Page 1

Agilent U2802A

31-Channel

Thermocouple Input

Device

User’s Guide

Agilent Technologies

Page 2

Notices

CAUTION

WARNING

© Agilent Technologies, Inc. 2008-2011

No p art o f this manu al may be re produce d in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

U2802-90003

Edition

Third Edition, October 28, 2011

Agilent Technologies, Inc.

3501 Stevens Creek Blvd.

Santa Clara, CA 95052 USA

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

Restricted Rights Legend

U.S. Government Restricted Rights. Software and technical data rights granted to

the federal government include only those

rights customarily provided to end user customers. Agilent provides this customary

commercial license in Software and technical data pursuant to FAR 12.211 (Technical

Data) and 12.212 (Computer Software) and,

for the Department of Defense, DFARS

252.227-7015 (Technical Data - Commercial

Items) and DFARS 227.7202-3 (Rights in

Commercial Computer Software or Computer Software Documentation).

Safety Notices

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

II U2802A 31-Channel Thermocouple Input User’s Guide

Page 3

Safety Information

The following general safety precautions must be observed during all phases of this instrument. Failure to comply

with these precautions or with specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies, Inc. assumes no liability for the

customer’s failure to comply with these requirements.

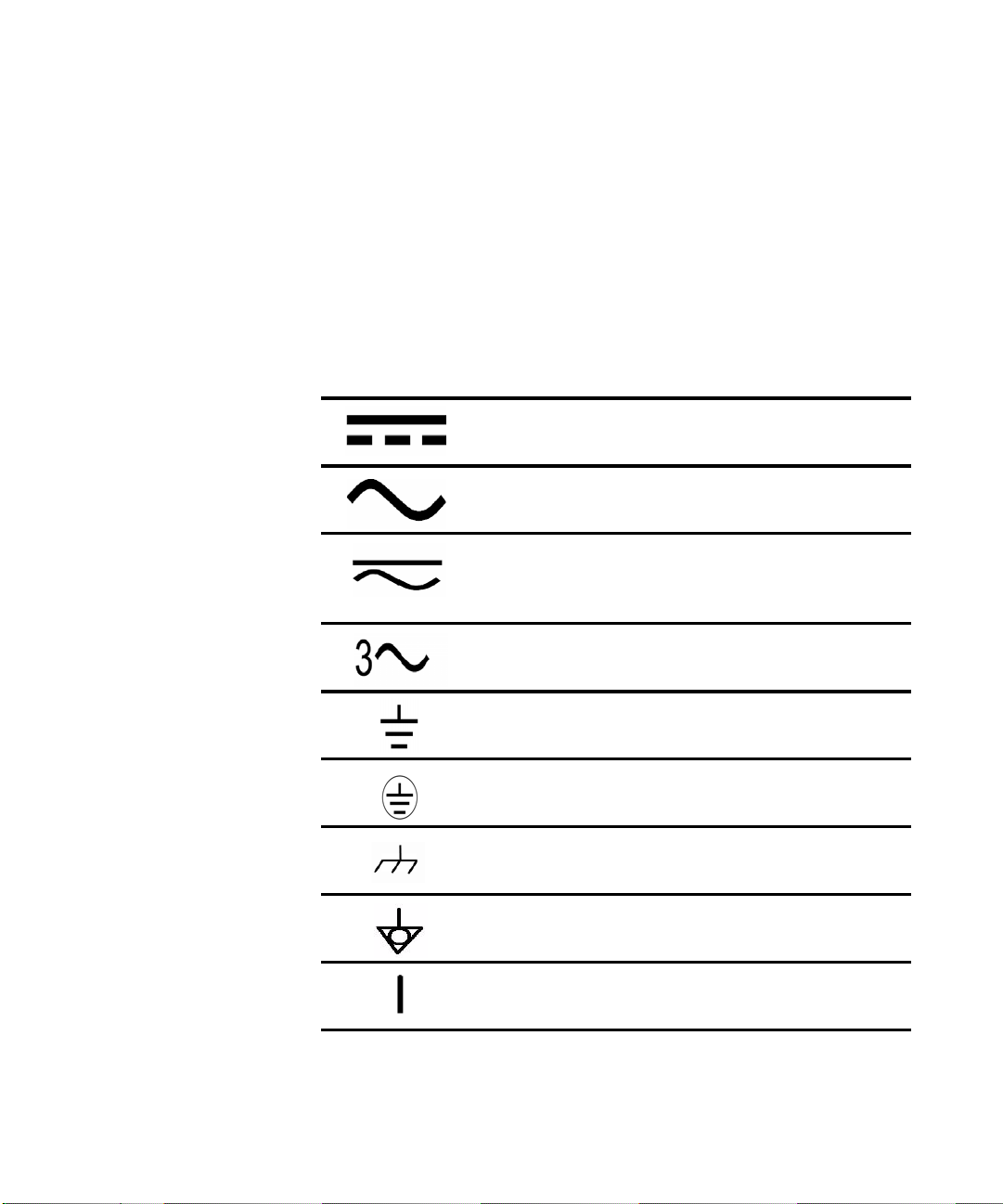

Safety Symbols

The following symbols indicate that precautions must be taken to maintain safe

operation of the instrument.

Direct current

Alternating current

Both direct and alternating current

Three-phase alternating current

Earth (ground) terminal

Protective conductor terminal

Frame or chassis terminal

Equipotentiality

On (Supply)

U2802A 31-Channel Thermocouple Input User’s Guide III

Page 4

Off (Supply)

Equipment protected throughout by double insulation or reinforced insulation

Caution, risk of electric shock

Caution, hot surface

Caution, risk of danger (See note.)

In position of a bi-stable push control

Out position of a bi-stable push control

IV U2802A 31-Channel Thermocouple Input User’s Guide

Page 5

Regulatory Markings

The CE mark is a registered trademark of the European

community. This CE mark shows that the product complies with

all the relevant European legal directive.

ICES/NMB-001 indicates that this ISM device complies

with Canadian ICES-001.

The CSA mark is a registered trademark of the Canadian Standards Association. A CSA mark with the indicators "C" and "US"

means that the product is certified for both the U.S. and Canadian

markets, to the applicable American and Canadian standards.

The C-tick mark is a registered trademark of the Spectrum Management Agency of Australia. This signifies compliance with the

Australian EMC Framework regulations under the terms of the

Radio Communications Act of 1992.

This product complies with the (2002/96/EC) marking

equipment. The affixed product label indicates that you must not

discard this electrical/electronic product in domestic household

waste.

U2802A 31-Channel Thermocouple Input User’s Guide V

Page 6

General Safety Information

WARNING

CAUTION

• Do not use the device if it is damaged. Before you use the device,

inspect the case. Look for cracks or missing plastic. Do not operate the

device around explosive gas, vapor or dust.

• Do not apply more than the rated voltage (as marked on the device)

between terminals, or between terminal and external ground.

• Always use the device with the cables provided.

• Observe all markings on the device before connecting to the device.

• Turn off the device and application system power before connecting to

the I/O terminals.

• When servicing the device, use only specified replacement parts.

• Do not operate the device with the removable cover removed or

loosened.

• Do not connect any cables and terminal block prior to performing

self-test process.

• Use only the power adapter supplied by the manufacturer to avoid any

unexpected hazards.

• Do not load the input and output terminals above the specified

operating limits. Input terminals should not exceed ±10 V with respect

to the module ground. Applying excessive voltage or overloading the

device will cause irreversible damage to the circuitry.

• Applying excessive voltage or overloading the input terminal will

damage the device permanently.

• If the device is used in a manner not specified by the manufacturer, the

protection provided by the device may be impaired.

• The U2802A can only be used with U2355A or U2356A DAQs and used

with the SCSI cables provided.

• Always use dry cloth to clean the device. Do not use ethyl alcohol or

any other volatile liquid to clean the device.

• Do not permit any blockage of the ventilation holes of the device.

VI U2802A 31-Channel Thermocouple Input User’s Guide

Page 7

Waste Electrical and Electronic Equipment (WEEE) Directive

2002/96/EC

This instrument complies with the WEEE Directive (2002/96/EC) marking

requirement. This affixed product label indicates that you must not discard this

electrical/electronic product in domestic household waste.

Product Category:

With reference to the equipment types in the WEEE directive Annex 1, this

instrument is classified as a “Monitoring and Control Instrument” product.

