Page 1

Instruction

VA-115

No.

AERCO INTERNATIONAL, Inc., Northvale, New Jersey 07647 USA

Installation, Operation

& Maintenance Instructions

ELECTRONIC

CONTROL VALVE

Type CXT-E

Printed in U.S.A. REVISED 4/18/07

Page 2

Telephone Support

Direct to AERCO Technical Support

(8 to 5 pm EST, Monday through Friday)

(800) 526-0288

AERCO International, Inc.

159 Paris Avenue

Northvale, NJ 07647

www.aerco.com

© AERCO International, Inc., 2006

The information contained in this

installation, operation and maintenance

manual is subject to change without

notice from AERCO International, Inc.

AERCO makes no warranty of any kind

with respect to this material, including

but not limited to implied warranties of

merchantability and fitness for a particular application. AERCO International is

not liable for errors appearing in this

manual.

Page 3

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

TABLE OF CONTENTS

SECTION PAGE

SAFETY PRECAUTIONS iii

1 - GENERAL INFORMATION 1-1

2 - INSTALLATION 2-1

3 - ADJUSTMENT 3-1

4 - OPERATION 4-1

5 - FUNCTIONAL DESCRIPTION 5-1

6 - ROUTINE MAINTENANCE 6-1

7 - TROUBLESHOOTING 7-1

8 - CORRECTIVE MAINTENANCE 8-1

9 - RECOMMENDED SPARES

9-1

i

Page 4

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

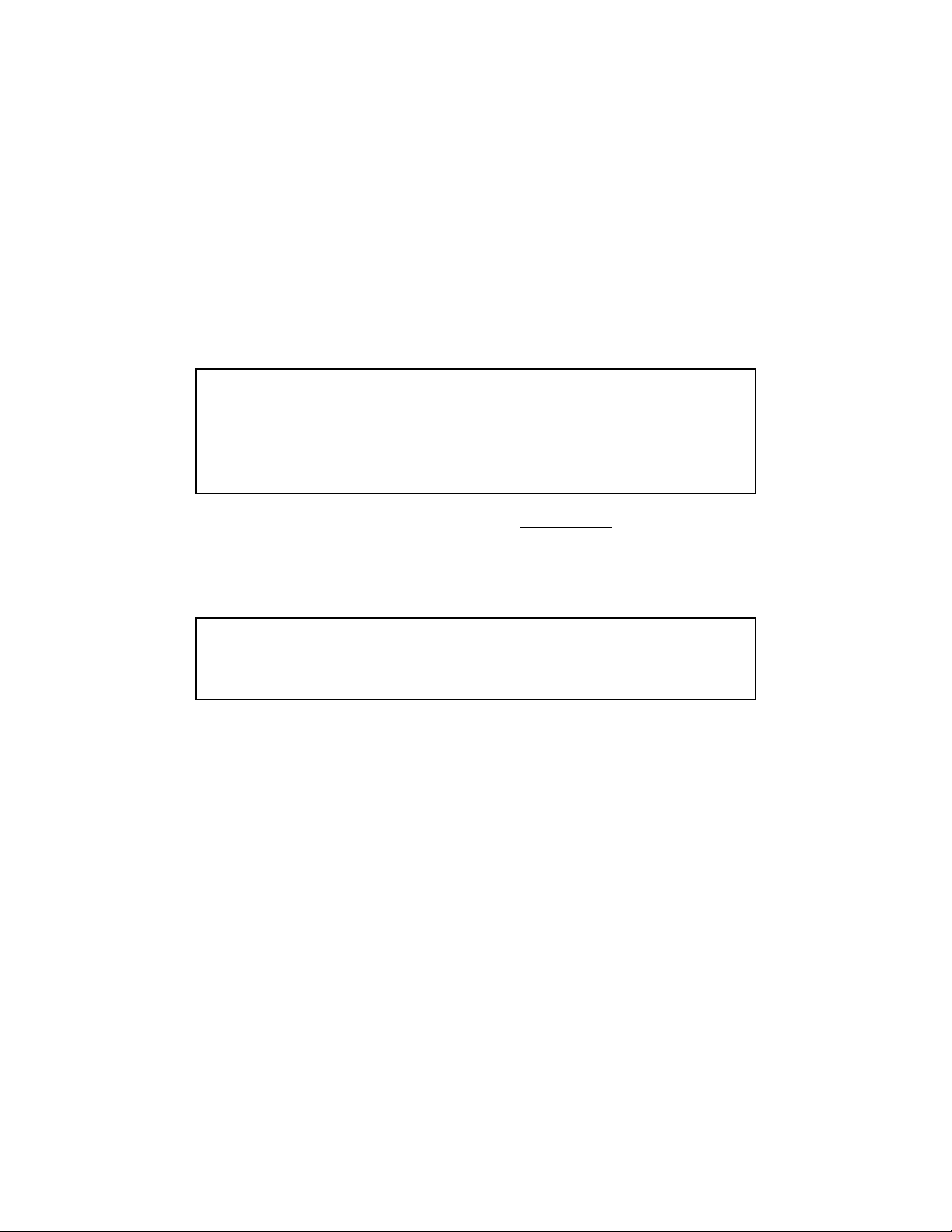

1-1 Reference Dimensions for AERCO Control Valves, Type CXT-E 1-2

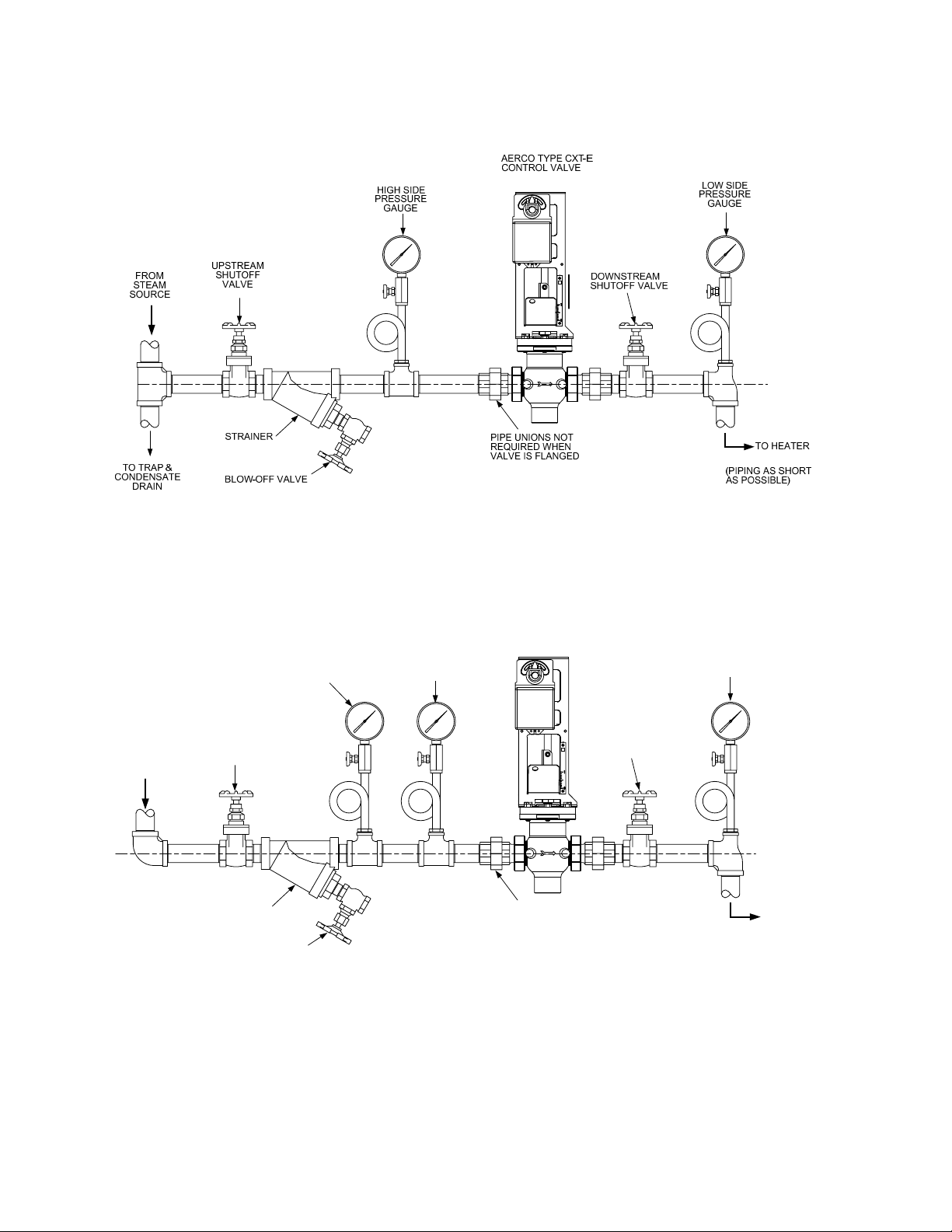

2-1 Recommended Control Valve, CXT-E Installation For Steam Flow 2-3

2-2 Recommended Control Valve, CXT-E Installation For Hot (Boiler)

Water Flow

3-1 Actuator Adjustment 3-2

5-1 Electronic Control Valve, Type CXT-E 5-1

6-1 Valve Shaft Seals 6-1

8-1 Valve Assemblies, Type CXT-E (Sizes 1.00” To 2.00”) 8-6

8-2 Valve Assemblies, Type CXT-E (Sizes 2.50” To 4.00”) 8-8

8-3 Cage Removal Tool 8-10

8-4 Linkage Assembly Installation Details 8-11

8-5 Actuator Replacement 8-13

8-6 Linkage Assemblies 8-14

2-3

ii

Page 5

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

SAFETY PRECAUTIONS

Installing or operating personnel must, at all times, observe all safety regulations.

The following warnings are general and must be given the same attention as

specific precautions included in the instructions

WARNING!

FLUIDS UNDER PRESSURE MAY CAUSE INJURY TO

PERSONNEL OR DAMAGE TO EQUIPMENT WHEN

RELEASED

CLOSE ALL SHUTOFF VALVES AND CAREFULLY

TRAPPED PRESSURES TO ZERO BEFORE PERFORMING ANY

MAINTENANCE. TAG THE PRESSURE SOURCE “OUT OF SERVICE” WHILE

PERFORMING MAINTENANCE TASKS.

DECREASE ALL

WARNING!

LIVE STEAM CAN CAUSE SEVERE BURNS

NEVER SEARCH FOR LEAKAGE IN A LIVE STEAM SYSTEM BY “FEEL”. USE

A MIRROR OR OTHER SUITABLE POLISHED OBJECT.

iii

Page 6

Page 7

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

1 - GENERAL INFORMATION

INTRODUCTION

This Instruction Manual provides installation, adjustment, operation and maintenance procedures for the

AERCO Electronic Control Valves, Type CXT-E. These Valves can be used for either steam flow or hot

