......................................... 121

Liquid Servo Settings Description..................................................................... 124

Liquid PWM Control Valve Settings Description............................................... 125

Spinner Spreader Servo Settings Description................................................... 125

Spinner Spreader PWM Control Valve Settings Description............................. 126

Spinner Speed PWM Valve Settings Description.............................................. 126

Dickey John NH3 Conversions ......................................................................... 127

Conversion Formulas............................................................................. 127

Application: DirectCommand™ Machine-Specific Setup........................................ 127

Map Screen: Zoom to Extent.................................................................................. 128

Map Screen: Zoom Detail....................................................................................... 128

Application Map Screen Items .......................................................................... 129

Run Time Environment: Rate Screen..................................................................... 129

Target Rate.................................................................................................. 129

Rate Screen: Container Level........................................................................... 130

Tank Fill....................................................................................................... 130

Tank Empty.................................................................................................. 131

Tank Partial Fill............................................................................................ 131

Adjust Container Amount ....................................................................... 131

Tank Alarms................................................................................................. 131

viii

Page 9

Container Alarm Screen..........................................................................131

Rate Screen: Liquid Flow/Pressure...................................................................132

Rate Screen: Spinner Spreader Settings...........................................................132

Spinner Spreader Product Settings..............................................................132

Spreader Control..........................................................................................133

Application Rate Control Configuration Screen.................................................134

Loading Prescriptions...................................................................................134

Shape File Conversion............................................................................................135

Liquid Application Control .......................................................................................136

Liquid Application Control Configuration............................................................136

Liquid Application Controller Settings................................................................139

Controller Settings - PWM ......................................................................139

Controller Settings - Servo, Calibrated Reflow or Ramsey Valve...........140

Rate Error Alarm Threshold...............................................................................140

Direct Injection ........................................................................................................141

Direct Injection Configuration Setup..................................................................141

Direct Injection Controller Settings ....................................................................143

Priming an Injection Pump.................................................................................144

Calibrating an Injection Pump............................................................................144

Injection Diagnostics..........................................................................................146

Spinner Spreader Granular Control ........................................................................147

Spinner Spreader Control Configuration............................................................147

Spinner Spreader Controller Settings................................................................148

Controller Settings - Spinner Spreader ........................................................148

Controller Settings - PWM ......................................................................149

Controller Settings - Servo......................................................................149

Fan Settings.................................................................................................150

Conveyor Rate and Product Density Look-Up...................................................150

NORAC UC5 Setup.................................................................................................151

Norac UC5 Setup Screen..................................................................................151

Automatic Setup...........................................................................................151

Retune..........................................................................................................152

Minimum Height Settings .............................................................................152

Norac UC5 Run Time Environment...................................................................153

Boom Height Screen....................................................................................153

Engage button.........................................................................................154

Boom Height Control Options.......................................................................154

Troubleshooting ......................................................................................................154

Troubleshooting DirectCommand Liquid Applications.......................................154

Troubleshooting Direct Injection Configurations................................................157

Direct Injection: Pump Doesn’t Run .............................................................157

Battery Power Pin-Outs...........................................................................................158

Direct Injection: Pump Runs Full Speed.......................................................158

Direct Injection: Application Error.................................................................159

Direct Injection: Discharge Flow Sensor Error .............................................159

Discharge Flow Sensor Pin Outs............................................................................160

Direct Injection: Inlet Restriction...................................................................160

VACUUM SWITCH PIN OUTS ...............................................................................160

Troubleshooting DirectCommand Granular Applications...................................160

TABLE OF CONTENTS

ix

Page 10

Troubleshooting Serial Control Applications (Liquid and Granular).................. 161

Troubleshooting Serial Control Applications (Liquid Only)................................ 162

Troubleshooting Serial Control Applications (Granular Only) ........................... 162

Miscellaneous......................................................................................................... 162

Glossary of Application Settings ....................................................................... 162

Configuration Settings ................................................................................. 162

Speed Input Settings ................................................................................... 162

Automatic Swath Control Settings............................................................... 163

Auxiliary Input Settings................................................................................ 163

Controller Settings....................................................................................... 163

Controller Settings: Direct Injection Pump Calibration................................. 164

Pump Calibration Setting........................................................................ 164

Rate Response Warning........................................................................ 164

Flow Monitor Warning ............................................................................ 164

Run Screen.................................................................................................. 165

Diagnostics............................................................................................................. 165

Input Diagnostics............................................................................................... 165

Harvest

Run Time Environment: Map Screen ..................................................................... 167

Map Screen: Zoom to Extent ............................................................................ 167

Map Screen: Zoom Detail ................................................................................. 167

