AEROFLEX UT80CRH196KD DATA SHEET

查询5962R9858301QXA供应商

Standard Products

UT80CRH196KD Microcontroller

Datasheet

September, 2002

FEATURES

q 20MHz 16-bit Microcontroller compatible with industry

standard’s MCS-96 ISA

- Register to Register Architecture

- 1000 Byte Register RAM

q Three 8-bit I/O Ports

q On-board Interrupt Controller

q Three Pulse-Width Modulated Outputs

q High Speed I/O

q UART Serial Port

q Dedicated Baud Rate Generator

q Software and Hardware Timers

- 16-Bit Watchdog Timer, Four 16-Bit Software Timers

- Three 16-Bit Counter/Timers

q Radiation-hardened process and design; total dose

irradiation testing to MIL-STD-883 Method 1019

- Total-dose: 100K rads(Si)

- Effective LET threshold: 25 MeV-cm2/mg

- Saturated cross section: 3.66e-7cm2/bit

- Latchup immune (LET > 128 MeV-cm2/mg)

q Error detection and correction for external memory accesses

q QML Q and QML V compliant part

INTRODUCTION

The UT80CRH196KD is compatible with industry standard’s

MCS-96 instruction set. The UT80CRH196KD is supported

by commercial hardware and software development tools.

Built on UTMC’s Commercial RadHardTM epitaxial CMOS

technology, the microcontroller is hardened against ionizing

dose and charged particles. The microcontroller’s on-board

1000 byte scratch-pad SRAM and flip-flops can withstand

charged particles with energies up to 25 MeV-cm2/mg.

The UT80CRH196KD accesses instruction code and data via

a 16-bit address and data bus. The 16-bit bus allows the

microcontroller to access 128K bytes of instruction/data

memory. Integrated software and hardware timers, high speed

I/O, pulse width modulation circuitry, and UART make the

UT80CRH196KD ideal for control type applications. The

CPU’s ALU supports byte and word adds and subtracts, 8 and

16 bit multiplies, 32/16 and 16/8 bit divides, as well as

increment, decrement, negate, compare, and logical

operations. The UT80CRH196KD’s interrupt controller

prioritizes and vectors 18 interrupt events. Interrupts include

normal interrupts and special interrupts. To reduce power

consumption, the microcontroller supports software invoked

idle and power down modes. The UT80CRH196KD is

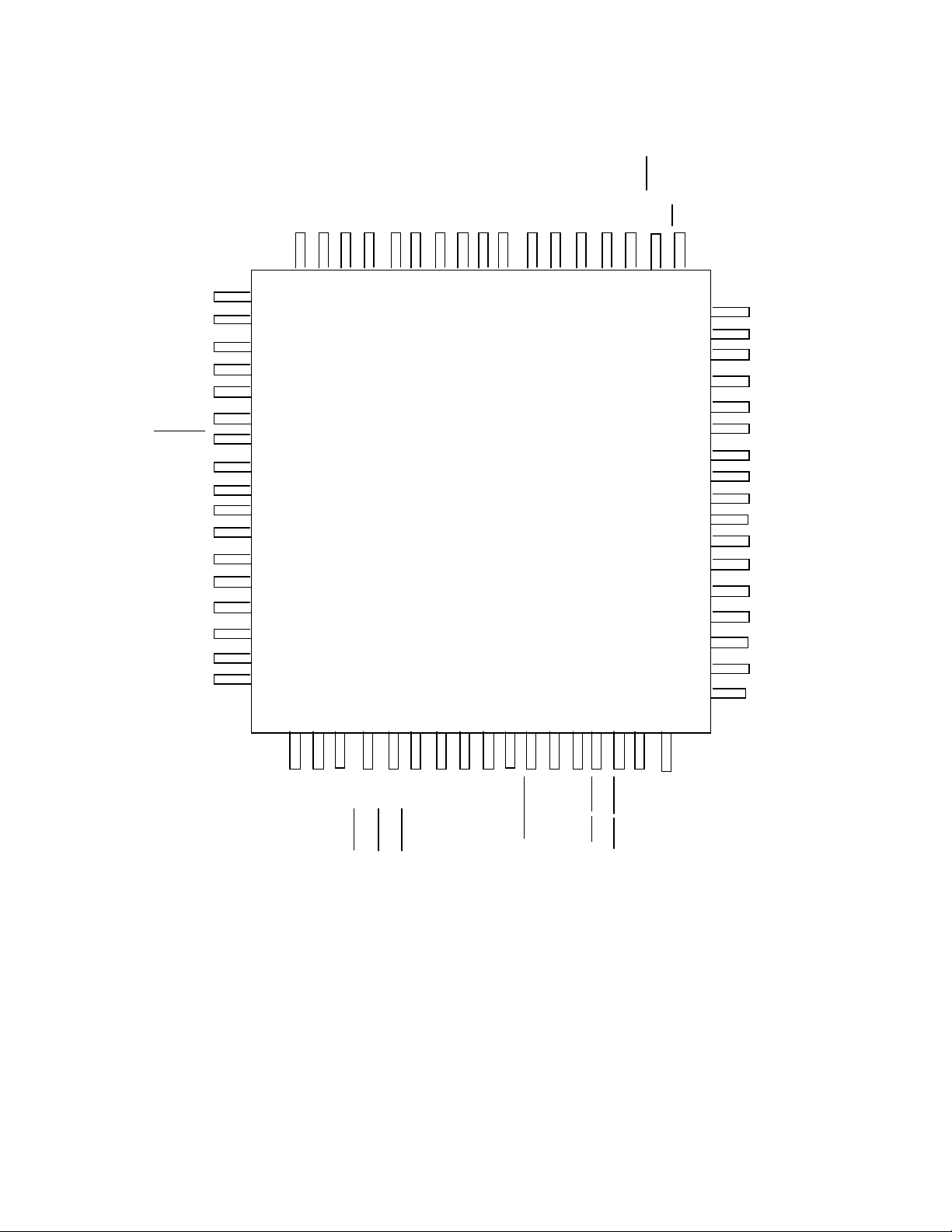

packaged in a 68-lead quad flatpack.

