Page 1

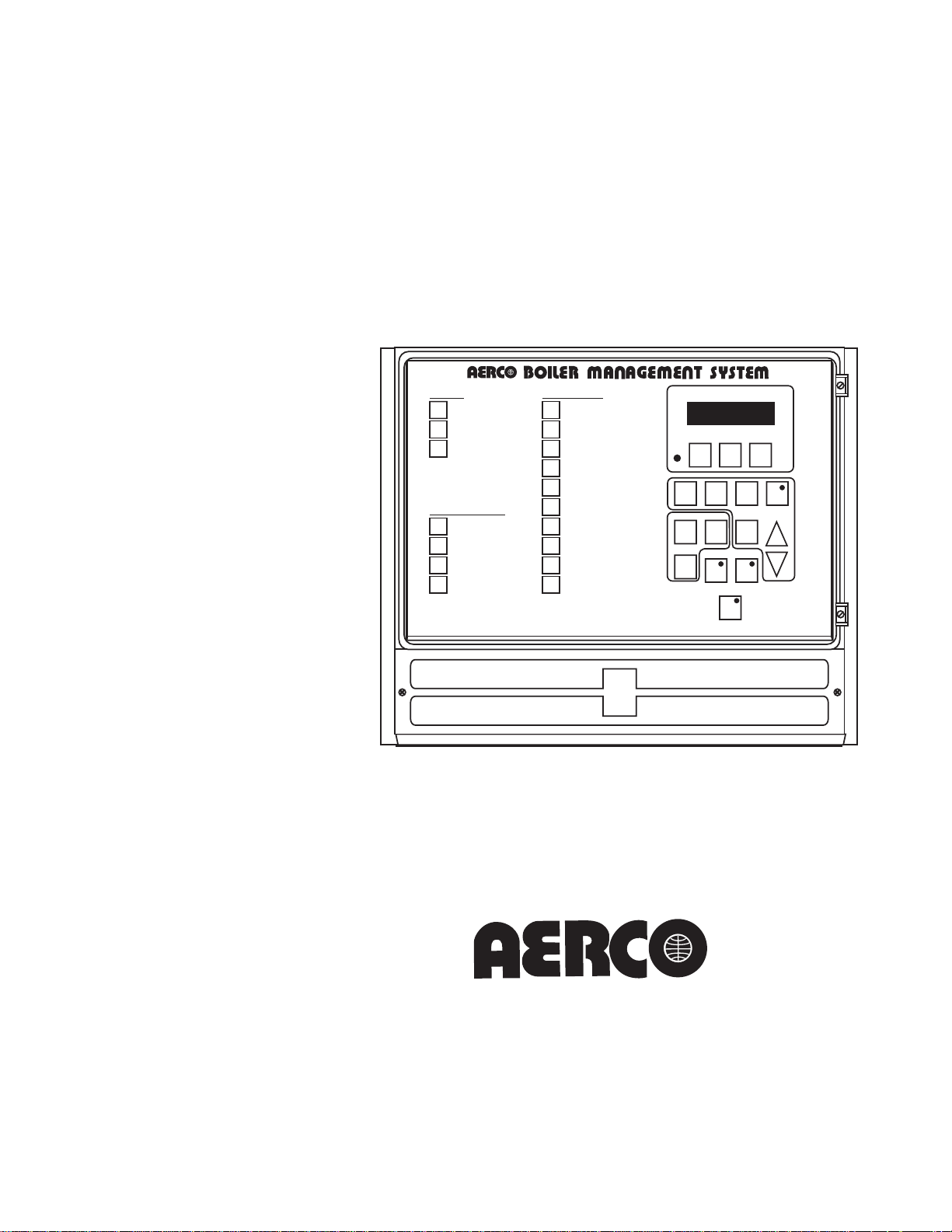

Boiler Management

System

Installation

Instructions

Boiler Management

System

Operation &

Troubleshooting

DISPLAY MODE

HDR

TEMP

AIR

TEMP

%

LOAD

FOR USE W/ INDOOR TEMP. SENS.

SET

POINT

OFF

SET

PROP

BAND

CONFG

SYS

Hold Key for

Display Header

Header Set

Temp., oF

Display Outside Air

Temp., oF

Display % Load &

No. of Units Operating

Display/Change Indoor

Sensor Reference Temp.,

Display/Change Setpoint

Temp when Activated

Display/Change

Hdr. Temp. / Indoor Ref. Temp.

System

Configuration

o

F

FIELD ADJUSTMENT MODE

FIELD

L.E.D. "On"

Enables Field Adjustment

ADJ

Select System Start Option

SYS

Display/Change Outside Air

START

Temp. for System Start

TEMP

Display/Change

Bldg Ref Temp — Indoor/Outdoor

REF

TEMP

Hdr Set Temp — Constant Set

HDR

Display/Change

TEMP

Minimum Or Maximum

LIMIT

Header Temp.

Display/Change

RESET

Header Temp. / Outside Air Temp.

RATIO

(Alarm Cancel) Reset Alarm Contact

%

Set Date

LOAD

And Time

Set Up

OFF

Set Back

SET

Clock

Select Fault

CONFG

Alarm Relay

SYS

Options

Enable BMS

ON

Disable BMS

OFF

Reset Mode

Point Mode

Raise/Lower

To Change

HEADER SET INDOOR AIR

DISPLAY

ADJ

HDR

TEMP

TEMP

SYS

REF

START

TEMP

LEVEL

PROP

SET

BAND

POINT

OFF

SET

ON OFF

CONFIG

AERCO INTERNATIONAL INC., NORTHVALE, N.J.

AIR

SYS

HDR

TEMP

LIMIT

RESET

RATIO

%

LOAD

FIELD

ADJ

Applicable to Serial Numbers 329985 and above

(EPROM Rev. K and above)

AERCO International, Inc.

AERCO International, Inc.

159 Paris Avenue

159 Paris Avenue

Northvale, NJ 07647-0128

Northvale, NJ 07647-0128

GF-108M

REVISED 3/13/08

Page 2

Telephone Support

Direct to AERCO Technical Support

(8 to 5 pm EST, Monday through Friday):

1-800-526-0288

AERCO International, Inc.

159 Paris Avenue

Northvale, NJ 07647-0128

www.aerco,com

© AERCO International, Inc., 2008

The information contained in this

installation, operation and maintenance manual is subject to

change without notice from

AERCO International, Inc.

AERCO makes no warranty of any

kind with respect to this material,

including but not limited to implied

warranties of merchantability and

fitness for a particular application.

AERCO International is not liable

for errors appearing in this

manual. Nor for incidental or

consequential damages occurring

in connection with the furnishing,

performance, or use of this

material.

Page 3

Table of Contents

Page

SECTION 1 ABOUT YOUR NEW BOILER MANAGEMENT

SYSTEM (BMS) 1-1

SECTION 2 FEATURES OF THE BMS 2-1

SECTION 3 INSTALLING THE BMS 3-1

3.1 MOUNTING THE BMS 3-1

3.2 GENERAL WIRING 3-1

3.3 PULSE WIDTH MODULATION WIRING 3=2

3.3.1 PWM Wiring at BMS 3-2

3.3.2 PWM Wiring at Boilers 3-2

3.4 RS485 (MODBUS) WIRING 3-2

3.4.1 RS485 Wiring at BMS 3-2

3.4.2 RS485 Wiring at Boilers 3-3

3.5 SENSOR INSTALLATION AND WIRING 3-3

3.5.1 Header Sensor 3-3

3.5.2 Outside Air Sensor 3-3

3.6 INTERLOCK WIRING 3-4

3.6.1 Interlock 1 Wiring 3-4

3.6.2 Interlock 2 Wiring 3-4

3.7 RELAY WIRING 3-4

3.7.1 System Start Relay 3-4

3.7.2 Fault Alarm Relay 3-4

3.7.3 Auxiliary Relay 3-4

3.8 SET BACK 3-4

SECTION 4 FAMILIARIZING YOURSELF WITH THE BMS 4-1

4.1 ABOUT BMS MODES 4-1

4.1.1 Selecting and Viewing Functions 4-1

4.1.2 Changing Function Settings 4-1

4.2 NORMAL MODE FUNCTIONS 4-4

4.2.1 HDR TEMP 4-4

4.2.2 AIR TEMP 4-4

4.2.3 % LOAD 4-4

4.2.4 SYS START TEMP 4-4

4.2.5 REF TEMP 4-4

4.2.6 HDR TEMP LIMIT 4-4

4.2.7 FIELD ADJ 4-4

4.2.8 SET POINT 4-4

4.2.9 PROP BAND 4-4

4.2.10 OFF SET 4-4

4.2.11 RESET RATIO 4-4

4.2.12 ▲ and ▼ Arrow Keys 4-5

i

Page 4

Table of Contents

(Continued)

4.2.13 ON and OFF Keys 4-5

4.2.14 CONFIG SYS 4-5

4.3 FIELD ADJUST MODE FUNCTIONS 4-5

4.3.1 HDR TEMP 4-5

4.3.2 AIR TEMP 4-6

4.3.3 % LOAD 4-6

4.3.4 Setting the Internal Clock With the % LOAD Key 4-6

4.3.5 SYS START TEMP 4-7

4.3.6 REF TEMP 4-7

4.3.7 HDR TEMP LIMIT 4-7

4.3.8 FIELD ADJ 4-8

4.3.9 SET POINT 4-8

4.3.10 PROP BAND 4-8

4.3.11 OFFSET 4-8

4.3.12 Setting Up a Reset Schedule 4-8

4.3.13 Manual Set Back 4-9

4.3.14 RESET RATIO 4-9

4.3.15 ▲ and ▼ Arrow Keys 4-9

4.3.16 ON and OFF Keys 4-9

4.3.17 CONFIG SYS 4-9

4.4 SYSTEM CONFIGURATION MODE FUNCTIONS 4-10

4.4.1 TEMP FAIL MODE 4-10

4.4.2 SYS ENABLE 4-11

4.4.3 MAX PWR INPUT 4-11

4.4.4 START AND STOP LEVEL Keys 4-12

4.4.5 BLR OP MODE 4-12

4.4.5.1 Sequential Mode 4-12

4.4.5.2 Parallel Mode 4-13

4.4.5.3 Combination Mode 4-13

4.4.5.4 Designating the Number of Combination Boilers 4-13

4.4.6 HDR SET MODE 4-13

4.4.7 INTGL RATE GAIN and DERIV GAIN Keys 4-13

4.4.7.1 TEMP BANDWIDTH 4-14

4.4.7.2 INTGL RATE GAIN 4-14

4.4.7.3 DERIV GAIN 4-14

4.4.8 AUX RELAY 4-15

4.4.9 ▲ and ▼ Arrow Keys 4-15

4.4.10 ON and OFF Keys 4-15

4.4.11 CONFIG SYS 4-15

ii

Page 5

Table of Contents

(Continued)