Harvest Button on Task Bar......................................................................... 168

Map Screen: Flow Delay................................................................................... 168

Run Time Environment: Harvest Screen................................................................ 169

Harvest Screen Display Items........................................................................... 169

Harvest Screen - Active Display Items.............................................................. 170

Harvest Setup Tabs................................................................................................ 171

Create a Harvest Configuration.............................................................................. 171

Configuration Settings....................................................................................... 172

Primary and Backup Speed Source............................................................. 172

Calibrate Distance ....................................................................................... 172

Combine Tab.......................................................................................................... 173

Combine Settings.............................................................................................. 173

Advanced Combine Settings ....................................................................... 173

Map Delays.................................................................................................. 173

GPS Offsets................................................................................................. 174

Antenna Offsets...................................................................................... 174

Head Offset............................................................................................ 174

Header Tab............................................................................................................. 174

Header Settings ................................................................................................ 175

Calibrate Header Sensor................................................................................... 175

Header Offset.................................................................................................... 176

Crops Tab............................................................................................................... 176

Crop Settings .................................................................................................... 177

Calibration Tab....................................................................................................... 177

Pre-Harvest Checklist ....................................................................................... 178

Calibration Sequence .................................................................................. 178

x

Page 11

Vibration Calibration.....................................................................................178

Temperature Calibration...............................................................................179

Moisture Calibration .....................................................................................179

Grain Weight Calibration..............................................................................179

Adding a New Calibration..................................................................................182

Diagnostics..............................................................................................................184

Appendix

“Company Warranty Statement” on page 186System Diagrams Reference ..........185

File Formats............................................................................................................185

Prescription Map File Types..............................................................................185

Boundary and Guideline File Types...................................................................185

System File Types.............................................................................................185

Module LED Diagnostic States ...............................................................................186

LED display........................................................................................................186

Company Warranty Statement................................................................................186

WARRANTY............................................................................................................186

PROPRIETARY TECHNOLOGY NOTICE............................................................................................... 186

COPYRIGHT NOTICE............................................................................................186

SERVICE AND SUPPORT .....................................................................................187

TABLE OF CONTENTS

xi

Page 12

xii

Page 13

GENERAL

GENERAL

INTRODUCTION AND COMPANY PROFILE

ABOUT US

Welcome to the Ag Leader Technology family. Ag Leader Technology, Inc. is the global leader in yield

monitor and precision farming systems and is committed to meeting the present and future needs of the

agriculture industry by providing high quality products and first class customer support.

INNOVATION

Ag Leader Technology manufactures and sells products which support a wide array of precision farming

practices. These include grain and cotton yield monitoring, application rate control and monitoring,

variable rate fertilizer application, site-verification, GPS guidance and interface to Autosteer

technologies.

COMPATIBILITY

GENERAL

Ag Leader Technology offers compatibility and supports integration of many different types and brands

of equipment used for precision farming. The latest equipment available is supported as well as older

series of combines, planters, sprayers, tillage equipment, etc.

QUALITY AND SUPPORT

Ag Leader Technology continues to provide the best customer support in the industry. Precision farming

doesn't come without questions. Ag Leader is committed to providing the most responsive,

knowledgeable and friendly technical support available. Our technical support team is available sevendays-a-week during peak seasons to answer your questions on the operation of Ag Leader products.

WE WANT TO HEAR FROM YOU!

Feel free to call and discuss:

• Operational questions about the display

• Features you would like to see implemented to improve the system or features you would like to see

added to the system to increase functionality

ABOUT THE DISPLAY

This display provides an entry-level precision farming solution to meet the year round needs of today’s

precision farming operation. It combines a greater level of simplicity with SeedCommand™,

DirectCommand™ and yield monitoring capabilities to meet the year-round needs of today’s precision

farming operation.

1

Page 14

The display is a GPS-compatible universal monitor/controller for use in crop production and protection. It

can easily be transferred between multiple vehicles through out the growing season to maximize your

return on investment cost.

The display features a 6.5-inch color touchscreen in which users will find a greater level of simplicity

combined with SeedCommand, DirectCommand and yield monitoring capabilities. The display is ideal

for operations just getting started in precision farming, but also fits operations requiring multiple displays.

Support for the AutoSwath feature makes the display a great investment for any operation looking for an

easy-to-use, input-cost saving solution.

The display has its own internal memory for recording GPS and logging all information collected during

various field activities. No external data card is needed for in-field data collection.

The display has been built to withstand the harsh environment associated with today's agricultural

industry. The weather-tight enclosure is designed to seal out any dirt and moisture that is encountered

during normal operating conditions.