(boiler) water flow applications.

If an AERCO Electronic Control System (ECS) is also included with the shipment, refer to AERCO

Instruction Manual AC-105. In addition to providing full coverage for the ECS, Instruction Manual AC-105

also includes all descriptions and procedures contained in this manual (VA-115).

ELECTRONIC CONTROL VALVE, TYPE CXT-E

Each Electronic Control Valve is comprised of three major sections; the Valve Body, the Linkage

Assembly and the Valve Actuator. The Control Valves are available in sizes ranging from 1 inch to 4

inches. An identical Actuator Assembly is used with each size Valve Body. The Linkage Assembly used

with each size Valve Body is identical, except for minor differences in the Shaft Adapter stroke of the

mechanical linkage. Figure 1-1 shows the basic dimensions for each size AERCO Electronic Control

Valve, Type CXT-E.

It should be noted that the Control Valves used for steam flow are identical to those used for hot (boiler)

water flow.

CONTROL VALVE ACCESSORIES

The accessories required for use with AERCO Electronic Control Valves, Type CXT-E will depend on the

specific application. Detailed installation instructions, including typical installation drawings are provided in

the INSTALLATION Section of this manual. However, please note the items listed below and ensure that

ALL mandatory items are available:

ACCESSORY

• Upstream Shutoff Valve

• Downstream Shutoff Valve

• Strainer and Blow-Off Valve

• High Side Pressure Gauge

• Low Side Pressure Gauge,

Compound Type for steam flow

If any of the above items have been furnished by AERCO with the CXT-E Control Valve, the necessary

drawings and/or instructions should be included with the shipment.

REQUIREMENT

- Mandatory

Suggested for ease of maintenance.

Required if a Bypass Line is used.

Mandatory

Recommended for adjustment and

maintenance

Recommended for adjustment and

maintenance.

1-1

Page 8

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

Figure 1-1. Reference Dimensions for AERCO Electronic Control Valves, Type CXT-E

1-2

Page 9

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

2 - INSTALLATION

INTRODUCTION

The installation procedures contained in this section apply to all sizes of AERCO Electronic Control

Valves, Type CXT-E, ranging from 1 inch to 4 inches. These procedures can be used for both steam and

hot (boiler) water flow systems.

ELECTRONIC CONTROL VALVE TYPE CXT-E INSTALLATION

Basically, the installation procedures for the Electronic Control Valve consist of:

• Installing the CXT-E Electronic Control Valve and associated steam or hot (boiler) water piping and

components.

• Connecting external electrical power and control signals to the Control Valve Actuator

Proceed as follows:

1. Refer to Figure 1-1 for dimensions of the Control Valve furnished with the Packaged Water Heater.

2. Next, refer to the recommended installation drawing in Figure 2-1 for steam flow, or Figure 2-2 for hot

(boiler) water flow.