SECTION 5 PROGRAMMING THE BMS MODE OF OPERAT

5.1 INDOOR/OUTDOOR RESET MODE 5-1

5.1.1 Selecting Indoor/Outdoor Reset Mode 5-1

5.1.2 Entering System Start Temperature 5-1

5.1.3 Determining the Reset Schedule 5-1

5.1.4 Entering the Building Reference Temperature 5-2

5.1.5 Entering the Reset Ratio 5-2

5.2 SETUP FOR REMOTE SETPOINT MODE 5-2

5.2.1 Entering Header Set and Boiler Operating Modes 5-2

5.2.2 Entering Remote Signal Type and Header Temperature Limits 5-2

5.3 SETUP FOR CONSTANT SETPOINT MODE 5-3

5.3.1 Entering Header Set and Boiler Operating Mode 5-3

5.3.2 Entering Header Reference Temperature 5-3

5.4 CONFIGURING BOILERS FOR PULSE WIDTH MODULATION (PWM) 5-3

5.4.1 C-More Control System PWM Setup 5-4

5.4.2 Configuring the Temperature Controller 5-4

5.5 SYSTEM INITIALIZATION AND POLLING 5-4

5.6 TESTING THE SYSTEM 5-5

ION

APPENDICES

Appendix A Specifications A-1

Appendix B Methods for Determining Reset Schedule

and Indoor/Outdoor Reset Ratio Charts B-1

Appendix C Normal (Read-Only) Mode Display Messages

and Defaults C-1

Appendix D Field Adjust Mode Display Messages and Defaults D-1

Appendix E Config Sys Mode Display Messages and Defaults E-1

Appendix F Sensor Resistance Data Sheet F-1

Appendix G Parts List G-1

Appendix H Troubleshooting H-1

Appendix I General BMS Wiring I-1

Appendix J Programming the BMS Using RS-232 Communication J-1

iii

Page 6

List of Figures

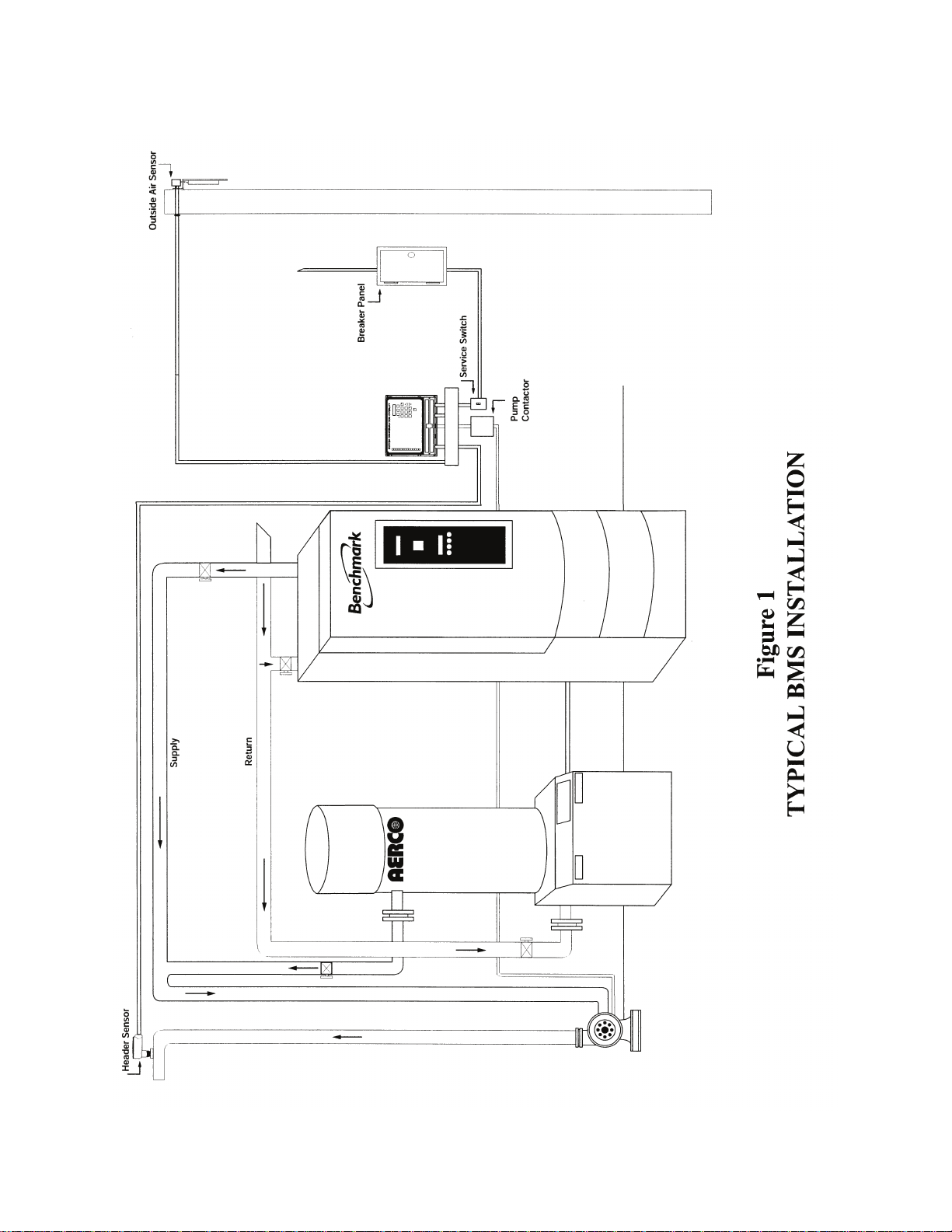

Figure 1 Typical BMS Installation 3-5

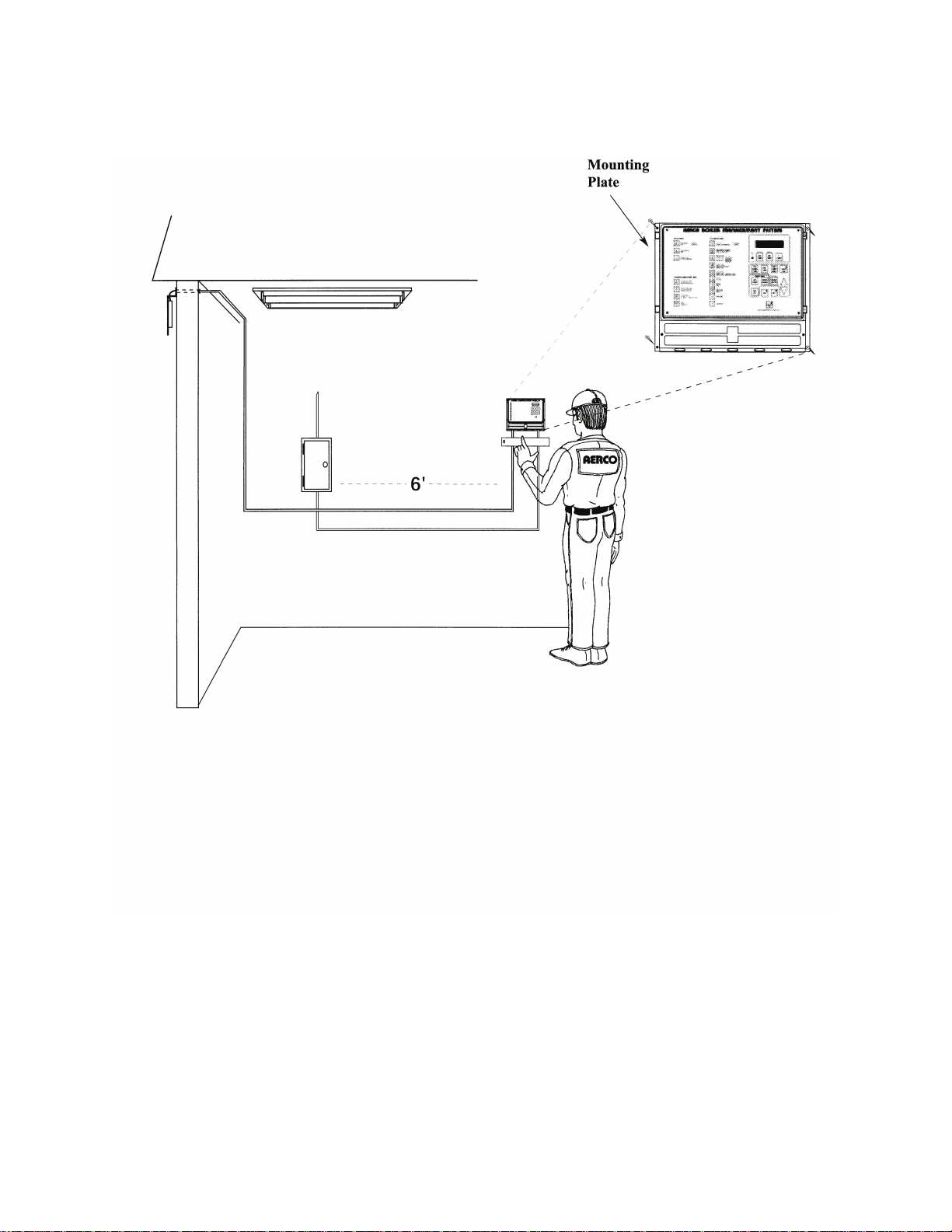

Figure 2 BMS Mounting 3-6

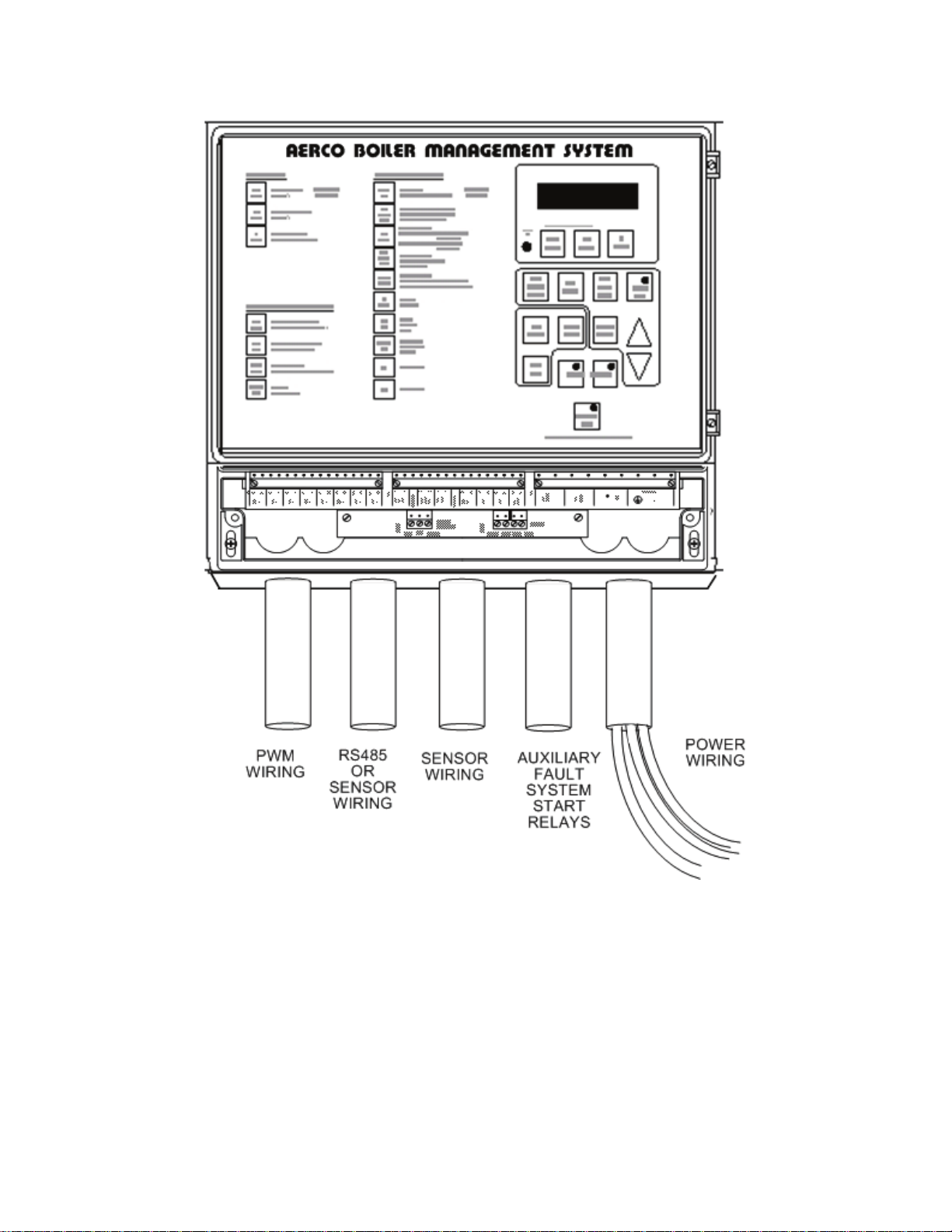

Figure 3 Wire Routing Locations at the BMS 3-7

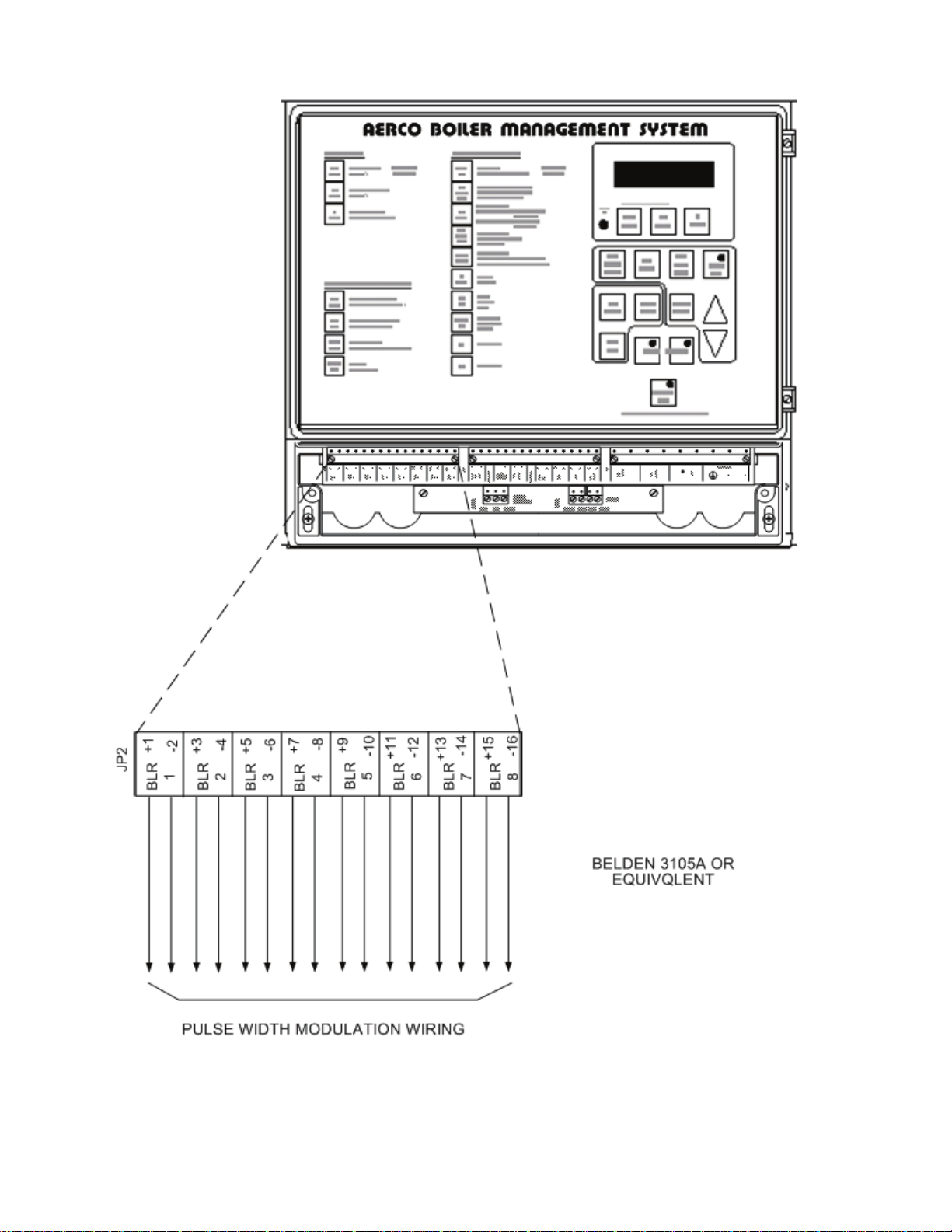

Figure 4 PWM Communication Outputs at the BMS 3-8

Figure 5 Pulse Width Modulation Connections at KC Series Boiler

Boiler With Modular Control Box 3-9

Figure 6 PWM & RS485 Connections at KC Series Boiler

With C-More Control Box 3-10

Figure 7 Pulse Width Modulation Connections at the Benchmark

Boiler With Modular Control Box 3-11

Figure 8 PWM & RS485 Connections at the Benchmark

Boiler With C-More Control Box 3-12

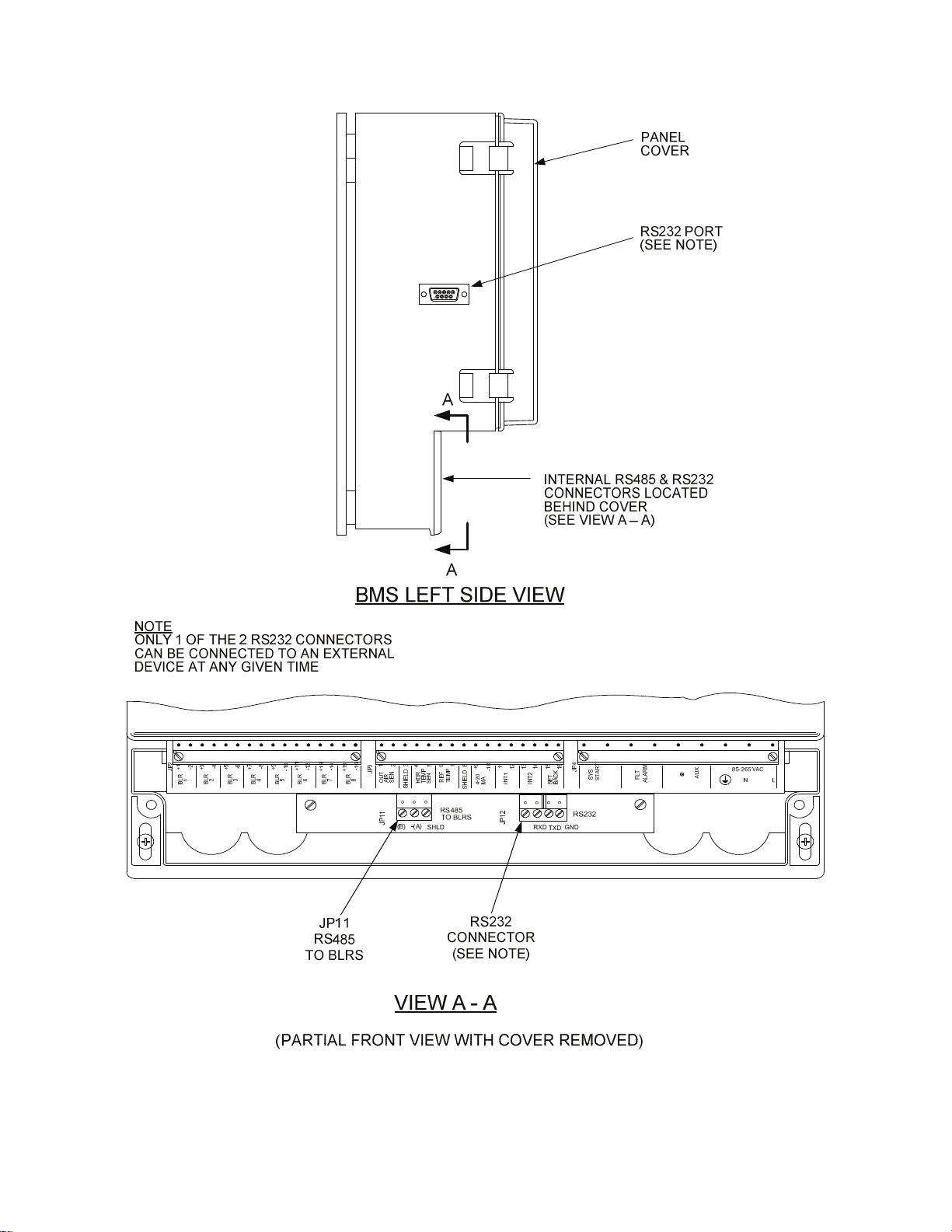

Figure 9 BMS RS485 & RS232 Connector Locations 3-13

Figure 10 BMS RS485 & RS232 Connector Pin Assignments 3-14

Figure 11 Header Sensor Installation With Well 3-15

Figure 12 Outside Air Sensor Mounting and Connections 3-16

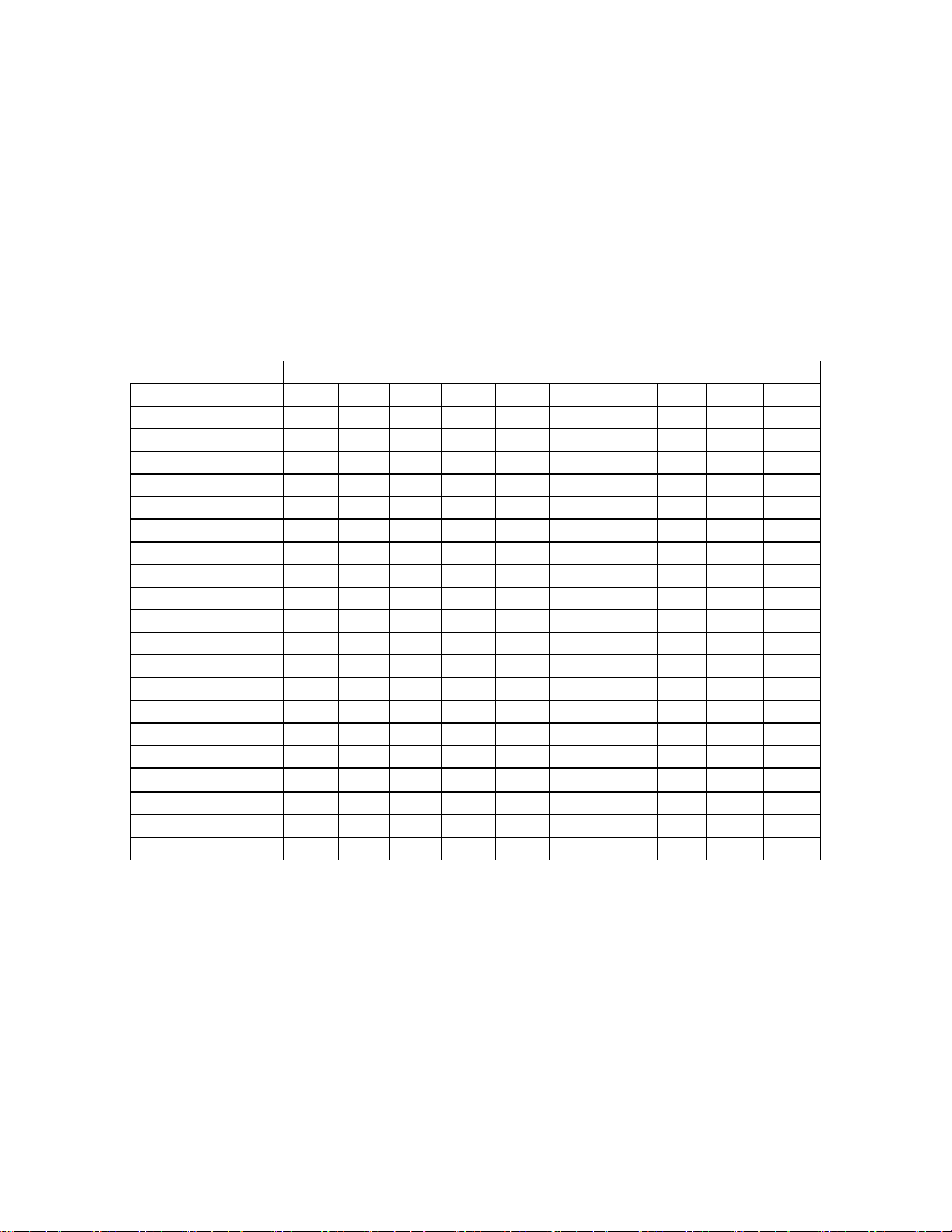

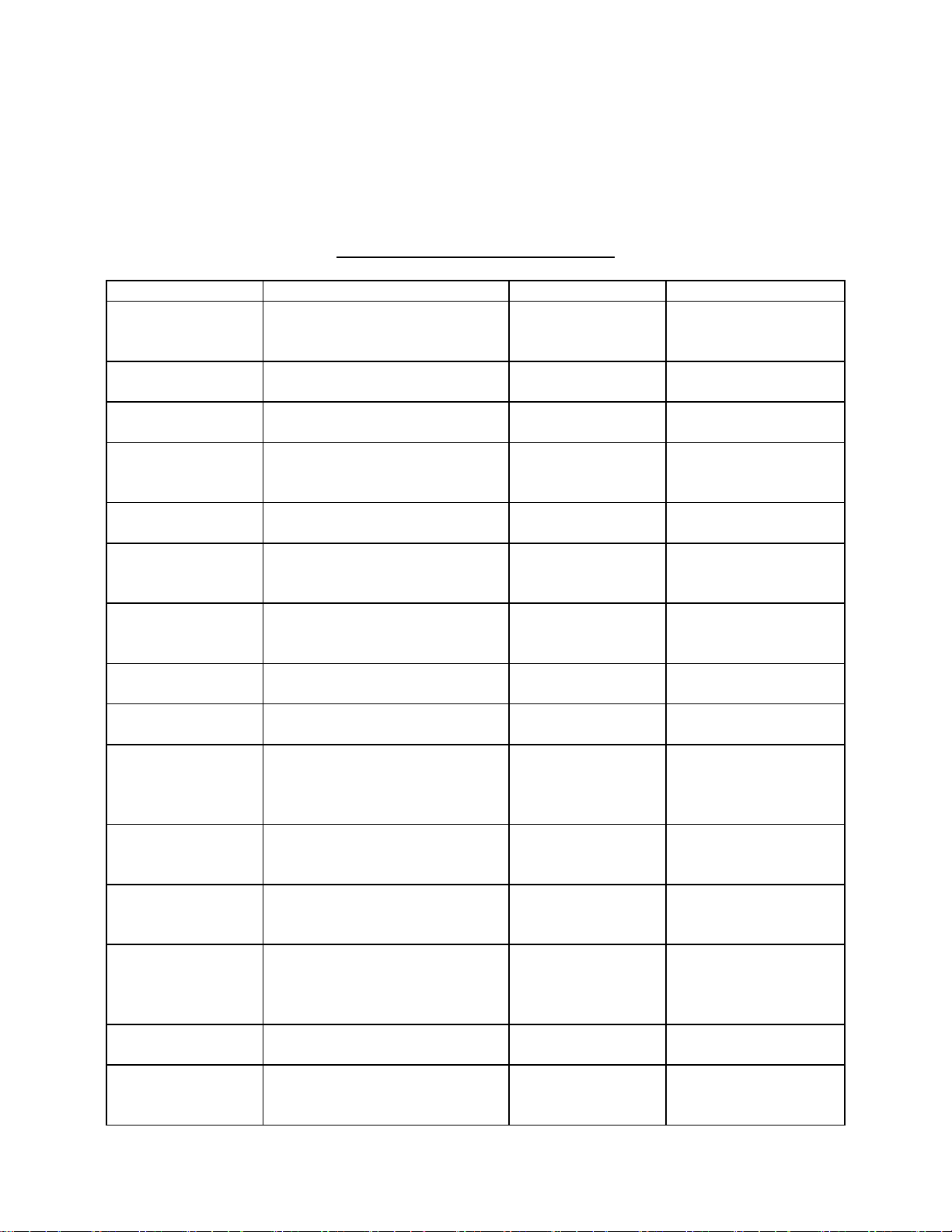

Figure 13 Normal and Field Adjust Mode Overlay 4-2

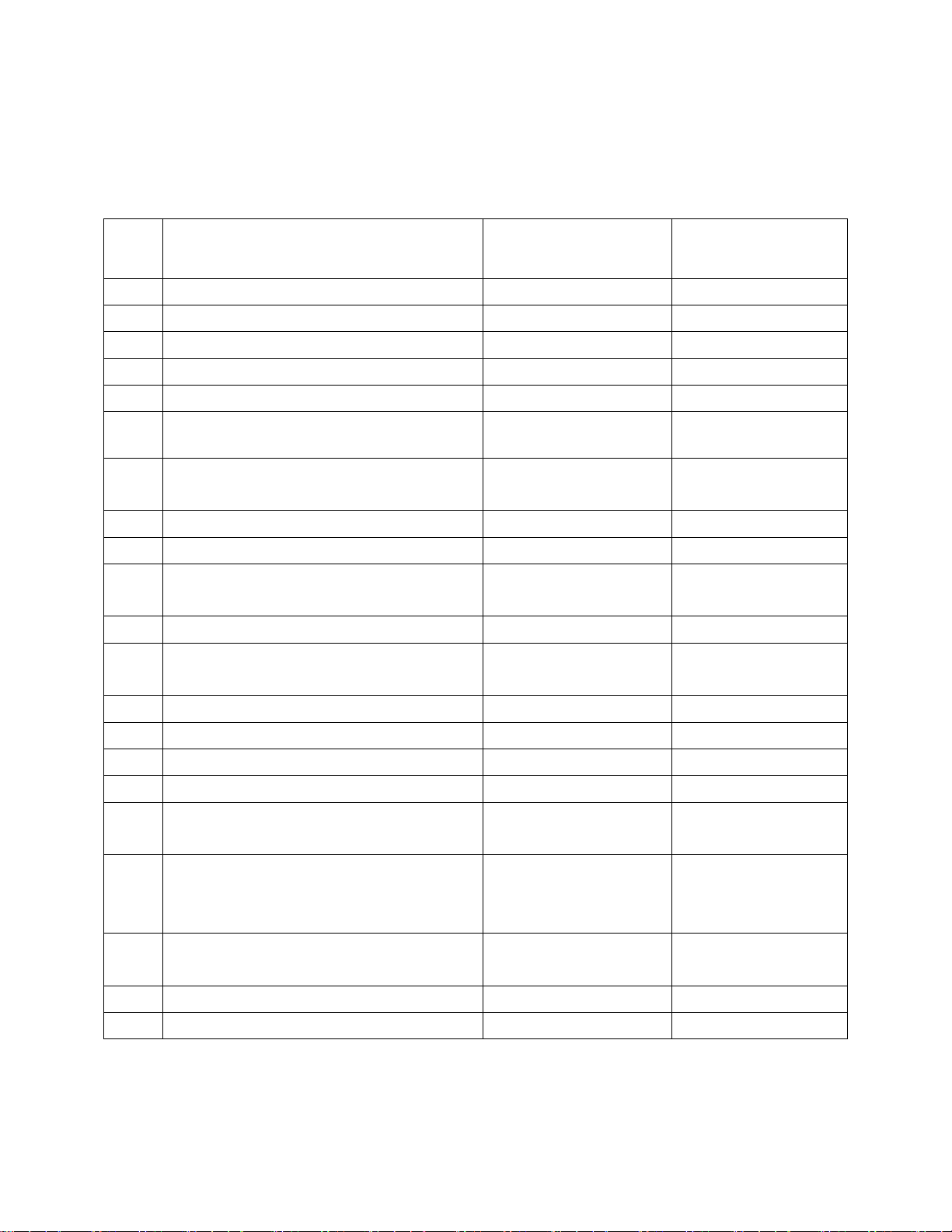

Figure 14 System Configuration Mode Overlay 4-3

iv

Page 7

Section 1 ______________________________

SIMPLE INSTALLATION AND

About Your

New Boiler

Management

System (BMS)

AERCO’s Boiler Management System

(BMS), stages and modulates AERCO KC

Series and Benchmark Boilers, allowing

them to operate efficiently as a system. It

provides a broad array of operating modes,

so that the nuances of specific applications

can be easily accommodated. The BMS can

control up to 40 boilers; 8 via pulse width

modulation (PWM) and up to 32 via Modbus

(RS485) communication. For Modbus

