Page 1

Instruction

GF-116

No.

AERCO INTERNATIONAL, Inc., Northvale, New Jersey, 07647 USA

Installation, Operation

& Maintenance Instructions

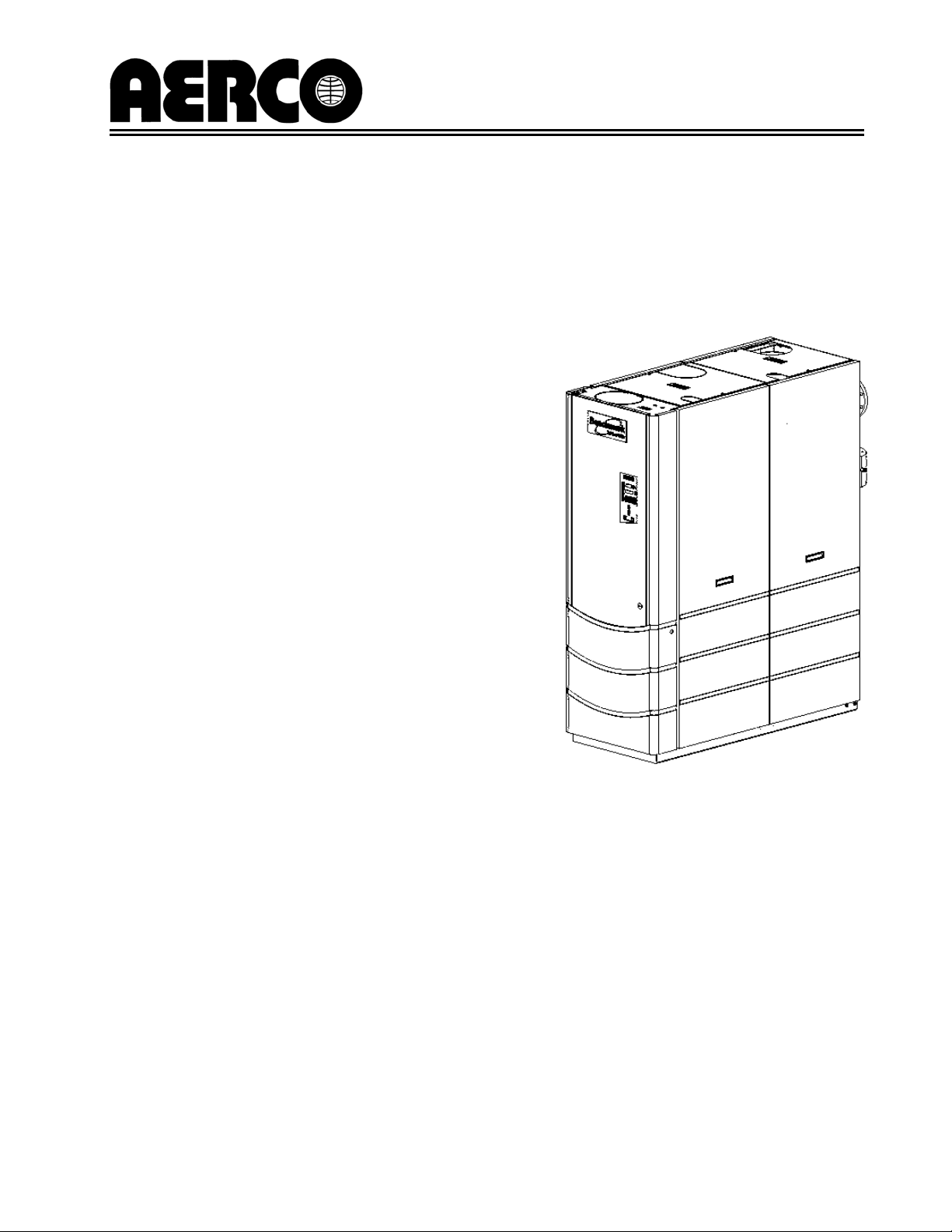

Benchmark 3.0LN

Series

Gas Fired

Low NOx

Boiler System

Condensing, Modulating

Forced Draft, Hot Wa t e r Boiler

3,000,000 BTU/H Input

Applicable for Serial Numbers G-10-1473 and above

Printed in U.S.A. REVISED JANUARY 27, 2011

Page 2

Telephone Support

Direct to AERCO Technical Support

(8 to 5 pm EST, Monday through Friday):

1-800-526-0288

AERCO International, Inc.

159 Paris Avenue

Northvale, NJ 07647-0128

www.aerco,com

© AERCO International, Inc., 2011

The information contained in this

installation, operation and maintenance manual is subject to

change without notice from

AERCO International, Inc.

AERCO makes no warranty of any

kind with respect to this material,

including but not limited to implied

warranties of merchantability and

fitness for a particular application.

AERCO International is not liable

for errors appearing in this

manual. Nor for incidental or

consequential damages occurring

in connection with the furnishing,

performance, or use of this

material.

Page 3

CONTENTS

GF-116 - AERCO BENCHMARK 3.0LN GAS FIRED LOW NOx BOILER

Operating & Maintenance Instructions

FOREWORD A

Chapter 1 – SAFETY PRECAUTIONS 1-1

Para. Subject Page

1-1 Warnings & Cautions 1-1

1-2 Emergency Shutdown 1-2

Chapter 2 – INSTALLATION 2-1

Para. Subject Page

2.1 Introduction 2-1

2.2 Receiving the Unit 2-1

2.3 Unpacking 2-1

2.4 Site Preparation 2-1

2.5 Supply and Return Piping 2-3

2.6 Condensate Drains 2-3

2.7 Gas Supply Piping 2-5

2.8 AC Electrical Power Wiring 2-6

Para. Subject Page

1-3 Prolonged Shutdown 1-2

Para. Subject Page

2.9 Modes of Operation and Field

Control Wiring

2.10 I/O Box Connections 2-9

2.11 Auxiliary Relay Contacts 2-11

2.12 Flue Gas Vent Installation 2-11

2.13 Combustion Air 2-11

2-7

Chapter 3 – CONTROL PANEL OPERATING PROCEDURES 3-1

Para. Subject Page

3.1 Introduction 3-1

3.2 Control Panel Description 3-1

3.3 Control Panel Menus 3-4

3.4 Operating Menu 3-5

3.5 Setup Menu 3-5

Para. Subject Page

3.6 Configuration Menu 3-6

3.7 Tuning Menu 3-8

3.8 Combustion Cal Menu 3-8

3.9 Start Sequence 3-8

3.10 Start/Stop Levels 3-10

Chapter 4 – INITIAL START-UP 4-1

Para. Subject Page

4.1 Initial Startup Requirements 4-1

4.2 Tools and Instruments for

Combustion Calibration

4.3 Natural Gas Combustion

Calibration

4-1

4-2

Para. Subject Page

4.4 Unit Reassembly 4-6

4.5 Over-Temperature Limit Switch 4-6

i

Page 4

CONTENTS

Chapter 5 – MODE OF OPERATION 5-1

Para. Subject Page

5.1 Introduction 5-1

5.2 Indoor/Outdoor Reset Mode 5-1

5.3 Constant Setpoint Mode 5-2

5.4 Remote Setpoint Mode 5-2

5.5 Direct Drive Modes 5-3

Para. Subject Page

5.6 Boiler Management System

(BMS)

5.7 Combination Control System

(CCS)

5-4

5-5

Chapter 6 – SAFETY DEVICE TESTING PROCEDURES 6-1

Para. Subject Page

6.1 Testing of Safety Devices 6-1

6.2 Low Gas Pressure Fault Test 6-1

6.3 High Gas Pressure Test 6-2

6.4 Low Water Level Fault Test 6-2

6.5 Water Temperature Fault Test 6-2

6.6 Interlock Tests 6-3

6.7 Flame Fault Test 6-3

Para. Subject Page

6.8 Air Flow Fault Test 6-4

6.9 SSOV Proof of Closure Switch 6-4

6.10 Purge Switch Open During

Purge

6.11 Ignition Switch Open During

Ignition

6.12 Safety Pressure Relief Valve

Test

6-5

6-5

6-6

Chapter 7 – MAINTENANCE REQUIREMENTS 7-1

Para. Subject Page

7.1 Maintenance Schedule 7-1

7.2 Ignitor-Injector 7-1

7.3 Flame Detector 7-2

7.4 Combustion Calibration 7-3

7.5 Safety Device Testing 7-3

7.6 Burner Assembly Inspection 7-3

Para. Subject Page

7.7 Condensate Drain Trap 7-4

7.8 Shutting the Boiler Down For An

Extended Period of Time

7.9 Placing The Boiler Back In

Service After A Prolonged

Shutdown

7-6

7-6

Chapter 8 – TROUBLESHOOTING GUIDE 8-1

Para. Subject Page

8.1 Introduction 8-1

Para. Subject Page

ii

Page 5

CONTENTS

Chapter 9 - RS232 COMMUNICATION 9-1

Para. Subject Page

9.1 Introduction 9-1

9-2 RS232 Communication Setup 9-1

APPENDICES

App Subject Page

A Boiler Menu Item Descriptions A-1

B Startup, Status and Fault

Messages

C Temperature Sensor Resistance

Chart

D Indoor/Outdoor Reset Ratio

Charts

E Boiler Default Settings E-1

F Dimensional and Part Drawings F-1

B-1

C-1

D-1

Para. Subject Page

9-3 Menu Processing Utilizing

RS232 Communication

9-4 Data Logging 9-2

App Subject Page

G Piping Drawings G-1

H Wiring Schematics H-1

I Recommended Periodic Testing

Checklist

J Benchmark Control Panel Views J-1

K Recommended Spare Parts K-1

9-1

I-1

WARRANTIES W-1

iii

Page 6

Page 7

FOREWORD

Foreword

The AERCO Benchmark 3.0LN Boiler is a modulating unit. It represents a true industry advance

that meets the needs of today's energy and env ironmental concer ns. Desig ned for application

in any closed loop hydronic system, the Benchmark's modulating capability relates energy input

directly t o f luctuating sy stem loads. T he Benchm ark 3. 0, w ith it s 15: 1 t urn down ratio and

condensing capabilit y, pr ovides ex tremely hig h ef ficiencies and makes it ideally suited for

modern low temperature, as well as, conventional heating systems.

The Benchmark 3.0 operates at inputs ranging from 200,000 BTU/hr. to 3,000,000 BTU/hr. The

output of t he boiler is a f unction of the unit ’s f iring r ate and r eturn w ater t emperature. O utput

ranges from 198,000 BTU/hr. to 2,900,000 BTU/hr., depending on operating conditions.

When installed and oper ated in accor dance w ith t his I nstruction M anual, t he Benchm ark 3. 0

Boiler complies with the NOx emission standards outlined in:

• South Coast Air Quality Management District (SCAQMD), Rule 1146.1

Whether used in sing ular or modular ar rangements, t he Benchmark 3. 0 of fers the maximum

flexibility in v enting with m inimum inst allation space requirements. The Benchmark's advanced

electronics are available in sev eral select able m odes of oper ation of fering t he m ost ef ficient

operating methods and energy management system integration.

For service or parts, contact your local sales representative or AERCO INTERNATIONAL.

NAME:

ORGANIZATION:

ADDRESS:

TELEPHONE:

INSTALLATION DATE: _____________________________________________

A

Page 8

Page 9

SAFETY PRECAUTIONS

CHAPTER 1 SAFETY PRECAUTIONS

1.1 WARNINGS & CAUTIONS

Installers and o perating p ersonnel M UST, at all

times, obs erve al l s afety r egulations. T he

following warnings and cautions are general and

must be gi ven th e s ame attention as s pecific

precautions i ncluded in t hese ins tructions. In

addition to all t he r equirements inc luded in th is

AERCO Ins truction Man ual, th e ins tallation of

units MUST conform with loc al bu ilding codes,

or, in th e absence of local c odes, ANSI Z223.1

(National Fuel Gas Code P ublication No. NF PA-

54). Where ASM E CS D-1 is r equired b y local

jurisdiction, the i nstallation m ust c onform to

CSD-1.

Where appl icable, th e equipment s hall be

installed in a ccordance w ith t he cu rrent

Installation Co de f or G as Bur ning Appliances

and Equipment, CG A B149, an d a pplicable

Provincial regulations for the class; which should

be ca refully f ollowed in all ca ses. Authorities

having j urisdiction s hould be c onsulted before

installations are made.

IMPORTANT

This I nstruction M anual is an int egral

part o f the pr oduct a nd m ust be

maintained in legible condition. It must

be g iven t o t he user b y t he inst aller

and k ept in a sa fe pla ce for future

reference.

WARNINGS!

MUST BE OBSERVED TO PREVENT

SERIOUS INJURY.

WARNING!

BEFORE ATT EMPTING TO PERFORM ANY MAINTENANCE ON THE

UNIT, SHU T OFF AL L G AS AND

ELECTRICAL INPUTS TO THE UNIT.

WARNING!

DO NOT USE MATCHES, CANDLES,

FLAMES, OR OTHER SOURCES O F

IGNITION TO CHECK FO R G AS

LEAKS.

WARNING!

FLUIDS UNDER PRE SSURE MAY

CAUSE I NJURY T O PERSO NNEL

OR DAM AGE TO EQUIPMENT

WHEN RELEASED. BE SURE T O

SHUT O FF ALL I NCOMING AND

OUTGOING W ATER SHUTOFF

VALVES. CAREFULLY DECREASE

ALL T RAPPED PRE SSURES T O

ZERO BEFO RE P ERFORMING

MAINTENANCE.

WARNING!

ELECTRICAL VO LTAGES UP T O

120 VAC MAY BE US ED I N T HIS

EQUIPMENT. T HEREFORE T HE

COVER O N THE UNIT ’S PO WER

BOX ( LOCATED BEHI ND T HE

FRONT PANEL DOO R) M UST BE

INSTALLED AT ALL TIMES, EXCEPT

DURING M AINTENANCE AND

SERVICING.

CAUTIONS!

Must be obser ved t o pr event

equipment da mage or loss o f

operating effectiveness.

CAUTION!

Many soaps used f or gas pipe leak

testing a re co rrosive to me tals. The

piping must

clean water a fter leak checks hav e

been completed.

be r insed t horoughly with

WARNING!

THE EX HAUST VENT PIPE OF THE

UNIT OPERATES UNDER A

POSITIVE PRESSURE AND T HEREFORE MUST BE C OMPLETELY

SEALED T O PREVENT LEAKAG E

OF COMBUSTION PRODUCTS INTO

LIVING SPACES.

CAUTION!

DO NOT use this boiler if any part has

been under w ater. Cal l a q ualified

service t echnician t o inspect and

replace any par t that ha s been under

water.

