Page 1

Allen Bradley PLC

OL-470 Series

Service Manual

Page 2

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Page 3

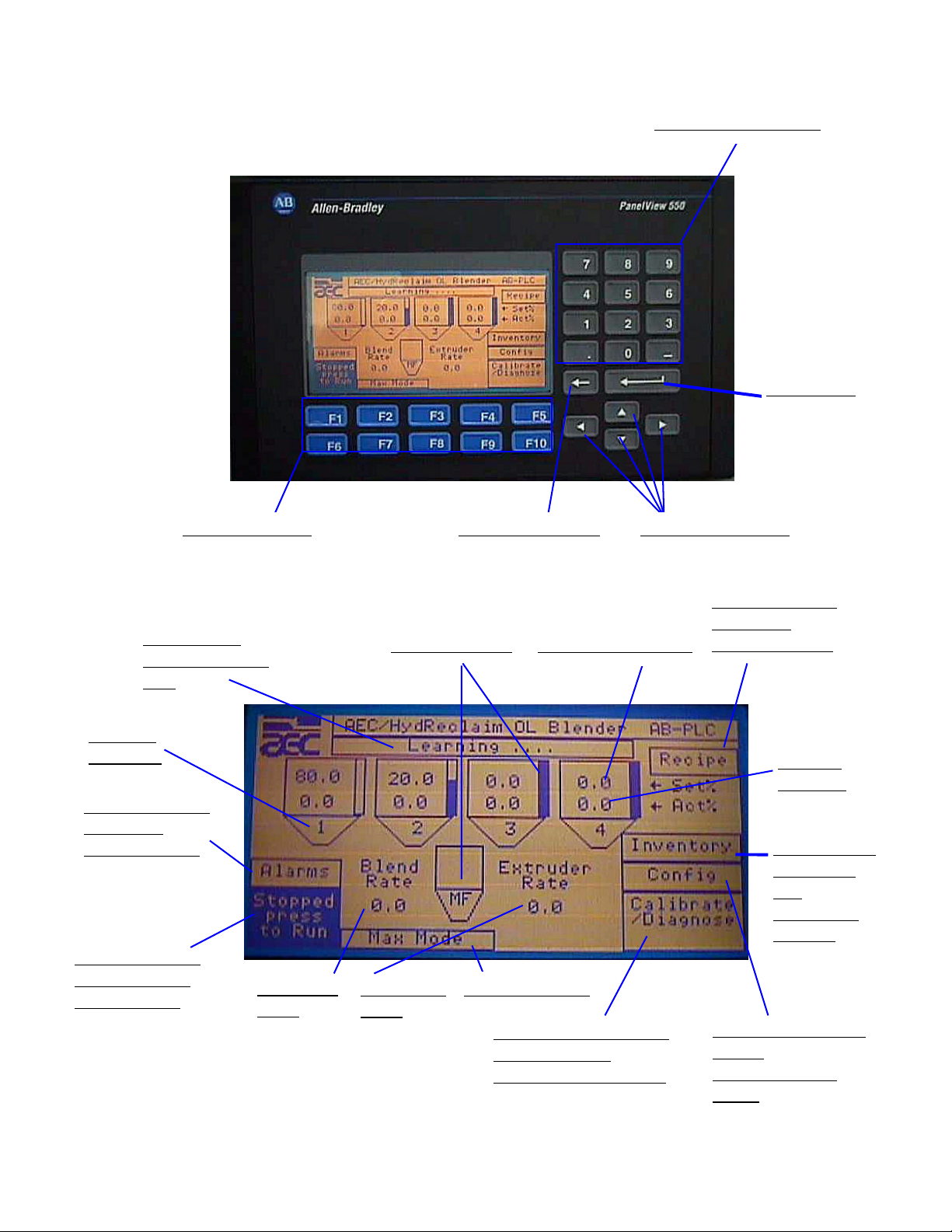

Number Entry Pad

Enter Key

Function Keys Backspace Key Directional Keys

“Learning”

