Page 1

AM/FM SIGNAL GENERATORS

2023A, 2023B, 2025

Maintenance Manual

Document part no. 46892/377

Page 2

AM/FM SIGNAL GENERATORS

2023, 2023A, 2023B, 2024 & 2025

Includes information on:

Option 1: No attenuator

Option 2: DC operation

Option 3: High power

Option 4: High stability frequency standard

Option 5: Rear panel connectors

Option 7: Fast pulse modulation

Option 10: 1 V peak mod input

Option 11: Fast pulse and high power

Option 12: SINAD

© IFR Ltd. 1999

No part of this book may be reproduced or transmitted in any form

or by any means, electronic or mechanical, including photocopying,

or recorded by any information storage or retrieval system, without

permission in writing by IFR Ltd.

Printed in the UK

Manual part no. 46882-377

Issue 1

8 March 1999

Page 3

This manual provides servicing information down to a defined circuit area for the 2023, 2023A,

2023B, 2024 and 2025 AM/FM Signal Generators.

Intended audience

The book is intended for qualified service engineers and assumes a knowledge of the instrument to

a level covered in:

Operating Manual 46882-225 for 2023 and 2024

Operating Manual 46882-373 for 2023A, 2023B and 2025.

Structure

Chapter 1 Technical description

This includes block diagrams and detailed board circuit descriptions. The circuit

descriptions refer directly to the servicing diagrams contained in Chapter 7.

Chapter 2 Maintenance

Refer to this chapter for board and unit access, service policy and routine safety

testing and inspection.

Chapter 3 Adjustment procedures

Refer to this chapter for information on password use and adjustment procedures.

Chapter 4 Initial repair

What to do if the instrument shows no signs of life.

Chapter 5 Fault diagnosis

Based on error message reports; narrows the search down to a defined circuit area.

Chapter 6 Replaceable parts

Contains instrument and board component parts, and a section on miscellaneous

mechanical parts.

Chapter 7 Servicing diagrams

Contains interconnection drawings, board circuits and component layout

diagrams.

About this manual

Associated publications

Refer to the relevant Operating Manual (part number 46882-225 for 2023 and 2024, part number

46882-373 for 2023A, 2023B and 2025) for an up-to-date list of associated publications.

ii 46882-377

Page 4

Contents

Precautions......................................................................................................................................................... iv

Précautions........................................................................................................................................................vii

Vorsichtsmaßnahmen

Precauz

Precauciones

Chapter 1 TECHNICAL DESCRIPTION

Chapter 2 MAINTENANCE...........................................................................................................................2-1

Chapter 3 ADJUSTMENT PROCEDURES .................................................................................................3-1

Chapter 4 INITIAL REPAIR .........................................................................................................................4-1

Chapter 5 FAULT DIAGNOSIS ....................................................................................................................5-1

Chapter 6 REPLACEABLE PARTS .............................................................................................................6-1

Chapter 7 SERVICING DIAGRAMS............................................................................................................7-1

ioni .......................................................................................................................................................xiii

.....................................................................................................................................................xvi

Adjustments..............................................................................................................................3-4

Recommended test equipment ................................................................................................3-7

Adjustment procedures............................................................................................................3-8

Adjustment procedures for instruments fitted with Option 3 or 11..................................3-22

Adjustment procedure tables................................................................................................3-24

Appendix A Calibration GPIB commands ........................................................................... A-1

Circuit notes..............................................................................................................................7-2

......................................................................................................................................... x

....................................................................................................1-1

46882-377 iii

Page 5

PRECAUTIONS

Precautions

These terms have specific meanings in this manual:

WARNING

Information to prevent personal injury.

Information to prevent damage to the equipment.

Important general information.

Symbols used on this product

The meaning of hazard symbols appearing on the equipment is as follows:

Symbol Nature of hazard

General hazard

Dangerous voltage

Toxic hazard

Static-sensitive components

General conditions of use

This product is designed and tested to comply with the requirements of IEC/EN61010-1 ‘Safety

requirements for electrical equipment for measurement, control and laboratory use’, for Class I

portable equipment and is for use in a pollution degree 2 environment. The equipment is designed

to operate from an installation category I and II supply.

Equipment should be protected from the ingress of liquids and precipitation such as rain, snow,

etc. When moving the equipment from a cold to a hot environment, it is important to allow the

temperature of the equipment to stabilize before it is connected to the supply to avoid

condensation forming. The equipment must only be operated within the environmental conditions

specified in Chapter 1 ‘Performance data’ in the Operating manual, otherwise the protection

provided by the equipment may be impaired.

This product is not approved for use in hazardous atmospheres or medical applications. If the

equipment is to be used in a safety-related application, e.g. avionics or military applications, the

suitability of the product must be assessed and approved for use by a competent person.

WARNING

Electrical hazards (AC supply voltage)

iv 46882-377

This equipment conforms with IEC Safety Class I, meaning that it is provided with a protective

grounding lead. To maintain this protection the supply lead must always be connected to the

source of supply via a socket with a grounded contact.

Be aware that the supply filter contains capacitors that may remain charged after the equipment is

disconnected from the supply. Although the stored energy is within the approved safety

requirements, a slight shock may be felt if the plug pins are touched immediately after removal.

Page 6

Fuses

Note that the internal supply fuse is in series with the live conductor of the supply lead. If

connection is made to a 2-pin unpolarized supply socket, it is possible for the fuse to become

transposed to the neutral conductor, in which case, parts of the equipment could remain at supply

potential even after the fuse has ruptured.

Removal of covers

Disconnect the supply before removing the covers so as to avoid the risk of exposing high voltage

parts. If any internal adjustment or servicing has to be carried out with the supply on, it must only

be performed by a skilled person who is aware of the hazard involved.

PRECAUTIONS

WARNING

Electrical hazards (DC supply voltage)

This equipment conforms with IEC safety Class III, meaning that for continued safety it must only

be connected to supplies and signal sources which conform to ‘Separated Extra-Low Voltage’

(SELV and SELV-E) voltage and insulation requirements. No hazardous voltages are generated

internally. See under ‘Performance data’ in Chapter 1 of the Operating Manual for the maximum

permitted voltage levels that can be applied.

WARNING

Fire hazard

WARNING

RF hazard

Make sure that only fuses of the correct rating and type are used for replacement.

If an integrally fused plug is used on the supply lead, ensure that the fuse rating is commensurate

with the current requirements of this equipment. See under ‘Performance data’ in Chapter 1 in the

Operating manual for power requirements.

Do not disconnect RF cables which are carrying high levels of RF power. High voltages, which

can cause RF burns, may be present at the end of the unterminated cables due to standing waves.

Switch off the transmitter or other source of RF power before disconnecting the cable from the

equipment.

WARNING

Toxic hazards

WARNING

Beryllia

46882-377 v

Some of the components used in this equipment may include resins and other materials which give

off toxic fumes if incinerated. Take appropriate precautions, therefore, in the disposal of these

items.

Beryllia (beryllium oxide) is used in the construction of the followin g

components in this equipment :

TR808 on AA1 and AA1/1;

TR1 and TR2 on AA2/1 and AA2/7.

Page 7

PRECAUTIONS

This material, when in the form of fine dust or vapor and inhaled into the lungs, can cause a

respiratory disease. In its solid form, as used here, it can be handled quite safely although it is

prudent to avoid handling conditions which promote dust formation by surface abrasion.

Because of this hazard, you are advised to be very careful in removing and disposing of these

components. Do not put them in the general industrial or domestic waste or despatch them by

post. They should be separately and securely packed and clearly identified to show the nature of

the hazard and then disposed of in a safe manner by an authorized toxic waste contractor.

WARNING

Beryllium copper

Some mechanical components within this instrument are manufactured from beryllium copper.

This is an alloy with a beryllium content of approximately 5%. It represents no risk in normal use.

The material should not be machined, welded or subjected to any process where heat is involved.

It must be disposed of as “special waste”.

It must NOT be disposed of by incineration.

Static-sensitive components

The presence of static-sensitive components is indicated in the equipment by yellow disks, flags or

labels bearing the symbol

components being permanently damaged by static charges or fast surges:

1. If a static-sensitive component is to be removed or replaced, the following anti-static

equipment should be used:

• A work bench with a grounded conductive surface.

• Metallic tools grounded either permanently or by repeated discharges.

• A low-voltage grounded soldering iron.

. Certain handling precautions should be observed to prevent these

• A grounded wrist strap and a conductive grounded seat cover for the operator

2. If a printed board containing static-sensitive components (as indicated by warning disk or

flag) is removed, it must be temporarily stored in a conductive plastic bag.

3. As a general precaution, avoid touching the leads of a static-sensitive component. When

handling a new one, leave it in its conducting mount until it is required for use.

4. If using a freezer aerosol in fault finding, take care not to spray programmable ICs as this may

affect their contents.

Suitability for use

This equipment has been designed and manufactured by IFR Ltd. to generate VHF and UHF

signals for the testing of radio communications apparatus. IFR Ltd. has no control over the use of

this equipment and cannot be held responsible for events arising from its use other than for its

intended purpose.

whose outer clothing should not be of man-made fiber.

vi 46882/377

Page 8

Précautions

Les termes suivants ont, dans ce manuel, des significations particulières:

PRECAUTIONS

WARNING

contient des informations pour éviter toute blessure au personnel.

contient des informations pour éviter les dommages aux équipements.

contient d’importantes informations d’ordre général.

