Page 1

Operating Instructions

Single Conveying Units

(Compressed Air Venturi Type)

ASV-05, ASV-05R, & ASV-052R

Bulletin No.: CV6-600

Part No.:

882.00191.00

ffective: 12/12

E

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 1of 36

Page 2

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Page 3

The manufacturer retains all rights to change the information in these operating instructions at

any time without notice.

We assume no liability for any errors or direct or indirect damage resulting in context with these

operating instructions.

Copying, translation or publication in any form except for personal use of purchaser requires

approval from the manufacturer.

All rights reserved.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 2 of 36

Page 4

Table of Contents

CHAPTER 1: SAFETY INSTRUCTIONS.. . . . . . . . . . . . . . . . . . 4

1.1. Warnings and Symbols ................................................................................................. 5

1.2. Explanations and Information ........................................................................................6

1.3. For Your Safety ..............................................................................................................7

How to Use this Manual……….………………………………………………………..7

Warnings and Precautions……………………………………………………………..7

Maintenance Responsibility……………………………………………………………8

1.4. For the Safety of the Units .............................................................................................. 9

CHAPTER 2: INSTALLATION INSTRUCTIONS……………….11

2.1. General Information ...................................................................................................... 11

2.2. Installing the Convey or Hopper.................................................................................... 12

2.3. Installing the Control and Maintenance Unit ................................................................. 13

2.4. Connecting the Compressed Air Supply ....................................................................... 14

2.5. Electrical Connection ................................................................................................... 15

CHAPTER 3: FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . 16

3.1. Method of Functioning ..................................................................................................16

3.2. Control and Maintenance Unit .....................................................................................17

CHAPTER 4: SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1. Preparations..................................................................................................................18

4.2. Setting the Mixing Ratio of the Components................................................................. 18

4.3. Basic Setting of the Filling Level in the Conveyor or Hopper........................................ 19

Fine Adjustment of the Filling Level in the Convey or Hopper…………………... 20

CHAPTER 5: MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1. Maintenance Intervals...................................................................................................22

5.2. Cleaning/Replacing the Filter Cartridge ........................................................................ 23

Disassembly……………………………………………………………………………24

Assembly..……………………………………………………………………………...24

5.3. Adjusting the Level Probe ............................................................................................ 24

5.4. Troubleshooting ............................................................................................................ 25

CHAPTER 6: TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . 27

6.1. Dimension Sheet ......................................................................................................... 28

6.2. Spare Parts Lists ......................................................................................................... 31

6.3 Quick Start Guide –XSV Loader………………………………...…………………………..34

6.4 Technical Assistance…………………………………………………………………………36

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 3 of 36

Page 5

Chapter 1: Safety Instructions

These safety instructions apply to anyone near the equipment operation.

»

Please inform everyone near the operating equipment about the direct and

indirect hazards associated with the equipment.

These operating instructions are to be used by everyone who is assigned

activities connected with the equipment.

Knowledge of the English language is required.

Make sure that all operating personnel are familiar with the operating

instructions and the function of the equipment.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 4 of 36

Page 6

1-1 Warnings and Symbols

The following warnings and symbols are used in these operating instructions.

»

This symbol indicates DANGER! Death or serious injury is possible if the

corresponding instructions, regulations or warnings are not observed.

This symbol indicates that serious injury is possible if the corresponding

instructions, regulations or warnings are not observed.

This symbol indicates that extensive damage to equipment is possible if

the corresponding instructions, regulations or warnings are not observed.

This symbol indicates information that is necessary for becoming familiar

with the equipment, i.e. technical correlations.

This symbol indicates that a technical term is explained at this point.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 5 of 36

Page 7

1-2 Explanations and Information

Various terms and designations are used frequently in these operating

instructions to ensure clarity. Therefore, please note that the terms used in the

text are defined as follows:

• Equipment

Equipment can mean an individual unit, a machine, or an installation.

