Page 1

HE-111

Double-Wall Heat Exchanger – Model DW

USER MANUAL

OMM-0065_0B

Applicable to Serial Numbers H-09-430 and above

Installation, Operation

& Maintenance Instructions

Double-Wall

Heat Exchanger

Model DW

Printed in U.S.A. Rev B Mar 2013

Page 2

2

HE-111

Double-Wall Heat Exchanger – Model DW

USER MANUAL

Telephone Support

Direct to AERCO Technical Support

(8 to 5 pm EST, Monday through Friday)

(800) 526-0288

AERCO International, Inc.

100 Oritani Dr.

Blauvelt, NY 10913

© AERCO International, Inc., 2009

OMM-0065_0A

The information contained in this

operation and mainten anc e manual is

subject to change without noti ce fro m

AERCO International, Inc.

AERCO makes no warranty of any kind

with respect to this material, including

but not limited to implied warranties of

merchantabilit y and fitnes s f or a

particular applicati o n. AER C O

International is liable for neither errors

appearing in this manual, nor for

incidental or consequential damages

occurring in connection with the

furnishing, performance, or use of this

material.

Page 3

HE-111 − CONTENTS

iii

TABLE OF CONTENTS

CHAPTER 1 GENERAL INFORMATION

1.1 INTRODUCTION .............................................................................................. 1-1

1.2 MECHANICAL OVERVIEW............................................................................ 1-1

1.3 ELECTRONIC CONTROL SYSTEM ............................................................... 1-2

1.4 OPTIONS AND ACCESSORIES ...................................................................... 1-3

1.4.1 MODBUS Communication Option ........................................................................... 1-3

1.4.2 Accessories ................................................................................................................ 1-3

CHAPTER 2 INSTALLATION

2.1 INTRODUCTION .............................................................................................. 2-1

2.2 RECEIVING, UNPACKING AND INSTALLING ........................................... 2-1

2.3 MAKING THE PIPING CONNECTIONS ........................................................ 2-5

2.4 INSTALLING THE CXT-E ELECTRONIC CONTOL SYSTEM ................... 2-6

2.4.1 Accessing the Control Box Interior ........................................................................... 2-7

2.4.2 Connecting the AC Power to the Control Box .......................................................... 2-8

2.4.3 Wiring the CXT-E Actuator ...................................................................................... 2-9

2.4.4 Verifying the Pre-wired Connections ........................................................................ 2-9

2.4.5 Wiring the Temperature Controller to the MO DB U S Contro l System ..................... 2-9

2.4.6 Control System Programming Information ............................................................. 2-10

CHAPTER 3 FUNCTIONAL DESCRIPTION

3.1 INTRODUCTION .............................................................................................. 3-1

3.2 MECHANICAL DESCRIPTION ....................................................................... 3-1

3.2.1 Overview ................................................................................................................... 3-1

3.2.2 Double-Wall Heat Transfer and Water Leakage ....................................................... 3-2

3.2.3 Principal Mechanical Components ............................................................................ 3-2

3.3 ELECTRONIC CONTROL SYSTEM ............................................................... 3-4

3.3.1 ECS Block Diagram .................................................................................................. 3-4

3.3.2 ECS Operational Summary........................................................................................ 3-5

3.3.3 Over-temperature Condition ...................................................................................... 3-5

3.3.4 Principal ECS Components ....................................................................................... 3-6

CHAPTER 4 ADJUSTMENT

4.1 INTRODUCTION .............................................................................................. 4-1

4.2 ADJUSTING THE ELECTRONIC CXT-E ACTUATOR ................................ 4-1

4.3 ADJUSTING THE ELECTRONIC CONTROL SYSTEM ............................... 4-2

4.3.1 Adjusting the Setpoint Temperature .......................................................................... 4-3

4.3.2 Adjusting the Over-temperature Alarm Limit ........................................................... 4-5

CHAPTER 5 OPERATION

5.1 INTRODUCTION .............................................................................................. 5-1

5.2 PRE-OPERATIONAL ........................................................................................ 5-1

5.3 STARTUP PROCEDURES ................................................................................ 5-1

5.4 SHUTTING DOWN AND DRAINING THE HEAT EXCHANGER ............... 5-3

Page 4

HE-111 − CONTENTS

iv

CHAPTER 6 SCHEDULED MAINTENANCE

6.1 INTRODUCTION .............................................................................................. 6-1

6.2 WEEKLY MAINTENANCE ............................................................................. 6-1

6.3 MONTHLY MAINTENANCE .......................................................................... 6-1

6.4 QUARTERLY MAINTENANCE ...................................................................... 6-2

6.4.1 First Three Months .................................................................................................... 6-2

6.4.2 Each Quarter .............................................................................................................. 6-2

6.5 SEMI-ANNUAL MAINTENANCE .................................................................. 6-3

6.6 ANNUAL MAINTENANCE ............................................................................. 6-3

CHAPTER 7 TROUBLESHOOTING

7.1 INTRODUCTION .............................................................................................. 7-1

7.2 TROUBLESHOOTING PROCEDURES ........................................................... 7-1

CHAPTER 8 CORRECTIVE MAINTENANCE

8.1 INTRODUCTION .................................................................................................8.1

8.2 CXT-E ELECTRONIC CONTROL VALVE ...................................................... 8-1

8.2.1 Valve Shaft Seal Retainer Replacement .................................................................... 8-7

8.2.2 Valve Disassembly .................................................................................................... 8-8

8.2.3 Valve Reassembly ................................................................................................... 8-11

8.2.4 Actuator Replacement ............................................................................................. 8-13

8.2.5 Linkage Assembly Replacement ............................................................................. 8-15

8.2.6 Recirculation Pump Replacement ............................................................................ 8-16

8.3 ELECTRONIC CONTROL SYSTEM ............................................................. 8-18

8.3.1 Replacing the Control Box Assembly ..................................................................... 8-18

8.3.2 Replacing the Temperature Contro ller .................................................................... 8-19

8.3.3 Replacing the Over-temperature Switch and Temperature Indicator ...................... 8-20

8.3.4 Replacing the DC Power Supply ............................................................................. 8-21

8.3.5 Replacing the DC Voltage Regulator ...................................................................... 8-21

8.4 RECOMMENDED SPARE PARTS ................................................................ 8-27

CHAPTER 9 DISASSEMBLY AND REASSEMBLY

9.1 INTRODUCTION 9-1

9.1.2 Tools Required .......................................................................................................... 9-1

9.2 CHECKING FOR A TUBING LEAK ............................................................... 9-1

9.3 REMOVING THE HEAT EXCHANGER SHELL ........................................... 9-1

9.4 REASSEMBLING THE HEAT EXCHANGER ................................................ 9-3

APPENDIX

A. CONTROL AND COMMUNICATION

A.1 TEMPERATURE CONTROLLER PROCEDURES ............................. A-2

A.2 MODBUS COMMUNICATION INFORMATION ............................... A-7

A.3 PROCESS AND DIAGNOSTIC ALARMS ........................................... A-8

B. WIRING DIAGRAMS

Page 5

HE-111 − CONTENTS

v

B.1 DW-SERIES HEAT EXCHANGER WIRING DIAGRAMS ..................B-2

B.2 TERMINAL BLOCK CONNECTIONS ..................................................B-3

C. PIPING CONNECTIONS

C.1 SINGLE HEAT EXCHANGER ...............................................................C-2

C.2 PARALLEL HEAT EXCHANGERS.......................................................C-3

C.3 SINGLE HEAT EXCHANGER WITH AN ACCUMULATOR .............C-4

C.4 SINGLE HEAT EXCHANGER WITH A STRATIFIED ..............................

STORAGE TANK ....................................................................................C-5

C.5 MULTIPLE HEAT EXCHANGERS WITH A STRATIFIED

STORAGE TANK ....................................................................................C-6

Page 6

HE-111 − SAFETY

vi

SAFETY PRECAUTIONS

Personnel involved in the inst allation, operation and m aintenance of the SmartPlate Water Heater must,

at all times, observe all safety regulations. The f ollowing Warnings are general and m ust be given the

same attention as specific Warnings and Cautions appearing throughout this Instruction Manual.

WARNING

FLUIDS UNDER PRESSURE MAY CAUSE INJURY TO

PERSONNEL OR DAMAGE TO EQUIPMENT WHEN RELEASED.

BE SURE TO SHUT OFF ALL INCOMING AND OUTGOING

WATER SHUTOFF VALVES. CAREFULLY DECREASE ALL

TRAPPED PRESSURES TO ZERO BEFORE PERFORMING

MAINTENANCE.

WARNING

ELECTRICAL VOLTAGES UP TO 240 VAC MAY BE USED IN

THIS EQUIPMENT. DEATH ON CONTACT OR SERIOUS

PERSONAL INJURY MAY RESULT IF EXPOSED CONNECTIONS

ARE TOUCHED.

WARNING

CLOSE ALL SHUT-OFF VALVES AND CAREFULLY DECREASE

TRAPPED PRESSURES TO ZERO BEFORE PERFORMING ANY

MAINTENANCE TASKS. TAG THE UNIT “OUT OF SERVICE”

WHILE PERFORMING MAINTENANCE TASKS.

Page 7

1-1

CHAPTER 1 GENERAL INFORMATION

1.1 INTRODUCTION

AERCO’s DW-series heat exchangers provide potable hot water for commercial and institutional

applications. These heat exchangers are available in steam-to-water configurations and are equipped

with electronic controls. This manual addresses the steam-to-water double-wall heat exchanger with

electronic controls.

The three steam-to-water DW heat exchangers available from AERCO include the:

• DW-24 with 24 square feet of heating surface

• DW-45 with 45 square feet of heating surface

• DW-68 with 68 square feet of heating surface

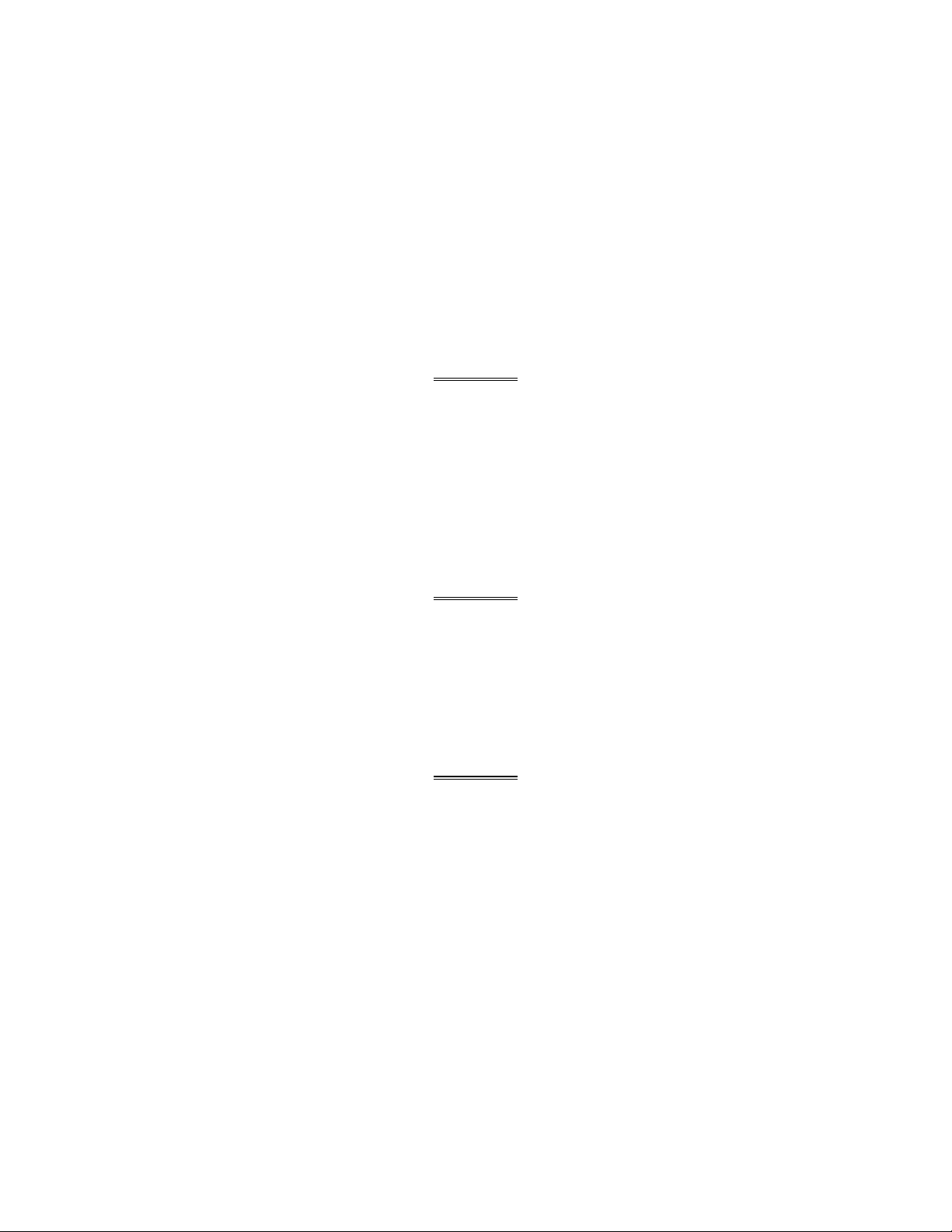

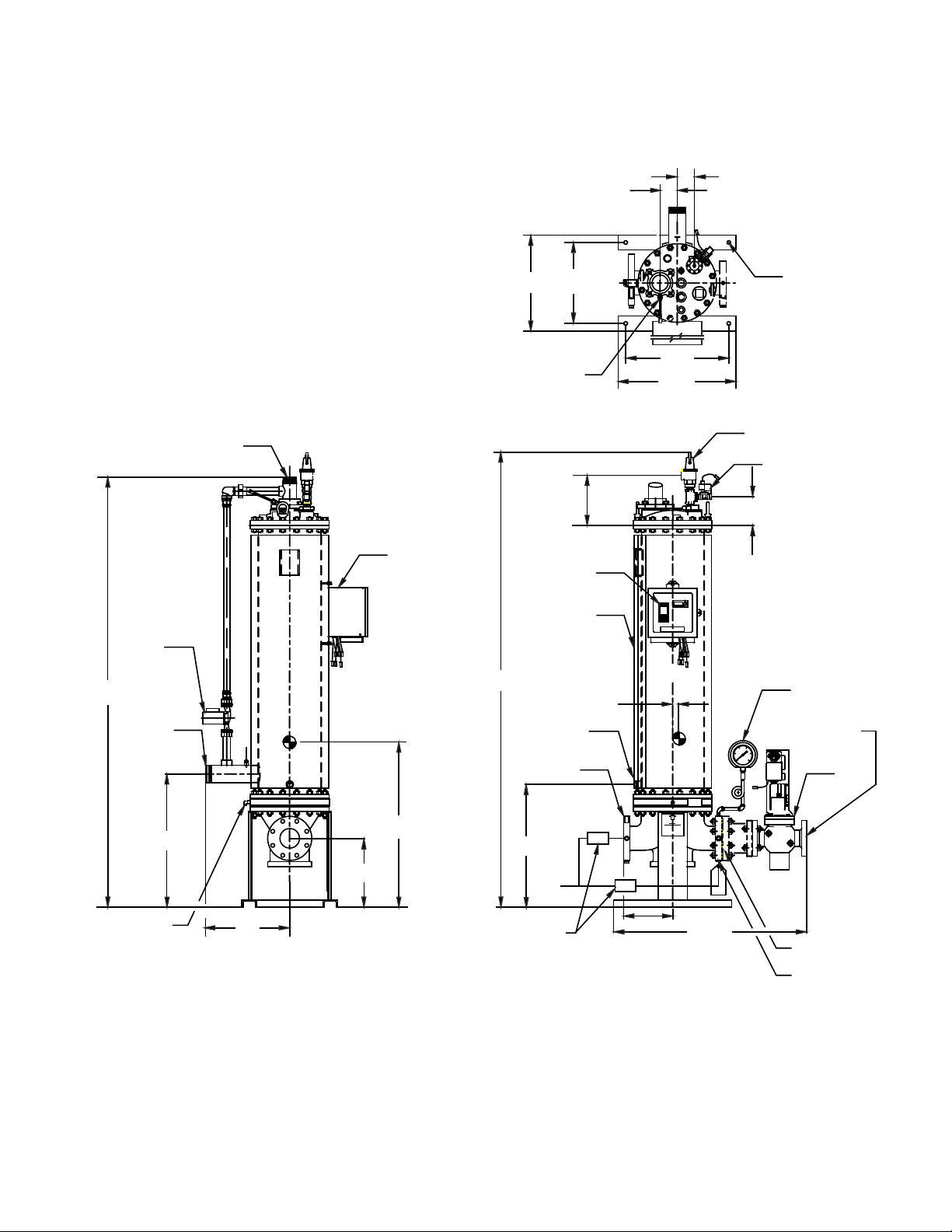

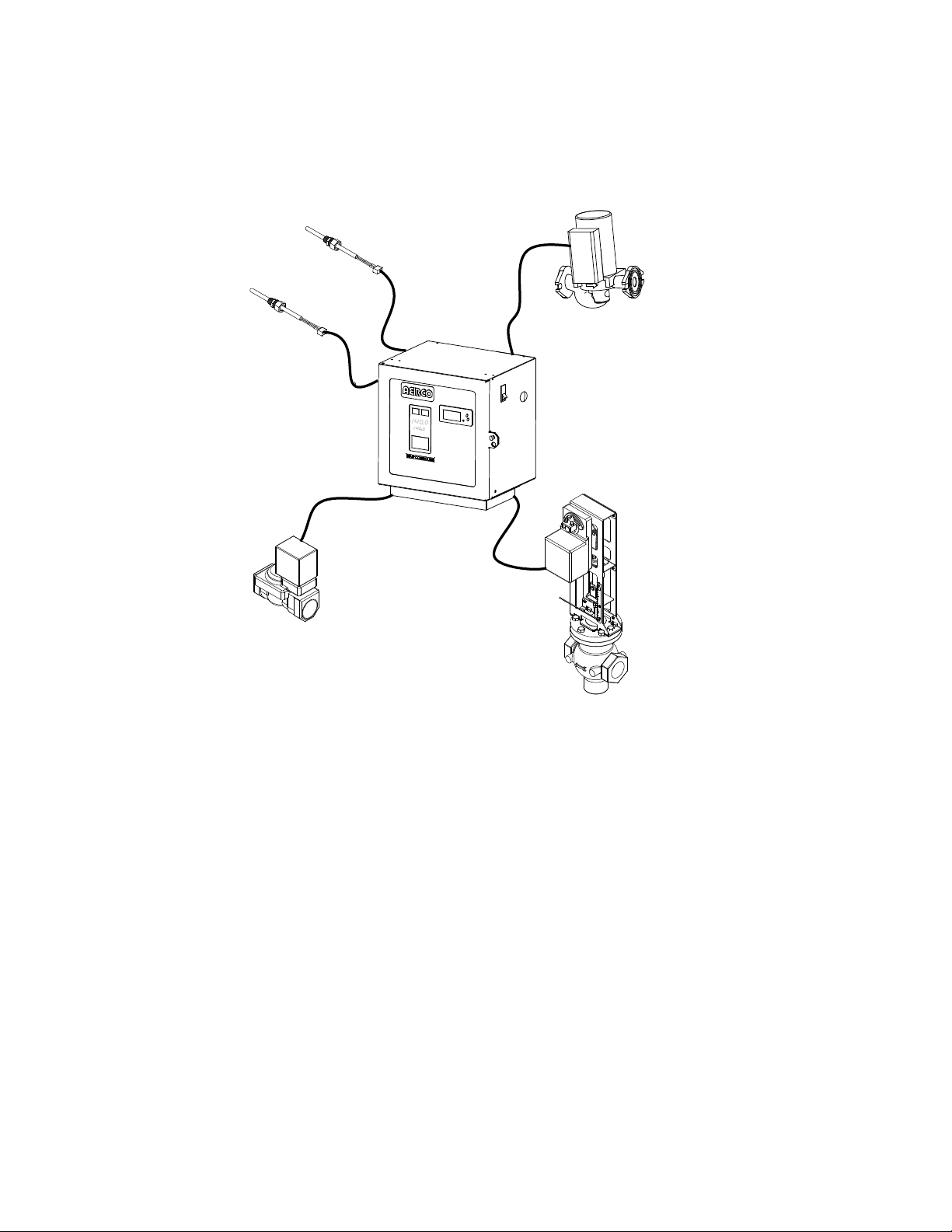

Figure 1-1 illustrates a typical AERCO DW-series heat exchanger.

Figure 1-1. DW-24 Heat Exchanger

This chapter provides a top-level mechanical overview of the DW-series heat exchanger (1.2), its

electronic control s ystem (1.3) and the opt ions and accessories ava ilable from AERCO ( 1.4) for units in

this series

1.2 MECHANICAL OVERVIEW

The AERCO double-wall steam-to-water heat exchanger is illustrated in Figure 1-2:

Rev B Mar 2013

Page 8

HE-111 − GENERAL INFORMATION

1-2

AERCO

STEAM INPUT

CONDENSATE OUTPUT

SHELL ENCLOSING THE

TUBE BUNDLE

COLD WATER

INPUT

HOT WATER OUTPUT

CONTROL BOX

RECIRCULATION

PIPING

RECIRULCATION

PUMP

UPPER HEAD ASSEMBLY

CXT-E CONTROL

VALVE

CXT-E ACTUATOR

LOWER HEAD ASSEMBLY

Figure 1-2. Mechanical Overview of the AERCO Double-Wall Steam-to-Water Heat

Exchanger

The DW steam-to-water heat exchanger includes the following principal mechanical parts and

assemblies:

• Shell and upper/lower head assemblies

• Enclosed double-wall tube bundle and tubesheets

• Input/output connections for steam, condensate and h ot/c ol d water

• Control Valve

• Recirculation piping and pump

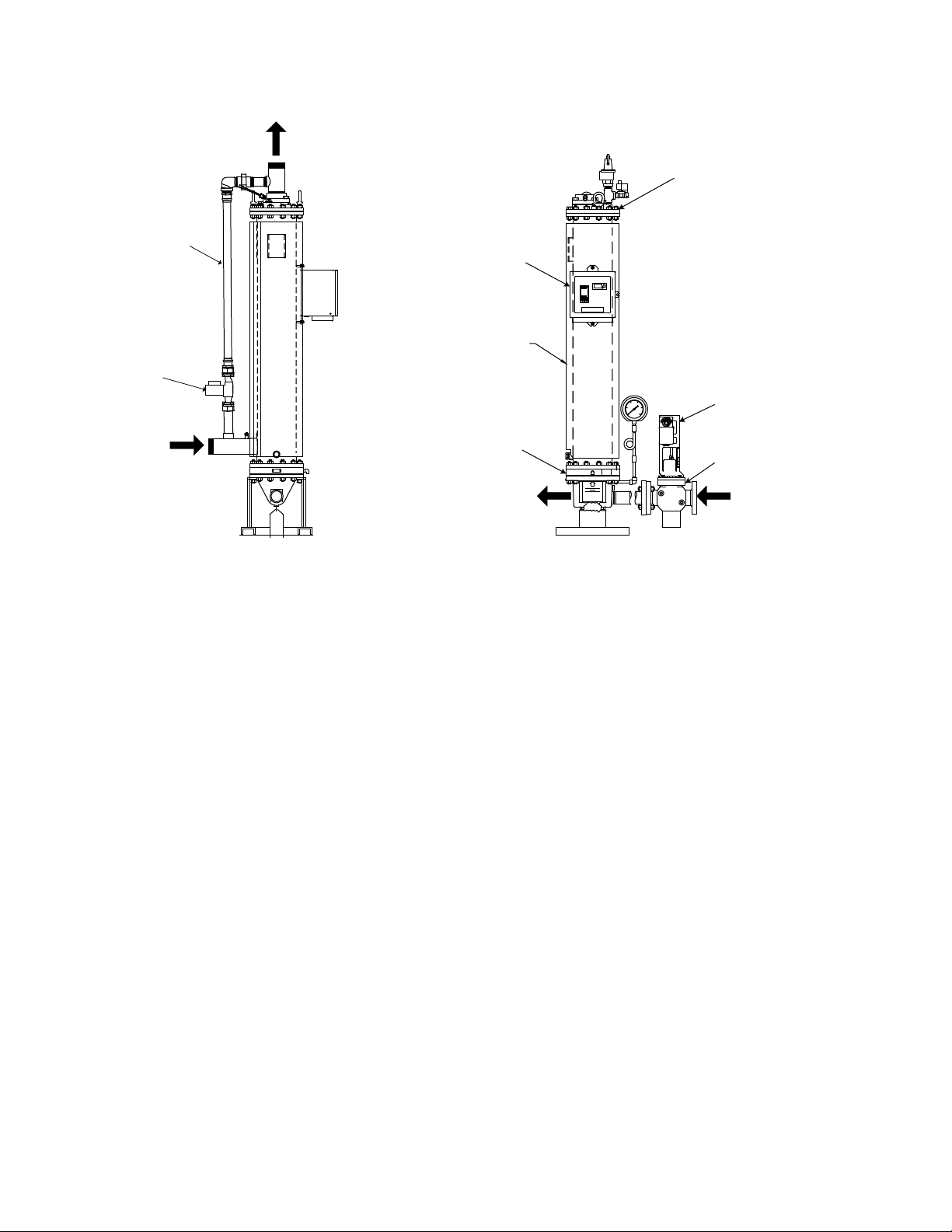

1.3 ELECTRONIC CONTROL SYSTEM

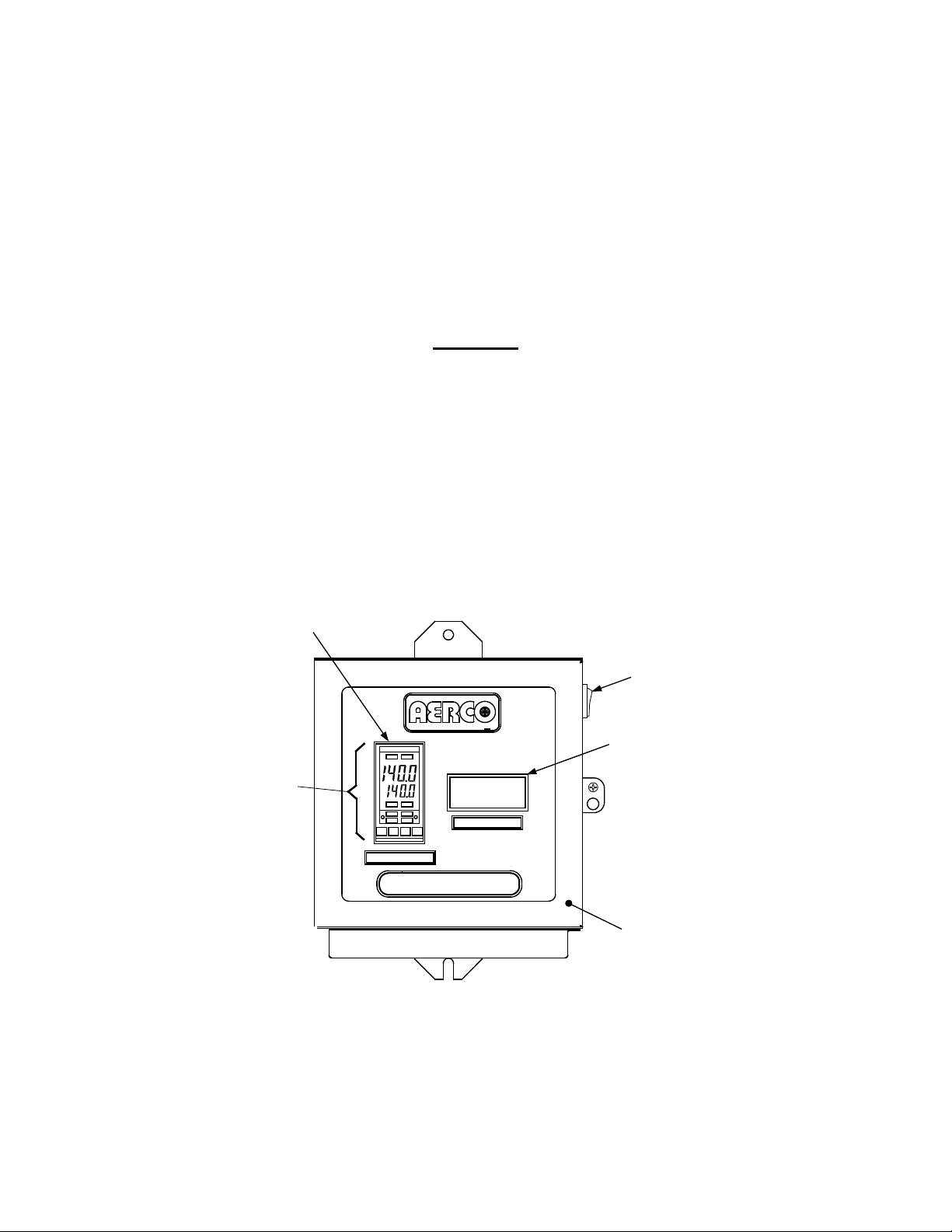

The Electronic Control S ystem (ECS; illustrated in Fig ure 1-3) includes the C ontrol Box components and

associated temperature sensors and actuators. The ECS:

• Controls the temperature of the hot water output to within ±4°F of the Control Box setting under

normal, diversified load conditions (load fluctuations of up to 25% of water heater capacity)

• Shuts down the heat exchanger when the maximum safe water temperature is exceeded

• Relays commands and alarms from/to the MODBUS Communication Option

The ECS and its components are described in Chapter 3.

Rev B Mar 2013

Page 9

HE-111 − GENERAL INFORMATION

1-3

DHW

DUAL OUTLET

TEMP. SENSOR

OVER-TEMPERATURE

SOLENOID VALVE

CONTROL BOX

ASSEMBLY

CONSTANT RATE

RECIRCULATION

PUMP

FEED-FORWARD

MIXTURE TEMP.

SENSOR

CXT-E CONTROL

VALVE ACTUATOR

CONTROL

VALVE

Figure 1-3. Electronic Control System Components

1.4 OPTIONS AND ACCESSORIES

1.4.1 MODBUS Communication Option

The ECS can be ordered with th e MODBUS Communication Opt ion to enable the ECS to be externall y

controlled by an Energy Management System, Building Automation System or computer (supplied by

others).

1.4.2 Accessories

Accessories available for the DW-series steam-to-water heat exchangers equipped with the CXT-E

Electronic Control Valve are listed in

Table 1. Re quired access ories ma y be supplied separatel y by AERCO if the y are not factory-ins talled on

the heater.

The accessories required will depend on the specific application. Detailed installation instructions,

including typical installation drawings are provided in Chapter 2 Installation. Please ensure that ALL

mandatory items are available for installation.

If any of these items have been furnished by AERCO, the necessary drawings and/or instructions are

included with the shipment.

Rev B Mar 2013

Page 10

HE-111 − GENERAL INFORMATION

1-4

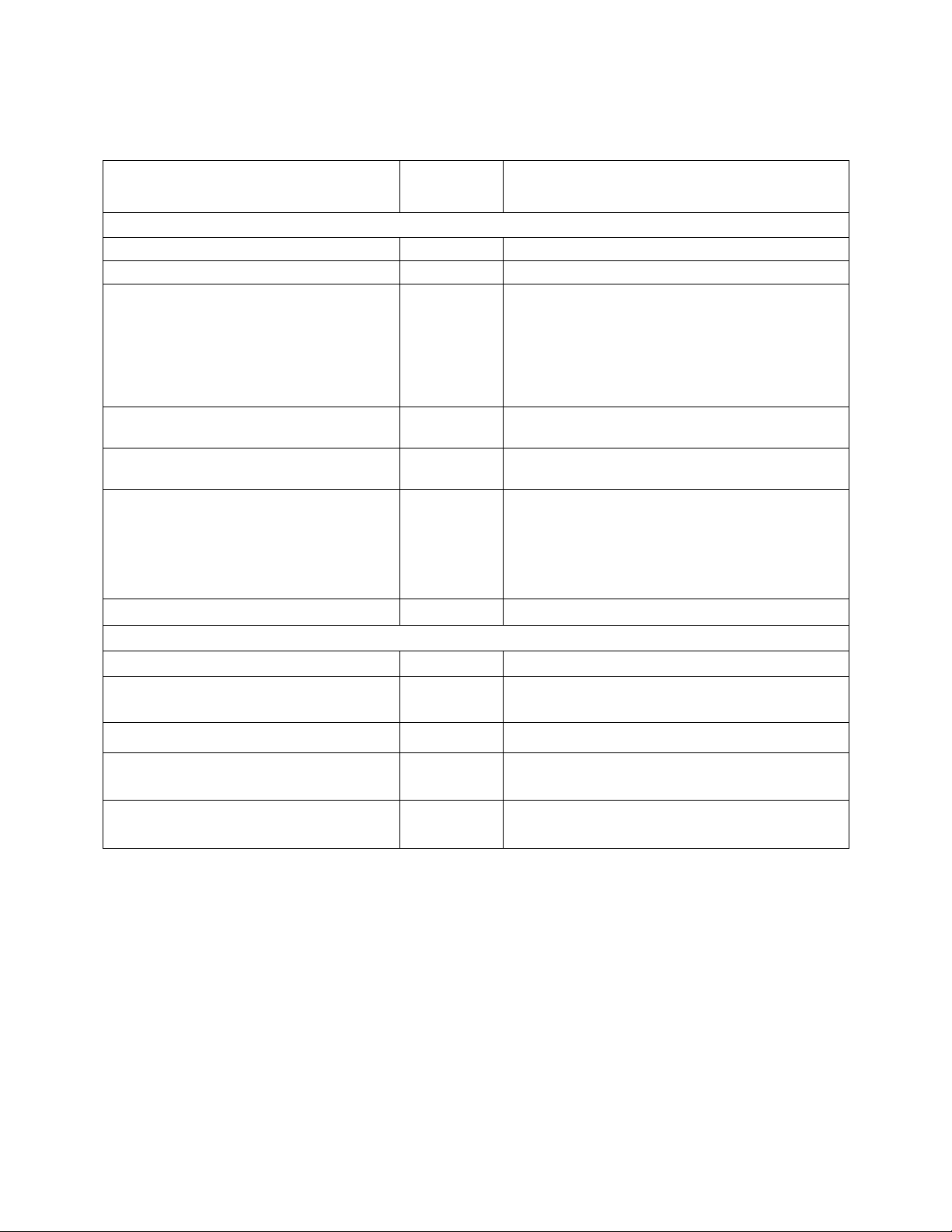

Supplied

I. DW-Series Heat Exchanger

Temperature Controller

Yes

Required

Pressure and Temperature Relief Valve

Yes

Required

including:

• Solenoid valve

• Water temperature sensor in heat

exchanger upper head

• Over-temperature indicating switch

required for the application

mounted on steam inlet connection

II. CXT-E Actuator and Valve

Required if a bypass line is used

Table 1. DW-Series Heat Exchanger and CXT-E Actuator/Valve Accessories

Description AERCO

Over-temperature Limit System,

Steam Flow Control Valve, sized as

Compound Steam Pressure Gauge,

Traps No Required

• Drip trap

• Valve trap

• Condensate trap

Vacuum Breaker Yes Required

Yes Required

Yes Required

Yes Required

Remarks

Upstream Shutoff Valve No Required

Downstream Shutoff Valve No

Strainer and Blow-Off Valve No

High Side Pressure Gauge No

Low Side Pressure Gauge, compoundtype for steam flow

No

• Suggested for ease of maintenance

•

Required

Recommended for adjustment and

maintenance

Recommended for adjustment and

maintenance.

