Page 1

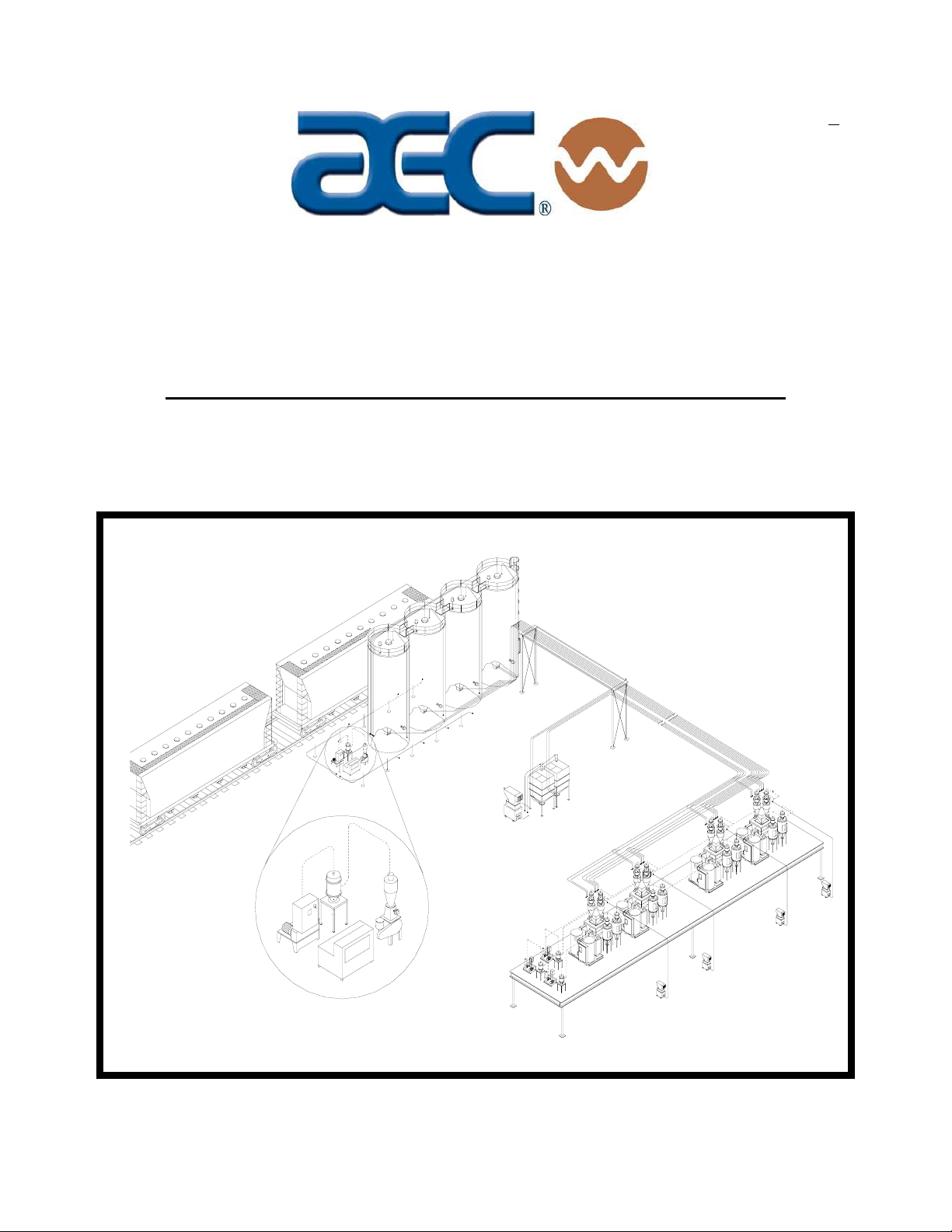

$30

Operation & Installation Manual

Continuous Vacuum/Pressure

Conveying Systems

Single- and Dual-Blower Systems

Important! Read Carefully Before Attempting to Install or Operate Equipment

00

Part No. A0553702 Revision D Bulletin No. WH3-605.4

Page 2

Write down your unit serial number(s) ________________ ________________

here for future reference ________________ ________________

________________ ________________

________________ ________________

________________ ________________

________________ ________________

________________ ________________

________________ ________________

________________ ________________

________________ ________________

________________ ________________

________________ ________________

Performance figures stated in this manual are based on:

• A standard atmosphere of 59°F (15°C) at 29.92” Hg (1,014 millibars) at sea level

• Bulk material density of 35 lbs. per cubic foot (560 kg per cubic meter)

• Operating power at 60 Hz

Altitude and bulk material density are important considerations when specifying

vacuum/pressure conveying systems. AEC can advise you on proper selection and

sizing of systems for your operating environment.

AEC is committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual

are subject to change without notice.

Page 2

© Copyright AEC, Inc. 2003

All rights reserved. Effective 9/30/03

Part No. A0553702 Bulletin No. WH3-605.4

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 3

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Page 4

Table of Contents

1 General Information ................................................. 9

1-1 Models Covered

1-2 Equipment Function

1-3 Necessary Documents

1-4 Standard Features

1-5 Options

1-6 The Vacuum/Pressure Conveying System

2 Safety ...................................................................... 13

2-1 Work Rules

2-2 Tools & Equipment Needed

2-3 Mechanical Installation

2-4 Safety Considerations

2-5 General Responsibility

2-6 Operator Responsibility

2-7 Maintenance Responsibility

2-8 Safety

3 Shipping Information ............................................. 21

3-1 Unpacking and Inspection

3-2 In the Event of Shipping Damages

3-3 If the Shipment is Not Complete

3-4 If the Shipment is Not Correct

3-5 Returns

4 Installation .............................................................. 23

4-1 Work Rules

4-2 Tools and Equipment

4-3 Installing Mechanical Components

4-4 Making Compressed Air Connections

4-5 Making Electrical Connections

4-6 Testing the Rotary Air Lock

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 3

Page 5

Table of Contents

5 Startup, Shutdown, and Operation....................... 39

5-1 Equipment Cycle

5-2 Alarms, Controls, and Indicators

5-3 Mechanical Indicators and Safety Features

5-4 Pre-Startup Checklist

5-5 Starting the System

5-6 Shutting Down the System

5-7 Unloading Railcars

6 Maintenance ........................................................... 50

6-1 Work Rules

6-2 Lubricating Components

6-3 Periodic Service

6-4 Maintaining Filter Chambers

6-5 Service Procedures

7 Troubleshooting..................................................... 55

(8) A Appendix A — Unloading Railcars .................. 57

9 Conveying System Options .................................. 63

10 Spare Parts ............................................................. 64

11 Technical Assistance............................................. 65

11-1 Contact Information

11-2 Returned Material Policy

11-3 Warranty

12 Safety Tag Information .......................................... 69

12-1 Safety Tags

12-2 Serial Number Tag

Page 4

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 6

Safety Considerations

AEC single- and dual-blower continuous vacuum/pressure systems and system

components are designed to provide safe and reliable operation when installed

and operated within design specifications, following national and local safety

codes.

To avoid possible personnel injury or equipment damage when installing,

operating, or maintaining this equipment, use good judgment and follow these

safe practices:

; Follow all SAFETY CODES.

; Wear SAFETY GLASSES and WORK GLOVES.

; Read and understand all product information before operating this

equipment.

; Disconnect and/or lock out power before servicing or maintaining this

equipment.

; Use care when LOADING, UNLOADING, RIGGING, or MOVING

this equipment.

; Operate this equipment within design specifications.

; OPEN, TAG, and LOCK ALL DISCONNECTS before working on

equipment. You should remove the fuses and carry them with you.

; Make sure the vacuum/pressure system and components are properly

GROUNDED before you switch on power.

; Do not jump or bypass any electrical safety control.

; Do not restore power until you remove all tools, test equipment, etc., and

the vacuum/ pressure system and related equipment are fully

reassembled.

; Only PROPERLY TRAINED personnel familiar with the information

in this manual should work on this equipment.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 5

Page 7

AEC

Continuous Vacuum/Pressure

Conveying Systems

This conveying system is manufactured by ACS, Inc. at the ACS-Wood Dale facility:

ACS, Inc.

