Page 1

Instruction Manual

P/N 30-48XX Dyno-Shaft

,!

WARNING:

Dyno-Shaft On-Vehicle Dynamometer is a valuable diagnostic

tool which must only be used in a safe manner and in

compliance with all applicable laws, rules and regulations. All

users of this product agree that AEM shall not be responsible or

liable for any personal injury, property or any other type or kind

of damage(s) resulting, directly or indirectly, from noncompliance.

AEM Performance Electronics

th

2205 126

Phone: (310) 484-2322 Fax: (310) 484-0152

Street Unit A, Hawthorne, CA. 90250

http://www.aemelectronics.com

Instruction Part Number: 10-4800 Rev D

© 2012 AEM Performance Electronics

Page 2

KIT CONTENTS

1 x 35-4740 Dyno-Shaft Controller Assembly

1 x 35-46XX Yoke Assembly (Style and P/N depends on kit purchased)

1 x 35-4780 Dyno-Shaft/AEMnet “Y” Harness

1 x Instruction Manual

Transmission Adapters (quantity and version depends on kit purchased)

Dyno-Shaft Kit Contents

INSTALLATION TIPS

1. Read the entire manual and instructions before beginning the installation.

2. Disconnect the negative battery cable(s) before beginning any work.

3. Make sure all connectors are fully seated and inserted.

4. Make sure all cables are routed away from heat sources or sharp objects.

TABLE OF CONTENTS

• Dyno-Shaft Installation 3

• Connecting to the AQ-1 9

• Using the Dyno-Shaft 10

• Connecting to a Series 2 EMS 15

• Connecting to a 3

• CAN BUS Message Structure 17

• Specifications 18

• Recommended Parts 18

• Replacement Parts 18

• Warranty 19

Page 2 10-4800 Dynoshaft REV D.docx

rd

party display or logger 16

Page 3

DYNO-SHAFT DESCRIPTION

The AEM Dyno-Shaft is a device that measures actual driveshaft torque from yoke

mounted strain gauges. This is not an inaccurate accelerometer based software

application, the AEM Dyno-Shaft provides repeatable, accurate measurement of

driveline torque and horsepower.

It is unaffected by headwind, crosswinds, tailwinds, vehicle weight discrepancies, uphills, down-hills, road surface changes, wheel spin or proximity to other vehicles

because the Dyno-Shaft actually measures driveline torque and RPM, it doesn’t attempt

to estimate it.

The AEM Dyno-Shaft is zero maintenance. Power is supplied to the rotating sensor unit

via an air-core transformer which is formed by the coil on the controller housing and a

matching coil on the sensor. The sensor sends data back to the controller via the same

mechanism. There are no batteries to die, no temperamental slip rings to wear out.

DYNO-SHAFT KIT DIFFERENCES

The Sportsman level kit is designed for applications where a cast iron style transmission

slip yoke is acceptable. The Pro kit is designed for the most demanding applications

and is based around a CNC machined, 4340 chrome-moly yoke.

DYNO-SHAFT INSTALLATION

Make sure that all the work described below is performed 100% per the manufacturer’s

service instructions. If you do not have the proper tools and knowledge to perform the

driveshaft work then take the driveshaft to a machine shop that can perform the work for

you. Absolutely do not attempt to do this work without the proper tools as driveshaft

imbalance or even complete driveline failure is a possibility.

Raise the vehicle per the manufacturer’s instructions. A vehicle hoist is probably best.

Make 100% sure that the vehicle is secure before beginning any work underneath it.

