Page 1

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

TID-0004_0A

HE-109

Hardware Procedure:

Heaters

Applies to:

removal and replacement of Coil

Assemblies and Risers contained in

ry safety

precautions when working with high

temperature, pressurized steam and

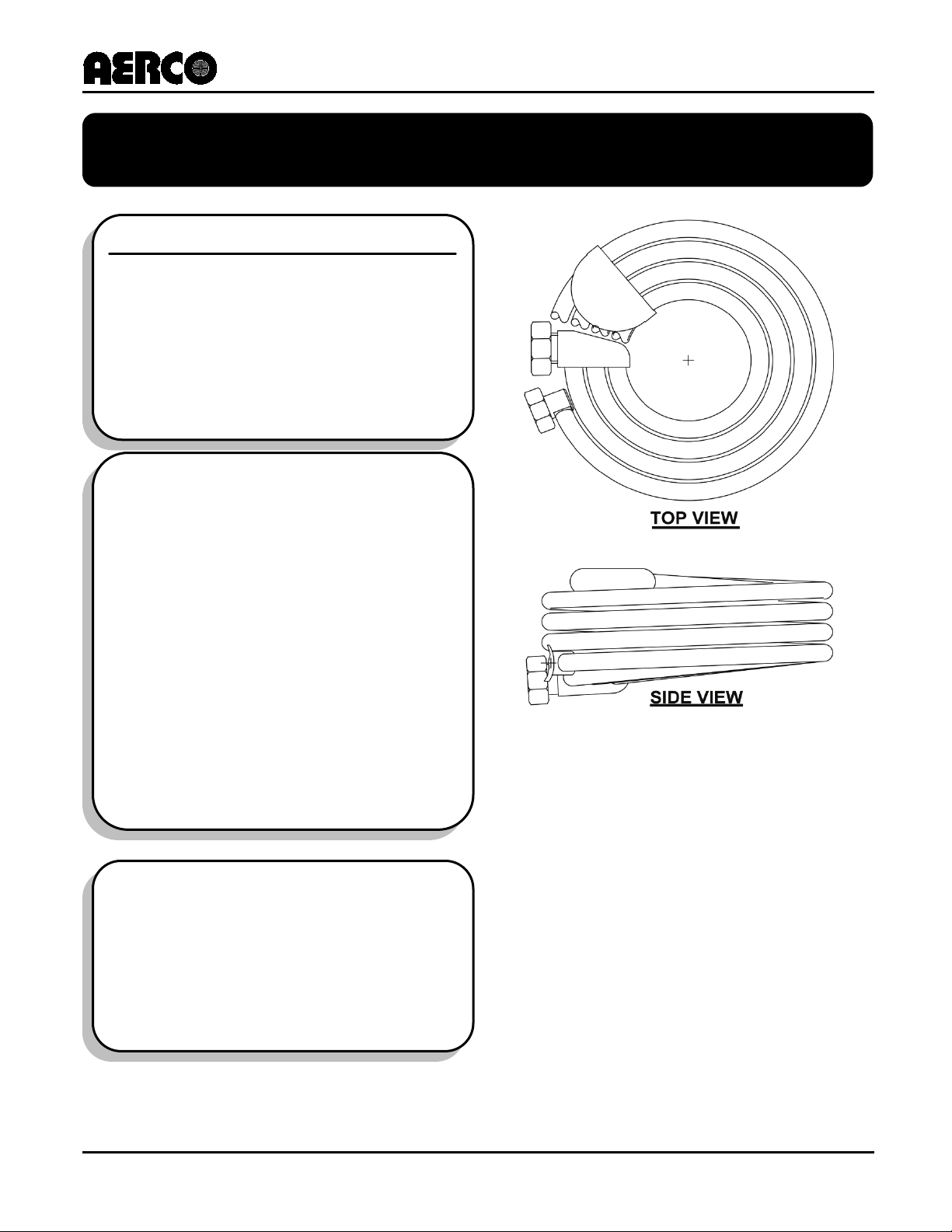

Coil Assembly in Water Heater Heat Exchanger

TECHNICAL INSTRUCTIONS

Coil and Riser

Replacement

Procedures for All Styles

of A, B, C, and D

Indirect-Fired Water

Indirect-Fire Water Heaters.

