Page 1

INTERNATIONAL, INC.

159 PARIS AVENUE • NORTHVALE, NJ 07647 • PHONE 201-768-2400

TECHNICAL SERVICE BULLETIN

Date: 04/11/07 REV. Number: 2006-02

Subject: ELECTRONIC CONTROL SYSTEM (ECS) & CONTROL

VALVE, CXT-E RETROFIT INSTRUCTIONS

Page 1 of 81

1. INTRODUCTION

This Service Bulletin provides the procedures necessary to remove an existing Control Valve Actuator

and Control Box and replace it with a new CXT-E Electronic Control Valve Actuator and Electronic

Control System (ECS). These procedures are applicable to all AERCO Indirect-Fired Water Heaters with

Control Valves ranging in size from 1 inch to 4 inches and currently equipped with pneumatic, electrohydraulic or self-contained valve actuators. In addition, this Service Bulletin applies to both steam-towater and water-to-water heaters. The types and models covered include:

• HELITHERM HEATER MODELS

• A-Plus

• B-Plus

• B-Plus II (Water Wizard)

• E-Plus

• DOUBLE-WALL HEATER MODELS:

• DW-24

• DW-45

• DW-68

These instructions must be performed by a skilled service technician capable of exercising the necessary

safety precautions when working with high temperature, pressurized steam and water systems.

The following paragraphs in this Section describe the safety precautions to be followed, the tools and test

equipment required to perform all procedures in this Service Bulletin and the contents of the Retrofit Kits

for all Heater Models.

:

1.1 SAFETY PRECAUTIONS

Installation, maintenance and operating personnel must, at all times, observe all safety regulations. The

following warnings are general and must be given the same attention as specific precautions included in

these instructions.

1

Page 2

FLUIDS UNDER PRESSURE MAY CAUSE INJURY TO

PERSONNEL OR DAMAGE TO EQUIPMENT WHEN RELEASED

Shut off all incoming and outgoing steam and water stop valves and

carefully decrease all trapped pressures to zero before performing any

maintenance.

Never search for leakage in a live steam line by sight alone or by “feel”.

Use a mirror or other suitable polished object.

Always provide yourself with personal protective equipment, (PPE) such as

gloves, eye protection, dust mask, hard hat, etc.

1.2 Tools Required

WARNING!

WARNING!

LIVE STEAM CAN CAUSE SEVERE BURNS

The following tools are required to perform the retrofit procedures specified in this Service Bulletin:

• Combination Wrenches: 7/16”, 9/16”, 5/8”, 13/16”, 1-1/16”, 1-1/8”, 8 mm

• Pipe Wrenches: 12”, 24”

• Vise-Grip Pliers

• Flat Tip Screwdriver, 1/2” Blade

• Phillips Head Screwdriver, No. 3

• Brass Wire Brush

• Needle Nose Pliers

• Tape Measure

• Black Marker

2

Page 3

1.3 Retrofit Kit Contents

The contents of the Retrofit Kits, Part No. 27004-[ ] are included in Appendices A through D of this

Bulletin. The contents included in these Appendices are as follows:

• Appendix A: Lists the Basic ECS Retrofit Kit contents for each Water Heater Model

• Appendix B: Lists Optional Items based on: valve size, flow rate, type of actuator

currently installed

• Appendix C: Lists Valve Kits required for previously installed Pneumatic and Electro -

Hydraulic Actuators

• Appendix D: Lists Valve Kits required for previously installed Self-Contained

Actuators

WARNING

HIGH VOLTAGE OF 120 VAC IS USED IN AERCO INDIRECT FIRED

WATER HEATERS. USE EXTREME CARE WHEN ACCESSING CIRCUITS

AND ELECTRICAL CONNECTIONS WITHIN THE EQUIPMENT. SERIOUS

PERSONAL INJURY OR DEATH MAY OCCUR IF THIS WARNING IS NOT

OBSERVED. FOLLOW OSHA APPROVED LOCKOUT/TAGOUT

PROCDURES.

2. EQUIPMENT ISOLATION AND REMOVAL PROCEDURES

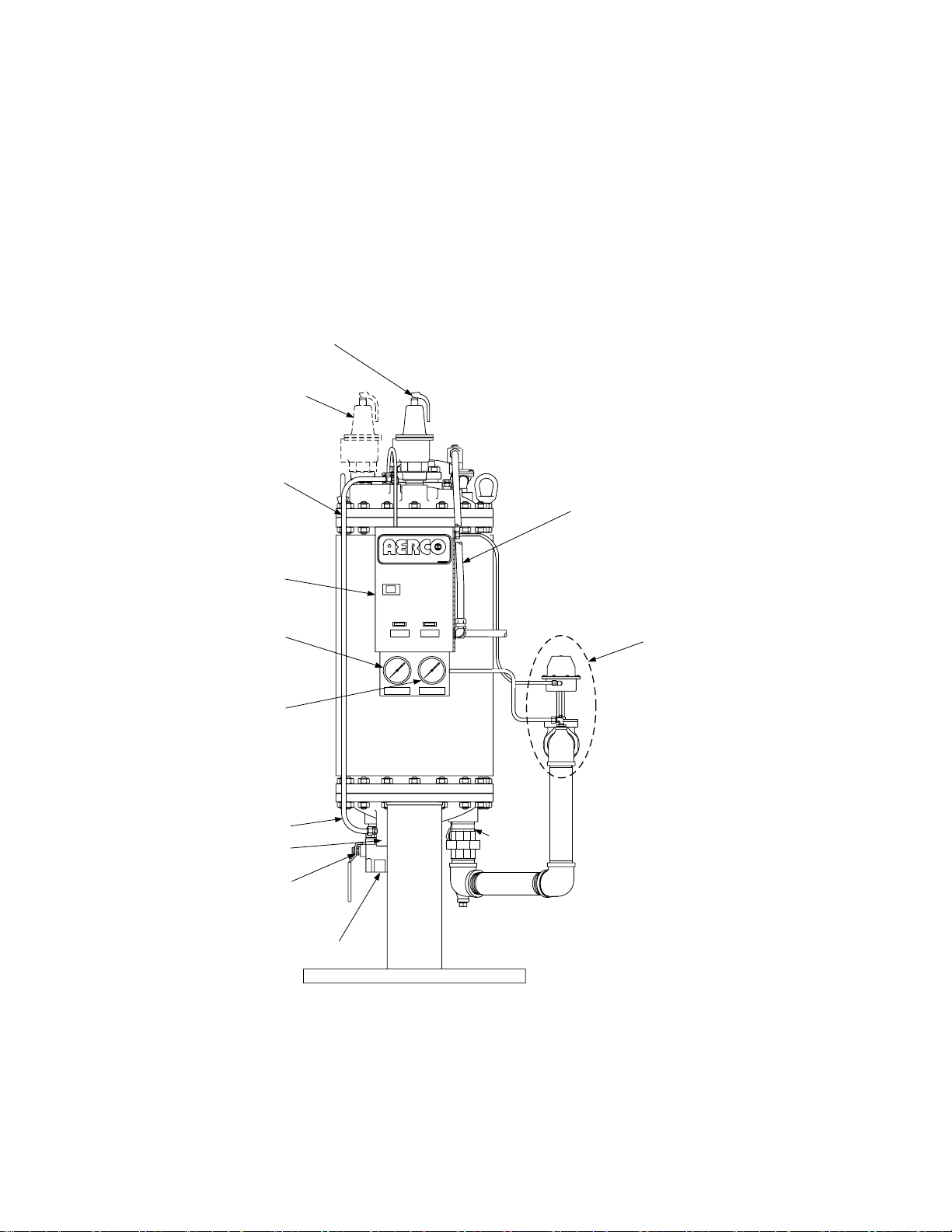

The locations of the major items to be removed from an AERCO Indirect Fired Water Heater are

shown in Figures 2-1 (Helitherm Models) and 2-2 (Double-Wall Models). These items include:

• Currently Installed Control Valve Actuator (Pneumatic, Self-Contained or Electro-Hydraulic)

• Control Box

• Top Head Solenoid Valve

• Thermal Element

• Shunt Tube

• Temperature Gauges & Capillaries

• Existing Feedback Sensor

• Load Alert Components (Except for Units With Electro-Hydraulic Valves)

In addition to the items listed above, the Drain Ball Valve (if installed) and Cold Water Inlet piping will

be temporarily disconnected to permit installation of a Flow Meter and Orifice Disk.

3

Page 4

NOTE

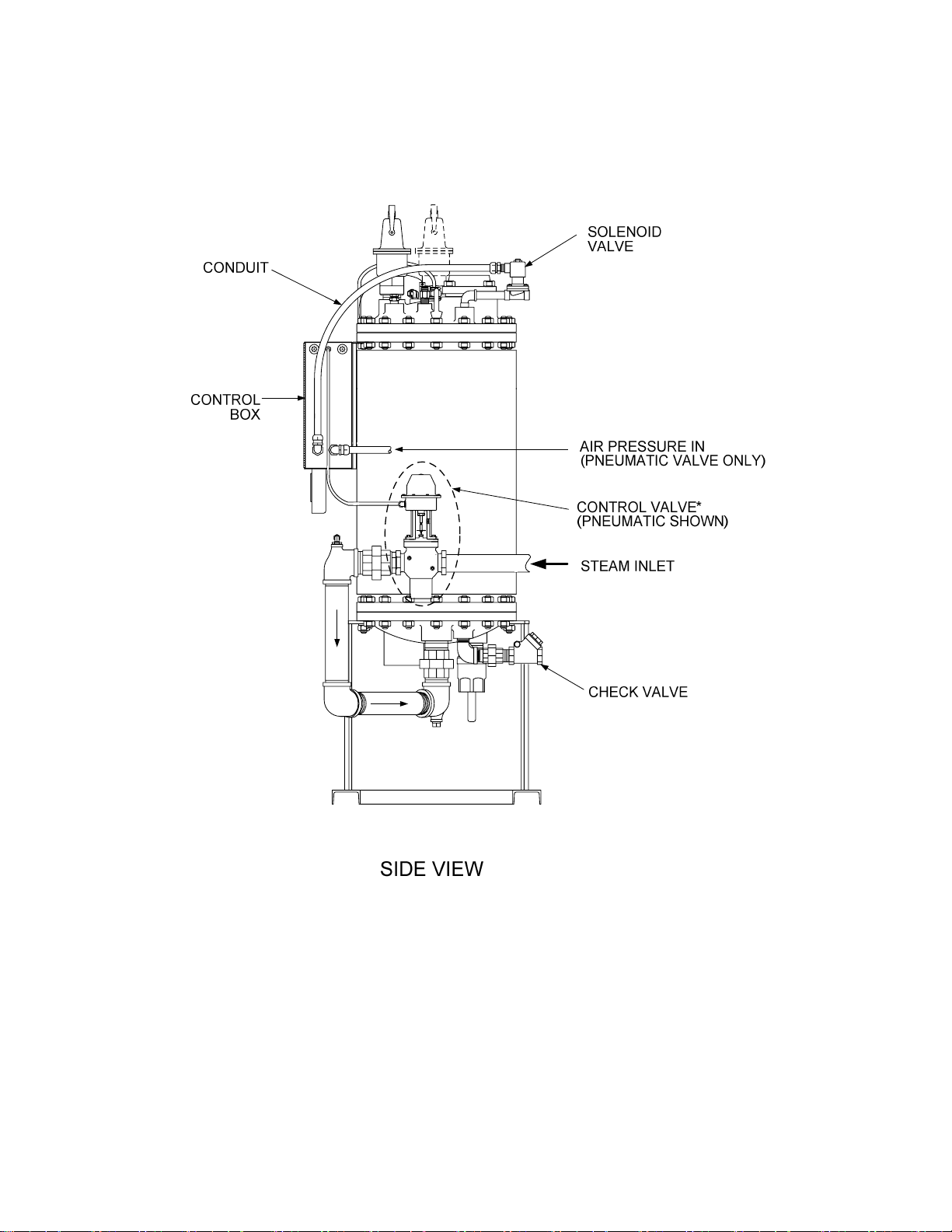

Figure 2-1 shows the locations of the affected components and assemblies for

a typical Helitherm, Model SW1B-Plus II Water Wizard installation. Figure 2-2

shows component locations for a typical Double-Wall, Model DW-24.

The actual size and location of affected components and assemblies may

vary, depending on Packaged Water Heater Model, size, and type of Control

Valve being retrofitted. Refer to the applicable AERCO Heat Exchanger

Manual provided with your installation for additional details.

P&T RELIEF VALVE

SECOND OPTIONAL

P&T RELIEF VALVE

SHUNT TUBE

WIRING CONDUIT TO

WATER SOLENOID VALVE

CONTROL BOX

HOT WATER OUTLET

TEMPERATURE GAUGE

COMPOUND

PRESSURE

GAUGE

SHUNT TUBE

COLD WATER IN

DRAIN BALL

VALVE

DRAIN

WATER HEATER

POWER ON TRIPPED

SHELL OUTLET

°F PSIG

STEAM PRESS.

PT.NO.128691

CONTROL VALVE*

*NOTE:

HEATER SHOWN WITH

PNEUMATIC CONTROL

VALVE. AN ELECTROHYDRAULIC OR SELFCONTAINED VALVE MAY

ALSO BE USED WITH THE

PACKAGED HEATER.

STEAM

IN

FRONT VIEW

Figure 2-1. Typical Helitherm Water Heater Component Locations (Sheet 1 of 3)

4

Page 5

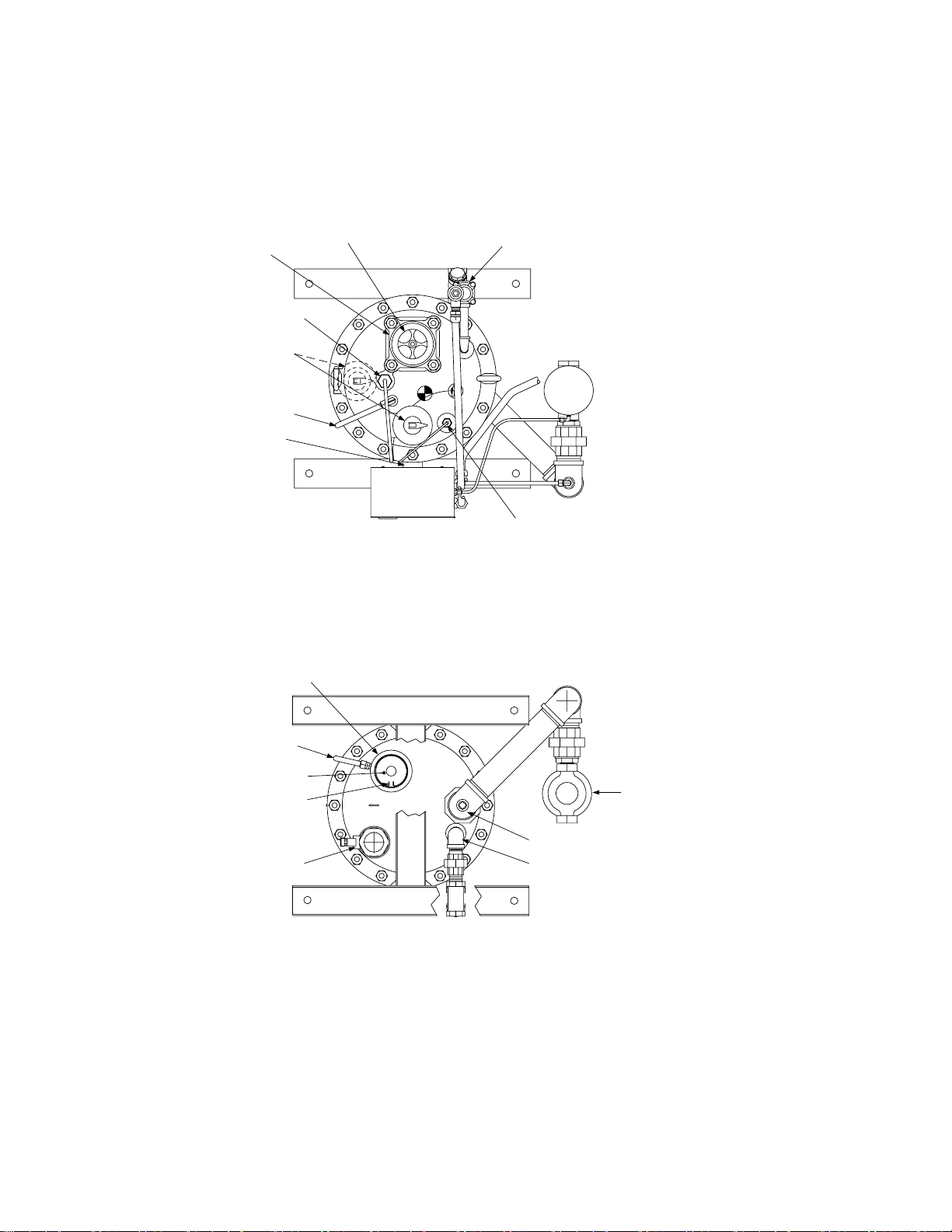

Figure 2-1. Typical Helitherm Water Heater Component Locations (Sheet 2 of 3)

5

Page 6

OUTLET

FLANGE

THERMAL

ELEMENT

P&T RELIEF

VALVE(S)

SHUNT TUBE

MOUNTING

BRACKET

(SAVE)

COLD WATER IN

LOAD ALERT**

CONTROL

BOX

TOP

SOLENOID

VALVE

FEEDBACK

SENSOR

VALVE

**NOTE:

LOAD ALERT NOT

USED WITH ELECTROHYDRAULIC CONTROL

VALVE.

