Page 1

Installation Instructions for

30-4110

Gauge-Type UEGO Controller

WARNING:

This installation is not for the electrically or mechanically

challenged! Use this sensor with EXTREME caution! If you are

uncomfortable with anything about this, please refer the

installation to an AEM trained tuning shop or call 800-423-0046

for technical assistance. You should also visit the AEM

!

This product is legal in California for racing vehicles only and should

Performance Electronics Forum at http://www.aempower.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

never be used on public highways.

ADVANCED ENGINE MANAGEMENT INC.

th

2205 126

Phone: (310) 484-2322 Fax: (310) 484-0152

Instruction Part Number: 10-4110 Rev 140520

2014 Advanced Engine Management, Inc.

Street Unit A, Hawthorne, CA. 90250

http://www.aemelectronics.com

Page 1

Page 2

AEM Gauge-Type UEGO Controller Parts

1 x UEGO Gauge Assembly

1 x UEGO Sensor

1 x O2 Sensor Bung

4 x Butt Connectors

1 x Installation Instruction

1 x 4 Lead Harness

1 x UEGO Sensor Harness

1 x Silver Bezel

1 x Black Lambda Faceplate

1 x White AFR Faceplate

Replacement Wideband Controller Components

30-2004 Replacement Bosch LSU49 Sensor

35-3441 96” Wideband LSU49 UEGO Sensor Replacement Cable

35-3401 36” Wideband UEGO Power Replacement Cable

35-4005 Mild Steel Oxygen Sensor Bung (welding required)

35-4001 Mild Steel Sensor Bung Plug

30-4008 Stainless Steel Tall Finned Oxygen Sensor Bung (welding required)

Congratulations! The 52mm (2-1/16”) AEM Universal Exhaust Gas Oxygen (UEGO)

Gauge features a digital readout and sweeping 24 color-coded light emitting diode

(LED) display, providing immediate reference to the engine air fuel ratio (or lambda) in

real-time. The AEM gauge is ideal for all vehicles including carbureted applications and

engine dynamometers. A user-selectable 0-5V analog output is included and can be

used with data loggers as well as most Electronic Fuel Injection (EFI) systems including

the AEM Engine Management System (EMS). A serial data stream is also integrated for

air fuel (or lambda) ratio output to a RS-232 com port.

Because the AEM gauge utilizes the internal AEM UEGO controller and Bosch UEGO

Sensor, it is accurate and repeatable to 0.1 of an air/fuel ratio point! With this, there is

no abrupt oscillation as found in many competitor gauges, which utilize a narrow band

oxygen sensor detecting only stoichiometry.

