Page 1

Infinity-8/10&812 Mini Harness

User Manual

30-3702/03

THIS PRODUCT IS LEGAL IN CALIFORNIA FOR RACING VEHICLES ONLY

AND SHOULD NEVER BE USED ON PUBLIC HIGHWAYS.

AEM Performance Electronics

AEM Performance Electronics, 2205 126th Street Unit A, Hawthorne, CA 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number: 10-3703

Document Build 11/25/2014

Page 2

AEM Infinity Harness Manuals2

1Introduction

Several universal wiring harness options are available for Infinity products. They range

in complexity from simple plug and pin kits to complete engine harness assemblies that

include power distribution centers. Custom wiring harness projects should only be

undertaken by experienced harness builders. If in doubt, please contact AEM for

recommendations.

30-3805 Universal V8 harness system for Infinity-8/10 systems

The Infinity Universal V8 Harness system consists of a universal core harness and

optional application specific extensions. It was designed with flexibility in mind. The

harness system includes many features and it can be used in many different

applications.

30-3807 Universal V8 harness system for Infinity-6/8h systems

The Infinity Universal V8 Harness system consists of a universal core harness and

optional application specific extensions. It was designed with flexibility in mind. The

harness system includes many features and it can be used in many different

applications.

30-3705 Universal Mini Harness for Infinity-6/8h systems

This harness is intended to be used as a starting point by experienced harness builders.

It saves time by including basic power distribution features that can be expanded to suit

many application requirements. It allows the harness builder to populate the ECU

connector with only the features needed by the application.

30-3702 Infinity-8/10/12 Mini-harness

This harness is intended to be used as a starting point by experienced harness builders.

It saves time by including basic power distribution features that can be expanded to suit

many application requirements. It allows the harness builder to populate the ECU

connector with only the features needed by the application. Includes 100 96" preterminated leads.

30-3703 Infinity-8/10/12 Mini-harness

This harness is intended to be used as a starting point by experienced harness builders.

It saves time by including basic power distribution features that can be expanded to suit

many application requirements. It allows the harness builder to populate the ECU

connector with only the features needed by the application.

30-3701 Infinity-8/10/12 Plug & Pin Kit

Bare necessities to begin a custom wire harness design. Includes 73 and 56 pin Molex

MX123 harness connectors, terminals and sealing plugs, main relay and relay socket.

30-3704 Infinity-6/8h Plug & Pin Kit

Bare necessities to begin a custom wire harness design. Includes 80 pin Molex MX123

harness connector, terminals and sealing plugs, main relay and relay socket.

This manual is focused primarily on the universal V8 harness system components but it

© 2014 AEM Performance Electronics

Page 3

can be used as a reference for any custom harness build based on the Infinity ECU.

Please read the entire User Manual prior to beginning any installation.

23702/3703 Kit Contents

Infinity-8/10/12 Mini-Harness

100 Molex MX64 terminals

30 Molex MX64 sealing plugs

User Instructions

3702 kits include 100 96" pre-terminated leads for populating

3

The Infinity-6/8h/8/10 ECUs use the MX123 Sealed Connection System from Molex.

AEM strongly recommends that users become familiar with the proper tools and

procedures before attempting any modifications or additions to these connector

housings. The entire Molex user manual can be downloaded direct from Molex at http://

www.molex.com/mx_upload/family//MX123UserManual.pdf

© 2014 AEM Performance Electronics

3ECU Connectors

Page 4

AEM Infinity Harness Manuals4

43703 and 3705 Connectors

Flash enable connector

Not usually needed. Used under certain conditions to force the ECU into flash

programming mode.

