PlateLoc Thermal

Microplate Sealer

User Guide

Agilent Technologies

Notices

© Agilent Technologies, Inc. 2008-2009

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

User Guide Part Number

G5402-90001

October/2006

Contact Information

Agilent Technologies Inc.

Automation Solutions

5301 Stevens Creek Blvd.

Santa Clara, CA 95051

USA

Technical Support: 1.800.979.4811

or +1.408.345.8011

service.automation@agilent.com

Customer Service: 1.866.428.9811

or +1.408.345.8356

orders.automation@agilent.com

European Service: +44 12081443513

euroservice.automation@agilent.com

Documentation feedback:

documentation.automation@agilent.com

Web: http://www.agilent.com

Acknowledgements

Microsoft and Windows are registered

trademarks of the Microsoft Corporation in

the United States and other countries.

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection

with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of

a U.S. Government prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR 52.22719(c)(1-2) (June 1987). U.S. Government

users will receive no greater than Limited

Rights as defined in FAR 52.227-14

(June1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Noticies

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or the

like that, if not correctly performed or

adhered to, could result in personal

injury or death. Do not proceed

beyond a WARNING notice until the

indicated conditions are fully

understood and met.

A CAUTION notice denotes a hazard. It

calls attention to an operating procedure,

practice, or the like that, if not correctly

performed or adhered to, could result in

damage to the product or loss of important

data. Do not proceed beyond a

notice until the indicated conditions are

fully understood and met.

CAUTION

Letter to our Customers

Dear Customer,

The Agilent Technologies acquisition of Velocity11 resulted in the following

changes:

• Creation of Agilent Technologies Automation Solutions, formerly Velocity11

• Renaming of some Velocity11 products

• New Customer Service and Technical Support contact information

• New website address for product information

Please make a note of the following changes as they impact this user guide.

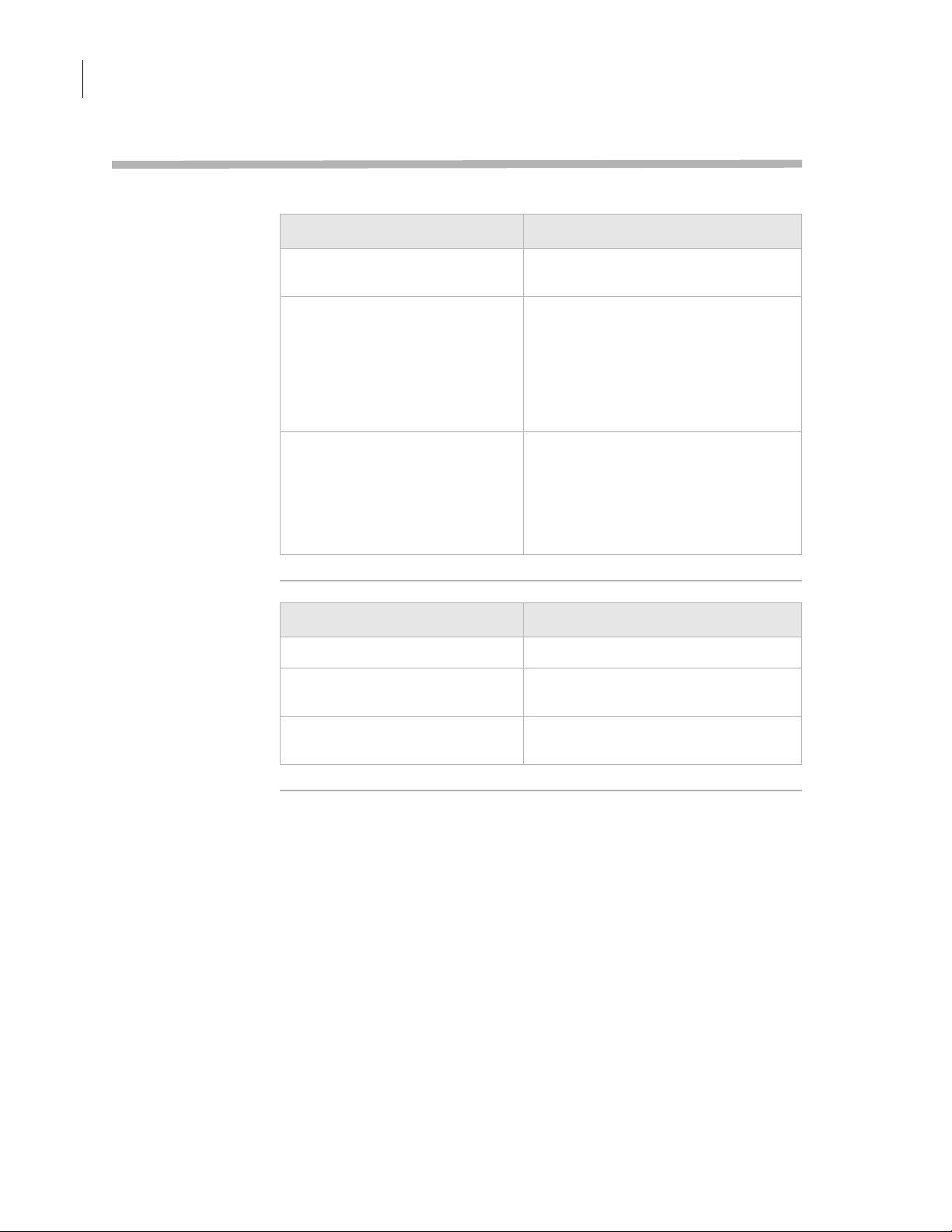

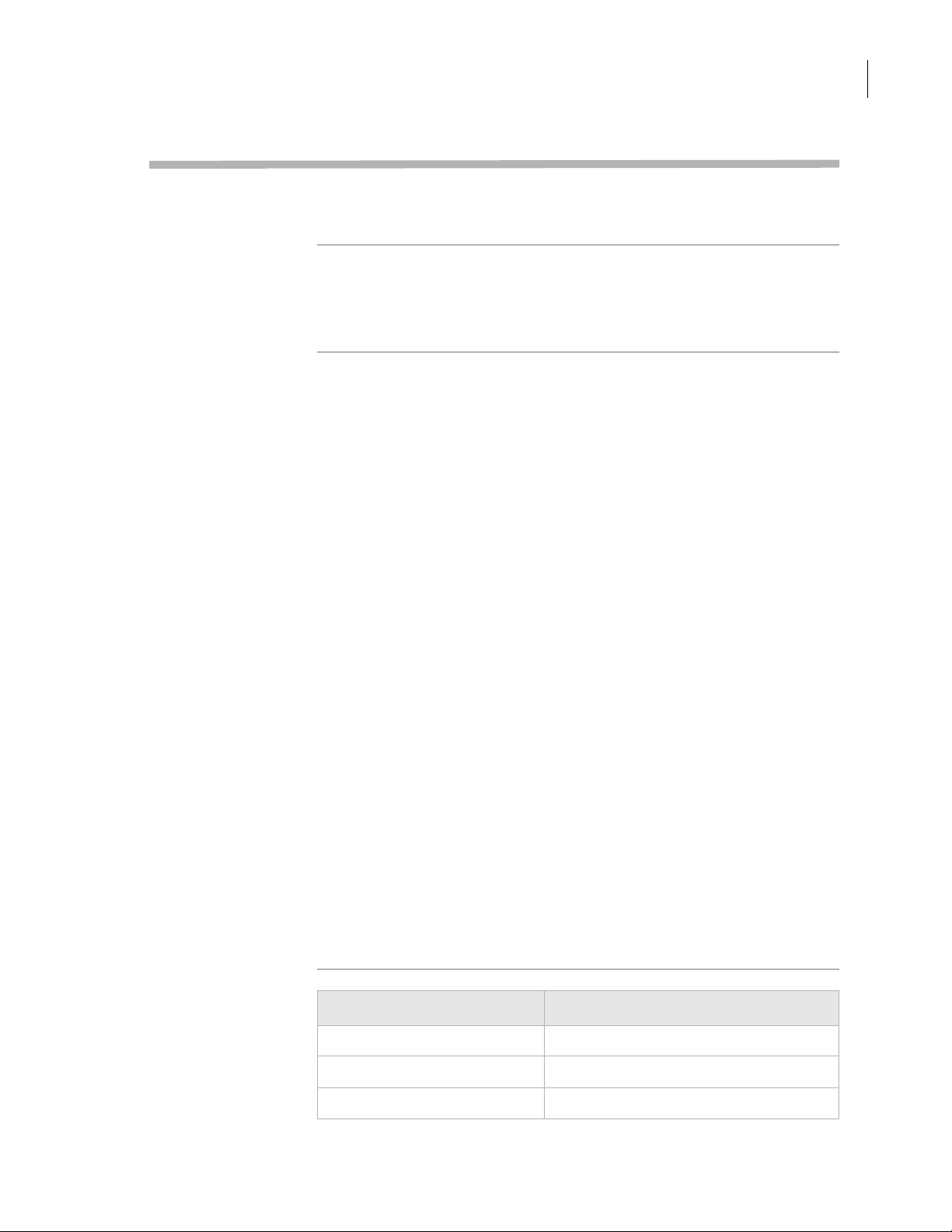

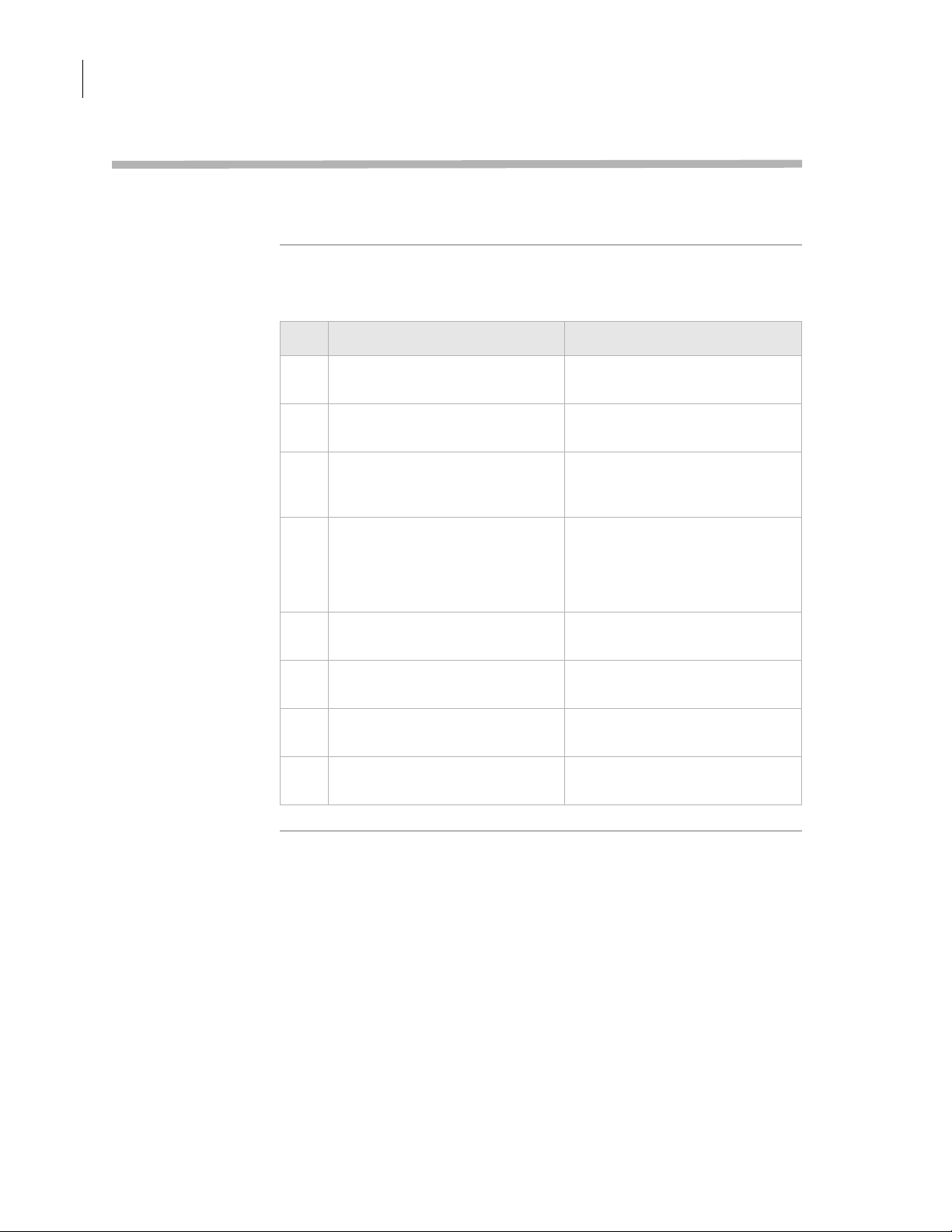

Velocity11 product name changes

Velocity11 product name Changes to …

Agilent Technologies

Access2 Automated Microplate

Loader

Element Automation System BioCel 900 System

IWorks Device Driver Programming

Interface

PlatePierce Seal Piercing Station Microplate Seal Piercer

VCode Barcode Print and Apply

Station

Velocity11 Robot 3- Axis Robot

VHooks Integration Interface VWorks Hooks Interface

VPrep Pipetting System Vertical Pipetting Station

VSpin Microplate Centrifuge Microplate Centrifuge

VStack Labware Stacker Labware Stacker

Automated Centrifuge Loader

VWorks DCL Interface

Microplate Barcode Labeler

New contact information

Documentation feedback: documentation.automation@agilent.com

Technical Support: 1.800.979.4811 or +1.408.345.8011

service.automation@agilent.com

Customer Service: 1.866.428.9811 or +1.408.345.8356

orders.automation@agilent.com

European Service: +44 12081443513

euroservice.automation@agilent.com

Web : http://www.agilent.com

Agilent Technologies, Inc., Automation Solutions, 5301 Stevens Creek Blvd., Santa Clara, CA 95051 USA

PlateLoc User Guide

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Who should read this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

