AEC TK Series Cooling Tower Water Treatment Systems User Manual

TK Series

Cooling Tower Water Treatment Systems

OPERATION & MAINTENANCE

MANUAL

DATA PRESENTED HEREIN IS THE BEST AVAILABLE AT THE TIME

OF PUBLICATION. AEC AND/OR ITS REPRESENTATIVES

ASSUME NO LIABILITY FOR ITS USE OR ABUSE.

PLEASE REVIEW THIS MANUAL COMPLETELY BEFORE

INSTALLING OR OPERATING YOUR NEW TK Series SYSTEM.

PLEASE CONTACT AEC WITH ANY QUESTIONS YOU MAY HAVE.

AEC, INC.

801 AEC Drive

Wood Dale, IL 60191-1198

(630) 595-1060 - Fax (630) 595-6641

www.aecinternet.com

1

TK Series O&M Manual Index

Page 3 Limited warranty

Page 5 Main component description

Page 6 Pre Installation Instructions

Page 8 Installation Intructions

Page 11 Electrical Drawing

Page 12 Start Up procedure

Page 14 Maintenance Daily

Page 15 Maintenance Quarterly

Page 16 Maintenance Yearly

Page 17 Backwash Timer Adjustment

Page 18 Towerperge Directions

Page19 Water Testing Program

Page 20 Trouble Shooting

Page 21 Filter Operation Drawing

Page 23 TK20 Filter Parts Drawing

Page 24 TK40 Filter Parts Drawing

Page 25 TK60 and TK80 Filter Parts Drawing

Page 26 Pump Assembly Drawing

Page 27 Valve Assembly Drawing

Page 28 Actuator Assembly Drawing

Page 29 Installation Drawing

Page 30 System Drawings

Page 34 Flow Distribution Drawing

Page 35 Return Header drawing (for multiple column systems)

Page 36 MSDS

2

AEC, INC.

TK SERIES

Limited Warranty

Warrant only to ___________________________________________________,

the original retail purchaser, that the products which are manufactured and assembled by AEC, Inc. are free

from defects in material and/or workmanship for a period of twelve months from the date of documented

installation provided installation occurs within 30 days from delivery or, in absence of documented installation

date, 12 months from the date of factory shipment. The warranty registration card in this manual MUST be

completed and returned to AEC, Inc. in order to establish the date of installation and extend the warranty

period. If, within the period provided by this warranty, any such product shall prove defective, it shall be either

repaired or replaced.

For repair/replacement, the original purchaser shall contact the manufacturer, as soon as possible after

discovery of the defect, but in all events prior to the expiration date of the warranty. Upon notification, the

manufacturer, AEC, Inc. 801 AEC Drive, Wood Dale, IL 60191, will advise the purchaser of the address to

which the defective item may be shipped; the serial number and the date of purchase of the item must be

included. UPS ground cost for shipping replacement parts(s) to the customer will be borne by AEC; shipping

other than regular service will be at the customer's expense. Customer is responsible for cost of shipping

defective part(s) back to AEC.

EXCLUSIONS

1. This warranty shall not apply to any failures resulting from: negligence, abuse, misuse, misapplication,

improper installation, alteration or modification, chemical corrosion, or improper maintenance due to

misapplication of the operation & maintenance manual.

2. Any items manufactured by other companies and used by AEC in its products may carry warranties by

the original manufacturers.

3. AEC, Inc. is not liable for incidental or consequential damages, loss of time, inconvenience, incidental

expenses, labor or material charges in connection with operation of, removal of or replacement of the

equipment.

AEC, Inc. is not responsible for any implied warranties or representations by others, and the foregoing

warranty is exclusive and in lieu of all warranties provided herein.

IMPORTANT

Read and fully understand the WARNING labels on the equipment. DO NOT

OPERATE this unit if any unsafe conditions exist.

WARNING

THE FILTER SYSTEM OPERATES UNDER PRESSURE. DO NOT OPEN THE BAND CLAMP WHILE

PUMP IS RUNNING AND/OR UNTIL ALL PRESSURE IS RELEASED THROUGH AIR RELIEF VALVE.

SECURELY TIGHTEN VESSEL AND STRAINER CLAMP ASSEMBLIES ACCORDING TO

MANUFACTURER'S INSTRUCTIONS. RAISE PRESSURE SLOWLY. DO NOT EXCEED THE MAXIMUM

WORKING PRESSURE OF THE FILTER VESSEL OR EXCEED THE MAXIMUM FLOW CAPACITY OF

THE REACTION COLUMN.

