Page 1

Agilent Technologies 85330A

Multiple Channel Controller

Operating, Programming,

and Service Manual

Part number: 85330-90019

Printed in USA

October 2002

Supersedes November 1999

Page 2

Notice

Restricted Rights Legend

Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical

Data and Computer Software clause at DFARS 252.227-7013 for DOD

agencies, and subparagraphs (c)(1) and (c)(2) of the Commercial Computer

Software Restricted Rights clause at FAR 52.227-19 for other agencies.

© Copyright Agilent Technologies, Inc. 1997,1999, 2002

ii 85330A Multiple Channel Controller

Page 3

What You’ll Find in This Manual…

Chapter 1 • Installation - Shows how a standard Agilent 85330A system is installed.

If you purchased a preconfigured system, Agilent has provided

documentation that contains installation information for your specific

system. Use the documentation for your special system instead of the

information in this chapter.

Chapter 2 • Performance Verification - Explains how to verify that the 85330A

system is operating properly.

Chapter 3 • Operator’sCheck - This is a quick check of the system to make sure it is

operating properly.

Chapter 4 • General Information - Describes a typical system, and includes

information on:

❍ Supplied items

❍ Features

❍ 85330A connectors

❍ Accessories

❍ Specifications

❍ Environmental Characteristics

❍ Compatible instruments

Chapter 5 • Manual Operation - Describes functions that can be performed manually

using the multiple channel controller’s front panel softkeys.

Chapter 6 • Programming - Describes the 85330A programming fundamentals with

examples.

Chapter 7 • Remote Programming Command Reference - A dictionary of the

85330As programming commands.

Chapter 8 • In Case of Difficulty - How to solve common system problems.

Chapter 9 • Service - Explains how to determine if the 85330A specific control cards

are working. This chapter does not explain how to troubleshoot the VXI

mainframe, which has its own service documentaiton.

85330A Multiple Channel Controller iii

Page 4

Appendix • Glossary of Terms - This glossary defines special terminology

associated with this system. Words shown in bold text are defined in the

glossary.

Warranty

Certification Agilent Technologies certifies that this product met its published

specifications at the time of shipment from the factory. Agilent further

certifies that its calibration measurements are traceable to the United States

National Institute of Standards and Technology (NIST, formerly NBS), to the

extent allowed by the Institute’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

Documentation Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS

PROVIDED "AS IS," AND IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO

THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW,

AGILENT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS

OR IMPLIED WITH REGARD TO THIS MANUAL AND ANY

INFORMATIONCONTAINEDHEREIN,INCLUDINGBUTNOT

LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. AGILENT SHALL NOT BE LIABLE FOR ERRORS

OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT OR ANY

INFORMATION CONTAINED HEREIN. SHOULD AGILENT

AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS COVERING THE MATERIAL IN

THIS DOCUMENT THAT CONFLICT WITH THESE TERMS,

THE WARRANTY TERMS IN THE SEPARATE AGREEMENT

WILL CONTROL.

Assistance Product maintenance agreements and other customer assistance agreements

are available for Agilent products.

For assistance, call your local Agilent Technologies office (refer to “Service

and Support” on page v).

iv 85330A Multiple Channel Controller

Page 5

Service and Support

Any adjustment, maintenance, or repair of this product must be performed

by qualified personnel. Contact your customer engineer through your local

Agilent Technologies Service Center. You can find a list of local service

representatives on the Web at:

http://www.agilent.com/find/assist

Click on “Contact Us” and select your country.

If you do not have access to the Internet, one of these centers can direct you

to your nearest Agilent Technologies representative:

United States (800) 403-0801

(800) 593-6635 for on-site service of systems

Canada (877) 429-9969

Europe (41 22) 780.6111 (Switzerland)

(33 1) 69 82 66 66 (France)

(49 7031) 464-6222 (Germany)

(44 188) 9696622 (Great Britain)

Japan 0120-32-0119

Latin America (11) 7297-3700 (Brazil)

Australia/New

Zealand

Asia-Pacific 080-047-669

1-800-802-540 (Australia)

0800-738-378 (New Zealand)

85330A Multiple Channel Controller v

Page 6

Safety and Regulatory Information

Review this product and related documentation to familiarize yourself with

safety markings and instructions before you operate the instrument. This

product has been designed and tested in accordance with international

standards.

WARNING The WARNING notice denotes a hazard. It calls attention to a procedure,

practice, or the like, that, if not correctly performed or adhered to, could result

in personal injury. Do not proceed beyond a WARNING notice until the

indicated conditions are fully understood and met.

CAUTION The CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

Instrument Markings

The ON symbol. The ON symbol is used to mark the

positions of the instrument line switch.

The OFF symbol. The OFF symbol is used to mark the

positions of the instrument line switch.

The ON symbol. The ON symbol is used to mark the

positions of the instrument line switch.

The OFF symbol. The OFF symbol is used to mark the

positions of the instrument line switch.

This symbol indicates that the power line switch is OFF or in STANDBY position.

The AC symbol. The AC symbol is used to indicate the

required nature of the line module input power.

The instruction documentation symbol. The product is

marked with this symbol when it is necessary for the user

to refer to the instructions in the documentation.

vi 85330A Multiple Channel Controller

Page 7

The CE mark is a registered trademark of the European

Community. (If accompanied by a year,it is when the design

was proven.)

The CSA mark is a registered trademark of the Canadian

Standards Association.

This is a symbol of an Industrial Scientific and Medical

Group 1 Class A product.

Safety Earth Ground

ICES /

NMB-001

This is a Safety Class I product (provided with a protective earthing

terminal). An uninterruptible safety earth ground must be provided from the

This is a marking to indicate product compliance with the

Canadian Interference-Causing Equipment Standard

(ICES-001).

The C-Tick mark is a registered trademark of the

Australian Spectrum Management Agency.

main power source to the product input wiring terminals, power cord, or

supplied power cord set. Whenever it is likely that the protection has been

impaired, the product must be made inoperative and secured against any

unintended operation.

BeforeApplying Power Verify that the product is configured to match the available main power

source as described in the input power configuration instructions in this

manual. If this product is to be powered by autotransformer, make sure the

common terminal is connected to the neutral (grounded) side of the ac power

supply.

WARNING Nooperatorserviceablepartsinside.Referservicingtoqualifiedpersonnel.To

prevent electrical shock do not remove covers.

WARNING For continued protection against fire hazard, replace line fuse only with the

same type and ratings (type nA/nV). The use of other fuses or materials is

prohibited.

WARNING To prevent electrical shock, disconnect the 85330A from mains before

cleaning. Use a dry cloth or one slightly dampened with water to clean the

external case parts. Do not attempt to clean internally.

85330A Multiple Channel Controller vii

Page 8

WARNING If this product is not used as specified, the protection provided by the

equipmentcould be impaired. This productmust be used ina normal condition

(in which all means for protection are intact).

CAUTION Always use the three-prong ac power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord may cause

product damage.

CAUTION Install the instrument according to the enclosure protection provided. This

instrument does not protect against the ingress of water.

This instrument protects against finger access to hazardous parts with the

enclosure.

viii 85330A Multiple Channel Controller

Page 9

Manufacturers Declaration

This is to certify that this product meets the radio frequency interference

requirements of Directive FTZ 1046/1984. The German Bundespost has

been notified that this equipment was put into circulation and has been

granted the right to check the product type for compliance with these

requirements.