3. Install the Control Valve with the Actuator Linkage in the vertical, upright position as shown in Figure

2-1 or 2-2.

4. For maintenance purposes, unions are required with threaded ends to simplify removal from the

steam or hot boiler water line.

5. Blow out all pipe lines to clear them of dirt chips, scale or other foreign matter which could adversely

affect Valve operation when in service.

6. Install an in-line strainer upstream of the Valve as shown in Figure 2-1 (steam) or Figure 2-2 (hot

boiler water). This will protect against foreign matter reaching the Valve during service operation.

7. If the Valve is controlling steam, ensure that the steam line is properly trapped to prevent

accumulation of condensate ahead of the Valve.

8. Install Shutoff Valves (metal-seated, gate-type) upstream and downstream of the Control Valve to

permit removal from the line for maintenance.

9. Pressure gauges should be installed on both sides of the Control Valve as shown in Figure 2-1

(steam) or Figure 2-2 (hot water).

2-1

Page 10

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

10. The gauge on the high pressure side of the Valve is for adjustment and maintenance purposes. The

gauge on the low pressure side is to ensure that the correct pressure is being introduced to the

Control Valve. For either steam or water flow, the low side gauge denotes the pressure of the fluid in

the line which may create a hazardous condition.

11. A temperature gauge should be installed in the high pressure side of a hot (boiler) water line as

shown in Figure 2-2.

CAUTION

DO NOT use the Actuator Linkage Frame at the top of the Control Valve Body for

leverage when installing the Control Valve. Use pipe wrenches on the inlet and

outlet hex of the Valve Body.

12. Install the Control Valve with the arrow on the Valve Body pointing in the direction of flow.

13. After the Control Valve has been installed in the steam or hot water line, ensure that all piping

connections are secure and leak tight..

14. If the Electronic Control Valve Type CXT-E is furnished separately, without an AERCO Electronic

Control System (ECS), electrical power and control signal connections must be made at the 3-pin

Molex connector as follows:

Pin 1 COMMON

Pin 2 +24 VDC

Pin 3 4–to-20 mA Control Signal

This completes the installation procedures for Control Valves shipped separately.

2-2

Page 11

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

WATER

SOURCE

Figure 2-1. Recommended Control Valve, CXT-E Installation For Steam Flow

AERCO TYPE CXT-E

FROM

UPSTREAM

SHUTOFF

VALVE

STRAINER

BLOW-OFF VALVE

TEMPERATURE

GAUGE

HIGH SIDE

PRESSURE

GAUGE

CONTROL VALVE

PIPE UNIONS NOT

REQUIRED WHEN

VALVE IS FLANGED

DOWNSTREAM

SHUTOFF VALVE

LOW SIDE

PRESSURE

GAUGE

TO HEATER

(PIPING AS SHORT

AS POSSIBLE)

Figure 2-2. Recommended Control Valve, CXT-E Installation For Hot (Boiler) Water Flow

2-3

Page 12

Page 13

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

3 - ADJUSTMENT

INTRODUCTION

Place the AERCO Heater (or other equipment being controlled) into operation in accordance with the

instructions furnished with the Heater (or other equipment).

WARNING

The Upstream Steam or Boiler Water Shutoff Valves MUST be closed prior to

performing the following adjustment procedures. Failure to observe this

WARNING may result in personal injury.

CONTROL VALVE TYPE CXT-E ADJUSTMENT

All CXT-E Actuators are powered by 24 VDC and are controlled by a linear 4-to-20 mA control signal. A 4

mA control signal input places the Control Valve in the fully-closed position; while a 20 mA signal strokes

the Valve to the fully-open position.

The Control Valve Actuators are self-calibrating for all Valve sizes. Therefore, simply proceed as follows

to automatically adjust the Actuator:

NOTE

The following adjustment procedure must be performed any time that the CXT-E Actuator

is replaced or a mechanical adjustment is made to the Linkage Assembly or Valve.

1. Refer to Figure 3-1 and loosen the Actuator cover set screw.

2. Remove the Actuator cover to access the PC Board containing the terminal connections, DIP

switches, Auto-Stroke (Reset) button and LED shown in Figure 3-1.

NOTE

If the Control Valve is furnished with an AERCO Electronic Control System (ECS), power

is applied to the Valve Actuator when the Control Box POWER switch is set to ON.

3. Apply 24 VDC power across Actuator pins 2 (+) and 1 (Common). The LED will light indicating that

power is applied. Wait approximately 10 seconds while the unit performs a self-test. Upon successful

completion of the self-test, the LED will blink 3 times and then go off.

4. For full-stroke automatic adjustment, press the Auto-Stroke (Reset) button. The LED will light.

5. The Actuator will then rotate in both directions to find its open and closed Valve position stops.

6. Upon successful completion of the automatic adjustment, the LED will blink 3 times and then go off..

7. Turn off power to the Actuator. Replace and secure the cover by tightening the set screw.

3-1

Page 14

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

ACTUATOR

0

neptronic

1 2 3

90

COVER

SET SCREW

PC BOARD

TERMINALS

34 5

12

AUTO-STROKE

(RESET) BUTTON

LED

123

DIP SWITCHES (3)

(ALL IN UP POSITION)

Figure 3-1. Actuator Adjustment

3-2

Page 15

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

4 - OPERATION

This Section provides the basic checks and initial startup for the CXT-E Control Valve and Heater (or

other equipment) being controlled.

OP1. Refer to Figure 2-1 (Steam Flow) or Figure 2-2 (Hot Water Flow). To place the Control Valve and

Heater System into operation, proceed as follows:

a. Ensure that the AERCO Heater (or other equipment) is ready for operation in accordance

with the instructions provided with the Heater.

b. First, slowly open the upstream and the downstream shutoff valves.

c. Ensure that electrical input power is properly connected to the Electronic Control Valve, Type

CXT-E and ECS Control System.

d. Ensure that a 4-to 20 mA control signal is being supplied to pin 3 of the Control Valve

connector.

OP2. If it becomes necessary to take the Control Valve and Heater System out of operation, close the

upstream, downstream shutoff valves.

OP3. If the Control Valve/Heater System is not maintaining the desired setpoint temperature, refer to

Section 7 – TROUBLESHOOTING.

4-1

Page 16

Page 17

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

5 - FUNCTIONAL DESCRIPTION

INTRODUCTION

The AERCO Electronic Control Valves, Type CXT-E are highly responsive devices which precisely

modulate the position of the Valve shaft based on the control signal input. As mentioned in Section 1,

each Control Valve consists of a Valve Body, Linkage Assembly and Actuator. Figure 5-1 illustrates the

three major assemblies of the Control Valve. The following paragraphs provide a brief functional overview

of the Electronic Control Valve, Type CXT-E.