© 2014 AEM Performance Electronics

Page 5

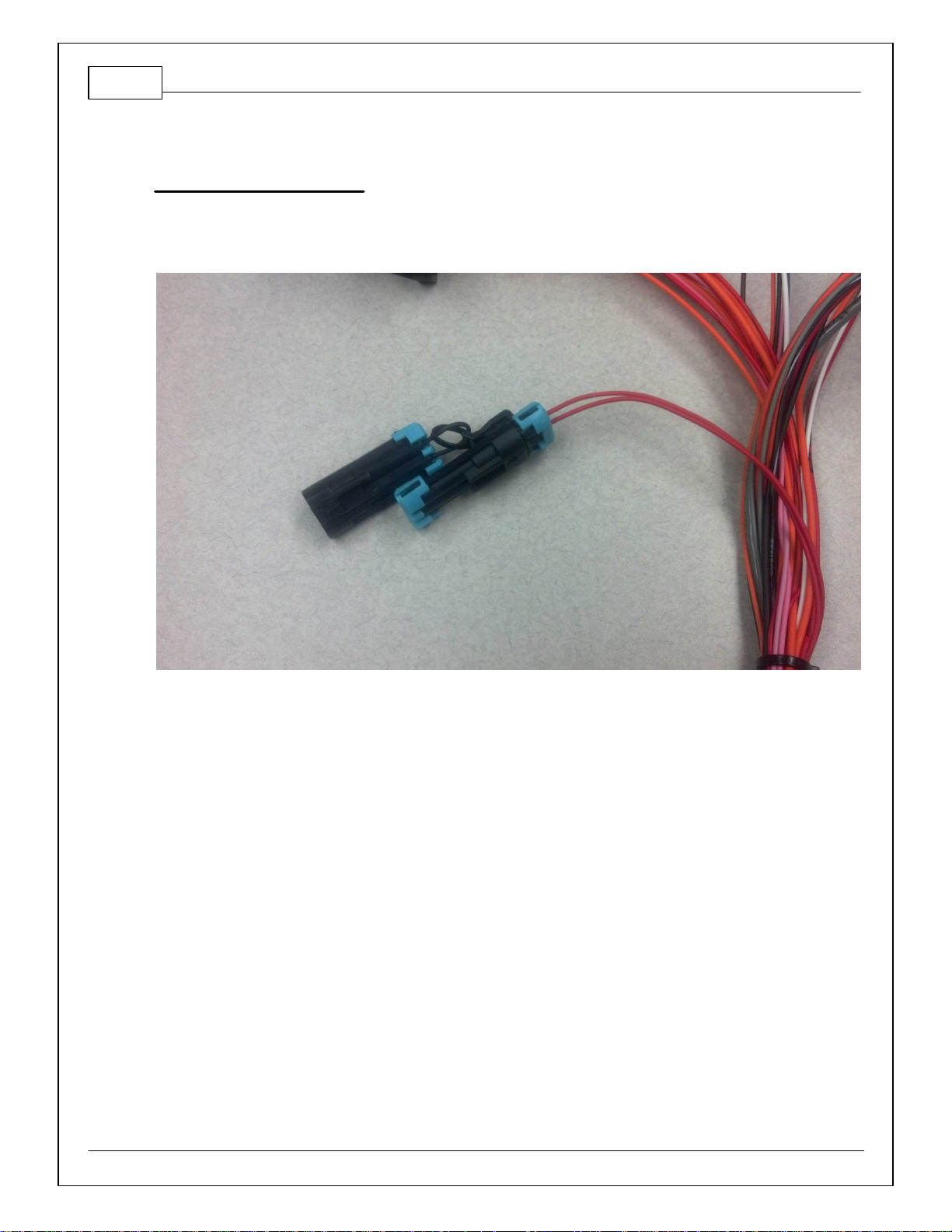

UEGO connector

Connect to 30-3600 UEGO extension harness.

5

© 2014 AEM Performance Electronics

Page 6

AEM Infinity Harness Manuals6

AEMNet connector

Connect to optional AEMNet enabled devices.

© 2014 AEM Performance Electronics

Page 7

EFI Main Relay

Required for normal power sequencing function.