q Standard Microcircuit Drawing 5962-98583

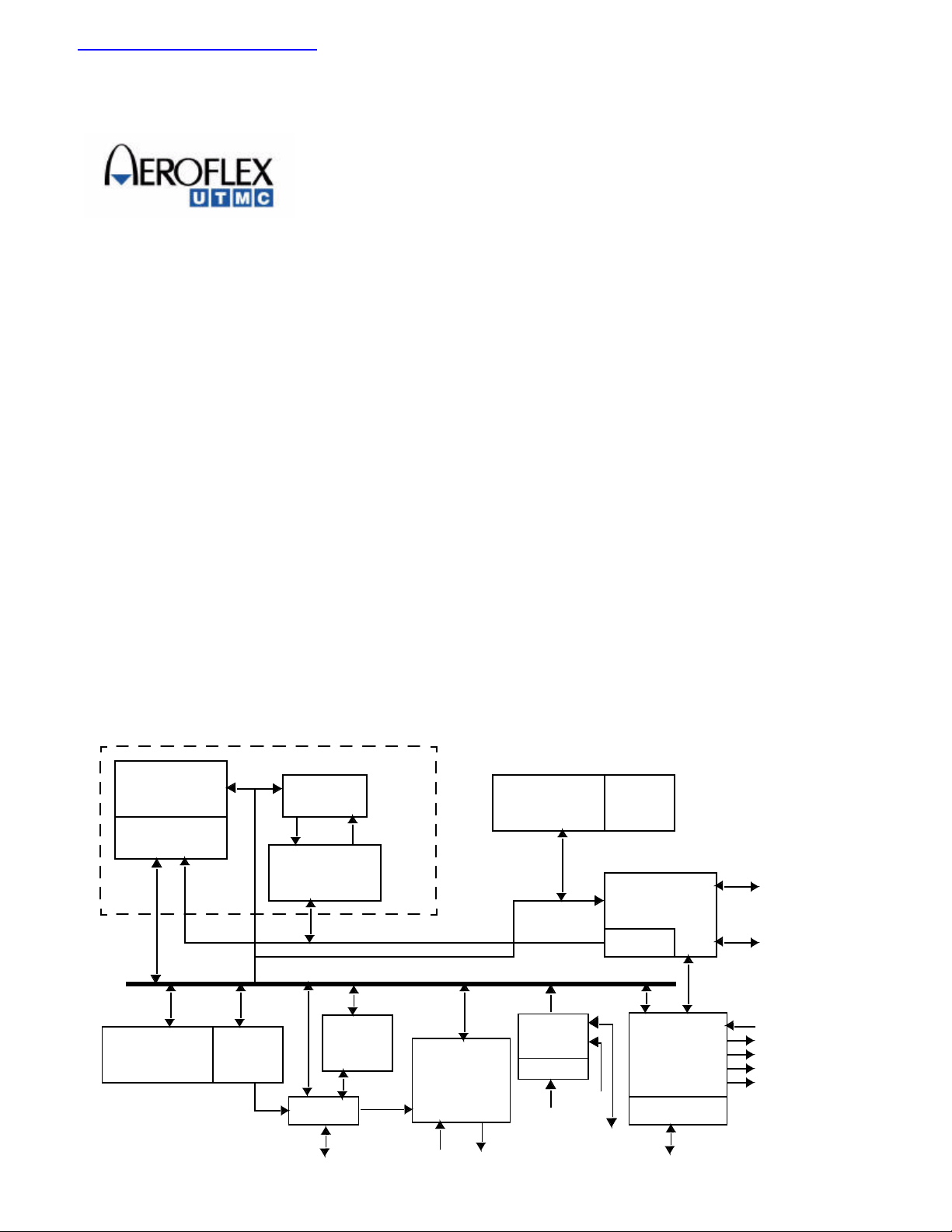

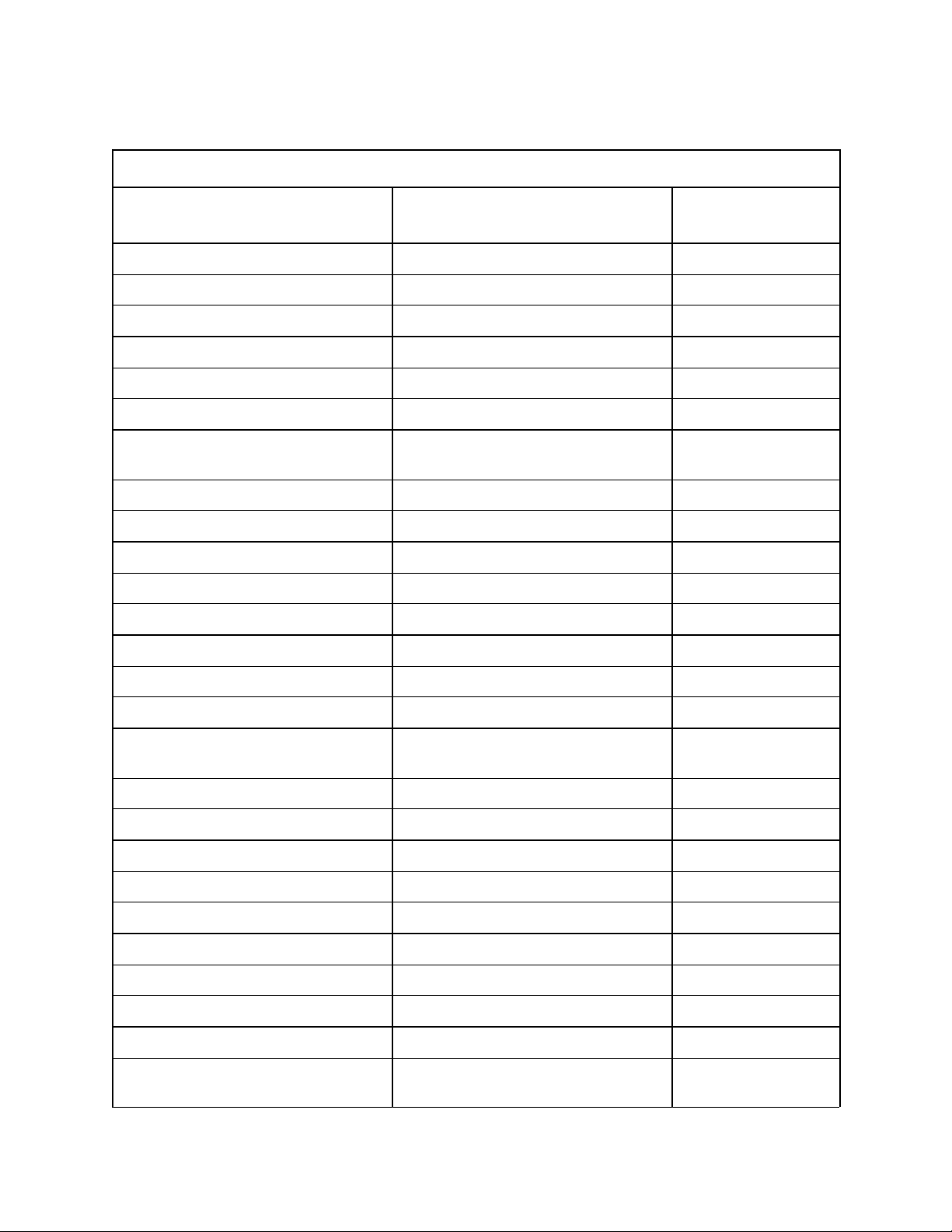

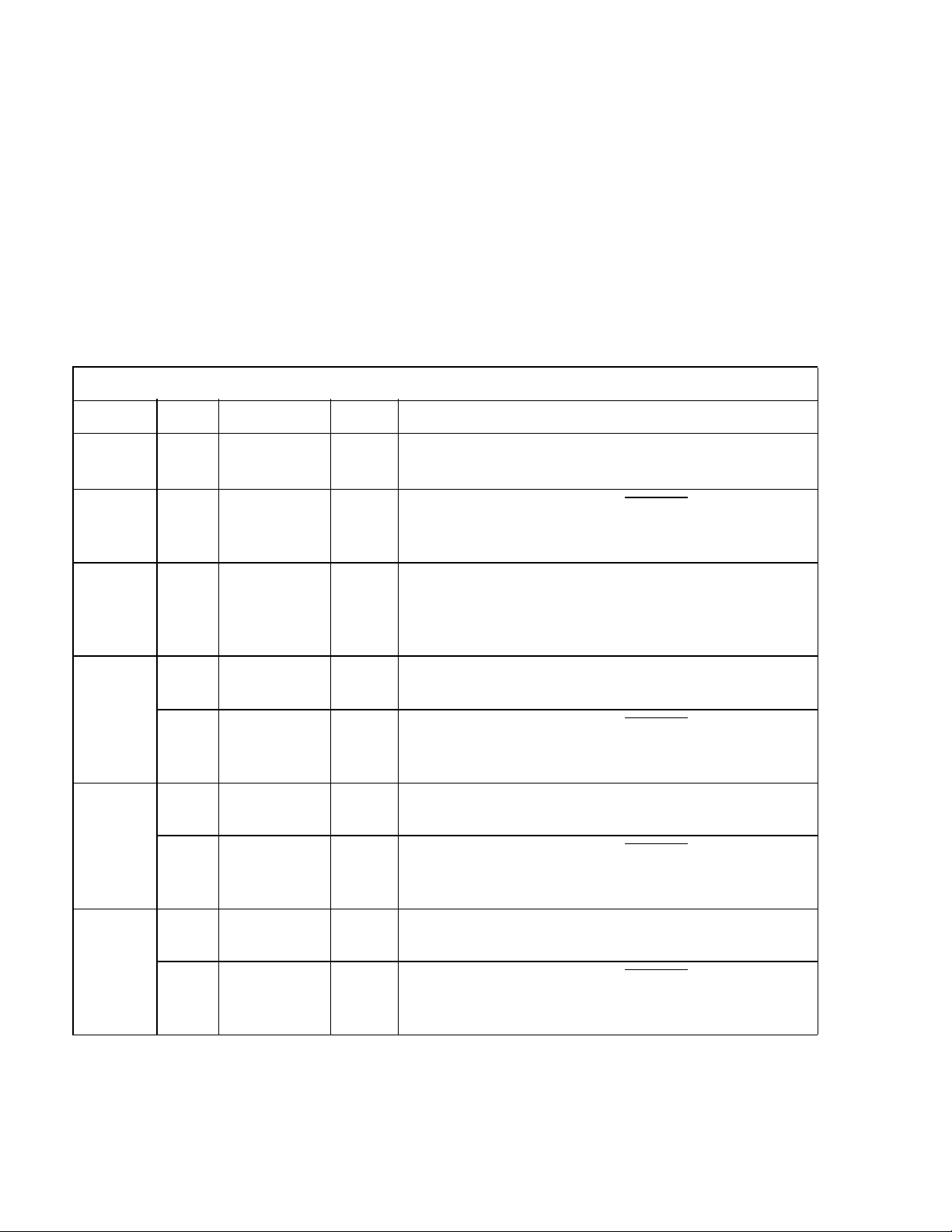

1000 Bytes

RAM

Register File

Watchdog

Timer

PWM

ALU

MicroCode

Engine

Serial

Port

PORT2

Figure 1. UT80CRH196KD Microcontroller

CPU

HSIO and

Timers

HSI HSO

Interrupt

Controller

Alternate

Functions

PORT0

EXTINT

ECB0-

ECB5

PTS

Memory

Controller

Queue

Alternate

Functions

PORT1

s

as

P

t

rs

IP

e

Fi

r

Co

Control

Signals

Address /Data Bus

HOLD

HLDA

BREQ

PWM1

PWM2

1.0 SIGNAL DESCRIPTION

Port 0 (P0.0 - P0.7): Port 0 is an 8-bit input only port when used

in its default mode. When configured for their alternate function,

five of the bits are bi-directional EDAC check bits as shown in

Table 1.

Port 1 (P1.0 - P1.7): Port 1 is an 8-bit, quasi-bidirectional, I/O

port. All pins are quasi-bidirectional unless the alternate

function is selected per Table 2. When the pins are configured

for their alternate functions, they act as standard I/O, not quasibidirectional.

Port 2 (P2.0 - P2.7): Port 2 is an 8-bit, multifunctional, I/O port.

These pins are shared with timer 2 functions, serial data I/O and

PWM0 output, per Table 3.

AD0-AD7: The lower 8-bits of the multiplexed address/data

bus. The pins on this port are bidirectional during the data phase

of the bus cycle.

AD8-AD15: The upper 8-bits of the multiplexed address/data

bus. The pins on this port are bidirectional during the data phase

of the 16-bit bus cycle. When running in 8-bit bus width, these

pins are non-multiplexed, dedicated upper address bit outputs.

HSI: Inputs to the High Speed Input Unit. Four HSI pins are

available: HSI.0, HSI.1, HSI.2, and HSI.3. Two of these pins

(HSI.2 and HSI.3) are shared with the HSO Unit. Two of these

pins (HSI.0 and HSI.1) have alternate functions for Timer 2.