FUNCTIONAL OVERVIEW

All Control Valves, Type CXT-E, regardless of size, utilize identical Actuators (Part No. 69009). The

Actuator is mounted on the upper portion of the Linkage Assembly and is secured to the Linkage shaft

(Figure 5-1). An Adapter is used to secure the Linkage to the Valve Body Shaft. The Valve Actuator is

powered by 24 VDC and is controlled by a linear 4-to-20 mA control signal input from the external

Temperature Controller. A 4 mA control signal corresponds to a fully closed valve position, while a 20 mA

signal corresponds to a fully open position.

As described in Section 3 (Adjustment), the Control Valve Actuator is self-calibrating for all sizes of

AERCO Control Valves. The CXT-E Valve Actuator also incorporates a fail-safe mechanism which

automatically closes the Control Valve in the event of a loss of input power loss or control signal.

LINKAGE

LINKAGE

SHAFT

ASSEMBLY

MECHANICAL

LINKAGE

ACTUATOR

LINKAGE

ADAPTER

VALVE

SHAFT

VALVE

BODY

Figure 5-1. Electronic Control Valve, Type CXT-E

5-1

Page 18

Page 19

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

6 - ROUTINE MAINTENANCE

INTRODUCTION

The following paragraphs provide the AERCO recommended routine maintenance procedures for the

Electronic Control Valve Type CXT-E and the Electronic Control System (ECS).

CXT-E CONTROL VALVE ROUTINE MAINTENANCE

MONTHLY

Once each month, check the Control Valve for leakage as follows:

1. Refer to Figure 6-1 and check the Packing Nut and Valve Top for evidence of leakage.

2. If there is leakage between the Packing Nut and Valve Top, tighten the Packing Nut until the leakage

stops. DO NOT FORCE the Packing Nut.

3. If tightening the Packing Nut does not stop the leak, the Packing Nut and Packing Assembly must be

replace in accordance with the procedures specified in the Control Valve CORRECTIVE

MAINTENANCE Section.

Figure 6-1. Valve Shaft Seals

SEMI-ANNUALLY

Every six months, check the following items:

1. Refer to Section 3 - ADJUSTMENT and perform the Actuator adjustment procedure specified. Verify

that the Actuator strokes the Control Valve from the fully closed to the fully open position.

2. Clean the Strainer in the heating fluid line (Figure 2-1 or Figure 2-2) in accordance with the

instructions furnished with the Strainer.

6-1

Page 20

Page 21

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

7 - TROUBLESHOOTING

INTRODUCTION

This Section provides the troubleshooting procedures necessary to isolate faults to the most probable

cause(s) for a malfunction of the Electronic Control Valve, Type CXT-E. Prior to performing the

troubleshooting steps and procedures specified in this Section, perform the following preliminary checks:

NOTE

In addition to the procedures contained in this Section, also check the Troubleshooting

Sections of the AERCO Heat Exchanger Manual (if used) or any other ancillary

equipment manuals included with the installation configuration.

1. Verify that all piping connections have been made in accordance with Figure 2-1 (Steam Flow) or

Figure 2-2 (Hot (Boiler) Water Flow).

2. Ensure that the Control Valve is installed with the flow arrow on the Valve Body pointing in the

direction of flow.

3. Ensure that both the upstream and downstream shutoff valves are fully open.

4. Check to ensure that the 3-pin Molex connector on the CXT-E Actuator is properly connected to an

AERCO Electronic Control System (ECS) or other type of Controller being used. Proper electrical

connections are as follows:

• Pin 1: Common

• Pin 2: +24 VDC

• Pin 3: 4-20 mA Control Signal

TROUBLESHOOTING PROCEDURES

The troubleshooting procedures for the Control Valve, Type CXT-E are provided in Table 7-1. When a

fault occurs, proceed as follows:

1. Refer to the FAULT INDICATION column in the Table 7-1 and locate the fault that best describes the

existing conditions.

2. Proceed to the PROBABLE CAUSE column and, if more than one item is listed, start with the first

item shown for the fault condition.

3. Perform the corresponding checks and procedures listed in the CORRECTIVE ACTION column for

the first PROBABLE CAUSE.

4. Continue checking each additional PROBABLE CAUSE for the existing fault until the fault has been

corrected.

5. Refer to the applicable procedures in Section 8 – CORRECTIVE MAINTENANCE if component

removal and/or replacement is required.

7-1

Page 22

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

TABLE 7-1. TROUBLESHOOTING – CONTROL VALVE CXT-E

NO. FAULT INDICATION PROBABLE CAUSE CORRECTIVE ACTION

T1 System not operating.

Control Valve is closed

and outlet water temp. is

far below setpoint.

T2 System over-heats by

more than 10°F above the

desired setpoint.

Outlet temp is below OverTemp limit setting

CAUTION

Over-tightening the Packing Nut may trap the Valve

Stem and slow or stop

Valve motion.

1. No power supplied to

Control Valve

2. Control signal not

being supplied from

Temp. Controller.

1. Control Valve not fully

closed.

2. Temp. Controller not

set properly or

defective.

3. Valve Actuator not

properly secured to

Linkage Assembly.

1. Disconnect Valve Actuator plug and

verify that 24 VDC power is present at

pin 2 of Actuator cable. Restore power

if necessary. If System includes an

over-temp limiting device, ensure that it

has not tripped.

2. Verify presence of 4 - 20 mA control

signal at pin 3 of Actuator cable. If

control signal is not present,

troubleshoot Temp. Controller.

1. Check the 4 – 20 mA control signal

being supplied to Actuator. If signal is

greater than 4 mA when heater outlet

temperature is 10°F (or more) above

the desired setpoint, proceed to next

item in list.

2. Check the current setting of Temp.

Controller providing the 4 – 20 mA

control signal to the Valve Actuator.

Readjust if necessary. If adjustment

does not clear fault, troubleshoot the

Controller.

3. Check Actuator U-bolt securing it to

Linkage Assembly. Tighten if needed

and readjust the CXT-E Control Valve

per Section 3.

T3 System outlet water

temperature is below

desired setpoint

CAUTION

Over-tightening the Packing Nut may trap the

Valve Stem and slow or

stop Valve motion.

4. Foreign matter in

Valve Seat.

1. Temp. Controller not

properly set.

2. Control Valve not

opening properly.

7-2

4. If Valve still does not close after

checking the above items, disassemble

the Valve and clean the Seat per steps

CM18 – CM28 in Section 8. Readjust

the CXT-E Control Valve per Section 3.

1. Check the current setting of the Temp.

Controller. If the setting is below the

desired setpoint, readjust as necessary.

2. Check as follows:

a. Ensure Actuator is secured to

Linkage Assembly. Tighten if needed

and readjust the CXT-E Control

Valve per Section 3.

b. Verify that 24 VDC power and 4 – 20

mA control signal are present at

Actuator pins 2 and 3 respectively.

c. To ensure Valve is not binding,

check Seal Retainer per steps CM1CM10 of Section 8 Corrective

Maintenance. Replace items as

necessary.