The affixed product label is shown as below:

Do not dispose in domestic household waste

To return this unwanted instrument, contact your nearest Agilent office, or visit:

http://www.agilent.com/environment/product

for more information.

U2802A 31-Channel Thermocouple Input User’s Guide VII

Page 8

Environmental Conditions

The table below shows the general environmental requirements for the product.

Environmental Conditions Requirements

Temperature Operating temperature from 0

Humidity Relative humidity at 50% to 85% RH (Non-condensing)

Altitude Altitude up to 2000 meters

Storage compliance –40 °C to +70 °C

°C to +55 °C

VIII U2802A 31-Channel Thermocouple Input User’s Guide

Page 9

In This Guide...

1Getting Started

This chapter introduces the new Agilent U2802A 31- channel

thermocouple input device and provides quick start information. It

also provides product outlook, installation configuration and

troubleshooting guide.

2 Features and Functions

This chapter contains details of the product features, applications,

system overview and theory of operation. From this chapter, you

will understand the Agilent U2802A 31- channel thermocouple

input system overview and functionality of this device.

3 Pin Configurations and Assignments

This chapter described the Agilent U2802A 31- channel

thermocouple input device pin configurations and connector pinout

for user’s reference.

4 Product Specifications

This chapter specifies the environmental conditions,

characteristics, and specifications of the Agilent U2802A

31- channel thermocouple input device. It also covers the system

accuracy, typical performance and guidelines to make accurate

temperature measurements.

5 Calibration

This chapter contains the calibration information and factory

restore calibration procedure for the Agilent U2802A 31- channel

thermocouple input device.

U2802A 31-Channel Thermocouple Input User’s Guide IX

Page 10

Declaration of Conformity (DoC)

The Declaration of Conformity (DoC) for this instrument is

available on the Web site. You can search the DoC by its product

model or description.