What this guide covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

What’s new in this user guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Accessing Velocity11 user information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Chapter 1. PlateLoc intr oduction. . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description of the PlateLoc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Hardware overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connection panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Plate requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Seal material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lab automation system software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PlateLoc workflows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Contents

i

Chapter 2. Unpacking and install ation . . . . . . . . . . . . . . . . . . . 21

Installation workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Meeting Lab requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unpacking the PlateLoc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting the power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting and disconnecting the air source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connecting and disconnecting the argon source (Gas-Purging PlateLocs only) . . . . . 34

Connecting to the controlling computer (lab automation systems only) . . . . . . . . . . 37

Installing the PlateLoc ActiveX software (lab automation systems only) . . . . . . . . . . 38

Chapter 3. Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Turning on and turning off the power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Turning on and turning off the air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Turning on and turning off the argon (Gas-Purging Platelocs only) . . . . . . . . . . . . . . 47

Tilting and stowing the touch screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Adjusting the touch screen contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Loading and unloading a roll of seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Creating and managing profiles (lab automation systems only) . . . . . . . . . . . . . . . . 59

Establishing communications with the PlateLoc (lab automation systems only) . . . . 62

Contents

ii

PlateLoc User Guide

Chapter 4. Sealing plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Loading an insert and a plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Setting the sealing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Starting the seal cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Stopping a seal cycle in progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Chapter 5. Optimizing seal quality. . . . . . . . . . . . . . . . . . . . . . . 77

Reasons for running optimization tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Optimization test guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Adjusting the sealing parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Chapter 6. Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . 83

Cleaning the hot plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Cleaning the touch screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 7. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Hardware problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Diagnostic tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Reporting problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Appendix A. Integrating the PlateLoc into th ird-party

systems

PlateLoc ActiveX control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Integrating the PlateLoc ActiveX control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendix B. Quick reference . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Touch screen menus and commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

PlateLoc Diagnostics parameters and commands . . . . . . . . . . . . . . . . . . . . . . . . 120

Appendix C. Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Preface

Preface

PlateLoc User Guide

This preface introduces the PlateLoc User Guide. This preface contains

the following to pics:

❑ “Who should re ad this guide” on page iv

❑ “What this guide cov ers” on page v

❑ “What’s new in this user guide” on page vii

❑ “Accessing Velocity11 user information” on page viii

iii

iv

Preface

PlateLoc User Guide

Who should read this guide

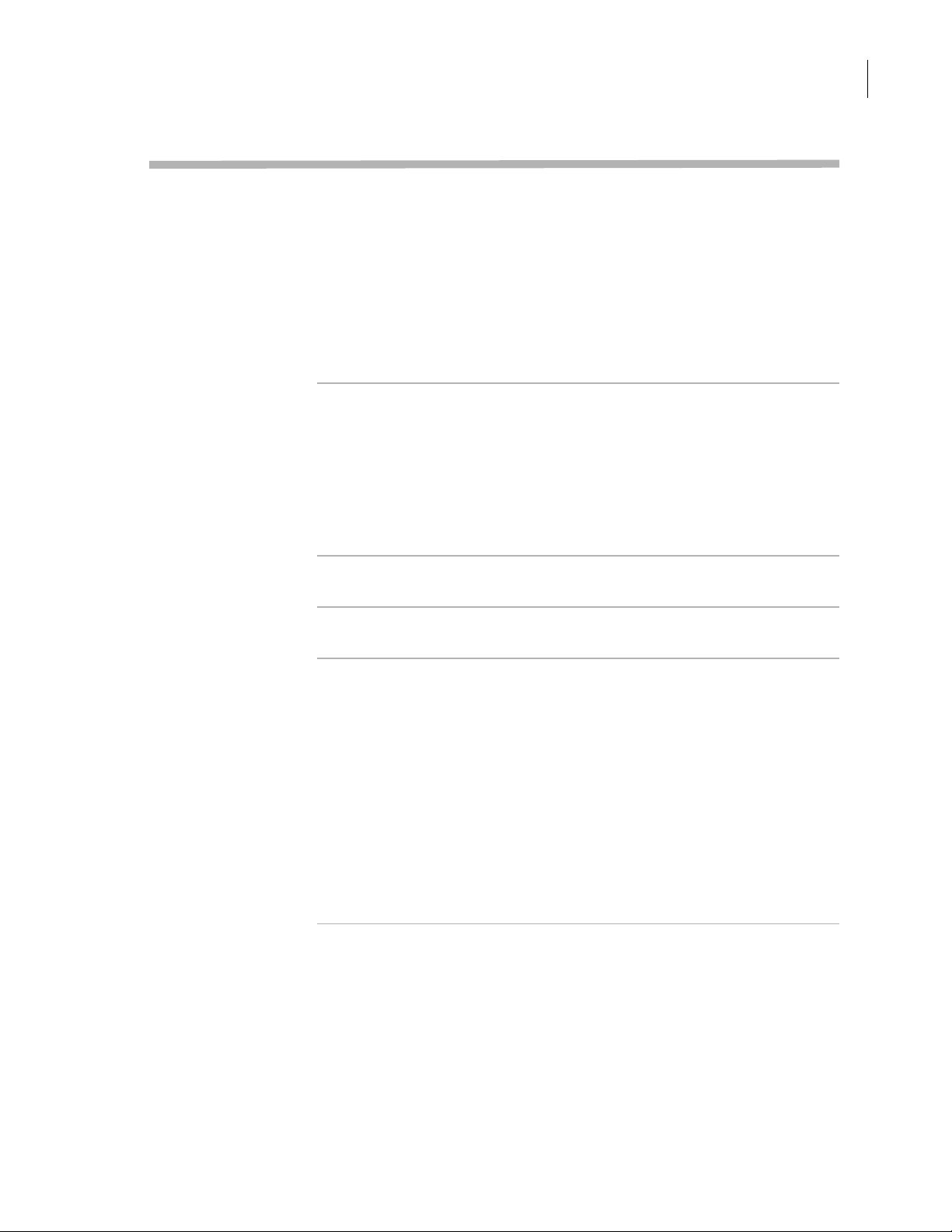

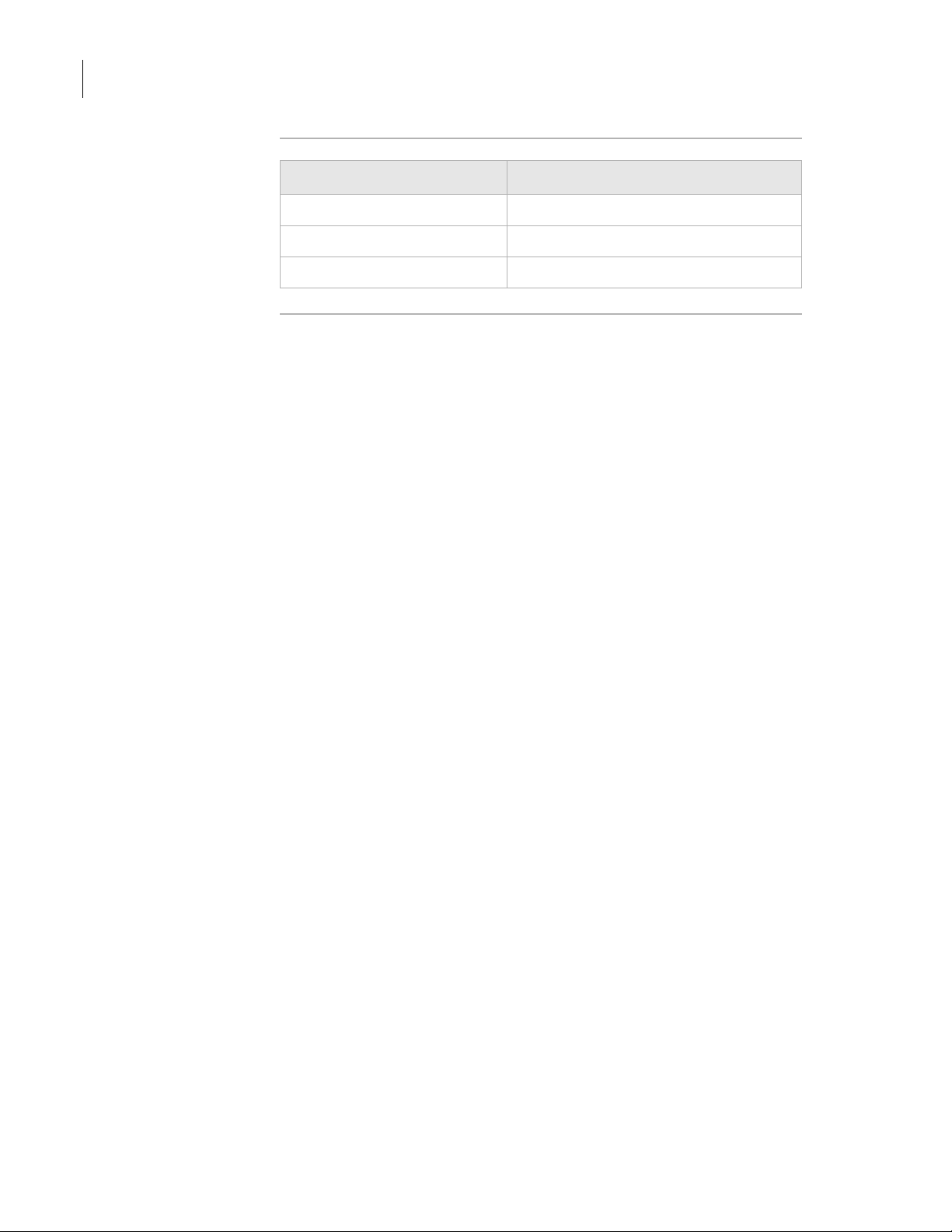

Job roles This user guide is for people wit h the following job role s:

Job role Responsibilities

Installer Someone who unpacks, puts together,

and tests the PlateLoc before it is used.

Related topics

Lab manager, administrator, or

technician

Someone who is responsible for:

❑ Solving the more challenging

problems that might arise

❑ Developing training materials and

standard operating procedures for

operators

Operator Someone who performs the daily

production work using the PlateLoc

and solves routine problems.

Your organiza tio n may ch oos e to cr ea te

its own procedures for operators

including the procedures in this guide.

For more information about... See...

What this guide covers “What this guide covers” on page v

What’s new in this version “What’s new in this user guide” on

page v ii

How to access different formats of

this user guide

“Accessing Velocity11 user information”

on page viii

Preface

PlateLoc User Guide

What this guide c overs

What is covered This guide covers the installation, setup, and operation of the PlateLoc

that is used in the following ways:

❑ As a single device, controlled from the built-in touch screen

interface

❑ Integra ted with other de vices in a Velo city11 la b automat ion system ,

controlled from a computer

This guide also provides the ActiveX reference information needed to

integrate the Plat eLoc in a third-party lab automation system.

What is not covered This guide does not provide instructions for:

❑ Creating protocols and setting task parameters in the Velocity11 lab

automation software

❑ Operating other devices in Velocity11 lab automation systems

❑ Operating the PlateLoc integrated into a third-party lab automation

system

v

Firmware version This guide documents PlateLoc firmware version 3.7.2.

Software version This guide documents PlateLoc ActiveX (PlateLoc.ocx) version 7.

Relate d guides The PlateLoc User Guide should be used in conjunction with the

following user documents:

❑ Velocity11 lab automation system user guides, such as the BenchCel

User Guid e and the BioCel Us er Gui de . T hese user guides provide the

system setup requirements and user operation instructions.

❑ Velocity11 lab automation system software user guides, such as the

VWorks User Guide. These user guides explain how to create

protoc ols and set task para meters for each device in the system.

❑ Third-party lab automation system user documents. These

documents e xplain how to set up and use the third-party lab

automation system.

vi

Preface

PlateLoc User Guide

Related topics

For more information about... See...

Who should read this guide “Who should read this guide” on

page iv

What’s new in this version “What’s new in this user guide” on

page v ii

How to access different formats of

this user guide

“Accessing Velocity11 user information”

on page viii

Preface

PlateLoc User Guide

What’s new in this user guide

About this topic This topic lists the new models and features that are described in this

revision of the PlateLoc User Guide.

New features This revision of the user guide describes a new PlateLoc model, the Gas-

Purgin g PlateLoc. The Gas-Purging PlateLoc uses argon to displace air

(containing moisture and oxygen) from the plate. The effect protects the

plate contents from hydration and oxidation.

Related topics

For more information about... See...