1-1

Page 10

SAFETY PRECAUTIONS

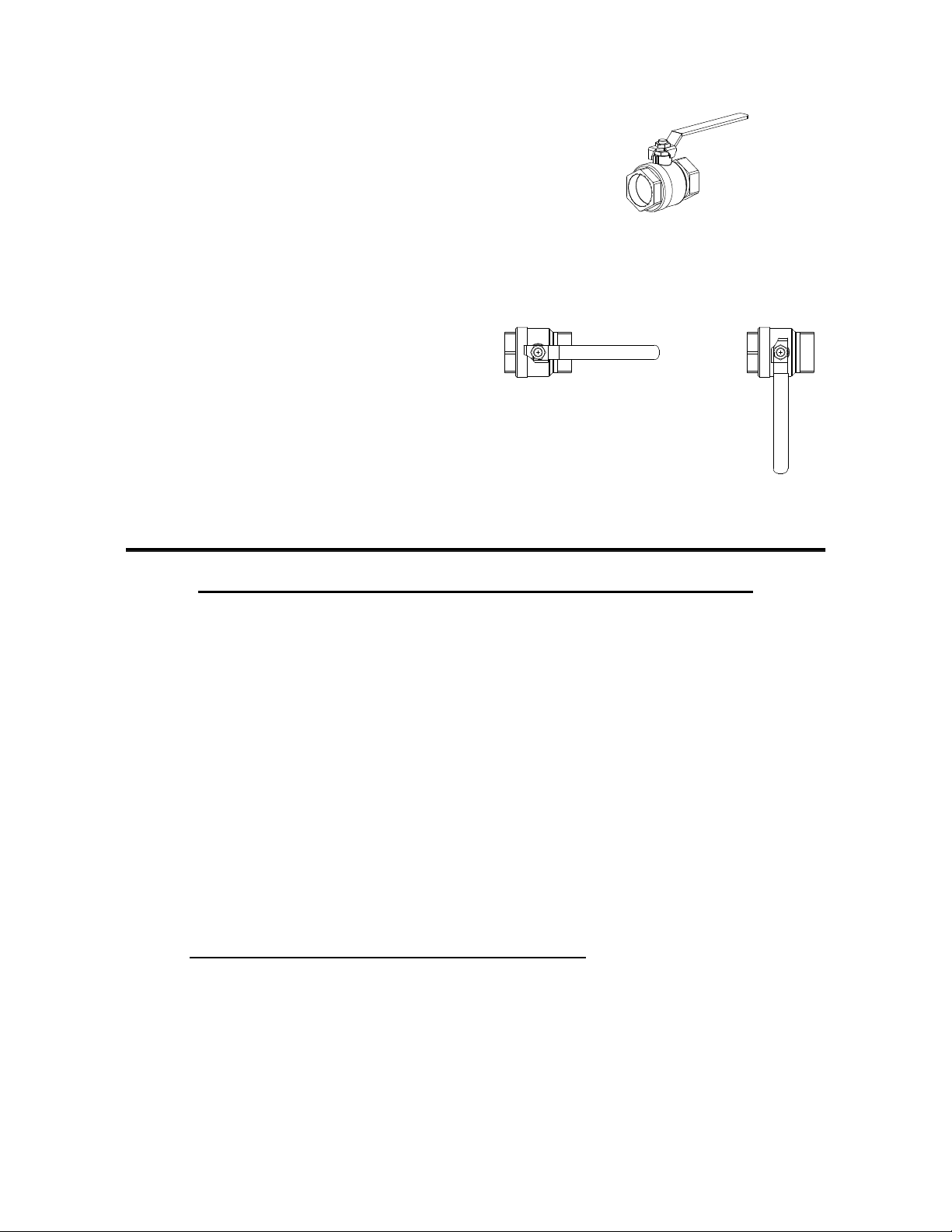

1.2 EMERGENCY SHUTDOWN

If over heating occurs or th e gas s upply f ails to

shut of f, c lose the m anual g as s hutoff val ve

(Figure 1-1) located external to the unit.

IMPORTANT

The Ins taller m ust identif y and indicate

the loc ation of the e mergency s hutdown

manual gas valve to operating personnel.

MANUAL GAS SHUTOFF VALVE

VALVE OPEN

VALVE CLOSED

1.3 PROLONGED SHUTDOWN

After pr olonged s hutdown, it is r ecommended

that the startup procedures in Chapter 4 and the

safety device test pr ocedures in C hapter 6 of

this m anual be performed, to ver ify a ll s ystemoperating parameters. If there is an emergency,

turn of f the elec trical p ower s upply to th e

AERCO b oiler a nd c lose t he m anual g as v alve

located ups tream the unit . T he ins taller m ust

identify the emergency shut-off device.

Figure 1-1

Manual Gas Shutoff Valve

IMPORTANT – FOR MASSACHUSETTS INSTALLATIONS ONLY

Boiler Ins tallations within t he Com monwealth of Ma ssachusetts must c onform to the f ollowing

requirements:

• Boiler must be installed by a plumber or a gas fitter who is licensed within the Commonwealth of

Massachusetts.

• Prior to u nit operation, the c omplete gas train and a ll connections must be lea k tested using a

non-corrosive soap.

• If a gl ycol s olution is us ed as anti- freeze protection, a b ackflow pr eventer must be ins talled

upstream of the Fill/Makeup Valve.

• The vent termination must be located a minimum of 4 feet above grade level.

• If side-wall venting is used, the installation must conform to the following requirements extracted

from 248 CMR 5.08 (2):

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or

structure used in whole or in part for residential purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet above

finished grade in the area of the venting, including but not limited to decks and porches, the following

requirements shall be satisfied:

1-2

1. INSTALLATION OF CARBON MONOXIDE DETECTORS

side wall horizontal vented gas fueled equipment, the installing plumber or gasfitter shall observe

that a hard wired carbon monoxide detector with an alarm and battery back-up is installed on the

floor level where the gas equipment is to be installed. In addition, the installing plumber or

gasfitter shall observe that a battery operated or hard wired carbon monoxide detector with an

alarm is installed on each additional level of the dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to

secure the services of qualified licensed professionals for the installation of hard wired carbon

monoxide detectors.

. At the time of installation of the

Page 11

Extracted Information From 248 CMR 5.08 (2) – Continued

a. In the event that the side wall horizontally vented gas fueled equipment is installed in

a crawl space or an attic, the hard wired carbon monoxide detector with alarm and

battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of

completion of installation, the owner shall have a period of thirty (30) days to comply with

the above requirements; provided, however, that during said thirty (30) day period, a

battery operated carbon monoxide detector with an alarm shall be installed.

SAFETY PRECAUTIONS

2. APPROVED CARBON MONOXIDE DETECTORS.

required in accordance with the above provisions shall comply with NFPA 720 and be ANSI/UL

2034 listed and IAS certified.

3. SIGNAGE

of the building at a minimum height of eight (8) feet above grade directly in line with the exhaust

vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign

shall read, in print size no less than one-half (1/2) inch in size, "GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION

equipment shall not approve the installation unless, upon inspection, the inspector observes

carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR

5.08(2)(a)1 through 4.

(b) EXEMPTIONS

1. The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in the

most current edition of NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or

structure separate from the dwelling, building or structure used in whole or in part for residential

purposes.

(c) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED.

the manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting

system design or venting system components with the equipment, the instructions provided by the

manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system

components; and

2. A complete parts list for the venting system design or venting system.

. A metal or plastic identification plate shall be permanently mounted to the exterior

. The state or local gas inspector of the side wall horizontally vented gas fueled

: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

Each carbon monoxide detector as

When

(d) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a Product Approved side wall horizontally vented gas fueled equipment does

not provide the parts for venting the flue gases, but identifies "special venting systems", the following

requirements shall be satisfied by the manufacturer:

1. The identification of each "special venting system" shall include the listing of either the

website, phone number or manufacturer’s address where the venting system installation

instructions can be obtained, and

2. The "special venting systems" shall be Product Approved by the Board, and the instructions

for that system shall include a parts list and detailed installation instructions.

(e) A copy of all installation instructions for the Product Approved side wall horizontally vented gas fueled

equipment and all the venting instructions, parts lists and/or design instructions for the venting system

shall remain with the appliance or equipment at the completion of the installation.

_______________________________ [End of Extracted Information From 248 CMR 5.08 (2)]

1-3

Page 12

Page 13

INSTALLATION

CHAPTER 2 INSTALLATION

2.1 INTRODUCTION

This Chapt er pr ovides t he d escriptions a nd

procedures nec essary t o unpack, ins pect an d

install th e AERCO Benchmark 3.0 Boi ler. Br ief

descriptions are also provided for each available

mode of oper ation. Det ailed procedures f or

implementing th ese m odes ar e pr ovided in

Chapter 5.

2.2 RECEIVING THE UNIT

Each Benchmark 3.0 S ystem is s hipped as a

single c rated unit. T he s hipping weight is

approximately 2,170 pounds. T he un it m ust be

moved w ith the pr oper rigging equ ipment for

safety and to avoid equipment damage. The unit

should b e c ompletely inspected f or e vidence of

shipping damage and shipment completeness at

the t ime of r eceipt f rom the c arrier a nd before

the bill of lading is signed.

NOTE

AERCO is no t r esponsible f or los t or

damaged freight.

Each u nit has a T ip-N-Tell indicator on th e

outside of the crate. This indicates if the unit has

been t urned on its s ide d uring s hipment. If the

Tip-N-Tell indicator is tripped, do not sign for the

shipment. Not e th e information o n t he c arrier’s

paperwork and r equest a f reight c laim and

inspection b y a c laims adj uster bef ore

proceeding. A ny other v isual d amage to t he

packaging m aterials s hould als o be m ade c lear

to the delivering carrier.

2.3 UNPACKING

Carefully unpack the unit tak ing c are not to

damage the un it enclosure when c utting away

packaging materials

• Pr essure/Temperature Gauge

• Spar e Ignitor-Injector

• Spare Flame Detector

• ASME Pressure Relief Valve

• Condensate Drain Trap & Adapter `

• 2” Gas Supply Shutoff Valve

When or dered, o ptional accessories may be

packed separately, pac ked with in the boiler

shipping c ontainer, or m ay be i nstalled on th e

boiler. A ny s tandard or opti onal ac cessories

shipped loose should be identified and stored in

a safe place until ready for installation or use.

2.4 SITE PREPARATION.

Ensure t hat t he s ite s elected f or ins tallation of

the Benchmark 3.0 Boiler includes:

• Access to AC Inp ut Po wer corresponding to

the or dered po wer c onfiguration. T he

available power configurations are:

• 208 VAC, 3-Phase, 60 Hz @ 20 A

• 460 VAC, 3-Phase, 60 Hz @ 15 A

• Access to Natur al G as line at a m inimum

static pressure of 3.5” W.C.(FM) or 4.0” W.C.

(IRI). M aximum static p ressure must n ot

exceed 2 psi.

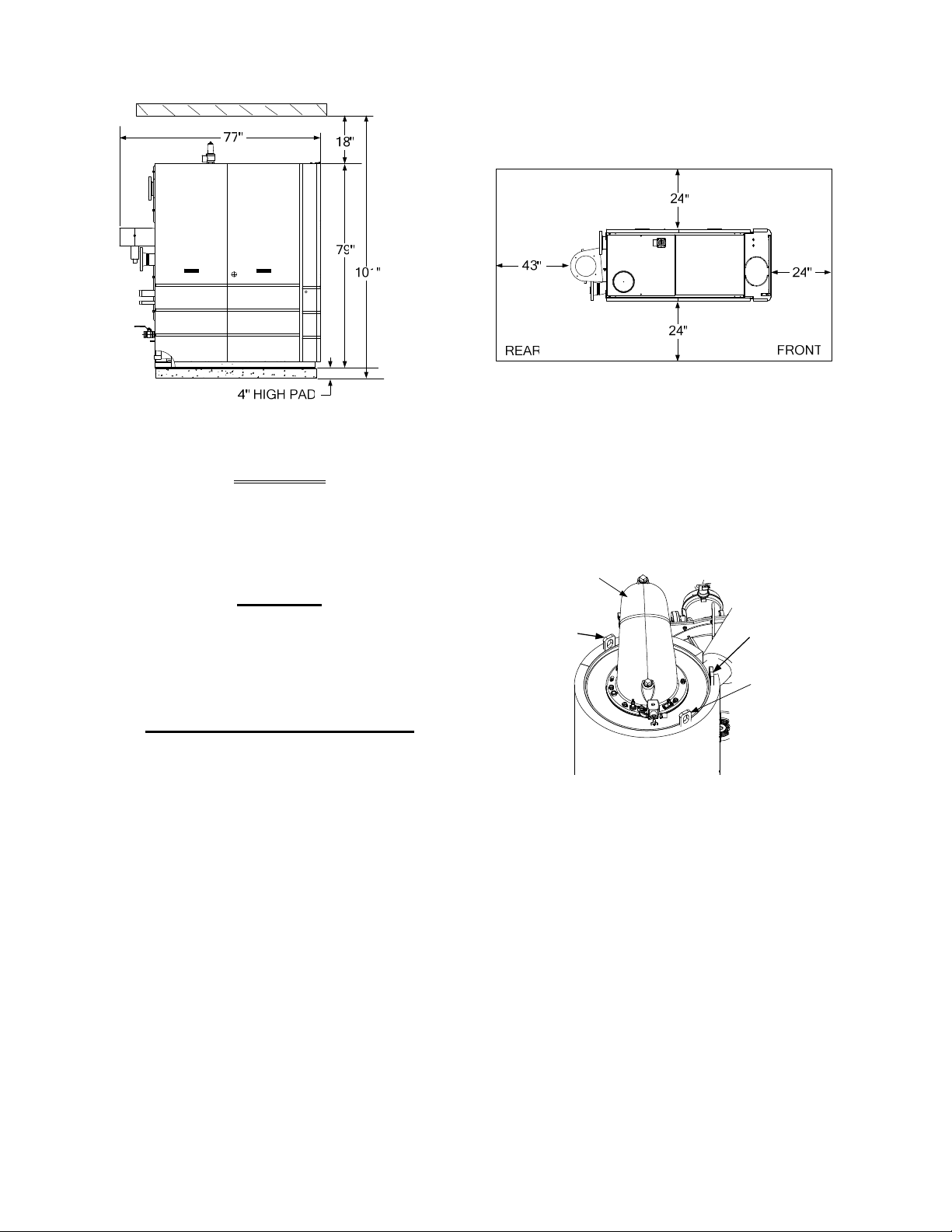

2.4.1 Installation Clearances

The unit m ust be i nstalled with t he prescribed

clearances f or s ervice as shown in F igure 2-1.

The minimum

AERCO, ar e l isted below. Ho wever, if Loc al

Building Cod es r equire a dditional c learances,

these c odes s hall s upersede A ERCO’s

requirements. Mi nimum ac ceptable c learances

required are:

clearance dimensions, required by

A close inspection of the unit should be m ade to

ensure that there is no e vidence of damage not

indicated by the Tip-N-Tell indicator. The freight

carrier s hould b e not ified im mediately if an y

damage is detected.

The f ollowing accessories c ome s tandard with

each un it and ar e eit her pack ed s eparately

within the unit’s packing container or are factory

installed on the boiler:

• Sid es: 24 inches

• Front : 24 inches

• Rear : 43 inches

• T op: 18 inches

All gas piping, water piping and electrical conduit

or c able m ust be ar ranged s o th at t hey d o not

interfere with the r emoval of an y panels, or

inhibit service or maintenance of the unit.

2-1

Page 14

INSTALLATION

Figure 2-1 Benchmark 3.0 Boiler Clearances

WARNING

KEEP T HE UNIT AREA CLEAR AND

FREE FRO M ALL C OMBUSTIBLE

MATERIALS AND FLAMMABLE

VAPORS OR LIQUIDS

.

CAUTION

While pac kaged in the shipping

container, the boiler m ust be m oved

by p allet ja ck o r forklift from th e

FRONT ONLY.

FOR MASSACHUSETTS ONLY

For M assachusetts i nstallations, th e

boiler m ust be ins talled by a plum ber

or gas fitter who is licensed within the

Commonwealth of M assachusetts. I n

addition, t he inst allation m ust comply

with all r equirements specif ied in

Chapter 1 (Safety Precautions), pages

1-2 & 1-3.