Rev B Mar 2013

Page 11

2-1

CHAPTER 2 INSTALLATION

2.1 INTRODUCTION

This chapter provides instructions for:

• Receiving the heat exchanger and installing it in a suitable location (2.2)

• Piping into the steam and water systems (2.3)

• Installing and connecting the Electronic Control System (2.4)

2.2 RECEIVING, UNPACKING AND INSTALLING

To prepare the heat exchanger for installation:

1. Carefully uncrate the heat exchanger.

2. Set the heat exchanger upright us in g a bl ock and tackle or hoist attac he d to t he lifting lugs (eye-bolts)

on the top head.

CAUTION

ALWAYS USE THE LIFTING LUGS to lift and/or move the heat exchanger.

3. To simplify in-place maintenance, install the heat exchanger in a location having the following

clearances:

a. Horizontal clearance: At least two (2) feet all-around

b. Headroom: At least six (6) feet measured upward from the top of the upper shell flange.

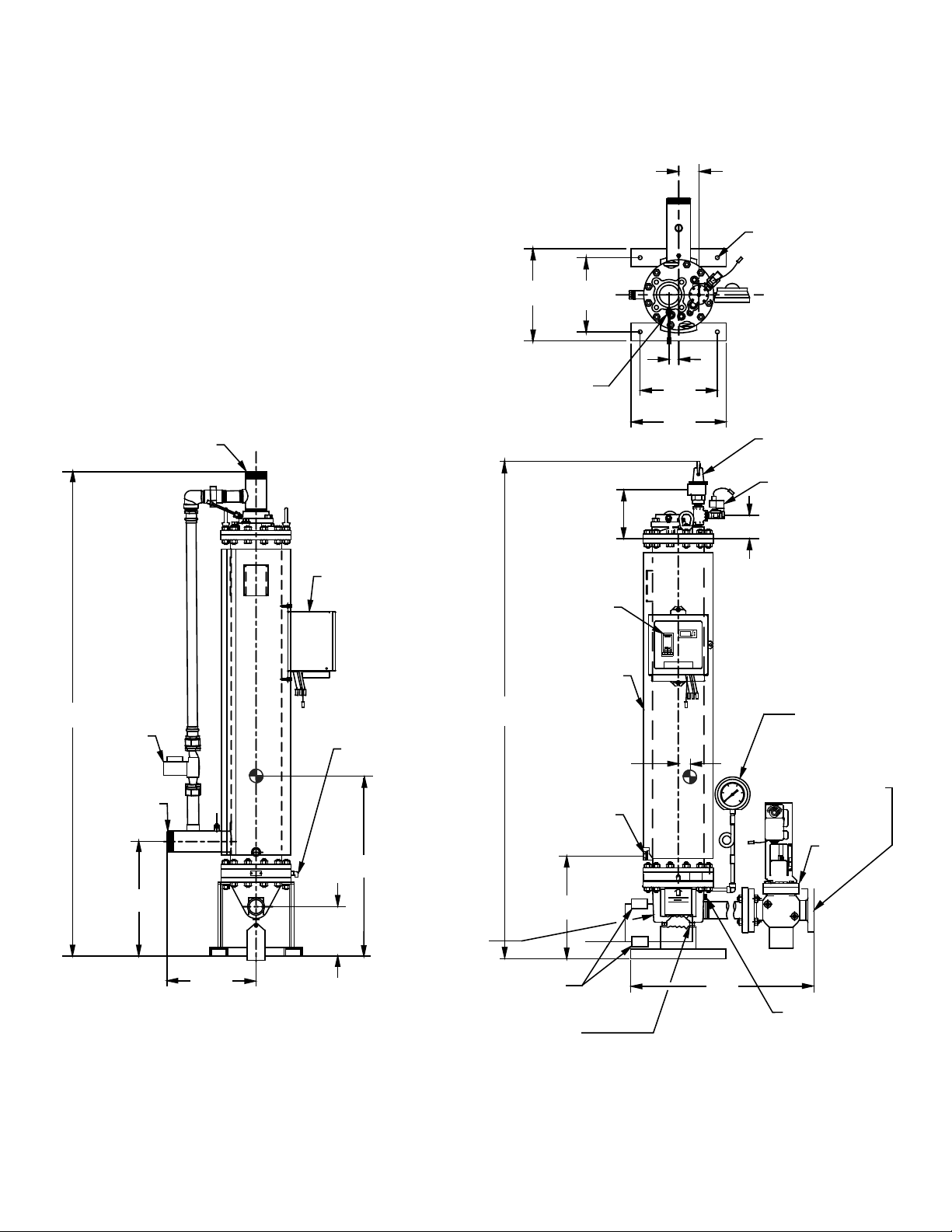

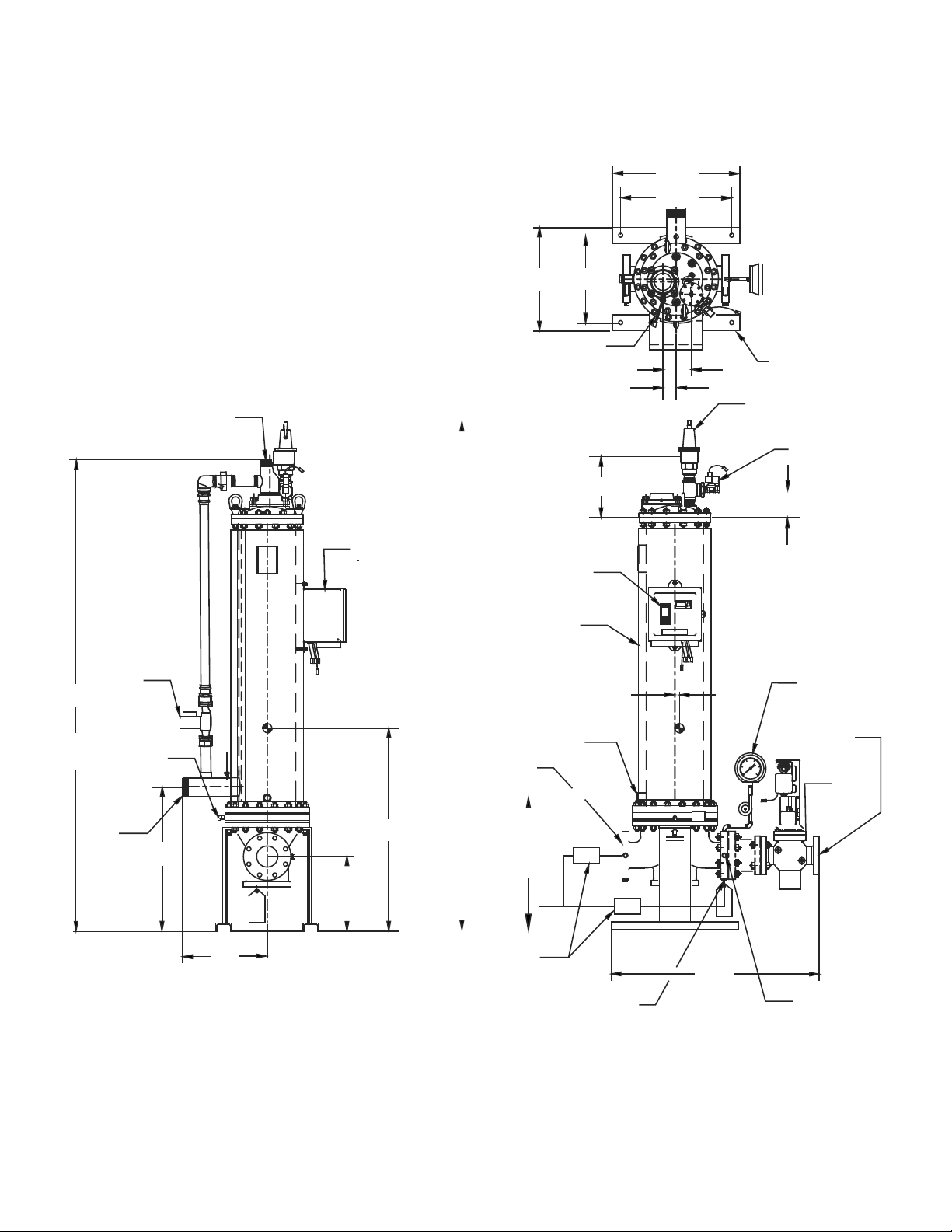

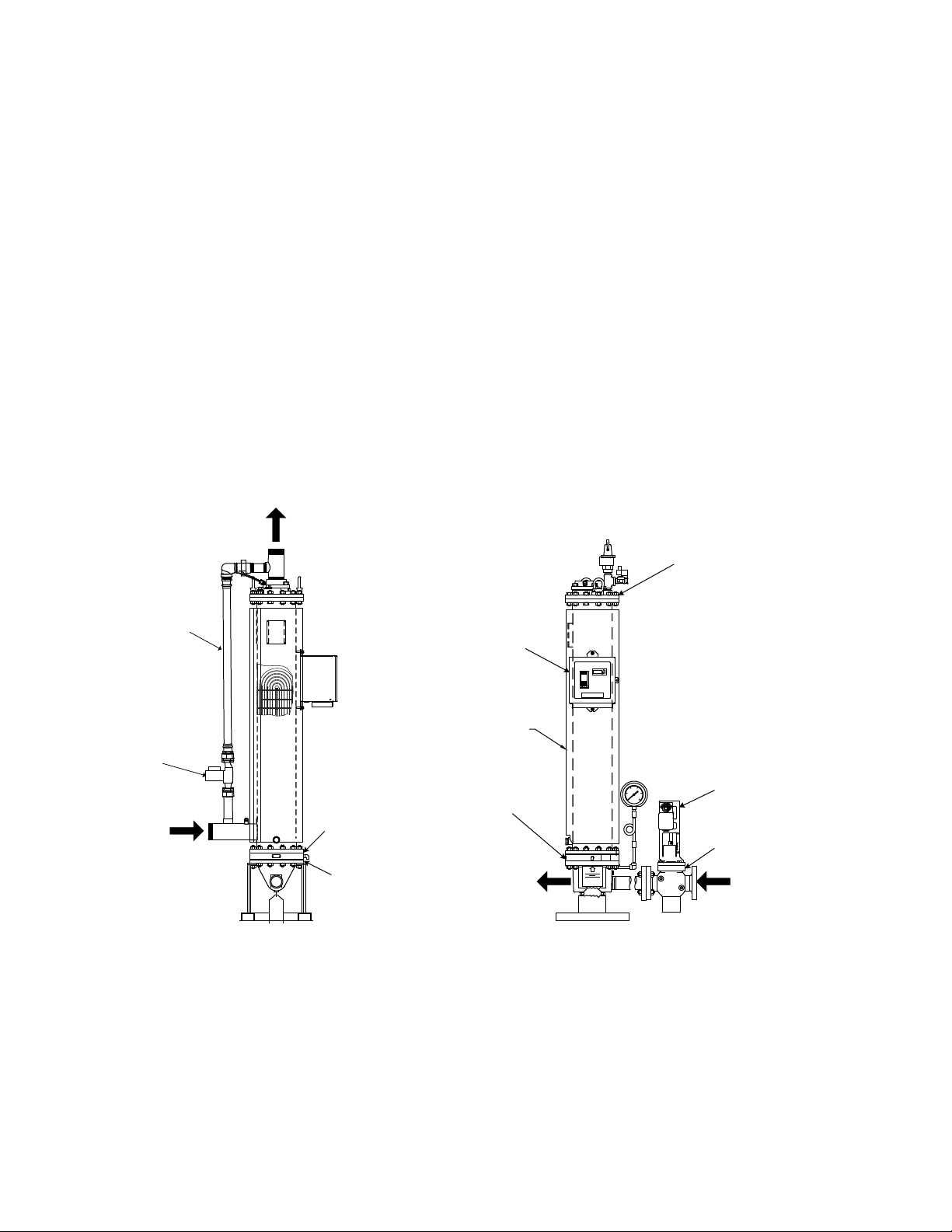

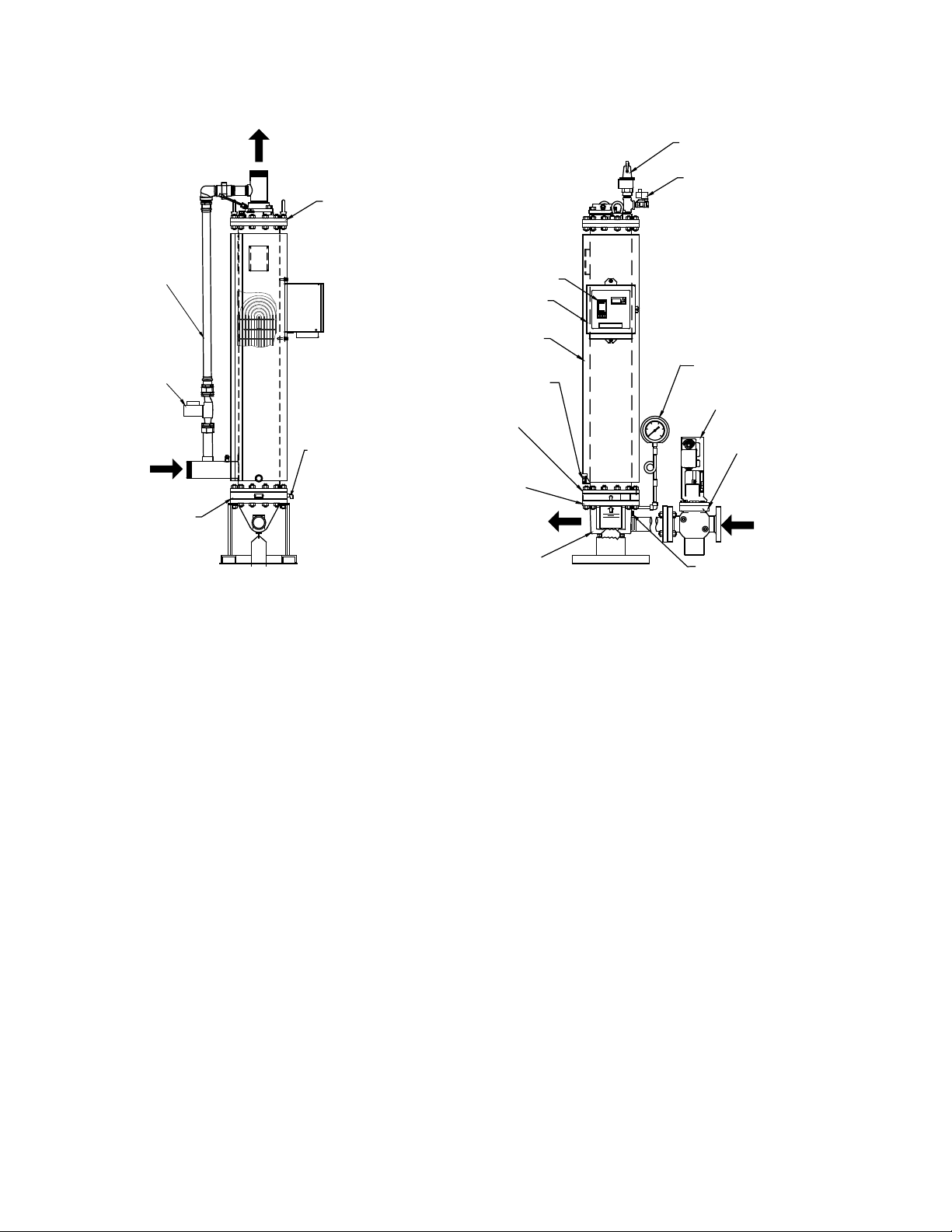

The dimensions of the AERCO Model DW-heat exchangers are presented in Figures 2-1 through 2-3.