Who should read this guide “Who should read this guide” on

page iv

What this guide covers “What this guide covers” on page v

vii

How to access different formats of

this user guide

“Accessing Velocity11 user information”

on page viii

viii

Preface

PlateLoc User Guide

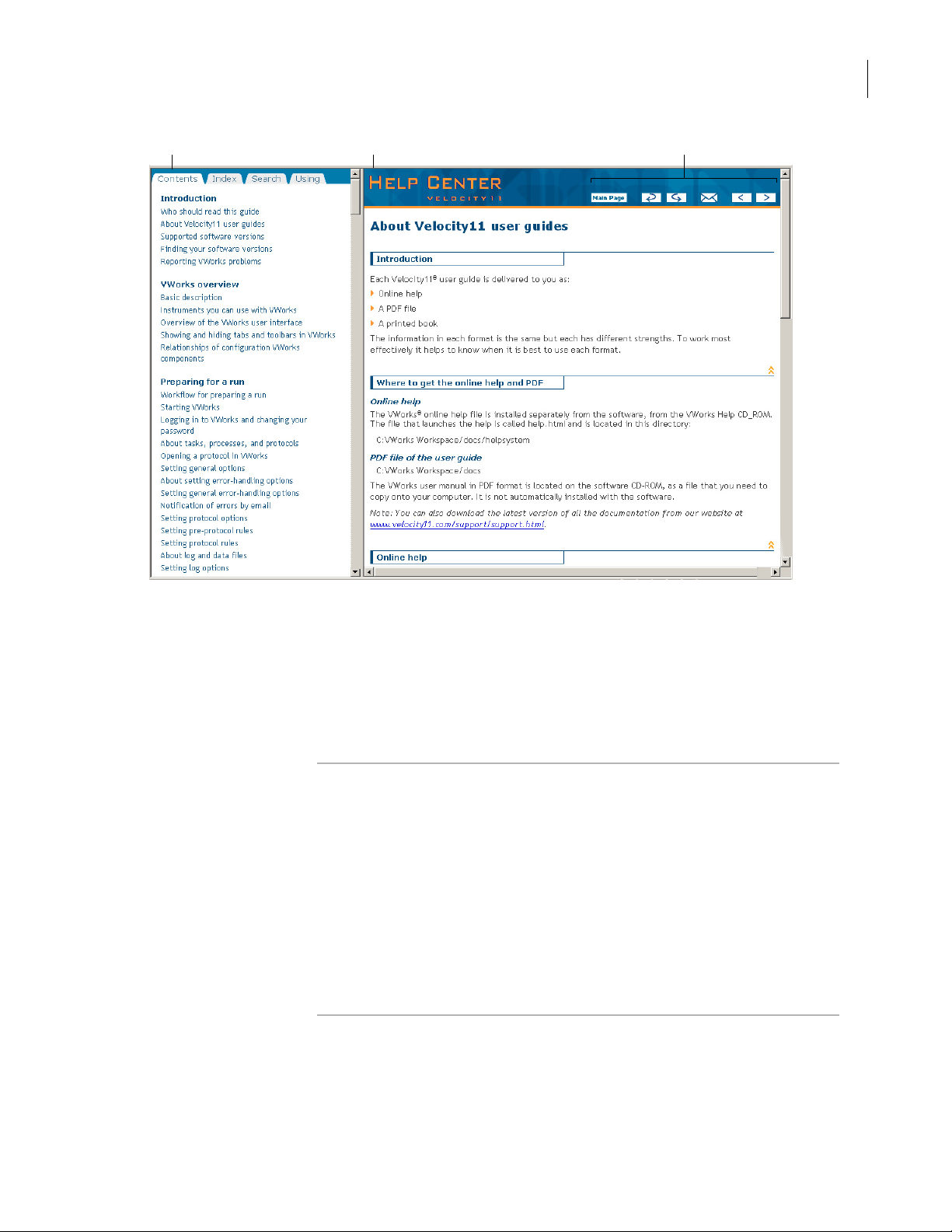

Accessing Velocity11 user information

About this topic This topic describes the diff erent formats of Velocity11 user information.

Velocity11 user information is provided to you as:

❑ Online help

❑ A PDF file

❑ A printed b ook

The information in each format is the same but each format has different

benefits.

Where to find the

user information

Online help

The online help is added to your computer with the software

installation.

Ve loci ty11 we bsit e

You can download the latest version of any PDF file from our website at

www.velocity11.com.

All Velocity11 user information can be searched from the website at

www.velocity11.com.

Online help The online help is the best format to use when you are working at the

computer and when you want to perform fast or advanced searches for

information.

To open the online he lp:

1. In the Velocity11 lab automation software, press F1.

Main featu r es

The online help includes a navigation pane, content pane, and

navigation buttons.

PlateLoc User Guide

Navigation pane Content pane Navigation buttons

Preface

ix

The navi gati on pane has four tabs. The Contents, Inde x , and Search ta bs

provide different ways to locate information. The Using tab contains

information about using the help system.

The content pane displays the online help topics.

Navigation buttons in the content pane allow you to navigate through

the pages.

PDF user guide Computer requirements

To open a user guide in PDF format, you need a PDF viewer. You can

download a free PDF viewer from the internet.

Printing and searching

We provide user guides in PDF format mainly for printing additional

copies. You can use them for simple searches, although these searches

are much slower than online help searches.

More information

For more information about using PDF documents, see the user

documentation for the PDF viewer.

x

Preface

PlateLoc User Guide

Related topics

For more information about... See...

Who should read this guide “Who should read this guide” on

page iv

What this guide covers “What this guide covers” on page v

What’s new in this revision of the

user guide

“What’s new in this user guide” on

page v ii

PlateLoc introduction

This chapter contains the following topics:

❑ “Description of the PlateLoc” on page 2

❑ “Hardware overview” on page 4

❑ “Connection panel” on page 7

❑ “Plate requirements” on page 9

❑ “Inserts” on page 10

❑ “Seal material” on page 13

Chapter 1: PlateLoc introduction

PlateLoc User Guide

1

1

❑ “Lab automation system software” on pa ge 14

❑ “PlateLoc workflows” on page 16

❑ “Safety infor m ation” on page 18

2

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Description of the PlateLoc

About this topic This topic describes the PlateLoc an d explains its uses.

Description The PlateLoc Thermal Plate Sealer is available in two models:

❑ PlateLoc. The PlateLoc is a device that applies seal material on top of

microplates (plates) to seal individual wells. Sealing the wells

protects the contents from evaporation, condensation, and crosscontamination duri n g transport or storage.

❑ Gas-Purging PlateLoc. In addition to the plate-sealing function of the

origina l PlateLoc, the Gas-Purging PlateLoc uses argon gas to

displace air, containing moisture and oxygen, in the plate

immediately before the sealing begins. Because argon is inert, it

does not react with the plate contents. The plate contents can be

protected from hydration and oxidation for up to 24 hours.

Typ i cal ly us e d fo r c o mpo und stor age ap p lic at ion s , the G a s -Pu rgin g

PlateLoc is best for plate contents that are sensitive to oxidation and

moisture (for example, DMSO).

Ways to use the

PlateLoc

Note: For typical polystyrene and polypropylene plates, th e gaspurging effects can last up to 24 hour s when the plates are stored

at room temperature. The effects can las t long er if th e plates are

stored at lower temperatures.

The PlateLoc can be used in the following ways:

❑ As a standalone device

❑ In a Velocity11 lab automation system

❑ In another company’s lab aut omation system

As a standalone device

You can set up the PlateLoc as a standalone device, operating the

PlateLoc from the built-in touch screen. You do not need to connect the

device to a computer.

Using the PlateLoc in the standalone mode allows you to manually load

and seal one plate at a time (a single seal cycle in one run). The

standalone device cannot automatically load and seal multiple plates in

one run.

In a Velocity 11 lab autom atio n s ystem

You can set up the PlateLoc in a Velocity1 1 lab automation system such

as the BenchCel or the BioCel. To install the PlateLoc in the system, you

must connect the device to the controlling computer. You can operate

the inte grated device using the software supplied with the lab

automation system , such as Be nch Works or VWorks. Integr ate d Pla te Loc

operation allows you to automate the loading and sealing of multiple

plates in one protocol run (multiple seal cycles in one run).

Related topics

Chapter 1: PlateLoc introduction

PlateLoc User Guide

In a third-party lab automation system

You can set up the PlateLoc in a third-p ar ty lab automation system. To

install the PlateLoc in the system, you must connect the device to the

cont rolling co mputer. You c an op e r ate the in t e gr ated Pla t eL oc using th e

third-party software. The integrated PlateLoc allows you to automate the

loading and sealing of multiple plates in one run.

Note: Communication between the third-party system and the PlateLoc

is achieved through th e use of ActiveX controls.

For more information about... See...

PlateLoc physical dimensions “Meeting Lab requirements” on page 23

Installing the PlateLoc “Unpacking and installation” on

page 21

3

How to use the PlateLoc as a

standalone device

Setting up the PlateLoc in a lab

automation system

How to use the PlateLoc in a lab

automation system

“Standalone device workflow” on

page 16

❑ “Lab automation system software”

on page 14

❑ “Integrating the PlateLoc into third-

party systems” on page 99

“Lab automation system workflow” on

page 17

4

Chapter 1: PlateLoc introduction

PlateLoc User Guide

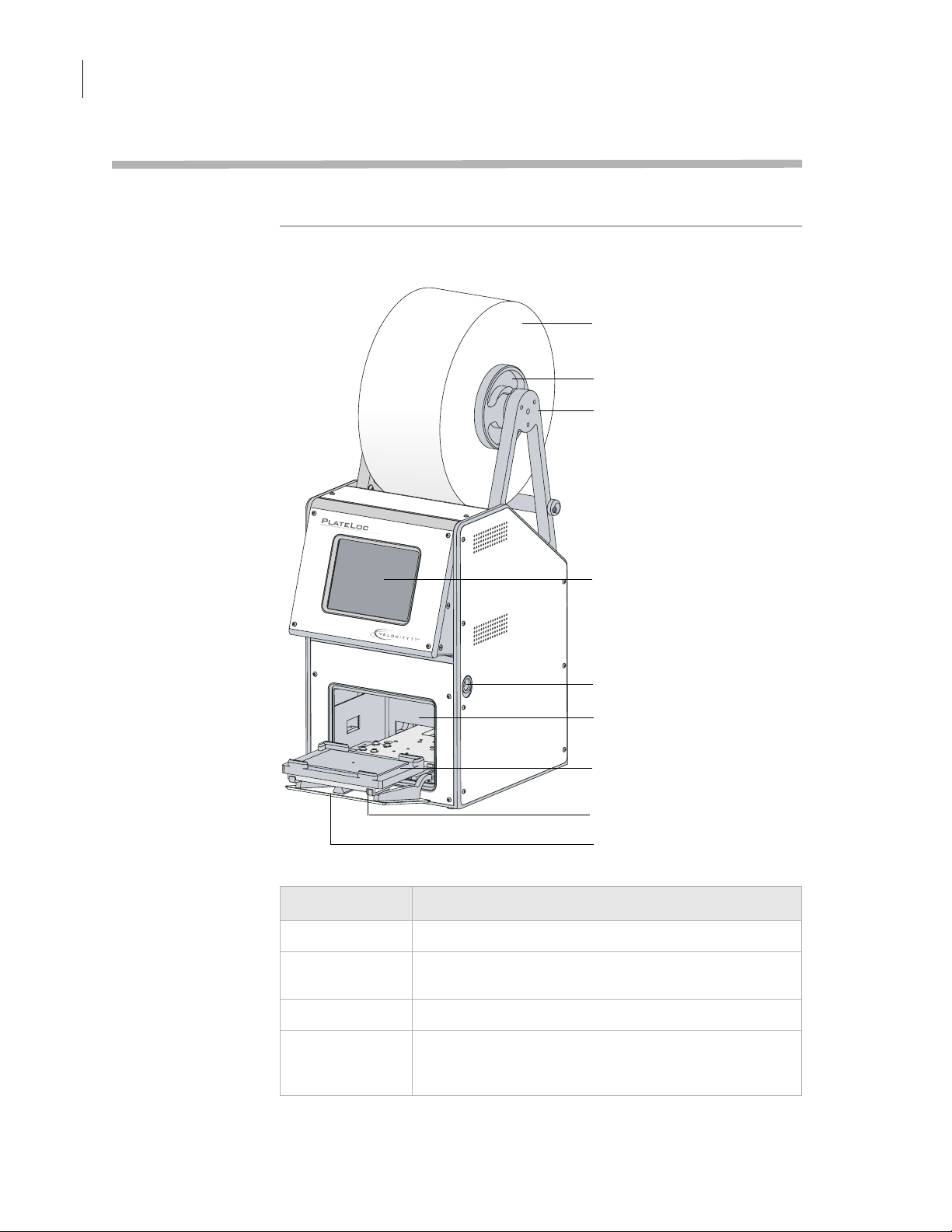

Hardware overview

About this topic This topic provides an overview of the PlateLoc hardware features.

Front features The following diagram shows the front of the PlateLoc. The table below

describes the fe atures shown in the di agram.

Roll of seal

Hub

Seal roll supports

Touch screen

Screen release lever

Sealing chamber

Plate stage

Plate-stage support

Door (opened)

Feature Description

Roll of seal The seal material.

Hubs The structures (together with the axle, not shown) that

hold the roll of seal and allow the roll to rotate.

Seal-roll sup po rt s The structure on which you mount the hubs and a xle.

Touch screen The interface that allows you to specify sealing

parameters, start and stop the seal cycle, and monitor

the seal cycle for standalone operation.

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Feature Description

Sealing chamber The area inside the device where plates are sealed.

Plate stage The removable metal platform on which plates are

loaded.

Door The movable structure that opens when the plate stage is

extended and closes when the stage enters the chamber.

5

Plate-stage

support

The structure on which you load the plate stage. The

plate-stage support extends when the door opens and

retracts when the door closes.