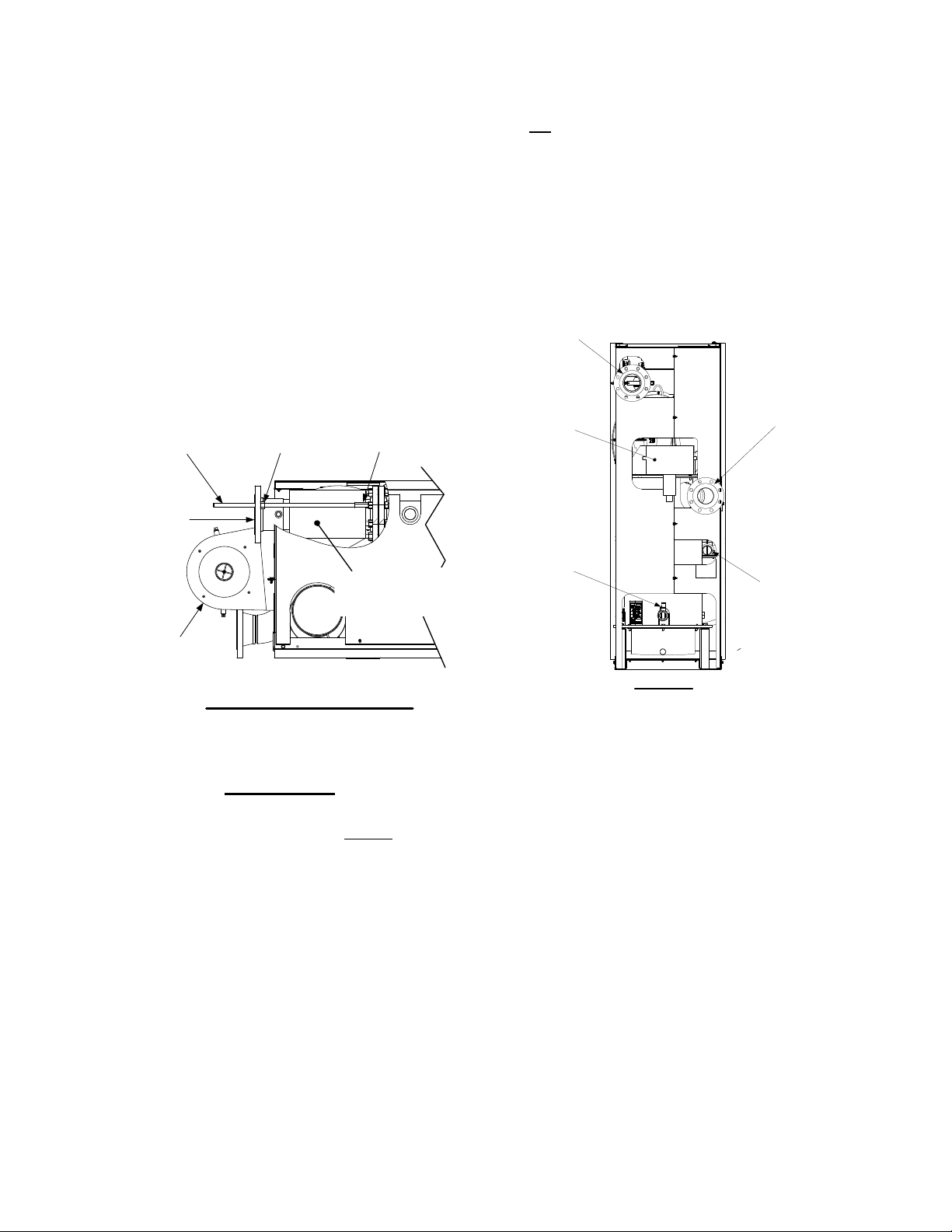

2.4.2 Setting the Unit

The unit m ust be ins talled on a 4 inc h to 6 inc h

housekeeping pad to ensure proper condensate

drainage. If anc horing th e unit, r efer to the

dimensional dr awings in A ppendix F for anchor

locations. A total of 3 lifting tabs are provided at

the top of the primary heat exchanger as shown

in F igure 2- 2. Ho wever, USE O NLY T ABS 1

AND 2 SHOWN IN FIGURE 2-2 TO MOVE THE

ENTIRE UNIT . T abs 1 and 3 ar e us ed o nly

when r emoving or r eplacing the unit’s pr imary

heat exchanger. Rem ove the f ront t op p anel

from the unit to provide access to the lifting tabs.

2-2

Remove the four (4) lag screws securing the unit

to the s hipping skid. Lift the unit off the s hipping

skid and pos ition it on t he 4 inc h t o 6 inc h

housekeeping c oncrete p ad ( required) in t he

desired location.

BURNER

ASSEMBLY

LIFTING

TAB 1

PRIMARY HEAT

EXCHANGER

LIFTING

TAB 2

LIFTING

TAB 3

Figure 2-2

Lifting Lug Locations

In m ultiple unit installations, it is important to

plan the pos ition of eac h unit i n ad vance.

Sufficient s pace f or pi ping c onnections a nd

future s ervice/maintenance r equirements must

also be taken into consideration. All piping must

include ample provisions for expansion.

If ins talling a Com bination Control Pa nel ( CCP)

system, it is important to identify th e

Combination Mode Boilers in advance and place

them in the pr oper ph ysical loc ation. Ref er to

Chapter 5 f or information o n Combination Mode

Boilers.

Page 15

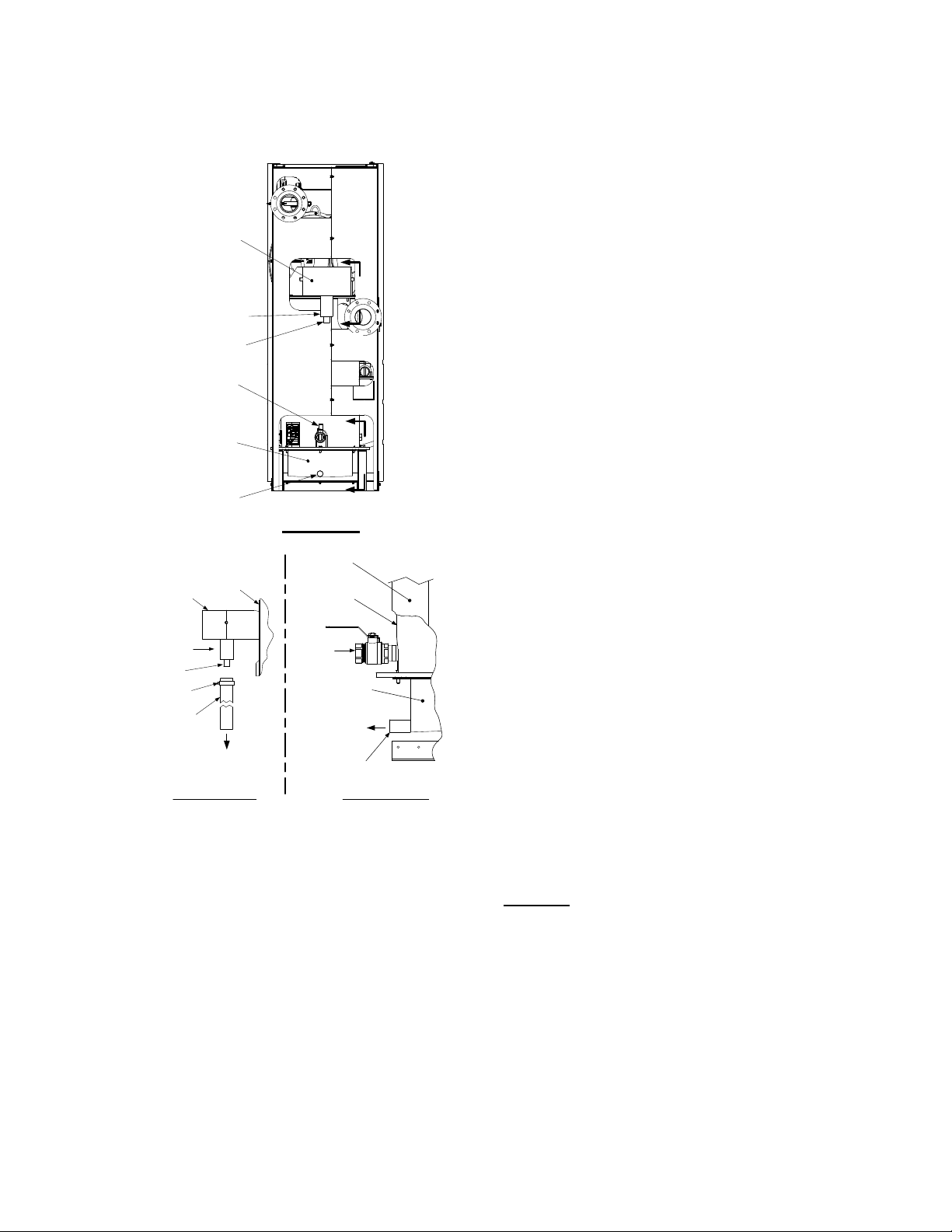

INSTALLATION

5

Y

2.4.3 Removal of Support Rod

Prior to ins tallation of w ater supply a nd return

piping, the 24” threaded rod shown in Figure 2-3

must be r emoved. T his r od is installed pr ior to

shipment from the f actory to prevent damage t o

the ins ulated m etal f lex h ose on the hot water

supply outlet of the b oiler. In order to install t he

water s upply piping, th is r od m ust be r emoved

as follows:

1. Refer to Figure 2-3 and back off the hex nut

on the outlet side of the flex hose.

2. Next, disconnect the coupling nut from the

flange stud.

3. Completely remove the threaded rod, hex

nut and coupling nut from the boiler.

5/8-11 x 24" LONG

THREADED ROD

OUTLET

FLANGE

5/8-11

HEX NUT

/8-11

COUPLING NUT

INSULATED

FLEX HOSE

(SEE IMPORTANT

NOTE BELOW)

This c an be eas ily accomplished b y r emoving

the top

panel nearest to the front of the unit.

2.5 SUPPLY AND RETURN PIPING

The Benc hmark 3.0 B oiler uti lizes 4” 1 50#

flanges f or the water s ystem s upply a nd r eturn

piping connections. The ph ysical location of the

supply and return piping connections are on the

rear of the unit as shown in Figure 2-4. Refer to

Appendix F, Dr awing A P-A-811 f or ad ditional

dimensional data.

BOILER SUPPL

4" – 150# FLANGED

CONNECTION

BOILER RETURN

EXHAUST

MANIFOLD

SHELL DRAIN

VALVE

4" – 150# FLANGED

CONNECTION

2" GAS INLET

CONNECTION

EXHAUST

MANIFOLD

PARTIAL TOP VIEW - REAR

Figure 2-3

Location of Threaded Support Rod

IMPORTANT

THE IN SULATED F LEX H OSE

SHOWN IN FIG URE 2- 3 M UST

LEVEL O R SLO PING UPWARD AS

IT EXITS THE BOILER. FAILURE TO

PROPERLY PO SITION T HIS HO SE

MAY CAUSE I NEFFECTIVE AI R

ELIMINATION R ESULTING IN E LEVATED T EMPERATURES THAT

COULD CO MPROMISE T HE TOP

HEAD GASKET.

2.4.4 Removal of Strap and Packing

Material From Heat Exchanger

Prior to c onnecting th e ex ternal g as s upply or

electrical po wer to t he unit. the s trap and

packing material m ust be r emoved f rom the top

of the primary he at exchanger. T his m aterial is

located i n the area of the ig nitor-injector an d

staged ignition solenoid on the b urner assembly

BE

REAR VIEW

Figure 2-4

Supply and Return Locations

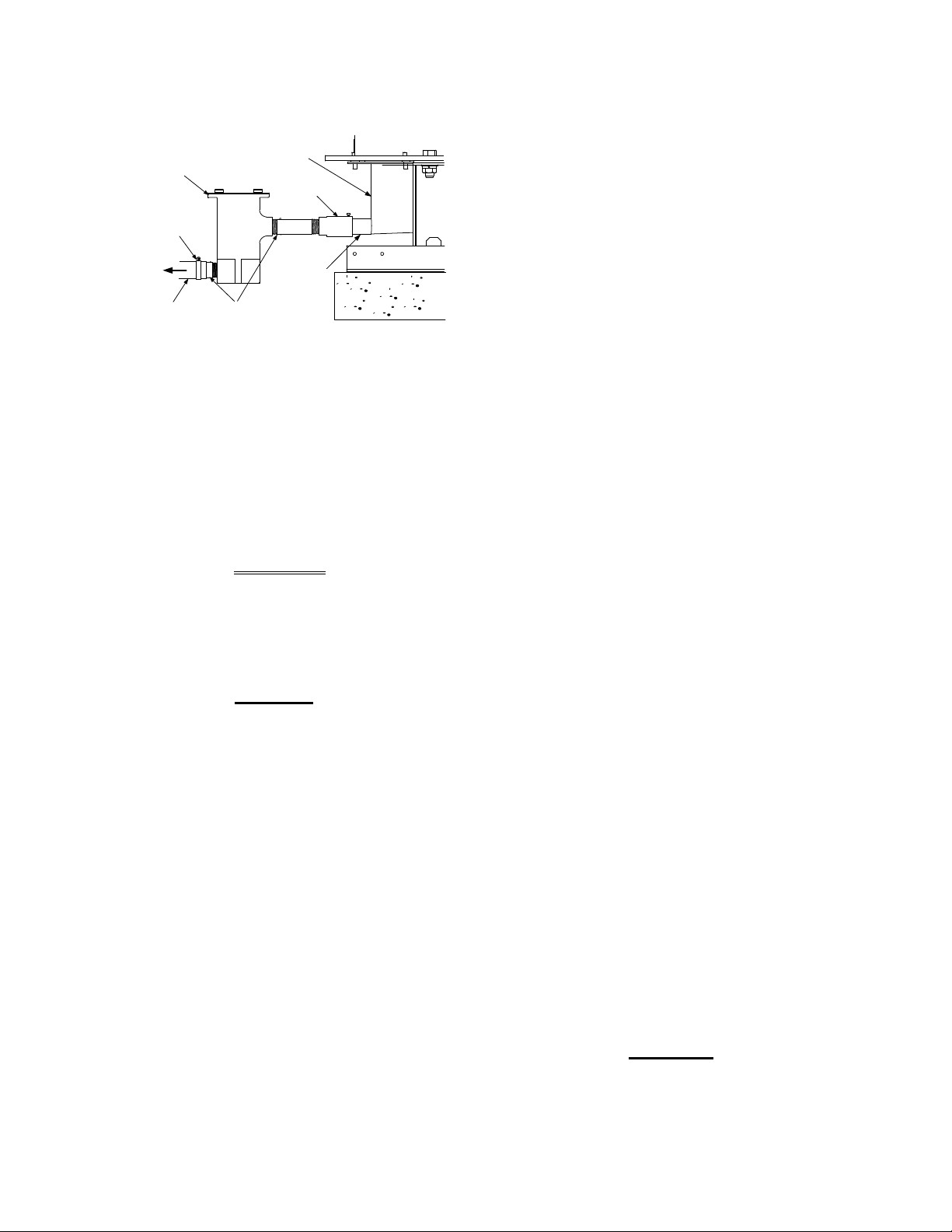

2.6 CONDENSATE DRAINS

The Benc hmark 3.0 Boi ler is d esigned t o

condense water vapor f rom the f lue pr oducts.

Therefore, the ins tallation must have pr ovisions

for suitable condensate drainage or collection.

Two condensate drain connections are provided

on th e r ear of the u nit as shown i n F igure 2- 5.

One dr ain connection is located o n the ex haust

manifold and th e oth er is loc ated on th e

connecting manifold.

The drain at th e bottom of the ex haust manifold

also i ncludes a c ondensate tr ap c ontaining a

float assembly. When condensate collects in the

exhaust m anifold, th e f loat r ises, ther eby

allowing i t to dis charge thr ough t he dr ain

opening. T he dr ain p ipe loc ated on t he

connecting m anifold m ust be c onnected to a

second c ondensate tr ap whic h is pac ked

separately within the unit’s shipping container.

2-3

Page 16

INSTALLATION

The pr ocedures to install and c onnect b oth of

the c ondensate drains ar e pr ovided i n

paragraphs 2.6.1 and 2.6.2.

EXHAUST

MANIFOLD

CONDENSATE

TRAP

DRAIN

SHELL DRAIN

VALVE

A

A

B

CONNECTING

MANIFOLD

EXHAUST

MANIFOLD

DRAIN

FRAME

REAR VIEW

UNIT

UNIT

FRAME

SHELL

B

2.6.2 Connecting Manifold Condensate

Drain

The c onnecting m anifold drain pi pe s hown i n

Figure 2-5, View B – B m ust be c onnected to a

separate c ondensate drain tr ap ex ternal t o th e

unit. T his c ondensate tr ap ( part n o. 24060) is

supplied w ith the un it along w ith a trap adapter

and a 3/4” NPT x 5” long n ipple. Refer to Figure

2-6 and install the trap as follows:

NOTE

The c ondensate tr ap d escribed in the

following s teps c an be installed o n t he

floor behind the unit as shown in Figure 2-

6. Ensure that the condensate trap inlet is

level with or be low t he c onnecting

manifold drain pipe. Ensure that the outlet

hose f rom the tr ap s lopes awa y ( down)

from the trap.

1. Apply Teflon tape to the threads of the 3/4” x

5” long nipple provided with the boiler.

2. Attach t he 3/4” N PT nip ple b etween th e

condensate trap inl et and the tr ap ada ptor

(Figure 2-6).

3. Attach another 3/4” NPT nipple (not supplied) to the condensate trap outlet on the

lower part of the trap.

CONDENSATE

TRAP

DRAIN

HOSE

CLAMP

1" I.D.

HOSE

VIEW “A - A”

TO FLOOR

DRAIN

DRAIN

VALVE

CONNECTING

MANIFOLD

TO

CONDENSATE

TRAP

CONDENSATE

DRAIN PIPE

VIEW “B - B”

Figure 2-5

Condensate Drain Connection Location

2.6.1 Exhaust Manifold Condensate

Drain

Refer to F igure 2- 5, V iew A – A a nd install as

follows:

1. Connect a length of 1 inch I.D. hose (part no.

91030) to the drain on the exhaust manifold

and secure it in place with a hose clamp.