Page 23

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

TABLE 7-1. TROUBLESHOOTING – CONTROL VALVE CXT-E (Continued)

NO. FAULT INDICATION PROBABLE CAUSE CORRECTIVE ACTION

T3 (Continued) 3. Steam pressure, or

heating fluid

temperature too low.

4. For Steam Heating

System, Trap or

Orifice in Heater

Condensate Line is

malfunctioning.

3. Check the high side steam pressure to

the Control Valve to ensure it is correct.

For high temperature (HT) water,

ensure there is good circulation.

a. If steam pressure or HT water

temperature is lower than the system

design spec., correct as necessary.

b. If high side steam pressure drops, or

there is no HT water circulation as

the Control Valve opens, there may

be a partially closed valve in the

upstream line. Also, the strainer may

be clogged. Correct as needed.

4. Check for improper operation of Trap or

clogged Orifice in Condensate Line as

follows:

a. If low side pressure gauge shows

pressure but steam does not heat

properly, CAREFULLY break

Condensate Line connection AHEAD

of Trap or Orifice.

b. Allow condensate to run out into floor

drain.

c. If Heater outlet temperature rises to

desired setpoint with condensate

connection open, repair or replace

Trap or unplug Orifice.

T4 Wide variations in

Heater outlet temperature during wide

variations in flow .

T5 Rapid fluctuations in

heater outlet temperature which do not

load changes

follow

1. System not properly

sized to maintain

desired setpoint.

1. Temp. Controller

sensitivity not set

correctly

2. Steam System Trap

or Orifice fault

7-3

1. Review system flow characteristics to

ensure Heat Exchanger and Valve are

properly sized to maintain the desired

outlet temperature.

1. Adjust Temp. Controller sensitivity

2. Refer to T3, Corrective Action 4 above

and proceed as indicated.

Page 24

Page 25

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

8 - CORRECTIVE MAINTENANCE

INTRODUCTION

This Section provides corrective maintenance for all sizes of Electronic Control Valves, Type CXT-E

CXT-E CONTROL VALVE CORRECTIVE MAINTENANCE

The corrective maintenance procedures for the Electronic Control Valve are divided into the following

major areas:

• Valve Shaft Seal Retainer Replacement

• Valve Disassembly

• Valve Reassembly

• Actuator Replacement

• Linkage Replacement

Refer to the applicable paragraphs which follow and perform the Corrective Maintenance steps indicated.

VALVE SHAFT SEAL RETAINER REPLACEMENT

Refer to Figure 8-1 or Figure 8-2 and proceed as follows:

WARNING

Ensure that the Control Valve has been isolated from the steam or hot (boiler)

water supply. Live steam or hot water can cause serious burns to personnel.

WARNING

Ensure that all electrical power to the Control Valve Actuator has been

disconnected. Serious personal injury may result if this Warning is not observed.

CM1. Loosen the Hex Nuts (17) under the Indicator Plate (Figure 8-1 or 8-2) approximately a half turn

clockwise.

CM2. Disconnect the Linkage Adapter from the Valve Shaft (16) by turning the Shaft clockwise (as

viewed from above). If the Valve Shaft cannot be turned by hand, use an open-end wrench to turn

the “double-nuts” on the Shaft until it disengages the Linkage Adapter threads.

CM3. Remove the Indicator Plate from the Valve Shaft (16).

CM4. Remove the two Cap Screws (19) securing the Linkage Assembly (26) to the Valve Top (21).

CM5. Remove the complete Linkage Assembly (26), with the Actuator Assembly (27) still attached,

from the Valve Top. Also, remove the Gasket (29).

CM6. If the Packing Nut (18) is faulty (leaking or binding the Shaft (16), it must be replaced.

CM7. Measure and record the current position of the Hex Nuts (17) from the end of the Valve Shaft.

This will simplify adjustment of the Actuator Linkage during reassembly.

8-1

Page 26

CM8. Next, completely remove the Hex Nuts (17) from the Valve Shaft (16).

CM9. Remove the Packing Nut (18) and the Packing Assembly (20) from the Valve Body.

CAUTION

Over-tightening the Packing Nut (18) may trap the Valve Stem and slow or stop Valve

motion.

CM10. Replace BOTH the Packing Nut (18) and the Packing Assembly (20) with a NEW Packing Nut

and Packing Assembly.

CM11. Replace the Hex Nuts (17) onto the Valve Body Shaft (25) and position them in the same location

noted in step CM7.

CM12. Attach the Actuator (27), Linkage (26) and Gasket (29) to the Valve Top using the two Cap

Screws (19) provided.

CM13. Install the Indicator Plate on the Valve Lower Shaft (16) and secure it in place with the Linkage

Adapter.

CM14. Reconnect the Linkage Adapter to the Linkage Shaft by replacing the Shaft Pin.

VALVE DISASSEMBLY

Refer to Figure 8-1, or Figure 8-2 and proceed as follows:

CM15. Close the upstream and downstream shutoff valves before and after the Control Valve. If it is

necessary to keep the Heater in operation, proceed in accordance with step OP3 in the

OPERATING Section of this manual before continuing. If not, proceed directly to the next step.

CM16. If the Control Valve is easily accessible for disassembly and reassembly, leave it installed in the

fluid line. If it is not easily accessible, remove the Valve from the line and clamp it in a bench vise

for easy accessibility.

CM17. Completely remove the Actuator (27) and Linkage Assembly (26) from the Valve Body as

described in steps CM1 through CM5.

CM18. Refer to Figure 8-1 or Figure 8-2. It is strongly recommended that disassembly of the Valve be

limited to only the steps necessary to restore the Valve to proper operation. However, the

following steps cover complete disassembly, if necessary. When performing Valve disassembly,

USE EXTREME CARE not to mar or scratch any surfaces. The following steps assume that the

Actuator and Linkage Assemblies have already been removed from the Valve Body.

CM19. Remove the following parts in the order specified:

CAUTION

CAREFULLY remove the Packing Nut (18) and Cap Screws (14) indicated below

to relieve any trapped pressure.

• Hex Nuts (17)

• Packing Nut (18)

• Packing Assembly (20)

• Cap Screws (14)

• Valve Top (21)

• Valve Top Gasket (13)

8-2

Page 27

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

CM20. Grasp the Lower Shaft (16) and carefully lift out the ENTIRE Shaft/Seat/Piston Assembly.

CM21. For Control Valves, 1-inch through 2-inch (Figure 8-1), disassemble the Shaft/Seat/Piston

assembly in the following order:

• Lock Washer (23)

• Retaining Ring (11)

• Pilot Spring (10)

• Valve Stem Retaining Nut (35)

• Lower Shaft (16) and Valve Stem (12)

• Retaining Disc (8)

• Disc Seat (7)

• Seat Retainer (34)

• Valve Plug Shaft (5)

CM22. For Control Valves, 2.5-inch, 3-inch and 4-inch, (refer to Figure 8-2), disassemble the

Shaft/Seat/Piston Assembly in the following order:

• Lock Washer (23)

• Pilot Spring Retainer (11)

• Pilot Spring Back-Up Washer (31), 4-inch Valve only

• Pilot Spring (10)

• Cap Screws (9)

• Retaining Disc (8)

• Lower Shaft (16) and Valve Stern (12)

• Valve Seat (7)

• Top Piston (6) and Bottom Piston (3) assembly

CM23. It is recommended that the Seat Cage (2) NOT BE DISASSEMBLED unless it must be replaced.

