AEC NEC Central Station Air and Water Cooled Chiller User Manual

$30.

00

Operation and Installation Manual

NEC Series

Water- and Air-Cooled

Central Chillers

Important! Read Carefully Before Attempting to Install or Operate Equipment

Part No. A0537138 Bulletin No. AE3-605A

Performance figures stated in this manual are based on a standard atmosphere of 59°F

(15°C) at 29.92” Hg (1,014 millibars) at sea level, using 60 hz power. Altitude is an

important consideration when specifying chillers. AEC/Application Engineering can

advise you on proper selection and sizing of systems for your operating environment.

AEC/Application Engineering is committed

to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual

are subject to change without notice.

© Copyright AEC/Application Engineering and AEC, Inc. 2008

All rights reserved. Effective 3/14/2008

Part No. A0537138 Bulletin No. AE3-605A.3

Page 2 NEC Series Water- and Air-Cooled Central Chillers

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Safety Considerations

AEC/Application Engineering NEC Series central chillers are designed to provide safe and

reliable operation when installed and operated within design specifications, following national

and local safety codes. To avoid possible personnel injury or equipment damage when installing,

operating, or maintaining this equipment, use good judgment and follow these safe practices:

; Follow all SAFETY CODES.

; Wear SAFETY GLASSES and WORK GLOVES.

; Use care when LOADING, UNLOADING, RIGGING, or MOVING this equipment.

; Operate this equipment within design specifications.

; OPEN, TAG, and LOCK ALL DISCONNECTS before working on equipment. It’s a good

idea to remove the fuses and carry them with you.

; Make sure the chiller is properly GROUNDED before switching on power.

; When welding or brazing in or around this equipment, be sure VENTILATION is

ADEQUATE. PROTECT adjacent materials from flame or sparks by shielding with sheet

metal. An approved FIRE EXTINGUISHER should be close at hand and ready for use if

needed.

; The refrigeration system can develop refrigerant pressures in excess of 500 psi. DO NOT

CUT into the system without first relieving pressure.

; Do not jump or bypass any electrical safety control.

; Do not restore power until all tools, test equipment, etc. have been removed and the panels

replaced.

; Only PROPERLY TRAINED personnel familiar with the information within this manual

should work on this equipment.

NEC Series Water- and Air-Cooled Central Chillers Page 3

Table of Contents

1 General Information .................................................7

1-1 Introduction

1-2 Necessary Documents

1-3 Models Covered

1-4 Available Options

1-5 Incorrect Shipment

2 Shipping Information................................................9

2-1 Unpacking and Inspection

2-2 In the Event of Shipping Damages

2-3 If the Shipment is Not Complete

2-4 If the Shipment is Not Correct

2-5 Returns

2-6 Uncrating

3 Installation...............................................................13

3-1 Electrical Connections

3-2 Process Water Connections

3-3 Water Connection Sizing

3-4 Galvanic Corrosion

3-5 Water Treatment

3-6 Water-Cooled Condenser Water Connections

3-7 Air-Cooled Condenser Installation

3-8 Motor Direction Check

4 Sequence of Operation .........................................29

4-1 Chilled Water Circuit

4-2 Refrigeration Circuit

4-3 Freezestat Control

4-4 Crankcase Heater

4-5 High Pressure Cutout

Page 4 NEC Series Water- and Air-Cooled Central Chillers

Table of Contents

4 Sequence of Operation ..................................Cont’d.

4-6 Low Pressure Cutout

4-7 Oil Pressure Safety Switch

4-8 Flow Switch

4-9 Remote Start/Stop Interlock

4-10 Control Nipple

4-11 Control Probe

4-12 Hot Gas Bypass (Optional)

4-13 Chilled Water Manifold (Optional)

4-14 Condenser Water Manifold (Optional)