MOUNTING THE DYNO-SHAFT SENSOR

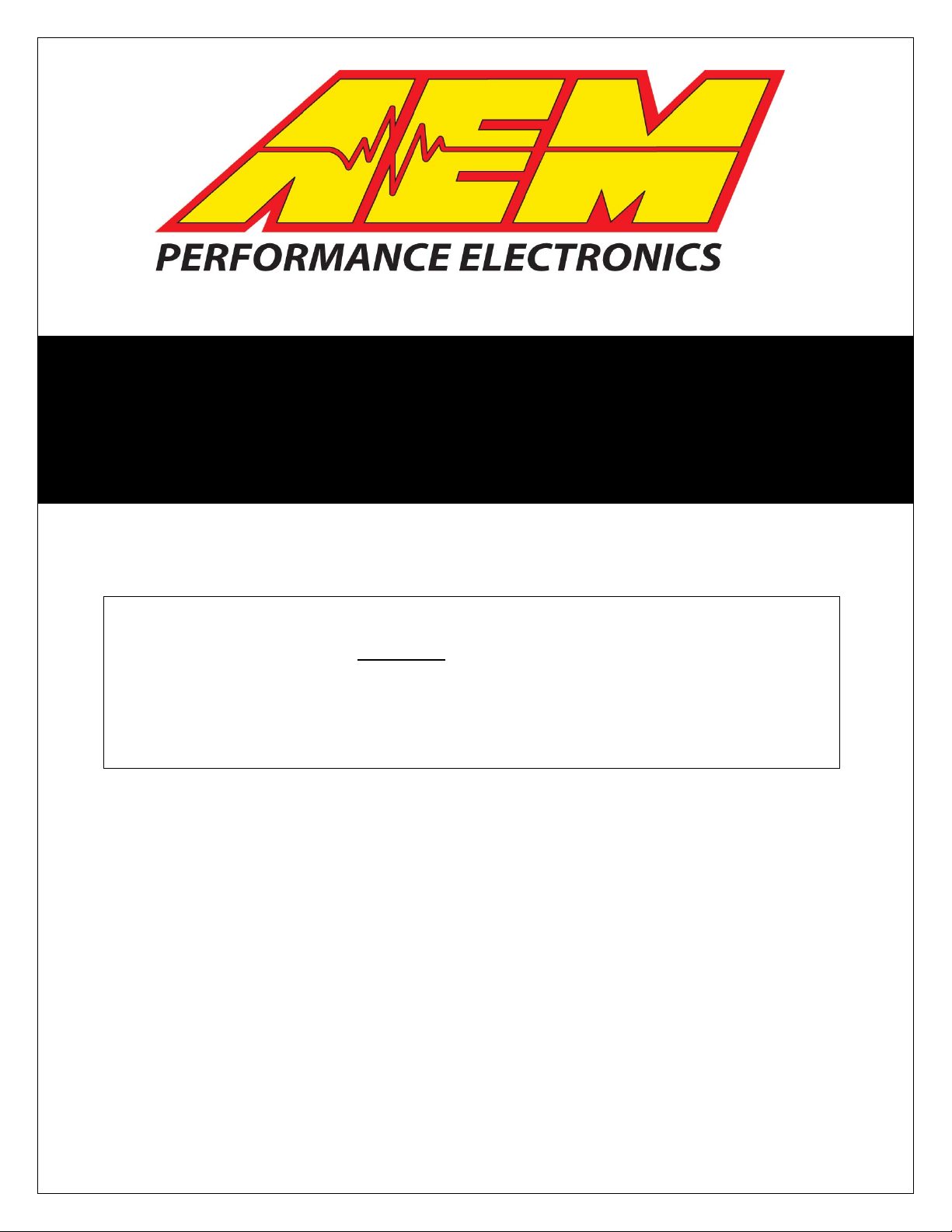

Before attempting to mount the Dyno-Shaft to your vehicle you need to check to make

sure there is proper clearance to fit the device.

Confirm that at least 1.5” of your existing slip yoke’s shaft remains available

outside of your transmission tail housing under all vehicle operating conditions.

If it doesn’t maintain at least this amount then do not attempt the installation.

Shortening the driveshaft or minimizing the driveshaft movement is required

before proceeding.

Confirm that there are no obstructions to mounting the controller behind the

transmission tail shaft housing (see picture).

Page 3 10-4800 Dynoshaft REV D.docx

Page 4

Dyno-Shaft Clearance Requirements

Once you are confident the Dyno-Shaft will fit on your vehicle you can proceed to

remove the driveshaft from the vehicle.

Remove the transmission slip yoke from the driveshaft. This may be a good time to

replace the u-joint with a new unit as they are a high wear item and are inexpensive. In

some cases a conversion u-joint may be necessary to connect the Dyno-Shaft supplied

slip yoke to the driveshaft. Compare which series u-joint your Dyno-Shaft kit is designed

for against your existing u-joint to make sure you purchase the correct u-joint. The

Dyno-Shaft application guide (http://www.aemelectronics.com/images/DynoShaft_Application_Guide.pdf) lists the various Dyno-Shaft kits and their associated ujoint series.