801 AEC Drive

Wood Dale, IL 60191

Phone: 630.595.1060

Fax: 630.595.6641

Page 6

The equipment is distributed in Europe by our European facility:

ACS-EUROPE

Daniels Industrial Estate

BATH ROAD

Stroud, Gloucestershire, England

GL5 3TJ

Phone: (44) 1453 768980

Fax: (44) 1453 768990

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 8

Annex B Information

The following design information is provided for your reference:

1. No modifications are allowed to this equipment that could alter the CE compliance

2. Ambient temperature: 40 degrees Celsius – Maximum (104 degrees Fahrenheit)

3. Humidity range: 50% relative humidity

4. Altitude: Sea level

5. Environment: Clean, dust-free and non-explosive

6. Radiation: None

7. Vibration: Minimal, i.e. machine mounting

8. Allowable voltage fluctuation: +/- 10%

9. Allowable frequency fluctuation: Continuous +/- 1%

Intermittent +/- 2%

10. Nominal supply voltage: 430/3/60 or 400/3/50 (Verify on serial number tag)

11. Earth ground type: TN (system has one point directly earthed through a

protective conductor)

12. Power supply should include a neutral power connection.

13. Over-current protection is supplied in the conveying system, but additional protection

should be supplied by the user.

14. The electrical disconnect in the door serves as the electrical disconnect device.

15. Conveying System is not equipped with local lighting.

16. Functional identification

17. Conveying System is equipped with a CE mark

18. Conveying System is supplied with an operating manual in the language of the

destination country.

19. Cable support may be required for power cord, depending on final installation.

20. No one is required to be in the interior of the electrical enclosure during the normal

operation of the unit. Only skilled electricians should be inside the enclosure for

maintenance.

21. Doors can be opened with a screwdriver, but no keys are required.

22. Two-hand control is not required or provided.

23. All Conveying Systems should be moved around and set in a place with a lift truck or

equivalent.

24. There are no frequent repetitive cycles that require manual controlrepetitive functions

are automatic while the conveying system is operating.

25. An inspection report detailing the functional test is included with the conveying system.

26. The machine is not equipped with cableless controls.

27. Color-coded (harmonized) power cord is sufficient for proper installation.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 7

Page 9

Charts and Figures

1

Typical Single Blower System for Free-Flowing Pellets 10

2

Typical Dual Blower System for Free-Flowing Pellets 11

3

Examples of Single Line and Multiple Line Hangers 24

4

Quick Change Couplers 25

5

Rotary Airlock/Cyclone Assembly 27

6

Rotary Airlock Rotation and Material Flow 33

7

Typical SVP System Electrical Schematic 34

8

Typical SVP Electrical Subpanel Layout 35

9

10

11

12

13

14

15

Typical CVP/CPP System Electrical Schematic 36

Typical CVP/CPP Electrical Subpanel Layout 37

Typical Vacuum/Pressure System Load Cycle 40

Typical SVP Control Panel Layout 42

Typical CVP/CPP Control Panel Layout 43

Typical Probe Installation Kit — Up to 3” OD 58

Style “A” Attachment 58

Page 8

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 10

1 General Information

1-1 Models Covered

AEC single vacuum pressure (SVP) systems have a single blower/motor combination

used for vacuum and pressure conveying. Continuous vacuum pump/continuous

pressure pump (CVP/ CPP) systems have dual blower/motor combinations and have a

dedicated pump for vacuum, as well as one for pressure, conveying.

In this manual, vacuum and pressure units are listed separately to maintain common

terminology. Keep in mind, however, that SVP systems employ one blower for

vacuum and pressure conveying.

AEC single-blower vacuum/pressure systems and dual-blower continuous vacuum

and/or pressure systems are offered in numerous configurations to meet your specific

requirements. All systems feature:

• Vacuum unit

• Pressure unit

• Remote-mount control unit

• Blow-through adapter with stand

• Rotary airlock

• Shear protector (pellet valve) – pellet systems only

• Self-cleaning filters or cyclone separators

A variety of components can be combined in a vacuum/pressure conveying system to

meet specific conveying requirements. This manual offers a general overview of

systems using AEC power units. Training in the proper operation and maintenance of

an AEC-designed system is available from the Service Department of AEC, Inc.

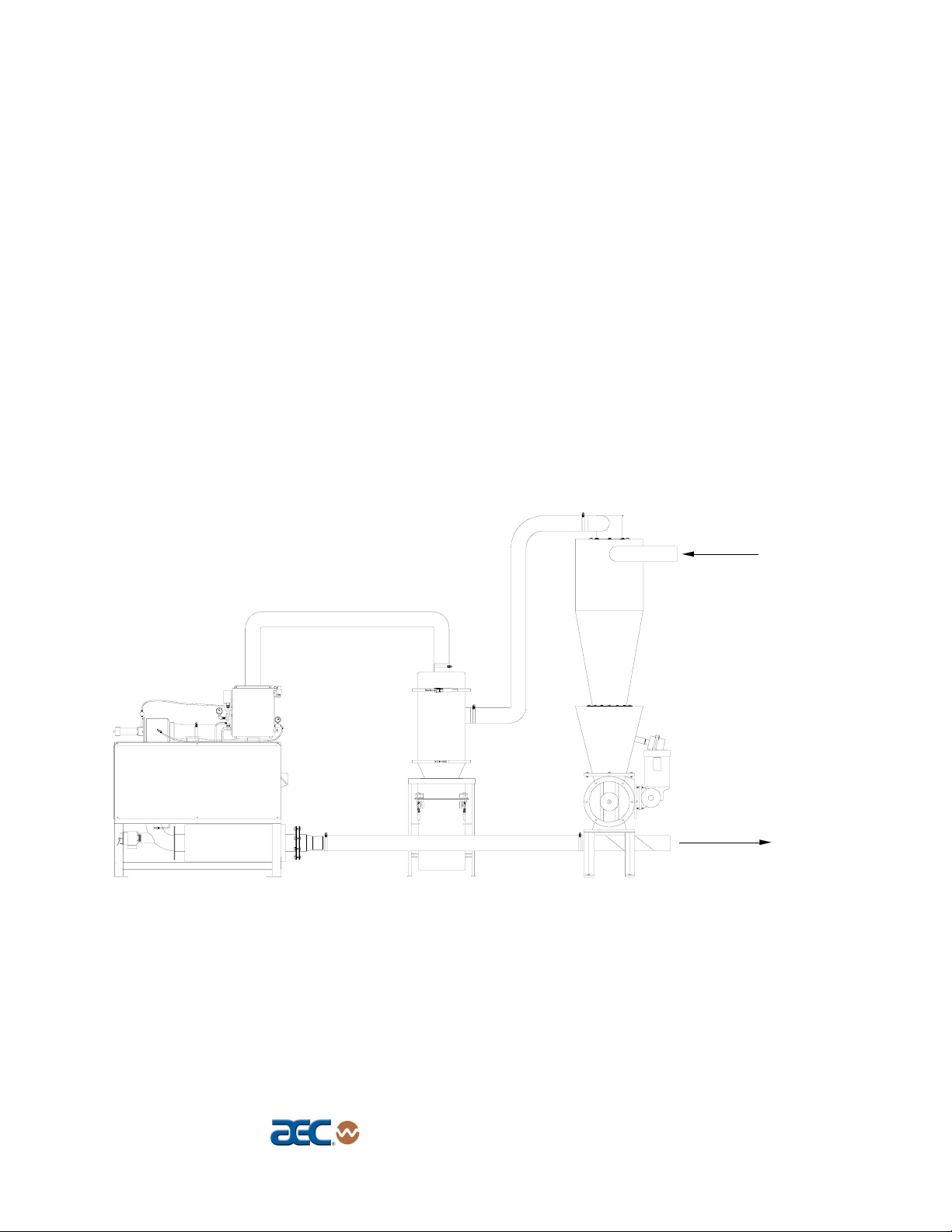

1-2 Equipment Function

Single-blower vacuum/pressure systems and dual-blower continuous vacuum and/or

pressure systems are designed to convey large quantities of free flowing pelletized,

powdered, or granular material over long distances. A typical application is unloading a

railcar to a storage silo. In such an application, material is drawn from the source by the

vacuum blower to a cyclone chamber or continuous cleaning filter receiver, where

conveying air and material are separated. The material passes through a rotary airlock

valve to a blowthrough adapter, where the pressure unit conveys material to the storage

silo.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 9

Page 11

Systems Used for Powders or Dusty Materials

Material lines on the vacuum side of the conveying system typically lead to a selfcleaning filter receiver, where material is separated from the airflow and passes through

a rotary airlock for transfer to the pressure side of the system. You can order the selfcleaning filter separately.