extrusion rate

box

Hopper

Number

Touch here to

go to the

Alarms Page

Touch here to

Start or Stop

the Blender

Blending

Rate

Hopper Level

Extrusion

Rate

Recipe Setpoints

Blender Mode

Touch here to go to

the Calibrate

&Diagnostics Page

Touch here to

go to the

Recipe Setup

Recipe

Actuals

Touch here

to go see

the

Inventory

Report

Touch here to go

to the

Configuration

Page

Page 2 of 20

Page 4

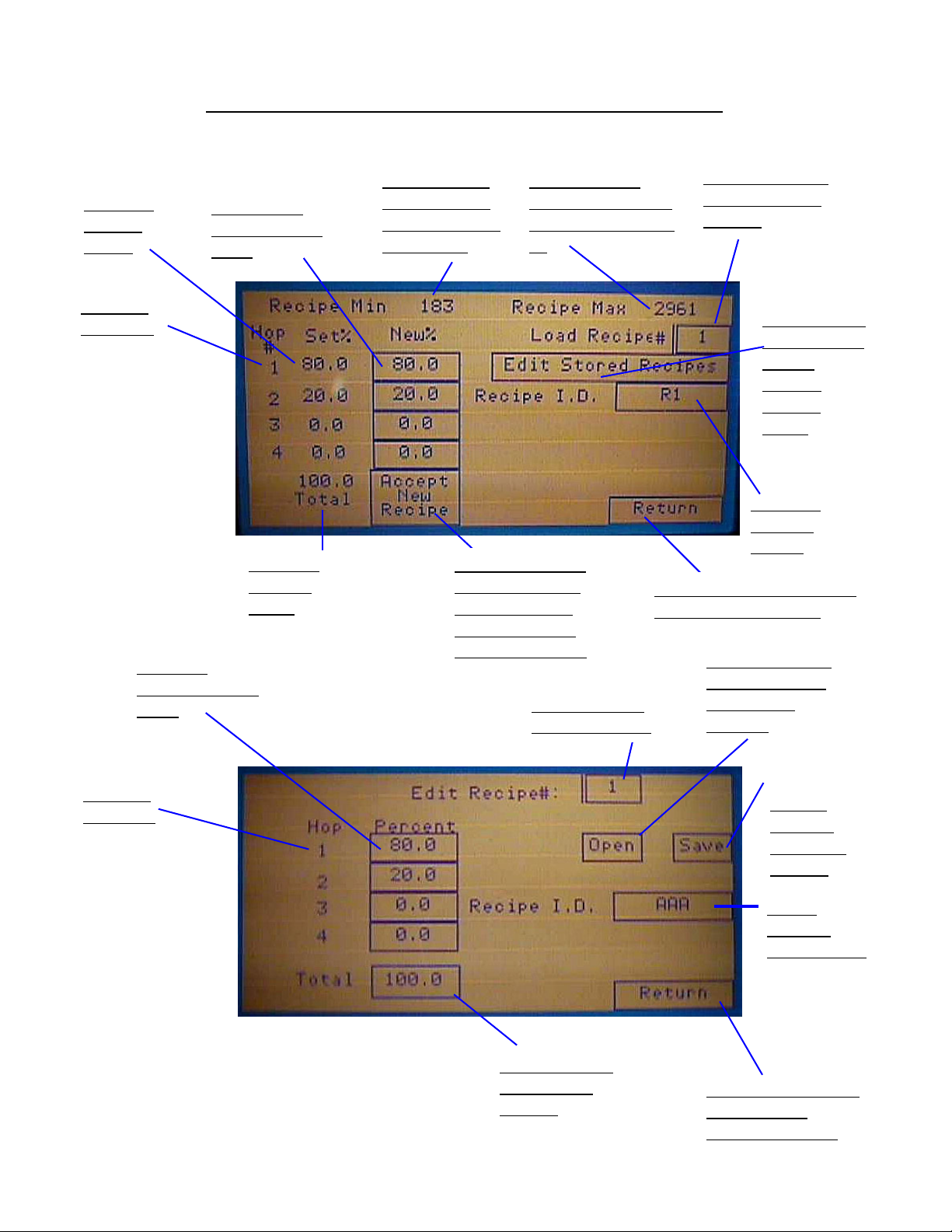

The “Recipe” and “Edit Recipe” Pages

Current

recipe

value

Hopper

Number

Enter in

recipe values

here

Enter new

recipe value

here

Current

Recipe

Total

Min rate the

blender can

run the given

recipe at

After you have

entered in the

“new” recipe

values, touch

here to accept

Max rate the

blender can run

the given recipe

at

Touch here to go back

to the “Main” page

Enter recipe

Number here

Touch here to

load a stored

recipe

Touch here

to go to the

“edit”