5 Startup Checklists..................................................35

5-1 Introduction

5-2 Water-Cooled NECW Startup Checklist

5-3 Water-Cooled NECW Chiller Startup

5-4 Air-Cooled NECR Startup Checklist

5-5 Air-Cooled NECR Chiller Startup

6 Graphic Panel..........................................................39

6-1 Indicator Lights

6-2 Switches

7 Routine Maintenance .............................................45

7-1 Lubrication

7-2 Condenser Maintenance

7-3 Evaporator Maintenance

7-4 Preventive Maintenance Service

8 Troubleshooting Checklist ....................................55

NEC Series Water- and Air-Cooled Central Chillers Page 5

Charts and Figures

1

NECW Water-Cooled Chiller Design Specifications 8

2

NECR Air-Cooled Chiller Design Specifications 9

3

One Circuit Dimensions Components and Clearances 10

4

Two Circuit Dimensions Components and Clearances 11

5

Three Circuit Dimensions Components and Clearances 12

6

Typical Air-Cooled Condenser Packages 13

7

Remote Air-Cooled Condenser Dimensions 14

8

Evaporator GPM Pressure Drop Curves 16

9

10

11

12

13

14

15

16

17

18

Condenser GPM Pressure Drop Curves 17

Typical Remote Air-Cooled Condenser Piping Installation 20

One Circuit One Pump Piping Schematic 21

One Circuit Two Pump Piping Schematic 21

One Circuit No Tank Piping Schematic 22

One Circuit No Pump No Tank Piping Schematic 22

Freezing Protection Curve 24

Typical Graphic Panel 30

Typical Subpanel Layouts 33

Typical NEC Chiller Electrical Schematic 34

Page 6 NEC Series Water- and Air-Cooled Central Chillers

1 General Information

1-1 Introduction

AEC/Application Engineering NEC Series Central Water Chillers are available in water-cooled

(NECW) and remote air-cooled (NECR) designs. They differ only in the condensing media used.

NEC units can be configured with one, two, or three independent circuits using 10 to 60 hp

compressors for each circuit.

This manual describes single-circuit NEC units. References are made to multiple circuit units as

needed.

A properly installed, operated, and maintained NEC chiller will provide many years of reliable

operation. To get the most satisfaction from your new chiller, read and follow the

instructions in this manual.

1-2 Necessary Documents

These documents are necessary for the operation, installation, and maintenance of AEC/

Application Engineering NEC chillers. Additional copies are available from AEC, Inc.

Familiarize the appropriate personnel with the following documents:

• This manual.

• The schematic and connection diagram in the control enclosure.

• Operation and installation manuals for accessories and options selected by the customer.

• The Customer Parts List included in the information packet.

1-3 Models Covered

Model numbers are listed on the chiller serial tag. A Q following the model number indicates a

specially constructed unit; not all information in this manual may apply. Please know the model

number, serial number, and operating voltage of your chiller if you need to contact AEC, Inc.

NEC chiller models are designated by the number of refrigeration circuits, total compressor

horsepower of all circuits (10 through 180), and the cooling method used. Air-cooled models are

designated

cooled NEC with three 10 hp compressors is designated as

NECR and water-cooled models are designated NECW. For example, a 3-circuit air-

NECR-3-30.

NEC Series Water- and Air-Cooled Central Chillers Page 7

NECR-2 and NECR-3 chillers with an A suffix are supplied with alternate remote air-cooled

condenser selections. See Figure 7 – Remote Air-Cooled Condenser Dimensions on Page 14 for

more information.

1-4 Available Options

NEC chillers are available with options to tailor the unit to your requirements. Some are factory

installed and some can be retro-fitted in the field. Consult your sales representative for more

information.

Operating Voltages

NEC chillers are available configured for 208/230-3-60, 380/415-3-50, 460-3-60,

515-3-50, and 575-3-60 volts.

Cooling Ranges

NEC chillers are offered in two cooling ranges. Standard chillers using R-22 refrigerant are used

with 30°F (-1ºC) to 65°F (18ºC) leaving water temperature processes. Low-temperature R-22

units are available for use with leaving water temperatures below 30ºF (-1ºC). Please note that

the temperature scales on the control panel exceed these ranges, but optimum operation is

achieved within the stated ranges.