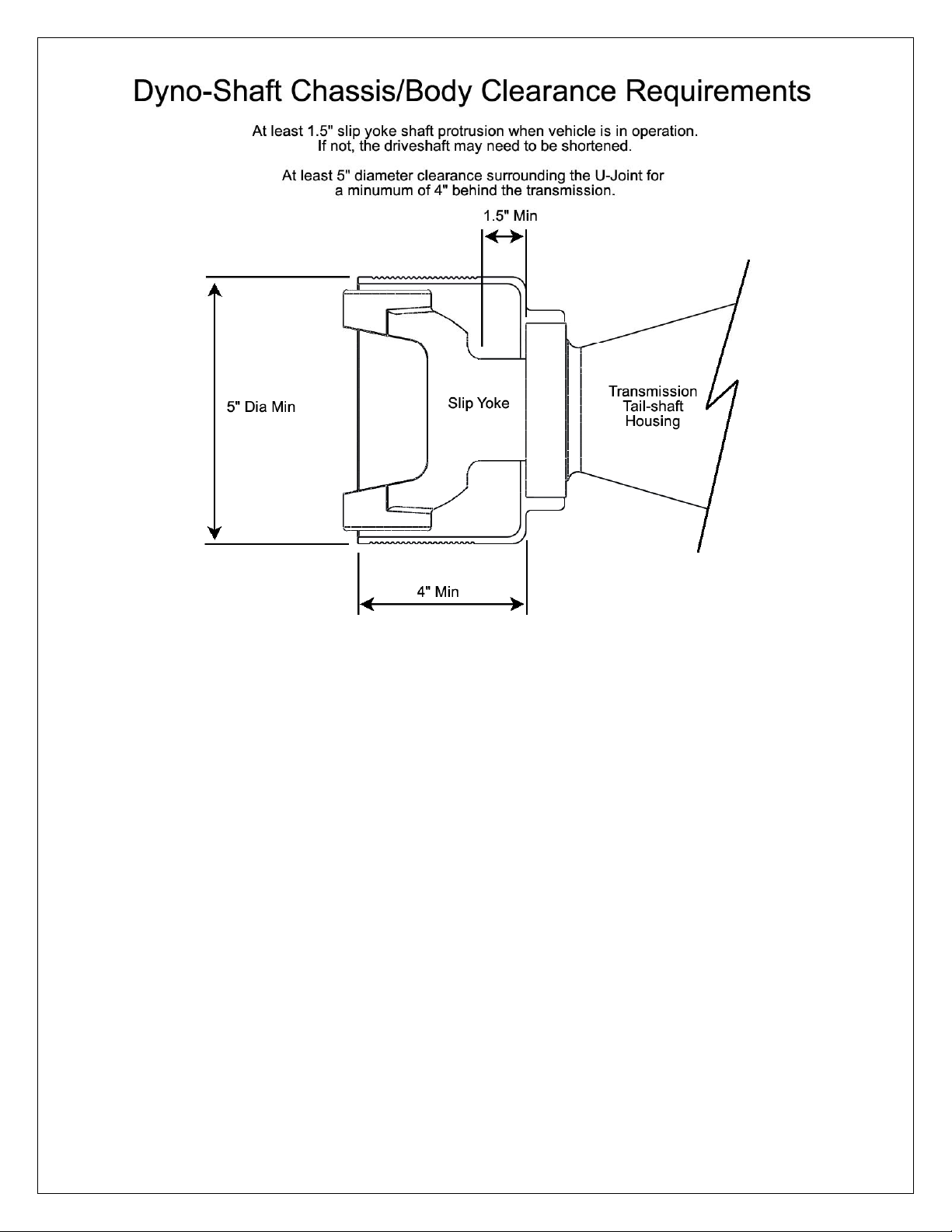

Replace the slip yoke on the driveshaft with the supplied Dyno-Shaft yoke.

Page 4 10-4800 Dynoshaft REV D.docx

Page 5

Dyno-Shaft sensor mounted on a Pro level Yoke

Re-balance the driveshaft if very high driveshaft RPM (7,000+) is expected.