http://regulations.corporate.agilent.com/DoC/search.htm

X U2802A 31-Channel Thermocouple Input User’s Guide

Page 11

Contents

Notices II

Safety Information III

Environmental Conditions VIII

In This Guide... IX

Declaration of Conformity (DoC) X

1 Getting Started

Introduction to Agilent U2802A 31-Channel Thermocouple Input 6

Product Overview 7

Standard Purchase Items Checklist 10

Installations and Configurations 11

IVI-COM Drivers 12

2 Features and Functions

Features 18

Applications 19

System Overview 20

Theory of Operation 21

3 Pin Configurations and Assignments

Pin Configurations 30

Connector Pinout 36

4 Product Specifications

General Specifications 40

Product Characteristics 41

System Accuracy Specifications 43

System Typical Performance 49

Making Accurate Temperature Measurements 51

Contents 1

Page 12

5 Calibration

Calibration Information 54

Zeroing Function 54

Restore Factory Calibration 55

Contents 2

Page 13

List of Figures

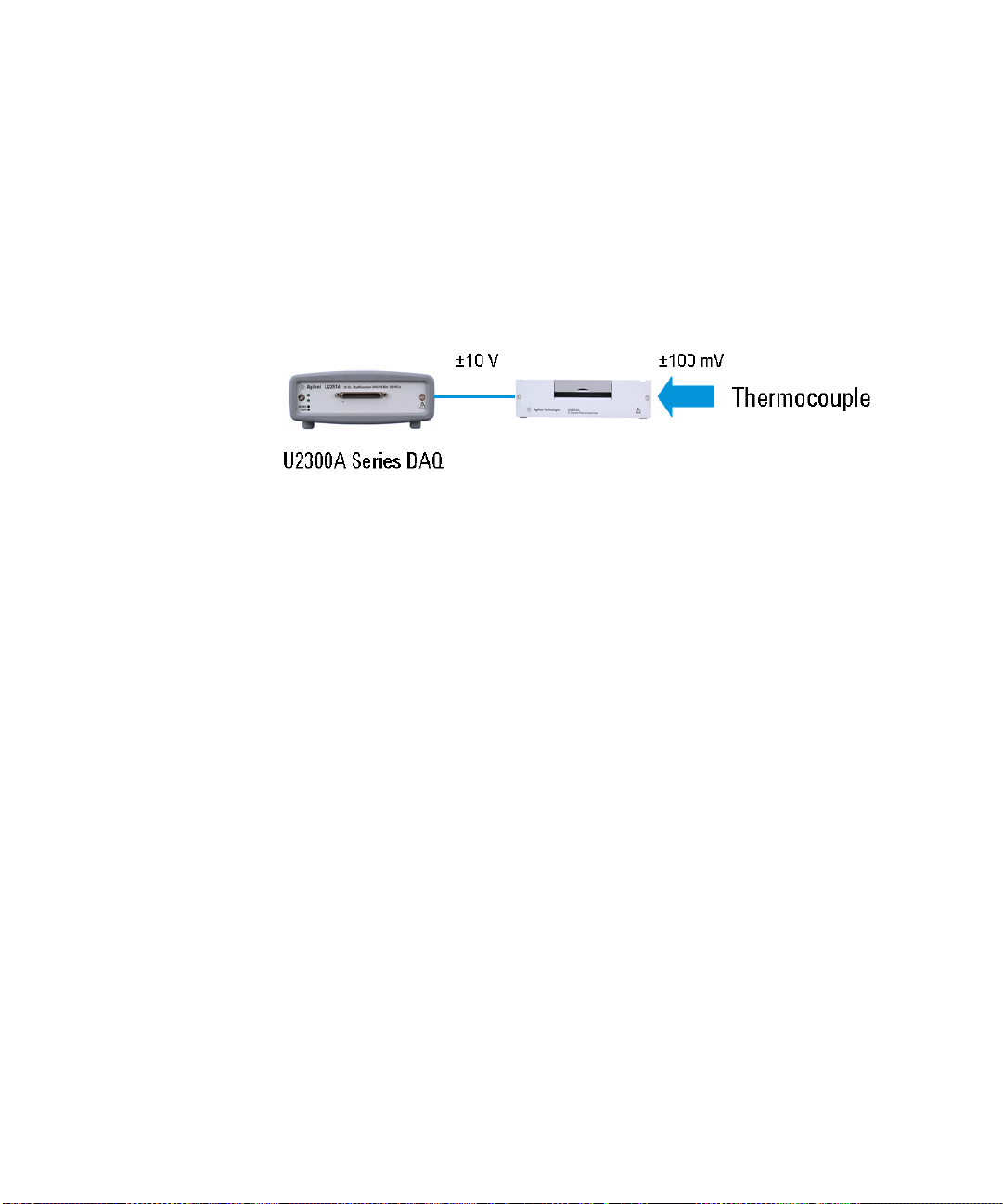

Figure 2-1 System overview of U2802A with DAQ 20

Figure 2-2 System functionality block diagram for U2802A 21

Figure 2-3 Functional block diagram for U2802A 22

Figure 2-4 Functional block diagram for thermocouple mode in U2802A 23

Figure 2-5 Floating signal source configuration in U2802A 24

Figure 2-6 Ground-referenced and differential signal sources configuration in

U2802A 25

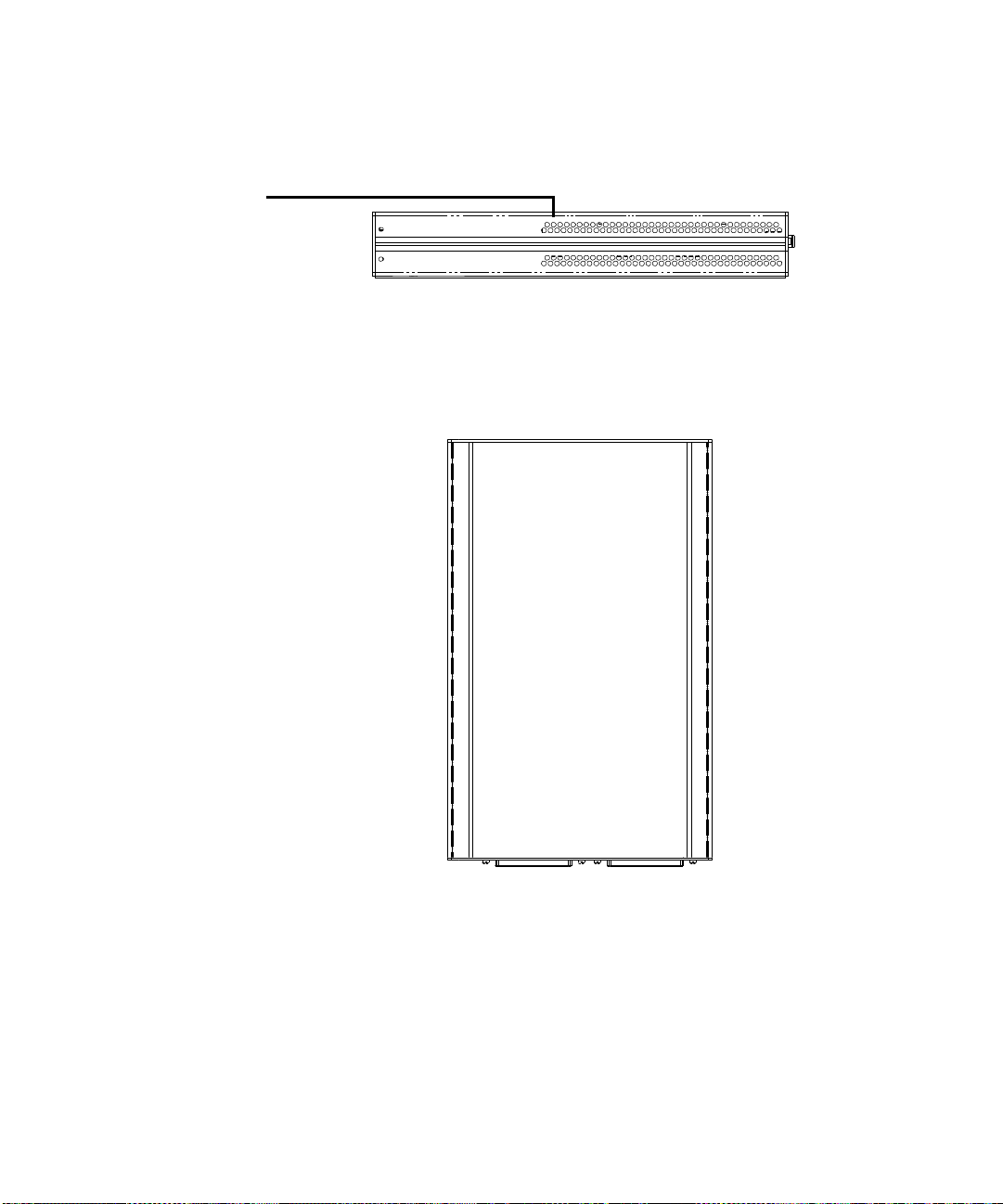

Figure 3-7 U2802A pin assignment 30

Figure 3-8 Connector 1 pin assignment for U2355A and U2356A 36

Figure 3-9 Connector 2 pin assignment for U2355A and U2356A 37

Figure 4-10 Thermoelectric characteristics for various thermocouple types 49

Figure 4-11 U2802A measurement accuracy plot for various thermocouples

type 50

Contents 3

Page 14

List of Tables

Table 4-1 U2802A measurement accuracy with U2355A or U2356A, at 23 °C ± 5 °C,

with different number of averaging points. 43

Table 4-2 U2802A measurement accuracy with U2355A, at 0 to 18 °C and 28 to 45 °C,

with different number of averaging points. 44

Table 4-3 U2802A measurement accuracy with U2356A, at 0 to 18 °C and 28 to 45 °C,

with different number of averaging points. 45

Contents 4

Page 15

Agilent U2802A 31-Channel Thermocouple Input

User’s Guide

1 Getting Started

Introduction to Agilent U2802A 31-Channel Thermocouple Input 6

Product Overview 7

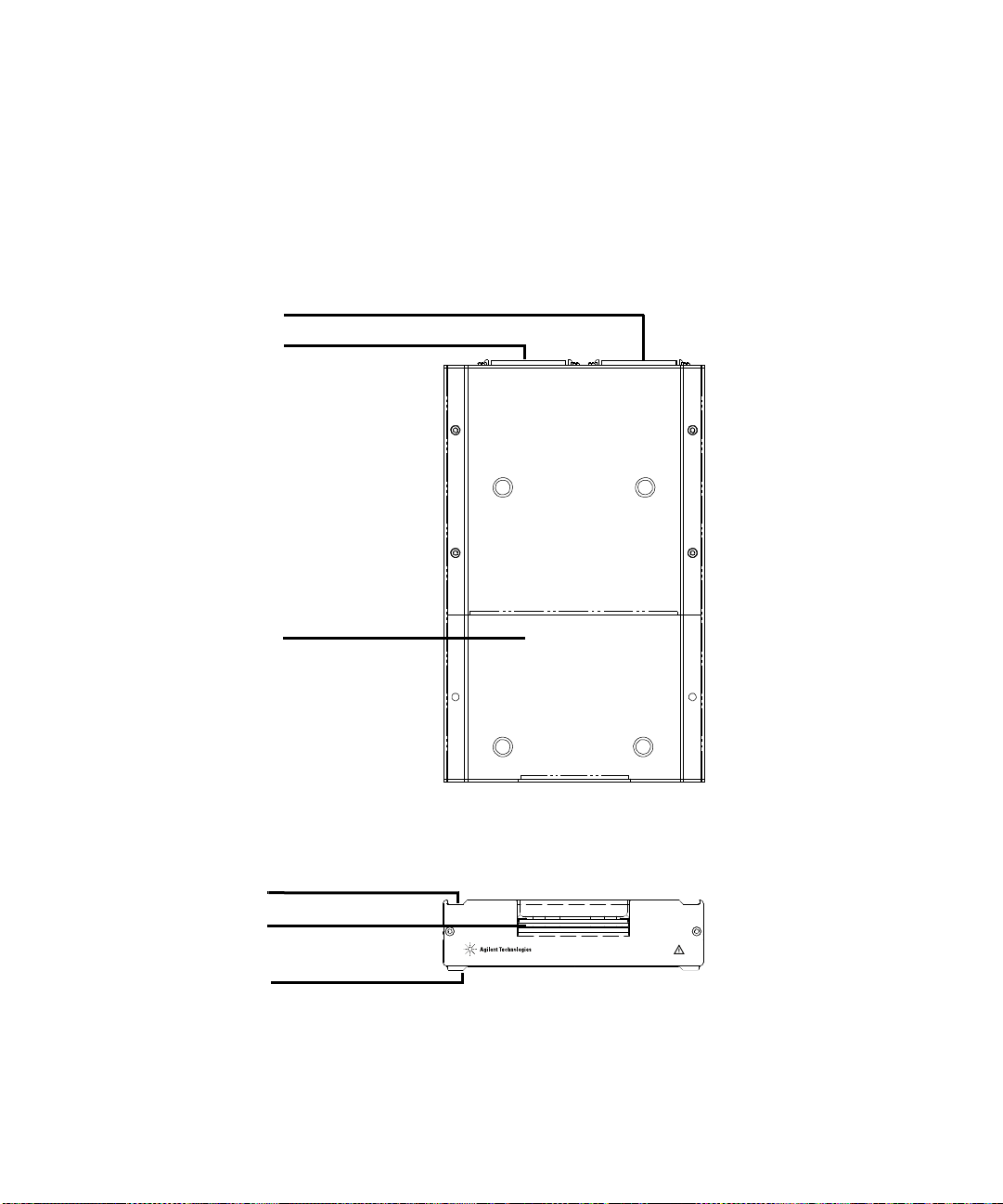

Product Outlook 7

Product Dimensions 9

Standard Purchase Items Checklist 10

Installations and Configurations 11

IVI-COM Drivers 12

This chapter introduces the new Agilent U2802A 31- channel

thermocouple input device and provides quick start information. It also

provides product outlook, installation configuration and troubleshooting

guide.

Agilent Technologies

5

Page 16

1Getting Started

Introduction to Agilent U2802A 31-Channel Thermocouple Input

The Agilent U2802A 31- channel thermocouple input is a thermocouple

input device that functions to convert low input voltage signal

(< ±100 mV) from a thermocouple into an output voltage range suitable for

data acquisition (DAQ) device (± 10 V).

The Agilent U2802A thermocouple signal conditioner is to be used in

conjunction with the U2355A or U2356A model DAQ to enable

temperature measurements using thermocouples.

It works as a standalone device attached to a single DAQ. The U2802A

thermocouple device is connected to the modular DAQ via SCSI cables.

Agilent U2802A accepts eight standard thermocouple types defined in the

NIST ITS-90 Thermocouple Database, which are Type B, E, J, K, N, R, S

and T.

