Page 1

155 D

Dunstabzugshaube

Cooker hood

Hotte aspirante

Cappa aspirante

Montage- und Gebrauchsanweisung

Installation and Operating Instructions

Instructions de montage et mode d’emploi

Istruzioni di montaggio ed istruzioni per l’uso

Page 2

Contents

Introduction...............................................................................23

Extractor version

Filter version................................................................................24

Electrical connections..............................................................25

Safety warnings fdt electrician

Specifications............................................................................26

.....................................................

....................................................

............,.......

25

23

Montage

Safety warnings for kitchen unit installer.....................................27

Wall unit mounting.......................................................................29

Wall mounting..............................................................................29

Safety warnings for user

Hood operation........................................................................ 31

Controls

Setting the fan speed..................................................................32

Hood lighting...............................................................................32

Intensive P

Fan timer.....................................................................................33

Switching off the fan....................................................................34

Hood operation before and after cooking

Warnings on the activated carbon filter...................................... 35

Display warning on saturation of

activated carbon filter............................................................ 35-37

Display warning on saturation of

metal grease filters

Changing the light bulbs..............................................................40

Cleaning......................................................................................40

Special Accessories

....................................................................................

.............................................................

.....................................................................................

................................................................................

....................................

................................................................

.................................................................41

38-39

27

30

31

33

35

Technical Assistance Service

22

.................................................

Printed on recycled paper.

AEG - putting words into action.

41

Page 3

Introduction

The hood is supplied as an extractor unit and can also be used

with a filtering function by fitting activated carbon filters (special

accessory).

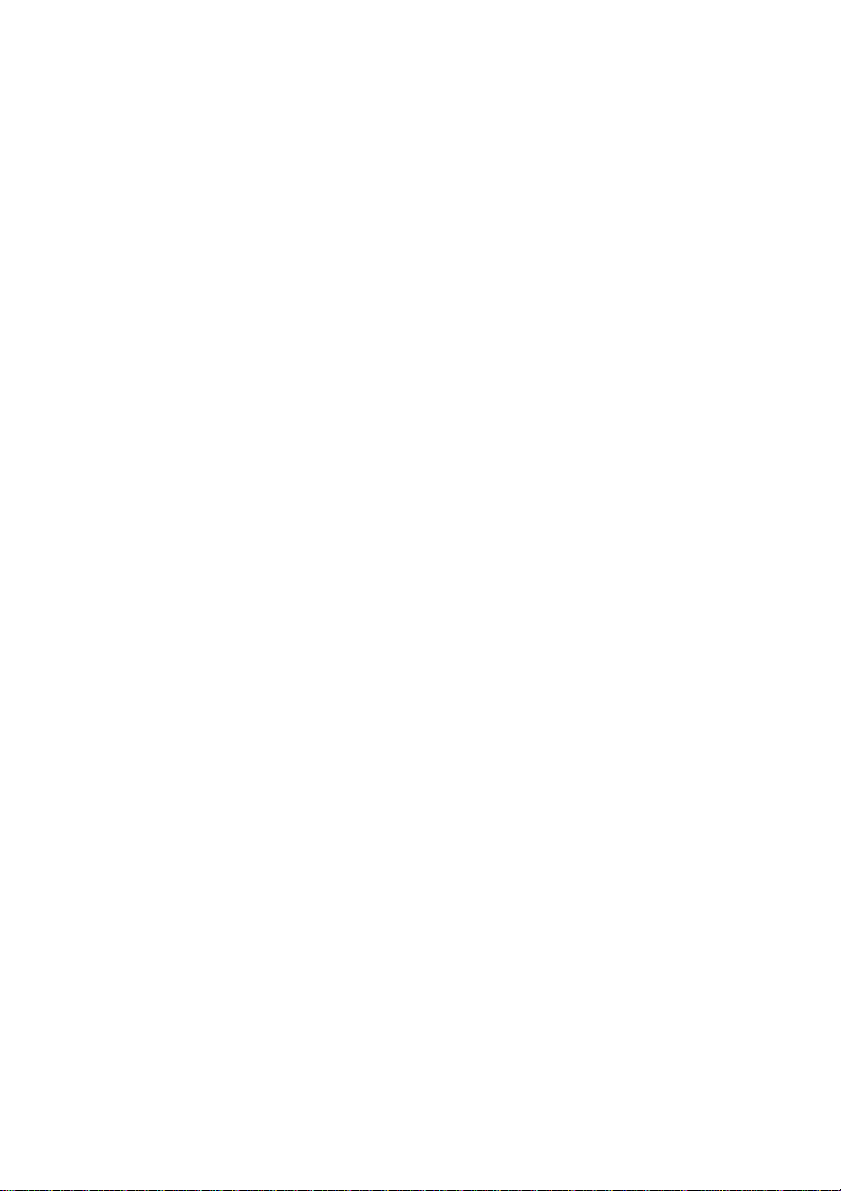

The unit features two outlet holes, one of which A is located on the

top of the unit while the other B is located on the rear.

