Page 1

User

,

Programming and

Service Guide

Agilent

11896A

Polarization Controller

Page 2

Notice

The

information

notice

contained

in

this

document

is

subject

to

change

without

.

Agilent

this

T

echnologies

material,

merchantability

shall

not

be

liable

consequential

of

this

material.

Agilent

Printed

P

in

art

Number:

US

A

makes

including,

and

tness

for

errors

damages

April

2000

no

warranty

but

not

limited

for

a

contained

in

connection

11896-90011

to

particular

herein

with

of

any

,

the

purpose

the

kind

with

implied

.

Agilent

or

for

incidental or

furnishing,

regard

warranties

T

echnologies

performance

to

of

,

or

use

c

Copyright Agilent T

echnologies 2000

All Rights Reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under the copyright laws

1400 F

ountaingrove P

arkway, Santa Rosa, CA 95403-1799, US

A

.

Page 3

Certication

Agilent

at

certies

National

the

International

Technologies

the time

of

shipment

that its

Institute of

Institute's calibration

Standards

certies

from

that

the

this

factory

product

.

calibration measurements

Standards and

facility,

Organization

T

echnology

and

to

members

Agilent

are

the

calibration

met

its

T

echnologies

traceable

,

to

the

.

published

to

the

extent

allowed

facilities

specications

further

United

States

by

of

other

iii

Page 4

W

arranty

This

Agilent T

material

During

repair

F

or warranty

facility

charges

charges

charges

another

and workmanship

the warranty

or replace

designated

to

to

, duties

country

echnologies

products which

service or

Agilent

return

,

the

and

.

instrument

for

period, Agilent

repair

by

Agilent

T

echnologies

product

taxes

for

product

a

period

T

echnologies

prove

,

this

product

T

echnologies

and

Agilent

to

Buyer

.

products

of

one

to

be

defective

must

.

Buyer

T

echnologies

However

returned

is

warranted

year

from

will,

be

shall

,

Buyer

to

Agilent

against

date

at

its

.

returned

prepay

shall

shall

T

defects

of

shipment.

option,

to

a

service

either

shipping

pay

shipping

pay

all

shipping

echnologies

in

from

Agilent T

Agilent T

instructions when

does not

rmware

Limit

The

or

interfacing,

environmental

or

NO

TECHNOLOGIES

OF

Ex

THE

REMEDIES

ANY

echnologies warrants

echnologies for

warrant that

will

be uninterrupted

a

tion

of

W

foregoing

inadequate

unauthorized

maintenance

OTHER

W

ARRANTY

MERCHANT

clusive

Remedies

REMEDIES

.

A

GILENT TECHNOLOGIES

DIRECT, INDIRECT

properly installed

arranty

warranty

maintenance

specications

.

SPECIFICALL

ABILITY

PRO

DAMAGES, WHETHER B

LEGAL THEORY

.

use

that its

with

software

an

instrument

on

the

operation

shall

by

or

not

Buyer

of

error-free

apply

modication

for

the

IS

EXPRESSED

Y

DISCLAIMS

AND

FITNESS

VIDED HEREIN

, SPECIAL, INCIDENT

ASED ON CONTRA

and

will

that

instrument.

the

instrument,

.

to

defects

,

Buyer-supplied

or

misuse

,

product,

OR

or

improper

IMPLIED

THE

FOR

A

P

ARTICULAR

ARE BUYER'S

SHALL

NOT

AL, OR CONSEQUENTIAL

CT

, TORT

rmware

execute

designated

its

programming

Agilent

or

software

resulting

from

software

operation

.

IMPLIED

A

GILENT

outside

site

preparation

W

ARRANTIES

PURPOSE.

SOLE AND

BE

LIABLE

, OR ANY OTHER

by

T

echnologies

,

or

improper

or

of

the

EXCLUSIVE

FOR

iv

Page 5

Assistance

Product

are

available for

F

or any

maintenance agreements

A

gilent

T

echnologies

assistance,

contact

your

and

products.

nearest

other

A

customer

gilent

assistance

T

echnologies

agreements

Service

Oce

.

v

Page 6

C

W

AU

A

Safety

The

following safety

yourself

Symbols

with each

symbols

of

the

are

symbols

used

and

throughout

its

meaning

this

before

manual.

operating

F

amiliarize

this

instrument.

The

TI

O

N

caution

procedure

damage

sign

until

The

R

N

I

N

G

warning

procedure

in

injury

indicated

sign

which, if

to

or

destruction

the

indicated

sign

which, if

or

loss

conditions

denotes a

not correctly

conditions

denotes

not

of

life

.

are

hazard

performed

of

the

instrument.

a

life-threatening

correctly

Do

not

proceed

fully

understood

to

the

instrument.

are

fully

performed

beyond

or

adhered

Do

not

proceed

understood

hazard.

or

adhered

a

warning

and

met.

It

calls

to

and

It

,

could

met.

calls

to

attention

beyond

,

could

sign

to

result

in

a

caution

attention to

result

until the

a

a

Instruction

Manual

L

vi

The

instruction

for

the

user

to

manual

refer

to

symbol.

the

The

instructions

product is

in

the

marked

manual.

with

this

symbol

when

it

is

necessary

Page 7

General

Safety Considerations

W

A

R

N

I

N

G

Before

grounded

socket

Any

outside

can

W

AR

N

I

N

G

This

ground

inserted

Any

instrument is

interruption is

W

A

R

N

I

N

G

There

personal

Any

instrument

trained

W

A

R

N

I

N

G

If

equipment

condition

this

through

outlet

interruption

the

result

is

a

Safety

in

incorporated in

in

interruption

are

many

injury

adjustments

service

this

instrument

(in

instrument

the

provided

of

the

instrument,

personal

Class

a

socket

of

outlet

the

likely to

prohibited.

points

.

Be

extremely

or

service

with

protective

personnel.

is not

could

be

impaired. This

which

all

is

switched

protective

with

protective

protective

or

disconnection

injury

.

I

product

the

power

provided

protective

make the

in

the

procedures

covers

used as

means

on

,

conductor

(grounding)

(provided

cord).

with a

conductor

instrument

instrument

careful.

removed

specied,

instrument must

for

protection

make

sure

of

the

earth

contact.

conductor

of

the

protective

with

a

protective

The

mains

protective earth

inside or

dangerous

which

that

can,

require

should

the

protection

are

intact)

it

has

ac

power

plug

outside of

.

Intentional

if

contacted,

operation

be

performed

be

used

only

been

properly

cable

,

inside

earth

earthing

shall

only

contact.

of

provided

in

.

to

a

or

terminal

be

the

cause

the

only

by

a

normal

by

the

N

O

Clean

T

E

the

cabinet

using

a

damp cloth

only.

vii

Page 8

How

This

manual provides

controller

.

to Use

This Manual

information

about

the

Agilent

11896A

polarization

Chapter

Chapter

Chapter

Chapter

Chapter 5

Appendix

Appendix

Appendix

1

provides

general information

and

specications

for

the

controller

2

3

describes

use

and

shows

how

how

how

to

to

make

to

manually

prepare

ber

the

optic

control

polarization

connections

the

lightwave

controller

polarization

for

controller

4

A

B

C

shows

using a

how

to

computer

control

provides procedures

Agilent 11896A

selecting scan

measurement

provides

a

polarization controller

rate

considerations

sample

the lightwave

for

verifying

and

measurement

GPIB

program

polarization controller

and

servicing

the

time

viii

Page 9

Contents

1.

General

Description

Instrumen

P

Theory of

Sp

ecications

Serial

Electrostatic

Reducing

2.

