Page 1

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

TECHNICAL INSTRUCTIONS

Technical Instruction Document TID-0142_0A

This document provides instructions for upgrading the Electronic

Control System (ECS)

numbers 27035, 27036 and 27037.

for Steam-to-Water (SW) Double Wall Heaters using kit

These instructions apply to the following Steam-To-Water (SW)

Double-Wall (DW) heater models:

This document replaces the following document (01/25/2011):

TSB-11-007_0A_SWDW_Recirculator-ECS_Upgrade

• SWDW-24

• SWDW-45

• SWDW-68

DISCLAIMER

The information contained in this manual is subject to change without notice from AERCO

International, Inc. AERCO makes no warranty of any kind with respect to this material, including,

but not limited to, implied warranties of merchantability and fitness for a particular application.

AERCO International is not liable for errors appearing in this manual, nor for incidental or

consequential damages occurring in connection with t he furnishing, performance, or use of these

materials.

AERCO Technical Support:

(Mon–Fri, 8am -5pm EST)

1 (800) 526-0288

Creation Date: 12/30/2014

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 1 of 24

Page 2

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

1. INTRODUCTION ......................................................................................................................... 3

1.1 Safety Precautions ............................................................................................................... 3

1.2 Tools & Supplies Required ................................................................................................... 4

1.3 Upgrade Kit Contents ........................................................................................................... 4

2. EQUIPMENT ISOLATIO N AND REMOVAL PROCEDURES ...................................................... 4

2.1 Isolating Water Heater .......................................................................................................... 7

2.2 Draining Water Heater .......................................................................................................... 7

2.3 Removal Of Hot Water Outlet Piping .................................................................................... 7

2.4 Removal Of Items Connected To Heater Shell ..................................................................... 8

2.5 Installation Of ECS Components On Top Head Assembly .................................................... 8

2.5.1 Thermocouple & Circulator Installation For SWDW Heaters – Brazed Fittings ............. 8

2.5.2 Thermocouple & Circulator Installation For SWDW Heaters – Compression Fittings . 12

2.5.3 Temperature Controller Replacement ........................................................................ 13

2.5.4 Setpoint Temperature Adjustment ............................................................................. 13

2.5.5 Wiring the ECS Control Box for the Circulator and Temperature Control ................... 15

3. POST INSTALLATION CONNECTIO NS AND ADJUSTMENTS ............................................... 18

3.1 Input and Output Water Heater Connections ...................................................................... 18

3.2 Adjustments ....................................................................................................................... 18

4. APPENDICES ............................................................................................................................ 21

4.1 APPENDIX A: 8" SWDW ECS RECIRC. LOOP UPGRADE ............................................... 21

4.2 APPENDIX B: 10" SWDW ECS RECIRC. LOOP UPGRADE ............................................. 22

4.3 APPENDIX C: 12" SWDW ECS RECIRC. LOOP UPGRADE ............................................. 23

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 2 of 24

Page 3

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

1. INTRODUCTION

This document applies to steam-to-water (SW) Double Wall (DW) heaters. It provides instructions

for upgrading an existing SWDW water heater with an ECS (Electronic Control System) system

and a flow sensor to an ECS system using a circulation pump.

These instructions must be performed by a skilled service technician capable of exercising the

necessary safety precautions when working with high temperature, pressurized steam and water

systems.

Operations and Maintenance Manual HE-111 is the required manual for SWDW models and is

available from the O&M Manuals section of the AERCO International website, www.aerco.com

The following paragraphs in this Section describe the safety precautions to be followed, the tools

and test equipment required to perform all procedures in this document and the contents of

the Upgrade Kits for all Heater Models.

1.1 Safety Precautions

Installation, maintenance and operating personnel must, at all times, observe all safety

regulations. The following warnings are general and must be given the same attention as

specific precautions included in these instructions.

FLUIDS UNDER PRESSURE MAY CAUSE INJURY TO

PERSONNEL OR DAMAGE TO EQUIPMENT WHEN RELEASED.

Shut off all incoming and outgoing steam and water stop

valves and carefully decrease all trapped pressures to zero

before performing any maintenance.

LIVE STEAM CAN CAUSE SEVERE BURNS

Never search for leakage in a live steam li ne by sight alone or

by “feel”. Use a mirror or other suitable polished object.

Always provide yourself with personal protective equipment,

(PPE) such as gloves, eye protection, dust mask, hard hat, etc.

HIGH VOLTAGE OF 120 VAC IS USED IN AERCO INDIRECT

FIRED WATER HEATERS. USE EXTREME CARE WHEN

ACCESSING CIRCUITS AND ELECTRICAL CONNECTIONS

WITHIN THE EQUIPMENT. SERIOUS PERSONAL INJURY OR

DEATH MAY OCCUR IF THIS WARNING IS NOT OBSERVED.

FOLLOW OSHA APPROVED LOCKOUT/ TAGOUT PROCDURES.

Burn permits may be required for certain installations

WARNING!

WARNING!

WARNING!

NOTICE:

requiring

braising.

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 3 of 24

Page 4

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

1.2 Tools & Supplies Required

The following tools are required to perform the retrofit procedures specified in this document:

• Combination Wrenches: 7/16”, 9/16”, 5/8”, 13/16”, 1-1/16”, 1-1/8”, 8 mm

• Pipe Wrenches: 12”, 24”

• Plumbers tools to handle pipe sizes up to 3”

• Vise-Grip Pliers

• Flat Tip Screwdriver, 1/2” Blade

• Phillips Head Screwdriver, No. 3

• Brass Wire Brush

• Needle Nose Pliers

• Tape Measure

• Black Marker

• Loctite 565 or equivalent

• Manufactures’ installation instructions referenced in text

• Brazing equipm ent for assembling P/N 97049 (if burn permit available)

1.3 Upgrade Kit Contents

The contents of the Upgrade Kits, P/N 27035, 27036, and 27037 are included in Appendices A

through C at the end of this document.

