Page 1

$30.00

Operation and Installation Manual

Economical Series

Water Temperature

Control Units

Important! Read Carefully Before Attempting to Install or Operate Equipment

Part No. 682.91343.00 Revision NEW Bulletin No. AE1-655

Page 2

Write down your unit serial number(s) ________________ ________________

here for future reference ________________ ________________

________________ ________________

________________ ________________

AEC is committed

to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual

are subject to change without notice.

© Copyright AEC, Inc. 2006

All rights reserved. Effective 7/27/2006

Part No. 682.91343.00 Revision NEW Bulletin No. AE1-655

Page 2 AEC Water Temperature Control Units

Page 3

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Page 4

Safety Considerations

Economical Series temperature control units are designed to provide safe and reliable operation

when installed and operated within design specifications, following national and local safety

codes.

To avoid possible personnel injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

; Only PROPERLY TRAINED personnel familiar with the

information within this manual should work on this

equipment.

; Follow all local SAFETY CODES.

; AEC Economical Series cabinets and piping are hot and are

a BURN HAZARD.

; Do not operate an AEC system without all outer panels

installed. Pressurized hot water leaks can cause serious

injury.

; Wear SAFETY GLASSES and WORK GLOVES.

; Use care when LOADING, UNLOADING, RIGGING,

or MOVING this equipment.

; Operate this equipment within design specifications.

; OPEN, TAG, and LOCK ALL DISCONNECTS before

working on equipment. We recommend following OSHA

Lock-Out/Tag-Out Standard 29 CFR 1910.147.

; Make sure the unit is properly GROUNDED before

switching power on.

; When welding or brazing in or around this equipment, be

sure VENTILATION is ADEQUATE. PROTECT

adjacent materials from flame or sparks by shielding with

sheet metal. An approved FIRE EXTINGUISHER should

be close at hand and ready for use if needed.

; Do not jump or bypass any electrical safety control.

; Do not restore power until all tools, test equipment, etc.

have been removed and the panels replaced.

AEC Water Temperature Control Units Page 3

Page 5

Table of Contents

1 General Information .................................................7

1-1 Introduction.....................................................................................7

1-2 Necessary Documents....................................................................8

1-3 Models Covered.............................................................................. 8

1-4 Standard Features .......................................................................... 8

1-5 Available Options............................................................................ 9

2 Shipping Information .............................................13

2-1 Unpacking and Inspection............................................................. 13

2-2 In the Event of Shipping Damages................................................13

2-3 If the Shipment is Not Complete....................................................14

2-4 If the Shipment is Not Correct....................................................... 14

2-5 Returns ......................................................................................... 14

2-6 Uncrating Your New Economical Series System........................... 15

3 Installation...............................................................17

3-1 Installation Location Considerations.............................................. 17

3-2 Process Approach Temperature Considerations........................... 17

3-3 External Piping Sizing Considerations .......................................... 17

3-4 Piping Considerations for Permanent Installations........................ 18

3-5 Piping Considerations for High Mobility Installations.....................19

3-6 Process Water Considerations......................................................19

3-7 Making Process Water Connections............................................. 20

3-8 Making Cooling Water Connections.............................................. 21

3-9 Making System Purge Connections.............................................. 22

3-10 Making Electrical Connections...................................................... 25

4 Identifying Controls and Features........................27

4-1 Identifying Mechanical Controls and Features .............................. 27

4-2 The Microprocessor Controller...................................................... 31

4-3 Controller Display..........................................................................31

4-4 Using Controller Keys ................................................................... 32

4-5 Using Graphic Panel Buttons........................................................ 33

4-6 Alarms........................................................................................... 34

4-7 Controller Factory Setup............................................................... 34

4-8 Controller Internal Switches.......................................................... 35

4-9 Controller Factory Setup............................................................... 35

4-10 Auto-Tuning the Controller............................................................ 35

4-11 Changing from Fahrenheit to Celsius............................................36

4-12 Operating the Unit with the Controller........................................... 36

Page 4 AEC Water Temperature Control Units

Page 6

5 Startup and Operation............................................38

5-1 Introduction...................................................................................38

5-2 Startup Checklist........................................................................... 38

5-3 Starting the Temperature Control Unit .......................................... 39

5-4 Operating the Unit with the Controller........................................... 40

5-5 Sequence of Operation................................................................. 41

5-6 Checking Motor Rotation Direction................................................ 42

5-7 Shutting Down the Temperature Control Unit ...............................42

6 Unit Maintenance....................................................43

6-1 Preventive Maintenance................................................................ 43

6-2 Corrective Maintenance................................................................ 44

6-3 Restoring the Controller to Factory Setup.....................................46

6-4 Electrical Connections................................................................... 54

6-5 Safety Devices.............................................................................. 55

6-6 Cleaning and Storage ................................................................... 57

7 Troubleshooting .....................................................59

I Index ........................................................................66

AEC Water Temperature Control Units Page 5

Page 7

Charts and Figures

Typical Economical Series Water Temperature Control Unit

1

2

3

4

5

6

7

8

and Specifications 11

Economical Series Unit Full-Load Amps 11

Typical Piping Schematic 23

Pump Curves; 60 Hz and 50 Hz 24

Pressure Drops 24

Typical E5CK Microprocessor Controller 31

Display Readout for Mode Settings 50

Setting List for Process Temperature Controller 53

9

Pressure Switch; Side View and Top View 58

Page 6 AEC Water Temperature Control Units

Page 8

1 General Information

1-1 Introduction

AEC water temperature control units are reliable, accurate, and easy-to-use process

temperature control units. They are self-contained, portable, and shipped ready to use.

The Economical Series water temperature control unit is designed to circulate water

through your process and to precisely, automatically, and reliably maintain it at a

specified temperature. Standard unit operating range is from 0ºF (-17ºC) to 250°F

(121°C), or up to 300°F (149°C) as an option. The unit is suited for use with city water,

water from portable or central chillers or towers, or well water.

These units are designed for rapid recirculation of a relatively small amount of water to

provide close and uniform temperature relation between To Process and From Process

lines. This performance, of course, depends on the configuration of your process and

any restrictions within the mold. The recirculation, combined with the large immersion

heater and cooling capability, gives fast and accurate response to bring the water up to

temperature or to changes in the settings when needed.

The ECU Series water temperature control unit is a self-contained system consisting of

a centrifugal pump, electric immersion heater, cool/vent solenoid valve, and electrical

control, including a PID microprocessor controller and thermocouple. It is designed for

use in process temperature control applications using water or a water/glycol mix. Any

other use or fluid is prohibited.

Some standard safety devices include a mechanical overtemperature safety thermostat,

a pressure relief valve, motor overload protection, a low pressure cutout switch, branch

fusing, and non-fused lockable rotary disconnect.

A properly installed, operated, and maintained AEC system provides years of reliable

operation. Please read and follow the instructions in this manual to get the most

satisfaction from your AEC system.

AEC Water Temperature Control Units Page 7

Page 9

1-2 Necessary Documents

The following documents are necessary for the operation, installation, and maintenance

of AEC water temperature control units. Additional copies are available from AEC.

Familiarize the appropriate personnel with these documents:

; This manual.

; The controller operation manual.

; The electrical schematic and connection diagram placed inside

the control enclosure.

; The operation and installation manuals for accessories and

options selected by the customer.

; The Customer Parts List included in the information packet.

1-3 Models Covered

This manual provides operation, installation, and maintenance instructions for AEC

water temperature control unit.

Make sure that you know the model number, serial number, and operating voltage of

your temperature control unit if you contact AEC.