Page 2

Page 3

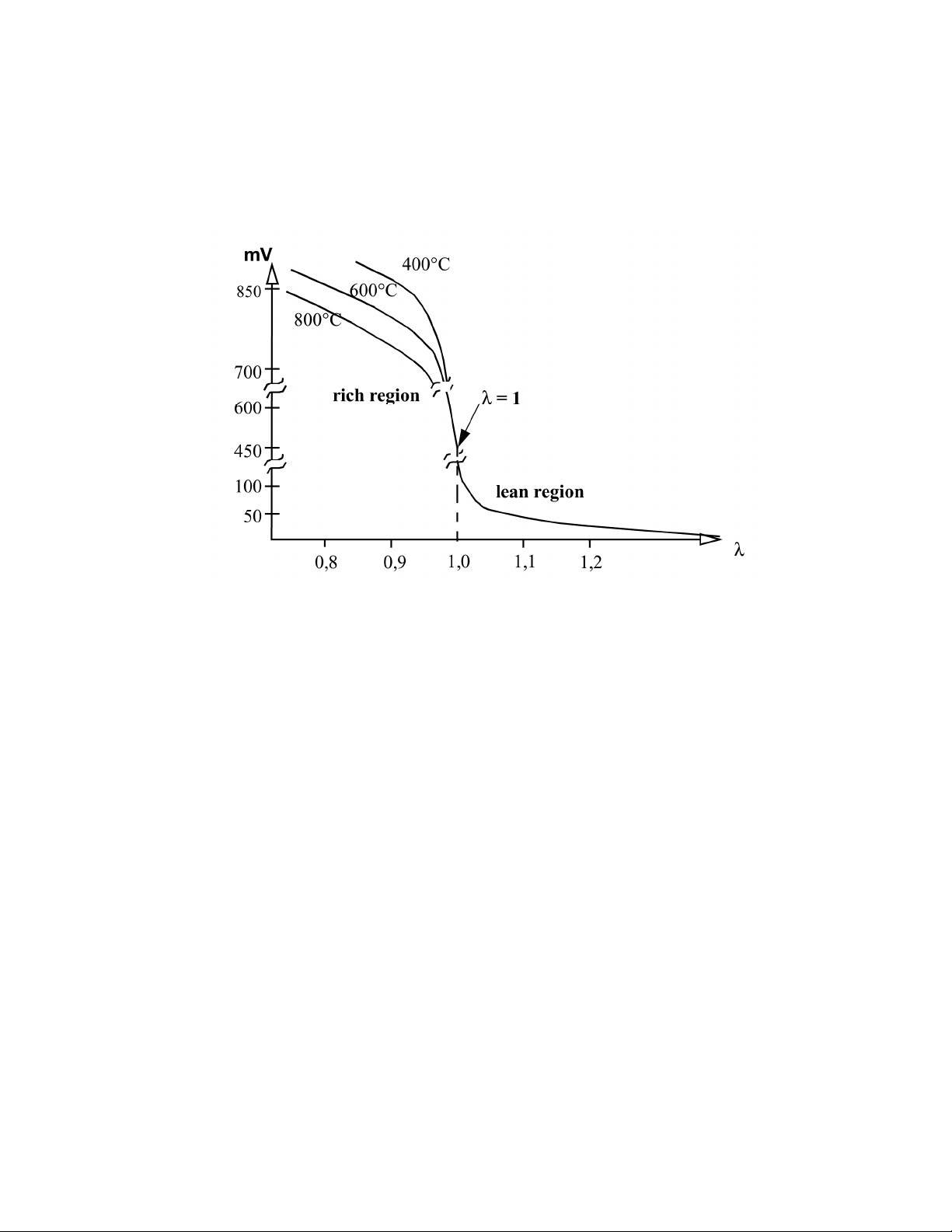

Typical production vehicle oxygen sensors rely on “Nernst Cell” technology, commonly

called “Narrow Band” and sometimes erroneously described as “Wide Band”. This is a

very cost effective method that outputs a voltage based on the oxygen content of the

gas being sampled. It is accurate in the region surrounding stoichiometric operation and

leaner. Unfortunately, in the rich region where high performance engines usually

operate, their accuracy and repeatability is virtually non-existent. (Figure 1)

Figure 1. Characteristic curve of a Nernst Cell O2 Sensor

The rich region output of narrow band O2 sensors is temperature dependent, which

renders it useless if an accuracy better than 1.5:1 AFR is desired. This is immediately

obvious given the fact that a single output voltage actually represents wildly different air

fuel ratios depending on the unregulated and unmeasured sensor temperature. These

sensors were designed for operating closed loop around stoichiometry (14.64:1 for

gasoline), and for performance tuning they are useless.

The heart of the AEM gauge is the Bosch LSU4.9 Universal Exhaust Gas Oxygen

(UEGO) sensor. This type of sensor is commonly referred to as “laboratory grade” and

works on a different principle than the narrow band oxygen sensor found in most

vehicles. Its unique design makes precision AFR measurements possible over the

entire operating range.

UEGO sensors use a “current pump” to determine the actual oxygen concentration

within the sensing element. The output is in the form of a very small current, which

varies depending on the air-fuel ratio. This is completely different from a narrow band

oxygen sensor, which directly outputs a voltage. The UEGO sensor design allows

measurement of the exact air fuel ratio over the entire operating range.

Page 3

Page 4

Each AEM UEGO sensor is individually calibrated and a resistor integral at the

connector body is laser trimmed with this value. This process replaces the “free air”

calibration procedure required by some manufacturers when changing sensors and

implements a sensor specific calibration for unparalleled accuracy. (Figure 2)

Figure 2. The connector module contains a laser trimmed calibration resistor,

which defines the characteristic of the sensor.