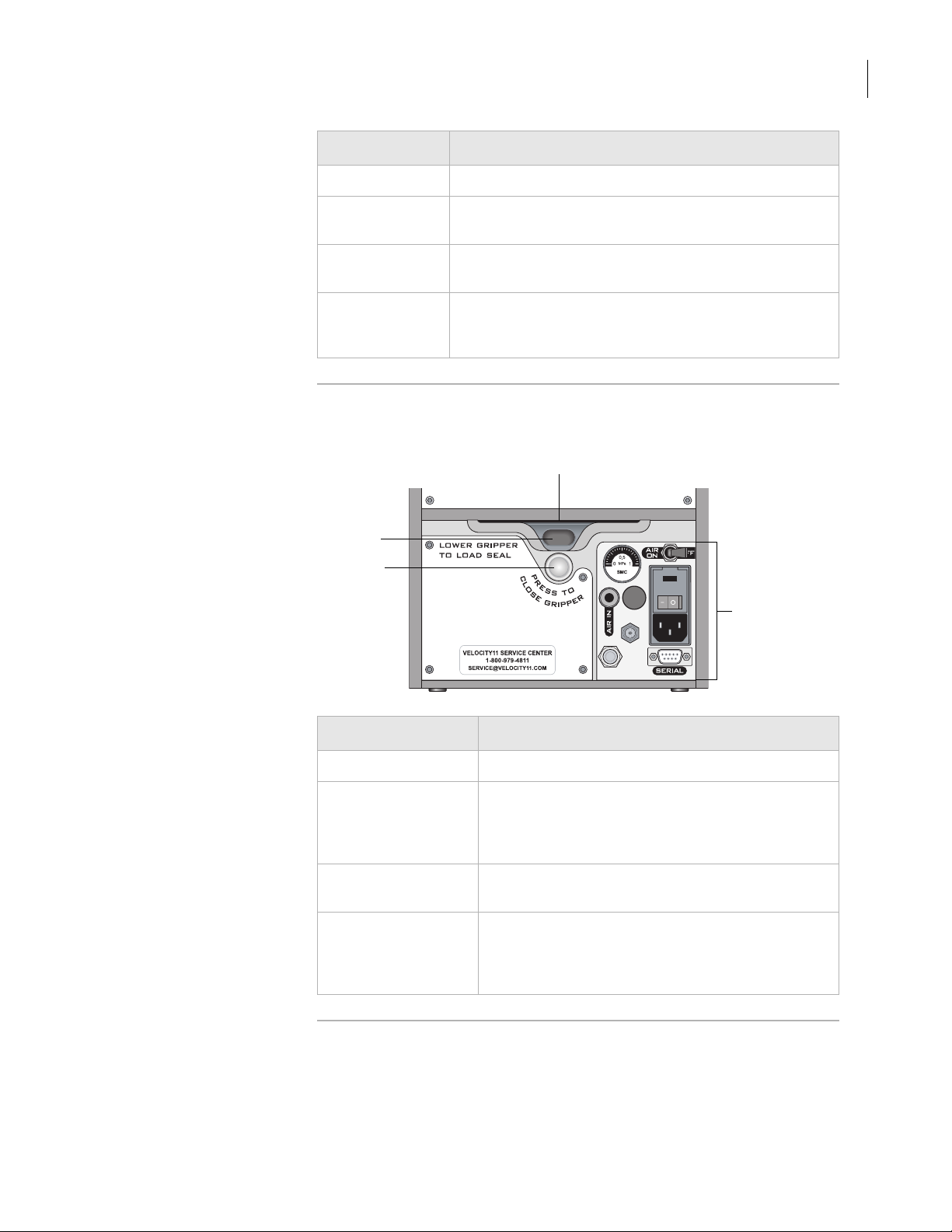

Rear features The following diagram shows the lower back side of the PlateLoc. The

table below it describes the features shown in the diagram.

Seal entry slot

Open-gripper button

Close-gripper button

00191

00191

PlateLoc

PlateLoc

connections

connections

Feature Description

Connection panel

Seal entry slot The narrow opening into which you insert the seal.

Open-gripper button The oval button that you push downward when

inserting the seal into the seal entry slot. Pushing the

button downward opens the grippi ng mechanism

that holds the seal in position.

Close-gripper button The silver button that you press to close the seal-

gripping mechanism.

Connection panel The area where you connect the power, air tubing,

argon tubing (Gas-Purging PlateLocs only), and

computer. The panel also contains a gauge that

allows you to verify air flow.

6

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Related topics

For more information about... See...

The connection panel “Connection panel” on page 7

The PlateLoc physical dimensions “Meeting Lab requirements” on page 23

Installing the PlateLoc “Unpacking and installation” on

page 21

Installing and operating the

PlateLoc

“PlateLoc workflows” on page 16

Chapter 1: PlateLoc introduction

PlateLoc User Guide

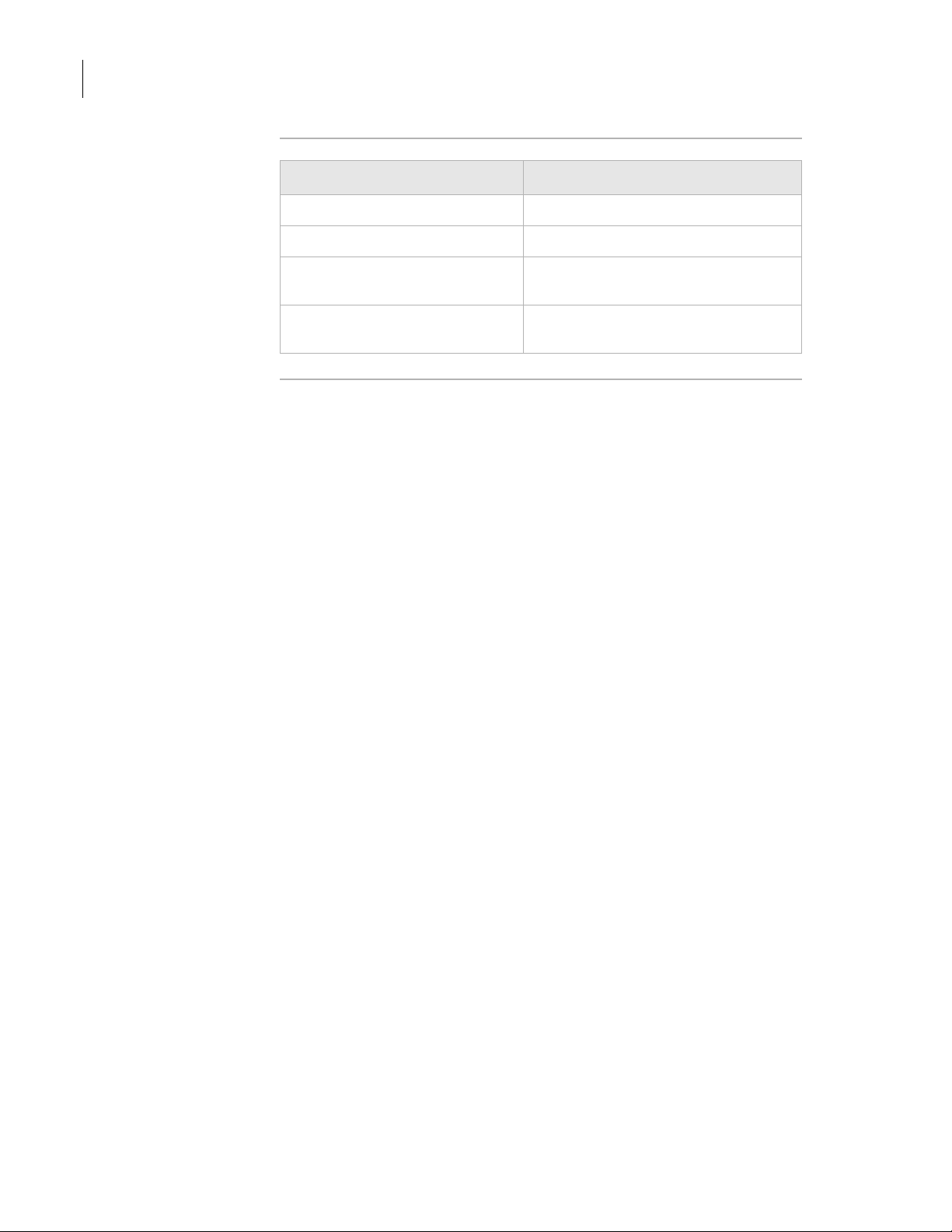

Connection panel

About this topic This topic describes the connection pane l on the back of the Pla teLoc.

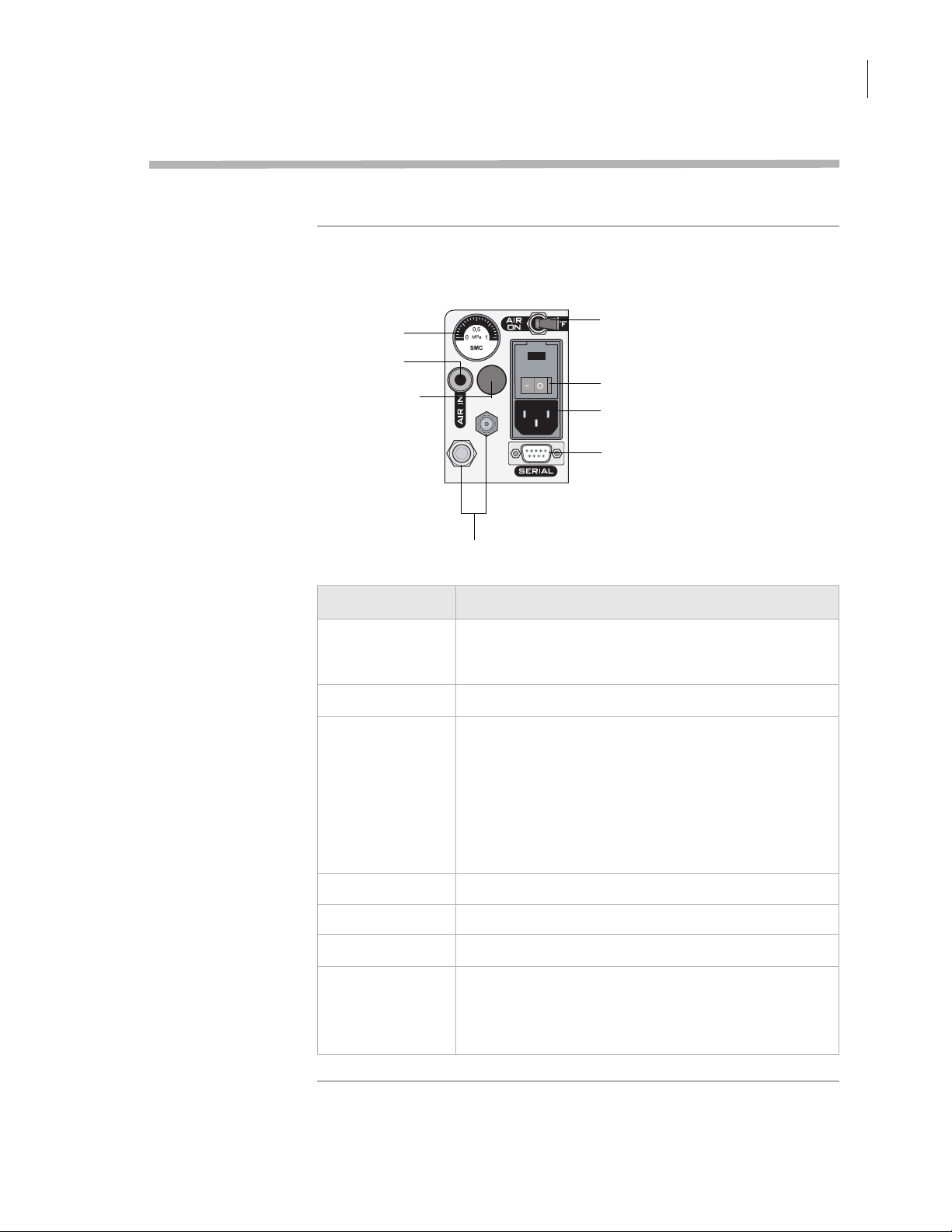

Description The following diagram shows the connection panel that is located on

the back of the PlateLoc. The table below the diagram describes each

component on th e panel.

7

Air flow gauge

Air-input fitting

Argon-input fitting

(Gas-Purging

PlateLocs only)

For Velocity11 service use only

Air on/off switch

Power switch

AC power entry

Serial port

Feature Description

Air flow gauge Indicates the presence of air flow inside the PlateLoc.

Compressed air is used to move pneumatic

components inside the PlateLoc.

Air-input fitting Connects the air tubing to the PlateLoc.

Argon-inpu t fitting

(Gas-Purging

PlateLocs only)

Connects the argon tubing to the G as-Purging PlateLoc.

Argon is used to displace air in the plate, thereby

removing oxygen and moisture.

Note: T here is no on/off switch for argon. Argon starts to

fill the sealing chamber automatically when a seal cycle

starts. For safety reasons, the argon stops filling the

sealing chamber automatically just before the seal is

applied.

Air on/off switch Turns on or off the air flow into the PlateLoc.

Power switch Turns on or off the power to the PlateLoc.

AC power entry Connects the power cord to the PlateLoc.

Serial port Connects the serial cable from the controlling computer

to the PlateLoc.

Use this port when installing the PlateLoc in a lab

automation system.

8

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Related topics

For more information about... See...

Installing and operating the

PlateLoc

“PlateLoc workflows” on page 16

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Plate requirements

About this topic This topic explains the requirements for the plates you can use in the

PlateLoc.

Acceptable plates The PlateLoc accepts plates made from a variety of materials. For a

complete list of the acceptab l e mate rials, see the PlateLoc Thermal Plate

Sealer Seal Selection Guide. You can locate the guide on the Velocity11

website at www.velocity11.com.

Use only plates tha t meet the standards established by the Society of

Biomolecular Sciences (SBS), including deep-well, PCR, and standard

plates in the 96-well, 384-well, and 1536-well formats. For the latest plate

standards, go to www.sbsonline.org. You can also contact the labware

manufacturer to inquire about SBS-standard plates.

Ideal seal cond itions can depend on the plate design, such as thickness

and geometry. For example, plates with raised chimneys that have flat

surfaces at the top can minimize cross-contamination, reduce

evaporation, and minimize condensation.

9

Note: Plates made from the same material but have different designs can

require different sealing parameters.

Velocity11 recommends that you run optimization tests to determine the

best sealing pa ramet e r s to use for each plate type. See “Optim iz in g sea l

quality” on page 77 for some opti mization test guidelines.

Challenging plates Because of the material or design, the f oll owing plat es might cause poor

seal results when used in the PlateLoc:

❑ Plates that have non-binding coatings

❑ Flexible plates that tend to bend during sealing

❑ Breiner Model 651182, 96-well V-bottom plates (when used with the

Velocity11 Peelable Aluminum Seal, 06643.001)

You should run some seali ng tests to d etermine w h ether optimal sealing

is possible with these plates or if you should use different plate types.

See “Optimizing seal quality” on page 77 for some optimization test

guidelines.

Related topics

For more information about... See...

Optimizing seal quality “Optimizing seal quality” on page 77

Inserts (plate supports) “Inserts” on page 10

Seal material “Seal material” on page 13

10

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Inserts

About this topic This topic describes inserts and their uses in the PlateLoc.

What are inserts Inserts are pads that support the bottoms of plates f or uniform seals. You

use inserts to support plates that tend to bend during a seal cycle.