• Operating Personnel

Operating personnel are individuals who are responsible for operating the

equipment. All personnel engaged in the use of the machine should

become familiar with its operation as described in the manual. Each

individual must take responsibility for understanding and following all

safety rules. Operating personnel should be at least 16 years old.

• Operator

The operator of the equipment (production manager, foreman, etc.) is the

person responsible for all production sequences. The operator instructs

the operating personnel on what should be done.

• Operating Instructions

The plant operating instructions describe the interaction of the equipment,

production sequences or methods. The plant operating instructions must

be compiled by the operator of the equipment.

• Equipment Foreman

When several operating personnel work on one machine, the equipment

foreman arranges the order. The equipment foreman must be appointed

by the operator.

• Trained Personnel

Trained personnel are persons who, due to their training, are authorized

to perform the required work.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 6 of 36

Page 8

1-3 For Your Safety

How to Use This Manual

• Please read this manual carefully before initial operation. Understanding the

instructions and equipment will help to avoid injuries as well as damage to

equipment. If you have questions, contact the manufacturer.

• The operators of this unit must be at least 16 years old.

• Store this manual near the site of the machine so that it is readily available to

the operators. Faulty operation may lead to accidents!

• Note that, for reasons of brevity, not every possible case of operation or

maintenance can be mentioned in this manual.

• Be aware of all safety instructions and danger signs on the unit. This will

avoid injuries and damage to material.

• Prepare precise instructions of the unit using this manual. Faulty operation

can lead to accidents!

Warnings and Precautions

• Only PROPERLY TRAINED individuals familiar with the information in this

manual should use this equipment.

• Proper clothing should be worn at all times in order to avoid injuries.

• Compare the connected loads to those of the main supply to avoid electrical

shock.

• When using lifting gear, pay close attention to the corresponding instructions

to avoid accidents.

• Operate this equipment within the local regulations and requirements of the

plant.

• NEVER modify or alter the unit without the manufacturer’s permission.

• If the unit has been switched off for safety reasons, it must be protected from

unauthorized use.

• The unit is exclusively intended for conveying plastic granules and regrind.

Any other usage is not permitted.

• This unit is not suitable for processing foods.

•

Attachments that are not delivered by the manufacturer must be constructed

according to the safety standard EN 294.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 7of 36

Page 9

• Check all lines, hoses, and coupling pieces regularly for leakage and

damage. Any errors must be eliminated immediately.

• The unit may only be used if all corresponding components have been

properly connected and are in accordance with relevant regulations.

• Observe the safety instructions for the connected units.

Maintenance Responsibility

• Before beginning maintenance work:

Assign a supervisor.

Inform all other responsible operating personnel.

Turn off the main power supply.

Set all compressed air lines on the unit at zero pressure.

Repair work should ONLY be done by qualified personnel.

• ALWAYS turn off the main supply for all electrical work to avoid risk of death

or injury.

• NEVER operate on a unit that is partially disassembled. This can cause

serious injuries including amputation and electric shock.

• In case of functional disturbances, switch the unit off IMMEDIATELY. Any

errors must be eliminated to avoid accidents.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 8 of 36

Page 10

1-4 Unit Safety

• The unit may ONLY be used for conveying cylindrical plastic granules and

regrind on injection molding machines.

• NEVER change the settings unless you are able to foresee the

consequences.

• Use ONLY original manufacturer parts.

• Follow a regular maintenance schedule.

• Keep records of all maintenance and repair work.

• Be aware that electronic subassemblies may be damaged by static

discharge.

• Before initial operation and at regular intervals, check all electrical

connections for proper fit.

• NEVER modify sensors without knowing their precise functions.

• Make sure all plugs are connected properly.

• Note the carrying capacity of the machine flange.

• Read the operating manuals of the connected units.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 9 of 36

Page 11

Chapter 2: Installation

These installation instructions are intended for people with skills in

electrical and mechanical areas due to their training, experience and

»

received instructions.

