Page 1

COMBINATION CONTROL PANEL

MODEL CCP

Domestic Water/Space Heating

Multiple Boiler Controller

Concept

AERCO International recommends individual KC water

heating and space heating systems wherever possible.

Individual water heaters and boilers achieve maximum

efficiency and precise temperature control. However,

when factors such as existing indirect storage water

heaters, restricted fuel input, or space limitations are

conditions to be met, AERCO KC Boilers can be used in a

dual service role.

Combination System Description

In order to accommodate the requirements for both space

heating and the production of domestic hot water, multiple

KC style boilers can be used in a combination space

heating and domestic water heating plant. Boiler modules

are piped in a multiple boiler arrangement as they would

be in a multiple unit space heating plant. See Combination

Boiler Plant Sizing section for recommendations on num-

ber of modules required. The necessary number of mod-

ules for domestic water production are isolated from the

heating system in the supply piping by means of a nor-

mally closed two way motorized valve. An external hot

water storage generator is used to convert boiler water to

produce potable water through a closed loop coil. Upon

demand for domestic water, the isolated (combination

duty) boilers produce a constant temperature supply

(70.220F) by operating in the internal setpoint mode.

The AERCO Combination Control Panel (CCP) is an

accessory panel designed to work in conjunction with an

AERCO Model 168 Boiler Management System (BMS) to

control the firing of the combination boiler modules and

the associated accessories for domestic water production.

The CCP panel allows operation of the combination boiler

modules to produce domestic water through the external

generator coil, and activates the circulating pump between

the boilers and the coil. The CCP uses a simple tank

aquastat to start domestic water production. It allows

control of up to four KC Boilers (Boiler Control Code -6) in

the constant set point mode, and allows a transfer of the

motorized valve and the control of the modules to the

BMS when the space heating requires their added input.

By utilizing a CCP Panel in tandem with a Model 168

Boiler Management System, the KC Boilers efficiency will

be maximized. Only the required energy (input) for

domestic water will be used, and the heating plant can

operate at lowest required temperatures for space heating

to maximize condensing efficiency.

Domestic Water Mode

The tank aquastat, or domestic water demand device, is

wired to the CCP to signal a demand for domestic water.

The CCP supplies 12VDC to the dry contacts of the

domestic water demand device (aquastat). Upon a

demand for domestic water, the CCP enables the combination boiler modules to begin firing to their internal

setpoint temperature. Each module will automatically

modulate its input to meet the requirement of domestic

water production. The closed motorized valve isolates the

normally higher temperature boiler water from the heating

system. The circulating pump between the combination

modules and the coil is activated simultaneously with the

combination modules. The boilers and pump will operate

continually until the domestic water aquastat is satisfied.

Heating Mode

The Boiler Management System (BMS) will activate the

heating plant and sequence/modulate the heating-only

boilers in the selected mode. When all dedicated heating

modules are operating at 100% input, the BMS will close

the Auxiliary contacts wired to the CCP Panel. The CCP

will then activate the motorized valve to open piping

between the heating system loop and the combination

boiler loop. The CCP supplies line voltage (120/1/60)

directly to the valve operator. The valve must be a three

wire control type with power open/power closed operator.

Operator timing on motorized valves should be in the 8 to

45 second range, and must be equipped with a dry contact SPST N.O. end switch. When the valve reaches the

full open position, the dry contact end switch of the valve

will close, signaling the supply piping between the heat-

ing-only and combination boilers is open. This transfers

control of the combination modules percentage of firing

input to the BMS. The BMS will then add the combination

modules to the heating system, and modulate them to

their required input level. The boiler modules will be

sequenced at the adjusted percentage as set in the BMS.

As the added input from the combination modules allow

the heating load (setpoint) to satisfy, the auxiliary contacts

of the BMS will open. The motorized valve will then be

Page 2

driven closed by the CCP Panel. The combination boilers

will be de-activated until needed either for domestic water

or for heating again. If domestic water is called for while

the valve is open for heating the CCP will automatically

close the motorized valve and transfer the control of the

combination modules back to domestic water production.