Systems Used to Convey Clean, Pelletized Material

Systems with solid state control units are used to convey clean, pelletized material. A

cyclone separator is furnished in the system to remove material from the vacuum side

airflow. A filter chamber is also furnished to clean the air entering the vacuum unit.

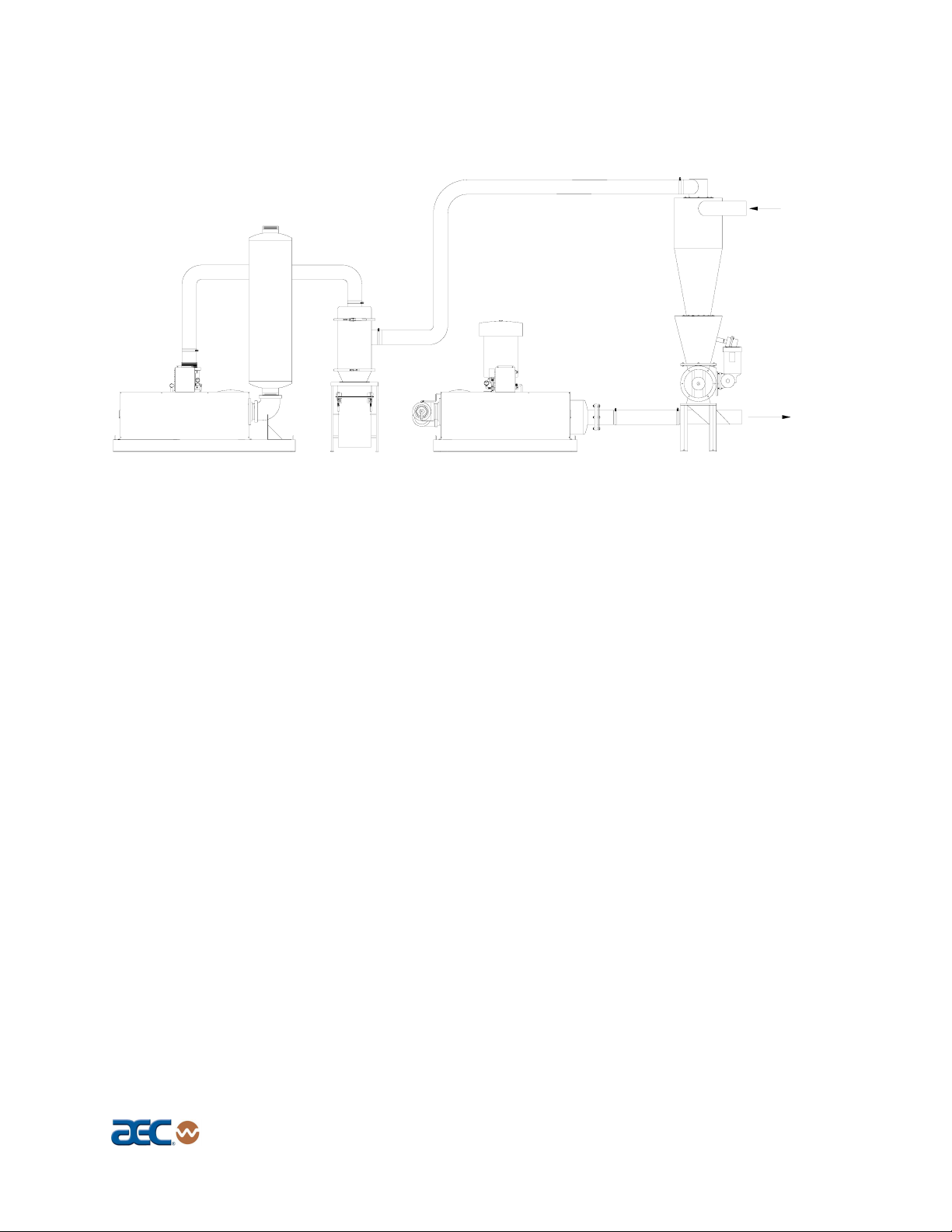

Figure 1

Typical Single Blower System for Free-Flowing Pellets

Product from

rail car

Page 10

Product

to silo

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 12

Figure 2

Typical Dual Blower System for Free-Flowing Pellets

1-3 Necessary Documents

The following documents are necessary for the installation, operation, and maintenance

of your single- or dual-blower vacuum/pressure system. You can obtain additional

copies from AEC, Inc. You should be familiar with these documents:

Product from

rail car

Product

to silo

; This manual

; Electrical connection diagram

; Electrical schematic drawing

; Final assembly drawings for vacuum and pressure units

; Manufacturer’s operation and installation manuals for rotary valve and filter

; Operation and installation manuals for accessories and options selected by the

customer, where available

1-4 Standard Features

• Continuous vacuum power unit

• Cyclone separator or filter receiver

• Rotary valve and blow-through adapter

• Continuous pressure unit

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 11

Page 13

1-5 Options

Single-blower vacuum/pressure systems and dual-blower continuous vacuum and/or

pressure systems are used with companion equipment including cyclones, filter

chambers, rotary airlock valves, and aftercoolers. In addition, the following options are

offered:

; Sound enclosures

; Diverter valves, with or without controls

; Stainless steel cyclone

; Stainless steel pressure takeoff

; Stainless steel filter receivers

; Filter chamber stand

; Common skid for mounting filter chamber, cyclone separator, rotary valve,

discharge adapter, and single-blower pumps

; PLC controllers

; Aftercoolers

; Rotary valve compressed air purge

1-6 The Vacuum/Pressure Conveying System

Vacuum/pressure conveying systems are used to convey high volumes of powder or

pelletized material long distances from railcars into storage silos. They are available

with filters designed specifically for powder or other dusty materials.

Vacuum/pressure systems for powder are similar to pellet systems except they are

equipped with a filter receiver rather than a cyclone separator. This ensures separation

of the material and maximum dust control.

Page 12

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 14

2 Safety

2-1 Work Rules

Install, operate, and maintain this equipment according to applicable work and safety

codes for your location. This includes OSHA, CE, NEC, CSA, SPI, and many other

local, national, and international regulations. Obey these specific work rules:

Read and follow the instructions in this manual before

installing, operating, or maintaining any equipment.

Additional copies are available from AEC, Inc.

Only qualified persons should work on, or with, this

equipment.

Work only with approved tools and devices.

Disconnect and lock out power while working on this

equipment.

2-2 Tools and Equipment Needed

You’ll need the following:

• Hand tools

• Fork lift or overhead lift

• Wire, conduit, and fittings for wiring runs (if receptacle is not

already in place)

• Mounting bolts with nuts and washers

2-3 Mechanical Installation

Conveying system may be mounted on a stand, or a mezzanine.

Be sure it is securely attached and additional bracing is used if

necessary. The sections on the following pages explain general

installation rules.

Read manual thoroughly before installing

conveying system.

Use approved safety straps or chains to lift the

conveying system at the marked lifting points.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 13

Page 15

2-4 Safety Considerations

The terms NOTICE, CAUTION, WARNING, and DANGER

have specific meanings in this manual. See Section 12 for a

complete list of specific safety warning information.

A NOTICE is used to indicate a statement of company policy

directly or indirectly related to the safety of personnel or protection

of property.

A CAUTION indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

A WARNING indicates a potentially hazardous situation which, if

not avoided could result in death or serious injury.

A DANGER indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This word will

be limited to the most serious situation(s).

The term IMPORTANT emphasizes areas where equipment

damage could result, or provides additional information to make a

step or procedure easier to understand. Disregarding information

marked IMPORTANT would not be likely to cause personal

injury.

Page 14

REPORTING A SAFETY DEFECT

NOTE: If you believe that your equipment has a defect which could cause

injury, you should immediately discontinue its use and inform

AEC, Inc., at our address listed in this manual.

The principle factors which can result in injury are:

1. Failure to follow proper operating and clean-out procedures,

i.e. lockout/tagout.

2. Failure to maintain a clean and safe working environment.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 16

2-5 General Responsibility

NO MATTER WHO YOU ARE…

Safety is important. Owners, operators, and maintenance

personnel must realize that every day, safety is a vital aspect of

their jobs.

If your main concern is loss of productivity, remember this:

Production is always affected in a negative way following an

accident. The following are some of the reasons, which can affect

your production:

• Loss of a skilled operator (temporarily or permanently)

• Breakdown of shop morale

• Costly damage to equipment

• Down-time

An effective safety program is responsible and economically

sound.

Organize a safety committee or group, and hold regular meetings.