Installation

Preparing

Initial

Connecting

P

Chec

P

T

urning on

Ligh

In

Cleaning

Cleaning non-lensed light

Cleaning light

Cleaning lensed connections

Information

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

t

conguration

Options

Accessories

olarization-dep

P

o

w

Sw

ept-w

Max/min

Num

o

w

er requiremen

king

o

w

er

tw

a

v

troduction

Denition

Handling

Cleaning

Equipment . . . . . . . . . . . . . . . . .

Process . . . . . . . . . . . . . . . . . .

Equipment . . .

Process

.

er

meter

a

v

elength

PDL

Operation

and

b

ers

Disc

ESD

and

Preparation

the

P

olarization

insp

ection

the

the

fuse

cable

.

the

Agilen

e

Connector

and handling

of terms

.

.

w

. . . .

.

.

.

.

.

.

enden

PDL

measuremen

.

Characteristics

.

.

.

harge

damage

.

Agilen

ts .

.

.

.

.

t

Care

.

.

.

.

.

.

.

.

.

ave adapters

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

t

loss

measuremen

measuremen

PDL

measuremen

.

.

.

.

.

.

Information

.

.

Controller

.

. .

t

11896A

. .

. .

. .

.

.

.

11896A

.

.

.

.

. .

. .

.

.

.

.

.

.

wave connectors .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

t

t

system

.

.

.

.

.

.

.

.

.

.

for

Use

.

.

.

to a

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . . . . . . . . . .

. . . .

ts

system

t

system

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

for

Use

.

.

.

.

p

o

w

er

source

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

. .

. .

. . . . . . . .

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. . . . . .

. .

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

. .

. .

. .

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

. .

. .

1-3

.

1-4

.

1-4

1-4

.

1-5

.

1-5

.

1-6

.

1-8

.

1-10

.

1-11

.

1-14

.

1-15

.

1-17

.

2-3

.

2-3

.

2-4

.

2-4

.

2-4

.

2-5

.

2-8

2-9

.

2-9

.

2-11

.

2-11

.

2-11

.

2-11

2-12

2-12

2-12

2-13

2-13

2-13

2-13

Contents-1

Page 10

Storage

Making

Summary

Insp

Visual

Optical

In

Insertion

Return

3.

Using

4.

Programming

the

F

ron

t-P

Error

Rear-P

Using

P

o

w

T

o

use

T

o

con

T

o

set

T

o

sa

T

o

recall

To

use

T

o

displa

Changing

T

alking

Program Message

Output

Device

Instructions

Instruction

White space

Program

Header t

Simple command header

Compound command header

Common command header

Combining commands

Duplicate mnemonics

Query command

.

.

.

connections

.

.

.

ection

tro

anel

anel

the

er-up function

v

to

.

.

insp

ection

p

erformance

duction

loss

loss

.

Agilent

co

F

Agilen

the

tin

uously

the

e

an

an

the

y

the

command

address

data

yp

11896A

F

eatures

des

.

eatures

t 11896A

Man

ual

sw

scan

rate

instrumen

instrumen

Lo

cal

or

c

hange

the

GPIB

Instrumen

Syntax

.

. .

header

(separator) .

.

es . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

testing

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

. .

. .

mo

de

eep

all

.

.

t

state

t

state

function

the

address

t

. .

. .

. .

. .

. .

. .

. .

. .

. .

.

. .

.

. . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

. .

.

.

.

.

.

. .

. .

P

olarization

.

.

.

.

.

.

.

.

. .

. .

. .

.

.

.

p

olarization

.

.

.

.

.

.

.

.

.

GPIB

address

.

.

.

.

. .

. .

. .

.

. .

. .

.

.

.

.

.

.

. . . . . . . . . . . .

. . .

Controller

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

states

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . . . . . . . .

. . . . . . . . .

.

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

..

. .

. .

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

. .

..

. .

. .

. .

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . .

. .

2-14

2-15

2-16

2-16

.

2-16

2-17

.

2-17

2-17

.

2-18

.

3-3

.

3-5

.

3-6

.

3-7

.

3-8

.

3-8

.

3-9

.

3-9

.

3-10

.

3-10

.

3-11

.

3-11

.

4-3

.

4-4

.

4-5

.

4-5

.

4-5

.

4-6

.

4-6

.

4-6

.

4-7

4-7

4-7

4-8

4-8

4-8

.

4-9

4-10

Contents-2

Page 11

Program

Program

Numeric

Program

Selecting

Initialization

Programming

In

terface

Command

Addressing

Comm

In

Instrumen

Lo

c

Bus

Device

In

Common

*CLS

*ESE

*ESR (Ev

*IDN

*OPC

*R

*RST

*SA

*SRE

*STB

*TST

*W

Instrumen

:ABOR

:INITiate:IMMediate

:PADDle:POSition .

:SCAN:RATE .

:SCAN:TIMer .

:SCAN:TIMer:CLEar . . . . . . . . . . . .

:STATus:OPERation :CONDition . . . . . . . . .

:STATus:OPERation :ENABle

:STATus:OPERation :EVENt .

header

data

program

message

m

ultiple

capabilities

and

unicating

con

troller)

terface

k

out

commands

terface

CL (Recall)

select

.

clear

clear

commands

(Clear

(Ev

(Identication

(Operation

(Reset) .

V(Sa

ve)

(Service

(Status

(T

est)

AI

(W

ait)

t

sp

t

syntax

.

o

v

er

data

.

.

.

t

address

.

.

Status)

en

t

en

t

ecic

.

.

options

terminator

subsystems

.

.

GPIB

.

.

o

v

er

.

.

co

.

.

.

.

.

.

.

.

Status

Status

. .

. .

.

.

Request

Byte)

.

.

.

.

commands

.

.

. . . . . . . .

. . . . . . . . . .

.

.

rules

.

.

data

.

.

.

.

.

.

.

.

.

.

.

.

.

concepts

.

.

.

.

the

bus

.

.

.

.

de

(selects

(selects

.

.

. .

.

.

.

.

.

. .

. .

. .

. .

.

.

.

. .

.

.

.

Enable)

Register)

Num

b

Complete)

.

.

.

.

.

.

.

.

.

.

Enable)

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

. . . . . . .

.

.

.

.

.

.

.

.

.

.

(HP

.

in

instrumen

. .

.

.

.

er)

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

. .

. .

.

.

.

.

. .

.

.

.

.

.

.

.

.

. .

. .

9000

series

. .

. .

.

.

terface)

. .

.

.

.

.

.

.

. .

. .

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

. . . . . . . . . .

. . . . . . . . . .

.

.

t)

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

.

.

. . . . . . . .

. . . . . . . . .

. . . . . . .

.

.

. .

..

..

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

.

. .

. .

. .

200/300

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

. .

.

.

.

. .

.

.

.

.

. 4-12

.

.

.

.

.

.

.

.

. .

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

. .

4-11

4-12

4-13

4-13

4-14

4-15

4-15

4-15

4-16

4-17

4-17

4-17

4-18

4-18

4-18

4-18

4-19

4-19

4-20

4-21

4-22

4-22

4-23

4-23

4-23

4-24

4-25

4-26

4-26

4-27

4-27

4-27

4-28

4-29

4-29

4-30

4-30

4-30

4-31

Contents-3

Page 12

5.