Symboles

La signification des symboles liés à cet équipement est la suivante:

Symbole Nature du risque

Risques généraux

Tension dangereuse

Danger produits toxiques

Conditions générales d’utilisation

Ce produit a été conçu et testé pour être conforme aux exigences des normes CEI/EN61010-1

“Règles de sécurité pour appareils électriques de mesurage, de régulation et de laboratoire”, pour

des équipements Classe I portables et pour une utilisation dans un environnement de pollution de

niveau 2. Cet équipement est conçu pour fonctionner à partir d’une alimentation de catégorie I et

II.

Cet équipement doit être protégé de l’introduction de liquides ainsi que des précipitations d’eau,

de neige, etc... Lorsqu’on transporte cet équipement d’un environnement chaud vers un

environnement froid, il est important de laisser l’équipement se stabiliser en température avant de

le connecter à une alimentation afin d’éviter toute formation de condensation. L'appareil doit être

utilisé uniquement dans le cadre des conditions d'environnement spécifiées au chapitre 1

"Performance data" du manuel d'utilisation, toute autre utilisation peut endommager les systèmes

de protection.

Ce produit n’est pas garanti pour fonctionner dans des atmosphères dangereuses ou pour un usage

médical. Si l'équipement doit être utilisé pour des applications en relation avec la sécurité, par

exemple des applications militaires ou aéronautiques, la compatibilité du produit doit être établie

et approuvée par une personne compétente.

WARNING

Sécurité électrique (tension d’alimentation alternative)

!

Cet appareil est protégé conformément à la norme CEI de sécurité Classe 1, c’est-à-dire que sa

prise secteur comporte un fil de protection à la terre. Pour maintenir cette protection, le câble

d’alimentation doit toujours être branché à la source d’alimentation par l’intermédiaire d’une prise

comportant une borne de terre.

Notez que les filtres d’alimentation contiennent des condensateurs qui peuvent encore être chargés

lorsque l’appareil est débranché. Bien que l’énergie contenue soit conforme aux exigences de

sécurité, il est possible de ressentir un léger choc si l’on touche les bornes sitôt après

débranchement.

Fusibles

Notez que le fusible d’alimentation interne est en série avec la phase du câble d’alimentation. Si la

prise d’alimentation comporte deux bornes non polarisées, il est possible de connecter le fusible au

46882-377 vii

Page 9

PRECAUTIONS

neutre. Dans ce cas, certaines parties de l’appareil peuvent rester à un certain potentiel même

après coupure du fusible

Retrait des couvercles

L’appareil doit être débranché avant de retirer les couvercles afin d’éviter tout contact avec les

éléments haute tension. Si toutefois un réglage interne ou une réparation nécessitent la présence

de l’alimentation, ils devront être effectués par une personne qualifiée et avisée des risques

encourus.

WARNING

Sécurité électrique (tension d’alimentation continue)

Cet équipement est conforme aux normes de sécurité CEI Classe III, c’est-à-dire qu’il ne doit être

connecté qu’à des sources d’alimentation ou de signaux qui suivent les recommandations de

tension et d’isolement du type ‘Tension extra-faible séparée’ (SELV at SELV-E). Aucune tension

dangereuse n’est générée en interne. “Performance data” dans le chapitre 1 du manuel

d’utilisation précise les niveaux de tension maximum acceptables en entrée.

WARNING

Risque lié au feu

Lors du remplacement des fusibles vérifiez l’exactitude de leur type et de leur valeur.

Si le câble d’alimentation comporte une prise avec fusible intégré, assurez vous que sa valeur est

compatible avec les besoins en courant de l’appareil. Pour la consommation, reportez-vous au

“Performance data” dans le chapitre 1 du manuel d’utilisation.

Danger RF

Ne jamais debrancher un câble RF connecté à une source de puissance RF en fonctionnement. Il

peut y avoir, à l'extrémité d'un câble non chargé, des tensions très importantes susceptibles de

causer des brûlures graves. Toujours éteindre la source de puissance RF avant de débrancher le

câble sur l'équipement.

WARNING

Danger produits toxiques

Certains composants utilisés dans cet appareil peuvent contenir des résines et d’autres matières qui

dégagent des fumées toxiques lors de leur incinération. Les précautions d’usages doivent donc

être prises lorsqu’on se débarrasse de ce type de composant.

WARNING

Le Béryllia

Le Béryllia (oxyde de Béryllium) entre dans la composition des composants suivants:

TR808 sur AA1 et AA1/1;

TR1 et TR2 sur AA2/1 et AA2/7.

Cette matière peut, lorsqu’elle est inhalée sous forme de vapeur ou de fine poussière, être la cause

de maladies respiratoires. Sous sa forme solide, comme c’est le cas ici, cette matière peut être

manipulée sans risque, bien qu’il soit conseillé d’éviter toute manipulation pouvant entraîner la

formation de poussière par abrasion de la surface.

Il est donc conseillé, pour éviter ce risque, de prendre les précautions requises pour retirer ces

composants et s’en débarrasser. Ne les jetez pas avec les déchets industriels ou domestiques ou ne

les envoyez pas par la poste. Il faut les emballer séparément et solidement et bien indiquer la

nature du risque avant de les céder, avec précautions, à une entreprise spécialisée dans le

traitement de déchets toxiques.

viii 46882/377

Page 10

PRECAUTIONS

WARNING

Bronze au béryllium

Dans cet équipement,certaines pièces mécaniques sont à base de bronze au béryllium. Il s'agit d'un

alliage dans lequel le pourcentage de béryllium ne dépasse pas 5%. Il ne présente aucun danger en

utilisation normale.

Toutefois, cet alliage ne doit pas être travaillé, soudé ou soumis à un processus qui implique

l'utilisation d'une source de chaleur.

En cas de destruction, il sera entreposé dans un container spécial. IL ne devra pas être détruit par

incinération.

46882-377 ix

Page 11

PRECAUTIONS

Vorsichtsmaßnahmen

Diese Hinweise haben eine bestimmte Bedeutung in diesem Handbuch:

WARNING

dienen zur Vermeidung von Verletzungsrisiken.

dienen dem Schutz der Geräte.

enthalten wichtige Informationen.

Symbole

Die Gefahrensymbole auf den Geräten sind wie folgt:

Symbol Gefahrenart

Allgemeine Gefahr

Gefährliche Spannung

Warnung vor giftigen Substanzen

Allgemeine Hinweise zur Verwendung

Dieses Produkt wurde entsprechend den Anforderungen von IEC/EN61010-1

“Sicherheitsanforderungen für elektrische Ausrüstung für Meßaufgaben, Steuerung und

Laborbedarf”, Klasse I transportabel zur Verwendung in einer Grad 2 verunreinigten Umgebung,

entwickelt und getestet. Dieses Gerät ist für Netzversorgung Klasse I und II zugelassen.

Das Gerät sollte vor dem Eindringen von Flüssigkeiten sowie vor Regen, Schnee etc. geschützt

werden. Bei Standortänderung von kalter in wärmere Umgebung sollte das Gerät wegen der

Kondensation erst nach Anpassung an die wärmere Umgebung mit dem Netz verbunden werden.

Das Gerät darf nur in Umgebungsbedingungen wie in Kapitel 1 "Leistungsdaten (Performance

data)" der Bedienungsanleitung beschrieben, betrieben werden; ansonsten wird der vom Gerät

vorgesehene Schutz des Anwenders beeinträchtigt.

Dieses Produkt ist nicht für den Einsatz in gefährlicher Umgebung (z.B. Ex-Bereich) und für

medizinische Anwendungen geprüft. Sollte das Gerät für den Einsatz in sicherheitsrelevanten

Anwendungen wie z.B. im Flugverkehr oder bei militaerischen Anwendungen vorgesehen sein, so

ist dieser von einer für diesen Bereich zuständigen Person zu beurteilen und genehmigen.

WARNING

Elektrische Schläge (Wechselspannungsversorgung)

Das Gerät entspricht IEC Sicherheitsklasse 1 mit einem Schutzleiter nach Erde. Das Netzkabel

muß stets an eine Steckdose mit Erdkontakt angeschlossen werden.

Filterkondensatoren in der internen Spannungsversorgung können auch nach Unterbrechung der

Spannungszuführung noch geladen sein. Obwohl die darin gespeicherte Energie innerhalb der

Sicherheitsmargen liegt, kann ein leichter Spannungsschlag bei Berührung kurz nach der

Unterbrechung erfolgen.

Sicherungen

Die interne Sicherung in der Spannungszuführung ist in Reihe mit der spannungsführenden

Zuleitung geschaltet. Bei Verbindung mit einer zweiadrigen, nicht gepolten Steckdose kann die

Sicherung in der Masseleitung liegen, so daß auch bei geschmolzener Sicherung Geräteteile immer

noch auf Spannungspotential sind.

x 46882/377

Page 12

Abnahme von Abdeckungen

Die Spannungsversorgung muß vor Abnahme von Gehäuseabdeckungen unterbrochen sein, damit

hochspannungsführende Teile gefahrlos zugänglich sind. Falls Abgleiche oder Servicearbeiten

unter Spannung notwendig werden, dürfen solche Arbeiten nur von fachkundigem Personal

durchgeführt werden, das die Gefahren kennt.

PRECAUTIONS

WARNING

Elektrische Schläge (Gleichspannungsversorgung)

Dieses Gerät entspricht der IEC Sicherheitsklasse III. Aus Sicherheitsgründen darf es nur an

Netzgeräte und Signalquellen angeschlossen werden, die in Spannung und Isolation der SELV und

SELV-E Richtlinie genügen (“Getrennte Niederspannung”). Im Gerät werden keine gefährlichen

Spannungen erzeugt. Im Handbuch, Kapitel 1, “Performance data” (Leistungsdaten), werden die

anschließbaren Höchstspannungen definiert.

