Page 1

$30.00

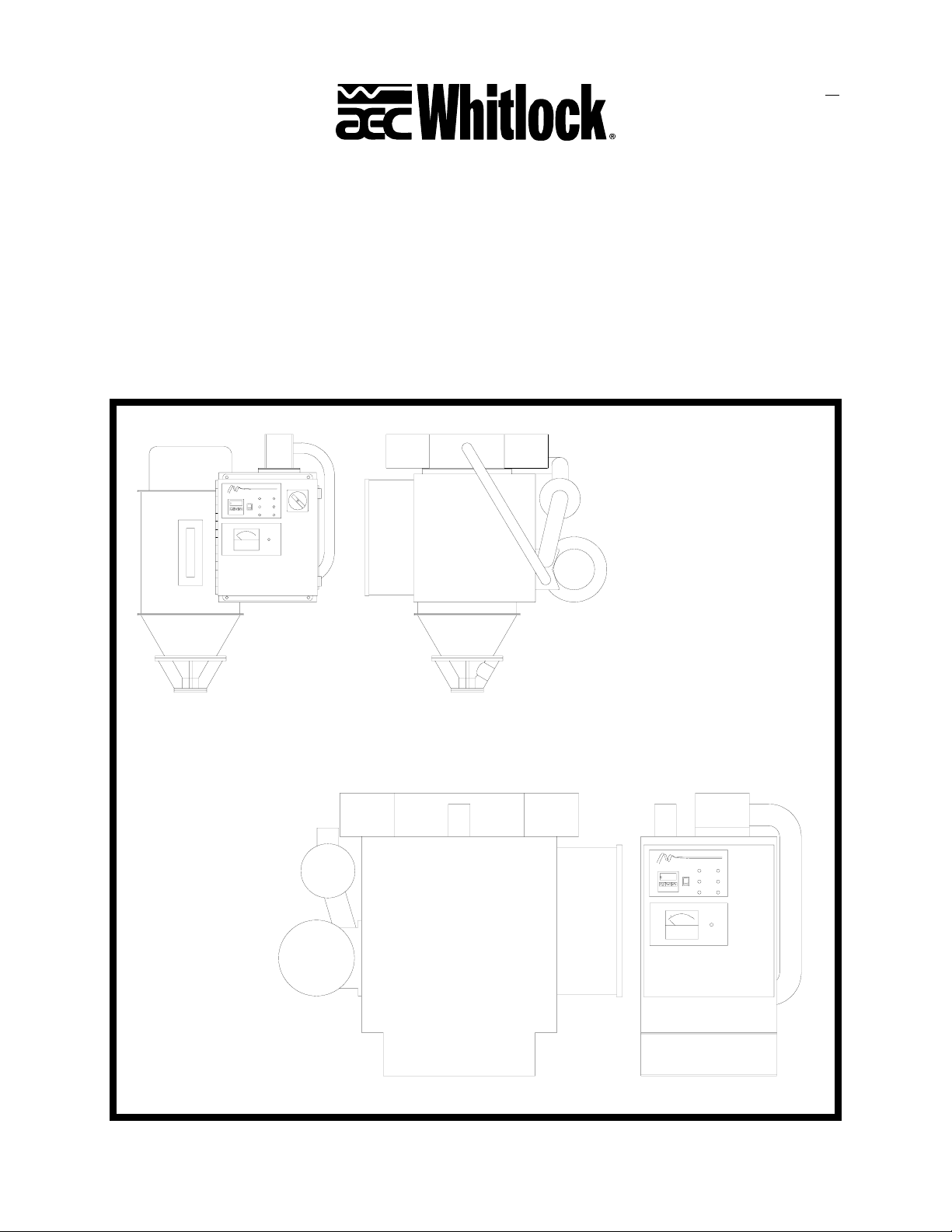

Operation and Installation Manual

WDMR and WDFR Series

Dehumidifying Dryers

Important! Read Carefully Before Attempting to Install or Operate Equipment

WD Series

Dehumidifying Dryer

Process

HI-Process

Heater on

Process Delivery

Process Delivery

Air Temp

Temperature

Temperature

ON

Left Bed

Righp Bed

Heater

Heater

888

Left Bed

Right Bed

OFF

In Regen

In Regen

Process Dew Point

-

20

15

10

25-

-

-

30

5

3540-

0

-

High Dew Point

DEW POINT (F)

WD Series

Dehumidifying Dryer

Process

HI-Process

Heater on

Process Delivery

Process Delivery

Temperature

Temperature

888

3540-

-

Part No. A0547682 Bulletin No. WH1-615

Air Temp

ON

Righp Bed

Left Bed

Heater

Heater

Left Bed

Right Bed

OFF

In Regen

In Regen

Process Dew Point

-

20

15

10

25-

-

-

30

5

0

High Dew Point

DEW POINT (F)

Page 2

Page 3

Performance figures stated in this manual are based on a standard atmosphere of 59°F

(15°C) at 29.92” Hg (1,014 millibars) at sea level, using 60 hz power. Altitude is an

important consideration when specifying dehumidifying dryers. AEC/Whitlock can advise

you on proper selection and sizing of systems for your operating environment.

AEC/Whitlock is committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual

are subject to change without notice.

© Copyright AEC/Whitlock and AEC, Inc. 2004

All rights reserved. Effective 7/23/2004

Part No. A0547682 Bulletin No. WH1-615.2

Page 2 WDMR and WDFR Series Dehumidifying Dryers

Page 4

Safety Considerations

AEC/Whitlock WDMR and WDFR Series dehumidifying dryers are designed to provide safe

and reliable operation when installed and operated within design specifications, following

national and local safety codes.

To avoid possible personnel injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

Follow all SAFETY CODES.

Wear SAFETY GLASSES and WORK GLOVES.

Disconnect and/or lock out power before servicing or maintaining the dryer.

Use care when LOADING, UNLOADING, RIGGING, or MOVING this equipment.

Operate this equipment within design specifications.

OPEN, TAG, and LOCK ALL DISCONNECTS before working on this equipment. It is a

good idea to remove the fuses and carry them with you

Make sure the dryer and components are properly GROUNDED before switching on power.

Do not jump or bypass any electrical safety control.

Do not restore power until all tools, test equipment, etc. have been removed and the dryer

and allied equipment are fully reassembled.

Only PROPERLY TRAINED personnel familiar with the information within this manual

should work on this equipment.

WDMR and WDFR Series Dehumidifying Dryers Page 3

Page 5

Table of Contents

1 General Information .................................................7

1-1 Models Covered

1-2 Equipment Function

1-3 Necessary Documents

1-4 Standard Features

1-5 Options

1-6 The Closed Loop Drying System

1-7 What is Desiccant?

1-8 The Process/Regeneration Cycle

1-9 Specifying a Drying System

2 Shipping Information..............................................13

2-1 Unpacking and Inspection

2-2 In the Event of Shipping Damages

2-3 If the Shipment is Not Complete

2-4 If the Shipment is Not Correct

2-5 Returns

3 Installation............................................................... 15

3-1 Work Rules

3-2 Rigging and Placing the Dryer

3-3 Making Electrical Connections

3-4 Checking for Proper Blower Rotation

3-5 Making Dryer/Drying Hopper Process Air Connections

3-6 Drying Hopper Air Trap Considerations

3-7 Installing the Optional Aftercooler

4 Level 1 Controllers .................................................25

4-1 Level 1 Control Panel Indicator Lights

4-2 Level 1 Switches and Meters

4-3 Level 1 PLC Controller

4-4 Level 1 Process Air Temperature Controller

4-5 Level 1 PLC LED Indicators

4-6 Level 1 Temperature Controller LED Indicators

4-7 Level 1 Temperature Controller Keys

Page 4 WDMR and WDFR Series Dehumidifying Dryers

Page 6

Table of Contents

5 Additional Level 2 Controller Features................. 33

5-1 Level 2 Control Panel

5-2 Level 2 Control Panel Indicator Lights

5-3 Level 2 Switches and Meters

5-4 Level 2 PLC Controller

5-5 Level 2 Process Air Temperature Controller

5-6 Level 2 Temperature Controller LED Indicators

5-7 Level 2 PLC LED Indicators

5-8 Level 2 Temperature Controller Keys

5-9 Level 2 Optional Communications Protocols

6 Startup, Shutdown, and Operation .......................41

6-1 Pre-Startup Checks

6-2 Startup

6-3 Shutdown

6-4 Setting the Process Air Temperature

6-5 Setting the High Temperature Alarm

6-6 Temperature Controller Internal Switches

6-7 Enabling the Temperature Controller Anti-Tamper Lockout Switch

6-8 Changing the Display from Fahrenheit to Celsius

7 Maintenance ............................................................ 47

7-1 Work Rules

7-2 Servicing Process Air Filters

7-3 Servicing the Dew Point Monitor

7-4 Symptoms of Worn Desiccant

7-5 Replacing Worn Desiccant

7-6 Replacing the Process Heater

7-7 Replacing the Regeneration Heater

7-8 Restoring the Temperature Controller to Factory Setup

7-9 Error Display and Output

7-10 Maintaining the Aftercooler

7-11 Entering Level 2 Controller Parameters/Advanced Topics

8 Troubleshooting ..................................................... 71

WDMR and WDFR Series Dehumidifying Dryers Page 5

Page 7

Charts and Figures

1

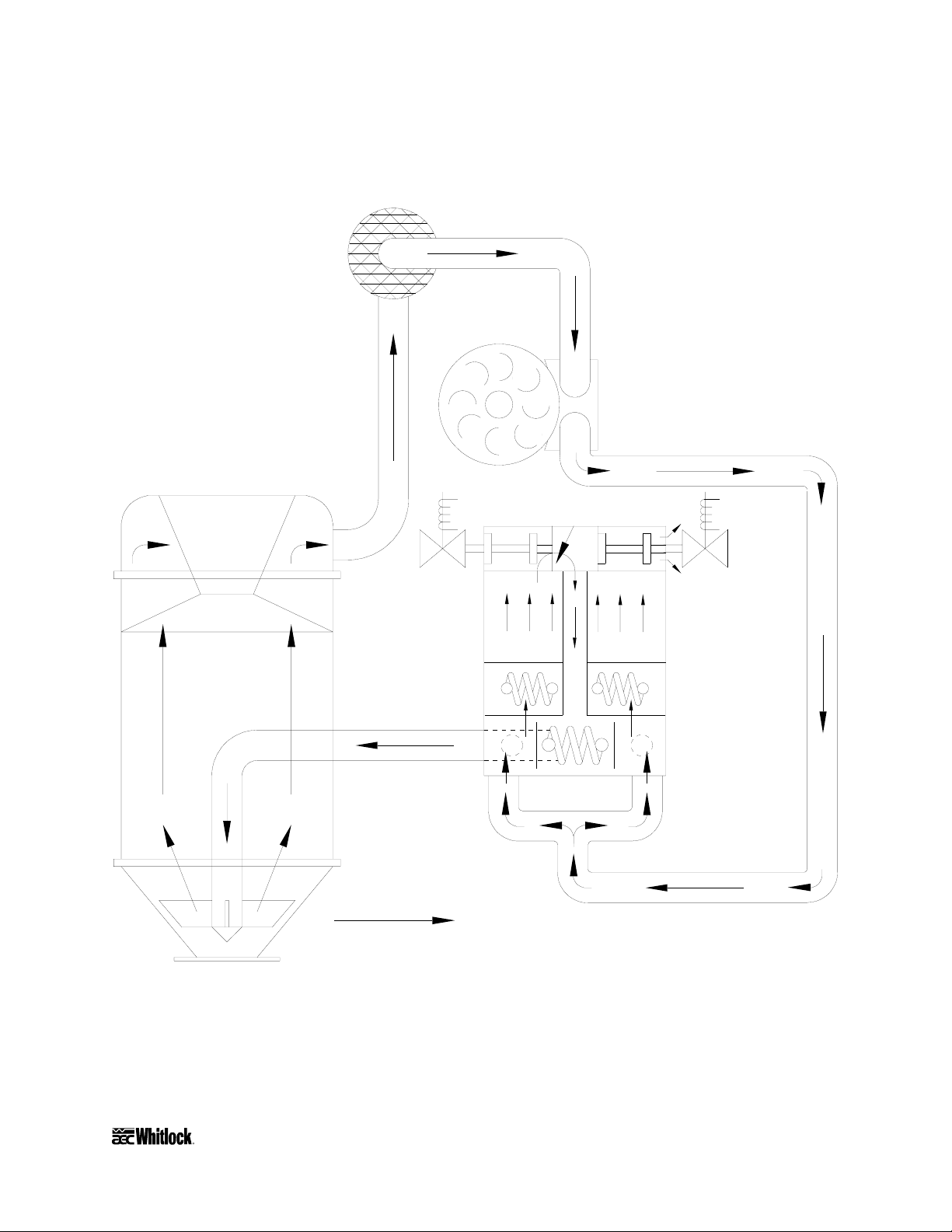

Typical Air Flow Schematic 9

2

WD10MR to WD50MR Dryer Specifications 10

3

WDMR Series Machine-Mount Dimensions 10

4

WDFR Series Floor-Mount Dimensions 11

5

Suggested Lift Rigging for WDMR and WDFR Dryers 16

6

Typical WD10MR/FR Electrical Schematic, Drawings 1 and 2 18, 19

7

Typical WD25MR/FR, WD50 MR/FR Electrical Schematic, Drawings 1 and 2 20, 21

8

Typical Control Subpanel Layout 22

9

Aftercooler Design Specifications 24

10

11

12

13

14

15

16

17

18

19

20

21

22

Typical Enclosure with Level 1 Control Panel, Optional Dew Point System, Disconnect 26

Level 1 Process Air Temperature Control Graphic Layout 27

Level 1 PLC Controller Details 30

Optional Level 2 Controller 34

Level 2 PLC Controller Details 37

Required Desiccant Amounts per Bed 52

Level 1 Controller Factory Preset Parameters 56

Level 2 Controller Factory Preset Parameters 59

Level 1 Controller Error Messages 60

Level 2 Process Temperature Controller Error Messages 66

Optional 7-Day Timer 66

Optional WD50MR/FR Aftercooler Spare Parts List 74

WD10MR and WD10FR Spare Parts List 75

23

24

Page 6 WDMR and WDFR Series Dehumidifying Dryers

WD25MR and WD25FR Spare Parts List 76

WD50MR and WD50FR Spare Parts List 77

Page 8

1 General Information

1-1 Models Covered

This manual provides instructions for installing and operating AEC/Whitlock WD10MR,

WD25MR, and WD50MR dehumidifying dryers. Models designated with

configurations and models designated with

represents air flow capacity. WD10 models have a 10 cfm (17 cmh) air flow capacity, WD25

models have a 25 cfm (42 cmh) air flow capacity, and WD50 models have a 50 cfm (85 cmh)

capacity.

