Practical Use of SpectrAA Series for

Multielement Analysis

Author

Brian D. Frary

Application Note

Atomic Absorption

Introduction

The SpectrAA system is designed for automatic multi-element analysis in flame furnace and hydride modes, up to 12 elements in 67 samples (45 in furnace mode) with

minimum operator supervision. When operating in the flame mode an operator

should be near at hand but can be carrying out other tasks.

When operating in the furnace mode the system can be left unattended as there are

no flammable gases and no exposed ignition source hence it can be left to operate

overnight.

A scenario is described for analysis by flame and shows how even a very complex

analytical program is easily handled by the SpectrAA.

The components of the system are:

SpectrAA-30 or SpectrAA-40 Atomic Absorption

Spectrophotometer

PSC-56 Programmable Sample Changer

GTA-96 Graphite Tube Atomizer

VGA-76 Vapor Generator Accessory

DS-15 Data Station

The above units except for the DS-15, are only fitted with an on/off power switch.

Programming and control of each unit in the system is through the DS-15 keyboard

but no computer programming knowledge is required by the operator. In fact the

system is designed for one finger operation using the “fill in the form” (F.I.T.F)

method developed by Agilent Technologies.

2

required (from 0.1% to 99.9%) and set a default time (1 to 500

seconds) for the system to achieve this. If the system is

unable to achieve the precision within the default time specified, measurement will stop and the precision achieved

printed out with the result. (The smaller the absorbance

signal the longer the measurement time required to obtain a

given precision).

This facility is extremely useful when high precision is required

but the element concentration (and thus absorbance) is

expected to vary widely. The operator can set the default time

for the lowest expected absorbance knowing that higher

absorbances will be read in a shorter time with no loss of

precision or waste of analysis time.

The concentrations of lead are expected to be low thus the

air-acetylene burner will be used to obtain higher sensitivity.

(NOTE When high sensitivity is not required a burner change

can be avoided by using a nitrous oxide-acetylene burner for

an air-acetylene flame. This eliminates programming a

“Pause” to change burners). PROMT mode could be used for

measurement but in this case the mean of three replicate

readings of 7-second integration is sufficient for the analytical

requirements.

Chromium forms ferro-chrome compounds in the air-acetylene flame and will therefore be determined using the nitrous

oxide-acetylene flame. This flame will also be used to determine molybdenum and silicon. All three elements will be

determined using five second integration and three replicates.

A delay of five seconds is programmed when using continuous aspiration so that each solution will be aspirated for five

seconds before any readings are taken. This ensures that the

previous solution is washed out of the nebulizer/burner

system. Cross contamination is prevented and the determinations will be more accurate. In addition a RINSE RATE and

RINSE TIME may be programmed if required (where sample

concentrations cover a wide range).

RECALIBRATION RATE and/or RESLOPE RATE are selected

on previous experience with the samples and elements.

Typical values could be reslope 10, recalibration 20.

