Page 1

GF-131

AERCO Control System (ACS)

Installation, Operation, and Maintenance Manual

OMM-0081_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

High Efficiency Innovation

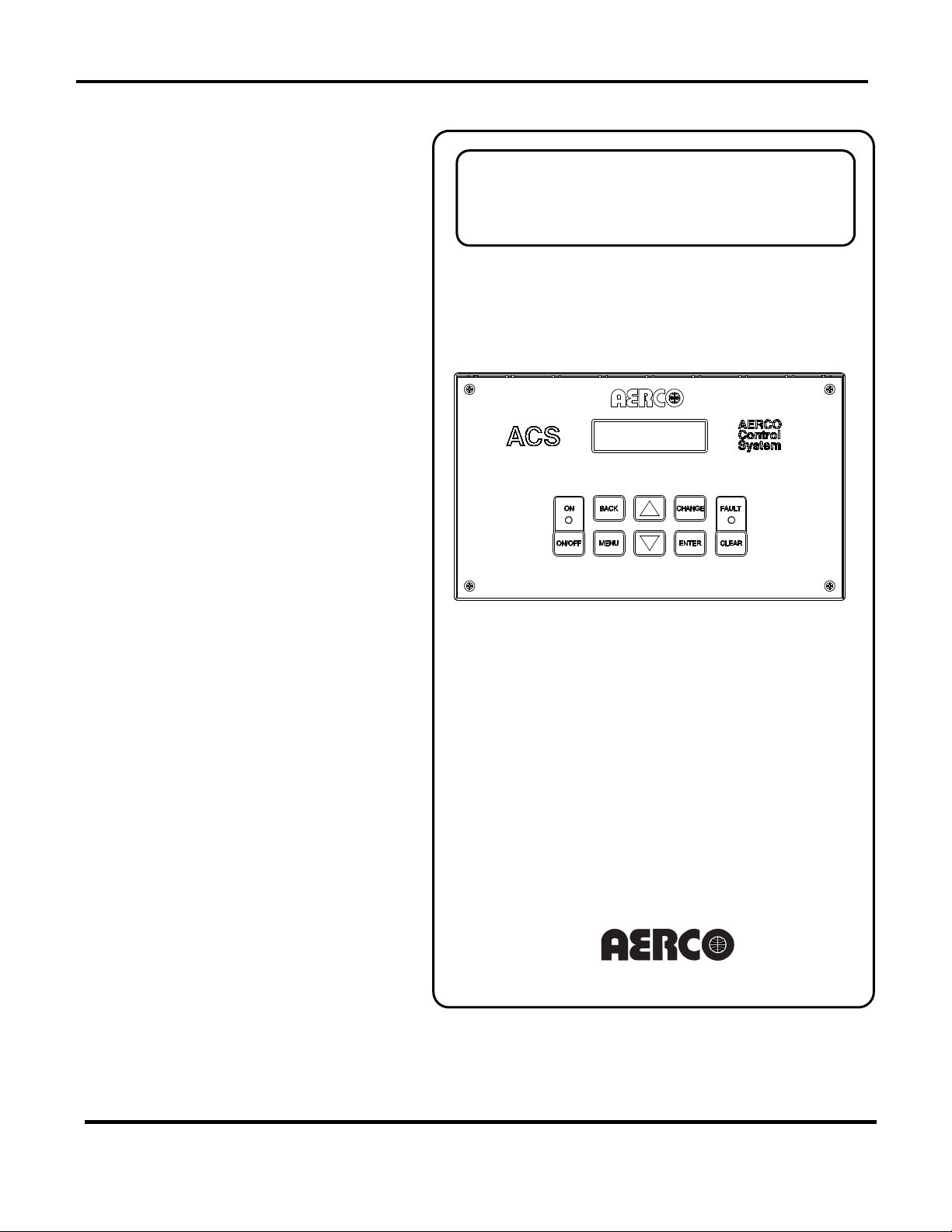

AERCO Control System

(ACS)

USER MANUAL

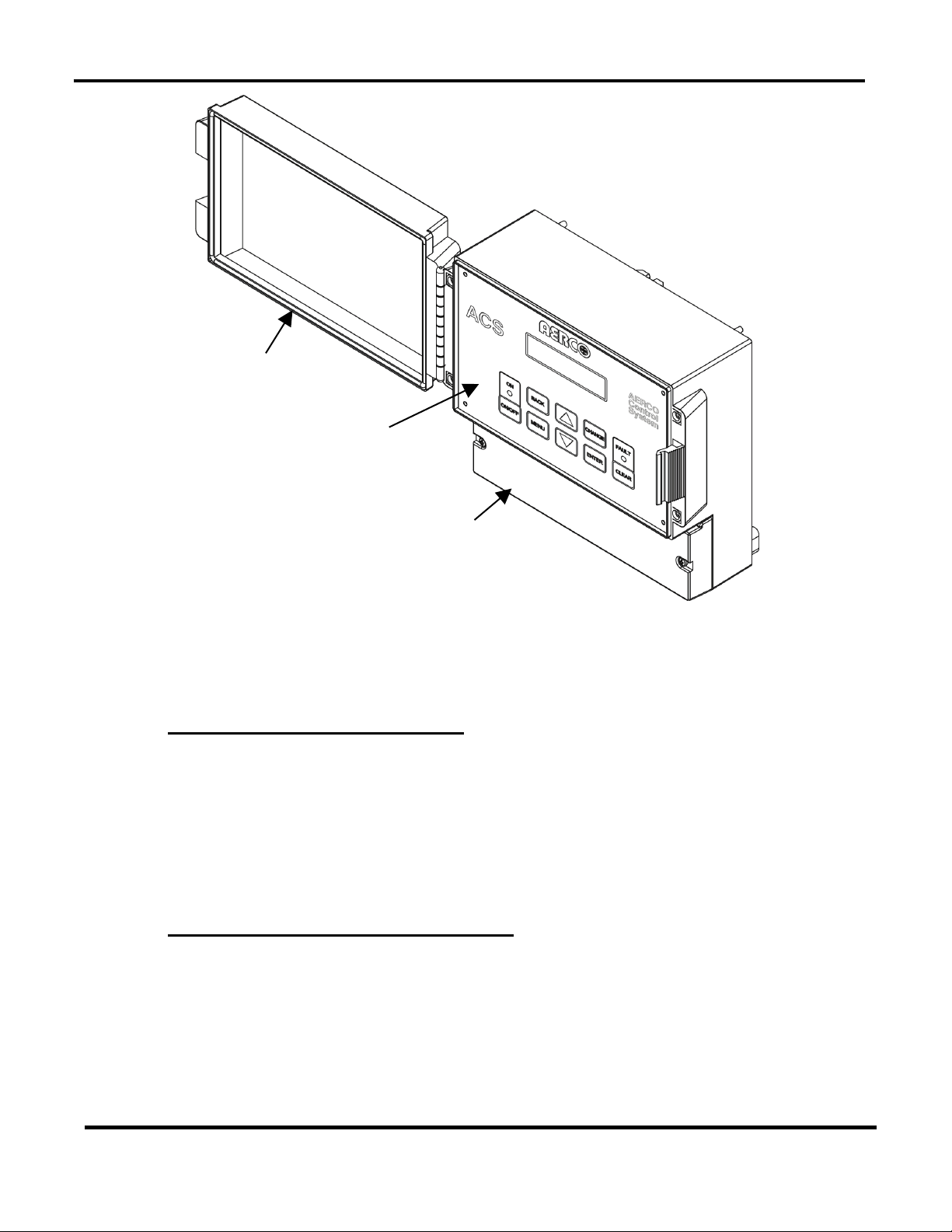

AERCO Control System (ACS) Front Panel

Revised: 04/23/2013

Used for up to Thirty-two (32)

• Benchmark Series Boilers

Installation, Operation, and Maintenance

AERCO Boilers including:

• AERCO Modulex Series Boilers

• AERCO KC-1000 Series Boilers

MC2: 04/23/13 Page 1 of 144

Page 2

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Technical Support:

1-800-526-0288

www.aerco.com

(Mon–Fri, 8am-5pm EST)

Disclaimer

The information contained in this manual is subject to change without notice from AERCO International,

Inc. AERCO makes no warranty of any kind with respect to this material, including but not limited to

implied warranties of merchantability and fitness for a particular application. AERCO International is not

liable for errors appearing in this manual. Nor for incidental or consequential damages occurring in

connection with the furnishing, performance, or use of this material.

MC2: 04/23/13 Page 2 of 144

Page 3

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Table of Contents

FOREWARD ................................................................................................................... 9

PHRASES, ABBREVIATIONS & ACRONYMS .......................................................... 9

1. ACS GENERAL INFORMATION ........................................................................... 11

1.1 SAFETY PRECAUTIONS AND WARNINGS .................................................. 11

1.2 INTRODUCTION .............................................................................................. 11

1.3 ACS GENERAL DESCRIPTION ...................................................................... 11

1.4 ACS FEATURES ............................................................................................. 12

1.4.1 Simplified Installation and Set-Up ........................................................... 12

1.4.2 User-Friendly Control System Interface ................................................. 12

1.4.3 Retention of Menu Option Settings ......................................................... 13

1.4.4 Application Flexibility .............................................................................. 13

1.4.5 Sequential or Parallel Operation ............................................................. 13

1.4.6 Accuracy ................................................................................................ 13

1.4.7 Bumpless Transfer ................................................................................. 13

1.4.8 Fault Alarm Surveillance ........................................................................ 13

1.4.9 ACS Programming Via RS232 Port. ....................................................... 13

2. ACS INSTALLATION ............................................................................................. 15

2.1 INTRODUCTION .............................................................................................. 15

2.2 SITE SELECTION AND MOUNTING .............................................................. 15

2.2.1 Mounting the ACS .................................................................................. 15

2.3 SITE SELECTION AND MOUNTING .............................................................. 16

2.4 POWER WIRING ............................................................................................. 17

2.5 SENSOR INSTALLATION AND WIRING ........................................................ 18

2.5.1 Header Sensor Installation ..................................................................... 19

2.5.2 Return Sensor Installation ...................................................................... 19

2.5.3 Outdoor Air Sensor Installation............................................................... 20

2.6 RS485 (MODBUS) WIRING AT THE ACS ...................................................... 22

2.6.1 ACS Bias Switches & Loop Termination Resistors ................................. 22

2.7 RS485 (MODBUS) WIRING, BIAS, AND TERMINATION AT AERCO

2.7.1 RS485 Wiring, Termination& Bias for Benchmark Series and KC1000 Boilers . 23

2.7.2 RS485 Wiring for Modulex Series Boilers .............................................. 29

2.8 SAMPLE RS485 (MODBUS) NETWORK DIAGRAMS ................................... 30

2.9 RS485 WIRING AT THE ACS ......................................................................... 31

BOILERS ................................................................................................................... 23

MC2: 04/23/13 Page 3 of 144

Page 4

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

2.10 INTERLOCK WIRING ...................................................................................... 32

2.10.1 Interlock 1 (INT 1) Wiring ....................................................................... 32

2.10.2 Interlock 2 (INT 2) Wiring ....................................................................... 32

2.11 SETBACK WIRING ......................................................................................... 32

2.12 RELAY WIRING ............................................................................................... 32

2.12.1 System Start Relay ................................................................................. 33

2.12.2 Fault Alarm Relay ................................................................................... 33

2.12.3 Auxiliary Relay ........................................................................................ 33

2.13 4-20 MA WIRING ............................................................................................. 33

2.14 MOUNTING AND WIRING THE OPTIONAL ACS RELAY BOX ..................... 33

2.15 RELAY PANEL INSTALLATION AND WIRING .............................................. 34

2.16 RELAY PANEL COMPONENTS ..................................................................... 39

2.16.1 Power ..................................................................................................... 39

2.16.2 Inputs .................................................................................................... 39

2.16.3 Outputs .................................................................................................... 39

2.17 RELAY PANEL OPERATION .......................................................................... 40

2.18 ACS PROGRAMMING FOR USE WITH THE ACS RELAY PANEL ............... 41

2.18.1 RS485 Menu .......................................................................................... 41

2.18.2 Configuration Menu ................................................................................ 41

3. OPERATION .......................................................................................................... 43