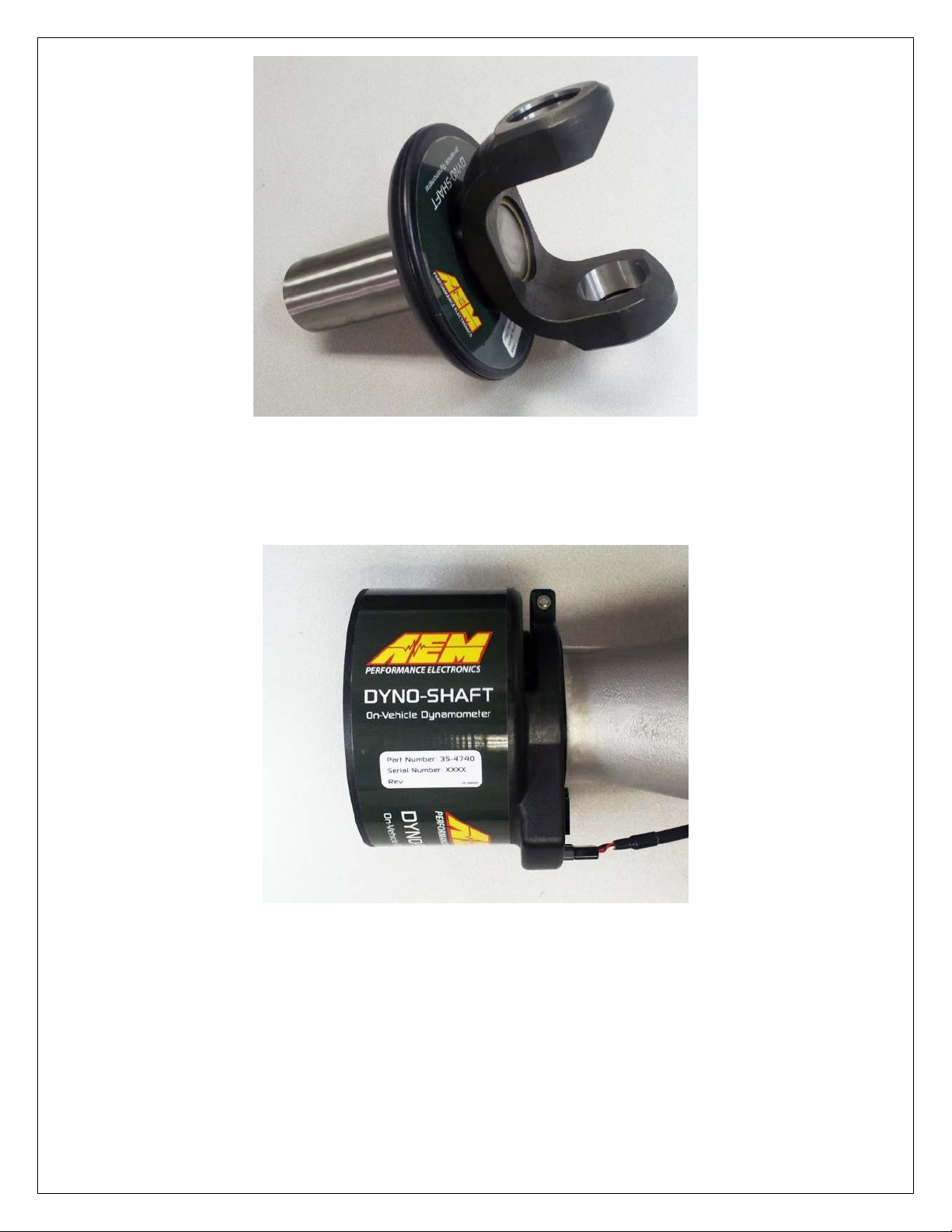

MOUNTING THE DYNO-SHAFT CONTROLLER

Dyno-Shaft Controller

Measure the OD of the transmission tail shaft housing and select the proper adapter. All

of the adapters are identical except for the inner diameter. Select an adapter that fits

over the tail shaft housing without having to be distorted or opened up any.

Place the adapter inside the clamp area of the Dyno-Shaft controller and install on the

tail shaft housing. The locating ribs on the adapters are designed to fit into the cavity

between the clamp arms and controller body. Do not attempt to pry the Dyno-Shaft

clamp area open to make things fit, select a larger ID adapter instead.

Page 5 10-4800 Dynoshaft REV D.docx

Page 6

In some cases (notably some T400 and T56 Magnum tail shaft housing castings) the

OD of the housing is just slightly smaller than the ID of the Dynoshaft controller. In this

situation no split adapter can work and a thin, flat, elastic band is supplied to shim up

the OD and act as the adapter and vibration isolation.

