Page 1

Installation Instructions for

30-4350

AEM Tru Boost

Boost Controller Gauge

WARNING:

This installation is not fo the electrically or mechanically

challenged! Use th EXTREME

uncomfortable with anything about this, please refer the

installation to an AEM trained tuning shop or call 800-423-0046

for technical assistance. You should also visit the AEM

,!

This product is legal in California for racing vehicles onl

Performance Electronics Forum at http://www.aempower.com

NOTE: AEM holds no responsibility for any engine damage tha

esults from the misuse of this product!

r

never be used on public highways.

ADVANCED ENGINE MANAGEMENT INC.

2205 126

Phone: (310) 484-2322 Fax: (310) 484-0152

Instruction Part Number: 10-4350 Rev 090506

© 2006 Advanced Engine Management, Inc.

is gauge with

th

Street Unit A, Hawthorne, CA. 90250

http://www.aempower.com

r

caution! If you are

Page 1

t

y and should

Page 2

EM’s Tru Boost boost controller gauge is a stand-alone boost controller that features a

A

ree digit LED digital readout with 24 sweeping multi color LED’s, two programming

th

uttons, and an on-board pressure sensor. The Tru Boost kit contains all necessary

b

components, including an AEM high performance boost control solenoid, to install and

use the Tru Boost.

Contents: See Figure 1.

(1) Tru Boost Ga

uge assembly

(1) Appearance kit (Silver bezel, silver pin guide, white faceplate)

(1) Installation kit (Butt

connector, 6 pieces)

(1) Tru Boost cable

(1) Boost solenoid

(1) Instruction manual

(1) Boost hose 10’

(1) 1/8” barb to 1/8”