DANGER! EXTREME CARE MUST BE TAKEN DURING PRESSURE TESTS. FAILURE TO FOLLOW

THESE INSTRUCTIONS EXPLICITLY CAN RESULT IN PERSONAL INJURY.

3

TK Series

AEC, INC.

Congratulations on your selection of a

System by AEC, Inc.

TK SERIES system is designed and manufactured for years of service.

Your

TK SERIES system is covered by a limited warranty as stated on the previous page.

Your

This warranty is for 12 months from the date of documented installation provided

installation occurs within 30 days from delivery or, in the absence of documented

installation date, 12 months from the date of factory shipment. In order to receive the

maximum warranty benefit, you must complete and return the Warranty Registration

Card below within 10 days of installation to register your warranty and ensure your

rights.

For Your Records

Date of Installation: ____________ Date Warranty Registration Card Mailed: ________

Complete the card below. Cut along dotted line. Return to:

801 AEC Drive - Wood Dale, IL 60191-1198

TK SERIES Cooling Tower Water Treatment

AEC, Inc.

-------------------------------------------------------------------------

TK SERIES Manufacturer's Warranty Registration

Model Number: ___________________ Serial Number: _________________

Company Name: ________________________________________

Address: ______________________________________________

City: ____________________ State: ________ Zip: _____________

Contact Person: _________________________________

Phone: ______________________ Date of Installation: _________________

4

TK SERIES

AEC, INC.

Getting to Know Your Cooling Tower Water Treatment System.

MAIN COMPONENT DESCRIPTION

A. SAND FILTER

This high-rate sand filter is a vertical pressure vessel with a special influent baffle in the top

of the tank, a bed of filter sand and an underdrain system which collects the filtered water

and directs it to the return piping. The filter operates under pressure. When closed

properly and operated without air in the water system, this filter will operate safely. The

system is equipped with a manual high-flow air release valve, an automatic pressure relief

valve set at 35 psi. With influent and effluent pressure gauges mounted on the control

panel support stand.

B. ACTUATED CONTROL VALVE ASSEMBLY

The valves are 24 volt, electric actuated, CPVC Three way diverting valves.

C. PUMP AND MOTOR

The pump has a cast brass impeller, motor bracket, and volute with stainless steel

fasteners to resist corrosion. The drip-proof, cool running, mechanical seal virtually

eliminates burnout and provides easy access for replacement. The pump is self-priming.

The totally enclosed motor with its external fan-cooled construction allows for operation in

noncombustible, dusty, dirty atmospheres. It is double shielded with pre-lubricated ball

bearings on both ends, has a NEMA 56C frame, and high tensile steel shaft, enclosed in a

heavy gauge rolled steel case. Motors are UL approved and CSA stamped.

D. STRAINER

The pump suction strainer assembly is fabricated of fiberglass reinforced noryl with a total

capacity of 440 cubic inches and is rated for a maximum operating pressure of 50 psi. It

has a clear lexan lid for viewing the integral cycolac strainer basket. The lid is held in place

by a stainless steel band clamp and includes an o-ring gasket for positive seal. The pump

strainer on TK -80 systems does not have the clear lexan lid. Extra care should be taken

during installation to provide a shut off valve in the inlet line to the pump (close to the

pump) so frequent inspections of the basket strainer can be made.

5

TK SERIES

AEC, INC.

E. MEDIA SAND

Filter media is shipped with the unit for field installation. The filter media is quartzite of

silica with a relative size of .45 to .55 mm & 1.7 uniform co-efficient. Clean filter media

will remove particles 20 microns in size and larger. Accumulated material on the top of the

media bed, called a filter cake, contributes to finer particle removal as the filter becomes

"dirtier". Removal of over 99% of 10 micron particles and 90% of 5 micron particles can be

expected over the course of a filter cycle.

F. REACTION MEDIA & REACTION COLUMN

The reaction column contains a patented high purity redox media. The media is a blend of

two dissimilar metals in a 50:50 ratio. The naturally occurring electrical potential between

these dissimilar metals creates an electron exchange effecting the crystal structure of and

preventing the formation of hard scale while creating an unfavorable environment for

bacteria, algae and corrosion. The reaction column has been specifically designed to

provide a controlled, up-flow pattern of the process water through the reaction media while

retaining the media within the column.