Note: The card door slot must be fully closed for the display to remain weather-tight.

SERVICE

There are no user-serviceable parts inside the display. Ag Leader Technical Support ph: (515) 232-5363

fax: (515) 232-3595

e-mail: support@agleader.com

CAUTION: This display has an internal lithium coin cell battery and an internal nickel metal hydride battery.

There is a risk of explosion if either battery is replaced by an incorrect type. Dispose of used batteries

according to the battery manufacturer’s instructions.

SYSTEM USES

• Grain yield monitoring

• Variety logging

• Liquid spray system control

• NH3 application control

• Granular and liquid fertilizer application

• Mapping tillage operations

• Mapping and logging product application

• Mapping of all field boundaries, sub-boundaries, waterways and terraces

SYSTEM FEATURES

• 6.5" color display

• Sunlight-readable screen

• Large internal memory

• Rugged sealed enclosure

2

Page 15

• Compatible with most NMEA GPS receivers

• DirectCommand product control using industry standard CAN-bus interface

• Adjustable volume control

DATA CARD USAGE

The display uses a compact flash card for transferring data in and out of the display. The system is

compatible with all current card sizes; 64 MB is the minimum recommended size for use with the system.

COLOR TOUCH SCREEN

The display features a 6.5-inch color touch screen display. The touch screen allows easy and intuitive

navigation through the screens on the display without the need for any external keypad or mouse

devices. Here are a few key things to remember if you are new to using a touch screen device.

• Do not use any sharp objects for running the touch screen device, this could result in damage to the

display. Using the tip of a finger is the recommended method of operating the display touch screen.

• Do not use any harsh chemicals to clean the touch screen. Using a damp soft cloth or an anti-static wipe

made specifically for cleaning computer displays is the correct way to clean the screen and the display

enclosure.

• The touch screen requires only a gentle touch of about half-second in duration to operate correctly. A

common mistake new users make is to try to navigate too quickly through the system using firm taps

instead of gentle presses on the display screen.

GENERAL

CAN-BUS TECHNOLOGY

The display uses Controller Area Network (CAN) technology. CAN systems are comprised of individual

modules, each with their own high speed processor, connected through a high-speed communications

cable. CAN has many benefits, including greater ability to configure and expand the system,

compatibility, simpler installs with less wiring, and increased system dependability.

TECHNICAL SPECIFICATIONS

Do not exceed the specifications below:

• Storage Temperature: -30°C to +70°C.

• Operating Temperature: -10°C to +65°C

• Operating Input Voltage: 9 –16 V DC

CAUTION: Exceeding these specifications may result in degraded operation and/or damage to the display.

SYSTEM UPGRADES

Ag Leader Technology will periodically provide operating program updates that will improve the

performance of your display. Required software updates will be available free of charge for download

from

www.agleader.com. On occasion, major releases will be made available that have significant product

feature additions or enhancements. These optional software updates may have an additional fee

associated with them.

3

Page 16

When registering your Ag Leader Technology products by one of the following methods, you can elect to

receive notice of any new product updates or features.

Register by mail: Ag Leader Technology

2202 South Riverside Dr.

P.O. Box 2348

Ames, IA 50010

Register by Fax: 515-232-3595

Register at the Ag Leader Web site at

http://www.agleader.com

CONVENTIONS USED IN THIS MANUAL

CAUTIONS AND WARNINGS

The user manual uses the following text formatting schemes to call attention to information related to

simplifying system operation and proper operating practices to prevent accidental data loss. If in doubt

about the results of performing an action or deleting an item from the system, back up all system files to

the external storage card prior to proceeding with the action.

Note: Provides informative tips to assist with system setup, calibration, and operation.

CAUTION: Indicates specific settings, calibrations, and procedures that must be followed for proper system

performance and operation.

WARNING: Indicates specific instructions to avoid accidental loss of data and system configurations

settings.

CROSS-REFERENCES AND WEB LINKS

Throughout this manual, numerous cross-references are provided to other pages or sections. These

cross-references are always shown in blue, italic text; and list the title and page number If you are

viewing this manual in a .PDF format, you can click on this blue text and go directly to the link.

Links to web sites are shown in blue, italicized, and underlined text, as in the following example: To see

the web site, go to:

www.agleader.com.

VIEWING THIS MANUAL ONLINE

This user manual can be viewed online at Ag Leader’s Web site. To view an online version, go to the Ag

Leader Web site, and click the Support link. You should see a page titled “Manuals and Quick Reference

Sheets.”