F are floor-mount models. The number designation

1-2 Equipment Function

Whitlock dehumidifying dryers are designed to generate heated, dehumidified air at carefully

controlled temperatures for use in closed-loop plastic drying systems. Drying systems are sized

to meet the specific requirements stated by the purchaser at the time of purchase.

Moisture removal from hygroscopic (moisture attracting) plastic pellets is an essential step in the

manufacture of high-quality plastic products.

AEC/Whitlock dehumidifying dryers are used to generate very low dew point air heated to a

controlled temperature for drying plastic pellets and regrind.

M are machine-mount

1-3 Necessary Documents

The documents listed below are necessary for the operation, installation, and maintenance of

AEC/Whitlock WD10MR/FR through WD50MR/FR dryers. Additional copies are available

from AEC, Inc. Familiarize the appropriate personnel with these documents:

This manual.

The schematic and assembly drawings included in the customer information packet.

The Customer Parts List included in the information packet.

Operation and installation manuals for any optional controls or auxiliary equipment in the

drying system.

WDMR and WDFR Series Dehumidifying Dryers Page 7

Page 9

1-4 Standard Features

Dual desiccant beds

Electric air control valve

13X desiccant

Up to 400ºF (204ºC) drying temperature range

1-5 Options

Options can tailor your AEC/Whitlock dehumidifying dryer to meet the exact requirements of

the drying task being performed.

Dew point monitor indicates dryer efficiency.

Electrical disconnect.

Seven day timer to allow programmable dryer startup.

Communications to meet customer needs.

Drying hoppers come in many sizes and mounting configurations.

Conveying equipment to transport material to and from the drying system.

1-6 The Closed Loop Drying System

AEC/Whitlock dryers force hot, dry air through the resin in the drying hopper, where the air

picks up moisture from the material and is drawn back to the dryer.

In the dryer, a desiccant bed strips moisture from the air. The dried process air is then re-heated

and delivered back into the drying hopper to dry material again.

This system is a closed loop, because ambient (outside) air is never introduced into the process

air. AEC/Whitlock uses the closed loop system because the process air is typically much drier

than ambient air, even after carrying moisture out of the plastic resin. Recycling process air

maintains drying efficiency at a consistently high level.

Page 8 WDMR and WDFR Series Dehumidifying Dryers

Page 10

P

Drying

hopper

Figure 1

Typical Air Flow Schematic

rocess

filter

Regeneration &

process

blower

Bed

shift

valve

Desiccant

bed

Left

regeneration

heater

Arrows represent air flow

Bed

shift

valve

Desiccant

bed

Right

regeneration

heater

Process

heater

WDMR and WDFR Series Dehumidifying Dryers Page 9

Page 11

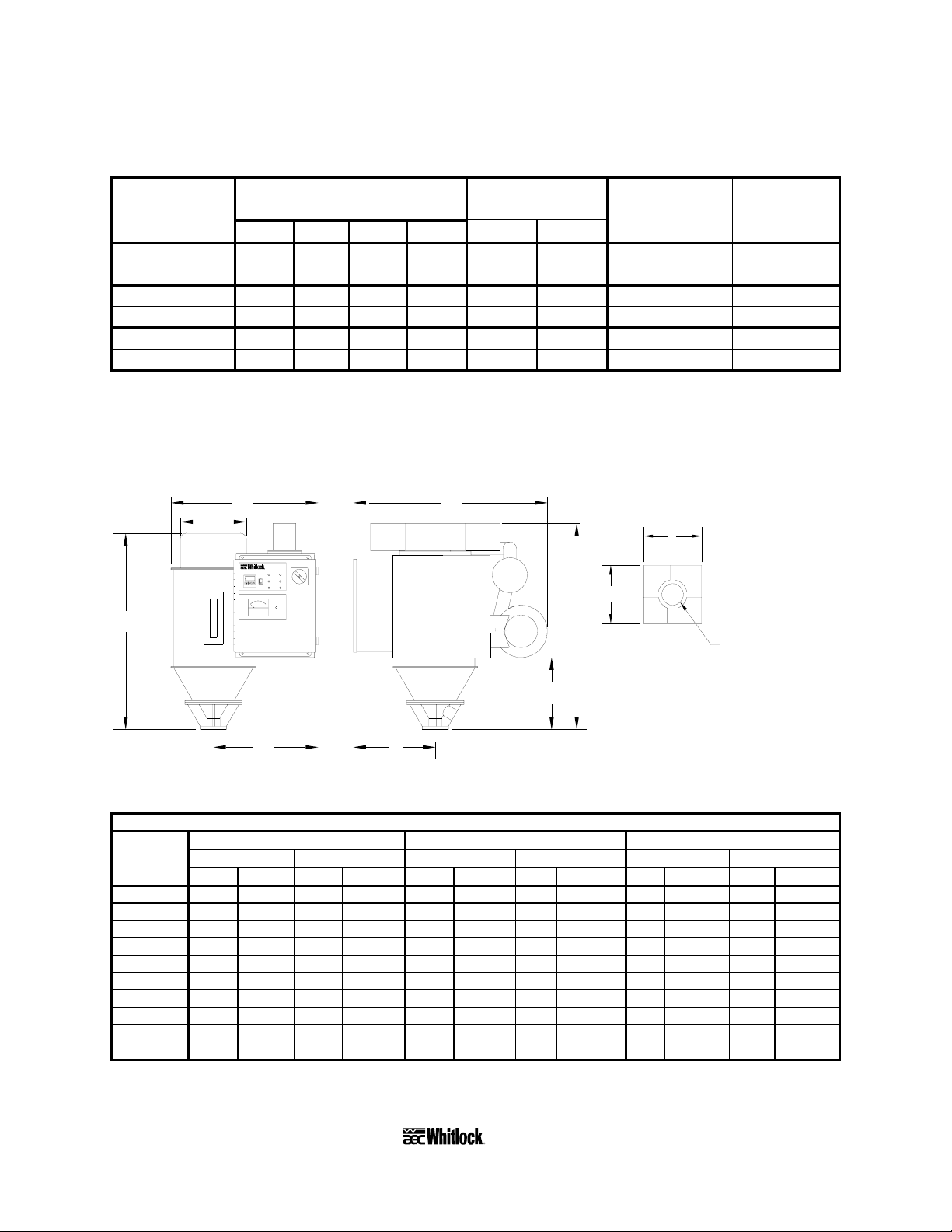

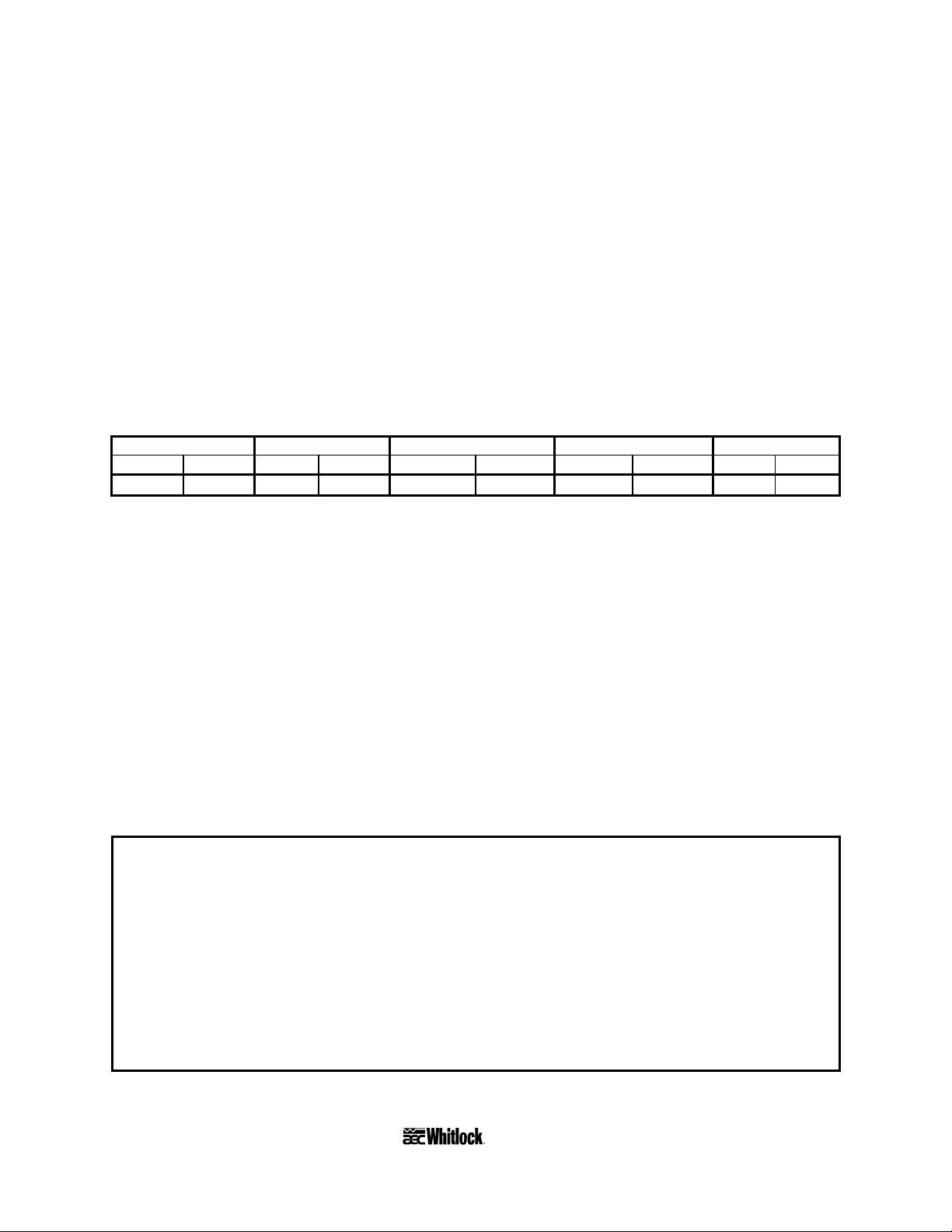

Figure 2

A

WD10MR through WD50MR Dryer Specifications

Hopper Process Full

Model size air flow Standard load

number cu. ft. liters lbs. Kg cfm cmh voltage amps

WD10MR 0.7 20 25 11.3 10 17 115/1/60 20.8

WD10MR 1.5 40 50 22.7 10 17 115/1/60 20.8

WD25MR 1.5 40 50 22.7 25 42 460/3/60 10.8

WD25MR 3.0 80 100 45.4 25 42 460/3/60 10.8

WD50MR 4.0 120 150 68.1 50 85 460/3/60 19.0

WD50MR 6.0 160 200 90.8 50 85 460/3/60 19.0

At high temperature operation.

Figure 3

WDMR Series Machine-Mount Dimensions

E

B

Process

HI-Process

Heater on

Process Delivery

Process Delivery

Air Temp

Temperature

Temperature

ON

Left Bed

Righp Bed

Heater

Heater

888

Left Bed

Right Bed

OFF

In Regen

In Regen

Process Dew Point

-

15

20

10

25-

-

-

30

5

3540-

0

-

High Dew Point

DEW POINT (F)

C

F

G

D

H

Mounting flange

J

J

Diameter hole:

K

Hopper mounting flanges on 0.75 and

Notes:

and 1.5 cu. ft. (20 & 40 liter) hoppers

are supplied blank so the customer

can drill to match existing machine throat.

3.0 cu. ft. (80 liter) hoppers and larger

are not supplied with a cast flange

(as shown).