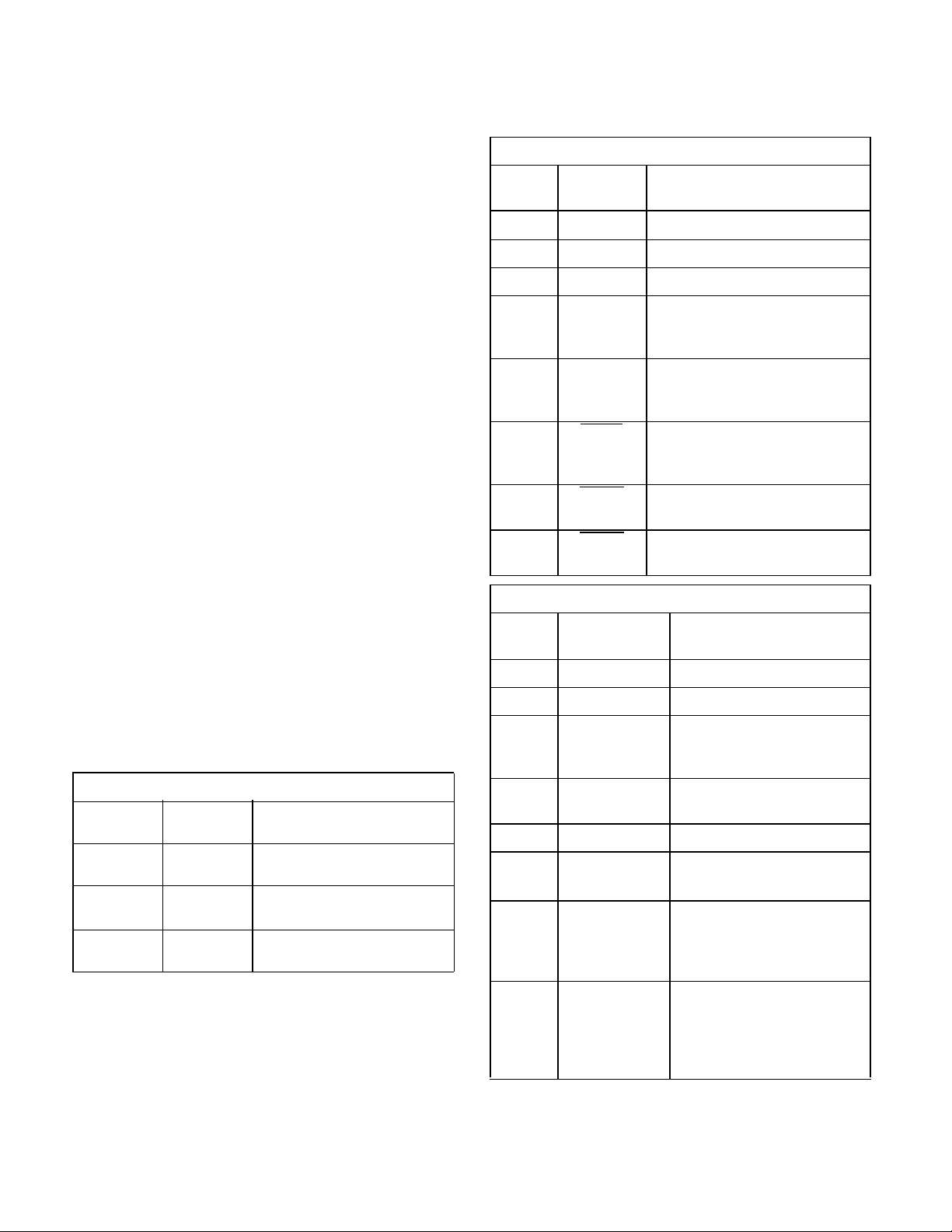

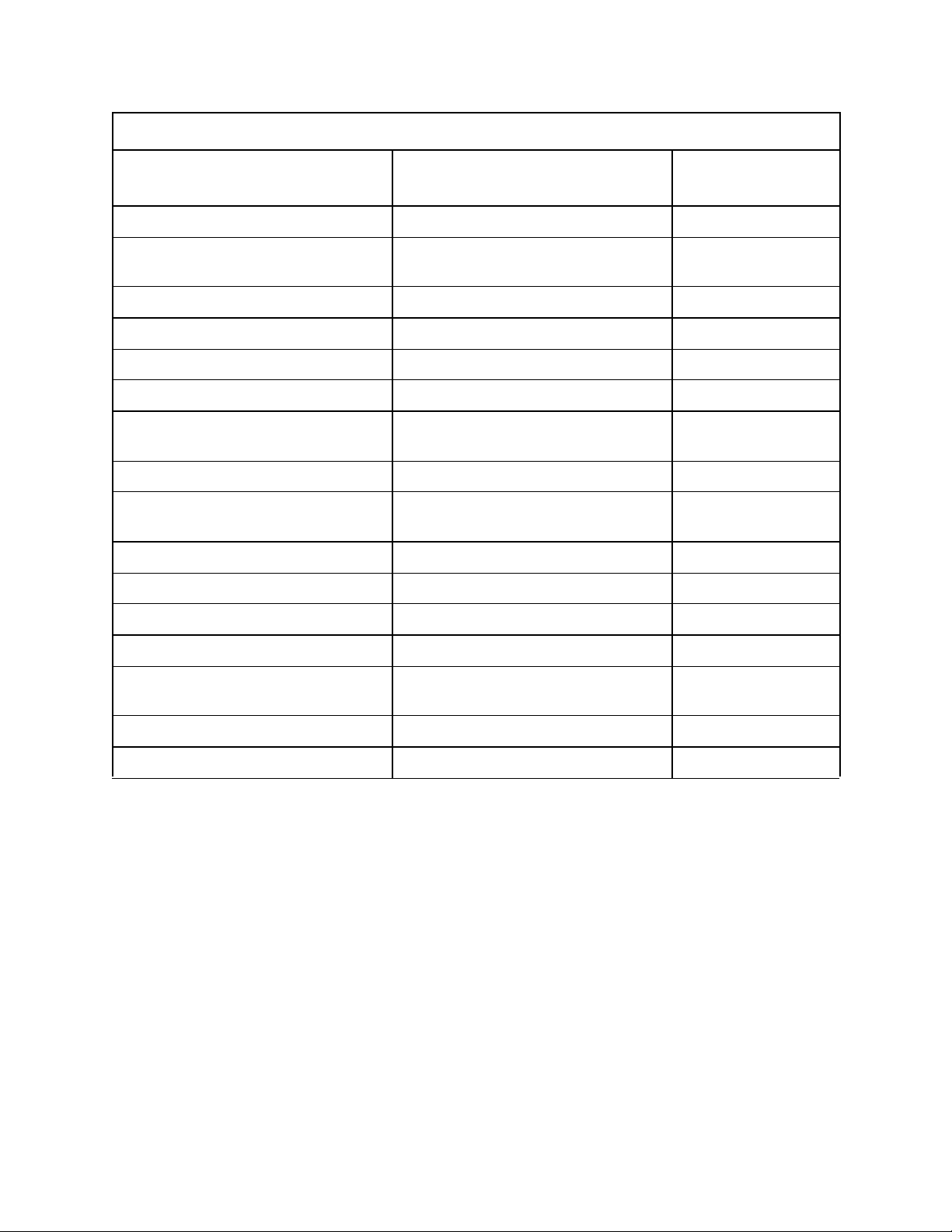

Table 2. Port 1 Alternate Functions

Port

Pin

Alternate

Name

Alternate Function

P1.0 P1.0 I/O Pin

P1.1 P1.1 I/O Pin

P1.2 P1.2 I/O Pin

P1.3 PWM1 Setting IOC3.2=1 enables P1.3 as

the Pulse Width Modulator

(PWM1) output pin.

P1.4 PWM2 Setting IOC3.3=1 enables P1.4 as

the Pulse Width Modulator

(PWM2) output pin.

P1.5 BREQ Bus Request, output activated

when the bus controller has a

pending external memory cycle.

P1.6 HLDA Bus Hold Acknowledge, output

indicating the release of the bus.

P1.7 HOLD Bus Hold, input requesting control

of the bus.

Table 3. Port 2 Alternate Functions

HSO: Outputs from the High Speed Output Unit. Six HSO pins

are available: HSO.0, HSO.1, HSO.2, HSO.3, HSO.4, and

HSO.5. Pins HSO.4 and HSO.5 are shared with pins HSI.2 and

HSI.3 of the HSI Unit respectively.

Table 1. Port 0 Alternate Functions

Port Pin Alternate

P0.0-P0.3,

P0.6

P0.4

P0.5

P0.7 EXTINT Setting IOC1.1=1 will allow P0.7

Name

ECB0-ECB4 Error Detection & Correction

Alternate Function

Check Bits

Input Port Pins

to be used for EXTINT (INT07)

Port

Pin

Alternate

Name

Alternate Function

P2.0 TXD Transmit Serial Data.

P2.1 RXD Receive Serial Data.

P2.2 EXTINT External interrupt. Clearing

IOC1.1 will allow P2.2 to be

used for EXTINT (INT07)

P2.3 T2CLK Timer 2 clock input and Serial

port baud rate generator input.

P2.4 T2RST Timer 2 Reset

P2.5 PWM0 Pulse Width Modulator

output 0

P2.6 T2UP-DN Controls the direction of the

Timer 2 counter. Logic High

equals count down. Logic low

equals count up.

P2.7 T2CAPTURE A rising edge on P2.7 causes

the value of Timer 2 to be

captured into this register, and

generates a Timer 2 Capture

interrupt (INT11).

2

1.1 Hardware Interface