WARNING

Feuergefahr

Es dürfen nur Ersatzsicherungen vom gleichen Typ mit den korrekten Spezifikationen

entsprechend der Stromaufnahme des Gerätes verwendet werden. Siehe hierzu Kapitel 1

“Leistungsdaten (Performance data)” der Bedienungsanleitung.

WARNING

Hochfrequenzstrahlung

Lösen Sie keine Kabel an welchen größere Pegel von Hochfrequenzleistung anliegen. An den

nichtabgeschlossenen Enden von HF Kabeln können auf Grund von Stehwellen hohe Spannungen

auftreten. Diese verursachen unter Umständen Verbrennungen. Schalten Sie den Sender oder die

Quelle der HF-Leistung vor dem Lösen des HF-Kabels ab.

WARNING

Warnung vor giftigen Substanzen

In einigen Bauelementen dieses Geräts können Epoxyharze oder andere Materialien enthalten sein,

die im Brandfall giftige Gase erzeugen. Bei der Entsorgung müssen deshalb entsprechende

Vorsichtsmaßnahmen getroffen werden.

WARNING

Beryllium Oxid

Beryllium Oxid wird in den folgenden Bauelementen dieses Geräts verwendet:

TR808 auf AA1 und AA1/1;

TR1 und TR2 auf AA2/1 und AA2/7.

Als Staub inhaliert kann Beryllium zu Schädigungen der Atemwege führen. In fester Form kann

es ohne Gefahr gehandhabt werden, wobei Staubabrieb vermieden werden sollte.

Wegen dieser Gefahren dürfen diese Bauelemente nur mit der entsprechenden Vorsicht ausgebaut

und entsorgt werden. Sie dürfen nicht mit Industrie oder Hausmüll vermengt oder per Post

versandt werden. Sie müssen separat verpackt und entsprechend der Gefährdung markiert werden.

Die Entsorgung muß über einen autorisierten Fachbetrieb erfolgen.

46882-377 xi

Page 13

PRECAUTIONS

WARNING

Beryllium Kupfer

In diesem Gerät sind einige mechanische Komponenten aus Berylium Kupfer gefertigt. Dies ist

eine Verbindung welche aus einem Berylliumanteil von ca. 5 % besteht. Bei normaler

Verwendung besteht kein Gesundheitsrisiko.

Das Metall darf nicht bearbeitet, geschweißt oder sonstiger Wärmebehandlung ausgesetzt werden.

Es muß als Sondermüll entsorgt werden.

Es darf nicht durch Verbrennung entsorgt werden.

xii 46882/377

Page 14

Precauzioni

Questi termini vengono utilizzati in questo manuale con significati specifici:

PRECAUTIONS

WARNING

riportano informazioni atte ad evitare possibili pericoli alla persona.

riportano informazioni per evitare possibili pericoli all'apparecchiatura.

riportano importanti informazioni di carattere generale.

Simboli

Significato dei simboli di pericolo utilizzati nell’apparato:

Simbolo Tipo di pericolo

Pericolo generico

Tensione pericolosa

Pericolo sostanze tossiche

Condizioni generali d’uso

Questo prodotto è stato progettato e collaudato per rispondere ai requisiti della direttiva

IEC/EN61010-1 ‘Safety requirements for electrical equipment for measurement, control and

laboratory use’ per apparati di classe I portatili e per l’uso in un ambiente inquinato di grado 2.

L’apparato è stato progettato per essere alimentato da un alimentatore di categoria I e II.

Lo strumento deve essere protetto dal possibile ingresso di liquidi quali, ad es., acqua, pioggia,

neve, ecc. Qualora lo strumento venga portato da un ambiente freddo ad uno caldo, è importante

lasciare che la temperatura all’interno dello strumento si stabilizzi prima di alimentarlo per evitare

formazione di condense. Lo strumento deve essere utilizzato esclusivamente nelle condizioni

ambientali descritte nel capitolo 1 ‘Performance data’ del manuale operativo, in caso contrario le

protezioni previste nello strumento potrebbero risultare non sufficienti.

Questo prodotto non è stato approvato per essere usato in ambienti pericolosi o applicazioni

medicali. Se lo strumento deve essere usato per applicazioni particolari collegate alla sicurezza

(per esempio applicazioni militari o avioniche),occorre che una persona o un istituto competente

ne certifichi l'uso.

WARNING

Pericoli da elettricità (alimentazione c.a.)

Quest ’apparato è provvisto del collegamento di protezione di terra e rispetta le norme di sicurezza

IEC, classe 1. Per mantenere questa protezione è necessario che il cavo, la spina e la presa

d’alimentazione siano tutti provvisti di terra.

Il circuito d’alimentazione contiene dei filtri i cui condensatori possono restare carichi anche dopo

aver rimosso l’alimentazione. Sebbene l’energia immagazzinata è entro i limiti di sicurezza,

purtuttavia una leggera scossa può essere avvertita toccando i capi della spina subito dopo averla

rimossa.

46882-377 xiii

Page 15

PRECAUTIONS

Fusibili

Notare che un fusibile è posto sul filo caldo del cavo di alimentazione. Qualora l’alimentazione

avvenga tramite due poli non polarizzati, è possibile che il fusibile vada a protezione del neutro

per cui anche in caso di una sua rottura, l’apparato potrebbe restare sotto tensione.

Rimozione dei coperchi

Prima di rimuovere i coperchi occorre scollegare la spina d’alimentazione onde evitare il rischio di

esposizione di parti ad alta tensione. Eventuali operazioni di manutenzione che richiedono la

presenza dell’alimentazione dovranno essere eseguite solo da parte di personale specializzato ed a

conoscenza dei pericoli coinvolti.

WARNING

Pericoli da elettricità (alimentazione a c.c.)

Questo strumento rispetta le norme IEC, classe III, e quindi, per una completa sicurezza, deve

essere collegato solo ad alimentatori e generatori di segnali che rispettano I requ isiti d i ten s ione ed

isolamento SELV e SELV-E (Separated Extra-Low Voltage). Nessuna tensione pericolosa è

generata al suo interno. Vedi capitolo 1 del manuale operativo per quanto concerne I livelli

massimi di tensione applicabili.

WARNING

Pericolo d’incendio

Assicurarsi che, in caso di sostituzione, vengano utilizzati solo fusibili della portata e del tipo

prescritti.

Se viene usata una spina con fusibili, assicurarsi che questi siano di portata adeguata ai requisiti di

alimentazione richiesti dallo strumento. Tali requisiti sono riportati nel cap. 1 “Performance data”

del manuale operativo.

WARNING

Rischio a RF

Non sconnettere cavi RF sui quali si stia trasmettendo un segnale RF ad alta potenza. Un'alta

tensione, che può causare bruciature, potrebbe essere presente alla fine di cavi non terminati a

causa delle onde stazionarie. Spegnere il trasmettitore od altra sorgente di segnale RF prima di

disconnettere il cavo dall'apparato.

WARNING

Pericolo sostanze tossiche

Alcuni dei componenti usati in questo strumento possono contenere resine o altri materiali che, se

bruciati, possono emettere fumi tossici. Prendere quindi le opportune precauzioni nell’uso di tali

parti.

WARNING

Berillio

xiv 46882/377

Berillio (ossido di berillio) è utilizzato nella costruzione dei seguenti componenti di

quest’apparato:

Page 16

PRECAUTIONS

TR808 schema AA1 e AA1/1;

TR1 e TR2 schema AA2/1 e AA2/7.

Questo materiale, se inalato sotto forma di polvere fine o vapore, può causare malattie respiratorie.

Allo stato solido, come è usato qui, può essere maneggiato con sufficiente sicurezza anche se è

prudente evitare condizioni che provochino la formazione di polveri tramite abrasioni superficiali.

A cause di questi pericoli occorre essere molto prudenti nella rimozione e nella locazione di questi

componenti. Questi non devono essere gettati tra i rifiuti domestici o industriali né. vanno spediti

per posta. Essi devono essere impacchettati separatamente ed in modo sicuro e devono indicare

chiaramente la natura del pericolo e quindi affidate a personale autorizzato.

WARNING

Rame berillio

Alcuni componenti meccanici in questo strumento sono realizzati in rame berillio. Si tratta di una

lega con contenuto di berillio di circa il 5%, che non presenta alcun rischio in usi normali.

Questo materiale non deve essere lavorato, saldato o subire qualsiasi processo che coinvolge alte

temperature.

Deve essere eliminato come "rifiuto speciale". Non deve essere eliminato tramite "inceneritore".

46882-377 xv

Page 17

PRECAUTIONS

Precauciones

Estos términos tienen significados específicos en este manual:

WARNING

contienen información referente a prevención de daños personales.

contienen información referente a prevención de daños en equipos.

contienen información general importante.

Símbolos

Los significados de los símbolos de peligro que aparecen en los equipos son los siguientes:

Símbolo Naturaleza del peligro

Peligro general

Voltaje peligroso

Aviso de toxicidad

Condiciones generales de uso

Este producto ha sido diseñado y probado para cumplir los requerimientos de la normativa

IEC/EN61010-1 “Requerimientos de la normativa para equipos eléctricos de medida, control y uso

en laboratorio”, para equipos clase I portátiles y para uso en un ambiente con un grado de

contaminación 2. El equipo ha sido diseñado para funcionar sobre una instalación de alimentación

de categorías I y II.

Debe protegerse el equipo de la entrada de líquidos y precipitaciones como nieve, lluvia, etc.

Cuando se traslada el equipo de entorno frío a un entorno caliente, es importante aguardar la

estabilización el equipo para evitar la condensación. Sólo debe utilizarse el aparato en las

condiciones ambientales especificadas en el capítulo 1 “Especificaciones” o “Performance data”

del Manual de Instrucciones/Manual de Operación, en caso contrario la propia protección del

equipo puede resultar dañada.

