Page 1

Agilent 1100 Series

Quaternary Pump

Reference Manual

sa

Page 2

Copyright Agilent

Technologies 1999

All rights reserved.

Reproduction, adaption,

or translation without

prior written permission

is prohibited, except as

allowed under the

copyright laws.

Part No. G1311-90003

Edition 01/00

Printed in Germany

Warra nty

The information

contained in this

document is subject to

change without notice.

Agilent Technologies

makes no warranty of

any kind with regard to

this material,

including, but not

limited to, the implied

warranties or

merchantability and

fitness for a particular

purpose.

Agilent Technologies

shall not be liable for

errors contained herein

or for incidental or

consequential damages

in connection with the

furnishing, performance,

or use of this material.

WAR N ING

For details of safety,

see Safety Information

on page 260.

Warning Symbols Used

In This Book

!

The apparatus is marked

with this symbol when

the user should refer to

the instruction manual

in order to protect the

apparatus against

damage.

Agilent Technologies

Hewlett-Packard-Strasse 8

76337 Waldbronn

Germany

Page 3

Agilent 1100 Series Quaternary Pump

Reference Manual

Page 4

In This Book

This manual contains technical reference information about the Agilent 1100

Series quaternary pump. The manual describes the following:

• installation,

• optimizing performance,

• troubleshooting,

• repairing,

• parts and materials,

• theory of operation, and

• specifications.

4

Page 5

Contents

1 Installing the Pump

How to install the quaternary pump 13

Site Requirements 14

Unpacking the Quaternary Pump 17

Optimizing the Stack Configuration 20

Installing the Quaternary Pump 22

Flow Connections of the Quaternary Pump 25

Priming and Purging the System 28

2 Optimizing Performance

How to optimize the quaternary pump to achieve best chromatographic results 31

Hints for Successful Use of the Quaternary Pump 32

Solvent Information 34

Prevent Blocking of Solvent Filters 35

Operational Hints for the Vacuum Degasser 36

Operational Hints for the Multi Channel Gradient Valve

(MCGV) 37

When to use the Continuous Seal Wash Option 38

When to Use Alternative Seals 39

Optimize the Compressibility Compensation Setting 40

3 Troubleshooting and Test Functions

The quaternary pump’s built-in troubleshooting and test

functions 43

Status Indicators 45

5

Page 6

Contents

Power Supply Indicator 46

Pump Status Indicator 46

Error Messages 47

Timeout 48

Shut-Down 49

Remote Timeout 50

Synchronization Lost 51

Leak 52

Leak Sensor Open 53

Leak Sensor Short 54

Compensation Sensor Open 55

Compensation Sensor Short 56

Fan Failed 57

Open Cover 58

Restart Without Cover 59

Zero Solvent Counter 60

Pressure Above Upper Limit 61

Pressure Below Lower Limit 62

Pressure Signal Missing 63

Missing Pressure Reading 64

Pump Configuration 65

Valve Fuse 66

Inlet-Valve Fuse 67

Valve Failed 68

Motor-Drive Power 69

Encoder Missing 70

Inlet-Valve Missing 71

Temperature Out of Range 72

Temperature Limit Exceeded 73

Servo Restart Failed 74

6

Page 7

Contents

Pump Head Missing 75

Index Limit 76

Index Adjustment 77

Index Missing 78

Stroke Length 79

Initialization Failed 80

Wait Timeout 81

Pressure Test 82

Running the Pressure Test 84

Evaluating the Results 86

Leak Test 88

Running the Leak Test 90

Evaluating the Results 92

4 Repairing the Pump

Instructions on simple, routine repair procedures as well as

more extensive repairs requiring exchange of internal

parts 97

Cleaning the Quaternary Pump 99

Using the ESD Strap 100

Overview 101

Simple Repair Procedures 102

Exchanging the Active Inlet Valve Cartridge or the Active Inlet

Valve 103

Exchanging the Outlet Ball Valve 106

Exchanging the Purge Valve Frit or the Purge Valve 108

7

Page 8

Contents

Removing and Disassembling the Pump Head Assembly 110

Exchanging the Pump Seals and Seal Wear-in Procedure 112

Exchanging the Plungers 115

Installing the Continuous Seal Wash Option 116

Exchanging the Wash Seals 119

Reassembling the Pump Head Assembly 121

Exchanging the Multi-Channel Gradient Valve (MCGV) 123

Exchanging the optional Interface Board 126

Exchanging Internal Parts 127

Removing the Top Cover and Foam 128

Exchanging the Low Pressure Pump Main Board (LPM

Board) 131

Exchanging the Damper 138

Exchanging the Fan 141

Exchanging the Pump Drive 143

Exchanging the Power Supply 147

Exchanging the Leak Sensor 152

Exchanging the Status Light Pipe 154

Assembling the Main Cover 155

Replacing the Top Cover and Foam 156

5 Parts and Materials

Detailed illustrations and lists for identification of parts and

materials 159

Overview of Main Assemblies 160

Control Module (B-version) 163

Solvent Cabinet 164

8

Page 9

Contents

Bottle Head Assembly 165

Hydraulic Path 166

Cover Parts 167

Sheet Metal Kit 168

Foam Parts 169

Power and Status Light Pipes 170

Leak Parts 171

Pump Head Assembly 172

Pump Head Assembly with Seal Wash Option 174

Outlet Ball Valve Assembly 176

Purge Valve Assembly 177

Active Inlet Valve Assembly 178

Accessory Kit G1311-68705 179

Seal Wash Option Kit 01018-68722 180

Cable Overview 181

Analog Cables 183

Remote Cables 185

BCD Cables 190

Auxiliary Cable 192

CAN Cable 192

External Contact Cable 193

RS-232 Cable Kit 194

LAN Cables 195

6 Introduction to the Quaternary Pump

An introduction to the pump, instrument overview, theory of

operation, external communication and internal

connectors 197

9

Page 10

Contents

Introduction to the Quaternary Pump 198

Overview 199

Electrical Connections 204

Instrument Layout 206

Early Maintenance Feedback (EMF) 207

The Electronics 209

The Low-Pressure Pump Main Board (LPM) 210

Firmware Description 214

Optional Interface Boards 216

Agilent 1100 Series Interfaces 218

Setting the 8-bit Configuration Switch 223

The Main Power Supply Assembly 228

7 Control Module Screens for the Quaternary Pump

Screens available from the Analysis screen 233

Screens available from the System screen 242

Screens available from the Records screen 244

Diagnostics and Tests 251

8 Specifications

Performance specifications of the quaternary pump 253

Performance Specifications 254

Warranty Statement 257

Safety Information 260

Lithium Batteries Information 263

10

Page 11

Contents

Radio Interference 264

Sound Emission 264

Solvent Information 265

Agilent Technologies on Internet 266

11

Page 12

Contents

12

Page 13

1

1 Installing the Pump

How to install the quaternary pump

Page 14

Installing the Pump

Site Requirements

Site Requirements

A suitable environment is important to ensure optimum performance of the

quaternary pump.

Power Consideration

The quaternary pump power supply has wideranging capability (see Table 1

on page 16). It accepts any line voltage in the range described in the above

mentioned table. Consequently there is no voltage selector in the rear of the

quaternary pump. There are also no externally accessible fuses, because

automatic electronic fuses are implemented in the power supply.

WARNING To disconnect the quaternary pump from line, unplug the power cord.

The power supply still uses some power, even if the power switch on

the front panel is turned off.

WARNING Shock hazard or damage of your instrumentation can result, if the

devices are connected to a line voltage higher than specified.

Power Cords

Different power cords are offered as options with the quaternary pump. The

female end of each of the power cords is identical. It plugs into the

power-input socket at the rear of the quaternary pump. The male end of each

of the power cords is different and designed to match the wall socket of a

particular country or region.

WARNING Never operate your instrumentation from a power outlet that has no

ground connection. Never use a power cord other than the power cord

designed for your region.

WARNING Never use cables other than the ones supplied by Agilent Technologies

to ensure proper functionality and compliance with safety or EMC

regulations.

14

Page 15

Installing the Pump

Site Requirements

Bench Space

The quaternary pump dimensions and weight (see Table 1 on page 16) allow

to place the quaternary pump on almost any laboratory bench. It needs an

additional 2.5 cm (1.0 inches) of space on either side and approximately 8 cm

(3.1 inches) in the rear for the circulation of air and electric connections.

If the bench should carry a complete Agilent 1100 Series system, make sure

that the bench is designed to carry the weight of all the modules.

NOTE The pump should be operated in a horizontal position!

Environment

Your quaternary pump will work within specifications at ambient

temperatures and relative humidity as described in Table 1 on page 16.

CAUTION Do not store, ship or use your quaternary pump under conditions where

temperature fluctuations could cause condensation within the quaternary

pump. Condensation will damage the system electronics. If your quaternary

pump was shipped in cold weather, leave it in its box and allow it to warm

slowly to room temperature to avoid condensation.

15

Page 16

Installing the Pump

Site Requirements

Table 1 Physical Specifications

Type Specification Comments

Weight 11 kg (25 lbs)

Dimensions

(height × weight × depth)

Line voltage

Line frequency

Power consumption 220 VA Maximum

Ambient operating temperature

Ambient non-operating temperature

Humidity

Operating Altitude Up to 2000 m (6500 ft)

Non-operating altitude Up to 4600 m (14950 ft) For storing the quaternary

Safety standards: IEC, CSA, UL Installation Category II, Pollution Degree 2

140 × 345 × 435 mm

(5.5 × 13.5 × 17 inches)

100–120 or 220–240 VAC,

50 or 60 Hz,

4–55

-40–70

< 95%, at 25–40

± 5%

°C (41–131 °F)

°C (-4–158 °F)

°C (77–104 °F)

± 10%

Wide-ranging capability

Non-condensing

pump

16

Page 17

Installing the Pump

Unpacking the Quaternary Pump

Unpacking the Quaternary Pump

Damaged Packaging

Upon receipt of your quaternary pump, inspect the shipping containers for

any signs of damage. If the containers or cushioning material are damaged,

save them until the contents have been checked for completeness and the

quaternary pump has been mechanically and electrically checked. If the

shipping container or cushioning material is damaged, notify the carrier and

save the shipping material for the carrier’s inspection.

CAUTION If there are signs of damage to the quaternary pump, please do not attempt to

install the quaternary pump.

Delivery Checklist

Ensure all parts and materials have been delivered with the quaternary pump.

The delivery checklist is shown in Table 2. To aid in parts identification,

please see Chapter 5 “Parts and Materials”. Please report missing or damaged

parts to your local Agilent Technologies sales and service office.