:ST

A

T

us:PRESet

:ST

A

Tus:QUEStionable

:ST

A

T

us:QUEStionable

:ST

A

T

us:QUEStionable

:SYST

:SYST

V

erication

P

erforming

V

V

V

V

V

If

the

V

erifying

Insertion

Return

Ho

w

P

ac

Instrumen

Sales and

Sales

Service

General

Serial-n

Safet

Reliabilit

Protection

Required

Adjustmen

Replacemen

To

T

To replace the p o

To replace the GPIB connector

Replaceable parts

Replaceable parts table format

Part ordering information

Direct mail-order system

Direct phone-order system

em:ERRor

em:VERSion

and

a

erify

startup

erify

the

erify

the

erify

the

erify

the

v

erication c

the

loss

to

Return

k

aging

t

service

and

service

Information

information

um

y

considerations

replace the

o

replace

Service

V

erication

.

.

SCAN

LOCAL

SA

ev

Agilent

loss

the

.

shipping

b

y

considerations

from

service

t

pro

t

pro

the

RA

VE

and

en

t

timer

heck

11896A Sp

.

.

.

.

.

Agilen

.

.

.

oces

oces

.

er

information

electrostatic

to

cedure

cedures

front-panel

p

olarization

wer supply

. . . . . . . . . . . . . . . . .

preparation

.

.

.

.

:CONDition

:ENABle

:EVENt

.

.

.

.

.

.

.

Information

Chec

k

.

.

.

. .

TE

function

function

RECALL

.

.

fails .

ecications .

.

.

.

.

.

.

.

.

t

11896A

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ols

.

.

.

.

.

.

.

assembly

assem

. .

. . . .

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

. .

. .

. .

. .

. .

. .

. .

.

.

.

. .

. .

. .

.

. .

. .

.

.

.

.

functions

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

for

Service

.

.

.

.

pro

cedure

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

disc

harge

.

.

.

.

.

.

.

. .

.

.

.

.

bly

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . .

. . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

.

.

.

.

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

.

.

.

.

.

. .

. . . . . . .

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

. .

.

.

. .

.

.

. .

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

. .

.

.

4-31

.

4-31

.

4-32

.

4-32

4-33

.

4-34

.

5-3

.

5-3

5-3

.

5-4

5-4

.

5-5

.

5-6

.

5-7

.

5-7

.

5-8

.

5-9

.

5-9

.

5-10

.

5-12

.

5-12

.

5-14

.

5-14

.

5-14

.

5-14

5-15

5-15

.

5-16

.

5-16

5-17

.

5-17

.

5-18

.

5-18

5-18

5-19

5-19

5-19

5-20

5-20

Contents-4

Page 13

A.

Choosing

Single

Sw

Dep

B

.

Measurement

Ov

Insertion

Optical

Extinction

P

Settling

P

Nominal

Index

Regular

Hotline

ept

the

w

w

a

a

orders

orders

Scan

v

elength

v

elength

olarization

Considerations

erall

insertion

loss

return

ratio

addle

angle

rep

time

addle rotation

quarter-w

.

.

.

.

.

Rate

PDL

PDL

application

loss

. .

v

ariation

loss .

. .

.

.

.

eatabilit

.

.

.

.

rates

a

v

e

.

.

.

.

.

.

.

.

and

Measurement

measuremen

measuremen

.

.

. .

. .

with paddle

.

.

.

.

.

.

. .

y

.

.

.

.

.

.

.

.

.

.

plates

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ts

.

ts

.

.

.

. .

. .

.

position

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

Time

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

..

.

. .

.

. .

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

. .

. .

..

. .

.

. .

.

.

.

.

.

. .

. .

.

.

.

.

.

.

. .

.

5-20

. 5-20

A-2

.

A

A

.

B-2

.

B-3

.

B-3

.

B-4

.

B-5

.

B-5

.

B-5

B-5

-3

-4

Contents-5

Page 14

Figures

1-1.

1-2.

1-3.

1-4.

1-5.

1-6.

1-7.

1-8.

2-1. Checking

5-1. Agilent

B-1. Block

Typical application

polarization

Setup for

optical

Setup for

optical

Example

Setup

of

for

Example of

Agilent

Example

11896A

of

controller.

single-wavelength PDL

power meter

swept-wavelength PDL

spectrum

swept-wavelength

single-wavelength

max/min

polarization

a

static-safe

the fuse

11896A assembly

diagram for

11896A. .

..

setup

analyzer

PDL

..

.

testing

.

.

using

the

.

.

. .

.

.

.

PDL

max/min

measurement

controller

work

station. .

.

.

.

.

level

replaceable

the

extinction

.

.

.

.

Agilent

.

.

.

.

.

measurements

.

.

.

.

.

.

measurements

.

.

.

.

.

.

test

data.

PDL

measurements

data.

block

..

.

.

.

.

.

.

parts

ratio

.

.

.

.

.

.

11896A

.

.

.

using

.

.

using

.

.

.

.

.

diagram.

..

.

.

.

of

the

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Agilent

.

.

.

.

.

an

an

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

1-3

.

1-5

.

1-6

.

1-7

.

1-8

.

1-9

.

1-10

.

1-16

2-5

.

5-21

B-4

Contents-6

Page 15

T

ables

1-1.

Performance

1-2.

Static-Safe A

2-1.

Accessories

2-2.

Agilent 11896A

2-3.

AC

Power

4-1.

Standard

4-2.

Standard

4-3.

Service

4-4.

Status Byte

4-5.

Error

Messages

5-1.

Agilent

5-2. Required

5-3. Assembly-Level

A-1.

Selecting A

Specications

ccessories

Supplied with

Power

Cables

Event

Event

Request

Status

Status

Enable

Register

T

echnologies

Tools

Replaceable P

veraging

Requirements

A

vailable

Enable

Register

.

.

.

.

Service

..

.

Time

.

.

.

.

the

.

Register

.

.

.

.

.

.

Numbers

.

.

.

,

Scan

.

.

.

.

.

.

Agilent

.

.

.

Register

.

.

.

.

.

.

.

.

.

.

.

.

arts

.

Rate

.

.

.

.

.

.

.

.

11896A

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

and

Measurement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

1-12

.

.

.

.

.

.

1-17

.

.

.

.

.

.

2-3

.

.

.

.

.

.

2-4

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

Time

2-7

.

4-20

. 4-21

.

4-24

.

4-25

.

4-33

.

5-13

5-16

.

5-21

.

A

-3

Contents-7

Page 16

Contents

Page 17

1

General

Information

Page 18

General

What

you'll nd

A

description

A

list

of

options and

Agilent

11896A

Information

Information

Information

in this

chapter

of

the Agilent

11896A polarization

accessories available

polarization

about

about

the

avoiding

controller

controller's

damage

serial

to

.

specications

number

label.

the

controller

controller.

and characteristics.

from

electrostatic

discharge

.