2. Route the hose to a nearby floor drain.

4. Connect the condensate trap and adaptor to

the connecting manifold drain pipe. Position

the trap so it is level and then tighten the

thumb screw on the adaptor.

5. Place a suitable support under the

condensate trap to maintain the trap in the

level position.

6. Connect a length of 1” I.D. polypropylene hose

to the outlet side of the condensate trap and

route it to a nearby floor drain.

If desired, a Tee fitting may be used to connect the

two drain ho ses from the exhaust m anifold and the

outlet side

of the of the condensate trap attached to

the connecting manifold.

If a floor drain is n ot available, a condensate pump

can be u sed to r emove the condensate to drain.

The m aximum co ndensate flow r ate i s 20 GPH.

The condensate dr ain t rap, a ssociated fittings a nd

drain lines m ust be removable fo r routine

maintenance.

2-4

Page 17

INSTALLATION

CONNECTING

CONDENSATE

TRAP

CLAMP

TO

FLOOR

DRAIN

1" I.D.

HOSE

MANIFOLD

3/4" NPT

NIPPLES

ADAPTOR

DRAIN

PIPE

Figure 2-6

Condensate Trap Installation

2.7 GAS SUPPLY PIPING

The AERCO Benchmark 3.0 Gas Components

and S upply Des ign G uide, G F-3030 m ust be

consulted prior to designing or installing any gas

supply piping.

WARNING

NEVER US E MATCHES, CANDLES,

FLAMES O R OT HER S OURCES O F

IGNITION TO CHECK FO R G AS

LEAKS

Many soaps used f or gas pipe leak

testing are corrosive to metals. There-

fore, piping must be rinsed thoroughly

with clean water af ter leak chec ks

have been completed.

All gas piping must be ar ranged so that it

does not i nterfere with r emoval of an y

covers, in hibit s ervice/maintenance, or

restrict ac cess bet ween the unit a nd

walls, or another unit.

A 2 inch gas inlet c onnection is l ocated o n th e

rear of the unit as shown in Figure 2-4.

Prior to i nstallation, al l p ipes s hould be d eburred and internally cleared of any scale, metal

chips or oth er f oreign particles. Do Not install

any f lexible c onnectors or unap proved gas

fittings. Piping must be supported from the f loor,

ceiling or walls only and m ust not be s upported

by the unit.

.

CAUTION

NOTE

A s uitable p iping c ompound, appr oved f or us e

with natur al gas , should b e used. An y excess

must be wipe d of f to prevent c logging of

components.

To avoid unit damage when pressure testing gas

piping, is olate the unit f rom the gas s upply

piping. At no t ime s hould the g as pr essure

applied to th e un it ex ceed 2 ps i. Leak tes t al l

external p iping th oroughly us ing a s oap a nd

water s olution or s uitable equivalent. T he g as

piping used must meet all applicable codes.

2.7.1 Gas Supply Specification

The gas s upply input s pecifications to the unit

for Natural Gas are as follows:

The m aximum static pr essure to th e unit m ust

not exceed 2 psi. The gas supply pressure to the

unit m ust be of s ufficient c apacity to provide

3000 c fh whi le m aintaining the gas pr essure at

3.5” W.C. for FM or 4.0” for IRI gas trains.

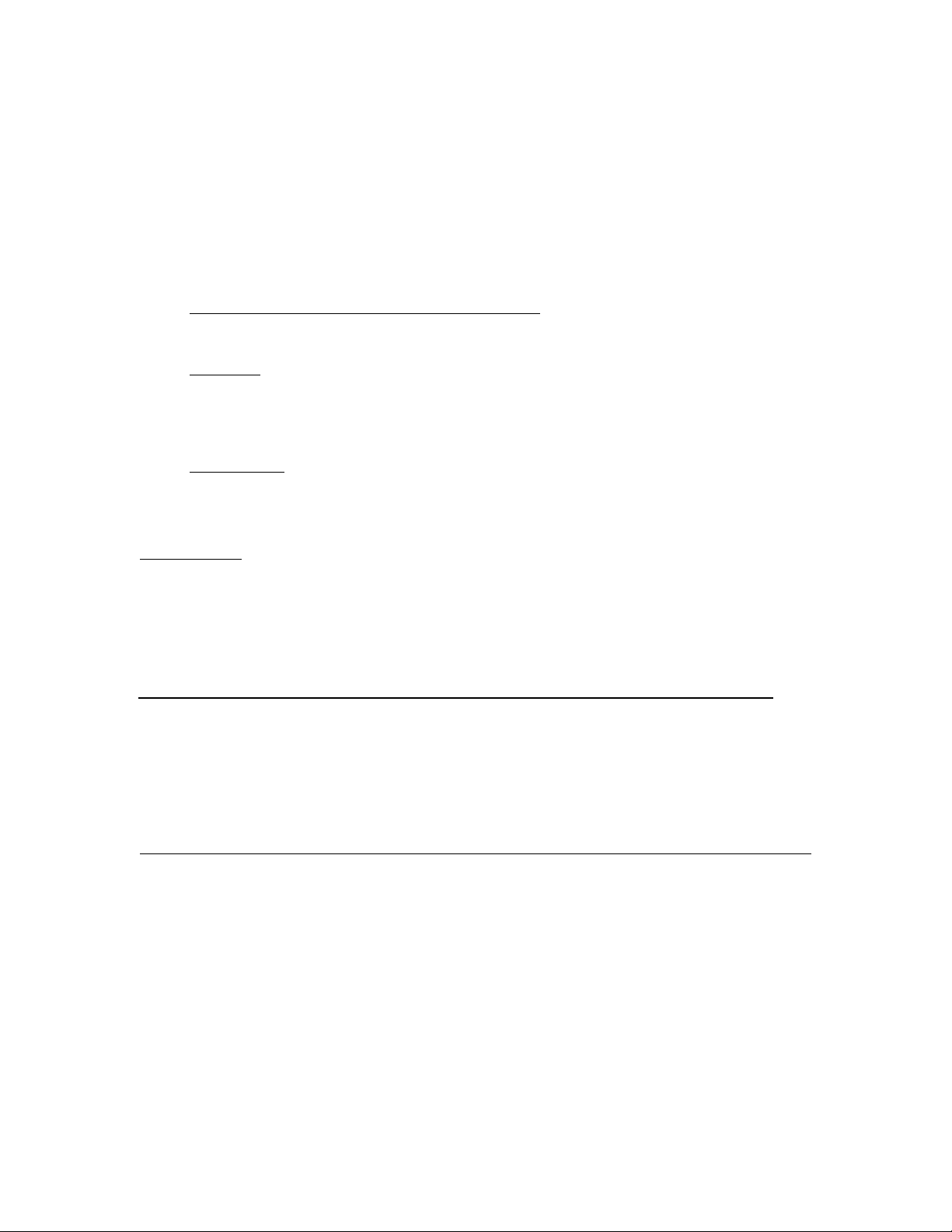

2.7.2 Manual Gas Shutoff Valve

A manual shut-off valve must be ins talled in the

gas supply line upstream of the Boiler as shown

in Figure 2-7. Maximum allowable gas pressure

to the Boiler is 2 psi

NOTE

Paragraph 2.7. 3 applies onl y to bo lier

installations with in t he Co mmonwealth of

Massachusetts.

2.7.3 External Gas Supply Regulator

For Mas sachusetts installations, a m andatory

external gas supply regulator must be positioned

as s hown i n F igure 2- 7. T he gas s upply

regulator m ust be pr operly ve nted to out doors.

Consult th e l ocal gas uti lity f or det ailed

requirements c oncerning ve nting of the th e

supply gas regulator.

NOTE

The external regulator must be capable of

regulating 3, 00,000 BTU/HR of natur al

gas while m aintaining a g as pr essure to

the boiler of 3.5” W.C. for FM or 4.0” W.C.

for IRI gas trains.

CAUTION

A lock -up st yle r egulator M UST be

used w hen g as supply pr essure w ill

exceed 14” W.C.

2-5

Page 18

INSTALLATION

2" MANUAL

SHUTOFF

VALVE

NATURAL

GAS

SUPPLY

TERMINAL BLOCK

MANDATORY

REGULATOR FOR

MASSACHUSSETTS

INSTALLATIONS ONLY

DIRT

TRAP

Figure 2-7

Manual Gas Shut-Off Valve Location

2.7.4 IRI Gas Train Kit

The IRI gas tr ain is a n opti onal g as tr ain

configuration which is required in some areas for

code c ompliance or f or ins urance purposes.

The IRI gas train is factory pr e-piped and wired.

See Appendix F, Drawing AP-A-803 for details.

2.8 AC ELECTRICAL POWER WIRING

The AERCO Be nchmark 3.0 E lectrical Po wer

Wiring Guide, GF-3060, must be c onsulted prior

to c onnecting a ny AC po wer wiring t o th e u nit.

External AC po wer connections are made to the

unit inside the Power Box on the f ront pa nel of

the u nit. Remove the f ront door of the unit to

access the P ower Box m ounted directly above

the Co ntrol Box . Loosen the f our Po wer B ox

cover scre ws a nd re move co ver t o a ccess t he

AC t erminal c onnections i nside the P ower Box

(Figure 2-8).

NOTE

All elec trical c onduit a nd hardware m ust

be ins talled s o that it do es not inter fere

with the removal of any unit covers, inhibit

service/maintenance, or pr event ac cess

between the unit and w alls or ano ther

unit.

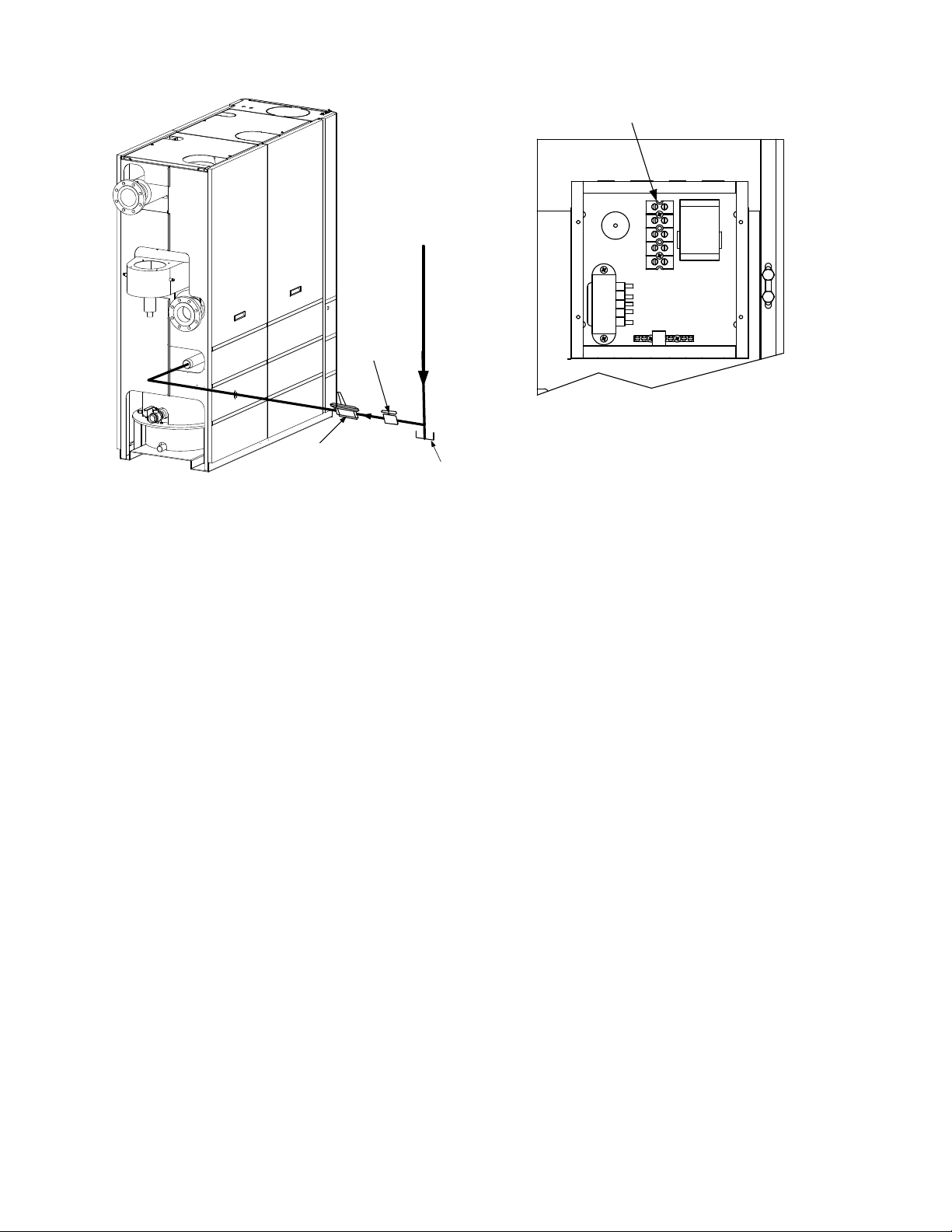

UPPER RIGHT CORNER OF FRONT PANEL

Figure 2-8

AC Input Terminal Block Location

2.8.1 Electrical Power Requirements

The AERCO Be nchmark 3 .0 Bo iler is ava ilable

in two different AC power configurations:

• 208 VAC/3-Phase/60 @20 amps

• 460 VAC/3-Phase/60 Hz @ 15 amps

Each of the power configurations utilize a Power

Box with a t erminal b lock that m atches the

configuration ordered. The two different terminal

block configurations are shown in F igure 2-9. A

wiring d iagram s howing t he r equired AC po wer

connections is provided on the front cover of the

Power Box.

Each B enchmark 3.0 Boil er must be c onnected

to a d edicated el ectrical circuit. NO O THER

DEVICES SHO ULD B E O N THE SAM E

ELECTRICAL CIRCU IT AS T HE BENCHMARK

BOILER. A m eans f or dis connecting AC p ower

from the unit ( such as a s ervice switch) must be

installed n ear th e un it f or normal oper ation and

maintenance. All e lectrical c onnections s hould

be m ade i n ac cordance with th e Nat ional

Electrical Co de and/or with an y a pplicable local

codes.

For elec trical p ower wiring diagr ams, s ee the

AERCO Benchmark 3.0 El ectrical Power Wiring

Guide, (GF-3060).