Promote this group from the management level. Through this

group, the safety program can be continually reviewed,

maintained, and improved. Keep minutes or a record of the

meetings.

Hold daily equipment inspections in addition to regular

maintenance checks. You will keep your equipment safe for

production and exhibit your commitment to safety.

Please read and use this manual as a guide to equipment safety.

This manual contains safety warnings throughout, specific to each

function and point of operation.

2-6 Operator Responsibility

The operator’s responsibility does not end with efficient

production. The operator usually has the most daily contact with

the conveying system and intimately knows its capabilities and

limitations.

Plant and personnel safety is sometimes forgotten in the desire to

meet incentive rates, or through a casual attitude toward machinery

formed over a period of months or years. Your employer probably

has established a set of safety rules in your workplace. Those

rules, this manual, or any other safety information will not keep

you from being injured while operating your equipment.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 15

Page 17

REMEMBER:

ONLY YOU can make safety work for you by constantly thinking

about what is safe and what is not. It is often the “just once” that

an operator reaches into a conveying system to remove material

and it results in serious injury.

Learn and always use safe operation. Cooperate with co-workers

to promote safe practices. Immediately report any potentially

dangerous situation to your supervisor or appropriate person.

• NEVER place your hands or any part of your body in any

dangerous location.

• NEVER operate, service, or adjust the conveying system

without appropriate training and first reading and

understanding this manual.

• NEVER try to pull material out of the conveing system with

your hands while it is running!

• Before you start the conveying system check the following:

• Remove all tools from the conveying system;

• Be sure no objects (tools, nuts, bolts, clamps, bars)

are laying in the hopper area;

• If your conveying system has been inoperative or

unattended, check all settings before starting the unit.

• At the beginning of your shift and after breaks, verify

that the controls and other auxiliary equipment are

functioning properly.

• Keep all safety guards in place and in good repair.

NEVER attempt to bypass, modify, or remove safety

guards. Such alteration is not only unsafe, but will

void the warranty on your equipment.

• When changing control settings to perform a different

mode of operation, be sure selector switches are

correctly positioned. Locking selector switches

should only be adjusted by authorized personnel and

the keys removed after setting.

• Report the following occurrences IMMEDIATELY:

• unsafe operation or condition

• unusual conveying system action

• leakage

Page 16

• improper maintenance

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 18

• NEVER stand or sit where you could slip or stumble

into the conveying system while working on it.

• DO NOT wear loose clothing or jewelry, which can

be caught while working on the conveying system. In

addition, cover or tie back long hair.

• Clean the conveying system and surrounding area DAILY, and

inspect the machine for loose, missing or broken parts.

• Shut off power to the conveying system when it is not in use.

Turn the switch to the OFF position, or unplug it from the

power source.

2-7 Maintenance Responsibility

Safety is essential to the good health of both operator and machine.

If you are a maintenance worker, you must make safety a priority

in order to effectively repair and maintain equipment.

BEFORE REMOVING, ADJUSTING, OR REPLACING

PARTS ON A MACHINE, REMEMBER TO DO THE

FOLLOWING:

• TURN OFF all air and electric supplies and all accessory

equipment at the machine.

• DISCONNECT AND LOCK OUT electrical and pneumatic

power, and attach warning tags to the disconnect switch and air

shutoff valve.

When you need to perform maintenance or repair work on the

conveying system above floor level, use a solid platform or a

hydraulic elevator. If there is a permanently installed catwalk on

your conveying system, use it. The work platform should have

secure footing and a place for tools and parts. DO NOT climb on

machines or work from ladders.

If you need to repair a large component, use appropriate handling

equipment. Before you use handling equipment (portable “A”

frames, electric boom trucks, fork trucks, overhead cranes) be sure

the load does not exceed the capacity of the handling equipment or

cause it to become unstable.

Carefully test the condition of lifting cables, chains, ropes, slings,

and hooks before using them to lift a load.

Be sure that all non-current carrying parts of electrical apparatus,

electrical component enclosures, and the conveying system frame

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 17

Page 19

2-8 Safety

2-8-1 Description and Objectives

This section includes information on safety devices and procedures that are

inherent to the Vacuum/Pressure Conveying System. This manual is not

intended to supersede or alter safety standards established by the user of this

equipment. Instead, the material contained in this section is recommended to

supplement these procedures in order to provide a safer working environment.

are correctly connected to earth ground with an electrical

conductor that complies with current codes. Install in accordance

with national and local codes, which apply.

When you have completed the repair or maintenance procedure,

check your work, remove your tools, rigging, and handling

equipment.

Do not restore power to the conveying system until all persons are

clear of the area. DO NOT start and run the conveying system

until you are sure all parts are functioning correctly.

BEFORE you turn the conveying system over to the operator for

production, verify all system enclosure panels, guards and safety

devices are in place and functioning properly.

At the completion of this section, the operator and maintenance personnel will

be able to:

• Identify and locate specific safety devices.

• Understand the proper use of the safety devices provided.

• Describe the function of the safety devices.

2-8-2 Safety Circuit Standards

Safety circuits used in industrial systems protect the operator and maintenance

personnel from dangerous energy. They also provide a means of locking out or

isolating the energy for servicing equipment.

Various agencies have contributed to the establishment of safety standards that

apply to the design and the manufacture of automated equipment. The

Occupational Safety and Health Administration (OSHA) and the Joint

Industrial Council (JIC) are just a few of the organizations that have joined

with the plastics industry to develop safety standards.

Page 18

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 20

Every effort has been made to incorporate these standards into the design of the

Vacuum/Pressure Conveying System; however, it is the responsibility of the

personnel operating and maintaining the equipment to familiarize themselves

with the safety procedures and the proper use of any safety devices.

2-8-3 Fail Safe Operation

If a safety device or circuit should fail, the design must be such that the failure

causes a “Safe” condition. As an example, a safety switch must be a normally

open switch. The switch must be held closed with the device it is to protect. If

the switch fails, it will go to the open condition, tripping out the safety circuit.

At no time should the safety device fail and allow the operation to

continue. For example, if a safety switch is guarding a motor, and the safety

switch fails, the motor should not be able to run.

2-8-4 Safety Device Lock-Outs

Some safety devices disconnect electrical energy from a circuit. The safety

devices that are utilized on this equipment are primarily concerned with the

pneumatics and electrical power disconnection, and the disabling of moving

parts that may need to be accessed during the normal operation of the machine.

Some of the safety devices utilize a manual activator. This is the method of

initiating the safety lock out. This may be in the form of a plug, disconnect

plug, lever or a handle. Within this lockable handle, there may be a location for

a padlock. Personnel servicing the equipment should place a padlock in the

lockout handle.

WARNING! Always disconnect and lockout all electrical power and pneumatic

(i.e. compressed air) sources prior to servicing or cleaning any

Vacuum/Pressure Conveying System. Failure to do so may result

in serious injury.

At no time must anyone remove the lockout or reconnect the twist

plug, other than the person who installed the lockout or who

unplugged the twist plug.

2-8-5 Lock-Outs, Plugs, and Other Safety Devices

The Vacuum/Pressure Conveying System utilizes several types of

safety devices.

The Line Cord Plug

This line cord plug allows the operator or maintenance personnel

to unplug the conveying system from its power source and tag it

out. This plug may be tagged with any number of approved

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 19

Page 21

WARNING!

electrical lockout tags. These tags are available at most electrical

supply stores.

Disconnect both of these items to ensure optimum maintenance

personnel safety when cleaning or servicing this equipment.

-Notes-

Page 20

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 22

3 Shipping Information

3-1 Unpacking and Inspection

You should inspect your AEC vacuum/pressure system and components for possible

shipping damage. If the container and packing materials are in re-usable condition, save

them for reshipment if necessary.

Thoroughly check the equipment for any damage that might have occurred in transit,

such as broken or loose wiring and components, loose hardware and mounting screws,

etc. In case of breakage, damage, shortage, or incorrect shipment, refer to the following

sections.

3-2 In the Event of Shipping Damages

Important!

According to the contract terms and conditions of the Carrier,

the responsibility of the Shipper ends at the time and place of

shipment. The Carrier then assumes full responsibility of the

shipment.

; Notify the transportation company’s local agent if you discover

damage.

; Hold the damaged goods and packing material for the examining

agent’s inspection. Do not return any goods to AEC, Inc. before the

transportation company inspection and authorization.

; File a claim against the transportation company. Substantiate the claim

by referring to the agent’s report. A certified copy of our invoice is

available upon request. The original Bill of Lading is attached to our

original invoice. If the shipment was prepaid, write us for a receipted

transportation bill.