3.1 INTRODUCTION .............................................................................................. 43

3.2 FRONT PANEL OPERATING CONTROLS AND DISPLAYS ......................... 43

3.3 ACS MENU STRUCTURE ............................................................................... 45

3.3.1 Menu Processing Procedure .................................................................. 45

3.4 OPERATING MENU ........................................................................................ 47

3.4.1 HEADER TEMP AND PERCENT OF LOAD .......................................... 47

3.4.2 HEADER SETPOINT ............................................................................. 47

3.4.3 OUTSIDE AIR TEMP ............................................................................. 47

3.4.4 I/O STATUS ........................................................................................... 48

3.4.5 RETURN TEMP ..................................................................................... 48

3.4.6 NETWORK BOILER OUTLET TEMPERATURE .................................... 48

3.4.7 NETWORK BOILER ERROR CODE ...................................................... 48

3.5 SETUP MENU .................................................................................................. 48

3.5.1 ENTER PASSWORD ............................................................................. 49

3.5.2 DATE AND TIME MENU OPTIONS ....................................................... 49

3.6 RS232 MENU ................................................................................................... 49

MC2: 04/23/13 Page 4 of 144

Page 5

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

3.6.1 RS232 MODE......................................................................................... 49

3.6.2 RS232 BAUD RATE ............................................................................... 49

3.6.3 MODBUS ADDRESS ............................................................................. 49

3.6.4 NETWORK TIMEOUT ............................................................................ 50

3.6.5 MODBUS PASS THRU .......................................................................... 50

3.7 RS232 MENU ................................................................................................... 50

3.7.1 RS485 BAUD RATE ............................................................................... 50

3.7.2 MIN SLAVE ADDR ................................................................................. 50

3.7.3 MAX SLAVE ADDR ................................................................................ 50

3.7.4 NUMBER NETWK BLRS ....................................................................... 50

3.7.5 MODBUS CNTL TYPE ........................................................................... 50

3.7.6 NETW BOILER Xx ADDRESS=Yyy ....................................................... 51

3.8 FIELD ADJUST MENU .................................................................................... 51

3.8.1 HEADER SET MODE ............................................................................. 51

3.8.2 HDR HIGH LIMIT ................................................................................... 51

3.8.3 HDR LOW LIMIT .................................................................................... 51

3.8.4 INTERNAL SETPT ................................................................................. 51

3.8.5 RESET RATIO ....................................................................................... 51

3.8.6 BLDG REF TEMP .................................................................................. 52

3.8.7 REMOTE SIGNAL .................................................................................. 52

3.8.8 OFFSET ENABLE .................................................................................. 52

3.8.9 Offset Menu Options .............................................................................. 52

3.8.10 Setting Up an Offset Schedule ............................................................... 52

3.8.11 Setting Up a Manual Offset Schedule .................................................... 53

3.9 CONFIGURATION MENU ............................................................................... 53

3.9.1 BLR CNTL SELECT ............................................................................... 53

3.9.2 BOILER OP MODE ................................................................................ 53

3.9.3 PARALLEL MODE ................................................................................. 54

3.9.4 SEQUENTIAL......................................................................................... 54

3.9.5 SYS INTLK CONFIG .............................................................................. 54

3.9.6 BLR START LEVEL ............................................................................... 54

3.9.7 BLR STOP LEVEL ................................................................................. 54

3.9.8 MAX POWER INPUT ............................................................................. 55

3.9.9 FAIL SAFE MODE .................................................................................. 55

3.9.10 LEAD BLR SELECT (Lead Boiler Selection) .......................................... 55

3.9.11 LAST BLR SELECT (Last Boiler Selection) ........................................... 55

3.9.12 ROTATE TIME ....................................................................................... 55

3.9.13 RET SENSOR MODE (Return Sensor Mode) ........................................ 55

3.9.14 PLANT DT LIMIT (Plant Delta-Temperature Limit) ................................. 55

3.9.15 BOILER DELAY ..................................................................................... 56

MC2: 04/23/13 Page 5 of 144

Page 6

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

3.9.16 DHW OPTION (Domestic Hot Water Option) ......................................... 56

3.9.17 NUMBER DHW BLRS (Number of Domestic Hot Water Boilers) ........... 56

3.9.18 DHW SIGNAL (Domestic Hot Water Signal) .......................................... 57

3.9.19 NUM DHW PRIORITY (Number of DHW Priority Boilers) ...................... 57

3.9.20 VALVE WAIT STATES ........................................................................... 57

3.9.21 SYS RELAY OPTION (System Relay Option) ........................................ 57

3.10 BOOST TEMP ................................................................................................. 57

3.10.1 RET TEMP BST DIS (RETURN TEMPERATURE BOOST DISABLE) . 57

3.10.2 BOOST MAX TIMER .............................................................................. 58

3.11 TUNING MENU ................................................................................................ 58

3.11.1 PROPORTIONAL BND .......................................................................... 58

3.11.2 INTEGRAL GAIN .................................................................................... 58

3.11.3 DERIVATIVE GAIN ................................................................................ 59

3.11.4 Decreasing Boiler Cycles ....................................................................... 59

3.11.5 HI_DB_SETPT_EN (High Deadband Setpoint Enable) .......................... 59

3.11.6 DEADBAND HIGH ................................................................................. 59

3.11.7 DEADBAND LOW .................................................................................. 59

3.11.8 SETPT DOWN RATE (Setpoint Down (descending) Rate ..................... 59

3.11.9 DEMAND OFFSET ................................................................................. 59

3.12 RELAY MENU ................................................................................................. 60

3.12.1 SYS START TEMP ................................................................................ 60

3.12.2 SYS START OPTION ............................................................................. 60

3.12.3 SYS START INTLK ................................................................................ 60

3.12.4 AUX RELAY OPEN ................................................................................ 60

3.12.5 AUX RELAY CLOSE .............................................................................. 60

3.12.6 FAULT ALRM RELAY ............................................................................ 60

3.12.7 FAULT ALARM BLRS ............................................................................ 61

3.12.8 FAULT ALRM CLEAR ............................................................................ 61

3.13 CALIBRATION MENU ..................................................................................... 61

3.13.1 HDR SENS OFFSET .............................................................................. 61

3.13.2 OUTD SENS OFFSET ........................................................................... 61

3.13.3 4 - 20 MA OFFSET ................................................................................. 61

3.13.4 RETN SENS OFFSET ............................................................................ 61

3.13.5 RAMP UP %/MIN ................................................................................... 61

3.13.6 RAMP DOWN %/MIN ............................................................................. 62

3.13.7 RESET DEFAULTS ................................................................................ 62

3.13.8 PASSTHRU WRITE ............................................................................... 62

3.13.9 VALVE WAIT TIME ................................................................................ 62

3.13.10 SYSTEM OVERRIDE (Modbus Enable/Disable) .................................... 62

MC2: 04/23/13 Page 6 of 144

Page 7

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

3.14 ACS QUICK-START GUIDE MENU ................................................................ 63

3.14.1 CONSTANT SETPT MODE (Default): .................................................... 64

3.14.2 REMOTE SETPT MODE: ....................................................................... 65

3.14.3 OUTDOOR RESET MODE .................................................................... 66

4. PROGRAMMING ACS OPERATING MODES ....................................................... 67

4.1 INTRODUCTION .............................................................................................. 67

4.2 OUTDOOR RESET MODE .............................................................................. 67

4.2.1 Selecting Outdoor Reset Mode .............................................................. 68

4.2.2 Determining Reset Schedule .................................................................. 68

4.2.3 Entering Reset Ratio and Building Reference Temperature ................... 69

4.2.4 SELECTING BOILER OPERATING MODE ........................................... 69

4.2.5 Entering System Start Temperature ....................................................... 70

4.2.6 Entering Boiler Start and Boiler Stop Levels .......................................... 70

4.3 REMOTE SETPOINT MODE ........................................................................... 71

4.3.1 Selecting Remote Setpoint Mode ........................................................... 71

4.3.2 Entering Header High Limit and Low Limit Temperatures ...................... 72

4.3.3 Selecting Remote Signal Type ............................................................... 73

4.3.4 Selecting Boiler Operating Mode ............................................................ 73

4.3.5 Entering Boiler Start & Stop Levels ........................................................ 74

4.4 CONSTANT SETPOINT MODE ....................................................................... 74

4.4.1 Selecting Constant Setpoint Mode ......................................................... 75

4.4.2 Selecting Internal Setpoint Temperature ................................................ 75

4.4.3 Selecting Boiler Operating Mode ............................................................ 76

4.4.4 Entering Boiler Start and Boiler Stop Levels .......................................... 76

4.5 “Temp and Load” Option............................................................................... 76

4.6 “Start Enabled” Option .................................................................................. 77

4.7 System Initialization and Polling .................................................................. 77

4.8 Testing the System ........................................................................................ 78

5. TROUBLESHOOTING ........................................................................................... 81

5.1 Fault Messages And Common Problems ..................................................... 81

APPENDIX A: ACS MENUS ...................................................................................... 85

APPENDIX B: STATUS AND FAULT MESSAGES ..................................................... 91

B.1 C-MORE STATUS AND FAULT MESSAGES .................................................. 91

B.3 Deciphering the “FAULT Code” Reading from the BCM (used in Modulex

MC2: 04/23/13 Page 7 of 144

B.2 CONVERSION EQUATIONS FOR TEMPERATURE VARIABLES .................. 96

Boilers) ..................................................................................................................... 97

B.4 BCM (BOILER COMMUNICATION MODULE) FAULT CODES ....................... 98

Page 8

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

APPENDIX C: RESET SCHEDULE AND OUTDOOR RESET RATIO CHARTS ..... 105

B.5 BCM (BURNER MANAGEMENT MODULE) FAULT CODES .......................... 99

B.6 ACS (AERCO CONTROL SYSTEM) I/O STATUS .......................................... 102

C.1 USING THE CHARTS TO DETERMINE RESET SCHEDULE ........................ 105

APPENDIX D: NTC TEMPERATURE SENSOR RESISTANCE ............................... 111

APPENDIX E: ACS WIRING DIAGRAM ................................................................... 113

APPENDIX F: ACS PARTS AND ACCESSORIES ................................................... 115

APPENDIX G: PROGRAMMING USING RS232 COMMUNICATION ....................... 117

G.1 INTRODUCTION ............................................................................................. 117

G.2.1 Logging on to a Remote Machine Using PuTTY .................................... 117

G.2.2 Running a Command on a Remote Machine Using PuTTY ................... 118

G.3 RS232 COMMUNICATION SET-UP ................................................................ 119

APPENDIX H: ACS MODBUS ADDRESS ASSIGNMENTS .................................................. 127

H.1 ACS CONTROLLER STANDARD INPUT REGISTER ASSIGNMENTS ........ 127

APPENDIX I: BOILER START AND STOP LEVELS ............................................... 143

C.2 DETERMINING RESET SCHEDULE BY FORMULA ...................................... 105

G.2 AQUIRING THE PuTTY APPLICATION .......................................................... 117

G.4 PROGRAMMING PROCEDURE ..................................................................... 119

H.2 ACS CONTROLLER STANDARD HOLDING REGISTER ASSIGNMENTS ... 134

MC2: 04/23/13 Page 8 of 144

Page 9

GF-131

AERCO Control System (ACS)

Installation, Operation, and Maintenance Manual

OMM-0081_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Phrase, Abbreviation or

A (Amp)

Ampere

ACS

AERCO Control System

ADDR

Address

ALRM

Alarm

AUX

Auxiliary

Building Automation System, often used interchangeably with EMS (see

below)

Symbol rate, or simply the number of distinct symbol changes (signaling

each symbol is 1 bit long.

BCM

Boiler Control Module used with AERCO Modulex Series Boilers

BLR

Boiler

BND

Band

A pair of resistors used to force the communication line to a definite logic

state so that noise is not picked up as invalid data during communication.

BLDG (Bldg)

Building

C-More Controller

(or Control Box)

A control system developed by AERCO and currently used in all

Benchmark and KC1000 Series product lines.

CNTL

Control

DHW

Domestic Hot Water

DYN

Dynamic

EMS

Energy Management System; often used interchangeably with BAS

Ethernet

A computer networking technology for Local Area Networks (LANs)

FOREWARD

The AERCO Control System (ACS) is AERCO’s solution for a flexible boiler plant controller. The

system can control a boiler plant comprised of AERCO Benchmark Series, Modulex Series or

KC1000 Boilers. The ACS can stage and coordinate the operation of up to thirty-two (32)

AERCO Boilers with maximized efficiency. With individual boilers with turn-down ratios as high

as 20:1, a 5-boiler plant can deliver a system turn-down ratio of 100:1 when the boilers are

staged to operate sequentially.

The ACS can also be used in a combination boiler plant to both supply building heat and also

heat water for domestic applications. There are multiple options built in to do this. Some of

these options require a mated AERCO Relay Box to be installed along with the ACS in order to

effectively and safely control the supporting hydronic valves and their interaction with the

boilers.

The ACS is fully compatible with a wide array of Building Automation Systems (BAS) or Energy

Management Systems (EMS) utilizing Modbus Protocol. The BAS or EMS communicates with

the ACS utilizing a RS232 interface. If the BAS or EMS uses a RS485 port, the ACS can be

ordered with a RS485-to-RS232 Converter which can be easily installed within the ACS wiring

compartment.

PHRASES, ABBREVIATIONS & ACRONYMS

The phrases, abbreviations and acronyms used in this document are listed in the following

table:

Phrases, Abbreviations and Acronyms

Acronym

BAS

Baud Rate

Bias Resistors

events) transmitted per second. It is not equal to bits per second, unless

Meaning

MC2: 04/23/13 Page 9 of 144

Page 10

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Phrase, Abbreviation

FDX

Full-Duplex

FLT

Fault

GND

Ground

HDR

Header

HDX

Half-Duplex

Hex

Hexadecimal Number (0 - 9, A - F)

Hz

Hertz (Cycles Per Second)

INTLK

Interlock

I/O

Input/Output

Input/Output (I/O) Box currently used on all Benchmark and KC Series

products

IP

Internet Protocol

ISO

Isolated

LSB

Least Significant Byte

LSD

Least Significant Digit

MA (mA)

Milliampere

MAX (Max)

Maximum

MIN (Min)

Minimum

A serial, half-duplex data transmission protocol developed by AEG

Modicon

MSB

Most Significant Byte

MSD

Most Significant Digit

MS/TP

Master-Slave/Token-Passing (usually over RS485 networks)

OFFS

Offset

OUTD

Outdoor

PTP

Point-to-Point (usually over RS232 networks)

REF (Ref)

Reference

Response Time

The maximum amount of time allowed to receive a response to a request

RS232

(or EIA-232)

A standard for serial, full-duplex (FDX) transmission of data based on the

RS232 Standard

RS422

(or EIA-422)

A standard for serial, full-duplex (FDX) transmission of data based on the

RS422 Standard

RS485

(or EIA-485)

A standard for serial, half-duplex (HDX) transmission of data based on

the RS485 Standard

RTN

Return

RTU

Remote Terminal Unit

SEN

Sensor

SETPT (Setpt)

Setpoint Temperature

SHLD (Shld)

Shield

SLTA

Serial LonTalk Adapter

SYS

System

TEMP (Temp)

Temperature

A resistor placed at each end of a daisy-chain or multi-drop network in

communication

VAC

Volts, Alternating Current

VDC

Volts, Direct Current

VFD

Vacuum Fluorescent Display

Phrases, Abbreviations and Acronyms (Continued)

or Acronym

I/O Box

Modbus®

Meaning

Terminating Resistor

MC2: 04/23/13 Page 10 of 144

order to prevent reflections that may cause invalid data in the

Page 11

GF-131

AERCO Control System (ACS)

Installation, Operation, and Maintenance Manual

OMM-0081_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Dimensions

Weight

Power Requirements

1. ACS GENERAL INFORMATION

1.1 SAFETY PRECAUTIONS AND WARNINGS

The warnings and cautions appearing throughout this manual should be reviewed and

thoroughly understood prior to attempting to install, operate, troubleshoot or repair the ACS

Controller.

1.2 INTRODUCTION

This manual provides installation, operation and troubleshooting instructions for the AERCO

Control System, Model 5R5-384.

1.3 ACS GENERAL DESCRIPTION

The ACS (Figure 1-1) is a rugged, flexible controller designed to stage and coordinate the

operation of up to 32 AERCO Benchmark Series, Modulex Series or KC1000 Boilers while

maximizing operational efficiency. Under normal load conditions, the ACS can precisely regulate

the header temperature of the boiler plant within ±2°F.

