Page 1

Page 2

Page 3

Chapter 5

Chapter 6

Chapter 7

Chapter 8

Contents

Preparations for operation

1. Confirmation inside granulator ----------------------------------------19

2. Confirmation of each unit condition ----------------------------------20

Operation ---------------------------------------------------------------------- 21

Maintenance and Check

1. Daily maintenance and check -----------------------------------------23

2. Every three months maintenance and check ---------------------25

3. Every six months maintenance and check ------------------------26

4. Exchange of grease -----------------------------------------------------26

5. Exchange point of the granulator cutters ----------------------------27

Troubleshooting ---------------------------------------------------------31

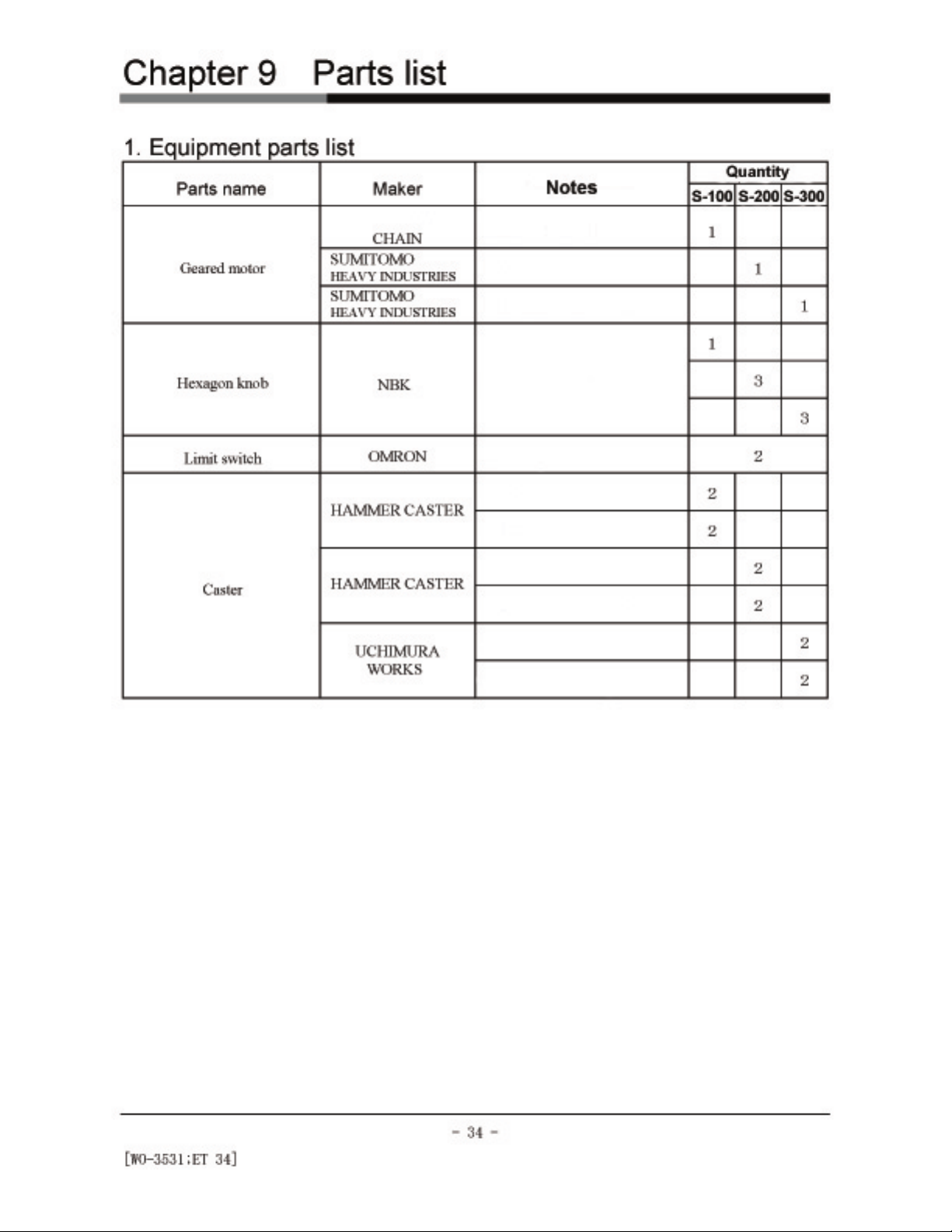

Chapter 9

Parts list

1. Equipment parts list ----------------------------------------------------- 34

2. Electric parts list --------------------------------------------------------- 35

Chapter 10 Specifications ---------------------------------------------------------------- 36

The attached drawing

[WO-3531;ET 2]

- Ⅱ -

Page 4

Page 5

Introduction

6. Improper or wrong maintenance, service, or handling; and

7. Your own transportation, repositioning, or reinstallation of our

products.