Tail shaft Housing Adapters

Proper Fitment of Adapter In Controller Clamp with Locating Ribs Between Clamp

Arms and Controller Body

This is a precision electronic measuring device, therefore you must ensure that hot

exhaust is not in close proximity controller. If there is a heat source near the controller

you *MUST* install a shield between the Dyno-Shaft and the hot component. In order to

protect itself, the Dyno-Shaft controller will automatically shut down when it’s driver

circuit reaches 250 degF. The parameter ”Control Temp” reports this temperature and

can be monitored to make sure the controller does not overheat. If the controller does

Page 6 10-4800 Dynoshaft REV D.docx

Page 7

overheat and automatically shutdown, it will automatically reactivate when the controller

temperature drops to 165 degF. During the over temp shutdown, the controller will

continue to report the “Control Temp” parameter. Parameters such as, Speed, Torque,

Power, Tank Volts, Sensor Volts, Power Level, Sensor Temp, S-Firm Error, Zero Offset

Ok, Good Cal, and LED Aligned, will stop reporting.

Orient the controller so the harness connector is at the top of the transmission unless

there is a heat source nearby. If there is, then orient the controller so the connector is as

far away from the heat source as possible.

Reinstall the driveshaft per the mfg instructions.

Working

Area

Verify proper sensor depth

Verify that the Dyno-Shaft sensor unit on the slip yoke is roughly in the middle of the

controller housing. Adjust the placement of the controller housing front to rear as

necessary. Excessive in/out driveshaft movement may cause the sensor signal to drop

out so ensure this is correct. Also confirm the controller is centered within the sensor

body.

At this point make 100% sure that there is no possibility the rotating sensor can

contact the transmission tail shaft housing or seal under any operating

conditions. If you fail to do this you may permanently damage the sensor!

Attach the supplied cable and route it to the monitoring device. Make sure it is routed

securely, away from heat sources and moving parts. It is imperative that the plug is

oriented correctly in the socket. Although it is a keyed plug, it is possible to install it

incorrectly. The release tab is toward the outside of the controller.

Page 7 10-4800 Dynoshaft REV D.docx

Page 8

Supplied Dyno-Shaft/AEMnet “Y” harness with proper connector orientation

Properly installed Dyno-Shaft connector with labeled wire colors

CONNECTING THE DYNO-SHAFT

The Dyno-Shaft uses the AEMnet electrical interface. AEMnet is an open architecture

software and hardware interface based on the CAN 2.0 specification, which provides

the ability for multiple enabled devices to easily communicate with each other through a

single cable. The hardware connection is made through a Deutsch 4P DTM connector

and contains 12 volt switched power and ground (2A max) as well as the CAN data

lines. Devices connected to the AEMnet transmit data through this one connection and

most of these devices receive power from this same connection as well.

The preferred connection for the Dyno-Shaft is the AEM AQ-1 Data Logger. It

includes the mating connector in its harness and no wiring is required.

Page 8 10-4800 Dynoshaft REV D.docx

Page 9

CONNECTING THE DYNO-SHAFT TO AN AQ-1 DATA LOGGER

The preferred device for configuring & logging the Dyno-Shaft is the 30-2500, AQ-1

Data Logger (sold separately). This logger has been pre-configured for the Dyno-Shaft

and already has the AEMnet connector preinstalled so there is no wiring required.

If using the AQ-1 Data Logger, simply connect the Dyno-Shaft connector to the AEMnet

connector on the AQ-1 Harness.

Within the AQ-1 setup software, the AEMnet page is used to select what parameters

are logged from the AEMnet. Devices connected to AEMnet are automatically detected

and configured when the Auto Discover button is pressed.

AQ-1 AEMnet Dyno Shaft Parameters

Page 9 10-4800 Dynoshaft REV D.docx

Page 10

AEMnet Dyno-Shaft Parameters

Speed – Driveshaft speed in rpm

Torque – Driveshaft torque in ft-lbs

Power – Driveshaft power in HP

Control Volts – Voltage measured at the controller, volts

Tank Volts – Charge voltage for transformer circuit, volts

Sensor Volts – Voltage level generated in the sensor, volts

Power Level – Power transmitted to sensor from controller, percent

Sensor Temp – Temperature measured inside the sensor, degrees F

Frequency - Drive frequency of the transformer circuit, Hz

Control Temp – Temperature measured inside the controller, degrees F

S-Firm Error – Indicates if there is a firmware error in the sensor 1 = Yes, 0 = No

C-Firm Error – Indicates if there is a firmware error in the controller 1 = Yes, 0 = No

Zero Offset OK – Indicates the Auto Zero was successful, 1 = Yes, 0 = No

Good Cal – Indicates the sensor calibration was successfully read 1 = Yes, 0 = No

LED Aligned – Indicates optical pickups on sensor and controller are aligned, 1 =

Aligned, 0 = not aligned

Auto Zero – Auto Zero on or off, 1 = On, 0 = Off

Using the Dyno-Shaft

After the first few times the Dyno-Shaft is used, the sensor zero value will need to be

reset as brand new yokes will twist slightly before they take a final set. This is especially

prevalent on the sportsman yokes. You can check to see if the Dyno-Shaft needs to be

zeroed by putting the vehicle in neutral, brakes off and monitoring the torque value with

no load applied to the driveshaft. A typical value will be less then +/- 2 ft-lbs. Resetting

the zero value is discussed in the section on Dyno-Shaft configuration. New DynoShafts can take an initial set of 100 lbs or more after the first few hard pulls but then

settle down to a repeatable value quickly thereafter.