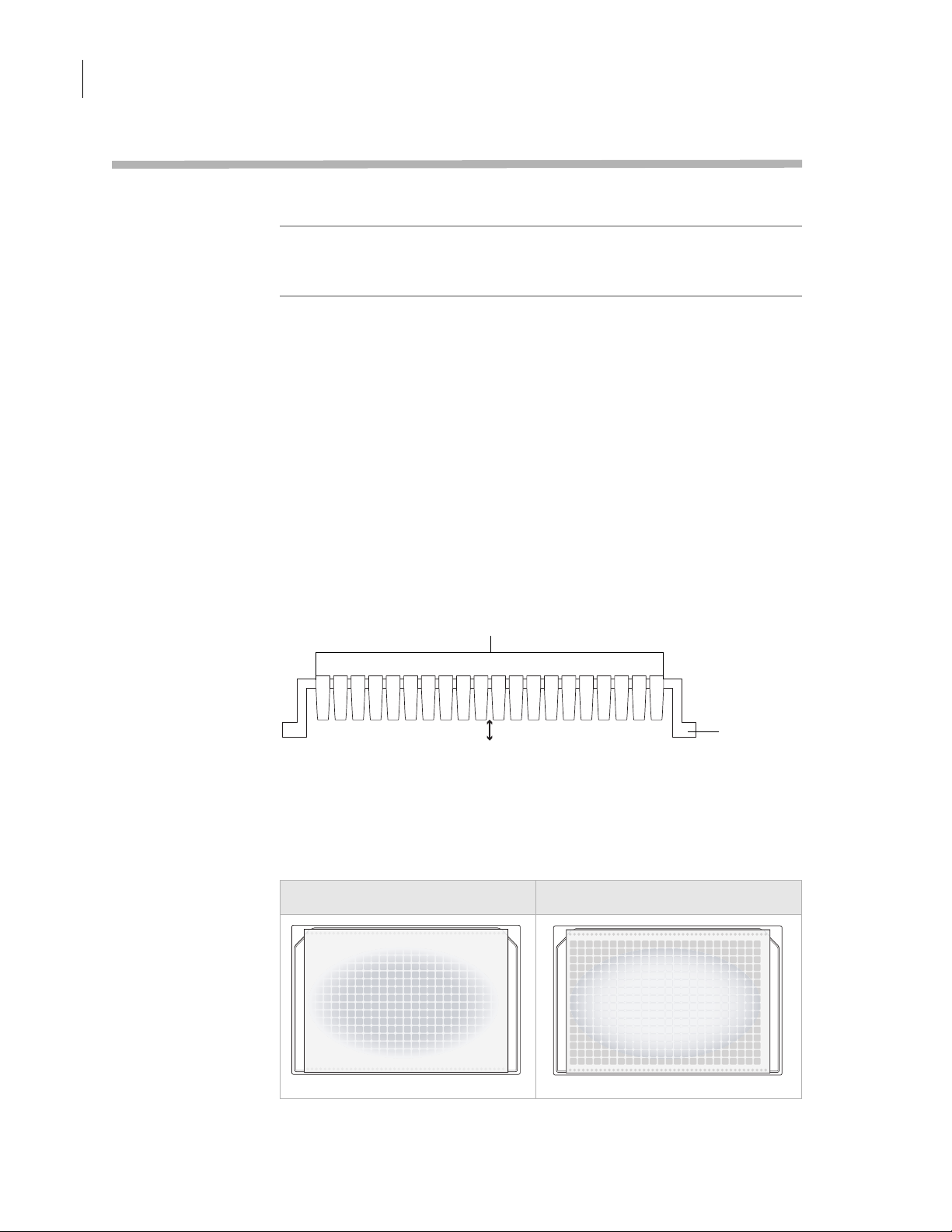

When to use inserts Causes of non-uniform seals

During the seal cycle, a heated m etal plate (hot plate) inside the sealing

chamber descends and presses the seal onto the plate. In a quality seal,

the seal material is applied to the plate uniformly. However, the

following factors can cause u neven plate sealing:

❑ Because of the material used, some plates tend to bend in the high-

temperature environment.

❑ In some plate designs, the plate skirt sits higher or lower than the

plate bottom, causing uneven sealing.

The following diagram shows the side profile of a plate. In this example,

the plate skirt extends past the bottom of the wells. Depending on the

plate ma ter ial, such pl at e desig ns can cause non-uniform sealing. When

the hot plate presses down, the wells at the center of the plate might

bend upward or downward.

Wells

Skirt

Bending movement

The following diagrams show the top view of sealed plates. Non-uniform

seals can result when the center of the plate bends upward (left) and

downward (right) during the seal cycle.

Plate center is higher Plate center is too low

00200

PlateLoc

shim too high

00200

00199

PlateLoc

shim too low

00199

Chapter 1: PlateLoc introduction

PlateLoc User Guide

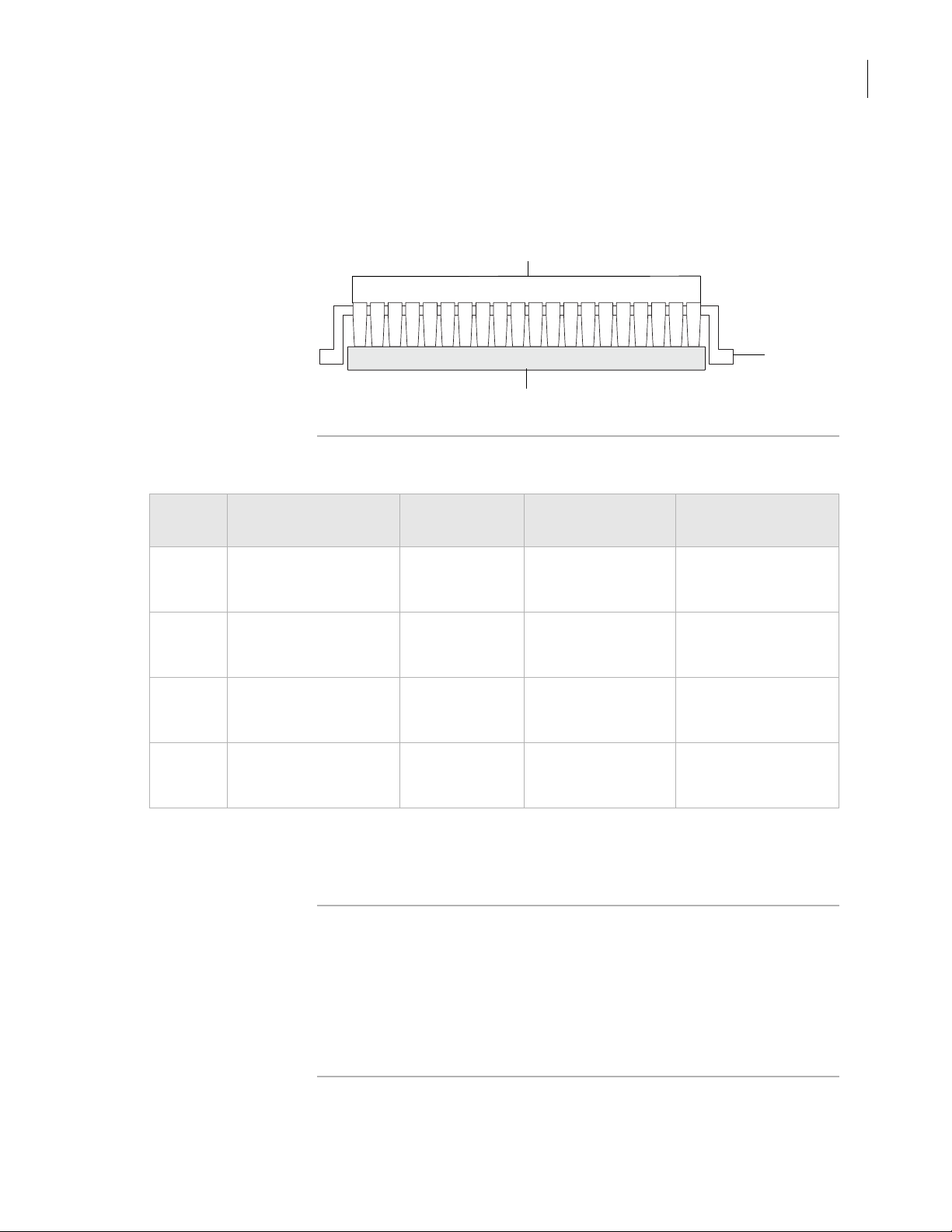

Using inserts to suppo rt plates

For plates that tend to bend or do not li e flat during the seal cycle, you

can place an insert under the plate to provide equal support under

every well. The following diagram shows an insert supporting the wells

for uniform sea lin g.

Wells

Skirt

Insert

11

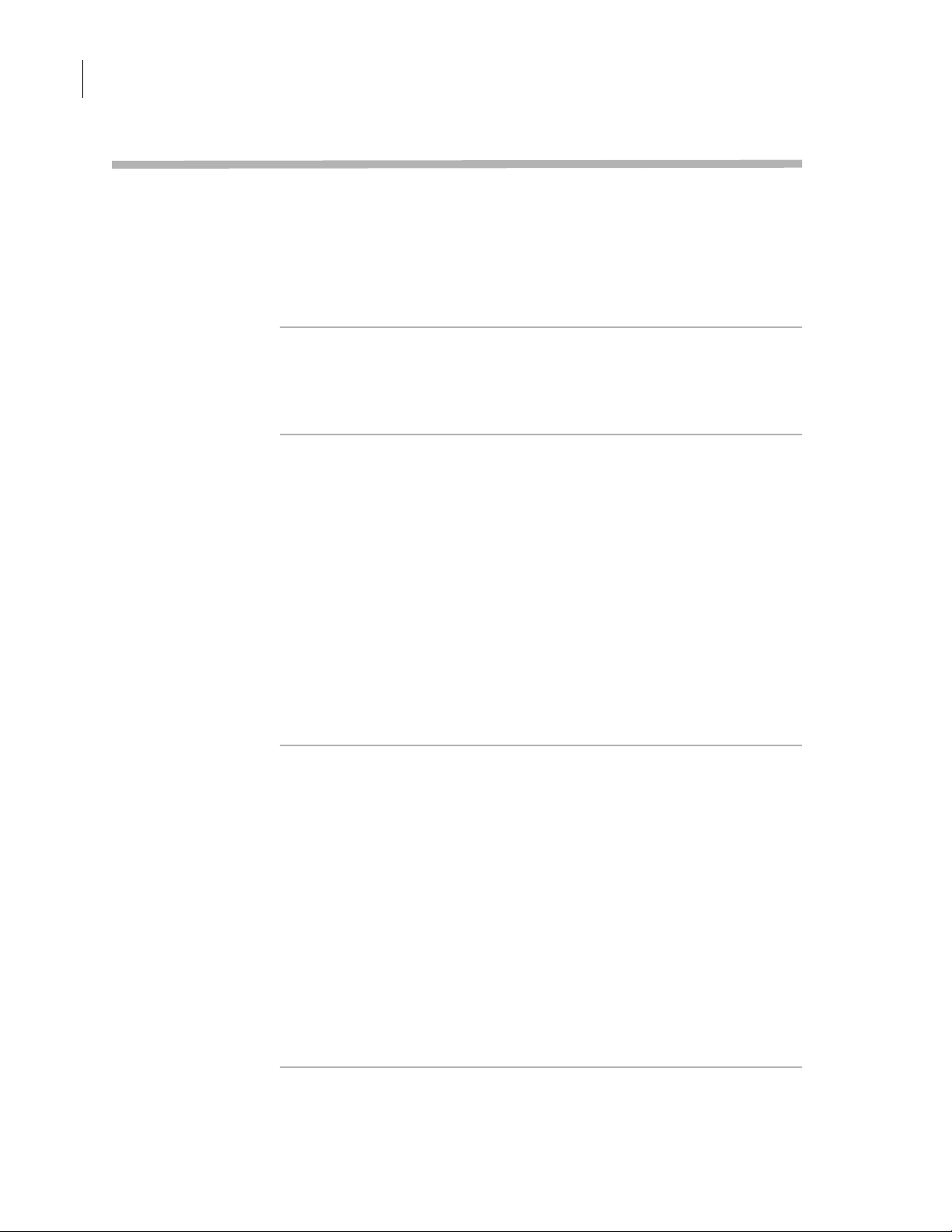

Inserts suppli ed with

The following table lists the inserts that are supplied with the PlateLoc.

the PlateLoc

Insert Description Thickness Height above plate

stage support

90 Metal pad with rubber

foam padding on the

plate-facing side

180 Metal pad 4.60 mm

235 Metal pad 6.00 mm

290 Metal pad 7.37 mm

8.65 mm

(0.340 in)

(0.180 in)

(0.235 in)

(0.290 in)

4 mm (0.2 in) Plates that require

0

mm (0 in)

1.4 mm (0.055 in) Plates that require

2.8 mm (0.11 in) Plates that require

Other types of inserts are available. For a complete list of available

inserts, see the PlateLoc Thermal Plate Sealer Seal Selection Guide. You

can locate the guide on the Velocity11 website at www.velocity11.com.

Use with...

flexible support

Plates that require

non-flexible support

under the wells

non-flexible support

under the wells

non-flexible support

under the wells

Insert selection The type of insert you use depends on the plate material and plate

design. Velocity11 recommends that you run optimization tests to

determine the best insert for the plate you are using. See “Optimizing

seal quality” on page 77 for some optimization test guidelines.

For insert selection guidelines and starting parameters to use, se e the

PlateLoc Thermal Plate Sealer Seal Selection Guide. You can locate the

guide on the Velocity11 website at www.velocity11.com.

12

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Related topics

For more information about... See...

Optimizing seal quality “Optimizing seal quality” on page 77

Plate requirements “Plate requirements” on page 9

Seal material “Seal material” on page 13

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Seal material

About this topic This topic explains the types of seal material that are available and the

factors that might affect seal quality.

13

Seal supplied with

the PlateLoc

A roll of se al is supplied with the Plate Loc. To ensure optimal seal

quality, Velocity11 recommends that you run optimization tests to

determine the best sealing parameters to use for each plate type and

application.

Selecting o ther seals !! DAMAGE HA ZARD !! Use only Velocity11 seals with the

PlateLoc. Seals from another manufacturer might not seal properly

in the PlateLoc and can damage the device.