Description of Document:

This Technical Instruction Document

provides the instructions necessary for

AERCO Indirect-Fired Heat Exchangers.

These instructions must be performed

by a skilled service technician capable

of exercising the necessa

water systems.

The original document was formatted as

HE-109, but has now been changed

To a Technical Instruction Document

(TID-0004), to better conform to the new

an Application Guide,

document definitions.

Revised: 06/20/2011

NOTE

Page 2

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

Technical Support:

1-800-526-0288

www.aerco.com

HE-109

TID-0038_0A

(Mon–Fri, 8am-5pm EST)

Disclaimer

The information contained in this manual is subject to change without notice from AERCO International,

Inc. AERCO makes no warranty of any kind with respect to this material, including but not limited to

implied warranties of merchantability and fitness for a particular application. AERCO International is not

liable for errors appearing in this manual. Nor for incidental or consequential damages occurring in

connection with the furnishing, performance, or use of this material.

PR2: 04/01/11 Page 2 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 3

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

HE-104

SW1B-Plus Heat Exchanger Installation, Operation & Maintenance Instructions.

HE-110

B-Plus II Water Wizard Heat Exchanger Installation, Operation & Maintenance

VA-109

For removal of CXT-S 1” thru 2” Control Valve prior to hydrostatically testing and

VA-110

For removal of CXT-S 2.5” thru 4” Control Valve prior to hydrostatically testing

VA-106

For removal of CXT-P Control Valve prior to hydrostatically testing and for

AC-103

For adjusting Barber-Coleman Temperature Controller for re-commissioning unit.

HE-109

TID-0038_0A

1. Introduction

This document provides the instructions necessary for removal and replacement of Coil Assemblies and

Risers contained in AERCO Indirect-Fired Heat Exchangers. These instructions must be performed by a

skilled service technician capable of exercising the necessary safety precautions when working with high

temperature, pressurized steam and water systems. It is imperative that the following Safety Warnings

and Precautions be observed at all times:

2. Overview of Procedure

Installation, maintenance and operating personnel must, at all times observe all safety regulations. The

following warnings are general and must be given the same attention as specific precautions included in

these instructions.

FLUIDS UNDER PRESSURE MAY CAUSE INJURY TO PERSONNEL OR DAMAGE

TO EQUIPMENT WHEN RELEASED

Shut off all incoming and outgoing steam and water stop valves and carefully decrease

all trapped pressures to zero before performing any maintenance.

WARNING!

Never search for leakage in a live steam line by sight alone or by “feel”. Use a

Always provide yourself with personal protective equipment, (PPE) such as

LIVE STEAM CAN CAUSE SEVERE BURNS

mirror or other suitable polished object.

gloves, eye protection, dust mask, hard hat, etc.

WARNING!

3. Reference Documents

Refer to the following AERCO documents when removing, replacing or adjusting the indicated

components and assemblies:

HE-107

SW1A-Plus Heat Exchanger Installation, Operation & Maintenance Instructions.

Instructions.

for re-commisioning unit.

and for re-commisioning unit.

re-commissioning unit.