Personnel using these installation instructions must be educated about

regulations for accident prevention, operating conditions and safety

regulations. Make sure all personnel are informed accordingly. The

installation instructions provided in the corresponding operating

instructions apply for all connected equipment.

Follow safety regulations with regard to lifting gear handling.

All installation work must be carried out with the electrical power and

compressed air supply OFF.

For installation work taking place at heights of over approx. 6 feet, use

only ladders or similar equipment and working platforms intended for this

purpose. At greater heights, the proper equipment for protection against

falling must be worn.

Use only suitable lifting gear, which is in proper working order and load

suspension devices with sufficient carrying capacity. Do not stand or

work under suspended loads!

Use suitable workshop equipment.

Install the equipment such that all parts are easily accessible; this

facilitates maintenance and repair work.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 10of 36

Page 12

2-1 General Information

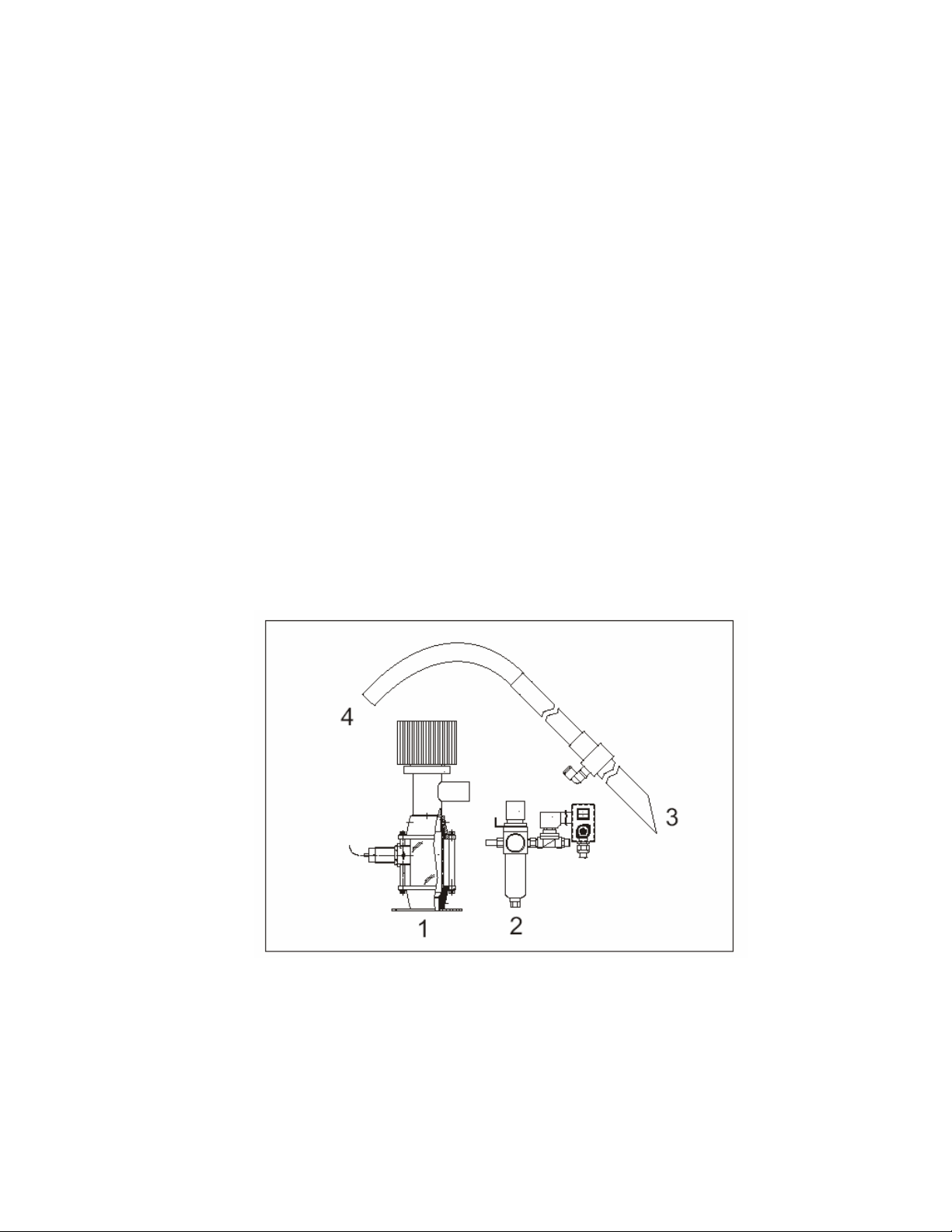

Unpack all parts of the single conveyor unit and make sure that every thing is

available:

• conveyor hopper with level sensor (1)

• control and maintenance unit (2)

• one venturi assembly (3)

• one section of vinyl flexible hose (4) with two hose clamps

• compressed-air hose

• operating instructions

The XSV-05/2R comes with two venturi assemblies.

The XSV-05/2R comes with two sets of vinyl flexible hose and four

hose clamps.

Figure 1: XSV-05 Parts

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 11 of 36

Page 13

2-2 Installing the Conveyor Hopper

The single conveyor unit is insensitive to shocks and can be installed directly on

the processing machine.

Make sure that all connections are tight so that the conveying performance is not

impaired. The conveyor hopper is equipped with a universal flange.

Depending on the position, drill the holes for fastening the

conveyor hopper to the processing machine.

Mount the conveyor hopper on the processing machine.

Install the vinyl flexible hose on the conveyor hopper and

on the venturi assemblies using the hose clamps that are

part of the supply.

Note: The hopper should not touch any other component.

4.3 In. (110 mm)

0.43 In.

(11 mm)

4.3 In.

(110 mm)