Table 2 Quaternary Pump Checklist

Description Quantity

Quaternary pump 1

Solvent cabinet 1 (5062-8581)

Solvent bottles 4 (3 transparent 9301-1420, 1 amber 9301-1450)

Bottle head assembly 4 (G1311-60003)

Waste tube, purge valve 1 (5042-2461, reorder number, 5m)

Vacuum degasser 1

Solvent tubes for the

degasser

Power cables 2

4 (G1322-67300)

17

Page 18

Installing the Pump

Unpacking the Quaternary Pump

Table 2 Quaternary Pump Checklist, continued

Description Quantity

CAN cable 1

Remote cable As ordered

Signal cable As ordered

Reference Manual 2 (1 for the pump, 1 for the degasser)

Accessory kit (see Table 3) 1

Accessory Kit Contents — Quaternary Pump

Table 3 Accessory Kit Contents G1311-68705

Description Part Number Quantity

Capillary, pump to injection device G1312-67305 1

Seal insert tool 01018-23702 1

Wrench; 1/4 – 5/16 inch 8710-0510 1

Wrench; 14 mm 8710-1924 1

ESD wrist strap

*

9300-1408 1

Hex key 4mm 8710-2392 1

Waste tube (reorder number, 5m) 5062-2463 1.2 m

Velocity regulator (reorder number) 5062-2486 2

PTFE Frit 01018-22707 5

*

ESD: Electrostatic Discharge

18

Page 19

Installing the Pump

Unpacking the Quaternary Pump

Accessory Kit Contents—Vacuum Degasser

Table 4 Accessory Kit Contents G1322-68705

Description Part Number Quantity

Syringe 5062-8534 1

Syringe adapter 9301-1337 1

Waste tube (reorder number, 5m) 5062-2463 1.2 m

Connecting tubes labeled A to D G1322-67300 4

19

Page 20

Installing the Pump

Optimizing the Stack Configuration

Optimizing the Stack Configuration

If your quaternary pump is part of a complete 1100 Series system, you can

ensure optimum performance by limiting the configuration of the system

stack to the following configuration. This configuration optimizes the system

flow path, ensuring minimum delay volume.

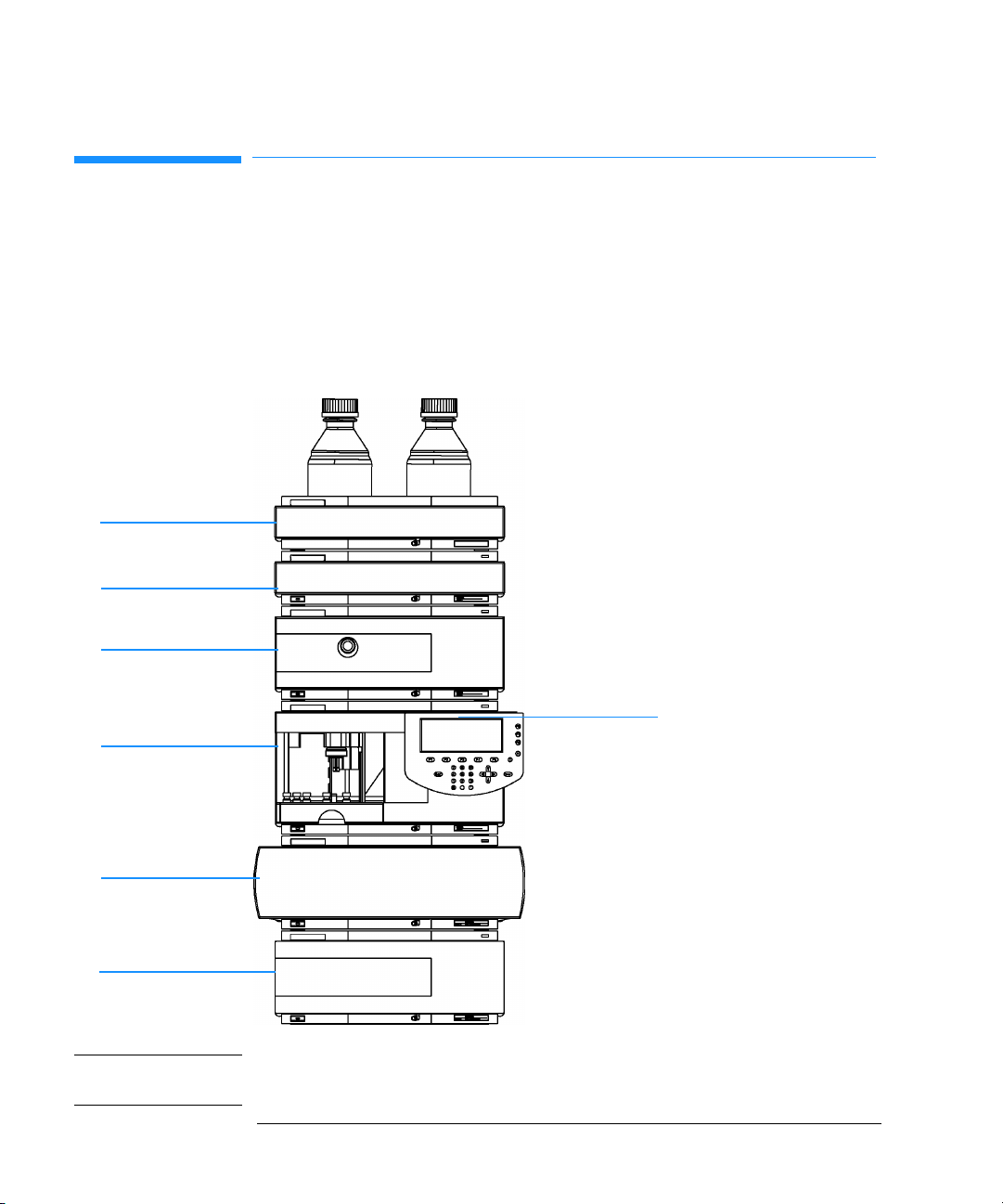

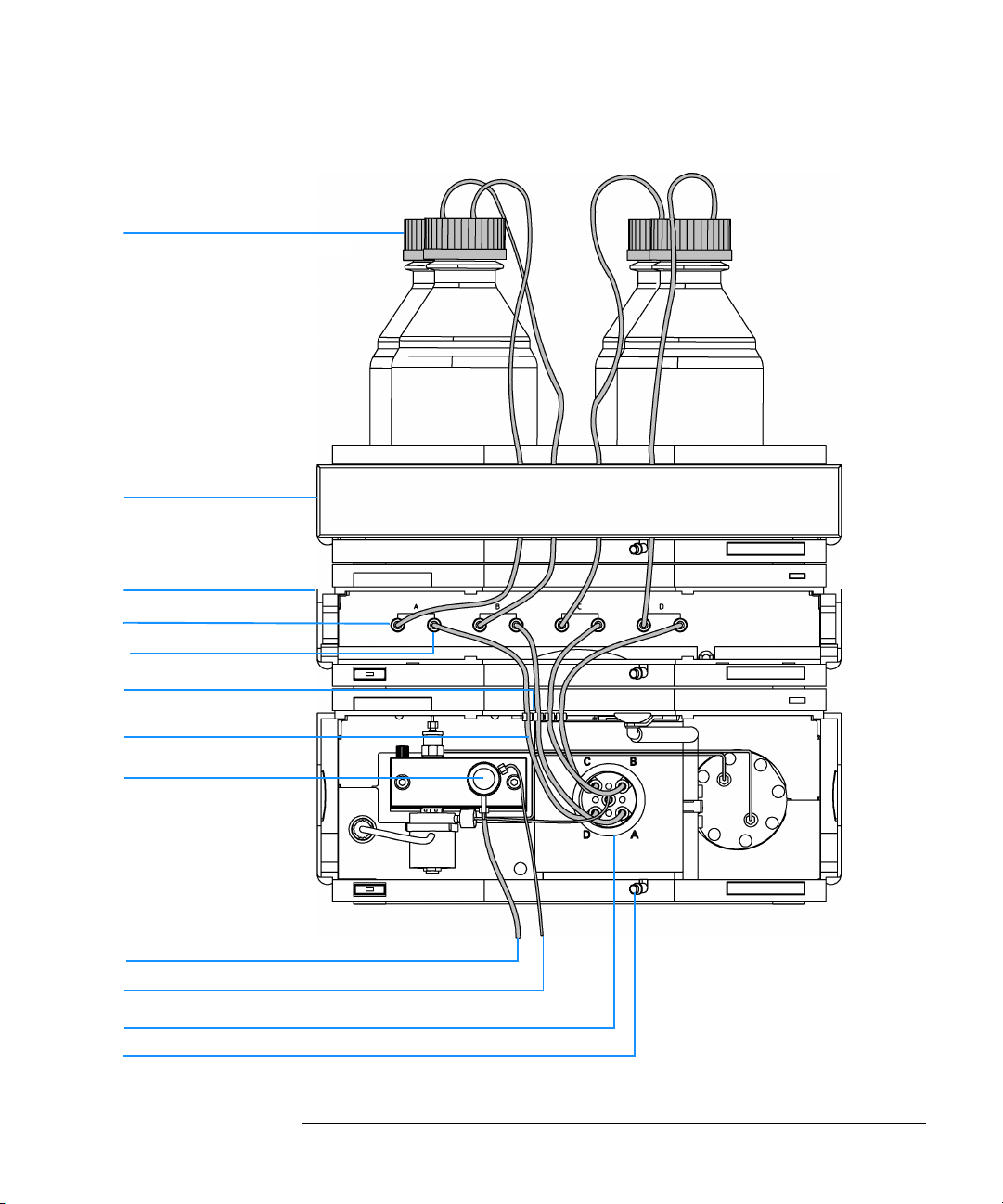

Figure 1 Recommended Stack Configuration (Front View)

Flow connections in the stack:

Example setup with 0.17mm ID green capillaries

Solvent bottles - degasser:

Solvent

cabinet

Vacuum

degasser

Quaternary pump

G1311-60003 (bottle-head assembly, PTFE-tubings)

Degasser - pump:

G1322-67300 (PTFE-tubings)

Pump - autosampler:

G1312-67305 (SST, green)

Pump purge valve - waste:

5062-2461 (PTFE tubing wide bore, reorder pack)

Control Module

Autosampler

Column compartment

Detector

Autosampler - column compartment:

G1313-87305 (SST, green)

Column compartment - column:

G1316-87300 (SST, green)

Column - detector:

DAD G1315-87311 (SST, coated)

VWD 5062-8522 (PEEK)

Detector - waste:

DAD 0890-1713 (PTFE, wide bore)

VWD 5062-8535 (PEEK)

5062-2463 (corrugated waste tubing, reorder pack)

NOTE For a detailed view of the flow connections refer to the section “Flow

Connections” in chapter 1 of the reference manuals of the individual modules.