This product has be designed and tested in accordance with IEC Publication

1010, Safety Requirements for Electronic Measuring Apparatus, and has

been supplied in a safe condition. The instruction documentation contains

information and warnings which must be followed by the user to ensure safe

operation and to maintain the product in a safe condition.

NOTE If test and measurement equipment is operated with unshielded cables

and/or used for measurements on open set-ups, the user must insure that

under these operating conditions, the radio frequency interference limits are

met at the boarder of his premises.

Hiermit wird bescheinigt, dass dieses Gerät/System in Übereinstimmung mit

den Bestimmungen von Postverfügung 1046/84 funkentstört ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses

Gerät/Systems angezeight und die Berechtigung zur Überprüfung der Serie

auf Einhaltung der Bestimmungen eingeräumt.

Zustzinformation für Mess-und Testgeräte:

Werden Mess- und Testgeräte mit ungeschirmten Kabeln und/oder in

offenenMessaufbauten verwendet, so ist vom Betreiber sicherzustellen, dass

die Funk-Entstörbestimmungen unter Betriebsbedingungen an seiner

Grundstücksgrenze eingehalten werden.

Sound Emmisions This is to declare that this product is in conformance with the German

Regulation on Noise Declaration for Machines (Laermangabe nach der

maschinenlaermrerordnung -3. GSGV Deutschland).

Acoustic Noise Emission Geraeuschemission

LpA < 70 dB

Operator Position

Normal Position

per ISO 7779

LpA < 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 t. 19

85330A Multiple Channel Controller ix

Page 10

Manufacturers Declaration

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Hewlett-Packard Co.

Manufacturer’s Address: 1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799

USA

Declares that the product:

Product Name: Multiple Channel Controller

Model Number: HP 85330A

Product Options: This declaration covers all options of the above

product.

Conforms to the following product specifications:

Safety:IEC 61010-1:1990 / EN 61010-1:1993

CAN/CSA-C22.2 No. 1010.1-92

EMC: CISPR 11:1990/EN 55011:1991 Group 1, Class A

IEC 801-2:1984/EN 50082-1:1992 4 kV CD, 8 kV AD

IEC 801-3:1984/EN 50082-1:1992 3 V/m, 27-500 MHz

IEC 801-4:1988/EN 50082-1:1992 0.5 kV sig. lines, 1 kV power lines

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carries the CE-marking accordingly.

The controller was tested with HP 85331A and HP 85332A switches.

Santa Rosa, CA, USA 12 July 1999

Greg Pfeiffer/Quality Engineering Manager

European Contact: Your local Hewlett-Packard Sal es and Service Office or Hewlett-Packard GmbH Department HQTRE, Herreneberger Strasse 130, D71034 Boblingen, Germany (FAX +49-7031-14-3143)

x 85330A Multiple Channel Controller

Page 11

Typeface Conventions

Typeface Conventions

Italics • Used to emphasize important information:

Use this software only with the Agilent 85330A system.

• Used for the title of a publication:

Refer to the Agilent Technologies 85330A System-Level User’s

Guide.

• Used to indicate a variable:

Type

LOAD BIN filename.

Instrument Display • Used to show on-screen prompts and messages that you will see on the

display of an instrument:

The Agilent xxxxxX will display the message

[Keycap] • Used for labeled keys on the front panel of an instrument or on a

computer keyboard:

Press

[Return].

CAL1 SAVED.

{Softkey} • Used for simulated keys that appear on an instrument display:

Press

{Prior Menu}.

User Entry • Used to indicate text that you will enter using the computer keyboard;

text shown in this typeface must be typed exactly as printed:

Type

LOAD PARMFILE

• Used for examples of programming code:

#endif // ifndef NO_CLASS

Path Name

Computer Display • Used to show messages, prompts, and window labels that appear on a

• Used for a subdirectory name or file path:

Edit the file

usr/local/bin/sample.txt

computer monitor:

The

Edit Parameterswindow will appear on the screen.

• Used for menus, lists, dialog boxes, and button boxes on a computer

monitor from which you make selections using the mouse or keyboard:

Double-click

EXIT to quit the program.

85330A Multiple Channel Controller xi

Page 12

Typeface Conventions

xii 85330A Multiple Channel Controller

Page 13

Contents

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

What You’ll Find in This Manual… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Documentation Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Safety Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Before Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Manufacturers Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Sound Emmisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Typeface Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1. Installation

Installation at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Preparing the Main Antenna Measurement System . . . . . . . . . . . . . . . . 1-2

Installing the Agilent 85330A Multiple Channel Controller . . . . . . . . . 1-2

Choosing the Proper Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Checking Operation of the Multiple Channel Controller . . . . . . . . . . . . 1-6

Loading the Driver from a Personal Computer . . . . . . . . . . . . . . . . 1-6

Viewing or Changing the GPIB Address of the Multiple Channel

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Selecting Positive or Negative-Edge Event Triggers . . . . . . . . . . . . . . . 1-8

Installing the Switch Control Units and Switches . . . . . . . . . . . . . . . . 1-10

Mounting the SCU and RF Switch . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Switch Control Unit Configuration Switches . . . . . . . . . . . . . . . . . 1-10

2. Performance Verification

In This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Performance Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Setting Up the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

85330 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Digital Oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Network Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Save Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Verifying the Multiple Channel Controller . . . . . . . . . . . . . . . . . . . . . . . 2-6

Turn-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

85330A Multiple Channel Controller xiii

Page 14

Voltage Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Output Trigger Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Pulse Receive and Cycle Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Counter Pulse Delay Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Measurement Busy Signal and Pulse Width Test . . . . . . . . . . . . . . 2-11

Verifying the Switch Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Verifying the RF Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Switch Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

RF Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Verifying Remote Ports 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

AUX 1 and AUX 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Pulse Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Measuring Pulses from AUX 1 or AUX 2 . . . . . . . . . . . . . . . . . . . 2-17

AUX 1 and AUX 2 Output Voltage Test . . . . . . . . . . . . . . . . . . . . . 2-18

When Finished with All Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

3. Operator’s Check

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4. General Information

In This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

In-depth Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Automated Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Preparing the 85330A to Control the System . . . . . . . . . . . . . . . . . . . . . 4-4

Special Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Switch Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

The Downloadable Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

System Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

PIN Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Supplied Equipment and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

85330A Multiple Channel Controller Characteristics . . . . . . . . . . . . . . . 4-9

Environmental Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Need More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

85330A Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Compatible Receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Compatible LO Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Compatible RF Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

xiv 85330A Multiple Channel Controller

Page 15

5. Manual Operation

In This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

To Use the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

About the Softkeys Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Utility Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Softkey Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

To View or Change the 85330’s GPIB Address . . . . . . . . . . . . . . . . . . . 5-4

Viewing GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Changing the GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

To Close Any Switch in the System (to select a channel) . . . . . . . . . . . 5-5

More about Switch Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

To Change the TTL State of AUX 1 or AUX 2 . . . . . . . . . . . . . . . . . . . 5-6

To View the Most Recent Error Message . . . . . . . . . . . . . . . . . . . . . . . . 5-6

To View the Revision of the Downloaded Driver . . . . . . . . . . . . . . . . . 5-6