NPT fitting

(1) Sintered Muffler

(2) –6 to 1/8” NPT f

(2) 3/16” barb to 1/8” NPT fitting

itting

Figure1. Kit Components

Page 2

Page 3

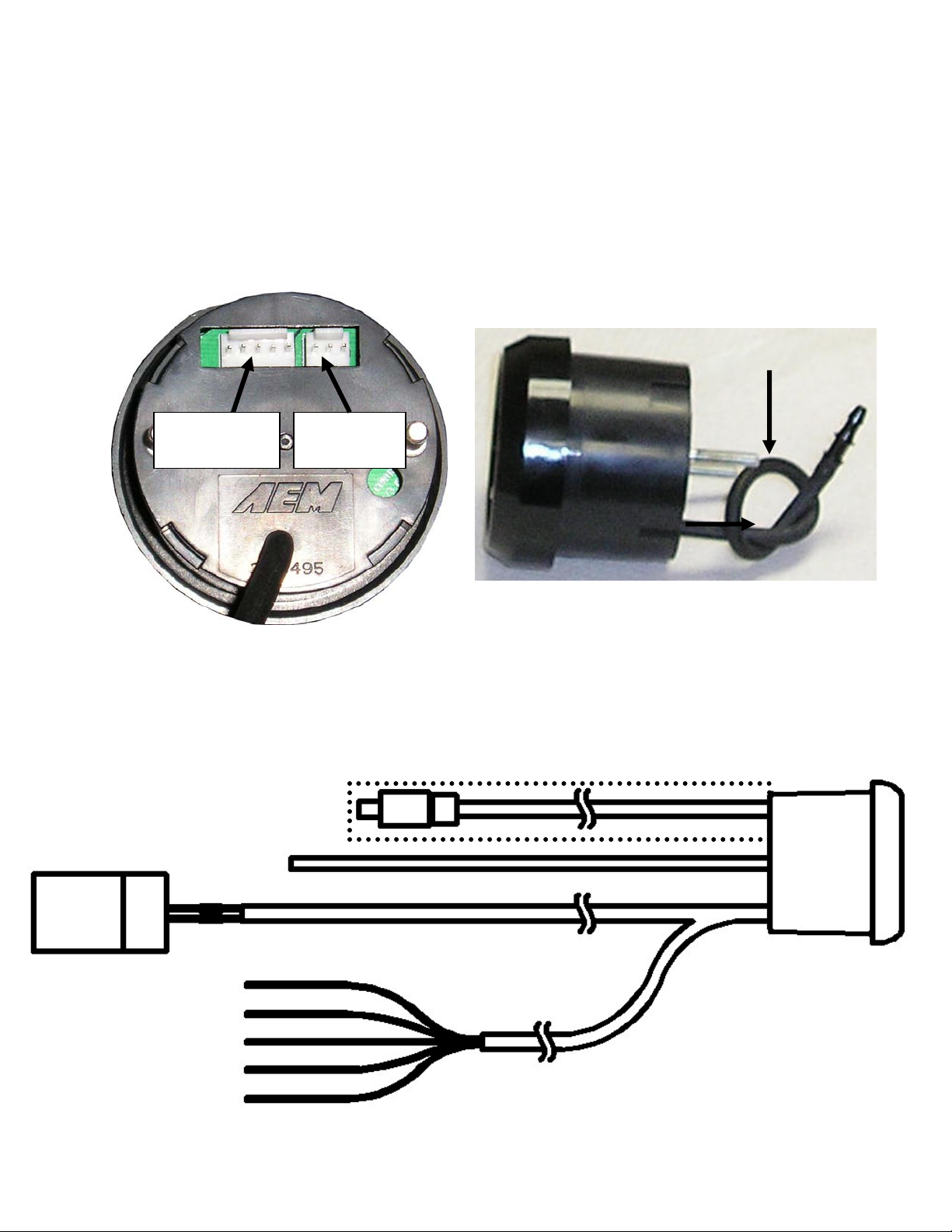

Installing the Gauge

The AEM Tru Boost boost controller gauge requires a standard 2 1/16” (52MM)

ounting hole and can be mounted in a flat panel or most standard gauge pods. The

m

included cable contains

connec t

ts to a mating 5-pin connector on the back of the gauge. See Figure 2. Connec

two wire bundles and a 5-pin connector. The 5-pin connector

the black and red wires in the long 2-wire bundle to the leads from the boost solenoid.

Polarity does not matter. Connect the black wire from the 5-wire bundle to a good

ground. Connect the 2 red wires to a fused, switched, +12Vdc power source. The gray

wire is an optional low side driver output. The orange wire is an optional scramble

boost input. The orange and gray wires do not need to be connected for the gauge

to

function.

Boost Hose

5-pin

connector

Figure 2. Connector Locations

The boost hose protruding from the back

ressure using the on-board pressure sensor, the boost

p sensor. See Figure 3. When

ose must be connected to manifold pressure. Connect the boost hose to manifold

h

pressure using the supplied tubing and 1/8” NPT barb or an existing manifold pressu

port. (NOTE: Do not pull on the boost hose) See Figure 4 for a connection diagram.

OPTIONAL 75 PSIA

SENSOR AND CABLE

MANIFOLD

PRESSURE

RED

B

LACK

BOOST

SOLENOID

D (SWITCHE

RE D, FUSED +12VDC)

RED (SWITC ED, FUSED +12VDC)

H

BLACK (POWER GROUND)

ORANGE (SCRAMBLE BOOST)

G

RAY (LOW SIDE OUTPUT)

3-pin

connector

Figure 4. Connection Diagram

Figure 3. Boost Hose

of the gauge is connected to the on-board

Page 3

re

Tru Boost

Page 4

Scramble Boost Connection (Optional)

Scramble boost is activated when the orange wire is grounded. Connect the

range wire to ground through a switcho as shown in Figure 5.

Switch

Figure 5. Scramble Boost Connection

Warning Light Connection (Optional)

The Tru Boost w is activated. Connect

e grey wire to a warni

ill ground the gray wire when the alarm

ng light as shown in Figure 6. th

Warning Light

+12Vdc Fused

Figure 6. Warning Light Connection

oost Solenoid Connec

B tions

When energized, ports 1 & 2 are connected, when de-energized, ports 2 & 3 are

onnected. The port numbers are clearly noted on the solenoid body. See Figures 7

c

and 8 for plumbing instructions.