1.1.1 Interfacing with External Memory

The UT80CRH196KD can interface with a variety of external

memory devices. It supports either a fixed 8-bit bus width or a

dynamic 8-bit/16-bit bus width, internal READY control for

slow external memory devices, a bus-hold protocol that enables

external devices to take over the bus, and several bus-control

modes. These features provide a great deal of flexibility when

interfacing with external memory devices.

1.1.1.1 Chip Configuration Register

The Chip Configuration Register (CCR) is used to initialize the

UT80CRH196KD immediately after reset. The CCR is fetched

from external address 2018H (Chip Configuration Byte) after

removal of the reset signal. The Chip Configuration Byte (CCB)

is read as either an 8-bit or 16-bit word depending on the value

of the BUSWIDTH pin. The composition of the bits in the CCR

are shown in Table 4.

There are 8 configuration bits available in the CCR. However,

bits 7 and 6 are not used by the UT80CRH196KD. Bits 5 and 4

comprise the READY mode control which define internal limits

for waitstates generated by the READY pin. Bit 3 controls the

definition of the ALE/ADV pin for system memory controls

while bit 2 selects between the different write modes. Bit 1

selects whether the UT80CRH196KD will use a dynamic 16bit bus or whether it will be locked in as an 8-bit bus. Finally,

Bit 0 enables the Power Down mode and allows the user to

disable this mode for protection against inadvertent power

downs.

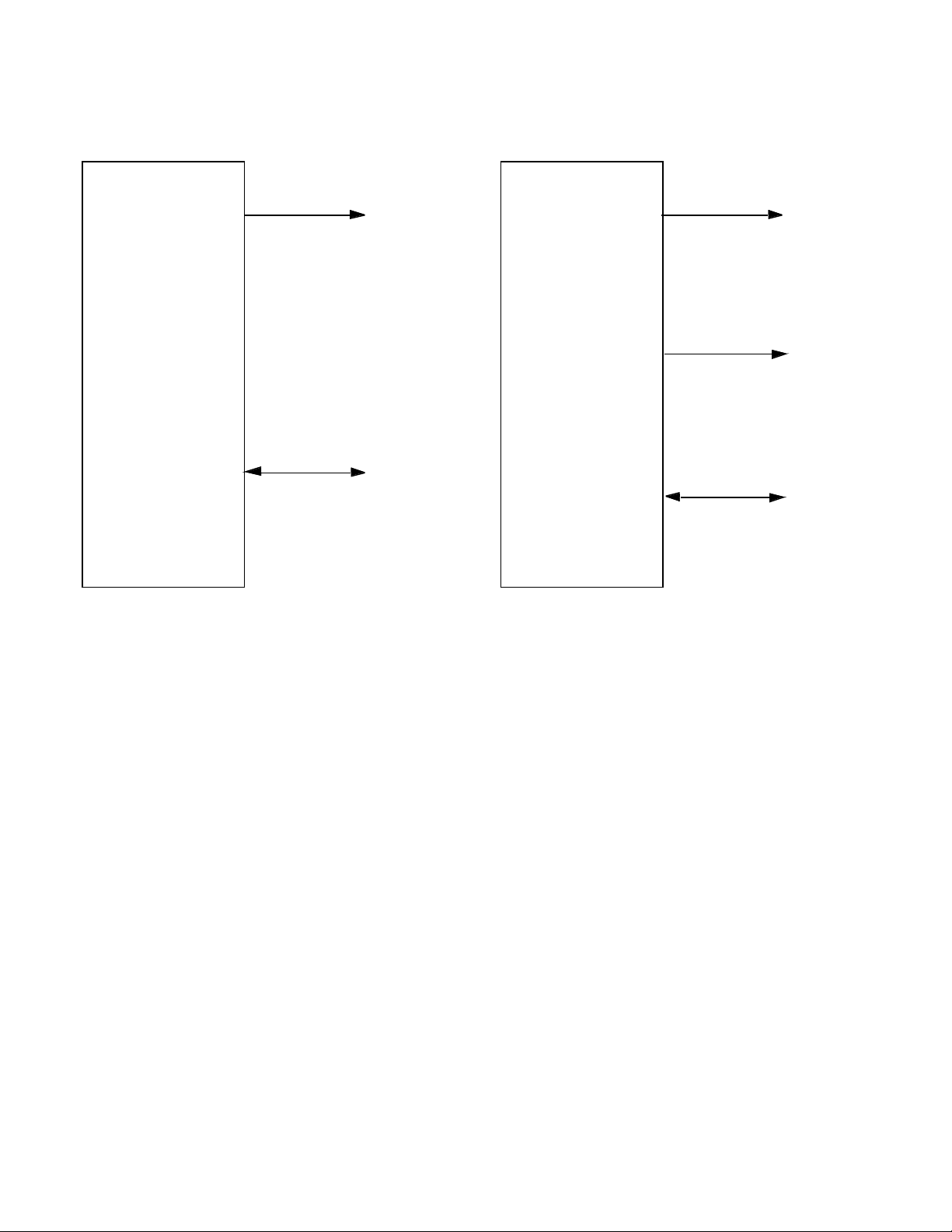

1.1.1.2 Bus Width and Memory Configurations

The UT80CRH196KD external bus can operate as either an 8bit or 16-bit multiplexed address/data bus (see figure 2) . The

value of bit 1 in the CCR determines the bus operation. A logic

low value on CCR.1 locks the bus controller in 8-bit bus mode.