Configuring the Dyno-Shaft

The Dyno-Shaft is configured using the AEM Dyno-Shaft Configuration window. To

access the configuration window, right click on the Dyno-Shaft in the AEMnet page

window and select Config…

Page 10 10-4800 Dynoshaft REV D.docx

Page 11

Opening the Dyno-Shaft Configuration Window

The AEM Dyno-Shaft Configuration window lists the firmware/hardware versions, as

well as the zero options. The “Zero” button is used to manually reset the zero value of

the Dyno-Shaft. The Auto Zero function allows the Dyno-Shaft to automatically reset

the zero value on power up. Auto Zero Mode is used to turn the Auto Zero function on

or off. The Auto Zero Threshold option sets the threshold for which Auto Zeroing is

active. Auto Zero Threshold is a digital value in “counts”, where three counts is

approximately 1 ft-lb of torque. The Dyno-Shaft will not Auto Zero if the initial torque

reading exceeds the Auto Zero Threshold.

Dyno-Shaft Configuration Window

Page 11 10-4800 Dynoshaft REV D.docx

Page 12

Viewing Dyno Plots Created by the AQ-1

The AQ-1 data log file is viewed from within AEMData.

The Dyno Plot view allows multiple vehicle power and torque data sets to be overlaid in

a special "Dyno Plot" configuration for use with AEM's Dyno-Shaft drive line torque

measurement system.

Also, two additional channels may be plotted against the same X axis in a separate

graph area.

AEMdata Dyno Plot display

Configuration

To display the configuration dialog, click the configure button on the Dyno Plot window

or right click on the view and select 'Configure Dyno Plot...'.

Channel Options

Channel settings are displayed on the first tab of the Dyno Plot Configuration dialog.

Page 12 10-4800 Dynoshaft REV D.docx

Page 13

AEMdata Dyno Plot configuration menus

The channels that are used to generate the plot are selected from here.

• Drive Power - Defaults to "DS Power". This is the log channel that contains the

calculated power data.

• Drive Torque - Defaults to "DS Torque". This is the log channel that contains the

measured torque data.

• Drive Speed - Defaults to "DS Speed". log channel that contains the drive shaft RPM.

• Engine Power - Not currently used.

• Engine Torque - Not currently used.

• Engine Speed - This channel contains the engine RPM data. If this data is available

then it is used to dynamically calculate engine torque & horsepower. If this channel is

not available then engine torque & horsepower will only be available in a single gear

using a user specified transmission ratio.

• 2nd Plot A - The 1st of 2 log channels that will be displayed on the secondary graph.

• 2nd Plot B - The 2nd of 2 log channels that will be displayed on the secondary graph.

Plot Mode X - Defaults to "Drive Shaft Speed". There are four options for the X Axis:

• Drive Shaft Speed, where the Power and Torque will be plotted on the Y-axis vs drive

shaft speed on the X-axis. This is the default setting.

• Engine Speed, Power and Torque will be plotted on the Y-axis versus engine RPM

on the X-axis. For this mode to be used either an Engine Speed channel has to be

defined above or a transmission ratio must be specified. The transmission losses

specified by the user will be used to correct the engine torque values.

• Vehicle Speed, Power and Torque is plotted versus vehicle speed on the X-axis. For

this mode to be used the final drive ratio and tire diameter must be specified.

• Wheel Speed, Power and Torque is plotted versus wheel RPM on the X-axis. For this

mode to be used the final drive ratio must be specified

Plot Mode Y - Defaults to "Drive Torque/Power". There are two options for the X Axis:

Page 13 10-4800 Dynoshaft REV D.docx

Page 14

• Drive Torque/Power, Plots raw drive shaft torque values. These values will typically

be much higher than the engine values due to the gear reduction in lower gears.

• Engine Torque/Power, Plots calculated engine torque and power. Requires either an

Engine Speed log channel or gear ratio to be entered as well as transmission losses.