To View Custom Option Number (If Applicable) . . . . . . . . . . . . . . . . . 5-7

To Manually Send Trigger Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

To Perform Service Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

6. Programming

In This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

GPIB Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Long and Short Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

To Choose a Measurement Configuration . . . . . . . . . . . . . . . . . . . . . . . 6-3

CW Measurement Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

To Use this Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Single Source Multiple-Frequency Configuration . . . . . . . . . . . . . . . . . 6-5

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

To Use this Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Dual Source Multiple-Frequency Measurements . . . . . . . . . . . . . . . . . . 6-7

8530A Control of Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

To Use this Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Fast Source Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

To Use this Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

To Use Direct Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Selecting a Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

To Use Run-Time Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Setup of the 85330A Multiple Channel Controller . . . . . . . . . . . . 6-12

Event Triggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Number of Frequency Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Number of Angular Increments (Events) . . . . . . . . . . . . . . . . . . . . 6-12

List of Switch States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Switch Settling Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

TTL Trigger and Ready Timeouts . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

85330A Multiple Channel Controller xv

Page 16

Using More than One Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Starting Run-Time Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Run-Time Measurement Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Run-Time Measurement Sequence for Multiple Controllers . . . . . 6-18

Using IMM vs. TTL Trigger for Source 1 . . . . . . . . . . . . . . . . . . . 6-18

Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

85330A Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

7. Remote Programming Command Reference

Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Common Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Standard Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

*CLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

*OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

*RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Standard Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

ROUTe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Subsystem Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

ROUTe:CLOSe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

ROUTe:CONTrol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

ROUTe:DELay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

RUNTime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

RUNTime:CONTroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

RUNTime:EVENt:COUNt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

RUNTime:EVENt:TRIGger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

TTL Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

IMM Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

RUNTime:INITiate:IMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

RUNTime:SOURce:COUNt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

RUNTime:SOURce:SOURCE1:TRIGger . . . . . . . . . . . . . . . . . . . . . . . 7-11

RUNTime:SOURce:SOURCE2:TRIGger . . . . . . . . . . . . . . . . . . . . . . . 7-11

RUNTime:SWITch:DELay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

RUNTime:SWITch:SCAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

RUNTime:SWITch:TRIGger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

RUNTime:TIMEout:EVENt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

RUNTime:TIMEout:RECeiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

RUNTime:TIMEout:REMote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

RUNTime:TIMEout:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

SYSTem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

SYSTem:ERRor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

8. In Case of Difficulty

The 85330A Does Not Show the Main Menu When Turned ON . . . . . 8-11

xvi 85330A Multiple Channel Controller

Page 17

9. Service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Troubleshooting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Troubleshooting the Multiple Channel Controller . . . . . . . . . . . . . 9-10

Troubleshooting the Switch Control Unit . . . . . . . . . . . . . . . . . . . 9-11

Troubleshooting the RF Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Troubleshooting the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Parts List Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Mainframe, Plug-in Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Switch Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

RF Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Interconnect Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Assembly and Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

E1330 Card Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

85330-60002 Card Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Switch Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Selecting Positive or Negative-Edge Event Triggers . . . . . . . . . . . 9-22

Selecting the Multiple Channel Controller’s GPIB Address . . . . . 9-23

Switching from the Internal to External Power Supply . . . . . . . . . 9-24

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

10. Accessory Documentation

11. Glossary

85330A Multiple Channel Controller xvii

Page 18

-xviii 85330A Multiple Channel Controller

Page 19

1 Installation

Installation

Installation at a Glance

The installation procedure is composed of the following basic steps:

1. If you just purchased an antenna measurement system, install all

components as described in the documentation that came with that

system. Do not connect the Agilent 85330A yet.

2. Turn on the system and perform a functional check.

3. If desired, verify the performance of the system components by referring

to the Performance Verification chapter of the system manual.

4. Install and verify the 85330A system as explained in this manual.

85330A Multiple Channel Controller 1-1

Page 20

Installation

Preparing the Main Antenna Measurement System

Preparing the Main Antenna Measurement

System

CAUTION As an antistatic precaution, do not touch exposed connector contacts!

Information about installing, performing an operational check, and verifying

the main antenna measurement system is explained in the appropriate

documentation listed below:

• Agilent 85301B Antenna Measurement System Manual

• Agilent 85301C Antenna Measurement System Manual

• Agilent 85310A Distributed Frequency Converter Manual

If you purchased an Agilent 8511 as a stand-alone unit, refer to the Agilent

8530A On-Site Service Manual for installation instructions. Verify the 8511

as explained in its operating and service manual.

Choosing the Proper

Configuration

Installing the Agilent 85330A Multiple Channel

Controller

There are two ways to install the Agilent 85330A system. Figure 1-1 on

page 1-3 is a flow chart that shows a installation configuration that is

appropriate for you to use.

How to use the figure

Follow the flow chart from the top. Determine if your measurements are

made with a single frequency (CW), or multiple frequencies. Proceed down

the appropriate flow chart path. Proceed in this way until you get to a box

that recommends either Figure 1-2 on page 1-4, or Figure 1-3 on page 1-5.

Fast Source Control

Fast source control speeds up frequency switching speed in

multiple-frequency measurements. It is only available in systems that use

two Agilent 836xx series synthesized sources. This mode uses TTL signals

to increment RF and LO source frequency, providing faster frequency

switching speeds than are possible under 8530A control. In the fast source

control configuration, the system’s computer must set up the sources with

appropriate frequency settings, triggering mode, and so on. When automatic

Run Time measurement mode is engaged, the 85330A automatically

increments the RF and LO source frequencies using TTL lines. More

information is provided in Chapter 6, “Programming.” When the sources are

controlled by a computer, the SCPI language mode must be selected. This is

shown in Figure 1-3 on page 1-5.

1-2 85330A Multiple Channel Controller

Page 21

Installation

Preparing the Main Antenna Measurement System

Figure 1-1 Flow Chart for Choosing the Correct Installation

NOTE If the receiver does not have the RECEIVER READY, as shown in

Figure 1-2 on page 1-4 and Figure 1-3 on page 1-5, then the STOP SWEEP

may be used.