4. Secure the heat exchanger in place, pref erabl y, by att aching it to the f loor. If you use pip ing to secur e

the heat exchanger in position, be sure to include ample provision for pipe expansion.

Rev B Mar 2013

Page 12

HE-111 − INSTALLATION

2-2

WIRE TO

COMPONENTS

M

A

N

R

U

N

H

O

L

D

*

83.33

(211.66)

32.18

(81.74)

17.26

(43.84)

COMPOUND

PRESSURE

GAUGE (S/W)

STEAM

INLET

15.44

(39.22)

12.44

(31.60)

13.00

(33.02)

16.00

(40.64)

FOUR .75

(1.91)Ø HOLES

1.63

(4.14)

OUTLET TEMP.

SENSOR

1/2" (1.27)

WATER SOLENOID

2.50" NPT

CONDENSATE

OUTLET

FLOAT & THERMOSTATIC

STEAM TRAP (BY OTHERS)

3/4" PLUGGED

DRAIN

TEMPERATURE

CONTROLLER

1.50 (3.81) THICK

INSULATION

CXT-E

VALVE

VACUUM BREAKER

(STEAM TO WATER)

8.11

(20.60)

3.80

(9.65)

1.75

(4.45)

30.50

(77.47)

18.66

(47.40)

3" NPT COLD

WATER INLET

3" NPT HOT

WATER OUTLET

115 VAC, 2A, 60 HZ

POWER SUPPLY REQUIRED

81.20

(206.25)

9.00

(22.86)

DOUBLE WALL TUBE

LEAK DETECTION PORT

(NOT TO BE PLUGGED)

RECIRC

PUMP

14.90

(37.85)

P&T RELIEF VALVE

1/2" NPT VALVE

TRAP CONNECTION

(STEAM TO WATER ONLY)

2.28

(5.79)

Figure 2-1. AERCO Model DW-24 Heat Exchanger Dimensions

Rev B Mar 2013

Page 13

HE-111 − INSTALLATION

2-3

AERCO

*

1

0

9

0

0

96.20

(244.35)

25.11

(63.78)

11.52

(29.26)

5.22

(13.26)

39.87

(101.27)

VACUUM BREAKER

(STEAM TO WATER)

COMPOUND

PRESSURE

GAUGE (SW)

CXT-E

VALVE

STEAM INLET

3/4" PLUGGED

DRAIN

TEMPERATURE

CONTROLLER

P&T RELIEF VALVE

1/2" (1.27)

WATER SOLENOID

1.00 (2.54)

1/2" NPT VALVE

TRAP CONNECTION

(STEAM TO WATER ONLY)

FLOAT &

THERMOCSTATIC

STEAM TRAP

(BY OTHERS)

4" 150# FLG

CONDENSATE

OUTLET

1.50 (3.81) THICK

INSULATION

FOUR .75

(1.91)Ø HOLES

OUTLET TEMP.

SENSOR

16.50

(41.91)

19.50

(49.53)

21.00

(53.34)

24.00

(60.96)

2.50

(6.35)

2.88

(7.32)

115 VAC, 2A, 60 HZ

POWER SUPPLY

REQUIRED

DOUBLE WALL TUBE

LEAK DETECTION PORT

(NOT TO BE PLUGGED)

27.24

(69.19)

15.97

(40.56)

14.00

(35.56)

36.00

(91.44)

RECIRC

PUMP

WIRE TO

COMPONENTS

3" NPT HOT

WATER OUTLET

89.00

(226.06)

3" NPT

COLD

WATER

INLET

Rev B Mar 2013

Figure 2-2. AERCO Model DW-45 Heat Exchanger Dimensions

Page 14

HE-111 − INSTALLATION

2-4

COMPONENTS

WIRE TO

AERCO

92.70

(235.46)

25.04

(63.60)

10.11

(25.68)

5.75

(14.60)

COMPOUND

PRESSURE

GAUGE (S/W)

STEAM INLET

CXT-E

VALVE

VACUUM BREAKER

(STEAM TO WATER)

39.87

(101.27)

3/4" PLUGGED

DRAIN

1.50" (3.81) THICK

INSULATION

TEMPERATURE

CONTROLLER

FLOAT &

THERMOSTATIC

STEAM TRAP

(BY OTHERS)

10.00 (25.40)

1.00 (2.54)

1/2" (1.27)

WATER SOLENOID

P&T RELIEF VALVE

1/2" NPT VALVE

TRAP CONNECTION

(STEAM TO WATER ONLY)

24.00

(60.96)

21.00

(53.34)

19.50

(49.53)

16.50

(41.91)

OUTLET TEMP.

SENSOR

3.50

(8.89)

3.50

(8.89)

FOUR .75

(1.91)Ø HOLES

87.56

(222.40)

27.16

(68.99)

16.50

(41.91)

36.00

(91.44)

115 VAC, 2A, 60 HZ

ELECTRICAL

POWER SUPPLY

REQUIRED

14.00

(35.56)

3" NPT

COLD WATER

INLET

3" NPT

HOT WATER

OUTLET

DOUBLE WALL TUBE

LEAK DETECTION PORT

4" 150# FLG.

CONDENSATE

OUTLET

RECIRC

PUMP

Figure 2-3. AERCO Model DW-68 Heat Exchanger Dimensions

Rev B Mar 2013

Page 15

HE-111 − INSTALLATION

2-5

TO HEATER

FROM

STEAM

SOURCE

UPSTREAM

SHUTOFF

VALVE

LOW SIDE

PRESSURE

GAUGE

CXT-E ACTUATOR

HIGH SIDE

PRESSURE

GAUGE

DOWNSTREAM

SHUTOFF VALVE

PIPE UNIONS (NOT

REQUIRED WHEN

VALVE IS FLANGED)

STRAINER

TO TRAP &

CONDENSATE

DRAIN

BLOW-OFF VALVE

NOTE:

KEEP PIPING AS SHORT

AS POSSIBLE)

CXT-E CONTROL

VALVE

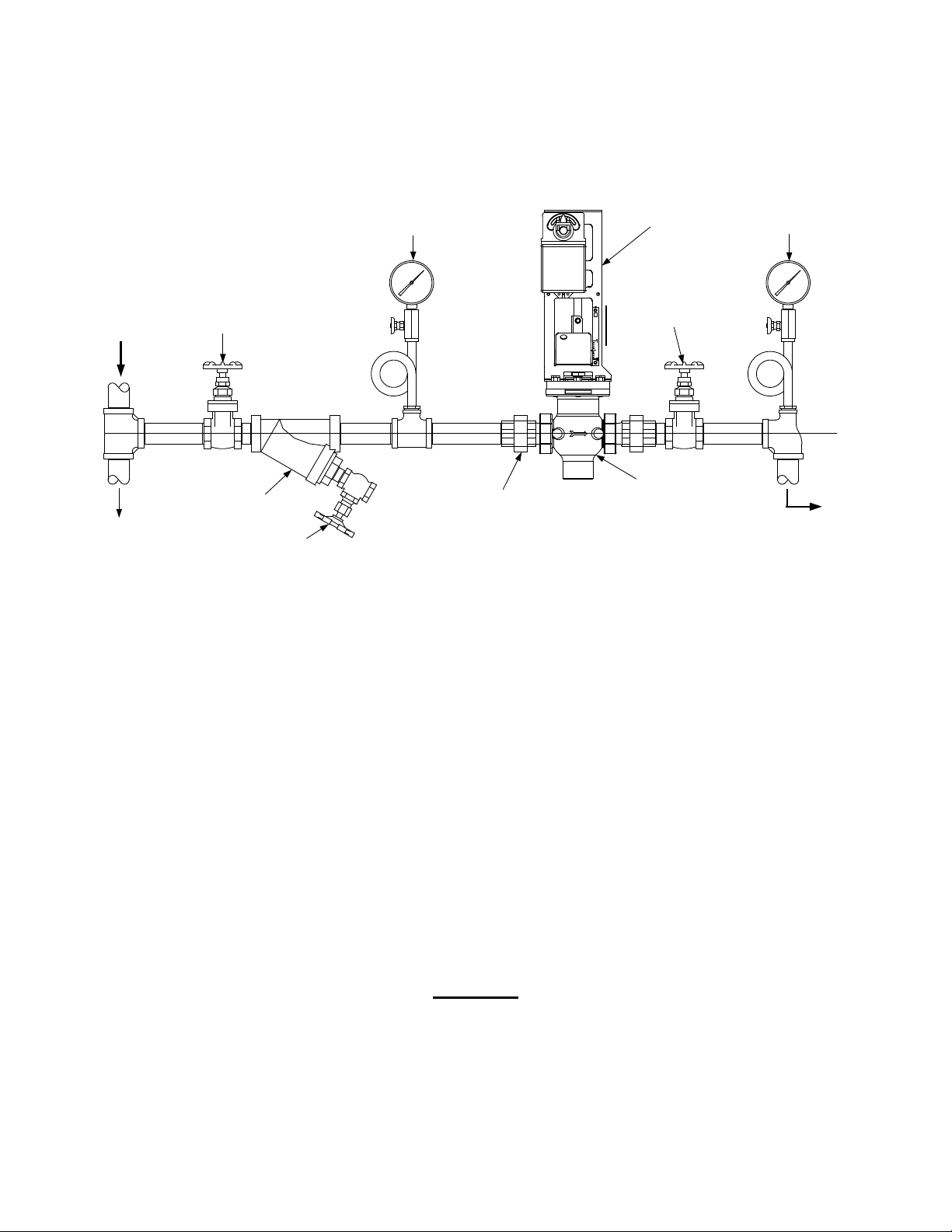

2.3 MAKING THE PIPING CONNECTIONS

Figure 2-4 illustrates the recommended CXT-E Control Valve installation for steam flow.

Figure 2-4. Recommended Control Valve, CXT-E Installation for Steam Flow

1. Install the CXT-E Control Valve with the Actuator linkage in the vertical, upright position, as shown.

2. For maintenance purposes, insta ll pipe unions with threaded e nds t o sim plif y remova l from the s team

line.

3. Blow out all pipe lines to rem ove dirt chips, scale or other for eign matter wh ich could a dversel y affect

Control Valve (“Valve”) operation when in service.

4. Install an in-line strainer upstr eam of the Valve (as illus trated on the left si de of Figur e 2-4) to protec t

against foreign matter entering the Valve during service operation.

5. Ensure that the steam line is properl y trapped to prevent accumulation of condens ate ahead of the

Valve.

6. Install metal-seated, gate-t ype s hutof f va lves ups tre a m and downstream of the Val ve so t hat it ca n be

readily removed from the line for maintenance.

7. Install pressure gauges on both sides of the Control Valve, as shown in Figure 2-4.

8. The high-side pressure gauge is provided for adj ustment and maintenance purposes . The low-side

pressure gauge is intended to ensure that the cor rec t pr ess ur e is available to monitor the operation of

the temperature regulator valve. The low-side pressure gauge measures the pressure of the steam`.

CAUTION

When installing the Valve, DO NOT us e the Ac tuator linkage frame at the top of the Valve

body for leverage. Use pipe wrenches on the inlet and outlet hex of the Valve body.

9. Install the Valve so that the arrow on the Valve body points in the direction of steam flow.

10. After the Valve has been installed in the steam or hot water line, ensure that al l piping connections

are secure and leak-tight.

Rev B Mar 2013

Page 16

HE-111 − INSTALLATION

2-6

The AERCO recommended heat exchanger and Control Valve piping arrangements for single and

parallel heat exchanger installations are presented in Appendix C.

11. For best heat exchanger performance, OBSERVE THE FOLLOWING VERY CAREFULLY when

installing the heat exchanger piping:

a. Do not use cement or red lead when assembling pipe joints.

b. For heat exchanger connec tion types, sizes, and exact locat ions, see Figure 2-1, Figure 2-2 or

Figure 2-3.

c. All piping to the heat exch anger top head should be provided with u nions or flanges LOCATED

BEYOND THE OU TSIDE DIAMET ER OF THE HEAT EXCHANGER H EAD to perm it removal of

the head and shell for in-place maintenance.

d. Include all of the stop va lves, check valves, s team traps, strai ners and other el ements shown in

Appendix C, or as specified separately by AERCO.

e. If the heat exchanger is furnished with the Control Valv e not connected as sho wn in Figure 2-1,

Figure 2-2, or Figure 2-3, mak e the piping bet ween t he Contro l Valve a nd the h eat exchang er as

short as possible, with sufficient unions or flanges included to allow easy Valve removal.

f. Reductions from a pipe to a smaller size connection at the heat exchanger or Control Valve

should be made directl y at the heat exchanger or Valve connection. Expansions f rom a pipe to a

larger size connectio n at the hea t exchan ger or Contr ol Valve should be m ade as far as pr actical

from the heat exchanger or Valve connection.

g. The condensate return p iping must be arranged to p ermit condensate to drain freely by gravity

from the heat exchanger connection. If condensate drain by gravity is not feasible, you may

substitute a pumping steam trap. Refer to the trap manufacturer’s instructions for sizing and

installation procedures.

CAUTION

Failure to provide proper condensate drainage can result in improper

operation of the heat exchanger and/or damage to the heat exchanger

condensate drainage system.

h. All drain discharges ― relief valve, over-temperature solenoid valve and heat exchanger shell

drain ― should be piped directly to a convenient floor drain.

IMPORTANT

Before making final p iping connections to and fr om the heat exchanger

and Control Valve, blow out all piping thoroughly.

2.4 INSTALLING THE CXT-E ELECTRONIC CONTROL SYSTEM

The Control Box and all other Electronic Control System (ECS) components are installed on the heat

exchanger assembly before it is shipped from the factory, so that the ECS installation consists of

connecting AC power t o the Control Box and making the internal power and control connec tions to the

CXT-E Control Valve. Ho wever, if your ECS was ordered with th e MODBUS Com munication option, you

are required to m ake several a dditional c onnections (startin g with step 8, belo w) to enabl e the ECS to be

controlled by an external Energy Management System (EMS), Building Automation System (BAS) or

computer.

Rev B Mar 2013

Page 17

HE-111 − INSTALLATION

2-7

TEMP CONTROLLER

HOLD

RUN

AUTO

MAN

2408

OVER TEMP SWITCH

PANEL

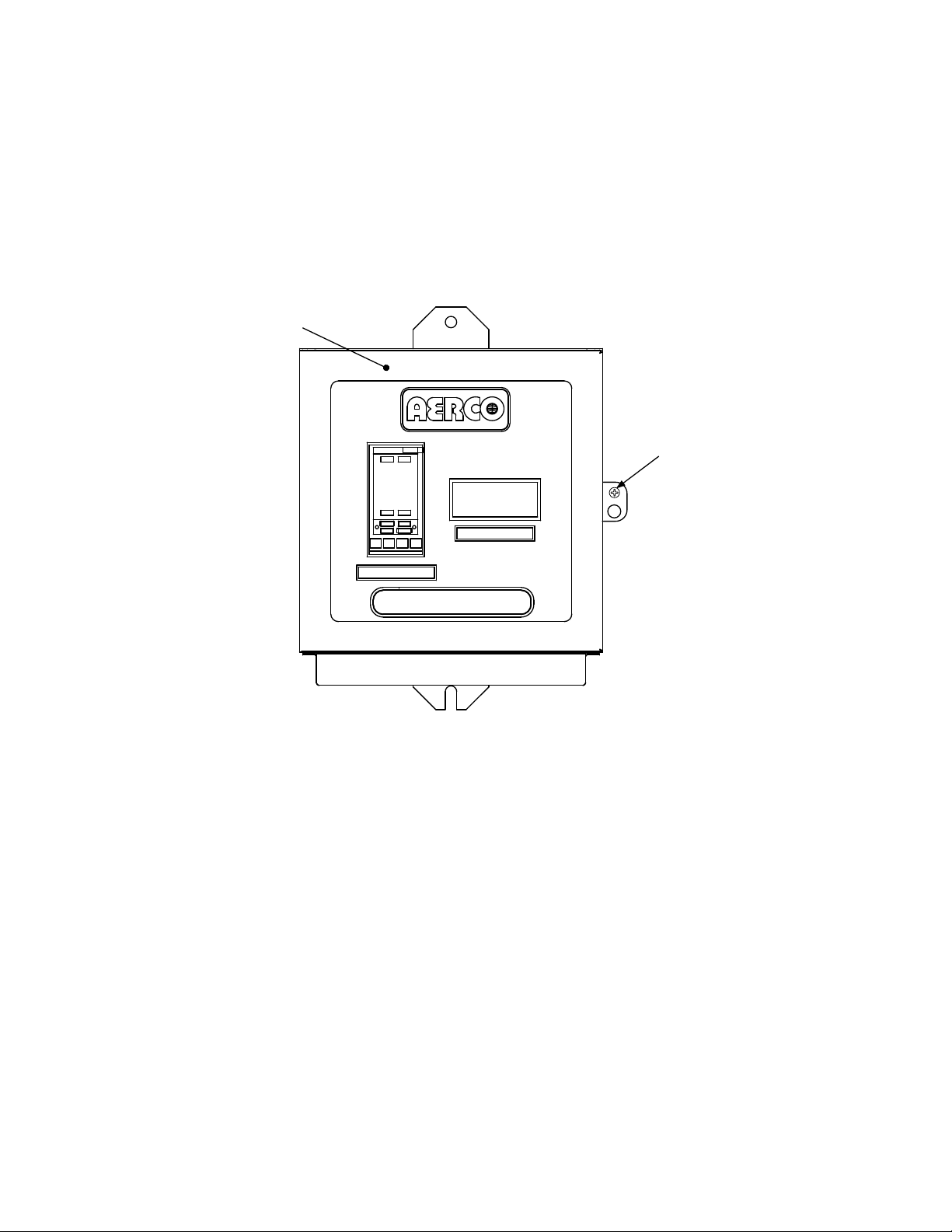

DOOR

CAPTIVE

SCREW

2.4.1 Accessing the Control Box Interior

NOTE

After installing the Contro l Box, you can inst all a lock (not supp lied) on its f ront do or to

prevent unauthorized access to ECS settings.