INSTALLATION

Disconnect the negative (-) battery cable. There are two harnesses that connect to the

back of the AEM UEGO gauge. The longer harness connects to the UEGO sensor.

The shorter harness contains four leads. The red and black leads must be connected in

order for the gauge to function. Connection of the white and blue wires is optional.

Connect the wires as shown below. (Figure 3) The harness ends with the four and six

pin connectors connect to the back of the gauge. When looking at the back of the

gauge as shown below, the six-pin connector connects on the left side and the four pin

on the right side. The locating tabs on the four and six pin connectors should be facing

up. (Figure 4)

Figure 3. Gauge Installation Connections

Page 4

Page 5

Figure 4. Gauge Side Harness Connections

RED <Power>

Connect to a switched 10-18 volt power source utilizing a 10A fuse.

BLACK <Ground>

Connect to a clean power ground.

*WHITE <Analog Output>

Connects to any auxiliary unit that accepts a 0-5 volt input.

*BLUE <Serial Output>

Connects to a RS-232 com port for hyper-terminal data logging.

*optional

Page 5

Page 6

Analog Output

(Skip this section if you are not connecting the product to an AEM EMS.)

If the AEM UEGO gauge is to be connected to an AEM EMS, the UEGO gauge’s

WHITE Analog Output wire shall be connected to an EMS Lambda input. Locating a

suitable Lambda input channel can be done using the Application Notes provided with

the EMS. If the Application Notes are not readily accessible, a current list of AEM

Engine Management Systems is illustrated below. (Table 1)

Lambda

AEM Series 2 EMS P/N

30-6100/30-6101 B47 B48 B65

30-6010/6012/6050/6052 C16 A23 C18

30-6000/6001/6002/6040/6042 D14 D16 D21

30-6060 D7 D14 D12

30-6310/30-6311/30-6313 76 75 92

30-6320 71 73 34

AEM EMS-4

30-6905 20

AEM Series 1 EMS P/N

30-1000/1001/1002/1040/1042 D14 D16 D21

30-1010/1012/1050/1052 C16 A23 C18

30-1020/1060 D7 D14 D12

30-1030/1031/1070 C13 C14 A16

30-1080 C16 C8 C14

30-1081 C16 B11 C14

30-1100/1101 B47 B48 B65

30-1110 1C 9C 13C

30-1120/1121/1130 B6 B14 B9

30-1220 30 31 60

30-1300 4 66 17

30-1310/1311/1312/1313 76 75 92

30-1320 71 73 34

30-1400 29 43 46

30-1401 44 43 46

30-1510 C2-31 C2-33 C2-32

30-1600/1601/1602/1603 19 NA 21

30-1610/1611/1612 46 52 50

30-1620/1621/1622/1623 29 55 30

30-1710 2N 4J 2C

30-1720 C3 D3 O3

30-1800 C3 A2 D4

30-1810 D19 B17 B19

30-1820/1821 A26 D25 C35

#1 Pin

Lambda

#1 Pin

Lambda

#1 Pin

Lambda

#2 Pin

Lambda

#2 Pin

Sensor

GND Pin

Sensor

GND Pin

35

Sensor

GND Pin

Table 1. Lambda input channel locations for AEM EMS

Page 6

Page 7

Below (Table 2) is a list of AFR values that should be entered into the 02 Sensor #1(#2)

Cal Table if inputting the analog signal to an AEM EMS. These calibration table(s) are

found in the AEMPro software: Setup | Sensors | Oxygen Sensor | Oxygen Sensor

#1(#2)