stored

recipe

page

Current

Recipe

Name

Touch here to

open a saved

recipe for

editing

Hopper

Number

Recipe Total

of entered

recipe

Touch

here to

save the

recipe

Enter

Recipe

Name here

Touch here to go

back to the

“Recipe” page

Page 3 of 20

Page 5

f

The “Inventory Report” and “Alarms” Pages

Report time

Accumulated

Hopper

Inventory

and date for

inventories

Machine name

or the report

Hopper

Number

Inventory Total

of entire

blender

Alarm log of

all alarms

with date and

time

Touch here to

clear all

inventories

Touch here

to go back

to the

“Main”

page

Touch here to print

the report

Touch

here to

scroll

through

the alarms

Touch

here to

print the

alarms

Touch here to

clear the

alarm log

Touch here to

acknowledge

all alarms

Touch here to go

back to the

“Main” page

Page 4 of 20

Page 6

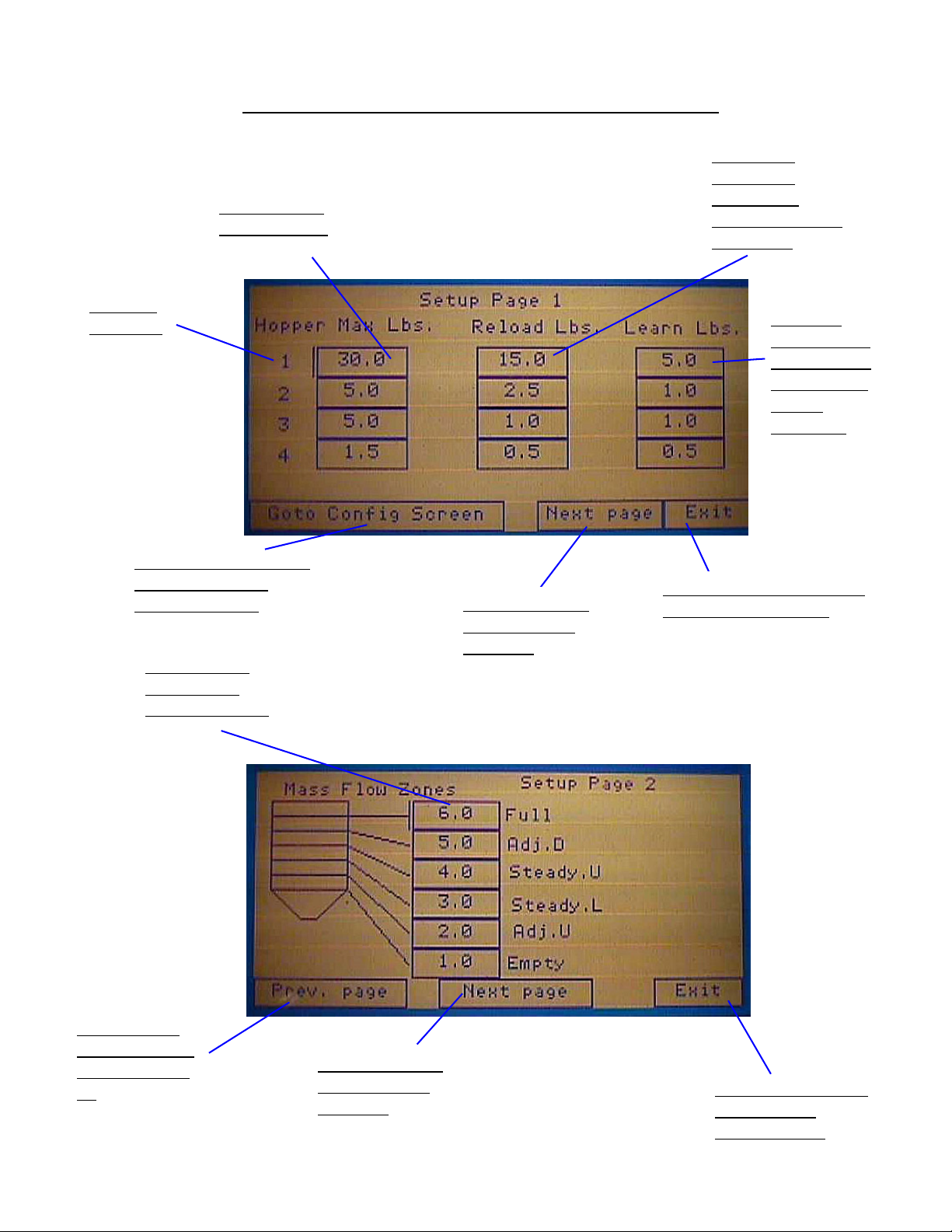

The “Blender Configuration” Pages

Enter in the

Hopper size

Enter the

weight at

which the

hopper should

reload at

Hopper

Number

Touch here to go to

the Panel View

Configuration

Enter in the

Mass Flow

hopper zones

Touch here to

go to “Setup

Page 2”

