AEROFLEX ACT F128K8 Service Manual

www.aeroflex.com

查询ACT-F1288N-060F6C供应商

ACT–F128K8 High Speed

1 Megabit Monolithic FLASH

Features

CIRCUIT TECHNOLOGY

■ Low Power Monolithic 128K x 8 FLASH

■ TTL Compatible Inputs and CMOS Outputs

■ Access Times of 60, 70, 90, 120 and 150ns

■ +5V Programing, +5V Supply

■ 100,000 Erase / Program Cycles

■ Low Standby Current

■ Page Program Operation and Internal

Program Control Time

■ Supports Full Chip Erase

■ Embedded Erase and Program Algorithms

■ Supports Full Chip Erase

■ MIL-PRF-38534 Compliant Circuits Available

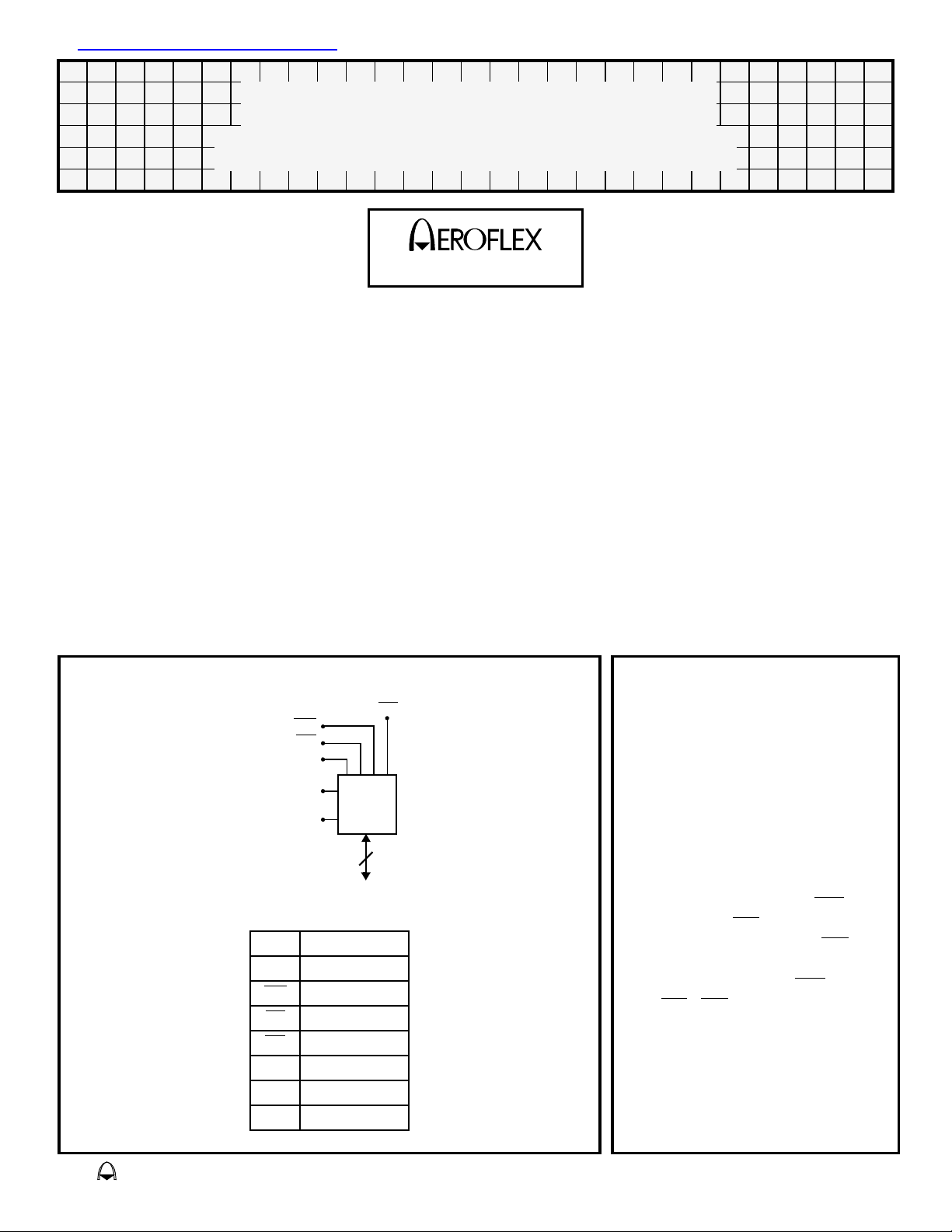

Block Diagram – DIP (P4) & Flat Packages (F6,F7)

CE

WE

OE

A0 – A16

Vss

Vcc

Pin Description

I/O

0-7 Data I/O

A

0–16 Address Inputs

WE

CE

OE

V

CC Power Supply

V

SS Ground

NC Not Connected

512Kx8

8

I/O0-7

Write Enable

Chip Enable

Output Enable

■ Industry Standard Pinouts

■ Packaging – Hermetic Ceramic

● 32 Lead, 1.6" x .6" x .20" Dual-in-line Package (DIP),

Aeroflex code# "P4"

● 32 Lead, .82" x .41" x .125" Ceramic Flat Package

(FP), Aeroflex code# "F6"

● 32 Lead, .82" x .41" x .132" Ceramic Flat Package

(FP Lead Formed), Aeroflex code# "F7"

■ Sector Architecture

● 8 Equal size sectors of 16K bytes each

● Any Combination of Sectors can be erased with one

command sequence.

■ Commercial, Industrial and Military

Temperature Ranges

■ DESC SMD Pending

5962-96690 (P4,F6,F7)

General Description

The ACT–F128K8 is a high

speed, 1 megabit CMOS

monolithic Flash module

designed for full temperature

range military, space, or high

reliability applications.

This device is input TTL and

output CMOS compatible. The

command register is written by

bringing write enable (WE

chip enable (CE

) to a logic low

level and output enable (OE

logic high level. Reading is

accomplished when WE

and CE

, OE are both low, see

Figure9. Access time grades of

60ns, 70ns, 90ns, 120ns and

150ns maximum are standard.

The ACT–F128K8 is

available in a choice of

) and

is high

) to a

eroflex Circuit Technology - Advanced Multichip Modules © SCD1676 REV A 5/6/98

General Description, Cont’d,

hermetically sealed ceramic packages; a

32 lead .82" x .41" x .125"flat package in

both formed or unformed leads or a 32 pin

1.6"x.60" x.20" DIP package for operation

over the temperature range -55°C to

+125°C and military environmental

conditions.