02 Volts

0.00

0.16

0.31

0.47

0.62

0.78

0.94

1.09

1.25

1.40

1.56

1.72

1.87

2.03

2.18

2.34

2.50

2.65

2.81

2.96

3.12

3.28

3.43

3.59

3.74

3.90

4.06

4.21

4.37

4.52

4.68

4.84

4.99

Lambda

0.683

0.705

0.725

0.747

0.768

0.790

0.811

0.832

0.854

0.874

0.896

0.918

0.939

0.960

0.981

1.003

1.025

1.045

1.067

1.087

1.109

1.130

1.152

1.173

1.194

1.216

1.236

1.258

1.280

1.301

1.322

1.343

1.365

Gasoline AFR Methanol AFR Propane AFR Ethanol AFR CNG AFR

10.00 4.42 10.72 6.15 9.90

10.32 4.56 11.07 6.34 10.22

10.62 4.69 11.39 6.53 10.52

10.94 4.83 11.73 6.73 10.84

11.24 4.97 12.05 6.91 11.13

11.56 5.11 12.40 7.11 11.45

11.88 5.25 12.74 7.30 11.77

12.18 5.38 13.06 7.49 12.06

12.50 5.52 13.41 7.68 12.38

12.80 5.66 13.73 7.87 12.68

13.12 5.80 14.07 8.07 12.99

13.44 5.94 14.41 8.26 13.31

13.74 6.07 14.73 8.45 13.61

14.06 6.21 15.08 8.64 13.93

14.36 6.35 15.40 8.83 14.22

14.68 6.49 15.74 9.02 14.54

15.00 6.63 16.09 9.22 14.86

15.30 6.76 16.41 9.41 15.15

15.62 6.90 16.75 9.60 15.47

15.92 7.04 17.07 9.79 15.77

16.24 7.18 17.42 9.98 16.08

16.54 7.31 17.74 10.17 16.38

16.86 7.45 18.08 10.36 16.70

17.18 7.59 18.42 10.56 17.02

17.48 7.73 18.75 10.75 17.31

17.80 7.87 19.09 10.94 17.63

18.10 8.00 19.41 11.13 17.93

18.42 8.14 19.75 11.32 18.24

18.74 8.28 20.10 11.52 18.56

19.04 8.41 20.42 11.70 18.86

19.36 8.56 20.76 11.90 19.17

19.66 8.69 21.08 12.09 19.47

19.98 8.83 21.43 12.28 19.79

Table 2. EMS Calibration Tables, P0 mode

When connecting to AEM’s Series1 EMS, make sure to verify that the O2 #1 Gain option is set

so the voltage from the O2 #1 Volts parameter matches the voltage input at the EMS from the

O2 sensor. An easy way to do this is to disconnect the UEGO sensor from the UEGO gauge.

When in this state, the UEGO gauge will output 2.35 volts. You can then adjust the O2 #1 Gain

until the O2 #1 Volts display in AEMPro reads 2.35 volts.

When connecting to AEM’s Series2 EMS,

Page 7

Page 8

1. Unplug the O2 Sensor from the 30-4110 Gauge.

2.

Open up the O2 Calibration Setup Wizard by navigating to Wizards -> Setup Wizard

-> Sensor: O2 #1 (AFR)

3.

Double click the AEM Digital Gauge (PN 30-4100) it will highlight and display

matched.

4.

Click Apply and close screen.

5.

Note: The 'O2 Gain' options have been removed from Series2 EMS firmware.

Next navigate to the O2 Sensor #1 Cal Table. This can be done by clicking on the

6.

Sensors Tab at the top of the screen or using the Display Explorer.

a.

Display Explorer navigation – Display -> Display Explorer -> Setup ->

Sensors -> Oxygen Sensor(s) -> O2 Sensor #1 Cal

b.

Double click to open the following tables. Channels – O2 Sensors & O2

Sensor #1 Cal

7.

Channels – O2 Sensor Table

a.

With the Gauge-Type UEGO Sensor unplugged the O2 #1 Volts parameter

should read 2.32V (+/- .02 Volts)

b.

With the Gauge-Type UEGO Sensor unplugged the O2 #1 should match the

gauge display at 14.7AFR.

c.

If the channel in AEMtuner is not displaying the correct 14.7 AFR value.

Select the entire 'O2 Sensor #1 Cal' table and increase or decrease until the

EMS matches the gauge display.

When connecting to a third party EFI system, the AEM UEGO gauge’s WHITE Analog Output

wire shall be connected to the analog O2 sensor input of that system. Consult the

documentation provided with the system for detailed instructions.

Serial Output

The serial output can be used for data logging when an EFI system is not accessible. To run the

data stream, a RS-232 (DB-9) Female Receptacle shall be purchased.