1-2

Page 19

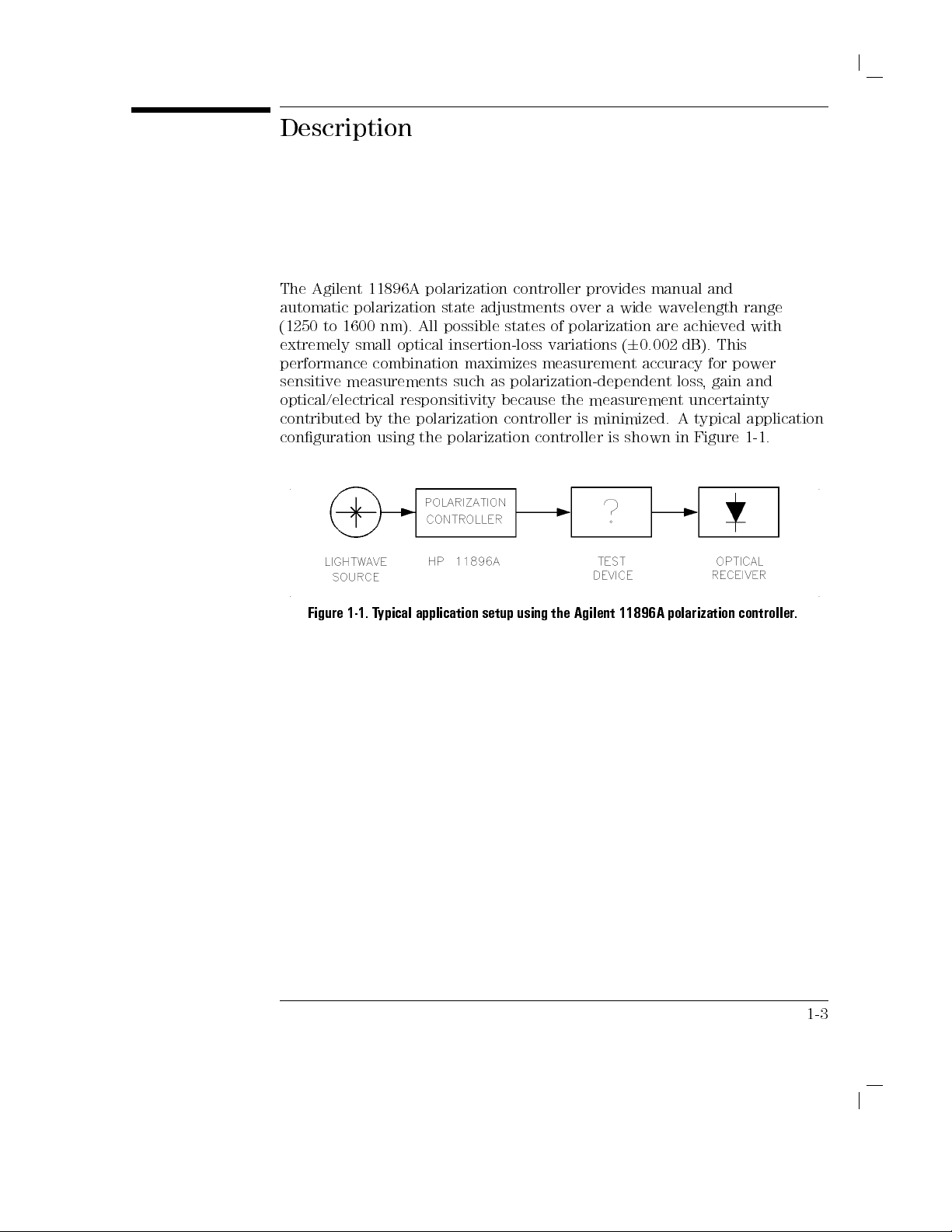

Description

The

Agilent 11896A

automatic

(1250

extremely

performance

sensitive

optical/electrical

contributed

conguration

polarization state

to 1600

nm). All

small optical

combination maximizes

measurements

responsitivity

by

the

using the

polarization

controller

adjustments

possible

states

insertion-loss variations

such

as

polarization-dependent

because

polarization

polarization

controller

controller

provides

over

of

polarization

a

wide

(

6

0.002

manual

wavelength

are

achieved

dB).

measurement accuracy

loss

the

measurement

is

minimized.

is

shown

uncertainty

A

in

and

This

for

,

gain

typical

Figure

range

with

power

and

application

1-1

.

Figure

1-1.

T

ypical

application

setup

using

the

Agilent

11896A

polarization

controller

.

1-3

Page 20

General

Information

Description

Instrument conguration

Options

Accessories

The standard

FC/PC

A

The

front-panel connector

gilent

11896A

following

Option

Option

Option

The

010

025

Fiber

Optics

introduction

Agilent 11896A

User

,

Programming,

options are

Description

Deletes

One

meter

Handbook

to

,

and

a

reference

polarization

interfaces

available:

FC/PC

front-panel

pigtail

(Agilent part

for

,

controller

and

Service

connector

ber

with

FC/PC

number 5952-9654)

ber-optic

measurements

includes:

Guide

interfaces

connector

is

an

.

.

interfaces

.

1-4

Page 21

General

Information

Description

P

ower

meter

measurement

PDL

system

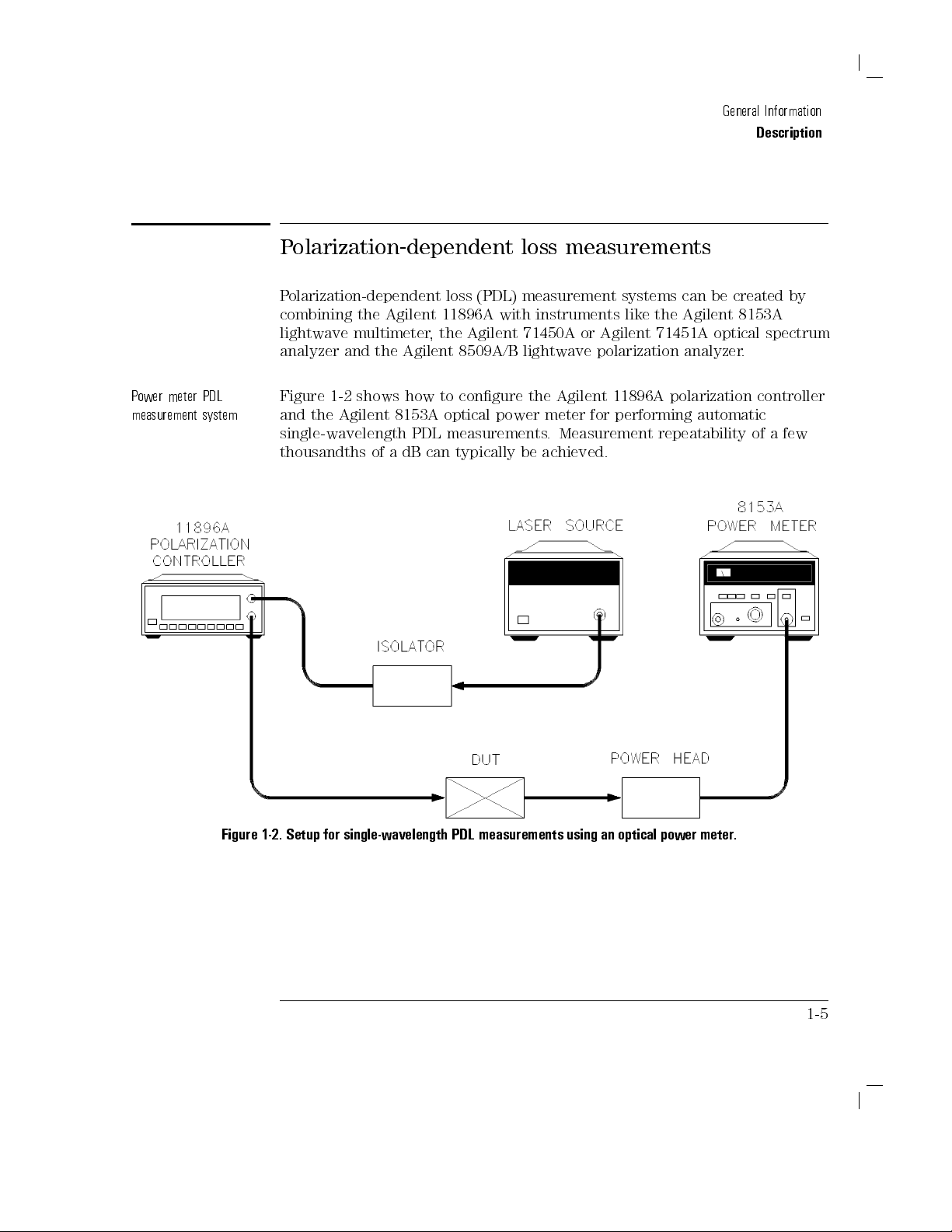

Polarization-dependent

Polarization-dependent

combining the

Agilent 11896A

lightwave multimeter

analyzer and

Figure

and

the Agilent

the

1-2 shows

8153A optical

single-wavelength

thousandths

of

a

, the

Agilent

how to

PDL

dB

can

loss (PDL)

with instruments

Agilent 71450A

8509A/B

congure the

power

measurements

typically

loss measurements

measurement

lightwave

Agilent

meter

.

