AEC Matador 0853 Driver's Manual

BOOK

No.

IOO

j F.W.2A.

DRIVER'S

TRACTOR,

A.

E.

C.

Model

(Air

Pressure

THE ASSOCIATED EQUIPMENT CO. LTD.

HANDBOOK

FOR

4 x 4

"M

October,

A T

0853-C.1.

Assisted

MEDIUM

ADO

Engine

Hydraulic

1943.

Brakes).

·

R"

2.

FUEL

,

VENT

TANK

pIPE

Fig. 1. Arrangement

of

Chassis.

TO DRIVERS.

HIS BOOKLET is to assist you in carrying out your duties

T

of

driving

4 x 4 Medium Tractor. While every care has been taken

in the design

maximum mileage between overhauls, certain ' adjustments

and

periodical lubrication are essential to obtain this mile-

age.

sequence so that all the tasks are completed once per fortnight.

that is performing satisfactorily should not

or

it that you understand the tasks

should you notice anything which may be wrong during your

inspection, report it. Do not overlook anything.

To

16

simple tasks, which must be carried

Apart from necessary adjustments and lubrication, a vehicle

any part dismantled, as this may lead to trouble. See to

and

maintaining the A.E.C.

and

manufacture

this end, routine maintenance is divided

of

the vehic!e to obtain

and

"Matador"

out

regularly

be

tampered with

your vehicle,

into

in

and

3

If

your vehicle

ment instead

Handbook

may be identified by the servo motor mounted inside the

chassis

servo motor.

member;

is

equipped with air pressure braking equip-

of

Hydraulic, you should ask

No.

IOO/FW 1 or

air pressure brakes are

lOO

for

Driver's

j FW3. Hydraulic brakes

not

fitted with a

O.S.

4

,CONTENTS.,

General

Controls

Starting

Frost

Instructions for using

Periodical Attention (items not covered

Routine Maintenance (Sixteen Tasks)

Special Tools

Running Faults and General Hints

Lubrication Chart

Data

and

Driving Instructions '

Precautions

the

Winch

Task No. 'I- Engine

Task No. 2- Engine Lubrication

Task No. 3- Engine Cooling System

Task No. 4Task

No.

Fuel

Supply System

S~Engine

Contr~ls

,

. . 35

Task No. 6- f These Tasks do

Task No. 7Task

No. 8- Steering

l they are replaced

Task No. 9- Charging System (Electrical)

Task No.

Task No.

Task

Task

10-Sta~ter

ll

- Clutch

Motor

and

Gearboxes

and

No. 12- Transmission Universal Joints

No. 13- Chassis

and

Road

Task No. I4- Body

Task No.

IS-Brake

System

Task No. I6- Tyres and Tools

..

by

the Tasks)

, ,

not

apply to this vehicle

by-Winch.

Lights

and

Springs

Axles

fnside rear cover

Page

5

7

11

16

19

22

25

26'

28

30

31

36

37

38

39

39

42

44

45

46

54

55

57

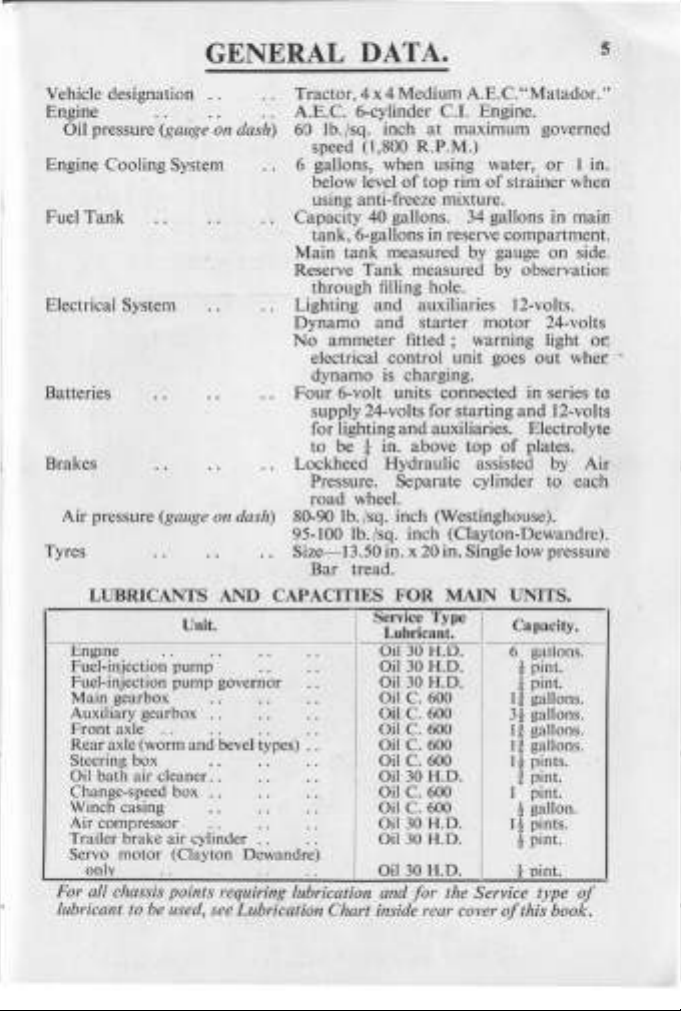

GENERAL DATA.

Vehicle designation

Engine

Oil pressure (gauge on dash)

Engine Cooling System

Tank

Fuel

Electrical System

Batteries

Brakes

Air pressure

Tyres

LUBRICANTS AND CAPACITIES

Engme

Fuel-injection

Fuel-injection pump governor

Main gearbox

Auxiliary gearbox

Front

axle

Rear

axle (worm and bevel types) . . Oil C. 600

Steering box

Oil bath air cleaner

Change-speed box

Winch casing

Air compressor

Trailer brake air cylinder

motor

Servo

only

For

all

chaSSIS

lubricant to be

..

(gauge on dash)

Unit.

. .

pump

.. . .

(Clayton Dewandre)

..

POll1ts

lIsed,

· .

· . · .

· .

· . · . · .

..

· . · .

..

· .

· . · .

· . · .

· .

· .

· . · .

..

requiring lubrication and for the Service type

see Lubrication Chart inside rear cover

Tractor,

Medium A.E.

C."Matador."

4x4

A.E.C. 6-cylinder C.l. Engine.

60 lb./

sq. inch

(1,800 R.P.M.)

speed

6 gallons, when using water,

below level

at

maximum governed

of

top

rim

of

or

I in.

strainer when

using anti-freeze mixture.

Capacity

40 gallons. 34 gallons in main

tank, 6-gallons in reserve compartment.

tank

Main

Reserve

measured by gauge

Tank

measured

by

observation

on

side.

through filling hole.

and

Lighting

Dynamo

No

ammeter

electrical control unit goes

auxiliaries 12-volts.

and

starter

fitted;

warning light

motor

24-volts

out

wher -

o(

dynamo is charging.

Four

6-volt units connected in series

supply 24-volts for starting

and

for lighting

t in. above

to be

auxiliaries. Electrolyte

top

and

of

Lockheed Hydraulic assisted

plates.

to

12-volts

by

Air

Pressure. Separate cylinder to each

road

wheel.

80-90 lb./sq. inch (Westinghouse).

95-100 lb. /sq. inch (Clayton-Dewandre).

Size- 13.50 in. x

20 in. Single low pressure

Bar tread.

FOR

..

· .

· .

..

· .

· .

..

· .

Service Type

--

MAIN

Lubricant.

Oil

30

H.D.

OiI30H

Oil 30 H.D.

Oil C. 600

Oil C. 600

Oil C. 600

Oil C. 600

Oil

Oil C. 600

Oil C. 600

Oil

Oil

OiI30H.D.