Special Manifolds

Chilled water and condenser water supply and return manifolds are available in both steel and

plastic pipe.

Hot Gas Bypass

A hot gas bypass system is offered for processes with low cooling loads.

Lead-Lag Control

Lead-lag controls, available on NEC-2 and NEC-3 chillers, allow the operator to distribute

service time between compressors.

Gauge Option

Factory-installed thermometers and pressure gauges on the evaporator inlet(s) and outlet(s)

facilitate flow balancing.

Low Voltage Monitor

An auto-reset low voltage monitor protects the compressor and control circuit from potentially

damaging brownout conditions.

Page 8 NEC Series Water- and Air-Cooled Central Chillers

2 Shipping Information

2-1 Unpacking and Inspection

You should inspect your AEC/Application Engineering NEC Series central chiller for possible

shipping damage. If the container and packing materials are in re-usable condition, save them for

reshipment if necessary.

Thoroughly check the equipment for any damage that might have occurred in transit, such as

broken or loose wiring and components, loose hardware and mounting screws, etc. In case of

breakage, damage, shortage, or incorrect shipment, refer to the following sections.

2-2 In the Event of Shipping Damages

Important!

According to the contract terms and conditions of the Carrier,

the responsibility of the Shipper ends at the time and place of shipment.

The Carrier then assumes full responsibility of the shipment.

; Notify the transportation company’s local agent if you discover damage.

; Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods to AEC, Inc. before the transportation company inspection and

authorization.

; File a claim against the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

; Advise AEC, Inc. regarding your wish for replacement and to obtain an RMA (return

material authorization) number.

NEC Series Water- and Air-Cooled Central Chillers Page 9

2-3 If the Shipment is Not Complete

Check the packing list. The apparent shortage may be intentional. Back-ordered items are noted

on the packing list.

You should have:

; AEC/Application Engineering NEC Series central chiller

; Bill of lading

; Packing list

; Operating and Installation packet

; Electrical schematic and panel layout drawings

; Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking. Determine that the item was not inadvertently taken from the area before you

checked in the shipment. Notify AEC, Inc. immediately of the shortage.

2-4 If the Shipment is Not Correct

If the shipment is not what you ordered, contact AEC, Inc. immediately. Include the order

number and item. Hold the items until you receive shipping instructions.

2-5 Returns

Important!

Do not return any damaged or incorrect items

until you receive shipping instructions from AEC, Inc.

Page 10 NEC Series Water- and Air-Cooled Central Chillers

2-6 Uncrating

Note: Due to the size and weight of NEC chillers, AEC, Inc. recommends using bonded

professional millwrights to unload and move NEC chillers.

Rig the chiller from the frame only, using spreader bars to prevent load transfer to any chiller

components. Rig the frame from at least four points and balance the load before lifting to clear

the skid. Lift the chiller slowly and only high enough to clear the skid. Use a pry bar to free the

skid if necessary. Lower slowly.

Use a forklift of adequate size when lifting the chiller by the fork pockets. Enter the fork pockets

from the control enclosure side. Insert the forks all the way into the pockets and be sure to

balance the load before lifting the chiller to clear the skid. Lift only as high as necessary. Use a

pry bar to free the skid if necessary. Lower slowly.

Retain the crating in case reshipment is necessary due to hidden shipping damage.

Caution!

Due to the weight of these units,

use extreme caution

when moving and placing NEC chillers.

NEC Series Water- and Air-Cooled Central Chillers Page 11

- Notes -

Page 12 NEC Series Water- and Air-Cooled Central Chillers

3 Installation

3-1 Electrical Connections

Figures 1 and 2

Check the serial tag voltage and amperage requirements and make sure your electrical service

conforms.

Bring properly sized power leads and ground from a fused disconnect (installed by your

electrician) to the unit. Use fuses in the disconnect switch, sized according to the National

Electrical Code recommendations listed on the electrical schematic in the control enclosure.

! WARNING !

• Electrical connections must comply with all applicable electrical

codes.

• The chiller must be grounded in accordance with NEC Article 250.

• Voltage must be within plus or minus ten percent (±10%) of the

nameplate rating.