7

© 2014 AEM Performance Electronics

Page 8

AEM Infinity Harness Manuals8

BATT GND

Connect directly to battery negative

BATT PWR

Connect directly to battery positive

Sensor GND

Connect to low reference (GND) of 5V analog sensors

SWT PWR

Ignition switch input.

5V REF

Connect to high reference (5V PWR) of 5V analog sensors

ACC PWR

Option for powering accessory relays

INJ PWR

Fused 12V power for injectors

IGN PWR

Fused 12V power for coils

Flying lead bundle

Wires are ink stamped with descriptions as follows:

Completing the harness

Use the supplied Molex MX64 terminals to add circuits and features as needed. Refer

to the Infinity-6/8h pinout for available options. Refer to the example schematic included

below for recommended wiring designs.

© 2014 AEM Performance Electronics

Page 9

9

5Installation Notes

Wiring Conventions and EMI

Some wire harness assemblies come pre-wired with all connectors, fuses, and relays

needed to operate an engine. Harnesses that include a PDC generally require

extension/termination of the flying leads to their appropriate devices, and additional

sensors and other devices can be wired into the harness as needed for the specific

application. The following guidelines should be adhered to while completing the required

wiring.

A proper wiring job includes proper termination of the wire at the sensor. The wire

terminal end must be moisture tight where it plugs into the sensor and it must have

strong, electrically sound terminals. The preferred method of securing a wire to a

terminal is to use a crimp terminal with NO solder. It is important to use the proper

crimping tool for sound terminal construction. Plastic terminal plugs must have moisture

tight seals. Inspect each plug to make sure the seals are in place. Di-electric grease can

be added in the terminal slots to further aid in corrosion resistance.

If a splice into a wire must be made and no solder-less terminals are available, then you

must properly solder the splice.

Noise can be a serious problem and can cause intermittent misfiring of the engine.

Every precaution should be taken to prevent interference to the ECU’s operation.

Resistive plug leads are REQUIRED.

To eliminate or reduce the chance of EMI, wires that carry high current must run in

twisted pairs. An example of this would be the power leads from a multiple spark ignition

system. These ignition systems can carry up to 100 amps for a couple milliseconds at

the time of discharge, which induces a strong magnetic field in close proximity of the

wires.

The routing of the wire loom is critical to EFI system performance and safety. The

following safety considerations should be made when installing the wire loom:

Heat protection: the loom should be placed away from or insulated from sources

of heat. The obvious item(s) that should be avoided are the exhaust manifolds,

EGR delivery tubes, and turbochargers. If it is absolutely necessary to route a

wire in close proximity to any of these items, then a suitable insulator must be

used.

Noise suppression: do not route wires near the HT leads. For coil-on-plug ignition

systems this is not as critical.

Moving component protection: route wires away from moving components such

as fans, the blower belt, or the throttle linkage. Also, make sure the wires are not

under any strain when the engine is at full deflection on the motor mounts.

Never have the wires in exposed bundles throughout the engine compartment.

Determining ECU Location

It is recommended that the ECU be placed in an environment that does not

© 2014 AEM Performance Electronics

Page 10

AEM Infinity Harness Manuals10

expose it to temperatures above 85° Celsius (160F).

In cases where the Infinity is to be used in place of the stock ECU, the location

that the stock ECU occupied is suitable.

On applications where the ECU is to be located in a different position than stock,

the interior of the vehicle is best.

The Infinity should be located in a place that reduces the length of extension wires

from the PDC while maintaining an environmentally sound location.

The ECU location must permit the PDC to be mounted in a serviceable location.

Power Distribution Center

PDCs included in the harness assemblies generally include all relays and fuses

necessary for proper function and should be mounted in a location which permits

serviceability. Ideally the PDC should be located in the passenger compartment, or if

necessary within the engine compartment as far away from heat sources as can be

achieved. Some PDCs contain flying lead bundles which must be wired to the battery,

fuel pump and radiator fan(s), switched ignition and possibly other interfaces. Routing of

this flying lead bundle should also be taken into account when determining the mounting

location of the PDC.