; Advise AEC, Inc. regarding your wish for replacement and to obtain an

RMA (return material authorization) number.

Parcel Post Shipment

; Notify AEC, Inc. at once in writing, giving details of the loss or

damage. This information is required for filing a claim with our

insurance company.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 21

Page 23

; Hold the damaged goods with the container and packing materials for

possible inspection by postal authorities.

United Parcel Service

; Contact your local UPS office regarding damage and insurance claims.

; Retain the container and packing.

; Notify AEC, Inc. at once.

3-3 If the Shipment is Not Complete

Check the packing list. The apparent shortage may be intentional. Back-ordered items

are noted on the packing list. You should have:

; AEC vacuum/pressure system and related system components

; Bill of lading

; Packing list

; Operating and Installation packet

; Electrical schematic and panel layout drawings

; Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items

during unpacking. Determine that the item was not inadvertently taken from the area

before you checked in the shipment. Notify AEC, Inc. immediately of the shortage.

3-4 If the Shipment is Not Correct

If the shipment is not what you ordered, contact AEC, Inc. immediately. Include the

order number and item. Hold the items until you receive shipping instructions.

3-5 Returns

Important!

Do not return any damaged or incorrect items

until you receive shipping instructions from AEC, Inc.

Page 22

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 24

4 Installation

4-1 Work Rules

The installation, operation, and maintenance of this equipment must be conducted in

accordance with all applicable work and safety codes for the location where it is used.

This may include, but is not limited to, OSHA, NEC, CSA, SPI, and any other local,

national, and international regulations. In addition, observe the following specific

rules:

; Always keep these operating instructions at hand and follow them when

performing installation, operation, and maintenance. If these instructions

become damaged or unreadable, obtain additional copies from AEC, Inc.

; Only qualified personnel must work on or with this equipment.

; Work shall be done only with approved tools and devices.

; The power disconnect of this unit has a lockout that permits the switch to be

locked in the

must be locked out when performing maintenance or service on any part

of the conveying system, in accordance with applicable safety regulations.

OFF position when placing a padlock in the hasp. This switch

; In units that require compressed air, disconnect the compressed air supply

before performing maintenance or service.

; Disconnect and/or lock out the power main at an external power disconnect

switch before performing electrical service.

; Keep hands, tools, clothing, etc. away from the rotary valve. Make sure the

valve has completely stopped before performing maintenance.

4-2 Tools and Equipment

You’ll need the following tools and equipment to install system components:

; Hand tools

; One-half inch (

washers, and red-head type anchors, if used

; Electric drill

; Wire for connecting the power units, rotary airlock, and level indicator

; Wire and a properly-sized fused disconnect switch for the power drop(s)

; Conduit for the power drop and airlock motor wiring

1

/2”) and three-eighths inch (3/8”) anchor bolts with nuts and

; Forklift

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 23

Page 25

4-3 Installing Mechanical Components

4-3-1 Installing Vacuum and Material Tubing

Use the following as a general reference when installing your system:

• Refer to the assembly prints often.

• Support overhead tubing about every ten (10) feet (3 m) with straps, pipe

hangers, or brackets. Keep the coupled joints rigid to avoid vacuum or

material leaks from tubing movement or misalignment.

• Cut all tube ends square, and chamfer internal edges smooth. Make sure

that the tube ends butt together inside the coupler.

• Tighten coupler nuts with a wrench to help provide a vacuum and

material-tight seal and proper contact of the internal grounding strip.

• If you must cut bends, do so on the straight section at either end, and

leave enough straight length for adequate insertion in the coupler.

• Make sure that material flow is in the direction of the arrows on flexible

material hose.

Figure 3

Examples of Single Line and Multiple Line Hangers

Page 24

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 26

4-3-2 Using Quick-Change Couplers and Flexible Material Hose

You can attach a quick-change coupler or standard tube coupler to the tube at

either end of the flexible material hose. Make sure that the material flow is in

the direction of the arrows on the flexible material hose. The tube on each end

of a flexible vacuum hose should fit the tube coupler for the system. You can

also fit a quick-change coupler to either tube.

If your system requires a quick-change rack, hold the rigid tubing in place with

U-clamps. Mount male quick-change couplings on the rigid piping of a quickchange rack. As your installation requires, bolt the rack in position to the wall

or floor before attaching the tubing.

Mount female quick-change couplers on the flexible hose of a quick-change

rack, allowing the ease and flexibility of selecting material flows or vacuum

flows, depending upon the requirements of your system design.

Figure 4

Quick Change Couplers

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 25

Page 27

4-3-3 Sheltering System Components

If the power unit, control unit, rotary valve, filter, and related equipment are

not installed inside the plant, provide a weather shed or other outbuilding to

shelter these components from the weather. You should provide such shelter

even with the NEMA 4 control option.

4-3-4 Installing the Vacuum and/or Pressure Units

1. Level and secure the vacuum and/or pressure units.

2. Check oil level in blower assembly.

4-3-5 Installing the Rotary Airlock/Cyclone Assembly

Each AEC cyclone separator comes complete with a throw-out cone for

efficient material to air separation and a rotary level indicator for a high level

cut-off.

An airlock is a precision piece of equipment operating with small internal

clearances. The airlock should be bolted to the discharge adapter supported

securely on a flat surface with sponge rubber gasket provided with the

equipment.

Though they are an integral part of a vacuum/pressure system, rotary airlocks

are specified separately to meet the exact requirements of the materials

conveyed. Refer to the separate guide the airlock manufacturer has included on

airlock installation and maintenance.

1. Level and secure the vacuum unit, pressure unit, and blow-through adapter

with stand to the floor using one half-inch (

1

/2”) bolts.

2. Bolt the rotary airlock and motor assembly you specified to the blow-

through adapter, if not already done at the factory. Use the one eighth inch

(1/8”; about 3 mm) -thick composite gaskets provided.

3. Tighten the bolts evenly to avoid distortion of the flanges. Draw up snug—

do not over-tighten. Exerting twisting or pulling pressure on the housing, as

with poor installation of related components, causes damage, excessive

wear, and air leaks.

Note: Verify that the rotation of the airlock is toward the larger, square-cornered outlet

of the blow-through adapter. See Figure 6 on Page 33 for more information.

4. Install the shear protector on top of the rotary valve.

Page 26

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 28

WARNING!

Note:

Shear points are present at the

open inlet and outlet of the rotary airlock.

For safety, you must cover the inlet and outlet

before performing this procedure!

THE AIRLOCK COULD SHEAR OFF YOUR FINGERS

if you do not take adequate safety measures!

HAND GUARDS ARE REQUIRED.

• The rotary airlock is a precision-machined device. Exerting twisting or

pulling pressure on the housing (as with poor installation of related

components) causes damage, excessive wear, and air leaks.

• The shaft seals are shipped loose and must be tightened before running

material through the airlock.

5. Install and/or inspect the optional rotary level indicator.

6. Mount the cyclone on top of the rotary airlock. The legs provided to the

airlock support the entire assembly. If the self-cleaning filter is purchased,

mount the airlock with the blow-through adapter to the discharge flange of

the filter receiver. The airlock/blow-through adapter can be oriented so the

airlock housing does not interfere with the filter receiver legs. Use the one

eighth inch (

evenly to avoid distorting flanges. Draw up snug—do not over-tighten.

7. Take care to align the pressure blower discharge muffler and the blow-

through adapter. Airlocks are precision-machined devices. Do not load or

twist the housing.

8. Connect the discharge end of the pressure blower to the inlet side of the

discharge adapter. Black heavy-duty high-temperature oil-resistant hose is

provided for the connection.

1

/8”; about 3 mm) -thick composite gaskets. Tighten bolts

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 27

Page 29

Figure 5

Rotary Airlock/Cyclone Assembly

Product from

rail car

High Level Switch

(option)

Product

to silo

9. Complete the pressure-side material line between the outlet side of the

blow-through adapter and the material destination. Connect the pressure

side material line to the blow-through adapter on the larger, squarecornered, tapered side. See Figure 11 on Page 40 for more information.

10. Complete the material line connections from the material manifold line or

the material source to the inlet of the cyclone separator or self-cleaning

filter.

11. Complete the vacuum line connections from the vacuum unit to the filter

chamber (in pellet conveying systems) and to the cyclone separator. In a

powder conveying system, no cyclone separator or vortex filter chamber is

provided. Complete the vacuum line connections from the pump to the

outlet tube on the self-cleaning filter.