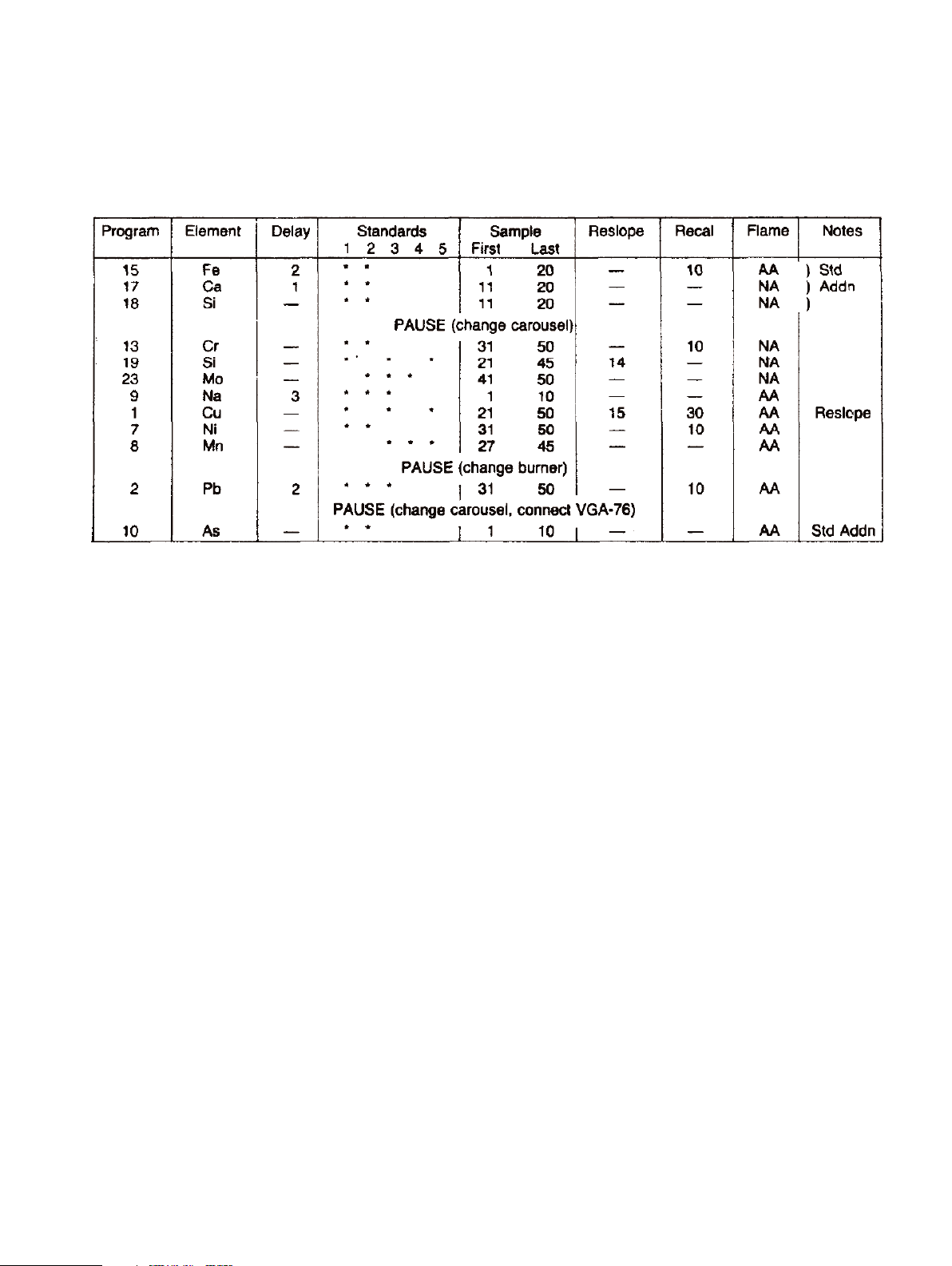

Up to five standards may be used for each element calibration. 5 mixed standards will be loaded into the sampler

carousel, but the number used will vary from element to

element (see Table 1).

Versatility and ease of use has been achieved in the system

design. The user friendly programming is designed to lead the

operator through the correct procedures.

At power up the DS-15 screen displays 3 modes of operation.

The operator selects one mode using the soft keys labelled:

DEVELOP METHOD

MODIFY METHOD

AUTOMATIC RUN

DEVELOP METHOD used by a chemist to set up and store

methods for the use of other staff.

MODIFY METHOD used in a similar manner.

AUTOMATIC RUN used for routine automatic analysis.

Flame Analytical Procedure

The following scenario shows how aII the facilities of the

system may be used to perform a complex analytical program.

A laboratory has the following samples for analysis:

• 20 steel samples for the determination of chromium,

copper, lead, manganese, molybdenum, nickel and silicon.

• 10 water samples for the determination of iron, sodium

and arsenic.

• 10 slag samples for the determination of calcium, iron

and silicon.

Steel Samples

Analytical method development has shown that most of the

elements in the steel samples can be determined by normal

calibration using mixed standards containing iron. The

SpectrAA- will be calibrated in the concentration mode using

the integration measurement mode for these elements.

Chromium and nickel concentrations must be determined

accurately over a narrow range and bracketing standards calibration will be used for these determinations. High precision

of measurement is also required thus PROMT mode will be

used.

PROMT is Precision Optimised Measurement Time. This

allows the operator to specify the precision of measurement

3

Water Samples

EPA methods specify standard additions calibration for water

analysis. Iron will be determined by this method using the airacetylene flame burning on a nitrous oxide-acetylene burner.

Continuous aspiration would normally be used for water samples but in this case the program “Fe in Slag” will be used

which uses the micro-sampling technique. Thus two different

sample types can be run on one program, the recalibration

rate being defined by the number of water samples.

Arsenic will also be determined by standard additions calibration but using hydride generation. Sodium will be determined

by EMISSION using normal calibration.

