Preparative separation of a binary

compound mixture – recovery of pure

compounds and solvent consumption

Abstract

This Application Note describes the separation of two compounds from

a binary compound mixture using the Agilent 1100 Series purification

system. The parameters purity, recovery, analysis run time, solvent con-

sumption and liquid phase composition are monitored and their interre-

lation is explained. Further, we discuss how the analysis can be opti-

mized with regard to these parameters.

Application

Udo Huber

Introduction

Separation of discrete compounds

from a mixture is a typical task in

preparative liquid chromatography. The simplest task is isolating

two compounds from a binary

mixture, however, it is also possible to isolate pure compounds

from more complex compound

mixtures, such as natural product

extracts 1, for example. The compounds to isolate are typically isomers or enantiomers

2,3

.

In this Application Note we

demonstrate the separation of two

compounds from a binary compound mixture using the Agilent

1100 Series purification system.

The method developed on an analytical column was scaled up to

preparative scale and the compounds were separated in milligram quantities. The separation

was done repeatedly, varying the

composition of the liquid phase to

achieve a separation with good

recovery and purity with minimum

solvent consumption.

Equipment

The system included two Agilent

1100 Series preparative pumps, an

Agilent 1100 Series diode array

detector, an Agilent 1100 Series

column organizer and an Agilent

220 micro plate sampler modified

for higher flow rates. The system

was controlled using the Agilent

ChemStation (revision A.08.04)

and the micro plate sampling software (revision A.03.02).