20

Page 21

Installing the Pump

Optimizing the Stack Configuration

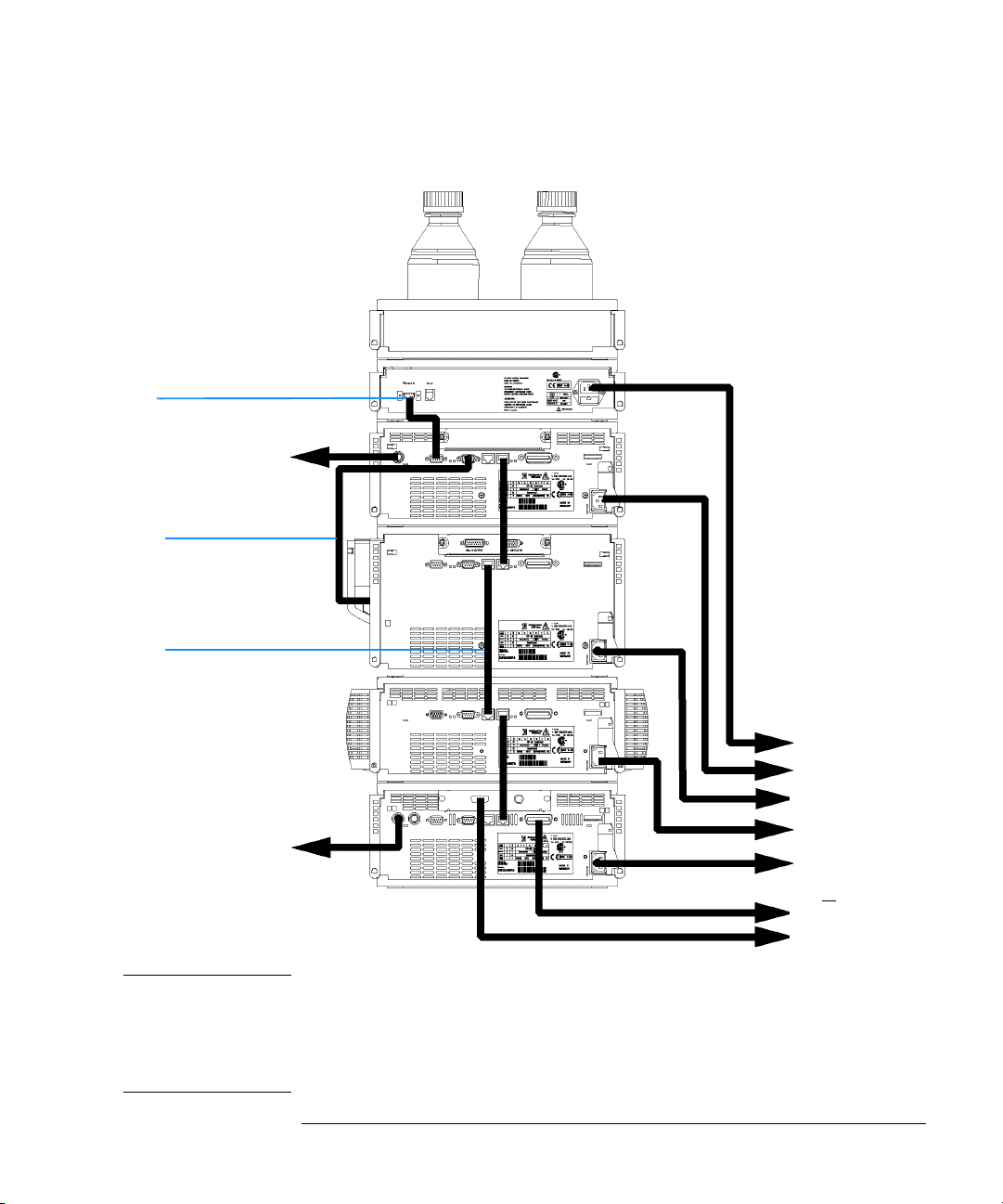

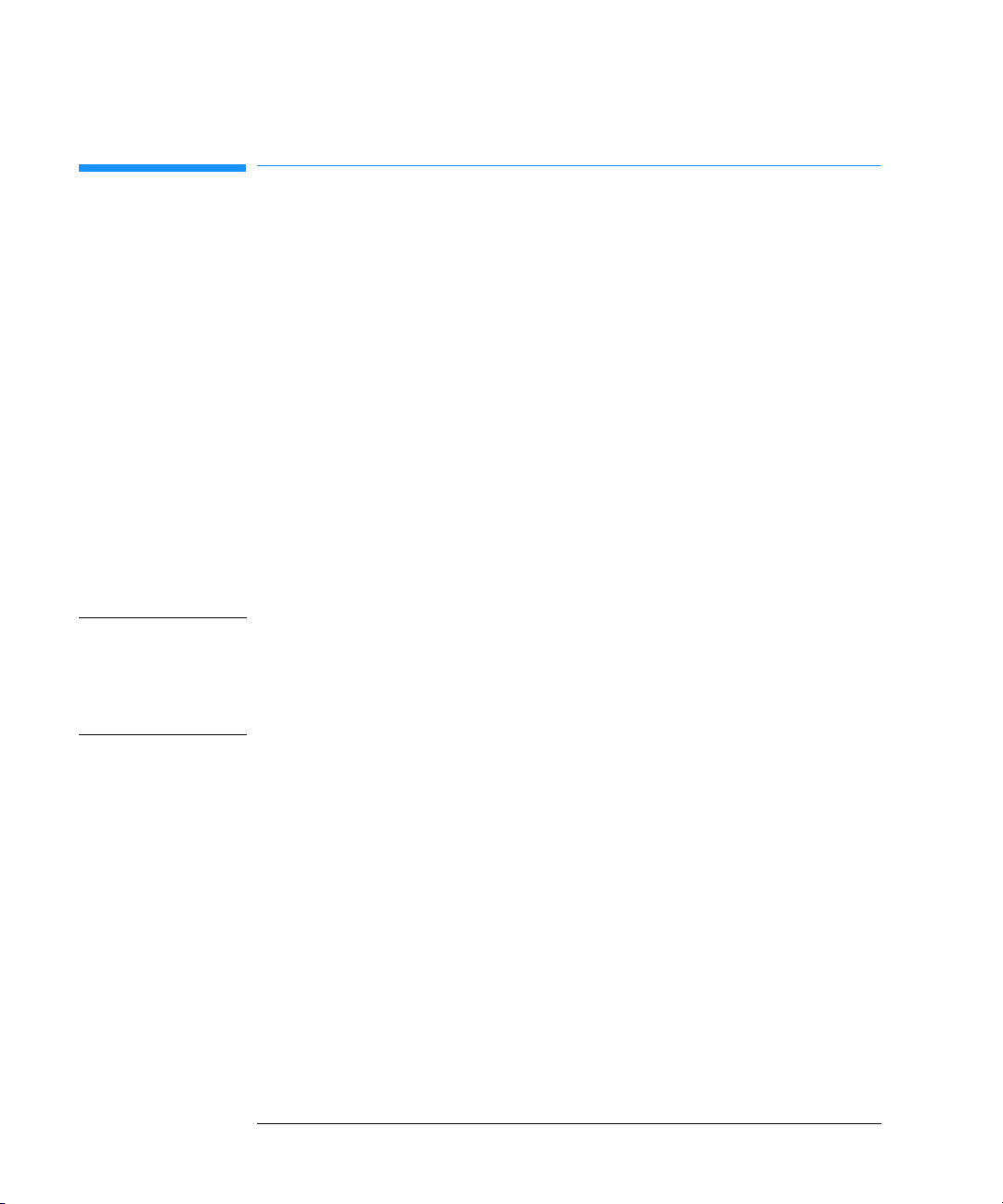

Figure 2 Recommended Stack Configuration (Rear View)

Remote cable

5061-3378

Pressure output to

recorder, for

PN see page 181

CAN Bus cable to

handheld controller

G1323-81600

CAN Bus cable for inter

module communication

5181-1516 (0.5m)

5161-1519 (1.0m)

AC power

Analog signal to

recorder,for

PN see page 181

GPIB or

LAN to ChemStation

for PN see page 181

NOTE If a single stack configuration becomes too high, e.g. if an additional module

like a G1327A ALS Thermostat is added or if your bench is to high, a two stack

configuration may be a better setup. Separate the stack between pump and

autosampler and place the stack containing the pump on the right side of the

stack containing the autosampler.

21

Page 22

Installing the Pump

S

Installing the Quaternary Pump

Installing the Quaternary Pump

Preparations Locate bench space.

Provide power connections.

Unpack the pump.

Parts required Pump

Power cord, for other cables see text below and “Cable Overview” on page 181

ChemStation and/or Control Module G1323A/B

1 Place the quaternary pump on the bench in a horizontal position.

2 Ensure the power switch on the front of the quaternary pump is OFF (switch

stands out).

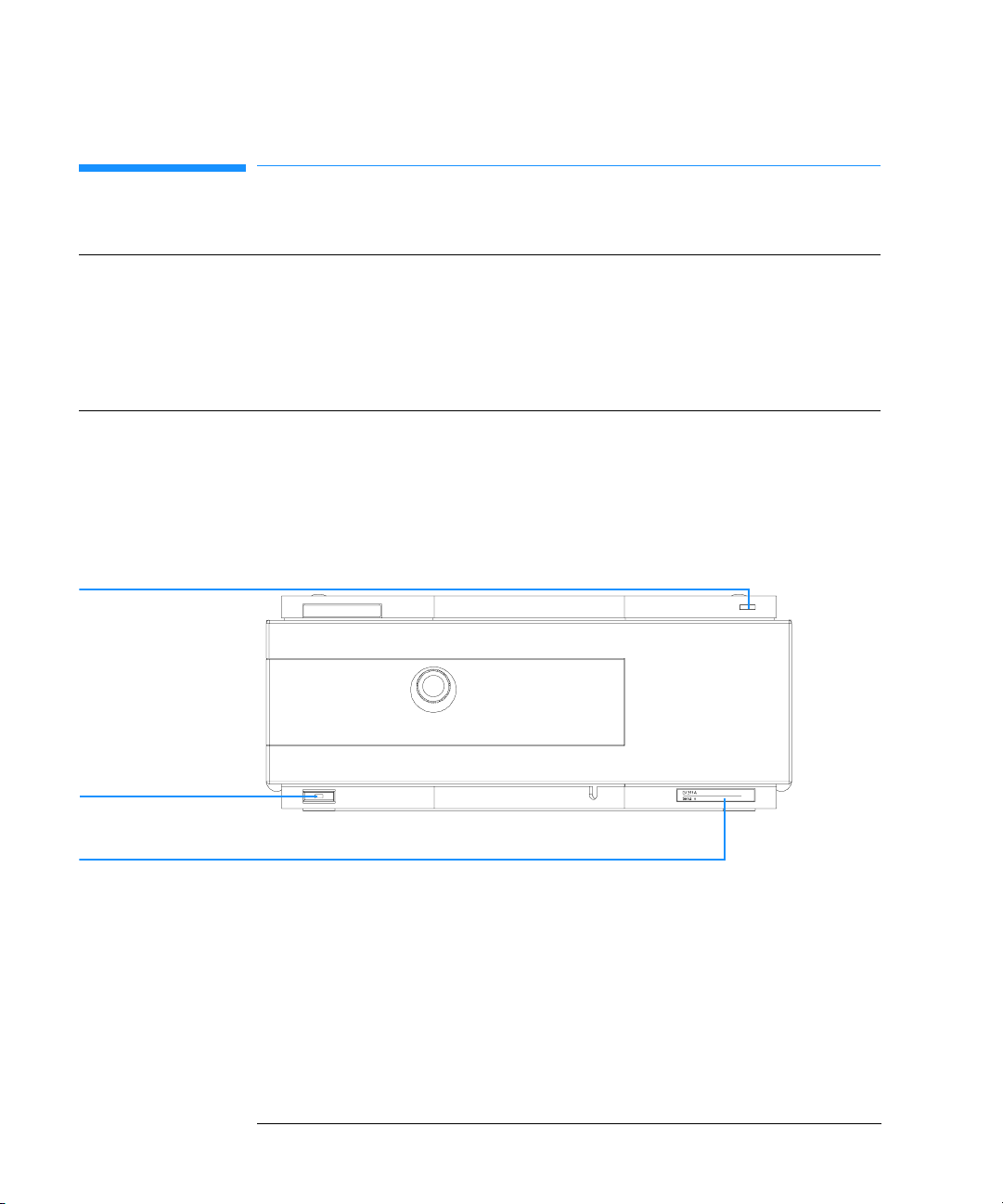

Figure 3 Front of Quaternary Pump

tatus Lamp

Power Switch

Serial number

3 At the rear of the quaternary pump move the security lever to its maximum

right position.