To view and/or print the display’s User Manual online, you will need the Adobe Acrobat or Adobe Reader

.pdf file format. The Adobe Reader software comes pre-installed on most personal computers. If Adobe

Reader is not installed on your computer the program is available for download at no charge. A link to

the Adobe download site is located at the Ag Leader Web site.

4

Page 17

HOW TO FIND INFORMATION YOU’RE LOOKING FOR

What do you do if you cannot find the information that you’re looking for? There are three different ways

at your disposal to find specific information quickly. These steps can include:

1. Look up the information in the Table of Contents.

2. Look up the information in the section indexes that are located at the end of each manual section

(Planting, Tillage, Application, and Harvest).

3. Use the Adobe Reader’s search function. While viewing this manual online in PDF format, press the

CTRL+F buttons on your keyboard. A search menu should appear, and from here, you may enter in a

search term.

DISPLAY HARDWARE

GENERAL

Front Back

• (A) Compact Flash Card Slot

The compact flash card slot has a sensor that allows the display to know when the door is open or closed.

If the door is opened when a card is in the display, an on-screen warning will appear indicating when the

card can safely be removed. The display comes with a compact flash card. The compact flash card will be

required to transfer files from the display to a desktop computer.

• (B) RAM Mount

For more information, see

• (C) 28-Pin Connector

The 28-Pin round connector contains CAN, RS-232 serial, and system power and ground connections.

• (D) Speaker

The built-in speaker is used for audible warnings. The speaker volume can be adjusted through the display

setup routine.

• (E) Power/Reset Switch

The Power/Reset switch is used for turning the display on and off in installations where the system is

connected to a continuous power supply. If the display ever stops responding, the manual power switch

may be held in for five seconds to restart the system. Only do this as a last resort, data loss could occur

during times of improper shutdown.

“Mounting the Display” on page 6.

INSTALLATION INSTRUCTIONS

All machine installation and mounting kits are shipped with instructions specific to that kit. Instructions

include special details relating to mounting, wiring and display configuration.

5

Page 18

Mounting the Display

Mount the display to a secure support inside the vehicle cab. The following must be considered when

choosing a mounting location.

• The display must be readily accessible to the machine operator.

• The display must not obstruct the machine operator's normal driving view.

• The display must not interfere with or limit access to any of the existing machine controls.

• The display CAN system cabling be routed and secured without interfering with existing machine controls.

WARNING: If drilling holes is required during the mounting process, care must be taken to insure that

damage is not done to existing vehicle wiring, mechanical, or cab structure. Refer to vehicle manufacturer

documentation for specific details on your equipment. Follow all OEM instructions, cautions, and warnings

when working around equipment.

Mounting Components

1. RAM Base, PN 4000280

2. RAM Arm - 5”, PN 4000279

3. 2”X6” Base, PN 400187

6

Page 19

Fuse Installation and Replacement

GENERAL

CAUTION: The fuse is to be placed in the fuse holder in-line with the battery power cable and used with

display only.

SCREEN ICON CONVENTIONS

The following control buttons are made available for entering names and calibration values into the

display.

7

Page 20

An on-screen Keyboard is made available when appropriate

for use during all setup processes. Press the keyboard

button to access the on-screen text entry screen.

An on-screen Numeric Keypad is made available for

changing configuration settings and calibration numbers.

Press the keypad button to access the on-screen numeric

entry screen.

8

Page 21

SETUP

SETUP

SYSTEM FUNCTIONALITY

Prior to setup, most of the functionality of the display is not

available until the basic setup process is completed, and the

Home screen will look like the picture below. The Run Time

Environment is not accessible, because the Map button does

not appear on the task bar at bottom.

You must complete these initial configuration steps for the Run

Time Environment to be active:

1. Grower, Farm, and Field management.

For more information, see

2. Equipment Operating Configuration.

For more information, see the configuration information described in each Operations chapter (for example,

Planting, Application, Tillage, etc.).

3. Product setup.

For more information, see the configuration information described in each Operations chapter.

“Management” on page 10.

SETUP

4. Start Field Operation.

For more information, see

“Start Field Operation” on page 17.

HOME SCREEN

After a Grower, Farm and Field has been selected, the Home

screen will appear as shown. Specific functions available at the

Home screen are described in the table below.

• Diagnostics button

Opens screens that display Device Information, Memory, Display, and module diagnostics.

For more information, see

The Start Field Operation button, the top center button which shows the Grower Farm and Field, opens

the Field Operation Wizard where you can enter information relating to your Growing Season, Grower,

Farm, Field, Crop Type and Product. For more information, see

“Diagnostics” on page 24.

“Field Notes” on page 16.

• Setup (wrench) button

Opens the Setup screen. For more information, see

“Setup Screen” on page 10.