The flash memory is organized as

128Kx8 bits and is designed to be

programmed in-system with the standard

system 5.0V Vcc supply. A 12.0V V

PP is

not required for write or erase operations.

The device can also be reprogrammed with

standard EPROM programmers (with the

proper socket).

The standard ACT–F128K8 offers

access times between 60ns and 150ns,

allowing operation of high-speed

microprocessors without wait states. To

eliminate bus contention, the device has

separate chip enable (CE

) and output enable (OE) controls. The

(WE

), write enable

ACT–F128K8 is command set compatible

with JEDEC standard 1 Mbit EEPROMs.

Commands are written to the command

register using standard microprocessor

write timings. Register contents serve as

input to an internal state-machine which

controls the erase and programming

circuitry. Write cycles also internally latch

addresses and data needed for the

programming and erase operations.

Reading data out of the device is similar

to reading from 12.0V Flash or EPROM

devices. The ACT–F128K8 is programmed

by executing the program command

sequence. This will invoke the Embedded

Program Algorithm which is an internal

algorithm that automatically times the

program pulse widths and verifies proper

cell margin. Typically, each sector can be

programmed and verified in less than 0.3

second. Erase is accomplished by

executing the erase command sequence.

This will invoke the Embedded Erase

Algorithm which is an internal algorithm

that automatically preprograms the array, (if

it is not already programmed before)

executing the erase operation. During

erase, the device automatically times the

erase pulse widths and verifies proper cell

margin.

Also the device features a sector erase

architecture. The sector mode allows for

16K byte blocks of memory to be erased

and reprogrammed without affecting other

blocks. The ACT-F128K8 is erased when

shipped from the factory.

The device features single 5.0V power

supply operation for both read and write

functions. lnternally generated and

regulated voltages are provided for the

program and erase operations. A low V

CC

detector automatically inhibits write

operations on the loss of power. The end of

program or erase is detected by Data

Polling of D7 or by the Toggle Bit feature on

D6. Once the end of a program or erase

cycle has been completed, the device

internally resets to the read mode.

All bits of each die, or all bits within a

sector of a die, are erased via

Fowler-Nordhiem tunneling. Bytes are

programmed one byte at a time by hot

electron injection.

A DESC Standard Military Drawing

(SMD) number is pending.

