Page 1

HE • CHE • BCHE

Mass Flow Series

Drying Hoppers

AEC, Inc.

801 AEC Drive

Wood Dale, IL 60191-1198

Tel (630) 595-1060

Fax (630) 595-6641

Part No. A0548656 Revision A Bulletin No. WH1-630B

Page 2

Performance figures stated in this manual are based on a standard atmosphere of 59°F

(15°C) at 29.92” Hg (1,014 millibars) at sea level, using 60 hz power. Altitude is an

important consideration when specifying dryer components. AEC/Whitlock can advise

you on proper selection and sizing of systems for your operating environment.

AEC/Whitlock is committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual

are subject to change without notice.

© Copyright AEC/Whitlock and AEC, Inc. 2011

All rights reserved. Effective 4/13/2011

Part No. A0548656 Revision A Bulletin No. WH1-630B.1

Page 2 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 3

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Page 4

Safety Considerations

AEC/Whitlock HE, CHE, and BCHE Mass Flow Series drying hoppers are designed to provide

safe and reliable operation when installed and operated within design specifications, following

national and local safety codes.

To avoid possible personnel injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

; Follow all SAFETY CODES.

; Wear SAFETY GLASSES and WORK GLOVES.

; Disconnect and/or lock out power before servicing or maintaining the dryer.

; Use care when LOADING, UNLOADING, RIGGING, or MOVING this equipment.

; Operate this equipment within design specifications.

; OPEN, TAG, and LOCK ALL DISCONNECTS before working on this equipment. You

should remove the fuses and carry them with you.

; Make sure the dryer and components are properly GROUNDED before you switch on

power.

; Do not jump or bypass any electrical safety control.

; Do not restore power until you remove all tools, test equipment, etc., and the dryer and

related equipment are fully reassembled.

; Only PROPERLY TRAINED personnel familiar with the information in this manual should

work on this equipment.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 3

Page 5

Table of Contents

1 General Information ................................................. 7

1-1 Introduction

1-2 Equipment Function

1-3 The HE Heater Drying Hopper Package

1-4 The CHE Control and Heater Drying Hopper Package

1-5 The BCHE Blower Controls Heater Drying Hopper Package

2 Shipping Information ............................................. 11

2-1 Unpacking and Inspection

2-2 In the Event of Shipping Damages

2-3 If the Shipment is Not Complete

2-4 If the Shipment is Not Correct

2-5 Returns

3 Installation ............................................................... 13

3-1 Work Rules

3-2 Necessary Documents

3-3 Installing Machine-Mount Drying Hoppers

3-4 Installing Floor-Mount Drying Hoppers

3-5 Making Hose Connections

3-6 Making Electrical Connections

3-7 Checking for Proper Blower Rotation

4 Startup, Shutdown, and Operation ....................... 21

4-1 Pre-Startup Checklist

4-2 Starting the Process

4-3 Shutting Down the Process

Page 4 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 6

Table of Contents

5 1/4 DIN Controllers ................................................. 25

5-1 Graphic Panel for 1/4 DIN Controller

5-2 Using the 1/4 DIN Temperature Controller

5-3 Using Temperature Controller Internal Switches

5-4 Using the Temperature Controller Anti-Tamper Lockout Switch

5-5 Changing the Display from Fahrenheit to Celsius

5-6 Setting the Process Air Temperature

5-7 Setting the High Temperature Alarm

5-8 Activating the Auto-Tune Function

5-9 Restoring the Controller to Factory Setup

6 1/16 DIN Controllers ............................................... 35

6-1 Graphic Panel for 1/16 DIN Controller

6-2 Using the 1/16 DIN Temperature Controller

6-3 Setting the Process Air Temperature on the 1/16 DIN Controller

6-4 Setting the High Temperature Alarm on the 1/16 DIN Controller

6-5 Restoring the 1/16 DIN Temperature Controller to Factory Setup

7 Maintenance ............................................................ 47

7-1 Work Rules

7-2 Cleaning Out the Drying Hopper

7-3 Replacing the Process Heater

7-4 Servicing Process Air Filters

8 Troubleshooting ..................................................... 53

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 5

Page 7

Charts and Figures

1

Typical HE Drying Hopper Package 8

2

Typical CHE Drying Hopper Package 9

3

Typical BCHE Drying Hopper Package 10

4

Machine Mounting Flange Dimensions 15

5

Drying Hopper Cover Bolt Patterns 16

6

Typical Single Hopper Drying Hose Installation 18

7

Typical Multiple Hopper Drying Hose Installation 19

8

Component Identification Exploded View 23

9

10

11

12

13

14

15

16

17

18

Graphic Panel for 1/4 DIN Controller 25

1/4 DIN Controller 26

1/4 DIN Temperature Controller Preset Parameters 32

Self-Diagnostic Error Messages 34

Graphic Panel for 1/16 DIN Controller 35

1/16 DIN Controller 37

Display Readout for Mode Settings 42

Default Setting List for 1/16 DIN Process Temperature Controller:

Protect / Level / Setup / Expansion

Available Board Options 46

Recommended Spare Parts List 51

43-45

Page 6 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 8

1 General Information

1-1 Introduction

AEC/Whitlock HE (Heaters), CHE (Controls and Heaters), and BCHE (Blower, Controls and

Heaters) Mass Flow Series drying hopper packages offer a high efficiency alternative for drying

multiple materials when used with a single or multiple dryer(s).

1-2 Equipment Function

AEC/Whitlock HE, CHE, and BCHE Mass Flow Series drying hoppers are used in conjunction

with a dehumidifying dryer unit. This dryer/drying hopper system generates heated,

dehumidified air to dry hygroscopic materials, such as plastic pellets. As in standard drying

systems, this operation removes moisture from the process air via molecular sieve desiccant beds

in the dehumidifying dryer unit. The system then sends this dry air to the HE, CHE, or BCHE

drying hopper, where heating elements are located. Heating the air at the drying hopper cuts

energy waste otherwise caused by heated air flowing through the dryer hose. After the system

heats air at the inlet of the drying hopper, it passes through the column of plastic resin in the

hopper and then returns to the dehumidifying dryer unit.

The drying hopper is designed to promote even drying and uniform material flow by using a

unique air/material diffuser cone. It is of modular construction, and can be configured and

oriented in numerous ways. You can easily change diameters on the process air inlet and outlet

with hand tools.

Material moves through the hopper in a first in, first out flow pattern. Located in the cover, the

removable air trap prevents introduction of moist ambient air into the drying system. Other

features on your system include lifting lugs plus a sight glass to let you see the material level.

Various types of material take-off compartments and/or drawer magnets can be installed at the

discharge point of the hopper. Contact your AEC/Whitlock sales representative for selecting

companion equipment.

Drying hopper systems are sized to meet specific customer requirements. Sections on the

following few pages list the differences between HE, CHE, and BCHE drying hopper systems.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 7

Page 9

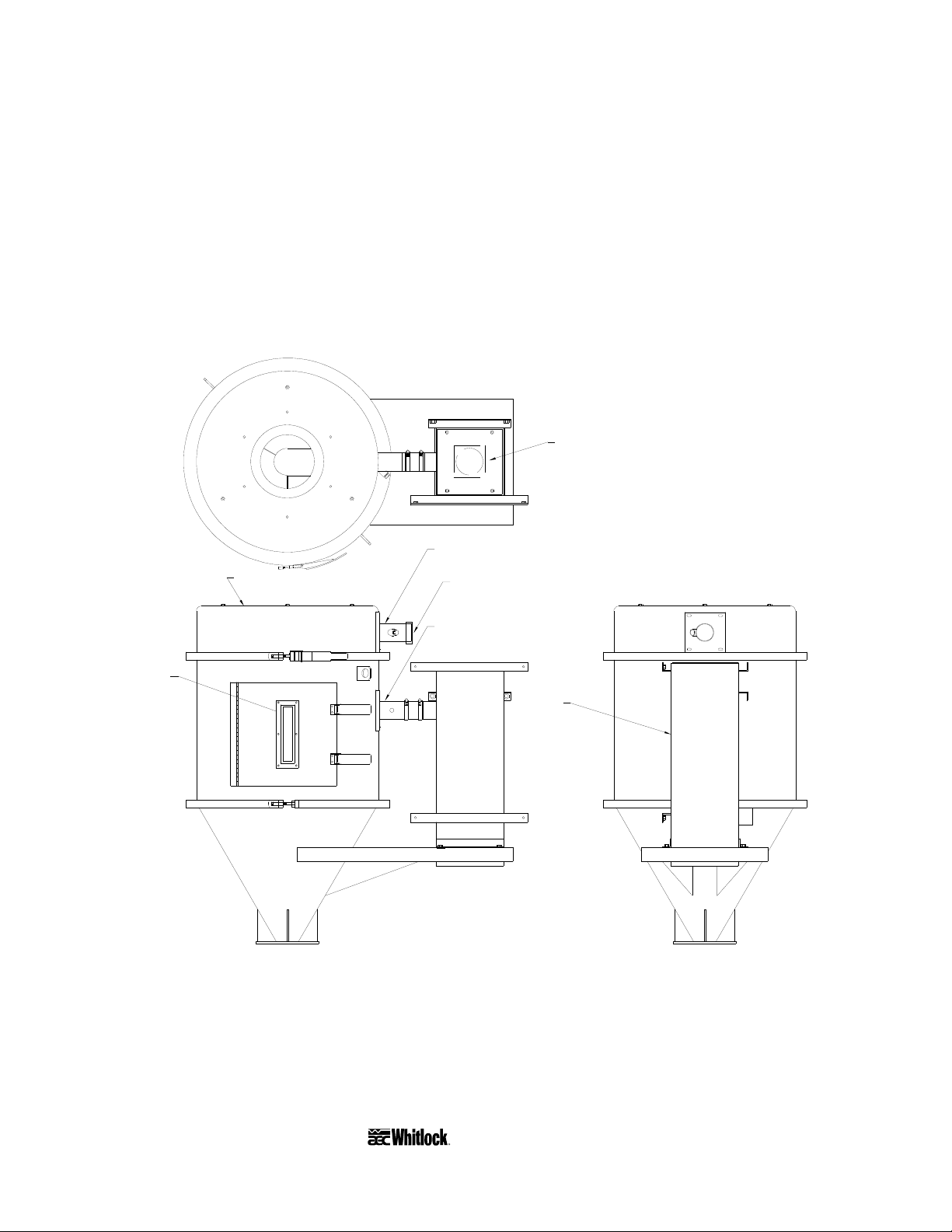

1-3 The HE Heater Drying Hopper Package

The AEC/Whitlock HE drying hopper package offers a process air heater removed from the

dryer and mounted at the hopper with the temperature controller at the dryer. The HE drying

hopper package is designed for application where one dryer is delivering dehumidified air to one

drying hopper.