9

Page 22

• View Operation Summary button

Opens the Select Summary screen, where you can select different configuration settings for

Seasons, Grower, Farm, Field, Operations, and Product. For more information, see

on page 23.

SETUP SCREEN

The Setup Screen is where you can access management information, adjust display and

GPS settings, and specify field operations. Begin by going to the Home Screen, and pressing

the Setup (wrench) tool. The Setup Screen appears, as shown.

“Summary”

Press the Management button, and the Management tabs

appear. These are described on the following pages.

MANAGEMENT

The Management tabs, which are accessible from the Management button on the Setup

screen, include Grower, Season and Field.

• For information on the Season Tab, see

• For information on the Field Tab, see

“Field Management Tab” on page 12.

GROWER MANAGEMENT TAB

The Grower is a global setting that refers to the business or

person the system is in operation for. Contact information can

be added for each grower. The Grower information will be

passed into mapping software for automatic Grower setup

within desktop software.

• Press the Add (plus sign) button to add a Grower.

• Press the Delete (minus sign) button to delete a Grower.

• You may edit an existing name of a Grower by highlighting that name and pressing the on-screen

keyboard.

“Season Management Tab” on page 11

.

• Press the Wrench Button to add or edit information for a Contact Person, Business Phone, Mobile

Phone, or import an .msf file. For more information on adding an .msf file, see

on page 11.

10

“Importing an .MSF File”

Page 23

Importing an .MSF File

A Management Setup File (.msf) is a file format that allows the display to import Grower and Field

information from desktop software via a Compact Flash Card. Follow the process outlined below to

import desktop software information from your Compact Flash Card.

Note: When importing management items from an .MSF setup file, the imported data will always update or

be added to existing management data and will not overwrite it.

1. In the Grower Tab, press the Wrench Button. A screen opens, showing the name of that

Grower in the Title Bar, as shown.

2. Press the Import MSF button, and the File Selection screen

appears. (Be sure that your Compact Flash Card is already

placed in the display)

3. Open this folder by pressing the Plus sign to the left of the

folder. Highlight the desired .msf file and press the checkmark

box.

SETUP

4. The .msf file now appears under the Grower Tab on the

Grower list.

SEASON MANAGEMENT TAB

A season is defined as the calendar year that the crop will be

harvested. Creating a season and setting it to active is

required prior to the system logging any data.

The seasons are displayed in lists, with the Active season

displayed in bold face type. All new data is logged to the active

season; therefore a season must be set as Active before you

can log any new data to it.

• Press the Add (plus sign) button to add a Season.

• Press the Delete (minus sign) button to delete a Season.

• You may edit an existing name of a Season by highlighting that name and pressing the on-screen

keyboard.

• Press the Set Active button to set the season selected in the Summary list box to the active season.

• Press the Season Reminder button to set the date that the system will prompt the user to create a new

season.

11

Page 24

FIELD MANAGEMENT TAB

A field consists of one or more outer boundaries. Each outer boundary can contain one or more inner

boundaries used to define any combination of roadways, waterways, building sites, or bodies of water. If

the display will be used for multiple Growers, enter each Grower business name and associate the field

names with the correct grower when the fields are setup within the system.

In the Field Tab, select a Grower underneath the drop-down

menu at the top. Each farm of that particular grower is shown

in a list, with the fields within that farm as subcomponents

within that list.

• Press the Add (plus sign) button to add a Field.

• Press the Delete (minus sign) button to delete a Field.

• You may edit an existing name of a Field by highlighting that

name and pressing the on-screen keyboard.

• Press the Wrench Button to add or edit information regarding that field and its boundary. The Field

Information screen opens, showing the name of that field in the Title Bar.

The example shows the “160” Field of the “Home” Farm.

• Farm

Name of farm.

• Area

Total acres of farm.

• Clear bounds

Press the Clear Bounds button to center the map on the current

GPS position. This is particularly useful if you have flyer points or

have logged a point outside the mappable range of your current location.

• FSA Number

The U.S. Farm Service Agency’s four-digit number assigned to every farm.

• FSA Area

Tillable acres as established by the FSA.

• Boundary

Press the Boundary button to import and export boundaries. A detailed explanation is described on the

following pages.

Import and Export Boundaries

Boundaries can be created with the display or imported from

desktop GIS software. For more information on creating

boundaries, see

files present in the display can also be exported for use in

desktop mapping software. Begin by pressing the Boundary

button on the Field Information screen, which can be viewed

after pressing the Field Tab’s Wrench Button button. The View

Boundary screen appears.

“Create a Boundary” on page 22. Any boundary

12

Page 25

Boundary Import

Boundary Export

SETUP

1. To import a boundary from the external data card, press

Import. The File Selection screen appears, as shown.

