Udo Huber

Saponification of procaine: Kinetic

measurements with the Agilent high

throughput analysis system

Abstract

In this application note we describe how the cleavage of procaine, a

p-aminobenzoic acid ester, can be monitored using the Agilent 220

microplate sampler (MPS) with the Agilent 1100 Series LC system. The

data of the measurements is transferred to ChemStore C/S, the data-

base module of the Agilent ChemStation Plus, for data analysis. We

show that the data can then be transferred easily to a spreadsheet

program, for example Microsoft®Excel®, for further calculations such

as determination of the rate coefficient.

Application Note

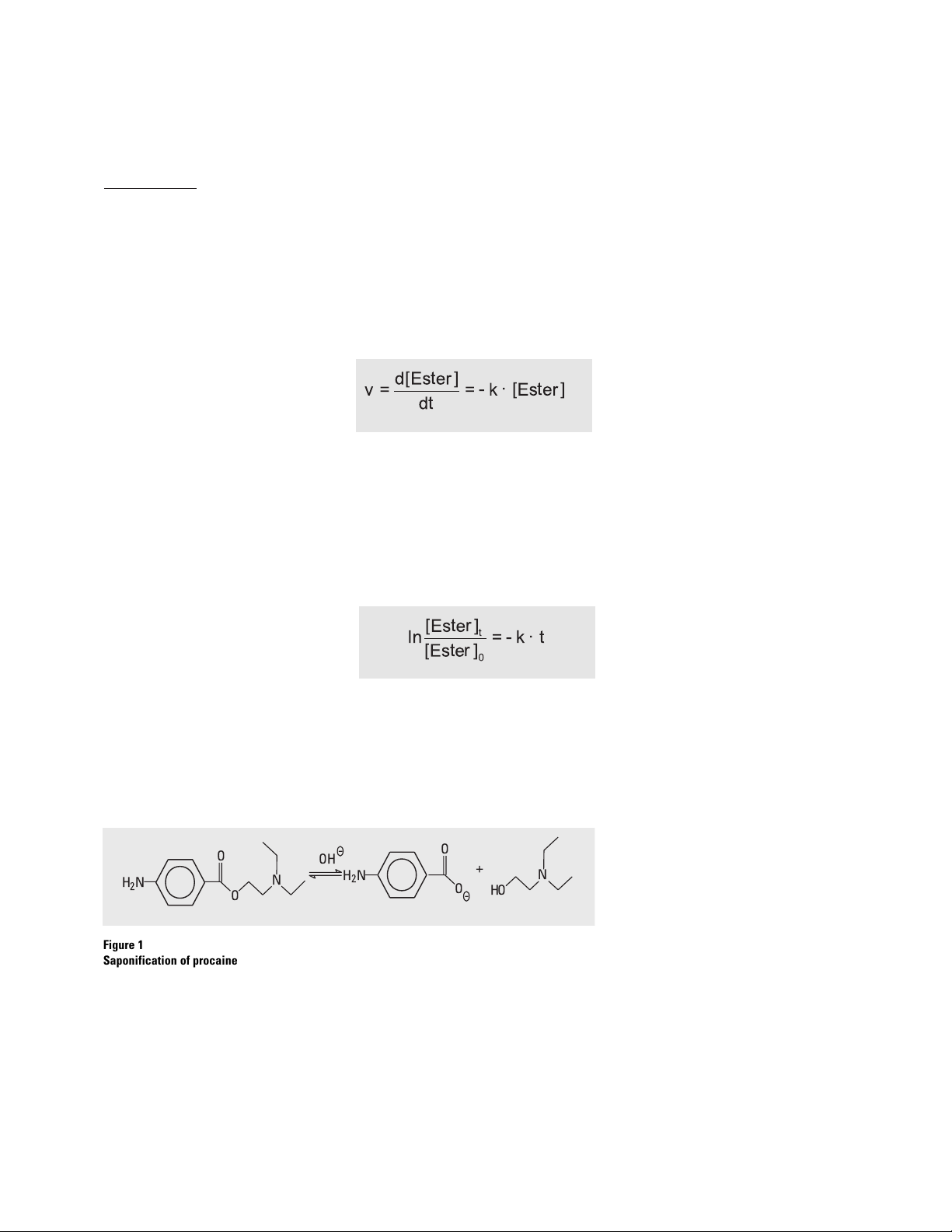

Procaine is a p-aminobenzoic acid

ester, which can be saponificated

into p-aminobenzoic acid (PABA)

and an alcohol. The reaction is

shown in figure 1.