To connect up the hose, you should first fit the bayonet-mounting

flange C on the outlet required (if using the top outlet, fix the flange

in place using the screw supplied as shown in Fig, 1.

Close off the unused hole using the bayonet-fitting caps D.

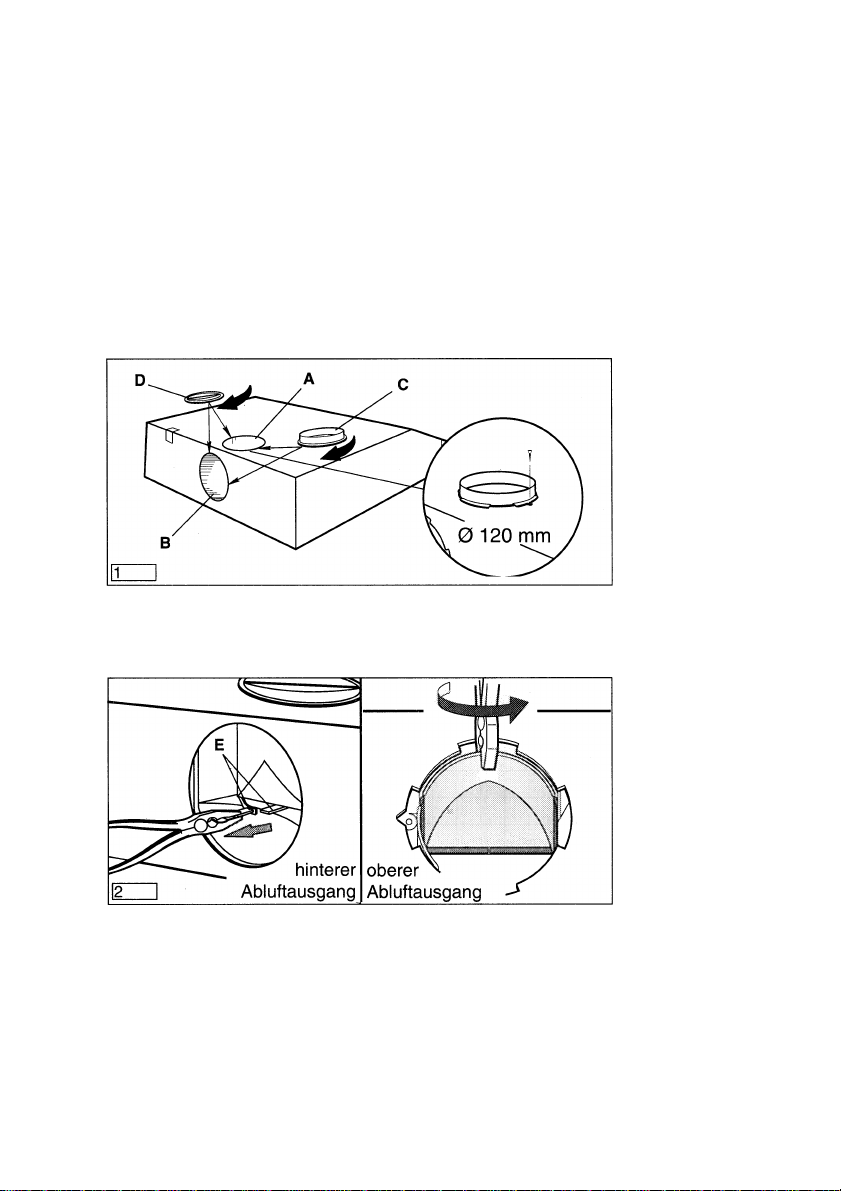

If using the rear hole, open the air passage by removing the

partition (E — Fig. 2)

