Aeroflex 6210 Datasheet

Microwave

6210 Reflection Analyzer

66221100 eennhhaanncceess tthhee ccaappaabbiilliittyy ooff 66220000BB sseerriieess bbyy pprroovviiddiinngg pprreecciissiioonn rreefflleeccttiioonn ccooeeffffiicciieenntt aanndd ttiimmee

ddoommaaiinn mmeeaassuurreemmeennttss

• Excellent directivity and test port match

for precise measurements of reflection

coefficient

• Time domain software for pinpointing

impedance discontinuities in devices or

systems

• Polar and Smith Chart displays to facilitate matching of devices in circuits

• Fast sweep rate to speed up alignment of

components in production test

• Wide range of calibration kits for 3.5 mm,

Type N and 7 mm connectors

• Works with standard 6200 series

Microwave Test Set for easy upgrade

route

The 6210 Reflection Analyzer is designed specifically for precision measurements of reflection

coefficient from 250 MHz to 26.5 GHz. 6210 fits

underneath a 6200B series Microwave Test Set

(MTS) which provides the synthesized signal

source and analyzer display to form a single integrated test system. 6210 consists of additional

hardware and software to enable error corrected

reflection coefficient measurements with both

cartesian and polar displays.

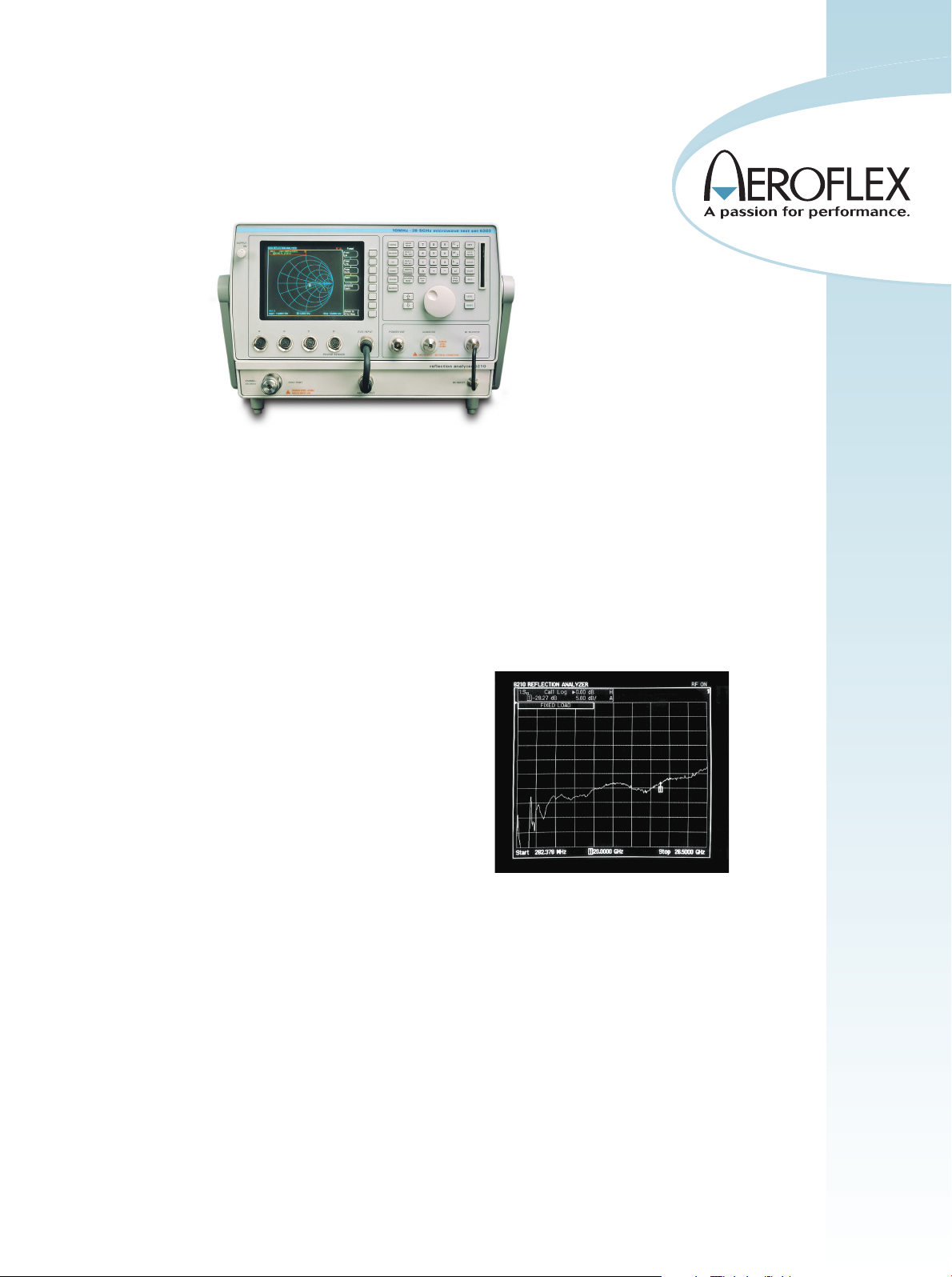

an autotester. An analysis of return loss measurements using an

autotester shows that errors are dominated by test port match and

directivity. The 6210 Reflection Analyzer makes error corrected

return loss measurements to give improved accuracy and reduced

uncertainty. The test port match and directivity achieved with 6210

is significantly better than that obtainable from autotesters.

6210 performs precision reflection coefficient measurements

from 250 MHz to 26.5 GHz

Depending upon the test port connector and the quality of the calibration kit a test port match of >40 dB and directivity of >50 dB can

be achieved.

Accurate Return Loss Measurements

Reflection coefficient is the primary performance

test for microwave systems and components.

Return loss and VSWR are derivatives of reflection

coefficient, they can be measured with a standard

scalar analyzer and a directional RF bridge such as

For the very latest specifications visit www.aeroflex.com

Improvement of accuracy obtained with 6210 compared to an

autotester.

In production areas this means less stand off due to measurement

uncertainty resulting in higher yield and shorter test and rework time.

To design engineers it means greater confidence in the quality of the

initial design.

The measurement can be displayed in log magnitude, linear magnitude, VSWR, phase, polar, real, imaginary or Smith Chart formats.

Integration of the synthesized source, reflection analyzer and display

unit into one system makes the 6210 ideal for both production testing

and design work. The soft key menu structure leads the user through

the measurement and prompts appear when data has to be entered.

Measurement setups and calibrations can be stored in the instrument

memory. The macro facility reduces test time in production areas by

automating repetitive test methods.