Este producto no ha sido aprobado para su utilización en entornos peligrosos o en aplicaciones

médicas. Si se va a utilizar el equipo en una aplicación con implicaciones en cuanto a seguridad,

como por ejemplo aplicaciones de aviónica o militares, es preciso que un experto competente en

materia de seguridad apruebe su uso.

WARNING

Nivel peligroso de electricidad (tensión de red)

Este equipo cumple las normas IEC Seguridad Clase 1, lo que significa que va provisto de un

cable de protección de masa. Para mantener esta protección, el cable de alimentación de red debe

de conectarse siempre a una clavija con terminal de masa.

Tenga en cuenta que el filtro de red contiene condensadores que pueden almacenar carga una vez

desconectado el equipo. Aunque la energía almacenada está dentro de los requisitos de seguridad,

pudiera sentirse una ligera descarga al tocar la clavija de alimentación inmediatamente después de

su desconexión de red.

Fusibles

Se hace notar que el fusible de alimentación interno está enserie con el activo del cable de

alimentación a red. Si la clavija de alimentación de red cuenta con sólo dos terminales sin

polaridad, el fusible puede pasar a estar en serie con el neutro, en cuyo caso existen partes del

equipo que permanecerían a tensión de red incluso después de que el fusible haya fundido.

xvi 46882/377

Page 18

Para retirar las tapas

Desconectar de red antes de retirar las tapas para evitar el riesgo que supone tener accesibles

aquellas partes del equipo expuestas a alta tensión. Aquellas operaciones que requieran tener

alimentación con las tapas abiertas para mantenimiento o ajuste deben de ser realizadas por

personal cualificado, que esté al tanto de los riesgos implicados.

PRECAUTIONS

WARNING

Nivel peligroso de electricidad (tensión de alimentación DC)

WARNING

Este equipo cumple con la norma de seguridad IEC clase III, lo que significa que para total

seguridad debe ser conectado a alimentaciones y fuentes de señal que cumplan los requerimientos

de tensión y aislamiento “Tensión Separada Extra-Baja” (SELV y SELV-E). Ninguna tensión

generada internamente implica riesgo para el operario.

En el capítulo 1 “Especificaciones” del Manual de Instrucciones/Manual de Operación podrá

encontrar los valores máximos permitidos que pueden aplicarse.

Peligro de incendio

Asegúrese de utilizar sólo fusibles del tipo y valores especificados como repuesto.

Si se utiliza una clavija con fusible incorporado, aseg úrese de que los valores del fusible

corresponden a los requeridos por el equipo. Ver sección de especificaciones del capítulo 1 del

Manual de Instrucciones/Manual de Operación/Funcionamiento para comprobar los requisitos de

alimentación.

WARNING

Peligro de RF

No desconecte cables de RF que transporten niveles altos de potencia de RF. Es posible la

presencia de altas tensiones, capaces de causar quemaduras por RF, en el extremo del cable sin

terminar, debido a ondas estacionarias. Desactive el transmisor u otra fuente de potencia de RF

antes de desconectar el cable de los equipos."

WARNING

Aviso de toxicidad

Alguno de los componentes utilizados en este equipo pudieran incluir resinas u otro tipo de

materiales que al arder produjeran sustancias tóxicas, Por tanto, tome las debidas precauciones en

la manipulación de esas piezas.

WARNING

Berilio

Berilio (óxido de berilio), se ha utilizado en la fabricación de los siguientes componentes del

equipo:

TR808 en AA1 y AA1/1;

TR1 y TR2 en AA2/1 y AA2/7.

La inhalación de este material, en forma de polvo fino o vapor, entrando en los pulmones, puede

ser causa de enfermedades respiratorias. En forma sólida, como se utiliza en este caso, puede

manipularse con bastante seguridad, aunque se recomienda no manejarlo en aquellas condiciones

que pudieran favorecer la aparición de polvo por abrasión de la superficie.

46882-377 xvii

Page 19

PRECAUTIONS

Por todo lo anterior, se recomienda tener el máximo cuidado al reemplazar o deshacerse de estos

componentes, no tirándolos en basuras industriales o domésticas y no utilizar el correo para su

envío. Deben, ser empaquetados de forma segura y separada, y el paquete debidamente etiquetado

e identificado, señalando claramente la naturaleza del riesgo y ponerlo a disposición de un

destructor autorizado de productos tóxicos.

WARNING

Berilio-cobre

Algunos componentes mecánicos contenidos en este instrumento incorporan berilio-cobre en su

proceso de fabricación. Se trata de una aleación con un contenido aproximado de berilio del 5%,

lo que no representa ningún riesgo durante su uso normal.

El material no debe ser manipulado, soldado, ni sometido a ningún proceso que implique la

aplicación de calor.

Para su eliminación debe tratarse como un "residuo especial". El material NO DEBE eliminarse

mediante incineración.

xviii 46882/377

Page 20

Contents

Chapter 1

TECHNICAL DESCRIPTION

Introduction....................................................................................................................................1-3

Synthesizer..............................................................................................................................1-3

RF processing

LF processing

AA1, AA1/1 RF board

Carrier frequency synthesis

RF board: Carrier generation (sheet 1)

RF board: VCXO loop (sheet 2)

RF board: Synthesizer (sheet 3)

RF board: Loop filter and autocal (sheet 4)

RF board: FM drive (sheet 5)

RF board: Level m

RF board: Frequency generator (sheet 7)

RF board: Interface and attenuator drive (sheet 8)

RF board: Output am

AA2 Attenuator board

Circuit functions

AA2/1 High power attenuator board

Circuit functions

High power attenuator board: Pulse m

High power attenuator board: Power am

AA2/2 Signal output board

Circuit function

AA2/5 Fast pulse m

Circuit functions

Fast pulse m

Fast pulse m

AA2/7 Fast pulse and high power board

Circuit functions

Fast pulse and high power board: Pulse m

Fast pulse and high power board: Attenuator (sheet 3)

Fast pulse and high power board: Power am

AB1, AB1/1 Control board

Introduction...........................................................................................................................

Control board: Microprocessor and m

Control board: DSP audio generator (sheet 2)

Control board: Interrupts and serial interface (sheet 3)

Control board: M

Control board: Standard selection (AB1 sheet 5, AB1/1 sheet 6)

Control board: Interface (AB1 sheet 6, AB1/1 sheet 7)

Control board: PSU filtering and regulation (AB1 sheet 7, AB1/1 sheet 9)

Control board: Power supplies (AB1 sheet 8)

Control board: 31 V dc power supply

AB2 SINAD board

AC1 Backlight inverter board

AF1 Front panel

AC power supply

AC/DC power supply

.........................................................................................................................1-3

..........................................................................................................................1-4

..................................................................................................................1-7

....................................................................................................1-7

...................................................................................1-7

.............................................................................................1-8

..............................................................................................1-9

..........................................................................1-10

...............................................................................................1-12

odulator (sheet 6)....................................................................................1-13

.............................................................................1-14

...............................................................1-16

plifier (sheet 9).................................................................................... 1-18

................................................................................................................1-19

...................................................................................................................1-19

...........................................................................................1-20

...................................................................................................................1-20

od & attenuator (sheet 1)..........................................1-21

p & RPP (sheet 2)................................................. 1-21

.........................................................................................................1-22

.....................................................................................................................1-22

odulator board.............................................................................................1-22

...................................................................................................................1-22

odulator board: Pulse mod (sheet 1).................................................................1-23

odulator board: RPP and atten (sheet 2) ...........................................................1-23

.....................................................................................1-24

...................................................................................................................1-24

od (sheet 2).........................................................1-24

........................................................1-24

p & RPP (sheet 4)........................................... 1-25

.........................................................................................................1-26

1-26

emory (sheet 1).........................................................1-26

......................................................................1-28

........................................................1-30

odulation and level (AB1 sheet 4, AB1/1 sheets 4 & 5)...........................1-34

........................................1-35

........................................................1-36

.........................1-37

......................................................................1-39

(AB1/1 sheet 8)........................................................ 1-39

......................................................................................................................1-39

.....................................................................................................1-39

..........................................................................................................................1-40

.........................................................................................................................1-40

...................................................................................................................1-40

46882-377 1-1

Page 21

TECHNICAL DESCRIPTION

List of figures

Fig. 1-1 Signal generator block schematic...................................................................................1-5

Fig. 1-2 100 MHz phase-locked loop...........................................................................................1-8

Fig. 1-3 Frequency synthesis

g. 1-4 FM/ϕM drive................................................................................................................1-13

Fi

Fig. 1-5 Frequency band selection

Fig. 1-6 Microprocessor and control block diagram

Fig. 1-7 Frequency standard selection

Fig. 1-8 Block diagram

List of tables

Table 1-1: Carrier generation.....................................................................................................1-7

Table 1-2: Attenuator board identification...............................................................................1-11

Table 1-3:

Table 1-4:

Table 1-5:

Table 1-6:

Table 1-7:

Table 1-8:

Table 1-9:

Table 1-10:

Table 1-11:

Table 1-12:

Table 1-13:

Table 1-14:

.....................................................................................................1-10

.............................................................................................1-16

..................................................................1-27

.......................................................................................1-36

of AC/DC power supply module .........................................................1-41

Attenuator control settings......................................................................................1-12

Frequency band selection .......................................................................................1-15

Attenuator selection................................................................................................1-17

Interrupts and chip selects ......................................................................................1-28

Memory bank addressing........................................................................................1-28

Interrupt lines..........................................................................................................1-31