Results and Discussion

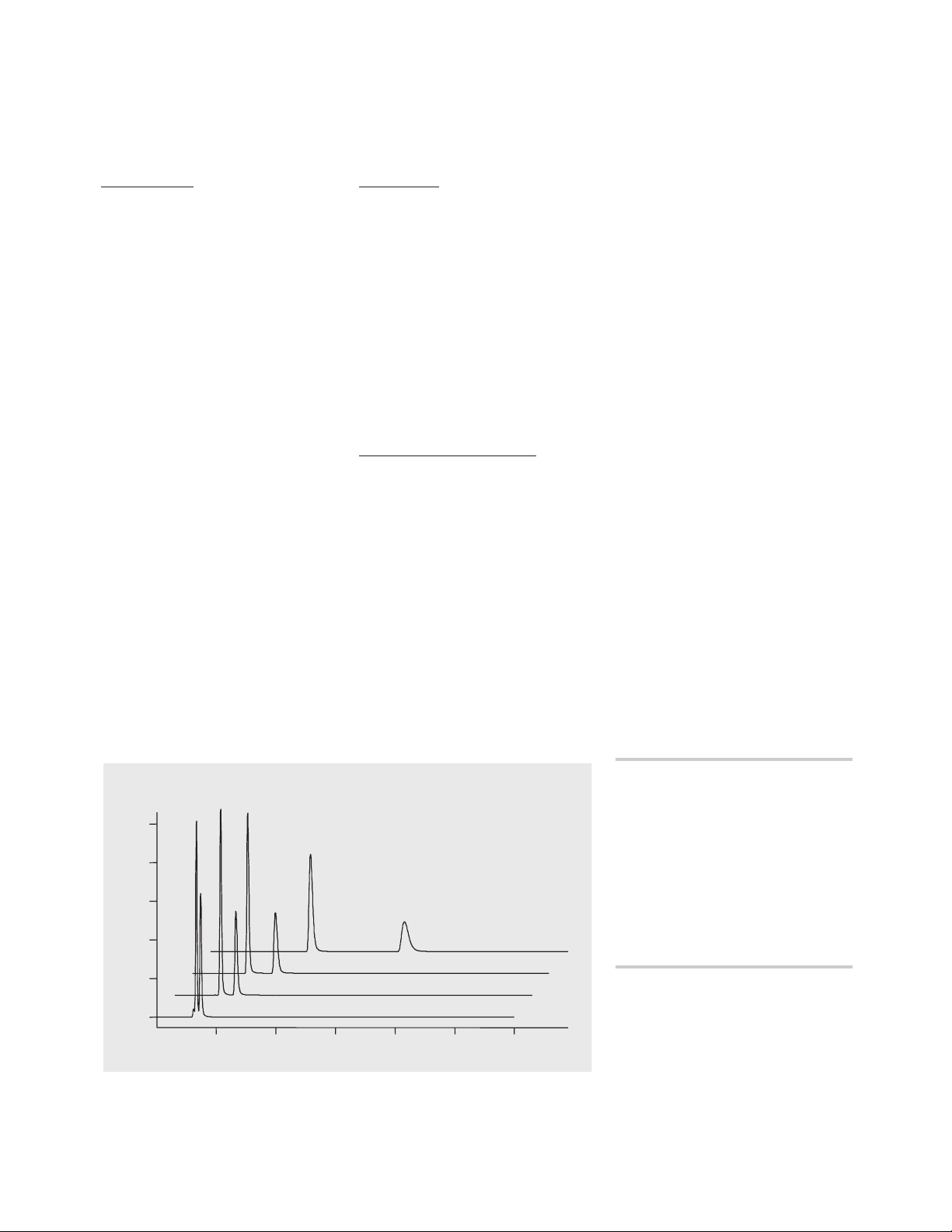

Overloading of the analytical column

The separation of the binary compound mixture was first done on

an analytical column. Separation

was achieved isocratically with a

water/ acetonitrile mixture

(figure 1).

Figure 1

Analytical separation of binary compound mixtures

Time [min]

24681012

Absorbance

[mAU]

0

500

1000

1500

2000

2500

30 % B

20 % B

15 % B

10 % B

Mobile phase: water = A

acetonitrile = B

Isocratic: between 10 and 30 % B

Stop time: 12 min

Column: Zorbax SB-C18

3 x 150 mm, 5 µm

Flow: 0.6 ml/min

Injection: 5 µl

Column temperature: ambient

UV detector: DAD 270 nm/16

(reference 360 nm/100)

Standard cell

(10 mm pathlength)

Since the crude product was very

soluble concentration overloading

was possible. Figure 2 shows that

the analytical column could be

loaded with up to 500–1000 µg of

each compound

Scale up to preparative scale

The scale-up from the analytical to

the preparative column was calculated using the formulae shown in

figure 3. After the first preparative

run the flow rate was changed to

25 ml/min to achieve comparable

retention times.

0.025 µg

0.25 µg

2.5 µg

25 µg

250 µg

Isocratic: 10 % B

Time [min]

2 4 6 8 10 12 14

Absorbance

[mAU]

0

1000

2000

3000

4000

5000

500 µg

1000 µg

Analytical column

Zorbax SB-C18

3 x 150 mm, 5 µm

Preparative column

Zorbax SB-C18

21.2 x 150 mm, 5 µm

Flow: 0.6 ml/min

Flow ~ 30 ml/min

Volume: 15 µl/injection

Volume: 750 µl/injection

x

1

=

r

2

1

×π

x1 = max. volume column 1

r1 = radius column 1

x2 = max. volume column 2

r2 = radius column 2

CL= ratio lengths of columns

= 15 µl

= 1.5 mm

= ?

= 10.6 mm

= 1

x

2

r

2

2

×π

×

1

C

L

V

1

V

2

r

1

r

2

2

2

=

.

.

Figure 2

Overloading of the analytical column

Figure 3

Scale up from analytical preparative column

taining the compound mixture.

The overall recovery of the compounds was 24.5 mg of compound

1 (98 %) and 23.9 mg of compound

2 (94 %). The overall analysis run

time could be minimized to about

2.6 minutes, that is, solvent consumption was about 65 ml per

analysis.

Fractionation under isocratic conditions with 20 % B in the mobile

phase

Figure 5a shows the preparative

run and the fractionation based on

retention time windows, figure 5b

shows the fractionation result.