2. EQUIPMENT ISOLATION AND REMOVAL PROCEDURES

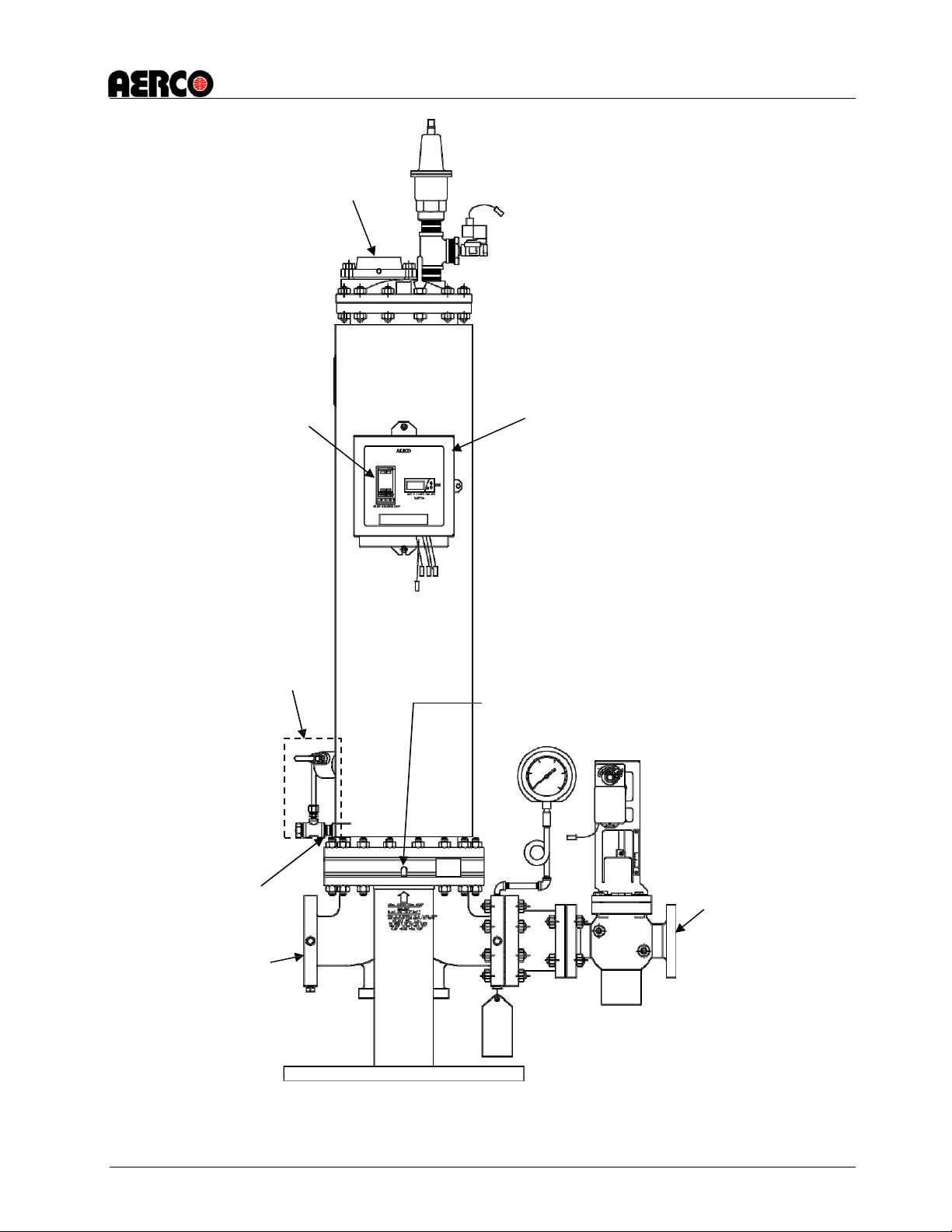

Figure 1 shows component locations for a typical Double-Wall, Model DW-24. The actual size and

location of affected components and assemblies may vary, depending on Packaged Water Heater

model and size. Refer to the applicable AERCO Heat Exchanger Manual provided with your

installation for additional details.

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 4 of 24

Page 5

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Hot Water

Outlet

Remove existing

ECS Control Box

Remove Flow Sensor

Plug vacated hole

Condensate

Outlet

Steam Inlet

Leak Detection Por t

Technical Instruction Document TID-0142_0A

temperature controller

and replace with P/N

64028-12

assembly and discard.

Install 61009-1 (Type J

Thermocouple) and 93029

(1/4” NPT x 3/16” Tube

Compression Fitting)

(Drain Hole) with 9-

22 (1/4” NPT Hex

Head Plug)

Figure 2-1:

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 5 of 24

Before Upgrade - Double-Wall Heater Component Locations (Sheet 1 of 2)

Page 6

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

ECS Control Box

Plug vacated hole

Condensate

Outlet

Leak Detection Port

Orifice Disc and Snap

Cold Water Inlet

Remove Flow Sensor

Hot Water

Outlet

Technical Instruction Document TID-0142_0A

assembly and discard.

Replace with P/N 61009-1

(Type J Thermocouple

and P/N 93029 (1/4” NPT

x 3/16” Tube Compression

Fitting)

Ring Within Cold

Water Inlet Opening

with P/N 9-22 (1/4”

NPT Hex Head Plug)

Figure 2-1: Before Upgrade - Double-Wall Heater Component Locations (Sheet 2 of 2)

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 6 of 24

Page 7

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

2.1 Isolating Water Heater

To isolate the Water Heater from all facility energy sources (steam, water, electrical power),

proceed as follows:

1. Disconnect and Lock-Out/Tag-Out external AC power supplied to the Control Box and any

other devices connected to the Heater.