1. Loosen the captive screw on the Control Box (Figure 2-5) front cover and open the hinged panel

door.

Figure 2-5. ECS Control Panel Front View

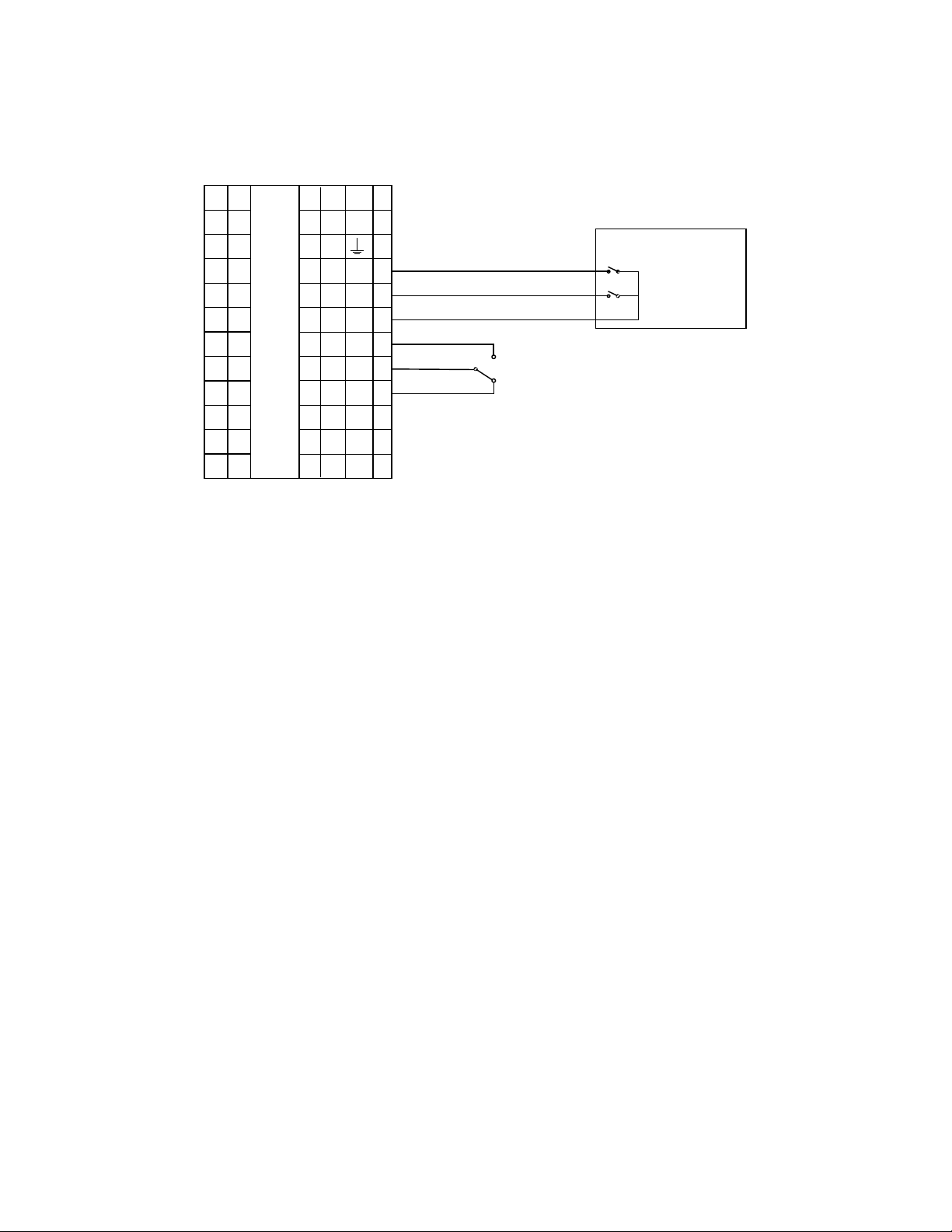

2. Loosen the captive scr ew at the top of the recessed panel (Figure 2-6). Swing down t he recessed

panel to access Terminal Block TB-2 on the bottom interior surface of the Control Box (see

Figure 2-7).

Rev B Mar 2013

Page 18

HE-111 − INSTALLATION

2-8

PANEL CAPTIVE

CONTROL BOX - INTERIOR BOTTOM VIEW

REAR

TB-2

LINE

NEUTRAL

GROUND

100

101

102

GND

FRONT

VOLTAGE

REGULATOR

TERMINAL

BLOCK TB-2

EXTERNAL POWER WIRING

(120 VAC)

SCREW

2408

OP 1

OP 2

SP2

REM

AUTO

RUN

MAN HOLD

TEMP CONTROLLER

TM

Figure 2-6. Recessed Panel Behind Control Box Door

2.4.2 Connecting AC Power to the Control Box

PT.NO.

F

SET

OVER TEMP SWITCH

PT.NO.

3. Feed the external 120 VAC power leads thr ough the cutout labele d “POWER IN” on the rig ht side of

the Control Box.

4. Connect the LINE, NEUTRAL and GROUND leads to the TB-2 terminals shown in Figure 2-7.

Figure 2-7. ECS Control Box AC Power Connections

2.4.3 Wiring the CXT-E Actuator

5. Connect the Control Box cable labeled ACTUATOR to the 3-pin connector plug on the CXT-E

Actuator.

Rev B Mar 2013

Page 19

HE-111 − INSTALLATION

2-9

2408 TEMP. CONTROLLER

COMPUTER CONTROL CABLE

RS232 9-PIN

RS232 25-PIN

RS485

SIGNAL NAME

TERMINAL

SIGNAL NAME

PIN NO.

PIN NO.

PIN NO.

GROUND

HD

GROUND 5 7

GROUND

RECEIVE

HE

TRANSMIT

3 2 A(-)

TRANSMIT

HF

RECEIVE 2 3

B(+)

2.4.4 Verifying Pre-wired Connections

6. Check to ensure that al l pre-wired cable harn ess connec tors an d w ire le ads bet ween the C ontro l Box

and the following ECS components are secure:

• Recirculation Pump

• Over-Temperature Solenoid

• Outlet Dual Temperature Sensor

• Mixed Temperature Sensor

7. If the ECS was ordered with the MO DBUS C omm unication Optio n, proc eed to step 8. Otherwise, the

ECS installation is complete.

2.4.5 Wiring the Temperature Controller to the MODBUS Control System

Step 8, below, applies to the Euro therm, Mode 2408 Tem perature Controller equipped with a MODBUS

communication board and connected to an Energy Management System (EMS), Building Automation

System (BAS) or computer. The type of communication port (RS232-9, RS232-25, or RS485) mounted on

the EMS, BAS or com puter determines the relevant s ignal leads (Ground, Recei ve and Transmit) in the

control cable that you connect to the MODBUS dev ice and the Temperature Contr oller, as described in

Table 2-1.

NOTE

If required, the procedure for adding a communication board to the Temperature

Controller is provided in Appendix A

Table 2-1. MODBUS Communication Signal Connections

8. Refer to Table 2-1, Figure 2-8 and/or the ECS wiring dia gram in Appendix B to wire the Ground (HD) ,

Receive (HE) and Transm it (HF) terminals of the T emperature Controller to the RS23 2-9, RS232-25

or RS485 connector on the EMS, BAS or computer.

Examples of cable types suitable for this purpose are: Belden 9841, 8761, 3105A, or equivalent.

Ensure that the RS232 or RS485 cable connections do not exceed the following lengths:

• RS232 Cable: 50 feet, maximum

• RS485 Cable: 4,000 feet, maximum

NOTE

For best results, DO NO T run MODBU S com m unication wiring in t he sam e c onduit as

power wiring which can couple excessive noise and/or hum into the MODBUS lines.

Rev B Mar 2013

Page 20

HE-111 − INSTALLATION

2-10

1A

HA

1B

HB

1C

HC

2A

2B

1D

HE

HF

HD

3B

3D

3C

2D

3A

2C

JD

JF

JE

JB

JC

JA

LA

LB

LC

AA

AB

AC

VI

V+

V-

Input 1

C

2408 CONTROLLER

L

N

Input 2

MODBUS CONTROL

DEVICE

SHIELDED TWISTED PAIR

Figure 2-8. Cable Connections for Eurotherm 2408 Temperature Controller

2.4.6 Control System Programming Information

Appendix A lists the MOD BUS data addresses for the 2408 C ontroller. The procedures for changing the

Controller address is also provided in Appendix A. Also included are references to the manufacturer’s

handbooks covering the Temperature Controller communication option.

Rev B Mar 2013

Page 21

3-1

CHAPTER 3 FUNCTIONAL DESCRIPTION

COLD WATER

INPUT

HOT WATER OUTPUT

RECIRULCATION

PUMP

3.1 INTRODUCTION

The AERCO DW-series steam-to-water heat exchangers incorporate double–wall heat tubes, in which

steam circulating in a bundle of imm ersed double-wall prim ary tubes heats the s ervice water in the he at

exchanger’s shell. The following Mechanical Description (3.2) briefly discusses how double-wall heat

tubes work and describes each of the principal steam-to-water heat exchanger components. The

Mechanical Description is followed by a discussion of the Electronic Control System (3.3), which regulates

the heat exchanger water tem perature and activat es alarm s and shutdown proce sses in the event s afety

limits are exceeded.

3.2 MECHANICAL DESCRIPTION

3.2.1 Overview

Referring to Figure 3-1, c old service water enter ing the heat exchanger thr ough the Cold Water Input is

dispersed evenly througho ut the heat exchanger shell. As the cold water flows upward, it is heated by

steam circulating through the immersed tube bundle. The heated service water exits through the Hot

Water Output connection in the upper head assembly.

UPPER HEAD ASSEMBLY

RECIRCULATION

PIPING

UPPER

TUBESHEET

LOWER

TUBESHEET

CONTROL BOX

SHELL

LOWER HEAD

ASSEMBLY

CONDENSATE

OUTPUT

AERCO

CXT-E ACTUATOR

CXT-E CONTROL

VALVE

STEAM INPUT

Figure 3-1. AERCO Steam-to-Water Double-Wall Heat Exchanger

The heating steam enters through the CXT-E Control Valve at the bottom of the heat exchanger

assembly and flows thr ough the inner tubes of the double-wall tube bund le. The flowing steam transfers

its heat to the service water contained within the shell, condenses and exits through the Condensate

Output connection.

The flow rate of the heated water varies according to the demand for hot water. The flow rate of the

steam is regulated by the Tem perature Contr oller in th e Control Box so as to maintain the tem perature of

Rev B Mar 2013

Page 22

HE–111− FUNCTIONAL DESCRIPTION

3-2

STEAM

PRIMARY TUBE

INNER WALL

HEATED SHELL-SIDE

SERVICE WATER

PRIMARY TUBE

OUTER WALL

AIR SPACE

the delivered hot water t o within ±4 °F of the Contr ol Box sett ing, un der nor m al, divers ified lo ad con ditions

(load fluctuations of up to 25% of water heater capacity).

3.2.2 Double-Wall Heat Transfer and Water Leakage

As illustrated in Figur e 3-2, the heat exchanger’s prim ary tubes incorporate doubl e-wall construction in

which the inner and outer tube walls are separated b y air space. T he steam flows within the double-wall

primary tubes’ inner walls. Any condensate leaking outward through the inner walls is trapped within

vented air space bet ween the inner an d outer tube wal ls. A ny serv ice water th at l eaks inward t hrough t he

outer tube walls is sim ilarly contained within th e air space. T he accumulated leakage water is conducted

along these air spaces, collected in the bottom head (see 3.2.3.2) and discharged through an

atmospherically vented leak detection port. This construction effectively provides double protection

against primary steam or condensate leaking into the service water, or vice versa. However, it is not

unusual for moistur e to appear at the leak detection port at in itial heat exchanger start-up, even when

there are no tube leaks . This moisture results from water condens ing during the manufacturing proc ess

and being expelled when the system is initially operated.

Figure 3-2. Segment of a Double-Wall Primary Tube

3.2.3 Principal Mechanical Components

The AERCO DW -series heat exchanger cons ists of the following pri ncipal mechanical com ponents (see

Figure 3-3):

• Shell and heads (3.2.3.1)

• Double-wall U-bend tube bundle and tubesheet (3.2.3.2)

• Recirculation pipe and pump (3.2.3.3)

• Electronic CXT-E Control Valve (3.2.3.4)

Rev B Mar 2013

Page 23

HE–111 − FUNCTIONAL DESCRIPTION

3-3

COMPOUND PRESSURE

GAUGE

STEAM INPUT

SOLENOID VALVE

CONDENSATE OUT

PLUGGED DRAIN

TEMPERATURE CONTROLLER

CXT-E CONTROL VALVE

VACUUM BREAKER

PRESSURE AND

TEMPERATURE

RELIEF VALVE

CXT-E ACTUATOR

CONTROL BOX

SHELL

COLD

WATER

INPUT

HOT WATER OUTPUT

LEAK

DETECTION

PORT

RECIRCULATION

PUMP

RECIRCULATION

PIPING

OUTLET MANIFOLD

LOWER SHELL

FLANGE

UPPER SHELL

FLANGE

UPPER HEAD

ASSEMBLY

LOWER HEAD

ASSEMBLY

Figure 3-3. AERCO Double-Wall Heat Exchanger, Model DW-24

3.2.3.1 Shell and Heads

The heat exchanger body incorporates a stainless steel shell, bronze upper head and navy brass

tubesheets, forming a pressure vessel that conforms to ASME standards. The heat exchanger body

encloses the tube bundle and tubesheets.

3.2.3.2 Double-Wall U-Tube Bundle and Tubesheets

The double-wall U-bend copper tubes that conduct steam through the heater shell conform to BOCA

(National Plumbing Co de), IAPMO (Unif orm Plum bing Code) and NAPHC C (National Sta ndard Plum bing

Code), the three nat ional st andards that addr es s doubl e-w all cons tructi on. The o ut er wall of each doubl ewall tube is brazed to the upper tubesheet, and the inner wall is brazed to the navy brass lower

tubesheet. Any tube leak age from the air spaces between the inner and outer walls of the double-wall

tubes accumulates in t he space between t he bottom shell flang es which make up the bottom head. The

accumulated leakage water is discharged through the leak detection port.

3.2.3.3 Recirculation Pipe and Pump

Referring to Figure 3-3, th e recirculation pipe and constant-rate r ecirculation pump deliver a continuous

sample of the heated o utput water to a 1½-inch pipe junction with the Cold W ater Input pipe to reg ulate

steam flow at the Steam Input (see 3.3.2).

3.2.3.4 CXT-E Control Val ve

The CXT-E Control Valve regulates the flow rate of steam into the heat exchanger in response to

positioning control signaling from the Temperature Controller (see 3.3.2). The CXT-E Control Valve

consists of a valve body and linkage to the CXT-E Actuator. The CXT-E Actuator is discussed in 3.3.4.5.