PR2: 04/01/11 Page 3 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 4

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

HE-109

TID-0038_0A

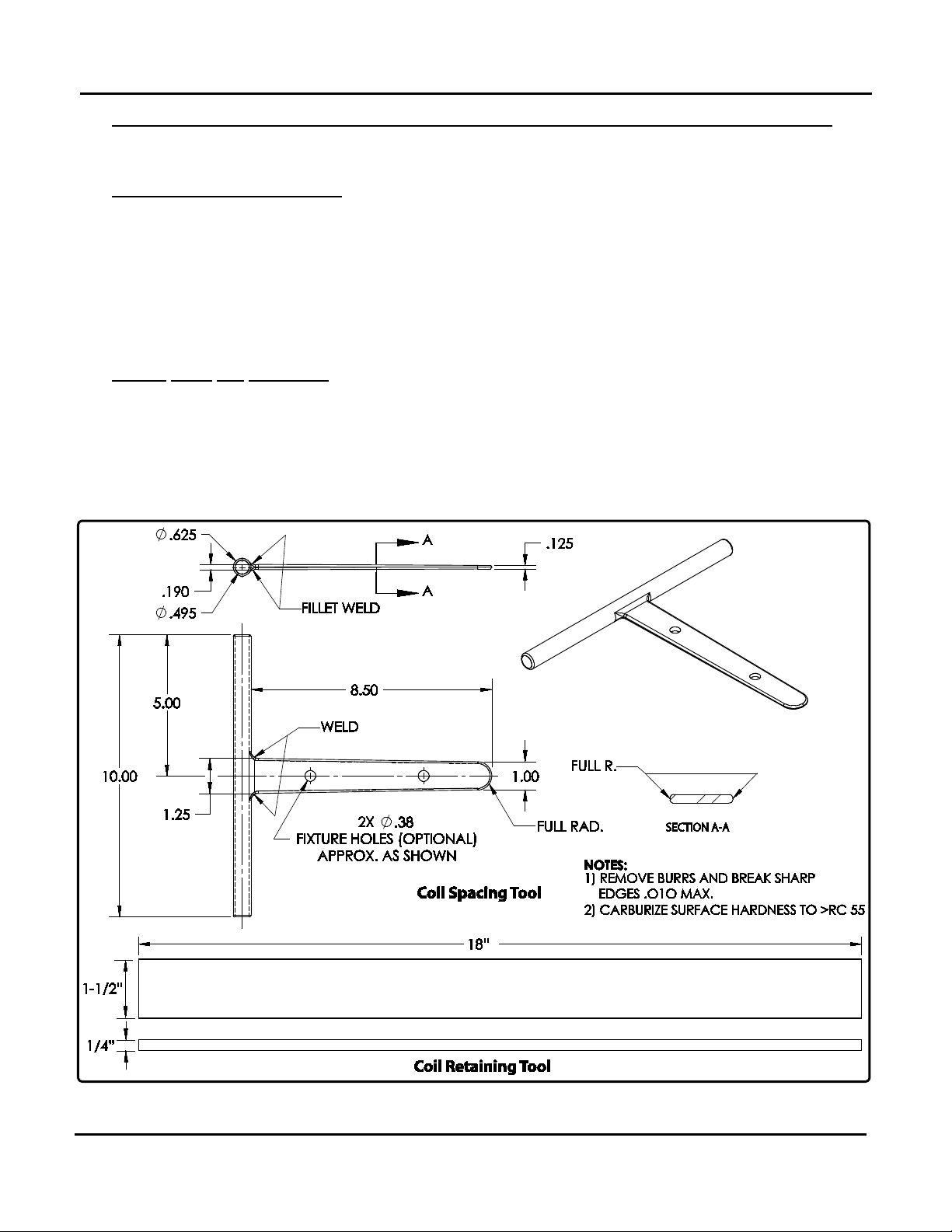

4. Tools and Equipment Required

The following common and special tools and equipment are required to perform the instructions contained

in this document:

Common Tools and Equipment

• Combination Wrenches: 7/16”, 5/8”,

13/16”, 1-1/16”, 1-1/8”

• Pipe Wrenches: 12” and 24”

• Chain Hoist

• Voltmeter:

• Brass Wire Brush

Special

Tools and Equipment

• Hydrostatic Pressure Pump: Range=

Up to 235 psig

• Torque Wrench, 75 ft.-lbs. With 1-1/4”,

1-5/16” & 1-1/2” Open-End Spanners

(1-1/4” Open-End Spanner required for

“A” Heater Only)

• Needle-Nose Pliers

• Gasket Removal Tool

• Carpenter’s Square

• Teflon Tape

• Orange Citric Cleaner

• Black Marker

• Coil Retaining Tool (Figure 1)

• Coil Spacing Tool (Figure 1)

• Short-Length Wrenches: 1-1 /4”, 1-

5/16”, 1-1/2”

(Overall wrench lengths should be

approx. 6 inches or less)

Figure 1: Tool Fabrication Details: Coil Spacing and Retaining Tools

Recommended Material: 1018 steel

PR2: 04/01/11 Page 4 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 5

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

procedures should be performed in the order specified to minimize repair time.