30

30

30

.D.

H.D.

H.D.

H.D.

UNITS.

Capacity.

gallons .

6

!

pint.

t pint.

If

gallons.

3!

gallons.

It

gallons.

It

gallons.

I!

pints.

t pint.

pint.

I

!

gallon.

J! pints .

! pint.

1 pint.

of

of

this book.

5

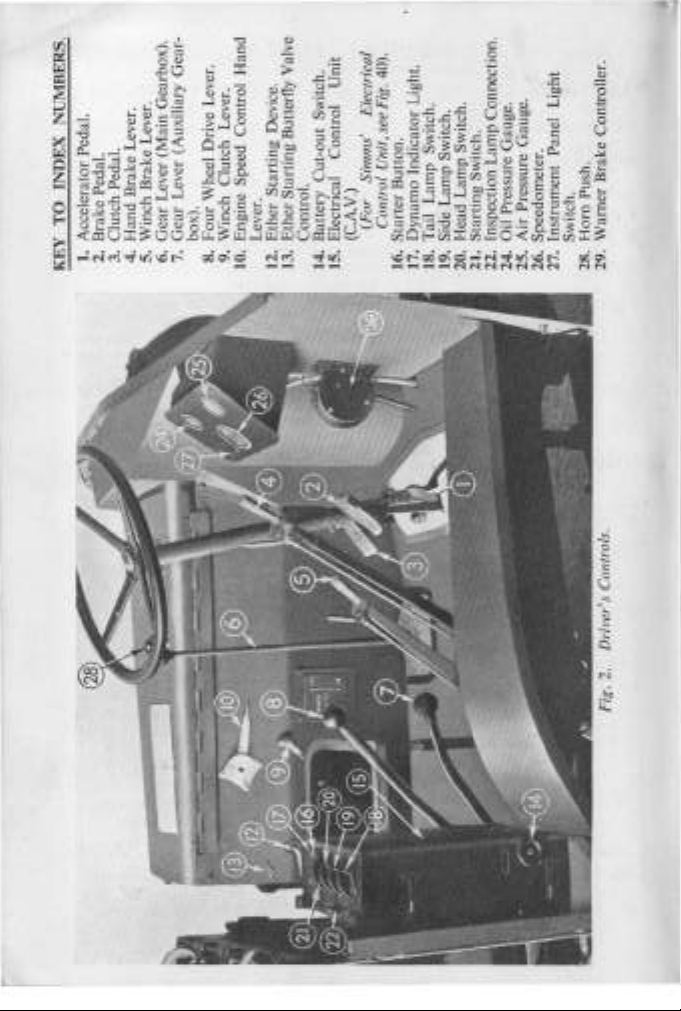

NUMBERS.

INDEX

Pedal.

Brake Lever.

TO

Brake

Hand

1. Accelerator Pedal.

2.

3. Clutch Pedal.

KEY

4.

Gear-

Gearbox).

Lever.

(Main

Brake

Lever (Auxiliary

Lever

Gear

Gear

5. Winch

7.

6.

Wheel Drive Lever.

box).

Four

8.

Hand

Lever.

9. Winch Clutch Lever.

10. Engine Speed Control

Starting Device.

Starting Butterfly Valve

Ether

Ether

12.

13.

Unit

Switch.

Control

Cut-out

Control.

14. Battery

15. Electrical

.)

Control Unit, see Fig. 40).

(For Simms' Electrical

(C.A.V

Light.

Switch.

Indicator

Lamp

Dynamo

18. Tail

16. Starter Button.

17.

Switch.

Switch.

Lamp

Lamp

Side

19.

20. Head

21. Starting Switch.

Connection.

Lamp

Oil Pressure Gauge.

25. Air Pressure Gauge.

26. Speedometer.

24.

27. Instrument Panel Light

22. Inspection

Brake Controller.

Horn Push.

Warner

Switch.

29.

28.

Fig. 2. Driver's Controls.

CONTROLS.

(The index numbers correspond to those in Fig. 2, unless otherwise stated).

FOOT

1.

Accelerator.

The

right-hand pedal operates the fuel injection

controls the speed

engine. Lift with toe, to

2. Brake.

The centre pedal operates the brakes

3.

Clutch.

The left-hand pedal operates the clutch.

pedal when driving

HAND.

4.

Brake.

This

is

operates the brakes

back;

to

forward position.

S.

Winch Brake,

Just behind the

should always be in

6.

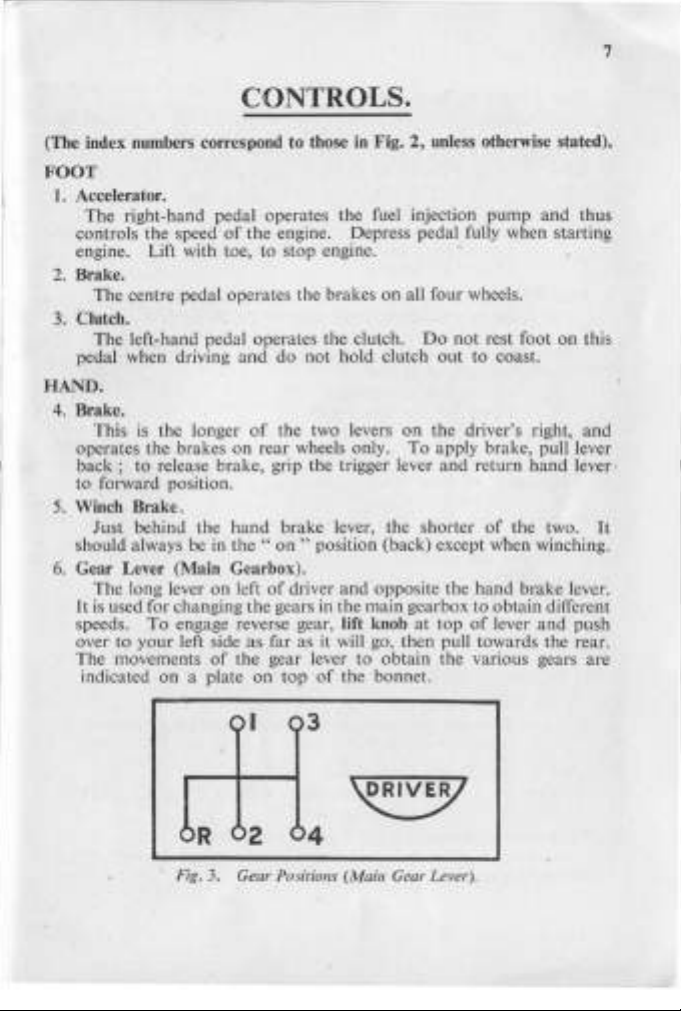

Gear Lever (Main Gearbox).

The long lever on left

It

is used for changing

speeds.

over to

The movements

indicated

the longer

to release brake, grip the trigger lever

To

your

on

of

the engine. Depress pedal fully when starting

stop

and

do

of

the two levers

on

rear

hand

brake lever, the shorter

the"

on

of

driver

the

engage reverse gear, lift knob

left side

of

a plate

gears in the

as

far as it will go, then pull towards the rear.

the

gear lever

on

top

engine.

on

all four wheels.

not

hold clutch

wheels only.

" position (back) except when winching.

and

to

of

the bonnet.

Do

on

To

opposite the

main

gearbox to obtain different

at

obtain

pump

and

thus

not

rest foot

out

to coast.

the driver's right,

apply brake, pull lever

and

return

of

hand

top

of

lever

the various gears are

on

hand

lever·

the two.

brake lever.

and

push

this

and

It

7

01

(3

02

04

Fig. 3. Gear Positions (Main Gear Lever).