85330A Multiple Channel Controller 1-3

Page 22

Installation

Preparing the Main Antenna Measurement System

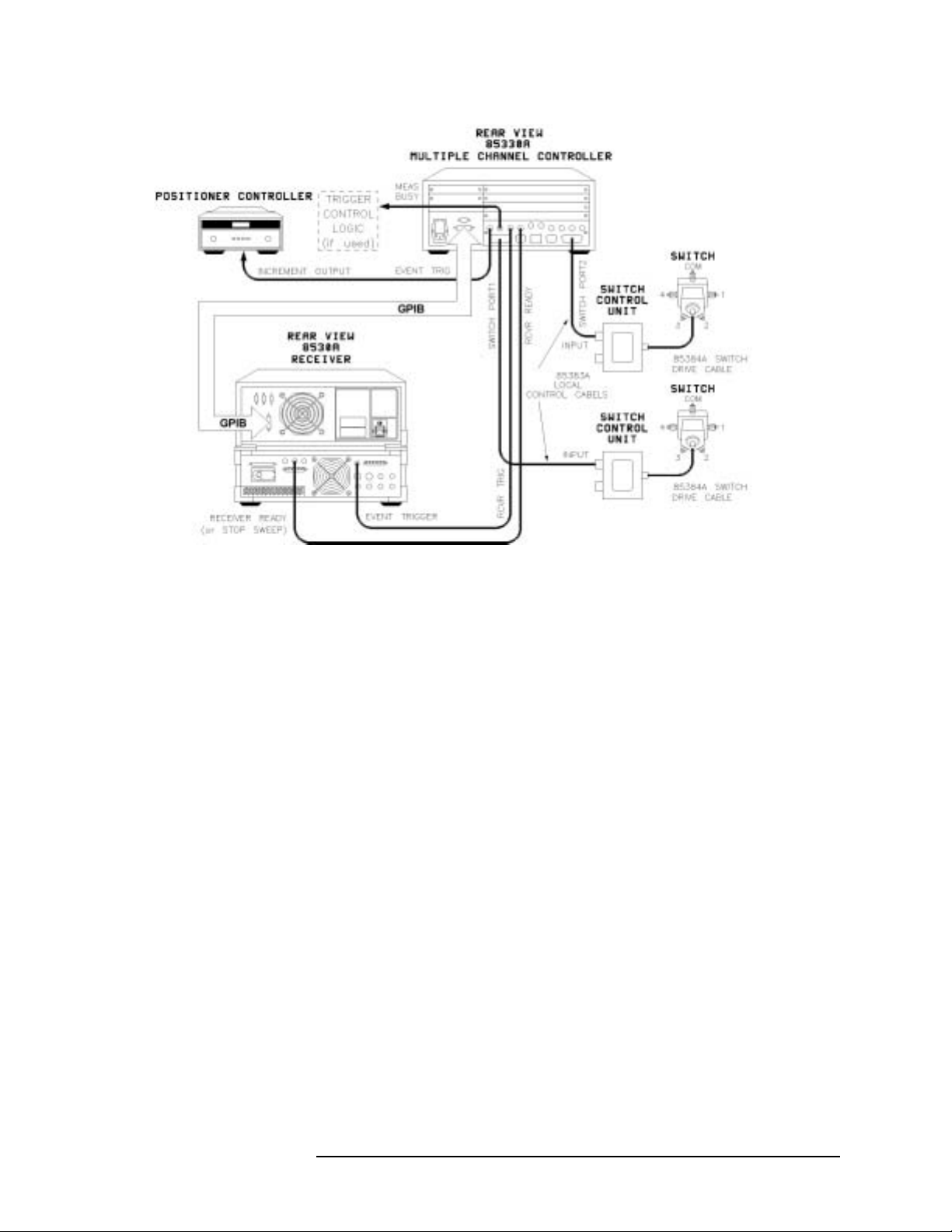

Figure 1-2 85330A Installation Diagram for 8530A Source Control

1-4 85330A Multiple Channel Controller

Page 23

Installation

Preparing the Main Antenna Measurement System

Figure 1-3 85330A Installation Diagram for Fast (TTL) Source Control

85330A Multiple Channel Controller 1-5

Page 24

Installation

Checking Operation of the Multiple Channel Controller

Checking Operation of the Multiple Channel

Controller

Turn the multiple channel controller ON; the following screen should

appear:

Select an instrument._

SYSTEM 85330A IBASIC

NOTE IBASIC is only present if the IBASIC option is installed.

If the display shows

loaded.

If you do not see this display, load the VXI mainframe downloadable driver

files as explained in “Loading the Driver from a Personal Computer,” next.

The 85330A contains 85330A driver files from the disk labeled 85330A

Downloadable Driver Disk. When your system was shipped, the driver files

were already loaded into the non-volatile memory of the 85330A

mainframe. Once loaded, it will remain when the mainframe is powered

down or when the power is interrupted to the mainframe.

If you must reload the drivers, a complete set of instructions are included in

the

INSTALL.TXT file on the supplied driver disk, or perform the following

instructions:

NOTE This method uses a personal computer (PC) to download the drivers over a

serial cable (supplied).

(see note below)

“DIG I/O” instead of “85330A”, then the drivers are no longer

NOTE The downloadable driver disk should not be set to the write-protected

position or the driver files will not load properly.

Loading the Driver from a Personal Computer

Equipment Needed

The following equipment was supplied with your system:

• Serial Cable: 24542U part number 24540-80014, 9-pin to 9-pin

• Adapter: 1252-7577, 9-pin to 25-pin (only needed if your computer has

a 25-pin serial connector)

• Downloadable Driver Disk: p/n 85330-10016 (rev A.02.31 or higher)

1-6 85330A Multiple Channel Controller

Page 25

Installation

Checking Operation of the Multiple Channel Controller

NOTE You can use other com ports, such as com2. However, you have to edit a file

called

“VXIDLD.CFG” so the software knows you are using a different port.

This configuration file can be edited with any ASCII text editor, such as

notepad. Save the changed file back to the supplied disk.

NOTE Agilent recommends that you make two backups of the driver disk. Make

one copy to a floppy disk, and one copy to the personal computer used with

the system.

Procedure

NOTE This procedure may not work on later versions of Microsoft®1 Windows®

such as Windows NT® and Windows 2000®.

1. Disconnect any GPIB cables from the mainframe. If it is easier, you can

disconnect the GPIB from the back of the system controller computer.

2. Turn the VXI mainframe ON.

3. On your PC, open a DOS command prompt window.

4. Insert the supplied driver disk into drive A. (Do not write-protect the

downloadable driver disk. The driver will not load if the write-protect

window is open. Make sure the tab is snapped fully into the closed

portion.)

5. In the DOS command prompt window, change to drive A.

6. In the DOS command prompt window, type

VXIDLD and press [Enter].

7. The mainframe download procedure takes approximately six or seven

minutes, and the mainframe will reboot.

NOTE There are several error messages that can be ignored. These are described in

the README.TXT file on the driver disk. Specifically, refer to the

description of the VXIDLD.CFG file.

8. Reconnect all the GPIB cables.

9. When finished, the following should be displayed:

Select an instrument._

SYSTEM 85330A IBASIC

(see note below)

NOTE IBASIC is only present if the IBASIC option is installed.

1 Microsoft, Windows, Windows NT, and Windows 2000 are U.S. registered trademarks of Microsoft Corporation.

85330A Multiple Channel Controller 1-7

Page 26

Installation

Selecting Positive or Negative-Edge Event Triggers

Viewing or Changing the GPIB Address of the Multiple Channel Controller

The factory default setting of the GPIB address is 9. To view the GPIB

address:

Press

[Select Instr] {SYSTEM} {GPIB} {READ}.

To change the current GPIB address:

1. Press

2. Enter the new address and press

[Select Instr] {SYSTEM} {GPIB} {SET}.

[Return].

Selecting Positive or Negative-Edge Event

Triggers

By default, the positive-edge of the EVENT TRIG line starts the

measurement. To change this so a negative-edge starts the measurement,

perform the following procedure.

CAUTION This device contains devices that are sensitive to static discharge. When you

remove the cover of this device, observe static safety precautions:

1. Place the unit on a grounded anti-static mat.

2. Wear a grounded wrist strap. Foot straps are only acceptable if you wear

one on each foot, and if you are standing on a grounded floor mat.

Refer to Figure 1-4 on page 1-9.