It is ideal for a broad variety of temperature and voltage measurement

applications in education, industrial and scientific environments. The

U2802A comes with an on- board EEPROM features. Hence, it allows user

to store calibration data in volatile memory. Therefore, the U2802A is

robust, cost- effective, and user friendly device.

For detailed product specifications, please refer to “General Specifications”

on page 40.

6 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 17

Product Overview

Connector 1

Connector 2

Detachable

Cover

U2802A

31-Channel Thermocouple Input

Railing Guide

Strain Release Assembly

Footer

Product Outlook

Top Vi e w

Getting Started 1

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 7

Front View

Page 18

1Getting Started

Side View

Bottom View

Ventilation

Holes

8 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 19

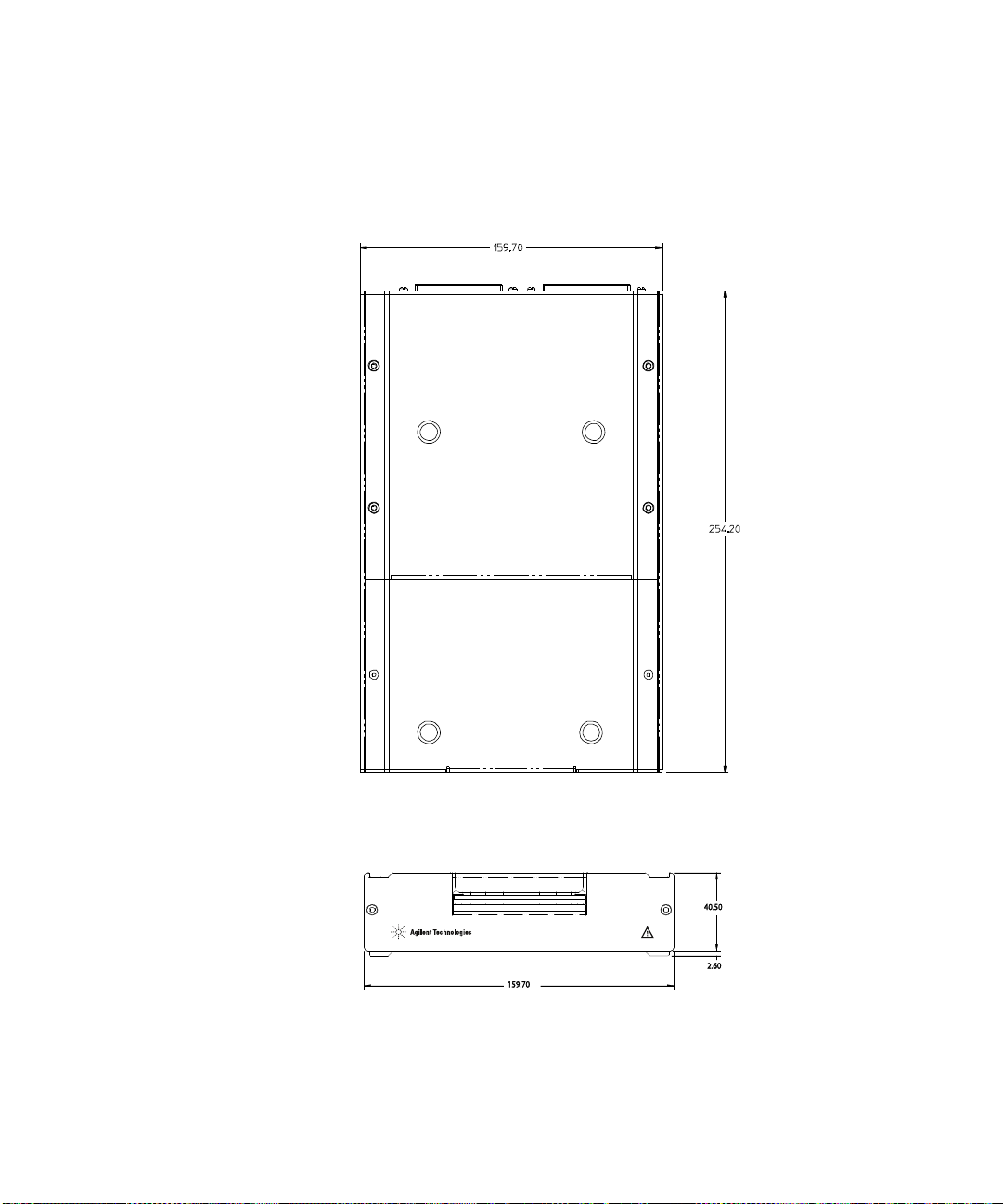

Product Dimensions

U2802A

31-Channel Thermocouple Input

Top Vi e w

Getting Started 1

Front View

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 9

Page 20

1Getting Started

Standard Purchase Items Checklist

Inspect and verify that you have all the following items upon standard

purchase of U2802A 31- channel thermocouple input device. If there are

missing items, contact the nearest Agilent Sales Office.

✔ Agilent U2802A 31- channel thermocouple input device

✔ Power supply splitter

✔ Two 68- pin SCSI cables (1 m)

✔ One J- type thermocouple

✔ Agilent USB Modular Products and Systems Quick Start Guide

✔ Agilent USB Modular Products and Systems Product Reference

DVD- ROM

✔ Agilent Automation- Ready CD- ROM (contains the Agilent IO Libraries

Suite)

✔ Certificate of Calibration

10 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 21

Installations and Configurations

NOTE

The U2802A is used in conjunction with the U2355A or U2356A DAQ. If

you are using the U2300A Series with the Agilent Measurement Manager,

follow the step- by- step instructions as stated in the Agilent USB Modular

Products and Systems Quick Start Guide.

You need to install IVI-COM driver before using the U2300A Series with Agilent

VEE, LabVIEW or Microsoft Visual Studio.

Getting Started 1

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 11

Page 22

1Getting Started

IVI-COM Drivers

The Agilent IVI- COM drivers simplify instrument control when you are

working in a COM- compatible environment. IVI- COM allows you to

programmatically control your instrumentation and make measurements

while providing a greater degree of instrument interchangeability and code

reuse. The Agilent IVI- COM drivers support the use of IntelliSense for

even greater ease- of- use within a Microsoft development environment.

The Agilent IVI- COM driver supports all Agilent Series DAQs. The Agilent

Firmware Revision: A.2006.10.10 is the minimum revision required for full

driver functionality.

An IVI- COM driver can program a particular set of instrument models. It

implements an instrument- specific interface tuned to the capabilities of

those models. The driver may also implement an IVI class- compliant

interface which implements a limited set of functionality common to all

instruments of the class. Instrument class- compliant interfaces are defined

by the IVI Foundation. The application writer must choose whether to use

the instrument- specific interface or the class- compliant interface.

The IVI inherent capabilities, through the IIviDriver interface, are available

in both the instrument- specific interface and class- compliant interface.

The general programming techniques are also the same.

Choosing Instrument-Specific Interface

With this interface, you have the benefit of full access to the instrument's

capabilities. All capabilities in the class- compliant interface are also

covered by the instrument- specific interface, but you will find some

capabilities in the instrument- specific interface that are not available

through the class- compliant interface. You may also see some performance

enhancements, as the driver can be tuned to use efficient programming

methods for that particular instrument.

Choosing Class-Compliant Interface

By limiting your program to the class- compliant interface, you have the

potential advantage of syntactic interchangeability. Hence, another

IVI- COM driver (and instrument) which supports the same class could be

substituted for the original driver, if the prior IVI- COM driver supports all

the capability groups used in the original driver. In this case, the

12 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 23

Getting Started 1

application will compile, link, and execute without error. The test results,

however, may be quite different because different instruments measure

and generate signals differently. For more information on class- compliant

interfaces and capability groups, visit www.ivifoundation.org.

Using Class-Compliant Interface

Generally, you gain no advantage from using class- compliant interface over

using just the instrument- specific interface. However, if you can isolate the

usage of the instrument- specific interface, you may see some advantages.

Replacing the IVI- COM driver then involves fixing the syntactic

incompatibilities in the isolated code.

IVI- COM drivers will be provided to users. The drivers can also be used in

a variety of development environments. For more information on IVI, visit

www.ivifoundation.org.