Front Side

WD10MR, WD25MR, WD50MR machine-mount dimensions in inches/cm

WD10MR WD25MR WD50MR

.7 ft.3/20 liters 1.5 ft.3/40 liters 1.5 ft.3/40 liters 3.0 ft.3/80 liters 4.0 ft.3/120 liters 6.0 ft.3/160 liters

Dimension in. cm in. cm in. cm in. cm in. cm in. cm

A 24´´ 61.0 cm 27´´ 68.6 cm 29´´ 73.7 cm 385/8´´ 98.1 cm 38´´ 96.6 cm 38´´ 96.6 cm

B 101/8´´ 25.7 cm 141/8´´ 35.9 cm 141/8´´ 35.9 cm 20´´ 50.8 cm 20´´ 50.8 cm 20´´ 50.8 cm

C 31´´ 78.7 cm 351/2´´ 90.2 cm 351/2´´ 90.2 cm 38´´ 96.6 cm 45´´ 114.3 cm 56´´ 142.3 cm

D 18´´ 45.7 cm 163/4´´ 42.6 cm 21´´ 53.3 cm 251/2´´ 64.8 cm 26´´ 66.1 cm 26´´ 66.1 cm

E 301/2´´ 77.5 cm 301/2´´ 77.5 cm 34´´ 86.3 cm 34´´ 86.3 cm 40´´ 101.6 cm 40´´ 101.6 cm

F 343/4´´ 88.3 cm 361/2´´ 92.7 cm 393/4´´ 101.0 cm 447/8´´ 114.0 cm 51´´ 129.6 cm 51´´ 129.6 cm

G 101/2´´ 26.7 cm 143/4´´ 37.5 cm 15´´ 38.1 cm 17´´ 43.2 cm 17´´ 43.2 cm 17´´ 43.2 cm

H 14´´ 35.6 cm 121/2´´ 31.8 cm 15´´ 38.1 cm 15´´ 38.1 cm 18´´ 45.7 cm 18´´ 45.7 cm

J 4´´ 10.2 cm 4´´ 10.2 cm 4´´ 10.2 cm 7´´ 17.8 cm 7´´ 17.8 cm 7´´ 17.8 cm

K 11/2´´ 3.8 cm 11/2´´ 3.8 cm 11/2´´ 3.8 cm 2´´ 5.1 cm 2´´ 5.1 cm 2´´ 5.1 cm

Page 10 WDMR and WDFR Series Dehumidifying Dryers

Page 12

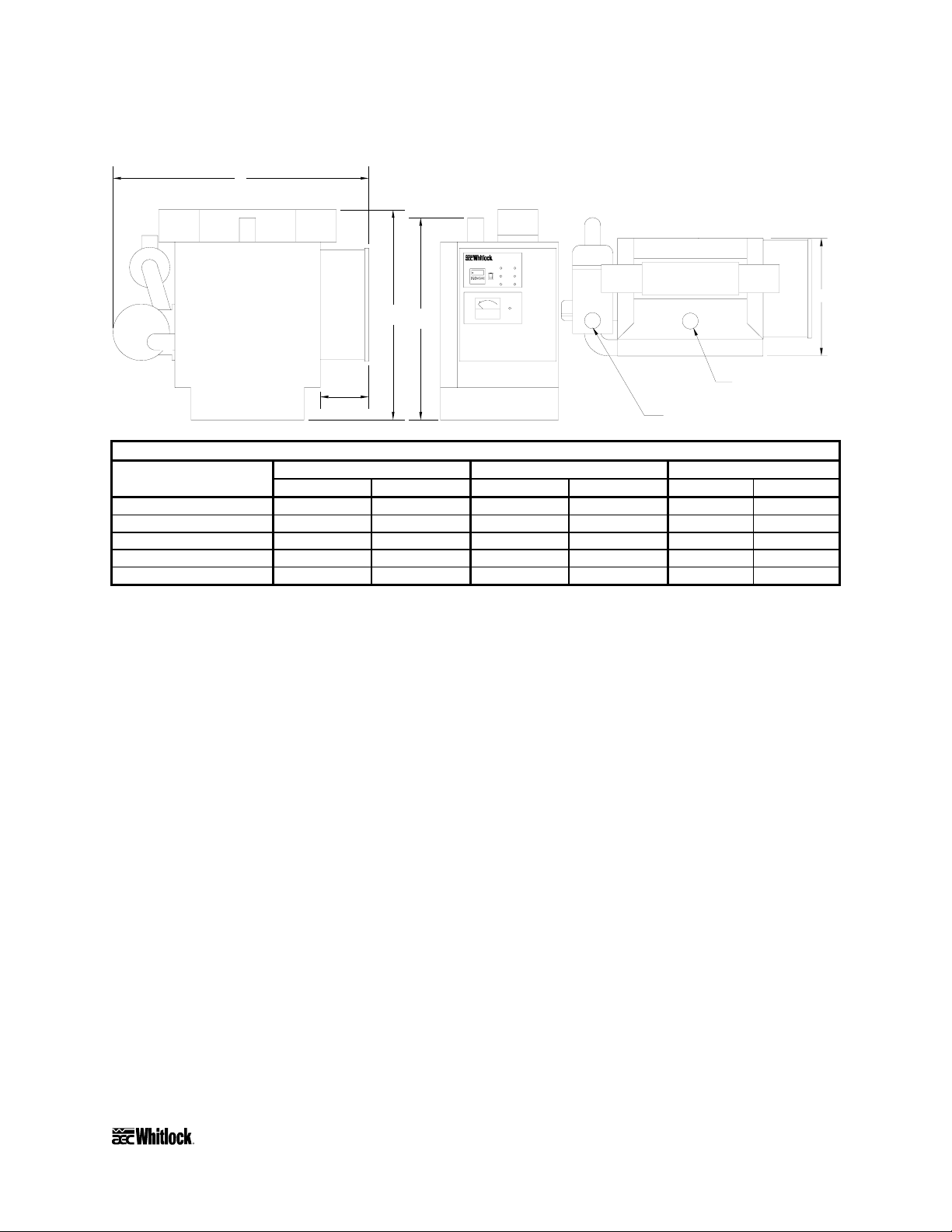

Figure 4

r

WDFR Series Floor-Mount Dimensions

B

Process

HI-Process

Heater on

Air Temp

Process Delivery

Process Delivery

Temperature

Temperature

ON

Left Bed

Righp Bed

Heater

Heater

888

Left Bed

Right Bed

OFF

In Regen

In Regen

Process Dew Point

-

20

15

10

25-

-

-

30

5

3540-

0

-

High Dew Point

C

D

DEW POINT (F)

2" OD (about 51 mm)

FMASSY

6"

15.2 cm

2" OD (about 51 mm)

return from hoppe

delivery to hopper

WD10FR, WD25FR, WD50FR floor-mount dimensions in inches/cm

WD10FR WD25FR WD50FR

Dimension in. cm in. cm in. cm

A 121/2 31.8 121/2 31.8 14 35.6

B 321/2 82.6 33 83.8 41 104.2

C 241/2 62.2 27 68.6 34 86.3

D 23 58.4 25 63.5 32 81.3

E 16 40.6 18 45.7 18 45.7

A

1-7 What is Desiccant?

Desiccant is a material that attracts and holds (absorbs) water from the air. The desiccant

AEC/Whitlock dryers use is a synthetic crystalline metal aluminosilicate blended with a clay

binder and formed into beads.

Absorbed water is driven from saturated desiccant by heating it to a high temperature (reducing

desiccant capacity to hold water) and forcing air through it. This moisture removal process is

called regeneration.

1-8 The Process/Regeneration Cycle

AEC/Whitlock WDMR and WDFR dryers have two desiccant beds. While one bed is on-line in

the process air loop, the other is off-line, being regenerated.

When a desiccant bed is on-line, it absorbs moisture from the process air. In time, the bed

becomes saturated with moisture and needs to be regenerated. The dryer automatically redirects

the process airflow to the second bed, and starts the regeneration cycle on the first bed.

WDMR and WDFR Series Dehumidifying Dryers Page 11

Page 13

During regeneration, the dryer system heats air and forces it through the desiccant bed. The

moisture driven off the bed bleeds to the atmosphere.

If you measure the temperature of the air bled to the atmosphere (bleed temperature), you should

observe a rise after a period of time. This condition, called bed breakthrough, indicates that the

bed is dry. At bed breakthrough, the bleed air temperature peaks at approximately 400°F

(204ºC).

1-9 Specifying a Drying System

Many variables were considered in the selection of your drying system, including type of

materials, residence time, throughput of the extruder or injection molding machine,

ambient air moisture and temperature, and the altitude at the processing site. Should your

operating environment change, AEC/Whitlock can advise you on necessary equipment and

process time and temperature modifications required for your system.

Page 12 WDMR and WDFR Series Dehumidifying Dryers

Page 14

2 Shipping Information

2-1 Unpacking and Inspection

You should inspect your Whitlock dehumidifying dryer for possible shipping damage. If the

container and packing materials are in re-usable condition, save them for reshipment, if

necessary.

Thoroughly check the equipment for any damage that might have occurred in transit, such as

broken or loose wiring and components, loose hardware and mounting screws, etc. In case of

breakage, damage, shortage, or incorrect shipment, refer to the following sections.

2-2 In the Event of Shipping Damages

Important!

According to the contract terms and conditions of the Carrier,

the responsibility of the Shipper ends at the time and place of shipment.

The Carrier then assumes full responsibility of the shipment.

Notify the transportation company’s local agent if you discover damage.

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods to AEC, Inc. before the transportation company inspection and

authorization.

File a claim against the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise AEC, Inc. regarding your wish for replacement and to obtain an RMA (return

material authorization) number.

WDMR and WDFR Series Dehumidifying Dryers Page 13

Page 15

2-3 If the Shipment is Not Complete

Check the packing list. The apparent shortage may be intentional. Back-ordered items are noted

on the packing list. You should have:

WDMR or WDFR Series dryer

Bill of lading

Packing list

Operating and Installation packet

Electrical schematic and panel layout drawings

Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking. Determine that the item was not inadvertently taken from the area before you

checked in the shipment. Notify AEC, Inc. immediately of the shortage.

2-4 If the Shipment is Not Correct

If the shipment is not what you ordered, contact AEC, Inc. immediately. Include the order

number and item. Hold the items until you receive shipping instructions.

2-5 Returns

Important!

Do not return any damaged or incorrect items

until you receive shipping instructions from AEC, Inc.

Page 14 WDMR and WDFR Series Dehumidifying Dryers

Page 16

3 Installation

3-1 Work Rules

The installation, operation, and maintenance of this equipment must be conducted in accordance

with all applicable work and safety codes for the installation location. This may include, but is

not limited to, OSHA, NEC, CSA, and any other local, national, and international regulations.

• Read and follow these operating instructions when installing, operating, and maintaining

this equipment. If the instructions become damaged or unreadable, you can obtain

additional copies from AEC/Whitlock.

• Only qualified personnel familiar with this equipment should work on or with this dryer.

• Work with approved tools and devices.

• Disconnect the electricity before maintenance or service. If the dryer is installed with a

power cord that can be unplugged, unplug it. If the dryer is permanently wired to a power

main, you must install a fused power disconnect to allow the disconnect to be locked in the

OFF position. Open and lock out the disconnect installed in the control enclosure.

3-2 Rigging and Placing the Dryer

Take care when rigging and placing the dryer. Figure 5 on the following page shows a suggested

safe rigging diagram. It lets you lift the dryer/hopper unit vertically for installation on the

machine throat. Adjust chain lengths at the center sling bracket before you lift the unit. Your

dryer has built-in lifting lugs.

Caution!

Use caution and observe safety rules when lifting and placing your dryer!

Note: Due to the large physical size of WD50MR dryer units, extra customer-provided support

is required to stabilize these units and to protect personnel when installing on machine

throats.

WDMR and WDFR Series Dehumidifying Dryers Page 15

Page 17

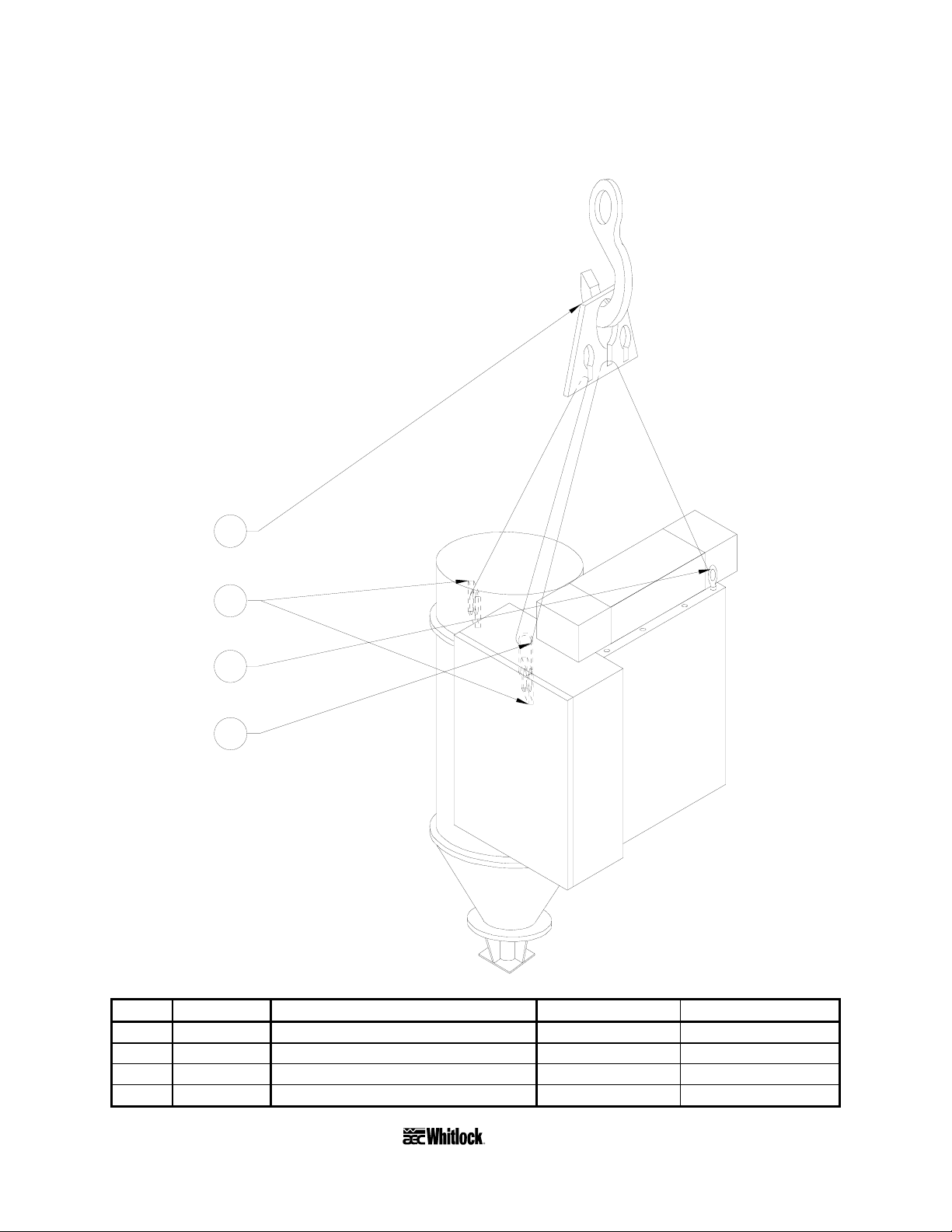

Figure 5

Suggested Lift Rigging for WDMR and WDFR Dryers

1

2

3

4

A0552486

Item Quantity Description Vendor Vendor part no.