Example -

From conventional calculations on a typical design:

Space Heating Load = 2840 MBH

Domestic Water Load = 1705 MBH

Diversity =

Factor

1705 MBH = .60

2840 MBH

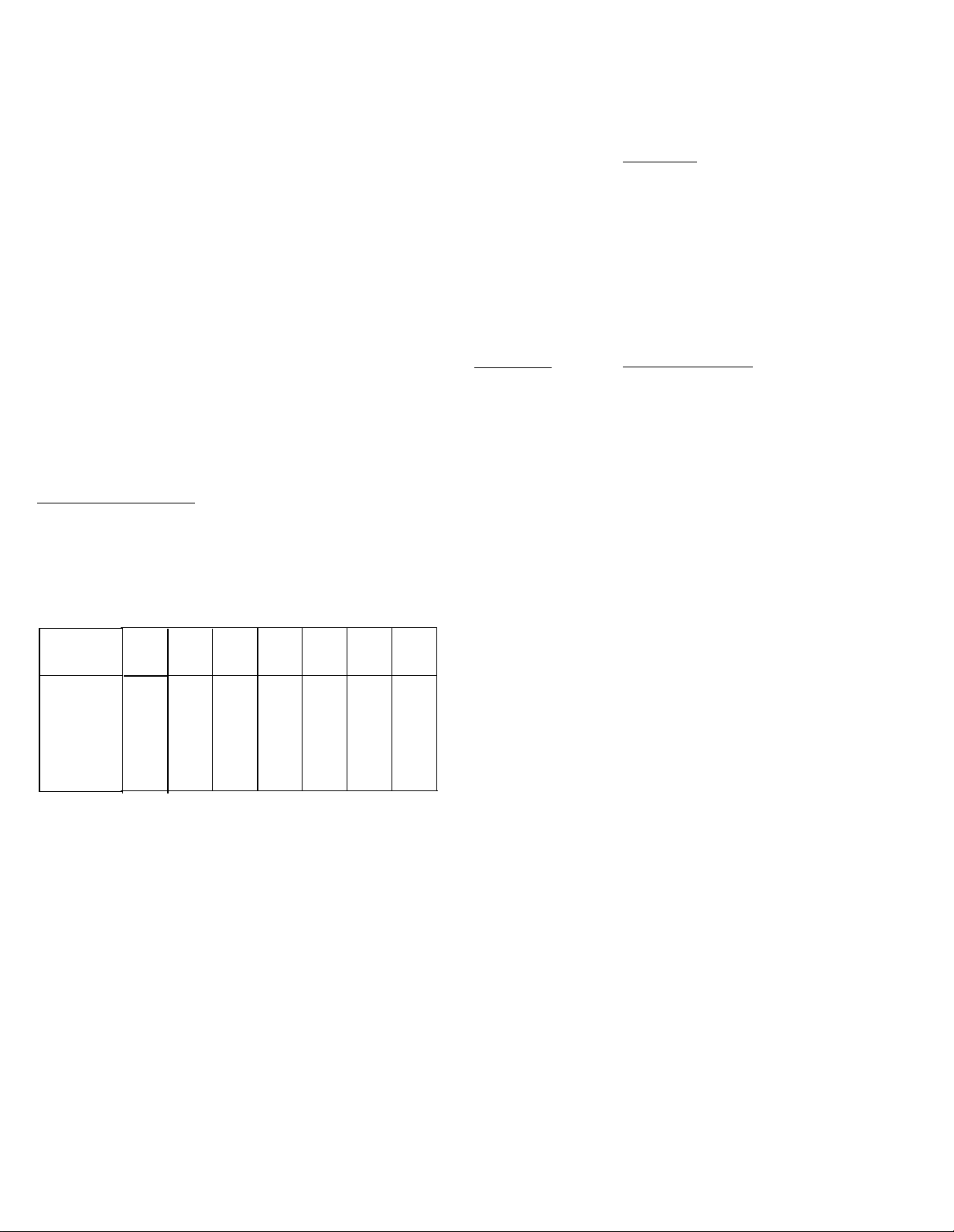

Combination Plant Sizing

The required size of a combination boiler plant is not

necessarily the simple sum of the heating modules and

the domestic water modules. ASHRAE has documented

and developed a method of sizing combination plants

based on the diversity of the loads. ASHRAE Systems

1984 Handbook published a researched method of estab-

lishing a relationship of domestic water load to heating

load, and a table of recommended percentage of additional BTUH to be added to the heating plant to handle

both loads.