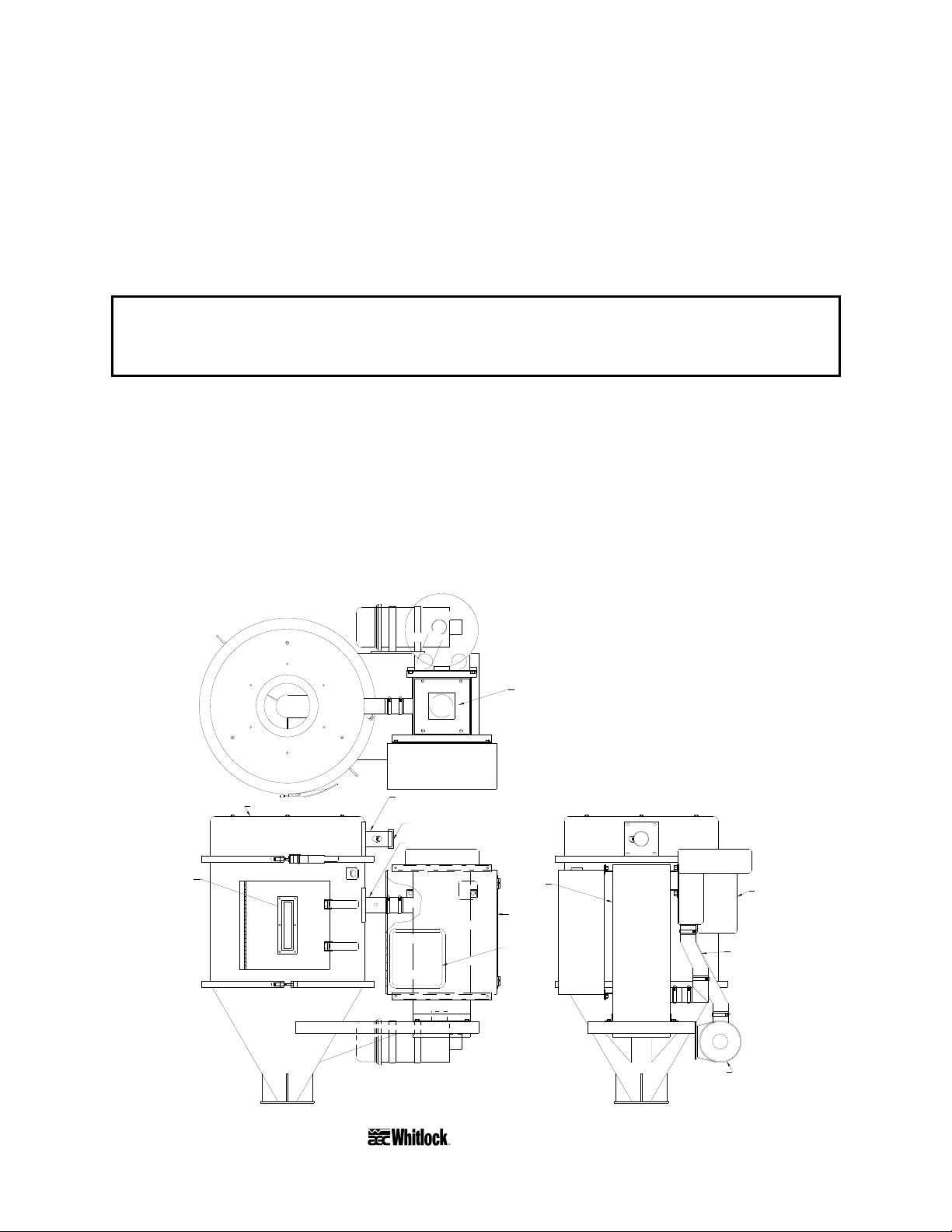

Figure 1

Typical HE Drying Hopper Package

Heater

Outlet transition

Sight

glass

Cover and air trap/diffuser

Return air outlet

Process air connection

Heater

Page 8 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 10

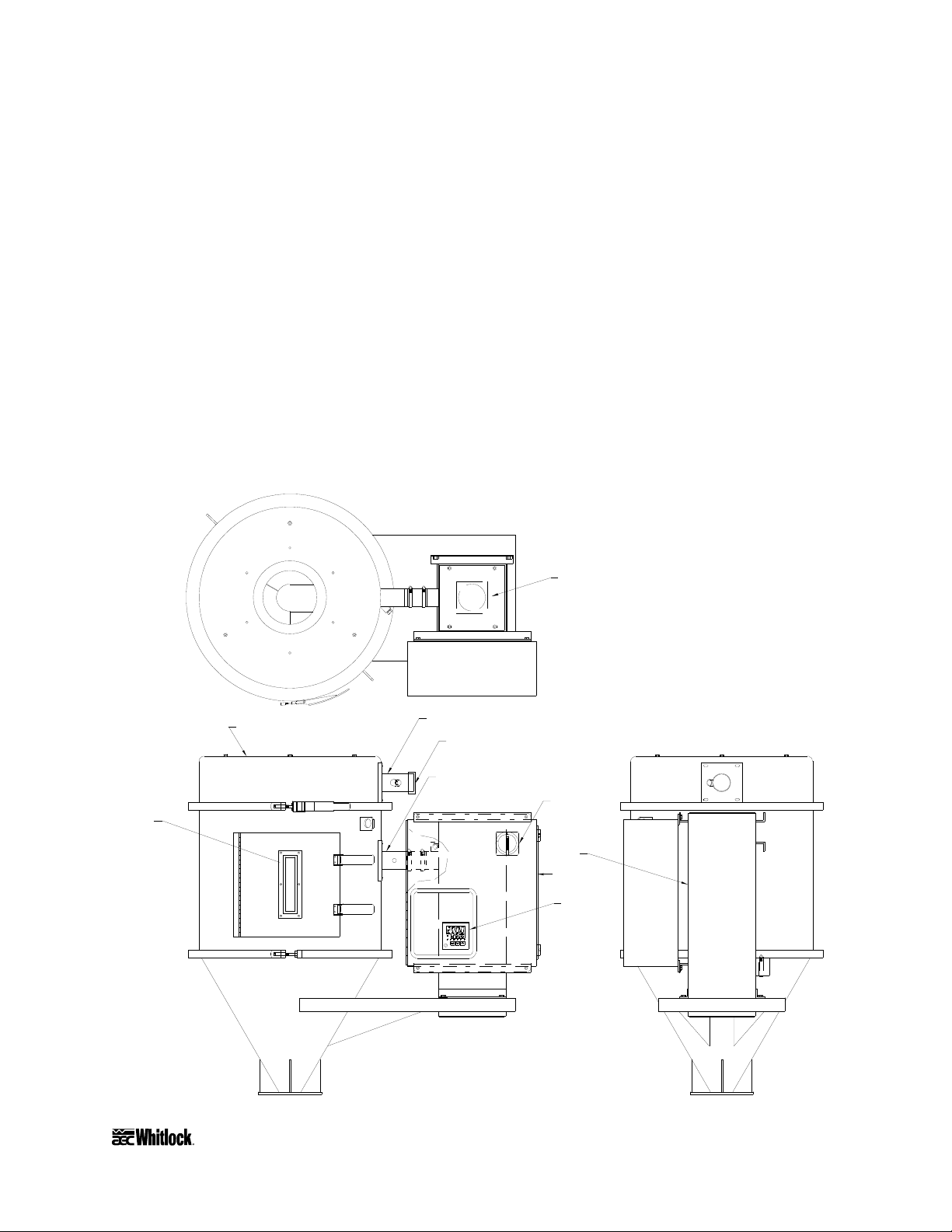

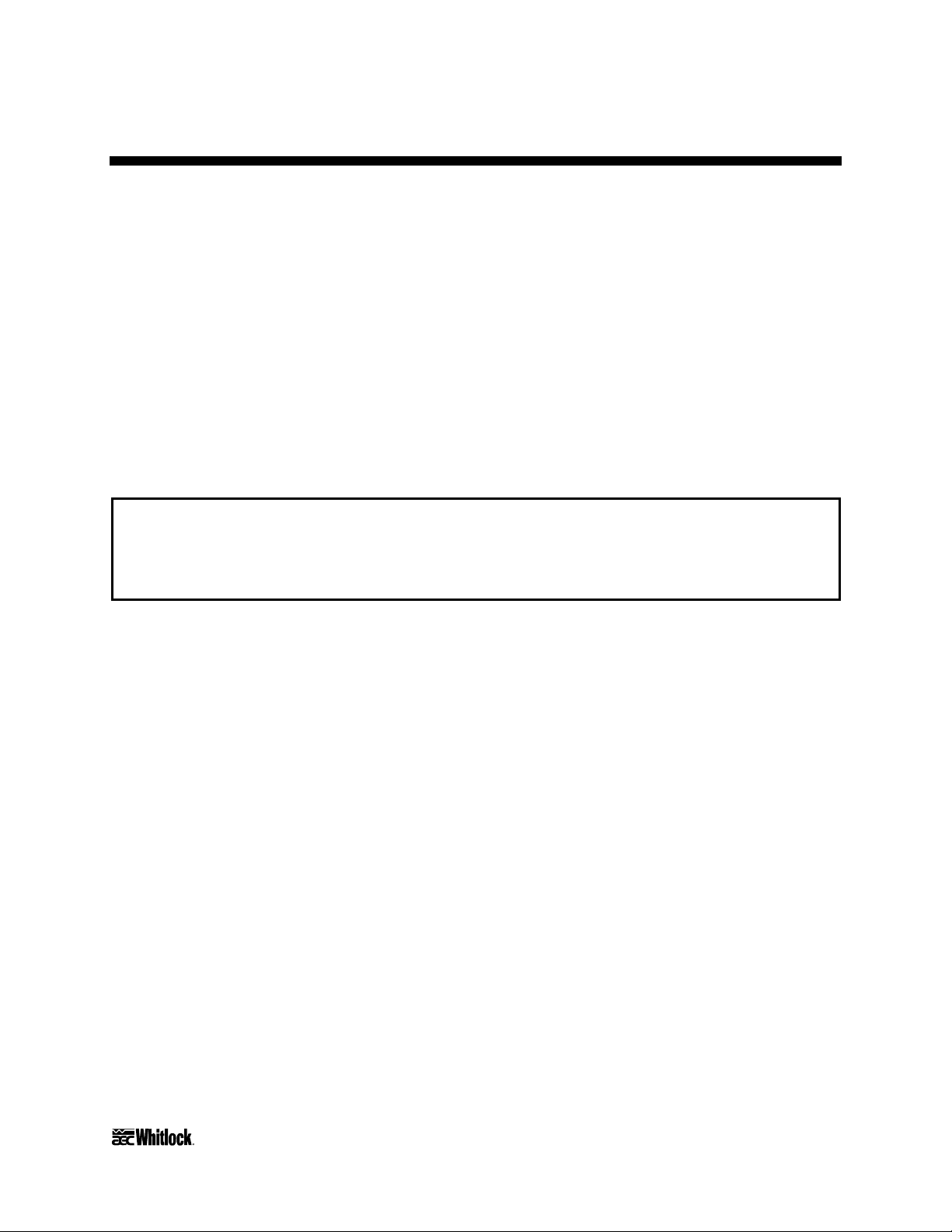

1-4 The CHE Control and Heater Drying Hopper

Package

The AEC/Whitlock CHE drying hopper package offers a process air heater removed from the

dryer and mounted at the hopper. The temperature controller is mounted at or on the drying

hopper. The design of the CHE package allows the dryer to deliver dehumidified air to multiple

drying hoppers to promote drying of different resins at different temperatures in different

hoppers.