control, the AERCO Boilers must be

equipped with C-More Control Systems.

PRECISE CONTROL

Utilizing PWM or Modbus control, the BMS

fully exploits the condensing and modulating

ability and efficiency of each boiler and

regulates the output of the boiler plant with

water supply temperature variation of no

more than ±2°F

Staging can be performed sequentially or in

parallel. The BMS can sample building

reference temperatures to modulate boiler

plant output, and will perform water supply

temperature night setback automatically

referenced to its internal clock.

OPERATION

Installation of the BMS is simple, and lowvoltage wiring is employed between the

BMS panel and boiler modules. There are

no complex design steps to be performed,

since a keypad in conjunction with the LCD

allows the operator to acquire, change, and

program settings through easy-to-use

labeled buttons. Each BMS function

consists only of selecting the function and

toggling values, which generally requires no

more than pressing four keys.

The instant a parameter is programmed, it is

automatically entered into the BMS

memory, avoiding multiple programming

steps to store information. In the event of

power loss, most factory default settings

remain in nonvolatile memory for up to 10

years and need not be reprogrammed.

However, date and time remain in memory

for about 30 days.

BMS PROGRAMMING VIA

RS232 PORT

If desired, the BMS can be programmed by

connecting a Laptop Computer, or other

type of terminal emulation device, to the

RS232 connector on the left side of the

BMS. See Appendix J for programming

using RS232 communication.

1-1

Page 8

Page 9

Section 2 ______________________________

SEQUENTIAL OR PARALLEL

Features of

OPERATION

the BMS____

APPLICATION FLEXIBILITY

Three different system or control options

can be selected at setup to match the needs

of any closed-loop system - Indoor/Outdoor

Reset, 4-to-20 mA Remote Setpoint, and

Constant Setpoint.

CONTINUOUS

COMMUNICATIONS

The BMS continually sends information to

the boilers and receives information from

them, providing total control of boiler plant

dynamics.

EXCEPTIONAL ACCURACY

The BMS control system uses a PID

(Proportional Integral Derivative) control

algorithm to respond dynamically to system

changes. Water temperatures are precisely

controlled by modulating energy in put. A

supply water temperature of ±2°F is

assured.

BUILDING INDOOR AIR

TEMPERATURE INPUTS

The BMS accepts building indoor air

temperatures directly from a thermistor

sensor or from a 4-to-20 mA signal.

Adjustments can be made to the header

setpoint temperature to compensate for

varying building temperatures and

conditions.

Modules can be either sequenced on, or run

in parallel, by selection from the front panel.

In sequential mode, boilers are brought on

one at a time, so turn-down ratio is 14

multiplied by the number of KC Series

boilers, or 20 multiplied by the number of

Benchmark boilers. This provides higher

energy savings and seasonal efficiency. In

parallel mode, all of the boilers are

modulated together at the same firing rate.