1 1 Adjustable alloy chain sling McMaster-Carr 33665T32

2 2 Existing hopper lifting bracket — —

3 1 Drop forged steel eye nut McMaster-Carr 3019T15

4 1 Chain connector McMaster-Carr 3712T23

Page 16 WDMR and WDFR Series Dehumidifying Dryers

Page 18

3-3 Making Electrical Connections

The serial tag lists voltage, phase, and amp draw information.

Line voltage must be within plus or minus ten percent (±10%) of the voltage listed on the

serial tag, or damage may occur. Phase imbalance must be less than two percent (2%).

Fulfill all national, state, and local safety and electrical code requirements.

A qualified electrician should make all electrical connections.

Make sure all electrical connections are tight.

Connect main power to the dryer at the disconnect or terminals in the upper right corner of

the control enclosure.

Install a fused disconnect with a lockout feature in the power main leading to the dryer.

The power drop must include a ground wire.

3-4 Checking for Proper Blower Rotation

Three-Phase Models

The blower rotates properly when air flows from the delivery outlet.

Caution!

In three-phase models, incorrect phasing of power leads

can cause backward rotation of blower motors

and CONTAMINATION OF THE DESICCANT!

Always check blower rotation before putting material in the drying hopper!

If the three-phase blower rotates improperly, reverse any two wires at the fused disconnect

outside the dryer or at the disconnect/terminal in the control enclosure. This assures that the

blower rotates in the proper direction.

WDMR and WDFR Series Dehumidifying Dryers Page 17

Page 19

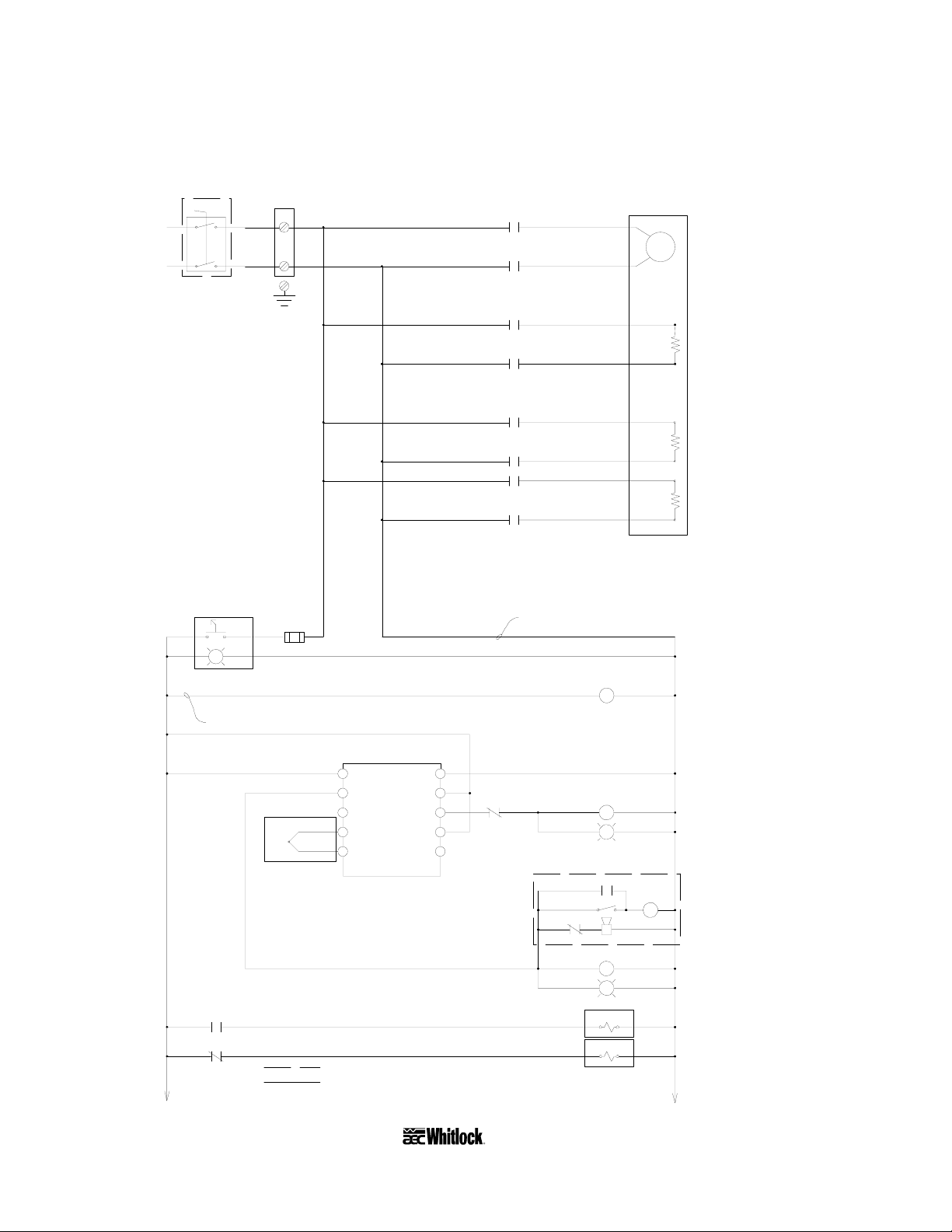

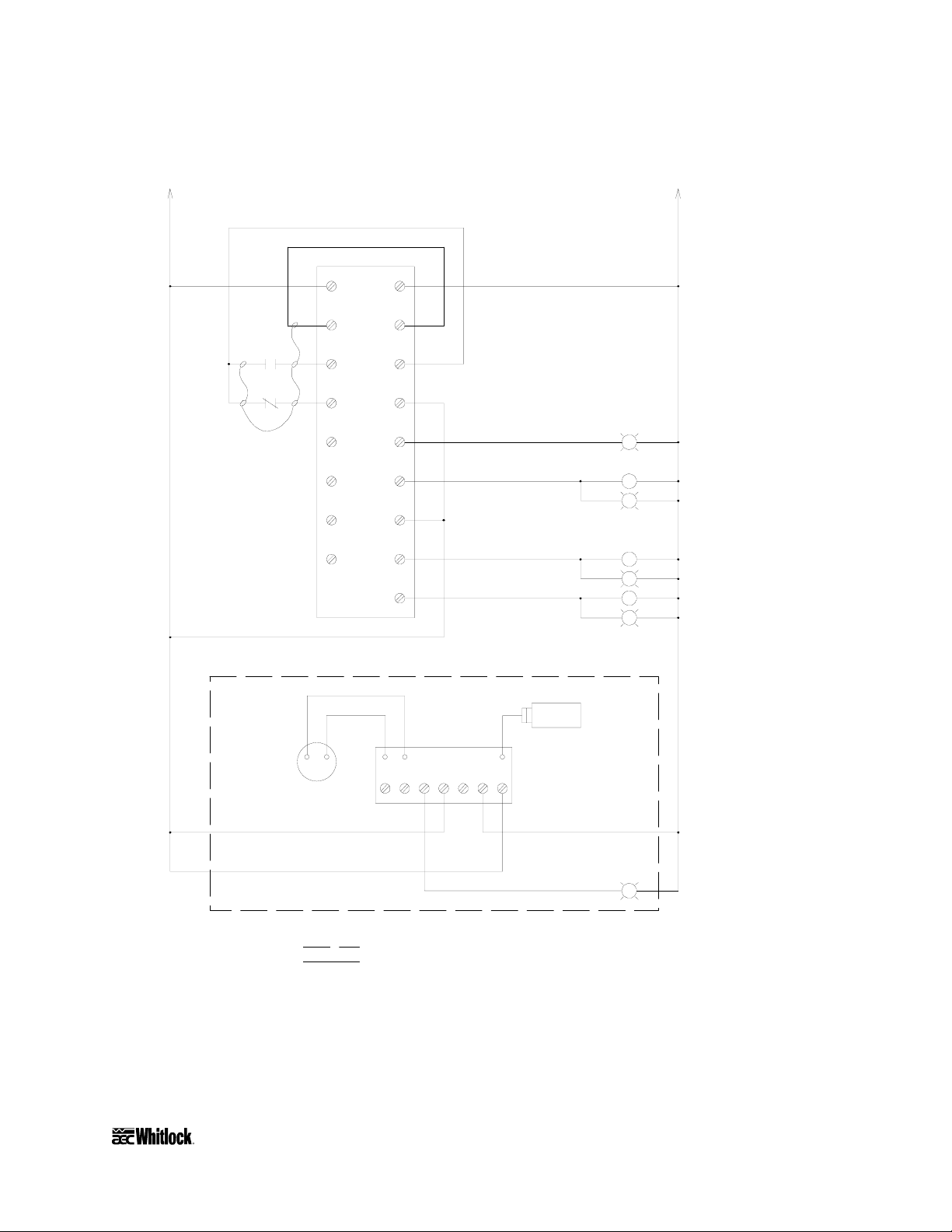

L1

L2

OPTIONAL

DISCONNECT

1DISC

115/60/1

Figure 6

Typical WD10MR/FR Electrical Schematic, Drawing 1

115/1/60

1DBLK

1L1

1L1

TB1

1L3

1L1

1L2

1M

1M

1T1

1MTR

1T2

BLOWER

CONTROL POWER

4

4

4

4

OFF ON

G

18GA RED (TYP)

SUBPANEL

GROUND

GROUND

1RS

3

OX

1LT

1L1

1L2

1L1

1L2

1L1

1L2

2FU

1L1

1L2 1L2

1C

1C

2C

2C

3C

3C

18GA WHT (TYP)

1H1

PROCESS

1HTR

2HTR

3HTR

1L2

1L2

HEATER

LEFT

REGENERATION

HEATER

RIGHT

REGENERATION

HEATER

POWER ON

BLOWER CONTACTOR

1H2

2H1

2H2

3H1

3H2

1M

4

4

4

4

2CR

2CR

LEGEND:

5 10

5

4

3

PROCESS

2

TEMPERATURE

CONTROLLER

[-]RED

TYPE "K"

5 5

[+]YEL

1TC

1L2

4

9

8

7

61

1CR

6

4

A054616

OPTIONAL COMPONENTS

COMPONENTS LOCATED EXTERNALLY

OF CONTROL ENCLOSURE

7

518

5

5

8

18

1C

OPTIONAL AUDIBLE ALARM

3CR

2RS

3CR

19

1AH

1CR

R

1SOL

2SOL

1L2

1L2

1L2

1LTG1LT

3CR SILENCE BUTTON

1AH

1L2

1L2

2LT

1L2

1L2

PROCESS HEATER CONTACTOR

"PROCESS HEATER ON"

AUDIBLE ALARM

PROCESS HIGH TEMP. RELAY

"HI-PROCESS AIR TEMP"