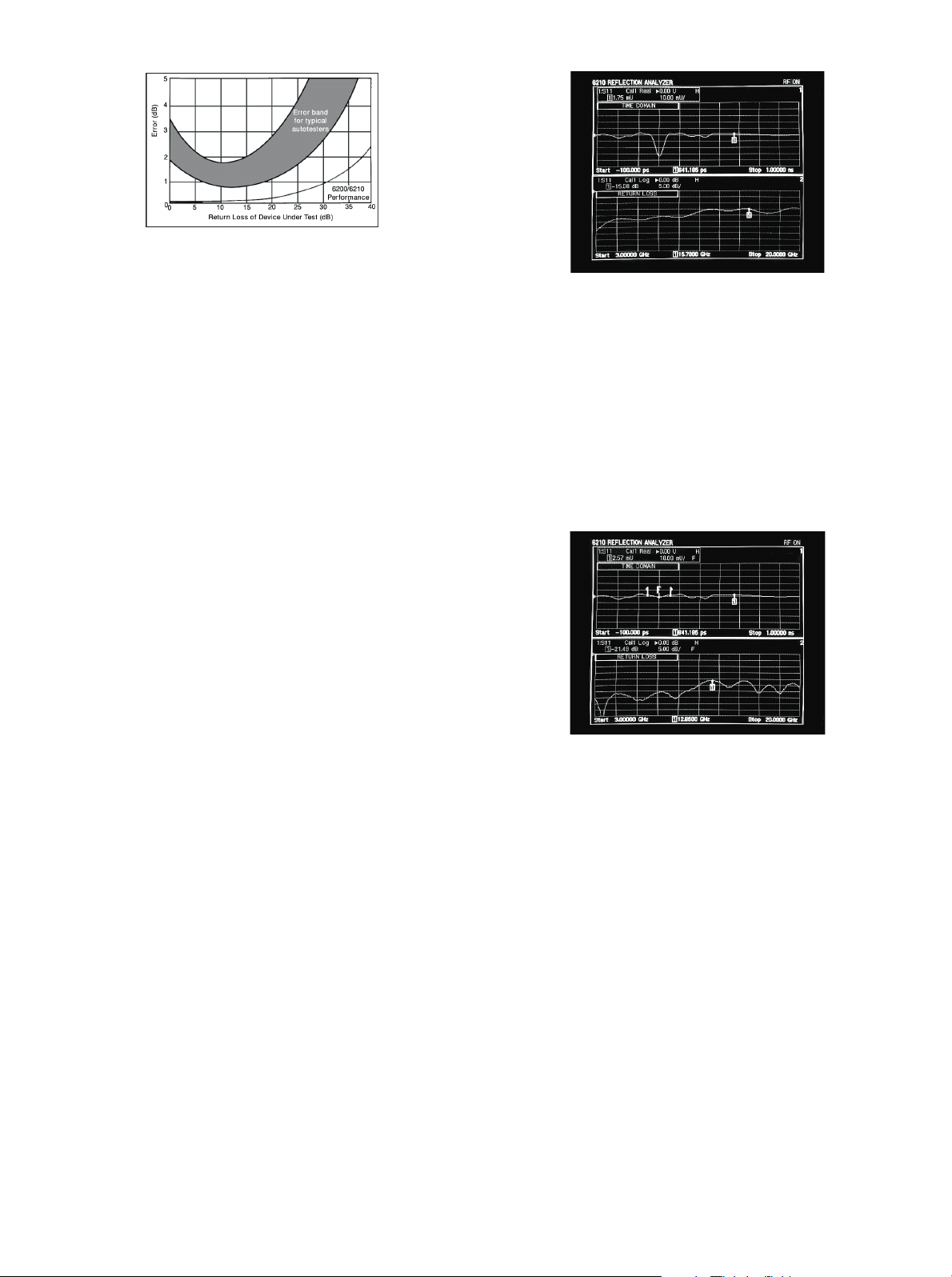

Time Domain Analysis

For design engineers early iterations of systems or components often

need trouble shooting. A poor return loss can be the result of bad

connector assembly, unoptimized track layout or incorrect component design. Time domain software gives a display of reflection coefficient against time (or distance) which simplifies diagnosis and pinpoints the problem area. The nature of the problem, capacitive or

inductive, can be identified from the reflection coefficient value.

Engineers can easily see if the device under test is faulty or needs

improved impedance matching between adjacent components.

Time domain works by performing an inverse Fourier transform on

the frequency domain data. Both lowpass and bandpass modes are

available. Lowpass mode simulates a traditional Time Domain

Reflectometer (TDR). It can be set up for both step and impulse

responses. Low-pass mode can only be used on devices whose frequency characteristics extend down to DC. For frequency selective

devices such as waveguide, filters and antennas bandpass mode must

be used. The display zoom feature can be used to examine the frequency range of interest with greater clarity rather than the complete

range of the calibration.

To overcome the effects of dispersion in waveguide a non linear

(warped) frequency sweep can be selected. A normal linear sweep

would blur the position of a discontinuity. Warped sweeps allow the

discontinuity to be pinpointed accurately.

Time domain response and return loss measurement of a

microwave component

Once a discontinuity has been identified the gating and fencing functions can be used to isolate it mathematically. Fencing allows the user

to see what the return loss would be without the effect of a particular

fault. Conversely gating allows the user to see what the return loss of

a specific fault or discontinuity is. These features are very powerful

tools for diagnosing and improving the performance of a system.