The turn-down ratio of the system is fixed at

14:1 for the KC Series boilers and 20:1 for

the Benchmark boilers.

BUMPLESS TRANSFER

When in sequential mode, the BMS stages

boilers on and off, one at a time, at

selectable percentages of firing rate. The

result is a seamless transition and

undetectable room temperature changes.

Sequential mode has several other unique

features:

Run-Time Equalization: The BMS se-

quences boilers on a first on-first off basis,

which automatically equalizes the run time

of all boilers in the plant.

Automatic Load Distribution: The BMS

continuously monitors the number of

modules that are available for operation. In

the event of a boiler malfunction or when

service is performed, the BMS automatically

compensates for a lack of response from

any unit and brings on the next available

boiler to satisfy demand. This feature

operates in both parallel and sequential

modes.

2-1

Page 10

Time Delay Between Boiler Starts:

A fixed, 30-second time delay between

boiler starts ensures smooth energy input

without spikes in electrical, gas, or venting

conditions.

AUTOMATIC SYSTEM START

Automatic system start contacts for

controlling auxiliary equipment such as

pumps and dampers can be selected to

close between 32°F and 100°F outside air

temperature, eliminating the need for the

plant operator to turn auxiliary equipment on

and off.

MINIMUM AND MAXIMUM

HEADER SET CLAMPING

The supply water temperature can be

clamped at a maximum high temperature or

minimum low temperature, to ensure that

the building temperature is optimal for the

greatest comfort.

Two Interlock Circuits

(Enable/Disable Contacts)

The BMS contains two normally-open

interlock circuits that require only a set of

dry contacts to enable or disable the boiler

plant. They can be used to monitor pumps,

combustion air dampers, or other equipment. Out-of-limit conditions trip the

interlocks, shutting down the boiler plant,

and providing a high level of protection.

ADJUSTABLE OFFSET

The Offset feature can allow the

temperature of the supply water to be offset

in 1° increments over a range of -50°F

below to +50°F above its current

temperature. This feature is employed for

night setback or morning warmup. The BMS

lets you select, over a 7-day period, the time

when the offset begins and ends.

CONTROL OF AUXILIARY

EQUIPMENT

The auxiliary relay uses a dry set of

contacts to operate auxiliary equipment. For

example, when the boiler plant is at 100%

load, these contacts close and can start an

auxiliary boiler, or notify an energy management system of a full-load condition.

FAULT ALARM SURVEILLANCE

The BMS continually monitors its sensors

for opens and shorts and the interlock

circuits for opens. However, the BMS fault

alarm relay does not close or indicate a fault

when a boiler has failed. The fault alarm

circuit consists of a dry set of 120 VAC

contacts rated at 5 A.

SIMPLE INSTALLATION

The BMS operates from 120 VAC, 50 to 60

Hz, and uses Belden 9841 or equivalent

wiring between modules for control and

monitoring. The lightweight panel can be

mounted up to 200 feet from the boilers

when using pulse width modulation

communication.

RUGGED AND RELIABLE

The BMS is housed in a NEMA 13-grade

enclosure and operates in ambient temperatures as high as 131°F (55°C).

POWER-OFF MEMORY

Most system configuration values are

retained in nonvolatile memory for up to 10

years. Date and time remain in memory for

approximately 30 days.

MODBUS COMMUNICATION

The BMS can monitor or control C-More

Boilers using Modbus communication via its

RS485 port. It can also be monitored or

controlled by a Building Automation System

(BAS) or a PC connected to its RS232 port.

2-2

Page 11

Section 3 ______________________________

3.2 GENERAL WIRING

Installing the

BMS________

Please follow the installation procedure in

the order presented. Incorrect wiring may

damage the unit and void the AERCO

warranty Do not omit steps, and do not

substitute other types of wiring for those

specified. Figure 1 shows a typical BMS

installation.

3.1 MOUNTING THE BMS

Use the mounting plate (Figure 2) supplied

with the BMS to securely mount the unit

away from moisture, and at an appropriate

height for easy reading of the display. To

reduce the possibility of electrical noise

entering the system, mount the BMS at

least 6 feet away from electrical devices

such as power panels, high voltage

transformers and transmission lines,

motors, and fluorescent lights.

All wiring and fusing must be in compliance

with the National Electrical Code and with

local electrical codes. Control wiring for the

sensors and communications links must run

in separate conduit and not in the conduit

providing line voltage in order to ensure

immunity from electrical noise.

All wiring should be installed in conduit

leading up to the bottom of the BMS panel.

There are five knock-outs in the bottom of

the panel by which wiring must enter the

BMS.

Shielded, twisted-pair cable should be used

for sensor and communication wiring. This

wiring should be 18 to 24 AWG. Examples

of suitable sensor and communication wire

are: Belden 9841, 8761, 3105A or equivalent. AC power wiring should be 16 to 18

AWG. A BMS wiring diagram is included in

Appendix I. Once mounting is complete and

the BMS is secured in place, loosen the two

captive screws on the wiring cover plate

with a Phillips screwdriver. Feed all wiring

through the knock-outs provided on the

bottom of the panel. All pulse width

modulation (PWM) and RS485 control wires

should be fed through the two knock-outs

furthest to the left.

Shock Hazard!

Extreme caution must be exercised

when connecting power wiring to

the BMS. The external circuit

breaker supplying Line voltage to

the the BMS must be turned off to

avoid electrical shock

Power wiring should be fed through the

right-most knock-out in the bottom of the

panel (Figure 3). The remaining knockouts

are for control wiring located on the middle

terminal block. The terminal blocks can be

detached from the BMS headers to simplify

field wiring.

Once power wiring is completed, apply line

voltage to the BMS, and press the ON key

on the BMS keypad to verify proper

connection. The display should show

INITIALIZING EPROM REV. n where n is

the current EPROM version.

3-1

Page 12

WARNING!

Turn off AC input power to the BMS

to avoid electrical shock.

3.3 PULSE WIDTH

MODULATION WIRING

Pulse width modulation (PWM) wiring

connections are made between the BMS

JP2 terminal block and the Relay or I/O Box

terminals at each AERCO Boiler. Shielded

twisted-pair wire is recommended.

3.3.1 PWM Wiring At BMS

To wire boilers for pulse width modulation

(PWM), connect the boiler control wires in

ascending order according to the numbers

on the BMS (Figure 4). For example, the

control wiring for boiler 1 at the BMS would

be connected as follows:

• Positive control wire connects to JP 2,

terminal 1 (+).

• Negative control wire connects to JP 2,

terminal 2 (-).

• Shield wiring connects to the negative (-)

control wire at Section BLR 1, terminal 2.

The shield is not terminated at the boiler.

All shields must be terminated on the

BMS end. The wiring terminals labeled

SHIELD at terminal block JP3 of the

BMS are not internally connected to

ground and are only used as a place to

terminate the sensor shields. The pulse

width modulation shield can be

connected to any minus (-) terminal of

the PWM terminal strip (JP2).

3.3.2 PWM Wiring At The Boilers

The pulse-width modulation (PWM) control

wiring from the BMS to each boiler is

connected at each boiler’s relay box or

input/output (I/O) box, depending on the

type of control system used. Modular control

systems utilize a relay box as shown in

Figure 5 (KC1000) and Figure 7

(Benchmark). The newer C-More control

system utilizes an I/O box as shown in

Figure 6 and Figure 8.

Regardless of the type of control system

used, the PWM wiring is connected to the

BMS + and – terminals as shown in the

respective illustrations. It is imperative that

positive (+) and negative (-) polarity be

observed when making these connections.

All boilers follow the same control wiring

scheme.

When using pulse width modulation, the

BMS may be mounted up to 200 feet from

the boilers.

3.4 RS485 (MODBUS) WIRING

All Modbus Networks are implemented

using a “Master - Slave” technique. The

BMS can function as either a “Master”

controlling C-More Slaves or a “Slave”

controlled by a “Master” Energy

Management System (EMS) or Building

Automation System (BAS). Therefore, the

following paragraphs provide only an overview of the required wiring connections.

Detailed information and setup procedures

for RS485 Modbus networks are provided in

Modbus Communication Manual GF-114.

Refer to GF-114 prior to implementing any

RS485 networks using Modbus.

RS485 wiring connections are made using a

“Daisy-Chain” configuration. Shielded

twisted-pair wire from 18 to 24 AWG is

required for all RS485 wiring.

3.4.1 RS485 Wiring At BMS

RS485 wiring connections are made at the

BMS at connector JP11 which is labeled

RS485 TO BLRS. The location of this

RS485 connector is shown in Figure 9. In

addition, Figure 9 also shows the locations

of the external and internal RS232

connectors which are used to interface the

BMS to an EMS Master if required. The pin

assignments for the RS485 and RS232

connectors are shown in Figure 10.

3-2

Page 13

Connect the RS485 wiring at the BMS as

follows:

• Connect the positive (+) lead to the +(B)

terminal of JP11.

• Connect the negative (-) lead to the -(A)

terminal of JP11.

• Connect the shield to the SHLD terminal

of JP11.

3.4.2 RS485 Wiring At Boilers

RS485 wiring connections are made at the

RS485 COMM terminals of each boiler’s I/O

Box as shown in Figures 6 (KC1000) and

Figure 8 (Benchmark). Connect the wiring

as follows:

• Connect the positive lead to the +

terminal

• Connect the negative lead to the terminal

• DO NOT terminate the shields to the

Ground (G) terminal at the Boiler end of

the RS485 loop. Connect the shields of

the incoming and outgoing leads

together. The RS485 loop should only be

terminated at the BMS.

RS485 loops should not exceed 4000 feet.

Detailed wiring diagrams for RS485 Modbus

communication networks are provided in the

Modbus Communication Manual GF-114.

3.5 SENSOR INSTALLATION

AND

There are two types of sensors that may be

installed -- header sensors and outside air

sensors. While an outside air sensor is

required for Indoor/Outdoor Reset mode, it

is not required for Constant Setpoint or 4-to20-mA modes of operation. However, it is

recommended to take full advantage of all

BMS features. The header sensor is

required for all modes of operation.

Sensor wiring and power wiring should be

run separately to reduce the chance of

electrical noise entering the sensor wiring.

WIRING

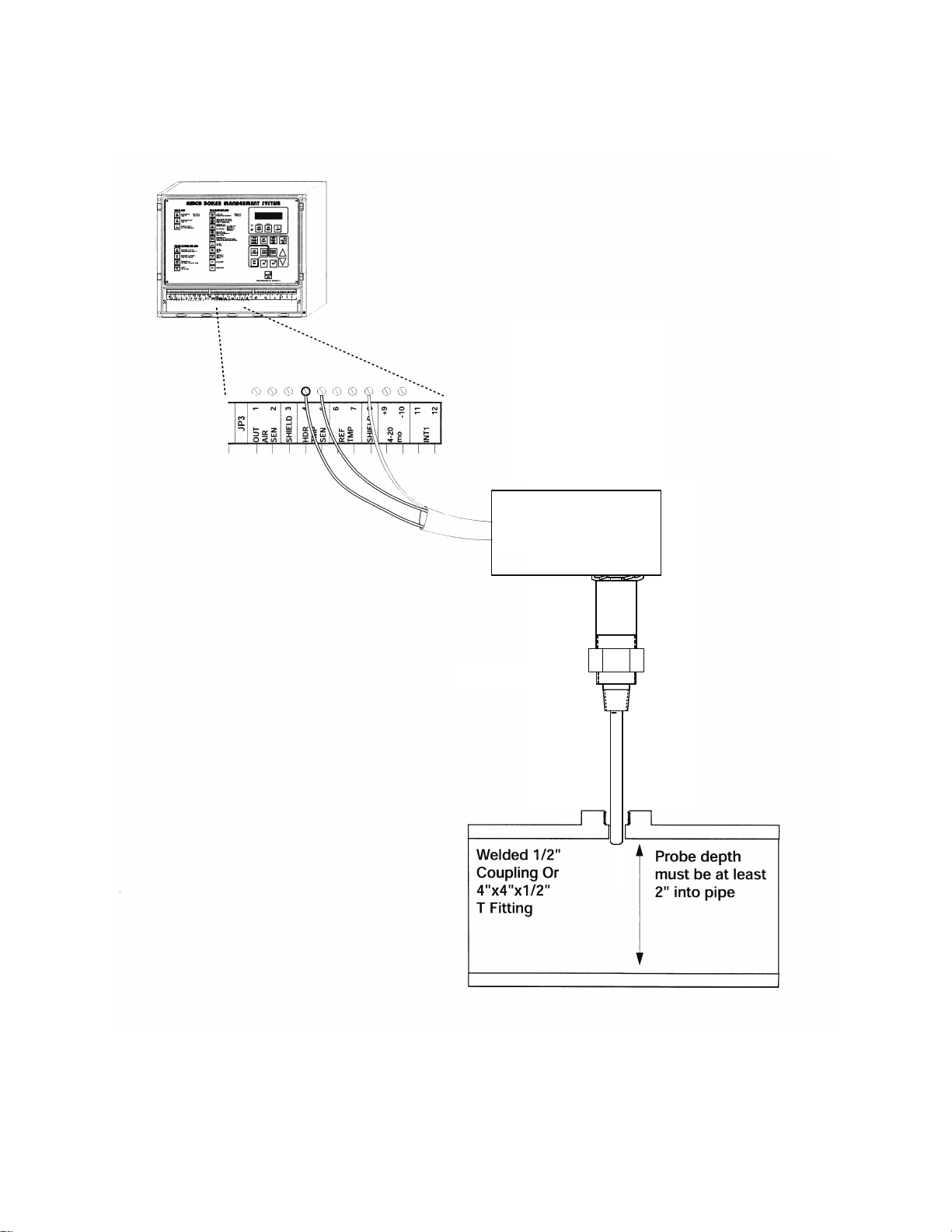

3.5.1 Header Sensor

The header sensor to be used with the BMS

is a sensor that requires a well as shown in

Figure 11. When installing the sensor, use a

1/2 inch NPT tapped coupling or a 4 x 4 x

1/2 Tee fitting. Use heat-conductive grease

when installing to aid in its response. The

sensor probe must be inserted at least 2

inches into the flow of water for proper

response. The header sensor must be

installed between 2 and 10 feet downstream

of the LAST boiler in the plant’s supply

water header.

The header sensor is a thermistor type

sensor. The Resistance vs. Temperature

Chart for the sensor is provided in Appendix

F. See Figure 11 for installation details.

Shielded pair 18 AWG cable (Belden # 8760

or equiv.) is recommended for header

sensor wiring. There is no polarity to be

observed. Connect the wires from the

sensor to BMS terminals 4 and 5 on JP3.

The ground for the shield is at BMS end of

the link, not the header sensor. Connect the

ground to JP3, terminal 8 (SHIELD). The

header sensor can be installed up to 600

feet from the BMS.