© 2014 AEM Performance Electronics

Page 11

6Infinity-8/10/12 ECU Pinout

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C1-1

LowsideSwitch_4_Out

Lowside switch, 4A max, NO

internal flyback diode.

No pullup

Normally used as A/C Relay Control output.

C1-2

LowsideSwitch_5_Out

Lowside switch, 4A max with

internal flyback diode. Inductive

load should NOT have full time

power.

No pullup

See Setup Wizard Page "LowSide Assignment

Tables" for output assignment and 2D table

"LS5_Duty [%]" for activation.

C1-3

LowsideSwitch_6_Out

Lowside switch, 4A max with

internal flyback diode. Inductive

load should NOT have full time

power.

No pullup

See Setup Wizard Page "LowSide Assignment

Tables" for output assignment and 2D table

"LS6_Duty [%]" for activation.

C1-4

UEGO 1 Heat_Out

Bosch UEGO controller

Lowside switch for UEGO heater control. Connect

to pin 4 of Bosch UEGO sensor. NOTE that pin 3 of

the Sensor is heater (+) and must be power by a

fused/switched 12V supply.

C1-5

UEGO 1 IA_In

Trim Current signal. Connect to pin 2 of Bosch

UEGO sensor

C1-6

UEGO 1 IP_In

Pumping Current signal. Connect to pin 6 of Bosch

UEGO sensor

C1-7

UEGO 1 UN_In

Nernst Voltage signal. Connect to pin 1 of Bosch

UEGO sensor

C1-8

UEGO 1 VM_In

Virtual Ground signal. Connect to pin 5 of Bosch

UEGO sensor.

C1-9

Flash_Enable_In

10K pulldown

Not usually needed for automatic firmware

updates through Infinity Tuner. If connection

errors occur during update, connect 12 volts to

this pin before proceeding with upgrade.

Disconnect the 12 volts signal after the update.

C1-10

+12V_R8C_CPU_In

Dedicated power management CPU

Full time battery power. MUST be powered before

the ignition switch input is triggered (See C1-65).

C1-11

Coil 4_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

C1-12

Coil 3_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

11

© 2014 AEM Performance Electronics

Page 12

AEM Infinity Harness Manuals12

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C1-13

Coil 2_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

C1-14

Coil 1_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

C1-15

Coil 6_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

C1-16

Coil 5_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

C1-17

LowsideSwitch_2_Out

Lowside switch, 4A max, NO

internal flyback diode.

No pullup

See Setup Wizard Pages "User GPOs" for activation

criteria and "LowSide Assignment Tables" for

output assignment

C1-18

LowsideSwitch_3_Out

Lowside switch, 4A max with

internal flyback diode. Inductive

load should NOT have full time

power.

No pullup

Normally used as MIL output. 'See Wizard page

"LowSide Assignment Tables" for output

assignment.

C1-19

AGND_1_Out

Dedicated analog ground

Analog 0-5V sensor ground

C1-20

AGND_1_Out

Dedicated analog ground

Analog 0-5V sensor ground

C1-21

Crankshaft Position

Sensor Hall_In

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Cam/Crank for options.

C1-22

Camshaft Position

Sensor 1 Hall_In

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Cam/Crank for options.

C1-23

Digital_In_2

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Cam/Crank for options.

C1-24

Digital_In_3

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Turbo Speed for calibration

constant.

© 2014 AEM Performance Electronics

Page 13

13

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C1-25

Digital_In_4

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Vehicle Speed for

calibration constant.

C1-26

Digital_In_5

10K pullup to 12V. Will work with

ground or floating switches.

See channel FlexDigitalIn [Hz] for raw frequency

input data.

C1-27

Knock Sensor 1_In

Dedicated knock signal processor

See Setup Wizard page Knock Setup for options.

