Page 1

Electronic Control System (ECS) and Type CXT-E Valve

USER MANUAL

Revised: 02/28/2014

Electronic Control

Electronic Control System

Installation, Operation, and Maintenance

Type CXT-E Electronic Valve

User Manual

System (ECS) and

Type CXT-E

Electronic Valve

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 1 of 82

AC-105 OMM-0003_0D

Page 2

Electronic Control System (ECS) and Type CXT-E Valve

Technical Support:

1-800-526-0288

www.aerco.com

User Manual

(Mon–Fri, 8am-5pm EST)

Disclaimer

The information containe d in this manual is subject to c hange without notice from AERCO Inter national,

Inc. AERCO makes no warranty of any kind with respect to this material, including but not limited to

implied warranties of merchantability and fitness f or a particular application. AE RCO International is not

liable for errors appearing in this manual. Nor for incidental or consequential damages occurring in

connection with the furnishing, performance, or use of this material.

Page 2 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 3

Electronic Control System (ECS) and Type CXT-E Valve

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTS.................................................................................................. 3

SAFETY PRECAUTIONS ............................................................................................... 5

1. GENERAL INFORMATION ..................................................................................... 7

1.1 INTRODUCTION ................................................................................................................... 7

1.2 ELECTRONIC CONTROL SYSTEM (ECS) ................................................................................. 7

1.2.1 Control Box Assembly............................................................................................................................. 9

1.2.2 Feed-Forward Flow Sensor ................................................................................................................... 11

1.2.3 Outlet Temperature Sensors ................................................................................................................ 11

1.2.4 Heating Fluid Inlet/Outlet Temperature Sensors ................................................................................. 11

1.2.5 Over-Temperature Solenoid Valve ....................................................................................................... 11

1.3 ELECTRONIC CONTROL VALVE CXT-E................................................................................. 12

1.3.1 Control Valve Accessories .................................................................................................................... 12

1.4 REFERENCE DOCUMENTS.................................................................................................. 14

1.4.1 AERCO Documents ............................................................................................................................... 14

1.4.2 Eurotherm Documents – (Available at www.eurotherm.com) ............................................................ 14

2. INSTALLATION ..................................................................................................... 15

2.1 INTRODUCTION ................................................................................................................. 15

2.2 ELECTRONIC CONTROL VALVE TYPE CXT-E INSTALLATION ................................................ 15

2.3 ELECTRONIC CONTROL SYSTEM (ECS) INSTALLATION ....................................................... 17

2.4 CHANGING COMMUNICATION ADDRESSES ON AERCO EUROTHERM TEMPERATURE

CONTROLLER ............................................................................................................................. 21

2.5 ENABLING REMOTE SETPOINT CONFIGURATION ON THE AERCO EUROTHERM

TEMPERATURE CONTROLLER .................................................................................................... 24

3. ADJUSTMENT ...................................................................................................... 25

3.1 INTRODUCTION ................................................................................................................. 25

3.2 CONTROL VALVE TYPE CXT-E ADJUSTMENT ...................................................................... 25

3.3 ELECTRONIC CONTROL SYSTEM (ECS) ADJUSTMENT ........................................................ 27

3.3.1 Setpoint Temperature Adjustment ...................................................................................................... 28

3.3.2 Over-Temperature Alarm Limit Adjustment ........................................................................................ 29

3.3.3 Over-Temperature Switch Sensor Adjustment ..................................................................................... 30

4. OPERATION .......................................................................................................... 31

4.1 INTRODUCTION ................................................................................................................. 31

4.2 PRE-OPERATIONAL CHECKS .............................................................................................. 31

4.3 INITIAL START-UP .............................................................................................................. 31

4.4 CHECKING WATER HEATER FLOW RATE ............................................................................ 32

4.5 CHECKING THE VALVE POSITION OUTPUT IN AUTO MODE ............................................... 32

5. FUNCTIONAL DESCRIPTION .............................................................................. 33

5.1 INTRODUCTION ................................................................................................................. 33

5.2 FUNCTIONAL OVERVIEW ................................................................................................... 33

5.3 OVER-TEMPERATURE CONTROL AND SAFETY FEATURES ................................................. 33

6. ROUTINE MAINTENANCE ................................................................................... 35

6.1 INTRODUCTION ................................................................................................................. 35

6.2 CXT-E CONTROL VALVE ROUTINE MAINTENANCE ............................................................ 35

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 3 of 82

AC-105 OMM-0003_0D

Page 4

Electronic Control System (ECS) and Type CXT-E Valve

TABLE OF CONTENTS

6.2.1 Monthly Maintenance ......................................................................................................................... 35

6.2.2 Semi-Annual Maintenance: .................................................................................................................. 35

6.3 ELECTRONIC CONTROL SYSTEM (ECS) ROUTINE MAINTENANCE ...................................... 36

6.3.1 Quarterly Maintenance: ....................................................................................................................... 36

6.3.2 Annually: .............................................................................................................................................. 36

6.3.3 Temperature Sensors: .......................................................................................................................... 36

6.3.4 Flow Sensor: ......................................................................................................................................... 37

6.4 HEAT EXCHANGER ROUTINE MAINTENANCE CLEANING .................................................. 38

6.4.1 Pumping System Set-Up Instructions: .................................................................................................. 38

6.4.2 Cleaning Procedure: ............................................................................................................................. 39

6.4.3 Testing HydroSkrub Effectiveness ........................................................................................................ 40

6.4.4 Calcium Carbonate Spot Test: .............................................................................................................. 40

6.4.5 pH Trend Charting: ............................................................................................................................... 40

7. TROUBLESHOOTING ........................................................................................... 41

7.1 INTRODUCTION ................................................................................................................. 41

7.1.1 Electronic Control System (ECS) Preliminary Check: ............................................................................. 41

7.1.2 Electronic Control Valve, CXT-E Preliminary Check: ............................................................................. 41

7.2 TROUBLESHOOTING PROCEDURES ................................................................................... 41

8. CORRECTIVE MAINTENANCE ............................................................................ 47

8.1 INTRODUCTION ................................................................................................................. 47

8.2 PART 1 - CXT-E CONTROL VALVE CORRECTIVE MAINTENANCE ......................................... 47

8.2.1 Valve Shaft Seal Retainer Replacement: .............................................................................................. 47

8.2.2 Valve Disassembly ................................................................................................................................ 48

8.2.3 Valve Reassembly ................................................................................................................................ 50

8.2.4 Actuator Replacement ......................................................................................................................... 58

8.2.5 Linkage Assembly Replacement ........................................................................................................... 59

8.3 PART 2 - ECS CORRECTIVE MAINTENANCE ........................................................................ 61

8.3.1 Control Box Assembly and Components .............................................................................................. 61

8.3.2 Control Box Assembly Replacement ..................................................................................................... 62

8.3.3 Temperature Controller Replacement ................................................................................................. 62

8.3.4 Over-Temperature Switch and Temperature Indicator Replacement .................................................. 63

8.3.5 DC Power Supply Replacement ............................................................................................................ 64

8.3.6 DC Voltage Regulator Replacement ..................................................................................................... 65

9. RECOMMENDED SPARE PARTS ........................................................................ 73

9.1 CXT-E CONTROL VALVE RECOMMENDED SPARE PARTS ................................................... 73

9.2 ELECTRONIC CONTROL SYSTEM RECOMMENDED SPARE PARTS ...................................... 73

APPENDIX A ................................................................................................................ 75

9.3 PROCESS ALARMS: ............................................................................................................ 76

9.4 EUROTHERM 2408 PROCESS ALARMS ........................................................................................ 76

9.5 DIAGNOSTIC ALARMS ........................................................................................................ 76

9.6 EUROTHERM 2408 DIAGNOSTIC ALARMS ................................................................................... 76

9.6.1 Clearing Hardware Error (Hw.Er) Display............................................................................................. 77

APPENDIX B ................................................................................................................ 79

Page 4 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 5

Electronic Control System (ECS) and Type CXT-E Valve

! ! !

!

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installing or operating personnel must, at all times, observe all saf ety regulat ions. The following

warnings are general and must be given the same attention as specific precautions included in

the instructions.

WARNING

FLUIDS UNDER PRESSURE MAY CAUSE INJURY TO

PERSONNEL OR DAMAGE TO EQUIPMENT WHEN RELEASED.

CLOSE ALL SHUTOFF VALVES AND CAREFULLY DECREASE

ALL TRAPPED PRESSURES TO ZERO BEFORE PERFORMING

ANY MAINTENANCE. TAG THE PRESSURE SOURCE “OUT OF

SERVICE” WHILE PERFORMING MAINTENANCE TASKS.

WARNING

LIVE STEAM CAN CAUSE SEVERE BURNS.

NEVER SEARCH FOR LEAKAGE IN A LIVE STEAM LINE BY

SIGHT ALONE OR BY “FEEL.” USE A MIRROR OR OTHER

SUITIBLE POLISHED OBJECT. ALSO, ALW AYS WEAR GLOVES

AND LONG SLEEVES.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 5 of 82

AC-105 OMM-0003_0D

Page 6

Electronic Control System (ECS) and Type CXT-E Valve

SAFETY PRECAUTIONS

(This page intentionally blank)

Page 6 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 7

Electronic Control System (ECS) and Type CXT-E Valve

1. GENERAL INFORMATION

1. GENERAL INFORMATION

1.1 INTRODUCTION

This Instruction Manual provides detailed coverage for both the AERCO Electronic Control

System (ECS) and the Electronic Control Valve CXT-E. This Control System and Valve

combination can be used with all models and sizes of AERCO Indirect Fired Water Heaters

which include the following Models:

• SW1A PLUS,

• SW1B PLUS, SW1B PLUS II,

• WW3E PLUS

Double- W all Heater Models DW-24, DW -45, DW-68 (Refer to HE-111 for SWDW-24 , S W DW45 & SWDW-68 Models)