SHUNT TUBE

ORIFICE DISC

SPRING RING

DRAIN VALVE

STEAM IN

CONDENSATE OUT

CONTROL

VALVE

BOTTOM

Figure 2-1. Helitherm Water Heater Component Locations (Sheet 3 of 3)

6

Page 7

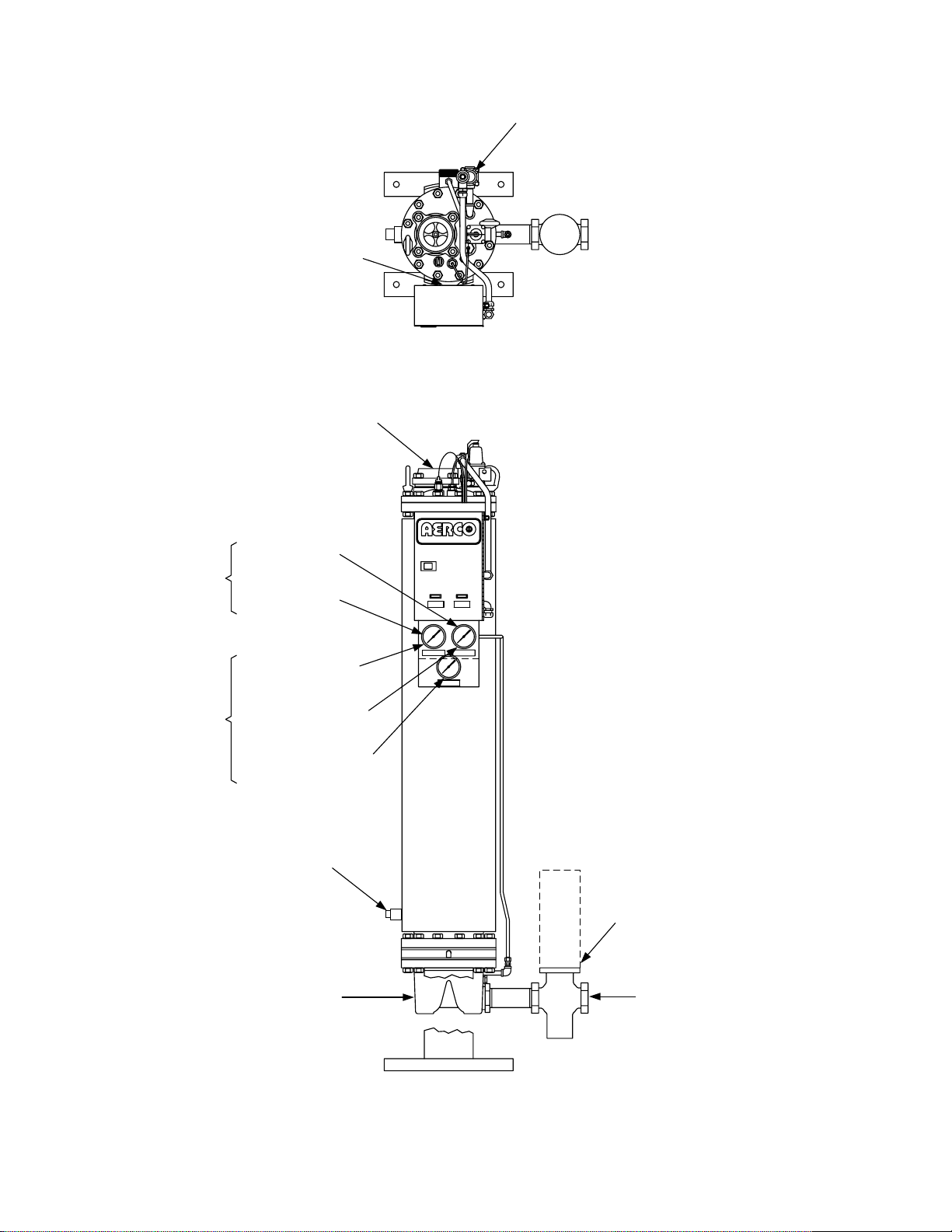

SOLENOID

VALVE

S/W

COMPOUND

PRESS. GAGE

TEMP. GAGE

-OR-

W/W

PRIMARY INLET

TEMP. GAGE

MOUNTING

BRACKET

(SAVE)

HOT WATER

OUTLET

CONTROL

BOX

WATER HEATER

POWER ON TRIPPED

TUBE OUTLET

TUBE INLET

°F °F

SHELL OUTLET

°F

VALVE

PT.NO.1

2869-1

PRIMARY OUTLET

TEMP. GAGE

SECONDARY OUT.

TEMP. GAGE

3/4" PLUGGED

DRAIN

CONTROL

VALVE

CONDENSATE/BOILER

WATER OUTLET

STEAM/BOILER

WATER INLET

Figure 2-2. Double-Wall Heater Component Locations (Sheet 1 of 2)

7

Page 8

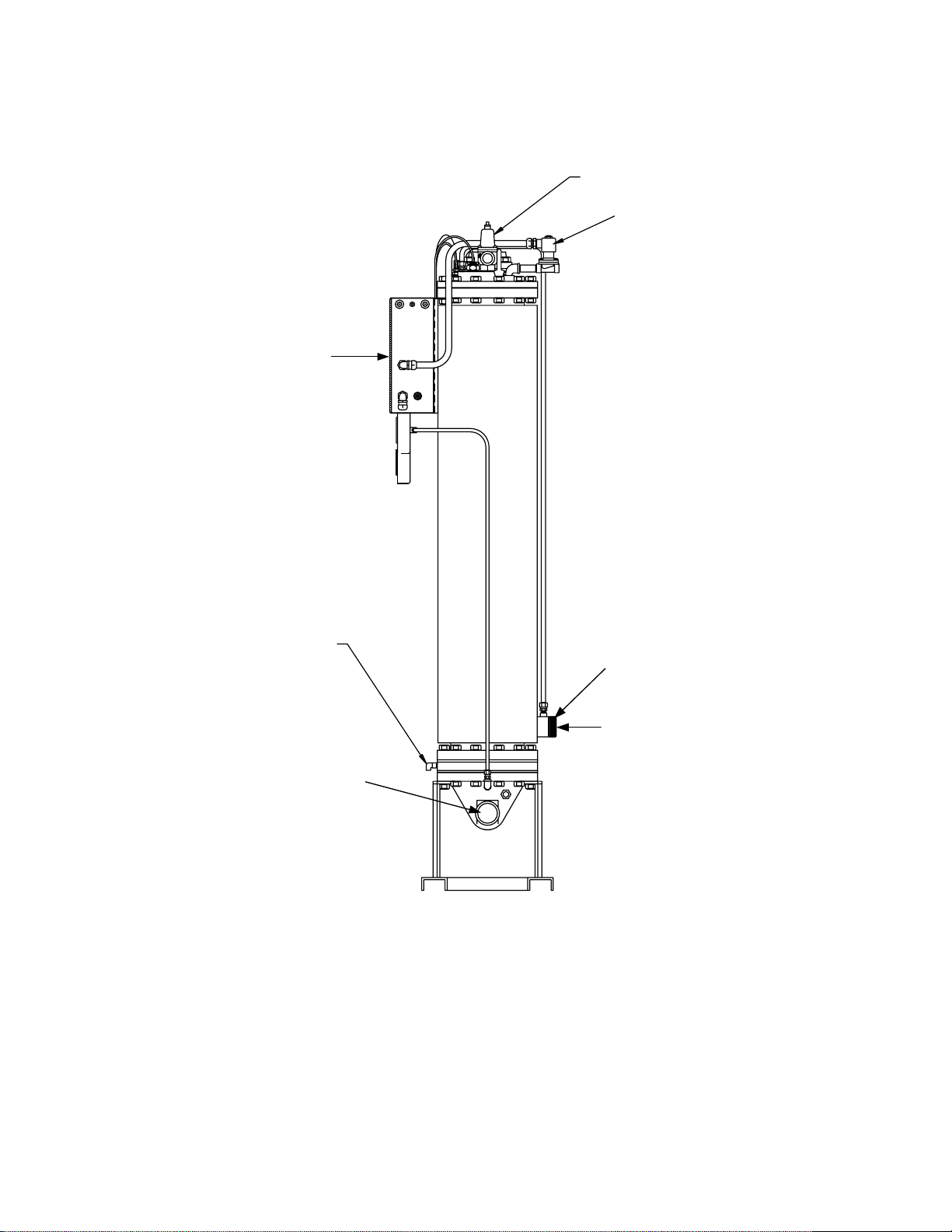

RELIEF VALVE

WATER

SOLENOID

CONTROL BOX

DOUBLE WALL

TUBE LEAK

DETECTION PORT

(NOT TO BE

PLUGGED OR

BLOCKED)

COLD WATER

INLET

ORIFICE DISC

& SPRING RING

STEAM/BOILER

WATER INLET

Figure 2-2. Double-Wall Heater Component Locations (Sheet 2 of 2)

NOTE

The majority of illustrations contained in these instructions show a typical

Water Wizard, Model SW1B Plus II Packaged Water Heater. Additional

supporting illustrations are provided only where significant differences exist

between the Water Wizard and the AERCO Heater being retrofitted. For

example: E-Plus Water-to-Water Heaters or Double-Wall (DW) Models.

8

Page 9

2.1 Isolating Water Heater

To isolate the Water Heater from all facility energy sources (steam, water, electrical power), proceed

as follows:

1. Disconnect and Lock-Out/Tag-Out external AC power supplied to the Control Box and any

other devices connected to the Heater.

2. Using a voltmeter, check to ensure that all incoming voltage readings are zero Before

continuing.

3. If the Heater is equipped with a Pneumatic Control Valve Actuator, close the valve supplying

air inlet pressure to the Pneumatic Controller.

4. Close all stop valves in the Steam Inlet and Condensate Outlet lines. On water-to-water

systems, do not rely on the Boiler Water Out Check Valve to stop the flow of water.

5. On the water-side, close the stop valves in the following order

:

(a) Hot water outlet line

(b) Recirculation line

(c) Cold water inlet line

6. Carefully open the Relief Valve located on the Top Head to relieve pressure in the Heater

Shell. Water should stop flowing from the valve within one minute. If water continues to flow

from the Relief Valve, one of the water stop valves is not securely closed.

2.2 Draining Water Heater

Allow the Water Heater to cool sufficiently prior to draining the unit. When sufficiently cooled, drain as

follows:

1. After ensuring there is no pressure build-up in the Heater Shell (para. 2.1, step 6), block open

the Relief Valve in the Top Head to avoid creating a vacuum in the Heater Shell when it is

drained.

2. Open the Drain Ball Valve in the Bottom Head and allow the potable water in the Heater Shell

to drain completely. If the unit is a Double-Wall Heater (DW-24, DW-45 or DW-68), the Drain is

located on the Shell and may either be plugged with a 3/4” NPT Plug or equipped with a Ball

Valve and additional drain piping. Remove Plug or open Drain Ball Valve as applicable.

9

Page 10

CAUTION

DO NOT DISCARD ANY OF THE REMOVED PARTS OR ASSEMBLIES

UNLESS IT IS SPECIFICALLY INDICATED THAT THEY WILL NO LONGER

BE USED. IT IS RECOMMENDED THAT ALL REQUIRED ITEMS BE

REMOVED AS INDICATED IN THE FOLLOWING STEPS PRIOR TO

PERFORMING ANY OF THEREPLACEMENT PROCEDURES IN SECTION

3.

2.3 Removal of Components on Top Head Assembly

Virtually all components currently installed in the Water Heater Top Head must be removed prior to

installing the new Electronic Control System and Electronic Valve Actuator. Refer to Figure 2-1, sheet

3 to locate the applicable Top Head components and proceed as follows:

1. Disconnect the pipe drain from the Water Solenoid Relief valve in the Top Head.

2. Disconnect the electrical leads between the Water Solenoid and the Control Box.

3. Remove the 120 VAC Water Solenoid from the nipple connecting it to the Heater Top Head.

This Solenoid will be replaced with a new 24 VDC Solenoid provided in the Retrofit Kit.

4. If a Self-Contained Control Valve is installed with the Heater, remove the Valve’s Temperature

Control Thermal Element from the Thermowell bushing in the Top Head.

5. If a Pneumatic Control Valve is installed with the Heater, remove the Thermal Element and

Bushing.

6. Remove the Dial Thermometer and Thermowell from the Top Head.

7. Remove the Aquastat Capillary and Thermowell from the Top Head.

8. Remove the Anticipator Check Valve (Load Alert) as follows:

(a) Disconnect the union or flange in the hot water outlet piping (located beyond the outside

diameter of the Top Head).

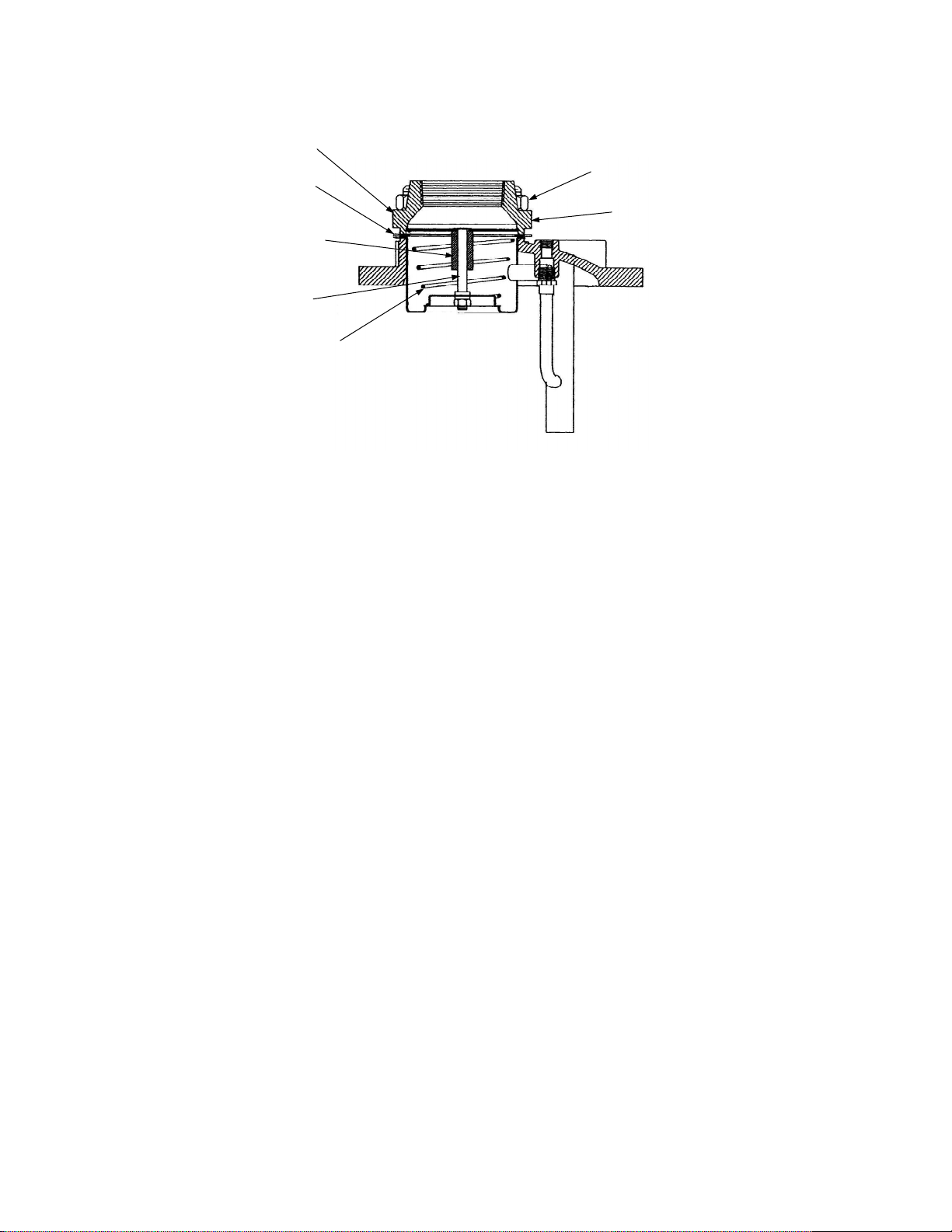

(b) Refer to Figure 2-3. Remove the four hex nuts securing the hot water Outlet Flange to the

Top Head. Remove the Flange, Flange Gasket and outlet piping connected to the Flange.