Aeroflex Circuit Technology SCD1676 REV A 5/6/98 Plainview NY (516) 694-6700

2

z

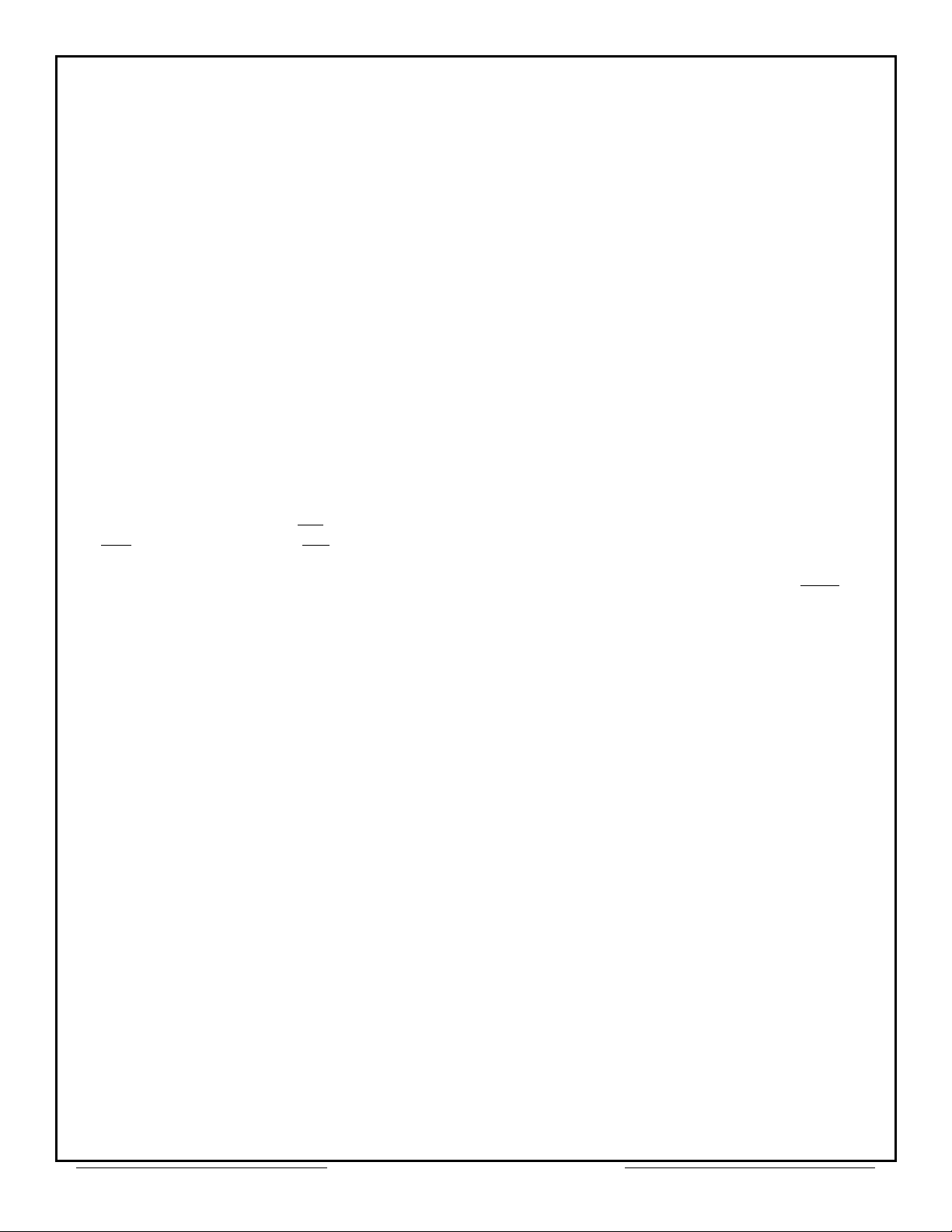

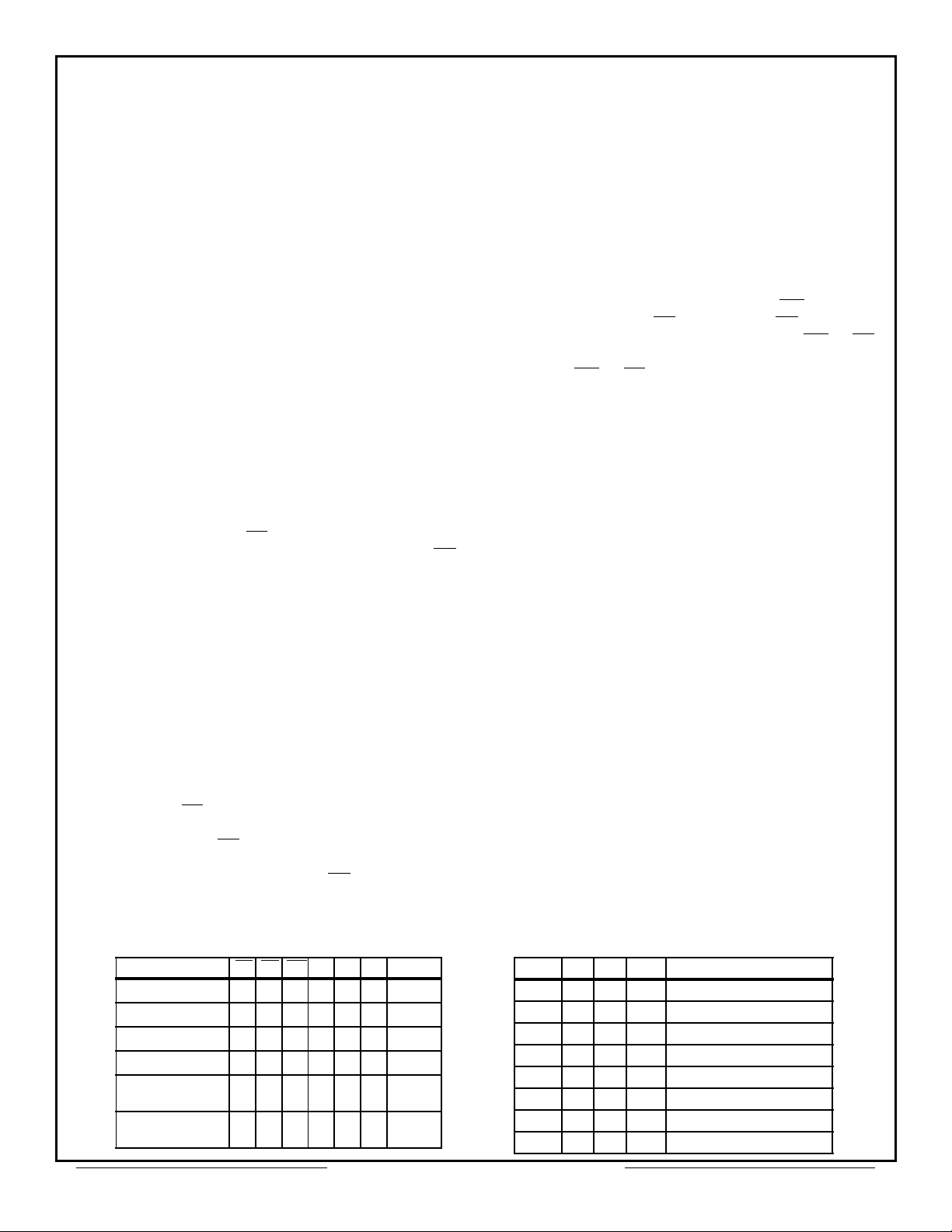

Absolute Maximum Ratings

Parameter Symbol Range Units

C -55 to +125 °C

Case Operating Temperature

Storage Temperature Range

Supply Voltage Range

Signal Voltage Range (Any Pin Except A9) Note 1

Maximum Lead Temperature (10 seconds)

Data Retention

Endurance (Write/Erase cycles)

A9 Voltage for sector protect, Note 2

Note 1. Minimum DC voltage on input or I/O pins is -0.5V. During voltage transitions, inputs may undershoot V

up to 20ns. Maximum DC voltage on input and I/O pins is V

overshoot to V

Note 2. Minimum DC input voltage on A9 is -0.5V. During voltage transitions, A9 may undershoot VSS to -2.0V for periods of up to 20ns.

CC + 2.0V for periods up to 20 ns.

T

STG -65 to +150 °C

T

CC -2.0 to +7.0 V

V

G -2.0 to +7.0 V

V

300 °C

10 Years

100,000 Minimum

ID -2.0 to +14.0 V

V

CC + 0.5V. During voltage transitions, inputs and I/O pins may

SS to -2.0v for periods of

Maximum DC input voltage on A9 is +12.5V which may overshoot to 14.0V for periods up to 20ns.

Normal Operating Conditions

Symbol Parameter Minimum Maximum Units

CC

V

V

V

Tc

V

Power Supply Voltage

IH

Input High Voltage

IL

Input Low Voltage

Operating Temperature (Military)

ID

A9 Voltage for sector protect

+4.5 +5.5 V

+2.0 V

+ 0.5 V

CC

-0.5 +0.8 V

-55 +125 °C

11.5 12.5 V

Capacitance

(VIN= 0V, f = 1MHz, Tc = 25°C)