Knowing the position and severity of faults in a device means that they

can be modified in the shortest possible time, speeding up design

cycles.

For the same device shown previously, this display shows time

domain response with fence around fault and return loss of

device with effect of discontinuity removed

Complex Reflection Coefficient

When building up systems which include devices such as transistors,

PIN diodes, varactor diodes, capacitors and resistors, it is often necessary to fully characterize these devices. This allows prediction of

the performance of a circuit at an early stage of the design reducing

the number of design iterations. In order to match consecutive

devices in a circuit it is essential to have knowledge of the complex

reflection coefficient of each stage (input and output). This enables

a matching circuit to be designed to ensure the overall circuit performance meets its specification. 6210 can display complex reflection

coefficient in either polar or Smith Chart format. The accuracy of the

device characterization can be enhanced by using the time domain

gating function and electrical delay.

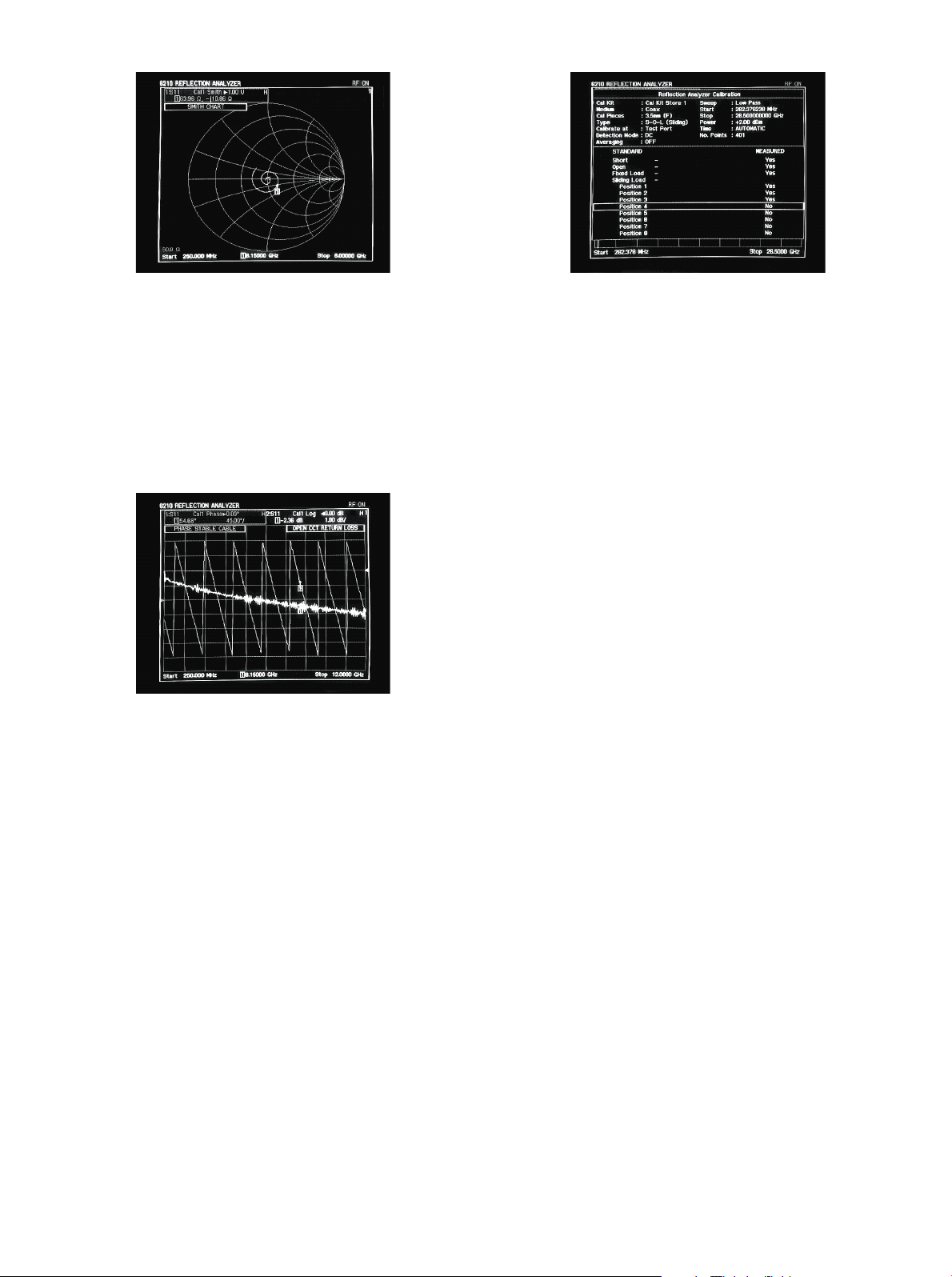

Smith Chart gives impedance information to aid design of

matching circuits

The electrical delay facility of 6210 allows the user to shift the reference plane. When characterizing devices on a substrate or in a test

fixture it is often necessary to shift the reference plane to the input of

the device. This removes the response of the length of transmission

line between the test port and the device input resulting in a display

of input impedance of the device.

Phase Display

Phase characteristics and open circuit return loss measurement

on a phase stable cable

The display can be formatted to show phase in degrees against frequency. This facility is invaluable for testing the phase stability of

cables and for phase matching lengths of transmission line such as

semi-rigid coax.

A cable with poor phase stability will introduce errors into measurements if moved after a calibration. Storing the phase characteristics

of a cable into a trace memory and then comparing with a live trace

enables the quality of the cable to be evaluated quickly.

Fast Calibration

An intuitive menu structure enables the user to quickly calibrate the

6210. Calibration kits are available for coaxial 3.5 mm, Type N and 7

mm connectors. Waveguide calibrations are also supported. A sliding load can give directivities of over 50 dB for coaxial measurements.