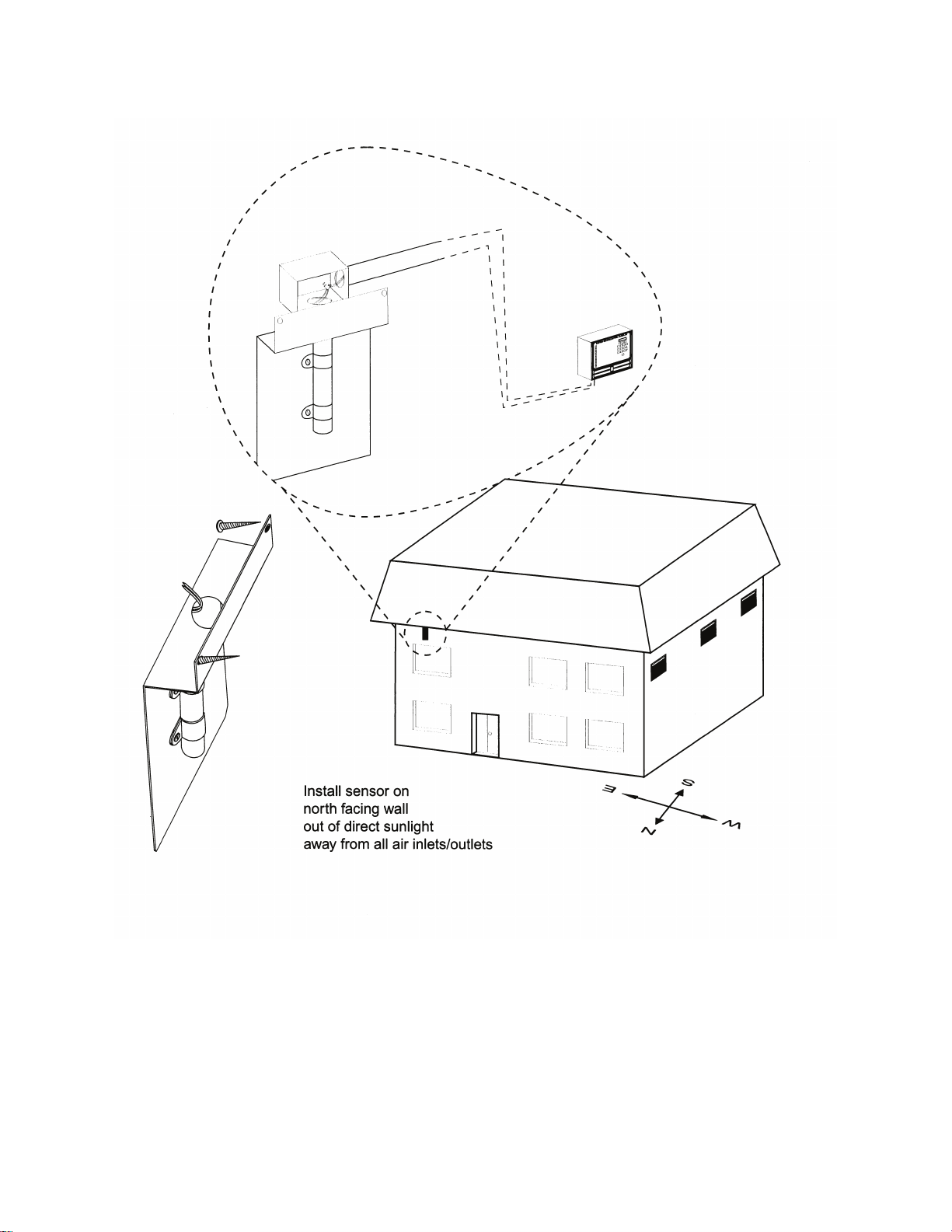

3.5.2 Outside Air Sensor

The Outside Air Sensor, AERCO part no.

122662, must be mounted on the North side

of the building, shielded from direct sunlight,

and away from air intakes or outlets from

the building. See Figure 12 for a typical

installation. The sensor includes a plate for

wall mounting. Shielded pair 18 AWG cable

(Belden # 8760 or equiv.) is recommended

for sensor wiring. There is no polarity to be

observed. Connect the sensor wires to BMS

terminals 1 and 2 on JP3. Connect the

shield to JP3, terminal 3 (SHIELD) at the

BMS. The shield must not be grounded on

the sensor end. The sensor can be mounted

up to 600 feet from the BMS.

3-3

Page 14

3.6 INTERLOCK WIRING

The BMS is equipped with two interlocks

designated Interlock 1 (INT 1) and Interlock

2 (INT 2). Since both interlocks must be

closed for the BMS to operate the boiler

plant, the associated wiring terminals are

jumpered, prior to shipment. If desired,

proving device switches can be connected

to either

used, interlock wiring connections are made

as described in the following paragraphs.

3.6.1 Interlock 1 Wiring

Interlock 1 is often used with auxiliary

equipment, such as air dampers or flow

switches. If used, connect the end proving

switch to INT 1 terminals 11 and 12 as

shown in the wiring diagram in Appendix I.

3.6.2 Interlock 2 Wiring

Interlock 2 is a general purpose interlock

which can be used with a variety of devices

or equipment or conditions that must be

proved prior to enabling the boiler plant. If

used, connect the end proving switch to INT

2 terminals 13 and 14 as shown in the

wiring diagram in Appendix I.

interlock in place of the jumper. If

NOTE

If necessary, Interlock 1 can be

programmed to operate the boilers

only when the outside air

temperature falls below the system

start temperature. See para. 4.4.2

for details. Interlock 2 cannot

programmed with this feature.

be

3.7 RELAY WIRING

The BMS contains a System Start Relay, a

Fault Alarm Relay and an Auxiliary Relay

which can be connected to external

monitoring or control devices. The contacts

for each of these relays are rated at 120

VAC, 5A and are fused internally at 5A with

replaceable fuses. The contact terminals

for these relays are shown in the wiring

diagram in Appendix I.

3.7 1 System Start Relay

The state of the System Start (SYS START)

relay contacts are controlled by the value

set for the SYS START TEMP function in

the Field Adjust Mode (para. 4.3.5). The

contacts are closed only when the outside

air temperature is less than the System

Start Temperature (SYS START TEMP)

which is set in the Field Adjust Mode. The

default for this temperature setting is 70°F.

3.7.2 Fault Alarm Relay

The state of the Fault Alarm (FLT ALARM)

relay contacts are controlled by the option

selected by pressing the CONFIG SYS key

when in the Field Adjust mode (para.

4.3.16). Contact closure can be set to ALL

FAULTS, INTERLOCK 1, INTERLOCK 2, or

NO INTERLOCK.

3.7.3 Auxiliary Relay

The state of the Auxiliary (AUX) relay

contacts are controlled by the AUX RELAY

CLOSE option selected when in the System

Configuration mode (para. 4.4.8). Contact

closure can be set to occur either when all

available boilers are at the maximum power

input or no boilers are available (all boilers

faulted or turned off).

NOTE

The SET BACK function is used only

if the header supply temperature will

be offset manually as described in

para. 4.3.13. Disregard para. 3.8 if

an automatic header temperature

reset schedule is used as described

in para. 4.3.12.

3.8 SET BACK

The SET BACK terminals shown in the

wiring diagram in Appendix I are used only

when implementing a manually-controlled

header temperature offset. If used, connect

a dry contact switch across SET BACK

terminals 15 and 16 on JP3.

3-4 3-5

Page 15

Page 16

Figure 2

BMS MOUNTING

3-6

Page 17

Figure 3

RECOMMENDED WIRE ROUTING LOCATIONS AT THE BMS

3-7

Page 18

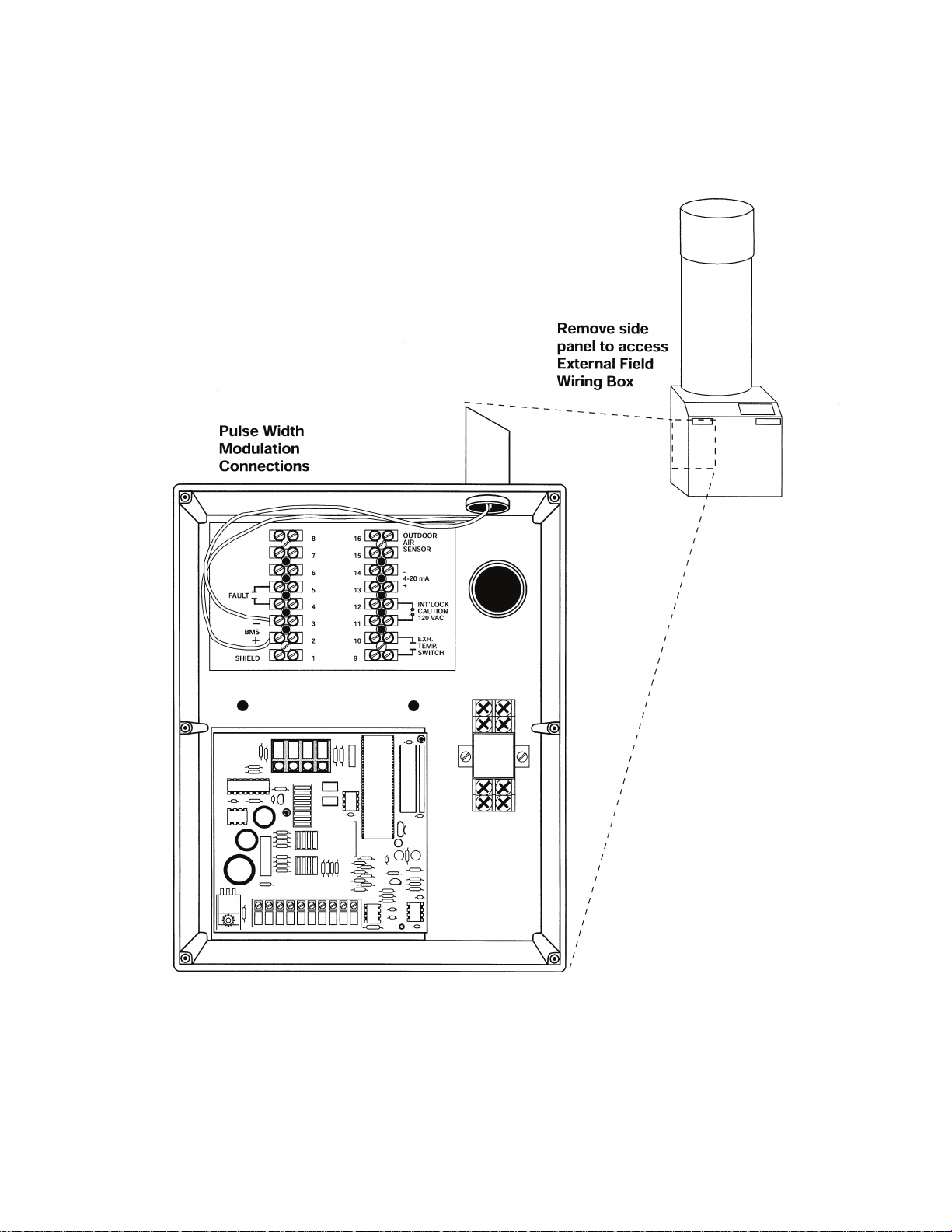

Figure 4

PWM COMMUNICATION OUTPUTS AT THE BMS

3-8

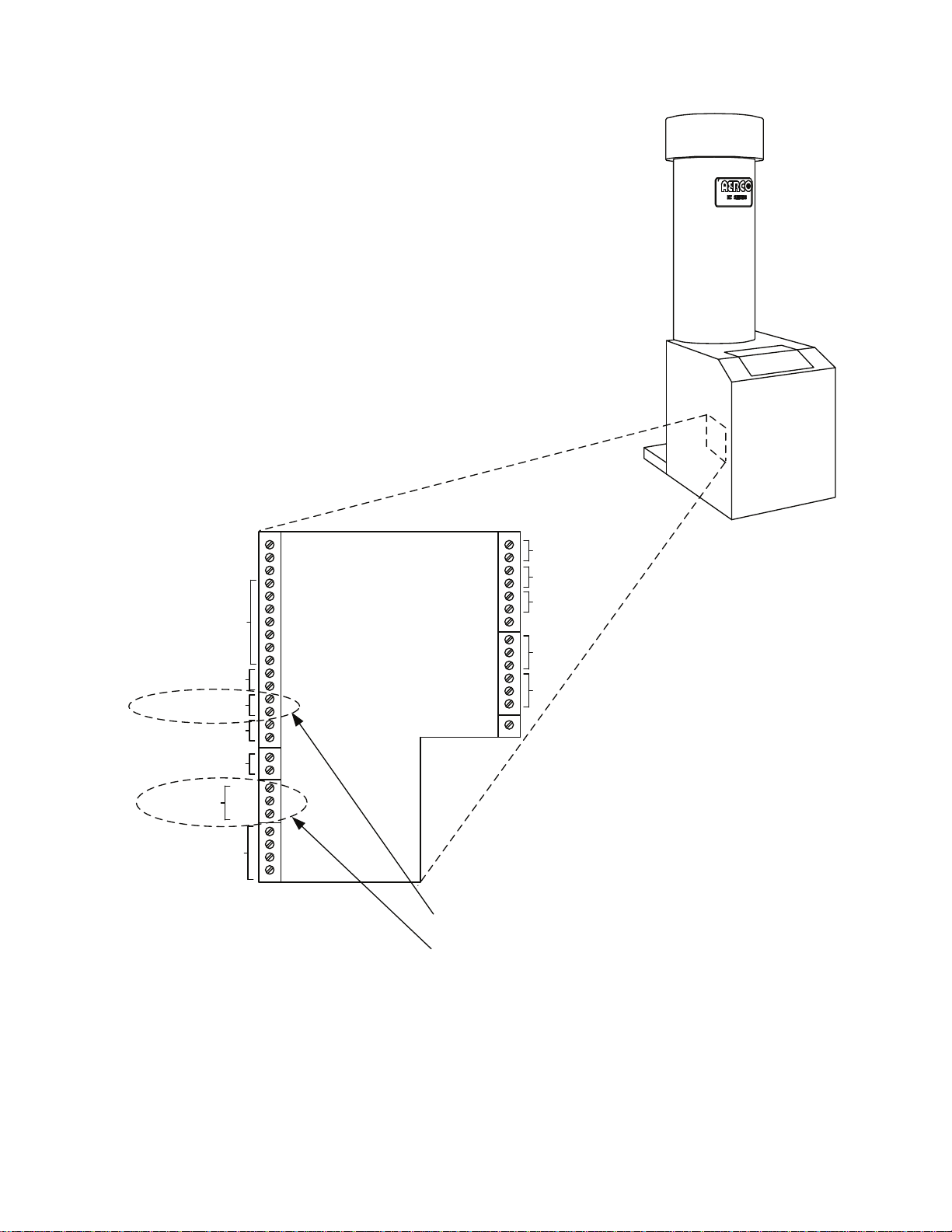

Page 19

Figure 5

PULSE WIDTH MODULATION CONNECTIONS AT

KC SERIES BOILER WITH MODULAR CONTROL BOX

3-9

Page 20

Remove sheet

metal cover to

access I/O Box

OUTDOOR SENSOR IN

SENSOR COMMON

AUX SENSOR IN

NOT USED

ANALOG IN

B.M.S. (PWM) IN

SHIELD

mA OUT

RS-485

COMM.