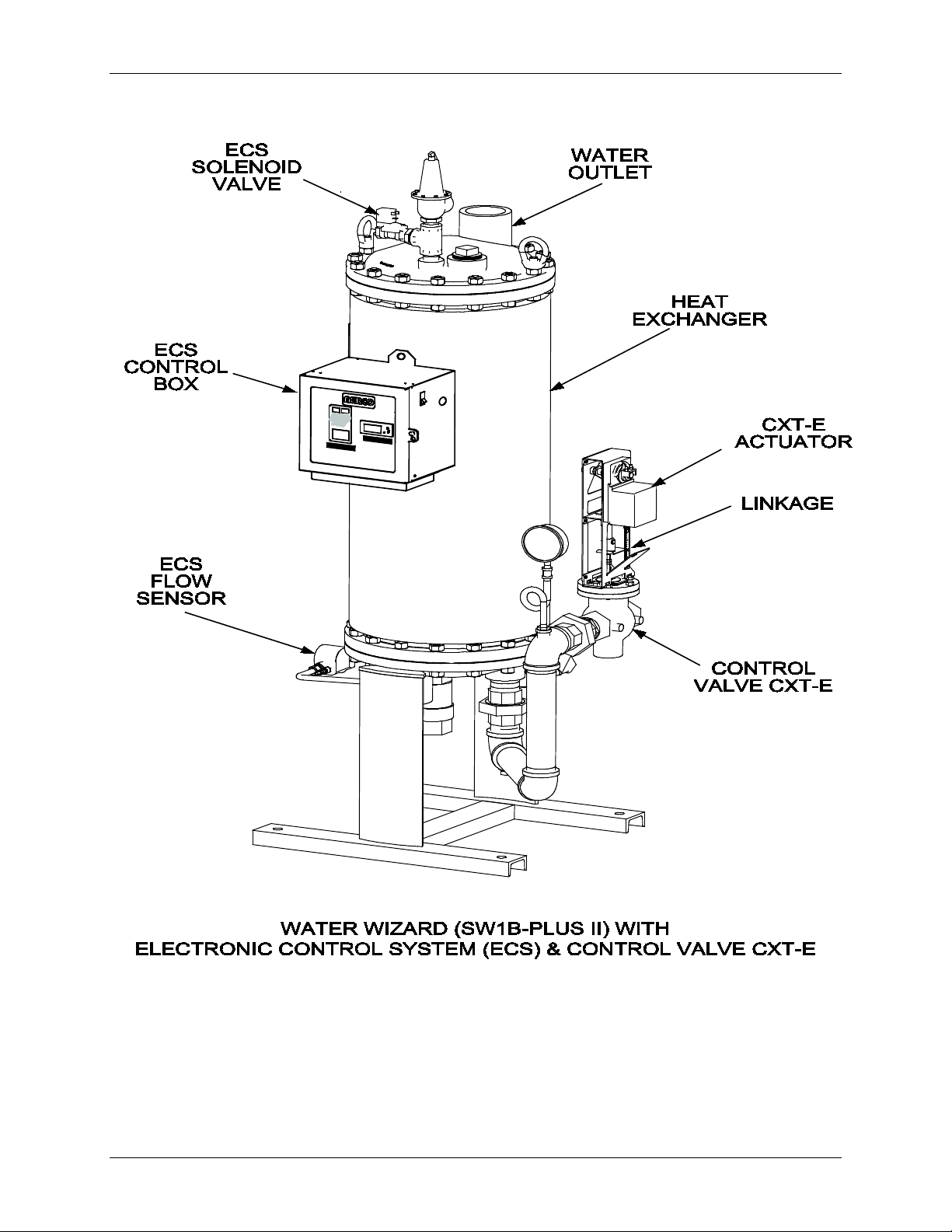

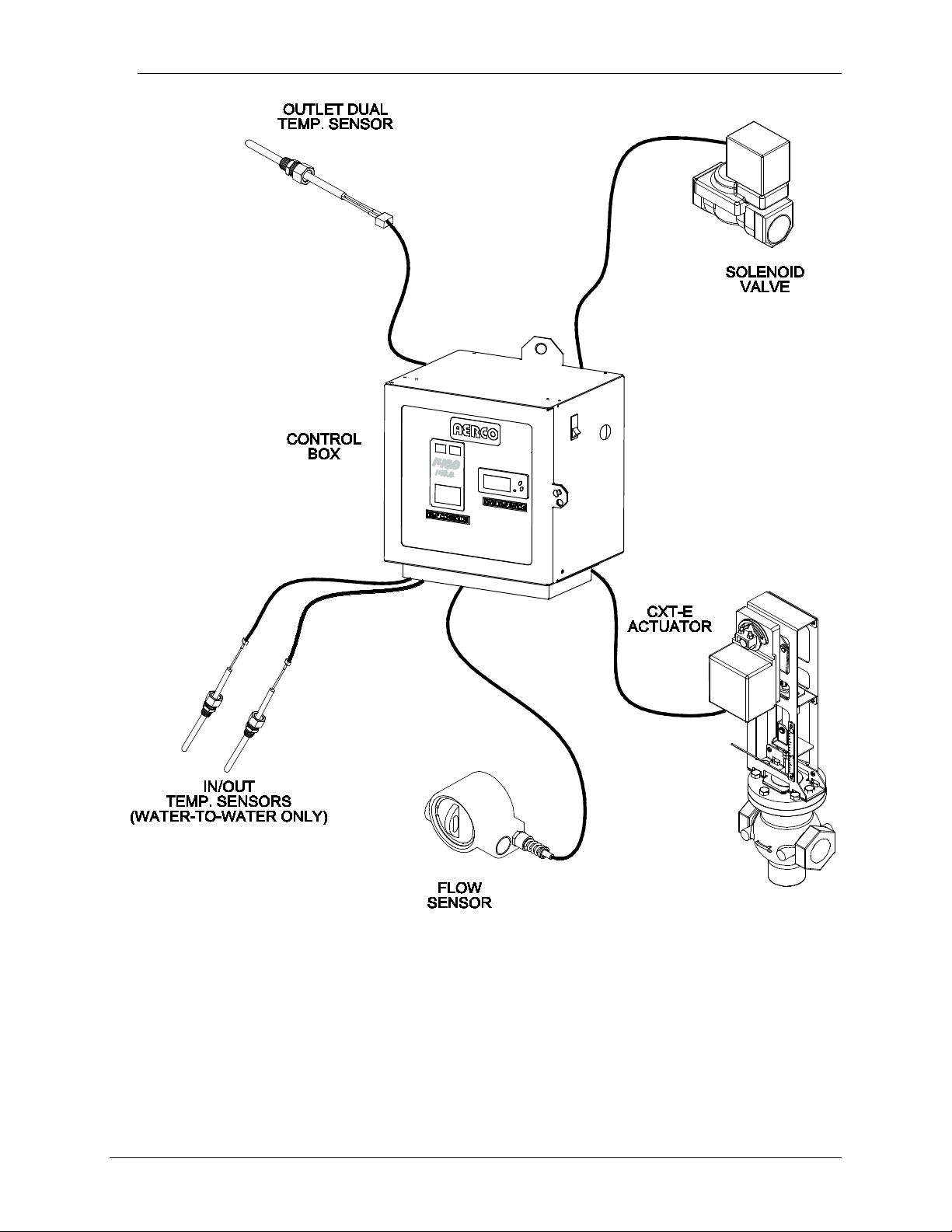

Figure 1-1 shows a typical installation with a Water Wizard, Model SW1B-Plus II Packaged

Water Heater. The remaining paragraphs in this section provide descriptions of the units,

assemblies and sub-assemblies included with the Electronic Control System (ECS) and the

Electronic Control Valve CXT-E.

NOTE:

This Instruction Manual provides detailed Installation, Operation,

Maintenance and Parts information and procedures for the Electronic

Control System and Electronic Control Valve. A separate Instruction

Manual for the Heat Exchanger is included with the Packaged W ater

Heater. Also, refer to the paragraph titled REFERENCE

DOCUMENTS at the end of this Section for additional documentation

which may be required for accessories or options provided with your

order.

1.2 ELECTRONIC CONTROL SYSTEM (ECS )

The Electronic Control System contains a Control Box Assembly which includes all of the

electronic circuitry for the ECS. In addition, the ECS includes several sensors and safety

devices which provide temperature and flow control information to the Control Box circuitry. The

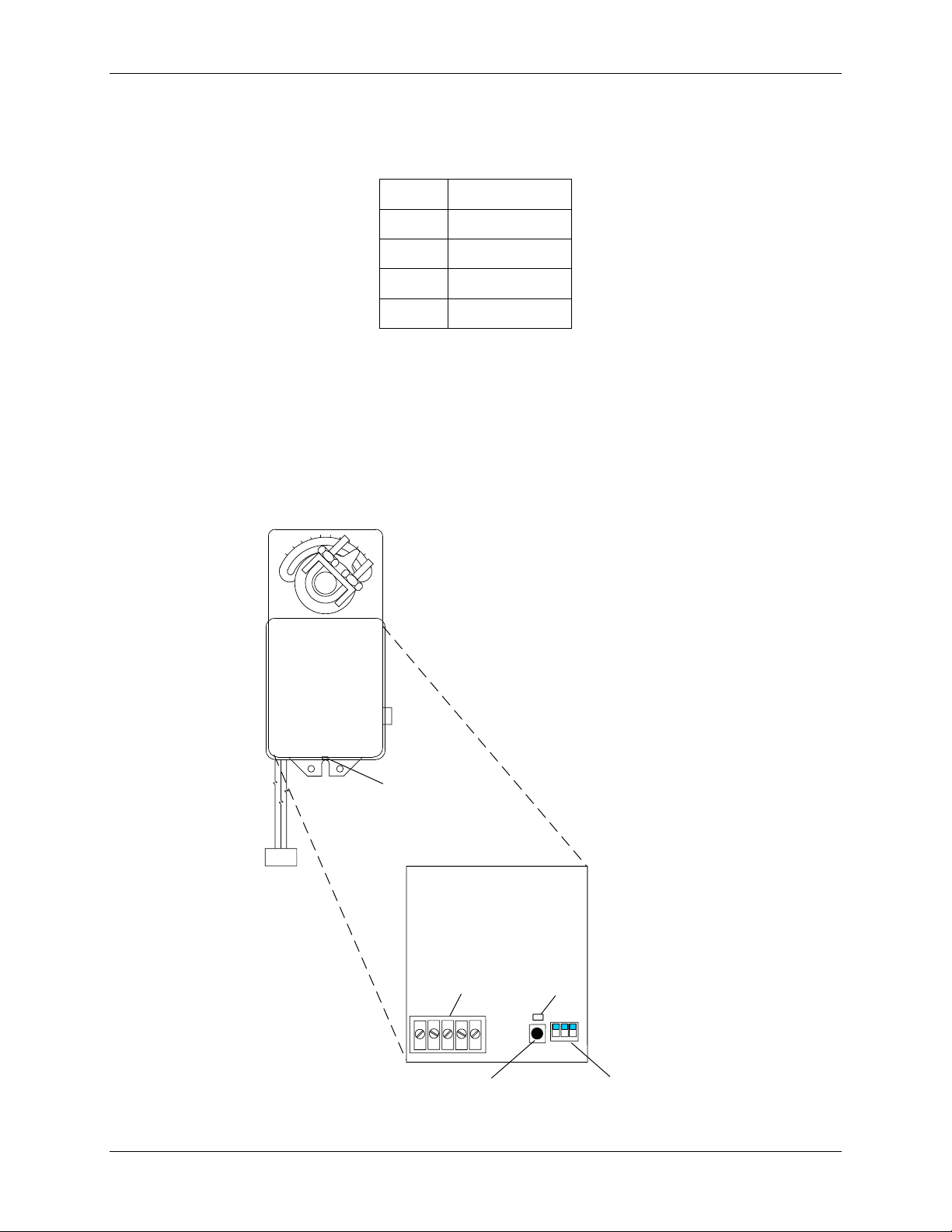

Control Box and the additional devices included in the ECS are shown in Figure 1-2. The

additional devices included in the ECS include:

• Feed-Forward Flow Sensor (Flowmeter)

• Outlet Dual Temperature Sensors (Type J Thermocouples)

• Heating Fluid Inlet/Outlet Temperature Sensors (Type J Thermocouples) – For Water-to-

Water Heat Exchangers Only

• Over-Temperature Solenoid Valve

If desired, the Electronic Control System (ECS) can be ordered with a Modbus Communication

Option. This option permits the ECS to be externally controlled by an Energy Management

System (EMS), Building Automation System (BAS), or Computer supplied by other

manufacturers.

A Gateway option exists to link with other communication protocols. Check with your AERCO

sales representative for more information.

The Electronic Control System assemblies and components are described in the following

paragraphs.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 7 of 82

AC-105 OMM-0003_0D

Page 8

Electronic Control System (ECS) and Type CXT-E Valve

1. GENERAL INFORMATION

Figure 1-1. Typical ECS & CXT-E Installation With a Packaged Water Heater

Page 8 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 9

Electronic Control System (ECS) and Type CXT-E Valve

1. GENERAL INFORMATION

Figure 1-2. Electronic Control System (ECS)