If, however, CCR.1 is a logic high, then the BUSWIDTH signal

is used to decide the width of the bus. The bus is 16 bits wide

when the BUSWIDTH signal is high, and is 8 bits when the

BUSWIDTH signal is low.

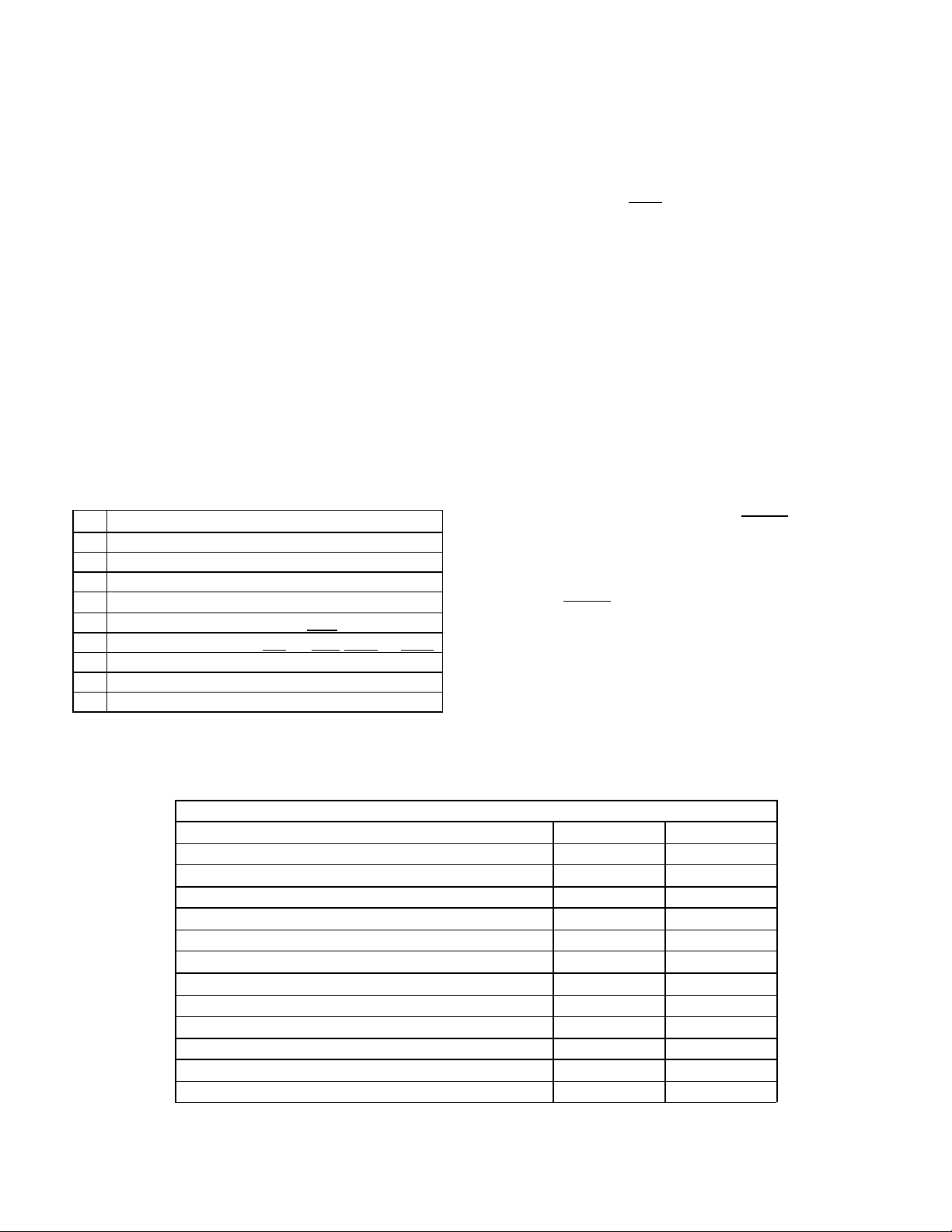

Table 4. Chip Configuration Register

Bit Function

7 N/A

6 N/A

5 IRC1 - Internal READY Mode Control

4 IRC0 - Internal READY Mode Control

3 Address Valid Strobe Select (ALE/ADV)

2 Write Strobe Mode Select (WR and BHE/WRL and WRH)

1 Dynamic Bus Width Enable

0 Enable Power Down Mode

1.1.2 Reset

To reset the UT80CRH196KD, hold the RESET pin low for at

least 16 state times after the power supply is within tolerance

and the oscillator has stabilized. Resets following the power-up

reset may be asserted for at least one state time, and the device

will turn on a pull-down transistor for 16 state times. This

enables the RESET signal to function as the system reset. The

reset state of the external I/O is shown in Table 9, and the register

reset values are shown in Table 8.

1.1.3 Instruction Set

The instruction set for the UT80CRH196KD is compatible with

the industry standard MCS-96 instruction set used on the

8XC196KD.