Note: The CHE hopper package uses separate power drops to each hopper and avoids feeding

high voltage power through the dryer. An interlock prevents operation of heaters on the

hopper when the dryer is not running.

Figure 2

Typical CHE Drying Hopper Package

Heater

Sight

glass

Cover and air trap/diffuser

Outlet transition

Return air outlet

Process air connection

Disconnect

Heater

Control

panel

Temperature

controller

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 9

Page 11

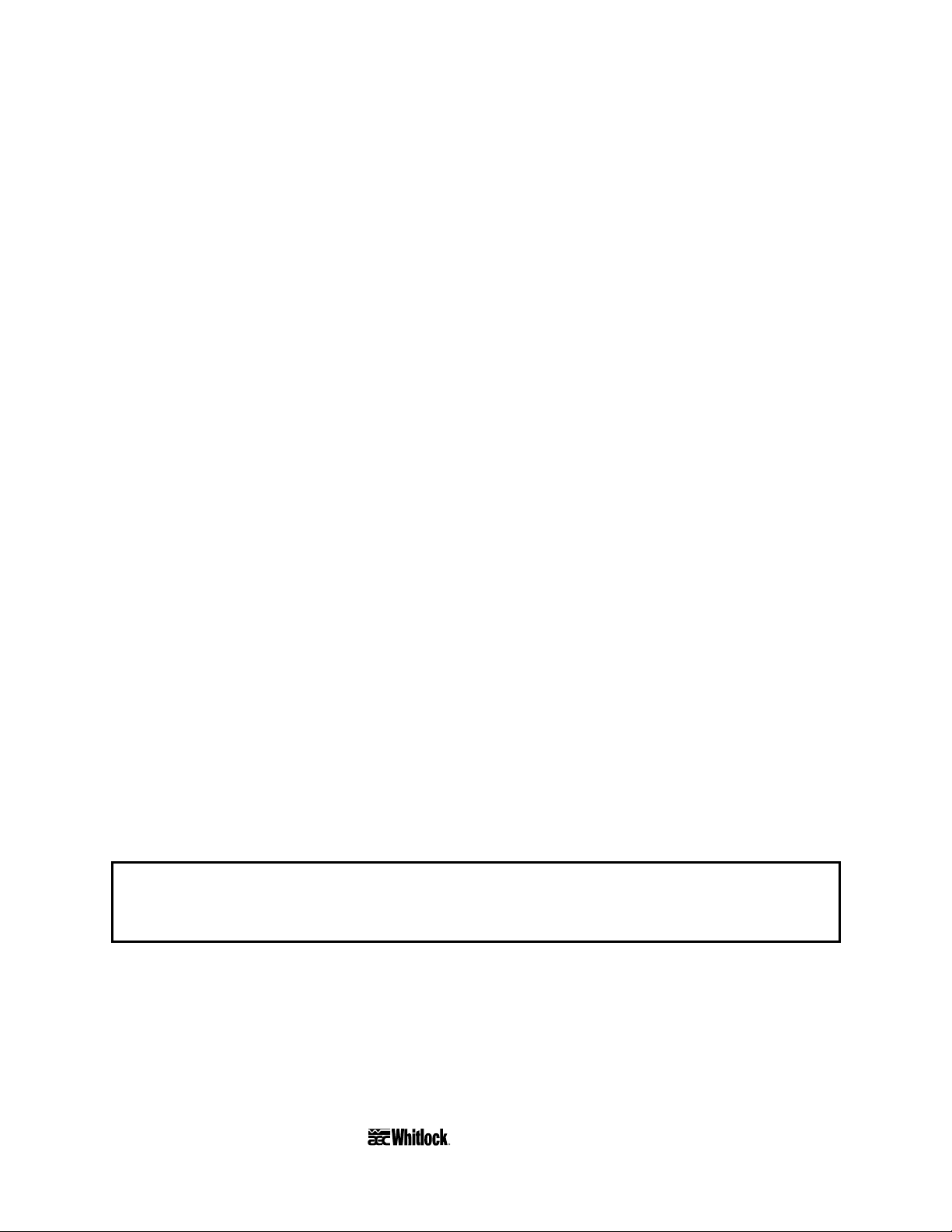

1-5 The BCHE Blower Controls Heater Drying

Hopper Package

The AEC/Whitlock BCHE drying hopper package features a process air blower, heater and

controls for each hopper in your system. BCHE also offers a process air heater removed from the

dryer and mounted at the hopper. The temperature controller is mounted at or on the drying

hopper.

Important!

The main dryer may or may not have a process blower.

Check your drying system for specific options.

The BCHE drying hopper package design allows one dryer to generate dehumidified air for

multiple hoppers. Materials can be dried by a single dryer at different temperatures. BCHE can

also serve as a stand alone hot air dryer for non-hygroscopic materials when an optional ambient

air filter is installed to filter air entering the system.

Note: The BCHE package utilizes individual power drops to each hopper.

Figure 3

Typical BCHE Drying Hopper Package

Sight

glass

Cover and air trap/diffuser

Outlet transition

Return air outlet

Process air connection

Heater

Heater

Control

panel

Temperature

controller

Filter assembly/

process air inlet

Blower

2" high-temp

flex hose

Page 10 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 12

2 Shipping Information

2-1 Unpacking and Inspection

You should inspect your AEC/Whitlock drying hopper unit for possible shipping damage. If the

container and packing materials are in re-usable condition, save them for reshipment, if

necessary.

Thoroughly check the equipment for any damage that might have occurred in transit, such as

broken or loose wiring and components, loose hardware and mounting screws, etc. In case of

breakage, damage, shortage, or incorrect shipment, refer to the following sections.

2-2 In the Event of Shipping Damages

Important!

According to the contract terms and conditions of the Carrier,

the responsibility of the Shipper ends at the time and place of shipment.

The Carrier then assumes full responsibility of the shipment.

; Notify the transportation company’s local agent if you discover damage.

; Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods to AEC, Inc. before the transportation company inspection and

authorization.

; File a claim against the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

; Advise AEC, Inc. regarding your wish for replacement and to obtain an RMA (return

material authorization) number.

Parcel Post Shipment

; Notify AEC, Inc. at once in writing, giving details of the loss or damage. This information is

required for filing a claim with our insurance company.

; Hold the damaged goods with the container and packing materials for possible inspection by

postal authorities.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 11

Page 13

United Parcel Service

; Contact your local UPS office regarding damage and insurance claims.

; Retain the container and packing.

; Notify AEC, Inc. at once.

2-3 If the Shipment is Not Complete

Check the packing list. The apparent shortage may be intentional. Back-ordered items are noted

on the packing list. You should have:

; AEC/Whitlock HE/CHE/BCHE Mass Flow Series drying hopper

; Bill of lading

; Packing list

; Operating and Installation packet

; Electrical schematic and panel layout drawings

; Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking. Determine that the item was not inadvertently taken from the area before you

checked in the shipment. Notify AEC, Inc. immediately of the shortage.

2-4 If the Shipment is Not Correct

If the shipment is not what you ordered, contact AEC, Inc. immediately. Include the order

number and item. Hold the items until you receive shipping instructions.

2-5 Returns

Important!

Do not return any damaged or incorrect items

until you receive shipping instructions from AEC, Inc.

Page 12 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 14

3 Work Rules

3-1 Work Rules

The installation, operation, and maintenance of this equipment must be conducted in accordance

with all applicable work and safety codes for the installation location. This may include, but is

not limited to, OSHA, NEC, CSA, and any other local, national and international regulations.

; Read and follow these operating instructions when installing, operating and maintaining this

equipment. If the instructions become damaged or unreadable, you can obtain additional

copies from AEC/Whitlock.

; Only qualified personnel familiar with this equipment should work on or with this

equipment.

; Work with approved tools and devices.

; Disconnect the electricity before maintenance or service.

; Always work from a stable, debris-free work platform.

; Remove any debris from the blower suction area.

3-2 Necessary Documents

The documents listed below are necessary for the operation, installation, and maintenance of

AEC/Whitlock drying hopper systems. Additional copies are available from AEC, Inc.

Familiarize the appropriate personnel with these documents:

• This manual.

• The electrical schematic included in the customer information packet.

• The Customer Spare Parts List included in the information packet.

• Operation and installation manuals for the dryer, optional controls or auxiliary equipment

in the drying system.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 13

Page 15

3-3 Installing Machine-Mount Drying Hoppers

Note: Figure 5 on Page 16 shows typical mounting bolt patterns.

Important!

Do not mount the drying hopper where excessive vibration is present.

AEC, Inc. is not responsible for any damages caused by excessive vibration.

1. Determine which position the process air inlet, outlet, access door, drawer magnet (if so

equipped) and slide gate/dump spout should be oriented.

You can rotate the assembly 90º to fit your installation and provide a neat and efficient

installation.

2. Loosen the band clamps fastening the cylindrical section to the cover.

3. Orient the outlet in the direction of the return air line, and re-tighten band clamps.

Important!

Using a degreaser, remove rust inhibitor before using your drying hopper.

4. While the drying hopper is still bolted to the shipping pallet, install any needed vacuum

hoppers, hopper loaders, etc. on the cover. The bolt patterns are shown in Figure 3.

Note: AEC/Whitlock VH, PVH, and 99XX Series units with vacuum hoppers and hopper

loaders use covers with the keyhole cutout. AL, VF and TF series vacuum hoppers and

hopper loaders use the circular cutout covers.

Important!

Provide external support for all material conveying piping.

5. Check the flange bolt pattern on the machine the drying hopper is to be mounted on. If

the flange bolt patterns do not match, drill out the drying hopper mounting flange so they

match.

Note: A special flange adapter may be required if the bolt pattern does not mate properly.

Contact your AEC sales representative for more information.

6. Position the included slide gate flange on the processing machine mounting flange and

position the spacers on the slide gate flange so the spacers are parallel to the desired

direction of the slide gate. The slide gate itself can be installed after you secure the drying

hopper to the processing machine.

Note: Some drying hoppers may be equipped with an optional standard slidegate/premium

slidegate or drawer magnet.