Below are the IVI- COM drivers provided:

✔ AgilentVEE support through COM mechanism using IVI- COM

✔ Visual Basic 6 support through COM mechanism using IVI- COM

✔ C++ support through COM mechanism using IVI- COM

✔ Visual Basic 7 support through COM Interop mechanism using IVI- COM

✔ C# support through COM Interop mechanism using IVI- COM

✔ National Instruments LabVIEW support through COM mechanism using

IVI- COM

The Agilent firmware update utility is provided to allow users to update

firmware on instruments. Update is made available through Agilent

Developer Network (ADN) website:

www.agilent.com/find/adn

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 13

Page 24

1Getting Started

Programming Environments

An IVI- COM driver works well in a variety of application development

environments (ADEs) below:

✔ Agilent VEE

✔ Microsoft® Visual Basic® 6

✔ Visual Studio C++

✔ Visual Basic 7

✔ C#

✔ National Instruments LabVIEW

IVI-COM Driver Installation

1 Verify that your PC meets the minimum system requirements.

2 Close all other applications on your PC.

3 Insert the Agilent USB Modular Products and Systems Product Reference

4 Wait for a few seconds for the auto- run window to appear.

5 If the auto- run window does not appear automatically, click Start > Run,

6 When the auto- run window appears, click Software Driver on the Agilent

DVD- ROM into the DVD- ROM drive of your PC.

then type <drive>:\Autorun.exe, where <drive> is your DVD-ROM

drive alphabet.

Modular Products Installation Menu.

14 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 25

Getting Started 1

7 Click IVI-COM to open the IVI- COM Driver Installation Menu.

8 Check on the U2300A Series and click Install and wait for the

Installation Dialog to appear.

9 When the Installation Dialog appears, click Next to begin the IVI Driver

installation.

10 Read the License Agreement(s). To accept the terms, click on the radio

button labeled I accept the terms in the License Agreement then click Next to

continue.

11 When the Setup Type dialog box appears, as shown below, clicking Install

will install all features for your configuration in standard locations on

your PC.

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 15

Page 26

1Getting Started

12 If you choose a Custom setup, the Select Features dialog box will appear.

1 When the Ready to Install dialog box appears, click Install to confirm your

2 When the Complete dialog box appears, click Finish.

a Click on any feature in the list to see the feature’s description and

space requirement. It is recommended that you install the sample

programs if you plan to program with the IVI driver. However, you

may omit this recommendation to save space.

b Select the check box for each feature to be installed. Clear the check

box to omit the feature selection.

c Click Next.

choices and begin copying files.

16 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 27

Agilent U2802A 31-Channel Thermocouple Input

User’s Guide

2 Features and Functions

Features 18

Applications 19

System Overview 20

Theory of Operation 21

Functionality of the System 21

Functional Block Diagram 22

This chapter contains details of the product features, applications,

system overview and theory of operation. From this chapter, you will

understand the Agilent U2802A 31- channel thermocouple input system

overview and functionality of this device.

Agilent Technologies

17

Page 28

2 Features and Functions

Features

The U2802A Thermocouple Input conditioning device is complete with the

following features:

✔ Up to 31 differential input mode, or 31- single ended inputs in voltage

input mode. Each of the 31 channels can be configured as either

thermocouple or voltage input mode independently.

✔ ×97.673 gain setting for thermocouple input mode.

✔ Built- in thermistor for cold junction compensation (CJC).

✔ Built- in zeroing function to compensate for overall system offset errors

due to temperature drift.

✔ On- board EEPROM that allows user to restore back original factory

calibration data.

✔ Open thermocouple detection that allows user to check for any loose or

broken thermocouple connection before starting the data acquisition

process.

✔ Supports thermocouple type J, K, R, S, T, N, E, and B.

18 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 29

Applications

Features and Functions 2

The U2802A Thermocouple Input conditioning device is designed for

robust and demanding industrial applications. This product is suitable for

a wide range of applications in various fields inclusive of:

✔ Consumer electronics

• Product thermal analysis and characterization

• Environmental testing (Eg: Temperature Cycle)

• Process monitoring (Eg: Oven or solder reflow temperature

monitoring)

✔ Education

• Study of electronic cooling properties

• Material properties testing

✔ Container temperature profiling

✔ Appliances testing

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 19

Page 30

2 Features and Functions

System Overview

Figure 2-1 System overview of U2802A with DAQ

The U2802A is essentially an amplifier module with a built- in temperature

sensor (thermistor). In thermocouple mode, the U2802A input channel is

used to amplify a differential voltage signal from a thermocouple (or any

low voltage signal source in the range of ±100 mV) by 100 times. The

signal is then output as an analog voltage in the ±10 V range into the DAQ

for conversion to a digital voltage reading.

The built- in thermistor in the U2802A can be read from Channel AI148 of

the U2300A series DAQ. The conversion from voltage to temperature for

this thermistor reading is done automatically by the AMM software. This

temperature reading will subsequently be used as the Cold Junction

Compensation (CJC) reference temperature.

With the correct voltage reading from the thermocouple and the CJC

temperature, the AMM software will then proceed to convert the

thermocouple voltage reading into a temperature reading, based on the

NIST ITS- 90 Thermocouple Database. This reading is then corrected for

both gain and offset errors due to the U2802A amplifiers using the

calibration constants stored in the U2802A EEPROM, which are read by

the PC via the DAQ's digital I/O lines.

The U2802A also has a built- in zeroing function, which allows users to

zero out the entire system's offset error, thus increasing the overall

accuracy of the system.

20 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 31

Theory of Operation

Functionality of the System

Features and Functions 2

Figure 2-2 System functionality block diagram for U2802A

13 Thermocouple voltage signals are detected at the U2802A thermocouple

inputs.

14 Signal is amplified with a gain of 97.673 by the U2802A.

15 The U2355A or U2356A DAQ converts the analog voltage signals to

digital voltage readings.

16 The AMM software (or IVI- COM driver) reads the Gain and Offset

calibration constants from the U2802A EEPROM via the DAQ DIO lines.

The digital voltage readings will be calibrated based on these constants.

17 The AMM software (or IVI- COM driver) converts the calibrated voltage

readings to temperature readings using the ITS- 90 conversion

polynomials.

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 21

Page 32

2 Features and Functions

Functional Block Diagram

The block diagram below in Figure 2- 3 illustrates the key functional

components of the U2802A.

Figure 2-3 Functional block diagram for U2802A

22 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 33

Features and Functions 2

The major functional blocks of the U2802A module are:

• Analog input channel circuitry

• Cold junction sensor

• Digital control logic

• EEPROM

Analog input channel circuitry

The analog circuitry for each channel consists of an instrumentation

amplifier with a fixed gain of 97.673, a 4 Hz RC low- pass filter, and an

output buffer. The multiplexers at the input and output of each channel

allows each channel to be configured for three modes of operation as

listed below:

Thermocouple input mode: In thermocouple mode, the thermocouples (or

any floating voltage source) should be connected to the TCn+ and TCn

terminals as illustrated in Figure 2- 4. All TCn

– terminals are internally

tied to module ground with a 10 MΩ resistor. The TCn+ and TCn

–

– signals

are routed to the differential inputs of the instrumentation amplifier.

Differential voltage signals at the TCn+ and TCn

– terminals are amplified,

filtered and driven out by single- ended output voltage to the

corresponding AI channel on Rear Connector 1.

Figure 2-4 Functional block diagram for thermocouple mode in U2802A

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 23

Page 34

2 Features and Functions

Bypass mode: In bypass mode, the TCn+ input is routed directly to the

corresponding AI channel on Rear Connector 1. The single- ended signals

tied to TCn+ should be referenced to a GND pin, and not to the TCn

input, as it is not directly connected to GND. The signal connection will

depend on the type of source used.

For floating signal sources, all input signals are connected to the ground

in the U2802A as illustrated in Figure 2- 3. However, it is not

recommended to tie ground- referenced signal sources in this manner. Any

potential differences between the signal source ground and the U2802A

ground could potentially induce excessive current to flow through the

ground wires causing the wires and module to be damaged.

–

Figure 2-5 Floating signal source configuration in U2802A

For ground- referenced signal sources and differential signal sources, the

configuration in Figure 2- 6 is recommended. Take note that the

corresponding DAQ channel will need to be configured as a DIFF input to

enable this type of connection.

24 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 35

Features and Functions 2

Figure 2-6 Ground-referenced and differential signal sources configuration in U2802A

Zero mode: In zero mode, the positive and negative inputs of the

instrumentation amplifier are shorted together. The output of the

instrumentation amplifier is driven out to the corresponding AI channel.