12. Check oil level in airlock gear reducer assembly.

CAUTION! When connecting the material line, make sure it

is supported and no load is placed on the rotary airlock!

Page 28

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 30

IMPORTANT! The power unit is sized for the total conveying distance.

In some cases, if the takeoff on the railcar does not have an

adjustment to restrict material flow into the vacuum side

material line, too much material may be drawn on the vacuum

side.

A solution for this condition is to install a manual valve

on a T in the material line as close to the take-off as possible.

Throttle this valve to supply some of the air requirement

of the vacuum unit to prevent excess material from plugging

the line.

4-3-6 Installing the Filter Chamber

Used in Combination with the Cyclone Separator Only

The filter chamber protects the vacuum blower from damage caused by

material carryover from the cyclone separator. Primary system filtration

occurs in the cyclone separator and any fines that are carried over to the

filter chamber are trapped in the cartridge filter in the filter chamber.

A vortex created in the filter chamber separates carryover from the air

stream, and a cartridge filter catches any dust and any fines into the upper

chamber. If used in a very dusty application the filters can be cleaned in

any one of the following ways:

• Install an atmospheric vent valve on the outlet of the filter chamber.

During the blowback cycle, when the valve is energized,

atmospheric air is introduced to the filter chamber, equalizing the

pressure inside the filter chamber with a rush of air across the filter.

• A compressed air filter cleaning blowback option is used for very

dusty applications, and cleans better than the option listed above.

1. Level and secure the filter chamber near the pump package. Use three

eighths-inch (

3

/8”) bolts to anchor the filter chamber.

2. Connect the piping between the vacuum inlet valve on the pump and

the outlet tube on the cover of the filter chamber. For easy filter

maintenance, use at least three (3) feet (1 m) of vinyl flex hose at the

end of the run to the filter chamber. The rest can be hard-piped as long

as it is properly supported.

3. If the filter chamber has the optional atmospheric valve, insert a short

piece of chamfered tubing into the valve body inlet, tighten the set

screws, and connect the flex hose to the tube with a clamp.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 29

Page 31

4. Connect the inlet tube of the filter chamber to the outlet of the cyclone

separator.

4-3-7 Installing the Filter Chamber Shroud

The cloth filter shroud is mounted to a ring on the underside of the filter

chamber stand. It reduces housekeeping duties around the filter chamber by

preventing dust from being stirred up when the dust and fines are discharged

from the VFC filter chamber. The dust container below the shroud is customersupplied—the standard 24” (61 cm) clearance stand is designed for use with a

5-gallon (19-liter) pail, and the optional 38” (96 cm) clearance stand is

designed for use with a 55-gallon (208-liter) drum.

1. Insert the filter shroud support wire into the slotted hole in the middle

of the cloth filter shroud. Use supplied hardware to secure.

2. Slip the filter shroud over the retaining ring located on the bottom side

of the filter stand mounting plate. Secure it with the worm clamp

provided.

3. Place the dust container you’ve supplied below the filter chamber

stand and insert the filter shroud.

4. On standard 5-gallon (19-liter) pails, the filter shroud should be

trimmed to project about one half of the way into the container. Don’t

trim the filter shroud on 55-gallon (208-liter) drums. Secure the

drawstring on the shroud around the drum, making sure the open end

of the shroud hangs freely inside the drum.

5. Make sure the operation of the counterweighted flapper dump valve is

not obstructed in any way by the filter shroud.

CAUTION! Do not obstruct the filter shroud in any way.

Empty the dust container before

the dust level obstructs the end of the filter shroud.

4-4 Making Compressed Air Connections

Note: If the system you specified uses a vacuum unit with non-reversing valving for

blowback, you must connect the vacuum unit to a source of clean, dry, lubricated

compressed air with an operating pressure of 80 psig (551.6 kPa/5.52 bars).

Page 30

CVP/CPP Systems

CVP/CPP systems do not require compressed air connections at the pumps.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 32

SVP Systems

Connect the pump to a minimum of 80 psi (551.6 kPa/5.52 bars) clean, dry,

lightly lubricated compressed air. Make

package.

the 1/8” NPT connection at the pump

4-5 Making Electrical Connections

Single-blower vacuum/pressure systems and dual-blower continuous vacuum and/or

pressure systems require connection to a 3-phase power supply. The control unit is

mounted on the vacuum unit or mounted in a remote location. Refer to local electrical

codes and the connection diagram and schematic enclosed with the unit.

Note: Refer to the specific electrical schematic included in your Customer Information

Packet when making electrical connections. Make sure all electrical connections

are tight.

Use the following as a general reference:

Power Drop

Check the nameplate voltage and amperage on the control unit and on each motor

in the system. Voltage must be within plus or minus five percent (±5%) of the

nameplate voltage.

• Bring properly sized power leads, in conduit, to the control unit. Bring power

through a properly-sized fused disconnect switch with approved lockout,

supplied by the customer.

• Ground the control unit for operator safety and equipment protection.

Rotary Airlock Motor

Run three wires from the rotary airlock motor back to the control unit.

IMPORTANT! Make sure the motor leads are connected so the rotary airlock

rotates in the proper direction. Refer to the electrical

schematic included in your Customer Information Packet to

verify terminal connection points.

Reverse any two motor leads to change direction.

See Figure 7 on Page 34 and Figure 9 on Page 36 for more

information.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 31

Page 33

Vacuum Unit Motor

If the control unit is mounted on the vacuum unit, the vacuum unit motor is prewired to the control unit. If the control unit is remotely mounted, bring three

properly sized leads in conduit from the terminals in the small junction box on the

vacuum unit to the control unit.

Check for proper motor rotation direction. Reverse any two motor leads to

change direction.

Pressure Unit Motor

Bring three properly sized leads in conduit from the terminals in the small junction

box on the pressure unit to the control unit. Check for proper motor rotation

direction. Reverse any two motor leads to change direction.

Vacuum Solenoid Valves (Single Blower Units, SVP Models)

If the control unit is mounted on the vacuum unit, these valves are pre-wired. If the

control unit is remotely mounted, connect three 14-gauge 300V MTW wires and

bring them in conduit to the vacuum unit junction box.

High Vacuum Switch

If the control unit is mounted on the vacuum unit, this switch is pre-wired. If the

control unit is remotely mounted, connect two 14 gauge 300V MTW wires and

bring them in through the conduit to the vacuum unit junction box.

High Pressure Switch

Run two 14 gauge 300V MTW wires from the control unit to the junction box on

top of the pressure unit. For solid state control units, connect the wires in both the

control unit and junction box. For relay units, connect the wires as shown in the

electrical schematic included in your Customer Information Packet.

High Level Switch

Provision for a single high level switch at the material receiving point is standard.

Run two 14 gauge 300V MTW wires from the switch to the control unit on

conduit. Where optional switch-selectable high level sensors are present, refer to

the connection diagram enclosed with this manual for terminal numbers.

Cyclone High Level Sensor

Run two 14 gauge 300V MTW wires from the sensor to the control unit in conduit.

4-6 Testing the Rotary Airlock

Page 32

Run the airlock motor and airlock, verifying that the airlock is turning in the proper

direction (See Figure 6). Measure the current draw with a clamp-on ammeter and

compare it with the rated draw on the motor nameplate.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 34

Gradually and evenly tighten the packing gland bolts on either side of the rotor until the

A

w

A

w

motor current draw is about eighty percent (80%) of the rating listed on the motor

nameplate.

Run the airlock motor and airlock for thirty (30) minutes. Again, tighten the packing

gland bolts until the motor current draw is about eighty percent (80%) of the rated draw

of the motor.

Figure 6

Rotary Airlock Rotation and Material Flow

Shear Protector

Opening

Motor

Pressure

take-off

ir flo

ir flo

Note: Make sure the shear protector (pellet valve) is installed on top of rotary valve in

all pellet systems. Opening should be located above downward side of rotation.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 33

Page 35

Figure 7

Typical SVP System Electrical Schematic

Page 34

Legend

------- Field wiring

Terminal Block

Notes:

1. 1PS opens on high pressure.

2. 1LS opens on throw-out cone high level.

3. 1VS closes on high vacuum.