12345

6789

Figure 5. Wire View of RS-232 (DB-9) Male Plug

Two wires need to be connected to a RS-232 serial port. The BLUE wire from the AEM UEGO

Gauge shall be connected to Pin #2 (RX) on the serial port for receiving data. Pin # 5 (GND) on

the serial port shall be grounded. If a standard 9-pin serial cable is to be cut instead, the (RX)

wire is typically RED and the (GND) wire is typically GREEN. However, this should be confirmed

with a continuity tester before attempting. (Figure 5)

Use HyperTerminal for testing the data stream. This software is found on most PCs prior to

Windows 7; other operating systems will require locating alternative terminal software such as

TeraTerm or RealTerm. To find HyperTerminal go to: Start | All Programs | Accessories |

Communications | HyperTerminal. Name the New Connection and click OK. Set the COM port

to the one being used and click OK.

Bits per Second = 9600

Data Bits = 8

Parity = None

Stop Bits = 1

Flow Control = Hardware

Page 8

Page 9

Verify the settings above and click OK. When power is supplied to the AEM UEGO Gauge, AFR

(or Lambda) data will be displayed, as shown below. (Figure 6)

Figure 6. Data logging with HyperTerminal

UEGO Sensor

The 30-4110 is compatible with Bosch LSU4.9 sensors *only*. This sensor can be

identified by the connector as shown in Figure 7.

Figure 7. Use only Bosch LSU4.9 Sensors!

If attempting to route the UEGO Sensor through a tight space, AEM recommends

routing the smaller six pin connector through the hole. If the UEGO sensor is to be put

through a conduit or firewall, a 1.05in (26.7mm) drill is required.

Page 9

Page 10

IMPORTANT INSTALLATION NOTE - UEGO Sensor Mounting Orientation

A weld-in M18 X 1.5 boss is supplied for sensor installation. Mount the O2 sensor in the

exhaust system at least 18 inches downstream from the exhaust port. If you anticipate

high EGT's (over 800C), run a turbocharger, run at high RPM for extended periods of

time or plan on running leaded race fuel then you must mount the sensor at least 36

inches or more downstream of the exhaust port as all of these can cause the sensor to

overheat. On turbocharged engines the UEGO sensor must be installed after the

turbo charger, if not, the pressure differential will greatly affect the accuracy of

the unit. For accurate readings, the sensor must be mounted before catalytic

converters and/or auxiliary air pumps. To prevent collection of liquids between the

sensor housing and sensor element during the cold start phase, the installation angle

should be inclined at least 10° from horizontal with the electrical connection upwards,

see below. (Figure 8)

Figure 8. Minimum mounting angle for the UEGO Sensor

Page 10

Page 11

Configuring Calibration Outputs

The AEM default position is (P0). When set to (P0) (Figure 10A), the gauge displays

AFR values. (P1) is the same as (P0), except the gauge displays lambda values. These

settings (P1 and P0) implement a linear calibration with the most useful voltage range

possible (0-5V). The AFR calibration (P2) is linear and similar to (P1) with a smaller

voltage range (1-2V). The AFR calibration (P3) emulates the Autronic Wideband O2

Sensor calibration (0-1V). The AFR calibration (P4) emulates a non-linear Nernst Cell

calibration (0-1V). Refer to the Table 3 and Figure 9 for specific calibration details.