4 Connect the power cable to the power connector at the rear of the quaternary

pump. The security lever will prevent that the cover is opened while the power

cord is connected to the quaternary pump.

5 Connect the required interface cables to the quaternary pump.

22

Page 23

Installing the Pump

Installing the Quaternary Pump

NOTE In an Agilent 1100 Series system, the individual modules are connected

through CAN cables. The Agilent 1100 Series vacuum degasser is an exception

. The vacuum degasser can be connected via the APG remote connector to the

other modules of the stack. The AUX output allows the user to monitor the

vacuum level in the degasser chamber. An Agilent 1100 Series control module

can be connected to the CAN bus at any of the modules in the system except

for the degasser. The Agilent ChemStation can be connected to the system

through one GPIB or LAN (requires the installation of a LAN- board) cable at

any of the modules (except for the degasser), preferably at the detector

(MUST for the DAD). For more information about connecting the control

module or Agilent ChemStation refer to the respective user manual. For

connecting the Agilent 1100 Series equipment to non-Agilent 1100 Series

equipment, see Chapter 6 “Introduction to the Quaternary Pump”

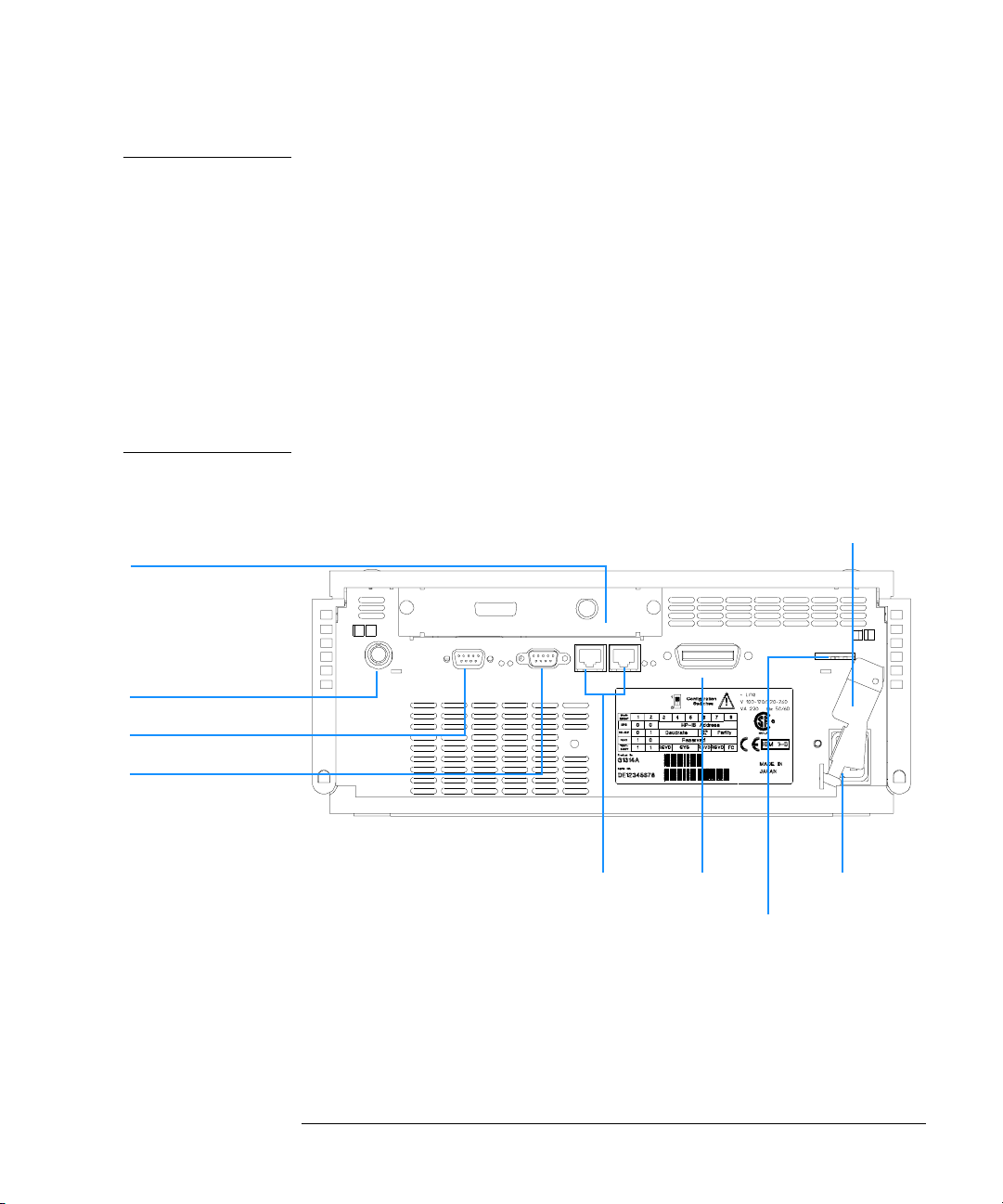

Figure 4 Rear of Quaternary Pump

Security lever

Slot for interface board

Analog pressure, 2mV/bar

APG Remote

RS-232C

CAN

GPIB Power

Configuration switch

6 Connect all capillaries, solvent tubes and waste tubing (see “Flow

Connections of the Quaternary Pump” on page 25).

7 Press in the power switch to turn on the quaternary pump.

23

Page 24

Installing the Pump

Installing the Quaternary Pump

NOTE The power switch stays pressed in and a green indicator lamp in the power

switch is on when the quaternary pump is turned on. When the line power

switch stands out and the green light is off, the quaternary pump is turned off.

8 Purge the quarternary pump (see “Priming and Purging the System” on page

28).

WARNING To disconnect the quaternary pump from line, unplug the power cord.

The power supply still uses some power, even if the power switch on

the front panel is turned off.

NOTE The pump was shipped with default configuration settings. To change these

settings, see “Setting the 8-bit Configuration Switch” on page 223.

24

Page 25

Installing the Pump

Flow Connections of the Quaternary Pump

Flow Connections of the Quaternary Pump

Preparations Pump is installed in the LC system.

Parts required Other modules

Parts from accessory kit, see “Accessory Kit Contents — Quaternary Pump” on page 18

Two wrenches 1/4–5/16 inch for capillary connections

WARNING When opening capillary or tube fittings solvents may leak out. Please

observe appropriate safety procedures (for example, goggles, safety

gloves and protective clothing) as described in the material handling

and safety data sheet supplied by the solvent vendor, especially when

toxic or hazardous solvents are used.

1 Remove the front cover by pressing the snap fasteners on both sides.

Figure 5 Removing the Front Cover

2 Place the vacuum degasser and the solvent cabinet on top of the quaternary

pump.

3 Put the bottle-head assemblies into solvent reservoirs containing your mobile

phase and place the bottle in the solvent cabinet.

4 Connect the inlet tubes from the bottle-head assemblies to the inlet

connectors A to D (typically the left connection of the channel) of the vacuum

degasser. Fix the tubes in the tube clips of the vacuum degasser.

25

Page 26

Installing the Pump

Flow Connections of the Quaternary Pump

5 Connect the solvent tubes to the outlet connectors (typically right connection

of the channel) of the vacuum degasser.

6 Connect the syringe adapter from the degasser accessory kit to the solvent

tube of channel A.

7 Using a piece of sanding paper connect the waste tubing to the purge valve

and place it into your waste system.

8 If the quaternary pump is not part of a Agilent1100 System stack or placed on

the bottom of a stack, connect the corrugated waste tube to the waste outlet

of the pump leak handling system.

9 Connect the pump outlet capillary (quaternary pump to injection device) to

the outlet of the purge valve.

10 Prime your system before first use (see “Priming and Purging the System” on

page 28).

26

Page 27

Installing the Pump

Flow Connections of the Quaternary Pump

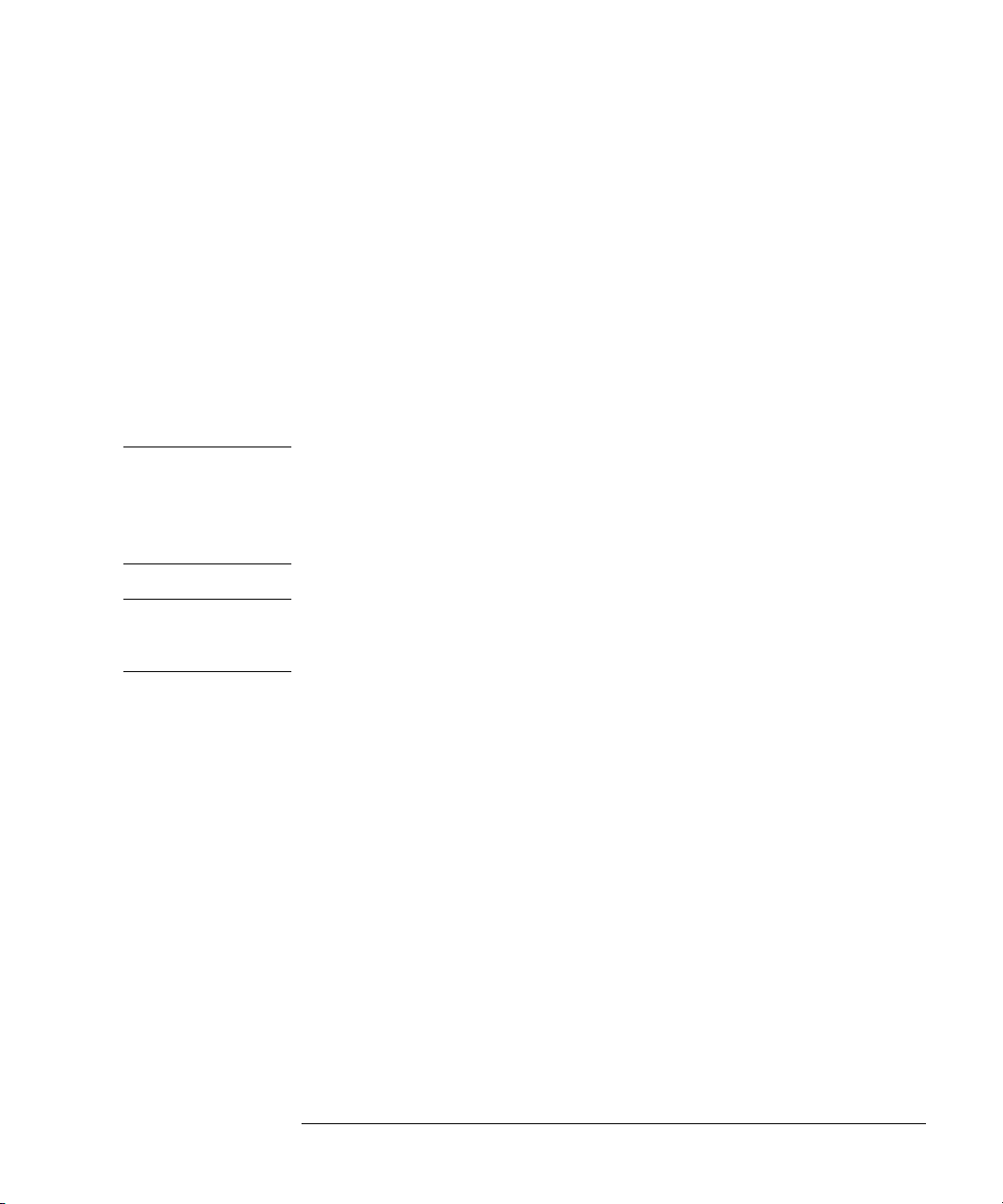

Figure 6 Flow Connections of the Quaternary Pump

Bottle-head assembly (G1311-60003)

Solvent cabinet

Vacuum degasser

Inlet

Outlet

Tube clip (1400-1578)

Tubings (G1322-67300)

Purge valve

Waste tubing (5062-2461)

Outlet capillary to autosampler (G1312-67305)

MCGV

Fitting for corrugated waste tubing (5062-2463, reorder pack, 5m)

27

Page 28

Installing the Pump

Priming and Purging the System

Priming and Purging the System

The system can be primed either by drawing solvent through the degasser

with a syringe or by pumping with the pump.