Retain the four hex nuts for reinstallation of a new Outlet Flange (Section 4).

(c) Remove the Spring Plate Assembly, Spring and Valve Plug Assembly from the Load Alert.

These removed components will no longer be used. Also, the Outlet Flange and Gasket

will be replaced with new components provided in the Retrofit Kit.

10

Page 11

OUTLET

FLANGE

FLANGE

GASKET

SPRING PLATE

ASSEMBLY

VALVE PLUG

ASSEMBLY

SPRING

HEX NUTS (4)

HOT WATER

OUTLET FLANGE

Figure 2-3. Anticipator Check Valve (Load Alert) Assembly

NOTE

For Double-Wall Heater Models (DW-24, DW-45, DW-68), the items removed

in paragraph 2.4 are located on the Shell of the Heater instead of the Bottom

Head. Therefore, refer to Figure 2-2 for Double-Wall Models.

2.4 Removal of Items Connected to Bottom Head

In order to install several new ECS components, the Drain Ball Valve must be disconnected and the

Cold Water Inlet Orifice Disc replaced. The locations of these items are shown in Figure 2-1, sheet 3.

Proceed as follows:

1. Disconnect any external piping connected to the Cold Water Inlet and Drain Ball Valve Outlet

on the Bottom Head.

2. Locate the Orifice Disc in the Cold Water Inlet (Figure 2-1, sheet 3).

3. Using a pair of pliers, disconnect the snap ring securing the Disc in the Bottom Head.

4. Remove the clip and the Orifice Disc from the Bottom Head. This Orifice Disc will be replaced

in Section 4 with a new Disc provided in the Retrofit Kit.

5. Next, temporarily remove the Drain Ball Valve from the Bottom Head (Figure 2-1, sheet 3).

Retain this Ball Valve for reinstallation in Section 4.

11

Page 12

2.5 Control Valve Actuator Removal

The Water Heater may currently be equipped with a Pneumatic, Self-Contained or Electro-Hydraulic

Control Valve Actuator. Therefore, refer to the appropriate paragraph for the type of Control Valve

Actuator currently installed.

NOTE

Following removal of the existing Control Valve Actuator, AERCO recommends that the Valve Seat and Packing be replaced using the appropriate

items included with the Retrofit Kit. If the Valve is relatively new (less than 1

year) and is currently equipped with a Pneumatic or Electro-Hydraulic

Actuator, replacement of these items may be omitted at the discretion of the

user. However, if the Valve is currently equipped with a Self-Contained

Actuator, replacement of these items is mandatory, since the Valve must be

virtually disassembled to remove the installed Actuator. A new Valve Top (plus

other items) must also be added to Self-Contained Valves before an ECS

Actuator and Linkage Assembly can be installed.

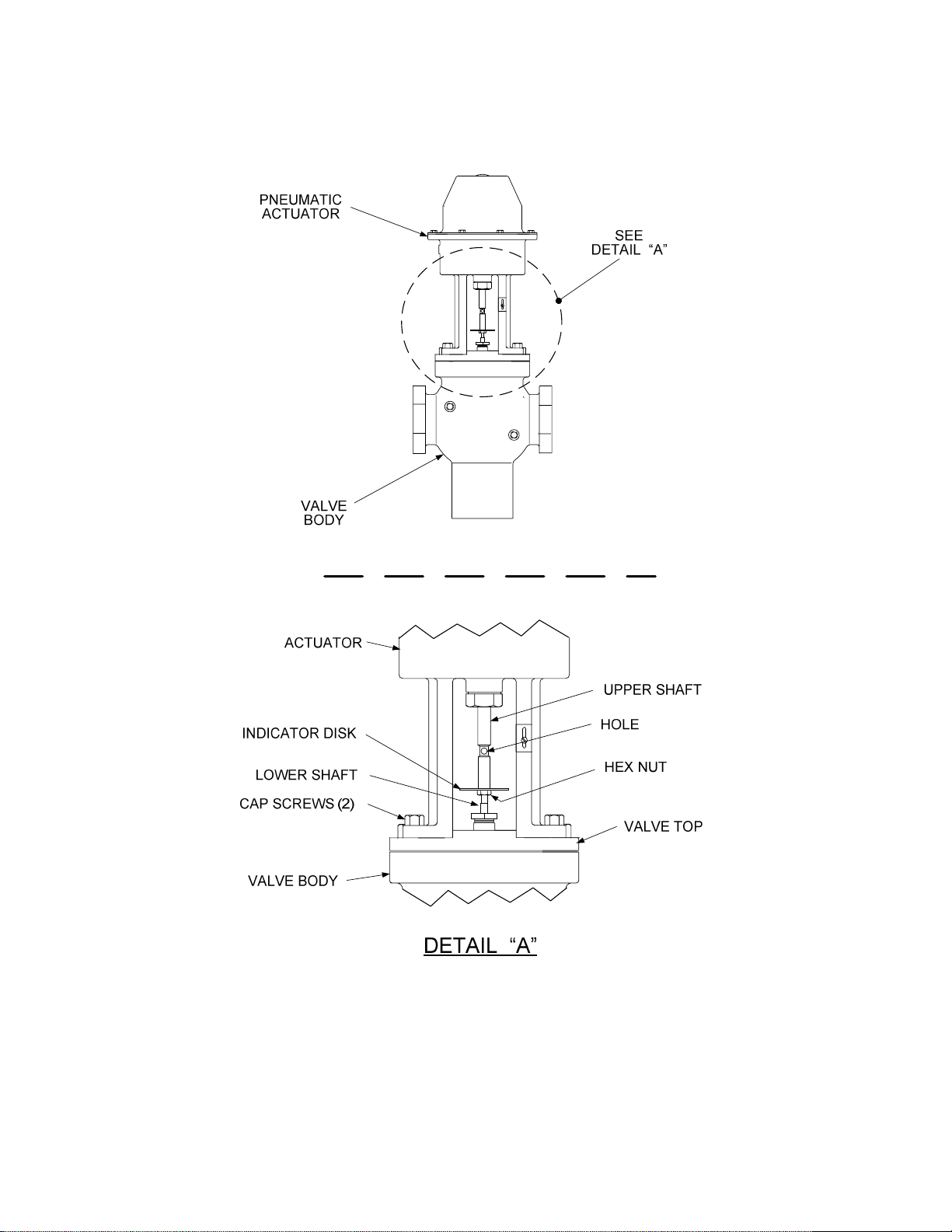

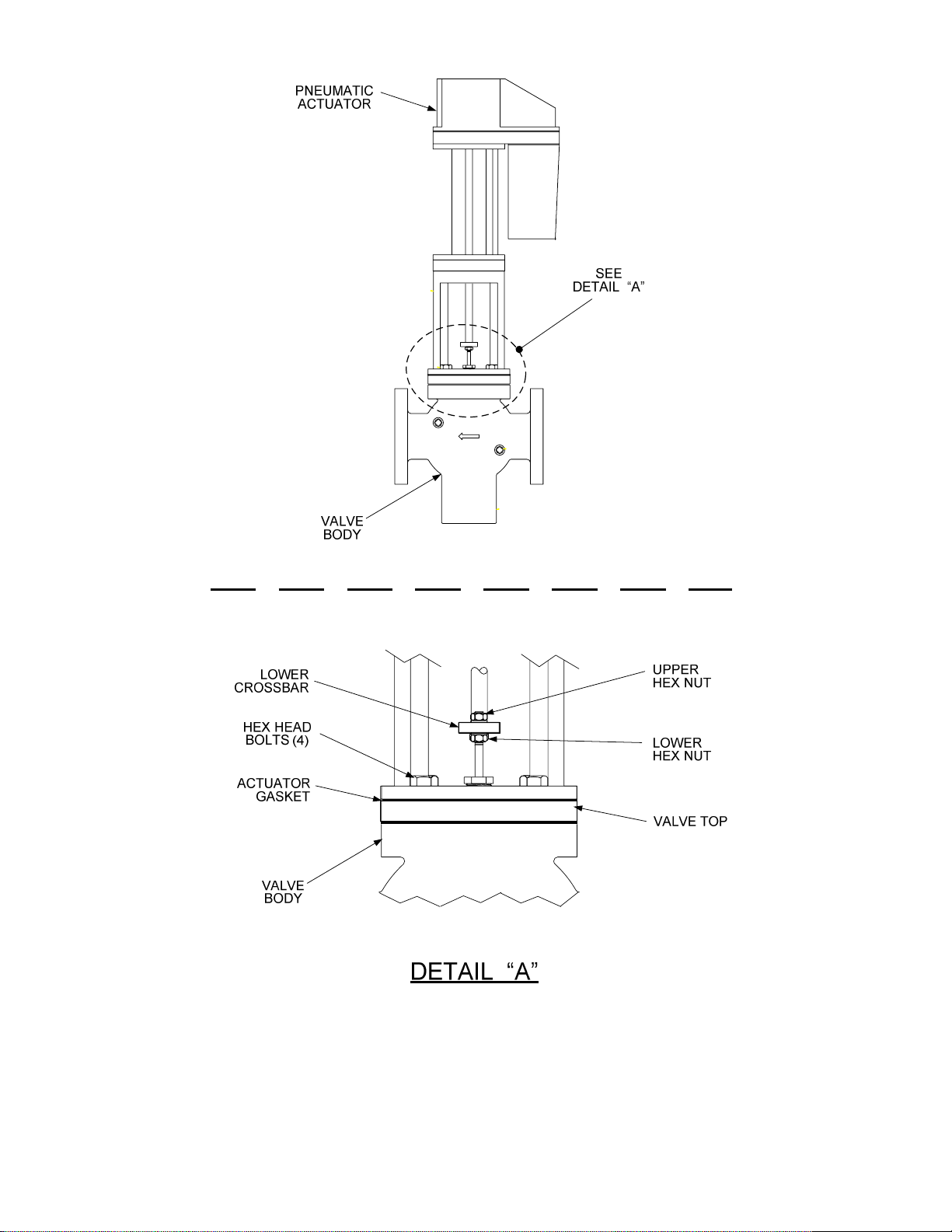

2.5.1 Pneumatic Control Valve Actuator Removal

Refer to Figure 2-4 and remove the Pneumatic Control Valve Actuator as follows:

1. Disconnect the compression fitting connecting the control air line from the Actuator Top.

2. Loosen the hex nut under the indicator disk.

3. Insert a 1/8 inch steel rod in the hole provided in the upper shaft. Hold the rod to keep the

upper shaft from turning when performing the next step.

4. Using a pair of pliers, grasp the lower shaft and rotate it counterclockwise to separate it from

the upper shaft. Use care to avoid scratching the lower shaft.

5. Remove the two 3/8-16 cap screws securing the Pneumatic Actuator to the Valve Body.

Remove the entire Actuator from the Valve.

12

Page 13

Figure 2-4. Pneumatic Control Valve Actuator Removal

13

Page 14

2.5.2 Electro-Hydraulic Control Valve Actuator Removal

Refer to Figure 2-5 and remove the Control Valve Actuator as follows:

1. Disconnect the electrical connectors from the Actuator.

2. Loosen the Upper Hex Nut above the Lower Crossbar shown in Figure 2-5.

3. While holding the Lower Shaft with a pair of pliers, completely remove the Upper Hex Nut.

4. Remove the four hex head bolts securing the Electro-Hydraulic Actuator to the Valve Top.

5. Lift the entire Actuator off the Valve Top. Also, remove the Actuator Gasket.

14

Page 15

Figure 2-5. Electro-Hydraulic Control Valve Actuator Removal

15

Page 16

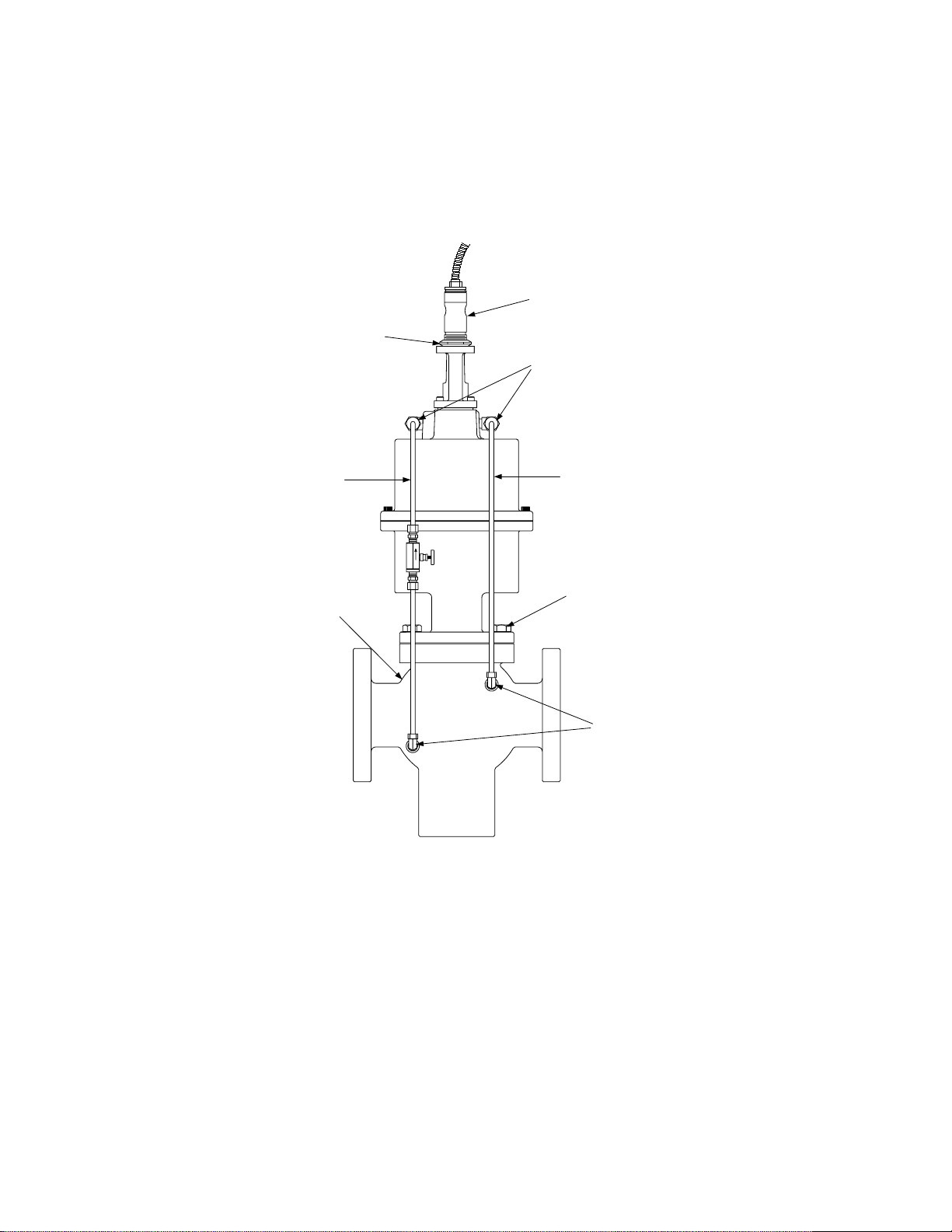

2.5.3 Self-Contained Control Valve Actuator Removal

Refer to Figure 2-6 and remove the Self-Contained Valve Actuator as follows:

1. Loosen the locknut on the thermal element adjustment sleeve. Unscrew the adjustment sleeve

to remove the sleeve and thermal element from the Actuator.

2. Carefully loosen the compression fittings on the upstream and downstream tubing to relieve

any trapped pressure buildup. Completely remove both the upstream and downstream tubing

assemblies and compression fittings. The tapped NPT ports in the Valve Body will be plugged

during the replacement procedures in Section 3.

3. Remove the hex head cap screws securing the Actuator to the Valve Body. Valve sizes from

1” to 2” have 6 cap screws, while sizes 2 ½” to 4” Valves have 8 cap screws.

CAUTION

Use care when performing step 4 to avoid damaging or scratching internal

Valve Body parts. It is imperative that the Actuator be lifted straight up to avoid

sticking or binding.