RIGHT VALVE SHIFT SOLENOID

LEFT VALVE SHIFT SOLENOID

1L2

Page 18 WDMR and WDFR Series Dehumidifying Dryers

Page 20

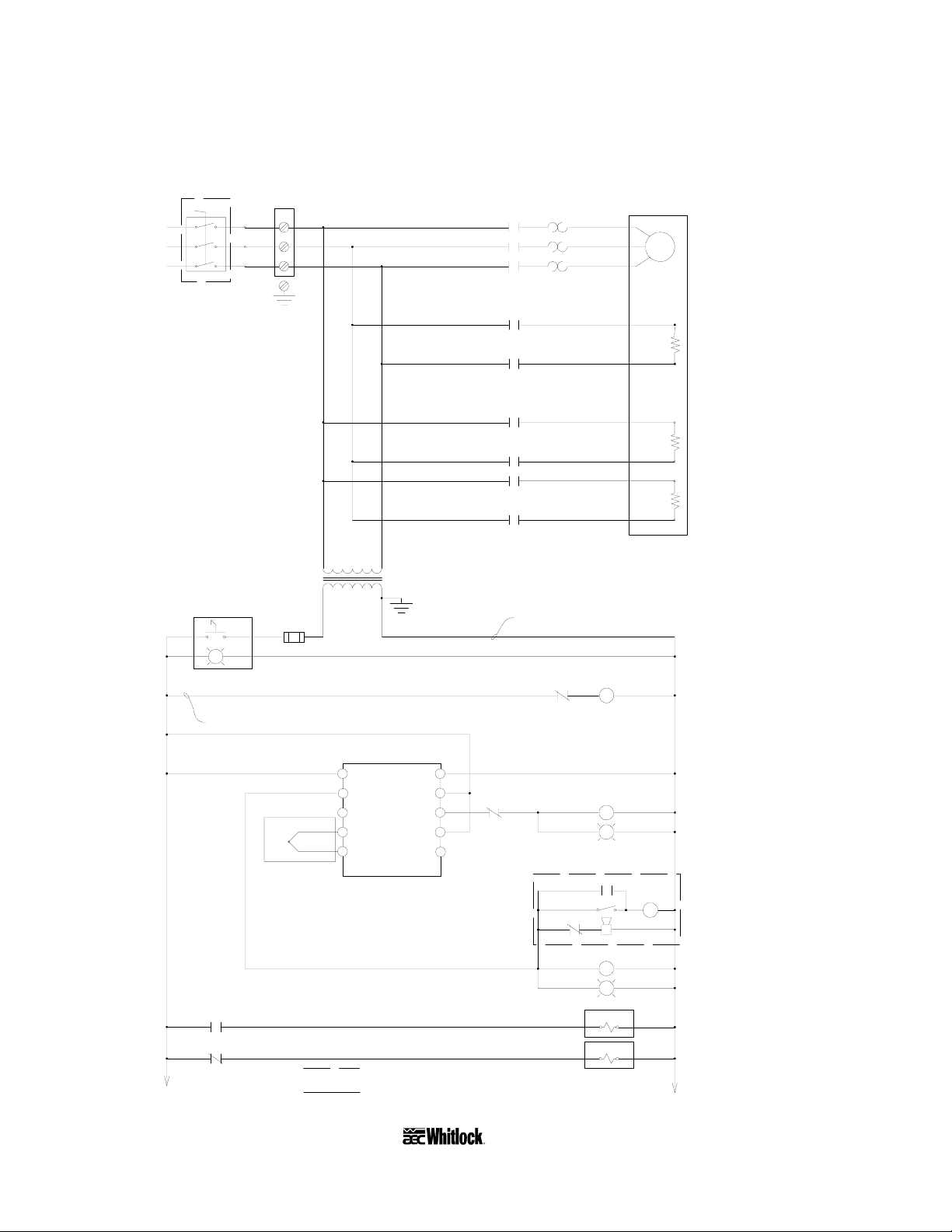

Figure 6

Typical WD10MR/FR Electrical Schematic, Drawing 2

L2

1L2

115/1/60

1L2

4 1L2

10

1PLC

L1

44

COM

99

11

12

-

1DMTR

000

001

002

003

004

005

+

1M

10

1CR

10

18GA BLUE 24VDC

INPUT WIRING

4

DEW POINT

METER

4

+24V

-24V

10

COM

4

0

13

1

14

COM

4

2

15

3

16

OPTIONAL DEW POINT CONTROL

RED BLK

1DPB

4

17 4

3LT

1L2

G

2CR

14

15

16

1DPT

7654321

1L2

4LT

G

2C

5LT

G

3C

6LT

G

"LEFT BED IN REGEN"

1L2

BED SHIFT RELAY

1L2

"RIGHT BED IN REGEN"

1L2

LEFT BED CONTACTOR

1L2

"LEFT BED HEATER" ON

1L2

RIGHT BED CONTACTOR

1L2

"RIGHT BED HEATER" ON

DEW POINT CONTROL BOARD

1L2

4

17

4

A054616

7LT

G "HIGH DEW POINT"

1L2

LEGEND:

OPTIONAL COMPONENTS

COMPONENTS LOCATED EXTERNALLY

OF CONTROL ENCLOSURE

Refer to your Customer Information Packet on actual drawings for your specific dryer.

WDMR and WDFR Series Dehumidifying Dryers Page 19

Page 21

Figure 7

Typical WD25MR/FR, WD50MR/FR Electrical Schematic, Drawing 1

1M 1OL

1M 1OL

1T1

1T1

1T2

1T2

1T3

1T3

1MTR

BLOWER

L1

L2

L3

OPTIONAL

DISCONNECT

1DISC

1DBLK

TB1

1L1

TB1

1L2

TB1

1L3

1L1

1L2

1L3

CONTROL POWER

4

4

4

4

OFF ON

G

18GA RED (TYP)

SUB-PANEL

GROUND

GROUND

1RS

OX

1LT

2FU

3

1L2

1L1

1L2

1L1

1L2

1L1 1L3

115V

1

1L3

1T

1T

GND

2 2

1C

1C

2C

2C

3C

3C

18GA WHT (TYP)

1H1

PROCESS

1HTR

2HTR

3HTR

2

2

HEATER

LEFT

REGENERATION

HEATER

RIGHT

REGENERATION

HEATER

POWER ON

1H2

2H1

2H2

3H1

3H2

1OL

20

1M BLOWER CONTACTOR

4

TYPE "K"

TC

5 5

2CR

4

2CR

4

4

LEGEND:

[-]RED

[+]YEL

4

5

5

4

3

PROCESS

TEMPERATURE

CONTROLLER

2

1

2

10

4

9

8

7

6

1CR

6

4

A0547615

OPTIONAL COMPONENTS

COMPONENTS LOCATED EXTERNALLY

OF CONTROL ENCLOSURE

2

7 1LTG1LT

518

5

5

8

18

1C PROCESS HEATER CONTACTOR

OPTIONAL AUDIBLE ALARM

3CR

2RS

3CR

19

1AH

1AH

1CR

2LT

R

1SOL1SOL

1SOL1SOL

2

2

"PROCESS HEATER ON"

2

3CR SILENCE BUTTON

2

AUDIBLE ALARM

2

PROCESS HIGH TEMP. RELAY

2

"HI-PROCESS AIR TEMP"

2

RIGHT VALVE SHIFT SOLENOID

2

LEFT VALVE SHIFT SOLENOID

2

Page 20 WDMR and WDFR Series Dehumidifying Dryers

Page 22

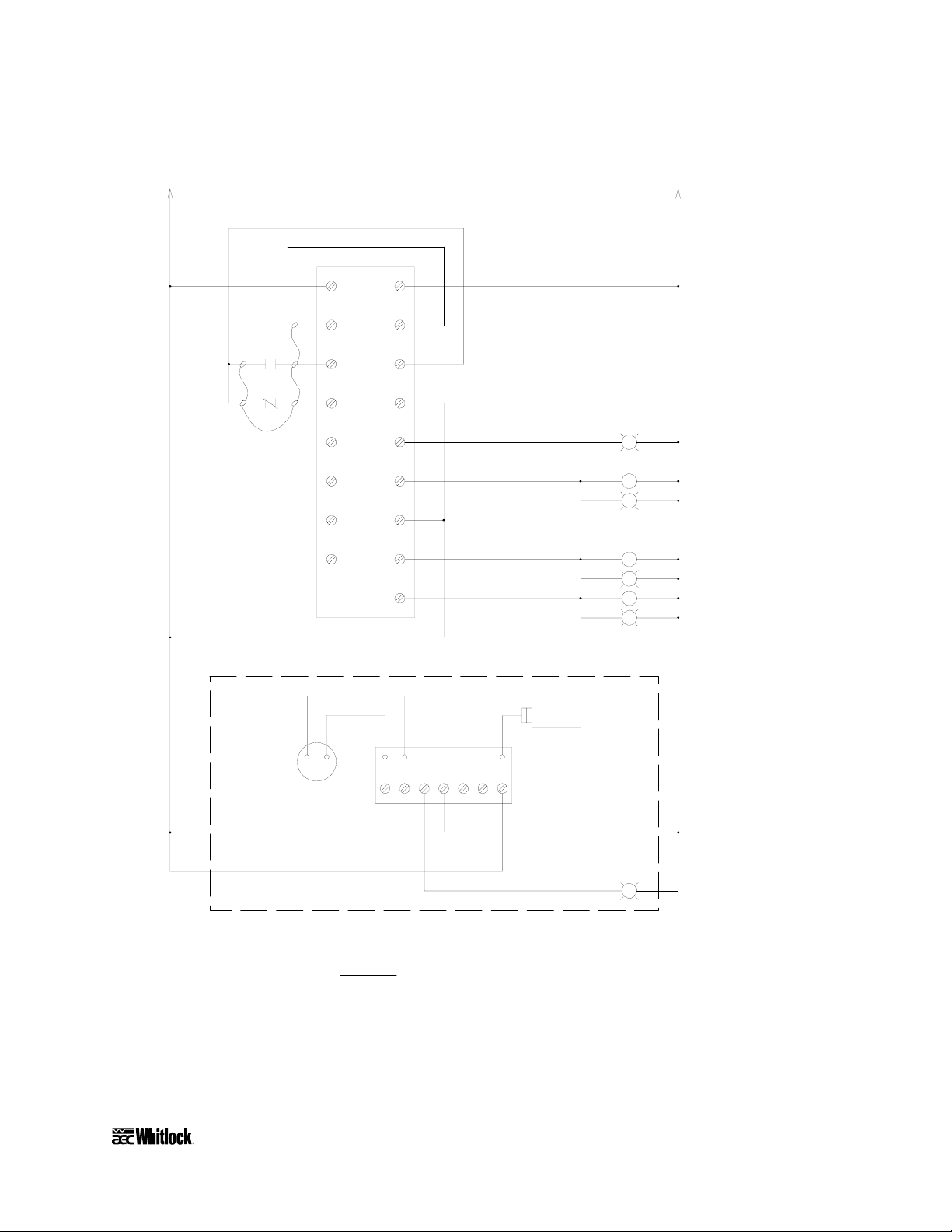

Figure 7

Typical WD25MR/FR, WD50MR/FR Electrical Schematic, Drawing 2

4 2

10

1PLC

L1

44

L2

2

2

COM

99

11

12

-

1DMTR

000

001

002

003

004

005

+

1M

10

1CR

10

18GA BLUE 24VDC

INPUT WIRING

4

DEW POINT

METER

4

+24V

-24V

10

COM

4

0

13

1

14

COM

4

2

15

3

16

OPTIONAL DEW POINT CONTROL

RED BLK

1DPB

4417

3LT

2

G

2CR

14

15

16

1DPT

7654321

2

4LT

G

2C

5LT

G

3C RIGHT BED CONTACTOR

6LT

G

"LEFT BED IN REGEN"

2

BED SHIFT RELAY

2

"RIGHT BED IN REGEN"

2

LEFT BED CONTACTOR

2

"LEFT BED HEATER" ON

2

2

"RIGHT BED HEATER" ON

DEW POINT CONTROL BOARD

2

4

17

4

A0547615

2

7LT

G

"HIGH DEW POINT"

LEGEND:

OPTIONAL COMPONENTS

COMPONENTS LOCATED EXTERNALLY

OF CONTROL ENCLOSURE

Refer to your Customer Information Packet on actual drawings for your specific dryer.

WDMR and WDFR Series Dehumidifying Dryers Page 21

Page 23

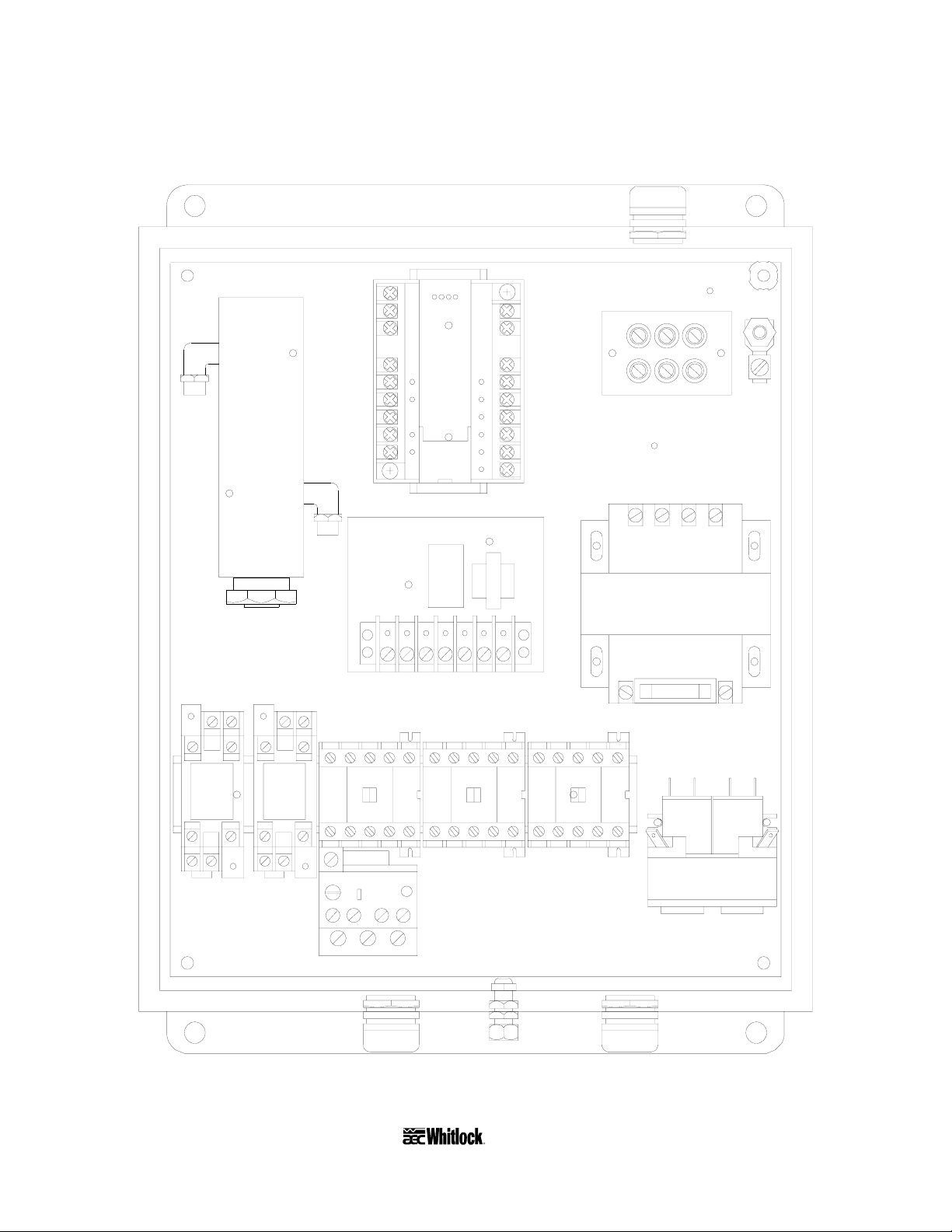

Figure 8

Typical Control Subpanel Layout

1DPT

1DBLK

omron

SYSMAC mini

PLC

1T

1DPB

2CR1CR

3C2C1M

1FU

GRD

1C

10L

A0547616

Refer to your Customer Information Packet on actual drawings for your specific dryer.