2. Using a voltmeter, check to ensure that all incoming voltage readings are zero Before

continuing.

3. If the Heater is equipped with a Pneumatic Control Valve Actuator, close the valve supplying

air inlet pressure to the Pneumatic Controller.

4. Close all stop valves in the Steam Inlet and Condensate Outlet lines. On water-to-water

systems, do not rely on the Boiler Water Out Check Valve to stop the flow of water.

5. On the water-side, close the stop valves in the following order:

(a) Hot water outlet line

(b) Recirculation lin e

(c) Cold water inlet line

6. Carefully open t he Relief Valve located on the Top Head to relieve pressure in the Heater

Shell. Water should stop flowing from the valve within one minute. If water continues to flow

from the Relief Valve, one of the water stop valves is not securely closed.

2.2 Draining Water Heater

Allow the unit to cool sufficiently prior to draining the unit. When sufficiently cooled, drain as

follows:

1. After ensuring there is no pressure build-up in the Heater Shell (section. 2.1, step 6), block

open the Relief Valve in the Top Head to avoid creating a vacuum in the Heater Shell when

it is drained.

2. Open the Drain Ball Valve in the Bottom Head and allow the potable water in the Heater

Shell to drain completely. If the unit is a Water-to-Water Double-Wall Heater (WWDW-24,

WWDW-45 or WWDW-68), the Drain is located on the Shell and may either be plugged with

a 3/4” NPT Plug or equipped with a Ball Valve and additional drain piping. Remove Plug or

open Drain Ball Valve as applicable.

CAUTION

DO NOT DISCARD ANY OF THE REMOVED PARTS OR ASSEMBLIES

UNLESS IT IS SPECIFICALLY INDICATED THAT THEY WILL NO

LONGER BE USED. IT IS RECOMMENDED THAT ALL REQUIRED

ITEMS BE REMOVED AS INDICATED IN THE FOLLOWING STEPS

PRIOR TO PERFORMING ANY OF THEREPLACEMENT

PROCEDURES IN SECTION 3.

2.3 Removal of Hot Water Outlet Piping

Disconnect the union and any external piping connected to the flange in the hot water outlet

piping (located beyond the outside diameter of the Top Head).

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 7 of 24

Page 8

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

2.4 Removal of Items Connected to Heater Shell

In order to install several new ECS components, the Flow Sensor and associated fittings/tubing

and the Cold Water Inlet Orifice Disc must be removed. Proceed as follows:

1. Disconnect any external piping connected to the Cold Water Inlet.

2. Disconnect the Flow Sensor and associated fittings/tubing and discard.

3. Take the ¼” NPT hex plug (9-22) from the kit and plug the side of the drain valve where

the Flow Sensor tubing was located.

4. Locate the Orifice Disc in the Cold Water Inlet.

5. Using a pair of pliers, disconnect the snap ring securing the Disc in the Inlet Nozzle.

6. Remove the clip and the Orifice Disc from the Inlet Nozzle and discard.

2.5 Installation of ECS Components on Top Head Assembly

The ECS components to be installed on the Top Head Assembly include:

• Cold Water Inlet

• Thermocouple and Circulator Installation

Note that brazing is preferred method of assembling P/N 970049. However, if a burn permit or

brazing equipment is not available, then compression fittings are acceptable. See sections 2.5.1

and 2.5.2.

2.5.1 Thermocouple & Circulator Installation For SWDW Heaters – Brazed Fittings NOTE: This is the preferred method if a burn permit is available.

Use Loctite™ 565 or equivalent on all threaded potable water fittings. Loctite 567 may also be

used. Refer to Figure 2-3 for proper positioning.

1. Obtain the following from the upgrade kit:

• 2” union (93326)

• 2” Nipple (90074)

• 3”/2” Reducing coupling (93325) x 2

• 3” Tee for Cold Water Inlet (22102) x1

• 1.5” x 7” Nipple (90058)

• 1.5” Flange w/ 2 3/8” x 16 bolts and nuts (59095) set hardware aside for use in Step 17.

2. Attach 2” Union to the Cold Water Inlet (Figure 2-2).

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 8 of 24

Page 9

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

Figure 2-2: Location of Cold Water Inlet

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 9 of 24

Page 10

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

22102

12614-8

Brazed 97049

Compression 97052

59095

90075 for SVVDVV24

93265

91045-45.00

Brazed 97049

Compression 97052

69101

59095

90074

93326

90058

93325

22102

93325

Technical Instruction Document TID-0142_0A

90076 for SVVDW45

90077 for SVVDW68

-- CUT AT ASSEMBLY TO SUITE --

3. Assemble remaining items as shown in Figure 2-3

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 10 of 24

Figure 2-3. Circulator

Sub-assembly

Page 11

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

Figure 2-4: Lower Assembly, with Part Numbers

4. Attach assembly to 2” Union so that upright is perpendicular to the ground.

5. Obtain the following from kit:

• 3” Tee for Hot Water Outlet (22102) x1

• 1.5” x 11.5” Nipple (90075) for SWDW24,

• 1.5” x 12.5” Nipple (90076) for SWDW45 or

• 1.5” x 13.5” Nipple (90077) for SWDW68

• 1.5” Union (93265)

6. Attach 3” Tee to the unit’s hot water outlet flange.

7. Attach nipple to the 3” Tee

8. Attach union to nipple

9. Obtain the following from kit:

• 1.5” Street elbow (12614-8)