Boiler plant control is accomplished via a RS485 network utilizing Modbus protocol. For facilities

that have taken a building-wide approach to energy efficiency, the ACS can be easily integrated

with an Energy Management System (EMS) or Building Automation System (BAS) utilizing

Modbus protocol. Physical connection to the remote EMS or BAS is accomplished via an RS232

interface. EMS/BAS integration will also permit utilization of the pass-thru function incorporated

in the ACS. The pass-thru function permits the remote system to monitor up to 35 operating

parameters from each boiler in the plant.

The ACS is housed in a NEMA 13 enclosure. A hinged clear-plastic cover over the unit’s panel

controls protects against incidental contact of control settings and provides a degree of

protection against airborne debris and the spraying or splashing of water. The physical

dimensions, weight and electrical power requirements for the ACS are as follows:

Each ACS shipment includes a Header Sensor Kit, Part No. GM-122790 which is required for all

modes of operation. Other available options which can be ordered with your shipment include:

• Outdoor Air Sensor Kit, Part No. GM-122781: Required for Outdoor Reset Mode

Operation

9.50” W x 7.25” H x 4.00” D

3 lbs.

85-to-265 VAC, Single-Phase, 50-60 Hz @ 1A

• Return Sensor Kit, Part No. 122790 (Same as Header Sensor Kit): Used for external

monitoring of boiler water return temperature

• RS485-to-RS232 Converter, Part No 124943: For use with EMS or BAS equipment that

has a RS485 Port

MC2: 04/23/13 Page 11 of 144

Page 12

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

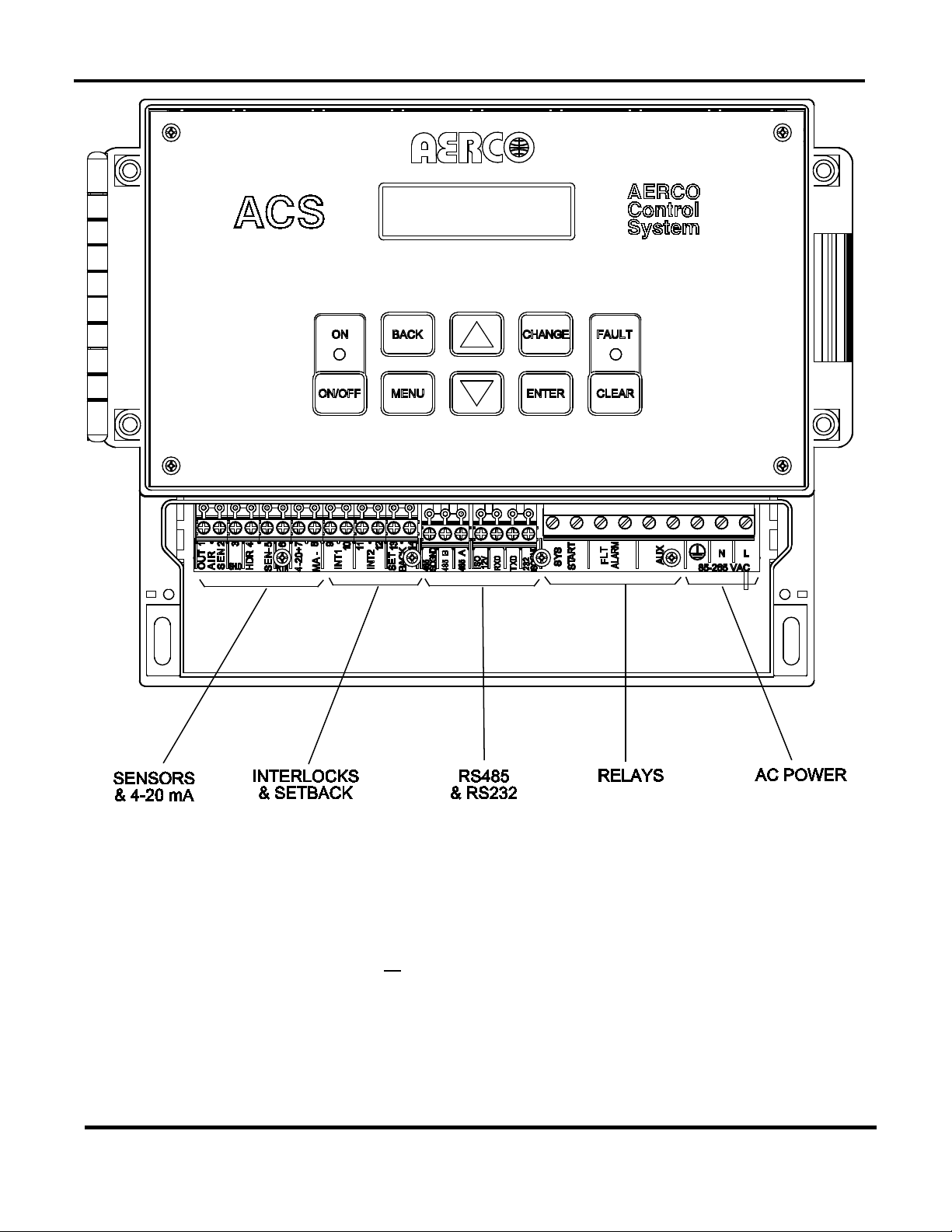

OMM-0081_0D

Cover

Clear Plastic

Front Panel

Wiring Compartment Cover

Figure 1-1: AERCO Control System (ACS)

1.4 ACS FEATURES

The following paragraphs briefly describe some of the unique features incorporated in the ACS.

1.4.1 Simplified Installation and Set-Up

The ACS system operates on single-phase input power ranging from 85 to 265 VAC, 50-60 Hz.

Connections to the boiler plant are accomplished utilizing a 2-wire RS485 network connected in

a daisy-chain configuration. When an EMS or BAS is used with the ACS, connections are made

via the RS232 port terminals. In the event that the EMS or BAS is not equipped with a RS232

port, the ACS can be ordered with a RS485 to RS232 Converter which can be easily installed

within the wiring compartment of the ACS. With the exception of AC power, interlock and

setback inputs and relay outputs, ACS connections are accomplished using shielded-twisted

pair cable.

1.4.2 User-Friendly Control System Interface

The unit incorporates a menu-driven architecture which is comprised of 9 primary menus. The

user interface to these menus is accomplished via the ACS control panel and a Vacuum

Fluorescent Display (VFD). The display is capable of displaying two lines with 16 characters per

line. Virtually all of the control panel keys are identical to the C-More Control System currently

used on AERCO Benchmark Series and KC1000 Boilers. This commonality will help simplify the

time required for system setup of the ACS.

MC2: 04/23/13 Page 12 of 144

Page 13

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

1.4.3 Retention of Menu Option Settings

By using non-volatile memory, the ACS retains program and menu settings during shut-down or

when input AC power is interrupted. Settings can be retained for more than 2 years.

1.4.4 Application Flexibility

Four different configuration options can be selected to match the needs of any closed-loop

system. These configurations are: Outdoor Reset, Constant Setpoint, Remote Setpoint via a 420 Ma input and Remote Setpoint via Modbus.

Three different domestic hot water (DHW) options are selectable for controlling the combination

boilers and valves that are being used to provide heated domestic water.

1.4.5 Sequential or Parallel Operation

Boilers can be programmed for either sequential or parallel operation using the ACS keypad

controls. When set for sequential operation, the boilers are brought on-line one at a time as

needed. When set for parallel operation, the boilers are all brought on-line together at the same

firing rate.

1.4.6 Accuracy

Using PID (Proportional Integral Derivative) and Ramp-Up/Ramp-Down Modulation Control

Algorithms, the ACS provides dynamic responses to all changes in boiler plant operation.

Header temperatures, as well as percentages of boiler input are precisely controlled with

virtually no over-shoot or short-cycling of boiler units. A header temperature accuracy of ±2°F is

virtually assured during continuous plant operation.

1.4.7 Bumpless Transfer

When operated sequentially, The ACS stages boilers on and off at selectable firing rate

percentages. The result is a seamless transition with undetectable room temperature changes.

In addition, when in sequential mode, the ACS sequences boilers using a first-on, first-off basis,

thereby equalizing the accumulated run time of all boilers in the plant.

The ACS also continuously monitors the number of Boilers that are available for operation. In

the event of a boiler malfunction, or required servicing, the ACS automatically compensates for

a lack of response from any unit and brings on the next available boiler to satisfy the demand.

This feature operates in both sequential and parallel modes.

1.4.8 Fault Alarm Surveillance

If an EMS or BAS is not used with the ACS to monitor faults, a Fault Alarm Relay can be

activated thereby notifying facility managers of faults associated with the ACS.

1.4.9 ACS Programming Via RS232 Port.

If desired, the ACS can be programmed by connecting a Laptop Computer or other terminal

emulation device to the RS232 Port terminals on the ACS. Detailed set-up instructions and

available command listings are provided in Appendix G. Most settings are also programmable

using Modbus.

MC2: 04/23/13 Page 13 of 144

Page 14

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

(This page intentionally blank)

MC2: 04/23/13 Page 14 of 144

Page 15

GF-131

AERCO Control System (ACS)

Installation, Operation, and Maintenance Manual

OMM-0081_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

2. ACS INSTALLATION

2.1 INTRODUCTION

This Chapter provides the descriptions and procedures necessary to mount the ACS and

connect all boiler plant units and applicable sensors. Guidelines are also provided for

connection of an EMS or BAS being used with the system. Refer to the wiring diagram provided

in Appendix E when making all wiring connections to the ACS.

2.2 SITE SELECTION AND MOUNTING

Ensure that the site selected for installation of the ACS provides the following:

Access to single-phase AC power from 110 to 240 VAC, 60 Hz nominal

Sufficient clearances to permit maintenance and setup/operational tasks on the ACS.

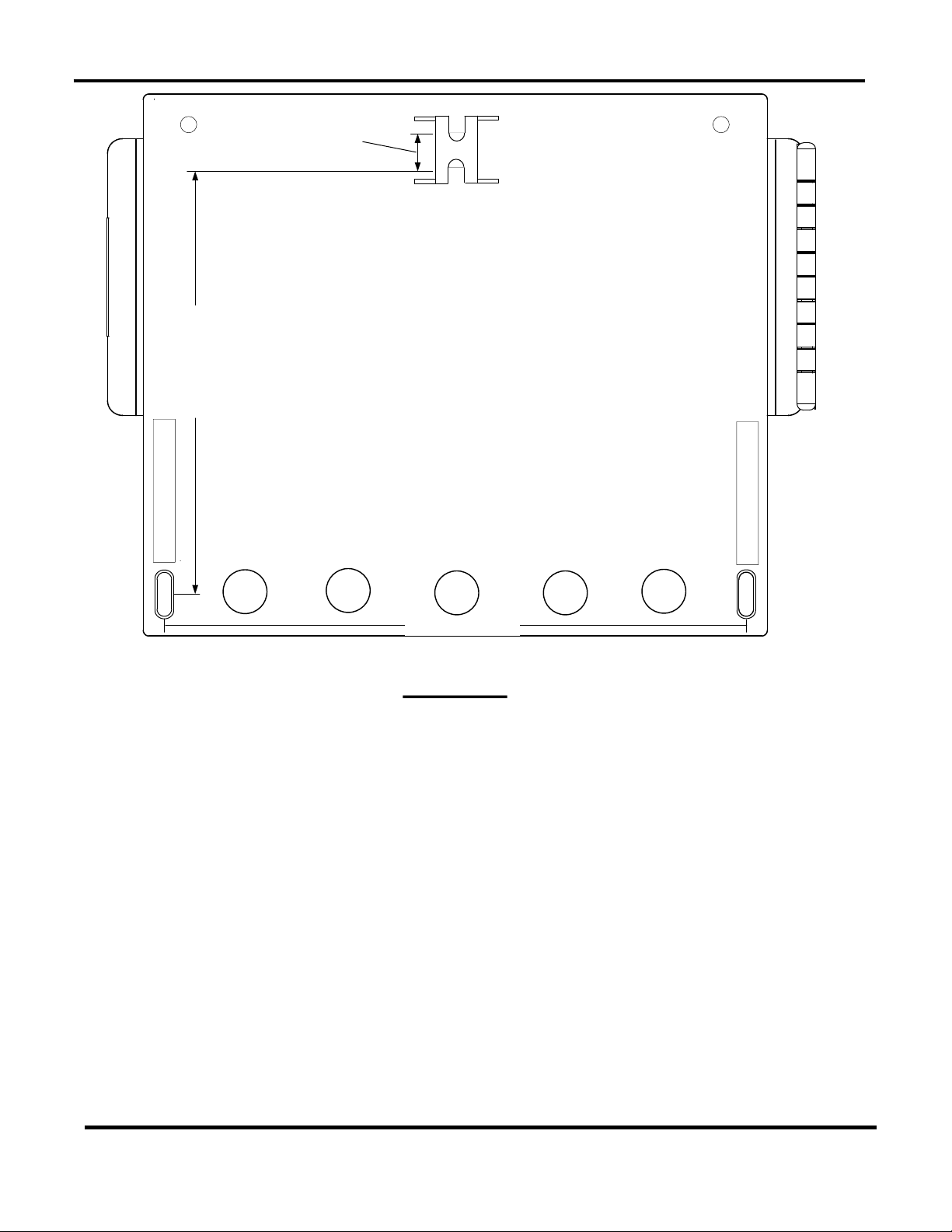

2.2.1 Mounting the ACS

AERCO recommends that the ACS be wall-mounted using a sheet of plywood or other suitable

material. For easy viewing, the ACS controls and display should be at eye level. Mounting is

accomplished using three screws (not provided). The spacing for the three screws are indicated

on the rear of the ACS in millimeters. Figure 2-1 shows the rear of the panel enclosure and also

indicates the required spacing for the three mounting screws in inches. Proceed as shown

below, to mount the unit:

Mounting the ACS Controller

1. First install a screw on the mounting surface at the top center location shown in

Figure 2-1. Leave a space of approximately 1/8 inch between the mounting surface

and the head of the screw.

2. Remove the wiring compartment cover from the front of the ACS (see Figure 1-1) to

provide access to the slots for the two lower mounting screw locations.