Since the reaction is first order

the rate of reaction can be

described as:

with:

v (rate of reaction)

k (rate coefficient)

[Ester] (concentration of

procaine)

Integration of this formula gives:

The rate coefficient k can be

determined from the slope of the

straight line in the graph

ln([Ester]

t

/[Ester]0) against time.

Introduction

Kinetic measurements play an

important role in pharmaceutical

chemistry. Not only for pharmacokinetics where the rate of active

compound degradation has to be

determined, but also for drug discovery to test the inhibition effect

of a compound on an enzyme. For

very fast reactions special apparatus, for example shock tubes,

have to be used but slower reactions can be monitored by analyzing reaction samples at specific

time intervals. This application

note describes how this is

achieved using the Agilent 220

MPS with the Agilent 1100 Series

LC System and the Agilent ChemStation Plus software. Saponification of procaine at pH=10 was

selected as a model scenario.

Figure 1

Saponification of procaine

v·-==

Esterd

][][Esterk

dt

][

ln

Ester

Ester

t

][

0

tk

·-=

O

H2N

OH

N

O

H2N

O

+

O

HO

N

Equipment

The system included an Agilent

1100 Series vacuum degasser, an

Agilent 1100 Series binary pump,

an Agilent 1100 Series thermostatted column compartment, an Agilent 1100 Series diode array detector and an Agilent 220 micro plate

sampler.

The system was controlled using

the Agilent ChemStation Plus (version A.07.01) and the micro plate

sampling software (version

A.03.01).