Extractor

version

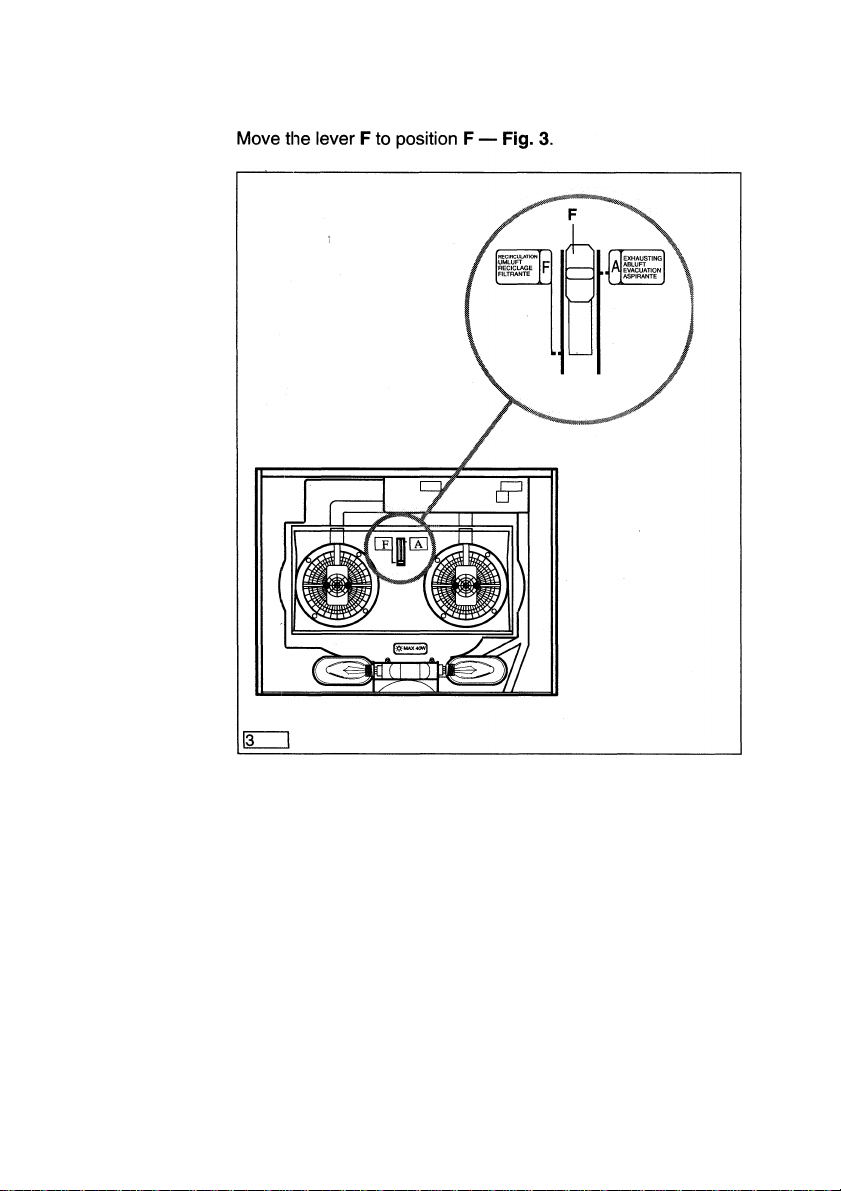

Move the lever F to position A — Fig. 3.

When connecting up the hood using a telescopic wall pipe,

you should preferably using the uninflammable outlet hose

No. E 610 899 007 (120 mm 0) from our range of special

accessories.

23

Page 4

Filter

version

The air is filtered and recirculated through the front grille.

You will need an original AEG KLF60/80 activated carbon filter for

filtering function. (See special accessories).

24

Page 5

Electrical connections

Check that the power supply voltage shown on the rating plate Safety

corresponds to the mains supply before proceeding to make any warnings for

electrical connections. If the unit is supplied ready-fitted with a electrician

plug, it can be connected to any easily accessible socket installed

In compliance with the regulations In force.

If a fixed connection is required, the hood must be installed

exclusively by an electrician registered with the local electrical

company. The hood should be installed using an omnipolar switch

with contacts that open to at least 3 mm.

Fused switches can be used for this purpose (with cartridge fuses

that can be extracted from the fuse holder), as can automatic

circuit breakers and contactors which open to more than 3 mm.