Page 14 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 16

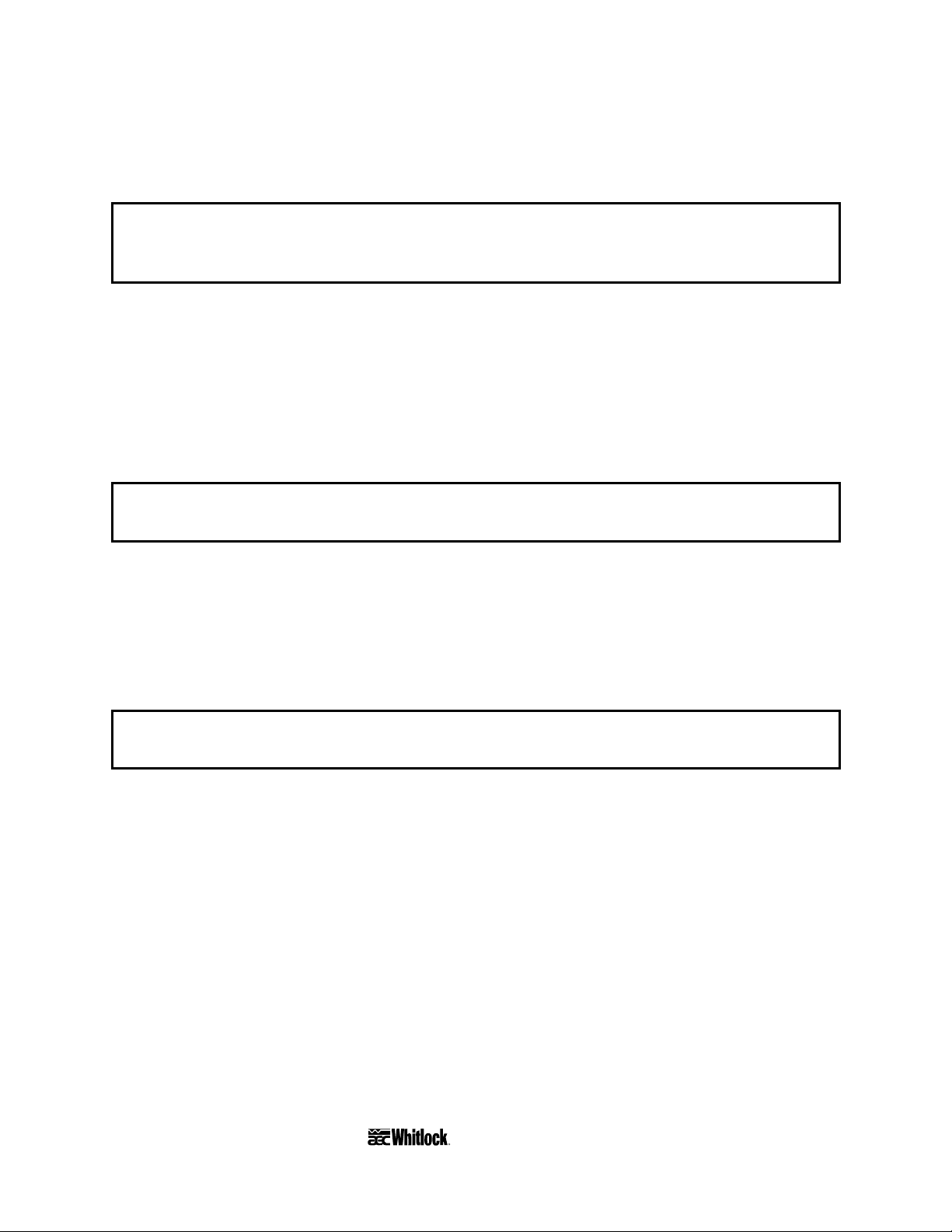

Figure 4

Machine Mounting Flange Dimensions

Mounting Flange Supplied With DH-1.5, DH-3.0, DH-4.0 & DH-6.0

Mounting Flange Supplied With DH-12.0, DH-17.0 & DH-23.0

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 15

Page 17

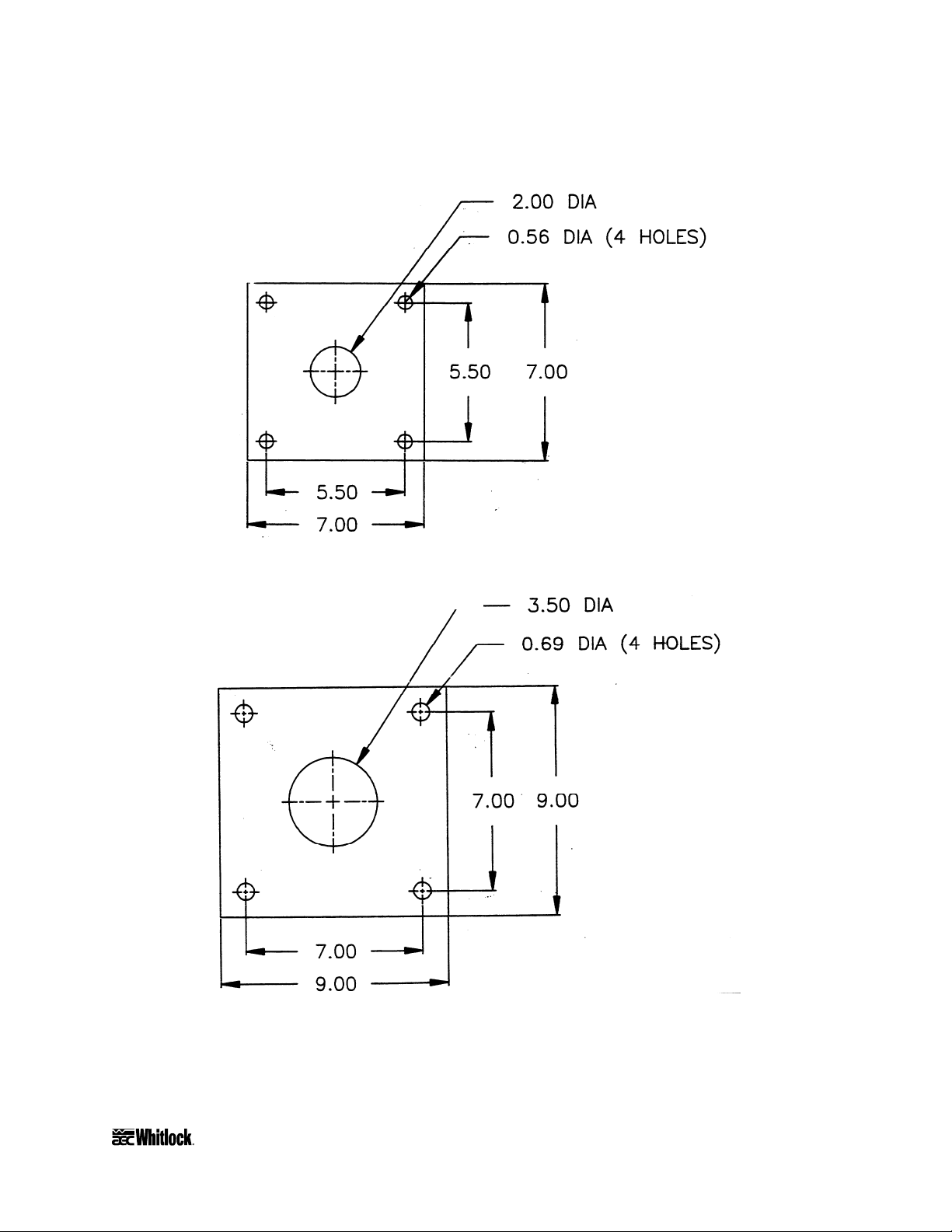

Figure 5

Drying Hopper Cover Bolt Patterns

Cover Cutout for AL, VF and TF Hopper Loaders and Vacuum Hoppers

Cover Cutout VH, PVH and 99XX Hopper Loaders and Vacuum Hoppers

Caution!

Make sure the band clamps are seated and tight and all other components

are secure before lifting the drying hopper from the shipping pallet.

Page 16 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 18

7. Rig the empty drying hopper by the lifting lugs and install it on the processing machine.

8. Insert properly-sized bolts through the drying hopper flange, the slide gate spacers and

the processing machine flange. Fasten securely.

9. Insert the slide gate through the slot made by the slide gate spacers. The slide lip may be

installed up or down.

10. Screw the two retaining bolts provided into the portion of the slide gate exposed when the

slide is fully inserted.

3-4 Installing Floor Mount Drying Hoppers

AEC/Whitlock HE, CHE, and BCHE Mass Flow Series drying hoppers are available in many

floor mount configurations. The size and quantity of the drying hoppers determine the style of

floor stands.

1. Select an installation location with sufficient access for the dump spout, slide gate and

access door.

You can rotate the assembly 90º to fit your installation and provide a neat and efficient

installation.

2. Secure the drying hopper stand to the floor or platform using the appropriate hardware.

3-5 Making Hose Connections

Hose and/or conduit connections must be made to deliver the process air from the dehumidifying

dryer to each drying hopper and back again. The exact connections will vary depending on the

size of the system and the number of drying hoppers involved.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 17

Page 19

Use one of the following procedures to install the air delivery and return lines:

HE drying hoppers

Dryer hose of the proper diameter has been supplied with the dehumidifying dryer. Cut the hose

to length and connect it between the dryer process air delivery tube and the drying hopper heater

inlet with two band clamps. Repeat for the air return line.

Figure 6

Typical Single Hopper Drying Hose Installation

Process air return

Process air supply

Page 18 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 20

CHE and BCHE Drying Hoppers

In systems where one dehumidifying dryer supplies air to several drying hoppers rigid manifold

lines should be installed for both air delivery and return. The manifold lines should include

butterfly valves leading to each drying hopper to throttle the air flow to the drying hopper

requirements. Air flow can be measured using a pitot tube and an instrument such as a hot wire

anemometer. The measurement should be taken in the line on the downstream side of the

butterfly valve, with all drying hoppers full of material and on line. A by-pass valve is also used

in the air supply line after the last drying hopper, to bleed any excess air flow to the return air

line. Do not bleed this air to atmosphere. Butterfly valves can be installed in the return line to be

able to turn a drying hopper off line. It is very important to have the air supply by-pass valve

installed on the last drying hopper if you choose to turn one drying hopper off line.

Figure 7

Typical Multiple Hopper Drying Hose Installation

Throttle/shutoff valve

Process

return

Bypass

valve

air

Process

supply

air

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 19

Page 21

3-6 Making Electrical Connections

CHE and BCHE Models

• Fulfill all national, state, and local safety and electrical code requirements.

• Connections should be made by a qualified electrician.

• Make sure all electrical connections are tight.

• Install a fused disconnect with a lockout feature in the power main leading to the drying

hopper.

• The power drop must include a ground wire.