System Setup Overview

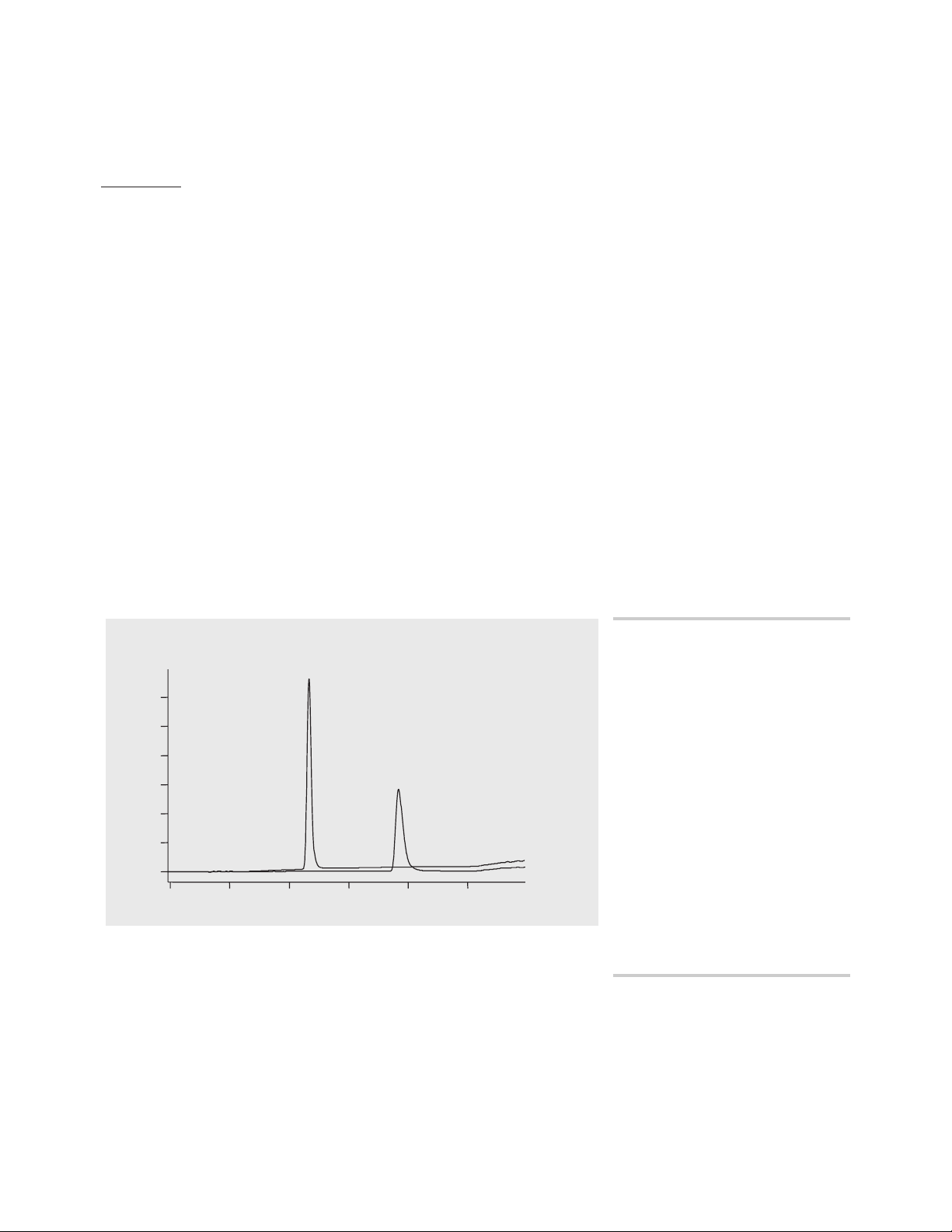

1. A chromatographic method for

measuring procaine and PABA

was developed on the Agilent

220 MPS and the Agilent 1100

Series LC system.

2. Standards for both compounds

were measured, the method

was calibrated and the run time

was extended to 20 minutes

(figure 2).

3. Three procaine samples were

dissolved in 0.025 M NaH2PO

4,

buffer adjusted to pH=10.

These samples were measured

with the method described

before, which gives an overall

run time of one hour for the

three samples.

4. The measurement was repeated

24 times to give an overall

study run time of 24 hours.

5. The measured data was automatically transferred to the

ChemStation Plus database

module were the Charts

amount against reaction time

was created.

6. To determne the rate coefficient

the data was then automatically

transferred to Microsoft Excel.

Time [min]

012345

Absorbance

[mAU]

0

50

100

150

200

250

300

PABA

Procaine

Mobile Phases: A= 0.025M NaH2PO4in

water (pH=2.5), B = ACN

Gradient: 5 % B for 3.5 min,

flow 1 ml/min

5 % B to 50 % B in 1.5 min,

flow 1 ml/min

50 % B for 0.5 min,

flow 1 ml/min

50 % B to 5 % B in 0.5 min,

flow 1 ml/min

5 % B, flow from 1 ml/min to

0.1 ml/min in 0.1 min

5 % B,

flow 0.1 ml/min for 18.9 min

5 % B, flow 0.1 ml/min to

1 ml/min in 0.1 min

5 % B for 0.9 min,

flow 1 ml/min

Stop time: 20 min

Column: Zorbax SB-C18, 4.6 x 75 mm,

5 µm

Column temp.: 50 ºC

UV detector: DAD 204 nm/16

(reference 360 nm/100)

Figure 2

Measurement of standards

Results and Discussion

Method calibration

A three-level calibration was done

after measuring standards for procaine and PABA using the method

in figure 2.

Study setup and sample

measurement

The method above was renamed

four times and set up in the Study

Parameters screen. Injection

ordered by method was selected

and three samples were set up, as

shown in figure 3. Since every

method runs for about 20 minutes,

each of the three samples was

analyzed every hour. To measure

the samples over 24 hours the

study was repeated six times. This

was set up in the Start Study window.