Measurement

be

achieved.

systems

like

or

Agilent

polarization

11896A

for

performing

can

the

Agilent

71451A

analyzer

polarization

automatic

repeatability

be

created

8153A

optical

.

by

spectrum

controller

of

a few

Figure

1-2.

Setup

for

single-wavelength PDL

measurements

using

an

optical

power

meter

.

1-5

Page 22

General

Information

Description

Swept-wavelength

measurement

Figure

system

SWPTW

Figure

PDL

Figure

and

the Agilent

swept-wavelength

A

VE

here

.

1-3.

Setup

for

1-3 shows

how to

71451A optical

PDL measurements

swept-wavelength

congure the

PDL

measurements

Agilent

11896A

spectrum analyzer

.

using

an

optical

polarization

for

performing

spectrum

analyzer

controller

automatic

.

1-6

Page 23

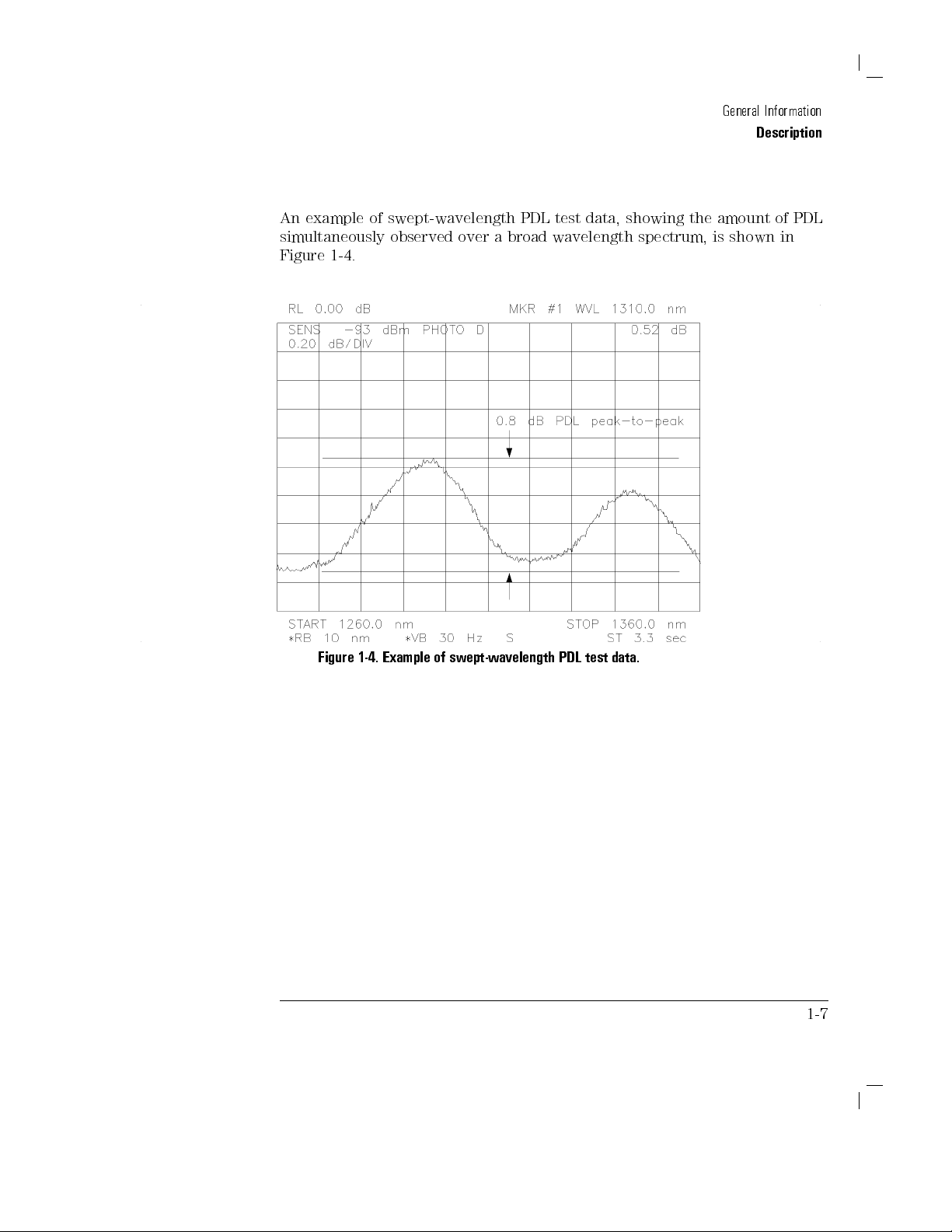

An

example

of

simultaneously

Figure

1-4

.

swept-wavelength

observed

over

a

PDL

broad

test

data,

wavelength

showing

spectrum,

the

General

amount

is

shown

Information

Description

of

PDL

in

Figure

1-4.

Example

of

swept-wavelength

PDL

test

data.