Symbol Parameter Maximum Units

AD

C

C

C

C

C

A0 – A16 Capacitance

OE

OE Capacitance

WE

Write Enable Capacitance

CE

Chip Enable Capacitance

I/O

I/O0 – I/O7 Capacitance

15 pF

15 pF

15 pF

15 pF

15 pF

Parameters Guaranteed but not tested

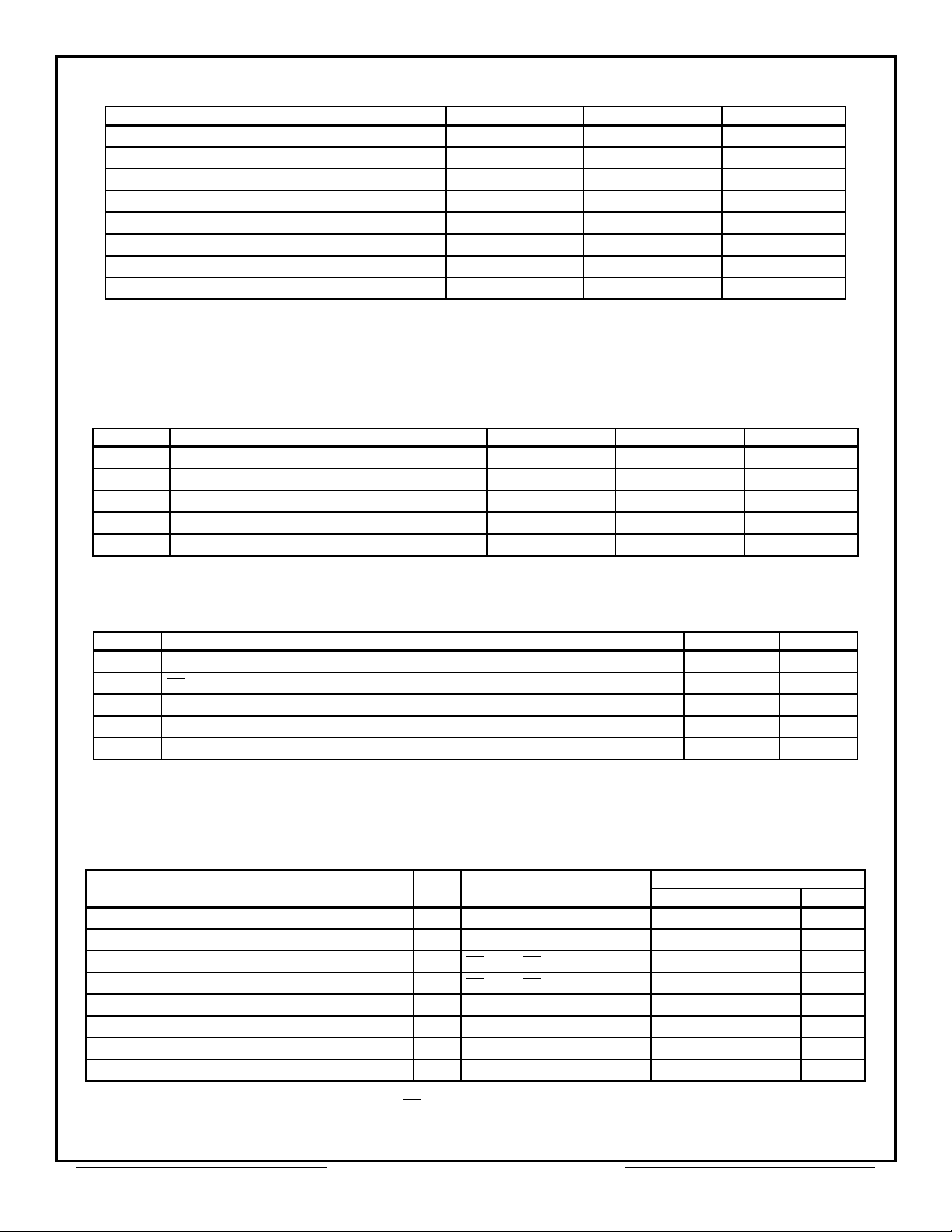

DC Characteristics – CMOS Compatible

(Vcc = 5.0V, Vss = 0V, Tc = -55°C to +125°C, unless otherwise indicated)

Parameter Sym Conditions

LI

I

CC = 5.5V, VIN = GND to VCC

Input Leakage Current

Output Leakage Current

Active Operating Supply Current for Read (1)

Active Operating Supply Current for Program or Erase (2)

Operating Standby Supply Current

Output Low Voltage

Output High Voltage

Low Power Supply Lock-Out Voltage (4)

V

LO

I

VCC = 5.5V, VIN = GND to VCC

CC1

I

CC2

I

CC3

I

OL

V

OH

V

LKO 3.2 V

V

= VIL, OE = VIH, f = 5MHz

CE

= VIL, OE = VIH

CE

CC = 5.5V, CE = VIH, f = 5MHz

V

IOL = +8.0 mA, VCC = 4.5V

IOH = –2.5 mA, VCC = 4.5V

Note 1. The Icc current listed includes both the DC operating current and the frequency dependent component (At 6 MHz). The frequency

component typically is less than 2 mA/MHz, with OE

Note 2. Icc active while Embedded Algorithm (Program or Erase) is in progress.

Note 3. DC Test conditions: V

IL = 0.3V, VIH = VCC - 0.3V, unless otherwise indicated.

at VIN.

Note 4. Parameter Guaranteed by design, but not tested.