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 12 of 36

Page 14

2-3 Installing the Control and Maintenance Unit

Install the control and maintenance unit at a freely accessible site. Check the

length of the connection cable and the length of the supplied hoses to the venturi

assemblies.

During installation, check the length of the air supply lines.

Figure 2: Control and Maintenance Unit

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 13 of 36

Page 15

y

2-4 Connecting the Compressed Air Supply

Before connecting the compressed air supply, check the following:

Check compressed air piping for correct installation and assembly.

Check the fittings, length and quality of the hose connections for

agreement with requirements.

Check all compressed air lines for leakages.

You need a compressed air supply with 70-90 psi (5-6 bar) system pressure.

The air should be free of oil and water.

1. Find the compressed air hose, which has

been supplied.

2. Connect it to the venturi assembly and to

the control and maintenance unit.

3. The compressed-air hose is firmly pressed

into each connecting socket.

4. Connect the control and maintenance unit

to the compressed air supply. Max. input

pressure 145 psi (10 bar) system pressure.

5. Set the pressure on the pressure reducer

at 70-90 psi (5-6 bar).

Figure 3: Venturi Assembl

Maximum input pressure: 145 psi (10 bar) system

overpressure.

Maximum output pressure: 90 psi (6 bar).

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 14 of 36

Page 16

2-5 Electrical Connection

Check with the local electricity board for regulations.

The operating voltage is 110 V, AC, PE, 50/60 Hz. Special voltages available by

request.

The connected load is approximately 15 W.

The connection is made using a mains connector. A separate protection of the

socket is not necessary.

Connect the plug of the sensor cable to the control unit.

Plug the main connector into a corresponding socket.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 15 of 36

Page 17

Chapter 3: Functional Description

y

This functional description is intended for the operating personnel of the

3-1 Method of Functioning

equipment.

General knowledge of operating conveyor units is required.

Ensure in each case that the operating personnel are

sufficiently informed.

The XSV-05/R and XSV-05/2R are designed for conveying dust-free

plastic granules and regrind material. Only the XSV-05/2R is capable of

conveying two materials.