We decline all responsibility for any problems or faults caused by

a failure to observe the above instructions.

Installing the socket directly above the hood or above the wall unit

mounted above the hood offers the following advantages;

1. The socket cannot be seen.

2. The unit can be disconnected whenever required by simply

taking out the plug.

Electrical connections

230 V - using fixed power supply line with plug.

(The unit should only be connected up by an authorized electri

cian).

25

Page 6

Specifications

Dimensions:

Height

152

Weight:

Net:

Gross:

Maximum absorbed power: 360 W

Motor absorption: 2 x 140 W

Lighting: 2 x 40 W

Fan powers (levels), levels in compliance with DIN 44971

Exhausting version:

min. 120 m^/h max. 254 mVh Intensive speed 385 m^/h

Recycling version:

min. 50 m^/h max. 180 m^/h Intensive speed 206 m^/h

Extractor system: 120 mm 0

10.5 Kg

11.5 Kg

Width

599

Depth (in mm)

505

26

Page 7

Montage

When used as an extractor unit, the hood must be fitted with a

120mm diameter hose.

If the outlet hose is installed In a horizontal position, it must

nevertheless be slanted at an angle of 10° so that the air can flow

outside without impediment.

If the cooking vapour Is passed through an outside wall, you will

need a telescopic wall pipe No. E 610 899 004 (120 mm o) from

our range of special accessories.

When installing the hood, make sure you respect the follow

ing minimum distance from the top edge of the cooking hob/

ring surfaces:

electric cookers

gas cookers

coal and oil cookers

The hood cannot be connected to flues of other appliances

that run on energy sources other than electricity.

It is advisable to apply for authorization from the relevant

controlling authority when connecting the outlet to an un

used chimney flue or combustion gas duct.

The air outlet installation must comply with the regulations

laid down by the relevant authorities.

650 mm

650 mm

700 mm min.

Safety

warning for

kitchen unit

installer

When the unit is used in its extractor version, a sufficiently

large ventilation hole must be provided, with dimensions that

are approximately the same as the outlet hole.

National and regional building regulations impose a number

of restrictions on using hoods and fuel-burning appliances

connected to a chimney, such as coal or oil room-heaters and

gas fires, in the same room.

The European decree on fuel-burning systems specifies a

maximum depression of 0.04 bar in such rooms.

Hoods can only be used safely with appliances connected to

a chimney if the room and/or flat (alr/environment combina

tion) is ventilated from outside using a suitable ventilation

hole approximately 500-600 cm^ large to avoid the possibility

of a depression being created during operation of the hood.

If you have any doubts, contact the relevant controlling

authority or building inspector’s office.

27

Page 8

Since the rule for rooms with fuel burning appliances is

“outlet hole of the same size as the ventilation hole”, a hole

of 500-600 cm^, which is to say a larger hole, could reduce the

performance of the extractor hood.

If the hood is used in its filtering function, it will operate

simply and safely in the above conditions without the need

for any of the aforementioned measures.

When the hood is used in its extractor function, the following

rules must be followed to obtain optimal operation:

— short and straight outlet hose

— keep bends in outlet hose to a minimum

— never install the hoses with an acute angle, they must

always follow a gentle curve only

— keep the hose as large as possible (120 mm 0).

Failure to observe these basic rules will drastically reduce

the performance and increase the noise levels of the extrac

tor hood.

28

Page 9

Drill four holes in the base of the wall unit using the template Wall unit

supplied. mounting

Mount the hood unit on the base of the wall unit using four

4,2 X 35 mm screws. -Fig.4

If using an interchangeable model, fit the plastic caps supplied in

any unused mounting holes. — Fig. 5

Position the template on the wall.

Drill four 8 mm 0 holes in the wall, 2 in points H and 2 in points I.

Fit the four 8 mm screw anchor plugs in the wall.

Screw two 5 X 45 mm screws in points H but do not tighten

them fully home.

Adjust the unit so that it is positioned at a right angle to the wall

by turning the two support screws G.

Now hang the hood on the wall (holes H). Tighten the first two

screws and, for safety’s sake, screw the other two 5 x 45 mm

screws (holes I) Into the holes in the hood. — Fig. 6

Wall

mounting

29

Page 10

Safety Never leave a cooking hob or ring on without a pot or pan on top

warnings of it, to avoid the possibility of excess heat damaging the unit. Gas,

for user oil or coal cooker flames in particular should never be left uncov

ered.