Speeds 60, 70, 90, 120 & 150ns

Minimum Maximum Units

10 µA

10 µA

35 mA

50 mA

1.6 mA

0.45 V

0.85 x V

CC V

Aeroflex Circuit Technology SCD1676 REV A 5/6/98 Plainview NY (516) 694-6700

3

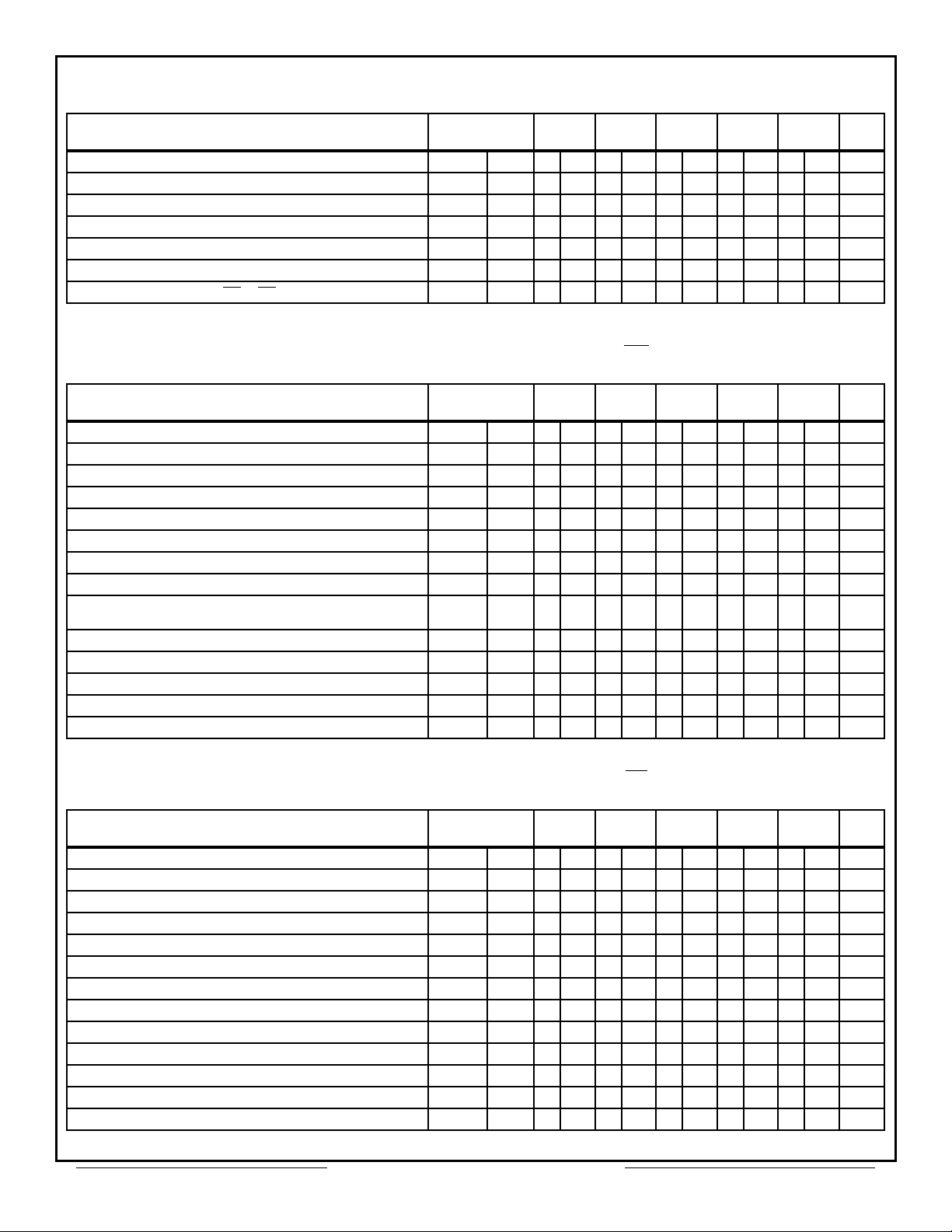

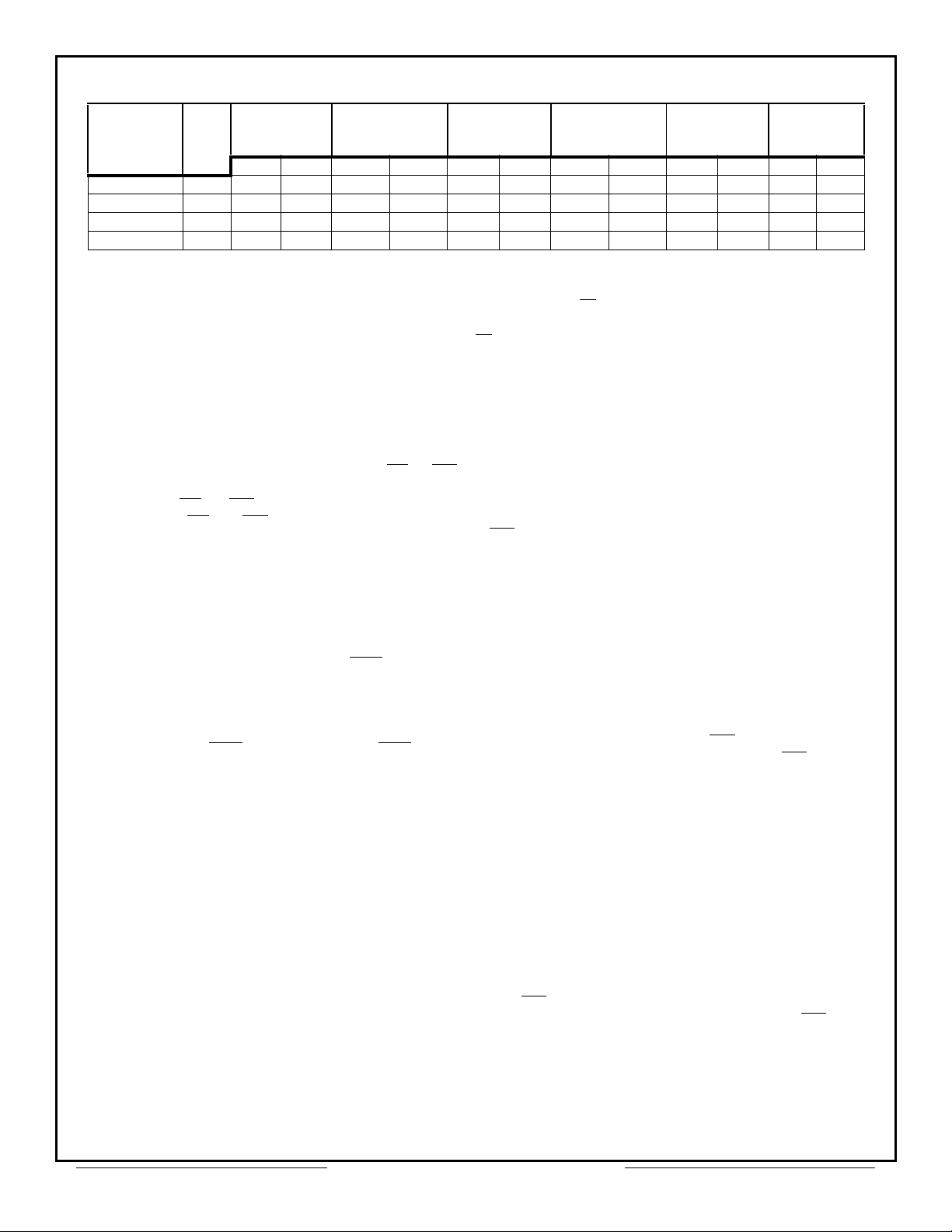

Parameter

Read Cycle Time

Address Access Time

Chip Enable Access Time

Output Enable to Output Valid

Chip Enable to Output High Z (1)

Output Enable High to Output High Z(1)

Output Hold from Address, CE

or OE Change, Whichever is First

Note 1. Guaranteed by design, but not tested

AC Characteristics – Write/Erase/Program Operations, WE Controlled

Parameter

Write Cycle Time

Chip Enable Setup Time

Write Enable Pulse Width

Address Setup Time

Data Setup Time

Data Hold Time

Address Hold Time

Write Enable Pulse Width High

Duration of Byte Programming Operation

Typ = 16 µs

Sector Erase Time

Read Recovery Time before Write

Vcc Setup Time

Chip Programming Time

Chip Erase Time

AC Characteristics – Read Only Operations

(Vcc = 5.0V, Vss = 0V, Tc = -55°C to +125°C)

Symbol

JEDEC Stand’d

AVAV tRC 60 70 90 120 150 ns

t

AVQV tACC 60 70 90 120 150 ns

t

ELQV tCE 60 70 90 120 150 ns

t

GLQV tOE 30 35 40 50 55 ns

t

EHQZ tDF 20 20 25 30 35 ns

t

GHQZ tDF 20 20 25 30 35 ns

t

t

AXQX tOH 0 0 0 0 0 ns

(Vcc = 5.0V, Vss = 0V, Tc = -55°C to +125°C)