3. Hang the ACS on the installed top screw. Position the unit so it is level.

4. Mark the locations for the two lower screws.

5. Remove the ACS and drill two pilot holes for the lower screws.

6. Replace the ACS on the installed top-center screw.

7. Secure the ACS to the wall by installing the two lower screws. DO NOT over-tighten

the screws.

MC2: 04/23/13 Page 15 of 144

Page 16

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

198 mm (7.8")

145 mm (5.7")

15 mm

(0.6")

REAR VIEW

Figure 2-1: ACS Mounting Provisions

2.3 SITE SELECTION AND MOUNTING

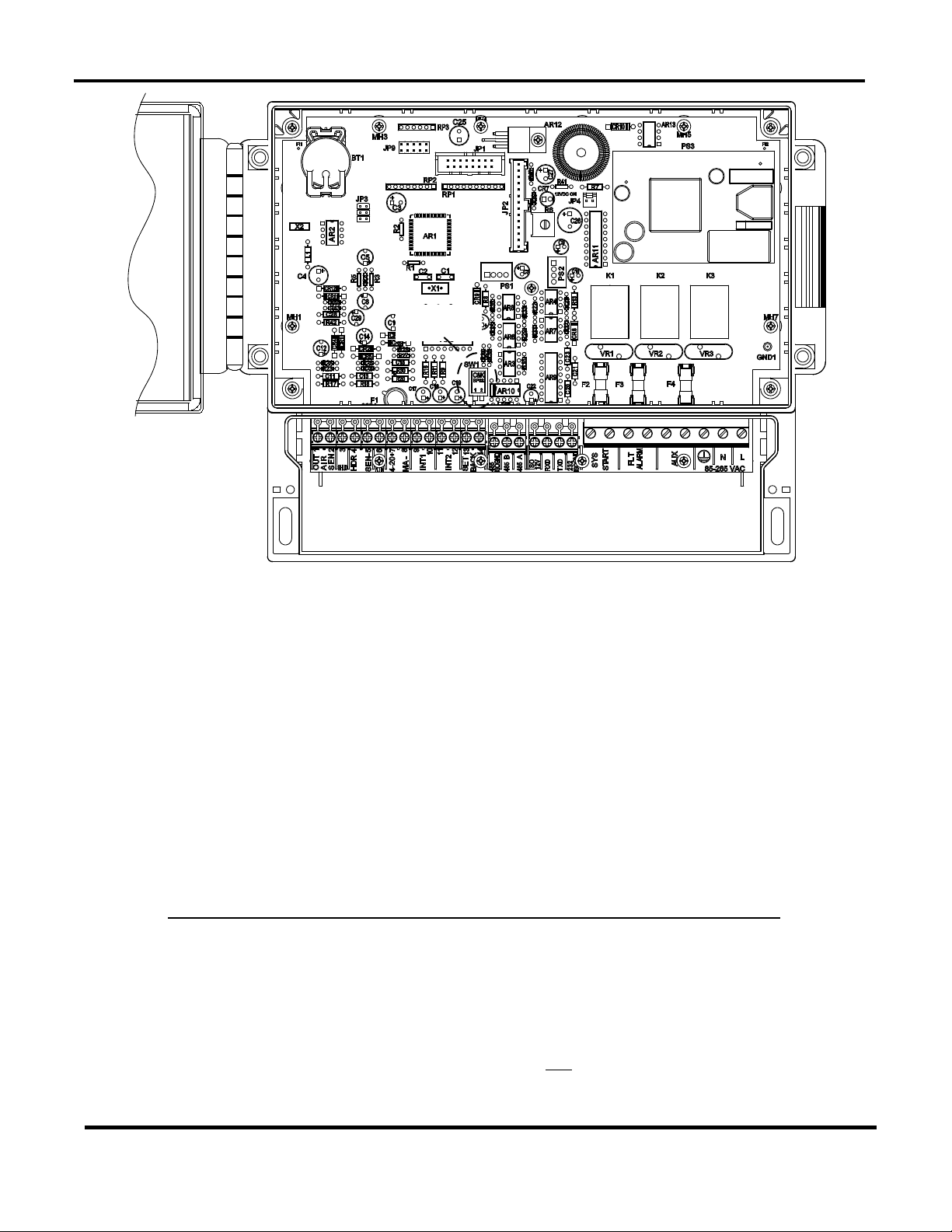

All wiring connections to the ACS are made at the terminals located behind the wiring

compartment cover as shown in Figure 2-2. Run all wiring through the knock-outs provided on

the bottom surface of the unit. Shielded, twisted-pair cable should be used for sensor and

communication wiring. This wiring should be 18 to 24 AWG. Examples of suitable sensor and

communication wire are: Belden 9841, 8761, 3105A or equivalent. AC power wiring should be

14 to 18 AWG. The ACS wiring diagram is provided in Appendix E. Once mounting is complete

and the ACS is secured in place, loosen the two captive screws on the wiring compartment

cover using a Phillips screwdriver. Feed all wiring through the knock-outs provided on the

bottom of the panel.

NOTE

Refer to the wiring diagram provided in Appendix E when making all wiring

connections to the ACS.

MC2: 04/23/13 Page 16 of 144

Page 17

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Wiring ACS Power Connections

DO NOT apply power to the ACS until all of the required external connections

THE ACS CAN BE POWERED BY SINGLE-PHASE AC VOLTAGES

RANGING FROM 85 TO 265 VAC. THEREFORE, EXERCISE

EXTREME CARE WHEN CONNECTING POWER WIRING TO THE

UNIT. ENSURE THAT THE EXTERNAL CIRCUIT BREAKER

SUPPLYING LINE VOLTAGE TO THE ACS IS TURNED OFF TO

AVOID SEVERE ELECTRICAL SHOCK.

2.4 POWER WIRING

Use 14 to 18 AWG wire for AC power connections and proceed as shown below:

1. Feed the power wiring through the right-most knock-out in the bottom of the panel

enclosure (Figure 2-2).

2. Connect the Line (black), Neutral (white) and Ground (green) wire leads to the L, N

and (GND) terminals. The terminal blocks can be detached from the ACS headers

if necessary to simplify field wiring connections.

3. Following completion of power wiring, turn on the external circuit breaker or switch and

apply power to the unit. The ACS display will momentarily show:

AERCO ACS

REV X.XX

(Where: X.XX represents the revision level of the installed ACS software)

4. Next, since the Header Sensor is not yet installed, the display will then show:

HEADER TEMP

SENSOR ERROR

The red FAULT LED indicator will also light and a fault message will alternately be

displayed as follows:

HEADER SENSOR

ERROR

5. Press the ON-OFF key on the keypad. The green ON LED indicator will light and the

ACS display will continue to show the above message.

6. After verifying proper power connections, press the ON-OFF key. The ON LED will turn

off.

7. Turn off the external power switch and/or circuit breaker. The ACS display will go

blank.

8.

described in paragraphs 2.5 through 2.11 have been completed.

MC2: 04/23/13 Page 17 of 144

Page 18

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Figure 2-2: ACS with Wiring Compartment Cover Removed

2.5 SENSOR INSTALLATION AND WIRING

Two types of sensors may be installed, including a Header Sensor and an Outside Air Sensor.

The Header Sensor is required for all modes of operation. The Outdoor Air Sensor is required

for operation in the Outdoor Reset Mode. All Sensor wiring should be run separately from power

wiring to avoid inducing electrical noise on the sensor wiring.

If desired, an optional Return Sensor may also be installed, which is the same type and part

number as the Header Sensor, however it is only used for Plant DT limit operation and for

monitoring purposes.

MC2: 04/23/13 Page 18 of 144

Page 19

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Header Sensor Installation

Return Sensor Installation

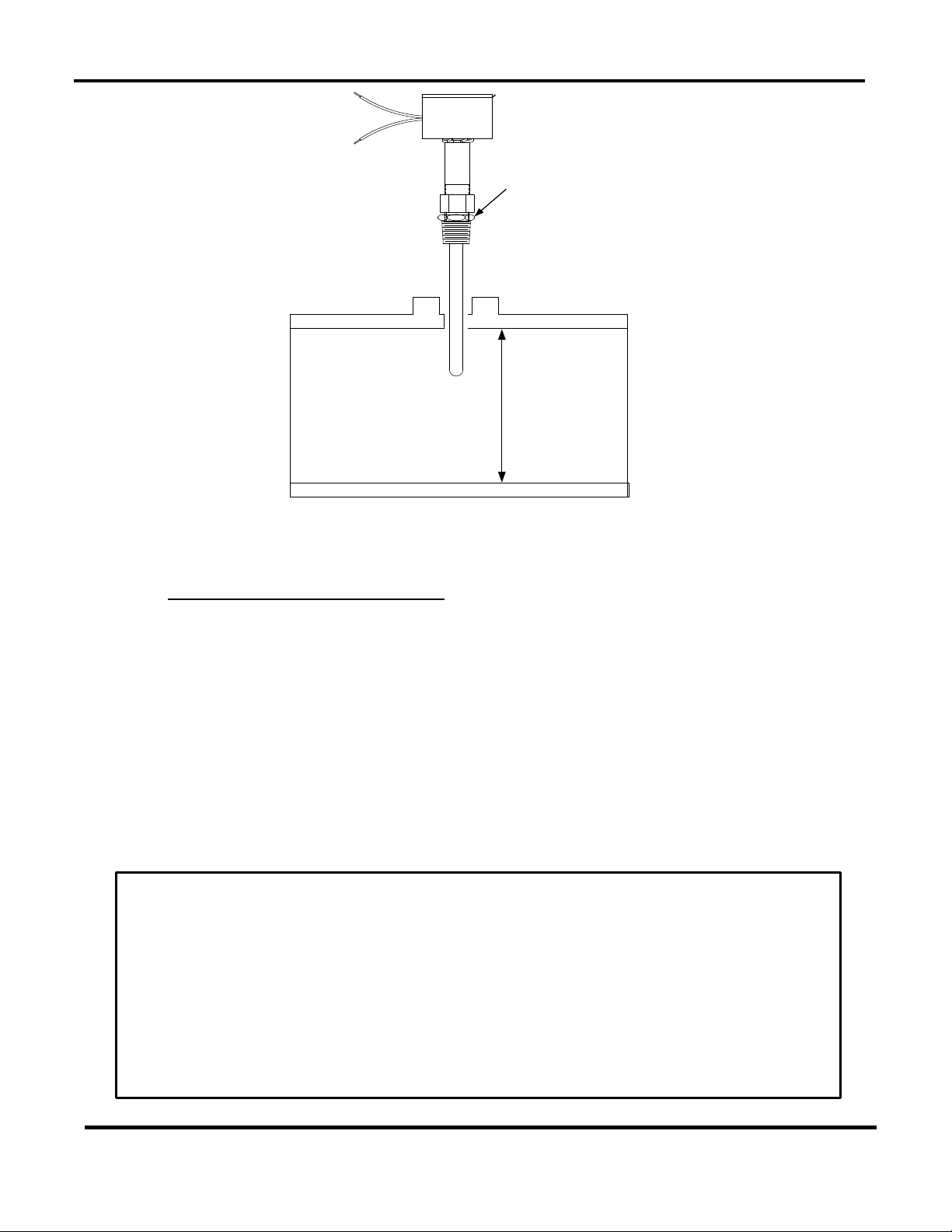

2.5.1 Header Sensor Installation

A Header Sensor Kit, (part no. 122790) is provided with the ACS. This Kit contains the Header

Sensor (64038), a Thermowell (122758) and some heat conductive grease which MUST be

used with the Sensor. When installing the Sensor, use a 1/2 inch NPT tapped coupling or a 4 x

4 x 1/2 inch Tee fitting. Shielded pair, 18 AWG cable (Belden # 8760 or equiv.) is recommended

for Header Sensor wiring. The Header Sensor must be installed between 2 and 10 feet

downstream of the LAST boiler in the boiler plant’s supply water header. Install the Header

Sensor as shown below:

NOTE

The Header Sensor is a thermistor type sensor. The Resistance vs.

Temperature Chart for this sensor is provided in Appendix D. Length of

Header Sensor wire leads should not exceed 600 feet.

1. Refer to Figure 2-3 for the Header Sensor installation details.

2. Install the Header Sensor and Thermowell into the 1/2 inch NPT tapped coupling or a 4 x

4 x 1/2 inch Tee fitting using heat-conductive grease provided. This will aid in its

response.

3. For proper response, ensure that the Header Sensor probe is inserted at least 2 inches

into the water flow.

4. Using shielded pair cable (Belden #8760 or equiv.) connect the Header Sensor leads to

HDR SEN terminals 4 and 5 on the ACS. There is no polarity to observe when making

these connections.

5. Terminate the cable shield at SHLD terminal 3 of the ACS. DO NOT terminate the shield

at the Sensor end of the cable.

2.5.2 Return Sensor Installation

The Return Sensor is required to activate the Plant Delta Temperature function, as described in

section 3.9.14, on page 54.

As mentioned in paragraph 2.5, the Return Sensor is identical to the Header Sensor.

Therefore, if a Return Sensor is being installed, another Header Sensor Kit (part no. 122790) is

required. The Return Sensor should be installed in the boiler water return line within 3 feet of the

first boiler in the boiler plant’s return water line. The installation details shown in Figure 2-3 for

the Header Sensor also apply to the Return Sensor. If used, install the Return Sensor as shown

below:

1. Refer to Figure 2-3 and install the Return Sensor and Thermowell into the 1/2 inch

tapped coupling or or Tee fitting using heat conductive grease.

2. Using shielded pair cable (Belden #8760 or equiv.), connect Return Sensor leads to

terminals 6 and 5 on the ACS. There is no polarity to observe when making these

connections.

3. Terminate the cable shield at SHLD terminal 3 of the ACS. DO NOT terminate the

shield at the Sensor end of the cable.