Interrupt lines..........................................................................................................1-31

Latch control lines..................................................................................................1-32

Buffered chip selects ..............................................................................................1-33

Latch control lines..................................................................................................1-33

Buffered chip selects ..............................................................................................1-33

Power supplies........................................................................................................1-40

1-2 46882-377

Page 22

Introduction

The 2023, 2023A, 2023B, 2024 and 2025 AM/FM Signal Generators cover the following

frequency ranges:

9 kHz to 1.2 GHz 2023 and 2023A

9 kHz to 2.05 GHz 2023B

9 kHz to 2.4 GHz 2024

9 kHz to 2.51 GHz 2025

Output levels from -140 dBm to +13 dBm are available. Factory fitted options are available to

extend the level to +25 dBm (+19 dBm above 1.2 GHz) and to provide SINAD measurement

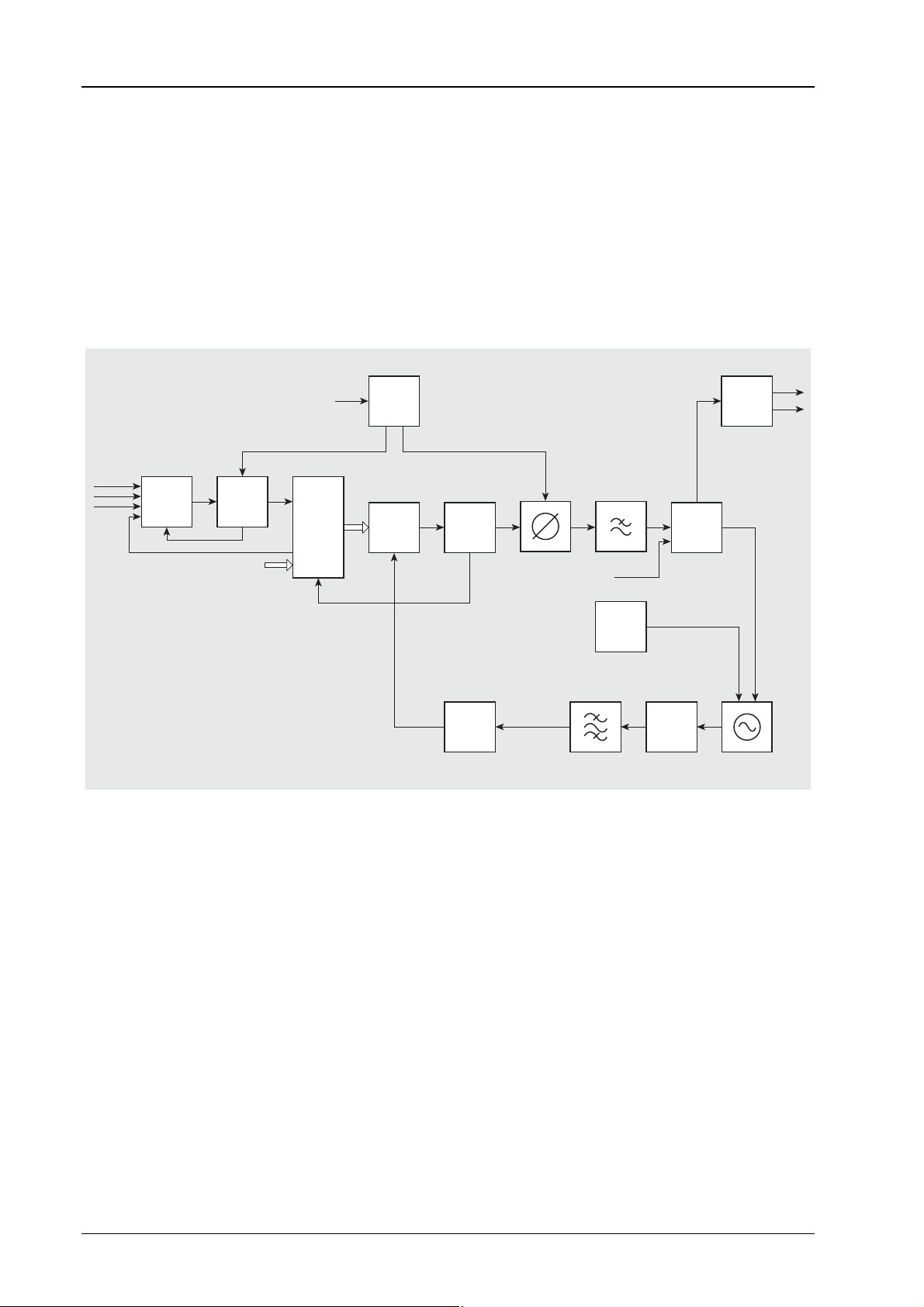

capability. Fig. 1-1 is a block diagram of the frequency synthesis and signal processing circuits.

Synthesizer

A VCXO operating at 100 MHz is phase locked to the internal (or external) frequency standard

using a phase comparator at 10 MHz. The VCXO signal is divided by 20 to give a 5 MHz

reference frequency for the fractional-N loop phase comparator.

A fractional-N loop is used to lock a multiplied low-noise VCO to the reference with a resolution

of l Hz. The VCO tunes from 400 to 535 MHz and is multiplied by three, four or five to yield a

signal in the range 1.2 to 2.51 GHz. A high speed programmable divider is used to divide the

multiplied VCO frequency down to 5 MHz and a phase comparator compares this signal with the

reference derived from the VCXO. The output from the phase comparator corrects the VCO

frequency. In order to provide the required division ratio, the programmable divider is required to

act as a fractional divider. The fractional-N gate array controls the division ratio of the

programmable divider. The variation of this division ratio by the controller enables the loop to

lock, with non-integer division ratios, to the reference with the resolution of 1 Hz without

introducing spurious signals.

FM is produced using a two-point modulation scheme. The FM signal is inserted into the loop by

summing the FM signal with the VCO tune line to modulate the VCO directly. Simultaneously,

the FM signal is fed to the fractional-N controller via a 1-bit oversampled A-D converter which

converts an analogue input into a bit stream of ‘1’s and ‘0’s. The controller uses this input to

modulate the division ratio in sympathy with the modulation. This allows frequencies less than

the loop bandwidth, including DC, to modulate the output frequency.

In order to maintain good FM performance of the two-point modulation system, the VCO FM

tracking characteristics are required to be known. The sensitivity of the FM system via the 1-bit

oversampled A-D converter is VCO independent and accurately calibrated by a DC calibration

system. The VCO tracking is derived by an automatic FM SELFCAL routine during calibration.

During an FM SELFCAL, the error signal on the tune line, for a frequency near the loop

bandwidth, is monitored while varying the FM calibration numbers, allowing the variation in VCO

sensitivities to be calibrated out. This will remove any perturbation of FM flatness near the loop

bandwidth due to mismatch of two modulation paths.

TECHNICAL DESCRIPTION

RF processing

The VCO on board AA1 operates in the range 400 to 535 MHz and feeds to a harmonic generator

whose 3rd, 4th and 5th harmonics are selected by voltage-tuned band-pass filters to pro vide a

frequency in the range 1.2 to 2.4 GHz (2.51 GHz on board AA1/1). To generate frequencies

below 1.2 GHz this signal is divided by factors of two to produce frequencies in the range 10 MHz

to 1.2 GHz. A bank of switched half octave harmonic filters follows which is used to reduce

unwanted harmonics at the output. Then the signal passes through the amplitude modulator where

the output level envelope is controlled. The output from the modulator is peak detected. For

frequencies less than 10 MHz the signal is mixed with an input from the 100 MHz VCXO. The

resulting output in the frequency range 9 kHz to 2.4 or 2.51 GHz is fed from the output amplifier

to attenuator board AA2. For pulse operation the signal is taken to the pulse modulator which

operates in the range 30 MHz to 2.51 GHz. Otherwise the pulse modulator is bypassed and the

signal is fed to the output attenuator. This is controlled by relays and provides attenuation in steps

of 11 dB up to 132 dB. The attenuator also includes an RPP (Reverse Power Protection) system to

protect the instrument from accidental application of reverse power.

46882-377 1-3

Page 23

TECHNICAL DESCRIPTION

LF processing

The LF processing all takes place on control board AB1 or AB1/1, and may be conveniently

subdivided into the following major functional elements.

LF output

A DSP (Digital Signal Processor) is used to generate the audio frequency signals used for internal

modulation. One output from the DSP is used to supply the front panel LF OUTPUT socket.

For external modulation the signal applied to the EXT MOD INPUT socket first passes through

AC/DC coupling selection and then can either be applied directly or via an ALC (Automatic Level

Control) circuit to the audio multiplexers. The external direct signal can also be summed with the

audio frequency from the DSP.

AM and level control

For amplitude modulation the modulation depth is set by a 12-bit A-D converter. A second A-D

converter is used to produce the ALC reference for the RF board. Square law correction is applied

to both signals.

FM/ϕM

For frequency modulation the signal amplitude controls the FM deviation. For phase modulation

the signal is passed through a differentiator circuit.

1-4 46882-377

Page 24

TECHNICAL DESCRIPTION

Fig. 1-1 Signal generator block schematic

46882-377 1-5

Page 25

TECHNICAL DESCRIPTION

1-6 46882-377

Page 26

AA1, AA1/1 RF board

Carrier frequency synthesis

The RF carrier of the instrument should be as clean in frequency (and level) as possible. To

achieve this goal the instrument relies on a single-loop fractional-N Synthesizer scheme and a

harmonic multiplier and UHF oscillator covering the fundamental range from 1.2 to 2.4 GHz

(AA1) or 1.2 to 2.51 GHz (AA1/1). Using this approach minimizes the RF processing circuitry

normally associated with conventional frequency doubling or mixing schemes.