See Step CM29.

NOTE

In any cleaning operation called for in these instructions, ALWAYS clean all

denoted parts thoroughly of all dirt and scale. Always use a clean cloth and, if

necessary, a solvent. NEVER use emery cloth or sandpaper unless instructed

otherwise herein.

CM24. CLEAN ALL PARTS THOROUGHLY. ALL DIRT AND/OR SCALE MUST BE REMOVED from the

outer surfaces of the Valve Plug Shaft (5) (Figure 8-1) or the Top Piston (6) and Bottom Piston (3)

(Figure 8-2) and from the surface of the Valve Stem (12).

CM25. Inspect the Valve Stem (12). If it is damaged or it does not seat properly on the Valve Seat (7), or

does not move freely in the Valve Seat Retaining Disc (8), the Valve Stem (12), Pilot Spring

Retainer (11) and Pilot Spring (10) must be replaced.

CM26. Inspect the outer surfaces of the Valve Plug (5) or the Top Piston (6) and Bottom Piston (3). If

they are scored or damaged so that they will not move freely up and down in the Seat Cage (2),

the Valve Plug or Pistons must be replaced. Also see Step CM32.

8-3

Page 28

CM27. Inspect the Valve Seat (7). If it is worn so that it will not seat properly with the Seat Cage (2), with

the Valve Stem (12), it must be replaced.

CM28. THOROUGHLY clean and inspect the seating and inner surfaces of the Seat Cage (2). If the

seating surface around the top of the Cage is worn or damaged so that the Valve Seat (7) will not

seat properly, or if the inner surfaces of the Cage are scored or damaged so that the Valve Plug

(5) or Pistons (3) and (6) will not move up and down freely, the Cage (2) must be replaced.

CM29. If the Cage (2) must be removed from the Valve Body (1), it will be necessary to fabricate a tool,

such as shown in Figure 8-3 for Cage removal. Insert the tool into the slots on top of the Cage (2)

and turn the Cage out of the Valve Body. To obtain a Cage Removal tool, contact AERCO or your

nearest Sales Representative.

VALVE REASSEMBLY

Refer to Figure 8-1 or Figure 8-2 when performing the following procedures.

CM30. If the Seat Cage has been removed, place a NEW Seat Cage Gasket (24) on the seating surface

of the Valve Body. Next, replace the Seat Cage (2) into the Valve Body (1), using the tool

described in Step CM29. Make the Seat Cage tight.

CM31. If disassembled or being replaced, reassemble the Top Piston (6) and Bottom Piston (3) onto the

Valve Plug Shaft (5), using the Top Piston Retaining Nut (46) (1-inch through 2-inch Valves), and

Bottom Piston Retaining Nut (50) or Bottom Piston Retaining Ring (4).

CM32. For Control Valves, 1-inch through 2-inch, (Figure 8-1), reassemble the Valve Plug/Seat/Shaft

assembly in the following order:

• Valve Plug (5)

• Seat Retainer (34)

• Valve Seat (7)

• Retaining Disc (8)

• Valve Stem (12) and Lower Shaft (16)

• Valve Stem Retaining Nut (35)

• Pilot Spring (10)

• Pilot Spring Retaining Clip (3)

• Lock Washer (23)

CM33. For Control Valves, 2.5-inch, 3-inch and 4-inch, (Figure 8-2), reassemble the Piston/Seat/Shaft

assembly in the following order:

• Top Piston (6) and Bottom Piston (3) assembly

• Valve Seat (7)

• Valve Stem (12) and Lower Shaft (16)

• Valve Seat Retaining Disc (8)

• Cap Screws (9)

• Pilot Spring (10)

• Pilot Spring Back-Up Washer (31), 4-inch Valve only

• Pilot Spring Retainer (11)

• Lock Washer (23)

8-4

Page 29

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

CM34. Holding the Lower Shaft (16), carefully replace the entire Shaft/Seat/Piston assembly into the Valve

Body (1) and Seat Cage (2).

CM35. Thoroughly clean the gasket surfaces of the Valve Body (1) and Valve Top (21) of all dirt and

scale. If necessary, use a wire brush, emery or both.

CM36. See Figure 8-1 or 8-2. Reassemble these parts in the following order:

• NEW Valve Top Gasket (13)

• Valve Top (21)

• Cap Screws or Hex Hd. Bolts (14) – Valve sizes 2-1/2” to 4” use 1/2”-13 Cap Screws. Valve

sizes 1” to 2” use 3/8”-16 Hex Hd. Bolts. Tighten using an alternating pattern to provide a

uniform seal and prevent Valve leakage.

• NEW Packing Assembly (20)

• Packing Nut (18)

• Hex Nuts (17)

• Indicator Plate (See Figure 8-1 or 8-2)

CM37. Replace the Actuator (27), Linkage (26) and Gasket (29) onto the Valve Top (21) and secure with

Cap Screws (19).

CM38. Position the Hex Nuts (17) at the original location noted during the removal process.

CM39. Install the Indicator Plate on the Valve Shaft (16) with the curved end facing upward (Figure 8-4).

CM40. Attach the Valve Shaft (16) to the Linkage Adapter by rotating the Shaft counterclockwise (as

viewed from above). If the Valve Shaft cannot be turned by hand, use an open-end wrench to turn

the “double-nuts” on the Shaft until it engages the Linkage adapter threads. Insert the Shaft into

the Linkage Adapter until the Hex Nuts (17) are snug against the Indicator Plate.

CM41. Press down on the Valve Shaft (16) to compress the Pilot Spring (10) in the Valve Body.

CM42. With the Pilot Spring compressed, verify that the Indicator Plate is aligned with the “0” (zero)

marking on the Scale (28). If necessary, rotate the Valve Shaft until the Plate is aligned with the

“0” Scale marking.

CM43. If the Valve had been removed from the heating fluid line, replace it in. the line. Reconnect the

electrical connector plug to the Actuator.

CM44. Prior to placing the Valve back into service, perform the Control Valve Adjustment procedure in

Section 3.