2-6

Page 19

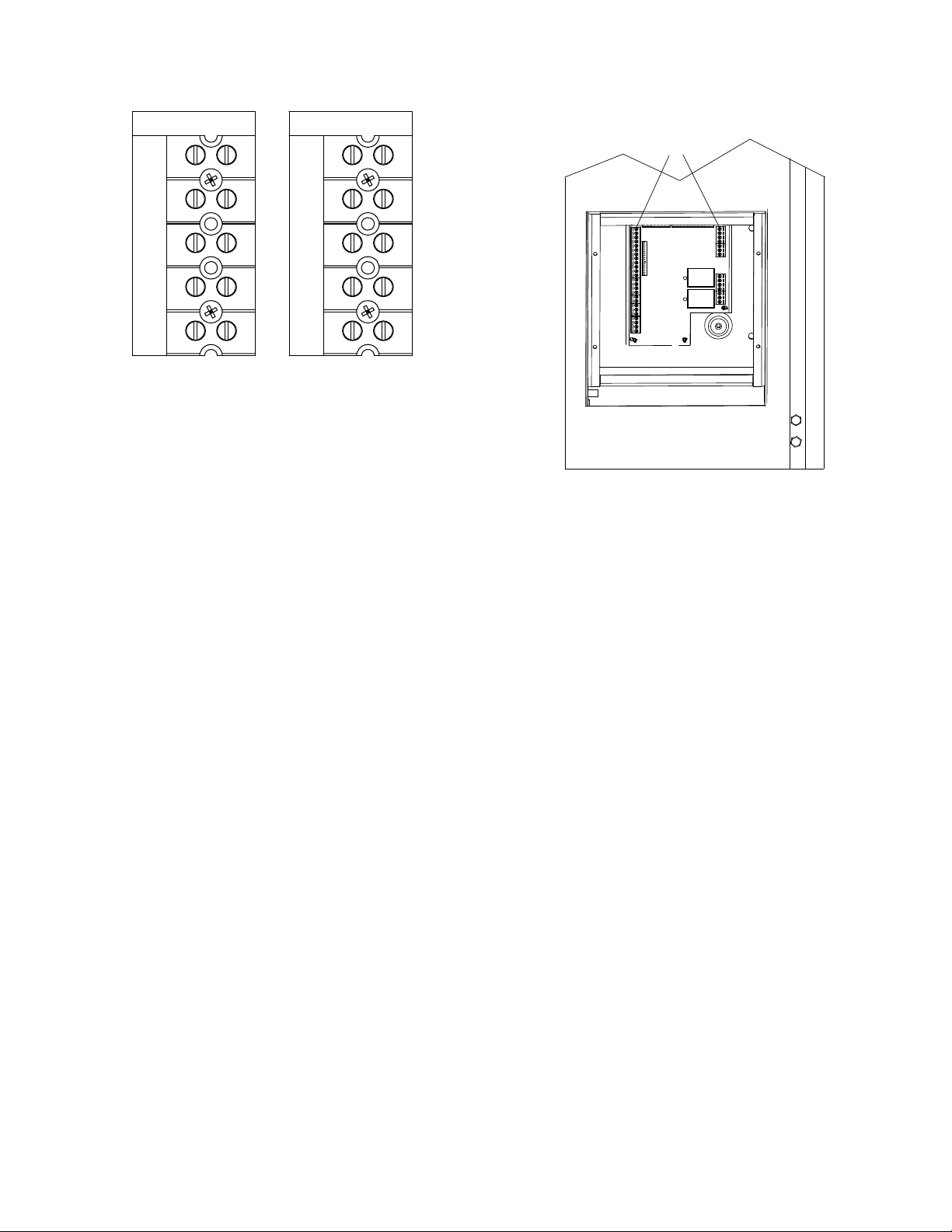

208 VAC, 3 PHASE

GND

NEU

460 VAC, 3 PHASE

GND

INSTALLATION

TERMINAL

STRIPS

L3

L2

L1

208 VAC, 3 Phase

L3

L2

L1

460 VAC, 3 Phase

Figure 2-9

AC Terminal Block Configurations

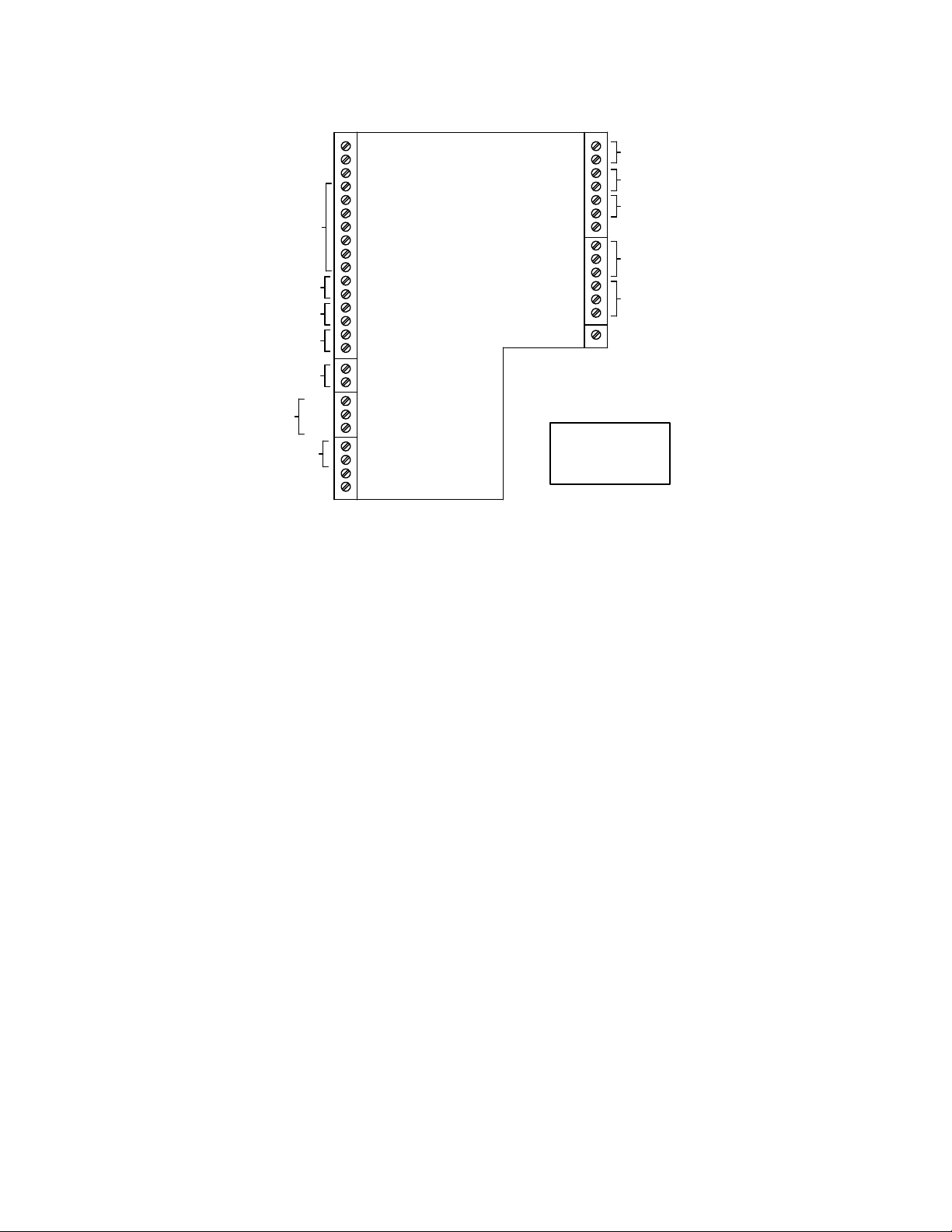

2.9 MODES OF OPERATION AND FIELD

CONTROL WIRING

The Benchmark 3.0 Boiler is available in several

different modes of operation. While each unit is

factory c onfigured an d wired f or its intend ed

mode, s ome addit ional f ield wir ing m ay be

required to c omplete the in stallation. This wiring

is t ypically c onnected t o t he I nput/Output ( I/O)

Box located on the lower portion of the unit front

panel ( Figure 2- 10) beh ind the r emovable f ront

door.

To a ccess t he I /O B ox t erminal st rips shown in

Figure 2-10, loosen t he f our c over s crews an d

remove the c over. A ll f ield wiring is ins talled

from the r ear of the pa nel b y r outing th e wires

through one of the four bushings provided.

LOWER RIGHT CORNER

OF FRONT PANEL

Figure 2-10.

Input/Output (I/O) Box Location

Refer to the wiring d iagram pr ovided on t he

cover of the I/O Box (Figure 2-11) when making

all wiring connections.

Brief des criptions of eac h mode of oper ation,

and the ir wiring r equirements, ar e pr ovided in

the f ollowing par agraphs. Additional information

concerning field wiring is provided in paragraphs

2.9.1 thr ough 2.9. 9. Ref er to Chapt er 5 f or

detailed i nformation on t he av ailable m odes of

operation

2-7

Page 20

INSTALLATION

OUTDOOR SENSOR IN

SENSOR COMMON

(AIR) AUX SENSOR IN

NOT USED

SHIELD

0 – 10V

AGND

+

+

-

+

-

+

G

-

ANALOG IN

B.M.S. (PWM) IN

mA OUT

RS-485

COMM.

NOT USED

Figure 2-11. I/O Box Terminal Strip

2.9.1 Constant Setpoint Mode

The Cons tant S etpoint M ode is us ed when it is

desired t o ha ve a f ixed s etpoint t hat d oes not

deviate. No w iring connections, oth er than AC

electrical po wer c onnections, ar e r equired f or

this mode. Ho wever, if desired, fault monitoring

or enable/disable interlock wiring can be utilized

(see paragraphs 2.9.9.1 and 2.9.10).

2.9.2 Indoor/Outdoor Reset Mode

This mode of oper ation i ncreases s upply water

temperature as outdoor temperatures decrease.

An outside air temperature sensor (AERCO Part

No. 122790) is required. T he sensor MUST BE

wired to the I/O Box wiring terminals (see Figure

2-11). Ref er to par agraph 2.10.1 f or add itional

information on ou tside air tem perature s ensor

installation.

2.9.3 Boiler Management System Mode

NOTE

BMS Mo del 16 8 c an utilize eit her p ulse

width m odulation ( PWM) or R S485

Modbus s ignaling to t he Boiler. BMS II

Model 5R 5-384 c an u tilize onl y RS 485

signaling to the Boiler.

When us ing an AERCO Boi ler M anagement

System ( BMS), th e f ield wir ing is c onnected

between th e BM S P anel and e ach Bo iler’s I/O

Box ter minal s trip ( Figure 2- 11). T wisted

shielded pair wire f rom 18 to 22 A WG must be

utilized for the connections. The BMS Mode can

2-8

REMOTE INTL'K IN

EXHAUST SWITCH IN

DELAYED INTL'K IN

NOT USED

NC

FAULT RELAY

COM

120 VAC, 5A, RES

NO

NC

AUX RELAY

COM

NO

120 VAC, 5A, RES

NOT USED

RELAY CONTACTS:

120 VAC, 30 VDC

5 AMPS RESISTIVE

DANGER

120 VAC USED

IN THIS BOX

utilize e ither pu lse width modulation ( PWM)

signaling, or RS485 Modbus signaling. For PWM

signaling, c onnections a re m ade f rom the

AERCO B oiler M anagement System to th e

B.M.S. ( PWM) IN ter minals on t he I/O Box

terminal s trip. F or RS 485 Mo dus s ignaling,

connections ar e m ade f rom the BMS t o th e

RS485 COMM terminals on the I/O Box terminal

strip. Polarity must be m aintained and the shield

must be c onnected o nly at th e AERCO BMS.

The boiler end of the shield must be left floating.

For ad ditional i nstructions, r efer to C hapter 5,

paragraph 5.6 in this m anual. Also, refer t o GF108M ( BMS Mod el 1 68) and G F-124 ( BMS I I

Model 5R5-384), BMS -Operations Guides.

2.9.4 Remote Setpoint and Direct Drive

Modes

The Benc hmark 3.0 Boi ler c an ac cept s everal

types of s ignal f ormats f rom an E nergy

Management S ystem ( EMS), Building

Automation S ystem ( BAS) or oth er s ource, to

control e ither the s etpoint ( Remote Setpo int

Mode) or f iring r ate ( Direct Dr ive Mo de) of the

Boiler. These formats are:

• 4 to 20 mA/1 to 5 VDC

• 0 to 20 mA/0 to 5 VDC

• PWM – ( Pulse Width Modulated signal. Se e

para. 2.10.4)

• Network (RS485 Modbus. See para. 2.10.8)

Page 21

INSTALLATION

While it is pos sible to c ontrol a bo iler or boi lers

using one of the previously described modes of

operation, it m ay not be the m ethod best suited

for the appl ication. Prior to s electing o ne of

these m odes of oper ation, it is r ecommended

that y ou consult w ith y our local AER CO

representative or the f actory f or the m ode of

operation th at will work bes t with your

application. F or more inf ormation on wiring th e

4 to 20 mA / 1to 5VDC or the 0 to 20 mA / 0 to 5

VDC, see paragraph 2.9.3.

2.9.5 Combination Mode

NOTE

Only BMS M odel 16 8 c an be ut ilized f or

the Com bination Mode, n ot the B MS II

(Model 5R5-384).

With a Com bination Mode un it, f ield wiring is

between the unit’s I/O Box wiring t erminals, the

CCP (Combination Control Panel), and the BMS

Model 1 68 ( Boiler Ma nagement S ystem). The

wiring m ust be ac complished us ing t wistedshielded pair wire from 18 to 22 A WG. Polar ity

must be m aintained. For further instructions and

wiring di agrams, r efer to the G F-108 Bo iler

Management System O perations Guide and the

CCP-1 data sheet.

2.10 I/O BOX CONNECTIONS

The t ypes of input and output s ignals and

devices to be connected to the I/O Box terminals

shown in F igure 2- 11 a re des cribed i n t he

following paragraphs.

CAUTION

DO NOT make any connections to the

I/O Box t erminals labeled “ NOT

USED”. A ttempting to d o so ma y

cause equipment damage.

2.10.1 OUTDOOR SENSOR IN

An outdoor air temperature sensor (AERCO Part

No. 12 2790) will be r equired pr imarily f or th e

Indoor/Outdoor reset mode of oper ation. It c an

also be used with another mode if it is desired to

use th e o utdoor s ensor e nable/disable f eature.

This f eature a llows the b oiler to be enabled or

disabled based on the outdoor air temperature.

The f actory def ault f or th e out door s ensor is

DISABLED. T o enable the sensor and/or select

an en able/disable o utdoor temperature, s ee the

Configuration menu in Chapter 3.

The outdoor sensor may be wired up to 200 feet

from the boiler. It is connected to the OUTDOOR

SENSOR IN and SENSOR COMMON terminals

in the I/O Box (see Figures 2-10 and 2-11). Wire

the s ensor us ing a t wisted s hielded pair wire

from 18 to 22 A WG. There is no po larity t o

observe when ter minating th ese wires. T he

shield is to be c onnected only t o t he terminals

labeled SHIELD in t he I/O Box. The sensor end

of the shield must be left free and ungrounded.

When mounting th e s ensor, it m ust be loc ated

on t he N orth s ide of th e bu ilding where an

average outs ide air tem perature is ex pected.

The sensor must be shielded from direct sunlight

as wel l as impingement b y the e lements. If a

shield is us ed, it m ust allo w f or f ree air

circulation.

2.10.2 AIR SENSOR IN

The AIR S ENSOR IN is c onnected t o the AUX

SENSOR IN and SENSOR COMMON terminals

on the I /O boar d. T he AI R SEN SOR m easures

the tem perature of the air inp ut to t he Air/Fuel

Valve. T his te mperature r eading is one of the

components us ed t o c alculate t he r otational

speed of the bl ower us ed in the c ombustion

Calibration process (Chapter 4).

The AUX SENSOR IN terminals can be used to

add a n ad ditional temperature s ensor f or

monitoring pur poses. T his in put is always

enabled a nd is a view-only input th at c an be

seen i n th e O perating M enu. T he s ensor m ust

be wired to the AUX SENSOR IN and SENSOR

COMMON t erminals a nd m ust be s imilar to

AERCO BALCO wire sensor Part No. 12449. A

resistance c hart f or this s ensor is pr ovided in

Appendix C.

2.10.3 ANALOG IN

The ANALO G IN + and – ter minals ar e us ed

when an ex ternal s ignal i s us ed t o dr ive t he

firing r ate ( Direct Dr ive Mode) or c hange th e

setpoint (Remote Setpoint Mode) of the Boiler.

Either a 4 to 20 mA /1 to 5 VDC or a 0 to 20 mA

/ 0 to 5 VDC s ignal m ay be us ed to vary t he

setpoint or firing rate. The factory default setting

is for 4 to 20 mA / 1 to 5 V DC, however this may

be changed to 0 to 20 mA / 0 to 5 VDC using the

Configuration Me nu des cribed i n Cha pter 3. If

voltage r ather t han c urrent is s elected as t he

drive s ignal, a DI P s witch must be s et on t he

PMC Board l ocated i nside th e Co ntrol B ox.

Contact the A ERCO f actory f or inf ormation o n

setting DIP switches.

All of the s upplied s ignals must be floating

(ungrounded) signals. Connections between the

signal s ource and the B oiler’s I/O Box must be

made using twisted shielded pair wire from 18 to

2-9

Page 22

INSTALLATION

22 AWG, s uch as Bel den 9 841 ( see

Figure 2-11). Polarity must be m aintained. T he

shield must be connected only at the source end

and m ust be left f loating ( not c onnected) at the

Boiler’s I/O Box.

Regardless of whether voltage or current is used

for the dr ive signal, they are linearly m apped to

a 40°F to 240°F setpoint or a 0% to 100% f iring

rate. No scaling for these signals is provided

2.10.4 B.M.S. (PWM) IN

NOTE

Only BMS Mod el 1 68 c an uti lize P ulse

Width Modulation (PWM), not th e B MS II

(Model 5R5-384).

These ter minals ar e used t o c onnect t he

AERCO Boi ler Ma nagement S ystem ( BMS)

Model 16 8 to the un it. T he BMS Mod el 1 68

utilizes a 12 m illisecond, ON/OFF dut y c ycle.

This duty cycle is Pulse Width Modulated (PWM)

to control firing rate. A 0% firing rate = a 5% ON

pulse and a 100% firing rate = a 95% ON pulse.