A carrier frequency resolution of 1 Hz cannot be achieved easily without the use of non-integer

division. In this instrument this operation is controlled by a dedicated ASIC which modifies the

division ratio of a programmable divider so that the average frequency is a non-integer division of

the input.

RF board: Carrier generation (sheet 1)

Frequencies from 1.2 to 2.4 GHz (AA1) or 1.2 to 2.51 GHz (AA1/1) are generated by

multiplication from a 400 to 535 MHz low-noise oscillator. The tuned circuit is formed by C102,

C108, varactor diodes D101 to D106 and printed inductors. A maintaining transistor TR101 is

tapped into the tuned circuit. The oscillator is tuned by a differential voltage applied to the

varactor diodes via L101 to L103. The VCO TUNE LOW line is used to phase lock the oscillator

and inject FM whilst the VCO TUNE HIGH line is used to pre-steer the VCO.

The signal from the VCO is buffered by IC101 and then amplified by TR102 to provide a suitable

level to drive the harmonic multiplier. The collector of TR102 is tuned by L104, C114 and C116.

Harmonics are generated by D107 which acts as a step recovery diode. The diode is self-biased to

improve the efficiency of harmonic generation by the network R110, R108 and C111. The

harmonics generated by D107 are filtered by a four stage band-pass filter with a centre frequency

in the range of 1.2 to 2.4 GHz (AA1) or 1.2 to 2.5 GHz (AA1/1). Each filter stage is formed by a

pair of parallel coupled lines. Each line is capacitively loaded at one end by a pair of back-to-back

varactor diodes to allow tuning over an octave. The stages are separated by buffer amplifiers

IC104 to IC107. These amplifiers compensate for the loss and frequency response inherent in

each filter stage and provide isolation so that tuning of the stages is independent. A pad at the

output of each buffer amplifier increases the isolation and provides a better match to the input of

the next filter stage. The filtered signal at the output of IC107 is split by R149 and R150 to feed

the synthesizer dividers (sheet 3) and the output dividers (sheet 7). The filter stages are tuned by a

voltage in the range of 1 to 24 V (AA1) or 1 to 31 V (AA1/1) derived from octal DAC IC103.

This is applied via scaling amplifier IC102a and buffer IC102b. Diodes D125 and D126 allow fast

tuning by shorting out R124 to reduce the charging time constant and so shorten the filter settling

time whenever the frequency is changed. A 1.25 V reference for the DAC is provided by IC108

via IC102c. Table 1-3 below gives the relationship between the VCO frequency, the harmonic

and the final output frequency.

TECHNICAL DESCRIPTION

When the varactor diodes (D108 - D123) need replacing, they must be replaced as a set. If

the alternative type diodes are fitted, resistor R717 will need repositioning accordingly.

Table 1-1: Carrier generation

Output frequency

(MHz)

1200 - 1600 3 400 - 533.3

1600 - 2000 4 400 - 500

2000 - 2510 5 400 - 502

Harmonic number

(N)

VCO frequency

(MHz)

46882-377 1-7

Page 27

TECHNICAL DESCRIPTION

RF board: VCXO loop (sheet 2)

100 MHz VCXO

The 100 MHz VCXO is used to derive all of the clock signals necessary for the fractional-N

Synthesizer. The use of a high frequency eliminates the need for a second phase-locked oscillator

to generate the necessary local oscillator frequency for the BFO. The reference divider provides a

5 MHz clock for the fractional-N Synthesizer and the FM A-D converter.

VCXO operation

The 100 MHz oscillator is built around TR201. Crystal XL201 together with L202 and D201

provide a series resonant circuit in the emitter circuit of TR201. At resonance it increases the gain

of the common-emitter stage and together with 180 degree phase shift network L204, C216, C215,

C219 and C220 connected between the base and collector of TR201 provides the necessary

conditions for oscillation. L203 tunes out the parasitic capacitance of the crystal package and

prevents other spurious oscillations from occurring.

A facility to fine tune the phase shift network is provided by C215. At the resonant frequency, the

circuit operates at maximum power levels when the correct phase shift is achieved around the

transistor. TR202 provides a buffered signal to the VCXO loop divider IC205. A second buffer,

TR203 provides local oscillator drive (at typically +3 dBm) to the BFO mixer (sheet 9). The BFO

DRIVE line to TR204 allows the second buffer amplifier to be powered down when the BFO is

not in use to prevent leakage of the 100 MHz LO onto the instrument output.

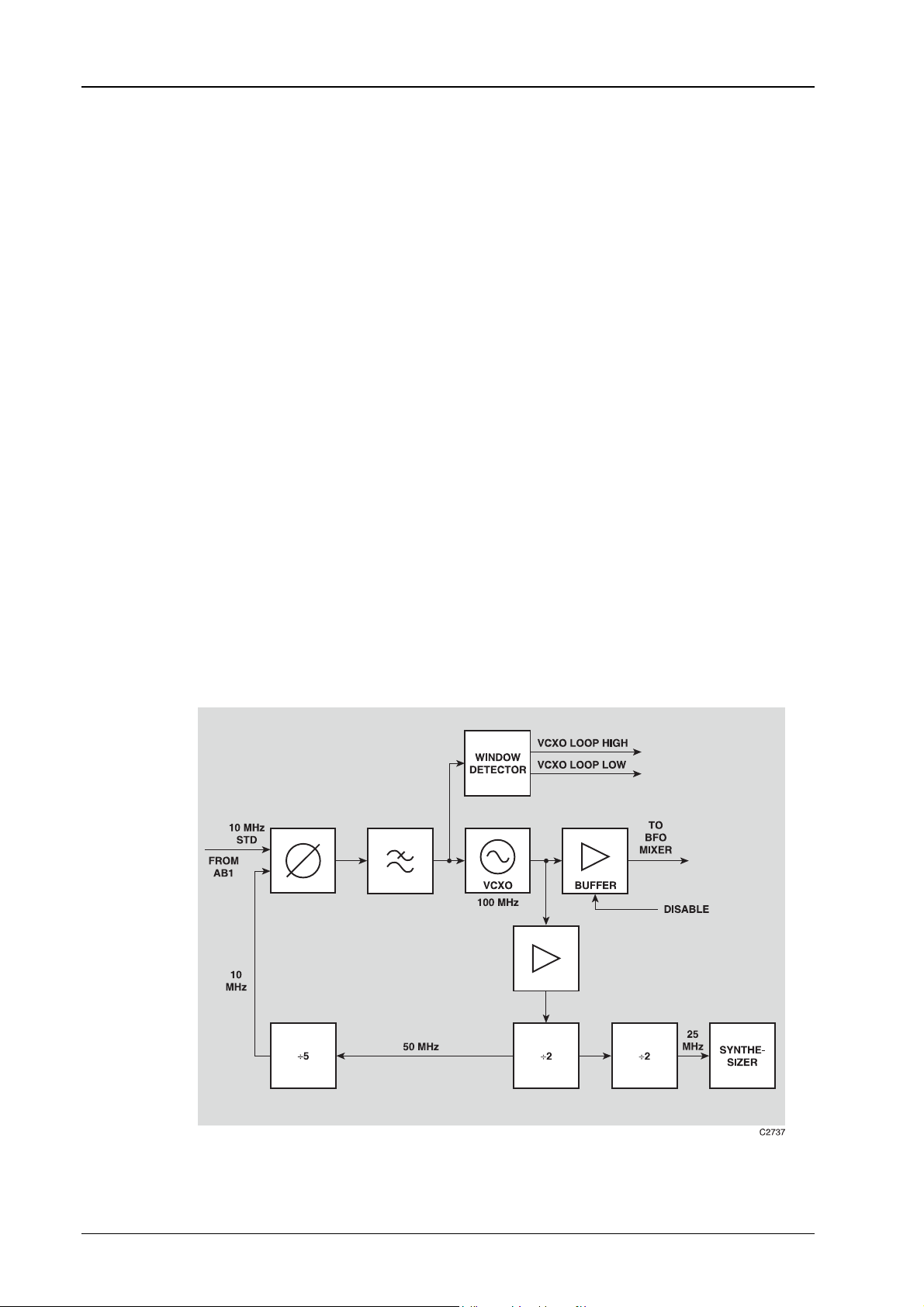

100 MHz phase-locked loop

The VCXO is used to provide a reference signal to the fractional-N loop and to the BFO band

mixer and is locked to the 10 MHz frequency standard provided from control board AB1 or AB1/1

via PLAB. The buffered 100 MHz signal is divided down to 10 MHz before phase comparison.

An integrator and active low-pass filter ensures the removal of the reference frequency from the

VCXO tune line. A window comparator monitors the VCXO tune line to detect when the

oscillator is outside its normal operating range. The block diagram of the phase-locked loop is

shown in Fig. 1-2.

Fig. 1-2 100 MHz phase-locked loop

1-8 46882-377

Page 28

Loop operation

The 100 MHz signal from the VCXO is buffered and amplified by TR205 to yield a CMOS logic

compatible signal for the dividers which follow. The signal is divided by two by IC205a and then

by five by IC202 to give 10 MHz for phase comparison. IC201 and IC203 form the loop

phase-frequency comparator. R203 and C208 remove the fast edges from the output of the phase

detector. A broken integrator is formed around IC204b. This has a break frequency of 80 Hz and

a gain at high frequency of four. IC204a, which follows, is a second-order active low-pass filter

with a cut-off of 700 Hz and a gain of two. The resulting loop bandwidth is approximately

150 Hz. The output from the active low-pass filter is further filtered by R212 and C213 to remove

any high frequency signals.