Page 22 WDMR and WDFR Series Dehumidifying Dryers

Page 24

3-5 Making Dryer/Drying Hopper Process Air

Connections

Floor Mount Models (FR)

Use high-temperature flexible dryer hose or rigid tubing to connect the dryer to the drying

hopper.

Keep the delivery hose to the drying hopper as short as possible to minimize heat loss. We

strongly recommend insulated hose for maximum energy savings.

Do not use insulated hose on the return from the drying hopper.

Do not shorten the return hose. The return air to the blower must be 150°F (66ºC) or

below. If the return air temperature is not below this point, you should purchase and install

the optional aftercooler to remove excessive heat. Consult AEC, Inc. for more information.

Aftercooler considerations also apply to machine-mount models.

Make sure that hoses are not kinked or collapsed.

Drying hopper air inlet and outlet locations vary, but always connect hoses so the dry process

air from the dryer enters the bottom of the drying hopper and flows out the top to return to

the dryer inlet.

3-6 Drying Hopper Air Trap Considerations

AEC/Whitlock’s exclusive air trap assembly on the top of the drying hopper prevents ambient air

from contaminating the material being dried.

Keep the material level at the mid point of the air trap for maximum efficiency.

Use a hopper loader or vacuum conveying system to maintain the proper material level.

3-7 Installing the Optional Aftercooler

Air-cooled WD10MR/FR and WD25MR/FR models use an air-to-air heat exchanger as an

aftercooler. No cooling water is required for this design. Return air from the hopper passes

through the air filter to trap fines and dust before entering the heat exchanger.

WDMR and WDFR Series Dehumidifying Dryers Page 23

Page 25

Installing Air Hose

Water-Cooled Aftercooler for WD50MR Dryers

Air is routed from the bottom of the aftercooler up through the top.

• Connect the hot incoming air hose from the drying hopper to the bottom 2” (about 51 mm)

tube stub with a hose clamp.

• Connect the cooled outgoing air hose to the 2” (about 51 mm) tube at the top of the cooler.

Run this hose to the inlet of the process air filter on top of the dryer.

Figure 9

Aftercooler Design Specifications

Entering air temp. Leaving air temp. Entering water temp. Leaving water temp. Initial flow rate

ºF ºC ºF ºC ºF ºC ºF ºC gpm lpm

250ºF 121ºC 130ºF 54ºC 80ºF 27ºC 85ºF 29ºC 3 gpm 11 lpm

Installing Water Lines

WD50MR/FR Models

• Use the ½” (about 13 mm) brass pipe nipples for water line connections. Connect the

entering water line to the pipe nipple, located in the center of the cover.

• Make sure you grip the nipple tightly when attaching a fitting. Doing so prevents damage

to the soft copper coils. You should make connections with flexible hose to allow removing

the coil assembly for cleaning.

• The aftercooler is designed to utilize either tower or city water as warm as 85ºF (29ºC).

Recommended flow rate is one to three (1 to 3) gallons per minute (4 to 11 liters per

minute).

Important!

You must use an aftercooler on WD50MR/FR models to operate

at process supply temperatures of 180ºF (82ºC) or below.

You are required to use a chilled water supply of 50ºF (10ºC) to

pre-condition the dryer return air so the dryer can properly

achieve low dew points and process temperatures.

If an aftercooler is used with a drying system, AEC highly recommends that a

high temperature return air filter element is substituted for the standard

element. Order Part No. A0538636 from the AEC/Whitlock Parts Department.

Page 24 WDMR and WDFR Series Dehumidifying Dryers

Page 26

4 Level 1 Controllers

Your dryer comes with the standard Level 1 control panel or the optional Level 2 control panel.

This chapter discusses the features of each, starting with Level 1 features. Level 2 features

begin in Chapter 5 on Page 33, with a graphic of the Level 2 control panel in Figure 13 on Page

34.

4-1 Level 1 Control Panel Indicator Lights

Control Power On

Control Power On indicator lights when the dryer control circuit energizes.

The

Process Heater On

The

Process Heater On indicator lights when the process air heater energizes.

High Process Air Temperature Alarm

The

High Process Air Temperature alarm indicator lights when the temperature at the process

air thermocouple is above the set high alarm value. When the indicator lights, the alarm relay

energizes and all the heaters turn off while the blower remains on to cool the dryer.

• The alarm mode and value are factory-set to track 25° above the process set point. The

alarm value is a deviation above the process set point, and the user can adjust it.

• When the temperature at the process thermocouple returns to within the acceptable range,

the alarm output de-energizes and all the heaters turn on again automatically.

• You can alter the alarm range. See Section 6-5 on Page 43 for more information.

Regen Heater On

The Regen Heater On indicator lights when the left or right bed regeneration heater is on.

Left Bed Regenerating and Right Bed Regenerating

The lit

being regenerated (off-line).

High Dew Point Alarm (optional)

The

dew point alarm point, factory set at -10°F (-23ºC).

Left Bed Regenerating or Right Bed Regenerating LED indicates the bed currently

High Dew Point alarm indicator lights when the process air delivery dew point exceeds the

WDMR and WDFR Series Dehumidifying Dryers Page 25

Page 27

Figure 10

Typical Enclosure with Level 1 Control Panel, Optional Dew Point System, Disconnect

Process Delivery

Temperature

180

OMRON

-

35

-

40

ON

OFF

Process Dew Point

-

-

-

25

-

30

DEW POINT (F)

1520

-

10

Process

Heater On

Left Bed

Heater

Left Bed

In Regen

-

5

0

HI-Process

Air Temp

Right Bed

Heater

Right Bed

In Regen

HI-Dew

Point

Page 26 WDMR and WDFR Series Dehumidifying Dryers

Page 28

Figure 11

Level 1 Process Air Temperature Control Graphic Layout

Process Delivery

Temperature

ON

180

OFF

OMRON

Process

Heater On

Left Bed

Heater On Heater On

Left Bed

In Regen

HI-Process

Right Bed

Right Bed

4-2 Level 1 Switches and Meters

ON/OFF Rocker Switch

The ON/OFF rocker switch energizes or de-energizes dryer control power.

Dew Point Meter (Optional)

Air Temp

In Regen

The Dew Point meter indicates the current process air delivery moisture content.

4-3 Level 1 PLC Controller

WD10MR/FR through WD50MR/FR dryers are equipped with an Omron programmable logic

controller (PLC).

• The “brick” type PLC has ten (10) I/O points: six (6) inputs and four (4) outputs.

• All inputs are 24 VDC; all outputs are 115 VAC.

• All programming and logic is factory-installed on a non-removable EEPROM and cannot

be modified.

WDMR and WDFR Series Dehumidifying Dryers Page 27

Page 29

4-4 Level 1 Process Air Temperature Controller

Standard AEC/Whitlock dryers use a microprocessor-based PID temperature controller for

maintaining process air temperature. The controller is a modular, self-contained unit you can

remove from the mounting housing. All parameters except for the process air set point are set

and adjusted at the factory; no field adjustment to the internal controls is normally necessary.

4-5 Level 1 PLC LED Indicators

Input LED Indicators

Process Blower On (Indicator 000)

The amber Process Blower On LED lights when the blower contactor energizes.

Hi-Process Air Temp (Indicator 001)

The amber

acceptable operating range. The LED turns off during a high process air temperature condition.

Hi-Process Air Temp LED lights when the process air temperature is within an

Output LED Indicators

Left Bed In Regen (Indicator 100)

The amber Left Bed In Regen LED lights when the left bed is in regeneration.

Right Bed In Regen (Indicator 101)

The amber

Left Bed Heater On (Indicator 102)

The amber Left Bed Heater On LED lights when the left bed regenerates and is in the heat-up

portion of the regeneration cycle.

Right Bed Heater On (Indicator 103)

The amber

up portion of the regeneration cycle.

Right Bed In Regen LED lights when the right bed is in regeneration.

Right Bed Heater On LED lights when the right bed regenerates and is in the heat-

Status LED Indicators

Power Indicator

The green

Page 28 WDMR and WDFR Series Dehumidifying Dryers

Power LED lights when power is applied to the PLC (100-240 VAC, 50/60 Hz).

Page 30

Run Indicator

The green Run LED lights when the PLC executes the program and operates normally.

Link Indicator

The Link indicator is not used.

Error Indicator

The red

operation (the

Error LED lights when an internal self-diagnosis detects an error and stops PLC

Run LED is off).

4-6 Level 1 Temperature Controller LED Indicators

888

During normal operation, the process value LED on the controller displays the process

temperature at the

messages if an error occurs. Press the

point.

The orange On Output LED lights when control output energizes the process air heater.

The AL alarm indicator lights when the process air temperature rises more than 25° from the set

point (factory default). The alarm relay in the PLC energizes when this LED lights. The

audible/visual alarm actuates if the dryer is so equipped. All heaters turn off and the blowers stay

on to cool the heaters. You can adjust the alarm value; see Section 6-5 on Page 43 for more

information.

Deviation Indicators

Process Value Numeric LED

TO PROCESS thermocouple. It also lists parameters during setup and error

Mode key once to display the process temperature set

ON

Output LED

AL

Alarm LED — High Temperature Alarm

∆ Arrow Up

The arrow up indicator lights when actual temperature is higher than the set point.

In Range

The in-range square indicator lights when temperature deviation is within plus or minus one

percent (±1%) of the set point.

WDMR and WDFR Series Dehumidifying Dryers Page 29

Page 31

∇ Arrow Down

r

r

r

(

)

y

The arrow down indicator lights when actual temperature is lower than the set point.

Figure 12

Level 1 PLC Controller Details

Up indicato

In Range

indicato

Down indicato

180

Process Value

numeric LED

Down key

Mode key

Membrane

ke

hidden

OMRON

Up key

4-7 Level 1 Temperature Controller Keys

Figure 6

OMRON

The lock-out membrane key provides protection against unauthorized set point changes when

used in conjunction with the internal protection switch. If the internal protection switch is

you must press this key simultaneously with the

key to change the set point or alarm point. If the protection switch is

Membrane Key (Hidden)

ON,

Up arrow key or the Down arrow

OFF, you can still make

changes by pressing the

Mode Key

The mode key lets you switch between set point and alarm parameters. See Sections 6-4 on Page

42 and 6-5 on Page 43, and Section 7-8 starting on Page 54 for more information.

Page 30 WDMR and WDFR Series Dehumidifying Dryers

Up arrow key or the Down arrow key.

Page 32

Note: During normal operation, use this key to change the set point or alarm setting only. The

factory alarm setting is 25° above the set point and is satisfactory for most applications.

Down Key

The Down arrow key lets you lower the process air set point temperature. During setup, it lets

you decrease the value of the parameter displayed on the set point LED readout.

Up Key

The Up arrow key lets you raise the process air set point temperature. During setup, it lets you

increase the value of the parameter displayed on the set point LED readout.

WDMR and WDFR Series Dehumidifying Dryers Page 31

Page 33

- Notes -

Page 32 WDMR and WDFR Series Dehumidifying Dryers

Page 34

5 Additional Level 2 Controller Features

5-1 Level 2 Control Panel

Optional

The optional Level 2 controller option operates identically to the standard Level 1 controller

covered in the previous chapter. However, this controller adds front-mounted

START/STOP

Air Temp.

and TEMP. SET POINT NORMAL/SHIFT switches and Blower On, High Regen

, and Dirty Filter indicators. The following page shows a typical Level 2 controller.

5-2 Level 2 Control Panel Indicator Lights

Process Heater On

The Process Heater On indicator lights when the process air heater is energized.

Hi-Process Air Temp

SYSTEM

The

Hi-Process Air Temp alarm indicator lights when the temperature at the process air

thermocouple is above the high alarm set value. This indicator lights when the alarm relay

energizes; all heaters turn off and the blower remains on.

The alarm mode and value are factory-set to track 25º above the process set point. The alarm

value is a deviation above the process set point. When the temperature at the process

thermocouple returns to within the acceptable range, the alarm output de-energizes and all

heaters turn on again automatically. You can adjust the alarm value; see Section 6-5 on Page 43

for more information.