4. 2LS closes on high level in silo.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 36

Transformer,

460 V to 115 V

Figure 8

Typical SVP Electrical Subpanel Layout

Fuse holder,

30 amp fuses

Disconnect

switch

Relay

60 sec.

timers

Overload

contactor

Overload

contactor

Terminal blocks

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 35

Page 37

Figure 9

Typical CVP/CPP System Electrical Schematic

Page 36

See Note #3

(typical)

Legend

----------------- Field Wiring

Indicates terminal block connection

Notes:

1. 1PS opens on high pressure,

2. 1LS opens on cyclone separator high level.

3. 2LS closes on high level of its respective silo.

4. 1VS closes on high vacuum.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 38

Figure 10

Typical CVP/CPP Electrical Subpanel Layout

Fuse holder,

30 amp fuses

Transformer,

460 V to 115 V

Relay

60 sec.

timers

Disconnect

switch

Overload

contactor

Overload

contactor

Terminal blocks

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 37

Page 39

- Notes -

Page 38

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 40

5 Startup, Shutdown, and Operation

5-1 Equipment Cycle

Systems with dual blowers have a slightly different equipment cycle than systems with

single blowers. Refer to electrical schematic and panel layout drawings included with

your system for more information.

A description of the cycles for each type follows:

SVP — Single Blower Vacuum Pressure Systems

When the system is started, the single vacuum/pressure blower and the rotary airlock

activate. The blower draws air from the atmosphere (goes into a vent cycle) and starts

to purge the pressure side material line for a set period of time as determined by the

vacuum on delay timer. After a set time period, the vent cycle ends and material is

drawn into the cyclone, where it is stripped from the conveying air and drops into a

rotary airlock.

The airlock allows material to pass to the pressure side of the system where it is blown

to the destination. The SVP blower replaces CVP/CPP blowers in single blower

vacuum pressure systems, but the load cycle remains the same. See Figure 11 on Page

40 for more information.

When the system is stopped in a non emergency situation (purge stop), the blower goes

into the Vent cycle and continues to purge the material in the pressure side of the

material line, while no material is drawn into the cyclone separator or the filter receiver.

The purge time controlled by the purge timer, adjustable from zero to ten (0-10)

minutes. You must restart the system after the purge cycle.

When level sensors in the cyclone or at the destination point detect a high level

condition, the vacuum unit goes into idle until material levels decline. The time for the

idle state is controlled by the Vacuum On delay timer, adjustable from zero to ten (0-

10) seconds. The system then returns to the conveying cycle. An automatic shutdown

module shuts down the vacuum/pressure blower and rotary airlock after a preset period.

The emergency stop button on the control unit shuts down all units in the system. The

system also goes into emergency stop when the high pressure sensor on the pressure

outlet opens.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 39

Page 41

CVP/CPP — Dual Blower Vacuum Pressure Systems

When the system is started, the pressure blower and rotary airlock energize and the

pressure blower starts to purge pressure-side material lines and builds up speed. At the

end of the period preset on a vacuum on delay timer, the vacuum blower energizes.

Material is drawn to the filter receiver or cyclone where it is stripped from the

conveying air and drops into a rotary airlock.

When the system is stopped in a non-emergency situation (purge stop), the vacuum unit

stops and allows the rotary airlock and pressure unit to continue conveying material,

purging pressure-side material lines. The purge timer shuts down the pressure unit and

rotary airlock after a preset period.

The system also goes into purge stop when level sensors in the cyclone, filter chamber,

or at the destination point detect a high level condition. You must restart the system

after the purge stop cycle.

The emergency stop button on the control unit shuts down all units in the system. The

system also goes into emergency stop when the high pressure sensor on the pressure

outlet senses high pressure.

Figure 11

Typical Vacuum/Pressure System Load Cycle

Page 40

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 42

Notes: The drawing on the previous page shows a typical CVP/CPP system for conveying

plastic pellets. For dusty material applications, replace the cyclone separator/filter

chamber combinations with one self-cleaning filter chamber.

In SVP systems, an SVP blower is used in lieu of CVP/CPP combination blowers.

5-2 Alarms, Controls, and Indicators

Single- and dual-blower vacuum/pressure systems include the following controls and

indicators:

Controls

Disconnect (DISC)

Position the disconnect switch to turn electrical power to the system on and off.

Start (1PB)

Push Start to start the system. The system does not start if blower or airlock

motor overloads have tripped out.

Emergency Stop (2PB)

Push Emergency Stop to completely stop system functions in an emergency.

Do not use it for normal system shutdown.

Purge Stop (3PB)

Push Purge Stop to shut down the system normally. The system ends vacuum

conveying while allowing the pressure side to empty the cyclone or filter

receiver, blowing material out the pressure side. The automatic shutdown module

in solid state units or purge timer in relay units controls the shutdown period.

Indicators

Power On Pilot Light (1LT)

Power On illuminates when the system energizes.

Purge Pilot Light (2LT)

Purge illuminates when the vacuum unit stops and the rotary airlock and

pressure unit purge the pressure-side material line.

Convey Pilot Light (3LT)

Convey illuminates when the system starts and the vacuum side conveys

material.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 41

Page 43

Figure 12

Typical SVP Control Panel Layout

Disconnect

POWER

POWER switch

PURGE switch

R

PURGE

A

_

O

F

N

O

F

0

STOP switch

PURGE

SILO

1 2

START

PURGE STOP switch

PURGE switch

START switch

Silo selector switch

Page 42

42079Q91

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 44

Figure 13

Typical CVP/CPP Control Panel Layout

POWER switch

PURGE switch

CONVEY switch

EMERGENCY STOP switch

POWER

1LT

PURGE

2LT

CONVEY

3LT

E.STOP

START

2PB 1PB

PURGE

STOP

3PB

START switch

PURGE STOP switch

O

F

F

1DISC

N

O

Disconnect

SILO

1 2

Silo selection switch

41275Q91

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 43

Page 45

5-3 Mechanical Indicators and Safety Features

Single-blower vacuum/pressure systems and dual-blower continuous vacuum and/or

pressure systems include the following components. Proper operation of the system

depends on your adjusting them to your specific material and application.

DANGER!! You must perform some adjustments

inside the control cabinet with power

ON.

USE EXTREME CAUTION in such

circumstances.

Only qualified personnel who

understand the equipment and who

know the hazards can be allowed to

perform such procedures.

HIGH VOLTAGE MAY BE PRESENT,

WHICH CAN CAUSE SEVERE INJURY

OR DEATH!

BE SAFETY CONSCIOUS!

Vacuum Gauge

The vacuum gauge indicates the operating vacuum on the vacuum side of the

system. It should read up to 10 in. Hg (339 millibars) during normal operation.

It is connected to the cross tee above the blower.

Pressure Gauge

This gauge indicates the operating pressure on the pressure side of the system. It

should read up to 5 psig (34.475 kPa/0.344 bars) during normal operation. It is

located directly in front of the pressure switch.

High Vacuum Switch (1VS)

The vacuum switch protects the vacuum pump from high amperage damage if a

material blockage should occur during conveying. It is located in the junction

box on the standard vacuum pump.

Page 44

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 46

IMPORTANT!

Pressure Switch

The vacuum/pressure system shuts down if the vacuum switch senses vacuum

greater than 14 in. Hg (406.8 millibars). The vacuum switch is nonadjustable

and therefore needs no adjustment.

The most common cause of high vacuum is plugged filters. When system

vacuum rises above the setting on the switch, the switch closes and begins the

purge cycle. After a preset time, the whole system shuts down.

Do not tamper with the vacuum switch.

Doing so voids your vacuum pump warranty!

The pressure switch protects the pressure pump from high amp damage if a

material line blockage occurs during conveying. The pressure pump shuts down

if the pressure switch senses air pressure greater than 6 psig (41.37 kPa/0.414

bars).

The pressure switch is adjusted at the factory and needs no adjustment.

IMPORTANT!

Pressure Relief Valve

Do not attempt to adjust the pressure switch.

It was pre-set at the factory.

Doing so voids your pressure pump warranty!

The adjustment for pressure relief is factory-set at about 1 psig (about 7 kPa/70

millibars) above the maximum allowable pressure set on the pressure switch. It

is located on the pressure unit.

The main cause for high pressure is a blocked material line on the pressure

side. When air pressure overcomes the spring tension on the mechanical

adjustment, the valve opens and relieves the pressure. The pressure relief valve

serves as a mechanical backup for the pressure switch. The pressure switch

should trip and shut down the pressure pump before the pressure relief valve

opens.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 45

Page 47

IMPORTANT! Do not attempt to adjust the relief valve

to more than 1 psig (about 7 kPa/70 millibars)

above the maximum operating pressure

for your system (typically 7 psig or about 48.265 kPa/0.482

bars).