Smoothing - Applies a smoothing factor to the data.

2nd Plot Split - Defines how much of the plot height is devoted to the primary plot.

Draw Legend - If checked then the summary info is shown on the bottom of the plot.

Atmospheric Power Correction - The method of power correction due to atmospheric

conditions is selected here.

Drive train Options

The drive train options are set on the Drive Tab.

Transmission Ratios

• Engine/Drive Ratio - If you don't have an engine RPM log channel selected in Engine

Speed (above) but you want to get engine Power and Torque values you can enter a

gear ratio here for the gear used to test in. Overdrive gears are less than 1. If this

method is used the Engine power and torque values are only accurate in that gear.

• Final Drive Ratio - Enter the final drive ratio here if you want to plot versus vehicle

speed or wheel speed. Example numbers: 4.11, 3.73, etc...

• Tire Diameter - Enter the tire diameter here if you want to plot versus vehicle speed.

Transmission Losses

• Percentage - This amount of power is assumed to be consumed by the transmission.

Default is 12%

Run Options - Data file to be used is selected in the Run 1 and Run 2 tabs.

Plot Run 1/Plot Run 2 - Defines if this data is displayed on the plot.

Data - Select the log file you wish to use. Using the selection tool, highlight the area of a

trace/graph. Once selected, click “fixed range” to lock in the time span.

Run Info - The date from the source file is entered but you can also override it.

Atmospheric Conditions

• Temperature - Enter the ambient test temperature here.

• Pressure - Enter the ambient pressure during the test here.

• Relative Humidity - Enter the relative humidity during the test here.

Axis - The min & max value for all axis can be set under the Axis tab.

Colors - The chart colors can be defined on the Colors tabs.

Page 14 10-4800 Dynoshaft REV D.docx

Page 15

Sample AEMdata Dyno Plot printout

Print Options - A user defined logo can be added to the hard copy of the dyno printout.

This is selected on the Print Options. A formatted Dyno Plot can be sent directly to a

printer by right clicking on the Dyno Plot window and selecting Print Dyno Plot.

A specially formatted screen capture can be saved as a png graphics file as well. Right

click on the Dyno Plot window and select Print to File.

CONNECTING THE DYNO-SHAFT TO A SERIES 2 EMS

When hooking the Dyno-Shaft to a Series 2 EMS, it is easiest to use the optional flying

lead adapters AEM has created that have been pre-pinned with the correct ECU

terminals for the CAN Bus pins.

AEM Series 2 AEMnet CAN1L CAN1H

EMS Adaptor P/N Pin Location Pin Location

30-6030 30-3430 C22 C21

30-6040 30-3431 A22 C2

30-6050 30-3432 D14 D10

30-6051 30-3432 D14 D10

30-6052 30-3432 D14 D10

30-6053 30-3432 D14 D10

Page 15 10-4800 Dynoshaft REV D.docx

Page 16

30-6060 30-3432 C28 C29

30-6100 30-3433 11A 12A

30-6101 30-3433 11A 12A

30-6300 30-3434 75 13

30-6310 30-3431 77 87

30-6311 30-3431 57/77 67/87

30-6320 30-3435 33 13

30-6600 30-3436 42 12

30-6601 30-3436 42 12

30-6610 30-3437 12 69

30-6611 30-3437 12 69

30-6620 30-3437 57 40

30-6820 30-3438 B29 B28

30-6821 30-3438 B29 B28

Selecting the Dyno-Shaft from the wizards in AEMTuner will auto-configure the CAN

bus receive channels. The data recorded will be available as standard channels within

the data log file.

The power and ground pins on the adapter should be connected to a Switched 12V

source and Ground capable of providing a sustained 1 amp current.

CONNECTING THE DYNO-SHAFT TO A 3rd PARTY DISPLAY OR LOGGER

Most displays and ECU’s that can be configured to monitor user defined CAN data can

be used to capture Dyno-Shaft data as well.

The Dyno-Shaft harness has an AEMnet “Y” adapter containing both male and female

connectors of the AEMnet connector

Connector Body: Deutsch DTM06-4S

Terminals: Deutsch 1062-20-0222 with WM-4S Lock

Connector Body: Deutsch DTM04-4P

Terminals: Deutsch 1060-20-0222 with WM-4P Lock

These two connectors are mates of each other so if you are wiring it in to an external

device pick one and use the P/N’s of the other to determine the required mate.