WDMR and WDFR Series Dehumidifying Dryers Page 33

Page 35

Optional Level 2 Controller

Process Delivery Temperature

Figure 13

ºF

POWER ON

PV

1 8 0

SV

1 8 0

OUT STOP HB

TEMP. SET POINT

SYSTEM START

NORMAL

Process

Heater on

Left Bed

Heater

ALM2ALM1

Left Bed

In Regen

Blower

On

Hi-Process

Air Temp

Right Bed

Heater

Right Bed

In Regen

High Regen

Air Temp.

Process Air Dew Point

High

Dew Point

Dirty

Filter

- 20

- 25

- 30

- 35

- 40

DEW POINT (ºF)

- 15

- 10

- 5

0

OFF

STOP

SHIFT

Page 34 WDMR and WDFR Series Dehumidifying Dryers

Page 36

Left Bed Heater

The Left Bed Heater indicator lights when the left bed regenerates and is in the heat-up portion

of the regeneration cycle.

Right Bed Heater

The

Right Bed Heater indicator lights when the right bed regenerates and is in the heat-up

portion of the regeneration cycle.

Left Bed In Regen

The

Left Bed In Regen LED lights when the left bed is in regeneration.

Right Bed In Regen

The

Right Bed In Regen LED lights when the right bed is in regeneration.

Blower On

The

Blower On indicator lights when the blower energizes.

High Regen Air Temp.

The

High Regen Air Temp. alarm indicator lights when the thermocouple above the

regeneration heater assembly senses an abnormally high temperature.

Caution!

Do not adjust the factory set point of 2CNTL and 3CNTL,

the 1/16 DIN panel-mounted temperature controller

located inside the enclosure.

The regeneration heaters shut down until the temperature falls below the alarm point. The

regeneration blower continues to run for cooling the heaters and desiccant bed. This indicator

shuts off and the alarm condition clears when the temperature drops below the alarm point. The

heaters re-energize automatically.

High Dew Point

The

High Dew Point alarm indicator lights when the process air delivery dew point exceeds the

dew point shift point.

Dirty Filter

The

Dirty Filter alarm indicator lights when the pressure differential across the process air return

filter exceeds the pressure switch setting. Replace or clean the filter when this indicator lights.

The indicator and the alarm condition clears after you service and reinstall the filter.

WDMR and WDFR Series Dehumidifying Dryers Page 35

Page 37

5-3 Level 2 Switches and Meters

POWER ON

Press the POWER ON rocker switch to energize or de-energize control power to the dryer.

SYSTEM START

Press the

position to shut down the dryer when it is operating.

TEMP. SET POINT NORMAL

Move the

operation. Move the switch to the

temperature on the ¼ DIN controller.

ALARM SILENCE

Optional

Press the ALARM SILENCE switch to silence the horn when a high temperature alarm activates.

The alarm repeats every five minutes until the problem causing the alarm condition is cleared.

Process Air Dew Point

The Process Air Dew Point meter indicates the current process air delivery moisture content.

SYSTEM START rocker switch to start the dryer. Move this switch to the STOP

TEMP. SET POINT NORMAL rocker switch to the NORMAL position for normal

SHIFT position to raise or lower temperature to the alternate

5-4 Level 2 PLC Controller

Your optional Level 2 PLC controller uses an Allen-Bradley programmable logic controller

(PLC). This “brick”-type controller has 16 I/O points: ten (10) inputs and six (6) outputs, and all

ten (10) inputs and six (6) outputs are 115 VAC.

All programming and logic is factory-installed on an EEPROM chip, and cannot be modified. A

battery backup retains programming if power fails. Battery life is five (5) years at room

temperature.

If the alarm indicator blinks intermittently, replace the battery within one (1) week.

Page 36 WDMR and WDFR Series Dehumidifying Dryers

Page 38

5-5 Level 2 Process Air Temperature Controller

Your AEC/Whitlock dryer uses a microprocessor-based PID controller for maintaining process

air temperature. The controller is a modular, self-contained unit that can slide out from the

housing. All parameters except the process air set point are set and adjusted at the factory; no

field adjustment to the internal controls is normally necessary.

Figure 14

Level 2 PLC Controller Details

PV

Output indicator

Stop indicator

Mode key

Level key

ºF

1 8 0

SV

1 8 0

ALM2ALM1

OUT STOP HB

Process air temperature

Process air temperature set point

High temperature alarm indicator

Not used

Not used

Down key

Up key

5-6 Level 2 Temperature Controller LED Indicators

—— PV ——

During normal operation, the red process value (PV) numeric LED indicator displays the process

temperature at the To Process thermocouple. It also lists parameters during setup and error

messages if any errors occur.

—— SV ——

During normal operation, the green set value (

set point you selected for the dryer. The dryer then maintains this set point temperature. This

LED indicator also displays parameter and pre-set function values during setup.

ALM1

High Temperature Alarm Indicator

The ALM1 high-temperature alarm indicator lights when the process temperature exceeds the set

point temperature by more than the alarm deviation value. This alarm output de-energizes the

heaters. Heaters re-energize when the temperature falls within the acceptable range.

Process Value Numeric LED

Set Value Numeric LED

SV) numeric LED indicator displays the process

WDMR and WDFR Series Dehumidifying Dryers Page 37

Page 39

ALM2

ALM2 Indicator

The ALM2 indicator is not used.

OUT

Output Indicator

The

OUT indicator lights when the controller signals the process heaters to be energized.

STOP

Stop Indicator

The STOP indicator is not used.

HB

HB Indicator

The HB indicator is not used.

5-7 Level 2 PLC LED Indicators

Input LED Indicators

Blower Input (I/0)

The Blower Input indicator lights when the blower contactor energizes.

Hi-Process Air Temp (I/1)

The

Hi-Process Air Temp indicator lights when process air temperature is outside the

acceptable operating range set as

Hi-Regeneration Air Temp — Left Bed/Right Bed (I/2, I/3)

The Hi-Regeneration Air Temp indicator is off during a regeneration bed high temperature

condition. This condition is based on the set point of

Start/Stop Input (I/5)

The

Start/Stop Input indicator lights when the dryer is running. It goes off when the dryer stops

during a normal shutdown sequence.

Note: Inputs

I/6 through I/8 are not used.

ALM1 on the temperature controller.

2CNTL and 3CNTL.

Page 38 WDMR and WDFR Series Dehumidifying Dryers

Page 40

Alarm Silence Input (I/9)

Optional

The Alarm Silence Input indicator lights momentarily when you silence the alarm horn.

Output LED Indicators

Blower On (O/0)

The Blower On indicator lights when the blower energizes.

Process Heater Enable (O/1)

The Process Heater Enable indicator lights when the process heaters can be energized. This

condition occurs when no blower failures or high temperature conditions exist.

Right Bed Regeneration Output (O/2)

The right

Bed Regeneration Output indicator lights when the right bed regenerates. When this

indicator is off, the left bed is energized.

Left/Right Regen Heater Output (O/3, O/4)

The

Regen Heater Output indicator lights when the indicated bed regeneration heater

energizes.

Alarm Horn Output (O/5)

Optional

The Alarm Horn Output indicator lights at a high process temperature condition.

Status LED Indicators

Power

The Power indicator lights when the PLC receives 115V control power.

Run

The Run indicator lights when the PLC executes the program in normal conditions.

Fault

The

Fault indicator lights when the PLC program has a problem or failure condition.

Force

The

Force indicator is not used.

WDMR and WDFR Series Dehumidifying Dryers Page 39

Page 41

5-8 Level 2 Temperature Controller Keys

Level Key

Press the Level key for two (2) seconds or more to select the next of three (3) indication

levels (0, 1, or 2) when you set specific control parameters. The PLC controller defaults to Level

0 on power-up.

Mode Key

The Mode key lets you scroll through parameters you can set in indication Levels 0 and

1. See Section 6-5 on Page 43 for more information.

Important!

During normal operation, use the Mode key

to change alarm settings only.

Factory alarm settings are 25º

above and below the set point,

and are satisfactory for most applications.

Down Key

The Down key lets you lower the process air set point temperature. During setup, it lets

you decrease the value of the parameter displayed on the

screen.

Up Key

The

increase the value of the parameter displayed on the

screen.

Up key lets you raise the process air set point temperature. During setup, it lets you

—— SV ——

—— SV ——

SV (set value) LED

SV (set value) LED

5-9 Level 2 Optional Communications Protocols

For SPI, RS-232C, RS-422, and RS-485 communications, a connection port on the electrical

cabinet lets you easily connect to your host computer. The connection port is a direct pin-to-pin

extension from the plug on the back of the temperature controller. Refer to the control module

communication manual (AEC part no. A0535959) for more information on pinouts. See

electrical schematic drawings A0550656 through A0550658 for more information on SPI

communications.

Page 40 WDMR and WDFR Series Dehumidifying Dryers

Page 42

WDMR and WDFR Series Dehumidifying Dryers Page 41

Page 43

6 Startup, Shutdown, and Operation

6-1 Pre-Startup Checks

Check the process and return hoses for tight connections.

Check all companion equipment, such as the drying hopper; verify that the loading system is

ready for operation.

Verify that all dryer electrical connections are tight.

Important!

Clean the rust-preventing oil from inside the drying hopper.

Failure to clean the hopper

fouls the desiccant

and voids your warranty!

6-2 Startup

1. Close the slidegate at the bottom of the drying hopper.

2. On three-phase models, make sure that the blower turns in the right direction before you

fill the hopper.

3. Fill the drying hopper with material.

4. Turn on (energize) the disconnect switch in your power drop, then turn on the one on the

dryer.

5. Turn the on/off switch to

The blower starts and the proper control panel indicators light.

6. If your dryer has a water-cooled aftercooler, make sure that sufficient cooling water

flows properly through the coil, and you have bled any trapped air from the system. Make

sure that the aftercooler has the proper supply water temperature.

ON.

7. Set the process set point on the temperature controller.

8. After the proper pre-drying time for the initial hopper fill has elapsed, fully open the

drying hopper slide gate.

Note: To allow proper residence time during continuous processing, maintain the material level

in the hopper at the midpoint of the air trap assembly.

Page 42 WDMR and WDFR Series Dehumidifying Dryers

Page 44

6-3 Shutdown

1. Turn off the conveying system supplying the drying hopper.

2. When processing is complete, close the hopper slide gate and shut down any in-line

companion equipment, such as the aftercooler.

3. Level 1 Controls: Turn the

On/Off selector switch to OFF.

Level 2 Controls: Push the Run/Stop rocker switch to the OFF position.

The unit shuts off after completing the regeneration cycle.

4. If needed, empty the drying hopper.

5. For maintenance or a long term shutdown, open (de-energize) the electrical disconnects

at the dryer and at the power drop.

6-4 Setting the Process Air Temperature

Level 1 Controllers

To change the process air temperature set point with the dryer running:

1. Press once.

2. Press

- or -

Press

to raise the set point to the desired temperature.

to lower the set point to the desired temperature.

3. Press

twice to restore.

Level 2 Controllers

To change the process air temperature set point with the dryer running:

• Press to raise the set point to the desired temperature.

• Press

to lower the set point to the desired temperature.

WDMR and WDFR Series Dehumidifying Dryers Page 43

Page 45

6-5 Setting the High Temperature Alarm

To change the process air temperature alarm setting:

1. Press twice.

2. When the AL LED lights, press and to set the high temperature alarm value

you want.

Note: The high temperature alarm value is a deviation of the process air temperature set point.

The alarm value tracks the set temperature. If the high temperature alarm is set to

high temperature alarm occurs if the process air temperature rises more than 25° above

the process air temperature set point.

3. Press again to restore.

The process air temperature readouts display.

The high temperature alarm is now set.

25, a

6-6 Temperature Controller Internal

Switches

The controller is set up and tested at the factory for optimum

operation, and the internal switches don’t need adjustment. If the

controller doesn’t work properly, or if you suspect that someone

has accidentally changed your settings, see Section 7-8 on Page 54

for more information.

6-7 Enabling the Temperature Controller Anti-

Tamper Lockout Switch

Level 1 Controllers

The PROTECT OFF slide switch prevents unauthorized changes to set points. If the switch is in

ON position, the Down arrow, Up arrow, and Mode keys are disabled. You

the

are only able to view the process set point and alarm settings. WD dryers are set at the factory

with protection turned

OFF. ON disables all front panel keys.

Page 44 WDMR and WDFR Series Dehumidifying Dryers

Page 46

To enable the lockout feature:

PROTECT

1. Disconnect main electrical power to the dryer.

1. Press up the latch at the bottom of the control module front panel and slide out the

control chassis.

2. Locate the slide-type switch marked

Slide it to the

ON position.

PROTECT on the circuit board.

OFF ON

3. Slide the chassis back into the control module housing.

Tamper protection is now enabled.

PROTECT

Note: You must use the

OMRON

hidden membrane key to change values. See Section 4-7 on Page

30 for more information.

Level 2 Controllers

The PROTECT slide switch prevents unauthorized changes to set points. If the switch is in the

SP or ALL position, the Down arrow, Up arrow, and Mode keys are

disabled. You are only able to view the process set point and alarm settings. WD dryers are

factory-set with the protection turned

To enable the lockout feature:

1. Disconnect main electrical power to the dryer.

1. Press up the latch at the bottom of the control module front panel and slide out the

control chassis.

2. Locate the slide-type switch marked

circuit board. Slide it to the SP or ALL position.