The single conveyor unit works

according to the Venturi Principle. An

external compressed air supply is

needed.

A venturi meter (A) is integrated in the

venturi assembly.

The venturi meter aspirates the material

in the lower part of the tube (C) and then

conveys the material into the conveyor

hopper using compressed air in the

upper part (B). In the hopper loader, the

material is separated from the air.

The filling level of conveyor hopper is

monitored and controlled by a level

sensor located on the sight glass below

the receiver.

Note: The venturi assembly is factory

pre-set for optimum conveying. DO NOT

ADJUST the venturi assembly.

Figure 4: Venturi Assembl

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 16of 36

Page 18

3-2 Control and Maintenance Unit

A. The unit is switched ON and OFF at the control and maintenance

unit.

B. At the regulator, the operating pressure is adjusted. A water

separator is integrated.

C. Regularly inspect the compressed air filter to make sure that it is

clean and functioning properly. Clean or replace this filter as

needed. For information, see Section 5-1: Maintenance.

B

C

Figure 5: Control and Maintenance Unit

A

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 17 of 36

Page 19

Chapter 4: Setup

This chapter is intended for the operating personnel of the

equipment.

General knowledge of operating conveyor units is required.

»

4-1 Preparations

The functional description must be read and understood.

Make sure that in each case the operating personnel are

sufficiently informed.

Check to see if the venturi assembly is inserted in the material to be

conveyed.

Switch the compressed air supply ON at the compressed air source.

Switch the conveyor unit electrical switch ON at the control and maintenance

unit.

The conveyor unit should now convey until the conveyor hopper is filled up to the

level sensor.

4-2 Setting the Mixing Ratio of the Components (XSV-05/2R

Units)

The mixing ratio of the components is adjusted at the regulator. By changing the

regulator pressure of each material, you will adjust the rate at which each

material is conveyed into the conveyor hopper. This will determine the ratio of

two materials entering a conveyor hopper.

The adjustment of the regulator will vary according

to the material, flow properties, particle size and conveying

distance.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 18of 36

Page 20

4-3 Basic Setting of the Filling Level in the Conveyor Hopper

The filling level in the conveyor hopper is mainly determined by the level sensor.

Figure 6: Conveyor Hopper

Filling Level Too Low

1. Using a screwdriver, turn the adjustment screw of the level sensor (A) ¼

rotation counter-clockwise.

2. Check the filling level during the next conveying procedure.

3. Repeat the process until the desired filling level in the conveyor hopper is

reached.

Filling Level Too High

1. Using a screwdriver, turn the adjustment screw (A) of the level sensor ¼

rotation clockwise.

2. Check the filling level during the next conveying procedure.

3. Repeat the process until the desired filling level in the conveyor hopper is

reached.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 19 of 36

Page 21

Fine Adjustment of the Filling Level in the Conveyor Hopper

During operation, use a screwdriver to carefully turn the adjustment screw (A) of

the level sensor until the desired filling level is reached.

If the filling level in the conveyor hopper cannot be lowered far enough using the

level sensor, the pressure on the control and maintenance unit can be reduced

gradually.

Before the fine adjustment, carry through a basic adjustment.

Clockwise rotation makes the filling level fall.

Counter-clockwise rotation makes the filling level rise.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 20 of 36

Page 22

Chapter 5: Maintenance

This chapter is intended for persons with skills in electrical and

mechanical areas due to their training and experience.

Personnel using the information in this chapter must be educated about

accident prevention, operating conditions, and safety regulations. Make

sure that all personnel are informed accordingly.

For maintenance work taking place at heights of over approx. 6 ft., use

only ladders or similar equipment and working platforms intended for this

purpose. At greater heights, personnel must wear the proper equipment

for protection against falling

Use only suitable lifting gear, which is in proper working order, and load

suspension devices with adequate carrying capacity.

Do not stand or work under suspended loads!