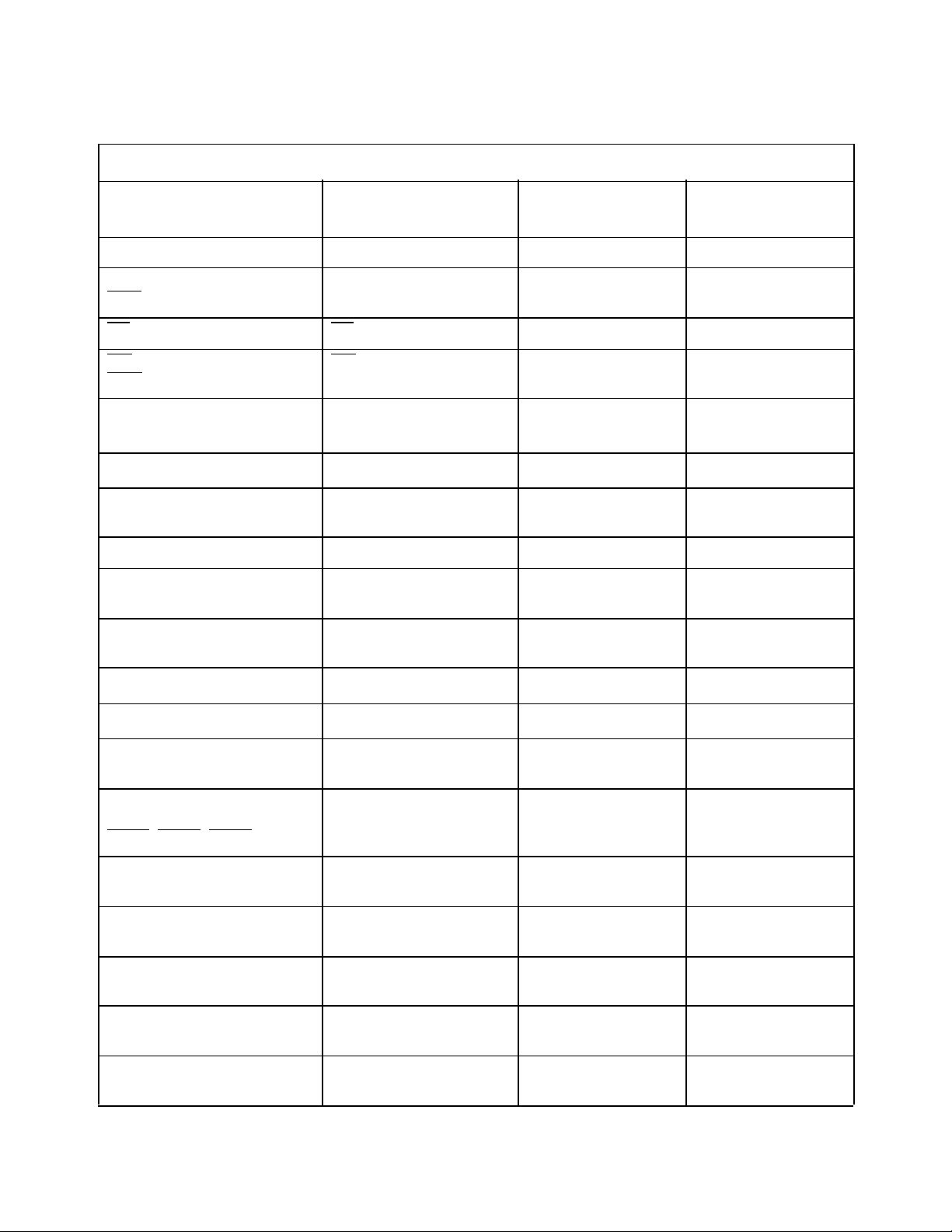

Table 5. Memory Map

Memory Description Begin End

External Memory

1

02080H 0FFFFH

Reserved 0205EH 0207FH

PTS Vectors 02040H 0205DH

Upper Interrupt Vectors 02030H 0203FH

Reserved 02020H 0202FH

Reserved 02019H 0201FH

Chip Configuration Byte 02018H 02018H

Reserved 02014H 02017H

Lower Interrupt Vectors 02000H 02013H

External Memory 00400H 1FFFH

Internal Memory (RAM) 0001AH 003FFH

Special Function Registers 00000H 00019H

Notes:

1.The first instruction read following reset will be from location 2080h. All other external memory can be used as instruction and/or data memory.

3

Table 6. Interrupt Vector Sources, Locations, and Priorities

Priority

(0 is the

Lowest

Priority)

Number Interrupt Vector Source(s)

Special Unimplemented

Unimplemented Opcode 2012h N/A N/A

Interrupt

Vector

Location

PTS

Vector

Location

Opcode

Special Software Trap Software Trap 2010h N/A N/A

INT 15

NMI

2

NMI 203Eh N/A 15

INT 14 HSI FIFO Full HSI FIFO Full 203Ch 205Ch 14

INT 13

EXTINT 1

2

Port 2.2 203Ah 205Ah 13

INT 12 Timer 2 Overflow Timer 2 Overflow 2038h 2058h 12

INT 11

Timer 2 Capture

INT 10 HSI FIFO 4 HSI FIFO

2

Timer 2 Capture 2036h 2056h 11

2034h 2054h 10

Fourth Entry

INT 9 Receive

INT 8 Transmit

RI Flag

TI Flag

3

3

2032h 2052h 9

2030h 2050h 8

1

INT 7

EXTINT

INT 6 Serial Port RI Flag and

INT 5 Software Timer Software Timer 0-3

2

Port 2.2 or Port 0.7 200Eh 204Eh 7

200Ch 204Ch 6

4

TI Flag

200Ah 204Ah 5

Timer 2 Reset

INT 4

INT 3 High Speed

INT 2 HSI Data Available HSI FIFO Full or

2

HSI.0

Outputs

HSI.0 Pin 2008h 2048h 4

Events on HSO.0 thru

2006h 2046h 3

HSO.5 Lines

2004h 2044h 2

HSI Holding Reg.

Loaded

INT 1 EDAC Bit Error Single Bit Error

2002h 2042h 1

Single Bit Error OVF

Double Bit Error

INT 0 Timer Overflow Timer 1 or Timer 2 2000h 2040h 0

All of the previous maskable interrupts can be assigned to the PTS.

Any PTS interrupt has priority over all other maskable interrupts.

4

Notes:

1. The Unimplemented Opcode and Software Trap interrupts are not prioritized. The Interrupt Controller immediately services these interrupts when they are

asserted. NMI has the highest priority of all prioritized interrupts. Any PTS interrupt has priority over lower priority interru pts, and over all other maskable

interrupts. The standard maskable interrupts are serviced according to their priority number with INT0 has the lowest priority of all interrupts.

2. These interrupts can be configured to function as independent, external interrupts.

3. If the Serial interrupt is masked and the Receive and Transmit interrupts are enabled, the RI flag and TI flag generate separate Receive and Transmit interrupts.

4. If the Receive and Transmit interrupts are masked and the Serial interrupt is enabled, both RI flag and TI flag generate a Serial Port interrupt.