4. Lift the Actuator Housing straight up and off the Valve Body. Doing so will also remove the

entire inner valve assembly (Figure 2-7), including the Valve Stem, Seat, Valve Plug Shaft and

Top/Bottom Pistons. Depending on the age and condition of the valve, considerable force may

be required to pull the Pistons through the Valve Body. If it cannot be removed, the Valve

Stem may be used as an impact hammer to remove scale build-up on the internal valve

surfaces and allow Piston removal.

Replacement parts for these removed items are provided in the applicable Retrofit Kit for the

Valve size being retrofitted. These items will be replaced in Section 3. The Retrofit Kit also

contains a new Lower Shaft, Valve Top/Gasket, plus additional replacement items for the

Valve being retrofitted.

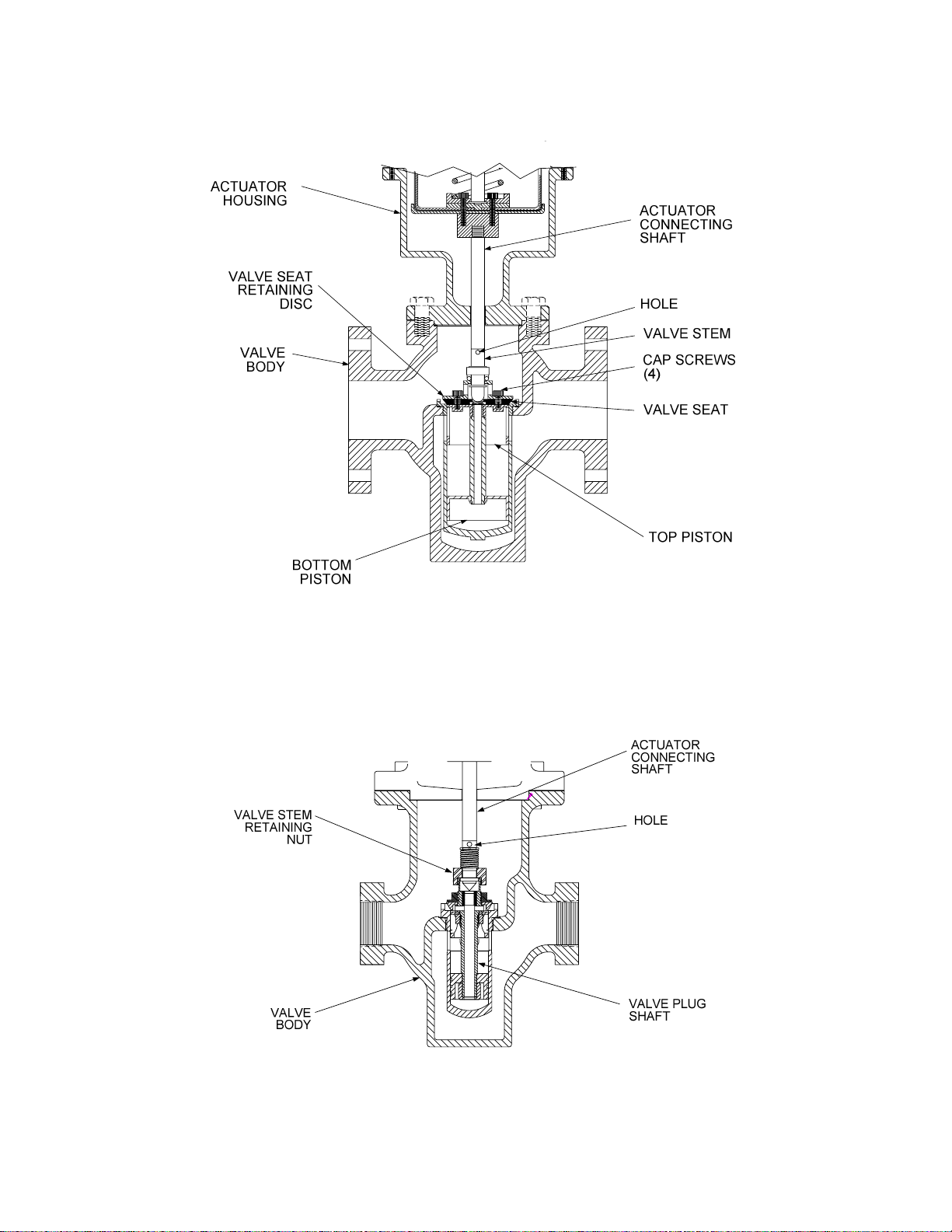

5. Proceed as follows, depending on the size of the Valve being retrofitted:

(a) For 2 ½ to 4 inch Valves, separate the Valve Seat Retaining Disc from the Valve Seat by

removing the four (4) cap screws (Figure 2-7).

(b) For 1 to 2 inch Valves, hold the Valve Plug Shaft with a pair of pliers and remove the

Valve Stem Retaining Nut from the Shaft (Figure 2-8).

6. Insert a 1/8 inch steel rod through the hole near the top of the Valve Stem (Figure 2-7 or 2-8).

NOTE

If “flats” are provided on the Actuator Connecting Shaft and Valve Stem, openend wrenches may be used in step 7 to disconnect the Valve Stem and

Actuator Shaft.

7. Grasp the Actuator Connecting Shaft (Figure 2-7 or 2-8) with a pair of pliers. Carefully turn the

Valve Stem counterclockwise and separate it from the Actuator Connecting Shaft.

16

Page 17

8. Replacement of all required Valve parts will be accomplished using the appropriate

instructions and illustrations in Section 3.

THERMAL ELEMENT

ADJUSTMENT SLEEVE

LOCKNUT

1/8" NPT

COMPRESSION

ELBOWS

DOWNSTREAM

TUBE

VALVE

BODY

UPSTREAM

TUBE

HEX HEAD

CAP SCREWS

1/4" NPT

COMPRESSION

ELBOW

Figure 2-6. Self-Contained Control Valve Actuator Removal

17

Page 18

Figure 2-7. Self-Contained Control Valve Actuator Removal – 2 ½” to 4”

Figure 2-8. Self-Contained Control Valve Actuator Removal – 1” to 2”

18

Page 19

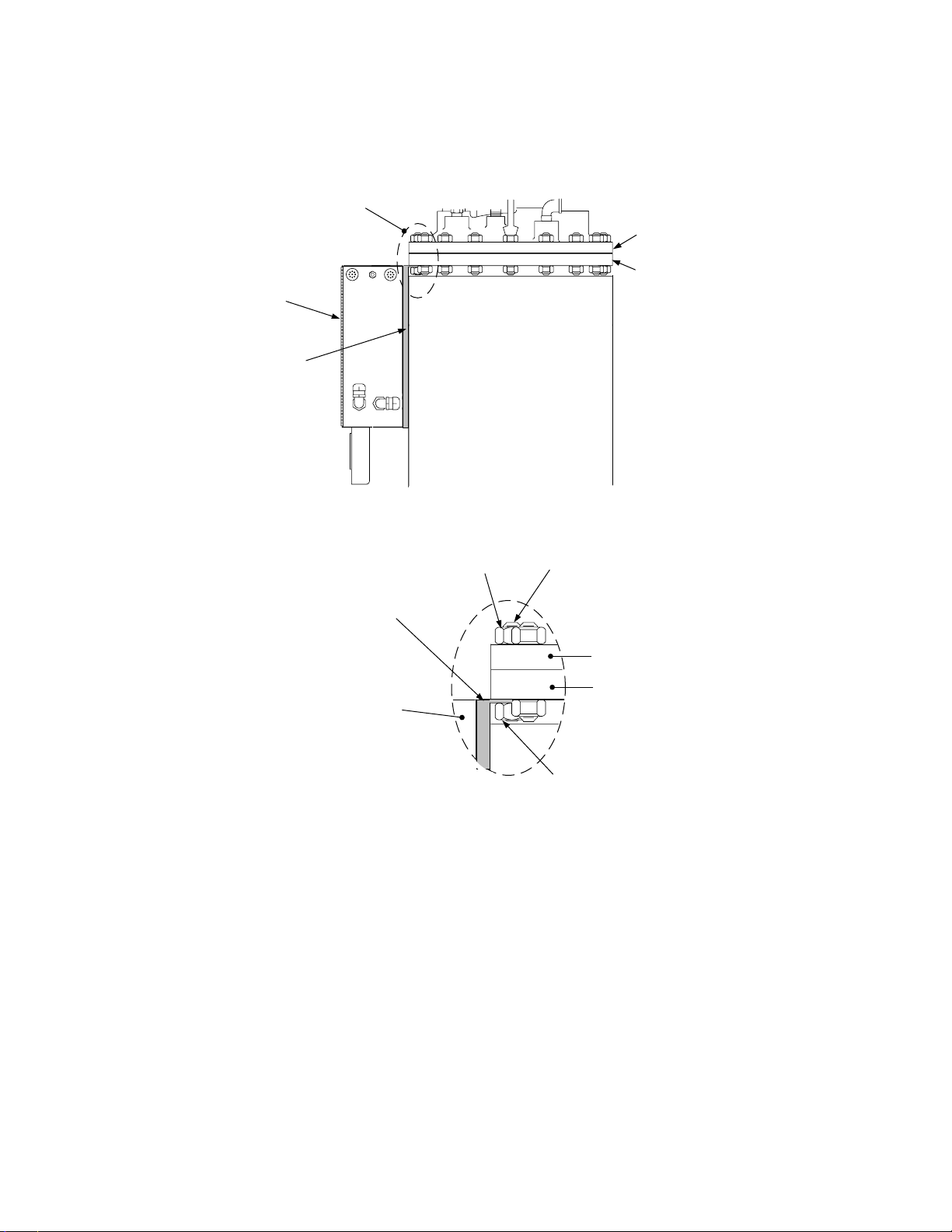

2.6 Control Box Removal

The existing Control Box (Figure 2-1) is secured to the Heat Exchanger using a special mounting

bracket. The top end of this mounting bracket contains a slotted cutout which is inserted around one

of the studs securing the top head to the shell flange. A hex nut secures the bracket in place. The

currently installed Control Box will no longer be used. However, the mounting bracket will be reused to

mount the new ECS Control Box. Remove the Control Box and mounting bracket assemblies as

follows:

1. Check to ensure that the external power source has been turned off.

2. Disconnect all power supply wiring to the Control Box. Also, disconnect all wiring between the

Control Box and any external Solenoid Valves.

3. If a Pneumatic Control Valve Actuator is currently installed on the Heater, disconnect the air

supply and control air tubing from the Control Box.

4. Disconnect the Pressure Gauge compression fittings.

5. Cut all wire ties leading to the Control Box. Do not cut the thermal element.

6. Loosen, but do not remove, the hex nut securing the Control Box Mounting Bracket to the Top

Head stud (Figure 2-9).

7. Completely remove the Control Box and Mounting Bracket from the Water Heater.

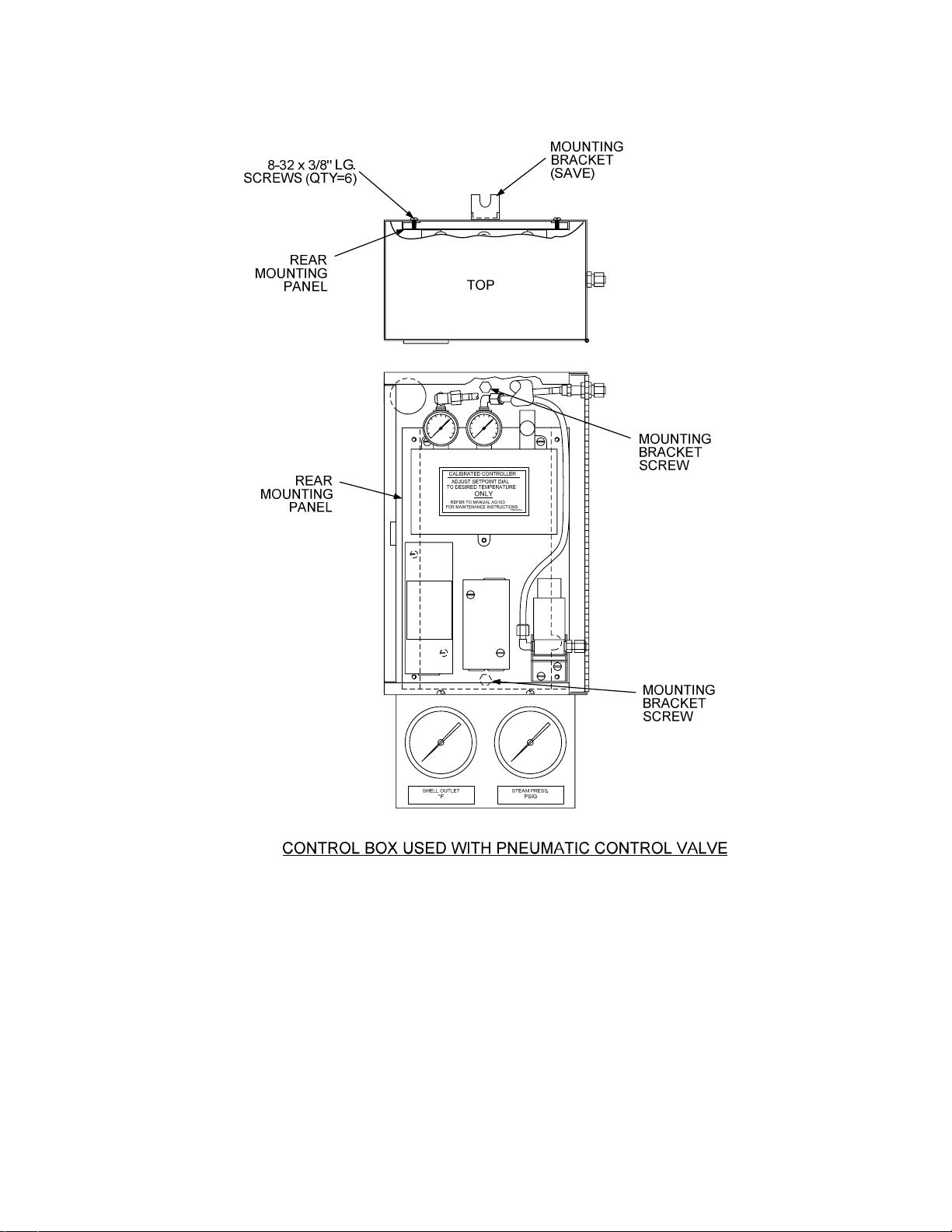

8. Open the Control Box door. From the rear of the Control Box, remove the six 8-32 screws

securing the Rear Mounting Panel to the enclosure (Figure 2-10).

9. Remove the Rear Mounting Panel from the Control Box to access the two screws securing the

Mounting Bracket to the Box

IMPORTANT

Save the Control Box Mounting Bracket when it is removed from the Control

Box. This Mounting Bracket will be used to install the new ECS Control Box.

10. Remove the two screws securing the Mounting Bracket to the Control Box. Separate the

Control Box and Mounting Bracket. This Control Box will no longer be used and can be

discarded. However, the Mounting Bracket will be reused to attach the new ECS Control Box

to the Heater in Section 4.

19

Page 20

SEE

DETAIL “A”

TOP HEAD

SHELL FLANGE

CONTROL

BOX

MOUNTING

BRACKET

HEX NUT

MOUNTING

BRACKET

(SAVE)

CONTROL

BOX

STUD

TOP HEAD

SHELL FLANGE

HEX NUT

DETAIL “A”

Figure 2-9. Control Box Mounting Details

20

Page 21

Figure 2-10. Control Box With Door Open

21

Page 22

3. RECOMMENDED REPLACEMENT OF VALVE ASSEMBLY PARTS

As mentioned in paragraph 2.5, AERCO recommends that the Valve Seat and Packing be replaced

on the Valve Body, prior to installing the ECS Retrofit Kit items described in Section 4. Valve Bodies

which previously utilized Self-Contained Actuators must

such as: a Valve Top, Valve Stem and a Packing Nut.

Refer to the applicable paragraphs which follow for the Valve size and Actuator type used on your

system.

be modified to include new additional items

NOTE

The procedures in paragraphs 3.1 and 3.2 which follow, assume that the

previously installed Pneumatic, Electro-Hydraulic or Self-Contained Actuator

has already been removed.