The voltage measured in this mode corresponds to the offset voltage of

the channel. This voltage can be subtracted out of the subsequent

thermocouple mode measurements in order to increase the measurement

accuracy. Do take note that this mode only works for channels that have

been configured to be in the thermocouple mode. Channels configured for

bypass mode will not be affected when this mode is selected.

Each channel is equipped with an open thermocouple detection feature,

where the 10 MΩ resistor is tied to the +15 V power supply rail. This

feature can only be globally enabled or disabled for all channels,

regardless of the channel mode setting. When enabled, outputs of the

channels are set to thermocouple mode where the inputs are left

open- circuited. This causes the positive power supply rail voltage (above

+10 V) to be saturated up, indicating that the channel either has a broken

thermocouple or the thermocouple is not connected. For channels set to

bypass mode, channels with an open- circuited input will also be saturated

to the positive supply rail voltage.

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 25

Page 36

2 Features and Functions

For bypass mode channels that are connected to valid voltage sources, the

10 MΩ pull- up resistor will cause additional current to flow through the

voltage source. However, this additional current measurement is small and

negligible for low impedance voltage sources.

For thermocouple mode channels connected to valid thermocouples, the

presence of the pull- up resistor introduces approximately 0.75 µA of

current through the thermocouple wires. This current introduces

additional errors when using thermocouples with high resistances, and the

measurement accuracy could be affected.

Cold junction sensor

A thermistor (RT1) is placed in between the screw terminals to measure

the temperature of the thermocouple junction for CJC. The output voltage

from the sensor is fed through a 4 Hz RC low-pass filter and buffered to

the AI148 pin on Rear Connector 1. The conversion from voltage to

temperature is done automatically by the AMM software.

Digital control

The digital control circuit consists of registers that controls the mode of

each channel and the open- thermocouple detect feature. The registers are

addressed and clocked via the digital I/O pins on Rear Connector 2. This

will be handled automatically by the AMM software.

EEPROM

The gain and offset calibration factors for each channel are stored in the

EEPROM during factory calibration and will be retrieved prior to taking

measurements. The EEPROM is tied to the digital I/O pins on Rear

Connector 2. The communication between the EEPROM and host PC is

automatically handled by the AMM software. In addition to the calibration

factors, the EEPROM stores the module ID, serial number, date of

calibration, which can also be retrieved before measurements are taken.

26 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 37

Features and Functions 2

Open Thermocouple Detection

The U2802A provides a built- in 10 MΩ resistor on each TC+ terminal,

which is pulled up to the internal +15 V power supply rail. This resistor

can be enabled or disabled via the digital I/O pins on Rear Connector 2.

When enabled, this 10 MΩ pull- up resistor and the 10 MΩ pull- down

biasing resistor will cause the output from any unconnected thermocouple

input channels to saturate to the maximum output voltage. The U2355A

and U2356A devices can read this saturated channel and detect that a

particular channel has an open thermocouple input.

Trigger, Counter, External Timebase, and Analog Output

The U2802A provides a direct access to the analog and digital trigger

lines, counter channels, external timebase input, and analog output

channels from the U2355A and U2356A devices. These lines are routed

directly from the Rear Connector 1 and 2 to the J60 screw terminal

connector. Please refer to pin description for Connector J60 on page 35.

Precautions should be taken when driving high slew rate and frequency

clocks into the Counter and External Timebase lines to avoid excessive

noise coupling into other analog and digital lines. If excessive coupling or

crosstalk is observed, clock output drive strengths and slew rates should

be lowered to reduce coupling while still maintaining proper digital

function.

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 27

Page 38

2 Features and Functions

28 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 39

Agilent U2802A 31-Channel Thermocouple Input

User’s Guide

3 Pin Configurations and Assignments

Pin Configurations 30

Pin Assignments 30

Pin Description 31

Connector Pinout 36

This chapter described the Agilent U2802A 31- channel thermocouple

input device pin configurations and connector pinout for user’s

reference.

Agilent Technologies

29

Page 40

3 Pin Configurations and Assignments

Pin Configurations

Pin Assignments

Figure 3-7 U2802A pin assignment

30 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 41

Pin Configurations and Assignments 3

Pin Description

Connector J71

Pin Pin name Description

1 TC1+ In thermocouple mode, TCx+ and TCx– are the thermocouple differential

2TC1–

3 TC2+ TC input or voltage input (See TC1+/– description)

4TC2–

5 TC3+ TC input or voltage input (See TC1+/– description)

6TC3–

7 TC4+ TC input or voltage input (See TC1+/– description)

8TC4–

9 TC5+ TC input or voltage input (See TC1+/– description)

10 TC5–

11 TC6+ TC input or voltage input (See TC1+/– description)

12 TC6–

13 TC7+ TC input or voltage input (See TC1+/– description)

14 TC7–

15 TC8+ TC input or voltage input (See TC1+/– description)

16 TC8–

17 GND Module Ground

18 TC17+ TC input or voltage input (See TC1+/– description)

19 TC17–

20 TC18+ TC input or voltage input (See TC1+/– description)

21 TC18–

22 TC19+ TC input or voltage input (See TC1+/– description)

23 TC19–

24 TC20+ TC input or voltage input (See TC1+/– description)

25 TC20–

26 TC21+ TC input or voltage input (See TC1+/– description)

27 TC21–

input. In voltage mode, single ended input at TCx+ and GND. TCx– is not

connected.

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 31

Page 42

3 Pin Configurations and Assignments

28 TC22+ TC input or voltage input (See TC1+/– description)

29 TC22–

30 TC23+ TC input or voltage input (See TC1+/– description)

31 TC23–

32 TC24+ TC input or voltage input (See TC1+/– description)

33 TC24–

34 GND Module Ground

32 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 43

Pin Configurations and Assignments 3

Connector J50

Pin Pin name Description

1

GND Module Ground

2 TC16– TC input or voltage input (See TC1+/– description)

3 TC16+

4 TC15– TC input or voltage input (See TC1+/– description)

5 TC15+

6 TC14– TC input or voltage input (See TC1+/– description)

7 TC14+

8 TC13– TC input or voltage input (See TC1+/– description)

9 TC13+

10 TC12– TC input or voltage input (See TC1+/– description)

11 TC12+

12 TC11– TC input or voltage input (See TC1+/– description)

13 TC11+

14 TC10– TC input or voltage input (See TC1+/– description)

15 TC10+

16 TC9– TC input or voltage input (See TC1+/– description)

17 TC9+

18 GND Module Ground

19 GND Module Ground

20 GND Module Ground

21 TC31– TC input or voltage input (See TC1+/– description)

22 TC31+

23 TC30– TC input or voltage input (See TC1+/– description)

24 TC30+

25 TC29– TC input or voltage input (See TC1+/– description)

26 TC29+

27 TC28– TC input or voltage input (See TC1+/– description)

28 TC28+

29 TC27– TC input or voltage input (See TC1+/– description)

30 TC27+

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 33

Page 44

3 Pin Configurations and Assignments

31 TC26– TC input or voltage input (See TC1+/– description)

32 TC26+

33 TC25– TC input or voltage input (See TC1+/– description)

34 TC25+

34 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 45

Pin Configurations and Assignments 3

Connector J60

Pin Pin name Description

1 COUNT302_CLK Directly connected to DAQ

2 COUNT302_GATE Directly connected to DAQ

3 COUNT302_UPDOWN Directly connected to DAQ

4 COUNT302_OUT Directly connected to DAQ

5 EXTD_AI_TRIG Directly connected to DAQ

6 EXT_TIMEBASE Directly connected to DAQ

7GND Module Ground

8 AO_GND Directly connected to DAQ

9 AO_GND Directly connected to DAQ

10 GND Module Ground

11 GND Module Ground

12 GND Module Ground

13 COUNT301_CLK Directly connected to DAQ

14 COUNT301_GATE Directly connected to DAQ

15 COUNT301_UPDOWN Directly connected to DAQ

16 COUNT301_OUT Directly connected to DAQ

17 EXTD_AO_TRIG Directly connected to DAQ

18 GND Module Ground

19 AO201 Directly connected to DAQ

20 AO202 Directly connected to DAQ

21 AO_EXT_REF Directly connected to DAQ

22 EXTA_TRIG Directly connected to DAQ

23 GND Module Ground

24 GND Module Ground

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1. Refer to the U2300A Series USB Multifunction Data Acquisition Devices User’s Guide for

connectivity

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 35

Page 46

3 Pin Configurations and Assignments

Connector Pinout

Rear panel pinout for Connector 1

Figure 3-8 Connector 1 pin assignment for U2355A and U2356A

36 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 47

Rear panel pinout for Connector 2

Pin Configurations and Assignments 3

Figure 3-9 Connector 2 pin assignment for U2355A and U2356A

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 37

Page 48

3 Pin Configurations and Assignments

38 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 49

Agilent U2802A 31-Channel Thermocouple Input

User’s Guide

4 Product Specifications

General Specifications 40

Product Characteristics 41

System Accuracy Specifications 43

Calculating System Accuracy 46

System Typical Performance 49

Making Accurate Temperature Measurements 51

This chapter specifies the environmental conditions, characteristics, and

specifications of the Agilent U2802A 31- channel thermocouple input

device. It also covers the system accuracy, typical performance and

guidelines to make accurate temperature measurements.