Rev B Mar 2013

Page 24

HE–111− FUNCTIONAL DESCRIPTION

3-4

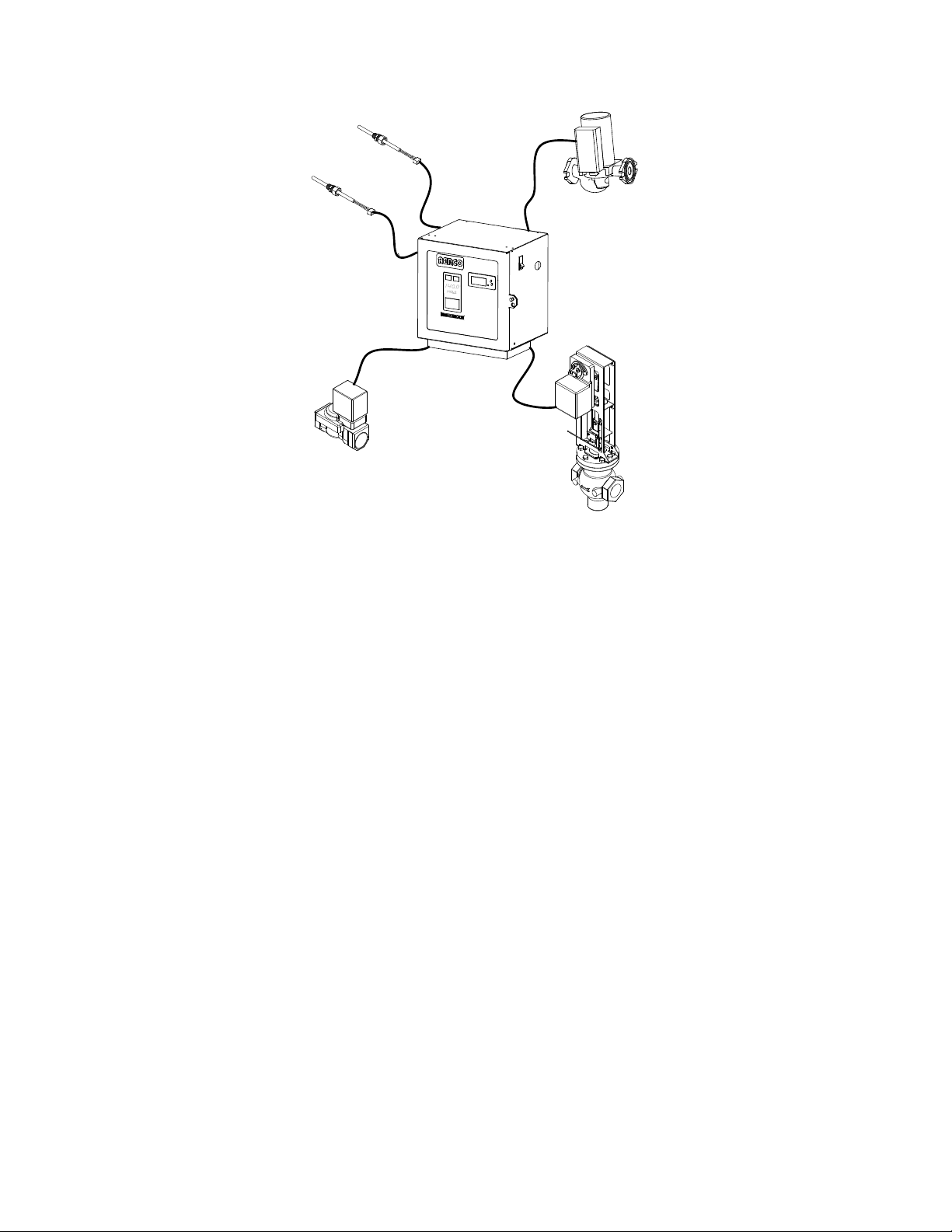

DHW

DUAL OUTLET

TEMP. SENSOR

OVER-TEMPERATURE

SOLENOID VALVE

CONTROL BOX

ASSEMBLY

CONSTANT FLOW

RECIRCULATION

PUMP

FEED-FORWARD

MIXTURE TEMP.

SENSOR

CXT-E ACTUATOR

CXT-E CONTROL

VALVE

3.3 ELECTRONIC CONTROL SYSTEM

The Electronic Control S ystem consists of the interna l Control Box components and a number of sensor

and safety devices distributed throughout the heat exchanger assembly (see Figure 3-4).

3.3.1 ECS Block Diagram

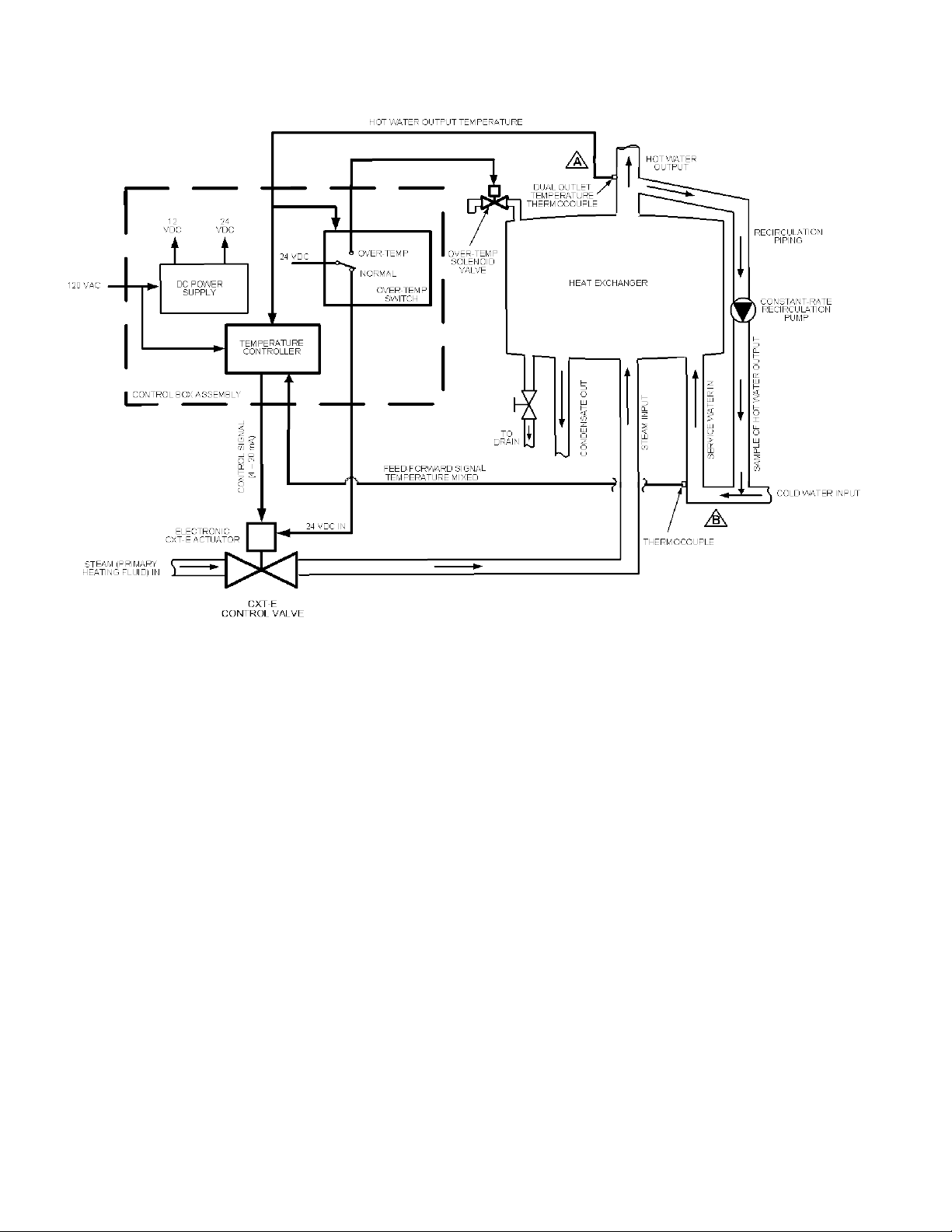

A simplified block diagram of the ECS is presented in Figure 3-5.

Figure 3-4. Electronic Control System Components

Rev B Mar 2013

Page 25

HE–111 − FUNCTIONAL DESCRIPTION

3-5

Figure 3-5. ECS Simplified Block Diagram

3.3.2 ECS Operational Summary

The ECS adjusts the flow rate of steam into the heat exchanger in response to:

• The water temperature at the Hot Water Output (at A)

• The water temperature of the sampled Hot Water Output mixed with the Cold Water Input (at B)

Changes in hot water dem and vary the flow rate of service water through t he heat exchanger, requirin g

compensating adjustments of the steam flow rate to maintain the service water temperature. To

determine what steam flow rate adjustments are required, the Temperature Controller m onitors (via the

feed-forward signal) t he temperature of a continuous sam ple of output hot water mixed (at B) with th e

cold water input. T he m ixture tem perature cha nges ac cording to the flo w rate of the incom ing cold water,

which in turn depends on the hot water demand.

The Temperature Co ntroller calc ulation of the optimum steam flow rat e into the heat exchanger is based

on a mathematical process known as the Proportional Integral D erivative (PID) algorithm , which accepts

as inputs the measured outlet and inlet temperatures of the system.

3.3.3 Over-temperature Condition

At startup, the operator programs the maximum safe water temperature into the Control Box. During

operation, the Temperature Controller monitors the Hot Water Output temperature to ensure that the

programmed max imum s afe tem per atur e is not ex c ee ded. If it is, t h e T em per ature C ontro ll er opera tes th e

Over-temperature Solenoid Valve (see 3.3.4.4) to relieve excessive temperature buildup in the heat

exchanger.

Rev B Mar 2013

Page 26

HE–111− FUNCTIONAL DESCRIPTION

3-6

TEMP CONTROLLER

HOLD

RUNAUTO

MAN

2408

PT.NO.

OVER TEMP SWITCH

PANEL

DOOR

TEMPERATURE

CONTROLLER

OVER-TEMPERATURE

SWITCH

3.3.4 Principal ECS Components

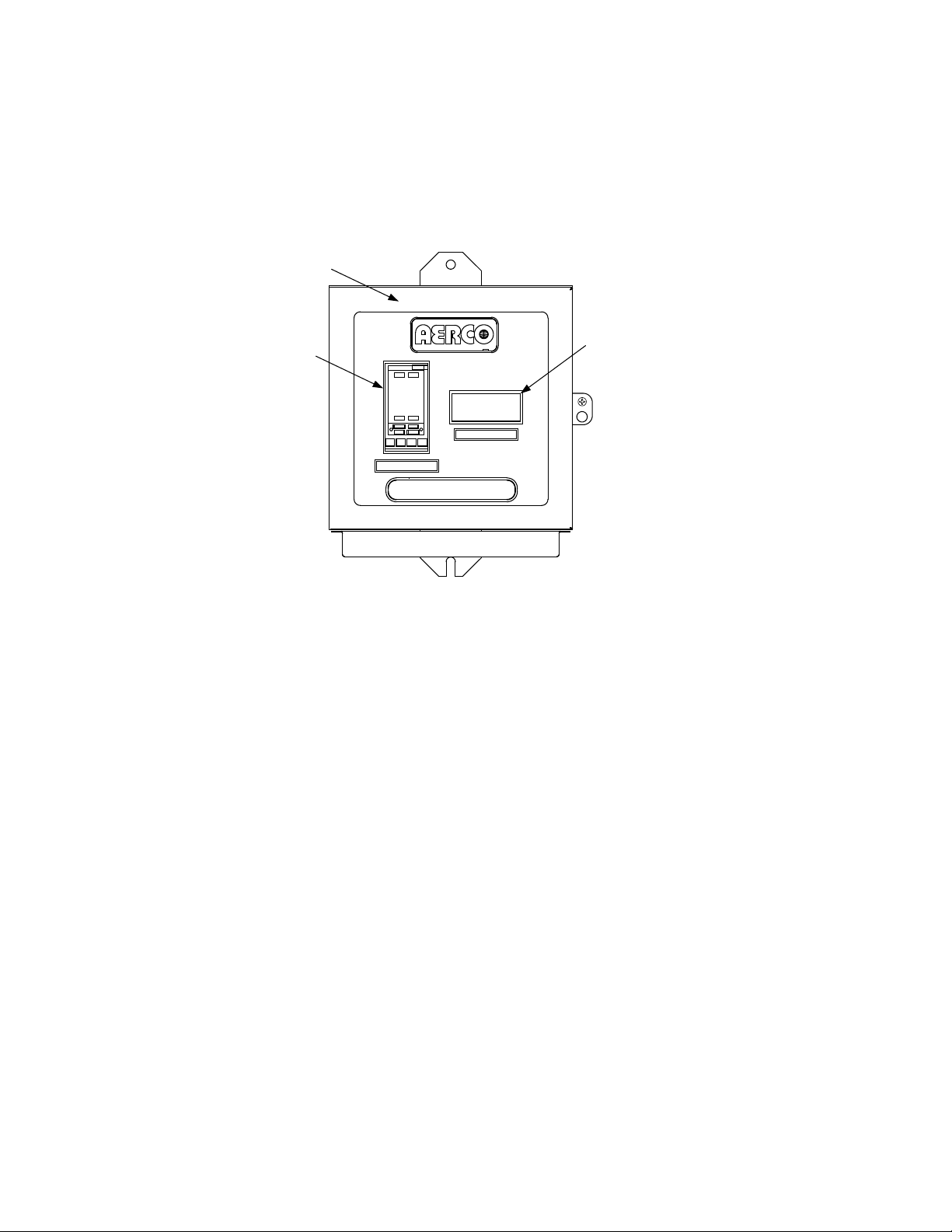

3.3.4.1 Control Box Assembly

The Control Box Assembly houses the components that monitor heat exchanger temperatures and

operate system controls. The Control Box is illustrated in Figure 3-6. The Control Box components include

the Temperature Controller, Over-temperature Switch and dc Power Supply/Voltage Regulator (not

shown).

Figure 3-6. Control Box Front View

Temperature Controller. The Temperature Controller processes data received from the

temperature and flow se nsors. Using the PID alg orithm, the T emperature Controller c alculates the

optimum steam flow rate to maintain the Hot W ater Output temperature within the programm ed

range. The Temperature Controller translates the optimum flow rate into a 4-to-20 mA control

signal to the CXT-E Control Valve Actuator to adjust the Control Valve opening.

Over-temperature Switch. The Over-temperature Switch compares the output hot water

temperature to the progra mmed high temperatur e limit, typicall y 20°F above the heater setpo int. If

the measured Hot Water Output temperature exc eeds the maxim um setting, the Over -temperature

Switch sounds an a udible alarm and activates t he Over-temperature Solen oid Valve, causing the

overheated water to be dumped from the heater shell. Simultaneously, the Over-temperature

Switch cuts off dc power to the CXT -E Control Valve Actuator, shutt ing off the flow of steam into

the heat exchanger.

DC Power Supply/Voltage Regulator. The dc power supply within the Control Box converts the

120 VAC primary power to 12 VDC and 24 VDC to operate the Control Box com ponents, Overtemperature Switch, Over-temperature Solenoid Valve and the CXT-E Actuator.

3.3.4.2 DHW Outlet Dual Temperature Sensor

The DHW outlet dual temperature sensor consists of dua l thermocouple sensing elements mounted in the

top head. The DHW outlet dual tem perature sensor continuous ly monitors t he service water temper ature

at the Hot Water Output and trans m its it sim ultaneously to bot h the T emperatur e Contro ller and the Ov er temperature Switch in the Control Box.

3.3.4.3 Feed-Forward Mixture Temperature Sensor

The feed-forward m ixture temperature sensor is ins talled in the Cold W ater Inlet nozzle to measure the

mixture temperature of the combined input cold water and the recirculated sample of the Hot Water

Output.

Rev B Mar 2013

Page 27

HE–111 − FUNCTIONAL DESCRIPTION

3-7

3.3.4.4 Over-temperature Solenoid Valve

The Over-temperature Solenoid Valve is operated by the Over-temperature Switch in the Control Box.

When the preset high temperature limit is exceeded at the Hot Water Output, The DHW Outlet Dual

Temperature Sensor s ignals the Over-temperature Sw itch, energizing th e Solenoid Valve and relieving

the temperature build-up in the heat exchanger.