• Phase imbalance must be less than 2% in accordance with NEMA

MG1-14.32.

• Air-cooled remote condensers must have properly-sized

disconnects conforming with all local codes.

NEC Series Water- and Air-Cooled Central Chillers Page 13

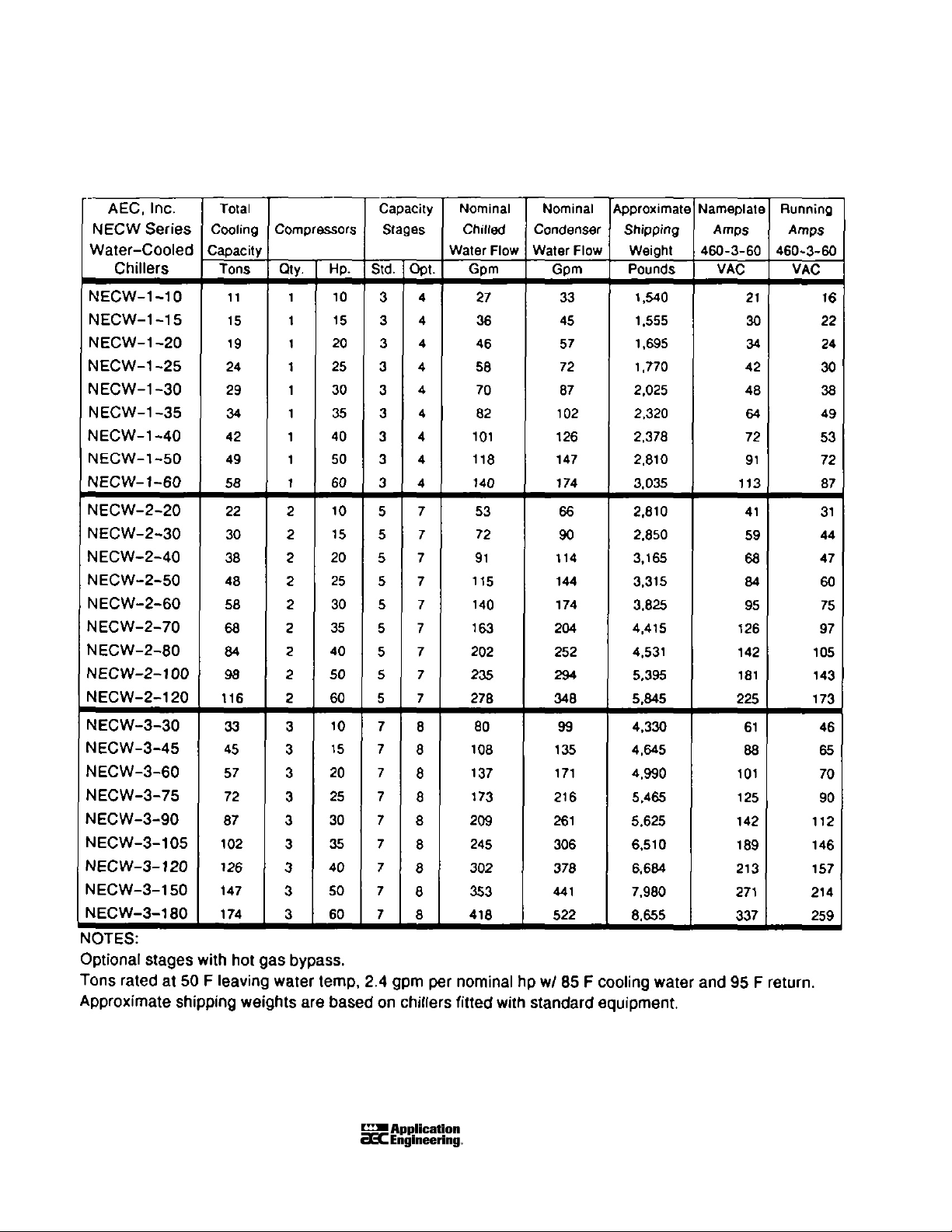