Two addition standards will be prepared from sample 1 and

used to produce the calibration graph. The other 9 samples

will be measured against this calibration because the matrices will be very similar.

Slag Samples

As the matrices will be complex and variable all elements will

be determined using STANDARD ADDITIONS calibration. The

dissolved solids concentration will be very high therefore continuous aspiration will not be used. Instead, the MICRO-SAMPLING feature of the PSC-56 will be used and measurements

made in peak height mode.

In micro-sampling the sampling probe dips into the solution

for a programmed time. During this time a certain volume of

liquid is drawn into the flame, the longer the time the greater

the volume (for a one second dip about 350 µL). An integration “window” of eight seconds is set on the system. This

allows enough time for the solution to travel through the nebulizer/burner system into the optical path to be measured. A

volume of 200 µL or more will give the same signal as continuous aspiration, 100 µL will give about 80% and 50 µL about

50% of the continuous aspiration signal. Micro-sampling is

also useful when only small volumes of sample are available

[1,2,3,4].

A RINSE between each sample and a SAMPLE FLUSH will

also be programmed. Using sample flush the probe dips into a

solution for half a second, the slug of liquid is drawn through

the capillary “flushing out” any traces of the previous solution

aspirated: no measurement is made on this solution. After

about 10 seconds the probe dips into the solution for the

specified dip time and the signal produced is measured.

Iron will be determined using the air-acetylene flame, silicon

and calcium using the nitrous oxide-acetylene flame, both

flames being run on the nitrous oxide-acetylene burner.

Typical system parameters for some elements are shown in

Figures 1 to 6.

Table 1.

Although RECAL will not be used for program 1, it is included here as it is part of the stored program.

AA = Air-Acetylene

NA = Nitrous Oxide-Acetyleen

4

Figure 1.

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

5

A DELAY of two minutes is programmed at the start of the

first program (15 iron) to ensure the burner is stabilized at its

operating temperature. FIRST and LAST sample numbers are

then entered, in this example 1 and 20.

The FIRST MEASUREMENT can be a calibration, a reslope or

sample.

If CALIBRATION is selected the system will calibrate with the

number of standards specified. If RESLOPE is selected this

will be applied to the stored calibration for that element. If

SAMPLE is selected the concentration values will be calculated from the stored calibration data. If there is no stored calibration then only the absorbance is measured. (Only copper

will be determined using a previously stored calibration and

thus the first measurement will be reslope.)

For the next program (17, calcium) a delay of 1 minute has

been entered to allow the burner to reach its operating temperature with the nitrous oxide-acetylene flame. First and last

sample numbers are entered as before. This procedure is followed for programs 18 (silicon), 13 (chromium), 19 (silicon)

and 23 (molybdenum) but without the delay time.

A delay of three minutes is entered for program 9 (sodium) which

will allow the burner to cool down to its operating temperature;

first and last sample numbers being entered as before.

Sample numbers are entered for program 1 (copper) and first

measurement is altered to RESLOPE. Sample numbers are

entered for programs 7 (nickel) and 8 (manganese).

A delay of two minutes is entered for program 2 (lead) to

allow the burner to reach its operating temperature as it will

be changed before this determination. The relevant sample

numbers are then entered for program 2 and 10 (arsenic).

The final entry to be made is PAUSE AFTER PROGRAM which

appears at the bottom of the screen. This PAUSE facility can be

used several times in a sequence, enabling carousels, standards

and reslope standards to be replaced; burners to be exchanged,

rotated, or their height adjusted; the VGA-76 to be fitted. Lamps

can also be exchanged if nine or more elements are being

determined and multi-element lamps are not being used.

The first PAUSE entry will be 18 which will enable the

carousels to be exchanged. When the system automatically

pauses after the completion of program 18, the operator can

insert the next PAUSE request, in our example 8, to change

the burner. Finally when this second pause command is acted

upon during operation the operator can insert the last PAUSE

request, in our example 2, to enable the VGA-76 to be

installed.

Programming the Automatic Run

It will be useful to draw up a table (Table 1) when planning

the analysis. This can then be used when compiling the

sequence control page on the DS-15 (Figure 8).

Elements requiring standard additions calibration will be

determined first.

AUTOMATlC RUN soft key is pressed and SEQUENCE SELECTION page (Figure 7) is displayed. The relevant programs are

selected on this page and the soft key for SEQUENCE CONTROL pressed. The programs selected are displayed by

number and title on the left side of the screen (Figure 8).

Figure 7.

Figure 8.