G. CONTROL PANEL

The control panel provides all controls for flow monitoring and automatic backwash

operations. The control panel is UL Listed, and includes the following standard items:

NEMA 3R enclosure; motor starter with thermal overload protection; transformer to convert

supply to 24 and 110 VAC control power; power disconnect; differential pressure switch to

initiate backwash (external to enclosure); adjustable timing controls; manual on/off switch;

self-powered flow monitor and manual backwash initiation switch. The sequence of the

adjustable timing controls is described under the Operation section of this manual. The

controls automatically stop the system's pump whenever valves are to be shifted which

prevents water hammer and pipe flexing.

H. SHUT-DOWNS

The TK SERIES system is designed to provide full effective operation, 24 hours per day, 7

days per week. If the system is to be shut down for any more than 5 days you should drain

the reaction columns of water. This can be accomplished by opening the ½” drain valve

slightly.

6

TK SERIES

AEC, INC.

PRE - INSTALLATION INSTRUCTIONS

¾ Prior to the installation and start up of your new TK SERIES cooling tower

water treatment system, the following cooling system preparation instructions

should be followed.

A) Carefully inspect the cooling tower and reservoir for any algae growth, which might

be present. If algae is present, completely remove and clean all surfaces before

installation and start-up.

¾ Cleaning and removing existing algae growth may require shocking the

cooling system with a strong algaecide and manually scrubbing all surfaces

where algae have established a base growth. A cover for the cooling tower

distribution pan or shading of areas exposed to direct sunlight is

recommended.

B) Disconnect and remove all treatment chemical drums and metering pump feed

systems.

C) Draining the pump tank and refilling with fresh water, is the preferred method of

elimating the residual chemicals in the cooling system. If this can not be

accomplished you should discontinue the use of all chemicals at least 5 days prior to

starting the TK Series system and increase the blow down to purge the system of

chemicals.

D) Inspect the cooling system for heavy scale deposits. These deposits should be

removed prior to the start up of your

will remove the old scale. More frequent cleaning of strainers be may necessary.

TK SERIES system. The TK SERIES system

See installation drawing Page 29

7

TK SERIES

AEC, INC.

INSTALLATION INSTRUCTIONS

STEP 1. LOCATION OF THE SYSTEM

¾ Place the TK SERIES Cooling Tower Water Treatment System on a firm level surface

adjacent to (within15 feet of) the cooling tower reservoir. The

not need to be anchored, unless required by local code or if the reaction column stand

is separate from the filtration skid. Select a location close to the cooling tower for

convenience, accessibility and serviceability. If the filter is to operate year-round,

exposure to winter conditions should be considered

Open all crates and check for the following components.

1. Reaction column(s)

a. 8, ¾ x 4 bolts /column

b. 8, ¾ x 5 bolts /column

c. 16, ¾ nuts /column

d. 32, ¾ flat washers /column

e. 16, ¾ lock washers/column

f. 1, 1 ½ dia. screen /column

g. 1, tee strainer clear bowl/column

h. 1, 53 lb can of AEC media/column

i. 1, 8” blind flange with 2” female npt thread/column

j. 1, 8” flange gasket/column

TK SERIES system does

2. TK SERIES filter assembly

a. 1, strainer housing

b. 1, strainer basket

c. 1, clear strainer lid

d. 1, 6” O-ring

e. 1, mounting gasket

f. 1, Tensioning clamp

g. 1, high flow air/pressure relief valve

h. 1, ¾ id drain hose with mounting Clips

i. 4, pump strainer mounting bolts

j. Sand 150 lbs Tk20, 250lbs TK40, 400 lbs TK60 and TK80

8

After unpacking and checking for all components, locate the system as close to the

cooling tower reservoir as possible.

1. Mount the pump strainer basket and gasket to the pump.

2. Plumb the pump suction line, be sure to use an isolation valve between the

pump tank and the TK SERIES system. Plumb the isolation valve within 2 feet

of the strainer basket if possible. Plumb a union immediately before the pump

strainer basket to allow for future service. Make sure to place the suction line

in a location where it will not pick up air returning from the tower.

3. Mount the column(s) to the column stand(s); Use the ¾ x 4 bolts for

mounting the bottom flange to the stand. Be sure to place the TK SERIES

sticker towards the front of the system.

4. Load the TK SERIES media into the column(s) (1 Can of media per column).

5. Clean off any excess media from the top flange. Place the 8” gasket on the top

flange of the column. Place the Blind flange on the gasket. Use the ¾ x 5 bolts

to mount the blind flange to the top of the column(s).