Dyno-Shaft/AEMnet Pin-out

Pin 1, White, CAN High

Pin 2, Green, CAN Low

Pin 3, Red, Switched 12V. (draws up to 1 amp when active)

Pin 4, Black, Battery Ground

Page 16 10-4800 Dynoshaft REV D.docx

Page 17

DYNO-SHAFT CAN 2.0 MESSAGE STRUCTURE

Configure the CAN message receive function on your device according to the

manufacturer’s specific directions using the following Dyno-Shaft message structure.

CAN 2.0, 29 bit format, 500 kBit/sec, 8 data bytes, big Endian

Message ID: 0x00000160

Transmit Rate: Every 65 ms

Byte Label DataType Scaling Offset Range

0

2

4

6 TorqueFraction 8bitunsigned 0.00390625ft‐lb/bit 0 0to0.99609375ft‐lb

7 PowerFraction 8bitunsigned 0.00390625HP/bit 0 0to0.99609375HP

DriveshaftRPM

DriveshaftTorque

DriveshaftPower

Message ID: 0x00000161

Transmit Rate: Every 65 ms

Byte Label DataType Scaling Offset Range

0

2

4

6 ‐‐‐ ‐‐‐ ‐‐‐ ‐‐‐ ‐‐‐

7 ‐‐‐ ‐‐‐ ‐‐‐ ‐‐‐ ‐‐‐

DriveshaftRPM

DriveshaftTorque

DriveshaftPower

16bit

unsigned 1rpm/bit

16bitsigned 1ft‐lb/bit

16bitsigned 1HP/bit

16bit

unsigned 1rpm/bit

16bitsigned 0.00390625ft‐lb/bit

16bitsigned 0.00390625HP/bit

0

0to65,535RPM1

0

‐32,767to+32,767ft‐lb3

0

‐32,767to+32,767HP5

0

0to65,535RPM1

0

‐128to+128ft‐lb3

0

‐128to+128HP5

Page 17 10-4800 Dynoshaft REV D.docx

Page 18

SPECIFICATIONS

Dyno-Shaft

Operating Current 1A (typical)

Operating Voltage (nominal) 10-18 volts dc

Data Stream 1 x AEMnet

Sample Rate ~15 Hz (65mS)

Max Operating Temp 225 F

Controller Shutdown Temp 250 F

Maximum Torque Based on yoke design

Maximum Dyno-Shaft RPM 10,000 RPM. Note: This is the sensor limits, not your

driveshaft limit.

RECOMMENDED PARTS

30-2500 AQ-1 Data logger

30-2501 AQ-1 Data logger with OBD-2

30-2340 4 Channel UEGO Controller

30-5130 Analog Gauge Style UEGO Controller

30-4100 Digital Gauge Style UEGO Controller

REPLACEMENT PARTS

35-4780 Dyno-Shaft/AEMnet “Y” Harness

Page 18 10-4800 Dynoshaft REV D.docx

Page 19

WARRANTY

12 MONTH LIMITED WARRANTY

Advanced Engine Management Inc. warrants to the consumer that all AEM High

Performance products will be free from defects in material and workmanship for a

period of twelve (12) months from date of the original purchase. Products that fail within

this 12-month warranty period will be repaired or replaced at AEM’s option, when

determined by AEM that the product failed due to defects in material or workmanship.

This warranty is limited to the repair or replacement of the AEM part. In no event shall

this warranty exceed the original purchase price of the AEM part nor shall AEM be

responsible for special, incidental or consequential damages or cost incurred due to the

failure of this product. Warranty claims to AEM must be transportation prepaid and

accompanied with dated proof of purchase. This warranty applies only to the original

purchaser of product and is non-transferable. All implied warranties shall be limited in

duration to the said 12 month warranty period. Improper use or installation, accident,

abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims any

liability for consequential damages due to breach of any written or implied warranty on

all products manufactured by AEM. Warranty returns will only be accepted by AEM

when accompanied by a valid Return Goods Authorization (RGA) number. Product

must be received by AEM within 30 days of the date the RGA is issued.

Please note that before AEM can issue an RGA for any product, it is first necessary for

the installer or end user to contact the AEM Performance Electronics tech line at 1-800423-0046 to discuss the problem. Most issues can be resolved over the phone. Under

no circumstances should a system be returned or a RGA requested before the above

process transpires.

Need additional help? Contact the AEM Performance Electronics tech department at

1-800-423-0046 or tech@aempower.com, or visit the AEM Performance Electronics

forum at http://forum.aempower.com/forum/

Page 19 10-4800 Dynoshaft REV D.docx

Loading...

Loading...