2.10.5 SHIELD

The SHIELD terminals are used to terminate any

shields us ed on s ensor wires c onnected to t he

unit. O nly s hields m ust be c onnected t o th ese

terminals.

IMPORTANT

DO NO T USE the m A OUT output to

remotely monitor Setpoint, Outlet Temp or

Fire Rate Out.

2.10.9 EXHAUST SWITCH IN

These ter minals per mit an ex ternal ex haust

switch to be c onnected to the ex haust m anifold

of the bo iler. T he ex haust s witch s hould be a

normally open type switch (such as AERCO Part

No. 123463) that closes (trips) at 500°F.

2.10.10 INTERLOCKS

The unit offers tw o i nterlock c ircuits f or

interfacing with En ergy M anagement Systems

and a uxiliary eq uipment s uch as pum ps or

louvers. These interlocks are called the Remote

Interlock and Dela yed I nterlock ( Figure 2- 11).

The w iring ter minals f or these int erlocks ar e

located i nside th e I/O Box on t he u nit f ront

panel. T he I/O Box c over c ontains a wiring

diagram which shows the terminal strip locations

for thes e inter locks ( REMOTE IN TL’K IN and

DELAYED INT L’K IN). Both interlocks,

described below, are factory wired in the c losed

position.

IMPORTANT

Both th e Rem ote In terlock and Del ayed

Interlock MUST be in the c losed pos ition

to allow the unit to fire.

2.10.10.1 REMOTE INTERLOCK IN

The r emote inter lock c ircuit is pr ovided to

remotely s tart ( enable) an d s top ( disable) th e

Boiler, if des ired. T he c ircuit is labe led

REMOTE INTL’K IN and is located inside the I/O

Box on t he f ront pan el. T he c ircuit is 24 V AC

and is factory pre-wired in the closed (jumpered)

position.

2.10.6 mA OUT

These terminals provide a 4 to 20 m A output to

the VFD (if so equipped) to control the rotational

speed of the blower. This function is enabled in

the Configuration Menu (Chapter 3, Table 3-4).

2.10.7 0 – 10V OUT

These ter minals pr ovide a 0 to 10V o utput to

control t he r otational s peed of the b lower. T his

function is e nabled i n t he Conf iguration Me nu

(Chapter 3, Table 3-4).

2.10.8 RS-485 COMM

These terminals are used for RS-485 MODBUS

serial c ommunication be tween the u nit a nd an

external “Master” such as a Boiler Management

System ( BMS), En ergy Management S ystem

(EMS), Building Automation S ystem ( BAS) or

other suitable device.

2-10

2.10.10.2 DELAYED INT ER LOCK IN

The del ayed interlock is t ypically used i n

conjunction with t he aux iliary r elay described in

paragraph 2. 10. T his inter lock c ircuit is loc ated

in the purge section of the start string. It c an be

connected to t he proving dev ice ( end s witch,

flow s witch etc .) of an aux iliary p iece of

equipment started by the Boiler’s auxiliary relay.

The dela yed i nterlock must be c losed f or the

boiler to fire.

If the delayed interlock is connected to a proving

device that requires time to close (make), a time

delay ( Aux Start O n D ly) that ho lds t he s tart

sequence of the boiler long enough for a proving

switch to make can be programmed. Should the

proving switch not prove within the programmed

time fr ame, the bo iler wi ll shut do wn. T he Aux

Start On Dly c an be programmed from 0 to 120

seconds. T his option is l ocate i n t he

Configuration Menu (Chapter 3, Table 3-4).

Page 23

INSTALLATION

2.10.11 FAULT RELAY

The f ault r elay is a s ingle pol e do uble thr ow

(SPDT) relay ha ving a normally op en and

normally c losed s et of r elay c ontacts that ar e

rated for 5 am ps at 12 0 VAC and 5 amps at 30

VDC. T he r elay e nergizes whe n an y f ault

condition occurs and remains energized until the

fault is c leared an d th e CLE AR button is

depressed. T he f ault r elay c onnections ar e

shown in Figure 2-11.

2.11 AUXILIARY RELAY CONTACTS

Each Bo iler is equ ipped w ith a s ingle po le

double t hrow ( SPDT) r elay th at is ener gized

when th ere is a dem and f or heat and deenergized after the d emand for heat is satisfied.

The relay is provided for t he control of auxiliary

equipment, such as p umps and l ouvers, or c an

be us ed as a Boiler status indictor (firing or not

firing). Its contacts ar e rated for 120 VAC @ 5

amps. Ref er to F igure 2- 11 t o l ocate the AUX

RELAY terminals for wiring connections.

2.12 FLUE GAS VENT INSTAL LATION

The minimum allo wable vent diam eter f or a

single Benchmark 3.0 Boiler is 8 inches.

The AERCO Benchmark Ventin g a nd

Combustion Air G uide, GF-2050, m ust be

consulted bef ore an y f lue gas ven t or in let air

venting is des igned or i nstalled. U/ L l isted,

positive pr essure, watertight v ent m aterials as

specified in AERCO’s G F-2050, m ust be us ed

for safety and code compliance. Since the unit is

capable of discharging low temperature exhaust

gases, h orizontal s ections of the f lue vent

system must be pitc hed bac k to the unit a

minimum of 1/4 inc h per f oot to avoid

condensate po oling a nd allo w f or pr oper

drainage.

The c ombined pr essure dr op of ve nt a nd

combustion air s ystems must not ex ceed 1 40

equivalent feet of 8 inch ducting. Fittings as well

as pipe lengths must be calculated as part of the

equivalent length.

For a n atural draft installation the draft must not

exceed ± 0.25 inch W.C. These factors must be

planned i nto t he vent ins tallation. If the

maximum allowable e quivalent lengths of piping

are ex ceeded, the unit will not oper ate pr operly

or reliably.

For Mas sachusetts boiler ins tallations, t he

Heatfab D ivision of the Se lkirk Cor poration

provides vent s ystems whic h c onform to all

applicable r equirements for ins tallations within

the C ommonwealth of Ma ssachusetts. Con tact

information for this supplier is as follows:

Selkirk Corporation

Heatfab Division

130 Industrial Blvd.

Turners Falls, MA 01376

Phone: 1-800-772-0739

www.heat-fab.com

2.13 COMBUSTION AIR

The AERCO Be nchmark Venting and C ombustion Air G uide, G F-2050 MUST be c onsulted

before any flue or combustion supply air venting

is des igned or im plemented. C ombustion a ir

supply is a d irect r equirement of ANSI 22 3.1,

NFPA-54, and local codes. These codes should

be c onsulted bef ore a p ermanent des ign is

determined.

The c ombustion a ir m ust be f ree of c hlorine,

halogenated h ydrocarbons, or other c hemicals

that c an become hazardous when used in gasfired eq uipment. Com mon s ources of t hese

compounds ar e s wimming poo ls, de greasing

compounds, plastic processing an d refrigerants.

Whenever the environment contains these types

of c hemicals, c ombustion air m ust be s upplied

from a c lean area out doors f or the pr otection

and longevity of the equipment.

The AER CO Benchmark 3.0 Boiler is U L listed

for 100% s ealed c ombustion. It c an als o be

installed us ing r oom air , provided ther e is an

adequate s upply. ( See p aragraph 2.1 3.3 f or

more information concerning sealed combustion

air). If the s ealed c ombustion air op tion is no t

being used, an in let s creen will b e at tached at

the air inlet on the top of the unit

The more c ommon methods of s upplying

combustion air are o utlined b elow. F or m ore

information c oncerning c ombustion air , c onsult

the AERCO B enchmark Ventin g an d

Combustion Air Guide, GF-2050.

2.13.1 Combustion Air From Outside the

Building

Air s upplied f rom outs ide the building m ust be

provided through two permanent openings. Each

opening m ust have a free area of not l ess than

one s quare i nch f or eac h 4000 BTU/H bo iler

input. T he f ree ar ea m ust tak e into ac count

restrictions such as louvers and bird screens.

2-11

Page 24

INSTALLATION

2.13.2 Combustion Air From Inside the

Building

When combustion air is provided from within the

building, it m ust be s upplied thr ough t wo

permanent op enings i n a n int erior wall. Each

opening m ust have a free area of not l ess than

one s quare inc h per 10 00 BTU/H of tota l b oiler

input. The free area must tak e into ac count any

restrictions such as louvers.

2.13.3 Sealed Combustion

The AER CO Benchmark 3.0 Boiler is U L listed

for 100%- sealed c ombustion. F or s ealed

combustion ins tallations, t he s creen on the a ir

inlet duct of the u nit must be removed. The inlet

air duc twork must then be attac hed dir ectly t o

the unit’s air inlet.

In a s ealed c ombustion air app lication, the

combustion air ducting pressure losses must be

taken into ac count when c alculating th e tota l

maximum allo wable v enting r un. See t he

AERCO Be nchmark Venti ng an d Com bustion

Air Guide, GF-2050. When using the boiler in a

sealed c ombustion a ir c onfiguration, each unit

must have a m inimum 8- inch diam eter

connection at the unit.

2.13.4 Temporary Combustion Air

Filtering During Construction

When the AERCO Benchmark 3.0 Boiler is used

to pr ovide he at tem porarily dur ing ongoing

building construction, accumulated drywall dust,

sawdust and similar particles can accumulate in

the un it’s c ombustion a ir i ntake f ilter and b lock

combustion air flow. In th ese situations, AERCO

recommends that a disposable air intake filter be

installed, temporarily, abo ve the bo iler

combustion air inlet.

AERCO recommends that the temporary air filter

be cut from a McMaster-Carr part no. 2 122K315

Polyester Air Filter Rol l Tackfield, 1/2” thick, 16”

wide, or e quivalent. C over the Benchmark 3.0

air in let with the b lue s ide of the f ilter m aterial

facing out ward to hold th e dus t on t he o utside

surface. Max imize th e s urface ar ea of the f ilter

covering the 8 " diameter opening b y c reating a

dome out of the filter material.

During c onstruction, c heck the f ilter f or dus t

accumulation a nd r eplace it when t he

accumulation becomes noticeable.

2-12

Page 25

CONTROL PANEL OPERATING PROCEDURES

CHAPTER 3 CONTROL PANEL OPERATING PROCEDURES

3.1 INTRODUCTION

The information in this Chapter provides a guide

to the operation of the Benchmark 3.0 Boiler

using the Control Panel mounted on the front of

the unit. It is imperative that the initial startup of

this unit be performed by factory trained

personnel. Operation prior to initial startup by

factory trained personnel will void the equipment

warranty. In addition, the following WARNINGS

and CAUTIONS must be observed at all times.

2

CAUTION

All of the installation procedures in

Chapter 2 must be completed before

attempting to start the unit.

WARNING

ELECTRICAL VOLTAGES IN THIS

SYSTEM MAY INCLUDE 460, 208

AND 24 VOLTS AC. IT MUST BE

SERVICED ONLY BY FACTORY

CERTIFIED SERVICE TECHNICIANS

WARNING

DO NOT ATTEMPT TO DRY FIRE

THE BOILER. STARTING THE UNIT

WITHOUT A FULL WATER LEVEL

CAN SERIOUSLY DAMAGE THE

UNIT AND MAY RESULT IN INJURY

TO PERSONNEL OR PROPERTY

DAMAGE. THIS SITUATION WILL

VOID ANY WARRANTY.

12

11

10

9

1

3

4

5

6

7

8

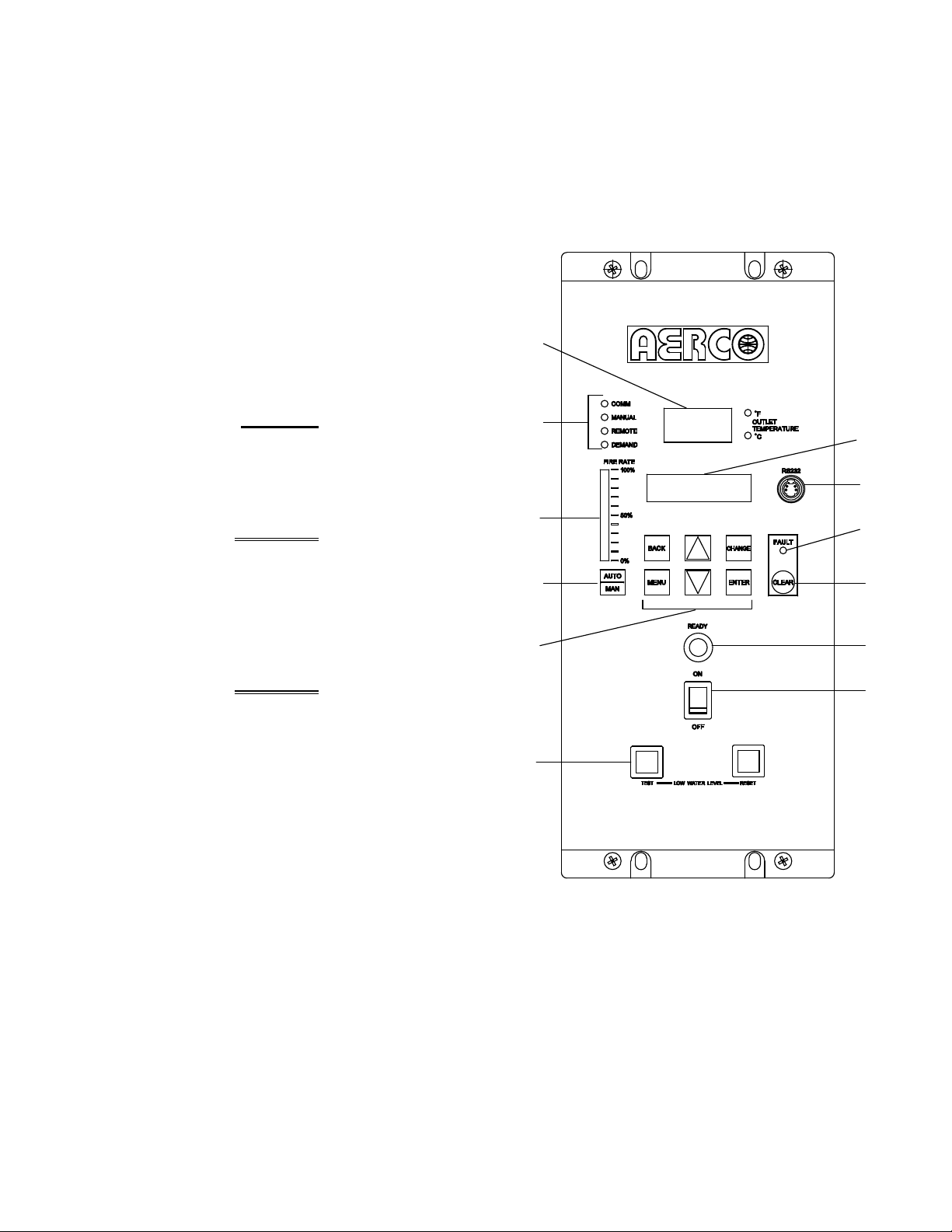

3.2 CONTROL PANEL DESCRIPTION

The Benchmark 3.0 Control Panel shown in

Figure 3-1 contains all of the controls, indicators

and displays necessary to operate, adjust and

troubleshoot the Benchmark 3.0 Boiler. These

operating controls, indicators and displays are

listed and described in Table 3-1. Additional

information on these items are provided in the

individual operating procedures provided in this

Chapter.

Figure 3-1.