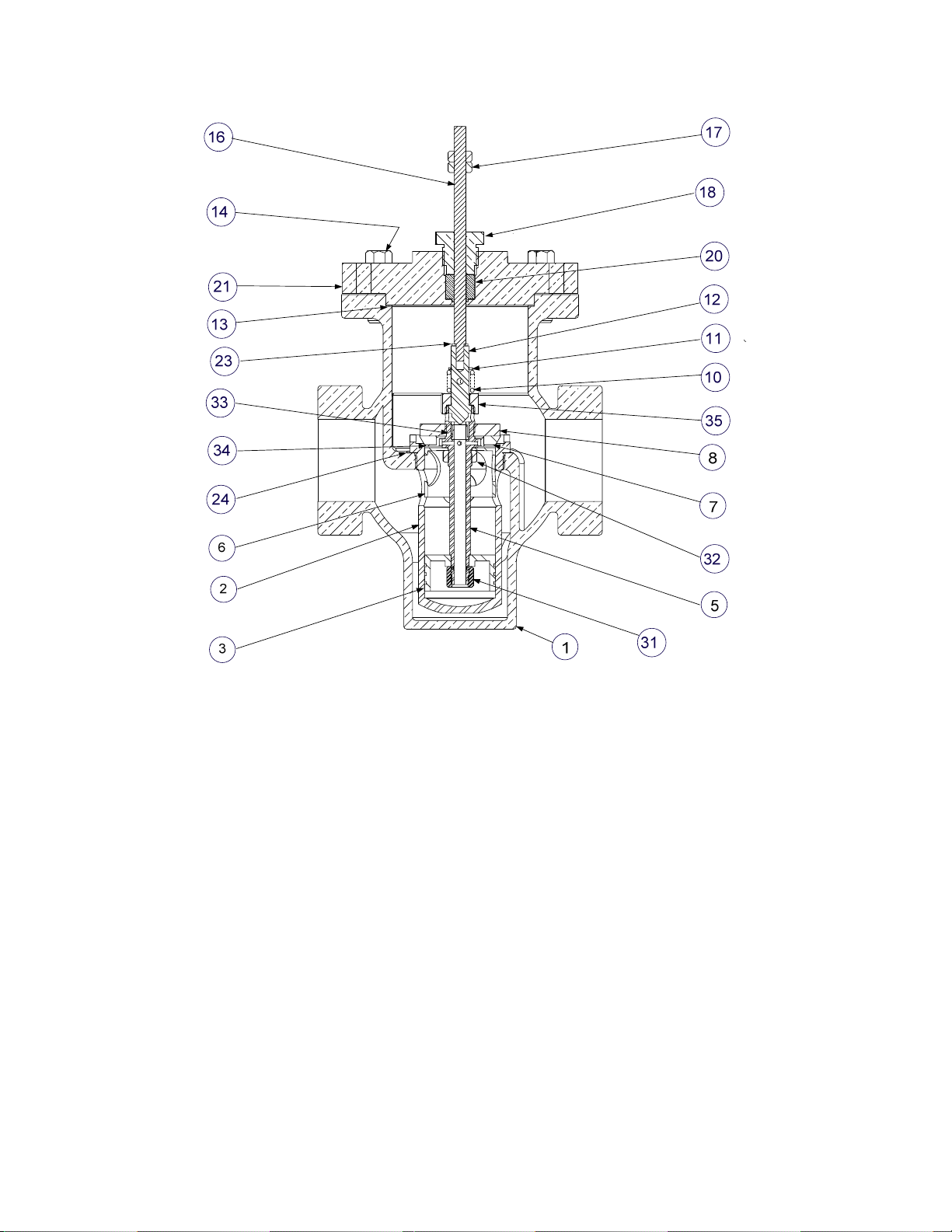

3.1 Valves Previously Equipped With Pneumatic or Electro-Hydraulic Actuators

The parts replacement items required for Valve Bodies which previously used Pneumatic or ElectroHydraulic Actuators are basically identical. Only minor variations exist for the various Valve Body

sizes. The Valve Body components for 1.00” to 2.00” and 2.50” to 4.00” are shown in Figures 3-1 and

3-2, respectively.

3.1.1 Valve Disassembly Procedure

Proceed as follows:

NOTE

Steps 1 through 5 which follow apply to all valve sizes shown in Figure 3-1

and 3-2.

1. Remove the Hex Nut (17) from the Valve Body Shaft.

2. Remove the Packing Nut (18) and Packing Assembly (20).

3. Remove the Bolts or Cap Screws (14) securing the Valve Top (21).

4. Remove the Valve Top (21) and Valve Top Gasket (13).

5. Carefully lift out the entire Shaft /Seat/Piston Assembly.

6. For 1 inch to 2 inch Valve sizes, refer to Figure 3-1 and remove the following items in the order

specified:

(a) Lock Washer (23)

(b) Retaining Ring (11)

(c) Pilot Spring (10)

22

Page 23

(d) Valve Stem Retaining Nut (35)

(e) Lower Shaft (16) and Valve Stem (12)

(f) Retaining Disc (8)

(g) Disc Seat (7)

(h) Seat Retainer (34)

(i) Valve Plug Shaft (5)

7. For 2 ½, 3 and 4 inch Valve sizes, refer to Figure 3-2 and remove the following items in the

order specified:

(a) Lock Washer (23)

(b) Pilot Spring Retainer (11)

(c) Pilot Spring Backup Washer (31), - 4 inch Valve Only

(d) Pilot Spring (10)

(e) Socket Head Cap Screws (9)

(f) Valve Seat Retaining Disc (8)

(g) Lower Shaft (16) and Valve Stem (12)

(h) Valve Seat (7)

(i) Top Piston (6) and Bottom Piston (3) Assemblies

8. Clean all parts thoroughly and remove all dirt and/or scale.

9. Next, proceed to the Valve Reassembly procedures in paragraph 3.1.2 and replace the items

indicated with the new parts provided in the Retrofit Kit.

23

Page 24

Figure 3-1. Valve Assembly Sizes 1.00” to 2.00”

24

Page 25

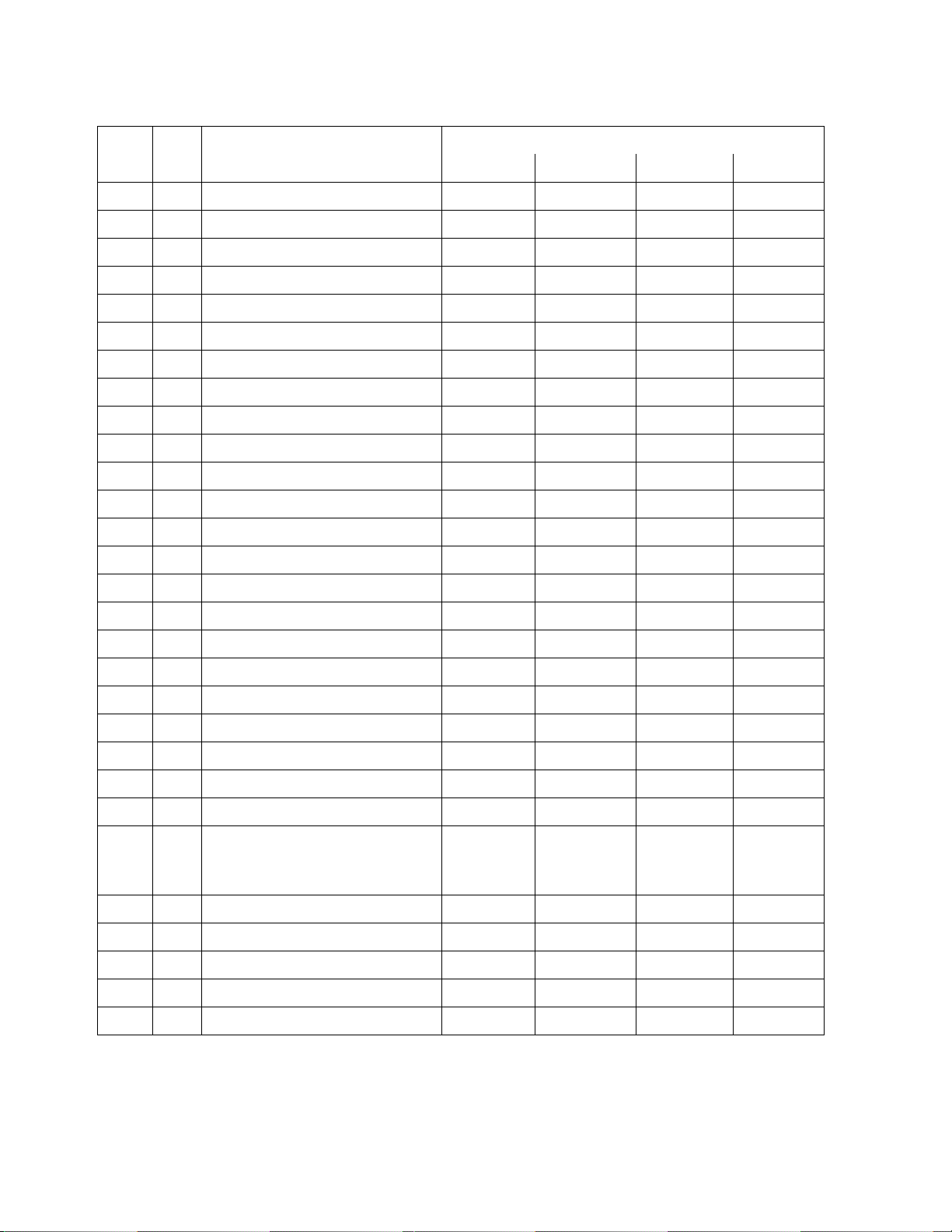

PARTS LIST TABLE FOR VALVE ASSEMBLY SIZES 1.00” TO 2.00”

VALVE SIZE AND PART NUMBERS

ITEM QTY PART NAME 1.00 INCH 1.25 INCH 1.50 INCH 2.00 INCH

1 1 VALVE BODY 20762 20759 20758 20761

2 1 SEAT CAGE 16844 16845 16837 16843

3 1 BOTTOM PISTON 121540 121525 121502 121529

4 NOT USED

5 1 VALVE PLUG SHAFT 16849 16839 16838 16848

6 1 TOP PISTON 121539 12154 121501 121530

7 1 DISC SEAT 121541 121527 121510 121531

8 1 RETAINING DISC 121542 121513 121504 121532

9 NOT USED

10 PILOT SPRING 121528 121528 121528 121528

11 1 RETAINING RING 121545 121545 121545 121545

12 1 VALVE STEM 122655 122654 122651 122650

13 1 VALVE TOP GASKET 122136 122136 122136 122136

14 6 BOLT, HEX, 3/8-16 122405 122405 122405 122405

16 1 LOWER SHAFT 121979 121980 121980 121982

17 2 HEX NUT, 1/4-20 6-226 6-226 6-226 6-226

18 1 PACKING NUT 122664 122664 122664 122664

19 2 BOLT, HEX 3/8-16 x 5/8 LG 54014 54014 54014 54014

20 1 PACKING ASSY 121567 121567 121567 121567

21 1 VALVE TOP 16943 16943 16943 16943

22 NOT USED

23 1 LOCKWASHER 122666 122666 122666 122666

24 1 SEAT CAGE GASKET 123080 123081 123082 123083

ITEMS

25

THRU

30

31 1

32 1 TOP PISTON RETAINING NUT 121543 121543 121543 121543

33 1 LOWER PILOT SEAT ASSY 121505 121505 121505 121505

NOT SHOWN

BOTTOM PISTON RETAINING NUT

122982 122982 122982 122982

34 1 SEAT RETAINER N/A 121559 121506 121506

35 1 VALVE STEM RETAINING NUT 121503 121503 121503 121503

25

Page 26

17

16

18

14

20

21

23

31

22

24

6

3

5

2

4

1

13

12

11

10

9

8

7

Figure 3-2. Valve Assembly Sizes 2.50” to 4.00”

26

Page 27

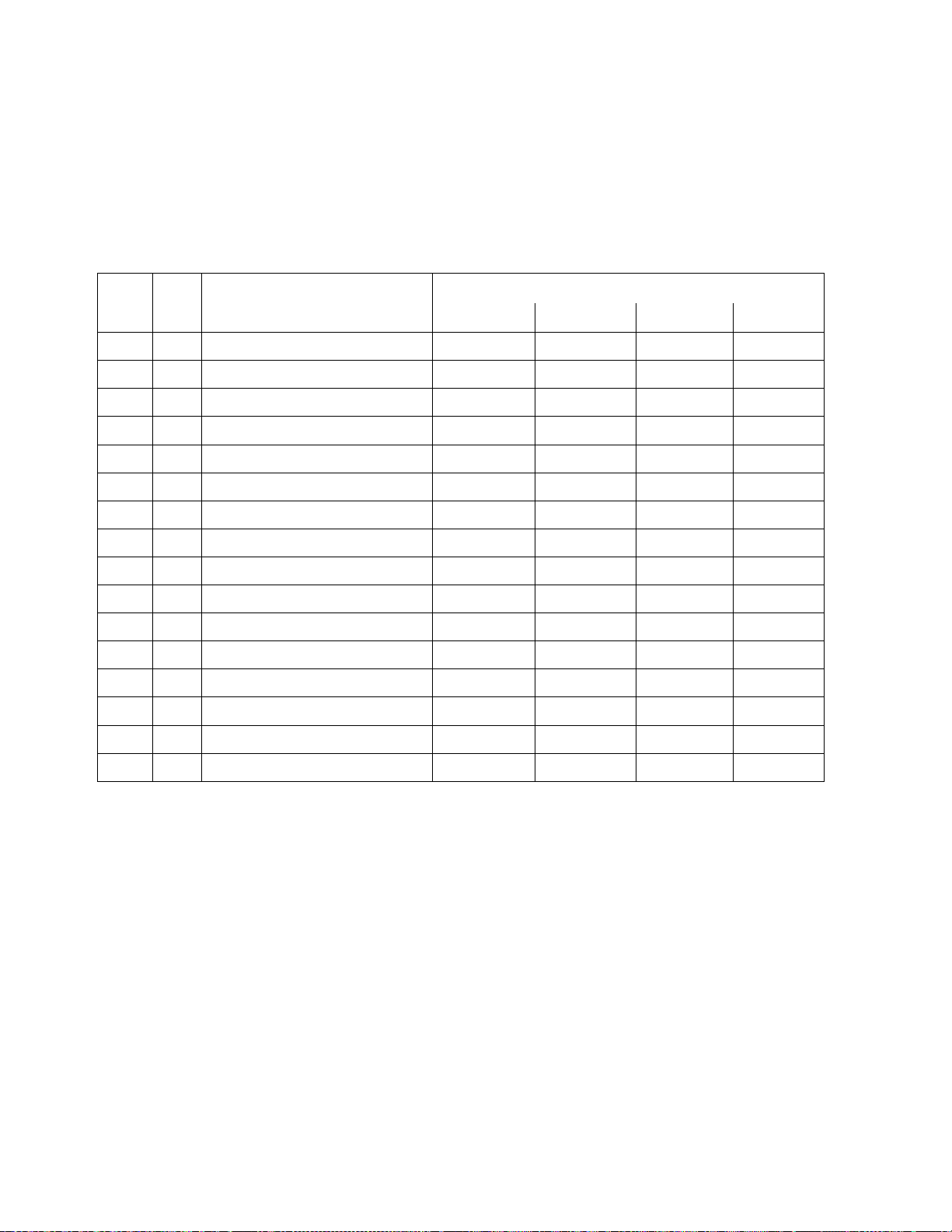

PARTS LIST TABLE FOR VALVE ASSEMBLY SIZES 2.50” TO 4.00”

VALVE SIZE AND PART NUMBERS

ITEM QTY PART NAME 2.50 INCH 3.00 INCH 4.00 INCH

1 1 VALVE BODY 20765-1 20766-1 20775

2 1 SEAT CAGE 16961 161004 161046

3 1 BOTTOM PISTON 16962 161007 161048

4 1 PISTON RETAINING RING 122173 122173 122234

5 1 VALVE PLUG SHAFT 16972 161006 161047

6 1 TOP PISTON 16970 161005 161050

7 1 VALVE SEAT 121935 122032 122178

8 1 VALVE SEAT RETAINING DISC 121934 122031 122177

9 4 10-32 x 3/4” LG. SOCKET HD. CAP 122174 122174 122238

10 1 PILOT SPRING 122081 122232 121823

11 1 PILOT SPRING RETAINER 122082 122082 122173

12 1 VALVE STEM 122648 122658 122659

13 1 VALVE TOP GASKET 122083 122204 122203

14 4 CAP SCREW 5/8-11 x 1-1/2” LG. N/A 6-310 6-310

15 2 3/8-16 NUT (4” VALVE ONLY) N/A N/A 6-264

16 1 LOWER SHAFT 122223 122230 122224

17 2 1/4-20 NUT 6-226 6-226 N/A

18 1 PACKING NUT 122664 122665 122665

19 2 3/8-16 x 5/8” LG. CAP SREWS 54014 54014 54014

20 1 PACKING ASSY 121567 121568 121568

21 1 VALVE TOP 18781 18823 18824

22 1 SEAT BACK-UP RING 122326 122327 122328

23 1 LOCKWASHER 122666 122667 122667

24 1 SEAT CAGE GASKET 123084 123085 123086

ITEMS

25

THRU

30

31 1 PILOT SPRING BACKUP WASHER N/A N/A 122246

NOT SHOWN

27

Page 28

3.1.2 Valve Reassembly Procedure

Reassembly is accomplished by basically reversing the previous Disassembly steps. Refer to Figure

3-1 or 3-2 for the applicable Valve size. Perform the following steps in the order specified and

REPLACE the items shown in BOLD type with the new parts provided in the Retrofit Kit.