1-4 Standard Features

• Compact, rugged cabinet with easy-access side panels

• Cast-and-flange design to reduce connection points

• Incoloy™ immersion heater with IEC contactors

• NEMA 1 electrical enclosure

• Off-the-shelf microprocessor controller; display includes

diagnostics features with indicator and warning status lights;

CE and CUL

Page 8 AEC Water Temperature Control Units

Page 10

• Independent high temperature safety thermostat

• Branch fusing

• ¼” cooling solenoid valve on all sizes

• EPDM/NI-Resist pump seal

• Adjustable low supply water pressure switch; factory-set at

16 psig (110 kPa/1.1 bars)

• 150 psig (1,034 kPa/10.3 bars) pressure relief valve

• ¾” water supply and drain connections; 1½” process

connections

• Automatic vent sequence

• 2” (76 mm) casters

• Operating range of 0ºF to 250ºF (-17ºC to 121ºC)

• One (1) -year parts and labor warranty at the factory; three

(3) -year controller warranty, and limited lifetime warranty

on wetted pump components.

1-5 Available Options

Economical Series systems are available with options to tailor the unit to your

requirements. Some are factory installed; some can be retro-fitted in the field. Consult

your sales representative for more information. Available Economical Series options

include:

• RS-232 or RS-485 communications

• Heater upgrade available to 12 kW

• Quick Cool function

• Manual bypass

• Auto system water purge (mold purge)

• Y-strainer

• Hammer arrestor (water hammer shock stop)

• Remote start/stop control

• Rubber feet; available in lieu of casters

• ½” slow-close cooling solenoid valves available on all sizes

• Two-zone stack rack with casters, common wiring and piping

available

AEC Water Temperature Control Units Page 9

Page 11

• 300ºF (149ºC) operation; includes graphite-impregnated

silicon carbide seal

• Audible and visual general fault alarm

• Electrical operation available in 208, 230, 460, and 575 volts,

60 Hz; 200, 380, and 415 volts, 50 Hz

• 10 foot power cord; no plug, shipped loose

• UL/CUL-listed electrical subpanel

Page 10 AEC Water Temperature Control Units

Page 12

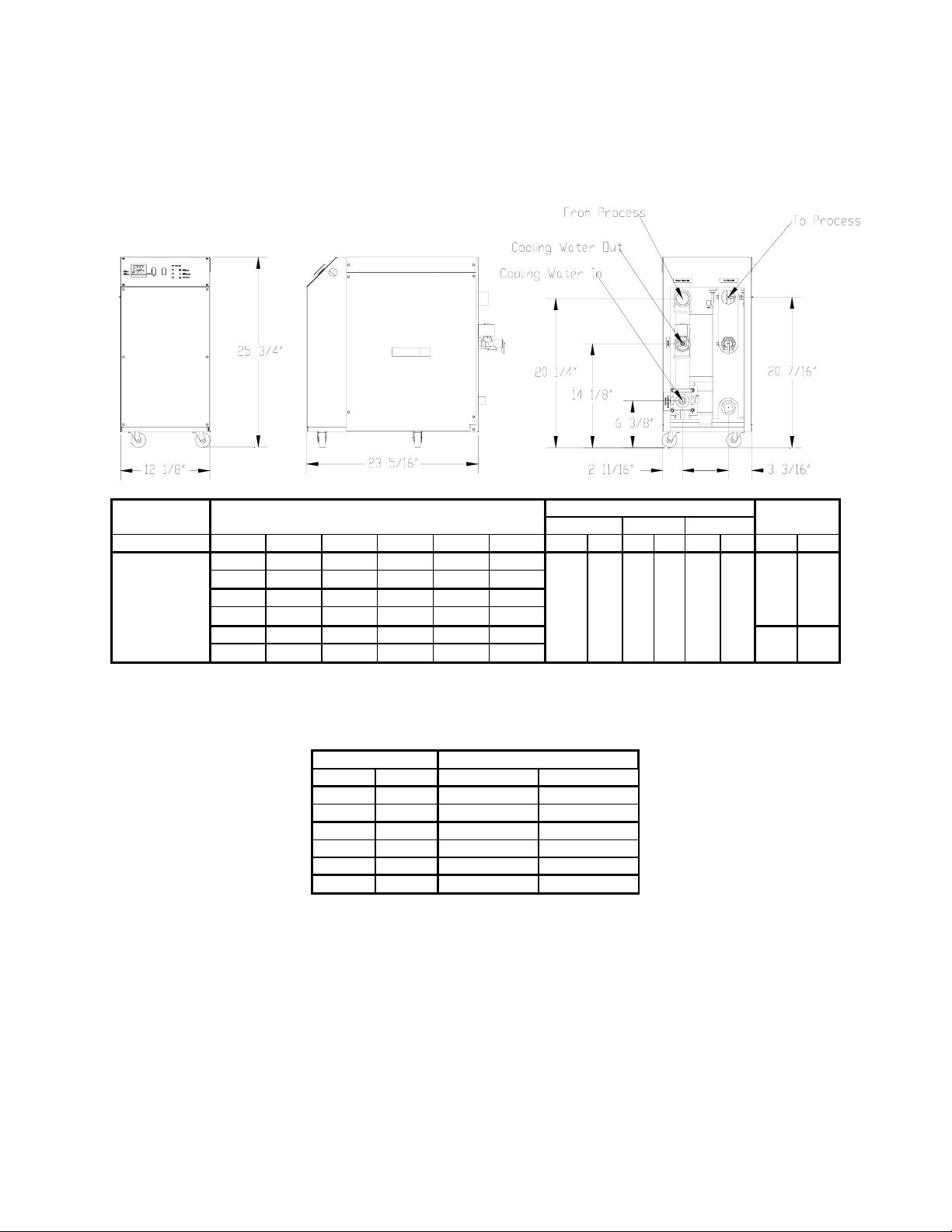

Figure 1

Typical Economical Series Water Temperature Control Unit and Specifications

Direct Injection

Model Dimensions Shipping

number Pump H W D weight

460 / 230 hp

ECU,

9 kW heater

1

2

3

5

7½

¾

kW

0.56

0.75

1.50

2.24

3.73

5.60

gpm

30

35

50

60

75

90

lpm

113.6

132.5

189.3

227.1

283.9

454.2

psig

25

30

30

35

54

63

kPa

172.4

206.9

206.9

241.3

372.3

434.4

in.

25¾”

cm

65.4

in.

12 “

cm

30.5

in.

23”

cm

58.4

lbs.

210

240

Kg

96

109

Figure 2

Economical Series Unit Full-Load Amps

Model Full-load amps at 460 volts

hp kW 9 kW heater 12 kW heater

0.75 hp

1.00 hp

2.00 hp

3.00 hp

5.00 hp

7.50 hp

0.56 kW

0.75 kW

1.50 kW

2.24 kW

3.73 kW

5.60 kW

12.7 amps 16.5 amps

13.1 amps 16.9 amps

14.7 amps 18.5 amps

16.1 amps 19.9 amps

18.9 amps 22.7 amps

22.3 amps 26.1 amps

AEC Water Temperature Control Units Page 11

Page 13

-Notes-

Page 12 AEC Water Temperature Control Units

Page 14

2 Shipping Information

2-1 Unpacking and Inspection

You should inspect your Economical Series temperature control unit for possible

shipping damage. If the container and packing materials are in re-usable condition, save

them for reshipment if necessary.

Thoroughly check the equipment for any damage that might have occurred in transit,

such as broken or loose wiring and components, loose hardware and mounting screws,

etc. In case of breakage, damage, shortage, or incorrect shipment, refer to the following

sections.

2-2 In the Event of Shipping Damages

Important!

According to the contract terms and conditions of the Carrier,

the responsibility of the Shipper ends at the time and place of shipment.

; Notify the transportation company’s local agent if you discover

damage.

; Hold the damaged goods and packing material for the

examining agent’s inspection. Do not return any goods to

AEC before the transportation company inspection and

authorization.

; File a claim against the transportation company. Substantiate

the claim by referring to the agent’s report. A certified copy of

our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was

prepaid, contact AEC at (847) 273-7700 for a receipted

transportation bill.

; Advise AEC regarding your request for assistance and to

obtain an RGA (return goods authorization) number.

AEC Water Temperature Control Units Page 13

Page 15

2-3 If the Shipment is Not Complete

Check the packing list. The apparent shortage may be intentional. Back-ordered items

are noted on the packing list. You should have:

; AEC Economical Series water temperature control unit

; Bill of lading

; Packing list

; Operating and Installation packet

; Electrical schematic and panel layout drawings

; Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items

during unpacking. Determine that the item was not inadvertently taken from the area

before you checked in the shipment. Notify AEC immediately of the shortage.