2)-C. Following is excluded from the warranty.

1. Any insufficient convey capacity, convey defect, weighing failure

resulting from property degeneration of the raw material.

2. Any clogging in pipe, convey defect, weighing failure resulting

from caking or cohesion of the raw material.

3. Lifetime of abrasion material such as hose or pipe is not

guaranteed.

4. Crystallization degree or moisture ratio (except for moisture ratio

for the resin tested and pre-confirmed and mutually recognized is

guaranteed.) is not guaranteed.

5. Failure/defect resulting from deformation and cohesion of resin.

6. Failure/defect resulting from any volatile additive yielded from

resin.

7. Failure/defect resulting from any condition that is not stated in

the

quotation.

3) Maintenance

Following inspection and maintenance must be performed in user’s

responsibility and expense.

This warranty does not cover any product faulty due to omitting the

specified maintenance.

3)-A. Inspection for operation.

3)-B. Periodical inspection designated in the instruction manual or in the

catalogue.

3)-C. Periodical replacement of parts designated in the instruction

manual or in the catalogue.

3)-D. Replace consumable parts when expire.

3)-E. Inspect, supplement, replace, clean following items.

○ Oil, filter, sealing material, grease, bearing

○ Ventilation duct, Freon gas

○ Oil filter of air apparatus

○ Sedimentary deposits

○ Other related items

3)-F. Adjust following items

○ V belt

○ Chain

○ Temperature control apparatus

○ Valve for water supply or drain, etc.

○ Pneumatic apparatus for pressurized air

○ Over heating protection equipment, etc.

[WO-3531;ET 4]