1. For 1 inch to 2 inch Valve sizes, refer to Figure 3-1 and reassemble or replace the following

items in the order specified:

(a) Valve Plug Shaft (5)

(b) Seat Retainer (34)

(c) Replace Disc Seat (7)

(d) Retaining Disc (8)

(e) Lower Shaft (16) and Valve Stem (12)

(f) Valve Stem Retaining Nut (35)

(g) Pilot Spring (10)

(h) Retaining Ring (3)

(i) Lock Washer (23)

(j) Proceed to step 3 and continue the Valve Reassembly process. Steps 3 through 6 apply

to ALL valve sizes.

2. For 2 ½, 3 and 4 inch Valve sizes, refer to Figure 3-2 and reassemble or replace the following

items in the order specified:

(a) Top Piston (6) and Bottom Piston (3) Assemblies

(b) Replace Valve Seat (7)

(c) Lower Shaft (16) and Valve Stem (12)

(d) Valve Seat Retaining Disc (8)

(e) Socket Head Cap Screws (9)

(f) Pilot Spring (10)

(g) Pilot Spring Backup Washer (31), - 4 inch Valve Only

(h) Pilot Spring Retainer (11)

(i) Lock Washer (23)

(j) Proceed to step 3 and continue the Valve Reassembly process. Steps 3 through 6 apply

to ALL valve sizes.

3. Replace Valve Top Gasket (13) and reassemble Valve Top (21) on Valve Body (1).

4. Secure Valve Top (21) to Valve Body (1) with the Bolts or Cap Screws (14).

28

Page 29

5. Replace Packing Assembly (20) and reassemble Packing Nut (18) in Valve Top (21).

6. The last step of the Valve Reassembly procedure is to replace two Hex Nuts on the Valve

Shaft. Valve sizes from 1 to 3 inches contain two 1/4-20 Hex Nuts in the Retrofit Kit. However,

4 inch Valves contain two 3/8-16 Hex Nuts in the Kit. Replace the appropriate Hex nuts on the

Valve Shaft.

3.2 Valves Previously Equipped With Self-Contained Actuators

The internal parts and assemblies contained in Valves which were previously equipped with SelfContained Actuators must basically be rebuilt with the items provided in the Retrofit Kit. The Retrofit

Kit for Valve sizes from 1.00” to 2.00” include an Inner Pilot Assembly Kit (29021-[ ]) and a Valve

Piston Assembly Kit (12168-[ ]). The items in these kits are shown in Figures 3-3 and 3-4. Kits for

Valve sizes from 2.50” to 4.00” include a Main Valve Assembly Kit (27006-[ ]) containing the items

shown in the exploded view in Figure 3-5.

In addition to replacement the parts contained in these Kits, new items must be added to ALL Valve

Bodies which previously used Self-Contained Actuators. These items include:

• Lower Shaft

• Valve Top

• Valve Top Gasket

• Hex Bolts (1” to 2” Valves) or Cap Screws (2.5” to 4.0” Valves) to secure Valve Top

• Packing Assembly

• Packing Nut

• 1/4” NPT Plugs which get inserted into tapped holes in Valve Body

Refer to Figure 3-1 (1” to 2” Valves) or Figure 3-2 (2.5” to 4” Valves) for the locations of these items.

29

Page 30

5

4

3

2

1

1.00"-2.00" CXT-P (PNEUMATIC)

ITEM

REQ

1

2

3

4

5

VALVE STEM

1

1

VALVE STEM RETAINING NUT

LOWER PILOT PRE-LOAD SPRING

1

1

PRE-LOAD SPRING RETAINING RING

1 LOCKWASHER

DESCRIPTION

1.00"

122655

121503

121528

121545

122666 122666 122666 122666

1.25"

122654

121503

121528

121545

1.50" 2.00"

122651

121503

121528

121545

122650

121503

121528

121545

Figure 3-3. Inner Pilot Assembly Kit (29021-[ ]) for 1.00” to 2.00” Valves

30

Page 31

Figure 3-4. Valve Piston Assembly Kit (121618-[ ]) for 1.00” to 2.00” Valves

31

Page 32

Figure 3-5. Main Valve Assembly Kit (27006-[ ]) for 2.50” to 4.00” Valves

32

Page 33

4. INSTALLATION OF RETROFIT KIT ITEMS

When installing the new Electronic Control Valve Actuator and Electronic Control System (ECS)

Control Box, a number of ancillary items must also be installed or replaced. These include a new

Flow Meter, a replacement Water Solenoid Valve and several Temperature Sensors.

To install the Retrofit Kit items, proceed as follows:

4.1 Installation of Control Valve Actuator and Linkage Assembly

Identical Actuator Assemblies, part no. 69009 are used on all AERCO Control Valve sizes from 1 inch

to 4 inches. However, there are two types of Linkage Assemblies designated part no. 24038-1 and -2

used with different sizes of AERCO Control Valves. Linkage Assembly, part no. 24038-1 is used on

AERCO Valve sizes ranging from 1 inch to 3 inches. The 24038-2 Linkage Assembly is used only on

4 inch Valves. The primary difference between these two assemblies is the Linkage Assembly

Adapter shown in Figure 4-1. In addition, the linkage pin location for 24038-1 assemblies will vary for

1 to 2 inch Valves and for 2 ½ to 3 inch Valves as shown in the upper portion of Figure 4-1.

Figure 4-1. Linkage Assemblies Part No. 24038-1 & 24038-2

33

Page 34

The installation procedures for the Linkage Assembly and Actuator Assembly are provided in

paragraphs 4.1.1 and 4.1.2 which follow.

4.1.1 Linkage Assembly Installation

Remove the Linkage Assembly from the Retrofit Kit and install as follows:

1. Check to ensure that the correct Linkage Assembly and Adapter are provided for the valve

size being retrofitted (Figure 4-1). Also, ensure that the Linkage pin is inserted in the correct

location for this valve size.

CAUTION

It is imperative that the Gasket provided with the Linkage Assembly be

installed between the Valve Top and Linkage Assembly. Failure to do so

will void the equipment warranty.

2. Refer to Figure 4-2 and position the Gasket and Linkage Assembly on the Valve Top as

shown.

3. Secure the Linkage Assembly to the Valve Top using the two 3/8-16 Hex Head Bolts provided.

4. Install two 1/4-20 Hex Nuts (1 to 3 inch Valves), or two 3/8-16 Hex Nuts (4 inch Valve) on the

Valve Shaft (Figure 4-2).

5. Rotate the two Hex Nuts clockwise towards the lower end of the Valve Shaft.

6. Install the Indicator Plate on the Valve Shaft with the curved end facing upward as shown in

Figure 4-3.

7. Attach the Valve Shaft to the Linkage Adapter by rotating the Shaft counterclockwise (as

viewed from above). If the Valve Shaft cannot be turned by hand, use an open-end wrench to

turn the “double-nuts” on the Shaft until it engages the Linkage Adapter threads.

8. Press down on the Valve Shaft to compress the Pilot Spring in the Valve Body.

9. Raise the Indicator Plate so it is contacting the bottom of the Adapter and observe the position

on the Linkage Scale. Rotate the Valve Shaft as necessary until the raised Indicator Plate is

aligned with the “0” (zero) marking on the Linkage Scale.

10. When properly aligned, raise the Hex Nuts on the Valve Shaft by rotating them

counterclockwise. Position the Hex Nuts so they are snug against the Indicator Plate.

11. Proceed to paragraph 4.1.2 to install the Actuator Assembly.

34

Page 35

U-BOLT &

HEX NUTS

ACTUATOR

HORIZONTAL

SHAFT

8 mm HEX NUTS (2)

LINKAGE

ADAPTER

HEX HEAD

BOLTS (2)

(ON BOTTOM SIDE

OF BRACKET)

INDICATOR

PLATE

GASKET

VALVE SHAFT

HEX NUTS (2)

VALVE TOP

Figure 4-2. Actuator and Linkage Installation Details

35

Page 36

ITEM QTY PART DESCRIPTION PART NUMBER

1 1 LINKAGE ASSEMBLY 24038-1 (1” TO 3” VALVES)

2 1 SCALE

3 2 8-32 HEX NUT 123322

4 2 3/8-16 X 5/8 LONG CAP SCREW 54014

5 1 GASKET 81046

59028-1 (1” VALVE)

59028-1.25 (1.25” VALVE)

59028-1.5 (1.5” VALVE)

59028-2 (2” VALVE)

59028-2.5 (2.5” VALVE)

59028-3 ( 3” VALVE)

59028-4 (4” VALVE)

Figure 4-3. Linkage Installation Details

4.1.2 Actuator Installation

Remove the Actuator Assembly (69009) from the Retrofit Kit and install as follows:

1. Depress and hold the Clutch Button (Figure 4-4) and rotate the pointer to approximately 80° on

the dial. Release the Clutch Button when properly positioned.

CAUTION

DO NOT DEPRESS THE CLUTCH BUTTON WITH POWER APPLIED TO

THE ACTUATOR

2. Slide the Actuator onto the Linkage Assembly Shaft (Figures 4-2 & 4-4). Ensure that the pin on

the Linkage Assembly is inserted in the center slot on the bottom of the Actuator (Figure 4-4).

36

Page 37

3. Press down on the Linkage Adapter and verify that the Indicator Plate is aligned with the “0”

Scale marking.

4. With the Indicator Plate properly aligned, tighten the U-bolt hex nuts using an 8 mm wrench.

Torque the nuts to 60 in-lbs.

5. This completes the mechanical installation of the Actuator Assembly. The electrical

connections will be made during installation of the Control Box in paragraph 4.7.

9

0

Figure 4-4. Actuator Assembly, Part No. 69009

37

Page 38

4.2 Installation of ECS Components on Top Head Assembly

The ECS to be installed on the Top Head Assembly include:

• Outlet Flange & Gasket

• Outlet Temperature Dual Sensor

• Water Solenoid Valve and piping

• Plugs for previously installed: Shunt Tube, Thermal Element, Feedback Sensor, etc., etc.

4.2.1 Outlet Flange

New Outlet Flange (95015) and Gasket (122152) are provided in the Retrofit Kit. This new Flange

contains a tapped hole which permits easy installation of the new Outlet Temperature Dual Sensor

described in para. 4.2.2. To install the new Outlet Flange and Gasket:

1. Ensure that the Outlet opening in the Top Head (see Figure 2-1, sht. 3) has been thoroughly

cleaned of any gasket residue from the previously installed gasket.

2. Position the new Outlet Flange and Gasket on the four studs protruding from the Top Head on

the Heater.

3. Secure the Outlet Flange to the Top Head using the four hex nuts previously removed in para.

2.3, step 8. Tighten the hex nuts using an alternating pattern to obtain a uniform seal.

Reconnect the outlet piping to new Outlet Flange.

4.2.2 Outlet Temperature Dual Sensor

The Outlet Temperature Dual Sensor (61008-1) provided in the Retrofit Kit includes two Type J

Thermocouples which are housed in a thermowell. The Thermocouple leads are terminated with a 4pin connector.

1. Install the Outlet Temperature Dual Sensor in the tapped hole provided on the new Outlet

Flange installed in the previous paragraph.

2. Connection of the Dual Sensor electrical connector will be accomplished following installation

of the ECS Control Box (para. 4.4).

4.2.3 Water Solenoid

The 120 VAC Water Solenoid removed in Section 2 will be replaced with the 24 VDC Solenoid Valve

provided in the Retrofit Kit. Proceed as follows:

1. Attach the new Solenoid Valve (49029) to the nipple in the Top Head (ref. Figure 2-1, sht. 3)

2. Reconnect the previously installed drain piping to the Solenoid Valve outlet.

3. Electrical connection of the Solenoid Valve will be accomplished following installation of the

ECS Control Box.

38

Page 39

4.2.4 NPT Plugs

Each Retrofit Kit contains four NPT Plugs in the following sizes:

• 1/4 inch

• 1/2 inch

• 3/4 inch

• 1 inch

These plugs are installed in the remaining tapped holes in the Top Head where components used with

the previous Control System were installed. The location and size of the required Plugs may vary

depending on the specific AERCO Heater Model being retrofitted. Refer to Figure 2-1 for reference.

Ensure that all tapped holes in the Top Head have been plugged before proceeding with the

installation.

4.3 Flow Meter Installation

As part of the Electronic Control System (ECS) Retrofit, a new Flow Meter must be added to the

Packaged Heater. The purpose of this meter is to provide a feed-forward signal to the Temperature

Controller contained in the ECS Control Box. The installation location will vary depending on whether

the AERCO Water Heater Model being retrofitted is a Helitherm Heat Exchanger (A-Plus, B-Plus, BPlus II and E-Plus), or a Double-Wall Heat Exchanger (DW-24, DW-45, DW-68). For Helitherm Model

Heaters, the Flow Meter is installed between the Cold Water Inlet and the Drain Outlet on the Bottom

Head of the Heater (Figures 4-5 and 4-6). However, for Double Wall Heater Models, the Flow Meter is

installed between the Cold Water Inlet and Drain Outlet on the Heater Shell. See Figure 4-7. All

required installation components are included in the Retrofit Kit. Proceed to paragraph 4.3.1

(Helitherm) or 4.3.2 (Double-Wall), as applicable.

IMPORTANT

Prior to installing the inlet or outlet tubes to the Flow Meter (step 2 of

paragraphs 4.3.1 and 4.3.2), it will be necessary to first temporarily remove

the strain relief assembly shown in Figure 4-8. After removal, perform the

following steps:

1. First, hand-tighten the inlet and outlet tube compression fittings to the Flow

Meter. Position the “flats” on the fitting to avoid interfering with

reinstallation of the strain relief in the next step.

2. Next, attach the strain relief to the Flow Meter cable (Figure 4-8).

3. After the strain relief is installed, fully tighten the inlet and outlet tube

compression fittings to the Flowmeter.

39

Page 40

Figure 4-5. Typical (B+) Helitherm Heater Flow Meter Location – Front View

COLD WATER

INLET

COMPRESSION FITTING

(1/4" NPT x 1/2" TUBE)

TO ECS

CONTROL

BOX

INLET TUBE

COMPRESSION FITTINGS

(1/2" NPT x 1/2" TUBE)

FLOW METER

COMPRESSION FITTINGS

(1/2" NPT x 1/2" TUBE)

FLEXIBLE OUTLET TUBE

COMPRESSION FITTING

(1/4" NPT x 1/2" TUBE)

DRAIN WITH

MODIFIED

NIPPLE

FRONT

REAR

Figure 4-6. Typical (B+) Helitherm Heater Flow Meter Location – Bottom View

40

Page 41

Figure 4-7. Double-Wall Heater Flow Meter Location

4.3.1 Flow Meter Installation For Helitherm Heaters

For A-Plus, B-Plus, B-Plus II and E-Plus Heaters, the Flow Meter connections are made at the Bottom

Head of the Heater. The Flow Meter Inlet side connects to the Cold Water Inlet using Rigid Tubing.

However, the Outlet side of the Flow Meter connects to the Drain Outlet using Flexible Tubing. A

typical B-Plus or B-Plus II installation is shown in Figures 4-5 and 4-6. Refer to these Figures when

performing the following steps:

1. Obtain the Flow Meter, Rigid Inlet Tube, Flexible Outlet Tube and Compression Fittings from

the Retrofit Kit. Refer to Appendix A for the applicable part numbers for the tubing and fittings

required for the unit being retrofitted.

2. Attach the Rigid Inlet Tube and Flexible Outlet Tube to the Flow Meter using the fittings

provided in the kit.

3. Next, obtain the Modified 2” NPT Nipple (9006) from the Retrofit Kit.

4. Remove the existing 2’ NPT Nipple from the Drain Outlet on the Bottom Head.

5. Install the new Modified 2” NPT Nipple in the Bottom Head. Attach the ¼ NPT coupling to the

tapped hole in the Modified Nipple.

41

Page 42

6. Connect the Flow Meter Outlet Flexible Hose to the Modified Nipple on the Drain Outlet using

the compression fitting. Connect the Rigid Flow Meter Inlet Tube to the Cold Water Inlet using

the compression fitting provided in the kit.