8-5

Page 30

Figure 8-1. Valve Assemblies, Type CXT-E (Sizes 1.00” To 2.00”)

8-6

Page 31

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

PARTS LIST TABLE FOR VALVE ASSEMBLIES, TYPE CXT-E ( SIZES 1.00” TO 2.00”)

VALVE SIZE AND PART NUMBERS

ITEM QTY PART NAME 1.00 INCH 1.25 INCH 1.50 INCH 2.00 INCH

1 1 VALVE BODY 20762 20759 20758 20761

2 1 SEAT CAGE 16844 16845 16837 16843

3 1 BOTTOM PISTON 121540 121525 121502 121529

4 NOT USED

5 1 VALVE PLUG SHAFT 16849 16839 16838 16848

6 1 TOP PISTON 121539 12154 121501 121530

7 1 DISC SEAT 121541 121527 121510 121531

8 1 RETAINING DISC 121542 121513 121504 121532

9 NOT USED

10 PILOT SPRING 121528 121528 121528 121528

11 1 RETAINING RING 121545 121545 121545 121545

12 1 VALVE STEM 122655 122654 122651 122650

13 1 VALVE TOP GASKET 122136 122136 122136 122136

14 6 BOLT, HEX, 3/8-16 122405 122405 122405 122405

16 1 LOWER SHAFT 121979 121980 121980 121982

17 2 HEX NUT, 1/4-20 6-226 6-226 6-226 6-226

18 1 PACKING NUT 122664 122664 122664 122664

19 2 BOLT, HEX 3/8-16 x 5/8 LG 54014 54014 54014 54014

20 1 PACKING ASSY 121567 121567 121567 121567

21 1 VALVE TOP 16943 16943 16943 16943

22 NOT USED

23 1 LOCKWASHER 122666 122666 122666 122666

24 1 SEAT CAGE GASKET 123080 123081 123082 123083

26 1 LINKAGE 24038-1 24038-1 24038-1 24038-1

27 1 ACTUATOR 69009 69009 69009 69009

28 1 SCALE 59028-1 59028-1.25 59028-1.5 59028-2

29 1 GASKET 81046 81046 81046 81046

30 2 NUT, HEX, #8-32 123322 123322 123322 123322

31 1

32 1 TOP PISTON RETAINING NUT 121543 121543 121543 121543

33 1 LOWER PILOT SEAT ASSY 121505 121505 121505 121505

34 1 SEAT RETAINER N/A 121559 121506 121506

35 1 VALVE STEM RETAINING NUT 121503 121503 121503 121503

BOTTOM PISTON RETAINING NUT

122982 122982 122982 122982

8-7

Page 32

ACTUATOR

27

LINKAGE

26

SHAFT PIN

LINKAGE ADAPTER

OR

17

16

18

19

29

15

20

21

23

31

22

30

28

0

INDICATOR PLATE

14

13

12

11

10

9

8

24

3

2

1

Figure 8-2. Valve Assemblies, Type CXT-E (Sizes 2.50” To 4.00”)

8-8

7

6

5

4

Page 33

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

PARTS LIST TABLE FOR VALVE ASSEMBLIES, TYPE CXT-E ( SIZES 2.50” TO 4.00”)

VALVE SIZE AND PART NUMBERS

ITEM QTY PART NAME 2.50 INCH 3.00 INCH 4.00 INCH

1 1 VALVE BODY 20765-1 20766-1 20775

2 1 SEAT CAGE 16961 161004 161046

3 1 BOTTOM PISTON 16962 161007 161048

4 1 PISTON RETAINING RING 122173 122173 122234

5 1 VALVE PLUG SHAFT 16972 161006 161047

6 1 TOP PISTON 16970 161005 161050

7 1 VALVE SEAT 121935 122032 122178

8 1 VALVE SEAT RETAINING DISC 121934 122031 122177

9 4 10-32 x 3/4” LG. SOCKET HD. CAP

SCREW

10 1 PILOT SPRING 122081 122232 121823

11 1 PILOT SPRING RETAINER 122082 122082 122173

12 1 VALVE STEM 122648 122658 122659

13 1 VALVE TOP GASKET 122083 122204 122203

122174 122174 122238

14 4 CAP SCREW 5/8-11 x 1-1/2” LG. N/A 6-310 6-310

15 2 3/8-16 NUT (4” VALVE ONLY) N/A N/A 6-264

16 1 LOWER SHAFT 122223 122230 122224

17 2 1/4-20 NUT 6-226 6-226 N/A

18 1 PACKING NUT 122664 122665 122665

19 2 3/8-16 x 5/8” LG. CAP SREWS 54014 54014 54014

20 1 PACKING ASSY 121567 121568 121568

21 1 VALVE TOP 18781 18823 18824

22 1 SEAT BACK-UP RING 122326 122327 122328

23 1 LOCKWASHER 122666 122667 122667

24 1 SEAT CAGE GASKET 123084 123085 123086

25 2 1/4” HEX HD. NPT PLUG 9-22 9-22 9-22

26 1 LINKAGE 24038-1 24038-1 24038-2

27 1 ACTUATOR 69009 69009 69009

28 1 SCALE 59028-2.50 59028-3 59028-4

29 1 GASKET 81046 81046 81046

30 2 8-32 HEX NUT 123332 123322 123322

31 1 PILOT SPRING BACKUP WASHER N/A N/A 122246

8-9

Page 34

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

BAR 1/4" SQUARE

TOOL STEEL

WELD ON INSIDE

ONLY

VALVE SIZE

1-INCH

1-1/4 INCH

1-1/2-INCH

2-INCH

2-1/2-INCH

3-INCH

ALL DIMENSIONS SHOWN ARE IN INCHES

C

B

1.25" 1.50"

PIPE OR TUBING - A

1" SCH. 40 PIPE

1-1/4" SCH. 40 PIPE

1-1/2" SCH. 40 PIPE

2-1/2" OD x .120" WALL

SEAMLESS STEEL

TUBING

2-1/2" OD x .120" WALL

SEAMLESS STEEL

TUBING

3" OD x .120" WALL

SEAMLESS STEEL

TUBING

A

D

HANDLE – 1 /2" DIA

COLD ROLLED STEEL

WELD

WELD

B

1.11 1-5/8 7-1/2

1.42

1.67

2.40

2.895

3.476

C D

2

2-3/8

2-5/8

3-3/8

3-15/16

7-1/2

8-1/4

8-1/4

9-1/2

8

8

1/2" STEEL

PLATE

TOOLS FOR 1-INCH TO 3-INCH VALVES

1/4" SQUARE BAR

TOOL STEEL

5

4-1/2

1/4

WELD

WELD

TOOL FOR 4-INCH VALVE ONLY

Figure 8-3. Cage Removal Tool

8-10

1/2

1

2" SCH. 40 PIPE

8

Page 35

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

ITEM QTY PART DESCRIPTION PART NUMBER

1 1 LINKAGE ASSEMBLY 24038-1 (1” TO 3” VALVES)

24038-2 (4” Valve)

2 1 SCALE 59028-1 (1” VALVE)

59028-1.25 (1.25” VALVE)

59028-1.5 (1.5” VALVE)

59028-2 (2” VALVE)

59028-2.5 (2.5” VALVE)

59028-3 ( 3” VALVE)

59028-4 (4” VALVE)

3 2 HEX NUT, 8-32 123322

4 2 CAP SCREW, 3/8-16 x 5/8 LONG 54014

5 1 LINKAGE GASKET 81046

Figure 8-4. Linkage Assembly Installation Details

8-11

Page 36

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

ACTUATOR REPLACEMENT

There are no repairable parts contained in the Actuator. Therefore, if the Troubleshooting procedures in

this Instruction Manual isolate the cause of the fault to the Actuator, it must be replaced as described in

the following steps:

CM45. Disconnect and lock-out/tag-out AC power going to the Control Box. Use a voltmeter to ensure

that all voltages are zero before continuing.