5

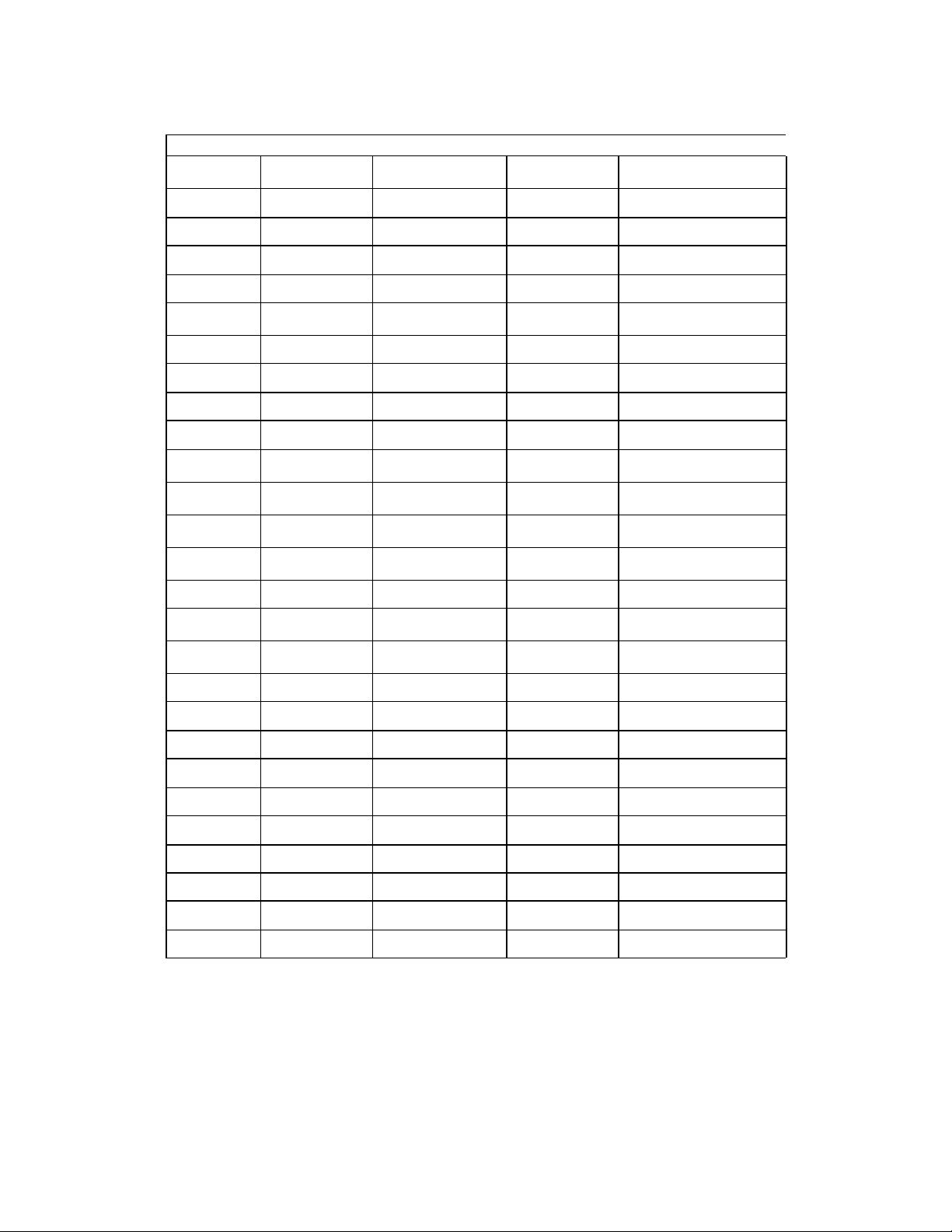

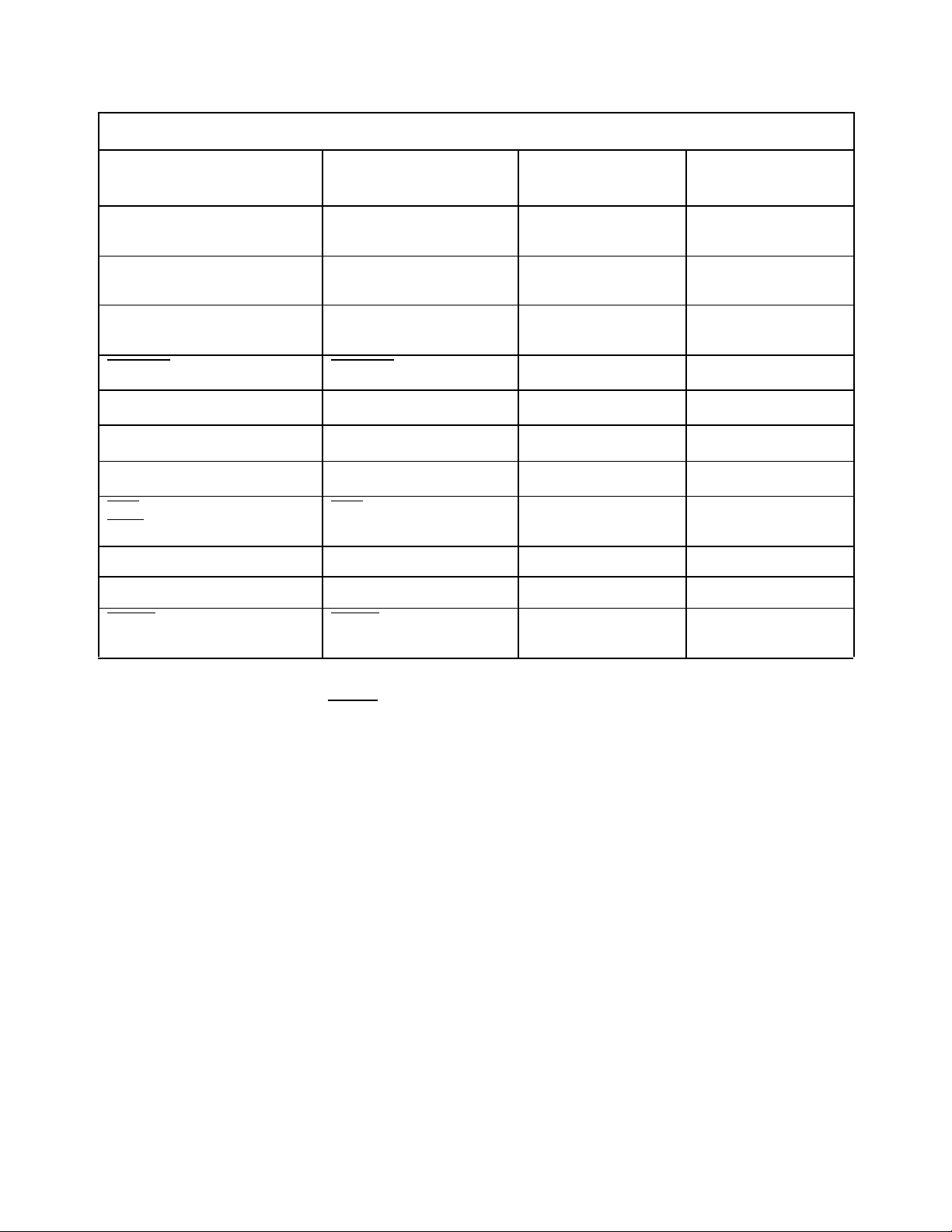

Table 7. SFR Memory Mapping

Address HWin 0 Read HWin 0 Write HWin 1

HWin 15

019H Stack Pntr (hi) Stack Pntr (hi) Stack Pntr (hi) Stack Pntr (hi)

018H Stack Pntr (lo) Stack Pntr (lo) Stack Pntr (lo) Stack Pntr (lo)

017H IOS2 PWM0_CTRL PWM2_CTRL ***

016H IOS1 IOC1 PWM1_CTRL ***

1

015H IOS0 IOC0

EDAC-CS

2

***

014H WSR WSR WSR WSR

013H INT_MASK1 INT_MASK1 INT_MASK1 INT_MASK1

012H INT_PEND1 INT_PEND1 INT_PEND1 INT_PEND1

011H SP_STAT SP_CON RESERVED ***

010H PORT 2 PORT 2 RESERVED

00FH PORT 1 PORT 1

00EH PORT 0 BAUD RATE

00DH Timer 2 (hi) Timer 2 (hi)

Timer 3(hi)

Timer 3(lo)

WDT-SCALE

2

2

2

2

PSW

RESERVED

RESERVED

T2CAPTURE (hi)

00CH Timer 2 (lo) Timer 2 (lo) IOC3 T2CAPTURE (lo)

00BH Timer 1 (hi) IOC2

00AH Timer 1 (lo) Watchdog

INT_PRI(hi)

INT_PRI(lo)

2

***

2

***

009H INT_PEND INT_PEND INT_PEND INT_PEND

008H INT_MASK INT_MASK INT_MASK INT_MASK

007H SBUF (RX) SBUF (TX) PTSSRV (hi) ***

006H HSI_status HSO_command PTSSRV (lo) ***

005H HSI_time(hi) HSO_time (hi) PTSSEL (hi) ***

004H HSI_time (lo) HSO_time (lo) PTSSEL (lo) ***

003H RESERVED HSI_mode RESERVED ***

002H RESERVED RESERVED RESERVED RESERVED

001H Zero_reg (hi) Zero_reg (hi) Zero-reg (hi) Zero_reg (hi)

000H Zero_reg (lo) Zero_reg (lo) Zero_reg (lo) Zero_reg (lo)

Notes:

1. For some functions that share a register address in HWindow0, the opposite access type (read/write) is available in HWindow 15 if

indicated by the three asterisks (***).

2. These registers are not available in the industry standard 8XC196KD. Therefore, industry standard development software will not recognize these

mnemonics, and you will only be able to access them via their physical addresses.

6

Table 8: Special Function Register Reset Values

Internal Register Binary Reset State

Stack Pointer (SP) XXXX XXXX XXXX XXXX XXXX

I/O Status Register 2 (IOS2) 0000 0000 00

I/O Status Register 1 (IOS1) 0000 0000 00

I/O Status Register 0 (IOS0) 0000 0000 00

Window Select Register (WSR) 0000 0000 00

Interrupt Mask Register 1 (INT_MASK1) 0000 0000 00

Interrupt Pending Register 1

(INT_PEND1)

Serial Port Status Register (SP_STAT) 0000 1011 0B

Port 2 Register (PORT2) 110X XXX1 XX

Port 1 Register (PORT1) 1111 1111 FF

Port 0 Register (PORT0) XXXX XXXX XX

Timer 2 Value Register (TIMER2) 0000 0000 0000 0000 0000

Timer 1 Value Register (TIMER1) 0000 0000 0000 0000 0000

0000 0000 00

Hexadecimal Reset

Value

Interrupt Pending Register (INT_PEND) 0000 0000 00

Interrupt Mask Register (INT_MASK) 0000 0000 00

Receive Serial Port Register (SBUF

(RX))

HSI Status Register (HSI_status) X0X0 X0X0 XX

HSI Time Register (HSI_time) XXXX XXXX XXXX XXXX XXXX

Zero Register (ZERO_REG) 0000 0000 0000 0000 0000

PWM0 Control Register (PWM0_CTRL) 0000 0000 00

I/O Control Register 1 (IOC1) 0010 0001 21

I/O Control Register 0 (IOC0) 0000 00X0 0X

Serial Port Control Register (SP_CON) 0000 1011 0B

Baud Rate Register (BAUD_RATE) 0000 0000 0000 0001 0001

I/O Control Register 2 (IOC2) X00X X000 XX

Watch Dog Timer Register (WATCH-

DOG)