Priming the system with a syringe is recommended, when:

• vacuum degasser or connected tubings are used for the first time or

vacuum tubes are empty or

• changing to solvents that are immiscible with the solvent currently in the

vacuum tubes.

Priming the system by using the pump at high flow rate

(3–5 ml/min) is recommended, when:

• pumping system was turned off for a length of time (for example,

overnight) and if volatile solvent mixtures are used, or

• solvents have been changed.

WARNING When opening capillary or tube fittings solvents may leak out. Please

observe appropriate safety procedures (for example, goggles, safety

gloves and protective clothing) as described in the material handling

and safety data sheet supplied by the solvent vendor, especially when

toxic or hazardous solvents are used.

Priming with a Syringe

Before using a new degasser or new tubings for the first time:

1 Prime all tubings with at least 30 ml of iso-propanol no matter whether the

channels will be used with organic mobile phase or with water.

If you are changing to a solvent that is immiscible with the solvent currently

in the tubing continue as follows:

2 Replace the current solvent with adequate organic solvent (see Table 5 on

page 30), if current solvent is organic or with water, if current solvent is an

inorganic buffer or contains salt.

3 Disconnect solvent outlet tube of the channel that is supposed to be primed

from your pump.

4 Connect syringe adapter to solvent outlet tube.

28

Page 29

Installing the Pump

Priming and Purging the System

5 Push syringe adapter onto syringe.

6 Pull syringe plunger to draw at least 30 ml of solvent through degasser and

tubing.

7 Replace the priming solvent with the new solvent of your choice.

8 Pull syringe plunger to draw at least 30 ml of solvent through degasser and

tubing.

9 Disconnect syringe adapter from solvent tube.

10 Connect the solvent tube to the appropriate channel of the MCGV.

11 Repeat step 3 to step 10 for the other solvent channels.

NOTE When priming the vacuum degasser with a syringe the solvent is drawn

through the degasser tubes very quickly. The solvent at the degasser outlet will

therefore not be fully degassed. Pump for approximately 10 minutes with your

selected flow rate before starting any application. This will allow the vacuum

degasser to properly degas the solvent in the degasser tubes.

NOTE The pump should never be used for priming empty tubings (never let the pump

run dry). Use the syringe to draw enough solvent for completely filling the

tubings to the pump inlet before continueing to prime with the pump.

Priming with the Pump

When the pumping system has been turned off for a certain time (for

example, overnight) oxygen will rediffuse into the solvent channels between

the vacuum degasser and the pump. Solvents containing volatile ingredients

will slightly lose these, if left in the degasser without flow for a prolonged

period of time. Therefore priming of the vacuum degasser and the pumping

system is required before starting an application.

1 Open the purge valve of your pump (by turning it counterclockwise) and set

flow rate to 3-5 ml/min.

2 Flush the vacuum degasser and all tubes with at least 30 ml of solvent.

3 Set flow to required value of your application and close the purge valve.

4 Pump for approximately 10 minutes before starting your application.

5 Repeat step 1 to step 4 for other solvent channels, where needed.

29

Page 30

Installing the Pump

Priming and Purging the System

Table 5 Choice of Priming Solvents for Different Purposes

Activity Solvent Comments

After an installation

When switching between

reverse phase and normal

phase (both times)

After an installation Ethanol or Methanol Alternative to Isopropanol

To clean the system when

using buffers

After a solvent change

After the installation of

normal phase seals (P/N

0905-1420)

Isopropanol

Isopropanol

Bidistilled water

Bidistilled water

Hexane + 5% Isopropanol Good wetting properties

Best solvent to flush air out of

the system

Best solvent to flush air out of

the system

(second choice) if no

Isopropanol is available

Best solvent to re-dissolve

buffer cristals

Best solvent to re-dissolve

buffer cristals

30

Page 31

2

2 Optimizing Performance

How to optimize the quaternary pump to achieve

best chromatographic results

Page 32

Optimizing Performance

Hints for Successful Use of the Quaternary Pump

Hints for Successful Use of the Quaternary

Pump

• Always place the solvent cabinet with the solvent bottles on top of the

quaternary pump (or at a higher level).

• When using salt solutions and organic solvents in the Agilent 1100

Quaternary Pump it is recommended to connect the salt solution to one of

the bottom gradient valve ports and the organic solvent to one of the upper

gradient valve ports. It is best to have the organic channel directly above

the salt solution channel. Regular flushing with water of all MCGV

channels is recommended to remove all possible salt deposits in the valve

ports.

• Before operating the quaternary pump flush the vacuum degasser with at

least two volumes (30 ml), especially when turned off for a certain length

of time (for example, during the night) and volatile solvent mixtures are

used in the channels (see “Priming and Purging the System” on page 28).

• Prevent blocking of solvent inlet filters (never use the pump without

solvent inlet filter). Growth of algae should be avoided (see “Prevent

Blocking of Solvent Filters” on page 35).

• Check purge valve frit and column frit in regular time intervals. A blocked

purge valve frit can be identified by black or yellow layers on its surface or

by a pressure greater than 10 bar, when pumping distilled water at a rate

of 5 ml/min with an open purge valve.

• When using the quaternary pump at low flow rates (for example,

0.2 ml/min) check all 1/16-inch fittings for any signs of leaks.

• Whenever exchanging the pump seals the purge valve frit should be

exchanged, too.

• When using buffer solutions, flush the system with water before switching

it off. The seal wash option should be used when buffer concentrations of

0.1 Molar or higher will be used for long time periods.

• Check the pump plungers for scratches when changing the plunger seals.

Scratched plungers will lead to micro leaks and will decrease the lifetime

of the seal.

• Pressurize the system according to the wear in procedure after changing

the plunger seals (see “Exchanging the Pump Seals and Seal Wear-in

32

Page 33

Optimizing Performance

Hints for Successful Use of the Quaternary Pump

Procedure” on page 112).

33

Page 34

Optimizing Performance

Solvent Information

Solvent Information

Always filter solvents through 0.4 µm filters, small particles can permanently

block the capillaries and valves. Avoid the use of the following

steel-corrosive solvents:

• Solutions of alkali halides and their respective acids (for example, lithium

iodide, potassium chloride, and so on).

• High concentrations of inorganic acids like sulfuric acid, especially at

higher temperatures (replace, if your chromatography method allows, by

phosphoric acid or phosphate buffer which are less corrosive against

stainless steel).

• Halogenated solvents or mixtures which form radicals and/or acids, for

example:

+ O

3

→ 2COCl

2

2CHCl

This reaction, in which stainless steel probably acts as a catalyst, occurs

quickly with dried chloroform if the drying process removes the

stabilizing alcohol.

+ 2HCl

2

• Chromatographic grade ethers, which can contain peroxides (for example,

THF, dioxane, di-isopropylether) such ethers should be filtered through

dry aluminium oxide which adsorbs the peroxides.

• Mixtures of carbon tetrachloride with 2-propanol or THF dissolve stainless

steel.

34

Page 35

Optimizing Performance

Prevent Blocking of Solvent Filters

Prevent Blocking of Solvent Filters

Contaminated solvents or algae growth in the solvent bottle will reduce the

lifetime of the solvent filter and will influence the performance of the pump.

This is especially true for aqueous solvents or phosphate buffers (pH 4 to 7).

The following suggestions will prolong lifetime of the solvent filter and will

maintain the performance of the pump:

• Use sterile, if possible amber, solvent bottles to slow down algae growth.

• Filter solvents through filters or membranes that remove algae.

• Exchange solvents every two days or refilter.

• If the application permits add 0.0001–0.001 M sodium azide to the solvent.

• Place a layer of argon on top of your solvent.

• Avoid exposure of the solvent bottles to direct sunlight.

Checking the Solvent Filters

The solvent filters are on the low-pressure side of the pumping system. A

blocked filter therefore does not affect the pressure readings of the pump.

The pressure readings cannot be used to identify blocked filters. If the

solvent cabinet is placed on top of the vacuum degasser the filter condition

can be checked in the following way:

Remove the tubing at the inlet port of the vacuum degasser. If the filter is in

good condition the solvent will freely drip out of the solvent tube (due to

hydrostatic pressure). If the solvent filter is partly blocked no solvent or only

very little solvent will drip out of the solvent tube.

Cleaning the Solvent Filters

• Remove the blocked solvent filter from the bottle-head assembly and place

it in a beaker with concentrated nitric acid (35%) for one hour.

• Thoroughly flush the filter with bidistilled water (remove all nitric acid,

some capillary columns can be damaged by nitric acid).

• Replace the filter.

NOTE Never use the system without solvent filter installed.

35

Page 36

Optimizing Performance

Operational Hints for the Vacuum Degasser

Operational Hints for the Vacuum Degasser

Operational Hints for the Vacuum Degasser

If you are using the vacuum degasser for the first time, if the vacuum

degasser was switched off for any length of time (for example, overnight), or

if the vacuum degasser lines are empty, you should prime the vacuum

degasser before running an analysis.

The vacuum degasser can be primed either by drawing solvent through the

degasser with a syringe or by pumping with the quaternary pump.

Priming the degasser with a syringe is recommended, when:

• vacuum degasser is used for the first time, or vacuum tubes are empty, or

• changing to solvents that are immiscible with the solvent currently in the

vacuum tubes.

Priming the vacuum degasser by using the quaternary pump at high flow rate

is recommended, when:

• quaternary pump was turned off for a length of time (for example, during

night) and volatile solvent mixtures are used, or

• solvents have been changed.

For more information see the Reference Manual for the Agilent 1100 Series

vacuum degasser.

36

Page 37

Optimizing Performance

Operational Hints for the Multi Channel Gradient Valve (MCGV)

Operational Hints for the Multi Channel

Gradient Valve (MCGV)

In a mixture of salt solutions and organic solvent the salt solution might be

well dissolved in the organic solvent without showing precipitations.