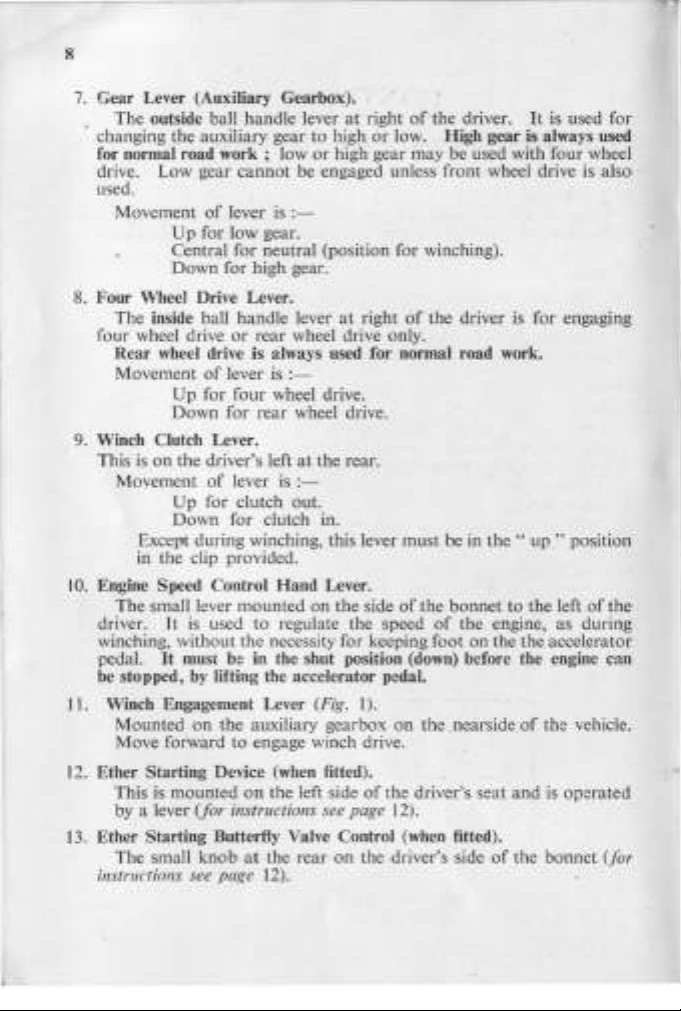

7.

Gear Lever (Auxiliary Gearbox).

The outside ball handle lever

th~

changing

for normal road

drive. Low gear

auxiliary gear to high,

work;

low

cannot

at

right

of

the driver.

or

or

high gear may be used with four wheel

low. High gear is always used

It

is

be engaged unless front wheel drive

used.

of

lever

is

Movement

Up

for low gear.

:-

Central for neutral (position for winching).

Down

for high gear.

8.

Four Wheel Drive Lever.

The

inside ball handle lever

four wheel drive

or

rear wheel drive only.

at

right

of

the driver is for engaging

Rear wheel drive is always used for normal road work.

Movement

9.

Winch Clutch Lever.

This

is

Movement

Except during winching, this lever must be

of

lever is

Up

for four wheel drive.

Down

for rear wheel drive.

on

the driver's left

of

lever is :-

Up

for clutch out.

Down

for clutch in.

:-

at

the rear.

in

the"

up " position

in the clip provided.

10.

Engine Speed Control Hand Lever.

The

small lever mounted on the side

Tt

is

used

driver.

to

regulate the speed

of

the bonnet to the left

of

the engine, as during

winching, without the necessity for keeping foot on the the accelerator

It

pedal.

be stopped,

11.

Winch Engagement Lever (Fig.

Mounted

must be in the shut position (down) before the engine can

by

lifting the accelerator pedal.

1).

on

the auxiliary gearbox

on

the nearside

of

the vehicle.

Move forward to engage winch drive.

12.

Ether Starting Device (when fitted).

This

is

mounted

by a lever

13.

Ether Starting Butterfly Valve Control (when fitted).

The small knob

instructions see page 12).

on

(for

the left side

instructions see page 12).

at

the rear

on

of

the driver's seat

the .driver's side

and

is

of

the bonnet (for

used for

is

also

of

the

operated

14.

Battery Cut-out Switch (C.A.V.)

Knob

presse.d

the battery

the Electrical Control

Control

15.

Electrical Control Unit. (Units

are fitted, the controls

shown

the following

16.

Starter Button.

17.

Dynamo Indicator Light.

and the starting switch (21)

or

the dynamo

18.

Tail Lamp Switch. This also controls the axle flood lamp.

19.

Side Lam p Switch.

20.

Head Lamp Switch.

21. Starting

it must be left in this position while the engine

the vehicle

must be switched

the engine stopped by lifting

the accelerator pedal.

22. Inspection Lamp Connection.

2-pin plug attached to the

inspection lamp supplied.

The battery cut-out switch

,

1-

(14) must

this lamp.

23.

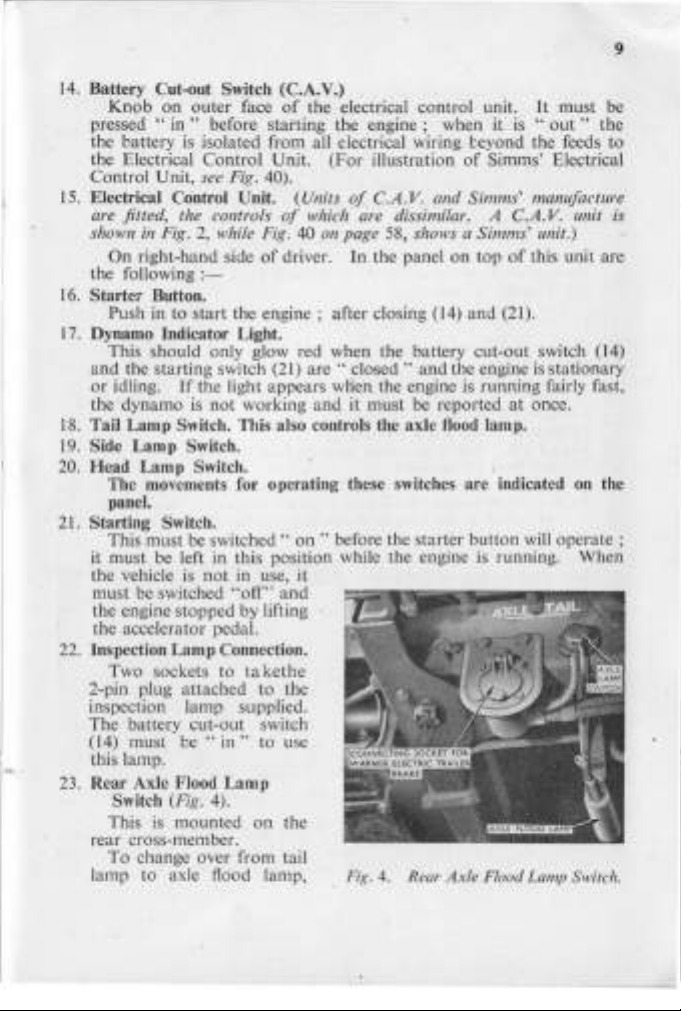

Rear Axle Flood

rear cross-member.

lamp to axle flood lamp,

on

..

in"

Unit, see Fig. 40).

in

Fig. 2, while Fig. 40

On

right-hand side

Push in to start the

This should only glow red when the battery cut-out switch (14)

idling.

The movements for operating these switches are indicated on the

panel.

Switch.

This must be

Two sockets to

Switch (Fig. 4).