Velocity11 offers a variety of seals with different properties, including:

❑ Clear seals. Allows you t o see the contents of the plate.

❑ Aluminum seals. Protects light-sensitiv e samples or compounds in

the plate.

❑ Pe elable seals. Allows you to peel the seal off the plate in a

downstream task.

❑ Non-pierceable seals. Protects the plate contents from accidental

piercing.

The type of seal you can use depends on a number of factors, including:

❑ Plat e material

❑ Plate design

❑ Plate properties (for example, optical and physical properties)

Related topics

❑ Plate contents (samples, reagents, and so on)

❑ Application (for example, PCR, DNA sequencing, compound

storage, and so on)

❑ Storage duration and conditions

For a complete list of seals and selection guidelines, see the PlateLo c

Thermal Plate Sealer Seal Selection Guide. You can locate the guide on

the Velocity11 website at www.velocity11.com.

Velocity11 recommends that you run optimization tests to determine the

best seals to use. See “Optimizing seal quality” on page 77 for some test

guidelines.

For more information about... See...

Plate requirements “Plate requirements” on page 9

Inserts (plate supports) “Inserts” on page 10

Optimizing seal quality “Optimizing seal quality” on page 77

14

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Lab automation system software

About this topic This topic describes the software you use to set up and control the

PlateLoc in a Velocity11 lab automation sy st em. For information about

integrating the PlateLoc in a third-party lab automation system, see

“Integrating the PlateLoc into third-party systems” on page 99.

Note: You do not need to read this topic if you are using the PlateLoc as

a standalone device.

Lab automation

requirements

Lab automation

system software

In a lab automation system, you can use a plate-loading robot to

automate the sealing of multiple plates. You use the lab automation

system software to se t up the communication between the system and

the PlateLoc, set up the sealing parameters, and control the automation.

Velocity11 provides lab automation platforms, including the BenchCel

and the BioCel plate-handling systems. You can install the PlateLoc in

these systems to automate the multiple-plate sealing process.

You use the Velocity11 lab auto mation system software, such as

BenchWorks and VWorks, to control the PlateLoc in the system. The

software allows you to:

❑ Create protocols. Protocols determine the sequence of tasks you

want to automate in a run. For example, you can use a protocol to

seal 10 plates in one protocol run.

❑ Set PlateLoc task parameters. The task parameters specify the sealing

temperature and duration for a multiple-plate run.

❑ Start and stop a run. You can st art and s t op t he pr ot oc ol run from the

controlling co mputer.

PlateLoc Diagnostics PlateLoc Diagnostics is a component of the supplied PlateLoc ActiveX

software that enables integration with a lab automation system.

Accessed through the Velocity11 lab automation system software, such

as BenchWorks and VWorks, PlateLoc Diagnostics allows you to:

❑ Create profiles. Profiles allow you to set up communication with the

lab automation system software and set default sealing parameter

values.

❑ Manually set up and run the PlateLoc. This is equivalent to setting up

and running the device from the touch screen. Use the manual

adjustments and controls t o run a single plate for diagnostic use

only.

❑ Check the odometer. The odometer indicates the number of sealing

cycl es the device has performed. You can refer to this value for

preventive maintenance purposes.

Related topics

For more information about... See...

Chapter 1: PlateLoc introduction

PlateLoc User Guide

15

Operating the PlateLoc in a lab

automation system

Creating and managing Plate Loc

profiles

“Lab automation system workflow” on

page 17

“Creating and managing profiles (lab

automation systems only)” on page 59

Creating and managing protocols Velocity11 lab automation software user

guide, such as the VWorks User Guide

Setting PlateLoc task parameters Velocity11 lab automation software user

guide, such as the VWorks User Guide

Starting and stopping the protocol

run

Using ActiveX control to configure

third-party lab automation

Velocity11 lab automation software user

guide, such as the VWorks User Guide

“Integrating the PlateLoc into third-

party systems” on page 99

software to interface with the

PlateLoc

16

Chapter 1: PlateLoc introduction

PlateLoc User Guide

PlateLoc workflows

About this topic This topic presents the workflows for operating the PlateLoc as a

standalone device and in a Velocity11 lab automation system.

Standalone device

workflow

The following table presents the basic steps for operating the PlateLoc as

a standalone device. When optimizing the seal quality, repeat steps 6

through 8.

Step Procedure See...

1 Turn on the PlateLoc. “Turning on and turning off the

power” on page 42

2 Turn on the air. “Turning on and turning off the

air” on page 44

3 Gas-Purging PlateLocs only. Turn

on the argon.

4 Adjust the touchscreen.

“Turning on and turning off the

argon (Gas-Purging Platelocs

only)” on page 47

❑ “Tilting and stowing the

touch screen” on page 49

❑ “Adjusting the touch screen

contrast” on page 51

5 Load the seal. “Loading and unloading a roll of

seal” on page 53

6 Set the sealing parameter s. “Setting the sealing parameters”

on page 68

7 Load an insert and a plate. “Loading an insert and a plate”

on page 66

8 Start the seal cycle. “Starting the seal cycle” on

page 72

Chapter 1: PlateLoc introduction

PlateLoc User Guide

17

Lab automation

system wor k flow

The following table presents the basic steps for operating the PlateLoc in

a Velocity11 lab automation system. When optimizing the seal quality,

repeat steps 8 through 9.

Note: The steps for installing and operating the PlateLoc in a third-party

lab automation system might differ. For details, refer to the third-party

user documenta tion.

Step Procedure See...

1 Turn on the PlateLoc. “Turning on and turning off the

power” on page 42

2 Turn on the air. “Turning on and turning off the

air” on page 44

3 Gas-Purging PlateLoc only. Turn

on the argon.

4 Option al. Adjust the touchscreen.

“Turning on and turning off the

argon (Gas-Purging Platelocs

only)” on page 47

❑ “Tilting and stowing the

touch screen” on page 49

❑ “Adjusting the touch screen

contrast” on page 51

5 Load the seal. “Loading and unloading a roll of

seal” on page 53

Related topics

6 Create PlateLoc profiles. “Creating and managing profiles

(lab automation systems only)”

on page 59

7 Establish communication with

the PlateLoc.

8 Create protocols and set task

parameters.

9 Star t the protocol run (seal

cycles).

For more information about... See...

Workflow for i ns talling and

operating the PlateLoc in a thirdparty automation system

Using ActiveX control to configure

third-party lab automation

software to interface with the

PlateLoc

“Establishing communications

with the PlateLoc (lab

automation systems only)” on

page 62

Velocity11 l ab automa tion s ystem

software user guide, such as the

VWorks User Guide

“Starting the seal cycle” on

page 72

The third-party product d ocumentation

“Integrating the PlateLoc into third-

party systems” on page 99

18

Chapter 1: PlateLoc introduction

PlateLoc User Guide

Safety information

About this topic This topic provides information for the safe operation of the PlateLoc.

Before using the

PlateLoc

Before using the PlateLoc, your organization should make sure that you

are properly trained in:

❑ General laboratory safety

❑ The correct and safe operation of the PlateLoc

❑ The correct and safe operation of lab automation systems or

components used in combination with the PlateLoc

If you are the person in your organization responsible for training others

on the PlateLoc and you have a safety question, contact Velocity11

Technical Support.

Safety standards The PlateLoc is CE certified and complies with the following CE safety

directive: EN 61010-1:1993, safety requirements for electrical equipment

for measurement, control, and laboratory use, including amendments 1

and 2.

The PlateLoc is designed to meet UL specifications.

For the latest compliance information, contact Velocity11 Technical

Support.

Safety labels Pay attention to safety labels on the PlateLoc. A safety label consists of a

warning symbol, a description of the warning, and information that

helps you to avoid the safety hazard.

The following diagram shows the safety lab el that is placed on the front

of the PlateLoc to warn you of high-temperature hazards.

00196

PlateLoc

Front

Chapter 1: PlateLoc introduction

PlateLoc User Guide

General precautions !! INJURY HAZARD !! Do not attempt to remove the PlateLoc

covers and disassemble the device. Doing so can cause injuries and

damage the device.

!! INJURY HAZARD !! Using controls, making adjustments, or

performing procedures othe r than tho se spec i fi ed i n this use r gui de

can expose you to hot surfaces, high pressure gases, and moving

parts. Ex posure to these hazards can cause severe injury.

The PlateLoc is designed for safe operation. Under normal operating

conditions, you are prote c ted from high tempera t ure, high pressu r e , and

moving parts. However, you should be aware of these hazards and

understand how to avoid being exposed to them.

Chemical ha zards !! INJURY HAZARD !! Chemicals that have low flash points (such

as reagents that are used in radioactive scintillation proximity

assays (SPAs) and solvents, including alcohols) must not be used in

the Plat e Lo c .

Some chemicals used when working with the PlateLoc can be

hazardous. Make sure you follow your local, state, and federal safety

regulations when using and disposing of the chemicals.

19

Argon gas (GasPurging Platelocs

only)

Gas cylinders and

pressure regulators

Read the recommendations in the MSDS (Material Safety Data Sheet) for

every chemical that you plan to use. The manufacturer of the chemical

should pr ovide you wi th the MSDS.

!! INJURY HAZARD !! Argon is an odorless, colorless, and

nontoxic gas that can cause rapid suffocation by displacing air.

Argon is heavier than air and can flow into low areas.

Always use argon in a well-ventilated area. Always turn off the argon

source when the PlateLoc is not in use.

You should set up an oxygen monitor in the lab to prevent accidental

suffocation. The oxygen monitor can set off an alarm if the oxygen level

falls below the acceptable threshold.

Follow the local, state, and federal safety codes for the placement and

mounting of gas cylinders. For example, you might have to attach a

standard cylinder bracket to a solid permanent structure to meet or

exceed all local seismic and safety requireme nts.

Always use good lab practices when handling high-pressure cylinders.

Make sure you follow any instructions provided with the cylinders.

20

Chapter 1: PlateLoc introduction

PlateLoc User Guide

High-temperature

hazards

!! INJURY HAZARD !! Do not touch the PlateLoc or pry open the

door while it is in operation. The hot surfaces can cause burn injury.

Use caution when removing a plate after it is sealed. The plate might still

be hot from the sealing process.

Do not reach into the PlateLoc when it is at warmed up to a high

temperature. When cleaning the metal plate (hot plate) inside the

device, make sure the temperature setting does not exceed 40 °C. For

details, see “Cleaning the hot plate” on page 84.

Moving-parts

hazards

The Pla te Loc conta ins mo vi ng parts tha t c an cause injury. Under normal

operating conditions, the PlateLoc is designed to protect you from the

moving parts. The door sensor is designed so that the seal cycle cannot

start unless the door is closed.

!! INJURY HAZARD !!

to acce ss the interior of the device through any other openings.

Exposure to the moving parts, such as the heated metal plate (hot

plate) or the seal-cutting blade can cause severe injurie s.

Do not disable the door sensor or attempt

In an emergency, turn off the Plat eLoc. The on/off switch is located on

the lower back side of the device.

Fuses Contact Velocity11 Customer Service to replace the Pla teLoc fuses. Do

not attempt to re place the fuses you rself.

Product use Velocity11’s products must only be used in the manner described in the

user guid es. Any other use can damage the p roduct or injure you.

Velocity11 is not responsible for damages caused, in whole or part, by

unauthorized modifications, or by procedures that are not explicitly

described in the product user guides. Any modifications or changes to

products not expressl y described in Velocity11 user guides are not

covered under the warran ty.

The PlateLoc is not intended or approved for diagnosis of disease in

humans or animals.

Related topics

For more information about... See...

Hardware description “Hardware overview” on page 4

Connection panel location and

description

Turning on and off the PlateLoc “Turning on and turning off the power”

Stopping the PlateLoc in an

emergency

Cleaning the hot plate “Cleaning the hot plate” on page 84

“Connection panel” on page 7

on page 42

“Stopping a seal cycle in progress” on

page 74

Unpacking and installation

This chapter contains the following topics:

❑ “Installation workflow” on page 22

❑ “Meeting Lab requirements” on page 23

❑ “Unpacking the PlateLoc” on page 27

❑ “Con ne c tin g the power so urce ” on page 30

❑ “Connecting and disconnecting the air source” on page 31

❑ “Connecting and d isconnecting the argon source (Gas-Purg ing

PlateLocs only)” on page 34

Chapter 2: Unpacking and install ation

PlateLoc User Guide

2

21

❑ “Connecting to the controlling computer (lab automation systems

only)” on pag e 37

❑ “Installing the PlateLoc ActiveX software (lab automation systems

only)” on pag e 38

22

Chapter 2: Unpacking and installation

PlateLoc User Guide

Installation workflow

About this topic This topic presents the workflow for unpacking and installing the

PlateLoc as a standalone device and in a Velocity11 lab automation

system.

Workflow The following table presents the workflow for unpacking and installing

the PlateLoc.

Note: If you are using the PlateLoc as a standalone device, skip steps 6

through 8.

Step Procedure See...

1 Prepare your lab for the

installation.

2 Unpack the PlateLoc. “U npacking th e PlateLoc” on

3 Connect the PlateLoc to the

power source.

4 Connect the PlateLoc to the air

source.

5 Gas-Purging PlateLocs only.

Connect the PlateLoc to the

argon source.

6 Lab automation syste ms on ly.

Connect the PlateLoc to the

controlling computer.

7 Lab automation syste ms only.

Install the PlateLoc ActiveX

software.

8 Lab automation syste ms on ly. In

the lab a ut o m ati on sof tware, add

the PlateLoc, and set the

properties for the device.

“Meeting Lab requirements” on

page 23

page 27

“Connecting the power source”

on page 30

“Connecting and disconnecting

the air source” on page 31

“Connecting and disconnecting

the argon source (Gas-Purging

PlateLocs only)” on page 34

“Connecting to the controlling

computer (lab autom atio n

systems only)” on page 37

“Installing the PlateLoc ActiveX

software (lab automation systems

only)” on page 38

Velocity11 l ab automa tion s ystem

software user guide, such as the

VWorks User Guide

Related topics

For more information about... See...