1. The power drop is brought to the main electrical enclosure at the drying hopper. Voltage

supplied to the unit must be within 10% of nameplate voltage. Ground the unit.

2. For the temperature controller, make sure the thermocouple is tightly in place at the inlet

of the drying hopper.

3. For CHE drying hoppers, wire the interlock from terminals located in the desiccant dryer

to terminals located in the CHE drying hopper enclosure. Use 14GA yellow wire. Refer

to the electrical diagrams from the dryer and drying hopper for terminal numbers.

4. Any companion equipment used with the drying hoppers will require additional

installation steps. Refer to the appropriate operating literature for this information.

3-7 Checking for Proper Blower Rotation

BCHE Models

The blower rotates properly when air flows from the hopper outlet. Incorrect phasing of power

leads causes backward rotation of blower motors and contamination of desiccant!

If the blowers rotate improperly, reverse any two (2) wires at the fused disconnect outside the

dryer or at the disconnect in the control enclosure.

Caution!

Do not reverse the wires at the motor starters!

Page 20 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 22

4 Startup, Shutdown, and Operation

4-1 Pre-Startup Checklist

; Verify that all dryer electrical connections and thermocouples are tight.

; Check blower and heater hose connections.

; Is the drying hopper mounted securely to and properly supported on the processing machine?

If the drying hopper is floor mounted, is the stand fixed to a stable, secured surface?

; Are the hose clamps securing the air diffuser inside the drying hopper tight? Is the air

diffuser plumb and centered in the conical drying hopper section?

; Has all rust inhibitor been removed from the drying hopper product contact surfaces? Is any

and all debris cleaned and removed from the area (especially around blower suction points)?

; Are all band clamps seated and tight?

; Are the access door and cleanout spout secure?

; Are the process and return hose connections secure?

; Is all companion equipment, such as the dryer, loading system and Aftercooler ready for

operation?

; Check blower connections on BCHE models.

4-2 Starting the Process

1. Close the slide gate on the drying hopper.

2. Fill the hopper until the material level is above the lower edge of the air trap cone in the

drying hopper cover.

3. Turn on (energize) the disconnect switch in your power drops, then turn on the power on

the dryer and drying hoppers. Refer to the dryer operation and installation manual for

further information on the desiccant dryer.

4. Make sure that the blowers turn in the right direction.

5. Set the process set point on the temperature controller to the desired temperature.

6. After the proper residence time for the initial hopper fill has elapsed, fully open the slide

gate at the drying hopper.

Note: To ensure proper residence time during continuous processing, the material level in the

hopper should be maintained at the midpoint in the air trap assembly.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 21

Page 23

4-3 Shutting Down the Process

Caution!

Allow the drying hopper to cool before handling.

1. Turn off the conveying system supplying the drying hopper, dryer and drying hopper

controls. If desired, empty the hopper.

2. When processing is complete, close the hopper slide gate and shut down any in-line

companion equipment, such as an Aftercooler.

3. Turn the dryer and drying hopper off.

4. For maintenance or long-term shut down, open (de-energize) the electrical disconnect at

the dryer, drying hopper and the one in your power drop.

Page 22 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 24

Figure 8

Component Identification Exploded View

3

8

19

5

17

10

12

9

1313

7

6

2

11

1

18

4

16

20

14

15

19

24

25

25

21

22

23

No. Part description No. Part description

1 Cone weldment 14 Sight glass

2 Cylinder weldment 15 Sight glass retainer

3 Cover 16 Thermometer, 0ºF to 550ºF c

4 Premium slide gate c 17 Access door

5 Air trap cone 18 Drain cap

6 Air/material diffuser 19 Access door latch

7 Flow cone (DH12.0 to DH23.0) 20 Control assembly

8 Outlet transition tube stub 21 Heater housing

9 Inlet transition tube stub 22 Heater

10 Latch clamp 23 Blower

11 T-bolt clamp 24 Filter c

12 High-temperature air hose 25 Filter clamps

13 Hose clamp

c Optional.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 23

Page 25

- Notes -

Page 24 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 26

5 1/4 DIN Controllers

5-1 Graphic Panel for 1/4 DIN Controller

The graphic panel on the front of the electrical enclosure on CHE and BCHE models using the

1/4 DIN temperature controller incorporates a schematic of the drying process with indicator

lights, warning lights, the power switch and a 1/4 DIN temperature controller.

Figure 9

Graphic Panel for 1/4 DIN Controller

Process Blower Light

DRYER

PROCESS

BLOWER

PV

ºF

3 0 0

SV

3 0 0

OUT SHIFT AT ALM1 ALM2

PROCESS

HEATER

AT

DRYING

HOPPER

ON

OFF

HIGH

TEMP

BCHE Models

This green indicator lights when the process blower is on.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 25

Page 27

Process Heater Light

r

r

CHE and BCHE Models

This green indicator lights when the process air heater is on.

High Process Air Temperature Light

CHE and BCHE Models

This red indicator lights when the temperature at the process air thermocouple is outside the set

alarm value. The alarm mode and value are factory-set to track 25° above the process set point.

Therefore, the alarm value is set as a deviation from the process set point.

When the indicator lights, the alarm relay is energized and all the heaters turn off while the

blowers remain on. When the temperature at the process thermocouple returns to within the

acceptable range, the alarm output is de-energized and the heaters will turn on again

automatically. The alarm range can be altered.

5-2 Using the 1/4 DIN Temperature Controller

Some AEC/Whitlock drying hoppers use a 1/4 DIN microprocessor-based PID temperature

controller for maintaining process air temperature. The controller is a modular, self-contained

unit you can remove from the mounting housing. All parameters except for the process air set

point are factory set and adjusted; normally, no field adjustment to the internal controls is

necessary.

Figure 10

1/4 DIN Controller

PV

PV (Process Value)

display

ºF

ºF (Fahrenheit) decal

3 0 0

SV

3 0 0

OUT indicator

SHIFT indicator

Level key

Page 26 HE • CHE • BCHE Mass Flow Series Drying Hoppers

OUT SHIFT AT ALM1 ALM2

Mode key

AT

Up key

Down key

SV (Set Value)

display

AT (Auto-Tune)

indicato

ALM1 (Alarm 1)

indicato

ALM2 (Alarm 2)

AT (Auto-Tune) key

Page 28

LED Displays and Indicators

PV (Process Value) Display

During normal operation, the large red

PV LED screen displays the actual process temperature at

the To Process thermocouple. It also lists parameters during setup, and error messages if an error

condition exists.

SV (Set Value) Display

During normal operation, the green

SV LED screen displays the process set point you selected

for the dryer to maintain. The screen also displays parameter and preset function values during

setup.

OUT

OUT (Output) LED Indicator

The orange

OUT LED lights when the control output energizes the process air heater.

SHIFT

SHIFT LED Indicator

The orange SHIFT LED is not used on WD Dryers.

AT

AT (Auto-Tune) LED Indicator

The orange AT LED flashes during the Auto-Tune sequence.

ALM1

ALM1 (Alarm 1) LED Indicator

The red ALM1 LED lights when the process air temperature has risen more than 25° from the set

point. The alarm relay is energized when this LED lights. All heaters turn off and the blowers

stay on to cool the heaters.

ALM2

ALM2 (Alarm 2) LED Indicator

The red

ALM2 LED is not used.

Controller Buttons

Level Button

Press and hold the Level button for two (2) seconds or more to select the next of three

indication levels (0, 1, and 2) where specific control parameters may be set. The controller

defaults to Level 0 on power-up.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 27

Page 29

Mode Button

Press the

Mode button to scroll through parameters you can set in Indication Levels 0

and 1.

Note: During normal operation, press this button to change the alarm setting only. The factory

alarm setting is 25º above the set point, and is satisfactory for most applications.

Down Button

Press the Down button to lower the process air set point temperature. During setup, press

this button to decrease the value of the parameter displayed in the SV (Set Value) LED screen.

Up Button

Press the Up button to raise the process air set point temperature. During setup, press this

button to increase the value of the parameter displayed in the SV (Set Value) LED screen.

AT

AT (Auto-Tune) Button

Press and hold the

AT

AT (Auto-Tune) button for one second or more to start the Auto-Tune

function. See Section 5-8 on Page 30 for more information.

5-3 Using Temperature Controller Internal Switches

The control is set up and tested at the factory for optimum operation, and the internal switches

don’t need to be adjusted. If the controller does not work properly, or you suspect someone has

inadvertently changed some settings, perform the Auto-Tune procedure as listed in Section 5-8

on Page 30. If that doesn’t work, see Section 5-9 on Page 31 for information on returning the

controller to factory setup.

Page 28 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 30

5-4 Using the Temperature Controller Anti-Tamper

Lockout Switch

The anti-tamper lockout slide switch prevents unauthorized changes to set points. If the SW101

switch is

On, the Level, Down, Up, and

AT

AT keys are disabled. Only

the process set point and alarm settings may be viewed. Your unit is factory-set with the

protection turned Off.

To enable the lockout feature:

1. Disconnect main electrical power to the dryer.

1. Press up the latch at the bottom of the control module’s front panel and slide out the

control chassis.

2. Locate the slide-type switch marked SW101 {PROTECT} on the left

circuit board. Slide it to ON.

OFF ON

SW101 {PROTECT}

3. Slide the chassis back into the control module housing. Tamper protection will now be

enabled.

5-5 Changing the Display from Fahrenheit to Celsius

To change the display from the factory °F setting to °C:

1. Disconnect main electrical power to the dryer.

1. Press up the latch at the bottom of the control module front panel and slide out the control

chassis.

2. Locate DIP switch SW201 {FUNCTION} on the right circuit board.

Slide the #5 pin to

OFF.

1. Slide the chassis back into the control module housing.

ON

123456

SW201 {FUNCTION}

2. Cover the °F label with the °C sticker included in the information packet.

5-6 Setting the Process Air Temperature

To change the process air temperature set point:

Press the Up button to raise the set point.

Press the

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 29

Down Button to lower the set point.

ºC

Page 31

5-7 Setting the High Temperature Alarm

To change the process air high temperature alarm setting:

1. Press the Level key for at least two seconds to gain access to Level 1 parameters.

2. When the

the value you want.

The alarm value is a deviation of the process air temperature set point. The alarm

value tracks the set temperature. If the high temperature alarm is set to

temperature alarm activates if the process air temperature rises more than 20° above the

process air temperature as set in Section 5-6 on the previous page.

3. Press the Level key until the Level 0 values (process air temperature set point and

process air temperature) display.

The high temperature alarm is now set.

PV LED displays AL-1, press the Up and Down keys to set

20, a high

5-8 Activating the Auto-Tune Function

Auto-tune fine-tunes the control PID to process requirements. Auto-tune whenever the process

under control changes.

Don’t be alarmed by control response. It may take the process temperature above and below the

set points as many as three times. It will then level off and control to the process set point. Autotuning can take up to thirty (30) minutes, and is best done before you run any process.