3. Slide the chassis back into the control module housing.

Tamper protection is now enabled.

OFF. SP or ALL disables all front panel keys.

PROTECT on the

SP OFF ALL

6-8 Changing the Display from Fahrenheit to Celsius

Level 1 Controllers

To change the display from the factory °F setting to °C:

1. Disconnect main electrical power to the dryer.

WDMR and WDFR Series Dehumidifying Dryers Page 45

Page 47

1. Press up the latch at the bottom of the control module front panel

and slide out the control chassis.

2. Locate the six-position DIP switch on the circuit board.

3. Move Switch

6 to the OFF position for Celsius.

4. Slide the chassis back into the control module housing.

Celsius Setup

ON

OFF

123456

5. Cover the

°F label with the °C label included in the information packet.

6. Reinstall the control and start the dryer unit.

Level 2 Controllers

1. Shut off power to the dryer and remove the controller from the chassis.

2. After setting all internal switch settings, set switch

switch is normally set to

OFF.

3. Insert the internal mechanism into the housing and power up the temperature controller.

(du) displays.

4. Press

to select the set value display as Celsius (ºC) or Fahrenheit (ºF).

5. Turn off the power two (2) seconds after the set value display changes.

6. Remove the internal mechanism from the housing, set pin number

switch to

OFF, replace it and turn on the power.

4 of the function switch to ON. This

4 of the function

Page 46 WDMR and WDFR Series Dehumidifying Dryers

Page 48

- Notes -

WDMR and WDFR Series Dehumidifying Dryers Page 47

Page 49

7 Maintenance

7-1 Work Rules

The installation, operation, and maintenance of this equipment is to be conducted in accordance

with all applicable work and safety codes for the installation location. This may include, but is

not limited to, OSHA, NEC, CSA, and any other local, national, and international regulations.

In addition, you must observe the following specific work rules:

Keep these operating instructions on hand and follow them when installing, operating, or

maintaining your dryer.

If the instructions become damaged or unreadable, you can obtain additional copies from

AEC/Whitlock.

Only qualified personnel familiar with this equipment should work on or with this unit.

Work only with approved tools and devices.

Disconnect power before servicing your dryer. If the disconnect switch you installed has a

lockout, lock it in the

OFF position before you perform any maintenance or service.

7-2 Servicing Process Air Filters

Important!

Operating the dryer without the process air filter installed voids your warranty!

Filter cleaning is an important part of your dryer maintenance program.

WD10MR/FR through WD50MR/FR dryers have a single cartridge canister-type filter in the

process air loop. It is mounted above the process blower on the rear of the dryer. This filter

protects the blower from plastic fines drawn in from the drying hopper. Regular filter cleaning is

essential to keep your dryer operating at peak efficiency.

You can wash or blow out the filter with compressed air, but remember—you reduce dirt

holding capacity with each washing. Washing a filter is risky, because dirt can reach the clean

side of the filter, and the filter could become damaged from high pressure washing or blowing.

You can carefully clean or wash the filter when air flow becomes restricted. Do not wash filters

more than six (6) times or use them for more than a year, whichever comes first.

Page 48 WDMR and WDFR Series Dehumidifying Dryers

Page 50

Use a detergent that won’t damage filter media. Such a detergent permits easy removal of dirt

particles through flushing and rinsing. An effective detergent removes the fine particles from the

pores of the filter media.

The filter manufacturer recommends FM 1400 washing compound. It is formulated specifically

for air filter element cleaning. It is non-sudsing and works in hot or cold water. FM 1400

contains biodegradable synthetic detergents and is non-phosphate, non-NTA. For more

information, contact Filter Service Corporation, 2603 A West Main, Farmington, NM

1-505-326-1127.

Recommendations for Cleaning and Replacing Filters

• Turn off and/or lock out electrical power to the dryer.

• Remove the threaded fastener securing the filter access cover, then remove the cover.

• Remove the nut on the center retaining rod to remove the filter cartridge.

Vacuuming

Clean a soiled filter by first vacuuming it. Vacuuming removes most large particles and surface

contaminants; you may not need to do any more for the first time you clean a filter. Use a

commercial-duty (recommended) or household vacuum cleaner. Vacuum the filter from the air

intake (dirty) side only.

Cleaning with Compressed Air

Blow clean, dry compressed air up and down the pleats, blowing out the filter from

the clean side. Remove loose dirt from the filter with compressed air or a water

hose. Compressed air should be less than 100 psi (689.5 kPa/6.89 bars). Use a

1

/8”-

dia. (3 mm-dia.) nozzle at least 2” (5 cm) away from the filter. Don’t shoot the air in

a crisscross motion against the grain of the pleats, as you could damage it.

Washing

As a last resort, wash the filter. However, do so only if the pressure drop is too

high from fine dirt embedded in the filter, or if oily mist is present near the

intake air location. Soak it in a solution of FM 1400 or comparable detergent and

warm water from five to ten minutes, then gently agitate for several minutes.

Rinse thoroughly with clean water to remove all detergent. Let the filter dry

completely before returning it to service. Do not use a light bulb to dry the filter.

You should get satisfactory filtration after second or third washings; however, dirt-

holding capacity of the filter decreases after each washing.

WDMR and WDFR Series Dehumidifying Dryers Page 49

Page 51

After each cleaning:

• Inspect the filter element. Briefly hold a light bulb behind the element and look

for any fatigued paper or residual dirt. Inspect for holes and tears by looking

though the filter toward a bright light. Check for damaged gaskets or dented

metal parts. Do not re-use a damaged filter!

• Inspect the end plates. Any end plate damage can allow air to bypass the filter.

• Look for rust on end plates and the metal core. Rust particles can flake off and contaminate

the dryer and resin.

• Check the gasket for damage. A damaged gasket allows contaminants into the process.

Replace as needed.

• Allow the filter to dry before re-using. Circulate warm air at less than 160ºF (71ºC). Do not

use a light bulb to dry the filter.

7-3 Servicing the Dew Point Monitor

The accuracy of the dew point monitor on WD10MR/FR through WD50MR/FR dryers depends

on proper operation of the dew point sensor and the control board. The dew point sensor is in the

process air stream and is therefore susceptible to contamination.

Dew point sensor life depends on:

• Air temperature and flow passing over the sensor

• The amount of fines (dust) in the process air

• The amount of plasticizer vapor in the process air

The dryer operator should monitor the initial dew point sensor readings and establish a periodic

replacement schedule as needed.

Caution!

Do not attempt to check the continuity

or resistance of the dew point sensor.

The sensor will be destroyed!

If you suspect that dew point readings on the dew point meter are incorrect, you can obtain a

dew point simulation calibrator from AEC/Whitlock (Part Number A0540143). This device

simulates various dew point outputs. It lets you confirm proper operation of the dew point

system control board.

Page 50 WDMR and WDFR Series Dehumidifying Dryers

Page 52

Caution!

Use caution when working inside the control cabinet,

as high voltage is present.

Do not attempt to make any adjustments to the

components on the dew point control board.

To check the dew point system control board:

1. Shut off the dryer, then remove the sensor cable from the sensor hex nut adapter.

2. Connect the cable to the plug on the rear of the simulator.

3. Turn on the dryer, then turn the rotary knob on the simulator to each position and note the

readings on the dew point meter on the dryer control panel. The readings should

correspond within a degree or two (1º to 2º) across the entire range.

4. If the readings agree, the control board is working properly and you should replace the

dew point sensor. If the readings do not agree, replace the control board and run the test

again to rule out the possibility of a bad sensor.

5. When you have finished testing, shut down the dryer and re-connect the control cable to

the sensor adapter.

7-4 Symptoms of Worn Desiccant

The moisture absorption capacity of desiccant used in your AEC/Whitlock dryer degrades after

an indefinite period of time. Useful life depends on variables such as material moisture content,

plasticizer vapors in the return air, and number of regeneration cycles.

Note: AEC recommends replacing desiccant every three (3) years if you run your dryer an

average of eight (8) hours per day, five (5) days per week. You should replace desiccant

more often if you run your dryer for longer time periods.

Your AEC/Whitlock dryer may need new desiccant if it exhibits any of the following symptoms:

• Plastic material is not being dried sufficiently (high scrap/reject rate).

• Air temperature at the top of the regenerating desiccant bed rapidly climbs to 350°F

(177ºC) or more shortly after the start of regeneration, even though a saturated bed has just

started heating.

• The process air dew point, measured with a portable dew point monitor, is higher than

-10°F (-23ºC) throughout the process drying cycle.

• Smoke or dust blows out of the process air outlet.

• Noticeable amounts of desiccant in the beds is a medium-brown color or darker.

WDMR and WDFR Series Dehumidifying Dryers Page 51

Page 53

If you notice any of these signs, replace the desiccant in the desiccant beds. Desiccant

replacement kits are available from the AEC/Whitlock Parts Department. If you want, an

AEC/Whitlock technician can repack desiccant beds at your site.

! WARNING !

Desiccant material causes eye irritation!

Breathing may be harmful and may cause skin irritation!

• Do not get in eyes.

• Avoid prolonged contact with skin.

• Use with adequate ventilation.

• Wash thoroughly after handling.

✚ FIRST AID ✚

In case of eye contact,

immediately flush eyes with plenty of water

for at least 15 minutes.

If irritation persists, see a physician.

7-5 Replacing Worn Desiccant

Caution!

Make sure desiccant beds are sufficiently cool

before replacing worn desiccant.

1. Disconnect electrical power to the dryer.

2. Remove the bolts securing the valve assembly. Remove the valve after disconnecting

actuator wiring.

Page 52 WDMR and WDFR Series Dehumidifying Dryers

Page 54

3. Using a shop vacuum, carefully remove all desiccant from each tower.

Important!

You should properly dispose of any discarded desiccant.

Consult local disposal regulations for more information.

4. Inspect each lower desiccant screen and insulation liner for tears or burn-through spots.

Replace as needed.

5. After cleaning each chamber, add a level layer of half the large bead desiccant on top of

the screen. Next, carefully add the full amount specified per bed of small bead desiccant.

Amounts are listed in the Required Desiccant Amounts per Bed table below. Smooth the

top level, and finally add another layer of the remaining large bead desiccant to the top.

Make sure this layer is level and smooth.

6. Repeat the previous step for the other bed.

7. Inspect the gaskets on the valve assembly. Replace as needed.

8. Remove heater elements from the heater plate assembly.

9. Re-install the valve and reconnect actuator wiring.

Figure 15

Required Desiccant Amounts per Bed

Dryer Large bead (Type 13X) Small bead (Type 13X) Total per bed

model Part no. lbs. Kg Part no. lbs. Kg lbs. Kg

WD10MR W00018050 1.0 0.454 W00018051 3.0 1.362 4.0 1.816

WD25MR W00018050 2.0 0.908 W00018051 7.0 3.178 9.0 4.086

WD50MR W00018050 3.0 1.362 W00018051 15.0 6.810 18.0 8.172

7-6 Replacing the Process Heater

WDMR and WDFR Series dehumidifying dryers use single-phase Calrod-type heater elements

mounted in the center compartment below the desiccant beds. The wattage of the heater varies

with model, voltage, temperature range, etc., but the replacement procedure is the same.

! WARNING !

Disconnect and lock out power before you replace heater elements!

WDMR and WDFR Series Dehumidifying Dryers Page 53

Page 55

Procedures

1. Let the dryer cool down thoroughly before removing heater elements.

2. Remove the four bolts securing the process heater access cover.

3. Sketch the heater wiring configuration so you can properly re-wire the heater.

4. Remove the wires to the heater plate assembly you are removing or replacing.

5. Remove the bolts securing the heater plate assembly, and slide out the assembly.

6. Remove the heater from the mounting plate by removing the large brass nuts and

washers.

7. Remove heater elements from the heater plate assembly.

8. Re-install the heater and heater plate assemblies in reverse order. Install new heater

gaskets (AEC Part No. W00018316) and securely tighten all fasteners.

Caution!

Heater loops should not touch each other.

“Hot spots” lead to premature heater failure!

7. Reinstall the wires based on the sketch you made earlier.

8. Secure the heater access cover.

7-7 Replacing the Regeneration Heater

WDMR and WDFR Series dehumidifying dryers use single heater elements located below each

desiccant bed.

! WARNING !

Disconnect and lock out power before you replace heater elements!

1. Let the dryer cool down thoroughly before removing heater elements.

2. Gain access to the regeneration heaters from the right side of the dryer. Remove the cover

plate secured by four bolts.

3. Sketch the heater wiring configuration so you can properly re-assemble the heaters.

4. Remove the wiring for the heater you are replacing.

5. Remove the four bolts securing each heater mounting plate. Slide out the heater.

Page 54 WDMR and WDFR Series Dehumidifying Dryers

Page 56

6. Re-install the new heaters in reverse order. Install new heater gaskets (AEC Part No.

W00018316) and securely tighten all fasteners.

Caution!

Heater loops should not touch each other.

“Hot spots” lead to premature heater failure!

7. Re-install the wiring based on the sketch you made earlier.

8. Secure the heater access cover.

7-8 Restoring the Temperature Controller to Factory

Setup

Level 1 Controllers

If preset parameters on the controller have been tampered with and it no longer properly controls

temperature, you can restore it to the factory setup. Perform the following procedures to restore

factory setup:

1. Turn off the power switch on the graphic display and remove all electrical power to the

dryer.

1. Press up the latch at the bottom of the module front panel and slide out the control

chassis.

1. Locate the slide-type lockout switch marked

circuit board. It should be

OFF.

2. Set the rotary-type alarm mode selector switch marked