LED LED Lambda AFR (Gasoline) Analog Output Voltage Modes

Number Color (λ) AFR LED "ON" Range P0 P1 P2 P3 P4

LED 1 Green 0.683 10 Rich Rich 0.000 0.000 1.000 0.000 0.905

LED 1 Green 0.700 10.25 Rich Rich 0.125 0.125 1.025 0.013 0.904

LED 1 Green 0.717 10.5 Rich Rich 0.250 0.250 1.050 0.025 0.903

LED 1 Green 0.734 10.75 Rich Rich 0.375 0.375 1.075 0.038 0.902

LED 1 Green 0.751 11.00 Rich 11.125 0.500 0.500 1.100 0.050 0.901

LED 2 Green 0.768 11.25 11.125 11.375 0.625 0.625 1.125 0.063 0.900

LED 3 Green 0.786 11.50 11.375 11.625 0.750 0.750 1.150 0.075 0.890

LED 4 Green 0.803 11.75 11.625 11.875 0.875 0.875 1.175 0.088 0.880

LED 5 Green 0.820 12.00 11.875 12.125 1.000 1.000 1.200 0.100 0.870

LED 6 Green 0.837 12.25 12.125 12.375 1.125 1.125 1.225 0.113 0.860

LED 7 Green 0.854 12.50 12.375 12.625 1.250 1.250 1.250 0.125 0.850

LED 8 Green 0.871 12.75 12.625 12.875 1.375 1.375 1.275 0.138 0.840

LED 9 Green 0.888 13.00 12.875 13.125 1.500 1.500 1.300 0.150 0.830

LED 10 Green 0.905 13.25 13.125 13.375 1.625 1.625 1.325 0.163 0.820

LED 11 Green 0.922 13.50 13.375 13.625 1.750 1.750 1.350 0.175 0.800

LED 12 Yellow 0.939 13.75 13.625 13.875 1.875 1.875 1.375 0.188 0.775

LED 13 Yellow 0.956 14.00 13.875 14.125 2.000 2.000 1.400 0.200 0.750

LED 14 Yellow 0.973 14.25 14.125 14.375 2.125 2.125 1.425 0.213 0.700

LED 15 Yellow 0.990 14.50 14.375 14.625 2.250 2.250 1.450 0.225 0.600

LED 16 Yellow 1.008 14.75 14.625 14.875 2.375 2.375 1.475 0.238 0.410

LED 17 Yellow 1.025 15.00 14.875 15.125 2.500 2.500 1.500 0.250 0.240

LED 18 Yellow 1.042 15.25 15.125 15.375 2.625 2.625 1.525 0.263 0.170

LED 19 Yellow 1.059 15.50 15.375 15.625 2.750 2.750 1.550 0.275 0.137

LED 20 Yellow 1.076 15.75 15.625 15.875 2.875 2.875 1.575 0.288 0.113

LED 21 Red 1.093 16.00 15.875 16.125 3.000 3.000 1.600 0.300 0.100

LED 22 Red 1.110 16.25 16.125 16.375 3.125 3.125 1.625 0.313 0.091

LED 23 Red 1.127 16.50 16.375 16.625 3.250 3.250 1.650 0.325 0.083

LED 24 Red 1.144 16.75 16.625 Lean 3.375 3.375 1.675 0.338 0.077

LED 24 Red 1.161 17.00 Lean Lean 3.500 3.500 1.700 0.350 0.076

LED 24 Red 1.178 17.25 Lean Lean 3.625 3.625 1.725 0.363 0.075

LED 24 Red 1.195 17.50 Lean Lean 3.750 3.750 1.750 0.375 0.074

LED 24 Red 1.212 17.75 Lean Lean 3.875 3.875 1.775 0.388 0.073

LED 24 Red 1.230 18.00 Lean Lean 4.000 4.000 1.800 0.400 0.072

LED 24 Red 1.247 18.25 Lean Lean 4.125 4.125 1.825 0.413 0.071

LED 24 Red 1.264 18.50 Lean Lean 4.250 4.250 1.850 0.425 0.070

Table 3. Calibration table of available outputs

Page 11

Page 12

18.0

17.0

1.18

16.0

1.08

Lambda (λ)

15.0

14.0

13.0

Air/Fuel Gasoline (AFR)

12.0

11.0

10.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

0.98

0.88

0.78

0.68

Analog Voltage (V)

AFR Small Volt Range (P2) AFR Autronic Emulation (P3)

AFR Nernst Emulation (P4) AEM GAUGE Default (P0 & P1)

Figure 9. Calibration graph of available outputs

To change the calibrations, a precision flat head screwdriver is needed. Locate the small hole located on

the back of the AEM gauge, as shown below. (Figure 10)

Figure 10. Calibration position screw location

With the screwdriver, clock the rotary switch into the desired calibration position, referring to the diagram

below (Figure 10A), and watch the alphanumeric readout, which will display the new position when

entered.

ROTARY SWITCH

P4

P3

P0

P1

P2

Figure 10A. Calibration screw position settings

The calibration will not be changed until the rotary switch reaches the middle of the new position.