• 1.5” Tube x 1.5” Male NPT adapter (97049) x2

• 1.5” Copper tube (91045-45.00)

• 1.5” Flange w/ 2 3/8” x 16 bolts and nuts (59095) set hardware aside for use in Step 17

• 1.5” Taco Circulator Cartridge (69101)—for measurement purposes

10. Braise one (1) 1.5” tube x 1.5” male NPT adapter to one end of tube.

11. Attach street elbow to 1.5” male NPT

12. Check for length—Size to accommodate the installation of the pump (69101) and the flange

adaptor (59095)

13. Cut 1.5” copper tube to length

14. Braise one (1) 1.5” tube x 1.5” male NPT adapter to other end of tube.

15. Attach flange to 1.5” male NPT adapter

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 11 of 24

Page 12

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

16. Obtain the following from kit:

• 1.5” Taco Circulator Cartridge w/ seals (69101)

• Bolts and Nuts for flanges from Step 10

17. Place pump seal in channel in flange on lower assembly.

18. Following Taco instructions included with circulator, Seat Circulator Cartridge on flange as

shown in Figure 2-3.

19. Insert bolts through lower flange and Circulator Cartridge and screw on nuts to snug

20. Place pump seal in channel on topside of Circulator Cartridge.

21. Seat tubing assembly on circulator

22. Attach tube assembly street elbow to upper union

23. Insert bolts through upper flange and Circulator Cartridge and screw on nuts to snug

24. Check for proper alignment

25. Tighten all connections and fasteners

26. Obtain the following from kit:

• Thermocouple (61009-1)

27. Screw thermocouple into threaded coupling on Cold Water Inlet

28. Connect the outlet piping to new Hot Water Outlet Tee.

29. Conduct checks laid out in section 3.1

2.5.2 Thermocouple & Circulator Installation For SWDW Heaters – Compression Fittings NOTE: This is an acceptable alternative to brazing; see Section 2.5.1.

Use Loctite™ 565 or equivalent on all threaded potable water fittings. Loctite 567 may also be

used. Refer to Figure 2-3 for proper positioning.

1. Obtain Compression fittings (97052) from upgrade kit and determine manufacturer.

2. Obtain Manufacturer’s Instruction Manual:

• Hoke/Gyralok

http://catalog.hoke.com/Asset/79002_Gyrolok_Catalog_Tech_Data.pdf

• Parker Fittings

Contact manufacturer www.parker.com/tfd

• Swagelok MS-13-151 R6

http://www.swagelok.com/downloads/WebCatalogs/EN/MS-13-151.PDF

3. Follow steps 1 through 8 in section 2.5.1 above.

4. Obtain the following from kit:

• 1.5” Street elbow (12614-8)

• 1.5” tube OD x 1.5” male NPT adapter (97052) x2

• 1.5” Copper tube (91045-45.00)

• 1.5” Flange w/ 2 3/8”-16 nuts (59095)

5. Following Manufacturer’s instructions, attach one (1) 1.5” tube ODx 1.5” male NPT adapter

to one end of tube.

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 12 of 24

Page 13

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

6. Attach street elbow to 1.5” male NPT

7. Check for length—Size to accommodate the installation of the adaptor, the flange and the

pump.

8. Cut 1.5” copper tube to length

9. Following Manufacturer’s instructions, attach one (1) 1.5” tube OD x 1.5” male NPT adapter

to other end of tube.