Symbol

JEDEC Stand’d

AVAC tWC 60 70 90 120 150 ns

t

ELWL tCE 0 0 0 0 0 ns

t

WLWH tWP 30 35 45 50 50 ns

t

AVWL tAS 0 0 0 0 0 ns

t

DVWH tDS 30 30 45 50 50 ns

t

WHDX tDH 0 0 0 0 0 ns

t

WLAX tAH 45 45 45 50 50 ns

t

WHWL tWPH 20 20 20 20 20 ns

t

WHWH1 14 TYP 14 TYP 14 TYP 14 TYP 14 TYP µs

t

WHWH2 60 60 60 60 60 Sec

t

GHWL 0 0 0 0 0 µs

t

VCE 50 50 50 50 50 µs

t

WHWH3 120 120 120 120 120 Sec

t

–60

Min Max

–60

Min Max

–70

Min Max

–70

Min Max

12.5 12.5 12.5 12.5 12.5 Sec

–90

Min Max

–90

Min Max

–120

Min Max

–120

Min Max

–150

Min Max

–150

Min Max

Units

Units

AC Characteristics – Write/Erase/Program Operations, CE Controlled

(Vcc = 5.0V, Vss = 0V, Tc = -55°C to +125°C)

Parameter

Write Cycle Time

Write Enable Setup Time

Chip Enable Pulse Width

Address Setup Time

Data Setup Time

Data Hold Time

Address Hold Time

Chip Select Pulse Width High

Duration of Byte Programming

Sector Erase Time

Read Recovery Time

Symbol

JEDEC Stand’d

AVAC tWC 60 70 90 120 150 ns

t

WLEL tWS 0 0 0 0 0 ns

t

ELEH tCP 30 35 45 50 50 ns

t

AVEL tAS 0 0 0 0 0 ns

t

DVEH tDS 30 30 45 50 50 ns

t

EHDX tDH 0 0 0 0 0 ns

t

ELAX tAH 45 45 45 50 50 ns

t

EHEL tCPH 20 20 20 20 20 ns

t

WHWH1 14 TYP 14 TYP 14 TYP 14 TYP 14 TYP µs

t

WHWH2 60 60 60 60 60 Sec

t

tGHEL 0 0 0 0 0 ns

Chip Programming Time

WHWH3 120 120 120 120 120 Sec

Chip Erase Time

Aeroflex Circuit Technology SCD1676 REV A 5/6/98 Plainview NY (516) 694-6700

t

4

–60

Min Max

–70

Min Max

–90

Min Max

–120

Min Max

–150

Min Max

12.5 12.5 12.5 12.5 12.5 Sec

Units

Device Operation

The ACT-F128K8 Monolithic module is composed of one,

1 megabit flash EEPROM.

Programming of the ACT-F128K8 is accomplished by

executing the program command sequence. The

program algorithm, which is an internal algorithm,

automatically times the program pulse widths and

verifies proper cell status. Sectors can be programed

and verified in less than 0.3 second. Erase is

accomplished by executing the erase command

sequence. The erase algorithm, which is internal,

automatically preprograms the array if it is not already

programed before executing the erase operation. During

erase, the device automatically times the erase pulse

widths and verifies proper cell status. The entire

memory is typically erased and verified in 3 seconds

(ifpre-programmed). The sector mode allows for 16K

byte blocks of memory to be erased and reprogrammed

without affecting other blocks.

Bus Operation

programming, the device will draw active current until the

operation is completed.

WRITE

Device erasure and programming are accomplished via

the command register. The contents of the register

serve as input to the internal state machine. The state

machine outputs dictate the function of the device.

The command register itself does not occupy an

addressable memory location. The register is a latch

used to store the command, along with address and data

information needed to execute the command. The

command register is written by bringing WE

low level (V

IL), while CE is low and OE is at VIH.

Addresses are latched on the falling edge of WE

whichever happens later. Data is latched on the rising

edge of the WE

or CE whichever occurs first. Standard

microprocessor write timings are used. Refer to AC

Program Characteristics and Waveforms, Figures 3,

8and13.

to a logic

or CE,

READ

The ACT-F128K8 has two control functions, both of

which must be logically active, to obtain data at the

outputs. Chip Enable (CE

) is the power control and

should be used for device selection. Output-Enable (OE

is the output control and should be used to gate data to

the output pins of the chip selected. Figure 7 illustrates

AC read timing waveforms.

OUTPUT DISABLE

With Output-Enable at a logic high level (VIH), output

from the device is disabled. Output pins are placed in a

high impedance state.

STANDBY MODE

The ACT-F128K8 has two standby modes, a CMOS

standby mode (CE

current consumed is typically less than 400 µA; and a

TTL standby mode (CE

mA. In the standby mode the outputs are in a high

impedance state, independent of the OE

If the device is deselected during erasure or

input held at Vcc + 0.5V), where the

is held VIH) is approximately 1

input.

Command Definitions

Device operations are selected by writing specific

address and data sequences into the command register.

Table 3 defines these register command sequences.

)

READ/RESET COMMAND

The read or reset operation is initiated by writing the

read/reset command sequence into the command

register. Microprocessor read cycles retrieve array data

from the memory. The device remains enabled for reads

until the command register contents are altered.

The device will automatically power-up in the read/reset

state. In this case, a command sequence is not required

to read data. Standard microprocessor read cycles will

retrieve array data. The device will automatically

power-up in the read/reset state. In this case, a

command sequence is not required to read data.

Standard Microprocessor read cycles will retrieve array

data. This default value ensures that no spurious

alteration of the memory content occurs during the

power transition. Refer to the AC Read Characteristics

and Figure 7 for the specific timing parameters.