2-4 If the Shipment is Not Correct

If the shipment is not what you ordered, contact AEC immediately. Include the order

number and item. Hold the items until you receive shipping instructions.

2-5 Returns

Do not return any damaged or incorrect items

until you receive shipping instructions from AEC.

Important!

Page 14 AEC Water Temperature Control Units

Page 16

2-6 Uncrating Your New Economical Series System

; AEC Economical Series water temperature control units are

shipped in a cardboard box surrounded by individual foam

pieces.

; Carefully open the top of the box and remove the front and

back pieces of foam.

Caution!

Be careful when cutting straps.

Straps may spring back and cause injury!

; From the top, slip two lifting straps between the bottom piece

of foam and temperature control unit. Spread the straps from

the center line so it is balanced.

; Loop the straps over a fork truck fork. Lift slowly and only

high enough to clear the box..

; Carefully slide the box from beneath the unit and lower the

unit. Lower slowly. The unit should land on its casters and can

be rolled into position.

; Retain the crating in case reshipment is necessary due to

hidden shipping damage.

AEC Water Temperature Control Units Page 15

Page 17

- Notes -

Page 16 AEC Water Temperature Control Units

Page 18

3 Installation

3-1 Installation Location Considerations

Economical Series systems are portable and can be installed almost anywhere. As with

all equipment installations, follow all applicable codes and regulations.

; The recommended ambient temperature range for Economical

Series installations is from +14ºF (-10ºC) to a maximum

operating ambient temperature of 131°F (55ºC). Recommended

ambient storage temperature range is from -13ºF to 149ºF (25ºC to 65ºC). If storing the unit below freezing temperatures,

make sure the unit has an antifreeze mixture circulated inside.

; Provide a minimum of twelve inches (12” or about 30 cm)

clearance on all sides of the cabinet to allow circulation of

cooling air.

; Locate the unit as close to the process as is practical.

3-2 Process Approach Temperature Considerations

If the differential (U) between COOLING WATER IN and TO PROCESS temperatures

is less than 10°F (7ºC), consult our Sales Department for advice on how to control low

approach applications.

3-3 External Piping Sizing Considerations

; All external hose and piping should be adequately sized to

assure minimum external pressure drop.

; Low external piping pressure drop is needed for best operation.

AEC Water Temperature Control Units Page 17

Page 19

Note: Use a backup wrench to support Economical Series system piping when making

process piping connections.

! CAUTION

All external valves, fittings, and hoses must be rated at a minimum of

150 psig and 250°F (1,034.25 kPa/10.34 bars and 121ºC).

The exception is when the temperature control unit

is optionally rated for 300ºF (149ºC) operation;

external valves fittings and hoses must then be rated at a minimum of

150 psig and 300ºF (1,034.25 kPa/10.34 bars and 121ºC).

3-4 Piping Considerations for Permanent

Installations

We recommend an optional (or customer-installed) strainer on the COOLING WATER

IN

inlet.

The unit must have at least 16 psig (110.32 kPa/1.1 bars) water supply pressure to

prevent pump cavitation that can be caused by the water “flashing” to steam. To avoid

damage to the pump or other components, make sure that maximum supply pressure

does not exceed 75 psig (517.1 kPa/5.17 bars).

Keep restrictions to a minimum by using proper inlet pipe sizing. If the water supply

piping is larger than ¾”, reduce the size at the unit. The table below contains the pipe

sizes that are used in the unit.

Pipe sizes for ¾ hp to 7.5 hp (0.56 kW to 5.59 kW) units

Location Size in inches NPT

To Process 1½”

From Process 1½”

Cooling Water In ¾”

Cooling Water Out

Common black pipe is recommended for permanent installations. Economical Series

water circuit piping is primarily ferrous (iron) and reacts electro-chemically with nonferrous metallic materials such as copper. Some water contains dissolved minerals that

greatly accelerate the reaction between dissimilar metals. Ferrous piping is

recommended to minimize galvanic action. If piping must be copper, use dielectric

unions at the unit.

- depends on solenoid used -

Page 18 AEC Water Temperature Control Units

Page 20

3-5 Piping Considerations for High Mobility

Installations

Mobile Economical Series systems must use high quality hose rated for at least 150

psig and 250°F (1,034.25 kPa/10.34 bars and 121ºC). Special 300°F (149ºC) high

temperature Economical Series systems must use hosing rated at 150 psig and 300°F

(1,034.25 kPa/10.34 bars and 149ºC) or greater.

Quick disconnects may be used for mobility, although they cause a drop in pressure.

If used, they must be sized carefully to minimize pressure drop. Don’t use quick

disconnects with check valves unless absolutely necessary.

! CAUTION

Non-relieving quick connect fittings or check valves on the water supply

must have a pressure relief piped to the drain.

Failure to do so could result in a dangerous over-pressure condition!

3-6 Process Water Considerations

Raw Water

Water treatment is vital in any piping system. In some cases, raw water may be used in

the system without problems; in other cases, it can result in large deposits of scale and

corrosion.

We offer a complete line of water treatment equipment. Contact your sales

representative for water testing and treatment options.

Distilled Water

Non-ferrous (brass, copper, or high-temperature plastic) piping is recommended for

distilled water processes.

AEC Water Temperature Control Units Page 19

Page 21

Deionized Water

Stainless steel (316 SS minimum) or PVC plastic components must be used with

deionized water. We recommends stainless steel because of the temperature constraints

with plastic.

3-7 Making Process Water Connections

Direct Injection

On the back of each unit, the connections are labeled appropriately. For Direct Injection

units connect the TO PROCESS hookup to the

entrance of the process and the

the exit of the process. Connect the

IN

to your plant water supply. Connect the COOLING WATER OUT line to an open

drain, or to the return line of

your central water system.

Make sure you carefully select the connecting lines and connectors between the

temperature control unit and the process to suit the needs and requirements of

your application.

If your unit has a maximum operating temperature of 250ºF (121ºC), the

connecting lines and connectors should have a service rating of at least 250ºF

(121ºC) and 150 psig (1,034.25 kPa/10.34 bars). If it has a maximum temperature

of 300ºF (149ºC), the lines and connectors should have a service rating of at least

300ºF (149ºC) and 150 psig (1,034.25 kPa/10.34 bars).

TO PROCESS — 1½” NPT

FROM PROCESS hookup to

COOLING WATER

This is the outlet for the tempered water leading to the process being controlled.

FROM PROCESS — 1½” NPT

Water from the process re-enters Economical Series system to be tempered and recirculated back into the process.

Page 20 AEC Water Temperature Control Units

Page 22

3-8 Making Cooling Water Connections

WATER IN — ¾”

The cooling water supply inlet from a cooling tower, a chiller, or a city water supply.

! CAUTION

If a non-relieving device such as a regulator, ball valve,

or check valve is installed on the WATER IN line,

you MUST install an expansion tank

of at least ½ gallon (about 2 liters) capacity.

Failure to do so can result in system overpressure from thermal expansion.

Install the tank configured as shown below:

Royal Series

unit

Expansion

tank

Non-relieving

device

Check the expansion tank frequently to make sure it is not flooded.

AEC Water Temperature Control Units Page 21

Page 23

Water Out

Size Depends on Solenoid Used

The cooling water outlet leading back to the cooling tower, chiller, or drain.

Net supply pressure must be between 25 psig and 55 psig (172.38 kPa/1.72 bars and

379.2 kPa/3.79 bars). Net supply below 15 psig (103.43 kPa/1.03 bars) may allow

water to flash to steam, cavitate the impeller, and damage the pump, which prevents

the unit from cooling properly. Operation above 55 psig (379.2 kPa/3.79 bars) may

cause premature opening of the relief valve from pump pressure and pressure surges.