10. Follow steps 15 through 29 in section 2.5.1 above.

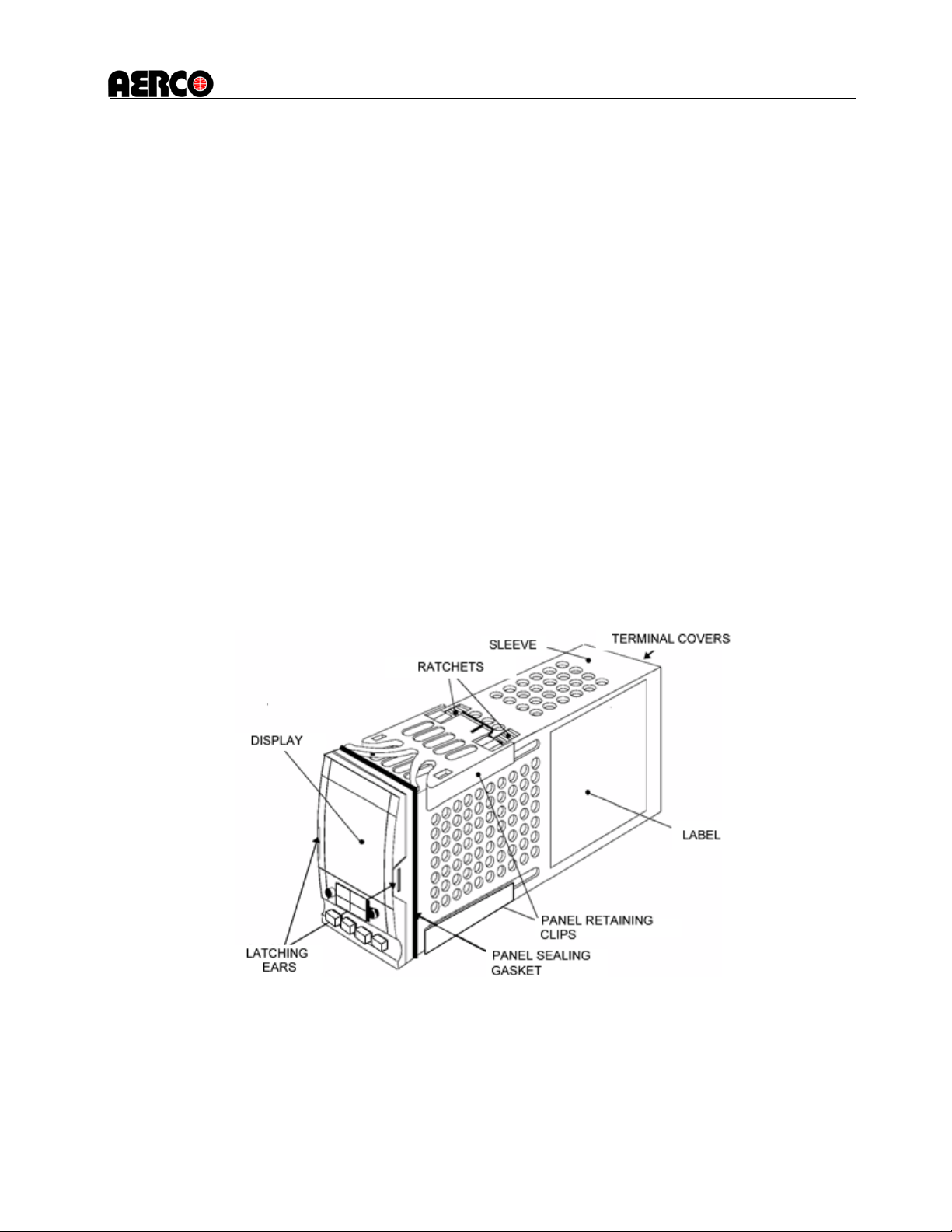

2.5.3 Temperature Controller Replacement

The Temperature Controller is located on the recessed panel behind the Control Box door as

shown in Figure 2-6. Removal and replacement is accomplished as follows:

1. Open the Control Box door to access the Temperature Controller.

2. The Temperature Controller is installed in a sleeve as shown in Figure 2-5. To unplug and

remove the

3. Controller from its sleeve, simply pry the latching ears outward and pull the Controller out of

the panel.

4. To install a replacement Temperature Controller, simply slide it into the front panel sleeve

until the latching ears click into place. Following replacement, adjust the setpoint

temperature to the required value using the adjustment procedure in Section 2.5.4.

5. Close and secure Control Box front door.

Figure 2-5: Temperature Controller Installation

2.5.4 Setpoint Temperature Adjustment

The setpoint temperature is adjusted using the controls and displays provided on the Temperature

Controller. These controls and displays are illustrated and described in Figure 2-6 and Table 2-1.

If necessary, setpoint temperature adjustment is accomplished as follows:

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 13 of 24

Page 14

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

1. With the Control Box door open, set the ON/OFF POWER switch on the right side to the ON

position. The Temperature Controller will initiate a self-test for approximately 3 seconds.

Following the self-test, the top display will show the current outlet water temperature of the

Heater and the lower display will show the current setpoint temperature stored in memory

(default = 140°F).

2. Ensure that the Temperature Controller is set to the AUTO (automatic) mode and the AUTO

indicator is lit. If the MAN indicator is lit, press the AUTO/MAN button to toggle the mode

setting. Indicator OP1 should also be lit.

3. If the lower display does not show the desired setpoint temperature, press the ▲ or ▼

arrow button to change the display to the desired value.

4. Two seconds after the ▲ or ▼ arrow button is released, the display will blink to indicate

that the Temperature Controller has accepted and stored the displayed value.

Figure 2-6. Temperature Controller Installation

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 14 of 24

Page 15

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

CONTROL or

INDICATOR

to the ECS Valve Actuator

communication is active.

MAN lights when in the manual mode.

Technical Instruction Document TID-0142_0A

Table 2-1. Temperature Controller Operating Controls, Indicators & Displays

MEANING FUNCTION

OP1

OP2

SP2

REM Remote Setpoint

Output 1 Indicator

Output 2 Indicator

Setpoint 2 Indicator

Indicator

Auto/Manual Button

and Indicators

Run/Hold Button and

Indicators

Page Button

Scroll Button

Down Button Press to decrease the value shown in the lower display

Up Button Press to increase the value shown in the lower display

OP1 lights when a 4 to 20 mA signal is being supplied

Not used for the ECS application

Not used for the ECS application

REM lights when the ECS is set up to be controlled by a

Remote (Modbus) signal. REM will also flash when Modbus

When button is pressed, the Controller is toggled between

the automatic (AUTO) and manual (MAN) modes.

AUTO lights wh en in the automatic mode.

Not used for ECS application

Press Page button to select a new list of parameters

Press Scroll button to select a new parameter in a list

NOTE:

External power at 120 to 240 VAC, 50/60 Hz is required to operate

ECS

the circuitry contained in the

are made internally by routing the power wiring through the

provided on the right side of the Control

Control Box. Power connections

cutout

Box.

2.5.5 Wiring the ECS Control Box for the Circulator and Temperature Control

To wire the Circulation Pump and Thermocouple into the ECS control box, follow these steps:

1. Loosen the captive Phillips head screw on the right front portion of the Control Box (Figure

2- to open the hinged door.

2. Swing open the door and loosen the captive Phillips head screw at the top of the recessed

panel (Figure 2-8). Swing down the panel to access terminal block TB-2 (Fig ure 2-9).

3. Circulator Electrical connections: Observe all applicable codes and safety procedures

when connecting to power supply. The motor is impedance protected, and does not require

overload protection. Either colored wire from the pump’s capacitor box can be attached to

either colored wire from the control box power supply. There is no “hot” or “common” wire

leading from the capacitor box. Typical installation would be to attach the white wire to

the white (common) power supply wire and either the yellow or blue wire to the black (hot)

power supply wire. The pump cannot run backwards.