6

Having completed the sequence control page the NOTES soft

key is pressed then the REPORT FORMAT soft key. This

screen enables the following to be displayed and printed on

the report:

Operator name

Date

Batch name

and the report parameters selected:

Format Sequential* or Multi-element

Data printed Mean Concentration only* or

Mean Concentration and %RSDor

Mean Concentration, %RSD & Mean

Absorbance or

Each Reading (Mean Concentration,

%RSD, Mean Absorbance and Every

Absorbance Reading).

Print During Run* or After Run or Manual

Instrument status Yes or No*

Notes Yes or No*

Calibration results Yes* or No

Calibration graph Yes or No*

Sample labels Yes* or No

Lines per page Select for page length used (usually 66)

See Figure 9. Parameters normally used are indicated by *.

If PRINT DURING RUN is selected then all the other features

selected will be printed during the run. All results obtained

after the start of the run can be inspected on the print-out.

However when using PRINT MANUAL or PRINT AFTER RUN,

only the results currently displayed on the screen are available

for inspection.

The analytical run can be completed in a slightly shorter time

if PRINT MANUAL is selected.

The absorbance values of all solutions are stored on the program disc as they are read (no matter which PRINT status is

selected). If a power failure occurs during the analysis the

only data lost will be that for the solution under analysis. No

other data is lost or corrupted.

At the end of the analytical run all the data may be archived

and a multi-element report produced. It is recommended that

the data is archived before another run is performed as the

program disc is cleared of data when START is pressed.

If SAMPLE LABELS is selected then a screen as shown in

Figure 10 is displayed (up to 12 alphanumeric characters can

be used). INCREMENT LABELS is a time saving facility. In

Figure 10, W113 is the first water sample and is entered as

sample 1. INCREMENT LABELS is pressed and samples 2 to

10 are automatically labelled W114 to W122. The cursor is

moved to sample 11, relabelled SL536 and INCREMENT

LABELS pressed. Samples 12 to 20 are automatically labelled

SL537 to SL545. Finally the cursor is moved to sample 21,

relabelled S907 and INCREMENT LABELS pressed. Samples

22 to 42 are automatically labelled S908 to S928. MORE

LABELS is pressed, samples 43 to 67 are displayed and are

automatically labelled S929 to S953.

Loading Off Carousels

Two carousels will be used, one for STANDARD ADDITIONS

calibration (water samples 1 to 10, slag samples 11 to 20), the

other for NORMAL calibration (steel samples 21 to 50).

The standard additions carousel will be loaded as follows:

Figure 9.

Figure 10.

7

Sample position 1 Blank

2 Addition 1

3 Addition 2

4 Addition 0 (sample 1)

5 to 13 Addition 0 (samples 2 to 10)

14 Blank

15 Addition 1

16 Addition 2

17 Addition 0 (sample 11)

18 to 26 Addition 0 (samples 12 to 20)

The second carousel, for normal calibration will be loaded:

Multi-element standards in standard positions 1 to 5. Blank

and reslope solutions in their respective positions. Water

samples in sample positions 1 to 10 and steel samples in

positions 21 to 50.

Operation

When the operator has fitted the required burner and

carousel the flame is lit and START key pressed.

Operation proceeds as foIlows:

The system recalls the first program in the sequence (15)

resets the sampler and checks all system parameters are correctly set. It waits 2 minutes for the burner to warm up while

aspirating distilled water. It then carries out the calibration of

the system with the addition standards for waters and measures the first 10 samples (waters). It then recalibrates the

system with the addition standards for slags and measures

samples 11 to 20 (slags).

The next program (17) is recalled and the system set up to

these parameters. The burner is allowed to warm up for the

programmed 1 minute before calibration proceeds. Samples 1

to 10 are then measured.

The next program (18) in the sequence is recalled and the

system set up on these parameters. Calibration proceeds

immediately as no delay has been programmed (the burner is

already at its operating temperature). Samples 1 to 10 are

measured for this element.

After sample 10 is measured the next program (13) is recalled

and the system “beeps” to remind the operator that a programmed PAUSE has been reached. The operator presses

STOP, changes carousels, alters PAUSE AFTER PROGRAM to

8 and presses START. As no delay has been programmed the

system proceeds to calibrate and then measures samples 31

to 40. A RECALIBRATION is then carried out and samples

41 to 50 are measured.

Program 19 is then recalled, the system set up, calibration is

performed and samples 21 to 35 are measured. RESLOPE is

performed and samples 36 to 45 measured.