Section 5.1 Instructions

END

HE-109

TID-0038_0A

5. Heater Isolation and Disassembly

The procedures in the following paragraphs are arranged to isolate, disconnect and

disassemble the unit to the extent necessary to repair or replace defective items. These

NOTE

5.1 Isolating Heater

To isolate the Heater from all facility energy sources (steam, water, electrical, etc.), proceed as follows:

1) Disconnect and Lock-Out/Tag-Out external AC power supplied to the Control Box and any other

devices connected to the Heater.

2) Using a voltmeter, check to ensure that all incoming voltage readings are zero Before

3) If the Heater is equipped with a Pneumatic Steam Valve, close the valve supplying air inlet

pressure to the Pneumatic Controller.

4) Close all stop valves in the Steam Inlet and Condensate Outlet lines

5) On the water-side, close the stop valves in the following order

6) Carefully open the Relief Valve located on the Top Head to relieve pressure in the Heater Shell.

7) While holding the Relief Valve open to prevent creating a vacuum in the Shell, open the Drain

• Hot water outlet line

• Recirculation line

• Cold water inlet line

Water should stop flowing from the valve within one minute. If water continues to flow from the

Relief Valve, one of the water stop valves is not securely closed.

Valve in the Bottom Head on the Heater. Completely drain the potable water from the Heater.

Isolating the Heater

continuing.

:

PR2: 04/01/11 Page 5 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 6

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

Using a 5/8” combination wrench, remove the Steam Pressure Line from the Steam Line and

Section 5.2 Instructions

END

5.2 Disconnecting Heater From the Facility

To disconnect the Heater from the facility piping and wiring connections, proceed as follows:

1) First, check the ceiling height to determine if the Heater Shell and Top Head can be hoisted up with

the Heater remaining in position.

2) If there is sufficient ceiling clearance to permit safe elevation of the Shell assembly, skip to step 8. If

there is insufficient clearance, proceed to step 3 to remove the Heater from its current location.

3)

Pressure Gauge.

4) Disconnect the Steam line from the Valve and Bottom Head.

5) Disconnect the water inlet from the Bottom Head.

6) Disconnect the drain line from the Bottom Head.

7) Disconnect the Condensate Drain piping from the Bottom Head.

8) Disconnect all electrical wires to the Control Box. Also, disconnect all wiring between the Control Box

and any external Solenoid Valve(s).

9) Using a 5/8” combination wrench, remove the Steam Pressure line from the Steam Line and Pressure

Gauge, if it was not performed in step 3.

10) Remove the water outlet piping from the Top Head.

11) Remove the pipe drain(s) from the Pressure Relief Valve(s).

12) Disconnect the pipe drain from the Water Solenoid Relief Valve.

13) Using a 13/16” combination wrench, disconnect the compression fittings on the Cold Water Feed

Tube from the Top Head and Bottom Head.

14) If controlled by a Pneumatic Valve, disconnect the incoming air supply to the Control Box and Steam

Valve.

15) If controlled by a Self-contained Valve, remove the thermal well from the Top Head that is attached to

the Valve.

Disconnecting the Heater from the Facility

HE-109

TID-0038_0A

PR2: 04/01/11 Page 6 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 7

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

Move the heat exchanger bundle a few feet to the side so that the Shell can be lowered to the floor.

Section 5.3 Instructions

END

Section 5.4 Instructions

END

Section 6.1 Instructions

END

5.3 Shell Removal

Remove the Heater Shell as follows:

HE-109

TID-0038_0A

1) Using a black marker, mark the edge of the Heater Bottom Head flange and Shell flange in order to

indicate their correct relative positions upon reassemble. The Top Head can remain attached to the

Shell.

2) Using the 1-1/16” combination wrench, unbolt the sixteen studs and nuts around the bottom ring of the

Shell. The two nuts located in-line with the mounting skid legs are to be removed with the stud left in

place.

3) Attach a chain hoist to the two lifting lugs on the Top Head. Lift the Shell up to clear the internal coil

bundle.

4) Using a light source, visually inspect the inside of the Heater Shell for evidence of damage to the

Copper Shell Liner. If any area of the Copper Liner is damaged, replace the Shell down on the Bottom

Head and contact your local AERCO Representative to process return of the Heater to AERCO for

repair.