1-7

Page 24

General

Information

Description

Max/min

PDL

measurement

system

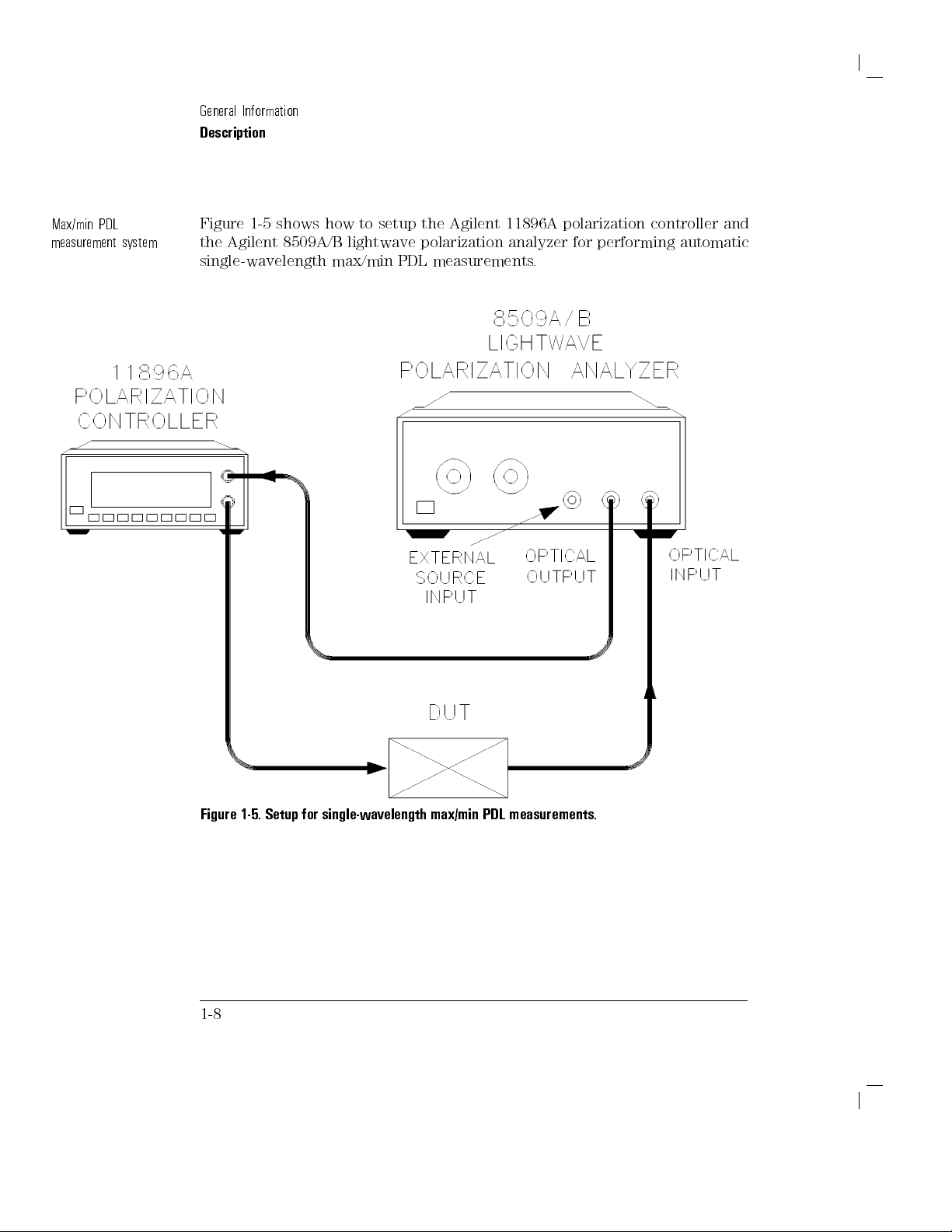

Figure

the

1-5 shows

Agilent 8509A/B

single-wavelength

how to

setup the

lightwave polarization

max/min PDL

measurements.

Agilent

11896A

polarization

analyzer for

controller

performing

and

automatic

Figure 1-5.

1-8

Setup for

single-wavelength

max/min

PDL

measurements.

Page 25

An

example

states

on

the

values

of

of

polarization

P

oincare

actually

max/min

are

sphere

occur

during

PDL

measurement

displayed

at

the

the

as

Stokes

points

where

measurement.

data

is

shown

parameters

maximum

and

and

General

in

Figure

PDL

minimum

Information

Description

1-6

.

The

markers

power

Figure

1-6.

Example

of

max/min

PDL

measurement data.

1-9

Page 26

Theory

of

Figure

The

transmitted signal

the

internal four-ber-loop

optimized

polarization

polarization

over

(000{999),

made

GPIB

RECALL

to

approximate

controller's

adjustability

an

angular

providing

manually

commands

registers

range

,

using

or

Operation

1-7.

Agilent

11896A polarization

enters the

assembly.

a quarter-wave

specied

is

achieved

.

This

180

front-panel

autoscanning

the

of

an

the

built-in

adjustment

.

controller block

polarization

The

controller

dimensions

retarder

wavelength range

by independently

range

is

divided

resolution

knobs

of

0.18

,

or

automatically

control

and

of

each

response

.

Complete

adjusting

into

.

A

and

the

diagram.

passes

loop

over

the

and

each

1000

equal

djustments

,

using

S

A

VE

through

are

continuous

loop

steps

can

be

remote

and

1-10

Page 27

Specications

This

section contains

Agilent

apply

All

after

Fiber

11896A polarization

over the

temperature range

specications apply

1 hour

continuous operation

pigtail

interfaces

stated.

and

Characteristics

specications

controller

after the

are

instrument's

assumed

and

characteristics

.

The

C

to +55

0

and

self-calibration

for

all

specications

C

(unless otherwise

temperature

cases

,

except

for

the

in

has

routines

where

this

chapter

been

have

otherwise

noted).

stabilized

been

run.

Specications

Characteristics

Calibration

cycle

Specications

Characteristics

functions

italics

Agilent

and performance

.

Technologies

recommended

periodic

Agilent

T

echnologies

recalibrations

11896A

describe

provide

calibration

polarization

service

warranted performance

useful,

warrants

are

facility

but

of

the

instrument

interval.

necessary

controller

every

nonwarranted,

instrument.

T

o

maintain

.

W

e

be

24

months

.

information

Characteristics

specications

specications

recommend

calibrated

.

at

that

an

over

the

Agilent

are

the

,

about

printed

the

in

1-11

Page 28

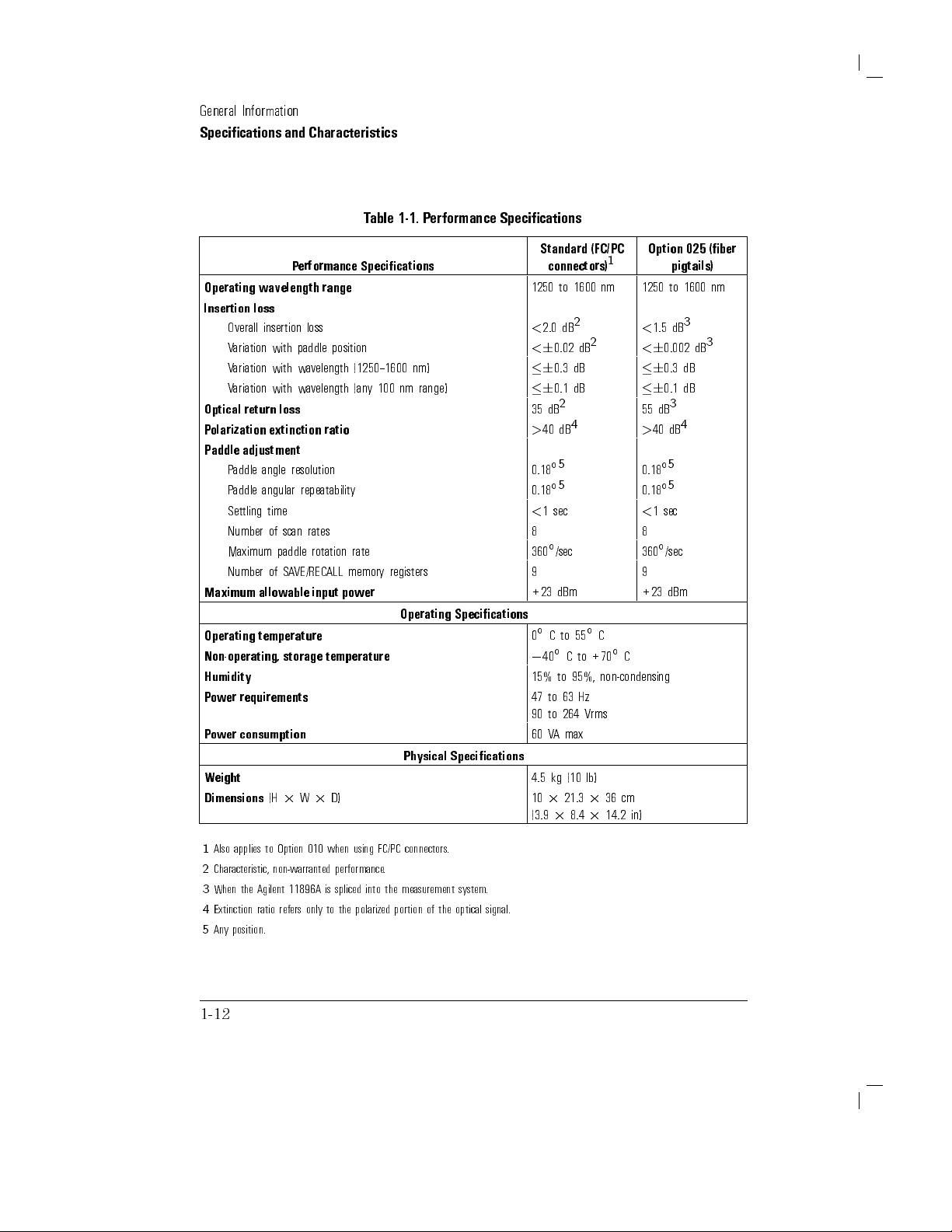

General

Information

Specications and

Characteristics

T

able

1-1.