MC2: 04/23/13 Page 19 of 144

Page 20

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

PROBE DEPTH MUST

EXTEND AT LEAST 2"

INTO PIPE

WELDED 1/2"

COUPLING OR

4"x4*x1/2"

T - FITTING

HEADER SENSOR

WITH THERMOWELL

INSTALLED

Outdoor Air Sensor Installation

Figure 2-3: Header Sensor Installation Details

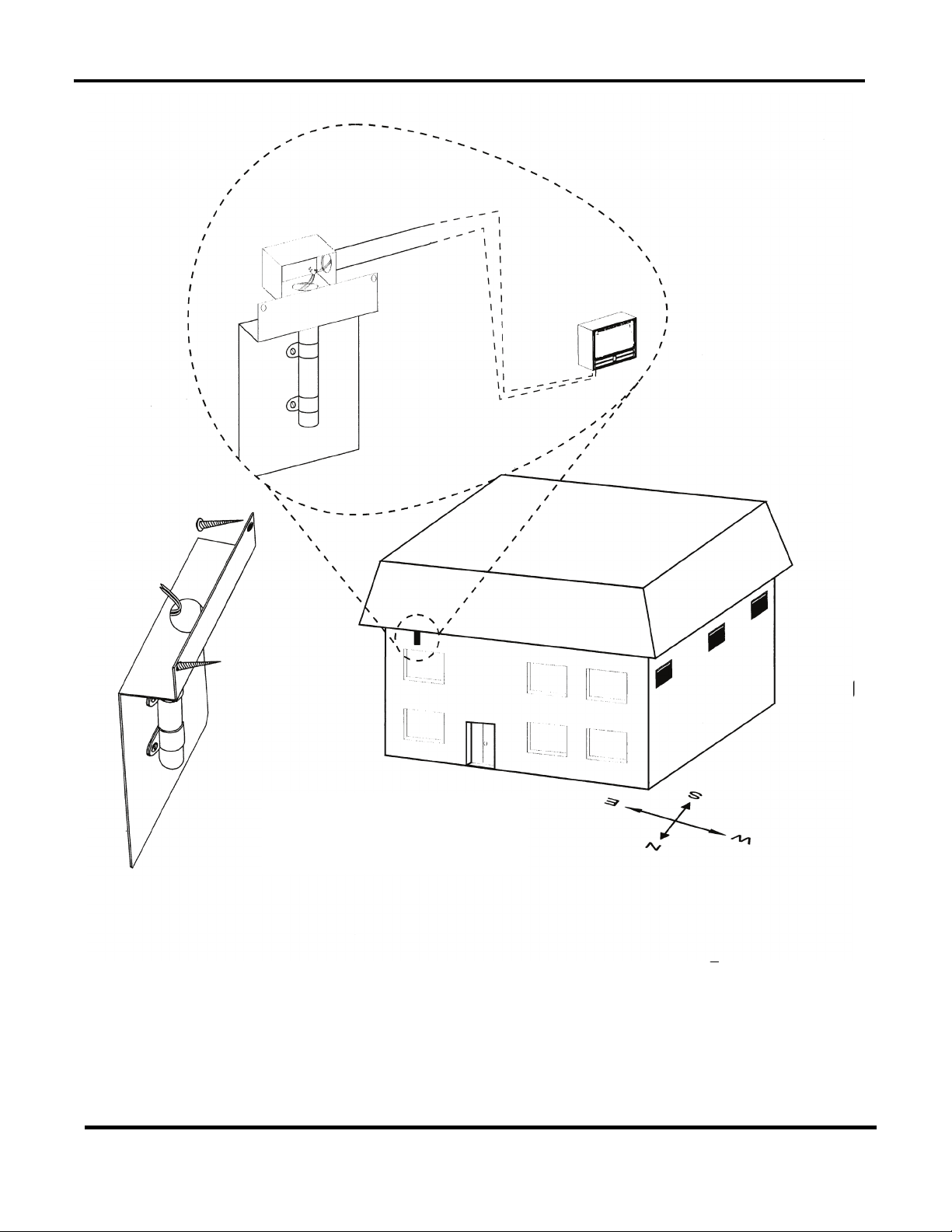

2.5.3 Outdoor Air Sensor Installation

The Outdoor Air Temperature Sensor (part no. GP-122662) is required when operating in the

ACS in the Outdoor Reset Mode (paragraph 4.2). An Outdoor Air Sensor Kit (part no. GM-

122781) is also available. This kit contains the Sensor (GP-122662) and a Mounting Bracket for

wall mounting. The Outdoor Air Sensor should be mounted on the North side of the building,

shielded from direct sunlight, and away from air intakes or outlets from the building. Shielded

pair 18 AWG cable (Belden # 8760 or equiv.) is recommended for sensor wiring. The Outdoor

Air Sensor can be mounted up to 600 feet from the ACS. See instructions below.

NOTE

The Outdoor Air Sensor is a thermistor type sensor. The Resistance vs.

Temperature Chart for this sensor is provided in Appendix E. Length of

Header Sensor wire leads should not exceed 600 feet.

1. Refer to Figure 2-4 for a typical Outdoor Air Sensor installation.

2. Attach the sensor to the mounting bracket and secure the bracket in a suitable location

on the North side of the building.

3. Using shielded pair cable (Belden #8760 or equiv.), connect the two Sensor leads to

terminals 1 and 2 on the ACS. There is no polarity to observe when connecting the

sensor.

4. Terminate the cable shield at SHLD terminal 3 of the ACS. DO NOT terminate the shield

at the Sensor end of the cable.

MC2: 04/23/13 Page 20 of 144

Page 21

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

INSTALL SENSOR ON NORTH

FACING WALL OUT OF DIRECT

SUNLIGHT AND AWAY FROM

ALL AIR INLETS/OUTLETS

Figure 2-4: Outdoor Air Sensor Installation

MC2: 04/23/13 Page 21 of 144

Page 22

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

MASTER

SLAVE

#1

SLAVE

#2

SLAVE#3SLAVE#4SLAVE

#5

Positioning the Two Bias Switches

details.

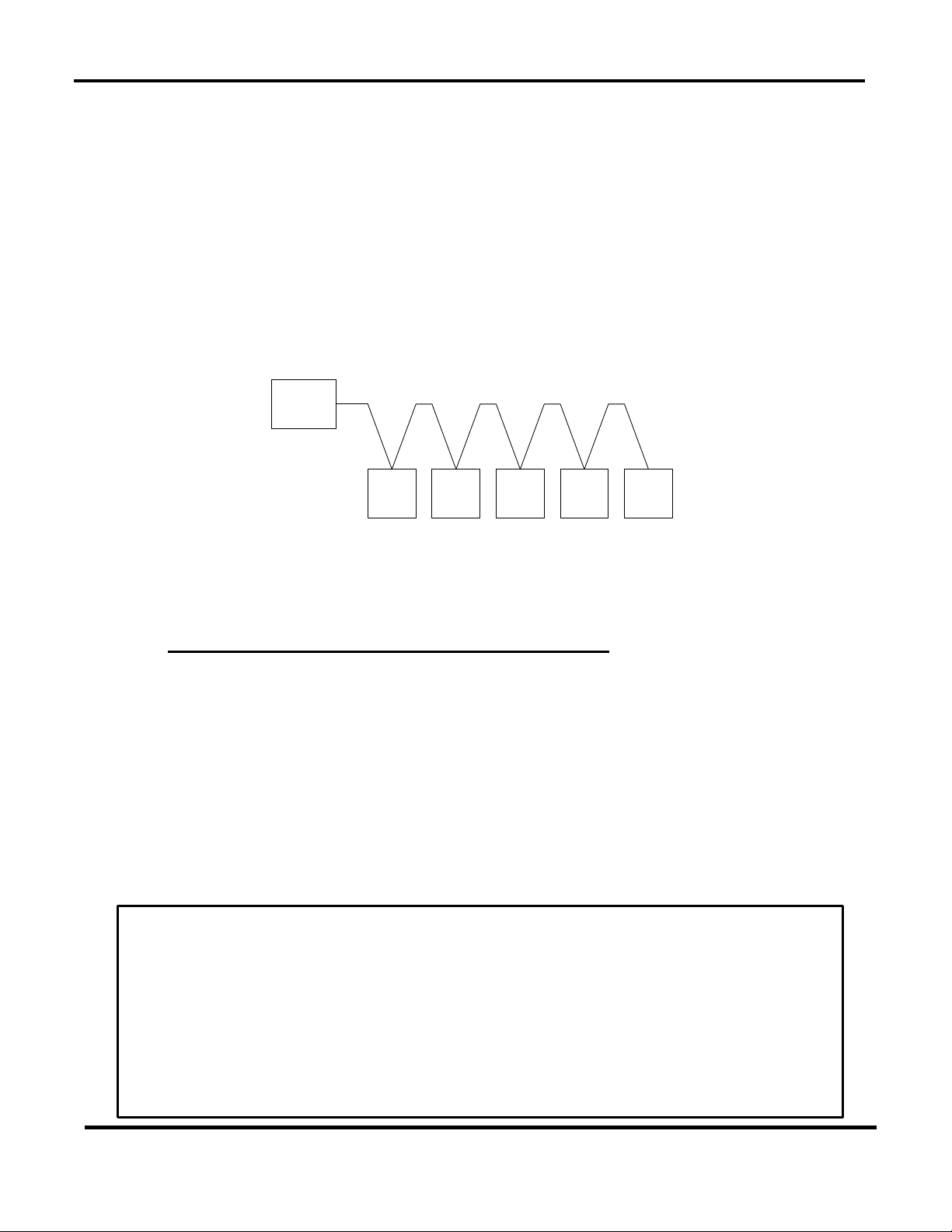

2.6 RS485 (MODBUS) WIRING AT THE ACS

The ACS communicates with the AERCO Boilers over a RS485 network using Modbus protocol.

All Modbus networks are implemented utilizing a Master/Slave scenario where only one device,

the Master, can initiate a communication sequence. AERCO Boilers equipped with C-More or

E8/BCM (Modulex) control systems can only function as Slaves on a Modbus network.

However, the ACS can function as a Master controlling C-More or BCM Boiler Slaves, or as a

Slave controlled by an Energy Management System (EMS) developed by other manufacturers.

Additional information on implementing Modbus networks is provided in AERCO Modbus

Communication Manual GF-114.

RS485 (Modbus) networks are wired in a “daisy chain” configuration similar to the example

shown in Figure 2-5. Shielded twisted-pair, 18 – 24 AWG cable (Belden #9841, #3105A, #8760

or equiv.) is recommended for RS485 wiring connections.

Figure 2-5: Typical Daisy-Chain Modbus/RS485 Network

At the ACS, RS485 (Modbus) wiring connections are made at the wiring terminals labeled 485

B+ and 485 A-. The cable shield is terminated at the SHLD terminal (3) of the ACS.

2.6.1 ACS Bias Switches & Loop Termination Resistors

Each ACS contains a built-in 120 ohm loop termination resistor and two bias DIP switches

which are mounted on the lower portion of the motherboard (Figure 2-6). The 120 ohm

termination resistor is always active and is designed to match the electrical impedance at the

ACS end of the RS485 loop. Therefore, only one additional termination resistor will be required

at the boiler end of the RS485 loop. The two bias switches are used to activate or deactivate

bias voltage on the RS485 network and should be positioned as follows, depending on the type

of AERCO boilers being used. See the instructions below:

NOTE

Refer to paragraph 2.7 for detailed instructions and illustrations describing

how to implement loop termination, bias and wiring connections on the

RS485 loop.

1. When wiring to Boiler Control Modules (BCMs) controlling Modulex Boilers, the ACS bias

switches must be activated by placing them in the on (down or towards wall) position.

Loop termination is accomplished by activating the termination resistor in the last BCM

on the RS485 loop.

2. When wiring to C-More control systems (Benchmark & KC1000 Boilers), the positions of

the ACS bias switches will depend on which one of the two available methods is used.

Loop termination will also depend on the method employed. See paragraph 2.7 for

MC2: 04/23/13 Page 22 of 144

Page 23

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

BIAS DIP

SWITCHES

NOTE:

THE BIAS DIP SWITCHES CAN BE ACCESSED

FROM THE WIRING COMPARTMENT WITHOUT

REMOVING THE FRONT PANEL FROM THE UNIT.