Shell Removal

5)

Set the Shell on clean surface. Use care to avoid damaging the bottom edge of the Copper Shell Liner.

5.4 Removal of Coils and Risers

The Coil Assemblies, Riser and Condensate Return are removed as follows:

1) Using the proper size open-end wrench, loosen the two Union Nuts securing the Coils to the Steam

Riser and Condensate Return.

2) Using a pipe wrench, remove the Steam Riser and Condensate Return from the Bottom Head.

Removal of Coils and Risers

\

6. Assembly Preparation

Prior to reassembling Heater components, the Bottom Head, Steam Riser, Condensate Return and Coils

must be cleaned, inspected and prepared as described in the following paragraphs:

6.1 Preparation of Bottom Head

The Bottom Head of the Heater must be cleaned, inspected and prepared for reassembly as follows:

Preparation of Bottom Head

1) Clean off all debris from the topside of the Bottom Head.

2) Visually inspect the internal pipe threads where the Risers are connected. The overall depth of

threads should measure, (1-1/8” for 2” NPT and 1” for 1” NPT)

3) If the threads are less then the required depth, use the appropriate 1” or 2” NPT tap to clean out the

threads.

4) Using the gasket removal tool, remove the Shell Gasket from the Bottom Head. Use care to avoid

creating scratches or indents in the Bottom Head casting’s gasket surface area. Any linear scratches

can potentially create a leak.

5) Apply pipe dope to the internal NPT threads in the Bottom Head.

PR2: 04/01/11 Page 7 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 8

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

SPUD

THREADS

SEALING

SURFACE

STEAM RISER OR

CONDENSATE RETURN

SPUD

Section 6.2 Instructions

END

HE-109

TID-0038_0A

6.2 Preparation of Riser and Return

Preparation of Riser and Return

1) Visually inspect all Steam Riser and Condensate Return Spuds, (Figure 2) threads and sealing

surfaces for damage, scratches, braze material and cleaning deposits. If defects are found with the

Spud threads or sealing surfaces, contact your AERCO Representative for instruction to return the

defective Riser.

2) Using a brass wire brush, clean the threads of the Spuds. Use care to avoid scratching the sealing

surfaces of the Spuds. Scratches can cause a leak path under the Coil Gasket. After brush cleaning,

wipe with a clean lint-free cloth.

3) Using a brass wire brush, clean the pipe threads on the Riser. After cleaning, wipe with a clean lintfree cloth.

4) Wrap two layers of Teflon tape around the Riser NPT threads.

THE USE OF TEFLON TAPE OR ANY LUBRICANT ON THE THREADS OF THE SPUDS

IS PROHIBITED AND MAY VOID THE WARRANTY.

CAUTION!

Figure 2: Preparation of Riser/Return Spuds

PR2: 04/01/11 Page 8 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 9

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

SEE

DETAIL ‘A’

0

DETAIL ‘A’

TAILPIECE

SEATING

SURFACE

UNION

NUT

SEALING

SURFACE

BOX

HEADER

Visually inspect all Tail Piece sealing surfaces for cleanliness and evidence of damage.

Section 6.3 Instructions

END

HE-109

TID-0038_0A

6.3 Preparation of Coil Assemblies

1)

(Figure 3).

2) Pull the Union Nut forward against the seating surface of the Tail Piece and rotate the Union Nut

Preparation of Coil Assemblies

several turns to check for any obstructions around the perimeter of the seating surface. (Figure 3).

3) Contact your local AERCO Representative for replacement of the Coil if obstructions prohibit the

rotation of the Union Nut.

4) Using a brass wire brush, clean the internal threads of the Union Nut.

5) Using a citric orange cleaner, spray the area between the Union Nut and Tail Piece. While pulling the

Union Nut forward against the seating surface of the Tail Piece, rotate the Nut to remove any residue

that can cause unneeded friction between the two surfaces.

6) Form the Coil by creating a 1/8” minimum gap between the individual tubes and a 1/8” to 1/4” gap

between the four layers of tubes as shown in Figure 4. Maintain a flat surface on the top and bottom

tube surface of the Coil.