However in the mixing point of the gradient valve, at the boundary between

the two solvents, micro precipitation is possible. Gravity forces the salt

particles to fall down. Normally the A channel of the valve is used for the

aqueous/salt solution and the B channel of the pump is used for the organic

solvent. If used in this configuration the salt will fall back into the salt

solution and will be dissolved. When using the pump in a different

configuration (e.g., D - salt solution, A -organic solvent) the salt can fall into

the port of the organic solvent and may lead to performance problems.

NOTE When using salt solutions and organic solvents in the Agilent 1100 Quaternary

Pump it is recommended to connect the salt solution to one of the bottom

ports and the organic solvent to one of the upper gradient valve ports. It is best

to have the organic channel directly above the salt solution channel.

Regular flushing with water of all MCGV channels is recommended to remove

all possible salt deposits in the valve ports.

37

Page 38

Optimizing Performance

When to use the Continuous Seal Wash Option

When to use the Continuous Seal Wash

Option

Highly-concentrated buffer solutions will reduce the lifetime of the seals and

plungers in your quaternary pump. The seal wash option allows to maintain

the seal lifetime by flushing the back side of the seal with a wash solvent.

The continuous seal wash option is strongly recommended when buffer

concentrations of 0.1 Molar or higher will be used for long time periods in the

quaternary pump.

The continuous seal wash option can be ordered by quoting part number

01018-68722 (kit contains parts for one pump head).

The seal wash option comprises a support ring, secondary seal, gasket and

seal keeper for both plunger sides. A wash bottle filled with water

/isopropanol (90/10) should be placed above the quaternary pump in the

solvent cabinet and gravity will maintain a flow through the pump head

removing all possible buffer crystals from the back of the pump seal.

NOTE Running dry is the worst case for a seal and drastically reduces its

lifetime.

The seal will build up sticky layers on the surface of the plunger. These sticky

layers will also reduce the lifetime of the primary seal. Therefore the tubes of

the wash option should always be filled with solvent to prolong the lifetime of

the wash seal. Always use a mixture of bidistilled water (90%) and isopropanol

(10%) as wash solvent. This mixture prevents bacteria growth in the wash

bottle and reduces the surface tension of the water. The flow rate should be

regulated to approximately 20 drops/minute. This can be done with the

velocity regulator supplied with the accessory kit.

For information on the installation of the continuous seal wash option refer

to “Installing the Continuous Seal Wash Option” on page 116.

38

Page 39

Optimizing Performance

When to Use Alternative Seals

When to Use Alternative Seals

The standard seal for the quaternary pump can be used for most applications.

However applications that use normal phase solvents (for example, hexane)

are not suited for the standard seal and require a different seal when used for

a longer time in the quaternary pump.

For applications that use normal phase solvents (for example, hexane) we

recommend the use of the polyethylene seals, part number 0905-1420 (pack

of 2). These seals have less abrasion compared to the standard seals.

NOTE Polyethylene seals have a limited pressure range 0–200 bar. When used above

200 bar their lifetime will be significantly reduced. DO NOT apply the seal

wear-in procedure performed with new standard seals at 400 bar.

39

Page 40

Optimizing Performance

Optimize the Compressibility Compensation Setting

Optimize the Compressibility

Compensation Setting

The compressibility compensation default setting is 100 × 10-6/bar for the

quaternary pump. This setting represents an average value. Under normal

conditions the default setting reduces the pressure pulsation to values

(below 1% of system pressure) that will be sufficient for most applications

and for all gradient analyses. For applications using sensitive detectors, the

compressibility settings can be optimized by using the values for the various

solvents described in Table 6. If the solvent in use is not listed in the

compressibility tables, when using isocratic mixtures of solvents and if the

default settings are not sufficient for your application the following

procedure can be used to optimize the compressibility settings.

NOTE When using mixtures of solvents it is not possible to calculate the

compressibility of the mixture by interpolating the compressibility values of

the pure solvents used in that mixture or by applying any other calculation. In

these cases the following empirical procedure has to be applied to optimize

your compressibility setting.

1 Start the quaternary pump with the required flow rate.

2 Before starting the optimization procedure, the flow must be stable. Use

degassed solvent only. Check the tightness of the system with the pressure

test (see “Pressure Test” on page 82).

3 Your pump must be connected to a Chemstation or a handheld controller, the

pressure and %-ripple can be monitored with one of these instruments,

otherwhise connect a signal cable between the pressure output of the

quaternary pump and a recording device (for example, 339X integrator) and

set parameters.

Zero 50%

Att 2^3

Chart Speed 10 cm/min

4 Start the recording device with the plot mode.

40

Page 41

Optimizing Performance

Optimize the Compressibility Compensation Setting

5 Starting with a compressibility setting of 10 × 10-6/bar increase the value in

steps of 10. Re-zero the integrator as required. The compressibility

compensation setting that generates the smallest pressure ripple is the

optimum value for your solvent composition.

Table 6 Solvent Compressibility

Solvent (pure) Compressibility (10

Acetone 126

Acetonitrile 115

Benzene 95

Carbon tetrachloride 110

Chloroform 100

Cyclohexane 118

Ethanol 114

Ethyl acetate 104

Heptane 120

Hexane 150

Isobutanol 100

Isopropanol 100

Methanol 120

1-Propanol 100

Toluene 87

-6

/bar)

Water 46

41

Page 42

Optimizing Performance

Optimize the Compressibility Compensation Setting

42

Page 43

3

3 Troubleshooting and

Test Functions

The quaternary pump’s built-in troubleshooting and

test functions

Page 44

Troubleshooting and Test

Functions

This chapter describes the instrument’s built in troubleshooting and test

functions.

Status Indicators

The quaternary pump is provided with two status indicators which indicate

the operational state (prerun, run, and error states) of the quaternary pump.

The status indicators provide a quick visual check of the operation of the

quaternary pump (see “Status Indicators” on page 45).

Error Messages

In the event of an electronic, mechanical or hydraulic failure, the quaternary

pump generates an error message in the user interface. The following pages

describe the meaning of the error messages. For each message, a short

description of the failure, a list of probable causes of the problem, and a list

of suggested actions to fix the problem are provided (see “Error Messages”

on page 47).

Pressure Test

The pressure test is a quick test designed to determine the pressure tightness

of the system. After exchanging flow path components (e.g. pump seals or

injection seal), use this test to verify the system is pressure tight up to 400 bar

(see “Pressure Test” on page 82).

Leak Test

The leak test is a diagnostic test designed to determine the pressure tightness

of the quaternary pump. When a problem with the quaternary pump is

suspected, use this test to help troubleshoot the quaternary pump and its

pumping performance. The following sections describe these functions in

detail (see “Leak Test” on page 88).

44

Page 45

Troubleshooting and Test Functions

Status Indicators

Two status indicators are located on the front of the quaternary pump. The

lower left one indicates the power supply status, the upper right one

indicates the quaternary pump status.

Figure 7 Location of Status Indicators

Status indicator

Power supply indicator

45

Page 46

Power Supply Indicator

The power supply indicator is integrated into the main power switch. When

the indicator is illuminated (green) the power is ON.

When the indicator is off, the module is turned OFF. Otherwhise check power

connections, availability of power or check functioning of the power supply.

Pump Status Indicator

The Pump status indicator indicates one of four possible instrument

conditions:

• When the status indicator is OFF (and power switch light is on), the

quaternary pump is in a prerun condition, and is ready to begin an analysis.

• A green status indicator, indicates the quaternary pump is performing an

analysis (run mode).

• A yellow indicator indicates a not-ready condition. The quaternary pump

is in a not-ready state when it is waiting for a specific condition to be

reached or completed (for example, immediately after changing a

setpoint), or while a self-test procedure is running.

• An error condition is indicated when the status indicator is red. An error

condition indicates the quaternary pump has detected an internal problem

which affects correct operation of the quaternary pump. Usually, an error

condition requires attention (for example, leak, defective internal

components). An error condition always interrupts the analysis.

• A flashing yellow status indicator indicates that the module is in its

resident mode. Call your local service provider for assistance upon

observing this error condition.

• A flashing red status indicator indicates a severe error during the startup

procedure of the module. Call your local service provider for assistance

upon observing this error condition.

46

Page 47

Troubleshooting and Test Functions

Error Messages

Error Messages

Error messages are displayed in the user interface when an electronic,

mechanical, or hydraulic (flow path) failure occurs which requires attention

before the analysis can be continued (for example, repair, frit exchange or

exchange of consumables required). In the event of such a failure, the red

status indicator at the front of the quaternary pump is switched on, and an

entry is written into the instrument logbook.

47

Page 48

Time out

The timeout threshold was exceeded.

Probable Causes • The analysis was completed successfully, and the timeout function

switched off the quaternary pump as requested.

• A not-ready condition was present during a sequence or multiple-injection

run for a period longer than the timeout threshold.

Suggested Actions ❏ Check the logbook for the occurrence and source of a not-ready condition.

Restart the analysis where required.

48

Page 49

Troubleshooting and Test Functions

Shut-Down

Shut-Down

An external instrument has generated a shut-down signal on the remote line.

The quaternary pump continually monitors the remote input connectors for

status signals. A LOW signal input on pin 4 of the remote connector generates

the error message.

Probable Causes • Leak detected in another module with a CAN connection to the system .

• Leak detected in an external instrument with a remote connection to the

system.

• Shut-down in an external instrument with a remote connection to the

system.

• The degasser failed to generate sufficient vacuum for solvent degassing.

Suggested Actions ❏ Fix the leak in the external instrument before restarting the quaternary

pump.

❏ Check external instruments for a shut-down condition.

❏ Check the vacuum degasser for an error condition. Refer to the Reference

Manual for the Agilent 1100 Series vacuum degasser.

49

Page 50

Troubleshooting and Test Functions

Remote Timeout

Remote Timeout

A not-ready condition is still present on the remote input .

When an analysis is started, the system expects all not-ready conditions (e.g.

a not-ready condition during detector balance) to switch to run conditions

within one minute of starting the analysis. If a not-ready condition is still

present on the remote line after one minute the error message is generated.

Probable Causes • Not-ready condition in one of the instruments connected to the remote

line.

• Defective remote cable.

• Defective components in the instrument showing the not-ready condition.

Suggested Actions ❏ Ensure the instrument showing the not-ready condition is installed

correctly, and is set up correctly for analysis.

❏ Exchange the remote cable.

❏ Check the instrument for defects (refer to the instrument’s reference

documentation).

50

Page 51

Troubleshooting and Test Functions

Synchronization Lost

Synchronization Lost

During an analysis, the internal synchronization or communication between

one or more of the modules in the system has failed.

The system processors continually monitor the system configuration. If one

or more of the modules is no longer recognized as being connected to the

system, the error message is generated.

Probable Causes • CAN cable disconnected.

• Defective CAN cable.

• Defective main board in another module.

Suggested Actions ❏ Ensure all the CAN cables are connected correctly.

❏ Switch off the system. Restart the system, and determine which module or

modules are not recognized by the system.

❏ Ensure all CAN cables are installed correctly.

51

Page 52

Troubleshooting and Test Functions

Leak

Leak

A leak was detected in the quaternary pump.

The signals from the two temperature sensors (leak sensor and

board-mounted temperature-compensation sensor) are used by the leak

algorithm to determine whether a leak is present. When a leak occurs, the

leak sensor is cooled by the solvent. This changes the resistance of the leak

sensor which is sensed by the leak-sensor circuit on the LPM board

Probable Causes • Loose fittings.

• Broken capillary.