This

is

mounted

To change over from tail

outer face

before

is

isolated from all electrical wiring ceyond the feeds to

:-

If

the light appears when the engine

is

not

switched"

is

not

be"

in"

of

the electrical control unit.

s~arting

Unit.

of

engine;

working and it must be reported

in use, it

"off"

ta

kethe

to use

Lamp

on

the

engine;

(For

illustration

of

of

which are dissimilar. A

driver.

are"

on

and

the

C.AY.

on

page 58, shows a Simms' unit.)

In

the panel

after closing (14) and (21).

closed"

" before the starter button will

Fig. 4. Rear

when it

and Simms' manufacture

on

and

Axle

It

is

"out"

of

Simms' Electrical

C.AY.

top

of

this unit are

the engine

is

is

running fairly fast.

is

Flood Lamp Switch.

stationary

at

once.

running. When

must be

operate;

9

the

unit is

10

move the lever to the

left;

to cut

tail lamp, move lever to the right.

The switch

"

on

be

marked"

tail"

" for either the axle lamp

INSTRUMENTS.

On

the instrument panel

just

mounted the following instruments :-

24.

Oil Pressure Gauge.

This registers lubricating oil pressure,

engine.

It

should read

60

lb.jsq. inch when the engine

the maximum governed speed

25.

Air Pressure Gauge.

This indicates

It

should normally read between

or

95

26

. Speedometer.

and 100 lb. /sq. inch (Clayton-Dewandre) (See

This registers the speed

Note.-Early

the

amount

vehicles

of

the vehicle

had

additional gauges showing the Radiator

water and Engine oil temperatures.

27. Instrument Panel Light Switch.

28. Horn Push. This is mounted

29.

Warner Brake Controller.

Although ilJustrated

front dash

it

is mounted

Fig. 31).

30.

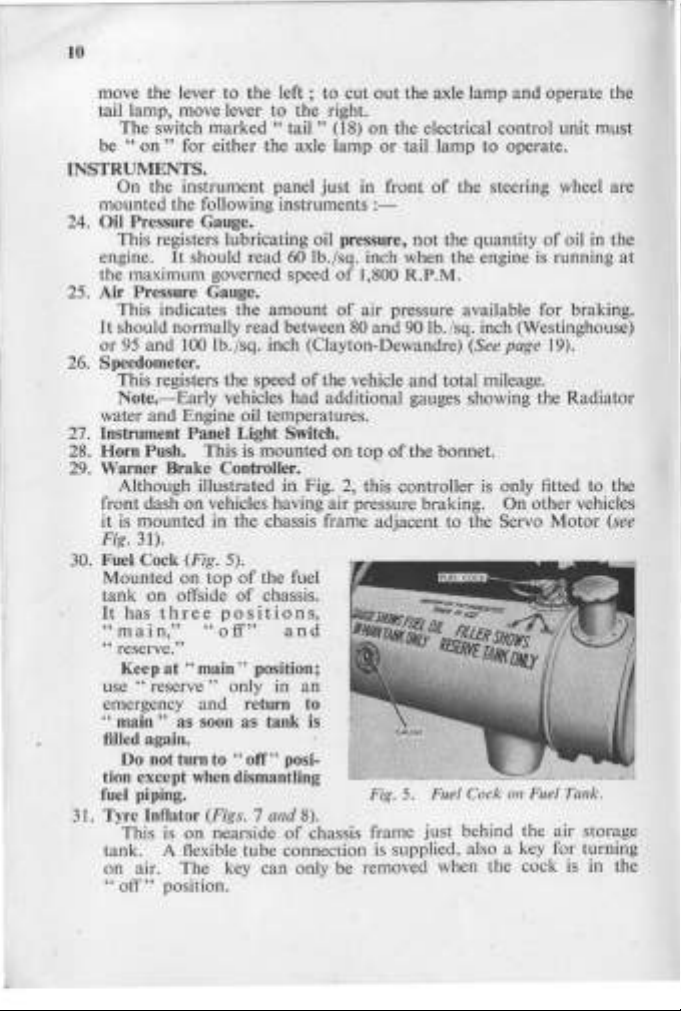

Fuel Cock (Fig. 5).

Mounted

tank

on offside

It

has

three

"main,"

on

vehicles having air pressure braking.

in

on

top

positions,

"off"

in

Fig.

the chassis frame adjacent to the Servo

of

the fuel

of

chassis.

and

" reserve."

Keep

at"

"

use

emergency

"

main"

main " position;

reserve"

only

and

as soon as tank

in

an

return to

is

filled again.

Do not turn to

tion except

when

"oft'''

posi-

dismantling

fuel piping.

3

J.

Tyre Inflator (Figs. 7

This

is

on

nearside

and

8).

of

chassis frame just behind the air storage

tank. A flexible tube connection

on

air. The key can only be removed when the cock

"

off"

position.

out

the axle lamp and operate the

(18)

on

the electrical control unit must

or

tail lamp to operate.

in front

of

J ,800 R.P.M.

of

air pressure available for braking.

80

on

top

2,

this controlJer

and 90

and

of

the bonnet.

of

the steering wheel are

not

the quantity

of

is

Ib.

/sq. inch (Westinghouse)

page

19).

total mileage.

is

only fitted to the

On

other vehicles

oil in the

running

Motor

Fig.

5.

Fu

el Cock on Fuel Tank.

is

supplied, also a key for turning

is

at

(see

in the

11

ENGINE STARTING AND DRIVING

INSTRUCTIONS.

A.

Before Starting the Engine, see

(i)

Radiator

is within 1 in. below the level

(ii)

Oil

(iii)

Fuel

(iv)

Main

The

oil level in the sump should be maintained as near

mark

as possible as this results in lower oil temperatures

lubricating qualities.

B. To

Start

(i) Close the battery cut-out switch (14), Fig.

(ii) Move the starting switch (21) to

(iii) Depress the accelerator pedal fully.

(iv)

Press the starter

(v) Release starter

starter running as

engine to come to rest, then begin again.

found necessary

depressed for a few moments after the engine starts,

as it has warmed

(vi) Immediately the engine starts, check the reading

gauge;

higher

(idling) as the oil warms up.

If

C. To

Start

When temperatures are sufficiently low to call for the use

starting device, the felt element in the main fuel filter must be exchanged

for the brass wire gauze type (carried

starting device)

is full

of

water, or,

in

the engine sump

tank

is full

and

change speed lever

the Engine (Temperatures above

button

button

If

the engine does not pick

it should be approximately 60 [b./sq. inch.

if

temperature is low, but may reduce to

the engine fails to

the Engine (Temperatures near

(see page 34), then proceed as follows

to

to

keep the accelerator pedal more

up

that:

if

anti-freeze solution

of

the

top

rim

of

is

up

to the

top

mark

cock is

do so will exhaust the

in " main"

is

in

neutral position.

(16) firmly.

as

soon

up

position.

16

deg. F.).

2.

the"

on

" position.

as the engine starts.

in a

few

seconds,

battery;

It will sometimes be .

slightly this will

start,

vent the fuel system (see page 34).

not

be necessary.

or

below

16

on

vehicles equipped with Ether

:-

is

the gauze strainer.

of

of

in use, it

the dipstick.

to

the full

and

higher

do

not

keep

wait for the

or

less fully

but

as soon

the oil pressure

It

25

deg.

will be

lb. /sq. inch

F.)