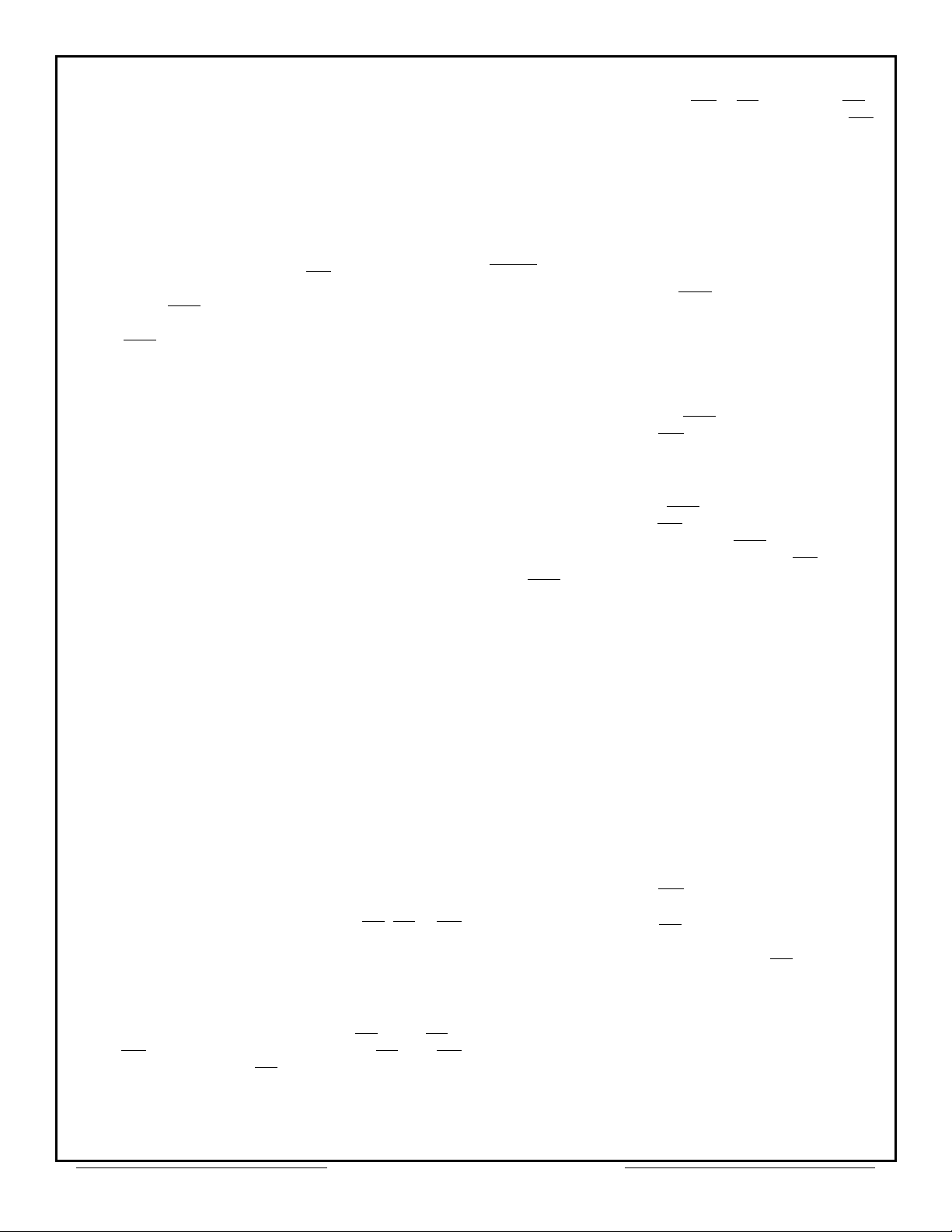

Table 1 – Bus Operations

Operation CE OE WE A0 A1 A9 I/O

READ

STANDBY

OUTPUT DISABLE

WRITE

ENABLE SECTOR

PROTECT

VERIFY SECTOR

PROTECT

Aeroflex Circuit Technology SCD1676 REV A 5/6/98 Plainview NY (516) 694-6700

L L H A

H X X X X X HIGH Z

L H H X X X HIGH Z

L H L A

L V

ID L X X VID X

L L H L H V

0 A1 A9 DOUT

0 A1 A9 DIN

ID Code

5

Table 2 – Sector Addresses Table

A16 A15 A14 Address Range

SA0 0 0 0 00000h – 03FFFh

SA1 0 0 1 04000h – 07FFFh

SA2 0 1 0 08000h – 0BFFFh

SA3 0 1 1 0C000h – 0FFFFh

SA4 1 0 0 10000h – 13FFFh

SA5 1 0 1 14000h – 17FFFh

SA6 1 1 0 18000h – 1BFFFh

SA7 1 1 1 1C000h – 1FFFFh

Table 3 — Commands Definitions

Bus

First Bus Write

Command

Sequence

Read/Reset 4 5555H AAH 2AAAH 55H 5555H F0H RA RD

Byte Program 6 5555H AAH 2AAAH 55H 5555H A0H PA PD

Chip Erase 6 5555H AAH 2AAAH 55H 5555H 80H 5555H AAH 2AAAH 55H 5555H 10H

Sector Erase 6 5555H AAH 2AAAH 55H 5555H 80H 5555H AAH 2AAAH 55H SA 30H

NOTES:

1. Address bit A15 = X = Don't Care. Write Sequences may be initiated with A15 in either state.

2. Address bit A16 = X = Don't Care for all address commands except for Program Address (PA) and Sector Address (SA).

3. RA = Address of the memory location to be read

PA = Address of the memory location to be programmed. Addresses are latched on the falling edge of the WE

SA = Address of the sector to be erased. The combination of A16, A15, A14 will uniquely select any sector.

4. RD = Data read from location RA during read Operation.

PD = Data to be programmed at location PA. Data is latched on the rising edge of WE

Write

Cycle

Req’d

Cycle

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

BYTE PROGRAMING

The device is programmed on a byte-byte basis.

Programming is a four bus cycle operation. There are

two "unlock" write cycles. These are followed by the

program set-up command and data write cycles.

Addresses are latched on the falling edge of CE

whichever occurs later, while the data is latched on the

rising edge of CE

rising edge of CE

begins programming using the Embedded Program

Algorithm. Upon executing the program algorithm

command sequence the system is not required to

provide further controls or timings. The device will

or WE whichever occurs first. The

or WE (whichever happens first)

Second Bus Write

Cycle

or WE,

Third Bus Write

Cycle

.

device prior to erase. Upon executing the Embedded

Erase Algorithm command sequence (Figure 4) the

device will automatically program and verify the entire

memory for an all zero data pattem prior to electrical

erase. The erase is performed concurrently on all

sectors at the same time . The system is not required to

provide any controls or timings during these operations.

Note: Post Erase data state is all "1"s.

The automatic erase begins on the rising edge of the last

WE

pulse in the command sequence and terminates

when the data on D7 is "1" (see Write Operation Status

section - Table 3) at which time the device retums to read

mode. See Figures 4 and9.

Fourth Bus

Read/Write

Cycle

pulse.

Fifth Bus Write

Cycle

Sixth Bus Write

Cycle

automatically provide adequate internally generated

program pulses and verify the programmed cell.