P

erformance

Specications

Operating

Insertion

Overall

wavelength

loss

insertion

Variation

V

ariation

V

ariation

Optical

return

P

olarization

Paddle

adjustment

P

addle

angle

P

addle angular

Settling

time

Number

Maximum

Number

Maximum

Operating

allowable

temperature

Non-operating,

Humidity

P

ower

requirements

P

ower

consumption

Weight

Dimensions

P

erformance

loss

with paddle

with

wavelength

with

wavelength

loss

extinction

resolution

repeatability

of

scan

rates

paddle

of

SA

VE/RECALL

storage

(H

2

W

range

position

ratio

rotation

memory

input

power

temperature

2

D)

Specications

(1250{1600

(an

y

100

nm

rate

registers

Operating

Physical

nm)

range)

Specications

Specications

Standard

connectors)

1250

to

<

2.0

<

6

0.02 dB

6

0.3

6

0.1

2

35

dB

>

40

dB

5

0.18

5

0.18

<

1

sec

1600 nm

2

dB

dB

dB

4

(FC/PC

2

Option

1

1250

to

<

1.5

<

6

0.002 dB

6

0.3

6

0.1

55

dB

>

40

dB

5

0.18

5

0.18

<

1

sec

8 8

360/sec 360/sec

9 9

+23

0C

0

15%

47

90

60

4.5

10

(3.9

40

to

to 264

V

A

kg

2

2

dBm

to

55

C

to

to 95%,

63

Hz

max

(10

21.3

8.4

+70

Vrms

lb)

2

2

+23

C

C

non-condensing

36

cm

14.2

in)

dBm

025

pigtails)

1600 nm

3

dB

dB

dB

3

4

(ber

3

1

Also applies to Option 010 when using FC/PC connectors.

2

Characteristic, non-warranted

3

When the Agilent 11896A is spliced into the measurement system.

4

Extinction ratio refers only to the polarized portion

5

Any position.

performance.

of the optical signal.

1-12

Page 29

Specications and

General

Information

Characteristics

1-13

Page 30

Serial

Numbers

Agilent

their

T

echnologies service

changes

Whenever

have

complete

to

the

parts:

ve

Technologies

performance,

to each

you contact

the

complete

and

accurate

the

rear

of

the

options installed

the

prex

numbers).

Whenever

type of

obtain information

including the

full prex

makes

usability

personnel have

equipment,

Agilent T

serial

number

information

polarization

in

the

(the

rst

four

you

about your

and

frequent

,

or

reliability

based

echnologies

available

possible

controller

polarization

numbers

refer

to

controller,

sux.

improvements

,

and

to

access

on

to

the

complete

about

to

ensure

.

A

serial-number

.

It

contains

controller

and

a

letter),

the serial

be

number when

sure

to

its

products

control

costs

records

equipment's

your

polarization

obtaining

the

serial

.

The

serial

and

the

to

use

the

to

.

Agilent

of

design

serial

the

most

label

is

number

number

sux

using it

complete

enhance

number

controller

attached

and

has

two

(the

last

to

number

.

,

,

1-14

Page 31

Electrostatic

Discharge

Information

Electrostatic

All

work on

station.

types

of ESD

Conductive table-mat

Conductive

Both

types

Of

the two

ESD

protection

accessories must

W

A

N

I

N

G

These techniques

working

discharge (ESD)

electronic

Figure 1-8

protection:

oor-mat

,

when

,

only

the

when

provide at

on

circuitry with

assemblies

shows an

and wrist-strap

and

used

together

table-mat

used

for a

static-safe

can

damage

should

example

heel-strap

,

provide

and

alone

.

least

1

a

voltage

or

be

of

a

combination.

combination.

a

wrist-strap

To

ensure user

M

of

isolation

work

station

potential

destroy

performed

static-safe

signicant

combination

safety,

from

should

greater

electronic

at

a

static-safe

work

station

level

of

provides

the

ground.

not

than

components

using

ESD

protection.

static-safe

be

used

500

volts

.

work

two

adequate

when

.

1-15

Page 32

General

Information

Electrostatic Discharge

Information

1-16

Figure

1-8.

Example

of

a

static-safe

work

station.

Page 33

General

Information

Reducing ESD

The following

testing and

Before

time each

suggestions may

servicing operations

connecting any

day

damage

coaxial cable

,

momentarily

help

.

ground

reduce

to

the

cable.

P

ersonnel

touching

assembly

Be

sure that

buildup of

T

able

1-2 lists

T

echnologies

Agilent

should

the

from

be

center

the

all instruments

static charge

static-safe accessories

using the

Part

grounded

pin

of

any

unit.

.

Agilent part

T

able

with

connector

are

1-2.

Static-Safe

a

resistor-isolated

properly

that

numbers

Number Description

9300-0797 Set

9300-0980 Wrist-strap

wire

includes:

.

(The

3M

static

wrist-strap

cord

1.5

m

control

and

(5

mat

wrist-strap

ft).

0.6

cord

ESD

damage

an

instrument

center

and

and

before

earth-grounded

can

be

obtained

shown.

Accessories

m

2

1.2

m

(2

are not

included. The

outer

removing

ft

2

4

that

occurs

connector

conductors

wrist

strap

to

prevent

from

Agilent

ft)

and

4.6

y

must

be

for

any

cm

(15

ordered

during

the

of

before

a

ft)

ground

separately

rst

the

.)

9300-1383 Wrist-strap

post-type

9300-1169 ESD

heel-strap

,

color

black,

connection.

(reusable

stainless

6

to

12

steel,

months).

without

cord,

has

four

adjustable

links

and

a

7

mm

1-17

Page 34

General

Information

Page 35

2

Installation

Preparation for Use

and

Page 36

Installation

What

Preparing

T

Making

you'll nd

urning

the

polarization

on

the controller

ber

optic

in this

connections.

and Preparation

chapter

controller for

.

use.

for Use

2-2

Page 37

Preparing

the

P

olarization Controller

for Use

Initial

Inspect

container

that

mechanically

polarization

Notify

the

the

Check"

the

of

K

eep

T

echnologies

a

claim

them

to

another

\How

P

ower cable

inspection

the

Agilent

or

the

contents

controller

the

carrier

contents

verication

in

shipping

stress

.

the

shipping

settlement.

for

possible

location

to

Return

cushioning

Chapter

11896A shipping

are

and

electrically

if:

are

incomplete

test

5).

container

materials

oce

will

If

future

or

the

Agilent

Table

2-1. Accessories

material

complete

.

(this

is

arrange

the

shipping

use

return

Description Agilent

is

damaged, keep

and

you

.

T

able

or

if

the

procedure

damaged

for

the

for

repair

materials

.