Enter in

the sample

size for the

weight per

count

learning

Touch here to go back

to the “Main” page

Touch here

to go back to

“Setup Page

1”

Touch here to

go to “Setup

Page 3”

Touch here to go

back to the

“Main” page

Page 5 of 20

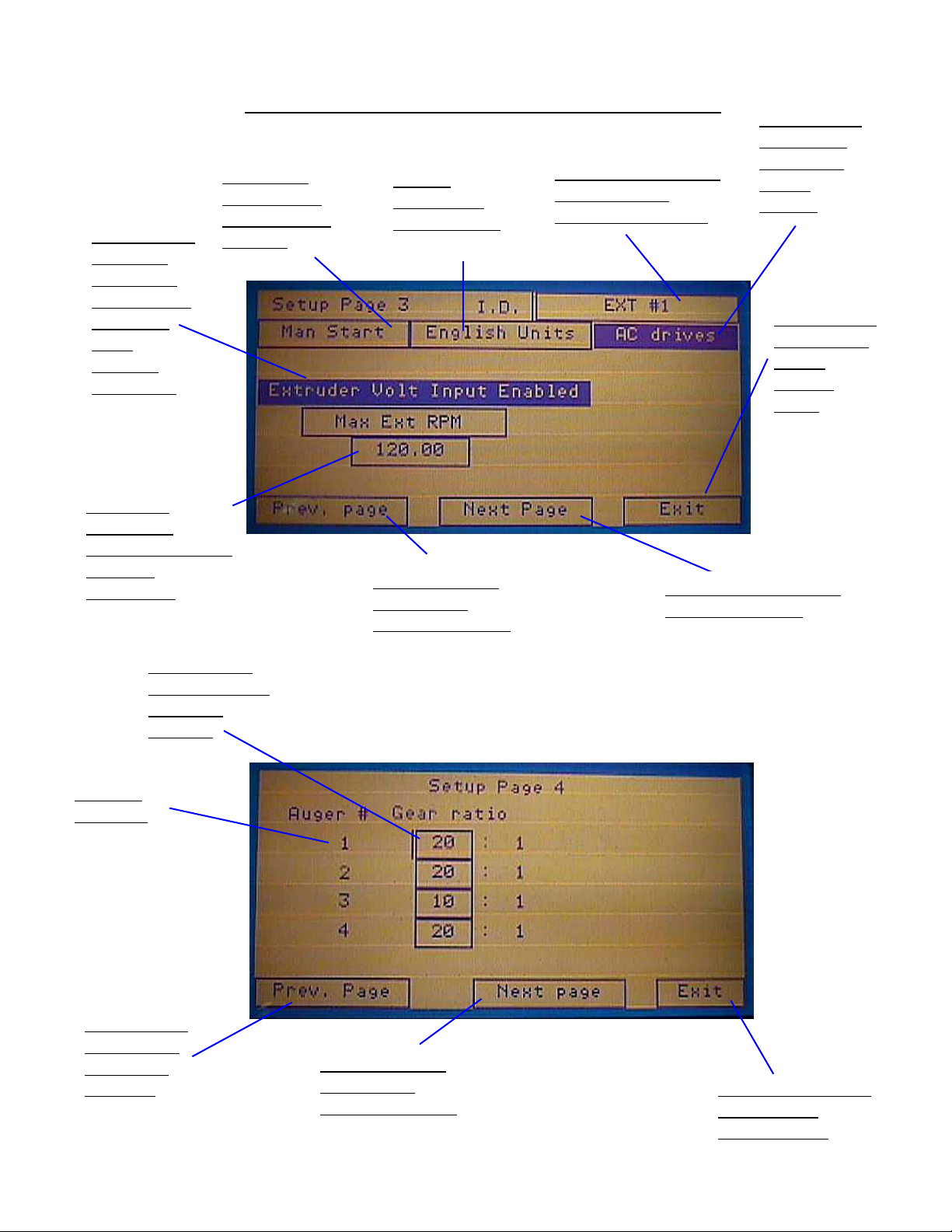

Page 7

f

Touch here

f

f

to either

enable or

disable the

extruder

RPM

voltage

eedback

Enter the

maximum

extruder RPM at

10Volts

reference

The “Blender Configuration” Pages

Enable or

disable the

“Auto Start”

eature

Select

English or

Metric units

Touch here to

go back to

“Setup Page 2”