PRESSURE RELIEF — ¾”

The pressure relief valve, located at the back of the unit, is pre-piped to approximately

four inches (4” or 10 cm) above the floor. This piping reduces the chance of scalding

nearby personnel if the relief valve should trip.

3-9 Making System Purge Connections

Economical Series systems equipped with the System Purge option have a compressed

air inlet marked MOLD PURGE. Connect to a clean, dry 100 psig (689.50 kPa/6.90

bars) air line. Install your own shutoff valve to prevent process liquid from backing up

into the plant air piping if the compressed air is turned off and the check valve fails.

Don’t depend on the solenoid valve to hold water pressure in the temperature

control unit.

Page 22 AEC Water Temperature Control Units

Page 24

Figure 3

Typical Piping Schematic

AEC Water Temperature Control Units Page 23

Page 25

Figure 4

Pump Curves; 60 Hz

Pump Curves; 50 Hz

12S,

50S

12S,

50S

Figure 5

Pressure Drops

Model Pressure drop flow and loss

hp kW 9 kW htr flow gpm

0.75 hp

1.00 hp

2.00 hp

3.00 hp

5.00 hp

7.50 hp

0.56 kW

0.75 kW

1.50 kW

2.24 kW

3.73 kW

5.60 kW

12.7 amps 30.0 gpm

13.1 amps 35.0 gpm

14.7 amps 50.0 gpm

16.1 amps 60.0 gpm

18.9 amps 75.0 gpm

22.3 amps 90.0 gpm

flow lpm

113.6 lpm

132.5 lpm

189.3 lpm

227.1 lpm

283.9 lpm

340.7 lpm

Page 24 AEC Water Temperature Control Units

loss psi

0.0 psi

1.0 psi

1.5 psi

2.0 psi

2.5 psi

5.0 psi

loss kPa

0.0 kPa

6.9 kPa

10.3 kPa

13.8 kPa

17.2 kPa

34.4 kPa

Page 26

3-10 Making Electrical Connections

Economical Series systems are designed for three-phase voltage operation. Refer to the

unit nameplate for proper voltage and amperage requirements.

Make sure you provide a correctly sized and protected supply of electrical power to

the unit.

Important!

Refer to National Electric Code (NEC) Article 430-24 through 430-26

for proper feeder conductor and supply disconnect sizing.

Maintain a safe ground and disconnect the power supply before servicing the unit. A

qualified electrician should make electrical connections, and disconnect and lock out

electricity using OSHA 29CFR 1910.147 standards when you need a service call.

Check serial tag voltage and amperage requirements and make sure your electrical

service conforms before making any electrical connections. Total running amps for

Economical Series systems are listed on the nameplate. Customer connections can be

run to the supply terminals from either side of the unit. Make sure that all three phases

are wired correctly. If not wired properly, the unit will run backwards. Again, check

the unit nameplate for correct voltage and amperage.

! DANGER

Improper electrical connections

can damage the unit and cause

serious operator injury or death!

Bring properly sized power leads and ground from a fused disconnect (installed by your

electrician) to the unit. Provide external overcurrent protection to the unit, using circuit

breakers or fuses. If you use fuses, make sure that they are dual-element time-delay

fuses, sized according to your electrical code. Make sure that all electrical connections

are tight.

AEC Water Temperature Control Units Page 25

Page 27

Important!

1. Electrical connections must comply with all applicable electrical codes.

2. The temperature control unit must be grounded in accordance with NEC

Article 250.

3. Voltage must be within plus or minus ten percent (±10%) of the nameplate

rating.

4. Make sure your installer provides external protection.

Refer to the electrical wiring schematic

in your Customer Information packet

for additional information.

Page 26 AEC Water Temperature Control Units

Page 28

4 Identifying Controls and Features

4-1 Identifying Mechanical Controls and Features

To Process Thermocouple

A type K ungrounded thermocouple with a 304SS probe is downstream from the heater

to sense process temperature.

Safety Thermostat

The safety thermostat mounted on the side of the heater tank protects against thermal

runaway. The thermostat guards against the unlikely event of “runaway” heating. If

overheating occurs, the safety thermostat shuts down heater outputs. The unit continues

to pump water through the system to prevent heater damage. We recommend that you

install an audible or visual alarm to the terminals provided. Factory installed alarms are

available; see the electrical schematics for more information.

Pressure Relief Valve

If the combined pressure of the cooling supply water and pump discharge exceeds 150

psig (1,034.25 kPa/10.34 bars), the pressure relief valve opens and relieves the

pressure. This is a non-adjustable ASME construction valve with a stainless steel

spring.

Important!

Route a pipe from the pressure relief valve

to a suitable drain to reduce potential scalding hazard.

The drain line must not have any restrictions or back pressure.

AEC Water Temperature Control Units Page 27

Page 29

Low Pressure Cutout Switch

This switch, set at 16 psig with a 2 psig differential (110.3 kPa/ 1.10 bars with a 13.79

kPa/0.14 bars differential) shuts down the unit if the

pressure drops below 16 psig (110.3 kPa/1.10 bars). For the 300 °F (148.9 °C) option,

this switch is set at 55 psig with a 2 psig differential (379.2 kPa/ 3.79 bars).

Pumps

Pumps range in power from ¾ hp to 7.5 hp (0.56 kW to 5.59 kW) and are equipped

with 3-phase ODP motors and seal flush lines as standard.

The pump is a bronze-fitted close-coupled centrifugal type. It features a split case

design to facilitate replacement of the seal. It has a high output capacity with excellent

discharge pressure helping it facilitate turbulence to maximize heat transfer, and is well

suited for the conditions under which it was designed to operate.

Heaters

The specially designed 9 kW three-phase low watt density electrical immersion heater

heats the water, and the controller regulates the temperature. The standard heater has an

incolloy sheath for best heat transfer and low fouling properties.

Low watt density immersion heaters at 12 kW are available options for these models,

depending upon the heating needs of the process. All models are built to provide full

heat as required by the process and determined by the controller, providing more

precise temperature control.

Solenoid Valves

COOLING WATER IN water

Economical Series systems use rugged, industrial design solenoids with replaceable

coils and/or internal components. Depending on required cooling capacity, solenoid

valves are available in sizes ranging from

valves are slow-closing.

1

/4” to 3/4”; 1/2” x 9/16” and 3/4” x 3/4” solenoid

Water Hammer Arrestor (Shock Stop)

Optional

Shock waves from fast-operating solenoid valves may damage some process systems.

For these applications, a welded metal bellows-type shock stop with a pre-charged and

sealed nitrogen blanket can be installed in the cooling piping.

Page 28 AEC Water Temperature Control Units

Page 30

Pump Starter

Economical Series high quality IEC-rated pump motor starters are industrial grade

motor controls with overload protection and manual reset.

Transformer

High quality industrial design transformers are specified to suit incoming voltage on the

application and provide 115 VAC control voltage. The 115 VAC circuit is protected by

primary fusing and secondary grounding.

Heater Contactor

Your unit uses high-quality IEC-rated industrial-grade electromechanical contactors for

heater controls.

AEC Water Temperature Control Units Page 29

Page 31

Cooling

The controller automatically regulates cooling by opening and closing the solenoid

valve. The unit cools by removing the required amount of warm water from the system.

This process permits an equal amount of cool plant water to enter the system well ahead

of the pump, allowing it to blend with the system water. The water supply temperature

governs the minimum operating temperature of the unit.

Note: The plant water supply temperature governs the minimum operating temperature

of the unit.

Electricals

The pump motor and the immersion heater operate on three-phase 50/60 cycle nominal

voltages with the control circuit operating at 115V single phase. The control circuit

voltage is provided by a single phase machine tool transformer with a grounded

secondary.

The 115V control circuit and controller outputs are fuse protected. The pump motor is

controlled by a full voltage magnetic non-reversing motor starter, with fused branch

circuit overcurrent and thermal overload protection.

Automatic Vent

This feature automatically triggers the purging of air from the system before you start

the unit. The vent actuates the solenoid valve, and forces trapped air and water out

through the drain, properly filling and priming the unit prior to startup. Complete

venting is necessary to prevent damage to the pump and heater.