The automatic programming operation is completed

when the data on D

7 (also used as Data Polling) is

equivalent to data written to this bit at which time the

device returns to the read mode and addresses are no

longer latched. Therefore, the device requires that a

valid address be supplied by the system at this particular

instance of time for Data

Polling operations. Data Polling

must be performed at the memory location which is

being programmed.

Any commands written to the chip during the Embedded

Program Algorithm will be ignored.

Programming is allowed in any sequence and across

sector boundaries. Beware that a data "0" cannot be

programmed back to a “1". Attempting to do so may

cause the device to exceed programming time limits (D5

= 1) or result in an apparent success, according to the

data polling algorithm, but a read from reset/read mode

will show that the data is still “0". Only erase operations

can convert “0"s to “1"s.

Figure 3 illustrates the programming algorithm using

typical command strings and bus operations.

CHIP ERASE

Chip erase is a six bus cycle operation. There are two

'unlock' write cycles. These are followed by writing the

“set-up” command. Two more “unlock” write cycles are

then followed by the chip erase command.

Chip erase does not require the user to program the

SECTOR ERASE

Sector erase is a six bus cycle operation. There are two

"unlock" write cycles. These are followed by writing the

"setup" command. Two more "unlock" write cycles are

then followed by the sector erase command. The sector

address (any address location within the desired sector)

is latched on the falling edge of WE

(30H) is latched on the rising edge of WE

time-out of 80µs from the rising edge of the last sector

erase command, the sector erase operation will begin.

Multiple sectors may be erased concurrently by writing

the six bus cycle operations as described above. This

sequence is followed with writes of the sector erase

command to addresses in other sectors desired to be

concurrently erased. The time between writes must be

less than 80µs otherwise that command will not be

accepted and erasure will start. It is recommended that

processor interrupts be disabled during this time to

guarantee this condition. The interrupts can be

re-enabled after the last Sector Erase command is

written. A time-out of 80µs from the rising edge of the

last WE

will initiate the execution of the Sector Erase

command(s). If another falling edge of the WE

within the 80µs time-out window the timer is reset.

(Monitor D3 to determine if the sector erase timer

window is still open, see section D3, Sector Erase

Timer.) Any commarid other than Sector Erase during

this period will reset the device to read mode, ignoring

the previous command string. In that case, restart the

erase on those sectors and allow them to complete.

, while the command

. After a

occurs

Aeroflex Circuit Technology SCD1676 REV A 5/6/98 Plainview NY (516) 694-6700

6

Loading the sector erase buffer may be done in any

sequence and with any number of sectors (0 to 7).

Sector erase does not require the user to program the

device prior to erase. The device automatically

programs all memory locations in the sector(s) to be

erased prior to electrical erase. When erasing a sector

or sectors the remaining unselected sectors are not

affected. The system is not required to provide any

controls or timings during these operations. Post Erase

data state is all "1"s.

The automatic sector erase begins after the 80µs time

out from the rising edge of the WE

sector erase command pulse and terminates when the

data on D7, Data

Status secton) at which time the device returns to read

mode. Data

within any of the sectors being erased.

Figure 4 illustrates the Embedded Erase Algorithm.

Polling, is “1" (see Write Operatlon

Polling must be performed at an address

pulse for the last

Data Protection

The ACT-F128K8 is designed to offer protection against

accidental erasure or programming caused by spurious

system level singles that may exist during power

transitions. During power up the device automatically

resets the internal state machine in the read mode. Also,

with its control register architecture, alteration of the

memory content only occurs after successful completion

of specific multi-bus cycle command sequences.

The device also incorporates several features to prevent

inadvertent write cycles resulting from Vcc power-up and

power-down transitions or system noise.

POWER-UP WRITE INHIBIT

Power-up of the device with WE = CE = VIL and OE =

IH will not accept commands on the rising edge ofWE.

V

The internal state machine is automatically reset to the

read mode on power-up.

Write Operation Status

D7

DATA POLLING

The ACT-F128K8 features Data Polling as a method to

indicate to the host that the internal algorithms are in

progress or completed.

During the program algorithm, an attempt to read the

device will produce compliment data of the data last

written to D

algorithm an attempt to read the device will produce the

true data last written to D7. Data

rising edge of the fourth WE

sequence.

During the erase algorithm, D7 will be "0" until the erase

operation is completed. Upon completion data at D7 is

"1". For chip erase, the Data

rising edge of the sixth WE

sequence. For sector erase, the Data

after the last rising edge of the sector erase WE

The Data

programming algorithm, erase algorithm, or sector erase

time-out.

See Figures 6 and 10 for the Data Polling specifications.

7. Upon completion of the programming

Polling is valid after the

pulse in the four write pulse

Polling is valid after the

pulse in the six write pulse

Polling is Valid

pulse.

Polling feature is only active during the

LOW Vcc WRITE INHIBIT

To avoid initiation of a write cycle during Vcc power-up

and power-down, a write cycle is locked out for V

than 3.2V (typically 3.7V). If V

register is disabled and all internal program/erase

circuits are disabled. Under this condition the device will

reset to read mode. Subsequent writes will be ignored

until the Vcc level is greater than V

responsibility to ensure that the control pins are logically

correct to prevent unintentional writes when Vcc is above

3.2V.

CC <VLKO, the command

LKO. It is the users

CC less

WRITE PULSE GLITCH PROTECTION

Noise pulses of less than 5ns (typical) on OE, CE or WE

will not initiate a write cycle.

LOGICAL INHIBIT

Writing is inhibited by holding anyone of OE = VIL, CE =

IH or WE = VIH. To initiate a write cycle CE and WE

V

must be logical zero while OE is a logical one.

D6

TOGGLE BIT

The ACT-F128K8 also features the "Toggle Bit" as a

method to indicate to the host system that algorithms are

in progress or completed.

During a program or erase algorithm cycle, successive

attempts to read data from the device will result in D

toggling between one and zero. Once the program or

erase algorithm cycle is completed, D

and valid data will be read on successive attempts.

During programming the Toggle Bit is valid after the

rising edge of the fourth WE

sequence. For chip erase the Toggle Bit is valid after the

rising edge of the sixth

sequence. For Sector erase, the Toggle Bit is valid after

the last rising edge of the sector erase

Toggle Bit is active during the sector time out.

See Figure 1 and 5.

pulse in the four write pulse

WE pulse in the six write pulse

6 Will stop toggling

WE pulse. The

6

Aeroflex Circuit Technology SCD1676 REV A 5/6/98 Plainview NY (516) 694-6700

7

Loading...

Loading...