Enter the machine

name for the

Inventory Report

Touch here

to specify

either AC

or DC

Drives

Touch here

to go back

to the

“Main”

page

Touch here to go to

“Setup Page 4”

Enter in the

gearbox ratio

or each

hopper

Hopper

Number

Touch here

to go back

to “Setup

Page 3”

Touch here to

go back to

“Setup Page 5”

Touch here to go

back to the

“Main” page

Page 6 of 20

Page 8

Alarm

Name

The “Blender Configuration” Pages

Enable or

disable the

“Shutdown”

procedure for

the given

alarm

Touch here to

go back to

“Setup Page 4”

Enter in the “Calibrate

and Diagnostics”

access password. “0”

disables this function.

Touch here to go back

to the “Main” page

Page 7 of 20

Page 9

The “Diagnostics” Pages

Touch here to go

to the “Auger

Calibration” page

Touch here

to go to the

“Check

Motors”

page

Touch here to go to

the “Extruder

Calibration” page

Touch here to go

to the “Load

Cell” calibration

page

Disable or Enable the

loading of the hoppers

Touch here

to go back

to the

“Main”

page

Hopper

Number

Enter the

calibration

weight

size.

Touch here

once you

have emptied

the hopper

Touch here after

you place the

test weight on

the hopper

Touch here to go back

to the “Diagnostics

Main” page

Page 8 of 20

Page 10

f

The “Diagnostics” Pages

f

Accumulated

Hopper

Inventory

Enter in the

hopper

number

Calculated

max rate for

auger

Enter in the

calibration

sample size

Instructions

Calculated

min rate for

auger

Touch here to

begin the

calibration

Enter the

speed from 0100 percent

or the auger

Hopper

Number

Touch here to

abort the

calibration

Enter in

the

calibration

speed

Accumulated

Weight for

calibration

Touch here to go back

to the “Diagnostics

Main” page

Touch here

to change

the mode

rom

“Normal” to

“Test”

Instructions

Touch here to go

back to the

“Diagnostics Main”

page

Page 9 of 20

Page 11

f

The “Diagnostics” Pages

255 second

counter for

steady zone

30 second

buffer counter

or averaging

the extrusion

weight per

count

Remote

“Steady

Flag”

Indicator

Indication of

extruder RPM

conditions

Indication of

whether or not the

current throughput

information is being

buffered for the

extruder weight per

count ratio

Instantaneous

extruder

information

Touch here

to go back

to the

“Diagnosti

cs Main”

page

Extruder

throughput and

rpm values that

were used for

the last ratio

calibration

Page 10 of 20

Page 12

The “Panel View Configuration” Pages

f

Language

Selection

Select

Configuration

Options

Touch here to go

back to Normal

Operation

Enter in

the Baud

Rate for

the Panel

View

Reset for

Video Screen

Panel View

Fault

Indicator

Communications from

PLC to Panel View

Indicator

Enter in the Node Address

or the Panel View

Touch here

to go back

to the

“Panel

View

Configurati

on Main”

page

Communications from

PLC to Panel View

indicator

Panel View fault

indicator

Page 11 of 20

Page 13

The “Panel View Configuration” Page

Data

Accumulated

Hopper

Inventory

Package

Setup

Baud Rate for

Printer Port

Handshaking

selection for

printer

Print format

selection

Touch here to

go back to the

“Panel View

Configuration

Main” page

Touch here to enable or

disable the printer, it

must be disabled if you

are downloading to the

panel view

Page 12 of 20

Page 14

The SLC500 Cards

Processor

Card

Power Supply

Power Indicator

Key Selector for

CPU “Mode”,

should be in

“Remote”

position.

Communications Indicators

Thermocouple

Card for

Loadcell Inputs

Analog Output

card for auger

drive

reference

signals

Digital Input

Card for

auger prox

inputs

Digital Output

Card for

loading valve

signals

Analog Input

Card for

Extruder RPM

voltage input

Page 13 of 20

Page 15

The Panel connections

Connector to Blender Drive Panel

Panel View 550

Loadcell

connectors

Panel View

Communications (DF1)

and Power Cable

SLC 500

5/04 64k

Page 14 of 20

Page 16

Downloading and Uploading to the SLC 500 PLC

t

t

Tools Needed: laptop or PC with “Rockwell Automation/ RSLogix 500” installed and

activated. When activating after you have installed the RSLogix 500 software you will

need to insert the “Token” disk that comes with the RSLogix 500 software. This disk is

“backed-up” on the server using a program called “WINDUPE”. The disk can only be

used on one computer (single license). For more information on installation see the

RSLogix 500 software package.