WIRING COMPARTMENT

Figure 2-6: Location of ACS DIP Switches

2.7 RS485 (MODBUS) WIRING, BIAS, AND TERMINATION AT AERCO BOILERS

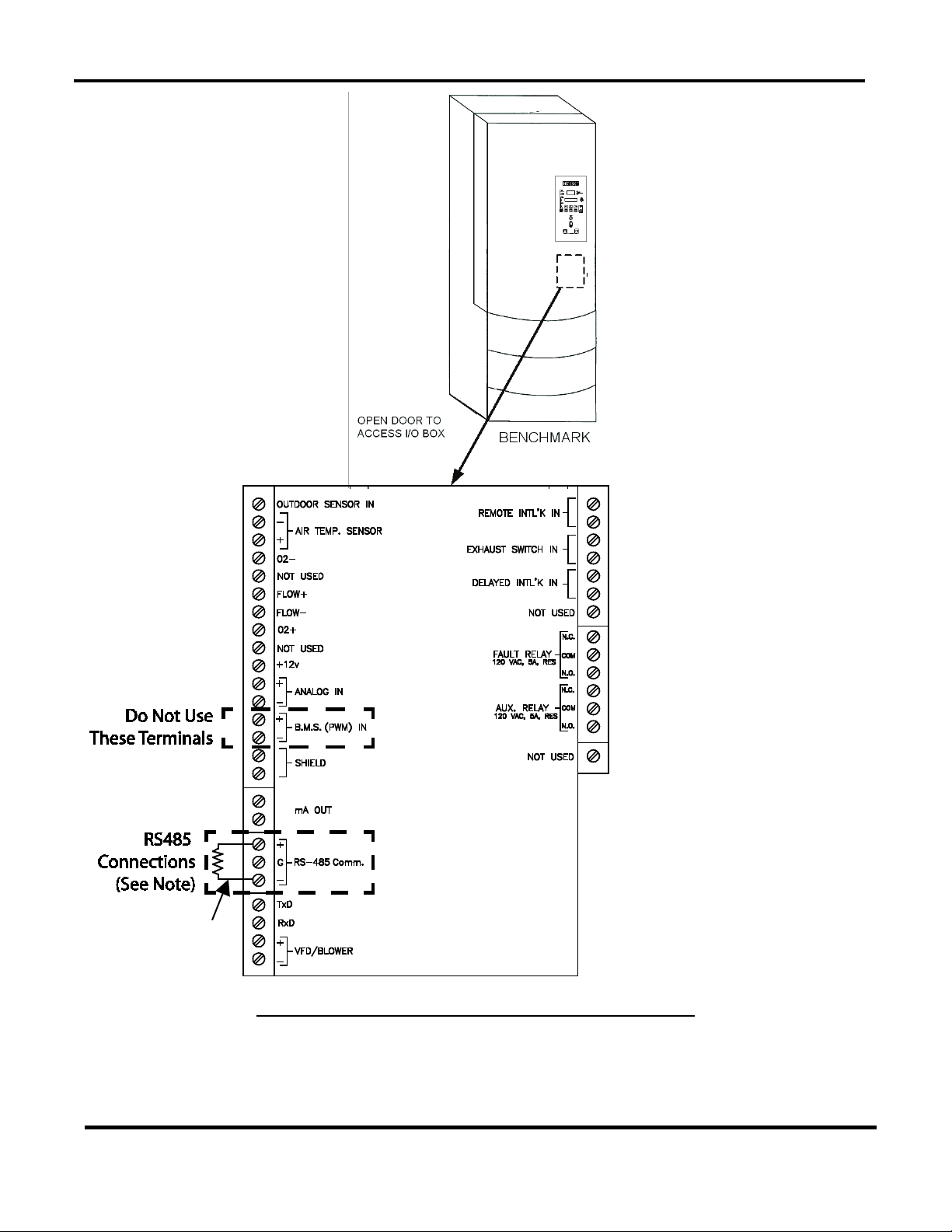

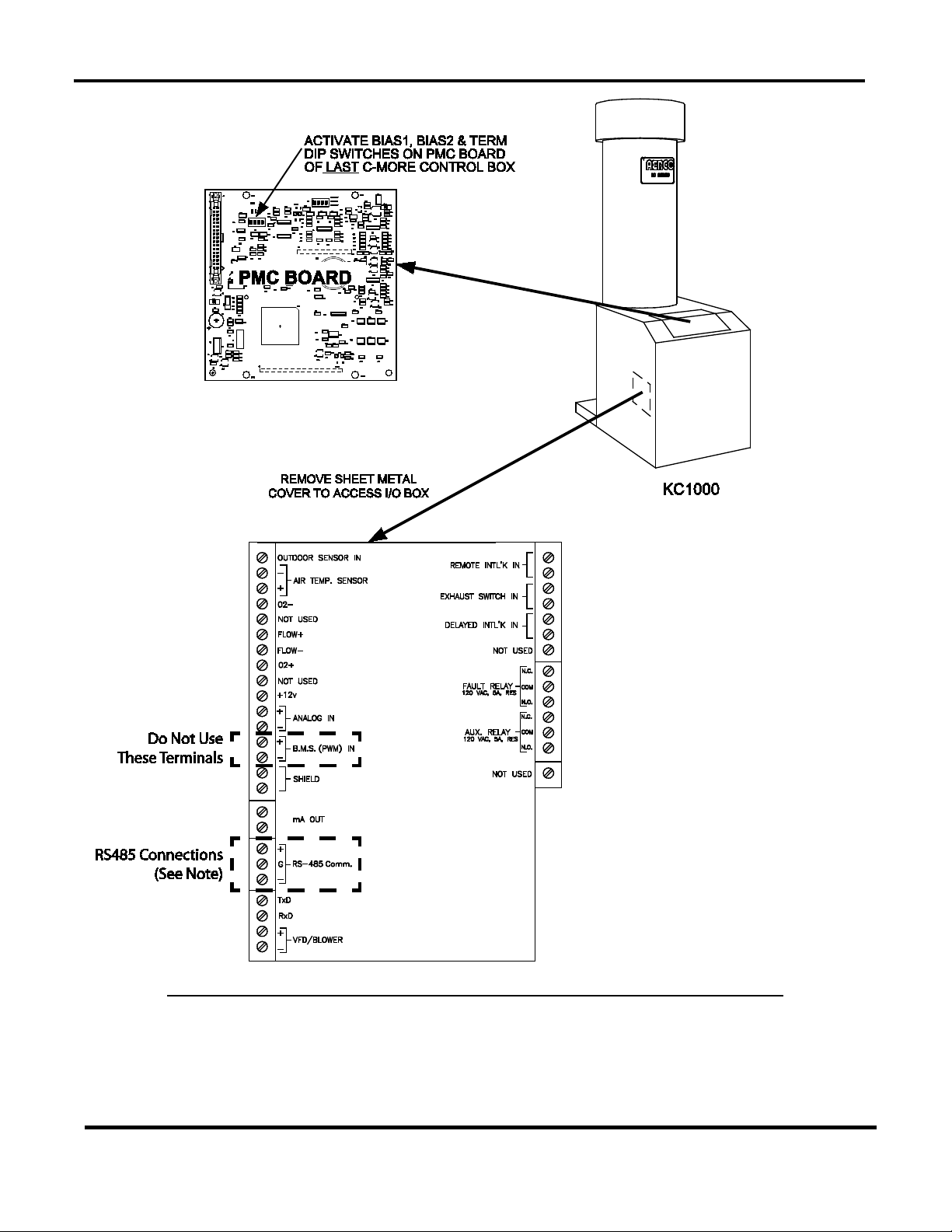

The RS485 wiring connections at the AERCO Boilers will depend on the type of AERCO Boilers

and Control Systems being used on the Modbus Network. Benchmark Series and KC1000

Boilers currently utilize C-More Control Systems. Modulex Series Boilers utilize Boiler Control

Modules (BCMs) with E8 Controllers.

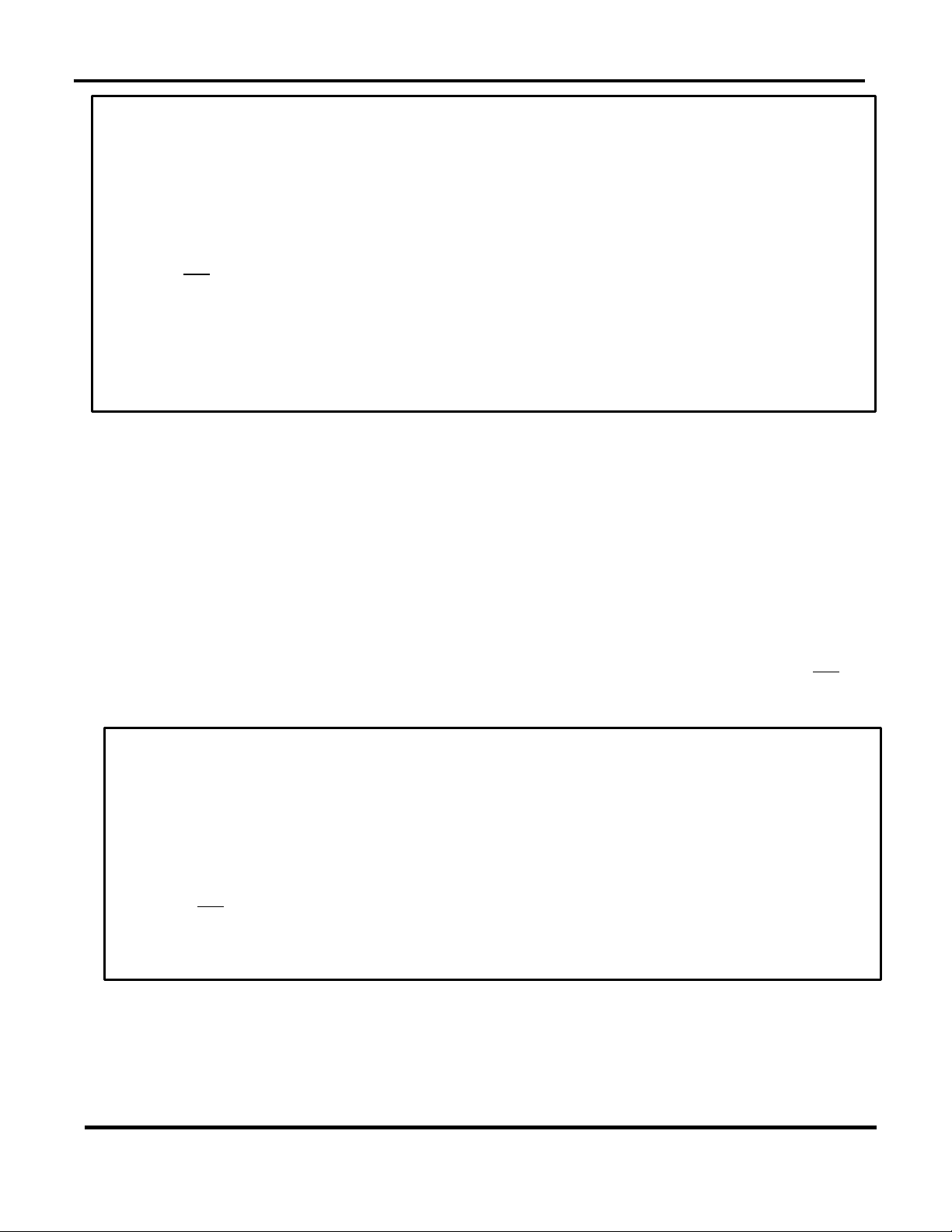

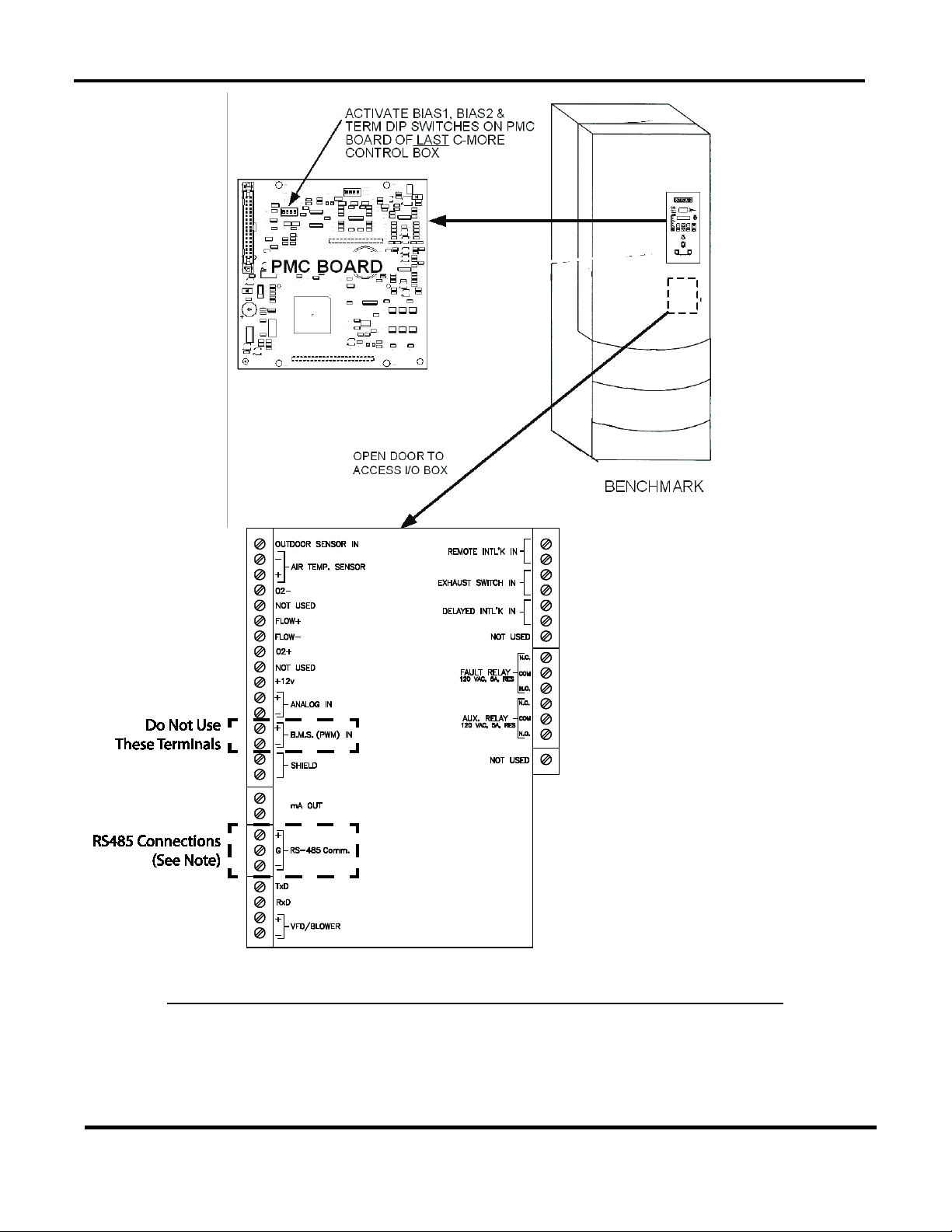

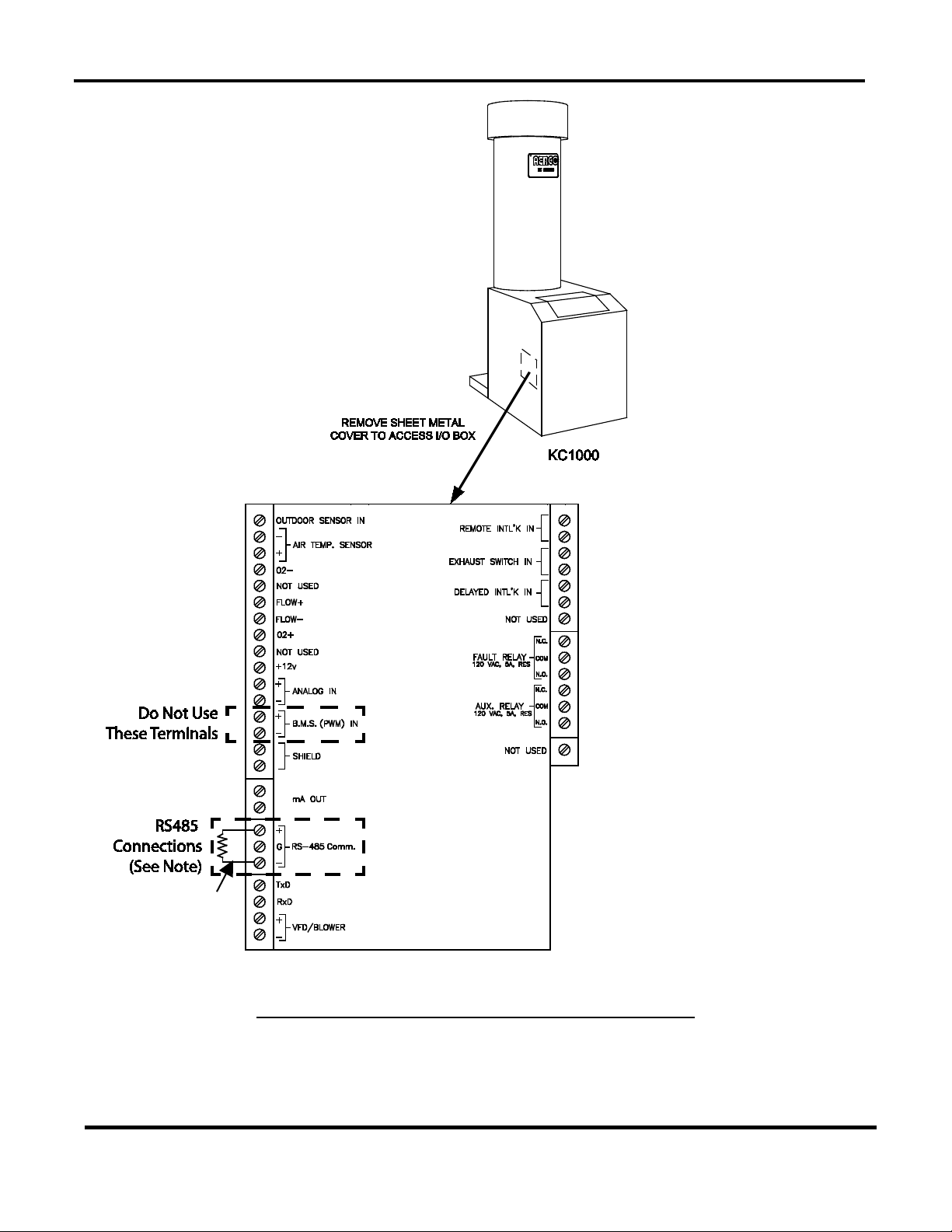

2.7.1 RS485 Wiring, Termination& Bias for Benchmark Series and KC1000 Boilers

RS485 wiring connections are made at the RS485 terminals of each boiler’s I/O Box (Figures 27 or 2-8). However, activating bias and loop termination can be performed using one of two