C1-28

Knock Sensor 2_In

Dedicated knock signal processor

See Setup Wizard page Knock Setup for options.

C1-29

+12V_Relay_Control_Ou

t

0.7A max ground sink for external

relay control

Will activate at key on and at key off according to

the configuration settings.

C1-30

Power Ground_In

Power Ground

Connect directly to battery ground

C1-31

CANL_A_Out

Dedicated High Speed CAN

Transceiver

Recommend twisted pair (one twist per 2") with

terminating resistor. Contact AEM for additional

information.

C1-32

CANH_A_Out

Dedicated High Speed CAN

Transceiver

Recommend twisted pair (one twist per 2") with

terminating resistor. Contact AEM for additional

information.

C1-33

LowsideSwitch_1_Out

Lowside switch, 4A max with

internal flyback diode. Inductive

load should NOT have full time

power.

No pullup

See Setup Wizard page Boost Control for options.

Monitor BoostControl [%] channel for output

state.

C1-34

LowsideSwitch_0_Out

Lowside switch, 4A max, NO

internal flyback diode.

No pullup

Switched ground. Will prime for 2 seconds at key

on and activate if RPM > 0.

C1-35

Analog_In_7

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

See the Setup Wizard Set Throttle Range page for

automatic min/max calibration.

C1-36

Analog_In_8

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

See the Setup Wizard Set Manifold Pressure page

for setup and calibration.

© 2014 AEM Performance Electronics

Page 14

AEM Infinity Harness Manuals14

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C1-37

Analog_In_9

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

See the Setup Wizard Fuel Pressure page for setup

and calibration.

C1-38

Analog_In_10

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

See the Setup Wizard Barometric Pressure page

for setup and calibration.

C1-39

Analog_In_11

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as Shift Switch input.

C1-40

Analog_In_12

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as Mode Switch input.

C1-41

+5V_Out_1

Regulated, fused +5V supply for

sensor power

Analog sensor power

C1-42

+5V_Out_1

Regulated, fused +5V supply for

sensor power

Analog sensor power

C1-43

HighsideSwitch_1_Out

0.7A max, High Side Solid State

Relay

See Setup Wizard page 'HighSide Assigment

Tables' for configuration options.

C1-44

HighsideSwitch_0_Out

0.7A max, High Side Solid State

Relay

See Setup Wizard page 'HighSide Assigment

Tables' for configuration options.

C1-45

Crankshaft Position

Sensor VR+_In

Differential Variable Reluctance

Zero Cross Detection

See Setup Wizard page Cam/Crank for options.

C1-46

Crankshaft Position

Sensor VR-_In

See Setup Wizard page Cam/Crank for options.

C1-47

Camshaft Position

Sensor 1 VR-_In

Differential Variable Reluctance

Zero Cross Detection

See Setup Wizard page Cam/Crank for options.

C1-48

Camshaft Position

Sensor 1 VR+_In

See Setup Wizard page Cam/Crank for options.

© 2014 AEM Performance Electronics

Page 15

15

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C1-49

VR+_In_2

Differential Variable Reluctance

Zero Cross Detection

See Non Driven Wheel Speed Calibration in the

Setup Wizard Vehicle Speed page.

C1-50

VR-_In_2

C1-51

VR-_In_3

Differential Variable Reluctance

Zero Cross Detection

See Driven Wheel Speed Calibration in the Setup

Wizard Vehicle Speed page.

C1-52

VR+_In_3

C1-53

DBW1 Motor -_Out

5.0A max Throttle Control Hbridge

Drive

+12V to close.

C1-54

DBW1 Motor +_Out

5.0A max Throttle Control Hbridge

Drive

+12V to open.