You will also need a standard straight thru serial cable (DB9 on each end) and a “Null”

modem converter that will plug into the cable and then to the SLC 500. The “Null”

modem converter can be made by getting 2 DB9 connectors and soldering pins 5-5, 2-3,

and 3-2.

COM Por

Straight Thru Serial

Cable

Null Modem

SLC 500

RS232 Por

of SLC 500

Downloading and Uploading Steps

Step 1: The first step is that you have to setup the communications drivers for

RSLinx. From the laptop run “Rockwell Software/RSLinx/RSLinx”. Then go under

“Communications”, then go to “Configure Drivers”. Delete all drivers listed under

“Configured Drivers” by highlighting the driver listed and the clicking “Delete” (you will

not be able to delete a “virtual” link driver). Now select “RS-232 DF1 Devices” under

“Available Drivers” and click “Add”. When the configuration screen appears click “Auto

Configure”, this will look for the SLC 500 through the cable link and will automatically

configure the driver. In the future if you change the Node Address of the SLC 500 you

will need to go back to this page and re-click the “Auto Configure” button. You can get

to this page by double-clicking the “RS-232 driver” listed under “Configured Drivers”.

Once the “Auto Configure” has been successfully completed then you will be able to

upload and download to the SLC 500. Remember to leave the RSLinx running.

Step 2: The first step whenever you are working with a SLC 500 that does have a

program in it (at a customer’s site) is to upload and save the program that is currently in

the SLC 500. That way you can download this original program back to the SLC 500 in

case of a problem with the new software you intend to download. Before proceeding be

sure to go to the panel view and write down all of the configuration settings so that you

can reprogram the unit when you are done downloading. If prompted for a password on

the panel view, we use 2 passwords, “5413” and “3145348”.

To upload the existing program from the customer’s SLC 500 to your laptop first run

“Rockwell Software/RSLogix 500/RSLogix 500”. Once the program is running go under

“Comms” and select “Upload”. Follow the instructions. Once the upload is complete go

under “File” and save the project into a directory that you have made in WIN95.

Page 15 of 20

Page 17

Downloading and Uploading to the SLC 500 PLC

t

f

Step 3: Whenever you are ready to download the new software, close the files that you

currently have on the RSLogix 500 program and then open the new files from wherever

you have stored them. You always want to open the file named “blend_4.RSS” or

“blend_8.RSS” found under “PLC Projects/AB OL Software/Standard”. Once the new

program is open, go under “Comms” and select “Download”. Follow the instructions.

After the program downloads you will be prompted “Put the PLC back into “RUN” mode”,

answer yes to this. This completes downloading and uploading to the SLC 500. Be sure

to reconfigure the SLC 500 blender setup parameters using the SLC 500. Then

recalibrate the load cells, and run an “auger calibration” for each hopper.

Downloading and Uploading to the Panel View

Tools Needed: Laptop with both RSLogix installed as described before and “Panel

Builder” installed. Panel Builder software does not use a “Token” disk to protect against

multiple installations (however you are legally only allowed to install this software to one

computer). For more information on installation see the Panel Builder software package.

You will also need one standard straight thru serial cable to connect between the com

port on the laptop and the RS-232 port of the Panel View.

COM Por

Straight Thru Serial

Cable

RS232 Port o

Panel View

Panel View

Step 1: The first step is that you have to setup the communications drivers for

RSLinx. From the laptop run “Rockwell Software/RSLinx/RSLinx”. Then go under

“Communications”, then go to “Configure Drivers”. Delete all drivers listed under

“Configured Drivers” by highlighting the driver listed and the clicking “Delete” (you will

not be able to delete a “virtual” link driver). The Panel Builder software uses it’s own DF1

driver and therefore you cannot have any drivers configured under the RSLinx software

or it won’t work. Be sure though to leave the RSLinx software running.

Step 2: The Panel View software program for the Allen Bradley OL-470 has the

printer port enabled in the software. This allows the customer to print reports from this

port. However, whenever you are uploading or downloading you must use this port for

communications and not printing. To set this up you will need to go to the “Panel View

Configuration” page, then “Printer Setup”, and then disable the printer port under “Port

Mode”. Once you have done this touch “Exit” and the touch “Run Mode” (this places the

Panel View back into normal operation mode). To get to the “Panel View Configuration”

page go to the Panel View and hold both the left and right arrows on the keypad. This will

bring up the configuration page for the Panel View System.