Simply expressed,

Domestic Water Load = Diversity Factor

Heating Load

The diversity factor is then converted to a percentage

increase in the base heating load plant from Table A.

Table A

Diversity

.4

Factor

Domestic

Heating %

Load to be

added to

Heating

Boiler

2

60%

1

.8

50% 40%

.6

30%

.5

20% 10%

.3

0%

From Table A, a diversity factor of .60 indicates a minimum of 30% of the domestic water heating load requirement should be added to the heating load for Total Boiler

Plant Capacity.

Total Plant Capacity =

2840 MBH + (.30X 1705 MBH) = 3352 MBH

Total Load

Output/Boiler

=

3352 MBH Output = 4KC Boilers

870 MBH/Boiler

Component Design

Domestic water sizing for a combination plant should be

done in accordance with ASHRAE and ASPE standards.

The storage tank size should be adequate for small

domestic water draws without short cycling the domestic

tank aquastat. The combination of recovery and storage

should be as prescribed in the ASHRAE/ASPE methods.

The recovery of the storage tank coil exchanger should

be based on a temperature drop of 2OF, or the same

temperature drop as the heating system that the plant

supplies. When sizing the circulating pump between the

combination boiler(s) and the tank coil, the flow of the

pump must be greater than the minimum module flow of

25 gpm per module. The head of the pump must be

capable of overcoming the pressure drop of the boilers,

the tank coil, and the frictional resistance of all piping/

accessories between them. Air elimination and expansion

accessories may be required in the coil loop as well as the

main heating loop.

Page 3

Recommended Piping and Wiring Details

Figure 1 -- Four Boiler Combination Plant Piping

Figure 2 -- Four Boiler Combination Plant Wiring

Page 4

Sequence of Operation

The four KC Boiler Combination plant shown in Figures 1

and 2 is typical of plant piping and wiring arrangements.

The KC boilers dedicated for heating-only must be

ordered for Control Mode -5 for BMS mode operation.

The boilers for combination duty must be ordered for

Combination Mode -6. The Combination mode boilers

internal setpoint should be adjusted to the design water

temperature used to size the coil in the storage/generator.

The tank aquastat should be set at the desired domestic

water tank temperature.

As the tank aquastat closes sensing a demand for domestic water recovery, the CCP will activate the coil pump and

Combination Boilers #1 & #2. The boilers will modulate

their own input as needed to maintain their setpoint. The

boilers will automatically reduce their input as the coil

water temperature approaches setpoint. Under heavy

load, the boilers will increase their input for maximum

recovery. The boilers and coil circulating pump will con-

tinue to operate until the tank aquastat is satisfied.

The system start within the Model 168 Boiler Management

System(BMS) activates the heating system circulating

pump and the heating-only modules. Heating Boilers #I &

#2 will fire normally as controlled by the BMS and modulate input up as the heating load increases. When both

dedicated heating modules reach 100% input, the BMS

Auxiliary contacts will close, activating the CCP panel.

The CCP will then open the motorized valve in the supply

piping. When the valve reaches 100% open, the end

switch will allow the CCP to transfer the control of both

combination boilers to the BMS. The BMS will modulate

the input of all four boilers to meet the needs of the heat-

ing system.

As the heating system temperature increases to the

required system setpoint, the auxiliary contacts of the

BMS will open. The opening of the Auxiliary contacts can

be adjusted from the keyboard of the BMS. As the auxiliary contacts open, the CCP closes the motorized valve to

isolate the domestic loop from the heating loop. The

control of the combination boilers is also returned to their

internal setpoint controls, and will only fire upon a signal

for domestic water production. If the domestic tank aquastat closes while the motorized valve is open for heating,

the CCP will automatically close the valve and return

Combination Boilers #I & #2 back to domestic recovery

service. This internal feature provides priority to domestic

water heating.

Represented by:

AERCO INTERNATIONAL, INC.

CCP-1 12/95 5M

4

HEAT EXCHANGERS • WATER HEATERS • BOILERS

CONTROL VALVES • STEAM GENERATORS

HOT WATER SYSTEMS

• 159 PARIS AVE., P.O. BOX 128 • NORTHVALE, N.J. 07647-0128

(201)768-2400. FAX 201-768-7789

Loading...

Loading...