1-8 85330A Multiple Channel Controller

Page 27

Installation

Selecting Positive or Negative-Edge Event Triggers

Figure 1-4 Positive/Negative-Edge EVENT TRIG jumpers

1. Remove the two screws that hold the E1330B board in place.

2. Remove the four screws that hold the 85330-60002 board in place.

3. Pull out the two boards at the same time. You can do this by pulling each

one out a little at a time, until they are both removed. Place the boards

on an anti-static surface.

Standard positive-edge operation is set at the factory by jumpering

E9 and E10 together.

4. To select negative-edge operation, move the jumper across E9 and E8.

5. Reinstall the boards and screws.

85330A Multiple Channel Controller 1-9

Page 28

Installation

Installing the Switch Control Units and Switches

Installing the Switch Control Units and Switches

MountingtheSCU and RF Switch

NOTE Make sure the 85383A local control cable can reach from the multiple

Switch Control Unit

Configuration

Switches

If desired, you can mount the SCU using the supplied mounting screws. You

must provide a mounting plate or drill holes in an existing structure before

mounting an SCU or a switch. Refer to the mounting diagram in Figure 1-5

on page 1-11.

channel controller to the SCU. Make sure the 85384A switch drive cable is

long enough to reach from the SCU to the switch.

Changing any of the DIP switches inside the SCU is not recommended. All

switch settings are made at the factory.

In a standard system (defined below), the following settings are used:

• SCU address is set to 0.

• Channel numbers 1 through 4 are used to select switch positions.

A “standard system” uses one 85330A with one or two switch control units,

each with a two-throw or four-throw switch module. Remember that 85330A

PORT 1 and PORT 2 are addressed independently. So:

• If you have two SCUs, both can use the default SCU address (0).

• You can use the default channel number assignments (1 through 4) for

both switch modules. Since each SCU is on a different port, and each

port is addressed independently, there is not a channel number conflict.

1-10 85330A Multiple Channel Controller

Page 29

Installation

Installing the Switch Control Units and Switches

Figure 1-5 SCU and Switch Mounting Diagram

85330A Multiple Channel Controller 1-11

Page 30

Installation

Installing the Switch Control Units and Switches

1-12 85330A Multiple Channel Controller

Page 31

Performance Verification

2 Performance Verification

In This Chapter • Recommended performance verification test equipment

• Performance verification tests

• Verifying the multiple channel controller

• Verifying the RF switches

Description This performance verification should be done once a year, or more

frequently as needed. This procedure verifies that the Agilent 85330A

system meets or exceeds its published specifications. Specifications are

listed in Chapter 4, “General Information.”If traceability to a local standards

organization is required, then it can be done with this procedure. One such

standards organization is the United States National Institute of Standards

and Technology (NIST, formerly NBS).

This verification can be performed at the measurement system’s site, or at a

service bench. The verification will verify all parts of the multiple channel

system: multiple channel controller, switches, and cables. This verification

does not check the performance of the measurement system’s transmitter or

receiver. Use the measurement system’s manual for more information on

that procedure.

85330A Multiple Channel Controller 2-1

Page 32

Performance Verification

Recommended Equipment

Table 2-1 lists the equipment that is mandatory when performing the

performance verification.

Table 2-1 Required Equipment

Qty Item Agilent Part or Model Number

1 Downloadable Driver Disk, rev A.03.00 85330-10016

1 Multimeter (20 Vdc, digital) E2377A

1 Digital Oscilloscope (100 MHz bandwidth

1 MHz Single-shot bandwidth)

1 Tee adapter (BNC male to female, female) 1250-0781

3 Cable (BNC male to male 122 cm) 8120-1840

1

Network Analyzer System

(50 MHz to 40 GHz

90 dB dynamic range)

1

Plotter or Printer

1 Torque wrench (2.4/3.5 mm @ 8 in-lb)

6

4, 5

1

2

54501A

3

8722C (Option 003)

HP 7550A+, or LaserJet

8710-1765

7

1. Other part numbers or model numbers may be used if they meet the minimum requirements.

2. Included with 85330A shipment.

3. System must include vector network analyzer, test port cables, and a calibration kit.

4. A 50 MHz to 26.5 GHz network analyzer may be used if the 3.5 mm adapters are used with the

microwave switches.

5. If a network analyzer is used with a frequency range less than the switches, the performance

verification will only be valid over the frequency range of the network analyzer.

6. Plotter or printer must be connected to the network analyzer and oscilloscope for test documentation.

7. Use this wrench for any 2.4/3.5 /SMA mm connections in this procedure.

2-2 85330A Multiple Channel Controller

Page 33

Performance Verification

Performance Verification Test

Performance Verification Test

The following verification procedure will verify the Agilent 85330 system in

two parts. The first part will verify the operation of the multiple channel

controller to make sure that it is controlling the switches and the receiver

correctly. The second part will check the switch’s RF performance and to

make sure that they are switching correctly.

Setting Up the Equipment

85330 System Connect the 85330 system to the switch control unit using the correct local

control cable. This should be set up the same way that the 85330A system is

used in the measurement system (Agilent 85301B/C). Do not connect the

Switch Control Units (SCU) to their switches at this time. Do not connect

the 85330A to any other instruments in the measurement system. An

example of a setup is shown in Figure 2-1. Do not turn ON the 85330A at

this time.

Figure 2-1 An Example Performance Verification Setup

85330A Multiple Channel Controller 2-3

Page 34

Performance Verification

Performance Verification Test

Digital Oscilloscope Set up the Agilent 54503A digital oscilloscope (or any oscilloscope) as

described in the following procedure, using the same settings.

NOTE The oscilloscope setup described in the following procedure will not display

a trace on the oscilloscope screen until a pulse is initiated. The oscilloscope

will then hold the trace until the [CLEAR DISPLAY] is pressed.

Procedure

Turn ON the oscilloscope and press the following keys on the 54503A:

[CHAN]: {1}

{ON}

{2v/Div}

{Offset: 0v}

{Coupling: DC}

{Input: 1 M

{Probe Ratio: 1:1}

Ω}

[CHAN]: {2}

{ON}}

{2v/Div}

{Offset: 5v}

{Coupling: DC}

{Input: 1 M

{Probe Ratio: 1:1}

[TRIG]:

{Trig’d}

{Edge}

{Source: 1}

{Adjust: 1v}

{ } (- Edge)

[TIMEBASE]:

{2 us/Div}

{Delay: 0}

{Reference: Cntr}

[SAVE] [1]

Ω}

2-4 85330A Multiple Channel Controller

Page 35

Performance Verification

Performance Verification Test

Network Analyzer Turn ON the vector network analyzer. Adjust the controls for the following

setup:

Measurement Display

Display: 4 Channel

Channel 1: S11 SWR

Channel 2: S21 Log Mag

Channel 3: S12 Log Mag

Channel 4: S22 SWR

Domain: Frequency

Start Frequency: 45 MHz

Stop Frequency: 40 GHz

Number of Points: 201

RF Source Power: Maximum

Measurement: Continuous

Averaging: As required

Set up the rest of the measurement display for your convenience and ease of

viewing.

Cables Connect one test port cable to Port 2 of the test set. The RF switch will be

connected directly to the test set Port 1. An example of this setup is shown in

Figure 2-1, “An Example Performance Verification Setup,” on page 2-3.