Control Panel Front View

3-1

Page 26

CONTROL PANEL OPERATING PROCEDURES

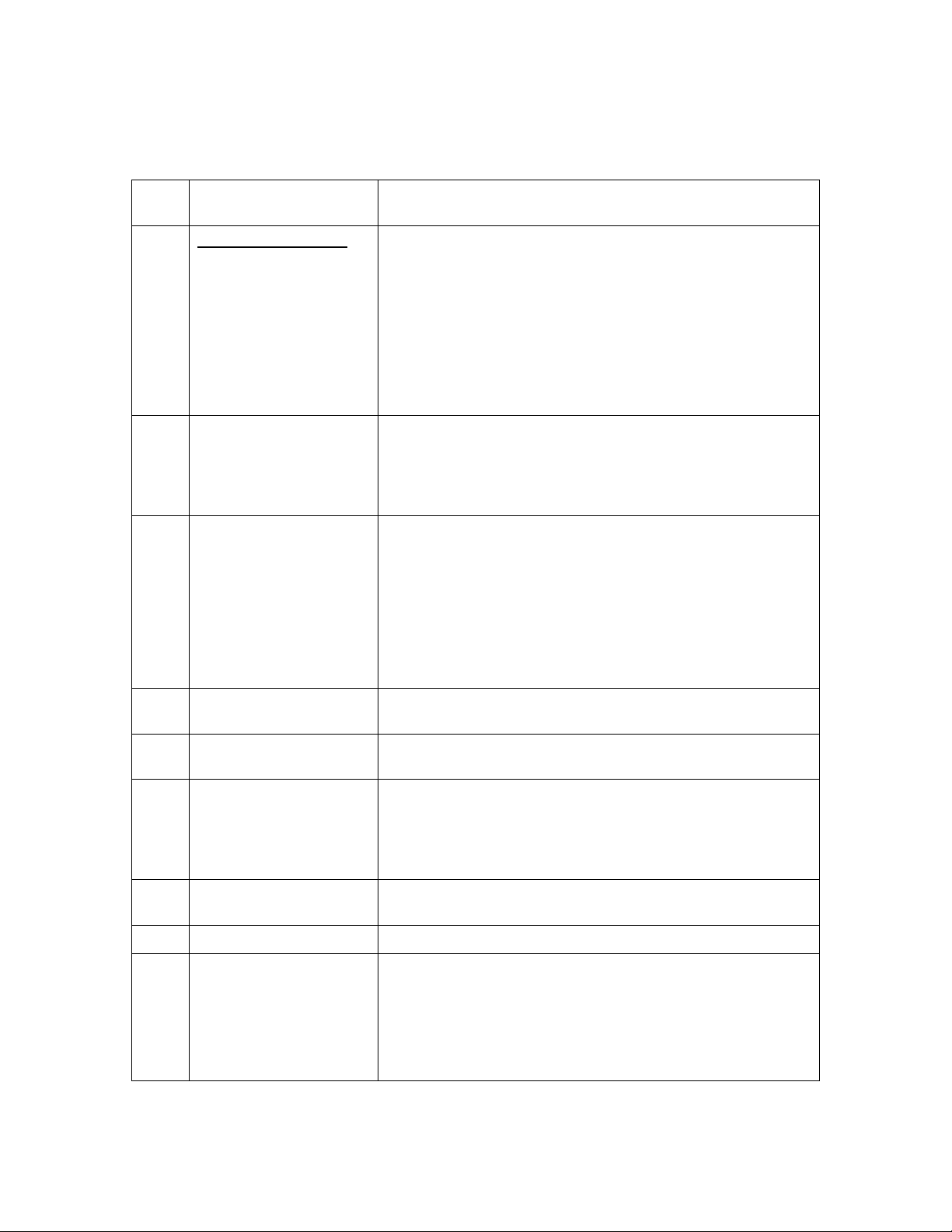

Table 3-1 Operating Controls, Indicators and Displays

ITEM

NO.

CONTROL, INDICATOR

OR DISPLAY

1 LED Status Indicators Four Status LEDs indicate the current operating status as

follows:

COMM

MANUAL

REMOTE

DEMAND

OUTLET

2

TEMPERATURE

Display

3 VFD Display Vacuum Fluorescent Display (VFD) consists of 2 lines each

Lights when RS-232 communication is occurring

Lights when the unit is being controlled using the front panel

keypad.

Lights when the unit is being controlled by an external signal

from an Energy Management System

Lights when there is a demand for heat.

3–Digit, 7–Segment LED display continuously displays the

outlet water temperature. The °F or °C LED next to the

display lights to indicate whether the displayed temperature is

in degrees Fahrenheit or degrees Celsius. The °F or °C blinks

when operating in the Deadband Mode.

capable of displaying up to 16 alphanumeric characters. The

information displayed includes:

Startup Messages

Fault Messages

FUNCTION

Operating Status Messages

Menu Selection

RS-232 Port

4

FAULT Indicator Red FAULT LED indicator lights when a boiler alarm

5

CLEAR Key Turns off the FAULT indicator and clears the alarm message

6

READY Indicator

7

ON/OFF Switch

8

LOW WATER LEVEL

9

TEST/RESET Switches

Port permits a Laptop Computer or External Modem to be

connected to the unit’s Control Panel.

condition occurs. An alarm message will appear in the VFD.

if the alarm is no longer valid. Lockout type alarms will be

latched and cannot be cleared by simply pressing this key.

Troubleshooting may be required to clear these types of

alarms.

Lights ON/OFF switch is set to ON and all Pre-Purge

conditions have been satisfied.

Enables and disables boiler operation.

Allows operator to test operation of the water level monitor.

Pressing TEST opens the water level probe circuit and

simulates a Low Water Level alarm.

Pressing RESET resets the water level monitor circuit.

Pressing the CLEAR key (item 6) resets the display.

3-2

Page 27

CONTROL PANEL OPERATING PROCEDURES

Table 3-1 Operating Controls, Indicators and Displays – Continued

ITEM

NO.

10 MENU Keypad Consists of 6 keys which provide the following functions for

CONTROL, INDICATOR

OR DISPLAY

the Control Panel Menus:

MENU

BACK

▲ (UP) Arrow When in one of the main menu categories (Figure 3-2),

▼ (DOWN) Arrow When in one of the main menu categories (Figure 3-2),

CHANGE

Steps through the main menu categories shown in Figure 3-

2. The Menu categories wrap around in the order shown.

Allows you to go back to the previous menu level without

changing any information. Continuously pressing this key

will bring you back to the default status display in the VFD.

Also, this key allows you to go back to the top of a main

menu category.

pressing the ▲ arrow key will select the displayed menu

category. If the CHANGE key was pressed and the menu

item is flashing, pressing the ▲ arrow key will increment the

selected setting.

pressing this key will select the displayed menu category. If

the CHANGE key was pressed and the menu item is

flashing, pressing the ▼ arrow key will decrement the

selected setting.

Permits a setting to be changed (edited). When the

CHANGE key is pressed, the displayed menu item will begin

to flash. Pressing the ▲ or ▼ arrow key when the item is

flashing will increment or decrement the displayed setting.

FUNCTION

11

12

ENTER

AUTO/MAN Switch

VALVE POSITION

Bargraph

Saves the modified menu settings in memory. The display

will stop flashing.

This switch toggles the boiler between the Automatic and

Manual modes of operation. When in the Manual (MAN)

mode, the front panel controls are enabled and the

MANUAL status LED lights.

When in the Automatic (AUTO) mode, the MANUAL status

LED will be off and the front panel controls disabled.

20 segment red LED bargraph continuously shows the

Air/Fuel Valve position in 5% increments from 0 to 100%

3-3

Page 28

CONTROL PANEL OPERATING PROCEDURES

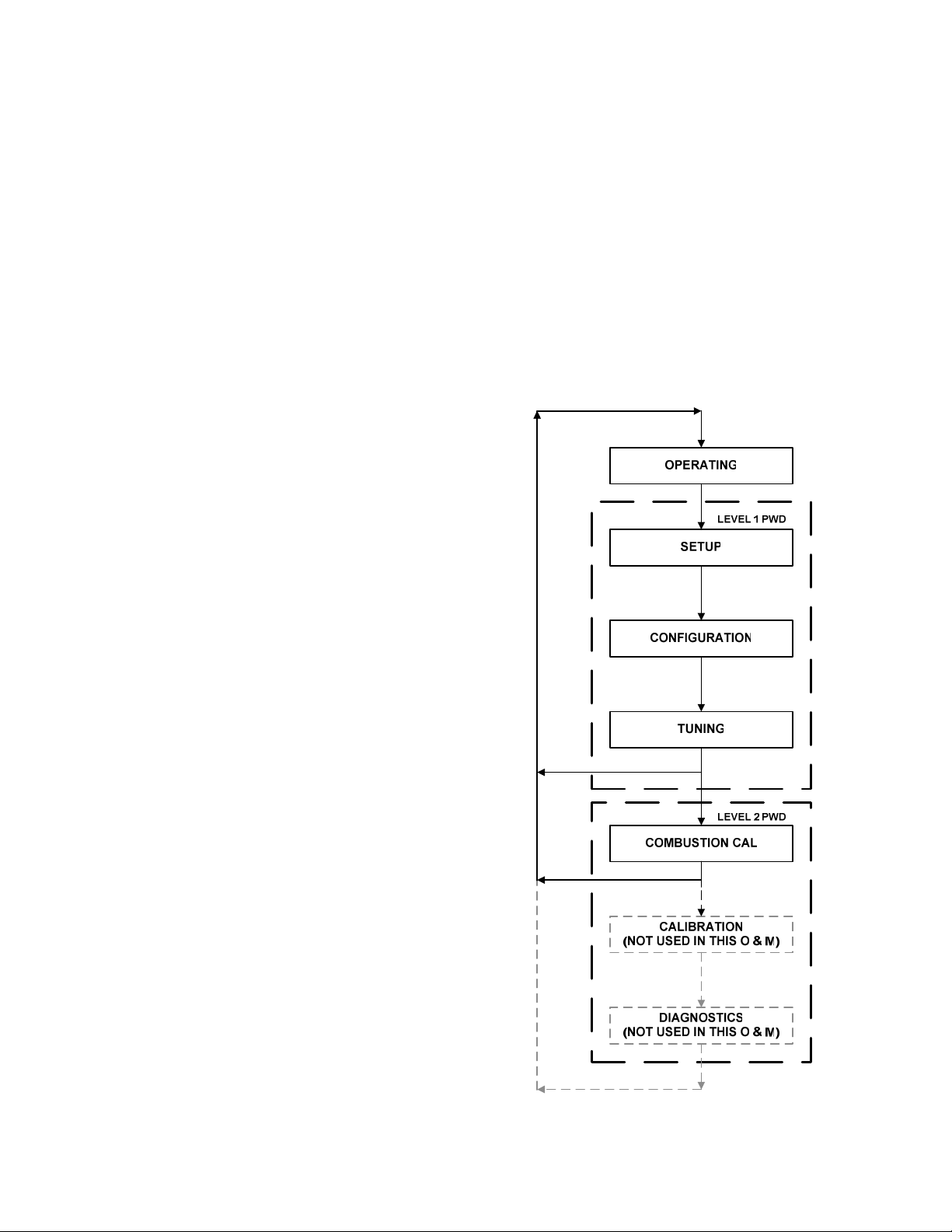

3.3 CONTROL PANEL MENUS

The Control Panel incorporates an extensive

menu structure which permits the operator to set

up, and configure the unit. The menu structure

consists of five major menu categories which are

applicable to this manual. These categories are

shown in Figure 3-2. Each of the menus shown,

contain options which permit operating

parameters to be viewed or changed. The

menus are protected by a password levels to

prevent unauthorized use.

Prior to entering the correct password, the

options contained in the Operation, Setup,

Configuration and Tuning Menu categories can

be viewed. However, with the exception of

Internal Setpoint Temperature (Configuration

Menu), none of the viewable menu options can

be changed.

Once the valid level 1 password (159) is

entered, the options listed in the Setup.

Configuration and Tuning Menus can be viewed

and changed, if desired. The Combustion Cal

Menu is protected by the level 2 password which

is used in Chapter 4 to perform combustion

calibration prior to service use.

available menu options in the Top-Down

sequence. Pressing the ▼ arrow key will

display the options in the Bottom-Up

sequence. The menu options will wraparound after the first or last available option

is reached.

6. To change the value or setting of a

displayed menu option, press the CHANGE

key. The displayed option will begin to flash.

Press the ▲ or ▼ arrow key to scroll

through the available menu option choices

for the option to be changed. The menu

option choices do not wrap around.

7. To select and store a changed menu item,

press the ENTER key.

3.3.1 Menu Processing Procedure

Accessing and initiating each menu and option

is accomplished using the Menu Keys shown in

Figure 3-1. Therefore, it is imperative that you

be thoroughly familiar with the following basic

steps before attempting to perform specific

menu procedures.

1. The Control Panel will normally be in the

Operating Menu and the VFD will display the

current unit status. Pressing the ▲ or ▼

arrow key will display the other available

data items in the Operating Menu.

2. Press the MENU key. The display will show

the Setup Menu, which is the next menu

category shown in Figure 3-2. This menu

contains the Password option which must be

entered if other menu options will be

changed.

3. Continue pressing the MENU key until the

desired menu is displayed.

4. With the desired menu displayed, press the

▲ or ▼ arrow key. The first option in the

selected menu will be displayed.

5. Continue to press the ▲ or ▼ arrow key

until the desired menu option is displayed.

Pressing the ▲ arrow key will display the

3-4

Figure 3-2. Menu Structure

Page 29

CONTROL PANEL OPERATING PROCEDURES

NOTE

The following paragraphs provide brief

descriptions of the options contained in each

menu. Refer to Appendix A for detailed

descriptions of each menu option. Refer to

Appendix B for listings and descriptions of

displayed startup, status and error

messages.

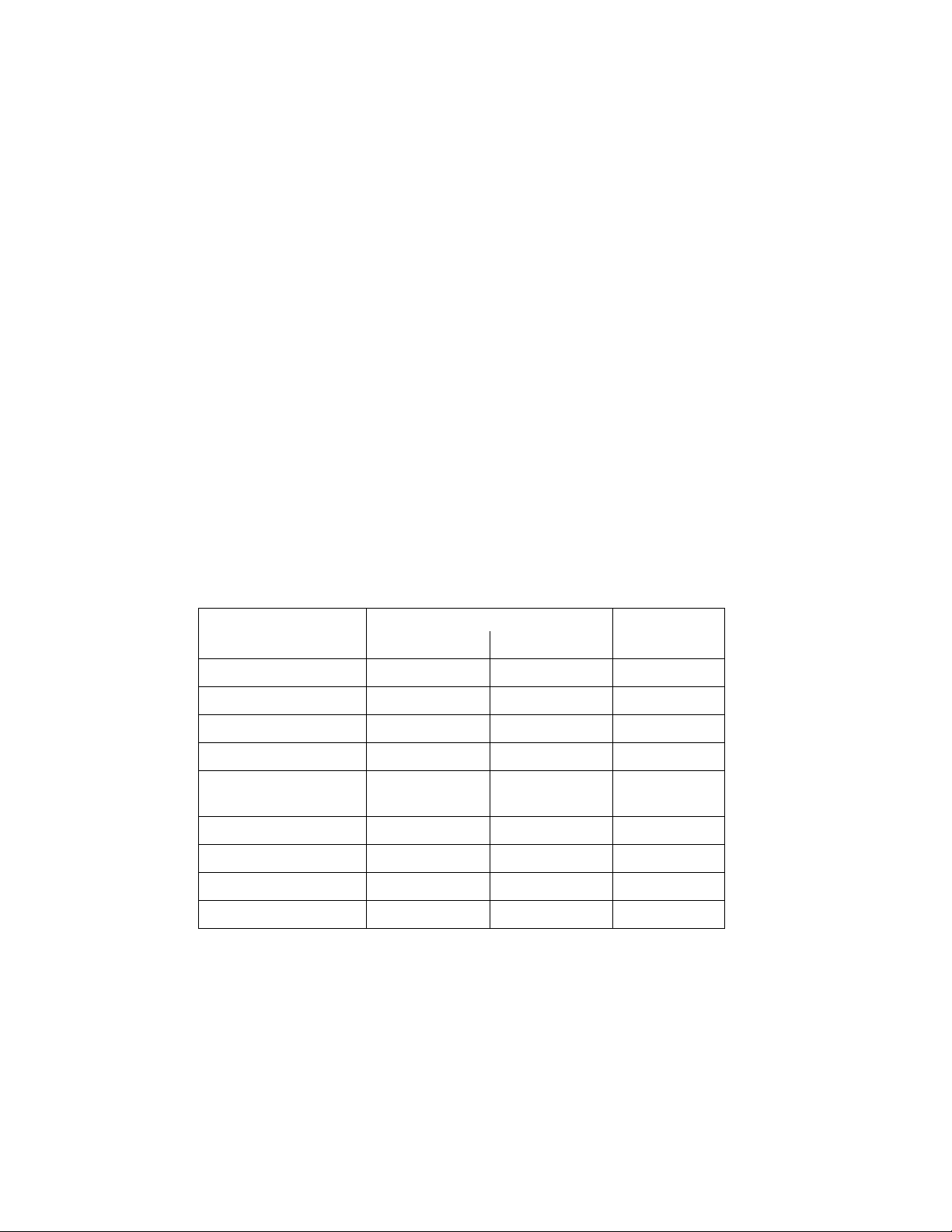

3.4 OPERATING MENU

The Operating Menu displays a number of key

operating parameters for the unit as listed in

Table 3-2. This menu is “Read-Only” and does

not allow personnel to change or adjust any

displayed items. Since this menu is “Read-Only”,

it can be viewed at any time without entering a

password. Pressing the ▲ arrow key to display

the menu items in the order listed (Top-Down).