.

of

the Ether

the

12

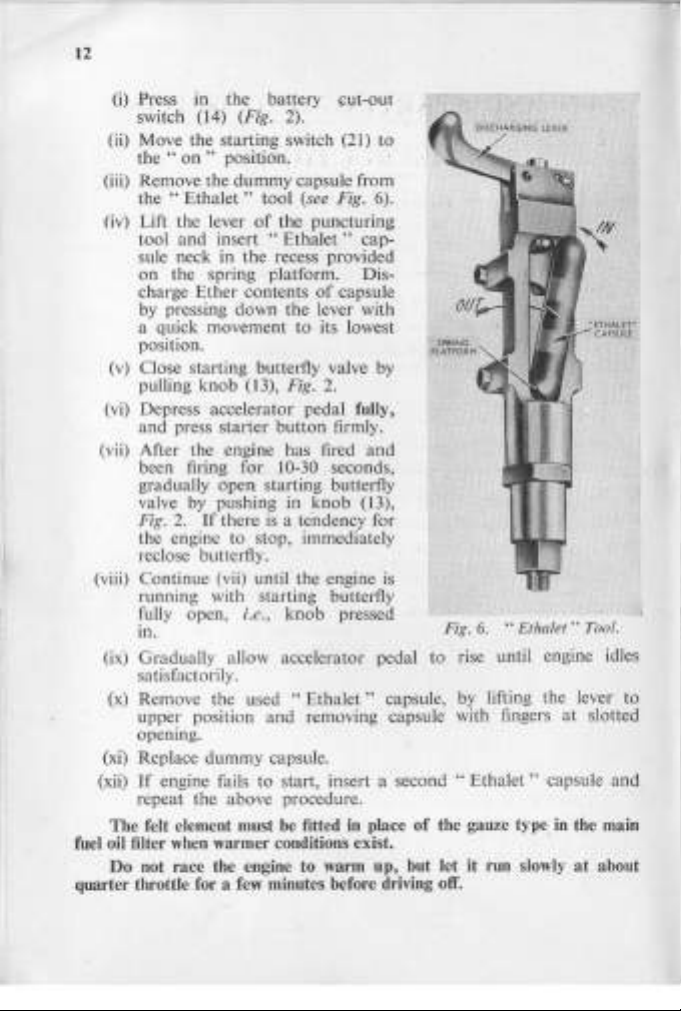

(i) Press in

th~

battery

f.:ut-oUI

switch (14) (Fig. 2). '

(ii) Move the starting switch (21) to

"

on"

the

position.

(iii) Remove the dummy capsule from

"Ethalet

the

(iv) Lift the lever

tool and insert

" tool (see Fig. 6).

of

the puncturing

"Ethalet"

cap-

sule neck in the recess provided

on the spring platform. Dis-

of

charge Ether contents

capsule

by pressing down the lever with

to

a quick movement

its lowest

position.

(v)

Close starting butterfly valve

by

pulling knob (13), Fig. 2.

(vi) Depress accelerator pedal fully,

button

and press starter

(vii) After the engine has fired

firmly.

and

been firing for 10-30 seconds,

gradually open starting butterfly

valve by pushing in knob (13),

Fig. 2.

If

there

is

a te'ndency for

the engine to stop, immediately

reclose butterfly.

(viii) Continue (vii) until the engine

is

running with starting butterfly

fully open,

in.

i.e., knob pressed

Fig.

6.

"Ethalet

" Tool.

(ix) Gradually allow accelerator pedal to rise until engine idles

satisfactorily.

(x) Remove the used

upper position

and

"Ethalet"

removing capsule with fingers

capsule,

by

lifting the lever to

at

opening.

(xi) Replace dummy capsule.

If

(xii)

engine fails to start, insert a second "

Ethalet"

capsule

repeat the above procedure.

The felt element must be fitted in place

of

the gauze type in the main

fuel oil filter when warmer conditions exist.

Do not race the engine to warm up, but let

it

fun slowly

quarter throttle for a few minutes before driving off.

slotted

at

about

and

13

When starting from cold in frosty weather, see

is in position

flap will permit the vehicle

temperatures

to

operate

is

D.

To

Lift the accelerator pedal with the toe,

until the engine stops.

Stop

on

the lower

up

to

90"

in

tropical climates.

the Engine.

F.,

portion

to

it

of

operate satisfactorily

should only be removed

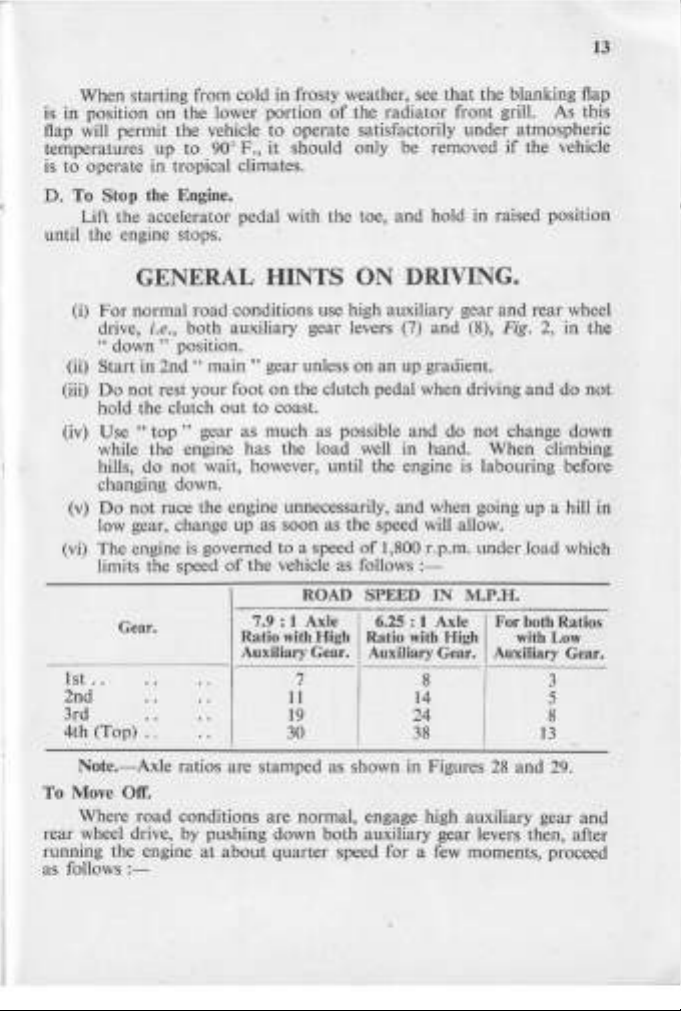

GENERAL HINTS ON DRIVING.

(i)

For

normal

road

drive,

i.

"

(ii) Start in 2nd "

Do

(iii)

hold the clutch

Use " top"

(iv)

while

hills,

changing down.

(v)

Do

low gear, change

The

(vi)

limits the speed

1st

..

2nd

3rd

4th (Top)

Note.-Axle

To Move

Where

rear wheel drive, by pushing down

running the engine

as follows :-

e., both auxiliary gear levers (7)

down"

not

rest

the

do

not

not

race the engine unnecessarily,

engine is governed to a speed

Gear.

· . · .

· .

· . · .

"

Off.

road

conditions use high auxiliary gear

position.

main"

gear unless

your

foot

on

out

gear as

engine

wait, however, until the engine is labouring before

up

of

· .

· .

ratios are stamped as shown in Figures

conditions

at

about

the clutch pedal when driving

to

coast.

much

has

the vehicle as fa

7.9:

Ratio

Auxiliary Gear.

as possible

the load well in hand.

as

soon

as the speed will allow.

ROAD SPEED

1 Axle 6.25: 1 Axle

with

High Ratio

7

11

19

30

are

normal, engage high auxiliary gear

both

quarter

speed for a few moments, proceed

that

the

radiator

and

on

an

up gradient.

and

and

of

1,800 r.p.m.

Haws

:-

with

Auxiliary Gear.