Figure 1

NECW Chiller Design Specifications

Page 14 NEC Series Water- and Air-Cooled Central Chillers

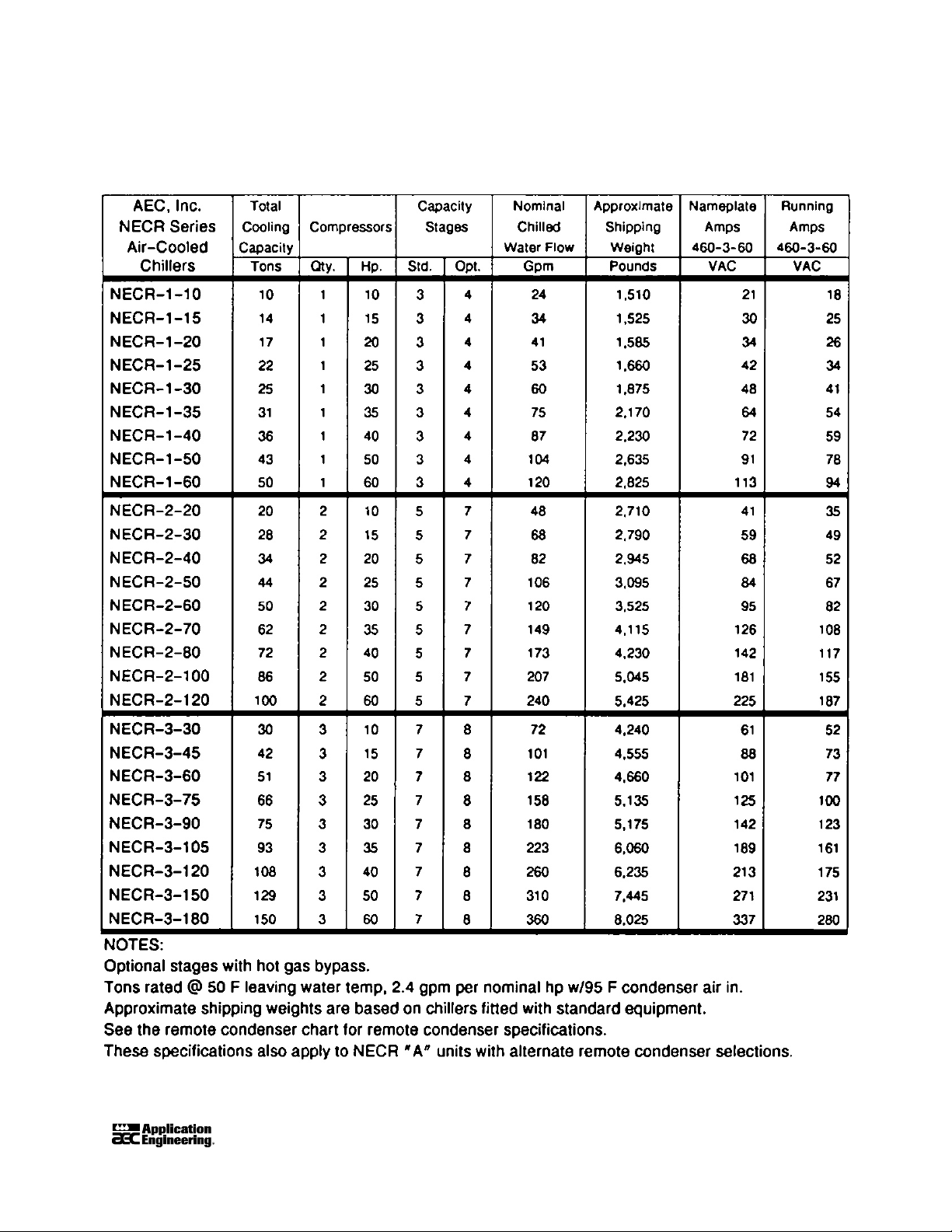

Figure 2

NECR Chiller Design Specifications

NEC Series Water- and Air-Cooled Central Chillers Page 15

Loading...

Loading...