Pressing the ▼ arrow key will display the menu

items in reverse order (Bottom-Up).

3.5 SETUP MENU

The Setup Menu (Table 3-3) permits the

operator to enter the unit password (159) which

is required to change the menu options. To

prevent unauthorized use, the password will

time-out after 1 hour. Therefore, the correct

password must be reentered when required. In

addition to permitting password entries, the

Setup Menu is also used to enter date and time,

units of temperature measurements and entries

required for external communication and control

of the unit via the RS-232 port. A view-only

software version display is also provided to

indicate the current Control Box software

version.

NOTE

The Outdoor Temp display item shown with

an asterisk in Table 3-2 will not be displayed

unless the Outdoor Sensor function has

been enabled in the Configuration Menu

(Table 3-4).

Table 3-2. Operating Menu

Available Choices or Limits

Menu Item Display Minimum Maximum Default

Status Message

Active Setpoint 40°F 240°F

AIR Temp -70°F 245°F

Outdoor Temp* -70°F 130°F

Valve Position In 0% Max Valve

Position

Flame Strength 0% 100%

Run Cycles 0 999,999,999

Run Hours 0 999,999,999

Fault Log 0 9 0

3-5

Page 30

CONTROL PANEL OPERATING PROCEDURES

Table 3-3. Setup Menu

Available Choices or Limits

Menu Item Display Minimum Maximum Default

Passsword 0 9999 0

Language English English

Time 12:00 am 11:59 pm

Date 01/01/00 12/31/99

Unit of Temp Fahrenheit or Celsius Fahrenheit

Comm Address 0 127 0

Baud Rate 2400, 4800, 9600, 19.2K 9600

Software Ver 0.00 Ver 9.99

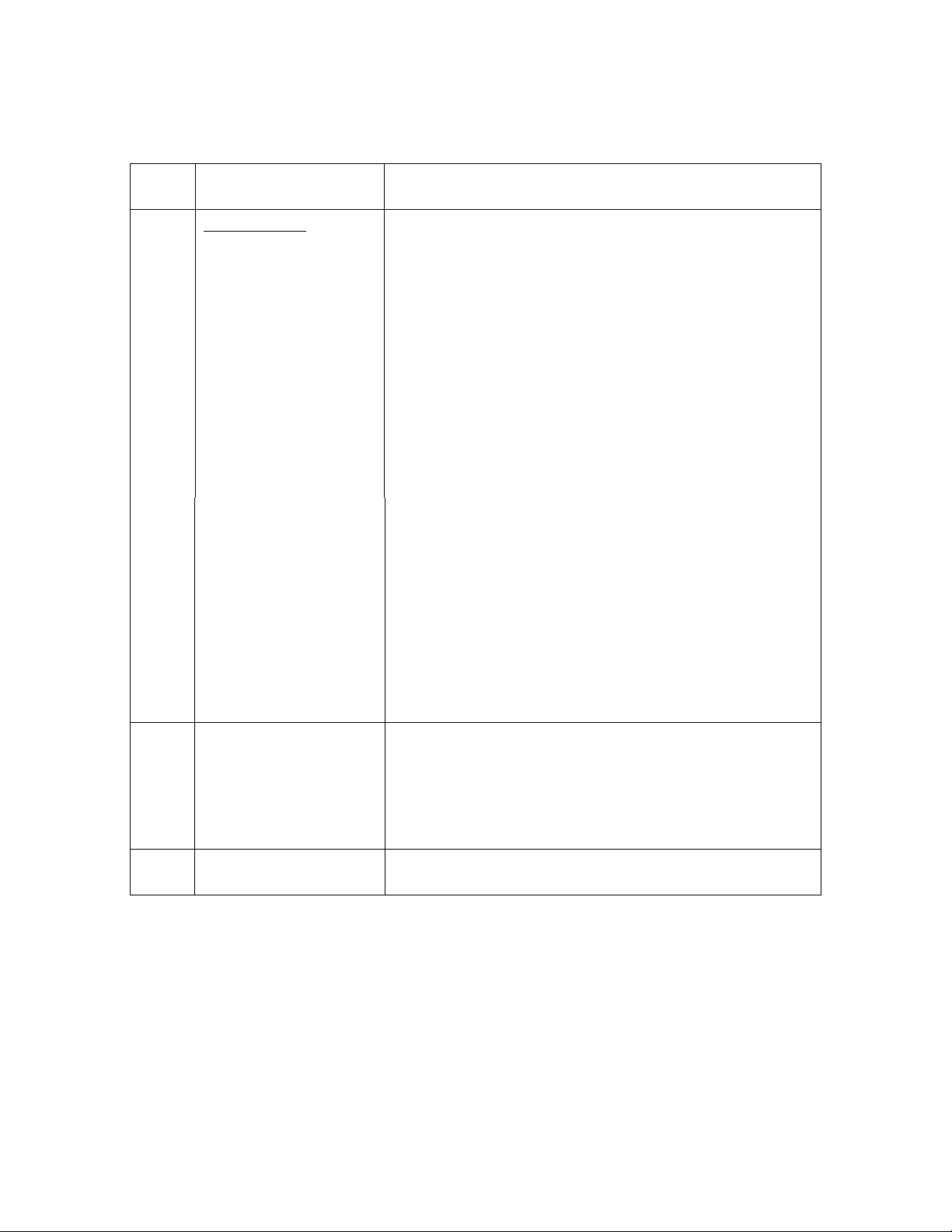

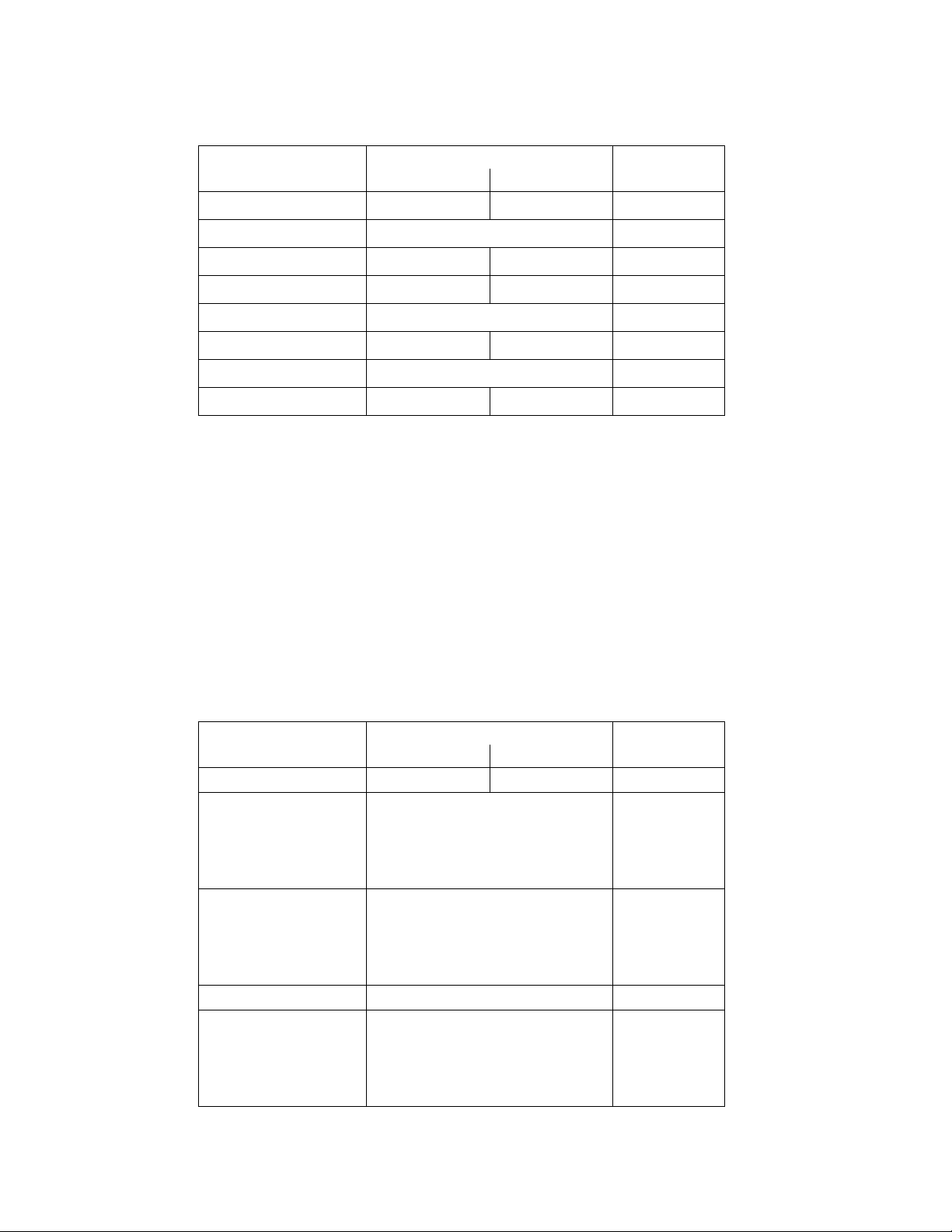

3.6 CONFIGURATION MENU

The Configuration Menu shown in Table 3-4

permits adjustment of the Internal Setpoint

(Setpt) temperature regardless of whether the

valid password has been entered. Setpt is

required for operation in the Constant Setpoint

mode. The remaining options in this menu

require the valid password to be entered, prior to

changing existing entries. This menu contains a

number of other configuration settings which

may or may not be displayed, depending on the

current operating mode setting.

Table 3-4. Configuration Menu

Available Choices or Limits

Menu Item Display Minimum Maximum Default

Internal Setpt Lo Temp Limit Hi Temp Limit 130°F

Unit Type KC Boiler, KC Boiler LN,

BMK Boiler, BMK Boiler LN,

BMK Boiler Dual, KC Water

Heater, KC Water Heater LN,

Water Heater 2010

Unit Size 0.5 MBTU, 1.0 MBTU

1.5 MBTU, 2.0 MBTU

3.0 MBTU, 3.5 MBTU

4.0 MBTU, 5.0 MBTU

Fuel Type Natural Gas, Propane Natural Gas

Boiler Mode Constant Setpoint,

Remote Setpoint,

Combination

Outdoor Reset

NOTE

The Configuration Menu settings shown in

Table 3-4 are Factory-Set in accordance

with the requirements specified for each

individual order. Therefore, under normal

operating conditions, no changes will be

required.

BMK Boiler

LN

1.0 MBTU

6.0 MBTU

Constant

Setpoint

Direct Drive

3-6

Page 31

CONTROL PANEL OPERATING PROCEDURES

Table 3-4. Configuration Menu - Continued

Available Choices or Limits

Menu Item Display Minimum Maximum Default

Remote Signal

(If Mode = Remote

Setpoint, Direct Drive

or Combination)

Bldg Ref Temp

(If Mode = Outdoor

Reset)

Reset Ratio

(If Mode = Outdoor

Reset)

Outdoor Sensor Enabled or Disabled Disabled

System Start Tmp

(If Outdoor Sensor =

Enabled)

Setpt Lo Limit 40°F Setpt Hi Limit 60°F

Setpt Hi Limit Setpt Lo Limit 220°F 200°F

Temp Hi Limit 40°F 240°F 210°F

Max Fire Rate 40% 100% 100%

Pump Delay Timer 0 min. 30 min. 0 min.

Aux Start On Dly 0 sec. 120 sec. 0 sec.

Failsafe Mode Shutdown or Constant Setpt Shutdown

4 – 20 mA/1 – 5V

0 -20 mA/0 – 5V

PWM Input (BMS)

Network

40°F 230°F 70°F

0.1 9.9 1.2

30°F 100°F 60°F

4 – 20 mA,

1-5V

*Analog Output

(See CAUTION at

end of Table 3-4 )

Low Fire Timer 2 sec. 600 sec. 2 sec.

Setpt Limiting Enabled or Disabled Disabled

Setpt Limit Band 0°F 10°F 5°F

Network Timeout 5 Sec 999 Sec 30 Sec

HI DB Setpt EN 0% 100% 30%

Demand Offsert 0 25 10

Deadband High 0 25 2

Deadband Low 0 25 2

*CAUTION:

1. DO NOT CHANGE the Analog Output Menu Item from its Default setting (Valve

Position 0-10V).

Off, Setpoint, Outlet Temp,

Valve Position 4-20 mA,

Valve Position 0-10V

*Valve

Position

0-10V

3-7

Page 32

CONTROL PANEL OPERATING PROCEDURES

3.7 TUNING MENU

The Tuning Menu items in Table 3-5 are Factory

set for each individual unit. Do not change

these menu entries unless specifically requested

to do so by Factory-Trained personnel.

3.8 COMBUSTION CAL MENU

The Combustion Cal (Calibration) Menu items in

Table 3-6 are used to vary the speed of the

unit’s blower motor based on air temperature

and air density at prescribed Air/Fuel Valve

Table 3-5. Tuning Menu

Available Choices or Limits

Menu Item Display Minimum Maximum Default

Prop Band 1°F 120°F 70°F

Integral Gain 0.00 2.00 1.00

Derivative Time 0.0 min 2.00 min 0.00 min

Reset Defaults? Yes, No, Are You Sure? No

Table 3-6. Combustion Cal Menu

positions (% open). This is accomplished by

providing a DC drive voltage to the motor which

adjusts the rotational speed of the blower to

maximize combustion efficiency and ensure the

unit conforms to the Nitrogen Oxide (NOx) and

Carbon Monoxide (CO) emissions specified in

Chapter 4. The firing rates (%) and default drive

voltages are listed in Table 3-6.

Available Choices or Limits

Menu Item Display Minimum Maximum Default

CAL Voltage 16% .25 8.20 1.80v

CAL Voltage 30% .25 8.20 3.20v

CAL Voltage 45% .25 8.20 3.70v

CAL Voltage 60% .25 8.20 3.80

CAL Voltage 80% .25 8.20 4.60

CAL Voltage 100% .25 8.20 6.00

SET Valve Position 0% 100% 0%

Blower Output Monitor Blower Output Voltage .00

3.9 START SEQUENCE

When the Control Box ON/OFF switch is set to

the ON position, it checks all pre-purge safety

switches to ensure they are closed. These

switches include:

• Safety Shut-Off Valve Proof of Closure

(POC) switch

• Low Water Level switch

• High Water Temperature switch

• High Gas Pressure switch

• Low Gas Pressure switch

• Blower Proof switch

If all of the above switches are closed, the

READY light above the ON/OFF switch will light

and the unit will be in the Standby mode.

When there is a demand for heat, the following

events will occur:

NOTE

If any of the Pre-Purge safety device

switches are open, the appropriate fault

message will be displayed. Also, the

appropriate fault messages will be displayed

throughout the start sequence, if the

required conditions are not observed.

3-8

Page 33

CONTROL PANEL OPERATING PROCEDURES

1. The DEMAND LED status indicator will light.

2. The unit checks to ensure that the Proof of

Closure (POC) switch in the downstream

Safety Shut-Off Valve (SSOV) is closed.

See Figure 3-3 for SSOV location.

Valve (Figure 3-6) will read between 25

and 35 to indicate that the valve is in

the low-fire position.

(b) The igniter relay is activated and

provides ignition spark.

(c) The gas Safety Shut-Off Valve (SSOV)

is energized (opened) allowing gas to

flow into the Air/Fuel Valve.

Figure 3-3.

SSOV Location

3. With all required safety device switches

closed, a purge cycle will be initiated and the

following events will occur:

(a) The Blower relay energizes and turns

on blower.

(b) The Air/Fuel Valve rotates to the full-

open purge position and closes purge

position switch. The dial on the Air/Fuel

Valve (Figure 3-4) will read 100 to

indicate that it is full-open (100%).

(c) The VALVE POSITION bargraph will

show 100%.

4. Next, the blower proof switch on the Air/Fuel

Valve (Figure 3-5) closes. The display will

show Purging and indicate the elapsed time

of the purge cycle in seconds. The normal

(default) time for the purge cycle is 7

seconds.