6. Thread a 2” male thread adaptor into the 2” female NPT hole in the top of the

blind flange. Within 6” of the top flange plumb a 2” union to allow for future

service.

7. Plumb a 2” line back to the pump tank. If you are installing a multiple column

unit you may want to plumb the column return lines in a header. If you do, the

header should be 3” line. See drawing (page 29). Do not plumb the return line

below the water line of the pump tank; if you do you will not be able to drain

the column(s) during media change out.

8. Locate the closest drain capable of handling the flow of the back wash for the

filter.

a. TK20 35 GPM/ 3 minutes.

b. TK40 65 GPM/ 3 minutes.

c. TK60 100GPM/ 3 minutes.

d. TK80 100 GPM/3 minutes.

If the drain will not handle the flow you may have to add a surge tank to allow

the filter to backwash at the proper flow rate. The surge tank should be large

enough to handle the total volume of back wash. Once the back wash has

taken place, the tank can be allowed to gravity feed to the drain over a longer

period of time.

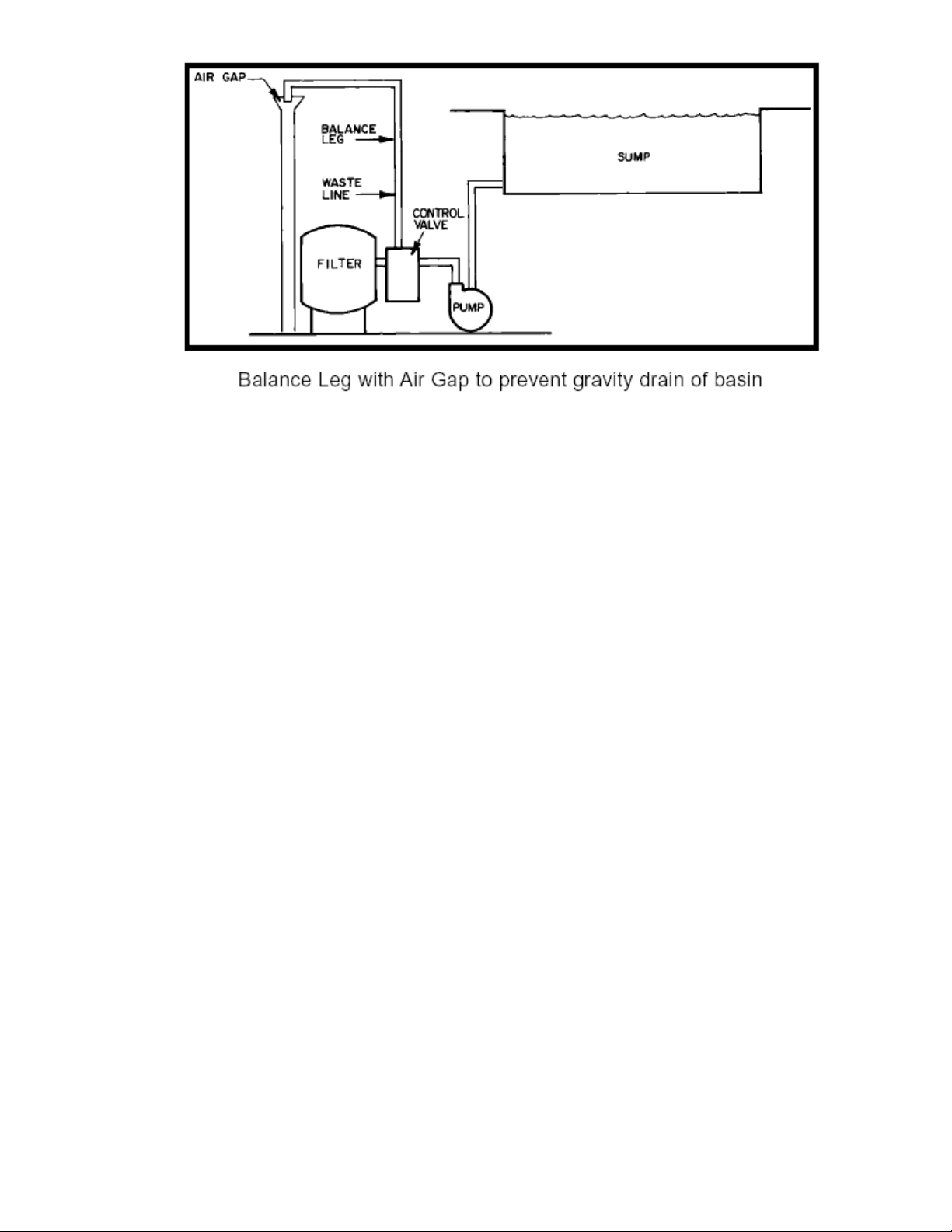

9. Plumb a 2” drain line, be sure to use a siphon break so if the power fails

during a backwash the pump tank does not drain. See Air gap drawing on

page 10

9

10. Plumb the bypass line from the TK SERIES system back to the pump tank see

drawing Page 29

11. Load the sand into the filter vessel. Remove the band clamp from the filter

tank, add enough water to cover the filter laterals, slowly pour the sand in the

vessel 150lbs/TK20, 250lbs TK40, 400lbs TK60and TK80. Clean all sand from

the sealing surface, Make sure the O-ring is in place, set the cover on the filter

vessel place the band on. Tighten the spring nut while GENTLY tapping on the

band clamp to insure uniform tension, DO NOT OVER TIGHTEN

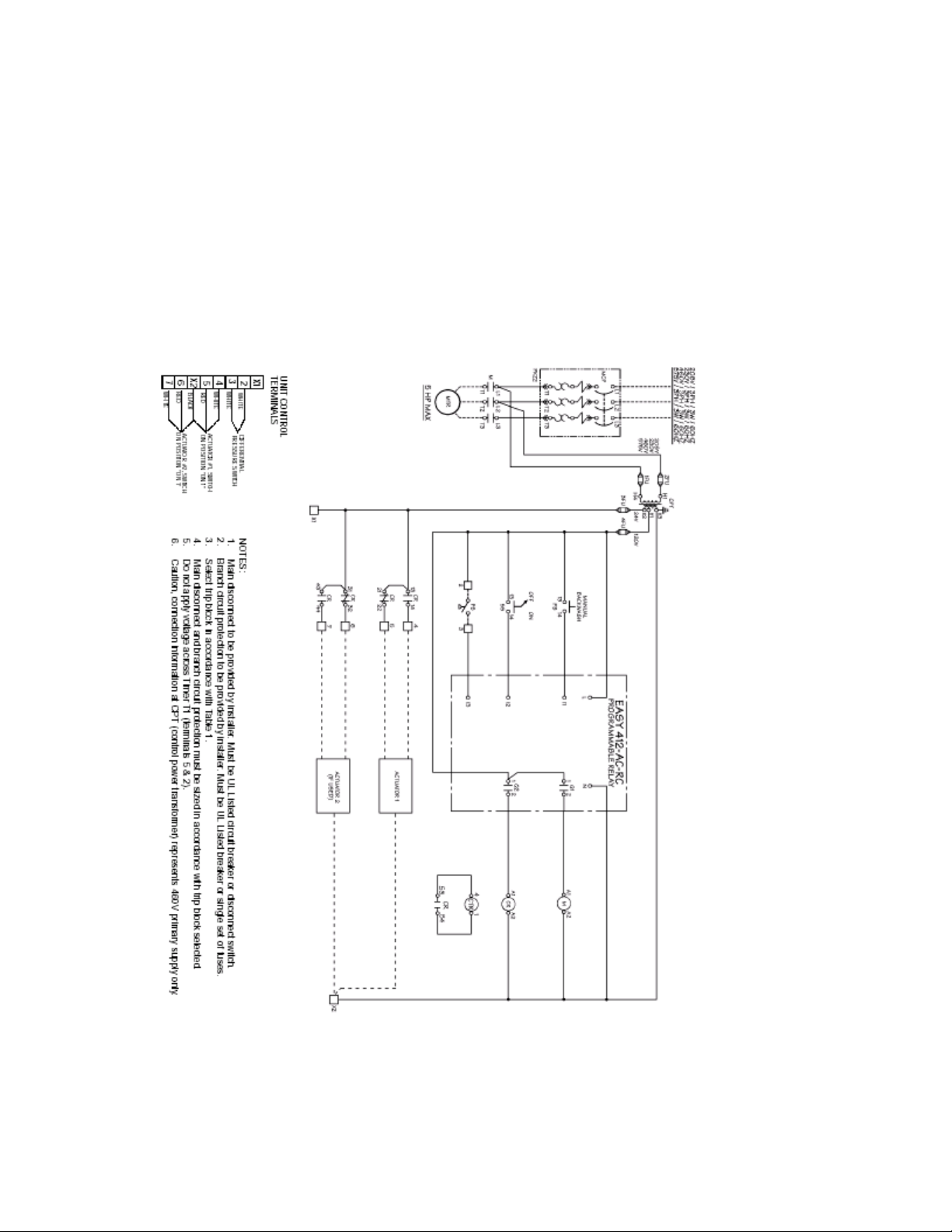

Electrical Connections

All systems are factory prewired and require only field connections to power source.