Page 16 of 20

Page 18

Downloading and Uploading to the Panel View

Step 3: If the existing Panel View already is running software (customer’s site), then

you will first need to upload and save this to a directory of your choice. That way if you

have any problems with the new software then you will be able to download the old

software back into the unit. If you are only changing the Panel View software and not the

SLC 500 software then you do not have to right down all of the “Setup” parameters for

the blender. These parameters will automatically be loaded into the panel view from the

SLC 500 once you have completed the download. To upload the existing software from

the panel view to your laptop first run “Panel Builder/Panel Builder”. Do not run the

“Application file Transfer Utility!!!!”. Once Panel Builder is running go to “Application”

and select “Upload”. When the upload is complete save the file onto the laptop into the

directory of your choice. Typically label it “Onsite “date”” and name the folder the

customer’s name. After this is done you will be ready to download the new software to

the panel view.

Step 4: Close any files that are currently open in panel builder and then open the

new software file (“4_comp.pba” or “8_comp.pba”, that is found under “PLC Projects/ABOL Software/Standard”). WHENEVER PROMPTED SELECT “REPLACE ALL” AND “ADD

ALL”. Once the file is open then go under “Applications” and select “Download”. Follow

the Instructions. When this is complete the Panel View will reboot automatically and

should come up in normal operation mode. This completes the uploading and

downloading of Panel View Software.

Page 17 of 20

Page 19

Remote DH+ Addressing

Purpose

This allows an OEM to connect a DH+ link to the AB OL blenders and communicate data

and set points. The blender can remotely be controlled as the OEM designs his custom

screens. The following are the AB DH+ addressing for all available data. The Node

Address for the SLC500 defaults to 10, the Node Address for the PanelViews defaults to

11. To change these addresses go online to the unit and modify these settings at the

unit. The original code that comes from AEC/HydReclaim will not be set up for the OEM’s

custom addresses and must be modified by the OEM or customer.

Addresses and Explanation of use

Machine Name — ST99:0.2 — Read/Write — Name of machine (example: “Ext 1”)

Blender Units — N11:0/0 — Read/Write — Maintained — 0 is metric, 1 is standard

Blender Mode — N11:2/0 — Read/Write — Maintained — 0 is set when the blender is

stopped, 1 is set when the blender is running.

Blender Alarm Active — 0:2/15 — Read Only — 0 is no alarms, 1 is alarm active

Acknowledge and Clear all alarms — N11:31 — Read Only — write a momentary 1 to

clear all alarms and turn off the alarm horn, this will delete the alarms so you should read

each alarm bit to determine what the alarm is before giving the option to clear the

alarms.

Hopper 1 Hopper 2 Hopper 3 Hopper 4 Mass Flow Hopper

Reload too long N11:11/0 N11:11/1 N11:11/2 N11:11/3 N/A

Out of Material N11:9/0 N11:9/1 N11:9/2 N11:9/3 N/A

No Material Flow N11:10/0 N11:10/1 N11:10/2 N11:10/3 N/A

Scale Exceeded N11:6/1 N11:6/2 N11:6/3 N11:6/4 N11:6/9

Loadcell Failure N11:12/0 N11:12/1 N11:12/2 N11:12/3 N11:12/8

Motor Failure N11:13/0 N11:13/1 N11:13/2 N11:13/3 N/A

Loading Enabled — B3:3/6 — Read/Write — Maintained — 0 is set to disable the loading

of the weigh hoppers, 1 is set to enable the loading of the hoppers.

Hopper Data — Read Only, see below for addresses

Hopper 1 Hopper 2 Hopper 3 Hopper 4 Mass Flow

Hopper is Loading N10:11/0 N10:11/1 N10:11/2 N10:11/3 N/A

Hopper Weight F9:1 F9:2 F9:3 F9:4 F9:10

Hopper % Full F9:221 F9:222 F9:223 F9:224 F9:41

Motor Speed in % F9:21 F9:22 F9:23 F9:24 N/A

Page 18 of 20

Page 20

Remote DH+ Addressing

f

Blender Total Rate — F9:90 — Read Only — total rate that all the augers are running at,

this is not the extrusion rate

Extrusion Rate — F25:1 — Read Only — the rate at which the extruder is taking away the

blended material

Stable Extrusion Flag — B3:3/1 — Read Only — this flag is set once the blender

accurately learns the extrusion rate. This flag should be read before using the

“Extrusion Rate” data described above, if this flag is set to “0” then the OEM should use

previous relationships for extrusion rate per RPM. This relationship can be developed

using the “Stable Extrusion Flag”, “Extrusion Rate”, and the current extruder RPM. Once

this relationship has been developed it should be stored by the OEM.