2. Select the desired file to import.

3. Press the checkmark box on the File Selection screen to

complete the import process.

1. To export a boundary to the external data card, press

Export.

2. A screen appears, telling you that the boundary was

exported successfully. Press the checkmark box.

3. Press the checkmark box on the View Boundary screen.

CONSOLE

The Console screen contains settings related to Time, Date, display console screen

settings, operating units and external card information. To go to the Console screen, press

the Console button on the Setup screen. The Console screen consists of four tabs: General,

GENERAL TAB

Note: The display will then shut down immediately. If you do not want to shut the monitor down, press the

Close (Red X) button.

• Brightness and volume percentages

To change these, press the Brightness/Volume button and use the up and down arrow buttons to change

the percentage of the Display Brightness and Speaker Volume.

Memory, Features and Advanced.

The General Tab consists of the following items:

• Time and Date settings

To change these, press on this button and use the up and down

arrow keys to adjust the hours, minutes, A.M./P.M. settings, month,

date and year. To make these changes effective, press the

checkmark/ Shutdown button.

• Calibrate Touchscreen

Press this to launch the Touch Screen Calibration wizard. Calibrate the touch screen by following the onscreen instructions.

13

Page 26

• Time Zone

Use the drop-down menu to select your time zone.

• Country/Language Selection

Use the drop-down menu to select the language.

• Operating Units

Select either Imperial or Metric.

MEMORY TAB

The Memory Tab displays the used and free space available

on the external data card, as well as the percentage of memory

used on that card.

The Memory Tab also includes the following items:

• Create Backup

Press to create a backup file of all configuration settings, products, and Grower-Field Management data

structure on the external memory card. Backup files are stored using the .ibk file format.

• Restore Backup

Press to restore a backup file from the external data card to the internal memory of the display.

• Copy to Card

Copies files which have not yet been copied to the external storage card. (Log files are stored using the .ilf

file format).

• Upgrade

Press to load program upgrade files from the external storage card in order to upgrade the display and

modules.

• Browse Files

Press to view all files on the external memory card.

• Clear Internal Memory

Press this button to clear the internal memory of the monitor. The system will present a warning dialog box

and ask if you would like to create a backup file prior to clearing the memory.

CAUTION: The display will be returned to a “new out-of-box” un-configured state when the memory is

cleared.

14

Page 27

FEATURES TAB

Unlock codes are unique to the serial number of each display

and the feature registration number. You must supply these

numbers to your dealer when purchasing any unlock codes.

Press the Unlock button, and the Feature Registration box

appears. Use the on-screen keyboard to enter the unlock code

and press the checkmark box to enable the feature. This

feature then appears and the status is shown as “Enabled”.

Note: Once a feature is unlocked, that feature remains with that display and cannot be transferred to another.

ADVANCED TAB

The Advanced Tab contains the following functions of interest

to most users:

• Copy Log Files to Memory Card at Shutdown

Checking this checkbox will copy all log files to the external

memory card when the display is turned off.

SETUP

• Copy All Log Files

Press to copy all logged data in the display to the external storage

card.

• About

Displays product licensing information and copyright information.

• Module Firmware Management

Displays a list of all firmware modules and firmware versions that are available for the display. For more

information, see

CAUTION: The Advanced Parameters, Copy Error Logs, Guidance Debug Files (Copy to Card, and Clear)

functionality is reserved for use by the manufacturer. Do not change any of these settings without specific

instruction from Technical Support.

“Module Firmware Management” on page 15

.

Module Firmware Management

The Module Firmware Management screen displays a list of all

firmware modules and firmware versions that are available for

the display.

Note: The Module Firmware Management list includes module firmware that you may not be running.

15

Page 28

• Upgrade

Makes necessary upgrades to all the modules’ firmware while the display’s firmware is upgraded.

• Import

Imports any firmware stored on the Compact Flash Card into the display memory.

• Remove

Removes unwanted module firmware from the Module Firmware Management list.

Note: Pressing the Remove button does not remove firmware from the module itself. It merely removes the

upgrade file from the display.

• Upgrade from Card

Upgrades an individual module directly from the Compact Flash Card.

FIELD NOTES

Markers are a collection of point objects shown as icons on the Map Screen. As the name suggests,

markers allow the operator to mark mapping points “on the go” and thus identify specific features within

a field.

You can create markers by pressing the Field Notes button on the Setup screen. The Field

Notes screen opens.

• Add

Press the Add button to add a Field Note. This marker then

appears on Map Options at the Map screen. For an

example, see

• Keyboard button

Press the on-screen keyboard button to edit the marker

name.