14

24

38

auxiliary gear levers then, after

the blanking flap

front grill. As this

under

atmospheric

if

the vehicle

hold

in raised position

and

rear

and

load

with

13

and

wheel

do

down

climbing

which

Low

3

5

8

29.

and

(8), Fig. 2, in the

do

not

change

When

when going up a hill in

under

IN

M.P.H.

For both Ratios

High

Auxiliary Gear.

8

28

not

and

14

(i) Depress

(ij)

Place"

and

hold down the clutch pedal.

main"

gear lever in 2nd gear position, i.e., press sideways

away from you, then pull towards the rear.

hand

(iii) Release

(iv) Allow clutch pedal to come up slowly

brake.

and

at

the same time press

down accelerator pedal.

(v)

When the vehicle has reached

below, press down the clutch pedal

about

the speed 5hown in the table

and

at

the same time release

the accelerator pedal.

(vi)

Move"

main"

gear lever to the 3rd gear position, i.e., push forward

half-way, then pull sideways towards you as far as it will go

then move forward.

(vii) Release clutch pedal slowly,

and

at

the same time press down the

accelerator pedal as before.

(viii) When the vehicle has reached the speed shown

and

table, for this gear, repeat the process

pull main gear lever into

4th gear position (top).

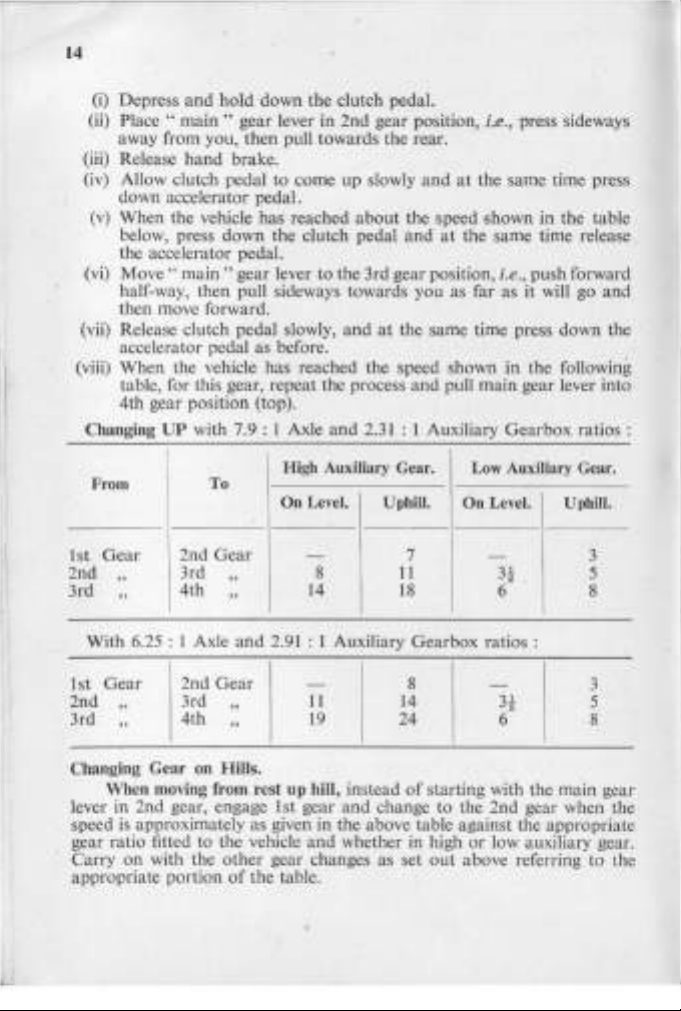

Changing

From

1st

2nd

3rd

With 6.25 : 1 Axle

Gear

"

"

UP

with 7.9 : 1 Axle

To

\ 2nd

Gear

3rd "

14th

"

and

and

2.31

: 1 Auxiliary Gearbox

High Auxiliary Gear.

On

Level.

- 7

8

14

2.91

: 1 Auxiliary Gearbox ratios :

UphiU.

11

18

Low

On

in

the following

ratios:

Auxiliary Gear.

Level.

- 3

Uphill.

3t

6 8

and

5

1st

2nd

3rd

Gear

"

"

3rd

4th

Gear

"

"

-

I

11

19

8

14

24

I

2nd

Changing Gear on Hills.

When moving from rest up hill, instead

lever in 2nd gear, engage 1st gear

speed

is

approximately as given

in

and

the above table against the appropriate

of

starting with the main gear

change to the 2nd gear when the

gear ratio fitted to the vehicle and whether in high

on

Carry

with the

appropriate portion

other

gear changes as set

of

the table.

out

-

3!

3

5

6 8

or

low auxiliary gear.

above referring to the

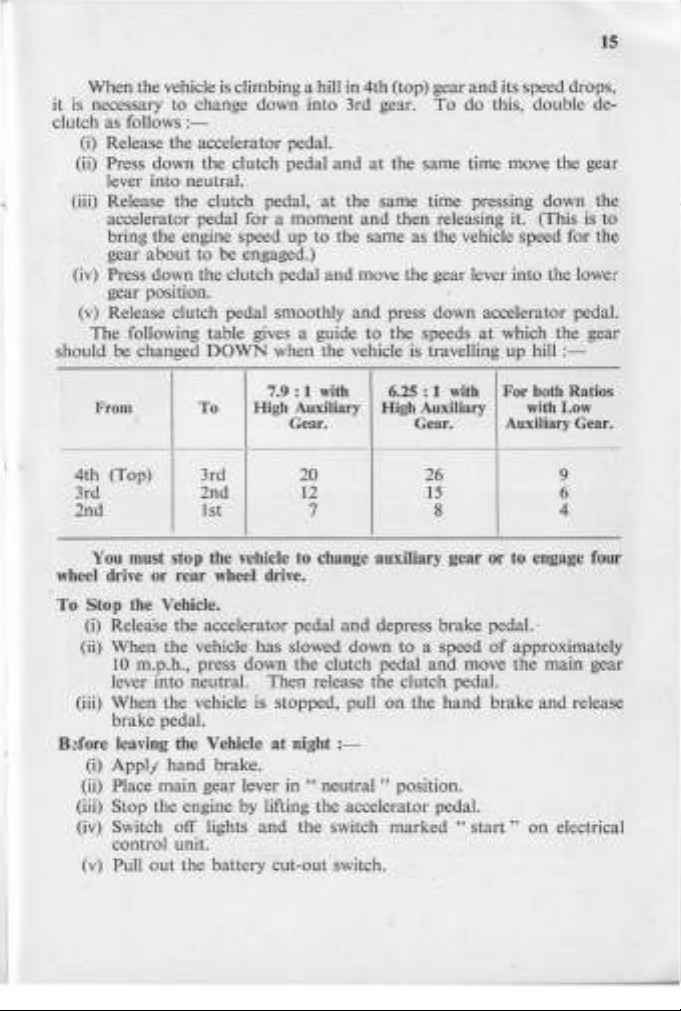

15

When the vehicle

is

necessary to change down into 3rd gear.

it

clutch as follows

(i)

Release the accelerator pedal.

(ii) Press down the clutch pedal

is

:-

climbing a hill

in

4th (top) gear

and

at

the same time move the gear

and

To

do this, double de-

lever into neutral.

(iii) Release the clutch pedal,

accelerator pedal for a moment

at

the same time pressing down the

and

then releasing it. (This is to

bring the engine speed up to the same as the vehicle speed for the

about

gear

(iv) Press down the clutch pedal

to be engaged.)

and

move the gear lever into the lower

gear position.