Make sure that the electric motors/switch cabinets are adequately

protected against moisture.

.

Use only proper work shop equipment.

Before starting maintenance work, appoint a supervisor.

Inform the responsible personnel before any maintenance work on the

system is started.

Never operate the equipment when it is partially disassembled.

All maintenance and repair work not described in this chapter may only be

carried out by service personnel or authorized personnel (appointed by the

manufacturer).

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 21of 36

Page 23

Disconnect the equipment from main electrical supply before

starting maintenance procedures to ensure that it cannot be

switched on unintentionally. Depressurize all compressed air

piping of the equipment before starting maintenance work.

Please observe the maintenance intervals.

Before starting maintenance work, clean the equipment of oil, fuel

or lubricants.

Ensure that materials and incidentals required for operation as well

as spare parts are disposed of properly and in an environmentally

sound manner.

Use only original manufacturer spare parts.

Keep record of all maintenance and repair procedures.

5-1 Maintenance Intervals

Daily:

Monthly:

Check the setting of the pressure regulator.

Empty the water separator.

Check danger signs on the unit for legibility and completeness.

Clean the cartridge filter and screen (depending on accumulation of

dust).

Blow out the filter from the inside using compressed air.

Check the electrical connections for proper functioning.

Every 6

months:

Check all electrical and mechanical connections for proper fit.

Replace filter and screen (depending on accumulation of dust).

The maintenance intervals provided are average values.

The maintenance intervals might be shortened due to your

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 22 of 36

individual process conditions.

Page 24

5-2 Cleaning/Replacing the Filter Cartridge

Switch the unit OFF.

Disconnect the main electrical plug.

Figure 7: XSV-05

Figure 8: XSV-05/R

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 23 of 36

Page 25

Disassembly

1. Remove the filter cartridge (A).

2. Blow out the filter cartridge (A) from the inside out using compressed air or

replace the filter.

3. Open the toggle-type fastener (B) and fold the hopper lid upward (C).

4. Check the screen (D) within the lid for material residue. (If you are

disassembling the screen for cleaning, draw the screen out of the fit of the

gasket ring).

5. Clean the screen (D) using compressed air.

6. Replace the screen and gasket ring as needed if damage you detect

damage.

Assembly

1. Assemble the screen and the gasket ring.

2. Check the screen for proper fit.

3. Clean the hopper loader using a vacuum cleaner.

4. Close the hopper lid.

5. Close the toggle-type fastener.

6. Assemble the filter cartridge.

5-3 Adjusting the Level Probe

See Chapter 4: Setup.

Order number level probe: ID 85480

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 24 of 36

Page 26

5-4 Troubleshooting

PROBLEM REMEDY (See Test Steps Below)

The unit is not conveying and is not

active.

The unit is not conveying; the

compressed air valve is switched

when the device is switched on.

The unit is not conveying; the

compressed air is flowing.

The unit is overfilled. G, L, M

The unit is not filled properly. C, D, E, F, I, J, K, L

A, B, G, H

C, F

C, D, E, F, I, J, K

Test steps:

Make sure the unit is switched ON.

Make sure the unit is plugged in and the proper voltage is present.

Make sure sufficient compressed air is available 70-90 psi (5-6 bar).

Make sure the venturi assembly is inserted in the material.

Make sure the compressed air hose is properly connected to the

venturi assembly.

Make sure the compressed air hose is properly connected to the

maintenance unit.

Make sure the level sensor is properly adjusted.

Make sure the cable of the level sensor is properly connected.

Make sure the filter to is not clogged.

Make sure the screen is not clogged.

Make sure the conveyor vinyl flexible hose is properly connected.