IC204c and d form a window comparator which detects when the VCXO tuning voltage range is

exceeded. The outputs from the comparators are attenuated to logic levels by R216 to R219 to

give VCXO LOOP HIGH and VCXO LOOP LOW lines to provide status interrupts to the main

processor via IC704 (sheet 8).

RF board: Synthesizer (sheet 3)

Synthesizer operation

Frequency synthesis control is performed by a dedicated ASIC, IC305. This generates all of the

necessary division ratios for programmable divider IC307 to synthesize any frequency within the

range 1.2 to 2.4 GHz (AA1) or 1.2 to 2.51 GHz (AA1/1). Synthesizer operation is summarized in

Fig. 1-3.

The 1.2 to 2.51 GHz (AA1) or 1.2 to 2.51 GHz (AA1/1) input signal from the harmonic generator

(sheet 1) is buffered by TR305 (sheet 3) to prevent divider spurious signals from IC309 reaching

the instrument output. Signal feedback is not used with this stage, to give high reverse isolation.

The buffered signal is divided by two by IC309 and then amplified by IC308 to obtain a sufficient

level to drive the input of programmable divider IC307. The programmable divider is used to

provide integer division in the range 120 to 240. Fractional division is achieved by the

modification of the integer division ratios, under the control of ASIC IC305, in such a way that the

average frequency over time is not an integer division ratio of the original. Control inputs to

IC307 are TTL compatible. The control outputs from ASIC IC305 are inverted by IC306 to

provide the correct polarity for IC307. Resistors R316 to R323 and R343 to R350 reduce the

amplitude of the control signals to 2.5 V. The outputs of IC307 are converted from ECL to TTL

levels by differential pair TR302 and TR303 and a single-ended amplifier TR304. Diode D307

provides Schottky clamping for TR304 to ensure fast switching. The signal on the collector of

TR304 is an all active edge squarewave at a 2.5 MHz rate. The fractional control ASIC and phase

detector both require a clock with active positive edges. IC310d converts the 2.5 MHz signal to a

5 MHz signal with a short duty cycle and an active positive edge. The remaining gates of IC310

provide buffering. The division ratio generated by ASIC IC305 will be modified every time a

positive edge is received at pin 51.

The reference for the main loop is obtained by dividing the 25 MHz signal present at IC302 pin 2

by five. The output of IC302 pin 11 is a 5 MHz rate pulse with a duty cycle of 40 ns. The clock

for the 1-bit oversampled A-D converter is obtained from IC302 pin 13 after buffering and

inversion by IC303a. The reference and divided output signal are compared by a phase frequency

comparator comprising IC311, IC312b and IC313a. The phase detector output to the loop

integrator and filter is available on pin 12 of IC311d. Under normal phase lock this will be a

5 MHz squarewave with nearly 50% duty cycle.

TECHNICAL DESCRIPTION

1-bit A-D converter

The DC input path to the Synthesizer consists of a third-order, single-bit, oversampling A-D

converter, whose bit stream output is used to dynamically control the Synthesizer frequency via

the Synthesizer ASIC.

46882-377 1-9

Page 29

TECHNICAL DESCRIPTION

Pin 6 of IC301b is used as the summing junction for four currents. These are: the input current

from control board AB1 or AB1/1 via R307 and R352; a negative offset current via R306; the bit

stream feedback via R310; and the DC nulling offset current via R311. IC301b integrates the sum

of these currents, and its output is further integrated by broken integrators IC301c and d. In these,

when the frequency rises to a point where C301 and C302 are at low impedance, the ICs act as

unity-gain amplifiers. Diodes D301 to D304 are used to enable the converter to recover cleanly

from an overload.

The output from the last integrator is fed via comparator TR301, which converts the input to TTL

levels, to D-latch IC304a, which is clocked at the same rate as the Synthesizer ASIC. The output

from the D-latch is fed back into the summing junction to close the converter control loop. The

output from IC304a is a pseudo random bit stream that represents the analogue FM input to

IC301b. The bit stream is used by the Synthesizer ASIC to control the main carrier frequency.

BIPOLAR

OFFSET

FM/FM

DC

NULLING

OFFSET

S

5 MHz

1-BIT

ADC

CONTROL

DATA

FRACTIONAL

CONTROLLER

CLK

FROM

VCXO

25 MHz

REF

DIV

5¸

DIVIDE

BY N

COUNTER

600-1200 MHz (AA1)

600-1255 MHz (AA1/1)

MHz

FN

LOOP

HIGH

WINDOW

COMPARATOR

5 MHz

2.5

x2

5 MHz

2¸

1.2-2.4 GHz (AA1)

1.2-2.51 GHz (AA1/1)

FM ATTEN

VCO

PRE- STEER

VCO TUNE HIGH

HARMONIC

GENERATOR

S

VCO

VCO

TUNE

LOW

FN

LOOP

LOW

C4438

Fig. 1-3 Frequency synthesis

The DC nulling offset current is supplied from a 1-bit oversampling D-A converter in the

Synthesizer ASIC. This balances the input current to make the converter read zero when DC

nulling and when in AC coupled FM mode.

RF board: Loop filter and autocal (sheet 4)

Loop filter

The input on the PHASE DETECTOR line is filtered by R404 and C401 to remove fast edges

before the signal reaches loop integrator IC402. The loop integrator has a break frequency set by

C402 of approximately 1.5 kHz and gain at high frequency of 1.2. The network R414, R415,

C405 and C406 provides rejection of unwanted noise in the 10 to 30 kHz range without

introducing a large phase shift at the loop bandwidth. IC404 is a unity gain second-order active

low-pass filter with a cut-off frequency of 40 kHz. The filtered signal from IC404 is attenuated

and summed with the FM drive signal on the FM ATTEN line by R433. This results in the VCO

TUNE LOW output to the VCO (sheet 1). Loop bandwidth is approximately 3 kHz.

1-10 46882-377

Page 30

Correct phase lock is monitored by IC406c and d which detect when the voltage at the output of

IC406a exceeds ±8 V. Hysteresis is provided by R443 and R444. The detected outputs from

D408 and D409 on the FN LOOP HIGH and FN LOOP LOW lines are attenuated to logic levels

by R449 to R452. Loss of phase lock is signaled by interrupting the main processor via IC703 and

IC704 (sheet 8).

VCO pre-steer

The VCO PRE-STEER voltage is generated by octal DAC IC103 (sheet 1). The signal from the

DAC is amplified by IC401a and b to provide a tuning voltage in the range 1 to 22 V.

Temperature compensation for the VCO is provided by D414. Under normal operation the presteer voltage is filtered by R423 and C411 to prevent noise injection onto the VCO tune line.

Diode D415 and IC408 allow fast tuning by shorting out R423 to reduce the charging time

constant. IC408 is only switched on using the PRE-STEER SWITCH line during frequency

changes that involve updating the pre-steer voltage.

Autocalibration

Dedicated hardware has been added to the Synthesizer to allow fast automatic calibration of the

VCO pre-steer and FM frequency response. Pre-steer calibration is achieved by minimizing the

loop error voltage present at the output of IC406a. This is achieved by IC406b which forms a

simple zero-crossing detector.

The FM frequency response calibration is performed by applying FM to the carrier with a 2 kHz

modulating tone. Calibration is performed by minimizing the amplitude of the resulting 2 kHz

tone present at the output of the loop filter. The magnitude of the FM drive voltage applied to the

VCO is adjusted automatically whilst the phase relationship between the loop error tone and the

applied modulating tone is monitored. The correct drive level is found at the point where the

phase switches from being in phase to being out of phase. IC407a is used to amplify the loop

error tone. TR402 and C417 are used to implement a crude charge pump phase detector. IC407d

is used to clip the 2 kHz modulating tone so that TR402 gate is driven with a squarewave. The

output from the phase detector is filtered by two RC sections and buffered by IC407b. The sign of

the filtered voltage, and hence the point of phase reversal is monitored by IC407c. The output of

IC407c is converted to logic levels by D412, R457 and R458. Forward biasing D404, D405,

D411 and D413 using the CAL DISABLE line suppresses the operation of the autocalibration

hardware.