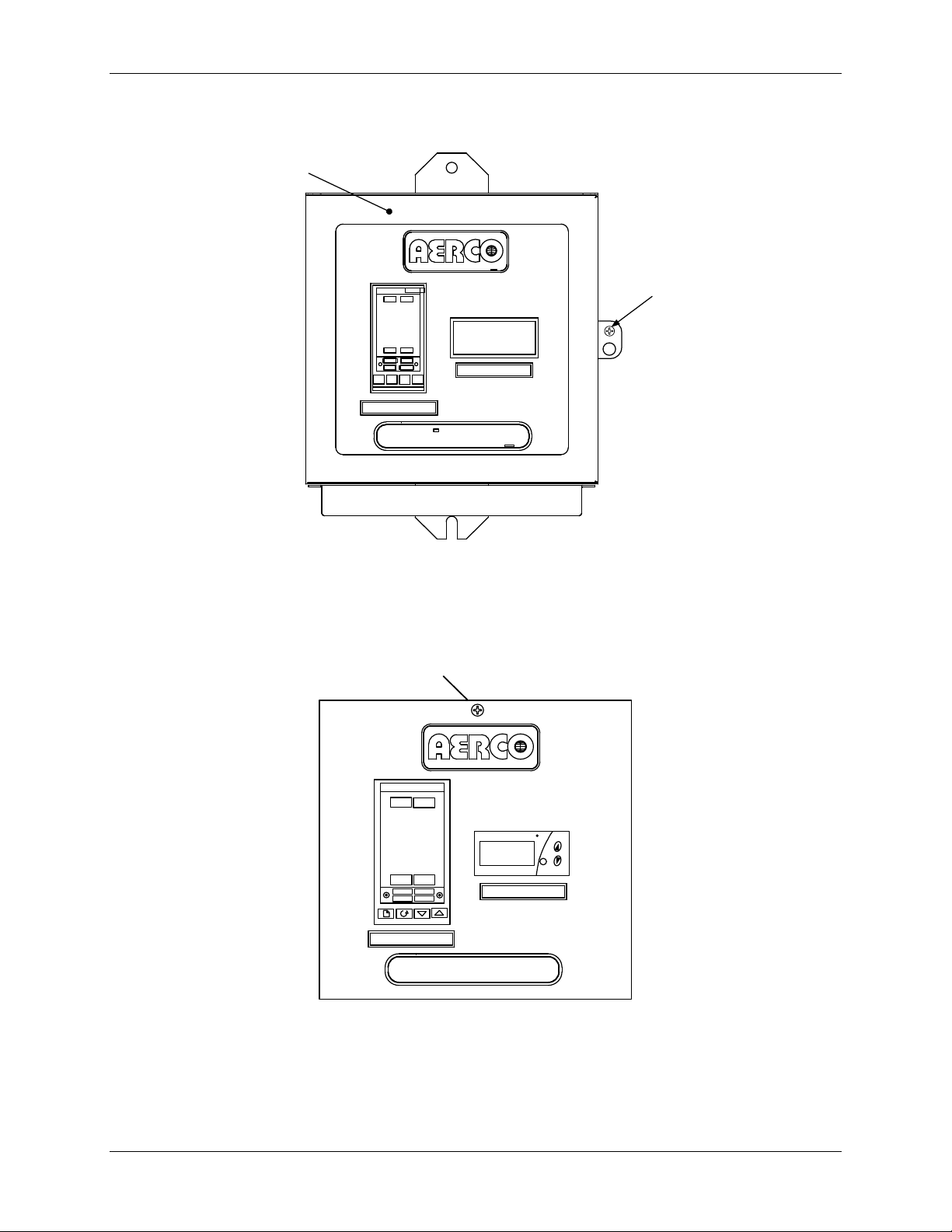

1.2.1 Control Box Assembly

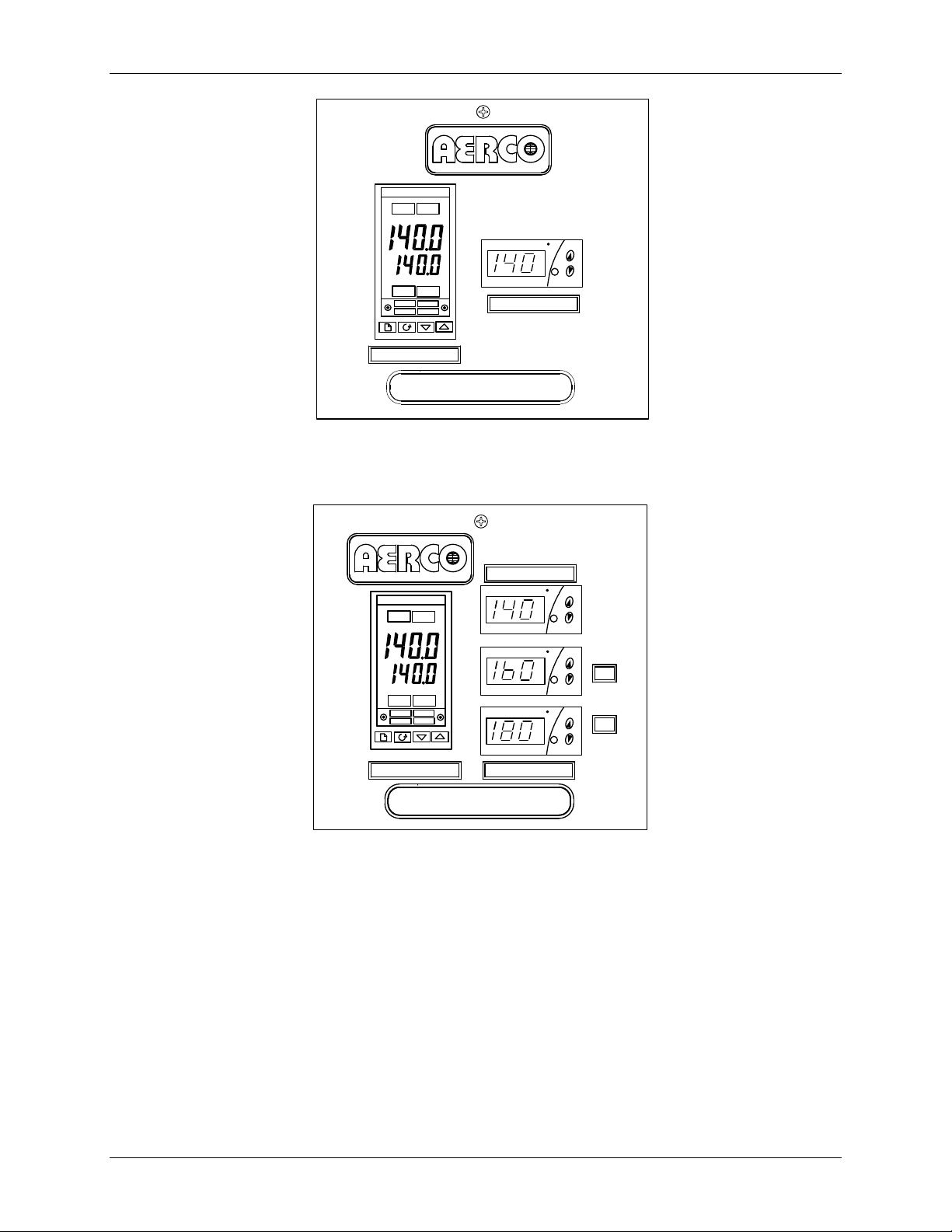

The Control Box Assembly is available in two models; one for Steam-to-Water Heaters and one

for Water-to-Water Heaters. The only difference between these two models are the Display

devices provided on the front panels. The panel of the Control Box model for W ater -to-Water

applications contain two additional Display devices which display the heating fluid (hot boiler

water) inlet and outlet temperatures. The Control Box front panels for both models are shown in

Figure 1-3.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 9 of 82

AC-105 OMM-0003_0D

Page 10

Electronic Control System (ECS) and Type CXT-E Valve

MODEL 69012-1

FRONT PANEL FOR STEAM-TO-WATER HEATERS

B-PLUS

TM

PT.NO.

SET

F

AUTO

RUN

MAN HOLD

OP 1

OP 2

SP2

REM

2408

OVER TEMP SWITCH

TEMP CONTROLLER

PT.NO.

WATER HEATER

MODEL 69012-2

FRONT PANEL FOR WATER-TO-WATER HEATERS

SET

F

SET

F

SET

F

AUTO

RUN

MAN HOLD

OP 1

OP 2

SP2

REM

2408

PT.NO.

OVER TEMP SWITCH

BOILER WATER TEMPTEMP CONTROLLER

E-PLUS

WATER HEATER

TM

PT.NO.

OUT

IN

1. GENERAL INFORMATION

Figure 1-3. ECS Control Box Models Showing Front Panel Differences

The Control Box is the heart of the ECS. It contains the Temperature Controller, an OverTemperature Switch and, when required, Inlet/Outlet Temperature Indicators for Water-to-Water

applications. The Temperature Controller is the “brain” of the ECS which processes data

received from the temperature and flow sensors. Using PID (Proportional Integral Derivative)

algorithms, the Temperature Controller provides a 4-to-20 mA control signal to the Control Valve

Actuator which precisely modulates the Control Valve for optimum outlet temperature control.

Page 10 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 11

Electronic Control System (ECS) and Type CXT-E Valve

1. GENERAL INFORMATION

An Over-Temperature Switch is also included in the Control Box to constantly monitor the Water

Heater outlet temperature to ensure the Heater does not exceed the preset high temperature

limit. Typically, the over-temperature limit is set 20°F above the desired Heater setpoint

temperature. If an over-temperature condition occurs, this Switch sounds an audible alarm,

activates the Over-Temperature Solenoid and cuts off power to the Control Valve Actuator. This

closes the Control Valve and shuts off the heating fluid (steam or hot boiler water) to the Heat er.

In addition, activation of the Over-Temperature Solenoid allows over-temperature water to be

dumped from the Heater shell.

The Control Box also contains a DC Power Supply and Voltage Regulator to provide the voltag e

levels required by the ECS Control Box circuitry, flow sensor and safety devices. It also provides

24 VDC power to the Control Valve CXT-E Actuator.

The Control Box components are housed in a steel enclosure with a hinged front door. This

door contains a clear polycarbonate window which permits maintenance personnel to view the

controls and displays of the Temperature Controller, and other display devices mounted on a

recessed panel behind the door. All sensor and control signal connections are made via cable

connections at the bottom of the Control Box. External AC power (120 to 240 VAC, 50/60 Hz) is

supplied via a cutout on the right side of the Control Box.

1.2.2 Feed-Forward Flow Sensor

The Feed-Forward Flow Sensor is installed between the cold water inlet and the drain valve on

the Water Heater as shown in Figure 1-1. The Flow Sensor monitors a portion of the inlet flow to

the Heater and provides a feed-forward signal to the Temperature Controller which is

proportional to the change in flow through the Heater.

1.2.3 Outlet Temperature Sensors

The Control System includes a Dual Temperature Sensor which is installed in the hot water

outlet of the Water Heater. This sensor contains two identical Type J thermocouples. The first

thermocouple connects directly to the Temperature Controller in the Control Box to provide the

outlet water temperature. The second thermocouple connects to the Over-Temperature Switch

in the Control Box.

1.2.4 Heating Fluid Inlet/Outlet Temperature Sensors

When the Heater utilizes hot (boiler) water as the heating fluid, two additional Temperature

Sensors (Type J thermocouples) are provided with the Control System. One temperature

Sensor is installed at the heating fluid inlet and t he other is installed at the heating fluid outlet.

These two Sensors are connected to two identical Temperature Display Indicators in the Control

Box to provide real-time indications of the inlet and outlet heating fluid temperatures. These

Temperature Indicators are physically identical to the Over-Temperature Switch, however they

are “Indicator-Only” devices and do not provide any switching functions.

1.2.5 Over-Temperature Solenoid Valve

As previously mentioned, the Over-Temperature Solenoid Valve operates in conjunction with

the Over-Temperature Switch in the Control Box. An over-temperature alarm is activated when

the preset high temperature limit is exceeded, thereby energizing and opening the Solenoid

Valve. This allows over-heated water and pressure build-up to be expelled from the Heater Shell

and relieve pressure build-up.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 11 of 82

AC-105 OMM-0003_0D

Page 12

Electronic Control System (ECS) and Type CXT-E Valve

ACCESSORY

REQUIREMENT

•

- Mandatory

•

Suggested for ease of

maintenance. Required if a

•

Mandatory

•

Recommended for adjustment

• Low Side Pressure Gauge,

Compound Type for steam flow

Recommended for adjustment

1. GENERAL INFORMATION

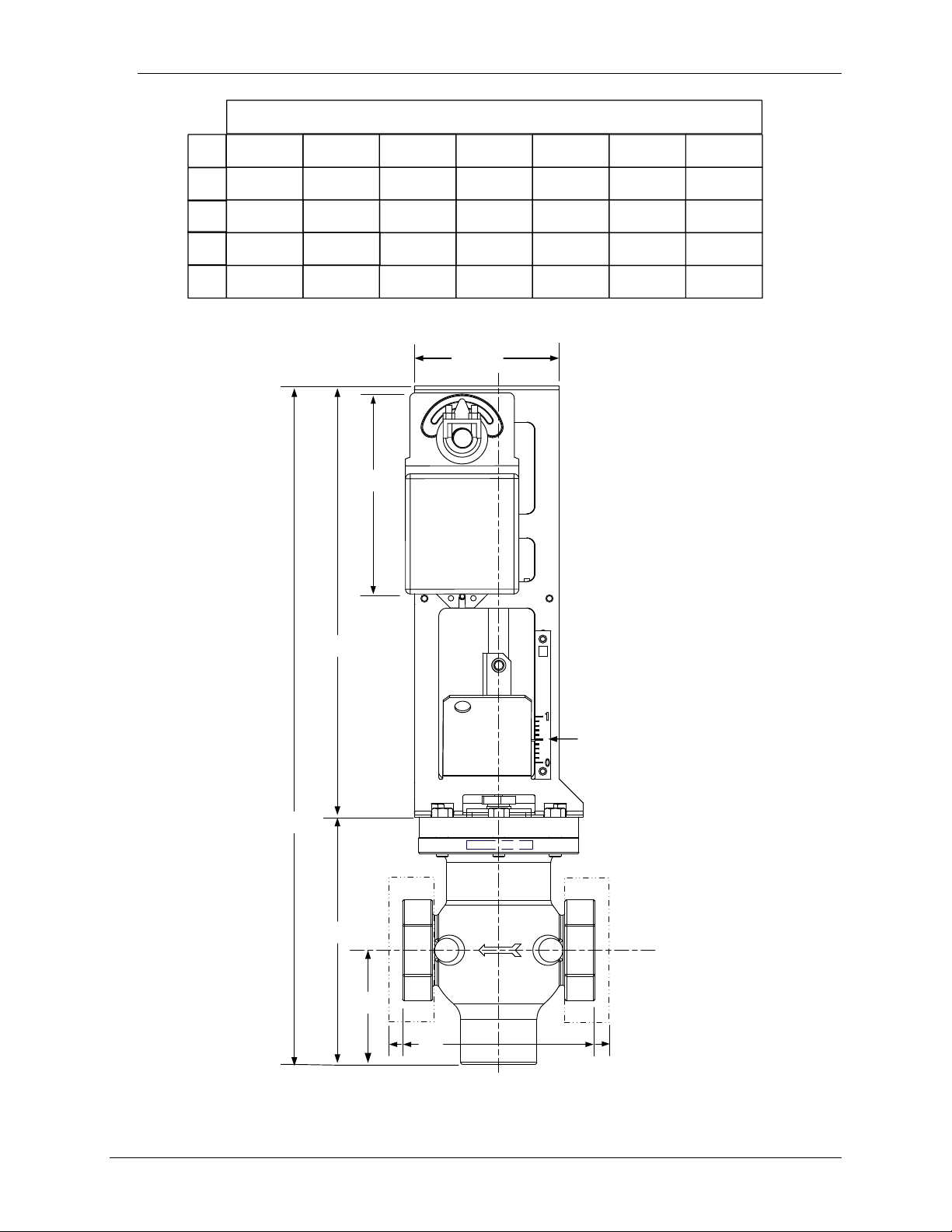

1.3 ELECTRONIC CONTROL VALVE CXT-E

Each Control Valve is comprised of three major sections; the Valve Body, Linkage Assembly

and the Valve Actuator. The Control Valves are available in sizes ranging from 1 inch to 4

inches. An identical Actuator Assembly is used with each size Valve Body. The Linkage

Assembly used with each size Valve Body is identical, except for minor differences in the Shaft

Adapter stroke of the mechanical linkage. Figure 1-4 shows the basic dimensions for each size

AERCO Control Valve CXT-E.

It should be noted that the Control Valves used for steam flow are identical to those used for hot

(boiler) water flow.

1.3.1 Control Valve Accessories

The accessories required for use with AERCO Electronic Control Valves, Type CXT-E will

depend on the specific application. Detailed installation instructions, including typical installation

drawings are provided in the INSTALLATION Section of this manual. However, please note the

items listed below and ensure that ALL mandatory items are available:

Upstream Shutoff Valve

Downstream Shutoff Valve

Bypass Line is used.

Strainer and Blow-Off Valve

High Side Pressure Gauge

and maintenance

and maintenance.

If any of these items have been furnished by AERCO with the Control Valve, the

necessary drawings and/or instructions should be included with the shipment.

Page 12 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 13

Electronic Control System (ECS) and Type CXT-E Valve

A

B

C

D

13.375

6.60"

4.50"

DIM. 1.00"

1.25" 1.50" 2.00" 2.50" 3.00" 4.00"

A

B

C

D

21.12 21.12 21.12 24.25 24.25

24.25

24.25

7.75 7.75

7.75

7.75 10.87 10.87 10.87

3.56

3.56

3.56 3.56 6.38 6.38 6.38

6.00

6.00 6.00 6.00 10.87 10.87 10.87

VALVE SIZES (INCHES)

POSITION

SCALE

1. GENERAL INFORMATION

Figure 1-4. Reference Dimensions for AERCO Control Valves, Type CXT-E

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 13 of 82

AC-105 OMM-0003_0D

Page 14

Electronic Control System (ECS) and Type CXT-E Valve

HE-104

SW1B-Plus Heat Exchanger Installation, Operation & Maintenance Manual

HE-105

WW3E Heat Exchanger Installation, Operation & Maintenance Manual

HE-106

DW-24, DW-45, DW-68 Double Wall Heat Exchanger Installation, Operation &

Maintenance Manual

HE-107

SW1A-Plus Heat Exchanger Installation, Operation & Maintenance Manual

HE-110

B-Plus II Water Wizard Heat Exchanger Installation, Operation & Maintenance

Manual

HA025132

2404/2408 Installation & Operation Handbook

HA02630

Series 2000 Communications Handbook

!