7. Position the Flow Meter so that the Paddle Wheel is in the “Vertical” plane as shown in Figure

4-8. Tighten all Flow Meter connection fittings.

Figure 4-8. Flow Meter Orientation

4.3.2 Flow Meter Installation For Double-Wall Heaters

Flow Meter connections for Double-Wall Heater Models DW-24, DW-45 and DW-68 are made on the

Shell as shown in Figure 4-7. As with Helitherm Models, Rigid Tubing is used for the Flow Meter Inlet

connection to the Cold Water Inlet and Flexible Tubing is used for the Outlet connection at the Drain.

Flow Meter installation is accomplished as follows:

1. Obtain the Flow Meter, Rigid Inlet Tube, Flexible Outlet Tube and Compression Fittings from

the Retrofit Kit.

2. Attach the Rigid Inlet Tube and Flexible Outlet Tube to the Flow Meter using the fittings

provided in the kit.

3. Next, obtain the 3/4” Close Nipple (9-234) and 3/4 x 1/4 x 3/4” Tee (59032) from the Retrofit

Kit.

4. If installed, remove the 3/4” NPT Plug from the Drain Port on the Heater Shell (Ref. Figure 2-2,

sht 1).

5. Install the Close Nipple and Tee in the Drain Port (Figure 4-7)

6. Connect the Flow Meter Outlet Flexible Tubing to the Drain Outlet Tee as shown in Figure 4-7.

Connect the Rigid Inlet Tube from the Flow Meter to the Cold Water Inlet using the

compression fitting provided.

7. Position the Flow Meter so that the Paddle Wheel is in the “Vertical” plane as shown in Figure

4-8.

42

Page 43

NOTE

Paragraph 4.4 applies ONLY to Water-to-Water Heater Models which include

E-Plus and Water-to-Water Double-Wall Models. Disregard the procedures in

paragraph 4.4 for ALL Steam-to-Water Heater Models and proceed directly to

paragraph 4.5.

4.4 Boiler Water Inlet and Outlet Temperature Sensors – (Water-to-Water Heaters)

If the Water Heater being retrofitted is an E-Plus or a Water-to-Water Double-Wall, two additional

Temperature Sensors (Type J Thermocouples) must be added. These are the Boiler Water Inlet

Temperature Sensor and Boiler Water Outlet Temperature Sensor. For E-Plus (Helitherm) Heaters,

the Inlet and Outlet Sensors are mounted in the Bottom Head and Top Head, respectively as shown in

Figure 4-9. For Water-to-Water Double-Wall Heaters, the Boiler Water Inlet and Outlet Temperature

Sensors are mounted at the locations shown in Figure 4-10.

These two additional Temperature Sensors are identical (part no. 61009-1) and therefore can be

installed in either location.

4.4.1 E-Plus Water Heaters

Refer to Figure 4-9 and install the Boiler Water Inlet and Outlet Sensors as follows:

1. Check to ensure that the capillary tubes and compression fittings have been removed from the

Boiler Inlet and Outlet Valve Spool Piece Assemblies shown in Figure 4-9. If they have not

been previously remove, disconnect and remove these items at this time.

2. Install the Boiler Water Inlet Temperature Sensor in the tapped opening in the Valve Spool

Piece Assembly which connects to the Boiler Water Inlet on the Bottom Head Heater.

3. Install the Boiler Water Outlet Temperature Sensor in the tapped opening in the Valve Spool

Piece Assembly which connects to the Boiler Water Outlet on the Top Head of the Heater.

4. The electrical connector plugs on the Inlet and Outlet Boiler Water Temperature Sensors will

be connected after the ECS Control Box is installed (paragraph 4.5).

43

Page 44

R

BOILER WATE

OUTLET SENSOR

LOCATION

BOILER WATER

VALVE SPOOL

PIECE ASSEMBLY

BOILER WATER

INLET SENSOR

LOCATION

OUTLET

CXT-E

CONTROL

VALVE

BOILER WATER

INLET

VALVE SPOOL

PIECE ASSEMBLY

Figure 4-9. E-Plus Boiler Water Inlet and Outlet Temperature Sensor Locations

4.4.2 Double-Wall Water Heaters

The sensor installation locations for a Water-to-Water Model DW-24 differ slightly from the locations

used for DW-45 and DW-68 Models as shown in Figure 4-10. DW-45 and DW-68 Sensors are

mounted on the Boiler Water Inlet and Outlet Flanges. However, since these flanges do not exist for

the DW-24, the Sensors are mounted on the bottom of the Boiler Water Inlet and Outlet as shown in

Figure 4-10. Install the Boiler Water Inlet and Outlet Sensors as follows for the Model being retrofitted:

1. Check to ensure that the capillary tubes and compression fittings have been removed from the

Boiler Inlet and Outlet Flanges shown in Figure 4-10. If they have not been previously remove,

disconnect and remove these items at this time.

2. For DW-45 and DW-68 Models, install the Boiler Water Inlet Temperature Sensor in the

tapped opening in the Boiler Water Inlet Flange shown in Figure 4-10. For a DW-24 Model,

install the Sensor in the tapped hole at the bottom of the Boiler Water Inlet as shown.

3. For DW-45 and DW-68 Models, install the Boiler Water Outlet Temperature Sensor in the

tapped opening in the Boiler Water Outlet Flange shown in Figure 4-10. . For a DW-24 Model,

install the Sensor in the tapped hole at the bottom of the Boiler Water Inlet as shown.

4. The electrical connector plugs on the Inlet and Outlet Boiler Water Temperature Sensors will

be connected after the ECS Control Box is installed (paragraph 4.5).

44

Page 45

LEAK DETECTION PORT

DO NOT

PLUG OR OBSTRUCT !

THIS IS A VENTED U - TUBE HEAT

BOILER

WATER

OUT

EXCHANGER CONSTRUCTED WITH

DOUBLE WALL TUBE.

AN INNER OR OUTER TUBE

FAILURE IS INDICATED BY

BOILER

WATER

IN

BOILER WATER

OUTLET SENSOR

BOILER

WATER

OUT

BOILER WATER

OUTLET SENSOR

DW-24

LEAK DETECTION PORT

DO NOT

PLUG OR OBSTRUCT !

THIS IS A VENTED U -TUBE HEAT

EXCHANGER CO NST RUCTE D WIT H

DOUBLE WALL TUBE.

AN INNER OR OUTER TUBE

FAILURE IS IN DICA TED BY

FLOW FROM THIS PORT.

BOILER WATER

INPUT SENSOR

BOILER

WATER

BOILER WATER

INPUT SENSOR

IN

DW-45, DW-68

Figure 4-10. Boiler Water Inlet and Outlet Temperature Sensor Locations for

Water–to–Water Double-Wall Heaters

45

Page 46

NOTE

Paragraph 4.5 applies ONLY to Steam-to-Water Heater Models which include

A-Plus, B-Plus, B-Plus II Helitherm Models and Steam-to-Water Double-Wall

Models. Disregard the procedures in paragraph 4.5 for ALL Water-to-Water

Heater Models and proceed directly to paragraph 4.6.

4.5 Compound Pressure Gauge

If the Water Heater being retrofitted is Steam-to-Water Model, a Compound Pressure Gauge is

included in the Retrofit Kit. The Compound Pressure Gauge range will be sized to match the

requirements of the Heater being retrofitted. In addition to the Gauge, all required fittings necessary

for installation will be included in the kit.

For Steam-to-Water Helitherm Models, the Compound Pressure Gauge will be mounted downstream

of the CXT-E Control Valve as shown in Figure 4-11. For Steam-to-Water Double-Wall Models, the

Gauge will be mounted on the steam inlet flange as shown in Figure 4-12.

COMPOUND PRESSURE GAUGE

(SHOWN ROTATED FOR CLARITY)

1/4" COUPLING

PIG TAIL

SHELL

CXT-E

ACTUATOR

LINKAGE

ASSY

CONTROL

VALVE

STEAM IN

SIDE VIEW

Figure 4-11. Compound Pressure Gauge Installation – Helitherm S/W Unit

46

Page 47

Figure 4-12. Compound Pressure Gauge Installation – Double-Wall S/W Unit

47

Page 48

4.5.1 Helitherm Steam-to-Water Units

For Helitherm Steam-to-Water units, refer to Figure 4-11 which shows a typical B-Plus Heater.

Proceed as follows:

1. Remove the Compound Pressure Gauge (8356-[ ]), Pig Tail (8-20) and 1/4” Coupling (9-3)

from the Retrofit Kit.

2. Install the Pig Tail in the tapped hole downstream of the CXT-E Control Valve.

3. Attach the 1/4” NPT Coupling and Pressure Gauge to the Pig Tail as shown in Figure 4-11.

Tighten all connections.

4.5.2 Double Wall Steam-to-Water Units

For Double-Wall Steam-to-Water units, refer to Figure 4-12. This Figure shows typical Compound

Pressure Gauge installation locations for DW-24 and DW-68 units.

1. Remove the Compound Pressure Gauge (8356-[ ]), Pig Tail (8-20), 1/4” NPT x 4” long Nipple

(91024) and two 1/4” NPT Couplings (9-3) from the Retrofit Kit.

2. For a DW-24 unit, install the 4” long NPT Nipple to the existing elbow on the Steam Inlet. For

DW-68 or DW-45 units, install the 4” long NPT Nipple to the Steam Inlet Flange.

3. Next install one of the 1/4” Couplings to the end of the 4” long Nipple.

4. Attach the Pig Tail, 1/4” Coupling and Compound Pressure Gauge as shown in Figure 4-12.

Tighten all connections

48

Page 49

4.6 Installation of New Orifice Disc

The Retrofit Kit contains a new Orifice Disc (part no. 49032-[ ]) sized for the applicable follow range

used by the Heater being retrofitted. The Orifice Disc is located in the Cold Water Inlet on the Water

Heater. For Helitherm Heater Models, the Cold Water Inlet is on the Bottom Head of the Heater as

shown in Figure 4-13. However, for Double-Wall Models, the Cold Water Inlet is located on the Shell

of the Heater as shown in Figure 4-14.

Refer to the applicable Figure for the unit being modified and install the new Orifice Disc and Spring

Ring as follows:

1. Obtain the Orifice Disc and Spring Ring from the Retrofit Kit.

2. Insert the Orifice Disc fully into the Cold Water Inlet until it contacts the stops. Ensure that the

Orifice is seated evenly in the Inlet.

3. Using a pair of needle-nose pliers, compress the ends of the Spring Ring and insert it fully into

place.

4. This completes the installation of the new Orifice Disc.

Figure 4-13. Cold Water Inlet Orifice Location – Typical Helitherm Heater

49

Page 50

FLOW

METER

SHELL

COLD WATER INLET

(SEE VIEW “A - A”)

A

INSULATION

A

DW-45, DW-68

ORIFICE

DISC

SPRING

RING

INLET

PIPE

VIEW “A - A”

Figure 4-14. Cold Water Inlet Orifice Location – Double-Wall Heater

50

Page 51

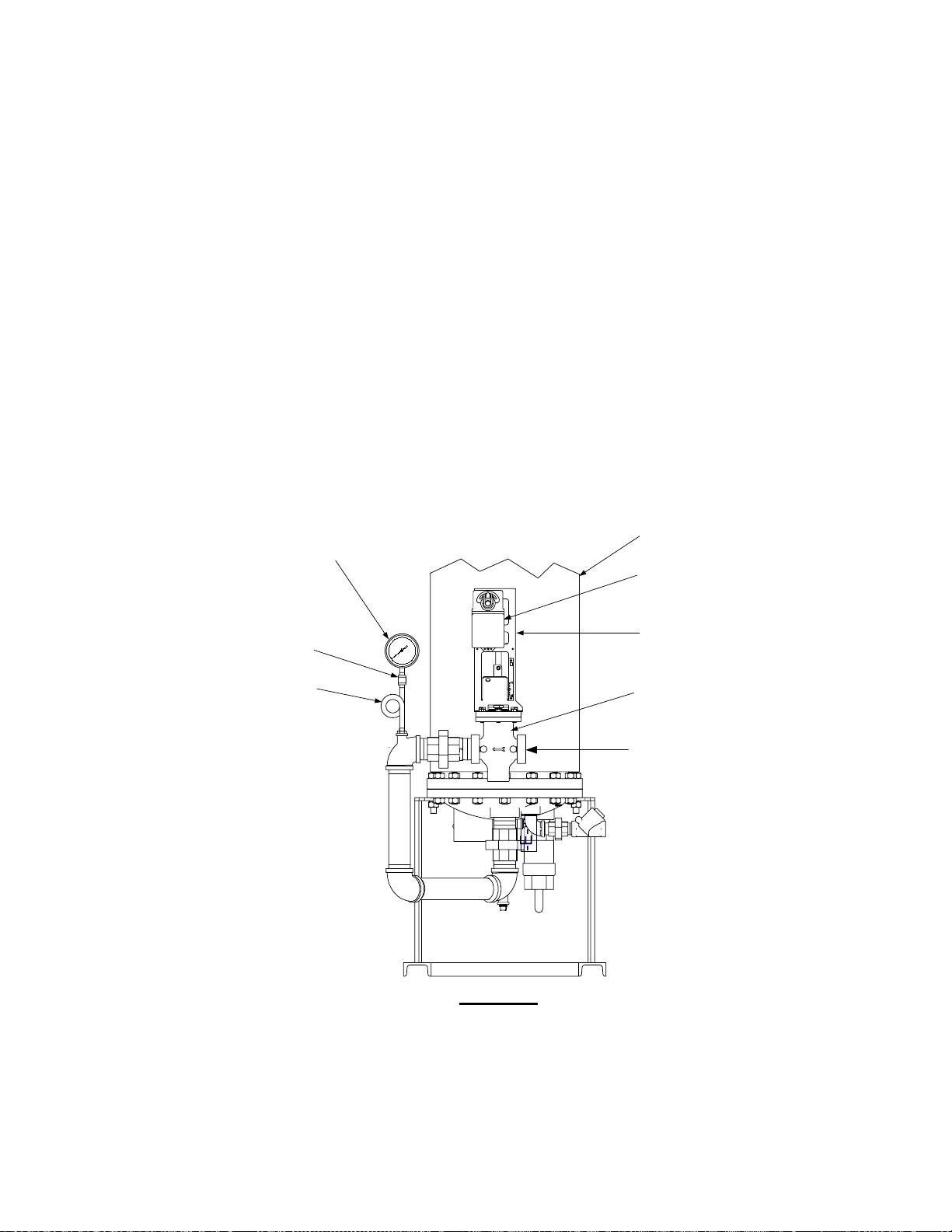

4.7 ECS Control Box Installation

The ECS Control Box is attached to the Water Heater using the old Control Box Mounting Bracket

removed in Section 2. Install the new ECS Control Box in accordance with the following steps:

1. Attach the ECS Control Box to the Mounting Bracket using the two 1/4-20 x 1/2 “ screws and

washers provided in the Retrofit Kit.

2. Insert the top end of the Mounting Bracket under the previously loosened hex nut at the top of

the Heater Shell (Figure 4-15). After the Bracket is vertically aligned, tighten the hex nut to

secure the Mounting Bracket and ECS Control Box to the Water Heater.

HEX NUTS

& STUD

MOUNTING

BRACKET

ECS CONTROL

BOX

SHELL

TEMP CONTROLLER

B+II

OVER TEMP SWITCH

SOLENOID

VALVE

TOP HEAD

SHELL FLANGE

MOUNTING

BRACKET

SCREWS

Figure 4-15. ECS Control Box Mounting Location

NOTE

External power at 120 to 240 VAC, 50/60 Hz is required to operate the

circuitry contained in the ECS Control Box. Power connections are made

internally by routing the power wiring through the cutout provided on the right

side of the Control Box.

3. Next, loosen the captive Phillips head screw on the right front portion of the Control Box

(Figure 4-16) to open the hinged door.

4. Swing open the door and loosen the captive Phillips head screw at the top of the recessed

panel (Figure 4-17). Swing down the panel to access terminal block TB-2 (Figure 4-18)

5. Feed the external 120 to 240 VAC, 60 Hz) power leads through the cutout in the right side of

the ECS Control Box.

51

Page 52

6. Connect the Line, Neutral and Ground leads to the TB-2 terminals shown in Figure 4-18.

7. Close the swing-down panel after the power leads are secured to TB-2. Tighten the captive

screw to secure the recessed panel.

8. Close the front door of the ECS Control Box and tighten the captive screw to secure it in the

closed position.

9. Check the labels on the Control Box cables and connect them to the following components:

NOTE

The BOILER WATER IN and BOILER WATER OUT cables shown with an

asterisk (*) are used on Water-to-Water Heaters ONLY (E-Plus or Double-Wall

Models).