Special care should be taken when using deep fat fryers since the

oil in them can overheat and burst into flames.

The risk of a fat fire increases when using dirty oil.

It is extremely important to note that overheating can cause a fire.

Never carry out any flambé cooking under the hood.

Always disconnect the unit from the power supply before

carrying out any work on the hood, including replacing the

light bulb (take the cartridge fuse out of the fuse holder or switch

off the automatic circuit breaker).

It is very important to clean the hood and replace the filter at

the recommended intervals. Failure to do so could cause

grease deposits to build up, causing a fire hazard.

30

Page 11

Hood Operation

The control panel is located on the front of the hood.

The control panel numbers and symbols (Fig. 7 from left to right)

are explained in the key below:

= Lighting, on/off.

-d-

= Fan switch (speeds 1-9).

o

= Fan timer, 15 minutes.

: Display showing fan speed (1-9), high speed (P), change

grease filters (F) and change activated carbon filters (C).

Controls

: Decrease fan speed button for reducing speed of motor

e

e

If the hood fails to operate correctly, briefly disconnect it from the

mains power supply for almost 5 sec. by pulling out the plug. Then

plug it in again and try once more before contacting the Technical

Assistance Service.

from high speed (P) down to speed 1.

= Increase fan speed button for increasing speed of motor

from 1 to 9 and high speed (P).

31

Page 12

Setting

the fan speed

(Fig- 8)

Press the ([^) button (F) to select the fan speed from 1 to 9,

keeping it pressed until the speed you want, e.g. speed 5, is shown

on the display (D).

The red display LED (D) will come on.

If you accidentally set a higher speed than you want, press the

decrease speed button ([^) (E) until the correct speed is shown

on the display (D).

Hood lighting

(Fig- 8)

32

Simply press the ([^) button (A) to switch the lighting on or off.

Page 13

To select the intensive speed (P), press the increase speed button

([^) (F) until the letter P (high speed) is shown on the display (D).

Press the ([^) button (E) to slow down from intensive-speed

operation. The speeds 9-1 will once again be shown on the

display.

Intensive

speed P

(Fig. 9)

If there is a high level of cooking fumes or vapour, the hood should

be left In operation for at least 15 minutes after the cooker has

been completely turned off.

Press the (|^ button (C) to switch on the fan timer. I wiii

automaticaliy switch off after 15 minutes operation at the

speed you have seiected. A red dot will flash on and off on the

display (D).

Fan timer

(Fig- 9)

33

Page 14

Switching off

the fan

(Figures 10-11)

Press the key (B) to switch off the fan at any speed

including P.

After 5 seconds the number “0” (Fig. 10) will be shown on the

display (D) followed, finally, by only the red dot (Fig. 11).

34

Page 15

The hood should always be switched on before you start cooking

and left on for approximately 15 minutes after you have finished

(fan timer

Hood

operation

before and

after cooking

The activated carbon filter should be replaced at least once every

120 operating hours.

The activated carbon filter cannot be cleaned or reused.

The effective elimination of cooking odours depends on the

functional adaptation of the volume of activated carbon to the

hood’s air flow and a carefully determined position of the filter

inside the hood.

This combination inevitably decreases the air flow compared to

the extractor version.

A decisive parameter for the elimination of cooking odours is what

is known as the “residence time” of the air sucked into the hood in

the activated carbon filter.

The correct “residence time” can only be obtained using original

AEG activated carbon filters (see Special Accessories).

After 120 operating hours, the letter (C) (activated carbon filter)

will flash on and off on the display (D) in alternation with the fan

speed setting.

Warnings

on the

activated

carbon fiiter

Display

warning on

saturation of

activated

carbon filter

(Fig. 12)

This means the activated carbon filter needs to be changed!

(This operation should be carried out every 120 operating hours!)

Warning! The metal grease filters must be cleaned when you

change the activated carbon filter.

35

Page 16

Proceed as follows to remove and change my activated carbon

filter:

Switch of the fan motor by pressing the button.

Take the precaution of removing my cartridge fuses from their

fuse holder^ or tripping my automatic circuit breaker to ensure the

fan motor cannot be switched on accidentally.

1. Remove the grille (Fig. 13).

— Open my latch L and swing the grille downwards.

— To remove the grille, pull it forwards from the right and

release it.