PR2: 04/01/11 Page 9 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Figure 3: Coil Assembly Preparation

Page 10

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

TOP VIEW

1/8" MINIMUM

1/8" TO 1/4"

1/8" TO 1/4"

SIDE VIEW

1/8" MINIMUM

Section 6.4 Instructions

END

HE-109

TID-0038_0A

Figure 4: Coil Assembly Spacing

6.4 Preparation of Coil Gaskets

Two 6-tab gaskets are provided with each replacement Coil Assembly. Proceed as follows:

1) Form the Gasket into a round shape

2) Using Needle-Nose Pliers, form the 6 tabs on each Coil Gasket by bending each tab outward 2 to 3

degrees as shown in Figure 5. This will secure the Gasket into the Spud’s inside diameter.

Preparation of Coil Gaskets

PR2: 04/01/11 Page 10 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 11

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

2 - 3°

Section 7.1 Instructions

END

HE-109

TID-0038_0A

Figure 5: Coil Gasket Preparation

7. Reassembly of Risers & Coil Bundle

Following preparation of all Heater components as described in Section 6, the Heater is ready for

reassembly as described in paragraphs 7.1 through 7.3.

7.1 Installing the Risers

1) Thread the Steam Riser into the Bottom Head.

2) Tighten the Riser until the center of the Spud is visually lined up to the cast notch on the Bottom Head.

3) Thread the Condensate Riser into the Bottom Head.

4) Tighten the Riser until the center of the Spud is visually lined up to the cast notch on the Bottom Head.

5) If this is a B+ II Water Wizard, thread the Sub-Cooling Coil onto the Condensate Riser, hand tight (ref.

paragraph 7.2). If this is not a B+ II Wizard Bundle assembly, proceed to step 9.

Installing the Risers

6) Measure the distance between the outside diameter of the Coil to the threaded stud protruding

through the Bottom Head on both sides of the Coil (Figure 6).

7) Position the Condensate Riser to create an equal distance between both measurements shown in

Figure 6.

8) Remove the Sub-Cooling Coil.

9) Thread a Steam Coil onto the Steam Riser, hand tight.

10) Position the Steam Riser so that the Condensate Tailpiece is aligned with the Spud on the

Condensate Riser.

11) Remove the Steam Coil.

12) Insert the properly formed Coil Gaskets into each Spud. Ensure that the Coil Gasket snaps into the

Spud (Fig. 7).

13) If the Coil Gasket is loose in the Spud, remove it and reform the six tabs to create a positive

connection into the Spud.

PR2: 04/01/11 Page 11 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 12

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

B*

A*

LOWER HEAD

SUB-COOLING

COIL

CONDENSATE

RISER

* MEASUREMENTS A & B SHOULD BE EQUAL

STUD

STUD

STEAM RISER OR

CONDENSATE RETURN

UNION NUT

COIL GASKET

BOX

HEADER

SPUD

HE-109

TID-0038_0A

Figure 6: Sub-Cooling Coil Alignment

Figure 7: Assembly of Coil to Steam Riser or Condensate Return

PR2: 04/01/11 Page 12 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 13

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

threads on the Riser Spuds.

Section 7.2 Instructions

END

Section 7.3 Instructions

END

The procedure in paragraph 7.2 are not required for Regular A, B, C or D Type Heaters.

NOTE

HE-109

TID-0038_0A

7.2 B+ II Wizard Sub-cooling Coil Installation

1) For Wizard Sub-cooling Coil, align the Union Nuts with the two Spuds on the Condensate Riser.

2) Hand thread the Unions Nuts down to the seating surface.

3) Position the Coil to a level position.

4) Using the 75 ft/lb torque wrench, tighten the Union Nuts.