Agilent Technologies

39

Page 50

4 Product Specifications

General Specifications

POWER CONSUMPTION

±12 VDC, 750 mA maximum

OPERATING ENVIRONMENT

• Operating temperature from 0 °C to 55 °C

• Relative humidity at 50% to 85% RH (non-condensing)

• Altitude up to 2000 meters

STORAGE COMPLIANCE

–40 °C to 70 °C

SAFETY COMPLIANCE

Certified with IEC 61010-1:2001/EN 61010-1:2001 (2nd Edition)

EMC COMPLIANCE

• IEC 61326-1:2002 / EN 61326-1:1997

• CISPR 11:1990/EN55011:1990 – Group 1, Class A

• CANADA: ICES-001: 2004

• Australia/New Zealand: AS/NZS CISPR11:2004

SHOCK & VIBRATION

Tested to IEC/EN 60068-2

IO CONNECTOR

• 2 x 68-pin female SCSI connector

• 2 x 34-pin screw terminal block

• 1 x 24 pin screw terminal block

DIMENSIONS (WxDxH)

159.7 mm x 254.2 mm x 40.5 mm

WEIGHT

1.036 KG

WARRANTY

Please refer to http://www.agilent.com/go/warranty_terms

• Three years for the product

• Three months for the product's standard accessories, unless otherwise specified

Please take note that for the product, the warranty does not cover:

• Damage from contamination

• Normal wear and tear of mechanical components

• Manuals

+A1:1998+A2:2001+A3:2003

40 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 51

Product Characteristics

GENERAL CHARACTERISTICS

Number of channels 31 differential and 1 CJC

Input voltage range for voltage mode ±10 V (signal + common mode)

Input voltage (thermocouple mode) ±100 mV

Sampling rate for thermocouple mode 10 kSa/s total for all channels

Sampling rate for overall module 500 kSa/s

Thermocouple types J, K, R, S, T, N, E and B

INPUT SPECIFICATIONS

Accuracy (thermocouple mode)

Overall gain error

Overall offset error

Nonlinearity

System noise (rms)

Gain (x1)

Gain (x100)

Common mode rejection ratio (60 Hz)

Voltage mode

Thermocouple mode

Cold junction accuracy ±1.0 °C typical (23 °C ± 5°C)

Product Specifications 4

0.06% (23 °C ± 5 °C)

15 µV (without zeroing) (23 °C ± 5 °C)

6 µV (with zeroing)

< 0.005% of Full Scale Range

100 µVrms

5 µVrms

> 60 dB

> 80 dB

±1.5 °C typical (0 °C to 18 °C, 28 °C to 55 °C)

INPUT CHARACTERISTICS

Bandwidth (voltage mode) > 500 kHz

Bandwidth (thermocouple mode) 4.0 Hz

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 41

Page 52

4 Product Specifications

Overvoltage protection

*

TC Mode

†

• Common mode: ±17 V (TC+ and TC– with

respect to GND)

• Differential mode: ±7 V (Differential voltage

between TC+ and TC–)

Bypass mode

• ±20 V (TC+ input with respect to GND)

Power Off Mode

• ±11 V (TC+, TC– input with respect to GND)

Input impedance > 1 GΩ

Input bias current ±2.5 nA max

Input offset current ±1.5 nA max

Gain drift 60 ppm / °C max

Offset drift 1 µV / °C max

Filter cutoff frequency (–3 dB) (thermocouple

mode)

4.0 Hz

Filter type (thermocouple mode) Low Pass RC Filter

OTHER FEATURES

Recommended warm up time 30 minutes

* The overvoltage protection levels specified above indicate the maximum voltage each input pin can

tolerate without resulting in any damages. However, prolonged exposure to these levels may affect

device safety and reliability. Hence, it should be avoided where possible.

† On the channels configured for thermocouple mode, the TC+ and TC– pins can tolerate up to ±17 V

of differential voltage for a few minutes. However, exceeding ±100 mV voltage range on these

channels can cause additional current to be drawn from the device’s power supply regulators,

which may damage the device if multiple channels are overdriven for prolonged periods. This

applies to the case where a voltage source is tied across the TC

greater than ±100 mV should be tied to TC

(grounded source), and have the channels set for bypass mode. Refer to Figure 2-5 on page 32.

+ and GND (floating source), or TCn+ and TC

n

+ and TCn– pin. Voltage sources

n

n+1

+

42 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 53

System Accuracy Specifications

NOTE

The Agilent U2802A thermocouple input measurement accuracy with the

U2355A and U2356A is as shown in Table 4- 1, Table 4- 2, and Table 4- 3.

• Assume a ±1 °C error in the CJ measurement due to sensor error and temperature

gradient error in the accuracy numbers in Table 4-1, Table 4-2, and Table 4-3 below.

• Table 4-1, Table 4-2, and Table 4-3 are derived from the U2802A and DAQ input accuracy

specifications without including the thermocouple error. Refer to “Calculating System

Accuracy” on page 46 for calculation methodology.

Thermocouple Measurements Accuracy

(U2355A, U2356A @ 23 °C ± 5°C)

ITS-90

T/C

Ty pe

B 0 1820 1100 1820 1.9 1.2 1.0

E –270 1000 –150 1000 1.7 1.6 1.6

J –210 1200 –150 1200 1.6 1.5 1.5

K –270 1372 –100 1200 1.5 1.4 1.4

N –270 1300 –100 1300 1.5 1.3 1.3

R –50 1768 300 1760 2.0 1.4 1.3

S –50 1768 400 1760 2.1 1.6 1.4

T –270 400 –100 400 1.5 1.4 1.4

Temperature

Range (°C)

Low High Low High

–200 –150 2.4 2.3 2.3

–210 –150 2.7 2.6 2.5

–200 –100 2.7 2.6 2.6

–200 –100 3.0 2.7 2.6

–200 –100 2.7 2.5 2.5

Product Specifications 4

Optimum

Measurement

Range(°C)

400 1100 4.4 2.5 2.0

–50 300 5.0 3.1 2.6

–50 400 4.5 2.8 2.4

Without

averaging

(± °C)

50 points

averaging

(± °C)

500 points

averaging

(± °C)

Tab l e 4 - 1 U2802A measurement accuracy with U2355A or U2356A, at 23 °C ± 5 °C, with

different number of averaging points.

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 43

Page 54

4 Product Specifications

T/C

Ty pe

Thermocouple Measurements Accuracy

(U2355A @ 0 °C to 18 °C and 28 °C to 45 °C)

ITS-90

Temperature

Range (°C)

Low High Low High

B 0 1820 1100 1820 3.4 2.4 2.2

E –270 1000 –150 1000 2.7 2.6 2.5

J –210 1200 –150 1200 2.5 2.4 2.4

K –270 1372 –100 1200 2.9 2.8 2.8

N –270 1300 –100 1300 2.6 2.5 2.5

R –50 1768 300 1760 3.8 3.1 3.0

S –50 1768 400 1760 4.2 3.4 3.2

T –270 400 –100 400 2.4 2.2 2.2

Optimum

Measurement

Range(°C)

400 1100 7.5 3.6 2.2

–200 –150 3.8 3.6 3.6

–210 –150 4.2 4.0 3.9

–200 –100 4.3 4.0 3.9

–200 –100 4.9 4.2 4.0

–50 300 8.5 4.6 3.3

–50 400 7.7 4.2 3.1

–200 –100 4.3 4.0 3.9

Without

averaging

(± °C)

50 points

averaging

(± °C)

500 points

averaging

(± °C)

Tab l e 4 - 2 U2802A measurement accuracy with U2355A, at 0 to 18 °C and 28 to 45 °C,

with different number of averaging points.