To auto-tune the control:

Press and hold down the

flashes.

The AT AT LED flashes to indicate that the control is tuning itself. When the AT AT LED

light stops flashing, the controller is tuned and ready for operation.

Page 30 HE • CHE • BCHE Mass Flow Series Drying Hoppers

AT

AT key for several seconds until the AT AT indicator

Page 32

5-9 Restoring the Controller to Factory Setup

If the controller pre-set parameters have been tampered with and it no longer controls

temperature properly, restore the factory setup using these procedures:

1. Turn off the power switch on the graphic display and remove all electrical power to the

dryer.

2. Press up the latch at the bottom of the control module front panel and slide out the control

chassis.

3. Locate the slide-type lockout switch marked SW101 {PROTECT}

on the left circuit board. It should be OFF.

OFF ON

SW101 {PROTECT}

4. Make sure the control output relays are installed on the right-hand circuit board. Your

unit uses one E53-S solid state relay (SSR) mounted in the socket marked S201 (HEAT).

This relay switches the heater on and off.

5. Set the output selector switch marked SW202 to PULSE. This slide-

type switch is near the control output socket.

6. Set the rotary-type alarm mode selector switch marked SW205 to Position 2 for

upper limit alarm only.

7. Set the rotary-type ALM2 switch marked SW203 to Position 0, the No Alarm

function.

8. Set the rotary temperature sensor selector switch to Position 2. It is marked

SW206 (INPUT TYPE) and is on the right-hand circuit board.

OFF ON

PUL-CUR

9

8

7

6

9

8

7

6

SW203 [ALM]

9

8

7

6

SW206 (INPUT TYPE)

Your unit is factory-equipped with Type K thermocouples; six (6) other

temperature sensor types can be used if the switch is properly set.

9. Set both transmission output selector DIP switches to OFF. They are marked SW207

(TRANSFER)

and are on the right circuit board on controls equipped with optional

communications. See the Communications Manual (AEC Part No. A0535959) for more

information.

SW205

0

1

2

3

4

5

0

1

2

3

4

5

0

1

2

3

4

5

10. The function selector DIP switch marked SW201 (FUNCTION) selects six control modes.

It is located on the right-hand circuit board. Put this switch in the setup configuration (see

the table below) when you enter the initial control parameters.

SW201 Setup Configuration

Switch Position Description

1 OFF Control mode

2 OFF Normal/reverse output

3 OFF Input shift

4 OFF Temperature sensor standard

5 ON Scale indication — ºF

6 ON PID constant indication

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 31

Page 33

11. Slide the control chassis back into the control housing. The remaining parameters are set

with the keypad.

12. Prepare your unit for startup with a real or simulated load. Restore electrical power.

Figure 11

1/4 DIN Temperature Controller Preset Parameters

Parameter

setting levels

0

1

2

Display at power-up.

Alarm range.

Proportional bandwidth.

Reset time.

Rate time.

Lower limit value of control range.

Upper limit value of control range.

Heating control period.

Shift set value.

Control output variable.

Temperature sensor type.

Alarm mode.

Unit number setting w/optional

communications.

Baud rate setting w/optional

communications.

Parameter

description

PV LED

display

Process

temperature

TDH SV LED

setting

Process

set point

25°F

39°F

109 seconds

27 seconds

0°F

400°F

20 seconds

0°F

Read only.

Varies with

network.

Varies with

network.

Page 32 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 34

13. Turn control power on.

The PV LED displays four zeros (0000), then displays the current process air

temperature.

14. Press the MODE key to page through the Level-0 control parameters. The PV LED

displays codes indicating the currently selected mode; the SV LED shows the current

setting of the selected parameter. Use the Up and Down arrow keys to select a setting. Set

the Level 0 parameters based on Figure 9 on the previous page.

15. Press the Level key for at least two seconds to access Level 1 parameters. Set them using

the procedure in the previous step.

Note: You can proceed to Level 2, but these parameters are read-only. Controls with optional

communications have user-set variables (unit address and ID) on Level 2.

16. Turn off the power switch on the graphic display and remove all electrical power to the

dryer.

17. Press up the latch at the bottom of the control front panel and slide out the control

chassis.

1. Set the #6 position of the DIP-type function selector switch to OFF.

It is marked SW201 {FUNCTION} and is on the right circuit board.

2. Turn the control power on. The PV LED displays four zeros

ON

12 3 4 5 6

SW201 {FUNCTION}

(0000), then displays the current process temperature.

3. Auto-tune the dryer using the procedure in Section 5-8 on Page 29.

If the control still fails to control, call the AEC/Whitlock Service Department.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 33

Page 35

Figure 12

Self-Diagnostic Error Messages

Message Cause Heater circuit

Temperature has risen beyond the temperature scale

OFF

ON

OFF

OFF

OFF

(flashes)

(flashes)

range.

Temperature has fallen below the temperature scale

range.

1. The thermocouple has burned out.

2. The short circuit bar has been removed.

Memory failure. the controller must be replaced if recovery

is not made by turning power off once and on again.

Analog-to-digital converter failure. The controller must be

replaced if recovery is not made by turning power off once

and on again.

Page 34 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 36

6 1/16 DIN Controllers

6-1 Graphic Panel for 1/16 DIN Controller

The graphic panel on the front of the electrical enclosure on CHE and BCHE models using the

1/16 DIN temperature controller incorporates indicator lights, warning lights, the power switch

and a 1/16 DIN temperature controller.

Figure 13

Graphic Panel for 1/16 DIN Controller

PROCESS

BLOWER ON

G R

PROCESS

TEMPERATURE

PV

SV

A

M

PROCESS

HEATER ON

G

DRYER

ONOFF

HIGH

TEMPERATURE

PROCESS AIR

R

DRYING HOPPER

LOW LEVEL

ALARM

PUSH TO

SILENCE

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 35

Page 37

Graphic Panel Controls and Indicators

PROCESS BLOWER ON Indicator

The green

PROCESS BLOWER ON indicator is lit when the process blower is operating.

PROCESS HEATER ON Indicator

The green PROCESS HEATER ON indicator is lit when the process air heater is on.

HIGH TEMPERATURE PROCESS AIR Indicator

The red

HIGH TEMPERATURE PROCESS AIR indicator is lit when:

• The temperature sensed by the process air thermocouple is outside the alarm set value.

• The alarm relay energizes and all the heaters turn off while the blowers remain on.

The alarm mode and value are factory-set to track 25º above the process set point. The alarm

value, therefore, is set as a deviation from the process set point. W h en the temperature at the

process thermocouple returns to within acceptable range, the alarm output de-energizes and the

heaters turn on again automatically.

DRYING HOPPER LOW LEVEL ALARM Indicator

The red DRYING HOPPER LOW LEVEL ALARM indicator is lit during a low level alarm

condition.

DRYER OFF ON Switch

The DRYER OFF ON switch is used to start or stop the drying cycle after the disconnect switch

is placed in the ON position.

PUSH TO SILENCE Switch

Press the PUSH TO SILENCE switch to stop the alarm during an alarm condition.

6-2 Using the 1/16 DIN Temperature Controller

Some AEC/Whitlock dryers use a 1/16 DIN microprocessor-based PID temperature controller

for maintaining process air temperature. The controller is a modular, self-contained unit you can

remove from the mounting housing. All parameters except for the process air set point are

factory set and adjusted; normally, no field adjustment to the internal controls is necessary.

Page 36 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 38

Figure 14

1/16 DIN Controller

STOP indicator

OUT1 indicator

MANU (Manual)

indicator

OUT2 indicator

Auto/Manual

key

PV

SV

OUT1

OUT2 MANU STOP RMT AT SUB1

Process value

(PV) indicator

Set value (SV)

indicator

Automatic

tuning (AT)

indicator

SUB1 indicator

RMT (Remote)

indicator

A

M

Display key

Up key

Down key

Identifying Temperature Controller LED Indicators on the 1/16 DIN

Controller

PV (Process Value) Numeric LED

During normal operation, the process value (

PV) numeric LED indicator displays the process

temperature at the To Process thermocouple. It also lists parameters during setup and error

messages if any errors occur.

SV (Set Value) Numeric LED

During normal operation, the set value (

SV) numeric LED indicator displays the process set

point you selected for the dryer. The dryer then maintains this set point temperature. This LED

indicator also displays parameter and pre-set function values during setup.

OUT1

The

OUT1 indicator lights when the controller transmits an energize signal to process heaters.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 37

Page 39

OUT2

Not used in this application.

MANU

The MANU (Manual mode) indicator lights when the system is in Manual operation mode.

STOP

Not used in this application.

RMT

The RMT (Remote) indicator lights during remote operation on dryer systems equipped with

optional RS-232C or RS485 external communication features.

AT

The AT indicator flashes during the auto-tuning procedure.

SUB1

The SUB1 indicator lights when the process temperature exceeds the set point temperature by

more than the alarm deviation value. The alarm output de-energizes heaters. Heaters re-energize

when the temperature returns within the acceptable range.

Identifying Temperature Controller Keys on the 1/16 DIN Controller

Figure 14

A

M

Auto/Manual Key

A

M

Press the

Auto/Manual key to select automatic operation or manual operation.

Display Key

Press the Display key to shift the display to the next set of parameters. The menu screen

then displays.

Page 38 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 40

Down Key

Press the Down arrow key to lower the process air set point temperature. During setup,

press this key to decrease the value of the parameter displayed on the set point LED readout.

Up Key

Press the Up arrow key to raise the process air set point temperature. During setup, press

this key to increase the value of the parameter displayed on the set point LED readout.

6-3 Setting the Process Air Temperature on the 1/16

DIN Controller

To change the process air temperature set point with the dryer running:

Press to raise the set point.

Press to lower the set point.

6-4 Setting the High Temperature Alarm on the 1/16

DIN Controller

If you cannot access Level 0 mode to change the high temperature alarm setting, you must

change the security lock-out level of the controller. See Section below to remove the security

lock-out.

1. Press

switch between modes. Level 0 displays.

2. Press to display Level 1. Lu-1 displays.

3. Press

once (keep the pressure on the button for about 1 to 1.5 seconds) in order to

once more for about one to one and a half seconds. Now use short presses

until AL-2 displays.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 39

Page 41

4. Press and to set the higher or lower value for the high temperature alarm.

5. Press for about one to one and a half seconds. Level 1 displays.

6. Press until Level 0 displays.

7. Press for about one to one and a half seconds to go to Operating mode (process air

temperature readout display).

Notes: • The high temperature alarm value is a deviation of the process air temperature set

point. The alarm value tracks the set temperature. If the high temperature alarm is

set to 25, a high temperature alarm occurs if the process air temperature rises more

than 25° above the process air temperature set point.

• The E5CK controller has several levels of securities to lock out access to

parameters and menu settings. If the controller will not allow you to change

settings, see Section 6-5 below to set the E5CK security to access the function you

need.