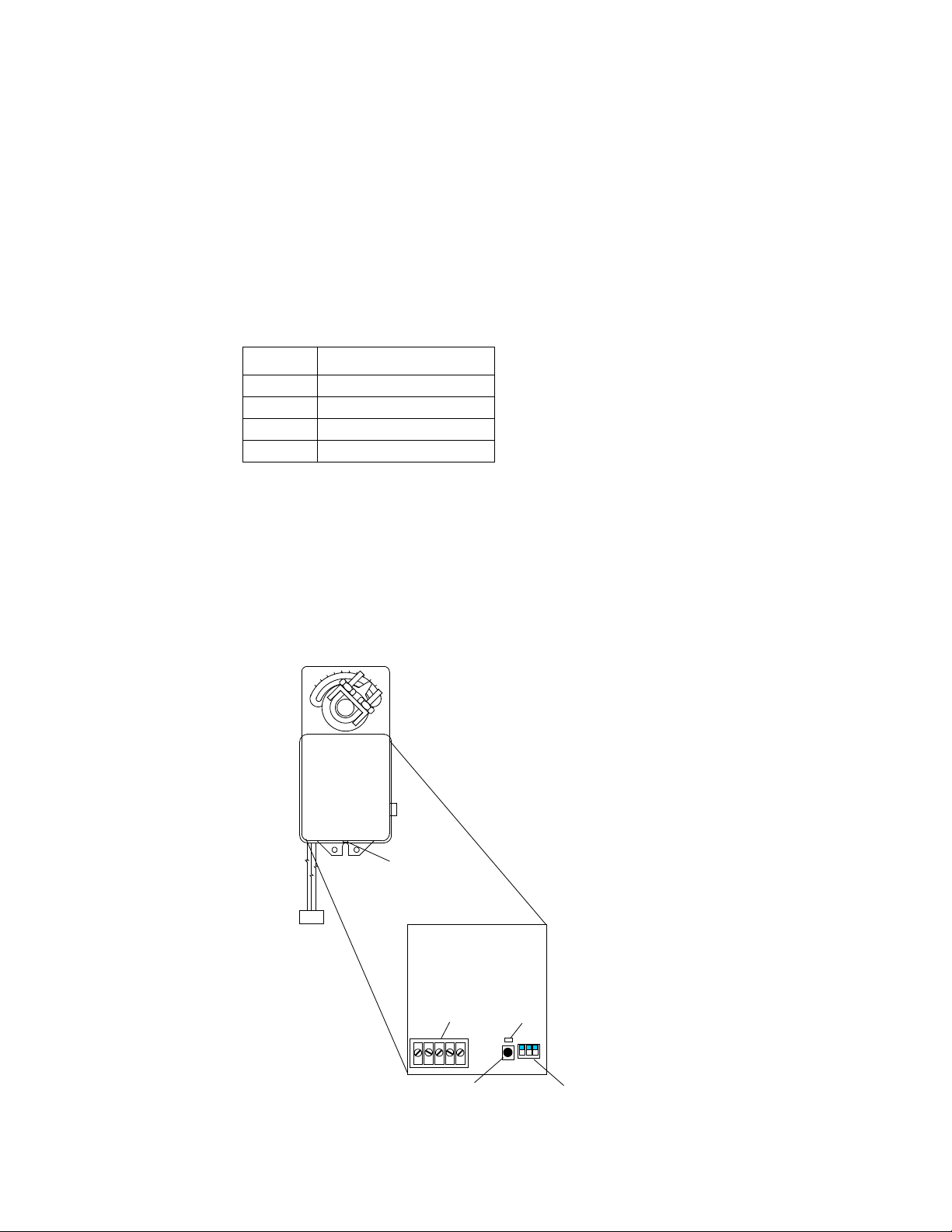

3.3.4.5 Electronic CXT-E Control Valve Actuator

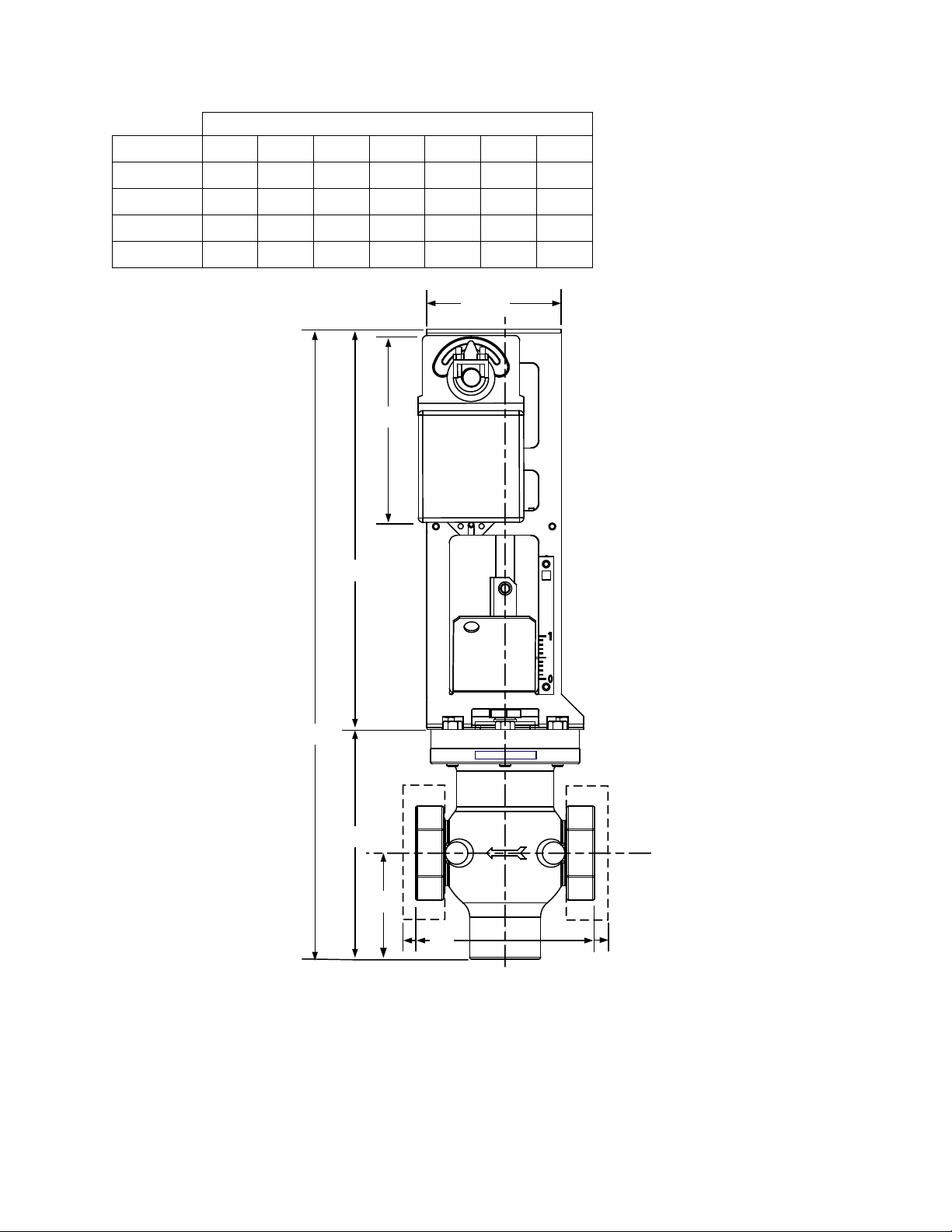

The Electronic CXT-E Actuator operates the CXT-E Control Valve, as discussed in 3.2.3.4. Control

Valves are available in pipe sizes ranging from 1 inch to 4 inches. Figure 3-7 identifies the basic

dimensions for each size Electronic CX T-E Control Valv e. The CXT-E Actua tor is identical for e ach size

valve. The linkage assemblies used with each size valve body are nearly identical, except for minor

differences in the shaft adapter stroke of the mechanical linkage.

Rev B Mar 2013

Page 28

HE–111− FUNCTIONAL DESCRIPTION

3-8

A

B

C

D

13.375

6.60"

4.50"

VALVE SIZES (INCHES)

Dimension 1.00 1.25 1.50 2.00 2.50 3.00 4.00

A 21.12 21.12 21.12 24.25 24.25 24.25 24.25

B 7.75 7.75 7.75 7.75 10.87 10.87 10.87

C 3.56 3.56 3.56 3.56 6.38 6.38 6.38

D 6.00 6.00 6.00 6.00 10.87 10.87 10.87

Figure 3-7. CXT-E Control Valve and Actuator

Rev B Mar 2013

Page 29

AC-105 INSTRUCTIONS - ECS & CXT-E

TEMP CONTROLLER

HOLD

RUN

AUTO

MAN

2408

PT.NO.

OVER TEMP SWITCH

PANEL

DOOR

OVER-TEMP

SWITCH

TEMPERATURE

CONTROLLER

POWER

SWITCH

[

SEE

FIGURE 4-3

CHAPTER 4 ADJUSTMENT

4.1 INTRODUCTION

This chapter explains the procedures you use to adjust the CXT-E Control Valve (“Valve”), Electronic

CXT-E Actuator (“Actuator”) and Electronic Control System (ECS). The ECS is factory adjusted to the

setpoint temperature s pecified on the sales order, and the Actuator is factory adjus ted (auto-stroked) to

ensure that it correctly operates the Valve from the fully-open to the fully-closed positions.

To the extent necessar y, perform all the procedures listed in 4.2 and 4.3 before placing the system into

operation and after replacing the Valve or any ECS components.

CAUTION

BE SURE that all steam shutoff valves are fully closed before performing any of the following

adjustment procedures.

4.2 ADJUSTING THE ELECTRONIC CXT-E ACTUATOR

The Actuator is self-calibrating for all size Valves. The Actuator is power ed b y 24 VDC and contro ll ed b y a

linear 4-to-20 mA control signal, as follows:

• A 4 mA control signal input operates the Valve to the fully-closed position (Valve shaft down)

• A 20 mA signal strokes the Valve to the fully-open position (Valve shaft up).

When properly connected t o the ECS, applying po wer to the Control Box applies +24 VDC power to the

Actuator. The power switch is located on the right side of the Control Box, as illustrated in

Figure 4-2.

Figure 4-1. Contr ol Box – Front View

IMPORTANT

Perform this adjustm ent af ter three m onths of use and annual ly there after . Also, t his adjustment is

mandatory each time the Actuator is replaced or when mechanical adjustments are m ade to the

Valve or its linkage.

Rev B Mar 2013 4-1

Page 30

AC-105 INSTRUCTIONS - ECS & CXT-E

1

1”

2

1.25” and 2.5”

3

1.5” and 3”

4

2” and 4”

0

90

neptronic

1 2 3

1 2

3

4 5

1

2

3

DIP SWITCHES (3)

(ALL IN UP POSITION)

AUTO-STROKE

(RESET) BUTTON

LED

TERMINALS

PC BOARD

COVER

SET SCREW

ACTUATOR

Automatically adjust the Actuator as follows:

1. Referring to Figure 4-2, loosen the set screw on the Actuator cover.

2. Remove the Actuator cover to access the PC board containing the terminal connections,

DIP switches, Auto-Stroke (Reset) Button and LED.

3. Referring to Figure 4-1, use the power s witch to tur n on th e Control Box and apply 24 VDC po wer to

the Actuator. (On the terminal strip: pin 2 = +24 VDC, pin 1 = Common) .

The LED will light indicating that power is applied to the Control Box.

4. Wait approximately 10 seconds for the un it to perform its self-test. T he LED will blink f rom one to f our

times, depending on the size of the Valve, as follows:

Blinks Valve Size

5. For full-strok e automatic adj ustment, press the Reset button. T he LED will lig ht and the Actuator will

rotate in both directions to find its open and closed Valve position stops.

6. When the autom atic adjustm ent is complete, the LED will b link f rom one to four tim es, depending on

the size of the valves, as described in step 4, above.

7. Turn the Control Box power off to disconnect power to the Actuator.

8. Replace the Actuator cover and tighten the set screw.

4-2 Rev B Mar 2013

Figure 4-2. Actuator Adjustment

Page 31

AC-105 INSTRUCTIONS - ECS & CXT-E

AUTO

RUN

MAN HOLD

OP 1

OP 2

SP2

REM

2408

UPPER DISPLAY

(DISPLAY HOT

WATER OUTLET

TEMPERATURE)

AUTO SETPOINT

MAN VALVE % OPEN

AUTO/MAN MODE

INDICATORS

AUTO/MAN

PUSHBUTTON

OP1 INDICATOR

ARROW

BUTTONS

LOWER DISPLAY

MODE

DISPLAYS

4.3 ADJUSTING THE ELECTRONIC CONTROL SYSTEM

The ECS is factory set b y AERCO t o the setpoint temperature spec ified on th e sales order. N ormall y, the

over-temperature alar m limit is set 20°F abo ve the specified set point. If no setpoint or o ver-temperature

alarm lim it is specified, the ECS is set to the factory default values of 140 °F (setpoint) and 160 °F (overtemperature alarm limit).

To change the setpoint and over -temper ature alarm lim its, use the controls provided on the T emperatur e

Controller and the Over -temperature Switch. These controls are visible thro ugh t he Control Box f r ont door

window and can be accessed by opening the panel door (Figure 4-1).

4.3.1 Adjusting the Setpoint Temperature

Figure 4-3 illustrates and Table 4-1 describes the Temperature Controller controls and indicators. Use

these controls/indicators to adjust the setpoint temperature as follows:

1. Turn the Control Box power switch on and open the Control Box door.

2. Wait approximately 3 seco nds while the Tem perature Controller performs its self-test. When the test

is completed, the upper display will indicate the current heat exchanger Hot Water Output

temperature, and the lower display will indicate the setpoint temperature stored in memory

(default = 140°F), as illustra ted in Figure 4-3.

3. Ensure that the Temperature Contr oller is s et to the A UT O(m atic ) mode and the AUTO indicat or is lit.

If the MAN(ual) indicat or is lit, pr ess the AUTO/MAN pushbutt on to toggle th e mode sett ing. I ndicator

OP1 should also be lit.

4. Press the ▲ or ▼ arrow buttons, as necessary, to change the disp lay to the desired value.

5. Two seconds after the ▲ or ▼ arrow button is released, the display will blink to indicate that the

Temperature Controller has accepted and stored the displayed value.

Figure 4-3. Temperature Controller

Rev B Mar 2013 4-3

Page 32

AC-105 INSTRUCTIONS - ECS & CXT-E

INDICATOR

Output 1 Indicator

OP1 lights when a 4-to-20 mA signal is supplied to the

OP2

Output 2 Indicator

Not used for the ECS application

SP2

Setpoint 2 Indicator

Not used for the ECS application

active.

AUTO

MAN

reset to 0%.

RUN

HOLD

Scroll Button

Press the Scroll button to select a new parameter in a

list

Down Button

Press the Down button to decrease the value shown in

Table 4-1. Temperature Controller Operating Controls, Indicators and Displays

CONTROL /

OP1

REM

MEANING FUNCTION

Actuator, or when the valve position is above 0%.

Remote Setpoint

Indicator

Auto/Manual Button

and Indicators

Run/Hold Button

and Indicators

REM lights when the ECS is set up to be controlled by

a Remote (MODBUS) signal.

REM will flash when MODBUS communication is

Pressing the button toggles the Controller between the

automatic (AUTO) and manual (MAN) modes.

• AUTO lights when in the automatic mode.

• MAN lights when in the manual mode.

When entering the MAN mode, the Valve position is

Not used for ECS application

Page Button Press the Page button to select a new list of

parameters

the lower display

Up Button Press the UP button to increase the value shown in the

lower displa y

4.3.2 Adjusting the Over-Temperature Alarm Limit

Adjust the over-temperature alarm limit setting using the controls and displays illustrated in Figure 4-4

and described in Table 4-2. Adjust the over-temperature alarm limit as follows:

OVER-TEMPERATURE ALARM LIMIT ADJUSTMENT

The over-temperature alarm limit setting is adjusted using the controls and display on the OverTemperature Switch. The controls and display are illustrated and described in Figure 4-4 and Table 4-2. If

necessary, over-temperature alarm limit adjustment is accomplished as follows:

1. With the Control Box door open, set the ON/OFF POWER switch on the right side to the ON position.

2. Press the SET button on the Over-Temperature Switch. SP will appear in the display.

3. Press the SET button again. The current over-temperature limit value stored in memory will be

displayed (default = 160°F).

4-4 Rev B Mar 2013

Page 33

AC-105 INSTRUCTIONS - ECS & CXT-E

INDICATOR

MEANING FUNCTION

LED Display

TEMP status

Displays current water temperature or setpoint.

RST

RESET Button

Resets the unit after an alarm condition.

UP Button

Increases the displayed temperature.

DOWN Button

Decreases the displayed temperature.

SET

SET Button

Used to access and store parameters in the unit.

4. If the display does not sh ow the desired over-temperature alarm setting, press the ▲ or ▼ arrow

button to change the display to the desired temperature setting.

5. Once the desired over-temperature alarm setting is displayed, press the SET button to store the

setting in memory.

6. To exit the programming mode, press the SET and ▼ buttons simultaneously, or simply wait one

minute.

7. Once the programming mode has been exited, the display will show the current outlet water

temperature of the Heater.

Figure 4-4. Over-Temperature Switch

Table 4-2. Over-Temperature Switch Controls and Indicators

CONTROL or

Rev B Mar 2013 4-5

Page 34

HE-111 − ADJUSTMENT

4-6

This page intentionally left blank.

Rev B Mar 2013

Page 35

5-1

CHAPTER 5 OPERATION

5.1 INTRODUCTION

This chapter provides instructions for:

• Preparing your heat exchanger and Electronic Control System (ECS) for operation (5.2)

• Turning on the heat exchanger and setting it to run automatically (5.3)

• Shutting down and draining the heat exchanger (5.4)

5.2 PRE-OPERATIONAL

1. Refer to Chapter 2 Installation and verify that:

a.Electrical power is properly connected to the ECS and the CXT-E Control Valve.

b.All piping connections have been made according to recommended configurations.

c. All connecting piping has been cleaned (blown) out.

2. Refer to Chapter 4 Adjustments and ver ify that the T em perature Control ler setpo int (4.3.1) and Overtemperature Switch alarm limit (4.3.2) have been set properly.

5.3 STARTUP PROCEDURES

1. Referring to Figure 5-1, press the power switch on the r ight side of the C ontrol Box to appl y power to

both the Electronic Control System (ECS) and the CXT-E Control Valve. When power is initially

applied, the Temperature Controller automatically performs a self-test sequence for approximately

three seconds.

2. When the self-test is complete, the Temperature Controller will show the present hot water outlet

temperature in the upper display and the setpoint temperature in the lower display.

3. Set the temperatures to the desired setpoints on the Over-temperature switch and the Eurotherm.

4. Set the Eurotherm into the Man mode and set the Valve position to 0%. If the temperature in the

heater increases, see Chapter 7 Troubleshooting.

5. Open the stop valve in the C old Water Input line and h old t he relief valve in t he heat exchanger upper

head assembly open to enable air to escape (to avoid an air poc ket build-up which coul d prevent the

heat exchanger from f illing with water ) . When water flo ws out of t he relief valve, the heat exchanger is

full.

6. Open an y stop valves in th e building or proc ess recirculat ion system , if such a s ystem is inc luded in

the Heater installation.

7. Open the sto p valve in t he Hot W ater Output l ine. Open hot water fauc ets or va lves in the building or

process to ensure a flow of water through the heat exchanger.