44 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 55

Product Specifications 4

Thermocouple Measurements Accuracy

(U2356A @ 0 °C to 18 °C and 28 °C to 45 °C)

ITS-90

T/C

Ty pe

B 0 1820 1100 1820 6.1 3.1 2.4

E –270 1000 –150 1000 3.0 2.6 2.6

J –210 1200 –150 1200 2.9 2.5 2.5

K –270 1372 –100 1200 3.3 2.9 2.9

N –270 1300 –100 1300 3.4 2.7 2.6

R –50 1768 300 1760 6.2 3.7 3.2

S –50 1768 400 1760 6.4 4.0 3.4

T –270 400 –100 400 3.0 2.4 2.2

Temperature

Range (°C)

Low High Low High

Optimum

Measurement

Range(°C)

400 1100 14.4 6.3 2.7

–200 –150 4.2 3.7 3.6

–210 –150 4.9 4.1 4.0

–200 –100 5.3 4.2 4.0

–200 –100 6.8 4.6 4.1

–50 300 15.7 7.2 3.8

–50 400 14.2 6.6 3.4

–200 –100 5.3 4.2 3.9

Without

averaging

(± °C)

50 points

averaging

(± °C)

500 points

averaging

(± °C)

Tab l e 4 - 3 U2802A measurement accuracy with U2356A, at 0 to 18 °C and 28 to 45 °C,

with different number of averaging points.

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 45

Page 56

4 Product Specifications

Calculating System Accuracy

The overall measurement system comprises of three major components:

1 DAQ (U2355A or U2356A)

2 Signal Conditioner (U2802A), which includes CJ Sensor error

3 Sensor (Thermocouples)

Errors introduced by each of the above components has to be accounted

for when calculating the total system accuracy. Since errors from each

component are not correlated with each other, the total system error will

be the root- sum- square (RSS) of all the errors:

Example:

Assume the following conditions:

• DAQ: Agilent U2355A

• Signal Conditioning: Agilent U2802A

• Ambient temperature: 23 °C

• Thermocouple type: J- type, standard limits of error

• Temperature to measure: 600 °C

E

TOTAL

2

= E

DAQ

2

+ E

SIG_COND

2

+ E

THERMOCOUPLE

2

Assume the following error specifications:

• U2355A: Gain error = 0.02% of reading

• Offset error = 1 mV

• U2802A gain = 97.673

• Gain error = 0.06% of reading

• Offset error = 15 µV (with respect to input)

• Zeroing error = 6 µV (with respect to input)

• CJ measurement accuracy = 1 °C

• Thermocouple = greater than 2.2 °C or 0.75% error

• Noise error has been omitted to simplify the example

46 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 57

Product Specifications 4

With zeroing, the offset errors from the DAQ and the U2802A can be

removed, and replaced with the zeroing error.

Based on the ITS- 90 Thermocouple table, a J- type thermocouple will

output 33.102 mV at 600 °C, and changes at a rate of approximately

59 µV/°C. This corresponds to (33.102 mV × 97.673) or 3.2332 V at the

input of the DAQ.

Hence, E

• E

DAQ

DAQ, ESIG_COND,

and E

ZEROING

are calculated as follows:

= 0.02% × 33.102 mV

= 6.62 µV

= 6.62 µV ÷ 59 µV/°C

= 0.112 °C

• E

SIG_COND

= (0.06% × 33.102 mV) ÷ 59 µV/ °C

= 0.337 °C

• E

ZEROING

= 6 µV ÷ 59 µV/°C

= 0.102 °C

Next, the cold junction sensor error is calculated.

At 23 °C, a J- type thermocouple output voltage changes at a rate of

52 µV/ °C. Thus, the CJ sensor error of 1 °C at 23 °C corresponds to

52uV/ °C × 1°C = 52 µV.

At 600 °C,

• E

CJC

= 52 µV ÷ 59 µV/°C

= 0.88 °C

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 47

Page 58

4 Product Specifications

Therefore,

E

THERMOCOUPLE

= 0.75% × 600 °C = 4.5 °C

Using the above individual component errors, the total measurement

system accuracy is calculated as below.

System accuracy without thermocouple sensor error:

E

= SQRT(E

TOTAL

DAQ

2

+ E

SIG_COND

2

+ E

ZEROING

2

+ E

CJC

2

)

= 0.95 °C

System accuracy with thermocouple sensor error:

E

= SQRT(E

TOTAL

DAQ

2

+ E

SIG_COND

2

+ E

ZEROING

2

+ E

CJC

2

+ E

THERMOCOUPLE

2

)

= 4.6 °C

48 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 59

System Typical Performance

Thermoelectric Characteristics

The thermoelectric characteristics for various thermocouple types is shown

in Figure 2- 10.

Product Specifications 4

Figure 4-10 Thermoelectric characteristics for various thermocouple types

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 49

Page 60

4 Product Specifications

NOTE

Typical Error vs. Measurement Performance

The U2802A measurement error with U2355A or U2356A at 23 °C ± 5 °C

is shown in Figure 2- 11.

Figure 4-11 U2802A measurement accuracy plot for various thermocouples type

Assume a ±1 °C error in the CJ measurement due to sensor error and temperature

gradient error in the accuracy numbers in Figure 4-2.

50 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 61

Making Accurate Temperature Measurements

Thermocouple measurement accuracy is very sensitive to cold junction

sensor errors and temperature gradients across the terminals. Keep the

module away from any heat sources and drafts to minimize any variation

between channels.

The channels located closest to the center near the reference thermistor

will have the best accuracy. It is important to use channels that are

physically close together on the screw terminals when taking relative

measurements. Channels that are closest together will have the best

agreement.

Product Specifications 4

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 51

Page 62

4 Product Specifications

52 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 63

Agilent U2802A 31-Channel Thermocouple Input

User’s Guide

5 Calibration

Calibration 54

Calibration Information 54

Zeroing Function 54

Restore Factory Calibration 55

This chapter contains the calibration information and factory restore

calibration procedure for the Agilent U2802A 31- channel thermocouple

input device.

Agilent Technologies

53

Page 64

5 Calibration

Calibration

Calibration Information

The Agilent U2802A is factory calibrated and the calibration constants are

stored in the EEPROM. During initial setup, the calibration constants are

read from the EEPROM before any measurements are taken.

Zeroing Function

The Agilent U2802A thermocouple input device operating in thermocouple

mode can be set to zero mode, where the differential inputs of each

channel are shorted together. This zeroing function is used to measure the

total system offset errors due to initial offset error, temperature drift

error, and long term drift error from the DAQ (U2355A or U2356A) and

the U2802A. This measurement can then be subtracted from subsequent

measurements in order to remove the system offset error.

54 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 65

Calibration 5

Restore Factory Calibration

The Restore Factory Calibration function in the Agilent U2802A is used to

restore calibration data from user’s settings to factory original settings. To

perform factory restore calibration, follow the step- by- step instructions

shown below:

1 Click Restore Factory Calibration in the thermocouple form.

2 A dialog box will appear as shown below.

3 Click OK to start the factory restore calibration process. Click Cancel

to not perform the restore factory calibration process.

Agilent U2802A 31-Channel Thermocouple Input User’s Guide 55

Page 66

5 Calibration

56 Agilent U2802A 31-Channel Thermocouple Input User’s Guide

Page 67

www.agilent.com

Contact us

T

o obtain service, warranty or technical support

assistance, contact us at the

following phone numbers:

United States:

(tel) 800 829 4444 (fax) 800 829 4433

Canada:

(tel) 877 894 4414 (fax) 800 746 4866

China:

(tel) 800 810 0189 (fax) 800 820 2816

Europe:

(tel) 31 20 547 2111

Japan:

(tel) (81) 426 56 7832 (fax) (81) 426 56 7840

Korea:

(tel) (080) 769 0800 (fax) (080) 769 0900

Latin America:

(tel) (305) 269 7500

Ta i w a n :

(tel) 0800 047 866 (fax) 0800 286 331

Other Asia Pacific Countries:

(tel) (65) 6375 8100 (fax) (65) 6755 0042

Or visit Agilent World Wide Web at:

www.agilent.com/find/assist

Product specifications and descriptions in this

document subject to change without notice.

© Agilent Technologies, Inc. 2008-2011

Third Edition, October 28, 2011

U2802-90003

Agilent Technologies

Loading...

Loading...