6-5 Restoring the 1/16 DIN Temperature Controller to

Factory Setup

If preset parameters on the controller have been tampered with and it no longer properly controls

temperature and displays dew point, you can restore the controller to factory setup.

1/16 DIN E5CK Operating Parameters

The E5CK controller has several mode selections. Within each mode are numerous parameters

that can be set. Before you can access the several modes of operating parameters, you must

change the security lock-out of the controller. AEC factory sets the security level to protect the

parameters from being accidentally changed. Below is an explanation of the operating modes,

how to change out the security level and the AEC default settings.

Available 1/16 DIN E5CK Modes

Menu Display

Level 0 Mode

For normal operation.

Page 40 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 42

Level 1 Mode

For adjusting primary control parameters. Execute: AT (auto-tuning); set alarm values; set the

control period; set PID parameters.

Level 2 Mode

For adjusting secondary control parameters. Nomad Cart uses E5CK default settings.

Setup Mode

For setting the basic specifications. Set parameters for input type, scaling, output assignments

and direct/reverse operation.

Expansion Mode

For setting expanded functions. Set: ST (self-tuning), SP setting limiter. Select: advance PID or

ON/OFF control.

Option Mode

This mode is only accessible when and option board is installed.

Calibration Mode

For calibrating communication unit E53-CKF. Not used.

A

M

A/M Key

Protect Mode

A

Limits the use of the menu and

M

Automatic/Manual keys. The protect function allows for

setting different levels of security. See Setting E5CK Security in Protect Mode on the

following page for E5CK security settings.

Manual Mode

Sets the controller to manual operation mode. Nomad carts are set for manual mode.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 41

Page 43

Figure 15

Display Readout for Mode Settings

PV

SV

SV

SV

SV

SV

SV

SV

Menu display

Level 0 mode

Level 1 mode

Level 2 mode

Setup mode

Expansion mode

Option mode

Calibration mode

Setting 1/16 DIN E5CK Security in Protect Mode

A

1. To access protect mode, press and hold the

more than one and a half to two (1.5 to 2) seconds.

M

A/M key and the display key for

2. The display should read SECr for security mode. If you press the display key for

short presses you will toggle between (SECr) and (KEYP) for AM protect.

3. With the display reading SECr, set the security levels by the arrow up and down keys.

Change the security level to 1 to make changes to the operating parameters. Nomad carts

are factory set to Security Level 5.

Available Security Levels

Security level

Mode 0 1 2 3 4 5 6

Calibration X

Option X X

Expansion X X

Setup X X

Level 2 X X X

Level 1 X X X X

Level 0 X X X X X X

To return to the main display (run mode), press and

hold the A/M and Display key for 1.5 to 2 seconds.

Page 42 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 44

Entering Operating Parameters to Select Modes for 1/16 DIN

Controllers

To enter the menu display:

1. Press for one second (keep the pressure on the button for about 1.5 to 2 seconds).

The screen displays

2. Press the

SV readout displays the mode you selected.

The

Up Arrow key to toggle through the different modes.

3. To switch parameters within a mode, press the

.

Display key once more for about

one and a half to two (1.5 to 2) seconds.

The PV readout displays the different parameters within each mode.

4. Use short presses on the Display key to display each parameter within a mode.

The SV readout displays the different values for the parameter within a mode.

5. Press and to set the higher or lower the values of a parameter.

6. Press for about one and a half to two (1.5 to 2) seconds to move up a level back

into the different modes.

7. Press

until Level 0 displays.

8. Press for about one to one and a half (1 to 1.5) seconds to go to Operating mode.

Figure 16

Default Setting List for 1/16 DIN Process Temperature Controller

Mode Parameter Setting range Default AEC setting

Protect SECr Security 0 to 6 1 5

Protect YEYP A/M Key Protect ON/OFF OFF ON

Manual Manual MV -5.0 to 105.0% 0.0 Default

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 43

Page 45

Figure 16

Default Setting List for 1/16 DIN Process Temperature Controller

Mode Parameter Setting range Default AEC setting

Level 0 SP Set Point SP Lower Limit to Upper Limit EU 0 Default

Level 0 r - S Run/Stop Run/Stop Run Default

Mode Parameter Setting range Default AEC setting

Level 1 AE AT Execute/Cancel Off/AT-1/AT-2 Off Default

Level 1 SP-0 Set Point 0 SP Lower to Upper EU 0 Default

Level 1 SP-1 Set Point 1 SP Lower to Upper EU 0 Default

Level 1 AL-1 Alarm Value 1 -1999 to 9999 EU 0 25.0

Level 1 AL-2 Alarm Value 2 -1999 to 9999 EU 0 25.0

Level 1 AL-3 Alarm Value 3 -1999 to 9999 EU 0 Default

Level 1 P Proportional Band 0.1 to 999.9 %FS 10.0 4.4

Level 1 I Integral Time 0 to 3999 SEC 233 84

Level 1 d Derivative Timer 0 to 3999 SEC 40 13

Level 1 C-SC Cooling Coefficient 0.01 to 99.99 1.00 Default

Level 1 C-db Dead Band -19.99 to 99.99 %FS 0.00 Default

Level 1 6F-r Manual Reset Value 0.0 to 100.0% 50.0 Default

Level 1 HYS Hysteresis (Heat) 0.01 to 99.99 %FS 0.10 Default

Level 1 CHYS Hysteresis (Cool) 0.01 to 99.99 %FS 0.10 Default

Level 1 CP Control Period (Heat) 1 to 99 SEC 20 Default

Level 1 C-CP Control Period (Cool) 1 to 99 SEC 20 Default

Mode Parameter Setting range Default AEC setting

Level 2 r-L Remote/Local RMT/LCL LCL Default

Level 2 SPrU Sp Ramp Time Unit M(Minutes)/H(Hour)s M Default

Level 2 SPrE Sp Ramp Set Value 0 to 9999 EU 0 Default

Level 2 LbA LBA Detection Time 0 to 9999 SEC 0 Default

Level 2 Au-5 MV at Stop -5.0 to 105.0 % 0.0 Default

Level 2 Au-E MV at PV Error -5.0 to 105.0 % 0.0 Default

Level 2 6L-H MV Upper Limit MV Lower Limit +0.1 to 105.0% 105.0 Default

Level 2 6L-L MV Lower Limit -5.0 to MV Upper Limit -0.1% -5.0 Default

Level 2 6rL MV Change Rate Limit 0.0 to 100.0 %/SEC 0.0 Default

Level 2 CnF Input Digital Filter 0 to 9999 SEC 0 Default

Level 2 ALH1 Alarm 1 Hysteresis 0.01 to 99.99% 0.02 Default

Level 2 ALH2 Alarm 2 Hysteresis 0.01 to 99.99% 0.02 Default

Level 2 ALH3 Alarm 3 Hysteresis 0.01 to 99.99% 0.02 Default

Mode Parameter Setting range Default AEC setting

Level 2 Cn5H Input Shift Upper Limit -199.9 to 999.9 °C 0.0 Default

Level 2 Cn5L Input Shift Lower Limit -999.9 to 999.9 °C 0.0 Default

Page 44 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 46

Figure 16

Default Setting List for 1/16 DIN Process Temperature Controller

Mode Parameter Setting range Default AEC setting

Setup Cn-E Input Type 0 to 21 2 3

Setup Cn-H Scaling Upper Limit Scaling Lower Limit +1 to 9999 EU -100 Default

Setup Cn-L Scaling Lower Limit

Setup dP Decimal Point 0 to 3 0 Default

Setup d-U °C/F Selection °C/F °C °Fc

Setup CnCE Parameter Initialize Yes/No No Default

Setup

Setup

Setup

Setup ALE1 Alarm 1 Type 0 to 11 2 Default

Setup

Setup ALE2 Alarm 2 Type 0 to 11 2 Default

Setup

Setup ALE3 Alarm 3 Type 0 to 11 2 Default

Setup

Setup

c Check sales order for temperature unit selection.

6UE1 Control Output 1

Assignment

6UE2 Control Output 2

Assignment

Sub 1 Auxiliary Output 1

Assignment

AL1n Alarm 1 open in

alarm

AL2n Alarm 2 open in

alarm

AL3n Alarm 3 open in

alarm

6rEu Direct/Reverse

Operation

-1999 to SP Setting Upper Limit -

0.1 EU

Heat/Cool/Alarm 1/ Alarm 2/Alarm

3/LBA

Heat/Cool/Alarm 1/ Alarm 2/Alarm

3/LBA

Alarm 1/Alm 2/Alm 3/LBA/S.

ERR/E333

NO/NC NO Default

NO/NC NO Default

NO/NC NO Default

OR-R/OR-D OR-R Default

0 Default

Heat Default

AL-1 Default

AL-2 Default

Mode Parameter Setting range Default AEC setting

Expansion SL-H Set Point Upper Limit

Expansion SL-L Set Point Lower Limit

Expansion CnEL PID/ON/OFF PID/ON/OFF PID Default

Expansion SE ST Adaptive Tuning (Fuzzy) OFF/ON OFF Default

Expansion SE-b ST Stable Range 0.1 to 999.9 °C/F 15 Default

Expansion

Expansion AE-G AT Calculated Gain 0.1 to 10.0 1.0 Default

Expansion

Expansion

Expansion AE-H AT Hysteresis 0.1 to 9.9 %FS 0.2 Default

Expansion LbAb LBA Detection Width 0.0 to 999.9 %FS 0.2 Default

rESE Standby Sequence Reset

rEE Automatic Return of

ALFA α

Setting Method

Display Mode

SP Lower Limit +1 to

Scaling Upper Limit

Scaling Upper Limit to SP

Lower Limit

0.01 to 1.00 0.65 Default

0/1 0 Default

0 to 99 SEC 0 Default

1300 400.0

-200 0

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 45

Page 47

Figure 17

Available Option Boards

Option type

Board no.

RS232C RS-485 Event input Transfer output

E53-CK01 E53-CK03 E53-CKB E53-CKF

Notes: • Option Mode only visible when an option board is installed.

• Use default settings for Communications board. Contact AEC Whitlock Engineering

for settings on “Event Input” and “Transfer Output” boards.

Mode Parameter Setting range Default AEC setting

Option Eu-A Multi-SP Function 0/1 0 Default

Option Eu-1 Event Input Assign 1 STOP/MAN STOP Default

Option SbCE Communication Stop Bit ½ BITS 2 Default

Option LEn Comm. Data Length 7/8 BITS 7 Default

Option PrEY Communication Parity None/Even/Odd Even Default

Option 6PS Comm. Baud Rate 1.2/2.4/4.8/9.6/19.2 9.6 kbps Default

Option U-n6 Comm. Unit No. 0 to 99 0 Default

Option Er-E Transfer Output Type SP/SP-M/PV/O/C-O SP Default

Option Er-H Xfer Output Upper Limit 5 5 Default

Option Er-L Xfer Output Lower Limit 5 5 Default

Page 46 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 48

7 Maintenance

7-1 Work Rules

The installation, operation, and maintenance of this equipment is to be conducted in accordance

with all applicable work and safety codes for the installation location. This may include, but is

not limited to, OSHA, NEC, CSA, and any other local, national, and international regulations.