About 21 mg of compound 1 with

a purity higher than 95 % could be

isolated, which is a recovery of

85 %. The isolated 23.5 mg of

Fractionation under isocratic conditions with 30 % B in the mobile

phase

Figure 4a shows the preparative

run and the fractionation based on

retention time windows, figure 4b

shows the fractionation result. It

can be seen that only about 12 mg

of compound 1 with a purity higher than 90 % could be isolated

together with many fractions con-

Figure 4

Fractionation with 30 % mobile phase B, b) isolation results, isocratic conditions

Mixed fractions

Analysis with 20 % B

0

5

10

15

20

25

30

0.5 1.5 2.5 3.5 4.5

Time [min]

Amount

[mg]

Pure

compound 1

024

Absorbance

[mAU]

0

500

1000

1500

2000

2500

P 2- _1

P 2- _3

P 2- _5

P 2- _7

P 2- _9

P 2- _11

P 2- _13

P 2- _15

P 2- _17

P 2- _19

Time [min]

a)

Fractions: 1 - 5 min

Width: 0.2 min

b)

Compound 1

Compound 1

Analysis with 30 % B

0

5

10

15

20

25

0.7 1.1 1.5 1.9 2.3 2.7 3.1

Time [min]

Compound 1

Compound 2

Mixed

fractions

Pure

compound 1

Amount

[mg]

4

Time [min]

02

Absorbance

[mAU]

0

500

1000

1500

2000

2500

P 2- _1

P 2- _2

P 2- _3

P 2- _4

P 2- _5

P 2- _6

P 2- _7

P 2- _8

P 2- _9

P 2- _10

P 2- _11

P 2- _12

P 2- _13

Fractions: 0.6 - 3 min

Width: 0.2 min

a) b)

Figure 5

a) Isolation results, isocratic conditions, 20 % mobile phase B, b) isolation results, isocratic conditions

compound 2 (93 % recovery) had a

purity of slightly less than 90 %.

The overall recovery was 24.3 mg

of compound 1 (97 %) and 23.5 mg

of compound 2 (93 %). The overall

analysis run time could be minimized to about 3.4 minutes, that

is, solvent consumption was about

85 ml per analysis.

Fractionation under isocratic conditions with 15 % B in the mobile phase

Figure 6a shows the preparative

run and the fractionation based on

retention time windows, figure 6b

shows the fractionation results. All

isolated 24 mg of compound 1 had

a purity higher than 98 %. The

recovery was 97 %. The isolated

23 mg of compound 2 (90 % recovery) had a purity of 96 %. The

overall analysis run time could be

minimized to about 4 minutes, that

is, solvent consumption was about

100 ml per analysis.

Fractionation under isocratic conditions with 10 % B in the mobile

phase

Figure 7a shows the preparative

run and the fractionation based on

retention time windows, figure 7b

shows the fractionation results.

24.4 mg of compound 1 were

Analysis with 15 % B

Compound 1

Compound 2

Pure

compound 1

Pure compound 2

Time [min]

0246

Absorbance

[mAU]

0

500

1000

1500

2000

2500

P2-_1

P2-_3

P2-_5

P2-_7

P2-_9

P2-_11

P2-_13

P2-_15

P2-_17

P2-_19

Amount [mg]

Fractions: 1 - 12 min

Width: 0.2 min

a)

b)

Analysis with 10 % B

Compound 1

Compound 2

Pure

compound 1

Pure

compound 2

a)

b)

Amount

[mg]

Time [min]

0246810

Absorbance

[mAU]

0

500

1000

1500

2000

P 2- _1

P 2- _5

P 2- _10

P 2- _15

P 2- _20

P 2- _25

P 2- _30

P 2- _35

P 2- _40

P 2- _45

P 2- _50

P 2- _54

Fractions:

1-12 min

Width:

0.2 min

Figure 6

a) Fractionation with 15 % mobile phase B, b)isolation results, isocratic conditions

Figure 7

a) Fractionation with 10 % mobile phase B, b) isolation results, isocratic conditions

30

25

20

15

10

5

0

0.5 1.5 2.5 3.5 4.5

Time [min]

30

25

20

15

10

5

0

0.5 2.5 4.5 6.5 8.5 10.5

isolated with a purity of 98 %

which is a recovery of 96 %. Compound 2 could be isolated with

97 % recovery (24.6 mg) and a

purity of over 98 %. Despite these

results the performance of the

separation is not optimum. There

are several fractions with no

product between the fractions

containing the pure compounds.