5) If the Union Nuts do not seat properly, remove the Sub-cooling Coil and re-clean all surfaces and

B+ II Wizard Sub-cooling Coil Installation

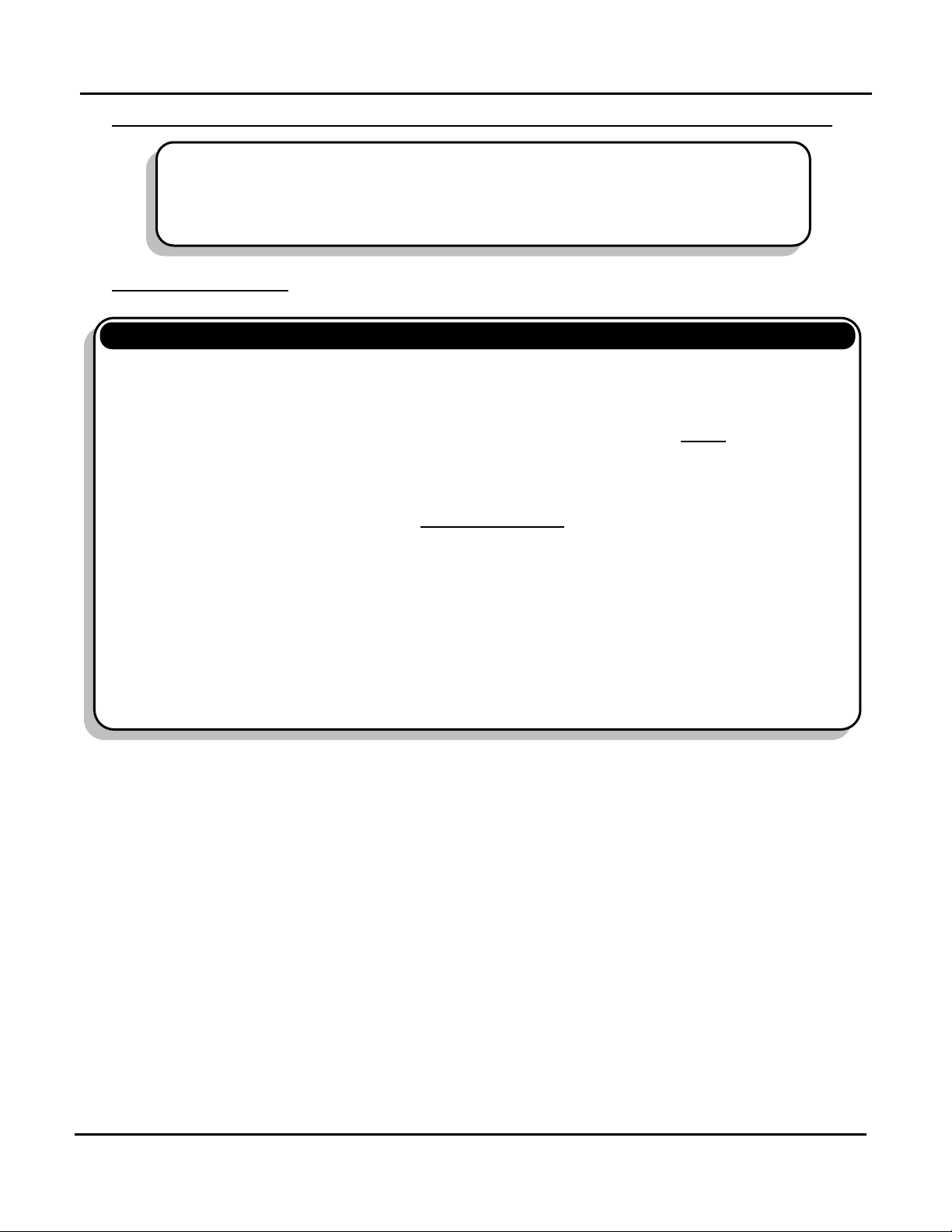

7.3 Steam Coil Installation

1) While holding the Steam Coil horizontally with the Union Nuts facing the Riser Spuds, hand thread the

Steam Union Nuts onto the Spud. (Figure 7).

2) Hand thread the Condensate Union Nut onto the Spud.

3) Position the Coil horizontally.

4) Using a Carpenter’s Square, check the vertical alignment to ensure that the Coil is installed inside the

perimeter of the Shell. It is important that all coils in the bundle line up vertically and are positioned to

ensure that they will not rub against the Liner of the Heater Shell.

5) If needed, use the appropriate Short-Length wrench to tighten the Union Nuts to a seating condition.

6) Insert the Coil Retaining tool through the first lower section of the Coil tubing. (Figure 8).

7) Using a Torque Wrench set for 75 ft-lbs, insert the wrench in the proper torque direction on the Union

Nut (Figure 8).