The vent process is controlled through a timer. If you have a large process, you may

need to complete the venting process by pressing the

mounted switch panel.

Page 30 AEC Water Temperature Control Units

VENT button on the front-

Page 32

Pressure Switch

A pressure switch built into each unit keeps the system from starting until the water

supply is turned

On and subjected to the minimum water supply pressure. This feature

protects the pump seal and the heater from damage through attempted operation

without water. The pressure switch is set at approximately 16 psig (110.32 kPa/1.10

bars) for 250°F (121ºC) units or 55 psig (379.23 kPa/3.79 bars) for 300°F (149ºC) units

prior to leaving the factory.

4-2 The Microprocessor Controller

The controller is an easy-to-operate microprocessor-based PID control device. When

the process reaches the set point, the PID control cycles the cooling valve and/or

immersion heater to maintain the proper leaving water temperature.

The controller has been fully factory tested. Set the desired process

temperature set

point and the

control does the

rest.

Built-in range of

operation on the

controller is 0°F to

250°F (-18ºC to

121ºC).

4-3 Controller Display

Typical E5CK Microprocessor Controller

OUT1

Figure 6

PV

SV

Figure 6

PV or Process Value Numeric LED

OUT2 MANU STOP RMT AT SUB1

AT

During normal

operation, the large

red

PV Process

Value LED on the

OMRON

E5CK

controller displays the actual process temperature at the To Process

thermocouple. It also lists parameter symbols during setup and

error messages if an error occurs.

AEC Water Temperature Control Units Page 31

Page 33

SV or Set Value Numeric LED

During normal operation, the green SV Set Value LED on the

controller displays the process set point you want the chiller to

maintain. It also displays parameter and pre-set function values

during setup.

OUT1 LED

The orange OUT1 LED lights when the controller output energizes

the immersion heater.

OUT2 LED

The orange OUT2 LED lights when the controller output energizes

the cooling valve.

MANU LED

The orange MANU LED lights when you place the controller in

Manual mode.

STOP LED

The orange STOP LED is not used.

RMT LED

The orange RMT LED is lit during remote operation.

AT LED

The orange AT LED flashes during auto-tuning.

SUB1 LED

The orange

SUB1 LED is lit during high temperature conditions.

4-4 Using Controller Keys

Figure 6

Note: Only those who are completely familiar with the unit controller should

perform the operations described in Sections 4-4 through 4-14.

Page 32 AEC Water Temperature Control Units

Page 34

AT

A

AT Key

Press and hold the

stop the auto-tune function.

Displ ay Key

The functions of the Display key change, based on how

long you press it. Press the Display key for less than one (1)

second to scroll through parameters within the mode. Press the

Display key for at least one (1) second or more to display the

menu; the Display function also lets you select the mode you need

to adjust.

T

AT key for two seconds to initiate or to

Important!

Do not change any of the control settings

without consulting AEC’s Service Department.

AEC warranty does not cover chiller failures

from tampering with controller settings!

Down Key

Each press of the Down Arrow key decrements or reduces

the values or settings on the SV Set Value display.

Up Key

Each press of the

the values or settings on the

Up Arrow key increments or advances

SV Set Value display.

4-5 Using Graphic Panel Buttons

ON/OFF Switch

Push the

temperature control cycle. The switch will be illuminated whenever the unit is on.

ON/OFF rocker switch to the ON ( | )energize the unit and begin the

AEC Water Temperature Control Units Page 33

Page 35

VENT Switch

Push the VENT switch for additional manual venting.

ALARM SILENCE Button

Optional

Push the ALARM SILENCE button to silence the alarm. You should investigate the

alarm condition and restore the unit to normal operation before continuing with the

temperature control cycle.

AIR PURGE

Optional

Press the AIR PURGE switch to initiate the purge. It is a momentary switch and must

be pressed to keep the purge valve open. Releasing the switch closes the cooling/vent

and compressed air solenoid valves.

QUICK COOL Button

Optional

Press the QUICK COOL button to open the cooling valve and quickly cool the process.

4-6 Alarms

Audible/Visual General Fault Alarm

Optional

The audible/visual general fault alarm sounds if any fault triggers, such as low water

pressure, over-temperature, or pump overload. A signal from any of the safety devices

activates a horn and flashing strobe.

Push the

The optional mechanical high temperature safety alarm is interlocked with the heater.

When triggered, the heater cuts out and the pump continues to run.

ALARM SILENCE button to silence the alarm.

4-7 Controller Factory Setup

The controller is set up and tested at the factory for optimum operation, and doesn’t

need to be adjusted. If the controller does not work properly, or you suspect someone

has accidentally changed some settings, you can do two things. First, perform the AutoTune Procedure described in the following section. If that doesn’t work, restore the

controller to the original factory settings as described later in this manual.

Page 34 AEC Water Temperature Control Units

Page 36

4-8 Controller Internal Switches

A

The controller is set up and tested at the factory for optimum operation, and adjusting

the internal switches is not necessary. If the controller does not work properly, or you

suspect someone has accidentally changed some settings, there are two things to do.

First, perform the Auto-Tune procedure described in Section 4-10 on Page 36. If that

doesn’t work, restore the controller to the orig-inal factory settings as described in

Section 6-3 on Pages 52 to 59.

4-9 Controller Factory Setup

The controller is set up and tested at the factory for optimum operation, and in most

cases doesn’t need to be adjusted. If the controller does not work properly, or you

suspect someone has accidentally changed some settings, you can do two things. First,

perform the Auto-Tune Procedure described in the following section. If that doesn’t

work, restore the control to the original factory settings as described in Section 6-3 on

Pages 63.

For your protection, all menu modes and levels except 0 and 1 are locked out at the

factory. Level 2 is unlocked for units with factory-installed communications options.

4-10 Auto-Tuning the Controller

The Auto-Tune function lets you fine-tune the control PID to process requirements.

Activate the Auto-Tune function whenever the process under control changes. Don't be

alarmed by control response. It may take the process temperature above and below the

set points as many as three (3) times. It will then level off and control to the process set

point. Auto-tuning can take up to 45 minutes, and is best done before any product is

run.

To auto-tune the controller:

T

Press and hold down the

flashes.

The

AT LED flashes to indicate that the control is tuning itself.

When the AT LED light stops flashing, the controller is tuned and ready for operation.

AT key for two (2) seconds until the AT indicator

AEC Water Temperature Control Units Page 35

Page 37

4-11 Changing from Fahrenheit to Celsius

Changing the control display from ºF to ºC is done in the Setup mode, which is pre-set

and locked out at the factory. Contact Customer Service if you need to change the

display.

4-12 Operating the Unit with the Controller

Level 0 Mode

To change the process temperature set point:

• Press the Down Arrow key to lower the set point to the

temperature you want.

• Press the Up Arrow key to raise the set point to the

temperature you want.

The set point automatically updates after a two (2) -second display.

4-13 Communications

A connection port on the electrical cabinet permits easy hook-up to the host computer

for RS-232C and RS-485 communications. The connection port is a direct pin-to-pin

extension from the back of the controller. For pin outs, consult the Communication

Manual for the Omron E5CK model controller.

Page 36 AEC Water Temperature Control Units

Page 38

-Notes-

AEC Water Temperature Control Units Page 37

Page 39

5 Startup and Operation

5-1 Introduction

The checklist below outlines start-up procedures for Economical Series water

temperature control units. This list assumes that installation information located in this

manual has been read and followed.

5-2 Startup Checklist

; Check the shipping papers against the serial tag to make sure

that system size, type, and voltage is correct for the process

under control.

; Check the transformer primary voltage connections to be sure

they are configured for the electrical power you are using. The

voltage at the main power connection must be within plus or

minus ten percent (±10%) of the voltage listed on the serial tag.

Electrical connections must conform to all applicable codes.

Make sure that a qualified electrician checks all electrical

connections.

; The safety thermostat is preset at the factory to 250ºF or 300ºF

(121ºC or 149ºC), depending on configuration. It trips at 265ºF

or 315ºF (129ºC or 157ºC), depending on configuration.