(v)

Release clutch pedal smoothly

The following table gives a guide to the speeds

should be changed

DOWN

when the vehicle

7.9: 1 with

From

High Auxiliary High Auxiliary

To

Gear. Gear.

4th (Top) 3rd

3rd

2nd 12

2nd 1st

You must stop the vehicle to change auxiliary gear

and

press down accelerator pedal.

at

is

travelling

6.25: 1

with

20 26

15

7 8 4

or

wheel drive or rear wheel drive.

Stop the Vehicle.

To

(i) Release the accelerator pedal

(ii) When the vehicle has slowed down to a speed

10

m.p.h., press down the clutch pedal

and

depress brake pedal. '

and

of

move the

lever into neutral. Then release the clutch pedal.

(iii) When the vehicle

is

stopped, pull

on

the

hand

brake

brake pedal.

B~fore

leaving the Vehicle

(i)

Appl/

hand

(ii) Place main gear lever

brake.

at

night

:-

in " neutral"

position.

(iii) Stop the engine by lifting the accelerator pedal.

(iv) Switch off lights

and

the switch marked

"start"

control unit.

(v) Pull

out

the battery cut-out switch.

its speed drops,

which the gear

up

hill

:-

For

both

Ratios

with

Low

Auxiliary Gear.

9

6

to engage four

approximately

main

gear

and

release

on

electrical

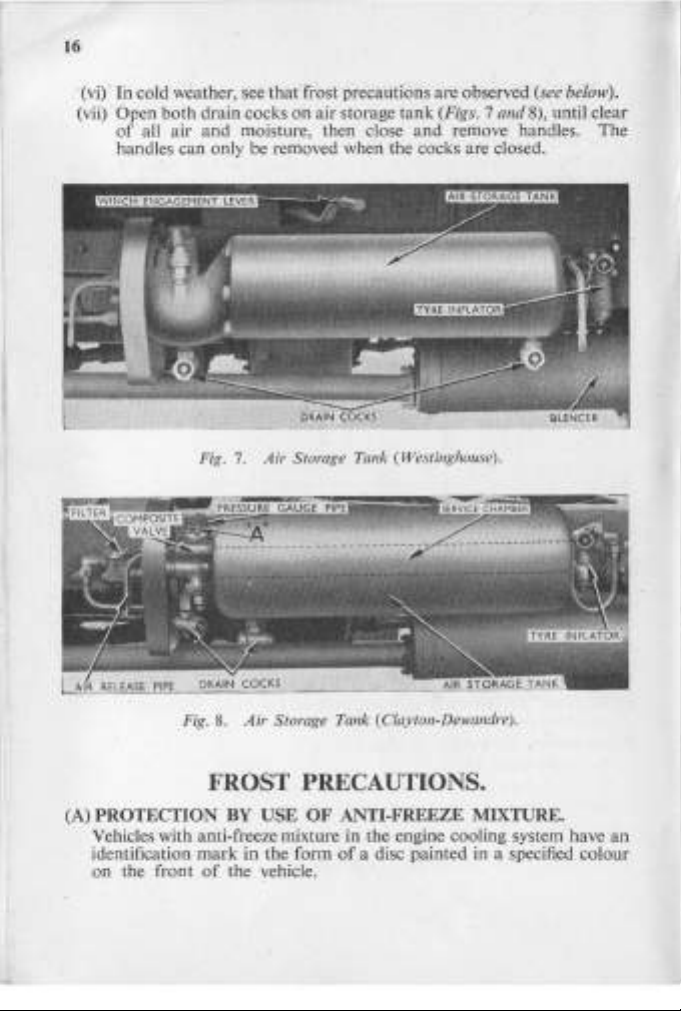

16

(vi) In cold weather,

See

thatCrost precautions are observed (see below).

(vii) Open both drain cocks on air storage tank (Figs. 7

of

all air and moisture, then close

and

remove handles. The

handles can only be removed when the cocks are closed.

Fig. 7. Air Storage Tank (Westinghouse).

and

8),

until clear

8.

Air

Fig.

Storage Tank (Clayton-Dewandre).

FROST PRECAUTIONS.

(A)

PROTECTION

Vehicles with anti-freeze mixture in the engine cooling system have

identification

on

the front

BY

mark

of

the vehicle.

USE

in

the form

OF

ANTI-FREEZE MIXTURE.

of

a disc painted in a specified colour

an

17

If

your vehicle

(i)

Do not drain the cooling system unless instructed to do so.

(ii)

If

the cooling system has to

number

mixture for re-use (approximately 6 gallons).

(iii)

Top

when the engine is hot.

Top

(iv)

over-fill.

(v)

If

for any reason the mixture

water, paint out the coloured disc.

Brake Anti-freezer:

and various other units in the air pressure system, from freezing in severe

weather, the anti-freezer fitted

filled

with"

are ordered,

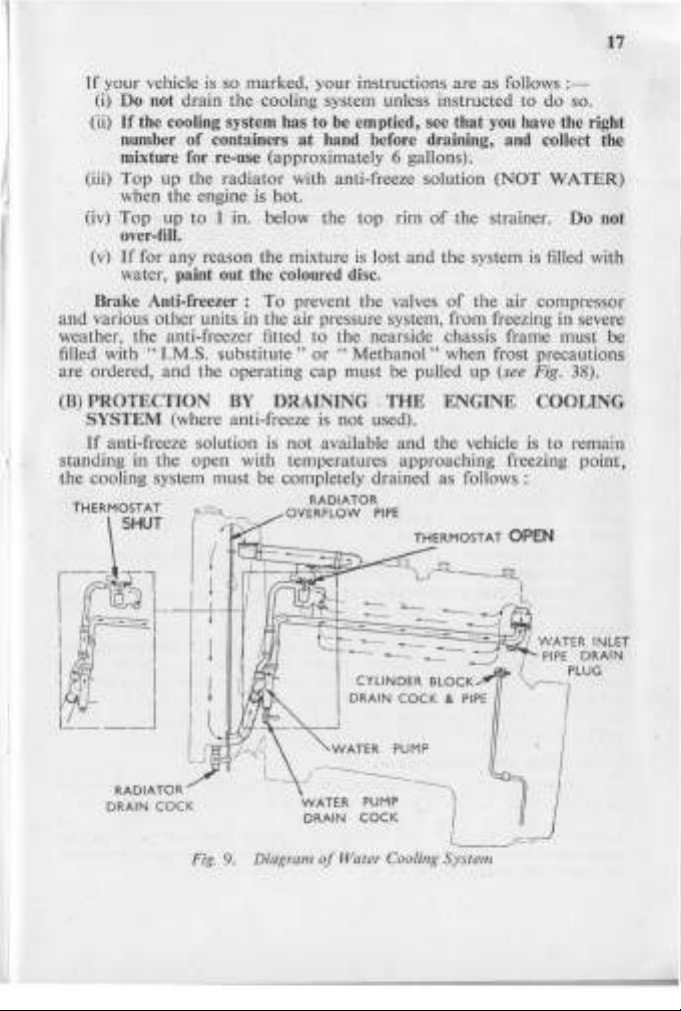

(B)

PROTECTION

SYSTEM

If

anti-freeze solution

standing

the cooling system must be completely drained as follows:

THERMOSTAT

in

SHUT

is

so marked, your instructions are as follows :-

be

of

containers

up

the radiator with anti-freeze solution

up to 1 in. below the

To

prevent the valves

I.M.S.

wbstitute"

and

the operating cap must be pulled up (see Fig. 38).

BY

(where anti-freeze is

the open with temperatures approaching freezing point,

DRAINING .

is

not

OVERFLOW

emptied, see that you have the right

at

hand before draining, and collect the

(NOT

WATER)

top

rim

of

the strainer. Do not

is

lost and the system

of

to

the nearside chassis frame must be

or

"Methanol"

not

available

RADIATOR

used).