!

1. GENERAL INFORMATION

1.4 REFERENCE DOCUMENTS

Refer to the following documents as necessary for additional information and procedures for the

applicable AERCO Heat Exchanger provided with your Electronic Control System (ECS) and CXT-E

Control Valve. In addition, if the ECS is provided with the Modbus Com munication option, refer to the

referenced Eurotherm documents listed.

1.4.1 AERCO Documents

1.4.2 Eurotherm Documents – (Available at www.eur ot herm.com)

CAUTION

DO NOT use the Actuator Linkage Frame at the top of the Control

Valve Body for leverage when installing The Control Valve. Use pipe

wrenches on the inlet and outlet hex of the Valve Body.

Page 14 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 15

Electronic Control System (ECS) and Type CXT-E Valve

2. INSTALLATION

2. INSTALLATION

2.1 INTRODUCTION

Normally, the Electronic Control System (ECS) is shipped already installed on the Packaged

Water Heater. However, the Control Valve, Type CXT-E is packed separately. For smaller size

Valves (1” to 2”), the packaged Valve is attached to the base of the shipping crate. For larger

size Valves (2 ½” to 4”), the packaged Valve may be shipped separately due to space

limitations within the Heater shipping crate. Therefore, the installation procedures consist

basically of:

• Installing the Electronic Control Valve, Type CXT-E and associated steam or hot (boiler)

water piping and components.

• Connecting external power to the ECS Control Box

• Connecting and checking electrical connections to the CXT-E Actuator and other ECS

components

IMPORTANT NOTE!

For Water-to-Wat er Doub le -Wall (WWDW) heaters equipped with the

ECS, the following minimum recirculation flow must be provided to

achieve ±4°F temperature control under normal diversified domestic

load conditions:

Double-Wall Model Minimum System Recirculation

WWDW24 10 gpm

WWDW45 15 gpm

WWDW68 20 gpm

2.2 ELECTRONIC CONTROL VALVE TYPE CX T-E INSTALLATION

The following procedures apply to all sizes of AERCO Electronic Control Valves Type CXT-E

ranging from 1 inch to 4 inches. In addition, the following steps can be us ed for both st eam and

hot (boiler) water flow systems. Proceed as follows:

1) Refer to Figure 1-3 for dimensions of the Control Valve furnished with the Packaged W ater

Heater.

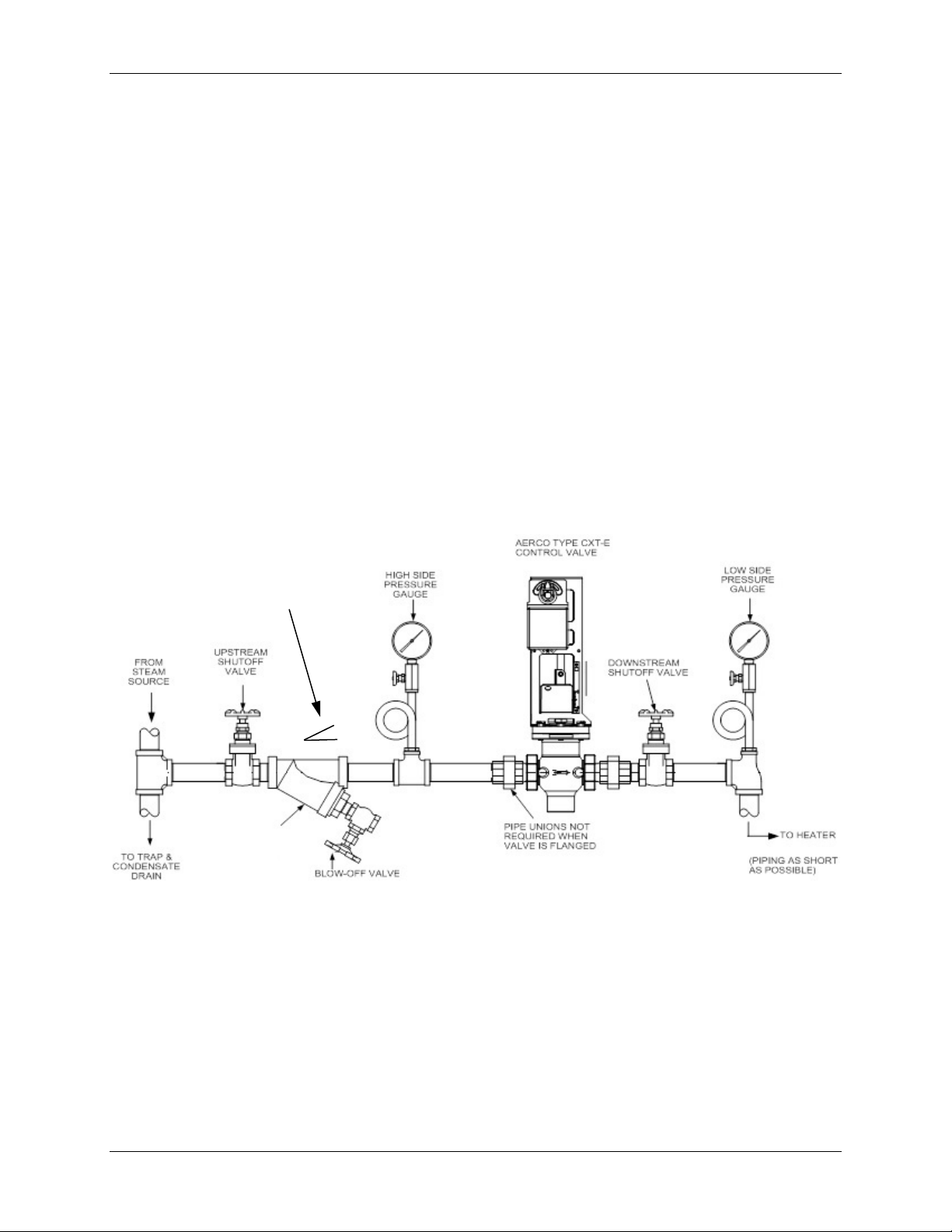

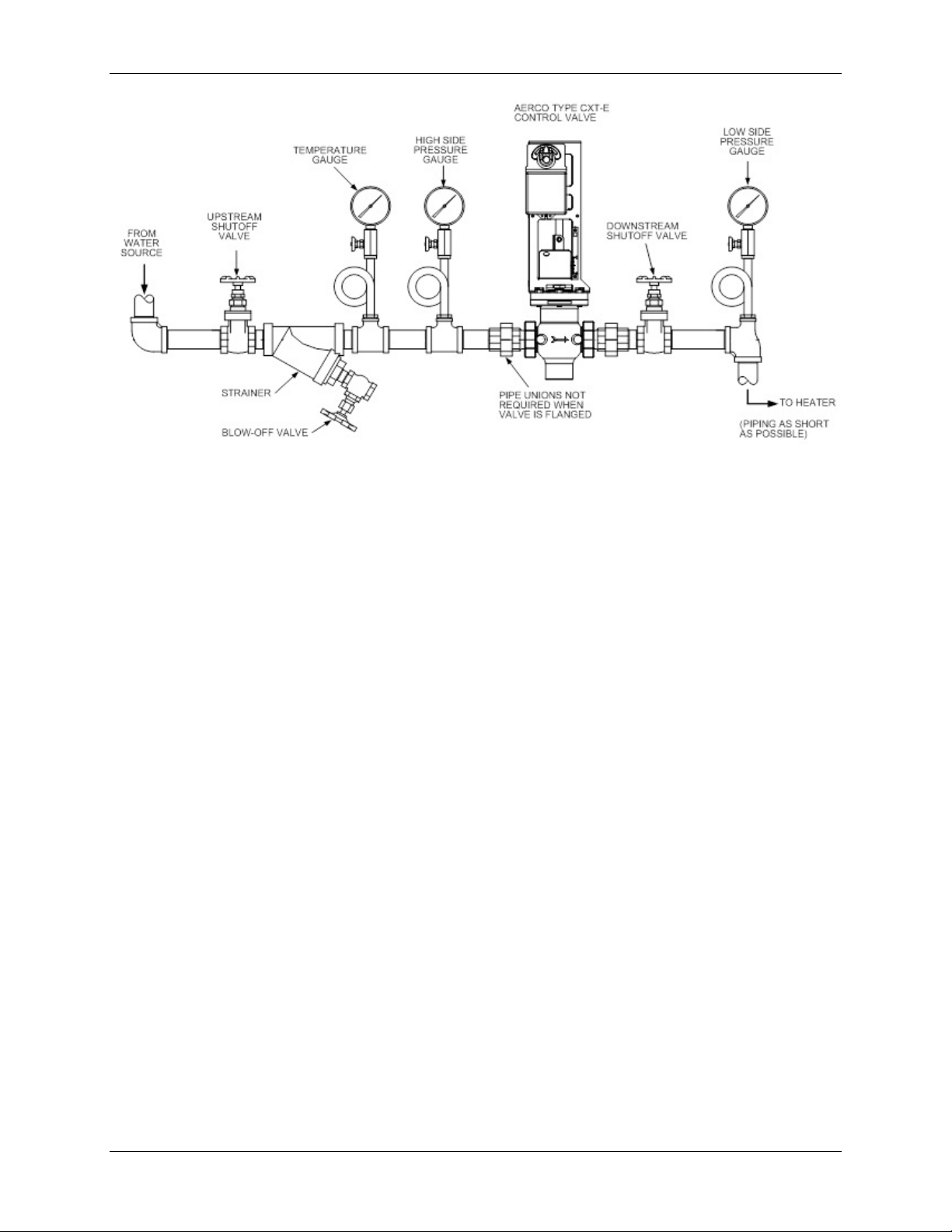

2) Next, refer to the recommended installation drawing in Figure 2-1 for steam flow, or Figure

2-2 for hot (boiler) water flow.

3) Install the Control Valve with the Actuator Linkage in the vertical, upright position as shown

in Figure 2-1 or 2-2.

4) For maintenance purposes, unions are required with threaded ends to simplify removal

from the steam or hot boiler water line.

5) Blow out all pipe lines to clear them of dirt chips, scale or other foreign matter which could

adversely affect Valve operation when in service.

6) Install an in-line strainer upstream of the Valve as shown in Figure 2-1 (steam) or Figure 22 (hot boiler water). This will protect against foreign matter reaching the Valve during

service operation.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 15 of 82

AC-105 OMM-0003_0D

Page 16

Electronic Control System (ECS) and Type CXT-E Valve

STRAINER WITH 0.020

FOR CLARITY

PIPING PITCH DIRECTION

1 TO 40 RATIO MINIMUM

2. INSTALLATION

7) If the Valve is controlling steam, ensure that the steam line is pr operly trapped to prevent

accumulation of condensate ahead of the Valve.

8) Install Shutoff Valves (metal-seated, g ate-type) upstream and downstream of the Control

Valve to permit removal from the line for maintenance.

9) Pressure gauges should be installed on both sides of the Control Valve as shown in Figure

2-1 (steam) or Figure 2-2 (hot water).

10) The gauge on the high pressure side of the Valve is for adjustment and maintenance

purposes. The gauge on the low pressure side is to ensure that the correct pressure is

being introduced to the Control Valve. For either steam or water flow, the low side gauge

denotes the pressure of the fluid in the line which may create a hazardous condition.

11) A temperature gauge should be installed in the high pressure side of a hot (boiler) water

line as shown in Figure 2-2.

12) Install the Control Valve with the arrow on the Valve Body pointing in the direction of flow.

13) After the Control Valve has been installed in the steam or hot water line, ensure that all

piping connections are secure and leak tight.

14) This completes the installation procedures for the Control Valve. Proceed to the next

paragraph titled ELECTRONIC CONTROL SYSTEM INSTALLATION.

Figure 2-1. Recommended Control Valve, CXT-E Installation For Steam Flow

Page 16 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

MEST STAINLESS

STEEL BASKET,

SHOWN ROTATED

DOWN 90 DEGREES

Page 17

Electronic Control System (ECS) and Type CXT-E Valve

2. INSTALLATION

Figure 2-2. Recommended Control Valve, CXT-E Installation For Hot (Boiler)

Water Flow

2.3 ELECTRONIC CONTROL SYSTEM (ECS ) INSTALLATION

As previously mentioned, the Control Box and all other Electronic Control System (ECS)

components are installed on the Packaged Water Heater prior to shipment from the factory.

Therefore, ECS installation basically consists of connecting external AC power to the System

and providing the necessary power and control signal connections to the Control Valve Type

CXT-E. However, if your ECS was ordered with the Modbus Communication option, several

additional signal lead connections will need to be made inside the Control Box. These signal

leads will permit the ECS to be controlled by an external Energy Management System (EMS),

Building Automation System (BAS), or Computer.

NOTE:

Following installation, a lock (Not Supplied) can be installed on the

front door of the Control Box, if desired, to prevent unauthorized

access to ECS settings.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 17 of 82

AC-105 OMM-0003_0D

Page 18

Electronic Control System (ECS) and Type CXT-E Valve

WATER HEATER

TEMP CONTROLLER

B-PLUS

TM

HOLD

RUN

AUTO

MAN

2408

PT.NO.

PT.NO.

OVER TEMP SWITCH

PANEL

DOOR

CAPTIVE

SCREW

B-PLUS

TM

PT.NO.

SET

F

AUTO

RUN

MAN HOLD

OP 1

OP 2

SP2

REM

2408

OVER TEMP SWITCH

TEMP CONTROLLER

PT.NO.