; The relief valve should be piped to an open, unrestricted drain.

; TO PROCESS, FROM PROCESS, WATER IN, WATER OUT,

MOLD PURGE connections should be complete.

and

! CAUTION

Only use components rated at a minimum of

150 psig and 250°F (1,034.25 kPa/10.34 bars and 121ºC).

; All outer panels must be in place.

; All external process valving should be set for proper operation

of the unit.

; Cooling and/or makeup water between 16 psig and 55 psig

(110.32 kPa/1.1 bars and 379.2 kPa/3.79 bars) must be

available for the unit to operate properly.

Page 38 AEC Water Temperature Control Units

Page 40

; Connect the main power to the unit disconnect switch, and

press the START switch to check for proper pump rotation

direction as described in Section 5-6 on Page 42. Pump rotation

should be clockwise, viewed from the motor end.

; Check your work and proceed to the Startup Procedure

section on the following page.

5-3 Starting the Temperature Control Unit

; Turn on the water supply, apply main power to unit, press

ON/OFF switch to the ON position.

; The unit automatically executes a one-minute venting sequence

to expel air trapped in the process piping. We recommend a

longer venting sequence on larger process systems. Press and

hold the VENT button to force the cooling/vent valve open and

eliminate air trapped in the process piping in larger process

systems.

The controller is OFF and the Vent Cycle indicator is lighted

during the vent sequence.

; Set the microprocessor controller to the process temperature

you want by pressing the Up Arrow button or the

Down Arrow button on the front of the controller.

; Allow your process to reach the set point temperature, then

auto-tune the control by pressing the AT key. See Section 4-10

on Page 36 for more information.

; Watch the drain for any bubbles or erratic flow, which

indicates if the system has been properly vented. If the stream

is steady, the unit was properly vented and all air is out of the

system.

; Operate the unit, checking for anything unusual that could

indicate improper operation.

Note: You can stop your temperature control unit at any time by pressing the

STOP button.

AEC Water Temperature Control Units Page 39

Page 41

! CAUTION

1) Your system operates with hot water under pressure. To reduce the risk of

scalding:

• Always wear work gloves and safety glasses when operating the unit.

• Never operate the unit with panels or shields removed.

• Pipe the relief valve to an open drain.

• Never install a fitting or hose that is rated less than 150 psig and 250°F

(1,034.25 kPa/10.34 bars and 121ºC).

2) To reduce the risk of electrical shock:

• All electrical installation and repairs should be done by a qualified

electrician.

• Ground the unit in accordance with electrical codes.

• Never attempt any repairs without first opening and locking out the main

disconnect.

• Never deactivate or neutralize any safety device.

5-4 Operating the Unit with the Controller

To change the process temperature set point:

• Press the Down Arrow key to lower the set point to the

temperature you want.

• Press the

you want.

Up Arrow key to raise the set point to the temperature

Page 40 AEC Water Temperature Control Units

Page 42

5-5 Sequence of Operation

The simplicity of design and the highly engineered controller make this unit almost

self-operating. The

are all that is required to operate this unit.

After you complete all connections, turn the water supply ON, then turn control power

ON. The unit automatically vents for a preset time of one (1) minute. If you need

additional vent time, press the VENT button on the control panel.

As the water comes in the water supply line, the water must enter the pump, up through

the tank and out through the

FROM PROCESS line, and through the solenoid line and out the drain line.

At this time, watching the drain for bubbles or erratic flow will indicate whether or not

the system has been properly vented. If a steady stream flows from the drain line, it is

certain that all the air is out of the system.

ON/OFF and VENT switches and the temperature controller buttons

TO PROCESS line, through the process, back through the

; TCU systems provide temperature control on processes by

directly heating the process water and injecting cooling water

into the process water.

; When the unit is energized, the pump starts and a one minute

vent sequence opens the cooling/vent valve to remove any air

trapped in the process piping.

; If the cooling water supply pressure is insufficient, the low

cooling water pressure cutout switch (set at 16 psig, 10 psig

differential [110.32 kPa/1.10 bars, 68.95 kPa/0.69 bars

differential]) opens. You need at least 16 psig (110.32

kPa/1.10 bars) for the best cooling capacity and to prevent

water boiling in the process circuit at high temperatures,

particularly at the pump suction.

; After venting, the microprocessor controller monitors the

PROCESS

probe, cycling open the cooling/vent valve to

TO

discharge warm water or energizing the immersion heater to

maintain the process set temperature.

AEC Water Temperature Control Units Page 41

Page 43

5-6 Checking Motor Rotation Direction

Check for correct pump rotation direction by looking at the end of the motor. Press the

ON/OFF switch from the OFF ( O ) position to the ON ( | ) button, and note the

direction that the motor turns. Rotation should be clockwise when viewed from the

motor end.

Note: Make sure that a qualified electrician performs the following steps.

To change rotation direction:

1. Disconnect and lock out power at the fused disconnect.

2. Reverse any two incoming leads at the power terminal blocks.

3. Do not switch leads at the motor or motor starters.

5-7 Shutting Down the Temperature Control Unit

Cool the unit down by selecting a set point of zero (0). Let the unit stabilize at one

temperature close to the incoming water temperature, then press the STOP button. Now

press the VENT button to relieve any remaining pressure in the system.

Page 42 AEC Water Temperature Control Units

Page 44

6 Unit Maintenance

! CAUTION

Never attempt to service a unit until a qualified

electrician has opened and locked out the main

The water supply should be turned off and internal

pressure should be relieved before you remove panels.

All electrical connections must be done by a qualified

electrician.

disconnect using OSHA 1910.147 standards.

! WARNING

Disconnect all power to the unit, let the unit

cool down, and turn off the water prior to any

servicing.

Failure to do so can result in SERIOUS INJURY

OR DEATH!

6-1 Preventive Maintenance

Draining

Drain the unit thoroughly if you are taking it out of service for a long period of time, or

you expose it to freezing. Drain plugs are provided at the base of the heater tank and at

the base of the pump.

AEC Water Temperature Control Units Page 43

Page 45

Periodic Checks

Every Six Months

Inspect all electrical connections for secure attachment and for safe and secure ground

connections. Inspect the power cable, especially at the entrance point to the unit. This

inspection should be made by a qualified electrician. Check for leaks, especially under

the pump, as it may indicate a worn pump seal.

6-2 Corrective Maintenance

Pumps and Seals

Before leaving our factory, we test each unit extensively, then we calibrate each unit.

Afterwards, the unit is drained and blown out with air to remove water from piping

systems. If the unit is allowed to stand idle for a long time before being installed in

your factory, the housing gasket at the pump can dry out and can possibly leak when

the unit is started. In most cases these gaskets will soon swell and form a tight seal. In

other cases, it may be necessary for you to tighten the pump bolts to stop a leaking

condition.

Pump seal surfaces can separate slightly because of rough handling or from vibration

during transit. This could cause a leak at the pump seal when the pump is started, but in

most cases the surfaces will mate again after the pump is allowed to run for a short

period of time. If they do not reseal, you may need to open the pump and free the seal

by hand. It is seldom necessary to install a replacement seal in a new unit unless the

seal has been damaged because the unit was started without water.

Our pump seals have a long period of service life. Some conditions, of course, can

shorten seal life, including the presence of grit, operation of the unit without water,

sustained high water temperature, or presence of certain chemicals in the water. Our

pump seal assembly has been developed to resist abrasive particles that are present in

many water systems. This is done by a special flushing system that uses water exiting

the pump to constantly wash the seal area.

Page 44 AEC Water Temperature Control Units

Page 46

It is also fitted with high temperature flexible components for maximum heat

resistance. These same components remain flexible even at low temperatures. Thus, the

standard seal is a fine combination of heat resistant and wear resistant components.

Unfortunately, even under normal use, the seal will eventually wear and require

replacement.

A small puddle underneath the unit is a sign of rotary seal wear, and if investigation

confirms the pump as the source, the seal should be replaced as soon as practical. The

water slinger is intended to provide temporary protection against this, but a continued

and substantial leak will ruin the motor bearing and cause further damage.