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 15 of 24

Page 16

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

4. Feed the external 120v 60 Hz power leads through the cutout in the right side of the ECS

Control Box.

5. Connect the Line, Neutral and Ground leads to the TB-2 terminals shown in Figure 2-9.

6. Close the swing-down panel after the power leads are secured to TB-2. Tighten the captive

screw to secure the recessed panel in the closed position.

7. Check the labels on the Control Box cables and connect them to the following components:

a. Label Connect To:

MIXED INLET TEMP THERMOCOUPLE 2-Pin Connector on

8. Fill system with domestic tap water – The system must be filled before operating the

circulator. The bearings are water lubricated and should not be allowed to operate dry.

Filling the system will result in immediate lubrication of the bearings. It is always good

practice to flush a new system of foreign matter before starting the circulator.

9. Put the controller in manual and leave it set to the zero (0) position.

10. Operate the circulator for 5 minutes immediately after flushing the system to purge

remaining air from the bearing chamber.

11. Refer to Instruction No. HE-111 for start-up procedures.

12.

Close the front door of the ECS Control Box and tighten the captive screw to secure it.

Thermocouple

Figure 2-7: Typical ECS Control Panel Front View

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 16 of 24

Page 17

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

Figure 2-8: Typical Recessed Panel Behind Control Box Door

Figure 2-9: Typical ECS Control Box AC Power Connections

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 17 of 24

Page 18

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

3. POST INSTALLATION CONNECTIONS AND ADJUSTMENTS

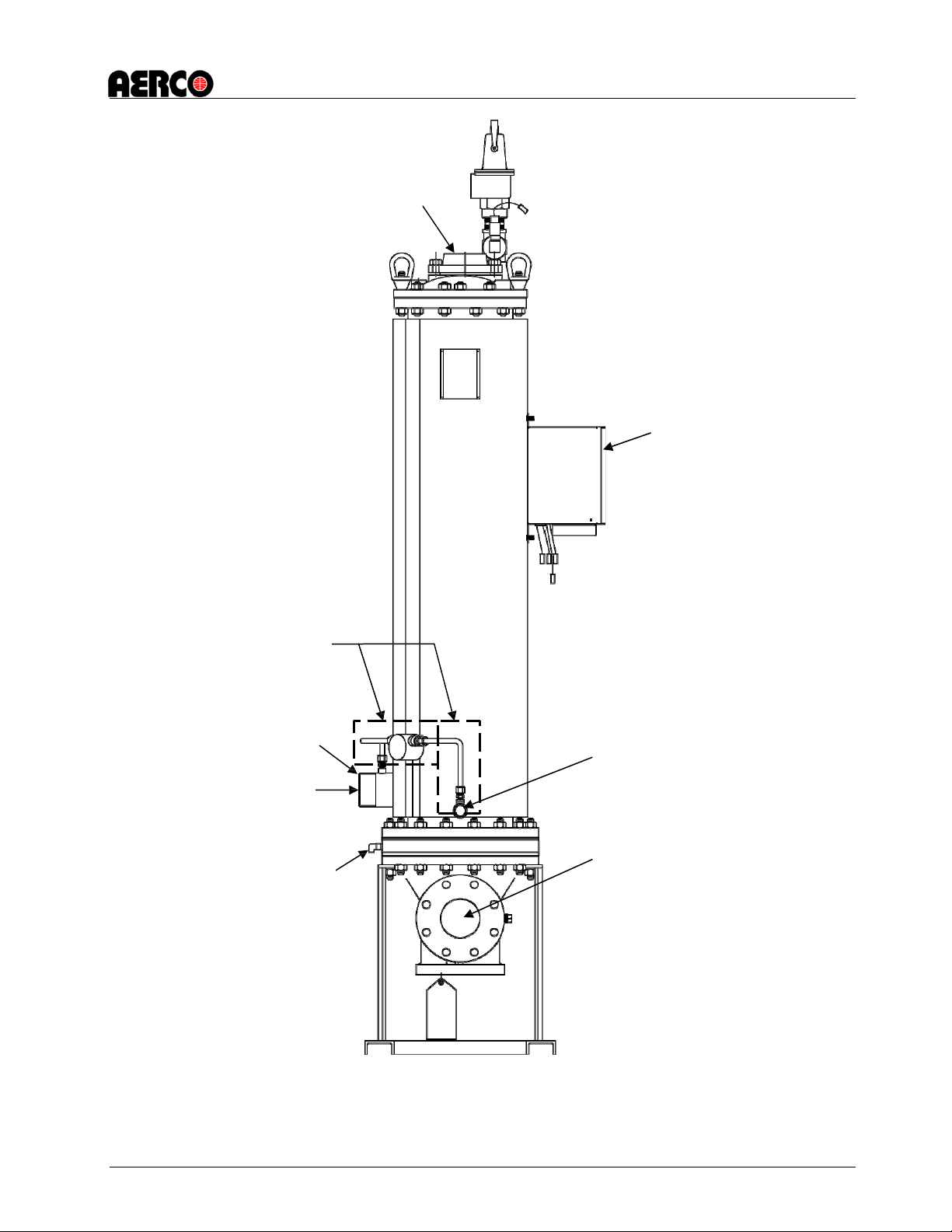

Figure 3-1 shows a typical DW-68 Double Wall S/W Heater with all ECS upgrade items

installed. Upon completion of all upgrade procedures in Section 4, the ECS upgrade heater must

be thoroughly checked to ensure that all required external connections have been made to the

modified Heater. I n addit ion, the ECS Control system adjustments must be made prior to placing

the Heater back into service.