WATER HEATER

PANEL CAPTIVE

SCREW

2. INSTALLATION

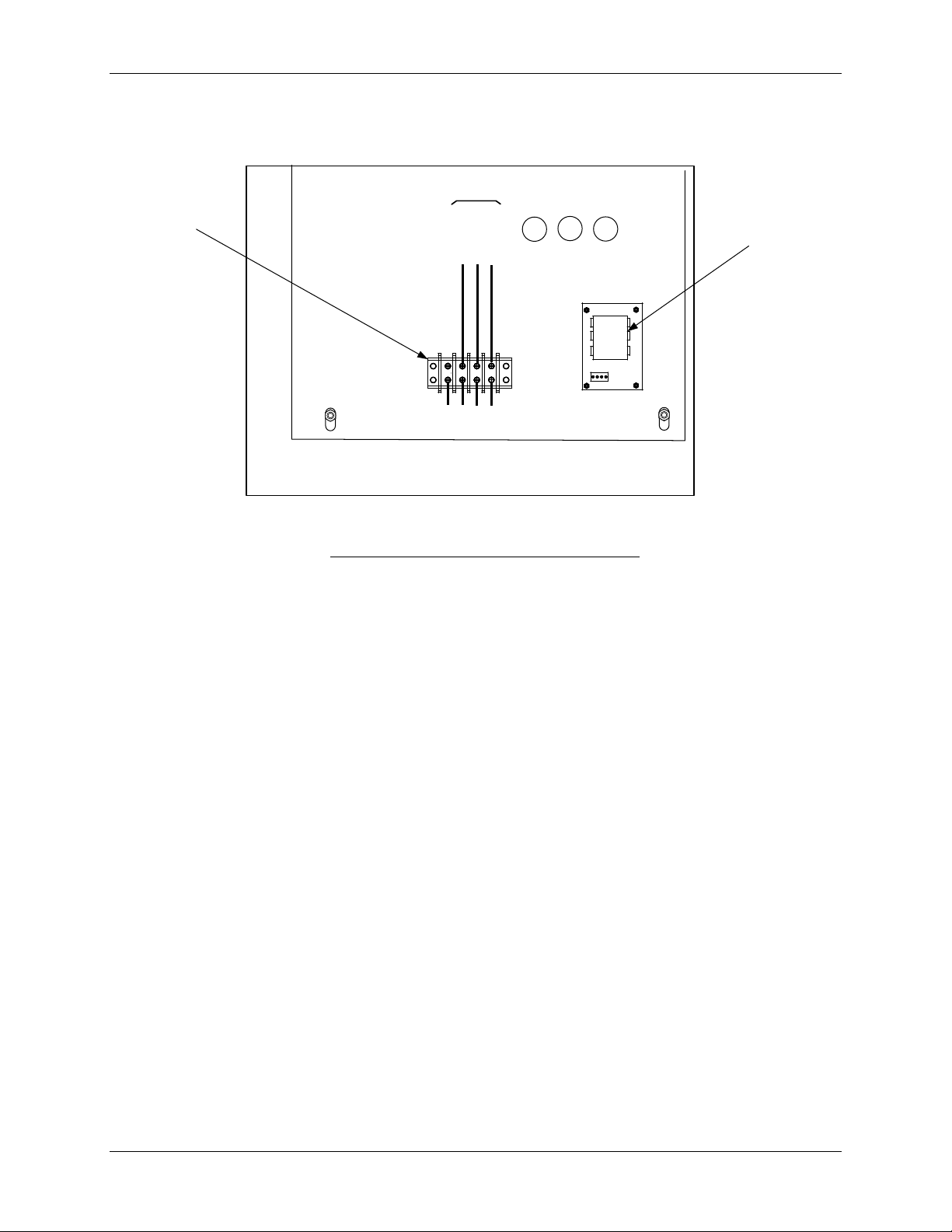

1) Loosen the captive screw on the right-front portion of the Control Box (Figure 2-3) to open

the hinged panel door.

Figure 2-3. ECS Control Panel Front View

2) Next, open the door and loosen the captive screw at the top of the recessed panel (Figure

2-4). Swing down the recessed panel to access Terminal Block TB-2 on the bottom interior

surface of the Control Box shown in Figure 2-5.

3) Feed the external 120/240 VAC power leads through the cutout labeled “POWER IN” on the

right side of the Control Box.

Figure 2-4. Recessed Panel Behind Control Box Door

Page 18 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 19

Electronic Control System (ECS) and Type CXT-E Valve

CONTROL BOX - INTERIOR BOTTOM VIEW

REAR

TB-2

LINE

NEUTRAL

GROUND

100

101

102

GND

FRONT

VOLTAGE

REGULATOR

TERMINAL

BLOCK TB-2

EXTERNAL POWER WIRING

(120 – 240 VAC)

2. INSTALLATION

4) Connect the LINE, NEUTRAL and GROUND leads to the TB-2 terminals shown in Figure 2-

5.

Figure 2-5. ECS Control Box AC Power Connections

5) Connect the Control Box cable labeled ACTUATOR to the 3-pin connector plug on the

Control Valve Actuator.

6) Check to ensure that all cable harness connectors and wire leads between the Control Box

and the following ECS components are secure:

a) Flow Sensor

b) Over-Temperature Solenoid

c) Outlet Dual Temperature Sensor

d) Heating Fluid Inlet/Outlet Temperature Sensors (Water-to-Water Heaters Only)

7) If the ECS was ordered with the Modbus Communication Option, proceed to step 8.

However, if this option is not included, no further steps are required for ECS installation.

NOTE:

Step 8 applies ONLY to Electronic Control Systems which include a

Temperature Controller (Eurotherm, Model 2408) equipped with a

Communications Board which allows connection to Modbus

Networks. The required signal connections will depend on the ports

available on the Energy Management System (EMS), Building

Automation System (BAS), or Computer being used with the ECS.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 19 of 82

AC-105 OMM-0003_0D

Page 20

Electronic Control System (ECS) and Type CXT-E Valve

COMPUTER CONTROL CABLE

RS232/9-PIN

RS232/25-PIN

RS485

SIGNAL NAME

PIN NO.

SIGNAL NAME

PIN NO.

PIN NO.

PIN NO.

GROUND

HD

GROUND

5

7

GROUND

RECEIVE

HE

TRANSMIT

3

2

A (-)

TRANSMIT

HF

RECEIVE

2

3

B (+)

2. INSTALLATION

CAUTION!

DO NOT route Modbus communication wiring in the same

conduit as power wiring. Attempting to do so may result in

excessive noise on the signal lines. Also, ensure that the RS232

or RS485 signal cable connections do not exceed the following

lengths:

RS232 Cable: 50 feet maximum

RS485 Cable: 4,000 feet maximum

8) To permit Modbus control of the ECS, refer to Table 2-1 and connect the appropriate wire

leads to the Temperature Controller terminals listed. Refer to the Temperature Controller

(Eurotherm 2408) pinouts shown in Figure 2-6 to locate the required terminals. Also, refer

to Appendix A for a listing of active Modbus data addresses for the 2408 Controller. In

addition, the Eurotherm documents referenced in this Appendix provide additional

communication information related to Modbus.

NOTE:

The complete wiring diagram for the Electronic Control System is

provided in Appendix B of this Instruction Manual. In addition, the

wiring connections for Terminal Block s TB-1 and TB-2 are provided

for reference purposes.

AERCO recommends that shielded, twisted-pair cable be used for

communication wiring. Examples of suitable wiring are: Belden 9841,

8761, 3105A, or equivalent.

Table 2-1. Modbus Communication Signal Connections

2408 TEMP. CONTROLLER

NOTE:

Page 20 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 21

Electronic Control System (ECS) and Type CXT-E Valve

1A

HA

1B

HB

1C

HC

2A

2B

1D

HE

HF

HD

3B

3D

3C

2D

3A

2C

JD

JF

JE

JB

JC

JA

LA

LB

LC

AA

AB

AC

VI

V+

V-

In1

In2

C

2408 CONTROLLER

L

N

SEE TABLE 2-1 FOR COMM CONNECTIONS

Page

Scroll

Down

Arrow

UP

Arrow

2. INSTALLATION

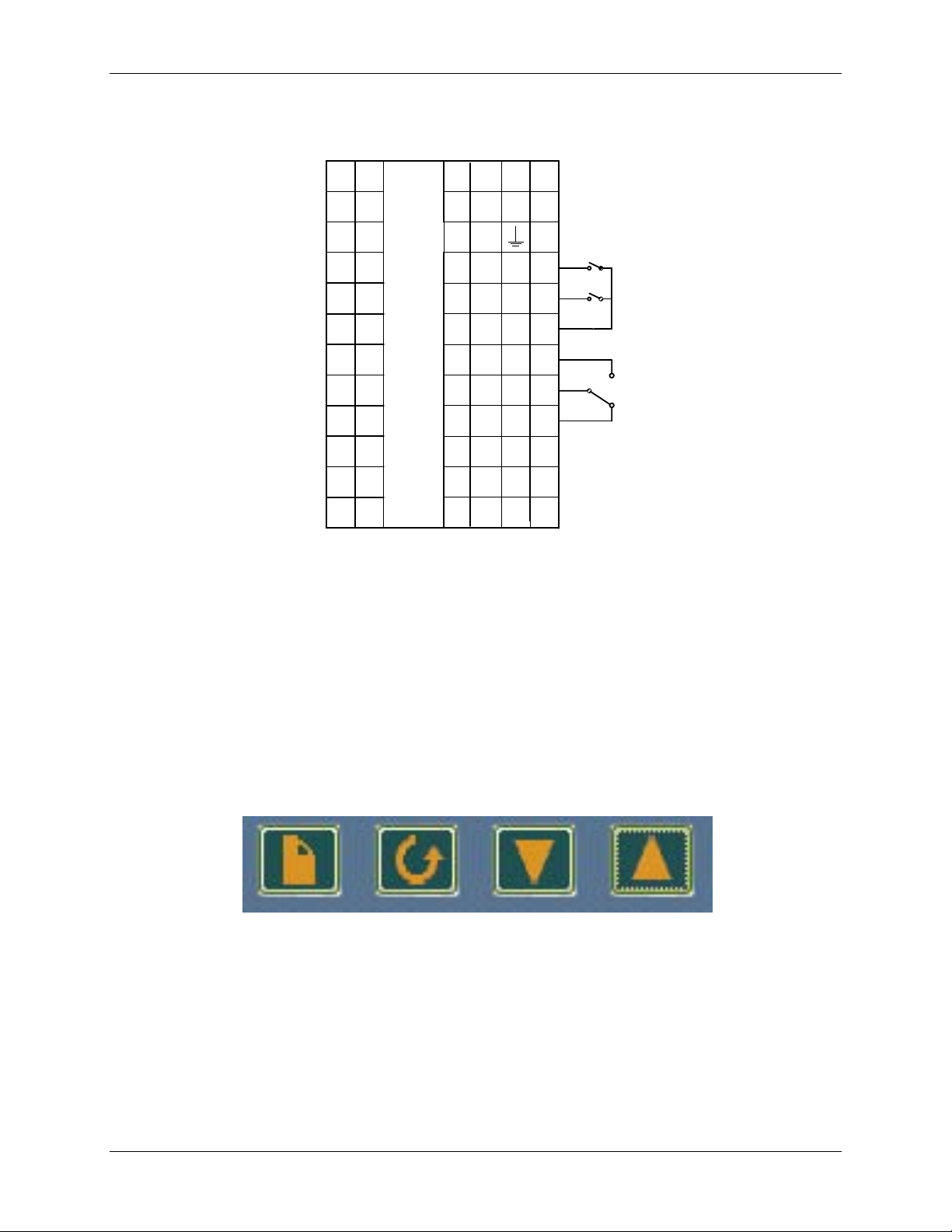

Figure 2-6. Temperature Controller (Eurotherm 2408) Terminal Connection

2.4 CHANGING COMMUNICATION ADDRESS E S O N AERCO EUROTHERM TEMPERATURE CONTROLLER

The address is defaulted t o 1 from the factory. Refer to the Button map below for all panel

navigation instructions.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 21 of 82