Make sure the compressed air supply is properly adjusted.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 25 of 36

Page 27

-Notes-

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 26 of 36

Page 28

Chapter 6: Technical Data

Maximum througput:

Weight: Approx. 6.61 lbs. (3 kg)

Operating voltage:

Connected load:

Total noise level:

Compressed air supply:

Max. product temperature:

330 lbs/h (149.7 kg/hr)

110 V, AC, PE, 50/60 Hz (standard)

Special voltage on request

Approx. 15 W

< 75 dB (A)

70-90 psi (5-6 bar)

176°F (80 °C)

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 27of 36

Page 29

6-1 Dimension Sheet

XSV-05

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 28 of 36

Page 30

XSV-05/R

1.25” OD

Dimensions and data are not binding. All dimensions are in mm (in.). All data are subject to change.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 29 of 36

Page 31

s

XSV-05/2R

1.25” OD

Dimensions and data are not binding. All dimensions are in mm (in.). All data are subject to change.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 30 of 36

Page 32

6-2 Spare Parts Lists

XSV-05

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 31 of 36

Page 33

XSV-05R

.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 32 of 36

Page 34

XSV-05/2R

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 33 of 36

Page 35

Spare Parts List (See figures on previous pages for parts location)

Position ID Number Designation

1 CT98171 Filter cartridge

2 CT18491 Screen (XSV-05 only)

2 CT29252 Screen (XSV-05R or XSV-05/2R)

3 CT31160 Lid gasket (XSV-05 only)

3 CT34161 Lid gasket (XSV-05R or XSV-05/2R)

4 CT100863 Vinyl flexible hose 1.25” x 10 ft.

5 CT85480 Proximity sensor

6 CT88351 Compressed air hose

7 CT29370 Complete control and maintenance unit

8 732.00008.00 Solenoid valve, 110 V

9 732.00066.00 Solenoid valve, 230 V

10 161.00171.00 Filter regulator

11 044.00642.00 Regulator valve (XSV-2R only) – not shown

12 CT31683 Venturi assembly 1.25”

13 CT97784 Hose clamp

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 34 of 36

Page 36

6-3 Quick Start Guide –XSV Venturi Loader

Unpack all parts. Check for the following:

• Conveying hopper with level sensor

• Control and maintenance unit

• Venturi assembly

• Vinyl flexible hose

• Compressed air hose

• Operating instructions

• Mount the conveying hopper using the flange provided on its base.

• Mount the control module at a location that is readily accessible. Make sure

that the compressed air hose and level sensor cable are long enough to

reach the control module.

• Connect the compressed air supply from the control module to the fitting

located on the material pick up wand.

• Connect shop compressed air to the regulator on the control module.

Compressed air connection must be 70-90 psi (5-6 bar).

• Plus the control module into the main power socket. Make sure that the

correct voltage is being used.

• Adjust the level sensor to sense the material that is being conveyed into the

conveying hopper.

• Maintain the unit as stated in Chapter 5 of this manual.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 35 of 36

Page 37

6-4 Technical Assistance

Parts Department

Call toll-free 7am–5pm CST [800] 423-3183 or call [630] 595-1060, Fax [630] 475-7005

The ACS Customer Service Group will provide your company with genuine OEM quality parts

manufactured to engineering design specifications, which will maximize your equipment’s performance

and efficiency. To assist in expediting your phone or fax order, please have the model and serial

number of your unit when you contact us. A customer replacement parts list is included in this manual

for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to providing

excellent customer service.

Service Department

Call toll-free 8am–5pm CST [800] 233-4819 or call [630] 595-1060

Emergencies after 5pm CST, call [847] 439-5655

We have a qualified service department ready to help. Service contracts are available for most

products.

Sales Department

Call [630] 595-1060 Monday–Friday, 8am–5pm CST

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales

Department for the name of the sales representative nearest you.

Contract Department

Call [630] 595-1060 Monday–Friday, 8am–5pm CST

Let us install your system. The Contract Department offers any or all of these services: project planning;

system packages including drawings; equipment, labor, and construction materials; and union or nonunion installations.

XSV-05, XSV-05/R, & XSV-05/2R Single Conveying Units - Venturi Style 36 of 36

Loading...

Loading...