TECHNICAL DESCRIPTION

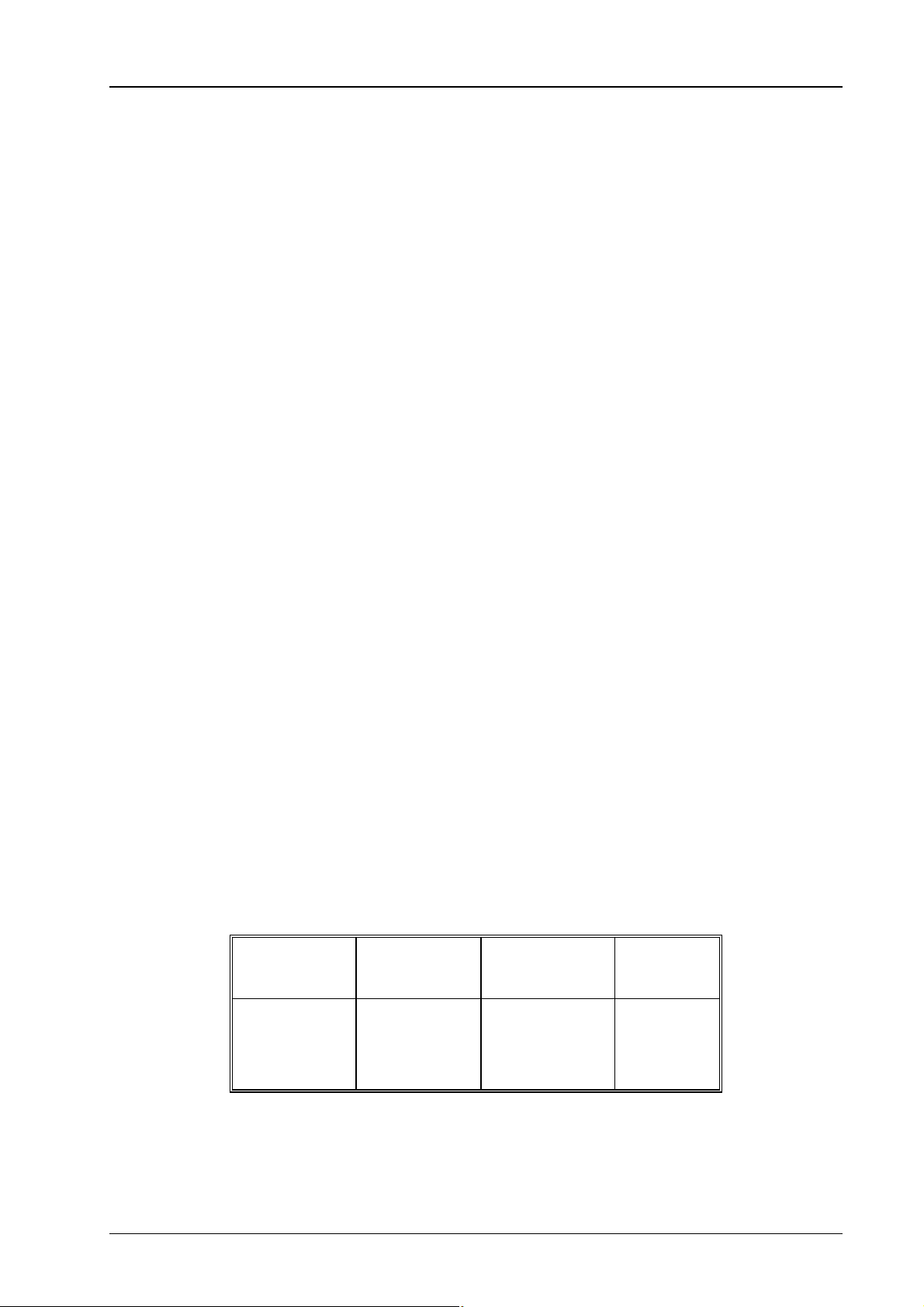

AA2 board identification

The AA2 BOARD SENSE line indicates one of three conditions to the processor: a standard

attenuator board AA2 is fitted; a high-power attenuator board AA2/1 is fitted ; no attenuator is

fitted. PLAE 15 indicates these conditions respectively by being: shorted to earth; open circuit;

connected to earth via a 1 kΩ resistor. The two output lines BOARD ID (A) and BOARD ID (B)

are connected by pull-up resistors R723 and R724 to IC705 (sheet 8). The logic is shown in Table

1-2. below.

BOARD ID

Board type PLAE 15 TR406 TR407 (A) (B)

Standard Shorted to

High power Open circuit ON ON L L

No attenuator Resistor ON OFF L H

Table 1-2: Attenuator board identification

OFF OFF H H

earth

46882-377 1-11

Page 31

TECHNICAL DESCRIPTION

Power amp cal comparator

Comparator IC401c compares the power amplifier detector level output from high power

attenuator board AA2/1 with the POWER AMP CAL signal on IC401c pin 10. The latter signal

comes from DAC IC103 (sheet 1). The comparator circuit performs a dual function. In

instrument calibration mode the AA2/1 detector output is calibrated using the POWER AMP CAL

signal to find the ‘trip level’, when the POWER AMP CAL output changes state. In normal

instrument operation the high power DAC signal is set 6 dB below the expected detector level.

Then, if due to some failure the power amplifier output falls by more than 6 dB, POWER AMP

CAL will flag an error, resulting in an error message being generated on the screen.

RF board: FM drive (sheet 5)

FM adjusts the instantaneous RF frequency in direct sympathy with the modulating signal. The

amount of frequency deviation is directly proportional to the magnitude of the modulation source.

With phase modulation the frequency deviation is also proportional to the frequency of

modulation.

For moderate modulation rates the signal is injected straight onto the VCO tune line after suitable

scaling by D-A converters (giving fine control) and fixed attenuators (giving coarse control). The

block diagram of the FM drive is shown in Fig. 1-4.

Inside the loop bandwidth this method is not valid as the loop cannot distinguish between FM and

other VCO frequency errors. It would therefore try to compensate for the modulation tone by

returning the carrier back to the original requested frequency. A digital system is used to

overcome this effect, which also has the benefit of extending the modulation range down to DC.

The modulation is sampled by a 1-bit oversampling A-D converter whose output controls the

Synthesizer gate array controller ASIC in such a way as to offset the carrier frequency in

proportion to the magnitude of the modulation. The speed at which the ASIC can perform this

function sets a limit to the overall bandwidth of the system. At frequencies above the loop

bandwidth the analogue system dominates.

Operation

The FM input to the RF module feeds the 1-bit oversampling A-D converter and the analogue FM

attenuator. The analogue attenuator provides the FM drive signal to the VCO and consists of two

stages. A 12-bit multiplying D-A converter, IC409, allows fine setting of the FM drive level.

Coarse setting is achieved by IC403 and by a pad switched by RLA. IC403 is an analogue

multiplexer; it is used to provide attenuation of 0, 20 or 40 dB, and can be used to connect the FM

input to ground. IC405a has 10 dB of gain and provides a high current drive for the final

attenuator stage. The final attenuator stage is switched by RLA and gives either 10 or 50 dB of

attenuation. The output from the final attenuator stage on the FM ATTEN line is summed with the

control voltage from the fractional-N loop across R431 and R432 (sheet 4) which provides a

25 Ω

drive to the VCO. The FM attenuator control settings are given in Table 1-3.

Table 1-3: Attenuator control settings

Atten (dB) AT2 AT1 AT0

OFF 0 0 0

20 1 0 0

40 1 1 0

60 0 1 0

80 0 1 1

1-12 46882-377

Page 32

TECHNICAL DESCRIPTION

VCO FM tracking autocalibration is performed by IC407 and associated circuitry (see

‘Autocalibration’ above for details). Digital FM and FM at low modulation frequencies is

achieved by the combination of the 1-bit oversampled A-D converter formed by IC301, IC304a

and synthesizer ASIC IC305 (sheet 3). The A-D converter samples the modulation source at a

high rate and passes the information to the gate array controller in a high speed serial data stream.

The ASIC then modifies the control to the main divider IC307 to change the instantaneous

frequency of the carrier.

RF board: Level modulator (sheet 6)

Amplitude modulator

The amplitude modulator is responsible for applying amplitude modulation to the carrier. To do

this a voltage-controlled pin diode modulator and envelope detector are used in a control loop to

apply amplitude modulation to the RF carrier. The control voltage from the control board is

predistorted before it is applied to the control loop to compensate for the inherent non-linearity of

the Schottky diode detector used for envelope detection.

PIN modulator

Diodes D501 to D507 are the pin diodes arranged as a dual π modulator. Transistors TR501 and

TR502 form a pair of voltage-controlled current sinks which produce complementary output

currents, one to drive the series diodes and one to drive the shunt diodes. Resistor R513 sets the

transconductance of these current sinks and hence the gain of the pin modulator. Capacitor C523

across R513 helps to speed up the modulator by providing lead compensation for the pin diodes;

the time constant of R513 and C523 being approximately equal to the charge lifetime of the pin

diodes. Resistors R509 and R511 are required to source current into the diodes when stored

charge needs to be removed quickly from the diodes since internal recombination alone is far too

slow.

Transistors TR506 and TR510 are two similar RF amplifying stages. TR506 recovers losses from

the pin modulator and TR510 recovers losses from the divider and filter stages (sheet 7). Since the

same DC biasing is used for both stages only one stage, that for TR506, will be described.

Resistors R516 and R542 fix the base voltage on TR503 which in turn sets the collector voltage on

TR506. The collector current is set by the value of R524. A two-inductor combination, L505 and

L506, is used to isolate the RF line from the DC circuitry. Diode D515 compensates for the

Fig. 1-4 FM/

ϕ

M drive

46882-377 1-13

Page 33

TECHNICAL DESCRIPTION

TR503 base-emitter variations with temperature. Resistors R521, R546, R547 and R555, R556 set

the RF gain of this stage.

The control voltage input to the modulator is converted into a digital word by an analogue to

digital converter. This converter is implemented with comparator IC501a and FILTER CAL from

one of the DACs in IC103, the status of the comparator being available as FILTER PEAK. This

measurement is used for self-calibration of the voltage-tuned band-pass filters on sheet 1 and also

for instrument fault diagnosis.

Peak detector and control loop

D510 is the Schottky detector diode used to detect the peak RF voltage on the microstrip line. The

output from this detector is not linear at low RF levels but obeys a square law transfer function,

hence if modulation distortion is to be eliminated, the control voltage from the control board must

compensate for this effect. Schottky diode D511 is used for temperature compensation of D510.

The modulation voltage on the AM INPUT line from control board AB1 or AB1/1 is larger than

that required by the control loop and is attenuated by R527 and R517. The voltage level from the

control board is approximately 1.4 V average with the modulation superimposed on it. An error

amplifier consisting of IC802a amplifies the differential error voltage between the modulation

input and the detector output. The output of this error amplifier then controls the pin modulator as

necessary to keep the error voltage as small as possible. Feedback in the form of C511 and R526

reduces the effective gain and phase shift of the error amplifier at high frequencies to ensure

adequate gain and phase margins.

Level modulator