AC-105 OMM-0003_0D

Diagram

Button Map

Page 22

Electronic Control System (ECS) and Type CXT-E Valve

2. INSTALLATION

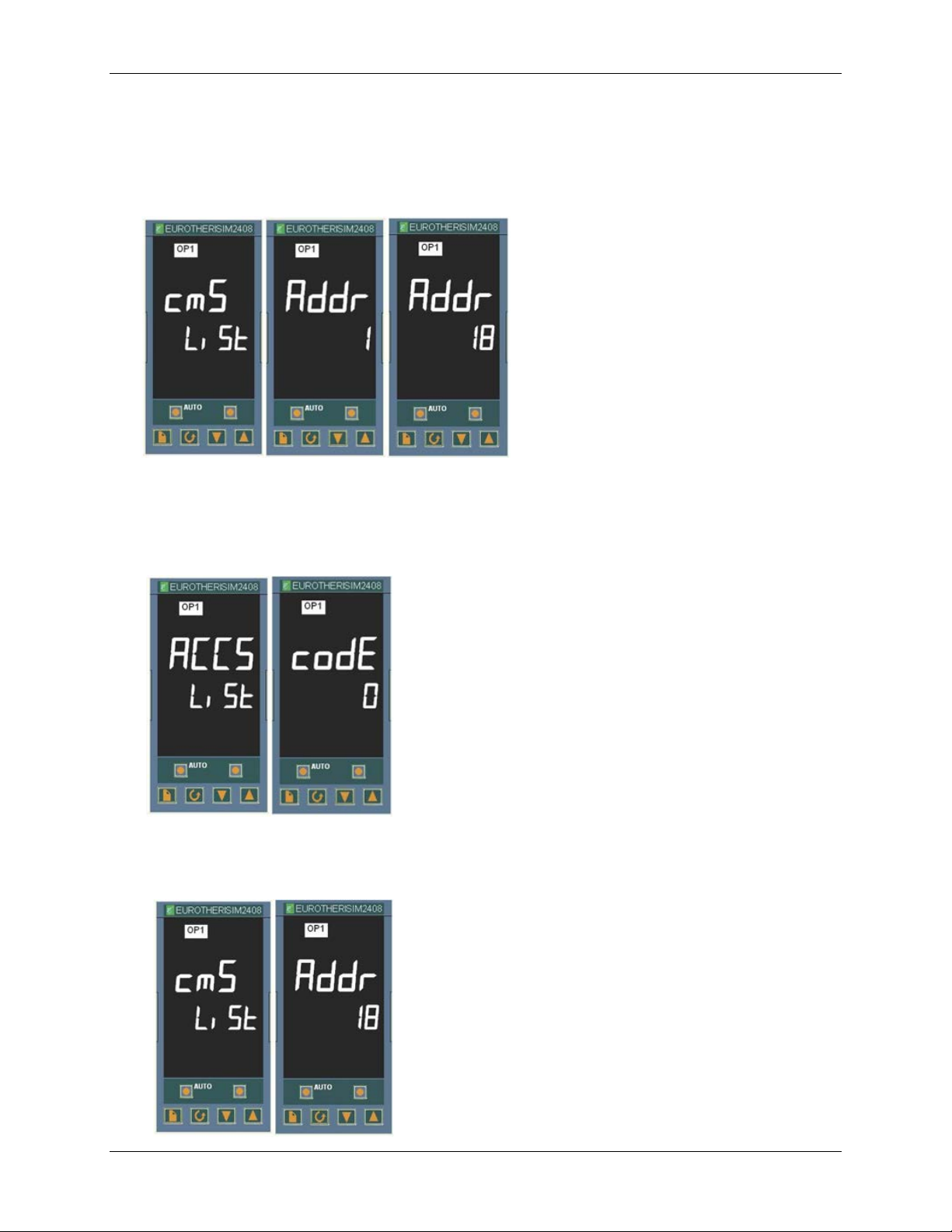

To change the modbus address:

1) Page to the ACCS list and Scroll down the list to codE.

2) Enter 24 using the Up Arrow. The number will display and flash PASS.

3) Scroll to Goto (current value is OPEr) and use the Down Arrow t o enter a value of Full. The

entry is confirmed by the flashing of the lower display momentarily off and then on.

Page 22 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 23

Electronic Control System (ECS) and Type CXT-E Valve

2. INSTALLATION

4) Go to the home screen by pressing the Page and Scroll buttons at the same time.

5) Page to the cmS list.

6) Scroll to the Addr screen

7) Use the Up Arrow to select the desired address number.

8) Go to the home screen by pressing the Page and Scroll buttons at the same time.

9) Page to the ACCS List and change the code to anything other than 24. The codE number

you have entered will flash off and then on to 0 to confirm that access is now set to OPEr

level and it is safe to return to use.

10) Confirm that the Addr is set properly by pressing Page button until the cmS list is

displayed and Scroll to Addr. If the value is correct, you are done. If not, then repeat the

steps over again.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 23 of 82

AC-105 OMM-0003_0D

Page 24

Electronic Control System (ECS) and Type CXT-E Valve

2. INSTALLATION

2.5 ENABLING REMOTE SETPOINT CONFIG URATION ON THE AERCO EUROTHERM TEMPERATURE CONTRO LLE R

The setpoint may be programmed to be remotely configured by executing the following steps.

See the previous instructions for changing communication addresses in the AERCO Eurotherm

Temperature Controller for more detailed directions for programming the controller.

1) Page to “ACCS”.

2) Scroll and enter code of 1.

3) Scroll and at the “GOTO” menu choose “Conf”.

4) At t he “Conf” screen enter the code of 2

5) Press the Scroll button once and then the Page button until you find “SP”.

6) Scroll until you find “rmt” and set the parameter value to “SP”.

7) Press the Page and Scroll button together at the same time to go to “exit”.

8) Press the Up arrow to select “yes” and then the instrument will reboot.

9) Onc e the instrument has returned to its normal state, press the Page button until you see

“SP”.

10) Scroll until you see “L-r” and using the Up arrow select “rmt”.

11) Once you have selected “rmt” press the Page and Scroll buttons at t he same t ime to return

to the normal temp display.

You should now be able to control the set point remotely.

Page 24 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 25

Electronic Control System (ECS) and Type CXT-E Valve

!

!

3. ADJUSTMENT

3. ADJUSTMENT

3.1 INTRODUCTION

This Section provides adjustment procedures for both the Control Valve, Type CXT-E and t he

Electronic Control System (ECS).

Prior to shipment, from AERCO, all CXT-E Control Valve Actuators are adjusted (auto-stroked)

to ensure that they properly position the Control Valve from the fully-open to the fully-closed

positions. In addition, the ECS is adjusted to the Setpoint Temperature specified on the Sales

Order. If no setting was specified, the default is 140°F.

It is recommended that the following procedures be performed to the extent necessar y, prior to

placing the system into operation. Also, the applicable procedures MUST be performed

following replacement of the CXT-E Control Valve or other ECS components. In addition, the

following procedure must be performed following maintenance or adjustment of linkage,

actuator or packing nut.

CAUTION

As a precaution, ensure that all heating fluid (steam or hot

(boiler) water) shutoff valves are fully closed prior to performing

any of the following adjustment procedures.

3.2 CONTROL VALVE TYPE CXT-E ADJUSTMENT

All CXT-E Actuators are powered by 24 VDC and are contr olled by a linear 4-to-20 mA control

signal. A 4 mA control signal input places the Control Valve in the fully-closed position(Valve

shaft down); while a 20 mA signal strokes the Valve to the fully-open position (Valve shaft up).

The Control Valve Actuators are self-calibrating for all Valve sizes. Therefore, simply proceed as

follows to automatically adjust the Actuator:

NOTE:

The following adjustment procedure must be performed any time that

the CXT-E Actuator is replaced or a mechanical adjustme nt is ma de

to the Linkage Assembly or Valve.

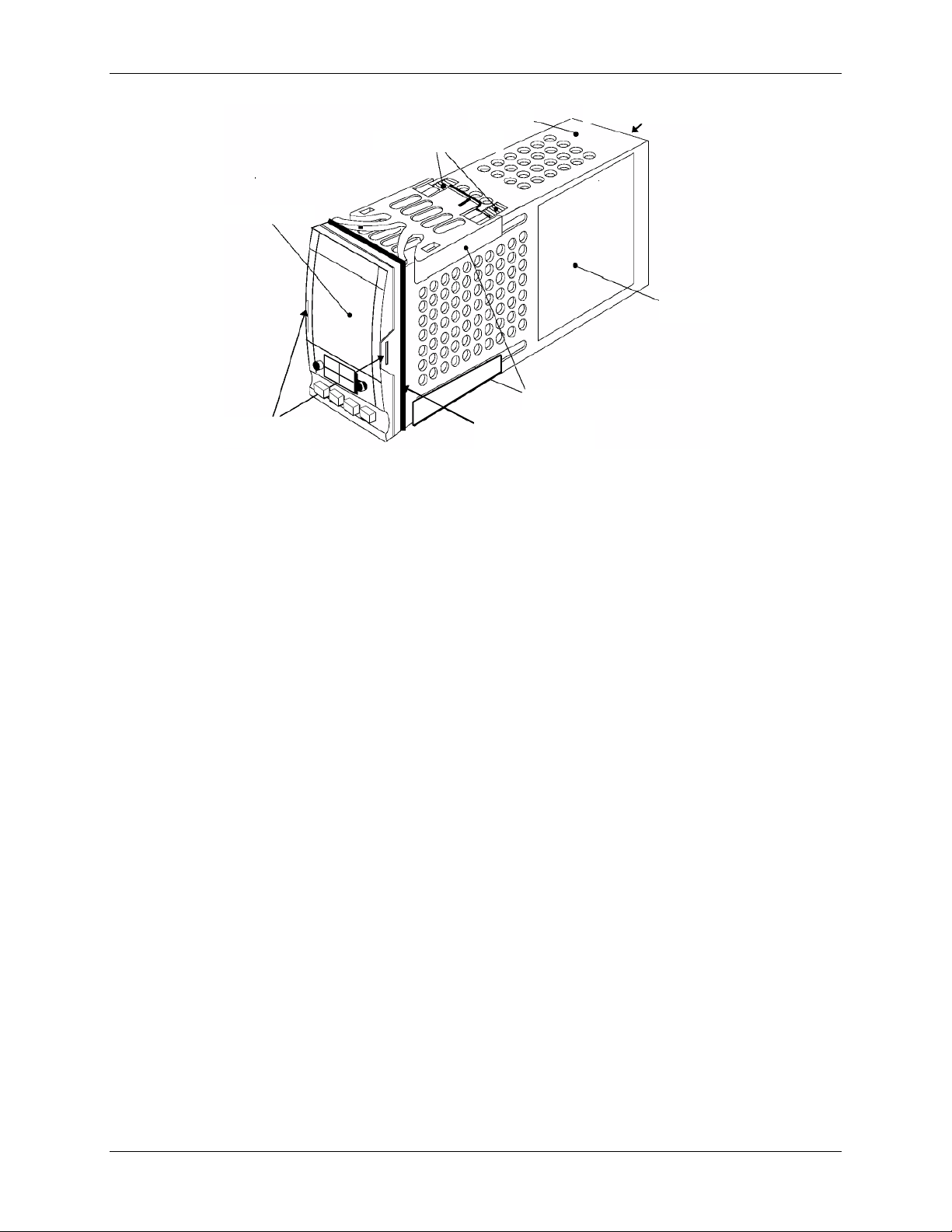

1) Refer to Figure 3-1 and loosen the Actuator cover set screw.

2) Remove the Actuator cover to access the PC Board containing the terminal connections,

DIP switches, Auto-Stroke (Reset) button and LED shown in Figure 3-1.

NOTE:

When properly connected to the ECS, +24 VDC power is supplied to

the Control Valve Actuator when the Control Box POWER switch is

set to the ON position. This switch is located on the right side of the

Control Box.

3) Set the ECS Control Box POWER switch to the ON position to apply 24 VDC power to the

Actuator (pin 2 = +24 VDC, pin 1 = Common). The LED will light indicat ing that power is

applied.

4) Wait approximately 10 seconds while the unit performs a self-test. The LED will blink fr om

one to four times depending on the size of the valve as follows:

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 25 of 82

AC-105 OMM-0003_0D

Page 26

Electronic Control System (ECS) and Type CXT-E Valve

Valve Size

1”

1.25” and 2.5”

1.5” and 3”

2” and 4”

0

90

neptronic

1 2 3

1 2

3

4 5

1

2

3

DIP SWITCHES (3)

(ALL IN UP POSITION)

AUTO-STROKE

(RESET) BUTTON

LED

TERMINALS

PC BOARD

COVER

SET SCREW

ACTUATOR

3. ADJUSTMENT

NOTE:

DO NOT PRESS THE RESET BUTTON before the 10 second period

has ended.

Blinks

1

2

3

4

5) For Full-Stroke automatic adjustment, press the Reset button. The LED will light.

6) The Actuator will then rotate in both directions to find its open and closed Valve position

stops.

7) Upon successful completion of the automatic adjustment, the LED will blink 1 to 4 times

(depending on the valve size shown above) and then go off.

8) Replace and secure the Actuator cover by tightening the set screw.

Figure 3-1. Actuator Adjustment

Page 26 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 27

Electronic Control System (ECS) and Type CXT-E Valve

WATER HEATER

TEMP CONTROLLER

B-PLUS

TM

HOLD

RUNAUTO

MAN

2408

PT.NO.

PT.NO.

OVER TEMP SWITCH

PANEL

DOOR

OVER-TEMP

SWITCH

TEMPERATURE

CONTROLLER

3. ADJUSTMENT

3.3 ELECTRONIC CONTROL SYSTEM (ECS ) ADJUSTMENT

The Electronic Control System (ECS) is preset at the setpoint temperature specified on the

Sales Order. The over-temperature alarm limit is normally set 20°F above the specified setpoint.

If no setpoint or over-temperature alarm limit is specified, the ECS will be set to the Factory

Default values of 140°F (setpoint) and 160°F (over-temperature alarm limit). If changes are

required, the setpoint and over-temperature alarm limits can be easily changed. This is

accomplished using the controls provided on the Temperature Controller and the OverTemperature Switch contained in the Control Box shown in Figure 3-2. These items can be

viewed through the window on the front door of the Control Box. To access thes e controls and

adjust the setpoint or over-temperature alarm limit, open the hinged Control Box door. Pr oceed

as follows to adjust the required parameters:

NOTE:

For “Water-to-Water” Heater applications, two additional

Temperature Display Indicators are mounted below the Over Temp

Switch. Although these Indicators are identical to the Over Temp

Switch, they are “Indicator-Only” devices which cannot be adjusted.

Figure 3-2. Control Box – Front View

NOTE:

When the Power Switch on the Control Box is set to the ON position,

it also energizes the internal DC Power Supply in the Control Box.

This in turn provides 24 VDC power to the Control Valve Actuator,

provided that the water temperature at the heater outlet is below the

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 27 of 82

AC-105 OMM-0003_0D

high temperature limit setting.

Page 28

Electronic Control System (ECS) and Type CXT-E Valve

AUTO

RUN

MAN HOLD

OP 1

OP 2

SP2

REM

2408

3. ADJUSTMENT

3.3.1 Se tpoi nt Te m perature Adjustment

The setpoint temperature is adjusted using the controls and displays provided on the

Temperature Controller. These controls and displays are illustrated and described in Figure 3-3

and Table 3-1. If necessary, setpoint temperature adjustment is accomplished as follows:

1) With the Control Box door open, set the ON/OFF POWER switch on the right side to the ON

position. The Temperature Controller will initiate a self-test for approximately 3 seconds.