CM46. Disconnect the cable connected to the Actuator.

CM47. Using an 8 mm wrench, loosen the hex nuts securing the Actuator to the Linkage Shaft.

CM48. Completely remove the defective Actuator from the shaft.

CM49. To install the replacement Actuator, depress and hold the Clutch button (Figure 8-5) and rotate

the pointer to approximately 80° on the dial. Release the Clutch.

CM50. Next, slide the Actuator onto the Linkage Shaft.

CM51. Ensure that the pin on the Linkage Assembly is inserted in the center slot on the bottom of the

Actuator (Figure 8-5).

CM52. Verify that the indicator plate on the Linkage Assembly is aligned with the 0 (zero) marking on the

Linkage scale. Also, ensure that the Actuator Dial is approximately at the 80° position.

CM53. Ensure that the Pin on the Linkage is inserted in the center slot on the Actuator.

CM54. Using an 8 mm wrench, tighten the hex nuts on the U-bolt to secure the Actuator to the shaft.

Torque nuts to 60 in-lbs.

CM55. Reconnect the Control Box cable to the Actuator.

CM56. Following Actuator replacement, perform the Control Valve Adjustment procedure in Section 3.

8-12

Page 37

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

DIAL &

POINTER

9

0

LINKAGE

SHAFT

COVER

0

CLUTCH

neptronic

COVER

SET SCREW

CABLE

CONNECTOR

1 2 3

CENTER

SLOT

Figure 8-5. Actuator Replacement

LINKAGE ASSEMBLY REPLACEMENT

As Figure 8-6 shows, the Linkage Assembly Part No. will vary, depending on valve size. CXT-E valve

sizes from 1.00 to 3.00 inches utilize Linkage Assembly Part No. 24038-1. However, 4.00 inch CXT-E

Valves utilize Linkage Assembly Part No. 24038-2. The primary difference between the 24038-1 and

24038-2 Linkage Assemblies is the Adapter shown in Figure 8-6. In addition, the Linkage Pin location for

the 24038-1 assembly will vary for 1.00 to 2.00 inch valves and for 2.50 to 3.00 inch valves. IT IS

IMPERATIVE THAT THE CORRECT ADAPTER AND PIN LOCATION BE USED FOR THE VALVE SIZE

BEING REPAIRED. The Linkage Assembly is attached to the Control Valve Top with two Cap Screws.

The Linkage Gasket (Part No. 81046) should also be replaced when installing a new Linkage Assembly.

8-13

Page 38

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

Figure 8-6. Linkage Assemblies

If necessary, the Linkage Assembly is removed and replaced as follows:

CM57. Remove the Actuator using steps CM45 through CM48 in the previous paragraph titled

ACTUATOR REPLACEMENT.

CM58. Next, refer to Figure 8-1 (1” to 2” Valves or 8-2 (2 ½” to 4” Valves) to locate item numbers shown

in parentheses in the following steps.

CM59. Loosen the Hex Nuts (17) under the Indicator Plate (Figure 8-1 or 8-2) approximately a half turn

clockwise. To simplify Linkage Assembly replacement, DO NOT remove the Hex Nuts. This will

simplify adjustment of the Linkage during reassembly.

CM60. Remove the Shaft Pin (Figure 8-1 or 8-2) securing the Linkage Shaft to the Linkage Adapter.

CM61. Remove the Linkage Adapter (Figure 8-1, 8-2) from the Valve Shaft (16) by rotating it counter-

clockwise. Also, remove the Indicator Plate.

8-14

Page 39

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

CM62. Remove the two Cap Screws (19) securing the Linkage Assembly (26) to the Valve Top (21).

CM63. Remove the Linkage Assembly (26) from the Valve Top. Also, remove the Gasket (29) which will

be replaced.

CAUTION

Ensure that the replacement Linkage Assembly, Adapter and Scale are identical

to those removed in the previous steps. Also, ensure that the linkage pin (Figure

8-6) is set to the proper position for the Control Valve size. Failure to observe this

precaution may result in improper Control Valve operation.

CM64. Using a new Gasket (29), position the replacement Linkage Assembly on the Valve Top (21).

Secure the Linkage Assembly to the Valve Top using the previously removed Cap Screws (29).

CM65. Install the Indicator Plate on the Valve Shaft (16) with the curved end facing upward (Figure 8-4)

CM66. Attach the Valve Shaft (16) to the Linkage Adapter by rotating the Shaft counterclockwise (as

viewed from above). If the Valve Shaft cannot be turned by hand, use an open-end wrench to turn

the “double-nuts” on the Shaft until it engages the Linkage adapter threads. Insert the Shaft into

the Linkage Adapter until the Hex Nuts (17) are snug against the Indicator Plate.

CM67. Press down on the Valve Shaft (16) to compress the Pilot Spring (10) in the Valve Body.

CM68. With the Pilot Spring compressed, verify that the Indicator Plate is aligned with the “0” (zero)

marking on the Scale (28). If necessary, rotate the Valve Shaft until the Plate is aligned with the

“0” Scale marking.

CM69. Replace the Actuator using steps CM49 through CM56 in the previous paragraph titled

ACTUATOR REPLACEMENT.

8-15

Page 40

Page 41

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

9 – RECOMMENDED SPARE PARTS

CXT-E CONTROL VALVE RECOMMENDED SPARE PARTS

AERCO recommends that the Spare Parts listed below be kept on hand for maintenance replacement

purposes The Recommended Quantity for the parts shown apply to each 1 to 5 Control Valves of the

same size.

NOTE

For Part Numbers of the items listed below, refer to Figure 8-1 for Control Valve sizes

ranging from 1.00” to 2.00”. Refer to Figure 8-2 for 2.50” to 4.00” Control Valves.

Table 9-1. Recommended Spare Parts For CXT-E Control Valves (1.00” – 4.00”)

RECOMMENDED

QUANTITY

2 Valve Seat 7

2 Valve Top Gasket 13

2 Packing Assembly 20

2 Seat Cage Gasket 24

2 Gasket (Linkage) 29

2 Lower Pilot Seat* 33*

* Used on Control Valve sizes ranging from 1.00” to 2.00” ONLY

PART NAME

FIGURE 8-1 OR 8-2

ITEM NUMBER

9-1

Page 42

Loading...

Loading...