• Loose or leaking purge valve, active inlet valve, or outlet ball valve.

• Defective pump seals.

Suggested Actions ❏ Ensure all fittings are tight.

❏ Exchange defective capillaries.

❏ Ensure pump components are seated correctly. If there are still signs of a

leak, exchange the appropriate seal (purge valve, active inlet valve, outlet

ball valve).

❏ Exchange the pump seals.

52

Page 53

Troubleshooting and Test Functions

Leak Sensor Open

Leak Sensor Open

The leak sensor in the quaternary pump has failed (open circuit).

The current through the leak sensor is dependent on temperature. A leak is

detected when solvent cools the leak sensor, causing the leak-sensor current

to change within defined limits. If the current falls outside the lower limit, the

error message is generated.

Probable Causes • Leak sensor not connected to the LPM board.

• Defective leak sensor.

• Leak sensor incorrectly routed, being pinched by a metal component.

Suggested Actions ❏ Ensure the leak sensor is connected correctly.

❏ Exchange the leak sensor.

53

Page 54

Troubleshooting and Test Functions

Leak Sensor Short

Leak Sensor Short

The leak sensor in the quaternary pump has failed (short circuit).

The current through the leak sensor is dependent on temperature. A leak is

detected when solvent cools the leak sensor, causing the leak-sensor current

to change within defined limits. If the current increases above the upper

limit, the error message is generated.

Probable Causes • Defective leak sensor.

• Leak sensor incorrectly routed, being pinched by a metal component.

Suggested Actions ❏ Exchange the leak sensor.

54

Page 55

Troubleshooting and Test Functions

Compensation Sensor Open

Compensation Sensor Open

The ambient-compensation sensor (NTC) on the LPM board in the quaternary

pump has failed (open circuit).

The resistance across the temperature compensation sensor (NTC) on the

LPM board is dependent on ambient temperature. The change in resistance is

used by the leak circuit to compensate for ambient temperature changes. If

the resistance across the sensor increases above the upper limit, the error

message is generated.

Probable Causes • Defective LPM board.

Suggested Actions ❏ Exchange the LPM board.

55

Page 56

Troubleshooting and Test Functions

Compensation Sensor Short

Compensation Sensor Short

The ambient-compensation sensor (NTC) on the LPM board in the quaternary

pump has failed (short circuit).

The resistance across the temperature compensation sensor (NTC) on the

LPM board is dependent on ambient temperature. The change in resistance is

used by the leak circuit to compensate for ambient temperature changes. If

the resistance across the sensor falls below the lower limit, the error message

is generated.

Probable Causes • Defective LPM board.

Suggested Actions ❏ Exchange the LPM board.

56

Page 57

Troubleshooting and Test Functions

Fan Failed

Fan Failed

The cooling fan in the quaternary pump has failed.

The hall sensor on the fan shaft is used by the LPM board to monitor the fan

speed. If the fan speed falls below 2 revolutions/second for longer than

5 seconds, the error message is generated.

Probable Causes • Fan cable disconnected.

• Defective fan.

• Defective LPM board.

• Improperly positioned cables or wires obstructing fan blades.

Suggested Actions ❏ Ensure the fan is connected correctly.

❏ Exchange fan.

❏ Exchange the LPM board.

❏ Ensure the fan is not mechanically blocked.

57

Page 58

Troubleshooting and Test Functions

Open Cover

Open Cover

The top foam has been removed.

The sensor on the LPM board detects when the top foam is in place. If the

foam is removed, the fan is switched off, and the error message is generated.

Probable Causes • The top foam was removed during operation.

• Foam not activating the sensor.

• Sensor defective.

• Rear of the module is exposed to strong direct sunlight.

Suggested Actions ❏ Replace the top foam.

❏ Exchange the LPM board.

❏ Ensure that the rear of module is not directly exposed to strong sunlight.

58

Page 59

Troubleshooting and Test Functions

Restart Without Cover

Restart Without Cover

The quaternary pump was restarted with the top cover and foam open.

The sensor on the LPM board detects when the top foam is in place. If the

quaternary pump is restarted with the foam removed, the quaternary pump

switches off within 30 s, and the error message is generated.

Probable Causes • The quaternary pump started with the top cover and foam removed.

• Rear of the module is exposed to strong direct sunlight.

Suggested Actions ❏ Replace the top cover and foam.

❏ Ensure that the rear of module is not directly exposed to strong sunlight.

59

Page 60

Troubleshooting and Test Functions

Zero Solvent Counter

Zero Solvent Counter

Pump firmware version A.02.32 and higher allow to set solvent bottle fillings

at the ChemStation (revision 5.xx and higher). If the volume level in the

bottle falls below the specified value the error message appears when the

feature is configured accordingly.

Probable Causes • Volume in bottle below specified volume.

• Incorrect setting of limit.

Suggested Actions ❏ Refill bottles and reset solvent counters.

60

Page 61

Troubleshooting and Test Functions

Pressure Above Upper Limit

Pressure Above Upper Limit

The system pressure has exceeded the upper pressure limit.

Probable Causes • Upper pressure limit set too low.

• Blockage in the flowpath (after the damper).

• Defective damper.

• Defective LPM board.

Suggested Actions ❏ Ensure the upper pressure limit is set to a value suitable for the analysis.

❏ Check for blockage in the flowpath. The following components are

particularly subject to blockage:

purge-valve frit.

needle (autosampler),

seat capillary (autosampler),

sample loop (autosampler), and

column frits.

capillaries with low internal diameters (e.g. 0.12mm id).

❏ Exchange the damper.

❏ Exchange the LPM board.

61

Page 62

Troubleshooting and Test Functions

Pressure Below Lower Limit

Pressure Below Lower Limit

The system pressure has fallen below the lower pressure limit.

Probable Causes • Lower pressure limit set too high.

• Air bubbles in the mobile phase.

• Leak.

• Defective damper.

• Defective LPM board.

Suggested Actions ❏ Ensure the lower pressure limit is set to a value suitable for the analysis.

❏ Ensure solvents are degassed. Purge the quaternary pump.

❏ Ensure solvent inlet filters are not blocked.

❏ Inspect the pump head, capillaries and fittings for signs of a leak.

❏ Purge the quaternary pump. Run a pressure test to determine whether the

seals or other pump components are defective.

❏ Exchange the damper.

❏ Exchange the LPM board.

62

Page 63

Troubleshooting and Test Functions

Pressure Signal Missing

Pressure Signal Missing

The pressure signal from the damper is missing.

The pressure signal from the damper must be within a specific voltage range.

If the pressure signal is missing, the processor detects a voltage of

approximately -120mV across the damper connector.

Probable Causes • Damper disconnected.

• Defective damper.

Suggested Actions ❏ Ensure the damper is connected correctly to the LPM board.

❏ Exchange the damper.

63

Page 64

Troubleshooting and Test Functions

Missing Pressure Reading

Missing Pressure Reading

The pressure readings read by the pump ADC (analog-digital converter) are

missing.

The ADC reads the pressure readings from the damper every 1ms. If the

readings are missing for longer than 10 seconds, the error message is

generated.

Probable Causes • Damper not connected.

• Defective damper.

• Defective LPM board.

Suggested Actions ❏ Ensure the damper is connected, clean and seated correctly.

❏ Exchange the damper.

❏ Exchange the LPM board.

64

Page 65

Troubleshooting and Test Functions

Pump Configuration

Pump Configuration

At switch-on, the quaternary pump has recognized a new pump

configuration.

The quaternary pump is assigned its configuration at the factory. If the

gradient valve is disconnected, and the quaternary pump is rebooted, the

error message is generated. However, the pump will function as an isocratic

pump in this configuration.The error message reappears after each

switch-on.

Probable Causes • Gradient valve disconnected.

Suggested Actions ❏ Reconnect the gradient valve.

65

Page 66

Troubleshooting and Test Functions

Valve Fuse

Valve Fus e

Valve Fuse 0 : Channels A and B

Valve Fuse 1 : Channels C and D

The gradient valve in the quaternary pump has drawn excessive current

causing the electronic fuse to open.

Probable Causes • Defective gradient valve.

• Defective connection cable (front panel to LPM board).

• Defective LPM board.

Suggested Actions ❏ Restart the quaternary pump. If the error message appears again, exchange

the gradient valve.

❏ Exchange the connection cable.

❏ Exchange the LPM board.

66

Page 67

Troubleshooting and Test Functions

Inlet-Valve Fuse

Inlet-Valve Fuse

The active-inlet valve in the quaternary pump has drawn excessive current

causing the inlet-valve electronic fuse to open.

Probable Causes • Defective active inlet valve.

• Defective connection cable (front panel to LPM board).

• Defective LPM board.

Suggested Actions ❏ Restart the quaternary pump. If the error message appears again, exchange

the active inlet valve.

❏ Exchange the connection cable.

❏ Exchange the LPM board.

67

Page 68

Troubleshooting and Test Functions

Valve Failed

Valve Failed

Valve 0 Failed: valve A

Valve 1 Failed: valve B

Valve 2 Failed: valve C

Valve 3 Failed: valve D

One of the valves of the multi-channel gradient valve has failed to switch

correctly.

The processor monitors the valve voltage before and after each switching

cycle. If the voltages are outside expected limits, the error message is

generated.

Probable Causes • Gradient valve disconnected.

• Connection cable (inside instrument) not connected.

• Connection cable (inside instrument) defective.

• Gradient valve defective.

Suggested Actions ❏ Ensure the gradient valve is connected correctly.

❏ Ensure the connection cable is connected correctly.

❏ Exchange the connection cable.

❏ Exchange the gradient valve.

68

Page 69

Troubleshooting and Test Functions

Motor-Drive Power

Motor-Drive Power

The current drawn by the pump motor exceeded the maximum limit.

Blockages in the flow path are usually detected by the pressure sensor in the

damper, which result in the pump switching off when the upper pressure

limit is exceeded. If a blockage occurs before the damper, the pressure

increase cannot be detected by the pressure sensor and the quaternary pump

will continue to pump. As pressure increases, the pump drive draws more

current. When the current reaches the maximum limit, the quaternary pump

is switched off, and the error message is generated.

Probable Causes • Flow path blockage in front of the damper.

• Blocked active inlet valve.

• Blocked outlet ball valve.

• High friction (partial mechanical blockage) in the pump drive assembly.

• Defective pump drive assembly.

• Defective LPM board.

Suggested Actions ❏ Ensure the capillaries and frits between the pump head and damper inlet

are free from blockage.

❏ Exchange the active inlet valve.

❏ Exchange the outlet ball valve.

❏ Remove the pump-head assembly. Ensure there is no mechanical blockage

of the pump-head assembly or pump drive assembly.

❏ Exchange the pump drive assembly.

❏ Exchange the LPM board.

69

Page 70

Troubleshooting and Test Functions

Encoder Missing

Encoder Missing

The optical encoder on the pump motor in the quaternary pump is missing or

defective.

The processor checks the presence of the pump encoder connector every

2 seconds. If the connector is not detected by the processor, the error

message is generated.

Probable Causes • Defective or disconnected pump encoder connector.

• Defective pump drive assembly.

Suggested Actions ❏ Ensure the connector is clean, and seated correctly.

❏ Exchange the pump drive assembly.