Following the self-test, the top display will show the current outlet water temperature of the

Heater and the lower display will show the current setpoint temperature stored in memory

(default = 140°F).

2) Ensure that the Temperature Controller is set to the AUTO (automatic) mode and the AUTO

indicator is lit. If the MAN indicator is lit, press the AUTO/MAN button to toggle the mode

setting. Indicator OP1 will be lit if the process is calling for heat.

3) If the lower display does not show the desired setpoint temperature, press the ▲ or ▼ arrow

button to change the display to the desired value.

4) Two seconds after the ▲ or ▼ arrow button is released, the display will blink to indicate that

the Temperature Controller has accepted and stored the displayed value.

Figure 3-3. Temperature Controller

Page 28 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 29

Electronic Control System (ECS) and Type CXT-E Valve

OP1 lights when a 4 to 20 mA signal is being

Not used for the ECS application

Setpoint 2

Indicator

Not used for the ECS application

REM lights when the ECS is set up to be

AUTO

MAN

When button is pressed, the Controller is

RUN

HOLD

Press Page button to select a new list of

Press Scroll button to select a new parameter

Press to decrease the value shown in the

Press to increase the value shown in the

3. ADJUSTMENT

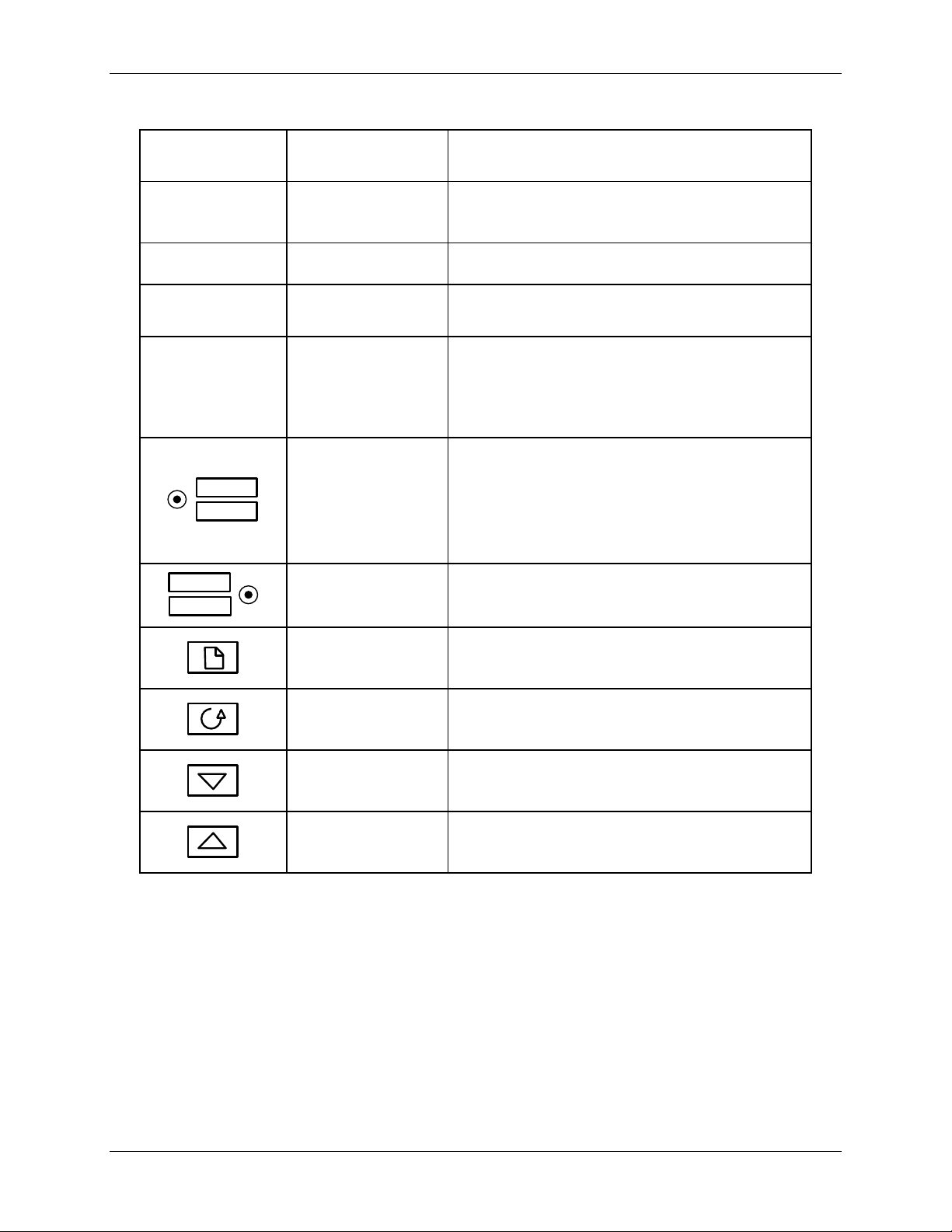

Table 3-1. Temperature Controller Operating Controls, Indicators & Displays

CONTROL or

INDICATOR

OP1 Output 1 Indicator

OP2 Output 2 Indicator

SP2

REM

MEANING

Remote Setpoint

Indicator

Auto/Manual

Button and

Indicators

Run/Hold Button

and Indicators

FUNCTION

supplied to the ECS Valve Actuator

controlled by a Remote (Modbus) signal.

REM will also flash when Modbus

communication is active.

toggled between the automatic (AUTO) and

manual (MAN) modes.

AUTO lights when in the automatic mode.

MAN lights when in the manual mode.

Not used for ECS application

Page Button

Scroll Button

Down Button

Up Button

parameters

in a list

lower display

lower display

3.3.2 Over-Temperature Alarm Limit Adjustment

The over-temperature alarm limit setting is adjusted using the controls and display on the OverTemperature Switch. The controls and display are illustrated and described in Figure 3-4 and

Table 3-2. If necessary, over-temperature alarm limit adjustment is accomplished as follows:

1) With the Control Box door open, set the ON/OFF POWER switch to the ON position.

2) Press the SET button on the Over-Temperature Switch. SP will appear in the display.

3) Press the SET button again. The current over-temperature limit value stored in memory will

be displayed (default = 160°F).

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 29 of 82

AC-105 OMM-0003_0D

Page 30

Electronic Control System (ECS) and Type CXT-E Valve

CONTROL or

INDICATOR

Displays current water temperature or setpoint.

Resets the unit after an alarm condition.

Increases the displayed temperature.

Decreases the displayed temperature.

Used to access and store parameters in the unit.

3. ADJUSTMENT

4) If the display does not show the desired over-temperature alarm setting, press the ▲ or ▼

arrow button to change the display to the desired temperature setting.

5) Once the desired over-temperature alarm setting is displayed, press the SET button to st ore

the setting in memory.

6) To exit the programming mode, press the SET and ▼ buttons simultaneously, or simply wait

one minute.

7) Once the programming mode has been exited, the display will show the current out let water

temperature of the Heater.

Figure 3-4. Over-Temperature Switch

Table 3-2. Over-Temperature Switch Controls and Indicators

MEANING FUNCTION

LED Display

RST

TEMP status

RESET Button

UP Button

DOWN Button

SET

SET Button

3.3.3 Over-Temperature Switch Sensor Adjustment

The Over-Temperature Switch can be adjusted to allow a ±10°F offset, in order to match the

value from a Eurotherm Temperature Controller. To use this function, complete the following

steps:

1) Press and hold the SET button for 8 to 12 seconds. The display will show 00. DO NOT

change these values.

2) Momentarily press the SET button. The SP parameter will be displayed.

3) Using the Up and Down arrow keys, scroll t o parameter P1.

4) Press the SET button. The display will show the current offset (default = 0).

5) Press the Up and Down arrows to enter the desired offset value (-10 to + 10°).

6) Press the SET button to store the selected offset value.

7) Press the SET and Down arrow buttons at the same time to quit the programming mode, or

wait one minute and the display will automatically exit the programming mode.

Page 30 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 31

Electronic Control System (ECS) and Type CXT-E Valve

4. OPERATION

4. OPERATION

4.1 INTRODUCTION

This Section provides the pre-operational checks, initial start-up procedures for the AERCO

Water Heater, Electronic Control System (ECS) and CXT-E Control Valve. In addition,

procedures are included to check the hot water outlet flow through the heater.

4.2 PRE-OPERATIONAL CHECKS

1) Verify that the ECS Temperature Controller setpoint and Over-Temperature Switch alarm

limit have been properly set using the procedures in Section 3 – ADJUSTMENTS.

2) Refer to Figure 2-1 (Steam Flow) or Figure 2-2 (Hot Water Flow). To place the Control Valve

and Heater System into operation, proceed as follows:

a) Ensure that the AERCO Heater is ready for operation in accordanc e with the instructions

provided in the Heater Operation & Maintenance Manual included with the equipment.

b) First, slowly open the upstream and the downstream shutoff valves until they are fully

open. Check to insure that the CXT Valve is not allowing the flow of steam or hot water.

c) Ensure t hat electrical power is properly connected to the ECS Control System and the

Electronic Control Valve, Type CXT-E.

4.3 INITIAL START-UP

In order to prevent a possible over-temperature condition during initial start-up, aerco

recommends that the following steps be performed in the order specified:

1) With the ECS Control Box door open, set the POWER switch on the right side of the box to

the ON position. This will provide power to the complete ECS and CXT-E Control Valve.

When power is initially applied, the ECS Temperature Controller automatically performs a

self-test sequence for approximately three seconds. Proceed immediately to the next step.

2) Upon completion of the self-test, the Temperature Controller will show the present water

heater outlet temperature in the upper display and the setpoint temperature in the lower

display.

3) Press the AUTO/MAN button on the front panel of the Controller (Figure 3-3) and toggle the

display to the MAN (Manual) mode. The MAN indicator will light when the Manual mode is

selected.

4) When in the Manual mode, the upper display will continue to show the current outlet water

temperature of the heater. The lower display will show the position of the CXT-E Control

Valve Actuator in %. When the Manual mode is initially selected, the lower display will show

0%, indicating that the Control Valve is fully closed.

5) Using the ▲ arrow button, set the CXT-E Control Valve to the 10% position and monitor the

outlet water temperature of the heater.

6) Next, continue to increase the valve “open” position in 5% increments until the water

temperature starts to increase at a moderate rate.

7) When the outlet water temperature has increased to within 20°F of the desired setpoint,

press the AUTO/MAN button and toggle the Temperature Controller to the AUTO mode. The

AUTO indicator will light and the MAN indicator will go off. When in the AUTO mode the

upper display will continue to show the outlet water temperature of the heater. The lower

display will show the selected setpoint temperature.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 31 of 82

AC-105 OMM-0003_0D

Page 32

Electronic Control System (ECS) and Type CXT-E Valve

4. OPERATION

8) When in the AUTO mode, the ECS will stabilize at the selected setpoint temperature (see

Section 3). Once stabilized, the ECS is set for unattended operation with no further operator

intervention.

IMPORTANT NOTE:

In order to accurately measure the outlet flow rate of the AERCO

Water Heater, it is imperative that the properly sized inlet orifice be

installed in the cold water inlet. Failure to do so will result in

erroneous flow rate readings.

4.4 CHECKING WATER HEATER FLOW R ATE

If desired, the water heater outlet flow rate in gallons per minute (GPM) can be monitored using

the controls and displays on the Temperature Controller. This is accomplished as follows:

1) Press the Scroll (

2) When Li.2 is shown in the upper display, the lower display will show the water heater outlet

flow rate in gallons per minute (GPM). The flow rate will be displayed for several seconds

and then the Controller will revert to the default displays (outlet water temperature and

setpoint).

) button and scroll to Li.2.

4.5 CHECKING THE VALVE POSITION OUTPUT IN AUTO MODE

1) Press the Scroll ( ) button and scroll to OP.

2) The display will indicate the percent open from 0 to 100. This should be checked with the

indicator scale on the CXT valve linkage. See Figure 1-4 for scale location.

Page 32 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 33

Electronic Control System (ECS) and Type CXT-E Valve

5. FUNCTIONAL DESCRIPTION

5. FUNCTIONAL DESCRIPTION

5.1 INTRODUCTION

The AERCO Electronic Control System (ECS) and Electronic Control Valve Type CXT-E

provide a highly responsive control system which provides virtually constant hot water flow at

the selected setpoint temperature. A simplified functional block diagram for the ECS and CXT-E

is shown in Figure 5-1. The following paragraphs provide a top-level functional overview of

system operation.

5.2 FUNCTIONAL OVERVIEW

The primary control mechanism for the ECS is an Electronic Process Controller which is

installed in the Control Box. The Controller utilizes PID (Proportional Integral Derivative)

algorithms to provide precise control of the Water Heater outlet temperature. Outlet temperature

control is accomplished by modulating the open/closed position of the CXT-E Control Valve

Actuator.

The Controller continuously monitors the Water Heater outlet temperature via a thermocouple

located in the outlet port. The Controller also receives a feed-forward signal from the flow

sensor mounted in the cold water inlet as shown in Figure 5-1. The f low sensor monitors flow

changes through the Water Heater and provides a feed-forward signal (0 to 5 VDC) to the

Controller proportional to the change in flow.

Using PID algorithms, the Controller provides a 4-to-20 mA output signal to the CXT-E Control

Valve Actuator. This 4-to-20 mA signal proportionally modulates the Control Valve position from

fully closed (4 mA) to fully open (20 mA). The control signal varies as necessary to maintain the

setpoint temperature programmed into the Controller. Under normal conditions, the Water

Heater outlet temperature is maintained within ±4°F of the desired setpoint based on a load

change of 50% or less.