C1-55

Power Ground_In

Power Ground

Connect directly to battery ground

C1-56

Injector 6_Out

Saturated or peak and hold, 3A max

continuous

Injector 6

C1-57

Injector 5_Out

Saturated or peak and hold, 3A max

continuous

Injector 5

C1-58

Injector 4_Out

Saturated or peak and hold, 3A max

continuous

Injector 4

C1-59

Injector 3_Out

Saturated or peak and hold, 3A max

continuous

Injector 3

C1-60

Power Ground_In

Power Ground

Connect directly to battery ground

C1-61

+12V_In

12 volt power from relay

12 volt power from relay. Relay must be

controlled by +12V Relay Control signal, pin C1-29

above.

C1-62

Injector 2_Out

Saturated or peak and hold, 3A max

continuous

Injector 2

C1-63

Injector 1_Out

Saturated or peak and hold, 3A max

continuous

Injector 1

C1-64

+12V_In

12 volt power from relay

12 volt power from relay. Relay must be

controlled by +12V Relay Control signal pin C1-29

above.

C1-65

+12V_SW_In

10K pulldown

Full time battery power must be available at C110 before this input is triggered.

C1-66

Analog_In_Temp_1

12 bit A/D, 2.49K pullup to 5V

See "Coolant Temperature" Setup Wizard for

selection.

© 2014 AEM Performance Electronics

Page 16

AEM Infinity Harness Manuals16

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C1-67

Analog_In_Temp_2

12 bit A/D, 2.49K pullup to 5V

See "Air Temperature" Setup Wizard for selection.

C1-68

Analog_In_Temp_3

12 bit A/D, 2.49K pullup to 5V

Normally used for Oil Temp input.

C1-69

Stepper_2A_Out

Automotive, Programmable

Stepper Driver, up to 28V and ±1.4A

Be sure that each internal coil of the stepper

motor are properly paired with the 1A/1B and

2A/2B ECU outputs. Supports Bi-Polar stepper

motors only.

C1-70

Stepper_1A_Out

Automotive, Programmable

Stepper Driver, up to 28V and ±1.4A

Be sure that each internal coil of the stepper

motor are properly paired with the 1A/1B and

2A/2B ECU outputs. Supports Bi-Polar stepper

motors only.

C1-71

Stepper_2B_Out

Automotive, Programmable

Stepper Driver, up to 28V and ±1.4A

Be sure that each internal coil of the stepper

motor are properly paired with the 1A/1B and

2A/2B ECU outputs. Supports Bi-Polar stepper

motors only.

C1-72

Stepper_1B

Automotive, Programmable

Stepper Driver, up to 28V and ±1.4A

Be sure that each internal coil of the stepper

motor are properly paired with the 1A/1B and

2A/2B ECU outputs. Supports Bi-Polar stepper

motors only.

C1-73

Power Ground_In

Power Ground

Connect directly to battery ground

C2-1

DBW2 Motor +_Out

5.0A max Throttle Control Hbridge

Drive

+12V to open.

C2-2

DBW2 Motor -_Out

5.0A max Throttle Control Hbridge

Drive

+12V to close.

C2-3

Power Ground_In

Power Ground

Connect directly to battery ground

C2-4

Injector 7_Out

Saturated or peak and hold, 3A max

continuous

Injector 7

C2-5

Injector 8_Out

Saturated or peak and hold, 3A max

continuous

Injector 8

C2-6

Injector 9_Out

Saturated or peak and hold, 3A max

continuous

Injector 9.

C2-7

Injector 10_Out

Saturated or peak and hold, 3A max

continuous

Injector 10.

C2-8

Power Ground_In

Power Ground

Connect directly to battery ground.

C2-9

+12V_In

12 volt power from relay

12 volt power from relay. Relay must be

controlled by +12V Relay Control signal, pin C1-29

above.

C2-10

Injector 11_Out

Saturated or peak and hold, 3A max

continuous

Not used

© 2014 AEM Performance Electronics

Page 17

17

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C2-11

Injector 12_Out

Saturated or peak and hold, 3A max

continuous

Not used

C2-12

Analog_In_17

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as A/C Analog Request input.