Calibration Perform a full, two port calibration at the test set Port 1, and at the end of the

test port cable connected to Port 2.

Save Setup Savethis instrument state setup in Save/Recall register 1. It will be used later

in the tests. Press:

[SAVE] {1}

85330A Multiple Channel Controller 2-5

Page 36

Performance Verification

Verifying the Multiple Channel Controller

Verifying the Multiple Channel Controller

This portion of the verification will check the 85330 multiple channel switch

controller to ensure that it is operating correctly. It will also check the

Switch Control Unit of the Agilent 85331/2 to make sure that it is switching

correctly. Document the test results by plotting or printing the test

instrument screens as each test is performed.

Turn-On Turn the multiple channel controller ON; the following screen should

appear:

Select an instrument._

SYSTEM 85330A IBASIC

(see note below)

NOTE IBASIC is only present if the IBASIC option is installed.

If you see the above display, the unit has passed its turn on tests and is

working properly. If you do not see this display, load the 85330A

downloadable driver files as explained in the “Loading the Driver from a

Personal Computer” on page 1-6.

Voltage Check Check the voltage on the switch control unit’s OUTPUT connector. This is

the connector that is used to daisy-chain the switch control units together.

The voltages are shown in Table 2-2. If an external power supply is used to

bias the switch control units, the supply may require some adjustment to

keep the voltage within the tolerances.

Table 2-2 Switch Control Unit Voltages

Pin Voltage

E, L, V

+12 ±1.8 Vdc

a

F, M, W, b ground

2-6 85330A Multiple Channel Controller

−12 ±1.8 Vdc

Page 37

Verifying the Multiple Channel Controller

Figure 2-2 Switch Control Unit Output Connector Voltages

Inputs/Outputs Press the following on the multiple channel controller:

[Clear Instr] [Select Instr]

You should see the following display:

Select an instrument._

Performance Verification

SYSTEM 85330A IBASIC

(see note below)

NOTE IBASIC is only present if the IBASIC option is installed.

This is the MAIN MENU.

Output Trigger Test The following test will determine if the rear-panel ports output the correct

signals. Note that a single press on the specific

single trigger pulse. If you hold down this key, a train of trigger pulses will

be outputted.

1. Connect a BNC cable between Channel 1 of the oscilloscope and the

multiple channel controller rear panel BNC connector that is being

tested.

2. On the oscilloscope, press:

[RECALL] [1]

3. Connect the BNC cable to the RCVR TRIG connector on the multiple

channel controller, and press:

{TRIGGER} key will cause a

{85330A} {TRIGGER} {RCVR}

On the oscilloscope, press [CLEAR DISPLAY]. You should see a negative

pulse, with an approximate width of one to three microseconds.

4. Connect the BNC cable to the SRC 1 TRIG connector on the multiple

channel controller, and press:

{SRC_1}

85330A Multiple Channel Controller 2-7

Page 38

Performance Verification

Verifying the Multiple Channel Controller

On the oscilloscope, press [CLEAR DISPLAY]. Set the [TIMEBASE] to {5 us/Div}.

You should see a positive pulse, with an approximate width of 10 to 14

microseconds.

5. Connect the BNC cable to the SRC 2 TRIG connector on the multiple

channel controller, and press:

{SRC_2}

On the oscilloscope, press [CLEAR DISPLAY]. You should see a positive

pulse, with an approximate width of 10 to 14 microseconds.

6. Remove the BNC cable from the multiple channel controller.

Pulse Receive and Cycle Test

The following test will determine if the rear panel ports successfully sense

the trigger pulses. These tests will output a train of 100 pulses.

1. Press the following on the multiple channel controller:

[Clear Instr] [Select Instr] {85330A}

2. Connect a BNC cable between the RCVR READY and RCVR TRIG

connectors. Press:

[More] {TEST} {RCVR} [1] [0] [0] [Return]

If the test is successful, the RCVR menu will appear on the display. If

the test fails, the following error message will appear:

-214, Trigger deadlock

3. Connect a BNC cable between the SRC1 READY and SRC1 TRIG

connectors. Press:

{SRC_1} [1] [0] [0] [Return]

If the test is successful, the RCVR menu will appear on the display. If

the test fails, the following error message will appear:

-214, Trigger deadlock

4. Connect a BNC cable between the SRC2 READY and SRC2 TRIG

connectors. Press:

{SRC_2} [1] [0] [0] [Return]

If the test is successful, the RCVR menu will appear on the display. If

the test fails, the following error message will appear:

-214, Trigger deadlock

5. Remove the BNC cable from the multiple channel controller.

2-8 85330A Multiple Channel Controller

Page 39

Performance Verification

Verifying the Multiple Channel Controller

Counter Pulse Delay Test

The following test determines if the on-board counter is operating correctly.

1. Connect BNC cables between the SRC1 TRIG, RCVR READY

connectors and the oscilloscope as shown in Figure 2-3 on page 2-10.

2. On the oscilloscope press:

[RECALL] [1]

[TRIG] {Source 2} {Adjust: 1.5v} { }

[TIMEBASE] {1 us/Div} {Delay: 4 us} {Ref: Centr}

[SAVE] [2]

(+ Edge}

3. Press the following on the multiple channel controller:

[Clear Instr] [Select Instr] {85330A} {RESET} [More] {TEST} {COUNTER}

4. Press the following on the multiple channel controller:

[4] [Return]

5. The negative edge of the displayed pulse should be 4 ±1 microseconds.

To use the scope measurement feature, press:

[∆t ∆v] {∆t Marker: ON}.

Rotate the front panel knob until the vertical marker line intersects the

negativeedge of the pulse. Note that the Start Marker reading will be the

pulse delay. See Figure 2-4 on page 2-10 for more information.

6. On the oscilloscope press:

[TIME BASE] {1 us/Div} {Delay: 1000 us} [CLEAR DISPLAY]

7. Press the following on the multiple channel controller:

[1] [0] [0] [0] [Return]

8. The negative edge of the displayed pulse should be 1,000 ±

1 microseconds.

To use the scope measurement feature, press:

[∆t ∆v] {∆t Marker: ON}.

Rotate the front panel knob until the vertical marker line intersects the

negativeedge of the pulse. Note that the Start Marker reading will be the

pulse delay. See Figure 2-4 for more information.

9. On the oscilloscope press:

[TIME BASE] {2 us/Div} {Delay: 15 ms} [CLEAR DISPLAY]

10. Press the following on the multiple channel controller:

[1] [5] [0] [0] [0] [Return]

11. The negative edge of the displayed pulse should be 15 ± 0.001

milliseconds.

To use the scope measurement feature, press:

[∆t ∆v] {∆t Marker: ON}.

Rotate the front panel knob until the vertical marker line intersects the

85330A Multiple Channel Controller 2-9

Page 40

Performance Verification

Verifying the Multiple Channel Controller

negativeedge of the pulse. Note that the Start Marker reading will be the

pulse delay. See Figure 2-4 for more information.

12. Remove the BNC cables.

Figure 2-3 Counter Pulse Delay Test Setup

Figure 2-4 15 millisecond Delay Trigger Example

2-10 85330A Multiple Channel Controller

Page 41

Performance Verification

Verifying the Multiple Channel Controller

Measurement Busy Signal and Pulse Width Test

The following test will determine if the MEAS BUSY port output pulse

width is correct. It will also test the EVENT TRIG input.