In addition, you must observe the following specific work rules:

; Keep these operating instructions on hand and follow them when installing, operating, or

maintaining your dryer.

; If the instructions become damaged or unreadable, you can obtain additional copies from

AEC/Whitlock.

; Only qualified personnel familiar with this equipment should work on or with this unit.

; Work only with approved tools and devices.

; Disconnect power before servicing your dryer. If the disconnect switch you installed has a

lockout, lock it in the OFF position before you perform any maintenance or service.

Note: Refer to your dryer O&I manual for dryer maintenance.

7-2 Cleaning Out the Drying Hopper

1. Turn off the conveying equipment filling the hopper.

2. Close the slide gate.

3. Position a Gaylord, barrel or other suitable container below the drying hopper cleanout

spout. Make sure it is large enough to hold the material that remains in the drying hopper.

Note: A section of gutter, flex hose, etc., is typically used to direct the flow of material from the

drain spout.

4. Remove the cap on the drain spout and allow the material to drain from the drying

hopper.

5. Remove the material below the drain spout outlet if desired. A hopper loader, central

vacuum system or pneumatic conveyer material pickup device may be used to remove the

remaining material without waste. A shop-type vacuum cleaner may be used if the

remaining material does not need to be saved for re-use.

6. Clean out any remaining material from below the slide gate. The air diffuser assembly

may be removed through the access door for a thorough cleaning.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 47

Page 49

7. Loosen the hose clamps securing the diffuser to the tube stub inside the drying hopper.

8. Re-install the air diffuser before operating the drying hopper.

7-3 Replacing the Process Heater

HE, CHE, and BCHE drying hoppers use Calrod-type heater elements mounted in a heater tube

located near the air inlet of the drying hopper. Heater wattage varies with model, voltage,

temperature range, etc., but the replacement procedure is the same. Check your customer spare

parts list that was included in your information packet.

! WARNING !

Disconnect and lock out power before you replace heater elements!

Procedures

1. Remove the bolts securing the process heater access cover. Typically the heater tube is

mounted in a vertical position with the heater access cover facing the floor.

2. Sketch the heater wiring configuration so you can properly re-wire the heater.

3. Remove the wires to the heater plate assembly you are removing or replacing.

4. Remove the bolts securing the heater plate assembly, and slide out the assembly.

5. Remove the heater from the mounting plate by removing the large brass nuts and

washers.

6. Re-install the heater and heater plate assemblies in reverse order. Install new heater

gaskets and securely tighten all fasteners.

Caution!

Heater loops should not touch each other.

“Hot spots” lead to premature heater failure!

7. Reinstall the wires based on the sketch you made earlier.

8. Secure the heater access cover.

Page 48 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 50

7-4 Servicing Process Air Filters

Optional

Important!

Operating the dryer without the process air filter installed voids your warranty!

Filter cleaning is an important part of your dryer maintenance program.

Drying hoppers with the optional process air filters have a single cartridge canister-type filter in

the process, air loop before entering the blower. The process filter is located in a filter housing

near the blower. The filter protects the blowers from plastic fines drawn in from the drying

hopper. Regular filter cleaning is essential to keep your dryer operating at peak efficiency.

The filters can be washed or blown out, but remember, you reduce dirt holding capacity with

each washing. The risk of dirt reaching the clean side of the filter during cleaning, plus possible

filter damage from high pressure washing or blowing, makes washing a gamble.

You can carefully clean or wash the filter when airflow becomes restricted. Do not wash filters

more than six (6) times or use them for more than a year, whichever comes first.

Use a detergent that won’t damage filter media. Such a detergent permits easy removal of dirt

particles through flushing and rinsing. An effective detergent removes the fine particles from the

pores of the filter media.

The filter manufacturer recommends FM 1400 washing compound. It is formulated specifically

for air filter element cleaning. It is non-sudsing and works in hot or cold water. FM 1400

contains biodegradable synthetic detergents and is non-phosphate, non-NTA. For more

information, contact Filter Service Corporation, 2603 A West Main, Farmington, NM

1-505-326-1127.

Recommendations for Cleaning and Replacing Filters

• Turn off and/or lock out electrical power to the dryer.

• Remove the threaded fastener securing the filter access cover, then remove the cover.

• Remove the nut on the center retaining rod to remove the filter cartridge.

Vacuuming

Try vacuum-cleaning a soiled filter first. Vacuuming removes most large particles and surface

contaminants, and may be all that’s needed the first time you clean a filter. Use a commercialduty (recommended) or household vacuum cleaner. Vacuum the filter from the air intake (dirty)

side only.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 49

Page 51

Cleaning with Compressed Air

Blow clean, dry compressed air up and down the pleats, blowing out the filter from

the clean side. Remove loose dirt from the filter with compressed air or a water

1

hose. Compressed air should be less than 100 psi (689.5 kPa/6.89 bars). Use a

/8”-x.

(3 mm-dia.) nozzle at least 2” (5 cm) away from the filter. Don’t shoot the air in a

crisscross motion against the grain of the pleats—you may damage it.

Washing

As a last resort, wash the filter. However, do so only if the pressure drop is too

high from fine dirt embedded in the filter, or if oily mist is present near the intake

air location. Soak in a solution of FM 1400 or comparable detergent and warm

water from five to ten minutes, then gently agitate for several minutes.

Rinse thoroughly with clean water to remove all detergent. Let the filter dry

completely before returning it to service. Do not use a light bulb to dry the filte r.

You should get satisfactory filtration after second or third washings; however, dirtholding capacity of the filter decreases after each washing.

After each cleaning:

• Inspect the filter element. Briefly hold a light bulb behind the element and look

for any fatigued paper or residual dirt. Inspect for holes and tears by looking

though the filter toward a bright light. Check for damaged gaskets or dented

metal parts. Do not re-use a damaged filter!

• Inspect the end plates. Any damage here can allow air to bypass the filter.

• Look for rust on the end plates and metal core. Rust particles can flake off and contaminate

the dryer and resin.

• Check the gasket for damage. A damaged gasket allows contaminants into the process.

Replace as needed.

• Allow the filter to dry before re-using. Circulate warm air at less than 160ºF (71ºC). Do not

use a light bulb to dry the filter.

Page 50 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 52

Figure 18

Recommended Standard Parts List

Part no. Qty. required Description

A0545157 1 Heater can for BCHE, DH 3.0 to DH 6.0 models, 3&5KW

W00012917 1 Heater gasket

W00013804 1 Heater element, 3KW, 460V

A0534092 1 Heater element, 5KW, 460V

A0546466 1 Heater can for BCHE, DH12.0, 9KW

A0534092 1 Heater element, 9KW, 460V

A0534079 1 Blower, 0.5HP, 230/460V, DH3.0-6.0

A0534080 1 Blower, 1.0HP, 230/460V, DH12.0

A0534059 1 Dryer hose, high temp, 2” X 12’ Long

A0534060 1 Dryer hose, high temp, 2-1/2” X 12’ Long

A0534061 1 Dryer hose, high temp, 4” X 12’ Long

W00001917 — Clamp for dryer hose, 2-2/12”

W00001465 — Clamp for dryer hose, 4”

A0534259 1 Temperature controller, 1/4 Din

A0548565 1 Temperature controller, 1/8 Din

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 51

Page 53

- Notes -

Page 52 HE • CHE • BCHE Mass Flow Series Drying Hoppers

Page 54

8 Troubleshooting

Problem Possible cause Corrective action

Suction in delivery tube,

pressure from the return

tube (BCHE models).

Loss or reduction of process

air temperature.

Material in drying hopper

cakes, or meltdown occurs.

Nothing displays when the

controller is turned on.

Phase is reversed on power

drop coming into the BCHE

enclosure.

Process heaters are faulty.

Solid-state temperature

controller faulty.

Process temperature was

adjusted in error by plant

personnel.

Dirty filters. Clean or replace filters.

Process temperature set too

high due to operator error.

High temperature alarm not

set properly.

Process set point is out of

acceptable range.

Function set for degrees

Celsius (ºC), set point at

degrees Fahrenheit (ºF).

Shift valve malfunction. Repair or replace shift valve.

The internal mechanism is

not inserted properly into the

housing.

The power supply is not

connected to its terminals

properly.

No power is supplied, or the

supplied power is not within

the specified range.

Disconnect switch or Control

Power switch not set to

Control Power fuse blown.

Controller not seated in

socket.

ON.

Stop the dryer. Change the

phase of two legs of the threephase power drop.

Check for open heaters.

Replace if required.

Replace.

Make sure that plant personnel

are aware of the proper

temperature set point. A sign

posted next to the controller is

helpful.

Check resin manufacturer’s

data sheet for proper drying

temperature. Make sure plant

personnel are aware of the

correct process temperature

set point.

Reset high temperature alarm.

Restore temperature controller

to factory pre-sets.

Verify correct Celsius or

Fahrenheit settings.

Properly insert the internal

mechanism into the housing.

Properly connect the power

supply to the power supply

terminals.

Supply a voltage of 85 to 125

VAC to the power supply

terminals of the controller.

Check control power fuse for

continuity. Turn disconnect

switch and control power

switch

Verify that the controller is

properly seated in socket.

ON.

HE • CHE • BCHE Mass Flow Series Drying Hoppers Page 53

Page 55

Problem Possible cause Corrective action

Process value is abnormal or

not obtained.

Premature heater failure.

Poor dew point performance.

Input polarity on thermo-

couple is wrong or

connection is wrong.

No compensating lead wires

used for extension of the

thermocouple.

Thermocouple and controller

are connected by wires other

than proper lead wires.

Sensor is broken or short-

circuited.

The controller is influenced

by noise or other induction.

Celsius temperatures used

instead of Fahrenheit or vice

versa.

Thermocouple is not in air

path.

Dirty filters. Clean or replace filters.

Voltage spikes. Install surge supressor.

Contaminated desiccant. Replace desiccant.

Regeneration heater failure. Replace heater.

Dirty filters. Clean or replace filters.

Regeneration high

temperature thermostat

failure.

Properly wire the terminals.

Use proper compensating lead

wires and terminals.

Use a dedicated thermocouple connector. If a

connector is a metal different

from the thermocouple and

controller, a temperature error

may result.

Replace with a good sensor.

Separate input wires as far as

possible from the origin of the

noise.

Setup mode level 2 display

d-U. S-V display shows

setting.

Verify that the thermocouple is

properly installed in the inlet

tube.

Replace thermostat.

Service Notes

Page 54 HE • CHE • BCHE Mass Flow Series Drying Hoppers