C2-13

Analog_In_18

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as DBW APP1.

C2-14

Analog_In_19

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as DBW APP2.

C2-15

Analog_In_Temp_4

12 bit A/D, 2.49K pullup to 5V

Normally used as Charge Out Temperature input.

C2-16

Analog_In_Temp_5

12 bit A/D, 2.49K pullup to 5V

Normally used as Airbox Temperature input.

C2-17

Analog_In_Temp_6

12 bit A/D, 2.49K pullup to 5V

Normally used as Fuel Temperature input.

C2-18

Analog_In_13

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

See Setup Wizard Oil Pressure page for setup

options. See OilPressure [psig] for channel data.

C2-19

Analog_In_14

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

© 2014 AEM Performance Electronics

Page 18

AEM Infinity Harness Manuals18

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C2-20

Analog_In_15

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as Exhaust Back Pressure input.

C2-21

Analog_In_16

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as DBW1_TPSB input.

C2-22

+5V_Out_2

Regulated, fused +5V supply for

sensor power

Analog sensor power

C2-23

+5V_Out_2

Regulated, fused +5V supply for

sensor power

Analog sensor power

C2-24

+5V_Out_2

Regulated, fused +5V supply for

sensor power

Analog sensor power

C2-25

VR+_In_5

Differential Variable Reluctance

Zero Cross Detection

See Driven Wheel Speed Calibration in the Setup

Wizard Vehicle Speed page.

C2-26

VR-_In_5

C2-27

VR-_In_4

Differential Variable Reluctance

Zero Cross Detection

See Non Driven Wheel Speed Calibration in the

Setup Wizard Vehicle Speed page.

C2-28

V R+_In_4

C2-29

LowsideSwitch_9_Out

Lowside switch, 4A max with

internal flyback diode, 2.2K 12V

pullup. Inductive load should NOT

have full time power.

12V pullup

See Setup Wizard page Tacho for configuration

options.

C2-30

AGND_2_Out

Dedicated analog ground

Analog 0-5V sensor ground

C2-31

AGND_2_Out

Dedicated analog ground

Analog 0-5V sensor ground

C2-32

AGND_2_Out

Dedicated analog ground

Analog 0-5V sensor ground

© 2014 AEM Performance Electronics

Page 19

19

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C2-33

Analog_In_20

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

C2-34

Analog_In_21

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as 3 Step Enable Switch input.

C2-35

Analog_In_22

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as USB Logging Request input.

C2-36

Analog_In_23

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power

supply and Sensor Ground pins as the low

reference. Do not connect signals referenced to

+12V as this can permanently damage the ECU.

Normally used as Charge Out Pressure input.

C2-37

Digital_In_6

No pullup. Will work with TTL

signals.

Input can be assigned to different pins. See Setup

Wizard page Input Function Assignments for input

mapping options.

C2-38

Digital_In_7

No pullup. Will work with TTL

signals.

See ClutchSwitch 1-axis table for setup options.

Input can be assigned to different pins. See Setup

Wizard page Input Function Assignments for input

mapping options.

C2-39

Power Ground_In

Power Ground

Connect directly to battery ground

C2-40

Power Ground_In

Power Ground

Connect directly to battery ground

C2-41

CanH_B_Out

Dedicated High Speed CAN

Transceiver

Not used

C2-42

CanL_B_Out

Dedicated High Speed CAN

Transceiver

Not used

© 2014 AEM Performance Electronics

Page 20

AEM Infinity Harness Manuals20

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C2-43

LowsideSwitch_8_Out

Lowside switch, 4A max with

internal flyback diode. Inductive

load should NOT have full time

power.

12V pullup

Activates if any of the following flags are true:

OilPressProtectOut, LeanProtectOut,

CoolantProtect. Output can be assigned to other

functions. See Setup Wizard page LowSide

Assignment Tables for additional options.