1. Connect a BNC cable between the SRC1 TRIG and EVENT TRIG

connectors.

2. Connect a BNC cable between the MEAS BUSY connector and the

oscilloscope channel 1.

3. On the oscilloscope press:

[TIME BASE] {10 us/Div} [CLEAR DISPLAY]

4. Press the following on the multiple channel controller:

[Clear Instr] [Select Instr] {85330A} [More] {TEST} {EVENT} [1] [Return]

5. While the measurement is cycling, observe the MEAS BUSY pulse on

the oscilloscope. The pulse width should be approximately 50

microseconds.

6. If the test is successful the RCVR menu will appear on the display.If the

test fails, the following error message will appear:

-214, Trigger deadlock

85330A Multiple Channel Controller 2-11

Page 42

Performance Verification

Verifying the Switch Control Unit

Verifying the Switch Control Unit

This test will determine if the multiple channel controller is controlling the

Switch Control Unit and that the SCU is operating correctly. If the system

has move than one SCU on a single port, then check each SCU.

1. Check to make sure that the multiple channel controller is connected to

each switch control unit. An example of this setup is shown in

Figure 2-5 on page 2-13.

2. Check each switch control unit. The Active light should be ON.

3. Press the following on the multiple channel controller:

[Clear Instr] [Select Instr] {85330A} {CLOSE}

4. Select {PORT 1} or {PORT 2} depending on the setup of your switch system.

If your system uses both PORT 1 and PORT 2, then perform the

following tests for both ports:

a. Press:

{PORT 1} or {PORT 2}

b. Enter each switch control unit’s address and switch number and

observe that unit’s lights. As each switch address is activated, the

light should turn ON.

To enter a unit address and switch number, press:

[x] [y] [z] [Return]

x = switch control unit’s address (normally 0)

y = switch number to be closed (normally 0)

z = switch number to be closed (0 = opens all switches)

For example,

{PORT 1} [1] [0] [3] [Return] will close switch 3 in the switch

control unit with address 1 that is connected to PORT 1. The switch

control unit address can be found on the units label. To close switch 4,

just press

[1] [0] [4].

c. Close each switch on a module and insure that the light turns ON.

5. Perform the above test for each Switch Control Unit in the system.

2-12 85330A Multiple Channel Controller

Page 43

Performance Verification

Verifying the RF Switches

Verifying the RF Switches

This portion of the verification will check the switches to make sure that

they are switching correctly. This portion will also test the RF performance

of the switches.

Switch Setup 1. Turn OFF the multiple channel controller before making any

connections.

2. Connect each switch to its switch control unit. Use the supplied switch

drive cable.

3. Connect the switch to the network analyzer. An example of this setup is

shown in Figure 2-5. Note that all of the switch ports will be tested, so

make sure that there is enough room to connect all of the ports to the

network analyzer.

4. Turn ON the multiple channel controller.

Figure 2-5 RF Switch Test Setup

85330A Multiple Channel Controller 2-13

Page 44

Performance Verification

Verifying the RF Switches

RF Performance Tests Recall the network analyzer setup that was saved earlier by pressing:

[RECALL] {1}

Perform each of the following tests on each input and output port of the

switch. Check the results of each of the tests against the switch’s

specifications shown in the Agilent 85331A/Agilent 85332A User’s Manual.

1. Connect the test port cable to the first switch port.

2. Close the switch path. This will turn the switch light ON on the switch

control unit.

a. Check the S11 (input match, ON).

b. Check the S22 (output match, ON).

c. Check the S21 (insertion loss, ON).

d. Check the S12 (reverse insertion loss, ON).

e. Document the test results by plotting the display to a plotter or

printer.

3. Open the switch path. This will turn the switch light OFF on the switch

control unit.

a. Check the S11 (input match, OFF).

b. Check the S22 (output match, OFF).

c. Check the S21 (isolation, OFF). Use averaging if required.

d. Check the S12 (reverse isolation, OFF). Use averaging if required.

e. Document the test results by plotting the display to a plotter or

printer.

4. Move the test port cable to the next switch port. Repeat all of the above

until all switch ports are tested.

2-14 85330A Multiple Channel Controller

Page 45

Performance Verification

Verifying Remote Ports 1 and 2

Verifying Remote Ports 1 and 2

Equipment Required

• Jumper (see below)

• Soldering iron

• 2 jumper wires

Jumpers Figure 2-6 shows the jumper assembly that can be used to verify remote port

1 and remote port 2. Using Agilent part number 1251-8863, solder one wire

from pin 6 to pin 8, and another wire from pin 7 to pin 9. A connector hood

is recommended for the 9-pin connector, such as L-com (part number

SDC9AG) (http://www.L-com.com).

Figure 2-6 Jumper Assembly

85330A Multiple Channel Controller 2-15

Page 46

Performance Verification

Verifying Remote Ports 1 and 2

Remote Port 1 and remote Port 2 Test Procedure

1. Download the 85330A drivers version A.03.00 or above.

2. When

select instrument is displayed, press:

{85330A}, {More}, {TEST}, {More}

3. Connect the modified connector to REMOTE 1 on the rear panel and

press:

{REM_1_2}

4. The display should read:

“85330A_144:REM1 0101 PASS, REM2 1100 FAIL”

5. Move the modified connector to REMOTE 2 on the rear panel and

press:

{REM_1_2}

6. The display should read:

“85330A_144: REM1 1111 FAIL, REM2 0011 PASS”

2-16 85330A Multiple Channel Controller

Page 47

Performance Verification

AUX 1 and AUX 2

AUX 1 and AUX 2

Pulse Test You can output one or more 500 µs pulses from AUX 1 or AUX 2 and

measure them with an oscilloscope. The number of pulses is selectable. The

pulses have a 50% duty cycle, and thus a total period of 1 ms. The amplitude

of the signal is roughly 0 to 4 volts. The pulses are not perfect square waves.

The leading edge rises higher than 4 volts, then curves down to

approximately 4 volts.

MeasuringPulsesfrom AUX 1 or AUX 2

NOTE The 85330A will not perform any other functions during this test. If you

NOTE To test AUX 2, use the same basic procedure as shown above.

1. Connect an oscilloscope to the AUX 1 or AUX.

2. Set the scope as necessary to view the waveform described above.

3. Press:

[Select Instr] {85330A} {→} {TEST} {→} {AUX 1} or {AUX 2}

4. The message TEST AUXn OUTPUT: # OF TESTS will appear.

5. Use the keyboard to enter the desired number of pulses. You can enter

the number in units or in scientific notation: For example:

100, or

1E2

6. Press the [Return] key. The pulses will appear on the scope.

enter a large number, such as 1E6, it will take a while to finish. You can

abort the test by cycling line power.

85330A Multiple Channel Controller 2-17

Page 48

Performance Verification

AUX 1 and AUX 2

AUX 1 and AUX 2 Output Voltage Test

The following test will determine if the rear panel ports successfully output

the correct DC switch drive levels.