36

Page 17

2. The activated carbon filter should under absolutely no circum

stances ever be washed. To remove it, press the two red

buttons B and pull it down and out (Fig. 14).

3. Clean the Inner housing using a hot detergent solution only

(never use caustic detergents, abrasive powders or brushes).

4. Fit the new activated carbon filter in its special frame. Inserting

the back end first and then pushing the front into place before

finally locking it into position using the lock devices (red

buttons. Fig. 14, B) on the activated carbon filter (Fig. 14, C).

6. Proceed as follows to reset the filter saturation display (coun

ter). Select any fan speed using my E or F buttons and

then press the B and F buttons at the same time,

continuing to hold them down for at least 3 seconds until the

flashing letter C stops being shown on the display (D) and then

press the button B.

The activated carbon filter display Is now ready for use again.

37

Page 18

Display

warning on

saturation

of metal

grease filter

(Fig. 15)

After 30 operating hours the letter (F- grease filters) will flash on

and off on the display (D) in alternation with the fan speed setting.

This means that the metal grease filters need to be cleaned!

(This operation should be carried out every 30 operating hours!)

Proceed as follows to remove and clean the metal filters:

Switch of the fan motor by pressing the button.

Take the precaution of removing my cartridge fuses from their

fuse holders or tripping the automatic circuit breaker to ensure the

fan motor cannot be switched on accidentally.

1. Remove the grille (Fig. 16).

— Open my latch L and swing the grille downwards.

— To remove the grille, pull it forwards from the right and

release it.

Remove the metal filter by operating the stops that fix them to the

grille.

38

Page 19

2. Clean the inner housing using a hot detergent solution only

(never use caustic detergents, abrasive powders or brushes).

3. Leave the metal grease filter panel to soak for approximately 1

hour in very hot water with grease-dissolving detergent and

then rinse it with very hot water. Repeat the operation if

necessary. Load the grease filter panel in a dishwasher,

selecting the most intensive washing programme and maxi

mum temperature, at least 65°C. Repeat the operation if

necessary.

4. When both metal grease filters have been cleaned and left to

dry, replace them by following the above operations in reverse

order (front first and then back).

5. Screw the fuses back in or reset the automatic circuit breaker.

6. Proceed as follows to reset the filter saturation display (coun

ter). Select any fan speed using my E or F buttons and

then press my [q] B and F buttons at the same time,

continuing to hold them down for at least 3 seconds until the

flashing letter F stops being shown on the display (D) and then

press the button B.

39

Page 20

Changing — Disconnect the unit from the mains power supply,

the light — Remove my cover

bulbs — Replace the old light bulb with a new light bulb (40 W max.).

— If the light does not come on, make sure the bulb has been

screwed in correctly before contacting the technical assist

ance service.

Cleaning Warning: always disconnect the hood from the mains power

supply before cleaning it.

Never insert pointed objects in the motor’s protective grille.

Wash the outside surfaces using a delicate detergent solution.

Never use caustic detergents or abrasive brushes or powders.

Only ever clean the switch panel and filter grille using a damp cloth

and delicate detergents.

Attention!

Attention! Failure to observe the instructions on cleaning the unit

and changing the filters will cause a fire hazard. You are therefore

strongly recommended to follow these instructions.

40

Page 21

MKZ telescopic wall pipe

120 mm outlet hose

KLF60/80 activated carbon filter

E-Nr. 610 899 004

610 899 007

610 899 421

Technical assistance service

You are welcome to telephone our technical assistance service

(see list of technical assistance centres) whenever you need

information or in the unlikely event of a fault.

When calling, please be ready to specify;

1. The model code number

2. The E-Nr.

3. The F-Nr.

This information is shown on the registration plate inside the unit behind the grease filter grille.

We reserve the right to change specifications and colours as a

result of our policy of continuing technological development.

41

Page 22

AEG

Bitte geben Sie unserem Kundendienst folgende Angaben

bei einer Störung an:

If your appliance has a fault, please contact our service

engineer and state the following numbers:

Veuillez donner les indications suivantes à notre service

après-vente en cas de panne:

In caso di difetto vi preghiamo di comunicare al servizio

tecnico assistenza clienti i seguenti dati:

E-Nr. 610

F-Nr.

AEG Hausgeräte AG

Postfach 1036

D-90327 Nürnberg

© Copyright by AEG

H 260 264 900

L 437B Ed. 06/95 :

Loading...

Loading...