3.1 Input and Output Water Heater Connections

The following items must be checked to ensure the proper connections have been made:

1. Drain Connection

Ensure that the side of the plugged Drain Ball Valve has been replaced and that

all external drain piping is reconnected.

2. Cold Water Inlet

Ensure that the Cold Water Inlet Flange is connected to the cold water inlet piping.

3. Steam Line

Ensure that the Steam supply line is connected to the inlet of the CXT-E Control Valve.

4. Condensate Line

Ensure it is connected to a nearby drain or condensate collection system.

5. Electrical Power

Ensure that AC power (110 to 240 volts) is connected to the ECS Control Box.

3.2 Adjustments

Prior to placing the unit into operation, the CXT-E Actuator, ECS Temperature Controller and ECS

Over-Temperature Switch must be set. The adjustment procedures for these items are provided in

Section 3 of Operation and Maintenance Manual HE-111. A copy of this manual is included in the

Upgrade Kit.

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 18 of 24

Page 19

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

Figure 3-1. DW-68 Double Wall Water Heater With ECS Control System &

CXT-E

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 19 of 24

Control Valve (Sheet 1 of

2)

Page 20

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

SIDE VIEW

Technical Instruction Document TID-0142_0A

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 20 of 24

Figure 3-1. DW-68 Double Wall Water Heater With ECS Control System &

CXT-E Control Valve (Sheet 2 of 2)

Page 21

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Assembly: 27035-1

Qty

Component

Description

1

61009-1

TYPE J THERMOCOUPLE, SINGLE ELEMENT

1

93029

COMPRESSION FITTING, ¼” NPT X 3/16” TUBE

1

64028-12

PROGRAMMED ECS TEMPERATURE CONTROLLER

1

9-22

¼” NPT HEX HEAD PLUG

UPGRADE KIT INSTRUCTIONS – 8”, 10”, AND 12” SW

DW,ECS

1

24262-1

RECIRC. LOOP UPGRADE, DW24 U-TUBE

1

12614-8

11/ 2" SS 90 DEG STREET ELBOW

2

22102

3" COLD WATER OUTLET, 8",10" & 12

2

59095

FLANGE-1 1/2" TACO FREEDOM

1

69101

CARTRIDGE CIRCULATOR

1

90058

NIPPLE 1 1/2" NPT SS 304 7" LG

1

90074

NIPPLE, 2" SCH. 40 X 2-1/2" LG

1

90075

NIPPLE, 1-1/2" NPT SCH. 40 X 11-1/2”

1

91045-45.00

COPPER TUBE, 1.5", 45" LG

1

93265

UNION, 1 1/2"NPT THREADED

2

93325

REDUCING COUPLING, 3" NPT X 2" NP

1

93326

UNION, 2" NPT THREADED

2

97049

ADAPTER, MALE PIPE, 1-1/2" TUBE X

Qty

Component

Description

1

61009-1

TYPE J THERMOCOUPLE, SINGLE ELEMENT

1

93029

COMPRESSION FITTING, ¼” NPT X 3/16” TUBE

1

64028-12

PROGRAMMED ECS TEMPERATURE CONTROLLER

1

9-22

¼” NPT HEX HEAD PLUG

1

2010-06

UPGRADE KIT INSTRUCTIONS – 8”, 10”, AND 12” SW DW,ECS

1

24262-2

RECIRC. LOOP UPGRADE, DW24 U-TUBE

BOM OF 24262-2

1

12614-8

11/ 2" SS 90 DEG STREET ELBOW

2

22102

3" COLD WATER OUTLET, 8",10" & 12

2

59095

FLANGE-1 1/2" TACO FREEDOM

1

69101

CARTRIDGE CIRCULATOR

1

90058

NIPPLE 1 1/2" NPT SS 304 7" LG

1

90074

NIPPLE, 2" SCH. 40 X 2-1/2" LG

1

90075

NIPPLE, 1-1/2" NPT SCH. 40 X 11-1/2”

1

91045-45.00

COPPER TUBE, 1.5", 45" LG

1

93265

UNION, 1 1/2"NPT THREADED

2

93325

REDUCING COUPLING, 3" NPT X 2" NP

1

93326

UNION, 2" NPT THREADED

2

97052

ADAPTER, MALE PIPE, 1-1/2" TUBE X

Technical Instruction Document TID-0142_0A

4. APPENDICES

4.1 APPENDIX A: 8" SWDW ECS RECIRCULATION LOOP UPGRADE Table A-1 Braised Fittings Construction

1 2010-06

BOM OF 24262-1

Assembly: 27035-2

Table A-2 Compression Fittings Construction

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 21 of 24

Page 22

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Qty

Component

Description

1

61009-1

TYPE J THERMOCOUPLE, SINGLE ELEMENT

1

93029

COMPRESSION FITTING, ¼” NPT X 3/16” TUBE

1

64028-12

PROGRAMMED ECS TEMPERATURE CONTROLLER

1

9-22

¼” NPT HEX HEAD PLUG

UPGRADE KIT INSTRUCTIONS – 8”, 10”, AND 12” SW

DW,ECS

1

24263-1

RECIRC. LOOP UPGRADE, DW24 U-TUBE

BOM OF 24263-1

1

12614-8

11/ 2" SS 90 DEG STREET ELBOW

2

22102

3" COLD WATER OUTLET, 8",10" & 12

2

59095

FLANGE-1 1/2" TACO FREEDOM

1

69101

CARTRIDGE CIRCULATOR

1

90058

NIPPLE 1 1/2" NPT SS 304 7" LG

1

90074

NIPPLE, 2" SCH. 40 X 2-1/2" LG

1

90076

NIPPLE, 1-1/2" NPT SCH. 40 X 12-1/2”