Program 23 is recalled, the system set up, calibration is performed and samples 41 to 50 measured.

Program 9 is recalled, the system is set up and changes to

the air-acetylene gas mixture waiting for the 3 minutes programmed delay while the burner cools down to its operating

temperature. Calibration is performed and samples 1 to 10 are

measured.

Program 1 is recalled, the system set up, a RESLOPE is performed and applied to the stored calibration. If the reslope is

correct, samples 21 to 36 are measured. A RESLOPE is

performed and samples 37 to 50 measured.

Program 7 is recalled, the system set up, calibration is performed and samples 31 to 40 measured. A RECALIBRATION is

performed and samples 41 to 50 measured.

Program 8 is recalled, the system set up, calibration is performed and samples 27 to 45 measured. Program 2 is recalled

and the system “beeps” to remind the operator that a programmed PAUSE has been reached. The operator presses

STOP, presses FLAME OFF, changes burners, alters PAUSE

AFTER PROGRAM to 2 then presses IGNITE and START. The

system waits 2 minutes for the burner to warm up then calibrates and measures samples 31 to 40. A RECALIBRATION is

then carried out and samples 41 to 50 are measured.

Program 10 is recalled and the system “beeps” to remind the

operator that a programmed PAUSE has been reached. The

operator presses STOP and FLAME OFF, connects the VGA-76

hydride generator, replaces the carousel in use by the one for

standard addition calibration and presses IGNITE. START is

pressed, the system performs the calibration procedure and

determines the arsenic concentrations of samples 1 to 10.

After the last sample is determined the flame is automatically

extinguished and the system “beeps” indicating the analytical

run has been completed.

Archiving and multi-element report

The INDEX key is pressed and page 19 UTILITIES selected.

From the display ARCHIVE is selected followed by the file (on

the utilities disc) for archiving. The ARCHIVE soft key is

pressed and the data is permanently stored.

After returning to the UTILITIES index, PRINT REPORTS is

selected. From the next display the data set required is

chosen and then the elements required. REPORT FORMAT

soft key is pressed and the following is displayed:

8

Format Sequential or multi-element*

Data printed Mean concentration only* or

Mean concentration and %RSDor

Mean concentration, %RSD and mean

absorbance or

Each Reading (Mean Concentration,

%RSD, Mean Absorbance and Every

Absorbance Reading).

Instrument status Yes or No*

Notes Yes or No*

Calibration results Yes* or No

Calibration graph Yes or No*

Sample labels Yes* or No

Weight correction Yes* or No

Lines per page Select for page length used (usually 66)

Parameters normally used are indicated by *

If WEIGHT CORRECTION is selected the measured concentration of the elements in the samples is automatically calculated before print out. This is a time (and error) saving facility.

PRINT REPORT is pressed and the multi-element report is

duly obtained (Figure 11).

Figure 11.

9

As all the analytical data is now archived other reports can be

generated at any time if required. For example a report showing all data for arsenic (program 25) is required. This is easily

produced by:

• Accessing the utilities disc, selecting the appropriate

archive file, then selecting the element to be printed (in

this case arsenic). Proceed to report format via the soft

key and select the options required, then print report.

• The SpectrAA- system can be used for an automatic run

in the same way. However as it has a manually operated

turret the operator must bring the next lamp into the

operating position when prompted by the DS-15. If multielement lamps are used then this requirement is reduced

or even eliminated.

References

1. L. M. Voth, “Analysis of High Dissolved Solids Solutions

by Flame Microsampling”, Varian Instruments At Work

Number AA-13, February 1981.

2. L. M. Voth, “Analysis of Battery Acids by Flame

Microsampling”, Varian Instruments At Work Number

AA-14 April 1981.

3. L. M. Voth, “Determination of Calcium and Magnesium in

Blood Serum by Automated Flame Microsampling”,

Varian Instruments At Work Number AA-15, April 1981.

4. L. M. Voth, “Determination of Chromium, Lead and

Cadmium in Drinking Water by Solvent Extraction and

Flame Microsampling”, Varian Instruments At Work

Number AA-16, August 1981.

For More Information

For more information on our products and services, visit our

Web site at www.agilent.com/chem

www.agilent.com/chem

Agilent shall not be liable for errors contained herein or

for incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

Information, descriptions, and specifications in this

publication are subject to change without notice.

© Agilent Technologies, Inc., 1985

Printed in the USA

November 1, 2010

AA048

Loading...

Loading...