The study was started and the

measured sample data was automatically transferred to a ChemStation Plus database study, which

was set up before.

Figure 3

Study setup

ChemStation Plus database

results and charts

The study results were loaded into

the ChemStation Plus database

module and Sample Name, Injec-

tion Time and Amount were dis-

played in Compound view. By

selecting procaine and/or PABA in

the Compound List the results

were displayed in a comprehensible table (Table Layout). The

results for a specific sample were

displayed using a Filter on the

field Sample Name. The reaction

is first order, as can be clearly

seen in the chart shown in

figure 4, which was created in the

Chart Layout view of the ChemStation database module.

0

20

40

60

80

100

120

Thu 12:00

Thu 15:00

Thu 18:00

Thu 21:00

Fri 00:00

Fri 03:00

Fri 06:00

Fri 09:00

Fri 12:00

Amount [mg/l]

Injection Time

Amount / Injected [PABA]

Amount / Injected [Procaine]

Figure 4

Saponification of procaine: Amount against reaction time

Determination of the rate

coefficient by exporting the

data to Microsoft Excel

The table created for procaine

containing the fields Sample

Name, Injection Time and

Amount in the ChemStation Plus

database module was filtered for

one sample and transferred to a

Microsoft Excel file. This was

done using the Export function of

the ChemStation Plus database

module by selecting Data and MS

Excel in the Export window. In

Microsoft Excel the injection time

difference was calculated in seconds beginning at the first injection at t0. The calculated value

gives the x-axis of figure 5.

The y-axis is calculated as

ln([Ester]t/[Ester]0). The negative

value of the rate coefficient is the

slope of the resulting straight line

(figure 5). The calculated results

for the first seven injections are

shown in table 1.

Sample injected (X) Time difference Time difference Procaine amount (Y) [Ester]

t

[hh:mm:ss] [s] [mg/l] [Ester]

0

2/3/00 11:02:59 AM = t

0

129.838290062179 = [Ester]0

2/3/00 12:06:45 PM 1:03:46 3826.00 125.14649513062 -0.036804741

2/3/00 1:10:30 PM 2:07:31 7651.00 120.783350276534 -0.072291306

2/3/00 2:14:27 PM 3:11:28 11488.00 116.502232323668 -0.108379319

2/3/00 3:18:14 PM 4:15:15 15315.00 112.19641294469 -0.146038731

2/3/00 4:22:05 PM 5:19:06 19146.00 108.006644852136 -0.184097002

2/3/00 5:25:56 PM 6:22:57 22977.00 104.201332127358 -0.21996484

Figure 5

Determination of rate coefficient

Table 1

Calculated results

ln

0 20000 40000 60000 80000 100000

0

-0.2

-0.4

ln ([E]t\[E]0)

-0.6

-0.8

-1

y = -0.0000099x + 0.0081439

R2 = 0.9996792

k = 9.9E-6

Time [s]

Conclusion

In this application note a kinetic

measurement for the saponification of procaine at pH=10 was performed and analyzed using the

Agilent 220 MPS, the Agilent 1100

Series LC system and the Agilent

ChemStation Plus. The progress of

the reaction was monitored in the

ChemStation Plus database module and the data was transferred

further to Microsoft Excel for calculation of the rate coefficient.

The transfer was done automatically. It was not necessary to

transfer the data manually, which

would have been a slow, tedious

and error-prone process.

Copyright © 2000 Agilent Technologies

All Rights Reserved. Reproduction, adaptation

or translation without prior written permission

is prohibited, except as allowed under the

copyright laws.

Printed 07/2000

Publication Number 5980-1661E

Udo Huber is an application

chemist based at Agilent

Technologies, Waldbronn,

Germany

For more information on our products and services, visit our website at:

http://www.agilent.com/chem

Microsoft and Excel are registered trademarks

of Microsoft Corporation.

Loading...

Loading...