8) Apply pressure to the Coil Retaining tool in the opposite direction of the pressure being applied to the

Torque Wrench and tighten the Union Nut.

9) When the Torque Wrench setting “clicks”, remove the Coil Retaining Tool.

10) Slowly reapply the pressure to the Torque Wrench holding the Coil by hand until the setting “clicks”. If

the Coil rotates during this operation, reinsert the Coil Retaining Tool and carefully apply a little more

torque.

11) Once again, reapply the pressure to the Torque Wrench without holding the Coil until the setting

“clicks”.

12) Repeat step 11 until the Torque Wrench setting “clicks” without rotating the Union Nut or twisting the

Coil.

13) Using the Coil Spacing Tool, perform a final spacing check of the Coil tubing by creating uniformed

gaps between the Coil tubes (see Figure 4). Check for spacing between the Box Header and Return

Bend. If the Return Bend is touching the Box Header, use the Coil Spacing Tool to separate the two

components. Check for spacing between the Coil tubes above and below the Box Header. Create

clearance using the Coil Spacing Tool.

14) Recheck all Union Nuts for the 75 ft/lbs setting without holding the Coil.

15) If a Union Nut or Coil rotates during this step, repeat steps 10 and 11.

Steam Coil Installation

PR2: 04/01/11 Page 13 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 14

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

COIL RETAINING

TOOL

BOX HEADER

RISER

UNION

NUT

INSERT COIL RETAINING

TOOL HERE

BOX

HEADER

RISER

TOP VIEW (PARTIAL CUT-AWAY)

SIDE VIEW

COIL

ASSEMBLY

COIL

ASSEMBLY

HE-109

TID-0038_0A

Figure 8: Positioning of Coil Retaining Tool

PR2: 04/01/11 Page 14 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 15

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

Section 8. Instructions

END

the failed Coil.

Section 9. Instructions

END

HE-109

TID-0038_0A

8. Hydrostatically Testing Coils & Risers

1) Install fittings into the inlet and outlet of the Bottom for the Risers that can supply a hydrostatic

pressure source.

2) One fitting should have a valve for the release of internal air pressure.

3) The other fitting should be attached to a source to apply the maximum allowable working pressure,

(MAWP) to the internal Coil and Riser Bundle.

4) Apply MAWP to the Coil Bundle.

5) Close off both inlet and outlet valves to retain the internal pressure for 20 minutes.

6) If leaks are detected, remove the internal pressure.

7) Remove the leaking Coil and inspect for causes for leak.

8) If the leak is due to debris, clean the Coil and reinstall.

9) If there are damages to any surfaces, contact your AERCO Representative for instruction for returning

the failed Coil.

Hydrostatically Testing Coils & Risers

9. Reassembly of Shell

1) Install fittings into the inlet and outlet of the Bottom for the Risers that can supply a hydrostatic

pressure source.

2) One fitting should have a valve for the release of internal air pressure.

3) The other fitting should be attached to a source to apply the maximum allowable working pressure,

(MAWP) to the internal Coil and Riser Bundle.

4) Apply MAWP to the Coil Bundle.

5) Close off both inlet and outlet valves to retain the internal pressure for 20 minutes.

6) If leaks are detected, remove the internal pressure.

7) Remove the leaking Coil and inspect for causes for leak.

8) If the leak is due to debris, clean the Coil and reinstall.

9) If there are damages to any surfaces, contact your AERCO Representative for instruction for returning

Reassembly of Shell

10. Reinstalling Heater in Facility

Reassemble all components that were disconnected in paragraph 5.2. When re-installing the Thermal

Element into the Thermal Well Bushing in the Top Head, be careful not to damage the Element against

the internal Coils. Straighten the Element before inserting.

11. Startup Procedure

Follow the Operating Procedures in the appropriate O & M Manual listed in paragraph 3 (Reference

Documents).

PR2: 04/01/11 Page 15 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 16

Coil/Riser Replace Instructions for Helitherm Water Heaters

Technical instructions

HE-109

TID-0038_0A

© AERCO International, Inc., 2011

PR2: 04/01/11 Page 16 of 16

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Loading...

Loading...