0000 0000 00

0000 0000 00

7

Table 8: Special Function Register Reset Values

Internal Register Binary Reset State

Transmit Serial Port Buffer (SBUF (TX)) 0000 0000 00

HSO Command Register

(HSO_command)

HSO Time Register (HSO_time) 0000 0000 0000 0000 0000

HSI Mode Register (HSI_mode) 1111 1111 FF

PWM2 Control Register (PWM2_CTRL) 0000 0000 00

PWM1 Control Register (PWM1_CTRL) 0000 0000 00

EDAC Control and Status Register

(EDAC_CS)

Timer 3 Value Register (TIMER3) 0000 0000 0000 0000 0000

Watchdog Timer Prescaler

(WDT_SCALE)

I/O Control Register 3 (IOC3) 1111 0000 F0

Interrupt Priority Register (INT_PRI) 0000 0000 00

PTS Service Register (PTSSRV) 0000 0000 0000 0000 0000

0000 0000 00

0000 0000 00

0000 0000 00

Hexadecimal Reset

Value

PTS Select Register (PTSSEL) 0000 0000 0000 0000 0000

Timer 2 Capture Register

(T2CAPTURE)

Program Counter (PC) 0010 0000 1000 0000 2080

Chip Configuration Register (CCR) XX10 1111 XF

0000 0000 0000 0000 0000

8

Table 9: External I/O Reset State

External I/O I/O Function After Reset

I/O State During

Reset

I/O State After Reset

Address/Data Bus (AD15:0) Address/Data Bus Pulled High Driven Output

ALE

ALE Pulled High Driven Output

ADV

RD RD Pulled High Driven Output

WR

WR Pulled High Driven Output

WRL

Port 0 (P0.0-P0.3; P0.6)

ECB(4:0)

[P0.0-P0.3; P0.6] and

ECB(4:0)

Port 0 (P0.4 and P0.5) P0.4 and P0.5

Port 0 (P0.7)

P0.7

Undefined Inputs

Undefined Inputs

Undefined Input

1

1

1

Undefined I/O

Undefined Inputs

Undefined Input

EXTINT

NMI NMI Pulled Down Pulled Down

HSI.0

HSI.0

Disabled Input

1

Disabled Input

T2RST

HSI.1

HSI.1

Disabled Input

1

Disabled Input

T2CLK

1,2

1

1

1

1

HSI.2/HSO.4 Undefined

HSI.3/HSO.5 Undefined

Disabled I/O

Disabled I/O

1

1

Disabled I/O

Disabled I/O

HSO.0 through HSO.3 HSO.0-HSO.3 Pulled Down Driven Low

Outputs

Port 1 (P1.0-P1.7)

P1.0-P1.7 Pulled Up Pulled Up

PWM1; PWM2;

BREQ; HLDA; HOLD

Port 2 (P2.0)

TXD

Port 2 (P2.1)

TXD Pulled Up Driven High

Output

RXD

Undefined Input

1

Undefined Input

RXD

Port 2 (P2.2)

P2.2 and EXTINT

Undefined Input

1

Undefined Input

EXTINT

Port 2 (P2.3)

P2.3 and T2CLK

Undefined Input

1

Undefined Input

T2CLK

Port 2 (P2.4)

P2.4

Undefined Input

1

Undefined Input

T2RST

1

1

1

1

1

1

9

Table 9: External I/O Reset State

External I/O I/O Function After Reset

Port 2 (P2.5)

PWM0 Pulled Down Driven Low Output

I/O State During

Reset

I/O State After Reset

PWM0

Port 2 (P2.6)

P2.6 Pulled Up Pulled Up

T2UP-DN

Port 2 (P2.7)

P2.7 and T2CAPTURE Pulled Up Pulled Up

T2CAPTURE

EDACEN EDACEN

ECB5 ECB5

READY READY

BUSWIDTH BUSWIDTH

BHE

BHE Pulled Up Driven Output

Undefined Input

Undefined I/O

Undefined Input

Undefined Input

1

1

1

1

Undefined Input

Undefined I/O

Undefined Input

Undefined Input

WRH

CLKOUT CLKOUT Driven Output Driven Output

INST INST Pulled Down Driven Output

1

1,2

1

1

RESET RESET Pulled Low by

System

Notes:

1. These pins must not be left floating. Input voltages must not exceed VDD during power-up.

2. Do not directly tie these pins to V

or GND; if EDACEN goes low, they may be driven by the UT80CRH196KD and bus contention may occur.

DD

Pulled Up

10

Bus Control

UT80CRH196KD UT80CRH196KD

AD8-AD15

AD0-AD15

16-Bit

Multiplexed

Address/Data

AD0-AD7

Bus Control

8-Bit

Latched

Address High

8-Bit

Multiplexed

Address/Data

16-Bit Bus 8-Bit Bus

Figure 2. Bus Width Options

11

P0.5

P0.4

V

SS

V

DD

V

SS

EXTINT/P2.2

RESET

RXD/P2.1

TXD/P2.0

P1.0

P1.1

P1.2

PWM1/P1.3

PWM2/P1.4

T2RST/HSI.0

T2CLK/HSI.1

HSI.2/HS0.4

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

P0.7/EXTINT

P0.6/ECB0

P0.2/ECB1

P0.0/ECB2

P0.1/ECB3

P0.3/ECB4

NMI

ECB5

VDDVSSXTAL1

9

8

7

6

5

4

3

2

1

68

UT80CRH196KD

TOP VIEW

VSSCLKOUT

67

66

BUSWIDTH

INST

ALE/ADV

RD

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

AD8

AD9

AD10

AD11

AD12

AD13

AD14

AD15

P2.3/T2CLK

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

SS

HS0.0

HS0.1

BR EQ/P1.5

HLDA/P1.6

HOLD/P1.7

HSI.3/HSO.5

HS0.2

T2UP-DN/P2.6

V

HS0.3

EDACEN

WR/WR L

PWM0/P2.5

T2CAPTURE/P2.7

READY

BHE/WRH

T2RST/P2.4

Figure 3. 68-pin Quad Flatpack Package

12

Legend for I/O fields:

TDI = TTL compatible input

(internally pulled low)

TO = TTL compatible output

TI = TTL compatible input

CI = CMOS only input

TUO = TTL compatible output

(internally pulled high)

TDO = TTL compatible output

(internally pulled low)

TUI = TTL compatible input

(internally pulled high)

TB = TTL compatible bidirectional

TUQ = TTL compatible quasi-bidirectional

(internally pulled high)

TUB = TTL compatible bidirectional

(internally pulled high)

TUBS = TTL compatible bidirectional Schmitt

Trigger (internally pulled high)

PWR = +5V (VDD)

GND = OV (VSS)

Table 10: 68-lead Flat Pack Pin Descriptions

QFP Pin# I/O Name Active Description

1 PWR V

DD

--- Digital supply voltage (+5V). There are 2 VDD pins, both of

which must be connected.

2 TB

ECB5

1

--- EDAC Check Bit 5. Asserting the EDACEN pin will cause the

error detection and correction engine to pass the EDAC Check

Bit 5 through pin 2 of the UT80CRH196KD.

3 TDI NMI High Non-Maskable Interrupt. A positive transition causes a vector

through the NMI interrupt at location 203Eh. Assert NMI for at

least 1 state time to guarantee acknowledgment by the interrupt

controller.

4 TI P0.3 --- Port 0 Pin 3. An input only port pin that is read at location 0Eh

in HWindow 0.

TB

ECB4

1

--- EDAC Check Bit 4. Asserting the EDACEN pin will cause the

error detection and correction engine to pass the EDAC Check

Bit 4 through pin 4 of the UT80CRH196KD.

5 TI P0.1 --- Port 0 Pin 1. An input only port pin that is read at location 0Eh

in HWindow 0.

TB

ECB3

1

--- EDAC Check Bit 3. Asserting the EDACEN pin will cause the

error detection and correction engine to pass the EDAC Check

Bit 3 through pin 5 of the UT80CRH196KD.

6 TI P0.0 --- Port 0 Pin 0. An input only port pin that is read at location 0Eh

in HWindow 0.

TB

ECB2

1

--- EDAC Check Bit 2. Asserting the EDACEN pin will cause the

error detection and correction engine to pass the EDAC Check

Bit 2 through pin 6 of the UT80CRH196KD.

13

Loading...

Loading...