5.3 OVER-TEMPERATURE CONTROL AND SAFETY FEATURES

The Control Box also contains an Over-Temperature Switch which continuously monitors and

displays the outlet water temperature of the Heater via the input received from the thermocouple

installed in the hot water outlet port. Normally, the Over-Temperature Switch is set 20°F above

the setpoint temperature for the Water Heater. If the configurable over-temperature limit is

exceeded, the Over-Temperature Switch alarm is triggered, which sounds an audible alarm,

disconnects power from the Control Valve Actuator and energizes the Solenoid Valve located in

the Water Heater top head, expelling over-heated water from the Heater.

The Solenoid Valve in the top head remains open until the water tem perature drops below the

over-temperature limit setting. Once the water temperature drops below the limit, the OverTemperature Switch resets automatically, silencing the audible alarm, de-energizing and closing

the Solenoid Valve, and reapplying power to the Control Valve Actuator.

It should be noted that the Over-Temperature Switch has a slightly slower response to

temperature changes than the Temperature Controller. Therefore, slightly differ ent temperature

readings may appear momentarily in their respective displays, particularly during system startup.

The Control Valve Actuator also incorporates a “Fail-Safe” feature which automatically closes

the Valve if there is a loss of the 4-to-20 mA control signal or loss of input power.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 33 of 82

AC-105 OMM-0003_0D

Page 34

COLD

WATER

IN

ACTUATOR

FLOW

SENSOR

HEAT

EXCHANGER

CONTROL VALVE

CXT-E

STEAM

IN

4 – 20 mA CONTROL SIGNAL

FEED-FWD SIGNAL

TO

DRAIN

OVER-TEMP

SOLENOID

VALVE

TEMPERATURE

CONTROLLER

120 VAC

IN

HOT

WATER

OUT

DUAL OUTLET TEMPERATURE THERMOCOUPLE

CONTROL BOX

HEAT

EXCHANGER

OVER-TEMP

24

VDC

DC POWER

SUPPLY

(0 – 5 VDC)

24 VDC IN

CONDENSATE OUT

WATER TEMPERATURE

TEMP

SWITCH

24

VDC

12

VDC

Electronic Control System (ECS) and Type CXT-E Valve

5. FUNCTIONAL DESCRIPTION

Figure 5-1. ECS Simplified Block Diagram

Page 34 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 35

Electronic Control System (ECS) and Type CXT-E Valve

INDICATOR

PLATE

VALVE

TOP

PACKING

NUT

P/O LINKAGE

ASSEMBLY

LOWER

SHAFT

!

!

6. ROUTINE MAINTENANCE

6. ROUTINE MAINTENANCE

6.1 INTRODUCTION

The following paragraphs provide the AERCO recommended routine maintenance procedures for the

Electronic Control Valve Type CXT-E and the Electronic Control System (ECS).

6.2 CXT-E CONTROL VALVE ROUTINE MAINTENANCE

6.2.1 Monthly Maintenance

Once each month, check the Control Valve for leakage as follows:

1) Refer to Figure 6-1 and check the Packing Nut and Valve Top for evidence of leak age.

CAUTION

Over-tightening the Packing Nut may trap the Valve Stem and

slow or stop Valve motion.

a) If there is leakage between the Packing Nut and Valve Top, tighten the Packing Nut

until the leakage stops. DO NOT FORCE the Packing Nut.

6.2.2 Semi-Annual Maintenance:

Every six months, check the following items:

1) Refer to Section 3 - ADJUSTMENT and perform the Actuator adjustment procedure

2) Clean the Strainer in the heating fluid line (Figure 2-1 or Figure 2-2) in accordance with the

b) If tightening the Packing Nut does not stop the leak, the Packing Nut and Packing

Assembly must be replace in accordance with the procedures specified in the Cont rol

Valve CORRECTIVE MAINTE NANCE Se c tion.

Figure 6-1. Valve Shaft Seals

specified. Verify that the Actuator strokes the Control Valve from the fully closed to the fully

open position.

instructions furnished with the Strainer.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 35 of 82

AC-105 OMM-0003_0D

Page 36

Electronic Control System (ECS) and Type CXT-E Valve

!

!

6. ROUTINE MAINTENANCE

6.3 ELECTRONIC CONTROL SYSTEM (ECS ) RO UTINE MAINTENANCE

6.3.1 Quarterly Maintenance:

Every three months, check the operation of the Over-Temperature Switch as follows:

WARNING

THIS PROCEDURE WILL RELE ASE HOT WATER. TAKE APPRO PRIATE

PRECAUTIONS TO AVOID BURNS.

1) Refer to Section 3 (ADJUSTMENTS) and lower the Over Temperature setting to

approximately 5°F below the present Setpoint shown in the lower display of the

Temperature Controller.

2) Verify that an Over-Temperature Alarm is generated and the following events occur:

• The CXT -E Control Valve closes.

• The Over-Temperature Solenoid (located at top of Heater) opens and expels water from

the system.

• The Over-Temperature Switch generates an audible alarm.

3) Following successful completion of the Over-Temperature Alarm check, return the Over-

Temperature Switch setting to its original Over-Temper ature setting.

6.3.2 Annually:

Once each year, AERCO recommends that the Temperature Sensor(s) and Flow Sensor be

checked to ensure there is no scale build-up or clogging that may degrade system operation.

Proceed as follows:

1) Close the upstream and downstream water supply valves to the Heater.

2) For W ater-to-Water Heaters ( E-Plus or Double-Wall) where hot boiler water is the heating

fluid, turn off the inlet and outlet valves in the fluid lines.

3) Check the Temperature Sensors and Flow Sensor as described in the following paragraphs

and steps. Upon completion of the Annual checks, restore the Heater to operation by

opening all valves which were closed in steps 1 and 2 above.

6.3.3 Temperature Sensors:

The Heater contains a Dual Temperature Sensor in the Heater outlet port. In addition, Water to

Water Heaters (E-Plus or Double-Wall) using hot (boiler) water as the heating fluid also contain

single-Element Sensors in the heating fluid inlet a nd outlet lines. Check and, if necessary, clean

these items by performing the following step:

1) Disconnect and remove the Dual Temperature Sensor (Thermocouple) at the Heater out let

and inspect for evidence of scale buildup on the stainless steel sleeve. If necessary, clean

the sensor using a wire brush.

2) For W ater-to-Water Systems, repeat step 1 for the Single-Element Sensors in the heating

fluid inlet and outlet lines.

3) After cleaning, reinstall the sensor(s) and ensure they are securely tightened.

Page 36 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 37

Electronic Control System (ECS) and Type CXT-E Valve

TURBINE SHAFT

MAGNETS (2)

TURBINE PADDLE WHEEL

PADDLE WHEEL INSERT

O-RING

O-RING

GROOVE

CLEAR POLYCARBONATE

WINDOW

SNAP RING

STRAIN

RELIEF

6. ROUTINE MAINTENANCE

6.3.4 Flow Sensor:

The Flow Sensor is installed between the Heater water inlet line and the Heater drain ( refer to

Figures 1-1 & 5-1). Check this sensor for evidence of blockage or scale build-up as follows:

1) Disconnect the electrical connector from the Flow Sensor.

2) Loosen the fittings at the Sensor inlet and outlet connections and completely remove the

Sensor. To ease removal, loosen the strain relief on the flow sensor cable. This creates

clearance for the removal of the fitting on the meter body.

3) Inspect the Sensor inlet and outlet for blockage and clean as necessary.

4) Refer to Figure 6-2 and disassemble the Flow Sensor as follows:

a) Remove the internal snap-ring.

b) Remove the clear polycarbonate window and O-ring.

c) Remove the turbine paddle wheel.

d) Clean all foreign matter from the Flow Sensor. If replacement parts are needed, order

the appropriate Flow Sensor Rebuild Kit (see Table 9-2) fr om your local AERCO Sales

Representative.

Figure 6-2. Flow Sensor, Part No. 64006 – Exploded View

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 37 of 82

AC-105 OMM-0003_0D

Page 38

Electronic Control System (ECS) and Type CXT-E Valve

! ! !

!

6. ROUTINE MAINTENANCE

5) After cleaning, reassemble the Flow Sensor as follows:

IMPORTANT NOTE!

Ensure that the paddle wheel magnets are installed facing the

internal wall of the Flow Sensor. If not correctly installed, the Sensor

will not function properly.

a) Reinstall the paddle wheel.

b) Apply a thin film of silicone grease on the O-ring in the groove of the clear

polycarbonate window.

c) Reinstall the polycarbonate window.

d) Reinstall the snap-ring.

6) After the Flow Sensor has been reassembled, reinstall the Sensor. Tighten the strain relief

and connect the electrical connector.

6.4 HEAT EXCHANGER ROUTINE MAINTENANCE CLEANING

AERCO recommends that the heat exchanger of the unit be cleaned annually using a solution

of Hydroskrub and water. Hydroskrub is distributed by AERCO International, Inc. and is

designed to dissolve the toughest water scale, lime, mud and rust deposits from virtually any

type of water-based equipment.

NOTE:

The following cleaning procedure applies to all sizes WWDW and

SWDW Heaters. For Helical Coil Type Water Heaters, refer to the

applicable manuals listed in Section 1, page 1-8 of this document for

cleaning/descaling procedures.

CAUTION

Please review MSDS, specifications, and our website

www.aerco.com for additional information, or call technical

service at (800) 526-0288.

CAUTION

Do not drain the unit without venting the shell! A vacuum in the

unit may displace the liner causing serious damage not covered

by warranty.

6.4.1 Pumpi ng System Set-Up Instructions:

Refer to the sample pumping set-up diagram shown in Figure 6-3 for a Double-Wall Heat

Exchanger. For Helical Coil Heaters, refer to the applicable manuals listed in Section 1,

paragraph 1.4.

1) Turn off the water heater and close the inlet and outlet isolation valves.

2) Drain at least half of the water-side volume from the heat exchanger. The amount of water

drained will depend on the size of the heater.

3) Prepare a 50% solution of Hydroskrub and clean water. The amount of the solut ion should

be approximately equal to the full volume of water that the heat exchanger holds.

4) Close the drain valve and connect a suitable size bucket and pump to the unit drain as

shown in Figure 6-3.

Page 38 of 82 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2: 02/28/14

OMM-0003_0D AC-105

Page 39

Electronic Control System (ECS) and Type CXT-E Valve

CIRCULATED HYDROSKRUB SOLUTION

FROM TOP OF HEAT EXCHANGER INTO

BUCKET

NOTE: IF A HOSE CONNECTION IS NOT

AVAILABLE IN THE HOT WATER OUTLET

PIPING, UNUSED PORT AT THE TOP OF

THE HEAT EXCHANGER, IF AVAILABLE,

MAY BE USED.

HYDROSKRUB SOLUTION CIRCULATED

FROM THE BOTTOM OF BUCKET TO THE

DRAIN CONNECTION OF THE HEAT

EXCHANGER.

CLOSE THE

COLD WATER INLET

ISOLATION VALVE

CLOSE THE

HOT WATER OUTLET

ISOLATION VALVE

DRAIN VALVE

HOSE CONNECTION

CIRCULATING

BUCKET

6. ROUTINE MAINTENANCE

5) Install a valve and hose connection in the outlet piping of the heater (Figure 6-3) and rout e

the hose back to the top of the circulation bucket.

Figure 6-3. Sample HydroSkrub Pumping System Set-Up for Double-Wall Heater

6.4.2 Cleaning Procedure:

1) Slowly add the prescribe amount of the Hydroskrub solution to the circulating bucket.

2) Open the drain and outlet hose connection valves and turn on t he pump. Periodically check

for leaks and maintain the liquid level in the bucket. A lowering volume level is an indication

that there is an open drain in the system.

3) Check the cleaning circuit to ensure that the HydroSkrub solution is flowing from the

circulation bucket, through the pump and the heater and back to the top of the top of the

bucket.

4) Return discharge foaming indicates an active HydroSkrub solution and the presence of

mineral deposits in the equipment.

5) Additional HydroSkrub and/or water may be required to maintain circulation and to prevent

the pump from cavitating.

6) Circulate through the Heat Exchanger and piping for 1 to 3 hours. Estimate the circulation

period based on the time in service and water hardness. If the heating equipment is more

than 40 gallons, the circulation time may need to be extended to complet e cleaning. When

foaming action stops, HydroSkrub strength is depleted (two pounds of deposits removed per

gallon used) or the equipment is free from calcium and other water-formed mineral deposits.

VD2: 02/28/14 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 39 of 82

AC-105 OMM-0003_0D

Page 40

Electronic Control System (ECS) and Type CXT-E Valve

6. ROUTINE MAINTENANCE

7) Periodically test the solution for effectiveness to determine if more HydroSkrub is needed.

Refer to “Testing hydroSkrob Effectiveness” in the next paragraph for details. If t he cleaning

solution is expended before circulation time is up, additional HydroSkrub will be needed and

circulation time may be extended to complete the cleaning.

8) Upon completion of t he cleaning process, begin flushing the solution by adding clean water

to the circulation bucket, then disconnect the return valve and hose connection from the top

of the circulating bucket and thoroughly flush. Continue water flushing the equipment for a

minimum of 10 minutes or until discharge runs clear.

9) HydroSkrub is biodegradable, and in most instances may be purged down sewers. Check

with local authorities before disposing of any complex compositions

10) Turn off water, shut off the pump and immediately close discharge valves to prevent

backflow.

11) Completely drain pump bucket. Disconnect hoses from equipment and thoroughly rinse the

bucket, pump, and associated hoses used.

6.4.3 Testing HydroSkrub Effectiveness

There are two methods of testing the effectiveness of HydroSkrub during cleaning: the calcium

carbonate spot test of the circulating solution and the charting of a trend in the pH of the

cleaning solution.

6.4.4 Calcium Carbonate Spot Test:

A calcium carbonate spot test is performed by exposing a form of calcium carbonate to the

HydroSkrub solution. Samples of the deposit, a Tums or Rolaids tablet, or bare concrete can be