NOT USED

REMOTE INTL'K IN

EXHAUST SWITCH IN

DELAYED INTL'K IN

NOT USED

NC

FAULT RELAY

COM

120 VAC, 5A, RES

+

+

-

+

-

+

G

-

NO

NC

AUX RELAY

COM

NO

120 VAC, 5A, RES

NOT USED

PWM Connections

RS485 COMM Connections

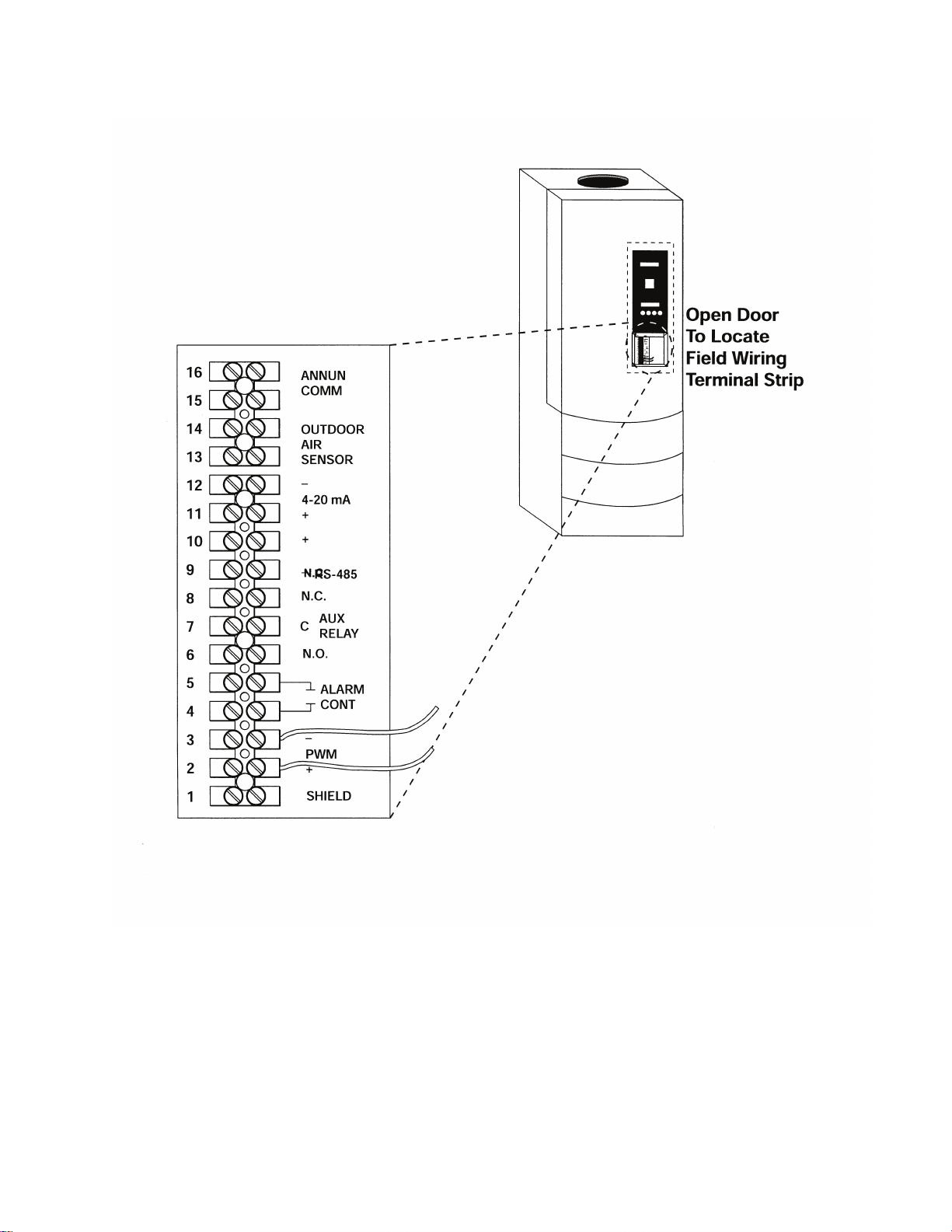

Figure 6

PWM & RS485 CONNECTIONS AT

KC SERIES BOILER WITH C-MORE CONTROL BOX

3-10

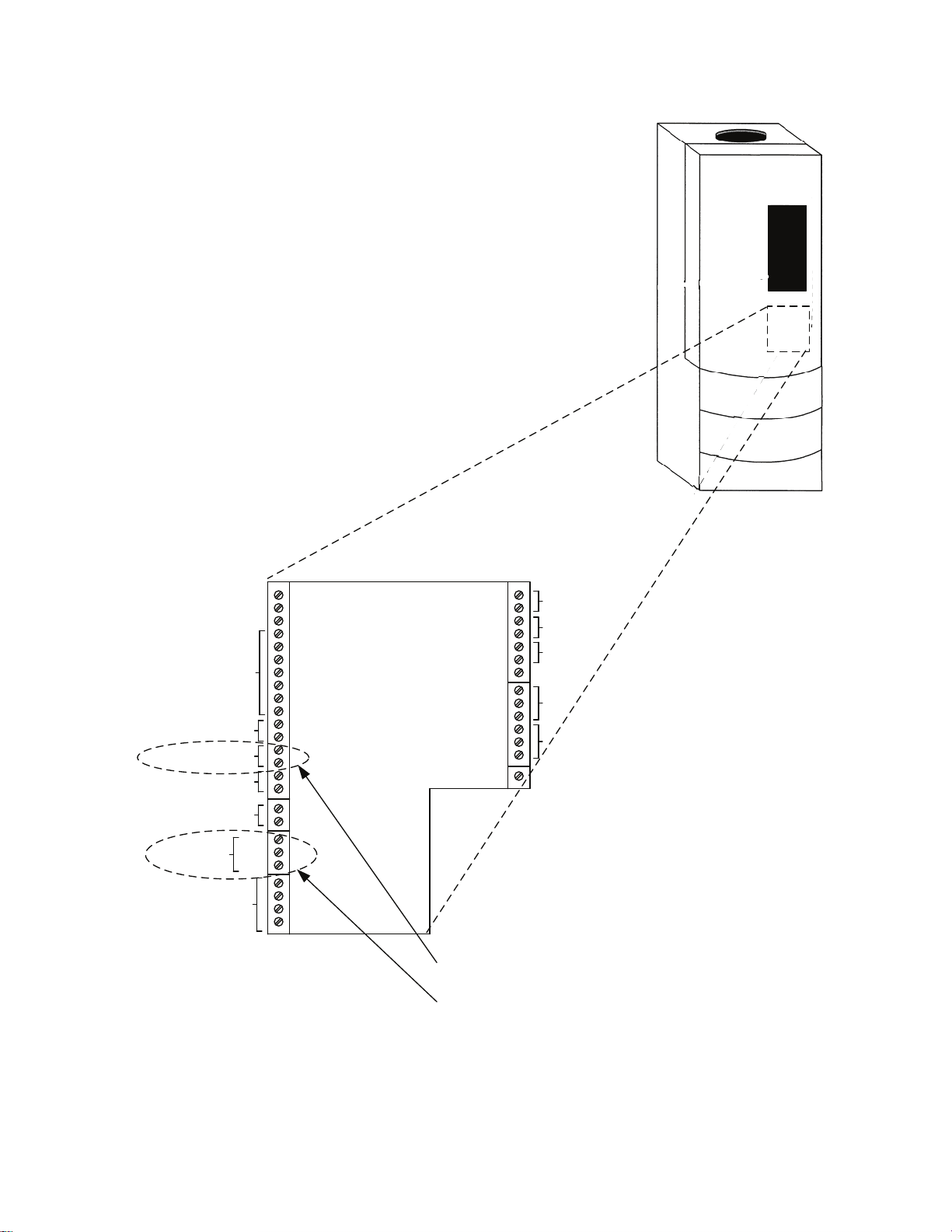

Page 21

Figure 7

PWM CONNECTIONS AT

BENCHMARK BOILER WITH MODULAR CONTROL BOX

3-11

Page 22

Open Door To

Access I/O Box

OUTDOOR SENSOR IN

SENSOR COMMON

AUX SENSOR IN

NOT USED

ANALOG IN

B.M.S. (PWM) IN

SHIELD

mA OUT

RS-485

COMM.

NOT USED

REMOTE INTL'K IN

EXHAUST SWITCH IN

DELAYED INTL'K IN

NOT USED

NC

FAULT RELAY

COM

120 VAC, 5A, RES

+

+

-

+

+

G

-

NO

NC

AUX RELAY

COM

NO

120 VAC, 5A, RES

NOT USED

PWM Connections

RS485 COMM Connections

Figure 8

PWM & RS485 CONNECTIONS AT

BENCHMARK BOILER WITH C-MORE CONTROL BOX

3-12

Page 23

Figure 9

BMS RS485 & RS232 CONNECTOR LOCATIONS

3-13

Page 24

Figure 10

BMS RS485 & RS232 CONNECTOR PIN ASSIGNMENTS

3-14

Page 25

1/2 “ NPT

Figure 11

HEADER SENSOR INSTALLATION WITH WELL

3-15

Page 26

Figure 12

OUTSIDE AIR SENSOR MOUNTING AND CONNECTIONS

3-16

Page 27

Section 4 ______________________________

Familiarizing

Yourself With

the BMS_____

4.1 ABOUT BMS MODES

The BMS has three basic modes: Normal

Mode, Field Adjust Mode and Configure

System Mode. The Normal Mode is a

“Read-Only” mode which only allows you to

view system settings. The Field Adjust

(FIELD ADJ) Mode and System

Configuration (CONFIG SYS) Mode allow

you to view or change BMS settings to

customize and tune the system to the

specific needs of your site. The BMS

keypad normally displays the functions

applicable to the Normal and Field Adjust

Mode. However, the keys perform slightly

different functions for Normal and Field

Adjust Modes. When operating in the

System Configuration Mode, you must

install the SYSTEM CONFIGURATION

OVERLAY sheet, supplied with the BMS,

over the keypad. Figures 13 and 14 show

the Normal/Field Adjust layout and the

System Configuration keypad layouts

respectively.

The following paragraphs describe the

operation of the BMS keypad for each

mode. In addition, tabular listings

summarizing keypad operation for each

mode are provided in Appendices C, D and

E. Ensure that 120 Vac power is supplied to

the BMS and the ON key LED is illuminated.

If the LED is not illuminated, press the ON

key.

4.1.1 Selecting and Viewing Functions

As previously mentioned, the Normal mode,

is a read-only mode which allows functions

to be viewed, but not changed. However,

functions associated with the keypad keys

can also be viewed in the FIELD ADJ and

CONFIG SYS modes, provided the

appropriate mode key (FIELD ADJ or

CONFIG SYS) is first selected. For

example, pressing the HDR TEMP key

displays the supply water temperature. You

can view all mode functions by simply

pressing its associated key. You must be in

the System Configuration mode (CONFIG

SYS) to view the functions associated with

the SYSTEM CONFIGURATION OVER-

LAY.

4.1.2 Changing Function Settings

To change, rather than simply display

settings and functions, the BMS must be in

the FIELD ADJ or CONFIG SYS mode. To

change a function value, press the ▲ and

▼ arrow keys until the display shows the

desired selection. Once you change the

value, associated with one or more function

keys they are automatically stored in nonvolatile memory. For example, if you change

the values for three separate functions in

the Field Adjust mode, you don’t need to

exit and then re-enter the mode for each

function change.

4-1 4-2

Page 28

Figure 13

NORMAL & FIELD ADJUST MODE OVERLAY

Page 29

Figure 14

SYSTEM CONFIGURATION MODE OVERLAY

4-3

Page 30

NOTE

Sample Normal Mode displays with

their Factory Default values are

provided in Appendix C.

4.2 NORMAL MODE DISPLAYS

AND FUNCTIONS

When power is applied to the BMS, it is

automatically placed in the Normal Mode. It

allows you to view the settings currently

stored in memory for BMS parameters. In

addition, you can enter the Field Adjust or

System Configuration Mode by pressing the

FIELD ADJ or CONFIG SYS key. The

functions provided by the keypad keys are

described in the following paragraphs.

4.2.1 HDR TEMP

Pressing and releasing this key displays the

actual header sensor water temperature in

°F. Pressing and holding this key displays

the header setpoint temperature presently

stored in memory.

4.2.2 AIR TEMP

Pressing and releasing this key displays the

actual outside air temperature. Pressing and

holding this key displays the actual inside

air temperature, only if an indoor air

temperature sensor is installed. If an indoor

air sensor is not installed, INDOOR AIR

TEMP NOT CONNECTED will be displayed.

4.2.3 % LOAD

Pressing and releasing this key displays the

actual firing rate percentage (% Load) for

the boiler plant. It also displays the number

of boilers presently operating.

4.2.4 SYS START TEMP

Pressing and holding this key displays the

System Start Relay temperature setting in

°F presently stored in memory. The system

will start whenever the outside air

temperatures drops below this setting.

4.2.5 REF TEMP

Pressing and holding this key displays the

Header Reference Temperature in °F

presently stored in memory.

4.2.6 HDR TEMP LIMIT

Pressing and holding this key displays the

header high limit temperature setting (°F)

stored in memory.

4.2.7 FIELD ADJ

Pressing and releasing this key places the

BMS in the Field Adjust Mode and lights the

FIELD ADJ key LED. When this key is

pressed, the display will read FLD

ADJUSTMENT MAKE SELECTION. Refer

to paragraph 4.3 for key functions when in

this mode.

4.2.8 SET POINT

Pressing and holding this key displays the

indoor setpoint temperature (°F) stored in

memory.

4.2.9 PROP BAND

Pressing this key displays the indoor air

proportional bandwidth. This bandwidth is a

variable used in an equation that solves for

the proper offset of supply water

temperature based on an indoor air

temperature. Normally the display will read

INDOOR PROP BAND 00.0°F/°F. See

paragraph 4.3.9 for additional information.

4.2.10 OFFSET

Pressing and holding this key displays the

Header Temperature Offset (°F) for the

present time and day-of-the-week. See

paragraph 4.3.10 for additional information

on setting up an offset schedule.

4.2.11 RESET RATIO

Pressing and holding this key will display

the header reset ratio if a value is currently

stored in memory. This function is only used

in the Indoor/Outdoor Reset Mode. If this

function is not set, or the Constant Setpoint

or Remote (4-20 mA) mode is used, the

display will show FUNCTION NOT VALID.

Also, ALARM CANCEL is printed directly

above this key. Pressing and releasing this

key will open the Alarm Relay contacts until

the Alarm condition reappears.

4-4

Page 31

4.2.12 ▲ and ▼ Arrow Keys

The ▲ and ▼ arrow keys are not active in

this mode, since no changes can be made

to the displayed settings

4.2.13 ON and OFF Keys

Pressing and releasing the ON or OFF key

enables or disables the BMS. In addition,

the corresponding key LED will light when

the key is pressed.

4.2.14 CONFIG SYS

Pressing and releasing this key places the

BMS in the System Configuration Mode and

lights the CONFIG SYS key LED. When this

key is pressed, the display will read

CONFIG. SYSTEM MAKE SELECTION.

Refer to paragraph 4.4 for key functions

when in this mode.

NOTE

Sample Field Adjust Mode displays

with their Factory Default values and

allowable entry ranges are provided

in Appendix D.

4.3 FIELD ADJUST MODE

DISPLAYS AND FUNCTIONS

The Field Adjust Mode allows you to view or

change settings currently stored in memory

for BMS parameters. Many of the settings in

this mode have been preset by AERCO to

their Factory Defaults. However, you can

reset many functions to suit the specific

needs of your BMS installation.

The Field Adjust Mode is entered by simply

pressing the FIELD ADJ key and verifying

that the FIELD ADJ key LED lights. When

this key is pressed, the display will read

FLD. ADJUSTMENTS MAKE SELECTION.

The following paragraphs describe the

functions of the keys when in the Field

Adjust Mode.