Screen displays lead the user through the calibration procedure

The overall performance of the 6210 is determined by the specification of the calibration kit used. The directivity, source match and

response errors can be characterized by measuring known standards.

Error correction routines in the 6210 then minimize errors during

normal measurements. IFR offer full calibration kits including short

and open circuits, fixed and sliding loads, connector gauges, test port

adapters and torque spanners. To verify calibrations optional airlines

are also available. The calibration kits are supplied in a protective

wooden storage box.

Economy calibration kits which include open and short circuits and

fixed loads are also available.

Active Device Measurement

For testing some active devices such as PIN and varactor diodes and

transistors it is necessary to have a biasing voltage on the output of the

test port. The optional bias tee (option 011) allows voltages to be

applied to the test port. The internal voltage/current source of the

MTS can be used as the supply.

Test Port Flexibility

The use of adapters at the test port to provide the most suitable test

port connector does not degrade measurement accuracy. This is

because calibration removes the effect of the adapter. Errors associated with scalar analyzers and autotesters using test port adapters are

therefore not encountered when using the 6210 Reflection Analyzer.

A range of ruggedized test port cables are available. Test port cables

allow error corrected measurements to be made remote from the

front panel connector with the choice of test port connectors including 3.5 mm male and female and Type N male and female or 7 mm.

All test port cables are phase stable so that repositioning the cable

after a calibration will still give good measurement accuracy.

Comprehensive Measurement System

A 6210 can be added to any 6200B series Microwave Test Set. All the

features of the 6200B are retained including absolute power measurement, frequency counter, voltage/current source, standard scalar

analyzer and synthesized sweep generator. The synthesizer can also

be used as a CW signal source.

6210 can be added to an MTS at any time giving an easy upgrade

route for users whose measurement requirements become more

demanding. The comprehensive marker functions, limit lines, scaling and plotting functions are all available when using the 6210

Reflection Analyzer.

For the very latest specifications visit www.aeroflex.com

Loading...

Loading...