Workflow for i ns talling and

operating the PlateLoc in a thirdparty automation system

Operating the PlateLoc “PlateLoc workflows” on page 16

The third-party product d ocumentation

Chapter 2: Unpacking and install ation

PlateLoc User Guide

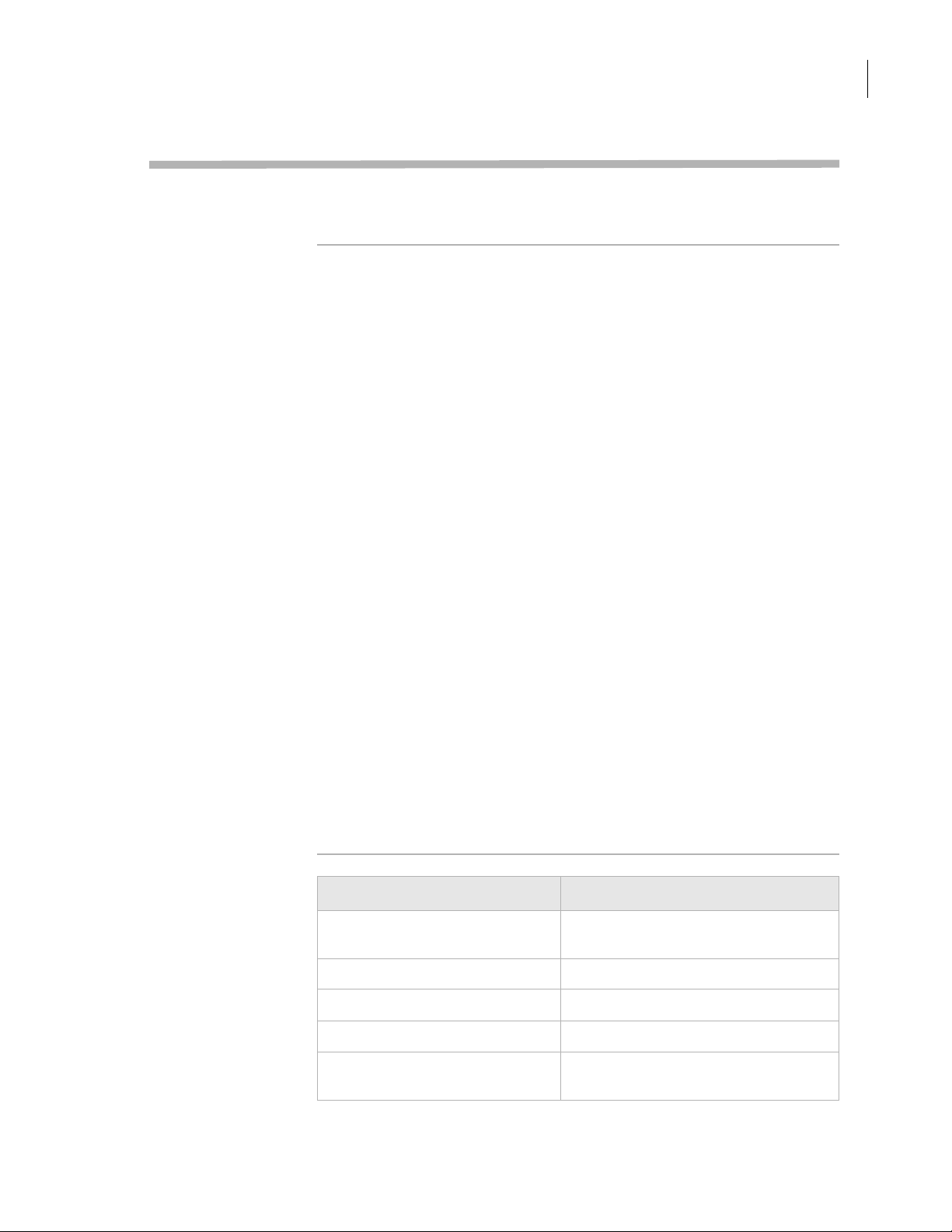

Meeting Lab requirements

About this topic This topic describes the requirements for installing the PlateLoc.

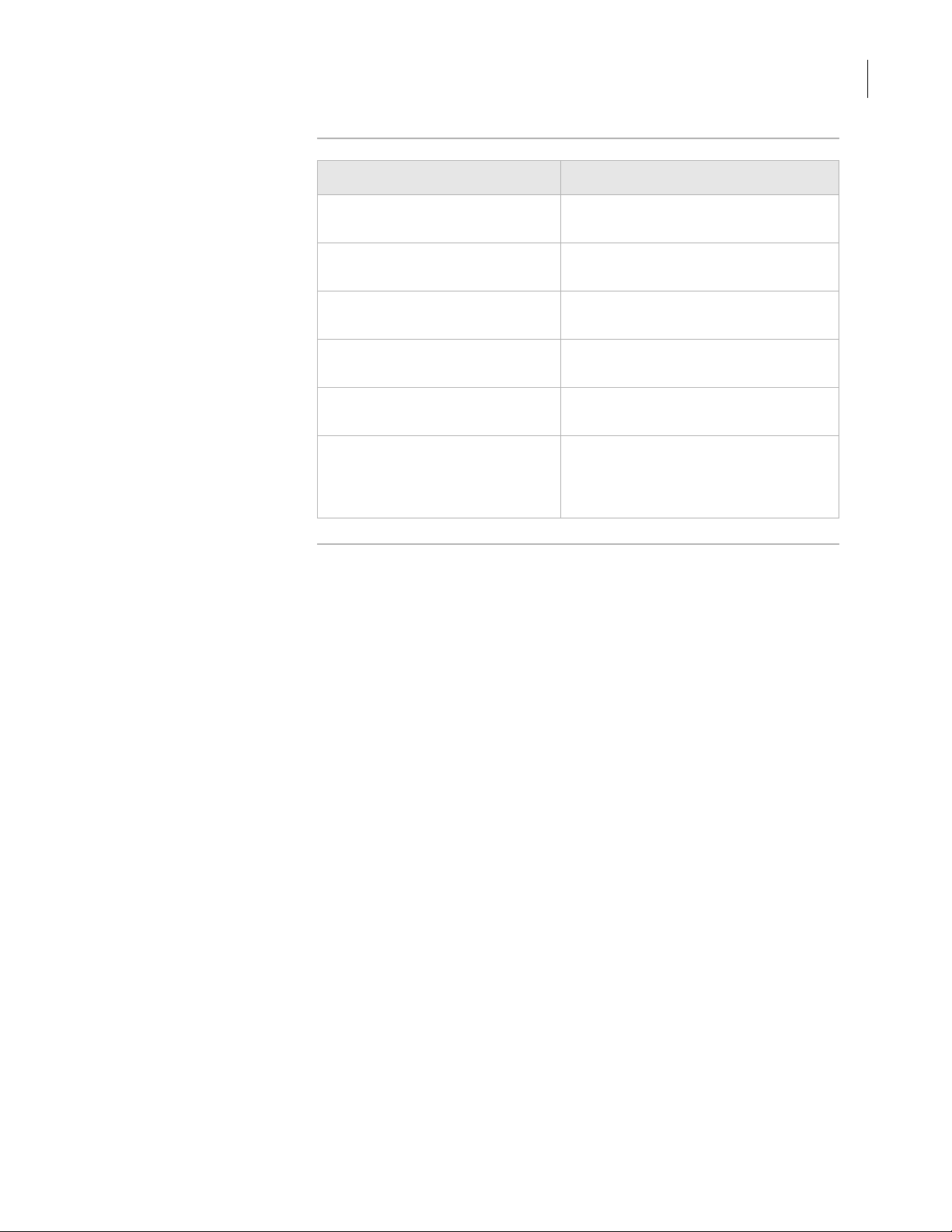

Lab space The weight and dimensions of the PlateLoc are as follows:

Dimension Value

23

Weight

Width

Height (with seal moun ted)

Depth (with door open and seal mounted)

21.6 cm (8.50 in)

58.4 cm (23.0 in)

20

21.6

58.4

39.9

39.9

cm (15.7 in)

kg (45 lb)

cm (8.50 in)

cm (23.0 in)

cm (15.7 in)

When planning lab space for the PlateLoc, you should consider the

following:

❑ Make s ure th e la b bench can su pport the w e ight of the P late Loc, and

the surface is level.

❑ Provide ad equate b ench space for the PlateLoc.

❑ Make sure there is sufficient clearance around the PlateLoc so that

you can reach the bac k of the device to turn off the power and air in

an emergency.

❑ Place th e PlateLoc within 1.8 m (6 ft) of the electrical outlets.

❑ Place the PlateLoc within 4.6 m (15 ft) of the air source.

❑ Gas-Purging PlateLocs only. Place the PlateLoc within 4.6 m (15 ft) of

the argon sour ce.

24

Chapter 2: Unpacking and installation

PlateLoc User Guide

❑ Gas-Purging PlateLocs only. Make sure the room is well ventilated

and an oxygen monitor is nearby.

❑ Lab automation system installation only. Check with the lab

automation system manufactur er for installation requirements.

Air sour c e The PlateLoc requires the use of oil-free compressed air to move

pneumatic components inside the device. The oil-free compressed air

can be from the following sources:

❑ Centralized source (house)

❑ Compressed-air cylinders

❑ Portable pumps

!! DAM AGE H AZAR D !!

leak int o the PlateLoc and void your warranty.

Using oil compressors can cause oil to

To maintain the desired air supply in the device, the Pla teLoc requires a

source of air as follows:

Requirement Value

Quality Clean, dry, compressed

Flow rate

Pressure

!! DAM AGE H AZAR D !!

psi) can damage the PlateLoc.

(100

70.8

Lpm (2.50 cfm)

0.62–0.69

Air pressure greater than 0.69 MPa

MPa (90–100 psi)

Environment The lab must meet the following environmental requirements.

Requirement Value

Ambient temperature

Humidity condition

4–40

°C (39–104 °F)

10–90%

RH, non-condensing

Velocity11 recommends that you do the following:

❑ Place the PlateLoc away from heat and air conditioning ducts.

❑ Place the PlateLoc away from direct sunlight.

Chapter 2: Unpacking and install ation

PlateLoc User Guide

Electrical The electrical requirements for the PlateLoc are as follows:

Model

Requirement

N. Ameri c a Europe

Voltage 115~ 230~

25

Argon source (GasPurging PlateLoc

only)

Frequency

Current

!! DAM AGE H AZAR D !!

circuit that is properly grounded.

50–60

Hz 50–60 Hz

A5 A

5

Always connect the PlateLoc to an AC

The Gas-Purging PlateLoc typically uses argon to displace air (oxygen

and moisture) in the plate. The argon can be from a centralized source

(house) or f rom a cylinder.

To maintain the desired argon supply in the device , mak e sure the argon

meets the following requirements:

Requirement Value

Quality 99.9% pure, welding grade, containing up to

ppb water

1

Note: The water content is more important

than the gas grade.

Pressure

!! INJURY HAZARD !!

oxygen monitor nearby to prevent accidental suffocation.

0.28

MPa (40 psi)

For safety re asons, you should install an

Computer If you are installing the PlateLoc in a lab automation system, you must

connect the device to the controlling computer (the computer that has

the lab automation system software i nstalled). You must also install the

PlateLoc Acti veX software to enable the device to interface with the

computer.

The lab automation system computer must meet the following minimum

requirements to interface with the PlateLoc:

❑ Pentium 3

❑ 256 MB RAM

❑ Windows 2000 or Windows XP

❑ 10 MB free disk space

❑ RS-232 DB9 serial port

For lab automation system requirements, see the Velocity11 lab

automation syst em softw ar e user guide o r the thir d-party la b automa tion

system software user documentation.

26

Chapter 2: Unpacking and installation

PlateLoc User Guide

Related topics

For more information about... See...

How to use the PlateLoc as a

standalone device

Setting up the PlateLoc in a lab

automation system

How to use the PlateLoc in a lab

automation system

“Standalone device workflow” on

page 16

❑ “Lab automation system software”

on page 14

❑ “Integrating the PlateLoc into third-

party systems” on page 99

“Lab automation system workflow” on

page 17

Chapter 2: Unpacking and install ation

Unpacking t he PlateLoc

About this topic This topic explains how to unpack the PlateLoc.

PlateLoc User Guide

27

Unpacking

precautions

Unpacking the

PlateLoc from its

shipping containe r

When unpacking the PlateLoc, be sure to:

❑ Note the dimensions of the shipping container before moving it to

make sure you have adequate clearance through doorways and

passages.

❑ Make sure the final location is nearby and easily accessible.

❑ Use care when lifting the PlateLoc to prevent perso nal inju ry and

damage to the device. The PlateLoc weighs 20 kg (45 lb) and might

require two people to lift it.

The PlateLoc and its components are shipped in two shipping

containers:

❑ The Plat eLoc con tainer. Contains the main body of the device and all

the items you need to install and operate the PlateLoc.

❑ The seal roll container. Contains a roll of seal.

To unpack the PlateLoc and the roll o f seal:

1. Open the top of the PlateLoc co nta iner.

2. Remove the thin layer of packing foam.

3. Remove the inner box and set it aside.

4. Carefully lift the PlateLoc out of the shipping container.

5. Remove the packing foams on the left and right sides of the device.

6. Remove the PlateLoc from the plastic bag and set it carefully on the

lab bench or final location where you want to install the device.

Note: A small block of foam p ieces is p acked inside t he PlateLoc.

You will remove the packing foam after you install the device and

turn on the air.

7. Open the inner box and remove the components from the box.

8. Open the seal roll container, remove the roll of seal, and remove the

seal from the plastic bag.

!! IMPORTANT !!

container in case you need to move or ship the PlateLoc.

!! DAM AGE H AZAR D !! The packing materials and shipping

containe r we re des ign ed to p rotec t th e dev i ce. Pa ckin g the P lateLoc

using other materials and containers can damage the device and

void your warranty.

Save the packing materials and shipp in g

28

Chapter 2: Unpacking and installation

PlateLoc User Guide

Inspecting the

contents

PlateLoc c ompon ents

After you unpack the PlateLoc and seal, check that you have the items

shown in the fol lowing diagram.