After the unit has been in service for a period of years where abrasive conditions are

present, you may find that the pump bracket (the top half of the pump casting), can be

eroded away in the area around the seat of the rotary seal. This area should provide a

straight, smooth bearing surface for the cup seal. Should your casting show signs of

erosion in this area, the casting needs to be replaced. The replacement cost of the

casting is very modest compared to the down time and maintenance cost for frequently

replacing the seal.

Under some conditions, the pump may not start. After turning off the power supply,

check the motor shaft to be certain it is free to turn. By removing the drip cover on top

of the motor, you’ll have access to the end of the shaft. It has been slotted to make it

easy to turn with a screwdriver. If the shaft is free to turn, next check that the motor

overloads are set, check for blown fuses, and finally check the power supply on each

leg to the motor. A qualified electrician should check the motor and its circuit.

Important!

If the pump motor wiring is disconnected for removal from the unit,

make sure that you check the actual rotation direction

when the motor is rewired to the unit.

A phase sensor does not always indicate proper rotation

if motor wire leads are reversed at installation.

Consult the elementary wiring diagram for more information.

AEC Water Temperature Control Units Page 45

Page 47

Heaters

Heaters may need to be cleaned chemically or mechanically to remove deposits and dirt

that reduce heat transfer and cause hot spots. Hot spots cause premature heater failure.

Install a new gasket when reassembling. Make sure a qualified electrician disconnects

and reconnects heater wires.

Solenoid Valves

; Clean annually; more often if using high mineral content water

or on high service level units.

; Sluggish operation, excessive leakage, and/or noise indicate

cleaning is necessary. Inspect the components for excessive

wear while the valve is disassembled.

; Rebuild kits are available from the Parts Department.

6-3 Restoring the Controller to Factory Setup

If the preset parameters on the controller have been tampered with and it no longer

properly controls temperature, you can restore the controller to factory setup

parameters.

E5CK Operating Parameters

The E5CK controller has several mode selections. Within each mode are numerous

parameters that can be set.

Before you can gain access to the several modes of operating parameters, you must

change the security lock-out of the controller. AEC sets the security level at the factory

to protect the parameters from being accidentally changed. The explanation that begins

on the following page is how to change operating modes, how to change out the

security level, and how to reset factory default settings.

Page 46 AEC Water Temperature Control Units

Page 48

Available E5CK Modes

Menu Display

Level 0 Mode

For normal operation. Execute AT auto-tuning, change to Manual

mode.

Level 1 Mode

For adjusting primary control parameters. Execute: Set alarm

values; set the control period; set PID parameters.

Level 2 Mode

For adjusting secondary control parameters. Economical TCU

units use E5CK default settings.

Setup Mode

For setting basic specifications. Set parameters for input type,

scaling, output assignments and direct/reverse operation.

Expansion Mode

Option Mode

Calibration Mode

For setting expanded functions. Set: ST (self-tuning), SP setting

limiter. Select: advance PID or ON/OFF control.

This mode is only accessible when an option board is installed.

For calibrating communication unit E53-CKF. Not used.

AEC Water Temperature Control Units Page 47

Page 49

Figure 7

Display Readout for Mode Settings

PV

SV

SV

SV

SV

SV

SV

SV

Setting E5CK Security in Protect Mode

Menu display

Level 0 mode

Level 1 mode

Level 2 mode

Setup mode

Expansion mode

Option mode

Calibration mode

4. To access protect mode, press and hold the

AT

AT key and

the Display key for two (2) seconds.

5. The display should read SECr for security mode. If you press

the Display key for short presses you will toggle

between SECr and KEYP for AT protect.

Page 48 AEC Water Temperature Control Units

Page 50

6. With the display reading SECr, set the security levels by the

arrow up and down keys. Change the security level to 1 to

make changes to the operating parameters. Economical TCU

units are factory set to Security Level 5.

Available Security Levels

Security level

Mode 0 1 2 3 4 5 6

Calibration X

Option X X

Expansion X X

Setup X X

Level 2 X X X

Level 1 X X X X

Level 0 X X X X X X

To return to the main display (run mode), press

and hold the AT and Display key for 2 seconds.

Entering Operating Parameters to Select Modes

To enter the menu display:

7. Press the Display key for two seconds.

The screen displays .

8. Press the

Up Arrow key to toggle through the different

modes.

The SV readout displays the mode you selected.

9. To switch parameters within a mode, press the Display

key once more for two (2) seconds.

The PV readout displays the different parameters within each

mode.

AEC Water Temperature Control Units Page 49

Page 51

10. Use short presses on the Display key to display each

parameter within a mode.

SV readout displays the different values for the parameter

The

within a mode.

11. Press the

Down Arrow key to lower values of a

parameter; press the Up Arrow key to raise values of a

parameter.

12. Press the

Display key for about two (2) seconds to

move up a level back into the different modes.

13. Press the

Down Arrow key until Level 0 displays.

14. Press the Display key for about two (2) seconds to go

to Operating mode.

E5CK Factory Setting for Process Temperature

15. Remove controller from housing and check for output board

number E53-R4R4 (Relay/Relay).

16. Make sure jumper setting for input type is set for thermocouple

TC-PT, middle jumper.

17. Return controller to housing.

18. Press the

Display key for one (1) second to enter Menu

Display.

19. Press the Up Arrow key to get to Setup mode; the

screen displays the

message.

20. To switch parameters within Setup mode, press the

Display key.

Page 50 AEC Water Temperature Control Units

Page 52

Figure 8

Setting List for Process Temperature Controller

Mode Parameter Setting range Default Solenoid Valve

Protect SECr Security 0 to 6 1 5

Protect KEYP A/M Key protect ON/OFF OFF ON

Level 0 PV/SV display — — —

Level 0 Switch to Manual mode -5.0 to 105.0% 0.0 Default

Level 0 MV monitor Cannot be set 0.0 Default

Level 0 r-S Run/Stop Run/Stop Run Default

Mode Parameter Setting range Default Solenoid Valve

Level 1 At AT Execute/Cancel OFF/AT-1/AT-2 0 Default

Level 1 SP-0 Set point 0

Level 1 SP-1 Set point 1

Level 1 AL-1 Alarm value 1 -1999 to 9999 EU 0 Default

Level 1 AL-2 Alarm value 2 -1999 to 9999 EU 0

Level 1 AL-3 Alarm value 3 -1999 to 9999 EU 0 Default

Level 1 P Proportional band 0.1 to 999.9% FS 10.0 0.5

Level 1 I Integral time 0 to 3999 SEC 233 55

Level 1 d Derivative timer 0 to 3999 SEC 40 9

Level 1 C-SC Cooling coefficient 0.01 to 99.99 1.00 Default

Level 1 C-db Dead band -19.99 to 99.99 0.00 Default

Level 1 oF-r Manual reset valve 0.0 to 100.0 50.0 Default

Level 1 HYS Hysteresis (heat) 0.01 to 99.99 0.10 Default

Level 1 CHYS Hysteresis (cool) 0.01 to 99.99 0.10 Default

Level 1 CP Control period (heat) 1 to 99 SEC 20 15

Level 1 C-CP Control period (cool) 1 to 99 SEC 20 Default

Set point lower limit to

Set point upper limit

Set point lower limit to

Set point upper limit

0 Default

0 Default

0=full heat,

+10=half heat

AEC Water Temperature Control Units Page 51

Page 53

Figure 8

Setting List for Process Temperature Controller (Cont’d.)