70

Page 71

Troubleshooting and Test Functions

Inlet-Valve Missing

Inlet-Valve Missing

The active-inlet valve in the quaternary pump is missing or defective.

The processor checks the presence of the active-inlet valve connector every

2 seconds. If the connector is not detected by the processor, the error

message is generated.

Probable Causes • Disconnected or defective cable.

• Disconnected or defective connection cable (front panel to LPM board).

• Defective active inlet valve.

Suggested Actions ❏ Ensure the pins of the active inlet valve connector are not damaged.

Ensure the connector is seated securely.

❏ Ensure the connection cable is seated correctly. Exchange the cable if

defective.

❏ Exchange the active inlet valve.

71

Page 72

Troubleshooting and Test Functions

Temperature Out of Range

Temperature Out of Range

The temperature sensor readings in the motor-drive circuit are out of range.

The values supplied to the ADC by the hybrid sensors must be between 0.5 V

and 4.3 V. If the values are outside this range, the error message is generated.

Probable Causes • Defective LPM board.

Suggested Actions ❏ Exchange the LPM board.

72

Page 73

Troubleshooting and Test Functions

Temperature Limit Exceeded

Temperature Limit Exceeded

The temperature of one of the motor-drive circuits is too high.

The processor continually monitors the temperature of the drive circuits on

the LPM board. If excessive current is being drawn for long periods, the

temperature of the circuits increases. If the temperature exceeds the upper

limit of 95 ºC, the error message is generated.

Probable Causes • High friction (partial mechanical blockage) in the pump drive assembly.

• Partial blockage of the flowpath in front of the damper.

• Defective pump drive assembly.

• Defective LPM board.

Suggested Actions ❏ Ensure the capillaries and frits between the pump head and damper inlet

are free from blockage.

❏ Ensure the outlet valve is not blocked.

❏ Remove the pump head assembly. Ensure there is no mechanical blockage

of the pump head assembly or pump drive assembly.

❏ Exchange the pump drive assembly.

❏ Exchange the LPM board.

73

Page 74

Troubleshooting and Test Functions

Servo Restart Failed

Servo Restart Failed

The pump motor in the quaternary pump was unable to move into the correct

position for restarting.

When the quaternary pump is switched on, the first step is to switch on the C

phase of the variable reluctance motor. The rotor should move to one of the

C positions. The C position is required for the servo to be able to take control

of the phase sequencing with the commutator. If the rotor is unable to move,

or if the C position cannot be reached, the error message is generated.

Probable Causes • Disconnected or defective cables.

• Blocked active inlet valve.

• Mechanical blockage of the quaternary pump.

• Defective pump drive assembly.

• Defective LPM board.

Suggested Actions ❏ Ensure the pump-assembly cables are not damaged or dirty. Make sure the

cables are connected securely to the LPM board.

❏ Exchange the active inlet valve.

❏ Remove the pump-head assembly. Ensure there is no mechanical blockage

of the pump-head assembly or pump drive assembly.

❏ Exchange the pump drive assembly.

❏ Exchange the LPM board.

74

Page 75

Troubleshooting and Test Functions

Pump Head Missing

Pump Head Missing

The pump-head end stop in the quaternary pump was not found.

When the quaternary pump restarts, the metering drive moves forward to the

mechanical end stop. Normally, the end stop is reached within 20 seconds,

indicated by an increase in motor current. If the end point is not found within

20 seconds, the error message is generated.

Probable Causes • Pump head not installed correctly (screws not secured, or pump head not

seated correctly).

• Broken plunger.

Suggested Actions ❏ Install the pump head correctly. Ensure nothing (e.g. capillary) is trapped

between the pump head and body.

❏ Exchange the plunger.

75

Page 76

Troubleshooting and Test Functions

Index Limit

Index Limit

The time required by the plunger to reach the encoder index position was too

short (quaternary pump).

During initialization, the first plunger is moved to the mechanical stop. After

reaching the mechanical stop, the plunger reverses direction until the

encoder index position is reached. If the index position is reached too fast,

the error message is generated.

Probable Causes • Irregular or sticking drive movement.

• Defective pump drive assembly.

Suggested Actions ❏ Remove the pump head, and examine the seals, plungers, and internal

components for signs of wear, contamination or damage. Exchange

components as required.

❏ Exchange the pump drive assembly.

76

Page 77

Troubleshooting and Test Functions

Index Adjustment

Index Adjustment

The encoder index position in the quaternary pump is out of adjustment.

During initialization, the first plunger is moved to the mechanical stop. After

reaching the mechanical stop, the plunger reverses direction until the

encoder index position is reached. If the time to reach the index position is

too long, the error message is generated.

Probable Causes • Irregular or sticking drive movement.

• Defective pump drive assembly.

Suggested Actions ❏ Remove the pump head, and examine the seals, plungers, and internal

components for signs of wear, contamination or damage. Exchange

components as required.

❏ Exchange the pump drive assembly.

77

Page 78

Troubleshooting and Test Functions

Index Missing

Index Missing

The encoder index position in the quaternary pump was not found during

initialization.

During initialization, the first plunger is moved to the mechanical stop. After

reaching the mechanical stop, the plunger reverses direction until the

encoder index position is reached. If the index position is not recognized

within a defined time, the error message is generated.

Probable Causes • Disconnected or defective encoder cable.

• Defective pump drive assembly.

Suggested Actions ❏ Ensure the encoder cable are not damaged or dirty. Make sure the cables

are connected securely to the LPM board.

❏ Exchange the pump drive assembly.

78

Page 79

Troubleshooting and Test Functions

Stroke Length

Stroke Length

The distance between the lower plunger position and the upper mechanical

stop is out of limits (quaternary pump).

During initialization, the quaternary pump monitors the drive current. If the

plunger reaches the upper mechanical stop position before expected, the

motor current increases as the quaternary pump attempts to drive the

plunger beyond the mechanical stop. This current increase causes the error

message to be generated.

Probable Causes • Defective pump drive assembly.

Suggested Actions ❏ Exchange the pump drive assembly.

79

Page 80

Troubleshooting and Test Functions

Initialization Failed

Initialization Failed

The quaternary pump failed to initialize successfully within the maximum

time window.

A maximum time is assigned for the complete pump-initialization cycle. If the

time is exceeded before initialization is complete, the error message is

generated.

Probable Causes • Blocked active inlet valve.

• Defective pump drive assembly.

• Defective LPM board.

Suggested Actions ❏ Exchange the active inlet valve.

❏ Exchange the pump drive assembly.

❏ Exchange the LPM board.

80

Page 81

Troubleshooting and Test Functions

Wait Timeout

Wait Timeout

When running certain tests in the diagnostics mode or other special

applications, the pump must wait for the plungers to reach a specific

position, or must wait for a certain pressure or flow to be reached. Each

action or state must be completed within the timeout period, otherwise the

error message is generated.

Possible Reasons for a

Wait Timeout

Probable Causes • Purge valve still open.

Suggested Actions ❏ Ensure that purge valve is closed.

• Pressure not reached.

• Pump channel A did not reach the delivery phase.

• Pump channel B did not reach the delivery phase.

• Pump channel A did not reach the take-in phase.

• Pump channel B did not reach the take-in phase.

• Solvent volume not delivered within the specified time.

• Leak at fittings, purge valve, active inlet valve, outlet ball valve or plunger

seals.

• Flow changed after starting test.

• Defective pump drive assembly.

❏ Exchange defective capillaries.

❏ Ensure pump components are seated correctly. If there are still signs of a

leak, exchange the appropriate seal (purge valve, active inlet valve, outlet

ball valve, plunger seal).

❏ Ensure correct operating condition for the special application in use.

❏ Exchange the defective pump drive assembly.

81

Page 82

Pressure Test

Description

The pressure test is a quick, built-in test designed to demonstrate the

pressure-tightness of the system. The test should be used when problems

with small leaks are suspected, or after maintenance of flow-path

components (e.g. pump seals, injection seal) to prove pressure tightness up

to 400 bar. The test involves monitoring the pressure profile as the pump runs

through a predefined pumping sequence. The resulting pressure profile

provides information about the pressure tightness of the system.

The column compartment outlet (or the outlet of the last module before the

detector) is blocked with a blank nut, and then the test is run using isopropyl

alcohol (IPA), while monitoring the pressure profile (using an integrator on

the analog output, or in the plot screen in the ChemStation). The pressure

profile is shown in Figure 8.

Figure 8 Typical Pressure-Test Pressure Profile with IPA

Pressure

Step 2

Step 1

Time [minutes]

Step 1 The test begins with the initialization of the pump. After initialization,

plunger 1 is at the top of its stroke. Next, the pump begins pumping solvent

82

Page 83

Troubleshooting and Test Functions

Pressure Test

with a flow rate of 510 µl/min and stroke of 100 µl. The pump continues to

pump until a system pressure of 390 bar is reached.

Step 2 When the system pressure reaches 390 bar, the pump switches off. The

pressure drop from this point onwards should be no more than 2 bar/minute.

Positioning the blank nut

To test the complete system’s pressure tightness, the blank nut should be

positioned at the column compartment outlet (or the outlet of the last

module before the detector).

If a specific component is suspected of causing a system leak, place the blank

nut immediately before the suspected component, then run the pressure test

again. If the test passes, the defective component is located after the blank

nut. Confirm the diagnosis by placing the blank nut immediately after the

suspected component. The diagnosis is confirmed if the test fails.

83

Page 84

Troubleshooting and Test Functions

Running the Pressure Test

Running the Pressure Test

Tools required

Parts and materials

required

¼-inch” wrench

Blank nut, 01080-83202

Isopropanol, 500 ml

Running the test from the ChemStation

1 Select the pressure test from the test selection box in the Diagnosis screen.

2 Start the test and follow the instructions.

NOTE Make absolutely sure that all parts of the flow path that are part of the

test are very thoroughly flushed with IPA before starting to pressurize

the system! Any trace of other solvents or the smallest air bubble

inside the flow path definitely will cause the test to fail!

The slope and plateau are evaluated automatically. “Evaluating the Results”

on page 86 describes the evaluation and interpretation of the pressure test

results.

Running the test from the Control Module

1 Place a bottle of LC-grade isopropyl alcohol in channel D.

2 Block column compartment outlet (or the outlet of the last module before the

detector) with a blank nut (01080-83202), See “Positioning the blank nut” on

page 83.

3 Open the purge valve. Set flow for channel D to 5 ml/min and flush the

degasser for about 10 minutes.

4 Set flow to 0 ml/min. Leave the purge valve open.

5 Connect the signal cable to the analog output at the rear of the pump module

(only if an integrator is used).

6 Press Execute to initialize the pressure test.

84

Page 85

Troubleshooting and Test Functions

Running the Pressure Test

Once the test is started, the pump moves the plungers into the start position.

When the plungers are in position, the user interface prompts you to close

the purge valve, and continue the test.

7 Close the purge valve, select continue on the control module and press Enter

to start the test.

The control module displays a graphical representation of the pressure.

“Evaluating the Results” on page 86 describes the evaluation and

interpretation of the pressure test results.

8 When the test is finished slowly open the purge valve to release the pressure

in the system.

85

Page 86

Troubleshooting and Test Functions

Evaluating the Results

Evaluating the Results

The sum of all leaks between the pump and the blank nut will be indicated by

a pressure drop of >2 bar/minute at the plateau. Note that small leaks may