Proceed as follows:

¾ ALL WIRING CONNECTIONS MUST FOLLOW ALL STATE AND LOCAL

CODES.

A) Check power supply wiring and related components for compatibility with the system

making sure all code requirements are met.

B) Make all contacts according to the appropriate phase/voltage wiring schematic

found within this manual

10

TK SERIES Electrical Drawing

11

TK SERIES

FILTER START UP PROCEDURE

(Flooded Suction Installations)

• Close the reaction column(s) flow control valve(s) and completely open “bypass to

reservoir” valve.

• Place the clear plastic drain hose from the high flow air relief valve, in a drain or

bucket.

• Open the isolation valve from the reservoir. Open high flow air relief valve at the top

of the filter chamber by turning it ¼ turn to its full open position. Allow air to escape

from the filter chamber until water flows from the air relief valve. Close the air relief

valve.

• Check all fittings for leaks.

Note: Insure that the strainer basket is full of water before attempting to start

pump motor. Running the pump without water in the basket will cause failure

of the pump seals.

• Make sure pump on/off switch is in the off position, Turn main disconnect switch to

the on position.

• Turn pump on/off quickly to check for proper pump motor rotation according on the

arrow on the pump. Correct if necessary.

• After verifying pump motor rotation, turn the system panel switch on and allow the

pump to run.

• Open high flow air relief valve once again until you achieve a steady stream of

water. Close the valve.

• Press manual backwash button on the control panel.

The following sequence will occur:

Pump will pause for 30 seconds while the two automatic valves rotate 180°.

Note: Valves must rotate simultaneously in the same direction. If they do

not, check the toggle switches on the valve motor housings to insure that

both switches are in the ON1 position.

Pump will restart and run for 3 minutes. During this time, check the discharge

from the filter to the drain.

Pump will then shut down for 30 seconds while the valves return to the run

position.

After a brief time delay the pump will restart.

Check the backwash counter to insure that the number has increased by one.

• The filter is now operational.

12

WARNING

THE SAND FILTER OPERATES UNDER PRESSURE AND SHOULD NEVER BE OPENED UNTIL THE

PUMP IS SHUT OFF AND THE PRESSURE IS BLED OFF THROUGH THE AIR RELIEF VALVE. NEVER

OPERATE THE SAND FILTER AT PRESSURES OVER 30 PSI. SUCH PRESSURES COULD INDICATE

THE NEED FOR CLEANING OR A MALFUNCTION IN THE SAND BED. THE FILTER SYSTEM IS

DESIGNED TO WITHSTAND WATER TEMPERATURES UP TO 120oF/49oC.

The factory preset time interval for back washing is 12 hrs do not lengthen this

interval without approval of AEC. Failure to comply can result in solidifying

sand.

TK SERIES

REACTION COLUMN START UP PROCEDURE

• With the filter in operation and the bypass open fully, slowly open the reaction

column isolation valve(s) fully followed by the reaction column control valve(s)fully.

• During this initial adjustment, run the flow rate thru the column(s) at the lower portion

of the flow range sticker.

• If the column flow is lower than the lower portion of the flow range sticker slowly

close the bypass valve until the proper flow rate is achieved for each column. The

reaction column control valves may need to be adjusted in multiple column systems

to properly balance the flow.

• Allow the system to operate at this rate for 24 hours. After that time, verify that the

system has backwashed at least 2 additional times, as indicated on the backwash

counter.

• The system is now ready for the full process flow rate. Slowly turn the bypass valve

toward the closed position until the flow is ¾ of the way up the flow range sticker.

On multiple column systems it will be necessary to adjust the reaction column

control valves to properly balance the flow to the individual columns.

• The system is now fully operational.

WARNING

THE REACTION COLUMN(S) OF THIS SYSTEM, EACH HAVE A MAXIMUM RATED FLOW CAPACITY

OF 25 GALLONS PER MINUTE PER COLUMN. OPERATING THE REACTION COLUMN(S) AT A FLOW

RATE GREATER THAN ITS DESIGNED PARAMETERS MAY RESULT IN THE LOSS OF REACTION

MEDIA, AND WILL REDUCE THE SYSTEMS’ EFFICIENCY.

13

Loading...

Loading...