1

91045-45.00

COPPER TUBE, 1.5", 45" LG

1

93265

UNION, 1 1/2"NPT THREADED

2

93325

REDUCING COUPLING, 3" NPT X 2" NP

1

93326

UNION, 2" NPT THREADED

2

97049

ADAPTER, MALE PIPE, 1-1/2" TUBE X

Qty

Component

Description

1

61009-1

TYPE J THERMOCOUPLE, SINGLE ELEMENT

1

93029

COMPRESSION FITTING, ¼” NPT X 3/16” TUBE

1

64028-12

PROGRAMMED ECS TEMPERATURE CONTROLLER

1

9-22

¼” NPT HEX HEAD PLUG

1

2010-06

UPGRADE KIT INSTRUCTIONS – 8”, 10”, AND 12” SW DW,ECS

1

24263-2

RECIRC. LOOP UPGRADE, DW24 U-TUBE

BOM OF 24263-2

1

12614-8

11/ 2" SS 90 DEG STREET ELBOW

2

22102

3" COLD WATER OUTLET, 8",10" & 12

2

59095

FLANGE-1 1/2" TACO FREEDOM

1

69101

CARTRIDGE CIRCULATOR

1

90058

NIPPLE 1 1/2" NPT SS 304 7" LG

1

90074

NIPPLE, 2" SCH. 40 X 2-1/2" LG

1

90076

NIPPLE, 1-1/2" NPT SCH. 40 X 12-1/2”

1

91045-45.00

COPPER TUBE, 1.5", 45" LG

1

93265

UNION, 1 1/2"NPT THREADED

2

93325

REDUCING COUPLING, 3" NPT X 2" NP

1

93326

UNION, 2" NPT THREADED

2

97052

ADAPTER, MALE PIPE, 1-1/2" TUBE X

Technical Instruction Document TID-0142_0A

4.2 APPENDIX B: 10" SWDW ECS RECIRCULATION LOOP UPGRADE

Assembly: 27036-1

1 2010-06

Table B-1 Braised Fittings Construction

Assembly: 27036-2

Table B-2 Compression Fittings Construction

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 22 of 24

Page 23

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Qty

Component

Description

1

61009-1

TYPE J THERMOCOUPLE, SINGLE ELEMENT

1

93029

COMPRESSION FITTING, ¼” NPT X 3/16” TUBE

1

64028-12

PROGRAMMED ECS TEMPERATURE CONTROLLER

1

9-22

¼” NPT HEX HEAD PLUG

1

2010-06

UPGRADE KIT INSTRUCTIONS – 8”, 10”, AND 12” SW DW,ECS

1

24264-1

RECIRC. LOOP UPGRADE, DW24 U-TUBE

BOM OF 24264-1

1

12614-8

11/ 2" SS 90 DEG STREET ELBOW

2

22102

3" COLD WATER OUTLET, 8",10" & 12

2

59095

FLANGE-1 1/2" TACO FREEDOM

1

69101

CARTRIDGE CIRCULATOR

1

90058

NIPPLE 1 1/2" NPT SS 304 7" LG

1

90074

NIPPLE, 2" SCH. 40 X 2-1/2" LG

1

90077

NIPPLE, 1-1/2" NPT SCH. 40 X 13-1/2”

1

91045-45.00

COPPER TUBE, 1.5", 45" LG

1

93265

UNION, 1 1/2"NPT THREADED

2

93325

REDUCING COUPLING, 3" NPT X 2" NP

1

93326

UNION, 2" NPT THREADED

2

97049

ADAPTER, MALE PIPE, 1-1/2" TUBE X

Qty

Component

Description

1

61009-1

TYPE J THERMOCOUPLE, SINGLE ELEMENT

1

93029

COMPRESSION FITTING, ¼” NPT X 3/16” TUBE

1

64028-12

PROGRAMMED ECS TEMPERATURE CONTROLLER

1

9-22

¼” NPT HEX HEAD PLUG

1

2010-06

UPGRADE KIT INSTRUCTIONS – 8”, 10”, AND 12” SW DW,ECS

1

24264-2

RECIRC. LOOP UPGRADE, DW24 U-TUBE

BOM OF 24264-2

2

22102

3" COLD WATER OUTLET, 8",10" & 12

2

59095

FLANGE-1 1/2" TACO FREEDOM

1

69101

CARTRIDGE CIRCULATOR

1

90058

NIPPLE 1 1/2" NPT SS 304 7" LG

1

90074

NIPPLE, 2" SCH. 40 X 2-1/2" LG

1

90077

NIPPLE, 1-1/2" NPT SCH. 40 X 13-1/2”

1

91045-45.00

COPPER TUBE, 1.5", 45" LG

1

93265

UNION, 1 1/2"NPT THREADED

2

93325

REDUCING COUPLING, 3" NPT X 2" NP

1

93326

UNION, 2" NPT THREADED

2

97052

ADAPTER, MALE PIPE, 1-1/2" TUBE X

Technical Instruction Document TID-0142_0A

4.3 APPENDIX C: 12" SWDW ECS RECIRCULATION LOOP UPGRADE Table C-1 Braised Fittings Construction

Assembly: 27037-1

Table C-2 Compression Fittings Construction

Assembly: 27037-2

--- END ---

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 23 of 24

Page 24

ECS Upgrade for SW Double Wall Heaters, Kits 27035, 27036, 27037

Technical Instruction Document TID-0142_0A

Change Log

Date Description Changed By

12/30/2014 Rev A: Initial release (replacement for TSB-11-007). Chris Blair

International Inc.

© AERCO International, Inc., 2014

12/30/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 24 of 24

Loading...

Loading...