Y

ou

may wish

it

to Agilent

11896A

Supplied with

See

container for

have

tested

2-1

lists

the

polarization

is

provided

or

the

cushioning

carrier's

inspection.

or

replacement without

are

to ship

Technologies

for

Service

Part

Number

Table

2-3

damage.

it until

the

accessories

controller

in

\P

in good

the

"in

Chapter 5.

the Agilent

Shipped

If the

shipping

you

have

polarization

shipped

does

not

erforming

material

The

a

shows

Agilent

V

waiting for

condition, retain

polarization

for service

. Refer

11896A

Comments

with the

polarization

veried

erication

controller

controller.

Operating and service manual 11896-90001 Shipped with the polarization

controller.

controller

with

the

pass

signs

to

2-3

Page 38

Installation

and

Preparing the

Preparation

Polarization

for

Use

Controller

for

Use

CA

Connecting the

The polarization

installation other

U

T

I

O

N

Do not

correct and

connect ac

the

proper

Agilent 11896A

controller is

a

than connection

power until

fuse

you

is

installed.

portable

to

a

have

to

instrument

power

source

veried

Damage

a

that

to

and

the

power

requires

.

the

line

equipment

source

no

physical

voltage

could

is

result.

P

ower

requirements

T

able

2-2.

Agilent

11896A

P

ower

Requirements

Characteristic Requirement

Input

Frequenc

P

ower

V

oltage

y

90

47

60

to

264 Vrms

to

63

VA

(maximum)

Hz

Checking the

The recommended

The

line

fuse is

Figure 2-1). The spare fuse is stored below the line fuse

fuse

fuse is

housed

in

a

a

2

A,

small

250

V

,

container

Agilent

in

part

the

number

line

2110-0710.

module

.T

(refer

o check the fuse

insert the tip of a screwdriver between the instrument and the side of

the

container. Gently pull outward to remove the container

defective or missing, install a new fuse in the proper position

fuse container

.

. If the fuse is

and reinsert the

2-4

to

,

Page 39

Preparing the

Installation

Polarization

and

Preparation

Controller

for

for

Use

Use

Figure

2-1.

Power

cable

The polarization

accordance with

controller is

equipped with

international safety

Checking

the

a

standards.

fuse.

three-wire

power

When connected

cable

to an

,

in

appropriate power line outlet, this cable grounds the instrument cabinet.

2-5

Page 40

Installation

Preparing the

F

W

A

R

N

I

NG

ailure

personal

connect

the

socket

earth-grounding

autotransformer

an

protective

V

arious

the

appropriate

shipped

for

illustrates

each

and

Preparation

Polarization

to

ground

injury

.

Before

its

protective

main

power

outlet

cable

that

protection

without

autotransformer

earth

contact

types

use

cable

power

in

of

ac

for

is

included

dierent

the

is

appropriate

cables

power

the

plug

for

Use

Controller

the

polarization controller

earth

.

has

a

,

make sure

are

outlets

area

with

areas

congurations

for

turning

terminals

Insert

the

protective

by

a

protective

of the

available

unique

to

which

the

unit.

.

T

able

Use

on

main power

using

its common

power source

to

the

Y

2-3

,

and

.

properly can

the

polarization controller

to

the

protective conductor

cable plug

earth

contact. DO

an

extension

ground

cable

conductor

terminal is

outlet socket.

connect

to

polarization

ou

can

lists the

identies

the

polarization

specic

geographic

controller

order additional

available ac

the

result in

only into

NOT defeat

,power

.

If you

connected to

areas

is

ac power

power cables

geographic

,you

must

of

a

the

cable,

are using

controller

.

The

originally

cables

,

area in

or

the

to

cable

which

2-6

Page 41

T

able

2-3.

AC

P

ower

Preparing the

Cables

A

vailable

Installation

Polarization

and

Preparation

Controller

for

for

Use

Use

2-7

Page 42

Turning

With

the

power

controller

moment,

refer

on by

numerals appear

to

\P

erforming

on

cable

rocking

the

Agilent 11896A

inserted

a

V

erication

the

front-panel

on the

into

the

front-panel

Check"

line

switch

in

module

to

LCD

Chapter

the

.

,

If

turn

\1"

the

5.

the

polarization

position.

LCD

fails

After

to

a

light,

2-8

Page 43

Lightwave

Introduction

Connector

Care

Lightwave

connection

nonrepeatable

best

Lightwave

connections

sources

or

components

Fiber

and

combinations

of

cables

cable

practices

,

receivers

optic

in

dierent

do

interfaces

procedures

or

inaccurate

to

clean,

connectors

may

be

used

,

patch

.

cables

are

environments

,

jackets

not

work

.

,

well

Dirty

care

are

used

and

can be

for

used

to

join

panels

at

indexes

together

damaged by

or

damaged lightwave

measurements

,

connect,

to

cables

,

terminals

dierent

.

There

.

connect

between

wavelengths

are

of

refraction.

Cables

and

a

improper cleaning

interfaces can

.

This

section

inspect

two

ber

lightwave

ends

optical

and

many

other

,

in

variety

should

of

In

general,

match

sizes

will

suggest

together

ports

on

types

single

or

,

core/cladding

dierent

each

other

and

result

some

connectors

.

These

devices

of

,

systems

multi-mode

types

and

in

.

laser

the

system.

However

to

to

repeatability

Lightwave connectors

connectors.

small ber

less in

microns

,

provide

another

diameter,

in

regardless

a

direct

.

When

becomes

In a

ber optic

core.

Because ber

and dust

diameter

of

and

these

,

dust

an

the

cable

type

low-loss

optical

connectors

important

dier from

system, light

cores are

particles range

and

very

,

the connectors

signal

transition from

are used

factor

in a

.

electrical or

is

transmitted

often

from tenths

minute

contamination

have only

one ber

measurement system,

microwave

system

through

62.5

microns

of a

(0.0625

micron

on

the end

one

function:

an

extremely

mm)

to

several

of

end

or

the

ber core can degrade the performance of the connector interface (where the

two cores meet). Therefore

connector

interface free of trapped foreign material.

, the connector must be precisely aligned and the

,

Connector (or

of a lightwave

insertion) loss is one important performance characteristic

connector.

Typical values are less than 1 dB of loss

,and

sometimes as little as 0.1 dB of loss with high performance connectors

.

2-9

Page 44

Installation

and

Preparation

Lightwave Connector

Care

for

Use

Return

loss

reection

The

best

40

dB

,

although

Causes

of

dierences

reections

use

and

removal

A

chieving

(no

air

gap)

1.

the

type

2.

using

lossy

or

is

not

be

less

dierence

is

another

the

better

physically

20

connector

in

the

caused

the

best

and

properly

of

connector

the

proper

reective

smooth

accurate

in

optical

important

(the

contacting

to

30

loss

numerical

by

damaged,

of

index

possible

.

cleaning

,

light

or

the

connection

.

F

or this

measurement

factor

larger

the

return

connectors

dB

is

more

common.

and

reections

aperture

worn,

matching

compounds

connection,

aligned,

will

and

connecting

not

depends

make

is

reason, lightwave

.

It

is

loss

have

include

of

two

or

loose

where

on

a

smooth

not

repeatable

systems

a

measure

,

the

smaller

return

core

bers

,

spacing

ber

ends

.

the

ber

two

things:

techniques

transition.

,

connections

.

of

reection:

the

reection).

losses

better

misalignment,

and

air

,

and

the

end

faces

.

If

the

connection

If the

measurement

can

make

the

less

than

gaps,

improper

are

ush

transition

data will

a

critical

is

2-10

Page 45

Installation