NOTE

When in the Field Adjust Mode, the

HDR TEMP and AIR TEMP keys are

used to set multiple functions

required for Modbus Network

operation. Refer to Modbus

Communication Manual GF-114 for

additional information on set-up and

installation of Modbus (RS485)

Networks.

4.3.1 HDR TEMP

The HDR TEMP key is used to set multiple

Modbus functions when the BMS is

configured as the Modbus Master and is

directly controlling C-More Boiler Controller

Slaves on the RS485 Network. This key is

used to set functions as follows:

NOTE

Default values for each function are

indicated below. Refer to Modbus

Communication Manual GF-114 for

required settings. Use the ▲ and ▼

arrow keys to increment or

decrement the displayed value.

1. Press key once. RS485 BAUDRATE is

displayed. Default = 9600.

2. Press key again. MIN SLAVE ADDR is

displayed. Default = 0.

3. Press key again. MAX SLAVE ADDR is

displayed. Default = 0.

4. Press key again. NUMBER OF NETW

BLRS is displayed. Default=0. This key

is used to set the maximum number of

C-More Boilers that will be controlled on

the Modbus Network.

5. Press key again. MODBUS CNTL TYPE

is displayed. Default = Round Robin.

6. Press key again. NETW BOILER 1

ADDRESS=0 is displayed. Default = 0.

This address must be the same as the

Comm Address stored in the C-More

Boiler Controller.

4-5

Page 32

7. Repeatedly pressing the HDR TEMP

key allows the NETW BOILER

ADDRESS to be set for each boiler

being controlled on the Modbus Network.

4.3.2 AIR TEMP

The AIR TEMP key is used to set multiple

Modbus functions when the BMS is

configured as a Modbus Slave to an EMS

(or BAS) Master. This key is used to set

functions as follows:

NOTE

Default values for each function are

indicated below. Refer to Modbus

Communication Manual GF-114 for

required settings. Use the ▲ and ▼

arrow keys to increment or

decrement the displayed value.

1. Press key once. RS232 MODE is

displayed. This function can be set to

NORMAL or MODBUS SLAVE. The

Default = MODBUS SLAVE.

2. Press key again. RS232 BAUDRATE is

displayed. Default = 9600.

3. Press key again. MODBUS ADDRESS

is displayed. Default = 128.

4. Press key again. NETWORK TIMEOUT

is displayed. Default = 60 sec.

5. Press key again. REMOTE SIGNAL. is

displayed. This function can be set to 420MA or MODBUS. Default = 4-20MA.

6. Press key again. MODBUS PASS

THRU is displayed. This function can be

set to ENABLED or DISABLED. Default

= DISABLED.

4.3.3 % LOAD

The % LOAD key has two separate and

distinct functions in the Field Adjust Mode.

Pressing and holding this key displays the

actual firing rate (load) percentage and the

number of boilers presently operating.

Releasing the % LOAD key changes its

function to Setting the Internal Clock as

described in the following paragraph.

4.3.4 Setting the Internal Clock With

The % LOAD Key

Pressing and releasing the % LOAD key

changes the first line of the display to SET

TIME CLOCK. The second line of the

display will show: MONTH, DATE, YEAR,

DAY, HOURS, or MINS. Since these

functions wrap around, it is strongly

suggested that you repeatedly press the %

LOAD key until the display shows MONTH:

in the second line. This will make the

following steps easier to follow:

NOTE

When performing the following

steps, use the ▲ and ▼ arrow keys

to increment or decrement the

displayed value. Pressing and

holding the ▲ or ▼ key will change

the displayed value at a rapid rate.

1. Press key until MONTH: is displayed.

Set the actual number of the month (1-

12).

2. Press key again to display DATE:. Set

the actual day of the current month

(1-31).

3. Press key again to display YEAR:. Set

the last 2 digits of the year.

4. Press key again to display DAY:. Set the

day that you want to be the first day of

the week. AERCO normally sets Sunday

as DAY 1, however any day of the week

can be set as DAY 1.

For example, if the actual DATE (day of

month) entered in step 2 is a Monday,

and you want Monday to be the first day

of the week, set DAY: to 1. Conversely,

if you want to retain Sunday as the first

day of the week, set DAY: to 2 to

indicate you are currently in the second

day of the week.

5. Press key again to display HOURS:. Set

the hours using the 24-hour format (0 to

23).

6. Press key again to display MINS. Set

the minutes (0 to 59).

7. This completes the Internal Clock

settings.

4-6

Page 33

4.3.5 SYS START TEMP

When in the Field Adjust Mode, the SYS

START TEMP key has two functions. First,

It lets you select the outdoor temperature at

which the system starts. Second, it lets you

select the system start option (TEMP ONLY

or TEMP AND LOAD).

For example, with the system start

temperature set at 70°F (SYS. START

RELAY 70°F), the system start relay will

close and enable the boilers when the

outside air temperature falls to 69°F (or

lower).

To always enable the boilers, regardless of

the system start temperature, or if an

outside air temperature sensor is not used,

see paragraph 4.4.2 in the System

Configuration Mode section.

• Pressing and releasing the SYS START

TEMP key once displays the System

Start Relay temperature. (AERCO

presets System Start to an outside air

temperature of 70°F). To change the

displayed start temperature, press the ▲

or ▼ arrow key.

• Pressing and releasing this key a second

time displays the System Start Option

which can be set to either outside air

temperature only (TEMP ONLY) or

outside air temperature and load (TEMP

AND LOAD). To change Start Option,

press ▲ or ▼ key to toggle the setting.

If TEMP ONLY is chosen, the BMS will

close the system start relay contacts when

the outdoor air temperature drops below the

system start temperature setting, without

regard to load.

The TEMP AND LOAD feature is used

when the System Start Relay will control

dampers. It keeps dampers closed until it is

necessary to open them for combustion.

This is designed to ensure that cold air is

not always entering the boiler room.

If TEMP AND LOAD is chosen, two

conditions are necessary for the system

start relay contacts to close and enable the

boilers. First, the firing rate (displayed as %

LOAD) must be above 11%. Second the

outdoor air temperature must be below the

system start temperature. The system start

relay contacts will open when the load

percentage falls below 7%.

4.3.6 REF TEMP

The REF TEMP key has two functions,

depending on the operating mode used by

the boilers connected to the BMS.

• In the Indoor/Outdoor Reset or Remote

Setpoint Mode, pressing and releasing

this key displays the Building Reference

Temperature (BLDG REF TEMP).

• In the Constant Setpoint Mode, pressing

this key displays the header supply water

temperature setpoint (HEADER REF.

TEMP).

To change the displayed Reference

Temperature, press the ▲ or ▼ arrow key.

4.3.7 HDR TEMP LIMIT

This key allows you to view or change the

low and high temperature limits for the

header supply water temperature.

In addition, when in the 4-to-20 mA Remote

Setpoint Mode, it automatically scales the 4to-20 mA signal. Accordingly, 4 mA will be

equal to the header low limit setting and 20

mA will be equal to the header high limit

setting.

• Pressing and releasing this key once

displays the header high limit

temperature (HDR HIGH LIMIT).

• Pressing and releasing this key a second

time displays the header low limit

temperature (HDR LOW LIMIT).

• Pressing and releasing this key a third

time displays the header offset

temperature (HEADER OFFSET).

To change the displayed header high, low

or offset temperature limits, press the ▲ or

▼ arrow key.

4-7

Page 34

4.3.8 FIELD ADJ

The FIELD ADJ key LED should be lit to

indicate that the BMS is already in the Field

Adjust Mode. Pressing and releasing this

key when already in the Field Adjust Mode

will cause the BMS to exit the Field Adjust

Mode and switch the BMS to the Normal

(Read-Only) Mode.

4.3.9 SET POINT

Pressing and releasing this key allows you

to view or change the indoor setpoint

temperature. This function is only used

when an indoor air temperature sensor is

connected to the BMS. If used, the input

can be provided by a resistive type sensor,

or a 4-to-20 mA input.

4.3.10 PROP BAND

Pressing this key displays the indoor air

proportional bandwidth. This bandwidth is a

variable used in an equation that solves for

the proper offset of supply water

temperature based on an indoor air

temperature. Normally, the display will read

INDOOR PROP BAND 00.0°F/°F.

AERCO presets the proportional bandwidth

to 00.00°F/°F. It should NOT be readjusted

unless your system has an indoor air

temperature sensor and is operating in the

Indoor Setpoint mode. If the indoor

temperature feature is not being used,

PROP BAND MUST be set to 00.00°F/°F or

the BMS will not run the boiler plant.

4.3.11 OFFSET

The OFFSET key is used to enable and set

up an Offset Schedule for the header supply

temperature. The schedule can be set up

for a 7-day period.

Pressing and releasing this key once will

display OFFSET ENABLE followed by OFF

or ON (Default is OFF). If an Offset

Schedule will be used, toggle the display to

ON using the ▲ or ▼ arrow key.

Normally, if an Offset Schedule is used, it is

controlled automatically using the set-up

procedures described in paragraph 4.3.12.

However, if desired, the header offset can

be controlled manually by connecting a

switch across the SET BACK wiring

terminals (see para. 3.8). If a manual offset

is used, refer to paragraph 4.3.13

IMPORTANT

Prior to setting up an automatic

Reset Schedule (para. 4.3.12) or

manual Set Back (para. 4.3.13),

refer to the paragraph 4.3.4 to

determine which Day of the Week

has been set as Day 1. AERCO

presets Day 1 of the week as

Sunday. However, any day of the

week can be specified as Day 1 by

performing the steps outlined in

paragraph 4.3.4.

4.3.12 Setting Up A Reset Schedule

The basic steps for setting up an automatic

Reset Schedule consist of first selecting the

temperature offset and then entering the

start and stop times for which the offset will

be in effect. Keep in mind that the BMS

uses a 24-hour clock (00:00 to 23:59).

In the following example, for Day 1, we want

to offset the setpoint temperature by -15°F

starting at 12:30 am (00:30) and return it to

the normal setpoint at 8:15 am (08:15).

Proceed as follows:

1. Press OFFSET key once and toggle the

display to OFFSET ENABLE ON.

2. Press key a second time. OFFSET

TEMP DAY 1

entry of the offset temperature. Set the

offset temperature to -15 using the ▲

and ▼ arrow keys.

3. Press key a third time. OFFSET ON

TIME DAY 1

prompting Hours to be entered for the

start time. Set the Hours to zero

(midnight) using the ▲ and ▼ arrow keys.

4. Press key a fourth time. OFFSET ON

TIME DAY 1: 0

prompting Minutes to be entered for the

start time. Set the Minutes to 30 using

the ▲ and ▼ arrow keys.

Æ

is displayed prompting

Æ

0: 0 is displayed

Æ

0 is displayed,

4-8

Page 35

5. Press key a fifth time. OFFSET OFF

TIME DAY 1

prompting Hours to be entered for off

time. Since the BMS uses a 24-hour

clock format, set the Hours to 8 using

the ▲ and ▼ arrow keys.

6. Press key a sixth time. OFFSET OFF

TIME DAY 1: 8

prompting Minutes to be entered. Set

the Minutes to 15 using the ▲ and ▼

arrow keys.

7. This completes the steps for setting the

Offset Temperature, and Start/Stop

Times for Day 1.

For a 7-Day Schedule, steps 2 through 7

would be repeated as needed. Offset

Schedule entries stored in memory can be

reviewed by repeatedly pressing the

OFFSET key as necessary.

4.3.13 Manual Set Back

If a switch is connected across the SET

BACK terminals (para. 3.8), the header

offset temperature can be controlled

manually by setting all offset times to zero.

Using the OFFSET key:

1. Toggle the display to OFFSET ENABLE

ON.

2. Set the desired OFFSET TEMP. A

different OFFSET TEMP can be entered

for each day if desired.

3. Set the OFFSET ON TIME and

OFFSET OFF TIME to zero for each

day.

Once programmed as described above,

closing the SET BACK switch will enable

the programmed OFFSET TEMP for that

day. Opening the SET BACK switch will

disable the OFFSET.

Æ

0: 0 is displayed

Æ

0 is displayed

4.3.14 RESET RATIO

The Reset Ratio is only used in the

Indoor/Outdoor Reset Mode of operation.

This ratio the amount that the supply water

temperature will rise for each degree drop in

outside air temperature. A reset ratio of 2.0

means that the supply water temperature

will increase 2°F for every 1°F decrease in

outdoor air temperature. For example, if the

building reference temperature is set at

70°F, when outside air temperature drops to

69°F, and the reset ratio is 1.8, the water

supply temperature will increase to 71.8°F.

AERCO presets the Reset Ratio to

1.2°F/°F. See Appendix B for Reset Ratio

Charts.

Pressing and releasing this key will display

the Header Reset Ratio (°F/°F) if a value is

currently stored in memory. When operating

in the Constant Setpoint or Remote (4-20

mA) mode, the display will show

FUNCTION NOT VALID.

4.3.15 ▲ and ▼ Arrow Keys

These keys are used to increment (▲) or

decrement (▼) the displayed variable, or

toggle the display through available options.

When these keys are depressed and held

the displayed value will increment or

decrement at a rapid rate.

4.3.16 ON and OFF Keys

Pressing and releasing the ON or OFF key

enables or disables the BMS. In addition,

the corresponding LED will light when the

corresponding key is pressed.

4.3.17 CONFIG SYS

When the BMS is in the Field Adjust Mode,

this key has two functions. First, it allows

you to select the types of faults which will

cause an alarm. Second, it allows you to

select how alarms are cleared.

• Pressing and releasing the CONFIG SYS

key once displays the FAULT ALARM

RELAY status and allows you to select

the types of faults which will cause an

alarm. The choices are: ALL FAULTS,

NO INTERLOCK, INTERLOCK 2 or

INTERLOCK 1.

Selecting ALL FAULTS causes the BMS

Fault Relay to close and generate an

alarm when either Interlock 1 or 2 opens.

It also closes the Fault Relay when any

of the fault messages listed in Appendix

H, Table H-1 are displayed.

4-9

Page 36

Selecting INTERLOCK 2 causes the

Fault Relay to close and generate an

alarm only when Interlock 2 opens.

However, if INTERLOCK 1 opens, a fault

message will be generated but the Fault

Relay will not be closed.

Selecting INTERLOCK 1 causes the

Fault Relay to close and generate an

alarm only when Interlock 1 opens.

However, if INTERLOCK 2 opens, a fault

message will be generated but the Fault

Relay will not be closed.

Selecting NO INTERLOCK causes the

Fault Relay to remain open and not

generate an alarm when either Interlock

1 or Interlock 2 opens.

It should be noted that the BMS will

always

Interlock 1 or 2 opens, regardless

selected Fault Relay option.

• Select the desired option using the

▲ or ▼ arrow key.

• Pressing and releasing the CONFIG SYS

key a second time displays FAULT

ALARM CLEAR and allows you to select

how faults are cleared. The available

choices are MANUAL RESET or

AUTOMATIC. Toggle to the desired

option using the ▲ or ▼ arrow key.

Prior to placing the BMS in the System

Configuration Mode, the FIELD ADJ key

must be pressed to exit the Field Adjust

Mode. Pressing and releasing the CONFIG

SYS key places the BMS in the System

Configuration Mode and lights the CONFIG

SYS key LED. When this key is pressed,

the display will read CONFIG. SYSTEM

MAKE SELECTION. Refer to paragraph 4.4

for key functions when in this mode.