Mode Parameter Setting range Default Solenoid Valve

Level 2 Remote/Local

Level 2

Level 2 SPrt Sp Ramp Set Value 0 to 9999 EU 0 Default

Level 2 Mu-5 MV at Stop -5.0 to 105.0% 0.0 Default

Level 2 Mu-E MV at PV Error -5.0 to 105.0% 0.0 Default

Level 2 OL-H MV Upper Limit

Level 2 OL-L MV Lower Limit

Level 2

Level 2 InF Input Digital Filter 0 to 9999 SEC 0 Default

Level 2 ALH2 Alarm 2 Hysteresis 0.01 to 99.99% 0.02 Default

Level 2

Level 2

SPrU Sp Ramp Time

Unit

OrL MV Change Rate

Limit

In5H Input Shift Upper

Limit

In5L Input Shift Lower

Limit

Only active with comm.

board

M(Minutes)/

H(Hours)

MV Lower Limit +0.1 to

105%

-5.0 to MV Upper Limit -

0.1%

0.0 to 100.0%/SEC 0.0 Default

-199.9 to 999.9 °C

-999.9 to 999.9 °C

Local Default

M Default

105.0 Default

-5.0 Default

0.0 Default

0.0 Default

Mode Parameter Setting range Default Solenoid Valve

Setup In-t Input Type 0 to 21 2 2

Setup

Setup InIt Parameter Initialize Yes/No No Default

Setup

Setup

Setup

Setup Alt1 Alarm 1 Type 0 to 11 2 Default

Setup

Setup ALt1 Alarm 2 Type 0 to 11 3 Default

Setup

Setup

d-U °C/F Selection °C/F °C °F

OUt1 Control Output 1

Assignment

OUt2 Control Output 2

Assignment

Sub 1 Auxiliary Output 1

Assignment

AL1n Alarm 1 open in

alarm

AL2n Alarm 2 open in

alarm

6rEu Direct/Reverse

Operation

Heat/Cool/Alarm 1/Alarm

2/Alarm 3/ LBA

Heat/Cool/Alarm 1/Alarm

2/Alarm 3/ LBA

Alarm 1/Alm 2/Alm

3/LBA/S.ERR/E333

NO/NC NO Default

NO/NC NO Default

OR-R/OR-D OR-R Default

Heat Default

Cool Cool

AL-1 AL-2

Page 52 AEC Water Temperature Control Units

Page 54

Figure 8

Setting List for Process Temperature Controller (Cont’d.)

Mode Parameter Setting range Default Solenoid Valve

Expansion

Expansion

Expansion CntL PID/ON/OFF PID/ON/OFF PID Default

Expansion

Expansion St Stable Range

Expansion

Expansion

Expansion

Expansion

Expansion AT-H AT Hysteresis 0.1 to 9.9% FS 0.2 Default

Option Eu-n Multi-SP function 0/1 0 Default

Option

SL-H Set Point Upper

Limit

SL-L Set Point Lower

Limit

ST Adaptive Tuning

(Fuzzy)

ALFA α

At-G AT Calculated

Gain

rESt Standby

Sequence Reset

Setting Method

rEt Automatic Return

of Display Mode

Eu-1 Event input

assignment 1

SP Lower Limit +1 to

Scaling Upper Limit

Scaling Upper Limit to SP

Lower Limit

OFF/ON OFF ON

0.1 to 999.9 °C/F

0.01 to 1.00 0.65 Default

0.1 to 10.0 1.0 Default

0/1 0

0 to 99 SEC 0 Default

STOP/MAN STOP Default

1300 250ºF; 300ºC opt.

-200 0

15 Default

Default

AEC Water Temperature Control Units Page 53

Page 55

Communications Option

Mode Parameter Setting range Default

Communications stop bit 1 to 2 2 2

Communications data length 7 to 8 7 7

Communications parity None, Even, Odd Even Even

Communications baud rate

Communications unit number 0-99 0 0

1.2, 2.4, 4.8,

9.6, 19.2 K

9.6 9.6

Transfer Output

Mode Parameter Setting range Default

Transfer output type

SP, PV,

SP RAMP, MV

PV PV

Solenoid or

Modulating

Valve

Solenoid or

Modulating

Valve

Transfer output upper limit -200 to 1300 1300 250

Transfer output lower limit -200 to 1300 -200 0

6-4 Electrical Connections

Make sure that a qualified electrician inspects all electrical components and

connections every six (6) months for secure attachment and ground connections.

Inspect all wiring for fraying or damage, especially power lines where they enter the

unit. All wiring connections must be tight.

Page 54 AEC Water Temperature Control Units

Page 56

6-5 Safety Devices

Make sure that only qualified electricians test safety devices!

Safety devices should be tested for function every six (6) months. Perform the

following procedures for testing:

Motor Overload

Disconnect main power. Open the electrical enclosure and rotate the manual TEST

button on the motor overload to the tripped position. Close the enclosure and reconnect

main power. Push the START button. The unit should not start and the Pump

Overload

Press the RESET button. The unit is now ready for operation.

Pressure Switch

indicator should illuminate.

Caution!

With the unit running, program a set point of 30ºF (-1ºC). Allow the process

temperature to drop under 100ºF (38ºC). When the process temperature reaches that

point, turn off the water supply. The pump should stop and the Low Water Pressure

indicator should illuminate. Turn the water supply on to reset the pressure switch.

Adjusting the Pressure Switch

The pressure switch used in your Economical Series water temperature control unit is

factory set at 16 psig (110.3 kPa/1.1 bars). However, if the process does not require the

unit to operate at 250ºF (121ºC), you can adjust the switch to meet your process needs.

Tools Required

• Small flat blade screwdriver

• #2 Phillips head screwdriver

AEC Water Temperature Control Units Page 55

Page 57

! CAUTION

HAZARDOUS ELECTRICAL CURRENT PRESENT.

Maintain a safe ground and disconnect the power

supply before servicing the unit.

Make sure a qualified electrician makes electrical

connections; disonnect/lock out electricity using OSHA

20CFR 1910.147 standards when servicing the unit.

To adjust the pressure switch:

Using a small, flat-blade screwdriver, carefully remove the plug at the top

of the switch.

Figure 9

Pressure Switch

Side View and Top View

Phillips head screw

Under the plug is a Phillips-head adjusting screw:

Turn the screw counterclockwise to reduce the pressure.

- or -

Turn the screw clockwise to increase the pressure.

A quarter turn (90º rotation) approximates 15 psi (103.4 kPa/

1.0 bars).

Replace the plug on the top of the switch.

If the plug gets damaged, the switch is still sealed internally.

Page 56 AEC Water Temperature Control Units

Page 58

Safety Thermostat

Disconnect main power. Open the electrical enclosure and disconnect the neutral lead

on the safety thermostat from the terminal strip. Protect the stripped lead to prevent

short circuits. Close the enclosure, reconnect main power, and push the START button

and press ON/OFF switch to the ON position. The heater should not turn on and the

Over Temperature indicator should illuminate. Disconnect main power before

reconnecting the thermostat lead.

Make sure that the high limit on the controller is set to the values

listed in the following table, based on the switch adjustment. This

prevents the pump from cavitating and damaging the seal, the

switch, and heater element(s).

psig kPa Max. temp. ºF Max. temp. ºC

5 psig 34.4 kPa 227ºF 108ºC

10 psig 68.9 kPa 240ºF 116ºC

15 psig 103.4 kPa 250ºF 121ºC

6-6 Cleaning and Storage

• Inspect the unit daily for leaks. Wipe down the unit

periodically to remove dirt and dust buildup, especially the

motor casing.

• Drain and flush the unit every six (6) months to remove

sediment buildup.

• Completely drain the unit and carefully blow out the piping

with pressurized air before placing the unit in storage.

AEC Water Temperature Control Units Page 57

Page 59

- Notes -

Page 58 AEC Water Temperature Control Units

Page 60

7 Troubleshooting

Condition Possible cause Solution

Check main disconnect, fuses,

wiring, and power lead to unit.

Voltage must be within plus or

minus 10% of nameplate rating.

Locate and repair.

Repair or replace.

Check for at least 16 psig

(110.32 kPa/1.1 bars) water

pressure on WATER IN or CITY

WATER MAKEUP.

Open water supply.

Reset and test each leg for

balanced amp draws.

Verify proper rotation. If not

clockwise, reverse any two

incoming power leads.

As long as there is satisfactory

process temperature control

there is no problem.

Clean the system.

Check for closed valves etc. Be