• Up and down arrow buttons

Press the up and down arrow buttons to rearrange the

order of the map icons.

• Change Icon button

Opens the Icon Selection screen, as shown, where you can change the appearance of a map icon.

“View Map Markers” on page 23.

Note: For information on viewing the Field Notes on the Map Screen, see “View Map Markers” on page 23.

16

Page 29

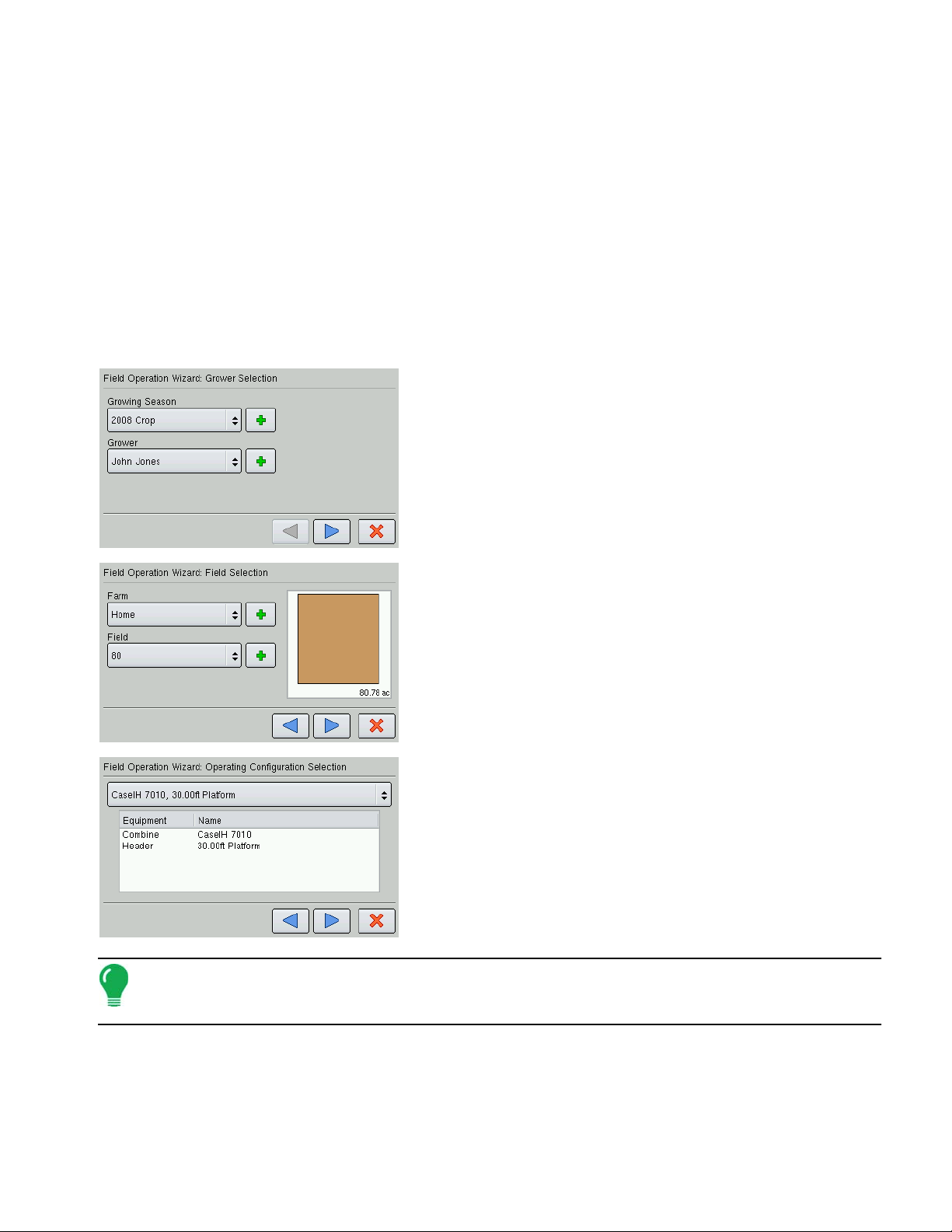

START FIELD OPERATION

You can start field operations after setting up a Grower, Farm and Field; and then creating an operating

configuration.

SETUP

• To set up a Planting Operating Configuration, see

• To set up a Tillage Operating Configuration, see

• To set up an Application Operating Configuration, see

• To set up a Harvest Operating Configuration, see

After creating an operating configuration, begin by returning to the Home screen. To Start Field

Operations, press the Start Field Operation button. The Field Operation Wizard appears. Follow the

steps in the Wizard to select an operating configuration.