Sample System Configuration mode

displays with their Factory Default

values are provided in Appendix E.

shut down the boilers when

of the

NOTE

4.4 SYSTEM CONFIGURATION

MODE DISPLAYS AND

FUNCTIONS

The System Configuration Mode allows you

to program and operate the BMS to

effectively run and manage the performance

of the boiler plant. In order to effectively use

this mode, the SYSTEM CONFIGURATION

OVERLAY provided with the BMS must be

placed over the keypad for proper

identification of key functions (Figure 12).

The System Configuration Mode is entered

by simply pressing the CONFIG SYS key

and verifying that the CONFIG SYS key

LED lights.

The keys described in the following

paragraphs allow you to view or change

settings currently stored in memory. If the

desired setting is not displayed for the

selected BMS parameter, press the ▲ or ▼

arrow key to increase, decrease or toggle

the displayed setting. All changes made will

be stored in memory.

4.4.1 TEMP FAIL MODE

Pressing and holding this key displays the

actual header sensor water temperature in

°F. This is a “Read Only” display and cannot

be changed.

Pressing and releasing this key allows you

to display and select a Temperature Failure

Mode (TEMP FAIL MODE) of either

SHUTDOWN or SWITCH INPUTS.

If SHUTDOWN is selected, regardless of

the operating mode, the BMS will shut down

the boiler plant whenever a temperature

sensor fails or either interlock opens. If the

BMS is operating in the Remote Setpoint

mode, the BMS will also shut down the

boiler plant if the remote 4-to-20-mA input

signal drops below 3 mA. If any of these

failures occur, the fault relay will close and

the BMS will display the appropriate failure

message.

4-10

Page 37

If SWITCH INPUTS is selected, the BMS will

automatically switch to Constant Setpoint

mode if a sensor or remote input error

occurs. Once the sensor or remote input

error has been cleared, the BMS will

automatically switch to the previous mode.

When selecting SWITCH INPUTS, the

reference temperature for the Constant

Setpoint mode must be preset. See Section

5 for programming steps.

Regardless of whether SHUTDOWN or

SWITCH INPUTS is selected, the BMS will

shut down and close the fault relay contacts

if the header sensor circuit fails.

4.4.2 SYS ENABLE

Pressing and releasing this key allows you

to select the INTERLOCK 1 enable setting

of START ENABLED or ALWAYS

ENABLED.

The START ENABLED feature will not

enable the boiler plant until the outside air

temperature falls below the system start

temperature. If the boiler plant begins to

operate and Interlock 1 is open, the BMS

will wait 30 seconds before stopping the

boilers and displaying a fault message.

This feature is intended for use with

auxiliary equipment having limit switches.

For instance, dampers with proving end

switches, can be triggered by the BMS

system start relay as the boilers start. If the

dampers do not open, the end switch wired

to Interlock 1 will not make (close) and the

BMS will shut down the boilers.

The ALWAYS ENABLED feature allows the

boilers to run, regardless of the system start

and outside air temperature settings. This

feature is used when there is a loss of an

outside air sensor or one is not installed. It

will also function if an outside air

temperature sensor is present. It should be

noted that if either Interlock 1 or 2 opens,

the BMS will shut down the boilers.

The system start relay will close only after

the outside air temperature falls below the

system start temperature, whether START

ENABLED or ALWAYS ENABLED is

selected. AERCO recommends that the

system be equipped with a flow switch that

is interlocked to the BMS. This is especially

important if ALWAYS ENABLED is selected

and the BMS is controlling the pumps based

on outside air temperature, or the BMS is

interfaced with an energy management

system that is controlling the pumps.

4.4.3 MAX PWR INPUT

This key provides two distinct functions.

First, it is used to establish the maximum

firing rate percentage for the boilers being

controlled by the BMS. Second, it permits

adjustment of the pulse width modulation

(PWM) signal supplied to the boilers.

• Pressing and releasing the MAX PWR

INPUT key once displays the maximum

allowable firing rate percentage for the

boilers (MAX POWER INPUT 100%). If

desired, the maximum firing rate of the

boilers can be limited to values below

100%. This is useful if there is a problem

with gas supply pressure.

For example, if gas pressure is too low,

the boilers can be run at a lower firing

rate temporarily until proper gas pressure

can be restored. If necessary, adjust the

firing rate using the ▲ or ▼ arrow key.

• Pressing and releasing the MAX PWR

INPUT key a second time displays a

PWM TIMEBASE CAL message. If

necessary, the PWM pulse width ON

time can be adjusted using the ▲ and ▼

arrow keys. Pressing the ▲ arrow key

increases the pulse width ON time and

pressing the ▼ key reduces the ON time.

The PWM TIMEBASE CAL is adjustable

from -30 to 30 (Default = 0).

The PWM TIMEBASE CAL should only

be adjusted when all boilers are

indicating a firing rate above or below the

firing rate being supplied by the BMS

PWM signal. If necessary, individual

boilers can be adjusted via their

respective C-More Control Systems.

4-11

Page 38

4.4.4 START LEVEL and STOP

LEVEL Keys

These keys allow you to set the energy

levels (firing rate percentages) at which

additional boilers are staged-in or stagedout of the system during Sequential or

Combination mode operation. While the

start level can be set at any percentage up

to 100%, it is best to keep it below 60%.

This allows the system to operate at

optimum efficiency under low loads. The

BMS is preset with 45% start and 18% stop

levels, which generally provide the best

performance.

When changing the start or stop levels, it is

important to remember that load-balancing

affects bumpless transfer. A sufficiently

wide gap between the start and stop levels

must be maintained to prevent cycling

between units. For example, in a two-boiler

system with a start level of 60% and a stop

level of 30%, when the first boiler reaches

60%, the BMS will distribute the load

between the two boilers, so that each will

have a firing rate of 30%. However, since

the stop level is 30%, the BMS will

automatically shut down one boiler and

allow the firing rate of the second boiler to

increase to 60%. The BMS will then repeat

this undesirable cycling. To avoid this, the

start level could be set to 65%, leaving the

stop level at 30%. When the BMS

distributes the load after the first boiler

reaches a 65% firing rate, the individual

load would be 32.5%, sufficiently above the

stop level. Conversely, the stop level could

be changed to 25%, leaving the start level

at 60%. In this case, when the BMS

distributes the load, there will be 5% margin

between this load (30%) and the stop level

(25%).

• Pressing the START LEVEL key

displays firing rate percentage at which

the boilers will start.

• Pressing the STOP LEVEL key displays

firing rate percentage at which the boilers

will stop.

4.4.5 BLR OP MODE

This key is used to select the Boiler

Operating Mode. It allows you to make

choices concerning the effective and

efficient way to fire the boilers based on the

building load. The mode choices include:

Parallel, Sequential, or Combination Mode.

Pressing the BLR OP MODE key displays

BOILER OP MODE followed by the

currently selected mode (PARALLEL,

SEQUENTIAL or COMBINATION). AERCO

presets the mode to SEQUENTIAL. If

necessary, use the ▲ and ▼ arrow keys to

toggle between the 3 available modes. The

following paragraphs describe the

advantages of each mode selection.

4.4.5.1 Sequential Mode

The Sequential Mode provides a greater

turn-down ratio than Parallel Mode. This is

because the turn-down ratio in Sequential

Mode is equal to the number of boilers

multiplied by 14 for KC Series boilers and

by 15 for Benchmark boilers. In Parallel

Mode, the turn-down ratio is fixed at 14:1 for

KC Series boilers and 15:1 for Benchmark

boilers, and does not consider the number

of boilers in the plant.

In Sequential Mode, each boiler is started

one at a time based on the load and

start/stop levels programmed in the BMS.

The BMS will start a single boiler when

there is a load demand. Once the first boiler

reaches the start level, a second boiler will

be started and the load will be distributed

evenly between the two boilers.

For instance, if a start level of 50% is

chosen, when the first boiler reaches 50% a

second boiler will start (after a 30 second

delay), and the BMS will distribute the load

25% for each boiler. If the firing rate of both

boilers reach the start level, a third boiler is

started by the BMS (after a 30 second

delay), and the load will be distributed

across all three boilers. This sequence will

continue base on load demand and the

number of boilers connected to the BMS.

4-12

Page 39

As the load drops off, the firing rates

decrease. When all boilers reach the stop

level, the first boiler turned on will be shut

off by the BMS and its load will be evenly

distributed to the remaining firing boilers.

This off-sequencing continues until only one

boiler is left firing. The last boiler will turn off

when its stop level is reached.

4.4.5.2 Parallel Mode

When operating in Parallel Mode, the

boilers are simultaneously started by the

BMS. The start and stop levels have no

effect when in Parallel Mode. The turn-down

ratio in Parallel Mode is fixed at 14:1 for KC

1000 Series boilers and 15:1 for Benchmark

boilers, regardless of the number of boilers

in the plant.

4.4.5.3 Combination Mode

Combination mode is used only when the

boiler plant will be used to satisfy both

space heating and domestic hot water

needs. This configuration, known as a

Combination System, is used in conjunction

with an AERCO Combination Control Panel

(CCP). This system uses BMS-mode boilers

dedicated to space heating and

Combination boilers that are primarily used

to satisfy the domestic hot water need. The

domestic combination boilers are also

available for the space heating load when

the domestic hot water load is satisfied. This

is accomplished using a motorized valve

and storage tank equipped with a heat

exchanger. For additional information on the

Combination System, see AERCO’s CCP-1

literature.

4.4.5.4 Designating the Number of

Combination Boilers

A maximum of 4 combination boilers can be

connected to the BMS. However, when

using the Combination Mode, it is necessary

to tell the BMS how many combination

boilers there are. This is accomplished as

follows:

IMPORTANT

When connecting combination boilers

to the BMS, it is important that you start

at the BLR 8 terminals on Terminal

Strip JP2 and work towards BLR 5.

1. With the COMBINATION MODE

selected, press the BLR OP MODE key.

The display will read: COMBINATION

MODE X OF CCP BOILERS, (where X

is the number of combination boilers).

2. Enter the number of combination boilers

connected to the BMS using the ▲ and

▼ arrow keys.

4.4.6 HDR SET MODE

This key has two functions. First, it is used

to select the Indoor/Outdoor Reset,

Constant Setpoint, or Remote Setpoint

boiler mode operation. Second, it is used to

select the type of indoor temperature sensor

used with the BMS, if one is installed. The

type of sensor can be either resistive

(thermistor) or a constant voltage signal with

current varying from 4 to 20 mA.

Pressing the HDR SET MODE key once

selects the Header Set Mode function. If the

desired mode is not displayed, toggle the

display to the desired mode (IN/OUTDOOR

RESET, REMOTE SET TEMP or

CONSTANT SETTEMP) using the ▲ or ▼

arrow key.

Pressing the HDR SET MODE key a

second time toggles the display to indicate

the type of indoor temperature sensor which

will be used with the BMS (THERMISTOR

or 4-20 mA). If necessary, toggle the display

to the desired sensor type using the ▲ or ▼

arrow key.

If the REMOTE SET TEMP mode is

selected and the Indoor Temperature

Sensor feature is used, the Sensor input

type must be THERMISTOR (resistive)

since the BMS has only one 4-to-20 mA

input.

4.4.7 INTGL RATE GAIN, TEMP

BANDWIDTH and DERIV GAIN Keys

These three keys provide PID (Proportional

Integral Derivative) control functions which

govern temperature control and response of

the BMS to the boiler system. Since each

system is different, these PID controls can

tune the BMS to the characteristics of your

4-13

Page 40

specific installation. The factory defaults

preset by AERCO work well for most

applications. In instances when there is a

large error between the setpoint and the

actual supply water temperature, the BMS

may appear to require PID tuning. However,

It is best to observe BMS operation over a

period of time prior to making any PID

changes. Contact AERCO or an AERCO

representative prior to making any PID

setting changes.

The functions provided by the PID function

keys are described in the following

paragraphs.

4.4.7.1 TEMP BANDWIDTH

Header Temperature Bandwidth (HDR

TEMP B.W.) concerns the system’s

response to the setpoint error. Setpoint

error is the difference between the supply

water temperature setpoint and the actual

supply water temperature. A constant

setpoint error will yield a constant and

proportionate correction factor for the

duration of the error. If there is a deviation

from the constant error, the correction factor

will be changed in proportion to the

deviation. For instance, a temperature

bandwidth of 50°F is chosen. The header

temperature setpoint is 180°F and the

actual incoming supply water temperature is

130°F

. This is a 50° error and the following

is true:

Temp. Error_____

X 100 = Firing Rate in %

Prop Bandwidth

Therefore:

50 X 100% = Firing Rate

50

1 X 100 = 100 % Firing Rate

With an error of 30° and a bandwidth of 50,

the following would be true:

30/50 X 100 = .6 X 100 = 60% Firing Rate.

4.4.7.2 INTGL RATE GAIN

Integral gain responds to the setpoint error

over a period of time. Integral references

the proportional bandwidth error signal and

sums itself with respect to the period of time

that an error exists. Based on the example

in the previous paragraph (4.4.7.1), if the

integral is 0.15 repeats per minute and the

firing rate is 60%, and a temperature error

exists for 1 minute, then the following is

true:

(0.15 reps/min.) x (60% firing rate) = 9%

actual firing rate

60% firing rate +9% firing rate = 69% firing

rate

If the error continues and is present for

another minute, another 9% correction

factor will be added:

69% firing rate +9% firing rate = 78% firing

rate

If, after a load change, the supply water

temperature stabilizes at a temperature

above or below the setpoint, the integral

gain should be increased. If, after a load

change, the supply water temperature

overshoots and oscillates excessively,

integral gain should be reduced.

4.4.7.3 DERIV GAIN

Derivative gain is a function of time. It

senses and responds to the rate of change

of the setpoint error. A slow rate of change

will yield a small amount of derivative gain.

Conversely, a fast rate of change will yield a

large derivative gain. Too high a derivative

gain setting will produce a large output for a

short time. This can result in overshoot of

the setpoint. Too low a derivative gain

setting will have the opposite effect,

producing a small output for a longer period,

and may result in slow system response or

the system undershooting the setpoint.

4-14

Page 41

4.4.8 AUX RELAY

This key is used to display or change the

firing rate at which the Auxiliary Relay

opens and closes. The Auxiliary Relay is

typically used with AERCO’s Combination

Control Panel (CCP) system or to start an

auxiliary boiler for use under peak load

conditions. If this boiler is of the noncondensing type, the OFF firing rate

percentage must be high enough to prevent

the boiler from operation in condensing

mode.

Pressing the AUX RELAY key once

displays the firing rate percentage at which

the relay opens (AUX RELAY OPEN). The

default value of 45% is acceptable for a

CCP system. However, to run another noncondensing boiler, this percentage may

need to be changed to approximately 70%.

The displayed percentage can be changed

in 1% increments from 1 to 99%.

Pressing the AUX RELAY key again

displays the firing rate percentage at which

the relay closes (AUX RELAY CLOSE). Two

options are available for this function: 100%

FIRING RATE, or 100% AND OFF

(default). Pressing the ▲ or ▼ arrow key

will toggle the display. If 100%

RATE is selected, the Auxiliary Relay

contacts close when the BMS indicates that

all boilers are at a 100% firing rate. If the

default setting of 100% AND OFF is

selected, the Auxiliary contacts close when

the BMS indicates that all boilers are at a

100% firing rate

determines that all boilers are off. The offstate is when each boiler has either faulted,

or someone has pressed the off button on