8. Slowly open all stop valves in the Steam Input and Condensate Output lines. If double block and

bleed valving is used, make sure that the drain (bleed) valve is closed tight.

IMPORTANT

To prevent a possible over-temperature condition during initial start-up, be sure to

perform the following steps in the order specified:

Rev B Mar 2013

Page 36

HE-111 − OPERATION

5-2

TEMP CONTROLLER

HOLD

RUNAUTO

MAN

2408

PT.NO.

OVER TEMP SWITCH

PANEL

DOOR

OVER-TEMP

SWITCH

TEMPERATURE

CONTROLLER

POWER

SWITCH

[

WATER TEMPERATURE AT

HOT WATER OUTLET

SETPOINT TEMPERATURE

AUTO

RUN

MAN HOLD

OP 1

OP 2

SP2

REM

2408

UPPER DISPLAY

LOWER DISPLAY

AUTO/MAN MODE

INDICATORS

AUTO/MAN

PUSHBUTTON

OP1 INDICATOR

ARROW

BUTTONS

Figure 5-1. Contr ol Box

9. Referring to Figure 5-2, press the AUTO/MAN pushbutton to toggle the AUTO/MAN display to the

10. The upper display will continue t o show the cur rent heat ex chan ger out let w ater temperature, and the

11. Using the ▲ arrow button, set the CXT-E Control Valve to the 10% position and monitor the heat

12. Continue to open the valve further in 5% increments until the Hot Water Output temperature begins to

13. When the Hot Water O utput water temper ature has increased to with in 20°F of the desired setp oint,

Rev B Mar 2013

MAN (Manual) mode. The MAN indicat or will light.

Figure 5-2. Temperature Controller

lower display will show the position of the CXT-E Control Valve Actuator in %. When the Manual

mode is initially selected, the lower display will show 0%, indicating that the Control Valve is fully

closed.

exchanger Hot Water Output water temperature.

increase at a moderate rate.

press the AUTO/MAN button to set the Temperature Controller to the AUTO mode. The AUTO

indicator will lig ht and the MAN ind icator will go off. When the T emperature C ontroller is in the AUTO

Page 37

HE-111 − OPERATION

5-3

mode, the upper display will continue to show the heat exchanger Hot Water Output water

temperature, and the lower display will show the selected setpoint temperature.

14. In the AUTO mode, the ECS will stabilize at th e selected setpoint tem perature. When stabilized, t he

ECS is set for unattended operation and no further operator intervention is required.

15. Close the Hot Water faucets or valves that were opened in step 7.

5.4 SHUTTING DOWN AND DRAINING THE HEAT EXCHANGER

To shut down the heat exchanger:

1. Set the Eurotherm to the MAN(ual) in the 0% Valve position.

2. Close all stop valves in the Steam Input and Condensate Output lines.

3. IN THIS ORDER, close the stop valves in the:

a. Hot Water Output line

b. Recirculation line

c. Cold Water Input line

When the heat exchange has been shut down accor ding to steps 1 and 2, drain the heat exchanger as

follows:

4. CAREFULLY open the relief valve in the heat excha nger upper head assembly to r elieve pres sure in

the heat exchanger shell. If water continu es to flow from the relief valve, one of the cold water stop

valves is either leaking or is not shut tightly. Stop the flow from the relief valve and proceed.

5. Holding the relief valve open (to prevent creating a vacuum in the she ll), open the plugged drain at

the bottom of the heater exchanger shell and drain the heat exchanger completely.

Rev B Mar 2013

Page 38

HE-111 − OPERATION

5-4

This page intentionally left blank.

Rev B Mar 2013

Page 39

6-1

CHAPTER 6 SCHEDULED MAINTENANCE

INDICATOR

PLATE

VALVE

TOP

PACKING

NUT

P/O LINKAGE

ASSEMBLY

LOWER

SHAFT

6.1 INTRODUCTION

This chapter lists the preventive maintenance procedures recommended for the heat exchanger and

Electronic Control System (ECS). These recommendations include procedures to be performed each

week (6.2), month (6.3), quarter (6.4), six-month interval (6.5) and year (6.6).

The recommended preventive maintenance schedule is summarized in Table 6-1 at the end of this

chapter.

6.2 WEEKLY MAINTENANCE

□ Tube Leaks

Check the leak detection tube once each we ek for evidence of leaks in th e heat exchanger tubes.

MAKE CERTAIN T HAT THE DETECT ION TUBE NEVER GET S PLUGGED. If any flui d is escaping

from the detection tube, shut do wn the he at ex c hang e r as out li ned i n Section 5.4 and see Section 9.2

to investigate the leak.

6.3 MONTHLY MAINTENANCE

□ Steam Strainer

After the first month of operation, cle an the strain er in the Steam Input line in ac cordance with the

instructions furnished with the strainer.

□ CXT-E Control Valve

Check the CXT-E Control Valve (“Valve”) for leaks, as follows:

1. Referring to Figure 6-1, check the packing nut and Valve top for evidence of leakage.

Figure 6-1. Valve Shaft Seals

2. If there is leakage between the pac king nut and Valve top, tighten the packing nut unt il the leakage

stops. DO NOT FORCE the packing nut.

Take care not to over -tighten t he packing n ut to avoid tr apping the va lve

stem and slowing or stopping Valve motion.

CAUTION

3. If tightening the packing nut does not s top the leak, the pack ing nut and packing assembly m ust be

replaced in accordance with the procedures specified in Sections 8.2.2 and 8.2.3.

Rev B Mar 2013

Page 40

HE-111 − SCHEDULED MAINTENANCE

6-2

6.4 QUARTERLY MAINTENANCE

6.4.1 First Three Months

□ Accumulated Shell Solids

After the first three months of initial operation, drain the heat exchanger as follows:

1. Close all stop valves in the Steam Input and Condensate Output lines.

2. IN THIS ORDER, close the stop valves in the:

a. Hot Water Output line

b. Recirculation line

c. Cold Water Input line

3. CAREFULLY open the relief valve in the upper he ad assem bly to relieve pressure in th e shell. If fluid

continues to flow from the relief valve, one of the Cold Water Input stop valves is either leaking or is

not completely shut off. Securely close all Cold Water Input stop va lves until there is no mor e flow

from the relief valve.

4. WITH THE RELIEF VALVE HELD OPEN (to prevent creating a vacuum in the shell), open the

plugged drain at the bottom of the shell (see Figure 3-3), and drain the heat exchanger completely.

5. Examine the water being drained.

a. If the am ount of solids in the water being drained ap pears to be heavy, set a schedule to drain

the heat exchanger every 3 months.

b. If the amount of solids appears to be light, set a schedule to drain the heat exchanger every 6

months.

c. Even if the am ount of s olids appears to be v er y light o r not at all, set a sche dule t o drai n the heat

exchanger at least once eac h year.

6. To refill the heat ex changer and place it b ack into operation, replace the drain plug an d perform the

Pre-Operational and Operational steps l isted in Chapter 5.

6.4.2 Each Quarter

□ Valve Calibration

Refer to 4.2 and perform the CXT-E Actuator adjustment procedure as instructed.

□ Over-temperature Switch

Check the operation of the Over-temperature Switch as follows:

1. Refer to 4.3.2 and lower the over-temperature setting to approximately 5°F below the present

setpoint, as shown in the lower display of the Temperature Controller.

2. Verify that an over-temperature alarm is generated and the following events occur:

a. The CXT-E Control Valve closes.

b. The Over-temperature Soleno id (located at top of heat exchan ger) opens and e xpels water fr om

the system.

c. The Over-temperature Switch generates an audible alarm.

3. When you have successfully completed the over-temperature alarm check, return the Overtemperature Switch to its original setting.

Rev B Mar 2013

Page 41

6-3

6.5 SEMI-ANNUAL MAINTENANCE

□ Actuator

Refer to Section 4.2 and perform the Actuator adjustm ent procedure presented ther e. Verify that

the Actuator strokes the Control Valve from the fully closed to the fully open position.

□ Temperature Controller

Check the Temperature Controller operation at least every 6 months. Make any necessary

adjustments per Secti on 5. 3, steps 7 through 11.

□ Steam Strainer

Clean the strainer in the Steam Input line in accordance with the instructions furnished with the

strainer.

6.6 ANNUAL MAINTENANCE

□ Temperature Sensors

AERCO recomm ends that you check the temperature sensors once a year to ensure that there is

no scale build-up or clogging that may degrade system operation. To check the temperature

sensors, proceed as follows:

HE-111 − SCHEDULED MAINTENANCE

1. Close the upstream and downstream water supply valves to the heat exchanger.

2. Check the DHW Outlet Temperature Sensor at the Hot Water Output port. If necessary, clean it using

the following procedure:

a. Disconnect and remove the DHW Outlet Temperature Sensor (dual thermocouples).

b. Inspect for evidence of scale buildup on the stainless steel sleeve.

c. If necessary, clean the thermocouples using a wire brush.

3. After cleaning, reinstall both thermocouples and ensure the y are tight ene d securely.

4. Open all valves that were closed in Step 1 and res tore the heat exchanger to operation.

□ Recirculation Pump

The recirculation pump is located in the recirculation line, just above the Cold Water Input.

1. Turn the power switch on the Control Box to OFF.

2. Ensure that the water has been drained from the unit (see 6.4.1, steps 1-4).

WARNING

BEFORE PERFORMING THE FOLLOWING STEPS, ENSURE THAT

THE POWER SWITCH ON THE SIDE OF THE ECS CONTROL BOX IS

OFF AND THE HEATER HAS BEEN DRAINED AS SPECIFIED IN

6.4.1, STEPS 1 THROUGH 4.

3. Locate the recirculation pump and disconnect the flanges from the recirculation piping.

4. Without pulling on the e lectrical conduit attached to the recirculation p ump, carefully s lide it out and

inspect it.

Rev B Mar 2013

Page 42

HE-111 − SCHEDULED MAINTENANCE

6-4

□

□

□

□ Shell Solids*

□

□

□

□

□ Over-temperature Switch

□

□

5. If there is evidence of sc ale build-up, disconnect the condu it and el ectric al power lines f rom the pump

and service or replace it, as necessary.

6. If there is no evidence of s cale build-up on the recirculation pump, r einstal l it an d r ec onnect t he wiring

and flanges.

Table 6-1. Recommended Maintenance Schedule

Maintenance Check Week

Tube Leak

Control Valve Leak

Vacuum Breaker(s)

Over-temperature Switch Alarm

Temperature Controller

Actuator Adjustment

Steam Strainer

Temperature Sensor

Month

(6.3)

√

√

√

√

√

√

√

√

√

√

(6.4)

Quarter

(6.5)

Six Months

(6.6)

Year

(6.7)

Recirculation Pump

* Perform the first test for shell solids upon com pletion of the first three m onths of heat exchanger

operation. Depending upon the results (see 6.4.1, Step 5), repeat this test quarterly, semiannually or annually.

Rev B Mar 2013

√

Page 43

7-1

CHAPTER 7 TROUBLESHOOTING

7.1 INTRODUCTION

This section provides you with troubleshooting proc edures for isolating faults t o the most probable cause

whenever malfunctions occur in the heat exchanger (Table 7-1), CXT-E Electronic Control Valve

(Table 7-2), or Electronic Control System (ECS; Table 7-3). Table 7-4 provides troubleshooting tips for

correcting control s ystem faults, and Table 7-5 provides the d ynamic temperature control settin gs for the

three models of the DW-Series water heater product line.

Before performing the tr oubleshoot ing steps and pr ocedures pr ovided in T ables 7-1 throu gh 7-4, com plete

the following preliminary checks:

1. ELECTRONIC CONTROL VALVE, CXT-E a. Verif y that all piping conne ctions have been made in accordanc e with Figure 2-4 and that all

electrical connections have been made in accordance with Figure 2-7.

b. Ensure that the Electronic Control Valve (“Valve”) is installed with the flow arro w on the Valve

body pointing in the direction of flow.

c. Ensure that both the upstream and downstream shutoff valves are fully open.

2. ELECTRONIC CONTROL SYSTEM

a. Ensure that all ECS electrical cable connections are secure.

b. Ensure that the CXT-E Control Valve actuator is connected to the Control Box cable plug.

NOTE

When system m alfunctions occur, check the troubles hooting sections of the manuals

for any other equipment included in this installation, as necessary, in addition to the

procedures provided i n this section. Appendix A of this manual contains process fault

and diagnostic alarm information for the Eurotherm, Model 2408 Temperature

Controller.

7.2 TROUBLESHOOTING PROCEDURES

When a heat exchanger fault occurs, proceed as follows:

1. Refer to the FAULT INDICATION column in the following tables and locate the fault that best describes the existing conditions.

2. Proceed to the PROBABLE CA USE column. If m ore than one item is listed, start with the f irst item shown for the fault condition.

3. Perform the corresponding check s and proc edures list ed in the C ORRECT IVE A CT ION colum n for the first PROBABLE CAUSE.

4. Continue checking each additio nal PROBABLE CAUSE for the existing fault u ntil the fault has been corrected.

5. If component removal and /or replacem ent is required, refer to the appl icable procedures in Chapter 8 Corrective Maintenance.

Rev B Mar 2013

Page 44

HE-111 − TROUBLESHOOTING

7-2

Table 7-1. TROUBLESHOOTING – HEAT EXCHANGER

NO. FAULT INDICATION PROBABLE CAUSE CORRECTIVE ACTION

T1 The heat exchanger

does not maintain the

required temperature

at rated capacity.

1. The Control Valve does not open.

2. There is a leak in either the inside or outside

wall of one or more of the heat exchanger

tubes, as indicated by a flow from the leak

detection port.

3. Recirculating pump failure.

4. The heat exchanger tubes are scaled up.

5. The heat exchanger is being used at a rate

higher than its design capacity.

6. Steam pressure is too low.

7. Condensate is backing up into the heat

exchanger because of a restriction in the

condensate drain line.

8. The condensate return piping has not been

installed so as to enable the condensate to

drain freely by gravity, and/or the condensate

check valve leaks or has failed.

9. Thermocouple is not installed in the water flow.

10. The Temperature Controller reads wrong.

1. Check the instructions in Table 7-2.

2. Refer to Cha pter 9, secti on 9.2, and proceed as instructed.

3. Proceed as follows:

a. Check input power to the re c irc ulation pump.

b. Check the temperature of the copper tube above the pump.

It should be the same as the outlet DHW temperature. If

cold, repair or replace the pump, as needed.

4. Contact AERCO or your nearest AERCO representative.

5. Contact AERCO or your nearest AERCO representative.

6. Check the supply pressure gauge ahead of the Control Valve. If

the reading is low, adjust the steam supply pressure to the

required value. If the steam supply line is restricted, the gauge

reading will drop excessively when the heat exchanger calls for

full steam, even though the pressure seems to be normal when

the load is light. If the steam supply pressure is correct, the

steam pressure compound gauge reading should reach design

pressure for steam in the heat exchanger tubes as the Hot

Water Output temperature starts to drop. If it does not, check

the operation of the Control Valve.

7. Contact AERCO or the nearest AERCO representative for the

trap size required and make the necessary correction.

8. If necessary, rearrange the condensate return piping to permit

condensate to drain freely from the heat exchanger connection.

Inspect the condensate check valve and replace it if it is leaking

or has failed. Also, ensure that there is no restriction in the

condensate drain line.

9. Check to ensure that the thermocouple sheath does not

protrude more than ½“ from the compression fitting.

10. Check by replacing the Temperature Controller with one known

to be correct.

Rev B Mar 2013

Page 45

HE-111 − TROUBLESHOOTING

7-3

Table 7-1. TROUBLESHOOTING – HEAT EXCHANGER, continued

5. The Steam Input does not c lose.

5. Check the instructions in Table 7-2, Item T11.

NO. FAULT INDICATION PROBABLE CAUSE CORRECTIVE ACTION

T2 Heat exchanger

overheats

T3 Hot water outlet

temperature

fluctuates widely

1. Temperature Controller is indicating the wrong value.

2. Water is preheated too hot.

3. Termocouple is not installed in the water flow.

4. Leaking valve in by-pass line, if any, around the

Control Valve.

1. The Control Valve does not close.

2. The Control Valve does not open.

3. There is a leak in either the inside or outside wall of

one or more of the heat exchanger tubes, as

indicated by a flow from the leak detection port.

4. The heat exchanger is being used at a rate higher

than its design capacity.

5. Steam pressure is too low.

1. Check by replacing the Temperature Controller with one

known to be correct.

2. Reduce the preheating to a temperature at least 10°F

below the desired Hot Water Output temperature.

3. Check to ensure that the thermocouple sheath does not

protrude more than ½“ from the compression fitting.

4. Maintain the valve to shut tight.

1. Determine if the packing is too tight. See the instructions in

Table 7-2.

2. Determine if the packing is too tight. See the instructions in

Table 7-2.

3. Refer to Chapter 9, Section 9.2, and proceed as instructed.

4. Contact AERCO or your nearest AERCO Representative

for advice in remedying this problem.

5. Check the supply pressure gauge ahead of the Control

Valve. If the reading is low, adjust the steam supply

pressure to the required value. If there is a restriction in the

steam supply line, the gauge reading will drop excessively

when the heat exchanger calls for full steam, even though

the pressure seems to be normal when the load is light. If