1. Grower Selection

Enter a Growing Season and Grower either by using the drop-down

arrows to select existing ones, or by pressing on the Add (plus sign)

arrow to create new ones. Press the blue right-arrow key at the

bottom of the screen to proceed to the next step.

2. Field Selection

Add a Farm and Field either by using the drop-down arrows to

select existing ones, or by pressing on the Add (plus sign) arrow to

create new ones. Press the blue right-arrow key at the bottom of

the screen to proceed to the next step.

“Create a Planting Configuration” on page 67.

“Create a Tillage Configuration” on page 61.

“Create an Application Configuration” on page 101.

“Create a Harvest Configuration” on page 171.

3. Operating Configuration Selection

Use the drop-down arrow to select a configuration. Press the blue

right-arrow button to continue.

4. Product Selection

Users creating Field Operating Configuration in either Planting or

Application must select a product from the drop-down list. Press

the blue right-arrow button to continue. At the Options screen, enter

in a Controlling Product and Units.

Note: If you are selecting an Application product, you may check the box marked Show Only Tank Mixes

and Blends at the Product Selection Screen. If this box is checked, the display will only allow the selection of

tank mixes that were previously set up.

5. When you complete the steps in the Wizard, you will return to the Home Screen.

17

Page 30

RUN TIME ENVIRONMENT: MAP SCREEN

The appearance of the map screen varies, depending upon which operation you are performing. As

examples, typical map screens for Tillage and Harvest are shown. Data shown at the Title Bar at the top

of the Map Screen show speed and distance logged. Icons on the Map Screen itself indicate features

pertaining to the specific operation you are viewing at the map screen. Buttons on the Task Bar at the

bottom of the map screen show all operations that you are currently performing.

• Map Screen - Tillage (Zoom Detail)

• (A) Title bar

• (B) Map Screen Icons

• (C) Task bar

• Map Screen - Harvest (Zoom to Extent)

• (A) Legend

• (B) Status Item

Title Bar

The Title Bar shows current speed in miles per hour (kilometers per hour) and area logged.

Task Bar Buttons

The task bar displays buttons relating to various functions of the display. These buttons include Home,

Mapping, Liquid Rate Control, Planting Rate Control, Harvest, Autoswath, and Logging. These buttons

are shown in front of a green background when you are at that screen; otherwise they are shown in front

of a blue background.

Home Button. Pressing the Home button takes you to the Home screen.

Map Button. Pressing the Map button takes you to the Map screen. Pressing it more than once cycles

the Map screen to zoom in and out.

ZOOM DETAILS ZOOM TO EXTENT PERSPECTIVE VIEW

Note: The Perspective View is only available when guidance is active.

AutoSwath Button. Pressing this button turns the AutoSwath feature on and off. When AutoSwath is

on, the icon is green; when it is off the icon is white.

18

Page 31

AutoSwath - ON AutoSwath - OFF

Area Logging Status Button. This button appears for configurations that do not use rate control, such

as Tillage, Harvest, Planting operations that do not use SeedCommand, and Application operations that

do not use DirectCommand. Pressing this button turns logging on and off.

ON OFF

Rate Control Button. Pressing this button takes you to the Rate Control screen, which is

shown for both Planting and Application.

The NORAC Engage button enables boom height control. This button can toggle back and forth

between Automatic Mode and Manual Mode.

• NORAC Engage - Enabled

When you enable Automatic Mode, this button turns green and an arrow appears above the

triangle. At the same time, the display beeps three times.

SETUP

• NORAC Engage - Disabled

When you disable Automatic Mode on any part of the boom and the display switches to

Manual Mode, this button turns grey and the display beeps twice. If less than the full boom

remains in Manual Mode, the display will continue beeping twice every three seconds.

The Master Switch Indicator, shown for SeedCommand or DirectCommand functions, shows if the

master switch is on (green) or off (red). The master switch is shown in the F1 position on the Auxiliary

Input Settings screen.

Master Switch - ON Master Switch - OFF

Map Screen Icons

The GPS button in the upper left-hand corner of the Map screen, displays the following colors:

• Differential GPS

Green if you are receiving a differential GPS signal

• GPS - No differential

Yellow if you are receiving GPS, but no differential signal

• No GPS

Grey if you are receiving no GPS signal.

19

Page 32

The Engage icon shows that the OnTrac2 autosteer system is on, off, or off but ready to engage. The

appearance of this icon displays the following:

• Engage - On Green

autosteer system is on.

• Engage - Ready Grey

autosteer system off but ready to engage.

• Engage - Off Grey with a red circle and slash