The overall analysis run time of

the separation is about 10.2 minutes, which means a solvent consumption of 255 ml per analysis.

Recovery against purity

Figures 8a and 8b show the recovered amount of the two compounds against purity. It can be

clearly seen that the recovered

amount with high purity increases

with less acetonitrile in the mobile

phase. Therefore, the analysis has

to be adjusted depending on

which parameter has higher priority. If high purity is required, for

example for activity testing, and

the recovery is not important, an

analysis with more acetonitrile

can be done. Both compounds

can be isolated with good purity

with relative short run times. On

the other hand, if good recovery

is required but purity is less

important, for example for isolation of intermediates in a synthesis sequence, less acetonitrile

should be used in the mobile

phase.

a)

b)

60

70

80

90

100

0 5 10 15 20 25

30 % B

Compound 2Compound 1

Recovered Amount [mg]

10 % B

Purity [%]

Purity [%]

Recovered Amount [mg]

Figure 8

a) Recovery against purity for compound 1, b) recovery against purity for compound 2

100

90

80

0 5 10 15 20 25

30 % B

20 % B

15 % B

20 % B

15 % B

10 % B

Recovery and solvent consumption

Another aspect of the separation

to keep in mind is the solvent consumption. Solvents for preparative

LC have to be of high purity and

are therefore rather expensive.

Since waste disposal and environmental protection are nowadays

important issues the chemist

should try to avoid unnecessary

solvent consumption. Figure 9

shows the recovery (purity > 90 %)

against solvent usage.

It can be seen that the solvent

consumption for down to 15 %

acetonitrile in the liquid phase is

less than 100 ml per analysis.

Using only 10 % acetonitrile in the

liquid phase more than doubles

the analysis run time and therefore the solvent consumption

(> 250 ml per analysis). Since the

results for recovery and purity are

already excellent for 15 % acetonitrile in the mobile phase it is not

necessary to run the analysis with

less acetonitrile.

Conclusion

This Application Note describes

the separation of two compounds

from a binary mixture using the

Agilent 1100 Series purification

system. The purification was performed isocratically using different liquid phase compositions. The

collected fractions were re-analyzed and the recovery and purity

of the compounds determined.

Further, the influence of the liquid

0

20

40

60

80

100

302015

10

% B

0

50

100

150

200

250

300

Recovery [%] (>90 % pure)

Solvent consumption [ml]

Compound 1

Compound 2

Solvent

Figure 9

Recovery against solvent consumption

phase composition on the parameters recovery, purity and analysis run time were investigated.

Also, the correlation of purity and

solvent consumption, which is an

important parameter regarding

costs, waste disposal and environment protection, was shown.

Copyright © 2000 Agilent Technologies

All Rights Reserved. Reproduction, adaptation

or translation without prior written permission

is prohibited, except as allowed under the

copyright laws.

Printed 10/2000

Publication Number 5988-0638EN

References

1.

“Isolation and purification of

hydroxyanthraquinones using the

Agilent 1100 Series purification

system”, Agilent Application Note,

2000, publication number 59880637EN

2.

B.R. Sadler, K. Chae, K.S. Ishaq,

K.S. Korach “Separation of indenestrol A and B isomeres and enantiomeres by high-performance liquid chromatography”, J. Chro-

matogr. A, 1998, 799(1-2), 117-124

3.

A.D. Cooper, T.M. Jefferies “Semipreparative high-performance liquid-chromatographic resolution of

brompheniramine enantiomeres

using beta-cyclodextrin in the

mobile phase” J. Chromatogr.,

1993, 637(2), 137-143

Udo Huber is an application

chemist based at Agilent

Technologies, Waldbronn,

Germany.

www.agilent.com/chem

Loading...

Loading...