PIPE

when frost precautions

THE

ENGINE COOLING

and

the vehicle is

is

filled with

the air compressor

to

remain

RADIATOR

DRAIN

COCK

Fig

. 9. Diagram

Mr~~=$~~~

I

I

- CYLINDER

DRAIN

~~~~~

___

- .

BLOCK

COCK & PIPE

~

WATER

PUMP

DRAIN

COCK

of

Water Cooling System

~"WATER

(

V--,

PIPE

DRAIN

PLUG

INLET

I

18

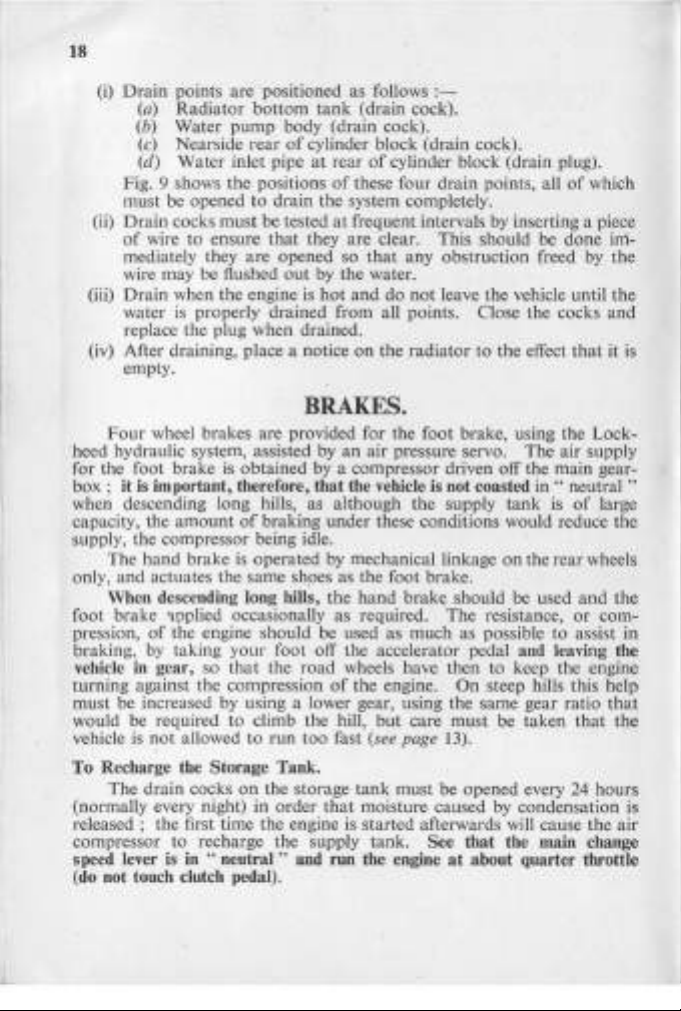

(i)

Drain

points are positioned as follows

(a)

Radiator

(b) Water pump body (drain cock).

(c)

Nearside

(d)

Water inlet pipe

Fig. 9 shows

must be opened

(ii)

Drain

cocks

of

wire

to

rear

the

to

must

ensure

bottom

tank

of

cylinder block (drain cock).

at

positions

drain the system completely.

be tested

that

they are clear. This should be done immediately they are opened so

wire may be flushed

(iii)

Drain

when the engine

is

water

properly drained from all points . Close the cocks

out

by the water.

is

hot

(drain cock).

rear

of

of

these four drain points, all

at

frequent intervals by inserting a piece

that

and

:-

cylinder block (drain plug).

of

any obstruction freed by the

do

not

leave the vehicle until the

which

and

replace the plug when drained.

(iv) After draining, place a notice

on

the

radiator

to

the effect

that

it

empty.

BRAKES.

Four

heed hydraulic system, assisted by

wheel brakes are provided for the foot brake, using the Lock-

for the foot brake is obtained

box ;

it

is important, therefore, that the vehicle is not coasted

when descending long hills, as although the supply

capacity, the

amount

of

braking under these conditions would reduce the

supply, the compressor being idle.

The hand brake

and

only,

actuates the same shoes as the foot brake.

is

operated

When descending long hills,

foot brake

pression,

braking, by taking

vehicle in gear, so

'lpplied occasionally as required. The resistance,

of

the engine should be used as much as possible to assist in

your

foot off the accelerator pedal and leaving the

that

the

turning against the compression

by

must be increased

would be required

vehicle is

not

allowed

using a lower gear, using the same gear ratio

to

climb the hill,

to

run

To Recharge the Storage Tank.

The

(normally every night)

drain cocks

on

the storage

in

order

released; the first time the engine is started afterwards will cause the air

compressor to recharge the supply tank.

"

speed lever is in

(do not touch clutch

neutral"

pedal).

an

air pressure servo.

by

a compressor driven off the main gear-

The

in " neutral"

tank

by

mechanical linkage

the

hand

brake should be used

road

wheels have then to keep the engine

of

the engine.

but

too

fast (see

that

care

page

tank

must be opened every 24 hours

moisture caused by condensation

on

the rear wheels

On

steep hills this help

must

be taken

13).

See that the main change

and run the engine

at

about quarter throttle

air supply

is

of

large

and

or

com-

that

that

the

the

is

is

19

During

gauge will rise to

2 minutes until

pressure.

a valve will operate with a hiss, indicating

the compressor will then automatically

With the Clayton

gauge

which the engine starts

which the gauge will rise steadily until approximately

is

reached.

Get

The

charging with the Westinghouse system, the

65 lb./sq. inch

both

The

compartments

gauge will

Dewandre

at

65

lb./ sq. inch,

and

used to the feel

air

pressure gauge must show

but

of

and

will remain

of

then

rise

the supply

to

approximately 90 lb. /sq. inch when

run

light. .

system

no

there will be a pause between the

when the gauge commences

the brakes as soon as possible.

at

at

this figure

tank

reach the same

that

the system is

pause takes place

air

to

register, after

100 lb. /sq. inch

least 75 lb. /sq. inch before

driving the vehicle.

of

Before getting out

your seat to leave the vehicle, always apply the.

hand brake.

USE OF WINCH.

The winch may be used for unditching the vehicle to which it is

fitted by attaching the winch cable

tractor

either

to

skid

It

may

pans

the front

also be used

provided

or

for

must

ditched vehicle, as shown in Fig.

Payout

To

(i) See

(ii)

(iii) See

(iv)

the Cable.

that

the winch engagement lever, which is

auxiliary gearbox

"

out"

position.

See

that

the winch

that

the winch clutch lever is in

The

winch

hand. Never

drum

payout

at

is

After the cable has been payed

allow another vehicle to pass over

which interfere with the proper winding on the drum.

To

Pull in the Cable.

(i) Place

(ii) Move

the

main

gear lever

the

gear lever in "

in

the"

winch engagement lever, which is

auxiliary gearbox

direction

to

engage

winch"

at

the

to

a suitable anchorage

in

line with the

the rear.

unditching a second vehicle, in which case the

be placed under the front wheels

10,

to

ensure sufficient hold.

mounted

the nearside

brake

is " off."

now

free

of

the chassis, is back in the

the"

up

" position in its clip.

and

the cable may be pulled

by driving the winch in reverse.

out

and

is lying

on

it

as

this will cause kinks in the cable

neutral"

and

the ground , never

the outside auxiliary

position.

mounted

the nearside

of

the chassis,

in

winch drive.

pressure

for

about

charged;

on

the

moment

of

the

on

out

on

at

Ull-

the

by

the

a forward

Loading...

Loading...