Doing so voids your pressure pump warranty!

Vacuum Vent Valve

SVP Pumps Only

When the purge button is pressed, the solenoid valve on the vent valve

energizes and the cylinder opens to draw vacuum from the atmosphere instead

of from the vacuum line. The vent valve breaks the vacuum, but supplies air to

purge material on the pressure side of the material line.

Vacuum On Delay Timer

1TR

Set the Vacuum On delay timer. It controls how long the vacuum blower is in

the idle state (SVP systems) or in the shutoff mode (CVP/CPP systems) before

resuming normal convey cycle. Set it so material can clear from the cyclone

separator or filter receiver before it is conveyed again. Timer range is zero to ten

(0-10) seconds.

Auto Shutdown Timer or Purge Timer

Set this timer to control how long the pressure unit continues to operate after

you press Purge Stop (3PB). Allow the unit to run long enough to empty the

cyclone/filter receiver, blow-through adapter, and the entire pressure side

material line.

If material is left in the pressure line when the system is shut down, it tends to

plug the line when you restart the system. When adjusting this time to your

application, start with the timer at the maximum setting and work back to the

optimum time. Turn it clockwise to increase the setting. When the timer times

out (zero to ten [0-10] seconds), the entire system shuts down. With SVP

systems, the pump goes into a vent cycle while it purges the pressure side of the

material line. In CVP/CPP systems, the vacuum pump shuts down while the

pressure motor runs for a preset time as determined by the purge timer.

Blowback Timer

Refer to the electrical schematic enclosed in the Customer Information Packet

for adjusting blowback on/off pulses and the duration of each pulse.

Page 46

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 48

Silo Selector Switch

AEC vacuum/pressure pumps are equipped with a silo selector switch. This

switch is wired to the high level switches inside individual silos, and selects

which high level sensor is monitored. Wire this switch according to the wiring

diagram and schematic.

Turn the silo selector switch indicator to the silo currently being filled by the

vacuum/pressure blower(s). When the selected high level silo indicator senses a

full silo, a purge stop cycle actuates.

Your AEC vacuum/pressure pump(s) package comes standard with a twoposition selector switch. More than two positions are available; stipulate the

number of positions you want when ordering.

5-4 Pre-Startup Checklist

Before operating the system, verify the following areas:

; Verify that you made a solid compressed air connection.

; Verify that you made all material, pressure, and vacuum connections and that

they are secure.

; For units equipped with a high temperature thermostat (

properly adjusted the high temperature shutdown setting.

; Verify that any companion equipment (filter receiver, cyclone, rotary airlock,

aftercooler) are ready to operate.

; Verify that the disconnect switches in your power drop and at the control

enclosure are energized.

; Verify that pump and rotary airlock are correct.

5-5 Starting the System

After you install the system and made all pre-startup checks, perform the following

procedure to start the unit:

; Make any final connections at the material source.

; Turn on compressed air.

; Press

; Make adjustments to the system (i.e. vacuum, blowback, automatic shutdown,

Start. System operation is automatic and continuous.

etc.) as needed.

1THS), verify that you

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 47

Page 49

5-6 Shutting Down the System

In certain operating conditions, pressing Emergency Stop or Purge Stop shuts

down the system. Refer to the following sections for an explanation of the operation

and conditions of each.

Operating Conditions Shutdown

The vacuum/pressure pump(s) automatically shut(s) down in the following conditions.

High Level Signal

The level switch in the silo or throwout cone signals a full condition. A purge

stop sequence occurs and the system shuts down.

Push the Start button to re-start the system.

High Vacuum

The vacuum switch senses vacuum in excess of 12 in. Hg (406.8 millibars) on

the vacuum side of the system. The Purge Stop sequence activates and the

entire system shuts down. Find the blockage and remove it.

Push the Start button to re-start the system.

High Pressure

The pressure switch senses pressure in excess of 6 psig (41.4 kPa/0.41 bars) on

the pressure side of the system. The vacuum/pressure system shuts down. Find

the blockage and remove it.

Push the Start button to re-start the system.

Note: A high vacuum condition causes units to begin the purge cycle, interrupting

vacuum conveying. In SVP systems when the purge cycle occurs, the pump

goes into vent cycle. In CVP/CPP systems, the vacuum unit turns off for a

preset time period. A high pressure condition causes the mechanical relief

valve to open on the pressure unit, affecting pressure conveying if the high

pressure switch fails to shut down the units.

Emergency Shutdown

In an emergency, press Emergency Stop (1PB) to stop system operation. Expect to

encounter material plugging the pressure line on subsequent startups.

Normal Shutdown

Page 48

Press Purge Stop (3PB) for normal operational shutdown. Vacuum conveying stops

immediately. After the system purges the cyclone/filter receiver, blow-through adapter,

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 50

and pressure side material lines of material (set duration in the Auto Shutdown Timer

or Purge Timer), the pressure side of the conveying system also stops.

Maintenance and Long-Term Shutdown

When shutting down the unit for maintenance or for a long period of time, follow the

procedure listed in Normal Shutdown in the previous section. Then continue with

the following steps:

1. Open (de-energize) the disconnect switch at the control enclosure and the one

at the power drop.

2. Turn off compressed air to the unit by closing the shutoff valve in the supply

circuit.

5-7 Unloading Railcars

Refer to Appendix A on Page 57 for information on proper procedures for unloading

railcars using AEC equipment.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems Page 49

Page 51

6 Maintenance

6-1 Work Rules

The installation, operation, and maintenance of this equipment must be conducted in

accordance with all applicable work and safety codes for the location where it is used.

This may include, but is not limited to, OSHA, NEC, CSA, SPI, and any other local,

national, and international regulations.

In addition, observe the following specific work rules:

; Always keep these operating instructions at hand, and follow them when

performing installation, operation, and maintenance. If the instructions become

damaged or unreadable, obtain additional copies from AEC, Inc.

; Only qualified personnel must work on or with this equipment.

; Perform work only with approved tools and devices.

; Refer to the Safety Label drawing included with your unit for the type and location

of equipment safety labels.

; The power disconnect of this unit has a lockout which permits the switch to be

locked in the

be locked out when performing maintenance or service on any part of the

conveying system, in accordance with applicable safety regulations.

; In units which require compressed air, disconnect the compressed air supply

before performing maintenance or service.

; Disconnect and/or lock out the power main at an external power disconnect switch

before performing electrical service.

; Keep hands, tools, clothing, etc. away from the rotary valve. Make sure the

valve is completely stopped before performing maintenance.

OFF position when placing a padlock in the hasp. This switch must

6-2 Lubricating Components

Single- and dual blower vacuum/pressure systems require the following lubrication:

Blowers

The blowers of the unit and pressure unit must be greased, and the oil in the

gearbox must be kept at the proper level. The recommended oil is listed in the

attached Blower Instruction Handbook and should be used as listed there.

Page 50

Pack the front bearings with a good, high temperature ball bearing grease, again as

listed in the blower manual.

Single- and Dual-Blower Continuous Vacuum/Pressure Systems

Page 52

Motors

No lubrication is required.

Rotary Airlock

After the first six months of operation, lubricate the airlock rotor shaft bearings with

good quality grease every three to six months at the grease fittings provided. Do not

over-lubricate!

Compressed Air Lubricator (Optional)

Check the lubricator for the vacuum unit compressed air supply daily for oil level.

Refill as needed with proper lubricant.

6-3 Periodic Service

The following section lists suggested periodic service for single- and dual-blower

vacuum/ pressure systems. The service schedule for your particular application is

determined by the material you convey and the operating environment.

Weekly Checks and Inspections

; Check motors for excessive noise or vibration.

; Check all hoses and pipe connections for tightness and leaks.

; Check all filters for dirt or wear; clean or replace as needed.

Monthly Checks and Inspections

; Check wiring for secure connections, frayed insulation, etc.

; Check the muffler on the vacuum unit for material particles that may have

plugged internal openings. This indicates poor filter maintenance at the filter

chamber or filter receiver. Fines may also enter the muffler during the

blowback cycle of solid state units if poor housekeeping conditions exist at the

unit. Material in the muffler can present a fire hazard. If you find any material,

replace the muffler.

; Check the motor and blower sheave bolts on the vacuum and pressure units.

Tighten them to 72 foot-pounds (98 N•m) of torque.

Quarterly Checks and Inspections

; Check the motor/blower drive belt on the vacuum and pressure units for signs

of wear and proper tension. Replace the belt if it shows any sign of wear.