Page 12

Page 13

Changing the gauge configuration

The AEM UEGO gauge comes configured with the black bezel and the black AFR

faceplate. However, a silver bezel, a white AFR faceplate, and a black Lambda

faceplate are also included in the gauge kit. To change the faceplate or bezel, orient

the gauge so you are looking at the faceplate. Rotate the bezel counter-clockwise to

unscrew it from the gauge cup. The bezel, glass lens, rubber spacer, faceplate, and

anti-glare shield are all removable. Reassemble the gauge as shown in the photo

below. Make sure the small light holes in the faceplate and anti-glare shield line up with

the light sensor on the circuit board. Do not over tighten the bezel when reassembling

the gauge. (Figure 11)

Figure 11. Gauge Assembly

For your reference, below is the multiplier for calculating the Air Fuel Ratio (AFR) of common

fuels from the Lambda value.

Gasoline AFR = Lambda x 14.64

Methanol AFR = Lambda x 6.47

Propane AFR = Lambda x 15.7

Ethanol AFR = Lambda x 9.00

CNG AFR = Lambda x 14.5

Specifications:

Gauge

Supply Current (nominal): 1.3 amps

0-5V Analog Outputs: 1

Measuring Range: Sweeping LED 0.751 to 1.143 Lambda

Measuring Range: Numerical Display 10.0:1 to 18.5:1 AFR Gasoline

Harness & Connector Temp Limit: 105C

Sensor

Type: Bosch UEGO LSU4.9

Accuracy: +/- 0.7%

Exhaust Temp Limit: 1030C

Cable & Protector Sleeve Temp Limit: 250C

Connector Temp Limit: 120C

Initial Warm-up Time: Less than 20 seconds

Weight: 80 grams

Heater Current: 1.2A at 12.0V (each sensor)

Mounting: M18 X 1.5 thread, Torque to 30 ft-lbs

Nominal Service Life:

80,000 km for Unleaded Fuel

50,000 km for Leaded Fuel 0.15g Pb/l

20,000 km for Leaded Fuel 0.40g Pb/l

10,000 km for Leaded Fuel 0.60g Pb/l

Page 13

Page 14

IMPORTANT Notes – PLEASE READ

The sensor contains a ceramic module and should not be subject to mechanical or

thermal shock or it may be damaged. The sensor is not designed for operation on

leaded fuels, doing so will dramatically shorten sensor life. Long term running in the rich

region (Lambda < 0.95) will shorten sensor life. High exhaust temperatures (over 850C)

will shorten sensor life. Engine oil consumption at a rate greater than 1 quart per 1,000

miles will shorten sensor life. With the UEGO Sensor installed, do not run the engine

without power applied to the gauge.

12 MONTH LIMITED WARRANTY

Advanced Engine Management Inc. warrants to the consumer that all AEM High Performance products will be free from defects in

material and workmanship for a period of twelve (12) months from date of the original purchase. Products that fail within this 12month warranty period will be repaired or replaced at AEM’s option, when determined by AEM that the product failed due to defects

in material or workmanship. This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty

exceed the original purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential damages

or cost incurred due to the failure of this product. The Bosch LSU 4.9 UEGO sensor has a limited life and is not warranted.

Warranty claims to AEM must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only

to the original purchaser of product and is non-transferable. All implied warranties shall be limited in duration to the said 12 month

warranty period. Improper use or installation, accident, abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims

any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by AEM.

Warranty returns will only be accepted by AEM when accompanied by a valid Return Goods Authorization (RGA) number. Product

must be received by AEM within 30 days of the date the RGA is issued.

Please note that before AEM can issue an RGA for any product, it is first necessary for the installer or end user to contact the AEM

Performance Electronics tech line at 1-800-423-0046 to discuss the problem. Most issues can be resolved over the phone. Under

no circumstances should a system be returned or a RGA requested before the above process transpires.

Need additional help? Contact the AEM Performance Electronics tech department at

1-800-423-0046 or tech@aempower.com, or visit the AEM Performance Electronics

forum at http://forum.aempower.com/forum/

Page 14

Loading...

Loading...