Figure 7. External Wastegate Connection

Figure 8. Internal Wastegate Connection

Ground

Page 4

Page 5

xternal Pressure Sensor

E

The Tru Boost is capa

optiona r

l external sensor kit. The 30-4351 sensor kit comes with an AEM 75psia senso

ble of reading boost levels up to 50 psig when using the

and a harness to connect the sensor to the Tru Boost. See Figure 9. Plug the single

row 3-pin connector into the mating connector on the back of the gauge. See Figure 2

.

Plug the black 3-pin connector into the pressure sensor. In order for the Tru Boost to

read the external sensor, the external sensor (E) must be selected in the pressure

sensor (SEn) option.

Figure 9. 30-4351 Tru Boost External Sensor Kit

onfiguring the Tru Boost

C

ser adjustable options. Descriptions of each option, along

with th

The Tru Boost has 9 u

e abbreviation and default value for each option shown in parenthesis, are listed

below:

isplay Units: (UnI - PSI)

D

Use the buttons on th

e front of the gauge to change the units displayed by the

gauge. Select from Psig (PSI), Bar (bAr), and Kpg (PAS).

cramble Boost: (SCb - 10.0)

S

Set the scramble boost du

ty cycle output. Duty cycle can be set between 10%

and 90%. The Tru Boost will output the selected duty cycle when the scramble boost

input is grounded.

cramble Boost Time: (SCr - 0.00)

S

Select the duration of time (0-2

5.5 seconds) the Tru Boost will output the

scramble boost duty cycle when the scramble boost input is grounded.

ressure Sensor: (SEn - I)

P

Select the pressure se

nsor to be used by the Tru Boost. The internal sensor (I)

is used for boost levels up to 29 psig. The optional external sensor (E) is used for boos

levels above 29 psig, up to 50 psig.

t

Page 5

Page 6

larm: (ALA - 30)

A

Set the boos

activated, the LED lights flash yellow and the warning light output (grey wire) is pu

t pressure at which the alarm will activate. When the alarm is

lled to

ground.

pring Pressure: (SPr – 2.00)

S

Enter the waste gate sprin

g pressure(3psi less then your spring). The Tru Boost

will keep the boost solenoid open from 1 psi until boost exceeds the selected value.

This value can be adjusted to reduce lead in boost spikes or reduce spool up time. If

the spring pressure is unknown, a conservative starting value of 5 is suggested.

ar Graph Full Scale: (FUL – 30)

B

Set the full-scale value of the

sweeping LED lights. The LED lights start at 0 psig

and stop at the full-scale value, increasing in 24 equal increments.

oost Setting A: (AXX – A10)

B

Set the output duty cycle

(10%-90%) for setting A. For setting A, the duty cycle

is displayed as “AXX”. When setting duty cycle, the gauge will display the current

manifold pressure. When either button is pressed to increase or decrease duty cyc

le,

the gauge will momentarily display the selected duty cycle before returning to manifold

pressure.

oost Setting B: (bXX – b10)

B

Same as A, except duty c

ycle is displayed as “bXX”.

OTE: While configuring the Tru Boost, the Tru Boost will stay in the

N

programming mode until either the run mode is reached, or the power

is turned

off. Also, since the Tru Boost does not change run modes while in the

programming menu, the corresponding run mode must be selected befo

re

entering the programming menu in order to view real time boost changes.

To enter the program menu, hold both buttons down for 2 seconds and release

then th

e gauge will display “PRG”. Hold both buttons again for 2 seconds and release

to move to the first option. Push both buttons at the same time to move to the next

option. The order of options is shown in the menu tree below. As a shortcut, the ga

uge

will skip to boost setting A if only the left button is pressed after “PRG” is displayed.

Page 6

Page 7

Page 7

Page 8

Using the Tru Boost

The Tru Boost has 3 running modes. In all modes, for manifold pressures less

than 0 psig, the sweeping LED’s remain off, the gauge displays pressure in units of

in-hg, and the displayed values are negative. In mode A, the gauge will output the duty

cycle selected for boost setting A. The gauge will output the duty cycle selected for

boost setting B when in mode B. In the “OFF” mode, the solenoid output is turned off.

Press and hold the left button for 2 seconds to change run modes. The order of run

modes is shown in the menu tree below. The gauge also remembers the peak boost

level achieved. Press and hold the right button for 2 seconds to display the peak boost.