available methods as described below in Method A and on the following page in Method B.

Where possible, Method B is the preferred method.

Method A: For Method A, the bias switches in the ACS are left in the deactivated (up) position.

Bias and termination are controlled at the boiler end of the RS485 loop by activating the bias

and termination DIP switches on the PMC board of the last C-More Control Box on the daisychain. Refer to sheet 1 of Figure 2-7 (Benchmark), or Figure 2-8 (KC1000) and proceed as

shown below:

MC2: 04/23/13 Page 23 of 144

Page 24

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

BIAS/Loop Term: METHOD A

towards the operator when using Method 1.

BIAS/Loop Term: METHOD B

in the down or toward the wall position toward the wall.

1. Using a daisy-chain wiring configuration, connect the RS485 positive lead to the RS485 +

terminal in the I/O Box for each boiler.

2. Connect the RS485 negative lead to the RS485 - terminal in the I/O Box for each boiler.

3. DO NOT terminate the shields to the Ground (GND) terminal at the boiler end of the RS485

loop. Connect the shields of the incoming and outgoing leads together. The RS485 loop shield

should only be terminated at terminal 3 of the ACS.

4. At the last boiler in the daisy-chain, activate the BIAS1, BIAS2 and TERM switches on the PMC

board in the C-More Control Box. Refer to GF-114, paragraph 4.3.2 for detailed instructions on

accessing the PMC board.

If an Oxygen Sensor is used, ensure that R1 DIP Switch is set to OFF (Disabled). Set it to ON

(Enabled) if there is no Oxygen Sensor used.

5. DO NOT activate the bias switches on the ACS. These switches must be in the up position

NOTE

With Method A, the last C-More on the daisy chain must remain powered

for the bus to be stable.

The advantage of using Method B is that the bias and termination of the

RS485 loop do not require any changes to be made to the DIP switches on

the PMC board in the last C-More Control Box. The bus is independent of

any C-More control box.

Method B: For Method B, bias is controlled at the ACS by setting the two bias switches (Figure

2-6) to the active (down) position. Termination at the boiler end of RS485 loop is accomplished

by activating the “MODBUS R6-ON” switch in the I/O Box in the last boiler on the daisy-chain. If

this is an older box, install a 120 ohm, 1/2 Watt termination resistor in the I/O Box of the last

boiler on the daisy-chain. Refer to sheet 2 of Figure 2-7 (Benchmark), or Figure 2-8 (KC1000)

and proceed as shown below:

1. Using a daisy-chain wiring configuration, connect the RS485 positive lead to the RS485 +

terminal in the I/O Box for each boiler.

2. Connect the RS485 negative lead to the RS485 - terminal in the I/O Box for each boiler.

3. DO NOT terminate the shields to the Ground (GND) terminal at the boiler end of the RS485

loop. Connect the shields of the incoming and outgoing leads together. The RS485 loop shield

should only be terminated at terminal 3 of the ACS.

4. At the last boiler in the daisy-chain, activate the “MODBUS R6-ON” dipswitch, or install a 120

ohm, 1/2 Watt termination resistor across the RS485 + and - terminals in the boiler’s I/O Box.

5. When using Method 2, activate the two bias switches in the ACS (Figure 2-6) by placing them

MC2: 04/23/13 Page 24 of 144

Page 25

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

(GND) terminal. The shields

must be terminated at the

shields of the incoming and

I/O Board

Do not terminate the shields of

the RS485 leads to the ground

NOTE

source ends only. Connect the

outgoing RS485 leads together.

METHOD A – BIAS & TERMINATION ACTIVATED AT C-MORE PMC BOARD

Figure 2-7: RS485 (Modbus) Wiring For Benchmark Series Boilers (Sheet 1 of 2)

MC2: 04/23/13 Page 25 of 144

Page 26

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

of the RS485 leads to the

at the source ends only.

Connect the shields of the

incoming and outgoing

Connect 120 OHM,

Box.

I/O Board

NOTE

Do not terminate the shields

ground (GND) terminal. The

shields must be terminated

RS485 leads together.

½ Watt resister

between + and –

RS485 terminals on

the LAST C-More

METHOD B – TERMINATION ACTIVATED AT I/O BOX

Figure 2-7: RS485 (Modbus) Wiring For Benchmark Series Boilers (Sheet 2 of 2)

MC2: 04/23/13 Page 26 of 144

Page 27

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

(GND) terminal. The shields

must be terminated at the

shields of the incoming and

I/O Board

Do not terminate the shields of

the RS485 leads to the ground

NOTE

source ends only. Connect the

outgoing RS485 leads together.

METHOD A – BIAS & TERMINATION ACTIVATED AT C-MORE PMC BOARD

Figure 2-8: RS485 (Modbus) Wiring For KC1000 Boilers (Sheet 1 of 2)

MC2: 04/23/13 Page 27 of 144

Page 28

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

(GND) terminal. The shields

must be terminated at the

shields of the incoming and

outgoing RS485 leads

Connect 120 OHM,

I/O Board

½ Watt resister

between + and –

RS485 terminals on

the LAST C-More

Box.

METHOD B – TERMINATION ACTIVATED AT I/O BOX

Figure 2-8: RS485 (Modbus) Wiring For KC1000 Boilers (Sheet 2 of 2)

MC2: 04/23/13 Page 28 of 144

Do not terminate the shields of

the RS485 leads to the ground

NOTE

source ends only. Connect the

together.

Page 29

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Y2

Y3

Y4

Y1

SW1

A1

I

0

BCM FRONT VIEW

7 6 5 4 3 2 1

Y2

JP2

JP1

T

C

V

JUMPER

SHOWN IN

“TERMINATED”

(UP) POSITION

MODBUS B (+)

MODBUS A (-)

RS485 Wiring at Boiler BCM of Modulex Boiler(s)

DO NOT terminate the shields at the Boiler end of the RS485 loop.

chain must have the termination jumper

2.7.2 RS485 Wiring for Modulex Series Boilers

RS485 wiring connections are made at the MODBUS terminals of each Boiler’s BCM Module as

shown in Figure 2-9. Connect the wiring as shown below:

1. Connect the positive lead to terminal 1 (MODBUS B +) of connector Y2.

2. Connect the negative lead to terminal 2 (MODBUS A -) of connector Y2.

3.

Connect the shields of the incoming and outgoing leads together. The

RS485 loop shield should only be terminated at the ACS.

4. The last BCM in the daisyengaged as shown in Figure 2-9.

5. The two ACS bias switches (Figure 2-6) must be activated by placing them

in the down position.

MC2: 04/23/13 Page 29 of 144

Figure 2-9: RS485 (Modbus) Wiring For Modulex Series Boilers

Page 30

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

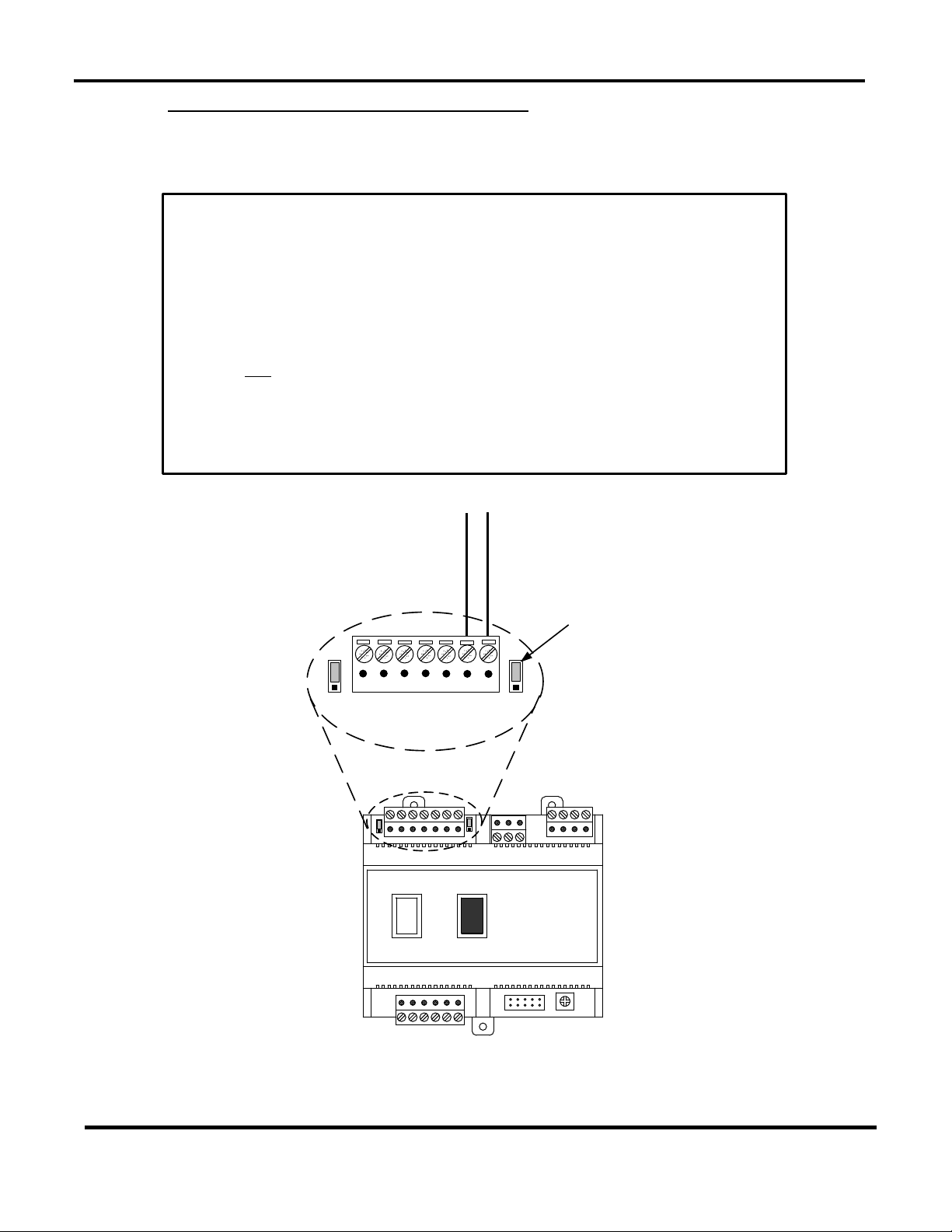

NOTE

turned on. Refer to Section 2.7 of this

termination.

NOTE

be turned to “ON”.