Extruder RPM — F9:29 — Read Only — available only if “Extruder RPM Voltage

Reference” is enabled (the customer supplies the blender with a 0-10 Volt/4-20 mA signal

that references drive speed, usually this can be taken from the drive itself and is

recommended if the customer plans to use the “Extrusion Rate” information for extrusion

control calculations.

Extruder RPM Voltage Reference — N11:0/1 — Read/Write — Maintained — when set to 1

this instructs the blender to use a 0-10V/4-20 mA signal to calculate extruder RPM. This

is then used by the blender to develop and buffer the relationship between extrusion rate

and extruder RPM. This should always be used when the customer is planning on using

the “Extrusion Rate” information for extrusion control calculations.

Maximum Extruder RPM — F9:180 — Read/Write — only used if the “Extruder RPM

Voltage Reference” is enabled, use this to adjust the displayed “Extruder RPM” value of

the blender. If the displayed RPM is too low then increase this value, if it’s too high then

decrease this value.

User Password — N11:35 — Read/Write — only used when the operator is accessing the

“Calibration/Diagnostics” page from the Panel View. If set to “0” then no password will

be necessary for the operator to calibrate the blender from the Panel View.

Handling the blender recipe — the current blender recipe that is running in the blender

can be read without any special procedure. In order for the OEM to properly change the

recipe remotely they will need to complete a procedure in the proper order and examine

certain addresses to ensure that the recipe that the operator enters is accepted. This

procedure is already handled at the Panel View, but if you wish for the operators to be

able to enter in the blender recipes at the OEM screen then this procedure must be

ollowed.

Reading the current running recipe (Read Only!)

Hopper 1 Hopper 2 Hopper 3 Hopper 4

Set % F9:91 F9:92 F9:93 F9:94

Actual % F9:171 F9:172 F9:173 F9:174

Lowest Rate at which the blender can run the current recipe: F9:40

Highest Rate at which the blender can run the current recipe: F9:39

Page 19 of 20

Page 21

Remote DH+ Addressing

f

Writing the current running recipe

Step 1: Write all new recipe set percentages to the “new” recipe location

Hopper 1– F101:0, Hopper 2– F102:0, Hopper 3– F103:0, Hopper 4– F104:0

Step 2: (optional) Read back in these same addresses to ensure that they made it to the

correct place, this can be done simply by displaying in a different box these values for

the operator to see.

Step 3: Read N11:2/15 to ensure that the recipe adds to “100”, this will be set if the new

recipe does not equal 100, and therefore the new recipe will not be accepted until it

does. Show the operators a message for this.

Step 4: Read B3:3/4 to see if the “New” recipe is ready for acceptance. Once this bit is

set then give the operators a button to “Accept New Recipe”. If this bit is not set the

operator should not be able to accept the new recipe.

Step 5: Write a “1” to B3:8/0 to accept and transfer the new recipe.

Step 6: Read B3:4/0 to see if the blender cannot run the recipe that you have

transferred. If this bit is set then read the following addresses to determine why the

recipe was not transferred.

Hopper 1 Hopper 2 Hopper 3 Hopper 4

Cannot Achieve Low Rate N11:8/0 N11:8/1 N11:8/2 N11:8/3

Cannot Achieve High Rate N11:7/0 N11:7/1 N11:7/2 N11:7/3

Step 7: Be sure to continuously display the “Set %” as described before under “Hopper

Data”. This will give the operators an understanding that the “New” recipe that they

have entered was accepted and transferred.

The reason that a given recipe cannot be ran by the blender is that the blender is

designed to run each motor within its designed range (3-98 % of motor speed). This

ensures overall blending accuracy and performance, but is generally the most difficult

topic for someone new to gravimetrical blending to comprehend. Each hopper has a

minimum throughput and a maximum throughput that is continuously updated. The

ollowing data in conjunction with the given recipe is used to calculate the “Blender Min

Rate” and the “Blender Max Rate”. These values are related to material density, gear

box ratio of the hopper, and the auger size of the hopper. If a different range is desired

contact AEC/HydReclaim for help.

To examine the range for a given hopper first write the desired hopper number to N11:4

Then the minimum throughput for that hopper can be read from F9:150

Also the maximum throughput for that hopper can be read from F9:140

This concludes all remotely accessible DH+ addresses and integration

Page 20 of 20

Loading...

Loading...