Hubs and axle

090

180

235

290

Inserts

Roll of seal

Plate stage

PlateLoc Thermal Plate Sealer

Air tubing Power cord

Seal-loading card PlateLoc User Guide

Fitting union tee

and NPT fittings

RS-232 DB9 serial cable

Metric fittings:

Union tee, adaptor, tube

ActiveX CD

Chapter 2: Unpacking and install ation

PlateLoc User Guide

Additional components for the Gas-Purging PlateLoc

If you ha ve the Gas-Purging PlateLoc, chec k that y ou hav e all the items in

the previous diagram and the items in the following diagram.

Argon tubing

or

29

Related topics

Fitting union tee

and NPT fittings

Metric fittings:

Union tee, adaptor, tube

Missing or damaged items

Inspect the items to make sure you ha ve everything listed and there is no

damage. If any of the items are missing or damaged, contact Velocity11

Technical Support.

For more information about... See...

Removing the packing foam inside

the PlateLoc

How to use the PlateLoc as a

standalone device

Setting up the PlateLoc in a lab

automation system

“Turning on and turning off the air” on

page 44

“Standalone device workflow” on

page 16

❑ “Lab automation system software”

on page 14

❑ “Integrating the PlateLoc into third-

party systems” on page 99

How to use the PlateLoc in a lab

automation system

“Lab automation system workflow” on

page 17

30

Chapter 2: Unpacking and installation

PlateLoc User Guide

Connecti ng the power source

About this topic This topic explains how to connect the PlateLoc to a grounded po wer

source.

Before you sta r t Make sure you have the supplied power cord.

Procedure To connect the power cord:

1. Plug one end of the power cord into the AC power entry located on

the back of the PlateLoc.

2. Plug the other end of the cord into an AC outlet with a grounded

circuit.

Related topics

00191

00191

PlateLoc

PlateLoc

connections

connections

For more information about... See...

Installation and operating

“Meeting Lab requirements” on page 23

requirements

To AC outlet with

grounded circuit

Chapter 2: Unpacking and install ation

PlateLoc User Guide

Connecti ng and disconnecting the air source

About this topic Compressed air is used to move pneumatic components inside the

PlateLoc. This topic explains how to connect the PlateLoc to the air

source and check the connections for leaks before use.

Before you sta r t Make sure you ha ve the following:

❑ Air tubing (supplied)

❑ NPT or metric fitting adaptor (supplied)

31

Connecting the air

source

To conn ect the PlateLoc to your air source:

1. Turn off the air at the source (house, cylinder, or pump).

2. Attach the following adaptor fittings to the air source connection if

necessary:

NPT fitting. If your air source uses a threaded connection, attach

the supplie d 1/4 -inc h o r 1/8 -in NPT fitt ing t o the conne ctio n. Th e

NPT fitting is threaded on one end and has a quick-release fitting

on the ot her end.

Metric fittings adaptor . If your lab requires metric fitti ngs at th e air

source, attach the supplied 1/4-inch metric adaptor fitting to the

air source connection. The metric adaptor fitting has a quickrelease fitting on one end.

3. Connect one end of the air tubing to the air source (house, cylinder,

or pump), and then connect the free end of the tubing to the quick

disconnect fitting at the air-input (AIR IN) port.

To connect the tubing, push the end of the tubing into the quick

disconnect fitting at the air source and on the back of the PlateLoc.

The following diagram shows the air tubing connection on the back

of the PlateLoc .

00191

00191

PlateLoc

PlateLoc

connections

connections

To air source (house,

cylinder, or pump)

32

Chapter 2: Unpacking and installation

PlateLoc User Guide

Checking the air

connections

Disconnecting the

air source

To check the air connections:

1. With the air source turned off, gently tug the air tubing at each

connection.

If you f e el r esistance a t the co nn ect i on, the t u b ing has been p r o perly

installed.

2. Tu r n on th e air so urce.

3. Listen near each connection for hissing sounds that might indicate a

leak.

If you hear hissing sounds, turn off the air at the source and on the

back of the Plate Loc, check and tighten the connections, and then

turn on the air again. If the problem persists, contact your facilities

department or Velocity11 Technical Support.

!! DAM AGE H AZAR D !! Do not pull the tubing out of the orange

quick disconnect fitting. Doing so can damage the fitting.

To disconnect the air tubing from the P lateLoc:

1. Turn off the air at the source (house, cylinder, or pump).

2. Turn off the air on the back of the PlateLoc.

3. Push and hold the locking collar against the fitting, and then gently

pull the air tubing out.

Note: Altern atively, you can use the SMC Pn eu matics tool (TG- 2)

to aid in this task. See th e manufacturer’s documentation for use

instructio ns. Co nt act your loc al SMC parts s u pplier for o rder ing

details.

The following diagram shows a close-up view of the quick

disconnect fitting.

Push and hold the locking collar.

Gently pull out the tubing.

Related topics

Chapter 2: Unpacking and install ation

PlateLoc User Guide

For more information about... See...

Air source requirements “Meeting Lab requirements” on page 23

33

Components for connecting the

PlateLoc to the air source

Air-input fitting on the connection

panel

“Inspecting the contents” on page 28

“Connection panel” on page 7

34

Chapter 2: Unpacking and installation

PlateLoc User Guide

Connecting and disconnecting the argon source (Gas-Purging PlateLocs only)

About this topic This topic explains how to connect the PlateLoc to the argon source.

Read this topic only if you have a Gas-Purging PlateLoc.

Before you sta r t !! INJURY HAZARD !! Make sure the area in wh ich you are

working is well ventilated and you have installed an oxygen

monitor nearby. Argon can cause rapid suffocation by displacing

air. Argon is heavier than air and can flow into low areas.

Make sure you ha ve the following:

❑ Argon tubing (supplied)

❑ NPT or metric adaptor fitting (supplied)

Connecting the

argon source

To conn ect the PlateLoc to your ar gon source:

1. Turn off the argon source (house or cylinder).

2. Attach the fol lo wing adap tor fit tings to the arg on sou rce if necessary:

NPT fitting. If your argon source uses a threaded connection,

attach the suppli ed 1/4-inch or 1/8-in NPT fitting to the

connection. The NPT fitting is threade d o n one end and has a

quick-release fitting on the other end.

Metri c fittings adap tor. If your lab requires metric fittings at the

argo n s ource, attach the supplied 1/4-inch metric adaptor fitting

to the argon s ource connection. The metric adaptor fitting has a

quick-release fitti ng on one end.

3. Connect one end of an argon tubing to the argon source, and then

connect the free end of that tubing to the quick disconnect fitting at

the argon-input port.

To connect the tubing, push the end of the tubing into the quick

disconnect fitting at the argon source and at the back of the

PlateLoc.

!! DAM AGE H AZAR D !!

the air- input (AIR IN) fitting. Doing so can cause errors w hen

you ope rat e th e PlateLoc.

The following diagram shows the connect ion from the back of the

PlateLoc to the argon source.

Do not connect the argon tubing to

00191

00191

PlateLoc

PlateLoc

connections

connections

Chapter 2: Unpacking and install ation

PlateLoc User Guide

To argon source

(house or cylinder)

35

Checking the argon

connections

Disconnecting the

argon source

!! INJURY HAZARD !! Argon is an odorless, colorless, and

nontoxic gas that can cause rapid suffocation by displacing air.

Argon is h eav ier tha n air a nd can f lo w in to lo w a reas. Make su re t he

oxygen monitor is turned on.

To check the argon connection:

1. With the PlateLoc turned off, gently tug the argon tubing at each

connection.

If you f e el r esistance a t the co nn ect i on, the t u b ing has been p r o perly

installed.

2. Turn on the argon source.

3. Listen near each connection for hissing sounds that might indicate a

leak.

If you hear hissing sounds, turn off the argon at the source, tighten

the connections, and then turn on the argon again. If the problem

persists, contact your facilities department or Velocity11 Technical

Support.

!! DAM AGE H AZAR D !! Do not pull the tubing out of the orange

quick disconnect fitting. Doing so can damage the fitting.

To disconnect the argon tubing from the PlateLoc:

1. Turn off the argon at the source (house or cy linder).

2. Push and hold the locking collar against the fitting, and then gently

pull the argon tubing out.

Note: Altern atively, you can use the SMC Pn eu matics tool (TG- 2)

to aid in this task. See th e manufacturer’s documentation for use

instructio ns. Co nt act your loc al SMC parts s u pplier for o rder ing

details.

36

Chapter 2: Unpacking and installation

PlateLoc User Guide

The following diagram shows a close-up view of the quick

disconnect fitting.

Push and hold the locking collar.

Gently pull out the tubing.

Related topics

For more information about... See...

Gas-Purging PlateLoc description “Description of the PlateLoc” on page 2

Argon source requirements “Meeting Lab requirements” on page 23

Components for connecting the

PlateLoc to the argon source

Argon-input fitting at the

connection panel

“Inspecting the contents” on page 28

“Connection panel” on page 7

Chapter 2: Unpacking and install ation

PlateLoc User Guide

Connecting to the controlling computer (lab automation systems only)

About this topic This topic e xplains how to connect the PlateLoc to the controlling

computer. Read this topic only if you are installing a PlateLoc in a lab

automation system.

Before you sta r t Make sure you have the RS-232 DB9 straight-through serial cable.

37

Connecting the

controlling computer

Related topics

To conn ect the PlateLoc to the controlling computer:

1. Turn off the controlling computer.

2. Connect one end of the supplied serial cable to the controlling

computer.

3. Connect the free end of the serial cable to the back of the PlateLoc.

00191

00191

PlateLoc

PlateLoc

connections

connections

To controlling computer

For more information about... See...

The controlling computer

requirements

“Meeting Lab requirements” on page 23

Workflow for i ns talling and

operating the PlateLoc in a thirdparty automation system

Using ActiveX control to configure

third-party lab automation

software to interface with the

PlateLoc

The third-party product d ocumentation

“Integrating the PlateLoc into thirdparty systems” on page 99

38

Chapter 2: Unpacking and installation

PlateLoc User Guide

Installing the PlateLoc ActiveX software (lab automation systems only)

About this topic This topic exp lains how to install the PlateLoc ActiveX software. You do

not need to read this topic if you are using the PlateLoc as a standalone

device.

PlateLoc ActiveX

description

PlateLoc ActiveX is the supplied software that allows the PlateLoc to

interact with the Velocity11 and third-party lab automation system

software.

Plate Loc A ctiveX i nc l ude s a com pon ent c al led PlateLoc D ia gnos ti cs , t h e

user interface that allows you to create and manage PlateLoc profiles

and manually control the device for diagnostic purposes.

Procedure To install the PlateLoc ActiveX software:

1. Insert the PlateLoc ActiveX CD into the controlling computer CDROM drive.

2. In the CD folder, double-click setup.exe.

3. Follow the instructions in the installation wizard window. Be sure to

sele c t th e

Complete setup option.

After insta llation After you install the PlateLoc ActiveX software, in the

Velocity11 lab automation system:

1. Add the PlateLoc device. See the Velocity11 lab automation system

software user guide for instructions.

2. Create PlateLoc profiles. See “Creating and managing profiles (lab

automation systems only)” on page 59.

3. Create protocol s. See the Velocity11 lab automation system softwar e

user guide for instructions.

In the third-par ty lab automation system:

1. Integrate the PlateLoc ActiveX control in the third-party lab

automation system software. See “Integrating the PlateLoc into thirdparty systems” on page 99.

Related topics

For more information about... See...

Chapter 2: Unpacking and install ation

PlateLoc User Guide

39

The controlling computer

requirements

Workflow for operating the

PlateLoc in a Velocity11 lab

automation system

Workflow for i ns talling and

operating the PlateLoc in a thirdparty lab automation system

Using ActiveX control to configure

third-party lab automation

software to interface with the

PlateLoc

“Meeting Lab requirements” on page 23

“Lab automation system workflow” on

page 17

The third-party product d ocumentation

“Integrating the PlateLoc into thirdparty systems” on page 99

40

Chapter 2: Unpacking and installation

PlateLoc User Guide

Getting started

This chapter contains the following topics:

❑ “Turning on and turning off t he power” on page 42

❑ “Turning on and turning off the air” on page 44

❑ “Turning on and turning off the argon (Gas-Purging Platelocs only)”

on page 47

❑ “Tilting and stowing the touch screen” on page 49

❑ “Adjusting the touch screen contrast” on page 51

Chapter 3: Getting started

PlateLoc User Guide

3

41

❑ “Loading and unloading a roll of seal” on page 53

❑ “Creating and managing profiles (lab automation systems only)” on

page 59

❑ “Establishing communications with the PlateLoc (lab automation

systems only)” on page 62

42

Chapter 3: Getting started

PlateLoc User Guide

Turning on and turning off the power

About this topic This topic exp lains how to turn on and turn off the power to the

PlateLoc.

Before turning on

the PlateLoc

Tu rning on the

PlateLoc

Make sure:

❑ The lab requirements are met.

❑ You have properly installed the Plate Loc.

❑ You are trained in the proper operation of the PlateLoc.

To turn on the PlateLoc:

1. Press the on/off switch on the back of the PlateLoc to the on

position (I).

The following diagram shows the location of the on/off switch on

the back of the PlateLoc. The on/off switch in the diagram is in the

on position.

00191

00191

PlateLoc

PlateLoc

connections

connections

Press to turn on.

When you turn on the PlateLoc, the touch screen displays the

Insufficient Air Pressure error message. This is because you have not yet

turned on the air to the PlateLoc. Proceed to “T urning on and turning off

the air” on page 44 to turn on the air.

Chapter 3: Getting started

PlateLoc User Guide

43

Tu rning off the

PlateLoc

Related topics

To turn off the P lateLoc:

1. Press the on/off switch on the back of the PlateLoc to the off

position (o).

The touch screen turns off.

00191

00191

PlateLoc

PlateLoc

connections

connections

For more information about... See...

Lab requirements “Meeting Lab requirements” on page 23

Connecting the PlateLoc to the

power source

“Connecting the power source” on

page 30

Press to turn off.

44