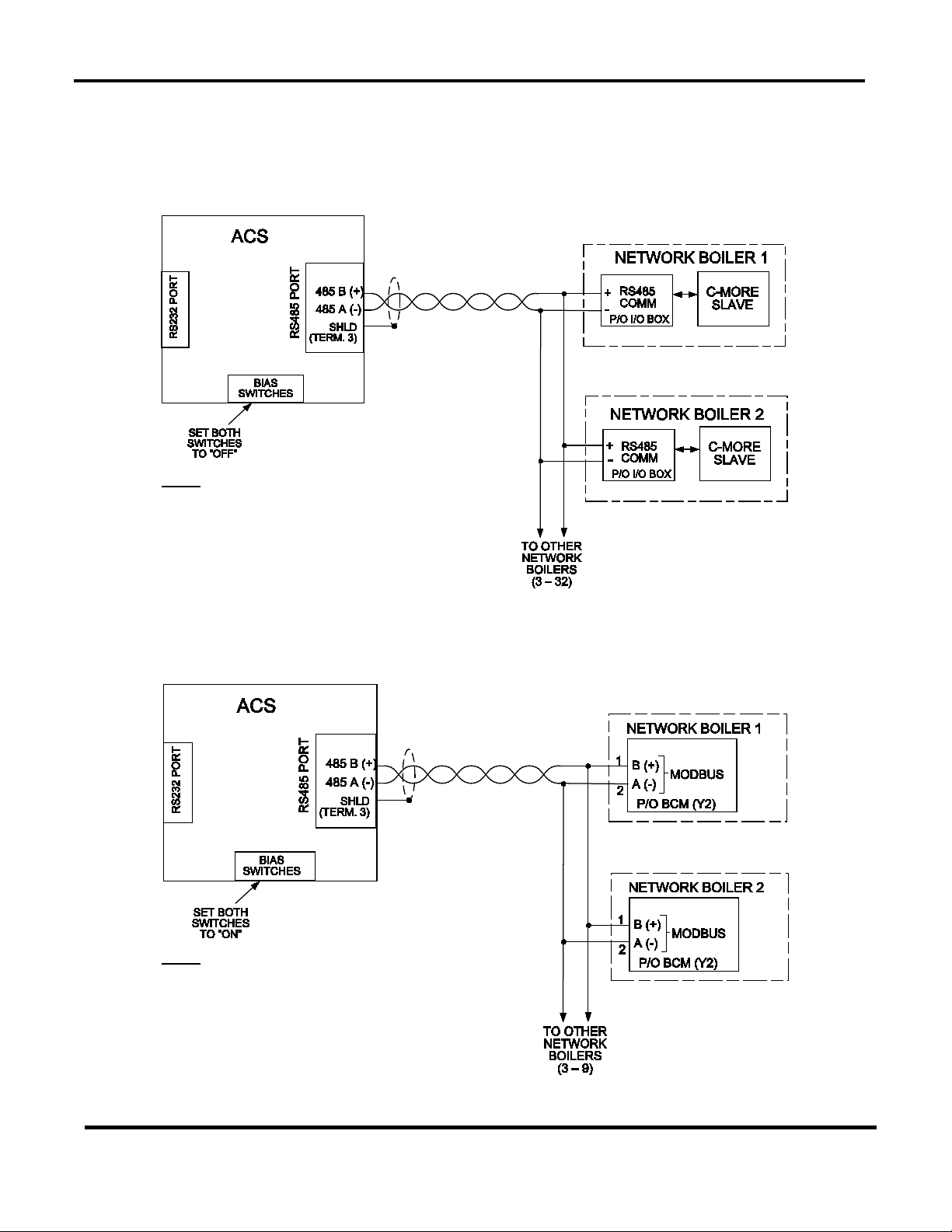

2.8 SAMPLE RS485 (MODBUS) NETWORK DIAGRAMS

Figure 2-10 shows a sample RS485 (Modbus) Network diagram with the ACS connected to

KC1000 or Benchmark Series Boilers equipped with C-More Control Systems. Figure 2-11

shows a similar sample diagram with the ACS connected to Modulex Series Boilers equipped

with BCMs and E8 Controllers.

The last C-More slave on the RS485 loop

must have its termination resister (TERM)

and bias (BIAS1, BIAS2) DIP Switches

manual for details on activating bias and

Figure 2-10: Sample RS485 (Modbus) Network For Benchmark or KC1000 Boilers

The last BCM slave on the RS485 loop

must have its termination resister (T)

activated. Refer to GF-115C for more

information.

The bias switches in the ACS should both

Figure 2-11: Sample RS485 (Modbus) Network For Modulex Series Boilers

MC2: 04/23/13 Page 30 of 144

Page 31

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

2.9 RS485 WIRING AT THE ACS

The ACS communicates with an external Energy Management System (EMS) or Building

Automation System (BAS) utilizing the wiring terminals labeled RXD (Receive Data), TXD

(Transmit Data) and 232 ISO GND (Isolated Ground). If the EMS does not contain an RS232

port, a RS485-to-RS232 Converter (AERCO Part No. 124943) is required to communicate with

the ACS. If a Converter is required, it can be installed inside the wiring compartment of the ACS,

or installed externally. The ACS provides an isolated 12 VDC output terminal (ISO 12V) which

can be used to power AERCO’s RS485-to-RS232 Converter if needed. Refer to Figure 2-12 for

sample network layouts.

Figure 2-12: Sample Network Connections To EMS

MC2: 04/23/13 Page 31 of 144

Page 32

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

CAUTION

2.10 INTERLOCK WIRING

The ACS is equipped with two interlocks designated Interlock 1 (INT 1) and Interlock 2 (INT 2).

Since both interlocks must be closed for the ACS to operate the boiler plant, the associated

wiring terminals are jumpered, prior to shipment. If desired, proving device switches can be

connected to either interlock in place of the jumper. If used, interlock wiring connections are

made as described in the following paragraphs.

DO NOT remove the factory-installed jumpers for INT1 or INT2

unless the respective Interlock is being connected to an external

proving device. The boiler plant WILL NOT operate if one or both

Interlocks remain open.

NOTE

If necessary, Interlock 1, Interlock 2 or both can be programmed to

operate the boilers only when the outdoor air temperature falls below

the system start temperature. The selection is made with “SYS

START INTLK” in the Relay Menu. The default is set to Interlock 1.

See paragraph 3.11 for details.

NOTE

NO power should be sent to the INT1, INT2, and SETBK terminals.

Only a dry contact may be applied.

2.10.1 Interlock 1 (INT 1) Wiring

Interlock 1 is often used with auxiliary equipment, such as air dampers or flow switches. It can

also be used as a general purpose interlock. If used, connect the end proving switch to INT 1

terminals 9 and 10 as shown in wiring diagram in Appendix E.

2.10.2 Interlock 2 (INT 2) Wiring

Similar to Interlock 1, Interlock 2 is a general purpose interlock which can be used with a variety

of devices or equipment or conditions that must be “proved” prior to enabling the boiler plant. If

used, connect the end proving switch to INT 2 terminals 11 and 12 as shown in wiring diagram

in Appendix E.

2.11 SETBACK WIRING

The SET BACK terminals, shown in the wiring diagram in Appendix E, are used only when

implementing a manually-controlled header temperature offset. If used, connect a dry contact

switch across SET BACK terminals 13 and 14. See the sub-section entitled Manual Offset

included in paragraph 3.8 (Field Adjust Menu),

2.12 RELAY WIRING

The ACS contains a System Start (SYS START) Relay, a Fault Alarm (FLT ALARM) Relay and

an Auxiliary (AUX) Relay which can be connected to external monitoring or control devices.

The contacts for each of these relays are rated at 120 VAC, 5A and are fused internally at 5A

with replaceable fuses. The contact terminals for these relays are shown in the wiring diagram

in Appendix E.

MC2: 04/23/13 Page 32 of 144

Page 33

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

NOTE

The state of the SYS START, FLT ALARM and AUX Relays are

controlled by options contained in the Relay Menu described in

Chapter 3, paragraph 3.11.

2.12.1 System Start Relay

The state of the System Start (SYS START) relay contacts are controlled by the value set for

the SYS START TEMP and SYS START OPTION in the Relay Menu. The contacts are closed

either when the outdoor air temperature is less than the System Start Temperature (SYS

START TEMP) or when there is a load, or both. The default value for this temperature setting is

70°F. See paragraph 4.5 for additional information.

2.12.2 Fault Alarm Relay

The state of the Fault Alarm (FLT ALARM) relay contacts are controlled by the option selected

for the FAULT ALRM RELAY, FAULT ALARM BLR and FAULT ALRM CLEAR in the Relay

Menu. Contact closure can be set to: ALL FAULTS, NO INTERLOCK, INTERLOCK 2 or

INTERLOCK 1. The default for this option is ALL FAULTS.

2.12.3 Auxiliary Relay

The state of the Auxiliary (AUX) relay contacts are controlled by the AUX RELAY CLOSE and

AUX RELAY OPEN options selected in the Relay Menu. Contact closure can be set to occur

either when all available boilers are at the 100% Fire Rate or for either when all boilers are at

100% Fire Rate or no boilers are available (all boilers faulted or turned off).

2.13 4-20 MA WIRING

The ACS can accept a remote 4 – 20 mA current signal representing a setpoint. This input is

fused internally at 0.63A. Connect the signal leads to the 4-20 + and 4–20 – terminals. Refer to

Chapter 4, paragraph 4.3 for Remote Setpoint programming using a 4 -20 mA input.

2.14 MOUNTING AND WIRING THE OPTIONAL ACS RELAY BOX

The ACS (Aerco Control System) Relay Panel is used in combination with the ACS to control up

to 2 isolation valves, boiler interlocks, and a Domestic Hot Water (DHW) pump in a Combination

heating plant where AERCO boilers are bring used for both Building Heat and Domestic Hot

Water heating.

Figure 2-13: AERCO Control System (ACS) Relay Box

MC2: 04/23/13 Page 33 of 144

Page 34

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

2.15 RELAY PANEL INSTALLATION AND WIRING

The ACS Relay Panel should be installed on a wall next to or as near as possible to the ACS.

The enclosure is the same as the ACS and so similar hardware can be used. See Section 2.2,

“Site Selection and Mounting” for further installation information.

Figure 2-14: AERCO Control System (ACS) Relay Box with Wiring Cover

Removed and Breakout Illustration of Connection Silk-Screening

MC2: 04/23/13 Page 34 of 144

Page 35

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Figure 2-14a shows sample wiring diagram of the relay box wiring and Figure 2-14b shows the

wiring to the ACS unit for a two-valve combination system. Your actual wiring may vary

depending on the type of valves being used:

Figure 2-14a: Wiring of the Relay Box (to the AERCO Control System (ACS)

MC2: 04/23/13 Page 35 of 144

Page 36

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Figure 2-14b: ACS Wiring: DHW Option 1

DHW Pump Enabled/Disabled by Building Controls

MC2: 04/23/13 Page 36 of 144

Page 37

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Figure 2-14c: ACS Wiring: DHW Option 2

DHW Pump Enabled/Disabled by ACS

MC2: 04/23/13 Page 37 of 144

Page 38

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

Figure 2-14d: ACS Wiring: DHW Option 3

MC2: 04/23/13 Page 38 of 144

Page 39

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

2.16 RELAY PANEL COMPONENTS

2.16.1 Power

The power connector is located at the left side of the wiring panel. It uses single phase AC

power from 110 to 240 VAC, 60 Hertz.

2.16.2 Inputs

The inputs are all dry switch (digital) inputs. The specifics are below:

• Aquastat In (Temperature) Switch

This switch input comes from the aquastat temperature switch located in the DWH

storage tank. The switch should have at least a 3 degree hysteresis or deadband.

• Valve End Switch In 1 & 2

These switch inputs come from the end switches of Valve 1 and Valve 2, respectively.

The valve end switches should close when the valves are completely open.

• Aux Relay Contact In

This switch input comes from the dry contact “Aux Relay” output of the ACS.

• Sys Relay Contact In

This switch input comes from the dry contact “Sys Relay” output of the ACS.

2.16.3 Outputs

The relay outputs are all dry contact and can switch up to 5A at 120VAC, or ?240 VAC. The

switch outputs connect directly to the ACS and are all dry contacts. The specifics are below:

• DHW Pump Relay

This SPST relay is used to activate a DHW pump when the DHW Aquastat is calling for

heat. When the Aquastat stops calling, the relay will remain activated for ?1 minute

before turning off.

• Valve I Relay

This SPDT relay controls the valve between the Building Priority boilers and the DHW

Priority boilers. The Normally Open (N.O.) contact is connected to the Valve 1 Open

and the Normally Closed (N.C.) contact is connected to the Valve 1 Close input. For a

valve with “spring return open” or “capacitor return open”, the N.O. contact would not be

used.

• Valve 2 Relay

This SPDT relay controls the valve between the Building boilers and the Building Priority

boilers. The Normally Open (N.O.) contact is connected to the Valve 2 Close and the

Normally Closed (N.C.) contact is connected to the Valve 2 Open input. For a valve with

“spring return open” or “capacitor return open”, the N.C. contact would not be used.

Interlock 1

4 Relay – These are 4 SPST relays used to enable or disable the Building Priority boilers

in this 2-valve system.

• Aquastat Switch Out

This SPST contact connects to the “Setback” input of the ACS.

• Valve End Switch Out

This SPST contact connects to the “Interlock 1” input of the ACS.

MC2: 04/23/13 Page 39 of 144

Page 40

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

2.17 RELAY PANEL OPERATION

Clear Plastic

Cover

Wiring Compartment Cover

Front Panel

Figure 2-15: ACS Relay Panel Front Panel

The board operates basically as follows:

a) In the normal idle state, all the inputs, except one of the Valve End Switch In inputs, would

be open. As a result, the Aquastat Out would be open and the Valve End Switch Out would

be closed. All the relays except the Interlocks Relay will be in their unpowered state – DHW

Pump off, Valve 1 closed(N.C. powered), and Valve 2 open (N.C. powered). Since the

Valve End Switch Output would be activated, all the Interlocks relays will be activated and

all its contacts closed thereby enabling the Building Priority boilers to run if needed.

NOTE

If no Valve 2 (Sys Relay) is used, the Interlocks Relay connection

will not need to be used.

b) When the tank calls for heat and the Aquastat Input closes, the DHW Pump relay will

activate. The ACS will activate Valve 1 to close if it is not already closed. Once closed the

ACS will allow the DHW Priority boilers to run to provide heat to the tank.

If all the DHW Priority boilers are running at 100% for more than 2 minutes, the ACS will

open Valve 1 and close Valve 2 and activate the Building Priority boilers to help with DHW

heating.

When the Aquastat Input opens, the DHW Pump will turn off after some time delay (currently

60 seconds). The DHW Priority boilers will also shut down and Valve 1 will close and Valve

2 open.

c) Generally if any of the two valves is fully open and its Valve End Switch Input closes, the

Interlock relays will activate to allow the Building Priority boilers to run. When the Valve End

Switch Input opens, the Interlock relays will de-activate.

d) The Valve 1 Relay output is labeled such that the Normally Closed (N.C.) contact is Valve 1

Close and the Normally Open (N.O.) contact is Valve 1 Open. The Valve 2 Relay output is

labeled such that the Normally Closed (N.C.) contact is Valve 2 Open and the Normally

Open (N.O.) contact is Valve 2 Close. It is important to make these connections correctly. In

this way, the unpowered state of the relay panel will keep the valves in the default state with

Valve 1 closed and Valve 2 open.

MC2: 04/23/13 Page 40 of 144

Page 41

GF-131

AERCO Control System (ACS)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation, and Maintenance Manual

OMM-0081_0D

2.18 ACS PROGRAMMING FOR USE WITH THE ACS RELAY PANEL

The AERCO CONTROL SYSTEM (ACS) can be programmed for 3 different types of DHW

options. For “Option 1” and “Option 3” operation, the ACS Relay Panel is not needed. It is

needed for Option 2 operation.

Below we will illustrate programming the ACS for a total of 8 boilers with 2 DHW Priority boilers,

2 Building Priority boilers, and the rest Building boilers. Valve 1 is in the boiler outlet header