1. On the oscilloscope press:

[RECALL] [1]

[TRIG] {AUTO}

[CLEAR DISPLAY]

2. Press the following on the multiple channel controller:

[Clear Instr] [Select Instr] {85330A}

3. Connect a BNC cable between the AUX 1 connector and channel 1 of

the oscilloscope.

a. Press:

{CLOSE} {AUX1} {0} or [f1]

The oscilloscope should show a trace of about 0 Vdc.

b. Press:

{1} or [f2]

The oscilloscope should show a trace of about 4 Vdc.

When Finished with All Tests

4. Connect a BNC cable between the AUX 2 connector and channel 1 of

the oscilloscope.

a. Press:

[Clear Instr] {CLOSE} {AUX2} {0} or [f1]

The oscilloscope should show a trace of about 0 Vdc.

b. Press:

{1} or [f2]

The oscilloscope should show a trace of about 4 Vdc.

All of the performance verification tests are now complete. Reconnect the

85330A system in the original measurement system configuration. Refer to

Chapter 1, “Installation” for more information.

2-18 85330A Multiple Channel Controller

Page 49

Operator’s Check

3 Operator’s Check

Purpose

This operator’s check verifies that the Agilent 85330A can close switches,

showing that the 85330A, switch control units, and switches are working.

You can perform this check daily, or as desired. This is not a performance

verification procedure (refer to Chapter 2, “Performance Verification” for

more information).

Procedure This procedure asks you to close every switch in your standard system, and

look for an appropriate signal with the measurement system.

1. Press:

2. If the

3. Press:

4. Enter the switch address using the numeric keypad. In a standard

5. Look at the channel LEDs on the front of the switch control unit. The

6. Perform a measurement with your system. The measurement system

7. Repeat these steps for each channel on each switch port.

[Select Instr] {85330A}.

{CLOSE} softkey does not appear, press [Prev Menu] until it does.

{CLOSE}

a. If the switch you want to close is connected to SWITCH PORT 1,

press

{PORT_1}.

b. If the switch you want to close is connected to SWITCH PORT 2,

press

{PORT_2}.

system, simply enter the channel number (1, 2, 3, or 4), and press

[Return]. If you have a custom system, refer to Chapter 5, “Manual

Operation” for instructions.

light for the selected channel should be ON. This shows that the SCU is

responding properly.

should be able to measure any signal present on the selected channel.

85330A Multiple Channel Controller 3-1

Page 50

Operator’s Check

3-2 85330A Multiple Channel Controller

Page 51

4 General Information

In This Chapter • Product description

• Required equipment

• Supplied equipment and software

• Agilent 85330A multiple channel controller characteristics

• Front panel features

• Rear panel features

• AC power cord

General Information

Figure 4-1 85330A System Overview

85330A Multiple Channel Controller 4-1

Page 52

General Information

Product Description The Agilent 85330A multiple channel controller adds high-speed

multiple-channel measurement capability to Agilent 8530A-based

automated measurement systems, using high-isolation solid state microwave

switch modules. The 85330A is a run time controller that orchestrates the

sequencing and synchronizing of all the required functions for

multiple-channel and multiple-frequency measurements, to allow very fast

data acquisition speed and data throughput of the measurement system.

• Option 908 - Rack Mount Kit Without Handles

Multiple Channel Controller rack mount kit without handles. To obtain

this item after receiving the 85330A, order part number 5062-3978.

• Option 913 - Rack Mount Kit With Handles

Multiple Channel Controller rack mount kit with handles. Toobtain this

item after receiving the 85330A, order part number 5062-3984.

• Option 910 - Additional Manual

This provides an additional manual. To obtain this item after receiving

the 85330A, order part number 85330-90019.

In-depth Information Measurement Speed Advantages

The multiple channel controller, when used with the Autoranged Fast Data

Acquisition mode, provides very fast measurement speeds. Even faster

measurements can be made when the RF/LO sources are controlled using

the direct TTL source control capabilities of the multiple channel controller.

Frequency states can be downloaded to the Agilent 8360 series of frequency

synthesizers. The multiple channel controller sends TTL triggers to the

sources (in two-source systems) at the appropriate time to change their

frequency. This method maximizes the frequency agility of the system by

allowing the sources to switch at their fastest rate.

Triggering

The 85330A receives triggers from the positioning system, and synchronizes

the data acquisition to the positioning system. It also controls the triggering

of the microwave receiver, and sequencing of the multiple channel data into

the receiver.

Lowering the Workload on the Computer Controller

When using 85330A as the system controller, the demands of the computer

are decreased during run-time. The computer is free to collect data from the

receiver and perform data manipulation, display, and storage.

4-2 85330A Multiple Channel Controller

Page 53

Installing the Detachable Power Cord

Install the instrument so that the detachable power cord is readily

identifiable and is easily reached by the operator.The detachable power cord

is the instrument disconnecting device. It disconnects the mains circuits

from the mains supply. The front panel switch is only a standby switch and

is not a LINE switch. Alternatively, an externally installed switch or circuit

breaker (which is readily identifiable and is easily reached by the operator)

may be used as a disconnective device.

Manual Operation Front panel softkeys allow you to:

• View or change the 85330A’s GPIB address.

• Close any switch in the system (select a channel).

• Change the TTL state of AUX 1 or AUX 2.

• View the revision of the downloaded driver.

General Information

• Perform service functions.

Refer to Chapter 5, “Manual Operation,” for more information.

Automated Operation During automated operation, the 85330A can control switches in two ways:

Direct Control The 85330A can directly control switch states

and issue triggers using GPIB commands.

Run Time

Mode Using GPIB commands, the 85330A

can be set up for a specific measurement sequence,

then automatically execute that measurement

(run-time mode).

85330A Multiple Channel Controller 4-3

Page 54

General Information

Preparing the 85330A to Control the System

Preparing the 85330A to Control the System

Configuring the 85330A is composed of the following steps:

1. Send the 85330A a series of GPIB setup commands prior to starting the

run-time sequence.

2. Start the run-time sequence by sending a specific GPIB command.

3. The 85330A then waits for a positioner trigger signal to begin the

sequence.

4. The 85330A repeats the sequence for the specified number of frequency

points to be measured.

More detailed information on this subject is explained in Chapter 6,

“Programming.”

Special Systems Special system configurations allow you to:

• Daisy-chain SCUs to provide many channels with a single multiple

channel controller.

• Add remote multiple channel controllers to expand the switch tree or

extend the physical distance that switches can be placed from the control

room. Additional remote multiple channel controllers can be up to

2 Kilometers away from the master.

Switch Components The 85330A controls the following items:

Switch control units

In standard systems, the system interface board communicates with one or

two SCUs. SCUs perform the following tasks:

• They decode binary information from the multiple channel controller to

determine which switch should be closed.

• They provide the necessary bias voltages to the switches, which causes

them to switch states.

In a standard system, one SCU is connected to the multiple channel

controller’sPORT 1 connector, and the other SCU is connected to PORT2.

The separate ports provide the ability to put switches at the transmit and

receive site.

4-4 85330A Multiple Channel Controller

Page 55

General Information

Preparing the 85330A to Control the System

PIN switch modules

The switches are broadband, high-isolation switches. Each switch is

supplied with a switch control unit. Specifications and performance

characteristics are provided in the Agilent 85331A and Agilent 85332A PIN

Switch User’s Manual.

The Downloadable Driver