Press and hold the right button for 4 seconds to clear the peak boost value.

Scramble Boost

Scramble boost is a feature that allows the driver to momentarily change the duty

cycle output of the Tru Boost. The output duty cycle for scramble boost is set in the

scramble boost (SCb) option. The scramble boost duration is set by the scramble boost

time (SCr) option. Scramble boost is activated by grounding the orange scramble boost

input wire.

Alarm

All 24 LED lights will flash yellow if manifold pressure exceeds the alarm level for

more than 1 second. The low side driver output will also switch to ground. The LED

lights will continue to flash and the output will stay grounded until either button is

pushed or the gauge is turned off.

Over-Boost

The boost solenoid will shut off and all 24 LED lights will flash red if manifold

pressure exceeds the alarm value by 10% for more than 1 second or if manifold

pressure exceeds the alarm level by 20% for more than 200 milliseconds. The solenoid

will remain off and the LED lights will continue to flash until either button is pushed or

the gauge is turned off.

Page 8

Page 9

Error Detection

ErP- If the external sensor is shorted or disconnected, the LED lights will flash

red and the center digits will display “ErP”. The error code will not activate when using

the internal pressure sensor.

ErS- If the boost solenoid is shorted or disconnected, the LED lights will flash red

and the center digits will display “ErS”. The error code will not activate when the Tru

Boost is on the off mode. Note: The solenoid always has a small pwm signal to allow

for fault detection.

Changing the gauge configuration

The AEM Tru Boost comes configured with the black bezel, black pin guide, and

the black faceplate. However, a silver bezel, a silver pin guide, and a white faceplate

are also included in the gauge kit. To change the faceplate, pin guide, or bezel, orient

the gauge so you are looking at the faceplate. Rotate the bezel counter-clockwise to

unscrew it from the gauge cup. The bezel, lens, pin guide, rubber spacer, faceplate,

diffuser, and anti-glare shield are all removable. Reassemble the gauge as shown in

Figure 10. Make sure the small light holes in the faceplate, diffuser, and anti-glare

shield line up with the light sensor on the circuit board. Do not over tighten the bezel

when reassembling the gauge.

Figure 10. Tru Boost Gauge Assembly

Page 9

Page 10

AEM Electronics warranty

Advanced Engine Management Inc. warrants to the consumer that all AEM High

Performance products will be free from defects in material and workmanship for a

period of twelve (12) months from date of the original purchase. Products that fail within

this 12-month warranty period will be repaired or replaced at AEM’s option, when

determined by AEM that the product failed due to defects in material or workmanship.

This warranty is limited to the repair or replacement of the AEM part. In no event shall

this warranty exceed the original purchase price of the AEM part nor shall AEM be

responsible for special, incidental or consequential damages or cost incurred due to the

failure of this product. Warranty claims to AEM must be transportation prepaid and

accompanied with dated proof of purchase. This warranty applies only to the original

purchaser of product and is non-transferable. All implied warranties shall be limited in

duration to the said 12-month warranty period. Improper use or installation, accident,

abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims any

liability for consequential damages due to breach of any written or implied warranty on

all products manufactured by AEM. Warranty returns will only be accepted by AEM

when accompanied by a valid Return Merchandise Authorization (RMA number.

Product must be received by AEM within 30 days of the date the RMA is issued.

Please note that before AEM can issue an RMA for any electronic product, it is first

necessary for the installer or end user to contact the EMS tech line at 1-800-423-0046

to discuss the problem. Most issues can be resolved over the phone. Under no

circumstances should a system be returned or a RMA requested before the above

process transpires.

AEM will not be responsible for electronic products that are installed incorrectly,

installed in a non approved application, misused, or tampered with.

Any AEM electronics product can be returned for repair if it is out of the warranty period.

There is a minimum charge of $50.00 for inspection and diagnosis of AEM electronic

parts. Parts used in the repair of AEM electronic components will be extra. AEM will

provide an estimate of repairs and receive written or electronic authorization before

repairs are made to the product.

Page 10

Loading...

Loading...