Label

Connect To:

VALVE ACTUATOR 3-Pin Molex Connector on Actuator

FLOWMETER 5-Pin Connector on Flow Meter

OUTLET TEMP 4-Pin Connector on Dual Sensor (Outlet Port)

*BOILER WATER IN 2-Pin Connector at Heating Fluid Inlet

*BOILER WATER OUT 2 Pin Connector at Heating Fluid Outlet

Figure 4-16. ECS Control Panel Front View

52

Page 53

CAPTIVE SCREW

(LOOSEN TO OPEN)

PT.NO.

2408

OP 1

OP 2

F

SET

SP2

REM

AUTO

RUN

MAN HOLD

TEMP CONTROLLER

B-PLUS

OVER TEMP SWITCH

TM

WATER HEATER

PT.NO.

Figure 4-17. Recessed Panel Behind Control Box Door

LINE

NEUTRAL

GROUND

102

101

100

GND

Figure 4-18. ECS Control Box AC Power Connections

53

Page 54

5. POST INSTALLATION CONNECTIONS AND ADJUSTMENTS

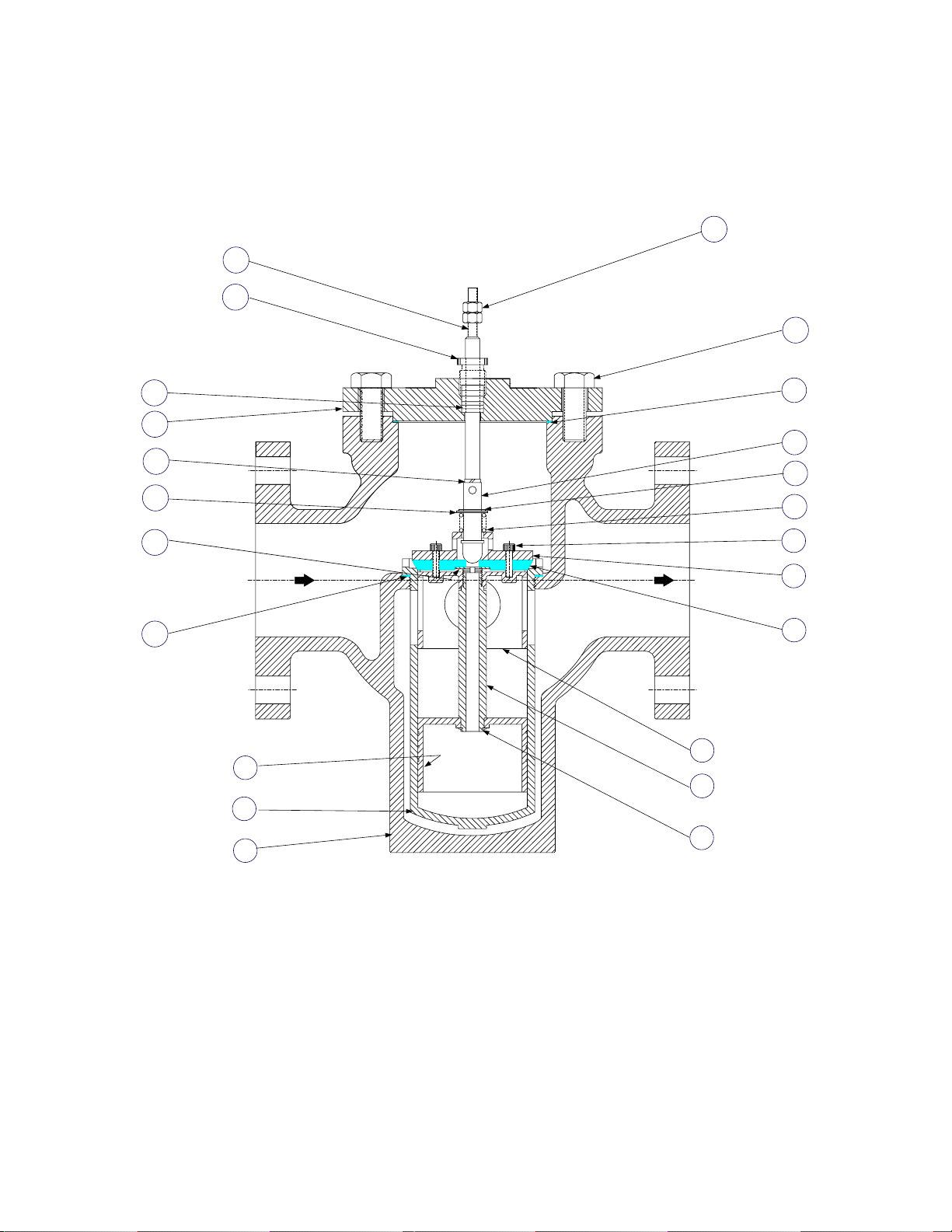

Figures 5-1 and 5-2 show a typical B-Plus Helitherm Water Heater and a DW-68 Double Wall S/W

Heater with all ECS and CXT-E Retrofit items installed. Upon completion of all retrofit procedures in

Section 4, the ECS Retrofit heater must be thoroughly checked to ensure that all required external

connections have been made to the modified Heater. In addition, CXT-E Actuator and ECS Control

system adjustments must be made prior to placing the Heater back into service.

5.1 Input and Output Water Heater Connections

The following items must be checked to ensure the proper connections have been made:

1. Drain Connection

Ensure that the Drain Ball Valve has been replaced and that all external drain piping is

reconnected.

2. Cold Water Inlet

Ensure that the Cold Water Inlet Flange is connected to the cold water inlet piping.

3. Steam or Boiler Water Line

Ensure that the Steam or Boiler Water supply line is connected to the inlet of the CXT-E

Control Valve.

4. Condensate Line

Ensure it is connected to a nearby drain or condensate collection system.

5. Electrical Power

Ensure that AC power (120 to 240 volts) is connected to the ECS Control Box

5.2 Adjustments

Prior to placing the unit into operation, the CXT-E Actuator, ECS Temperature Controller and ECS

Over-Temperature Switch must be set. The adjustment procedures for these items are provided in

Section 3 of Operation and Maintenance Manual AC-105. A copy of this manual is included in the

Retrofit Kit.

54

Page 55

MOUNTING

BRACKET

HEAT

EXCHANGER

ECS CONTROL

BOX

TEMP CONTROL LER

B+II

OVER TEMP SWITCH

CXT-E

ACTUATOR

LINKAGE

ASSY

FLOW

METER

CONTROL

VALVE

FRONT VIEW

Figure 5-1. B-Plus Package Water Heater With ECS Control System & CXT-E Control Valve

(Sheet 1 of 2)

55

Page 56

-E-

Figure 5-1. B-Plus Package Water Heater With ECS Control System & CXT-E Control Valve

(Sheet 2 of 2)

56

Page 57

Figure 5-2. DW-68 Double Wall Water Heater With ECS Control System & CXT-E Control Valve

(Sheet 1 of 2)

57

Page 58

HOT WATER

OUTLET

P & T RELIEF

VALVE

MOUNTING

BRACKET

ECS CONTROL

BOX

FLOW

METER

COLD

WATER

INLET

DRAIN

SIDE VIEW

58

Page 59

HOT WATER

OUTLET

P & T RELIEF

VALVE

MOUNTING

BRACKET

ECS CONTROL

BOX

FLOW

METER

DRAIN

COLD

WATER

INLET

SIDE VIEW

Figure 5-2. DW-68 Double Wall Water Heater With ECS Control System & CXT-E Control Valve

(Sheet 2 of 2)

59

Page 60

THIS PAGE INTENTIONALLY BLANK

60

Page 61

APPENDIX A

ECS RETROFIT KIT CONTENTS

FOR

PART NO. 27004-[ ]

61

Page 62

The basic ECS Retrofit Kit Contents for each type of AERCO Indirect Fired Water Heater are listed in

Tables A-1 through A-14 which follow

TABLE A-1. RETROFIT KIT PART NO. 27004-1 FOR SW1-A PLUS WATER HEATERS

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 1 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-1

11 1 LABEL ELECTRIC BOX 72010-2

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

PART

NUMBER

93029

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91018

18 1 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD 90003

19 1 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 1 COUPLING, 1/4” PRESSURE GAUGE 9-3

21 1 PIG TAIL PRESSURE GAUGE 8-20

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE N/A

23 1 CLOSE NIPPLE, 3/4” SHELL N/A

24 1 TEE, 3/4” x 1/4” 3/4” SHELL N/A

25 1 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

N/A

9-43

62

Page 63

TABLE A-2. RETROFIT KIT PART NO. 27004-2 FOR SW1-B PLUS WATER HEATER

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 1 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-1

11 1 LABEL ELECTRIC BOX 72010-3

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

PART

NUMBER

93029

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91018

18 1 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD 90003

19 1 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 1 COUPLING, 1/4” PRESSURE GAUGE 9-3

21 1 PIG TAIL PRESSURE GAUGE 8-20

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE N/A

23 1 CLOSE NIPPLE, 3/4” SHELL N/A

24 1 TEE, 3/4” x 1/4” 3/4” SHELL N/A

25 1 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

N/A

9-43

63

Page 64

TABLE A-3. RETROFIT KIT PART NO. 27004-3 FOR SW1-B PLUS II WATER HEATER

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 1 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-1

11 1 LABEL ELECTRIC BOX 72010-4

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

PART

NUMBER

93029

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91018

18 1 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD 90003

19 1 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 1 COUPLING, 1/4” PRESSURE GAUGE 9-3

21 1 PIG TAIL PRESSURE GAUGE 8-20

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE N/A

23 1 CLOSE NIPPLE, 3/4” SHELL N/A

24 1 TEE, 3/4” x 1/4” 3/4” SHELL N/A

25 1 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

N/A

9-43

64

Page 65

TABLE A-4. RETROFIT KIT PART NO. 27004-5 FOR SW1-E PLUS

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 3 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-1

11 1 LABEL ELECTRIC BOX 72010-5

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

WATER HEATER

PART

NUMBER

93029

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91020

18 1 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD 90003

19 1 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 1 COUPLING, 1/4” PRESSURE GAUGE N/A

21 1 PIG TAIL PRESSURE GAUGE N/A

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE N/A

23 1 CLOSE NIPPLE, 3/4” SHELL N/A

24 1 TEE, 3/4” x 1/4” 3/4” SHELL N/A

25 1 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

61009-1

9-43

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

65

Page 66

TABLE A-5. RETROFIT KIT PART NO. 27004-6 FOR 8” SW DOUBLE WALL

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 3 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-1

11 1 LABEL ELECTRIC BOX 72010-6

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

WATER HEATER

N/A

PART

NUMBER

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91026

18 1 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD N/A

19 1 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 2 COUPLING, 1/4” PRESSURE GAUGE 9-3

21 1 PIG TAIL PRESSURE GAUGE 8-20

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE 91024

23 1 CLOSE NIPPLE, 3/4” SHELL 9-234

24 1 TEE, 3/4” x 1/4” 3/4” SHELL 59032

25 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

N/A

9-43

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

66

Page 67

TABLE A-6. RETROFIT KIT PART NO. 27004-7 FOR 8” WW DOUBLE WALL

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 2 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-2

11 1 LABEL ELECTRIC BOX 72010-6

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

WATER HEATER

PART

NUMBER

93029

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91026

18 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD N/A

19 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 COUPLING, 1/4” PRESSURE GAUGE N/A

21 PIG TAIL PRESSURE GAUGE N/A

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE N/A

23 1 CLOSE NIPPLE, 3/4” SHELL 9-234

24 1 TEE, 3/4” x 1/4” 3/4” SHELL 59032

25 2 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

61009-1

9-43

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

67

Page 68

TABLE A-7. RETROFIT KIT PART NO. 27004-8 FOR 10” SW DOUBLE WALL

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 3 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-1

11 1 LABEL ELECTRIC BOX 72010-6

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

WATER HEATER

PART

NUMBER

N/A

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91023

18 1 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD N/A

19 1 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 2 COUPLING, 1/4” PRESSURE GAUGE 9-3

21 1 PIG TAIL PRESSURE GAUGE 8-20

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE 91024

23 1 CLOSE NIPPLE, 3/4” SHELL 9-234

24 1 TEE, 3/4” x 1/4” 3/4” SHELL 59032

25 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

N/A

9-43

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

68

Page 69

TABLE A-8. RETROFIT KIT PART NO. 27004-9 FOR 10” WW DOUBLE WALL

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 2 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-2

11 1 LABEL ELECTRIC BOX 72010-6

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

WATER HEATER

PART

NUMBER

93029

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91023

18 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD N/A

19 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 COUPLING, 1/4” PRESSURE GAUGE N/A

21 PIG TAIL PRESSURE GAUGE N/A

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE N/A

23 1 CLOSE NIPPLE, 3/4” SHELL 9-234

24 1 TEE, 3/4” x 1/4” 3/4” SHELL 59032

25 2 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

61009-1

9-43

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

69

Page 70

TABLE A-9. RETROFIT KIT PART NO. 27004-10 FOR 12” SW DOUBLE WALL

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 3 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-1

11 1 LABEL ELECTRIC BOX 72010-6

12 1 SOLENOID VALVE TOP HEAD 49029

13 1 FLOW METER BYPASS 64006

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

WATER HEATER

PART

NUMBER

N/A

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91028

18 1 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD N/A

19 1 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 2 COUPLING, 1/4” PRESSURE GAUGE 9-3

21 1 PIG TAIL PRESSURE GAUGE 8-20

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE 91024

23 1 CLOSE NIPPLE, 3/4” SHELL 9-234

24 1 TEE, 3/4” x 1/4” 3/4” SHELL 59032

25 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

N/A

N/A

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

70

Page 71

TABLE A-10. RETROFIT KIT PART NO. 27004-11 FOR 12” WW DOUBLE WALL

HEATER

ITEM

1 1 OUTLET FLANGE TOP HEAD 95015

2 1 PLUG. 1” TOP HEAD 9-75

3 1 PLUG. 3/4” TOP HEAD 9-73

4 1 PLUG 1/2” TOP HEAD 9-368

5 1 PLUG. 1/4” TOP HEAD 9-40

6 1 J THERMOCOUPLE, DUAL TOP HEAD 61008-1

7 2 COMP. FITTING, 1/4 NPT x 3/16” TUBE TOP HEAD/

8 1 OUTLET GASKET TOP HEAD 16949

9 1 GASKET TOP HEAD 122152

10 1 CONTROL BOX ELECTRIC BOX 69012-2

11 1 LABEL ELECTRIC BOX 72010-6

12 1 SOLENOID VALVE TOP HEAD 49029

QTY

PART DESCRIPTION

LOCATION

ON UNIT

VALVE LINE/

BOTTOM MANIFOLD

PART

NUMBER

93029

WATER

13 1 FLOW METER BYPASS 64006

14 1 FLEXIBLE HOSE, SS BRAID BYPASS 97009

15 1 COMP. FITTING, 1/2 NPT x 1/2” TUBE BYPASS 93028

16 1 COMP. FITTING, 1/4 NPT x 1/2” TUBE BYPASS 93027

17 1 INLET TUBE, FLOW METER BYPASS 91028

18 NIPPLE, MODIFIED, 1-1/4” BOTTOM HEAD N/A

19 NIPPLE, MODIFIED 2 NPT SCH. 80 BOTTOM HEAD N/A

20 COUPLING, 1/4” PRESSURE GAUGE N/A

21 PIG TAIL PRESSURE GAUGE N/A

22 1 NIPPLE, 1/4 NPT x 4” LG PRESSURE GAUGE N/A

23 1 CLOSE NIPPLE, 3/4” SHELL 9-234

24 1 TEE, 3/4” x 1/4” 3/4” SHELL 59032

25 2 J THERMOCOUPLE, SINGLE VALVE LINE/ BOTTOM

MANIFOLD

26 1 BUSHING, 1/2” x 1/4” VALVE LINE/ BOTTOM

MANIFOLD

27 1 WIRING DIAGRAM ECS 69008

61009-1

9-43

28 2 BOLT, 1/4-20 x 1/2” CONTROL BOX MTG. 6-138

29 4 FLAT WASHER, 1/4” CONTROL BOX MTG. 124664

71

Page 72

THIS PAGE INTENTIONALLY BLANK

72

Page 73

APPENDIX B

ECS RETROFIT KIT OPTIONAL ITEMS

73

Page 74

INTRODUCTION

The information included in this Appendix lists optional items which may vary, depending on:

• Type of Water Heater being retrofitted

• Required Water Heater flow rate

• Type of Control Valve Actuator previously installed

• Control Valve size

Table B-1 and the Tables/Appendices referenced therein, list the applicable items included in the