C2-44

LowsideSwitch_7_Out

Lowside switch, 4A max with

internal flyback diode. Inductive

load should NOT have full time

power.

No pullup

Normally used as Spare GPO1 output.

C2-45

UEGO 2 VM_In

Bosch UEGO Controller

Virtual Ground signal. Connect to pin 5 of Bosch

UEGO sensor.

C2-46

UEGO 2 UN_In

Nernst Voltage signal. Connect to pin 1 of Bosch

UEGO sensor

C2-47

UEGO 2 IP_In

Pumping Current signal. Connect to pin 6 of Bosch

UEGO sensor

C2-48

UEGO 2 IA_In

Trim Current signal. Connect to pin 2 of Bosch

UEGO sensor

C2-49

UEGO 2 HEAT_Out

Lowside switch for UEGO heater control. Connect

to pin 4 of Bosch UEGO sensor. NOTE that pin 3 of

the Sensor is heater (+) and must be power by a

fused/switched 12V supply.

C2-50

+12V_R8C_CPU_In

Dedicated power management CPU

Full time battery power. MUST be powered before

the ignition switch input is triggered (See C1-65).

C2-51

Coil 7_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

C2-52

Coil 8_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

C2-53

Coil 9_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

C2-54

Coil 10_Out

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to

coil primary. Must use an ignitor OR CDI that

accepts a FALLING edge fire signal.

© 2014 AEM Performance Electronics

Page 21

21

Infinity Pin

Hrdwr Ref.

Hardware Specification

Notes

C2-55

Highside Fuel Pump

Switch_Out

Highside switch, 0.7A max, Solid

State Relay, NO internal flyback

diode.

+12V High Side Drive. Will prime for 2 seconds at

key on and activate if RPM > 0.

C2-56

Not used

Not used

Not used

© 2014 AEM Performance Electronics

Page 22

AEM Infinity Harness Manuals22

7Power Distribution Infinity-8/10/12

© 2014 AEM Performance Electronics

Page 23

23

812 Month Limited Warranty

Advanced Engine Management Inc. warrants to the consumer that all AEM High

Performance products will be free from defects in material and workmanship for a

period of twelve (12) months from date of the original purchase. Products that fail within

this 12-month warranty period will be repaired or replaced at AEM’s option, when

determined by AEM that the product failed due to defects in material or workmanship.

This warranty is limited to the repair or replacement of the AEM part. In no event shall

this warranty exceed the original purchase price of the AEM part nor shall AEM be

responsible for special, incidental or consequential damages or cost incurred due to the

failure of this product. Warranty claims to AEM must be transportation prepaid and

accompanied with dated proof of purchase. This warranty applies only to the original

purchaser of product and is non-transferable. All implied warranties shall be limited in

duration to the said 12-month warranty period. Improper use or installation, accident,

abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims any

liability for consequential damages due to breach of any written or implied warranty on

all products manufactured by AEM. Warranty returns will only be accepted by AEM when

accompanied by a valid Return Merchandise Authorization (RMA) number. Product

must be received by AEM within 30 days of the date the RMA is issued.

Please note that before AEM can issue an RMA for any electronic product, it is first

necessary for the installer or end user to contact the EMS tech line at 1-800-423-0046 to

discuss the problem. Most issues can be resolved over the phone. Under no

circumstances should a system be returned or a RMA requested before the above

process transpires.

AEM will not be responsible for electronic products that are installed incorrectly, installed

in a non-approved application, misused, or tampered with.

Any AEM electronics product can be returned for repair if it is out of the warranty period.

There is a minimum charge of $50.00 for inspection and diagnosis of AEM electronic

parts. Parts used in the repair of AEM electronic components will be extra. AEM will

provide an estimate of repairs and receive written or electronic authorization before

repairs are made to the product.

© 2014 AEM Performance Electronics

Loading...

Loading...