- Ⅳ -

Page 6

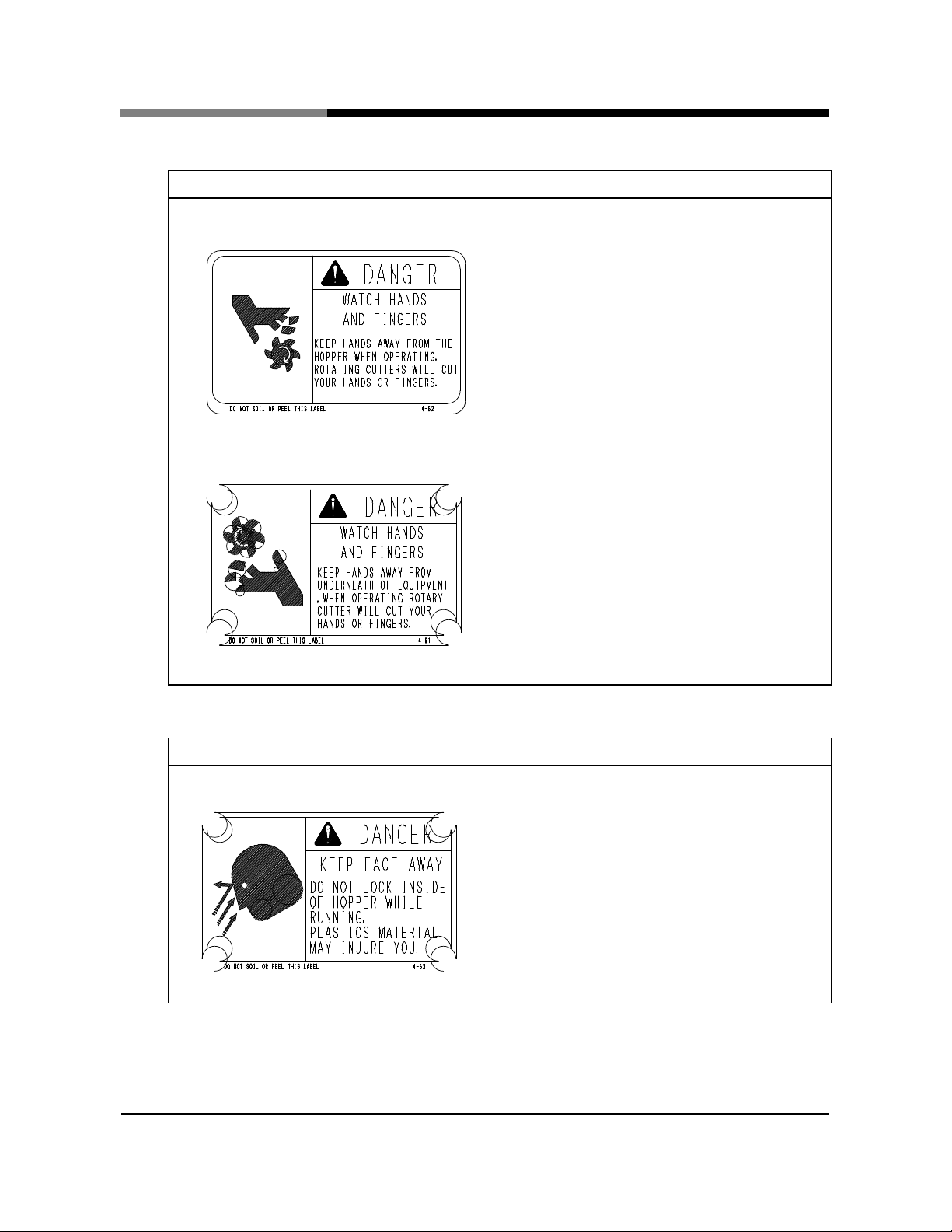

Chapter 1 For safe use

This chapter describes precautions for operation, maintenance

inspection and repair, identification of headings of precautions and

labels affixed to the product for using this product correctly and safely.

WARNING

When performing operation and maintenance inspection of this product,

be sure to follow the safety precautions described in this manual.

We shall assume no liability for any injury or accident caused by failing

to follow these precautions.

1. Precaution headings and their meanings

In this manual, indications are classified according to the degree of

danger as follows:

Heading Meaning

DANGER

WARNING

CAUTION

NOTE

※

This heading is used for cases where there is a possibility that

mishandling will lead to the user's death, and precautions to avoid

any such occurrence are described below the heading.

This heading is used for cases where there is a possibility that

mishandling will lead to the user serious injury, and precautions

to avoid any such occurrence are described below the heading.

This heading is used for cases where there is a possibility that

mishandling will lead to the user slight injury or damage to the

product, and precautions to avoid any such occurrence are

described below the heading.

Operating procedures and explanations requiring special attention

and emphasized information are described below this heading.

This mark is used for handling procedures requiring special

attention.

This mark is used for exceptional conditions and notes in figures

and tables.

[WO-3531;ET 1]

- 1 -

Page 7

WARNIN

G

2. Keeping items for safety operation

This is a general attention items to use this product safety.

1) Electric power

Do not check or exchange without our service division or the employee

in your company who has a good knowledge about the electricity,

because the operation includes the failure or the danger.

2) Never use in the gas

Never use this product in the combustible, explosive gas or vapor.

It is dangerous very much.

3) Prohibition of reconstruction

Never perform the reconstruction or modification without our

recognition. We do not responsible for the trouble by the

reconstruction.

Chapter 1 For safe use

4) Maintenance check and parts exchange

Before Checking and exchange, make sure to stop operation and put

“OFF“ the primary power supply.

5) Maintenance

Do not check or exchanges except the employee who has a good

knowledge about the product, because the operation includes the

failure or the danger. Please contact to the nearest our service division

(refer to the back cover), when you need the maintenance or repair.

- 2 -

[WO-3531;ET 2]

Page 8

1) Power sypply

2) Routine check

1) Wiping

Chapter 1 For safe use

CAUTION

Please use under the exact power supply voltage and frequency

according to the specifications, and establish a ground certainly.

The equipment system and parts have life expectancy.

Check the system and parts especially that the material contact at

regular year intervals, if the parts are needed to replace, request to our

service division.

NOTE

Do not use petroleum solvent. Wiping with the benzene, thinner,

polishing powder will seam the surface. If the labels become dirty, wipe

with the soft cloth that was soaked in water or hot water under 40℃ and

wring well.

[WO-3531;ET 3]

- 3 -

Page 9

it is

Support the feed hopper firmly, and open it

slowly when you open the openning cutting

When moving guranulator, watch for crevices,

stairs, or grades on the floor to prevent

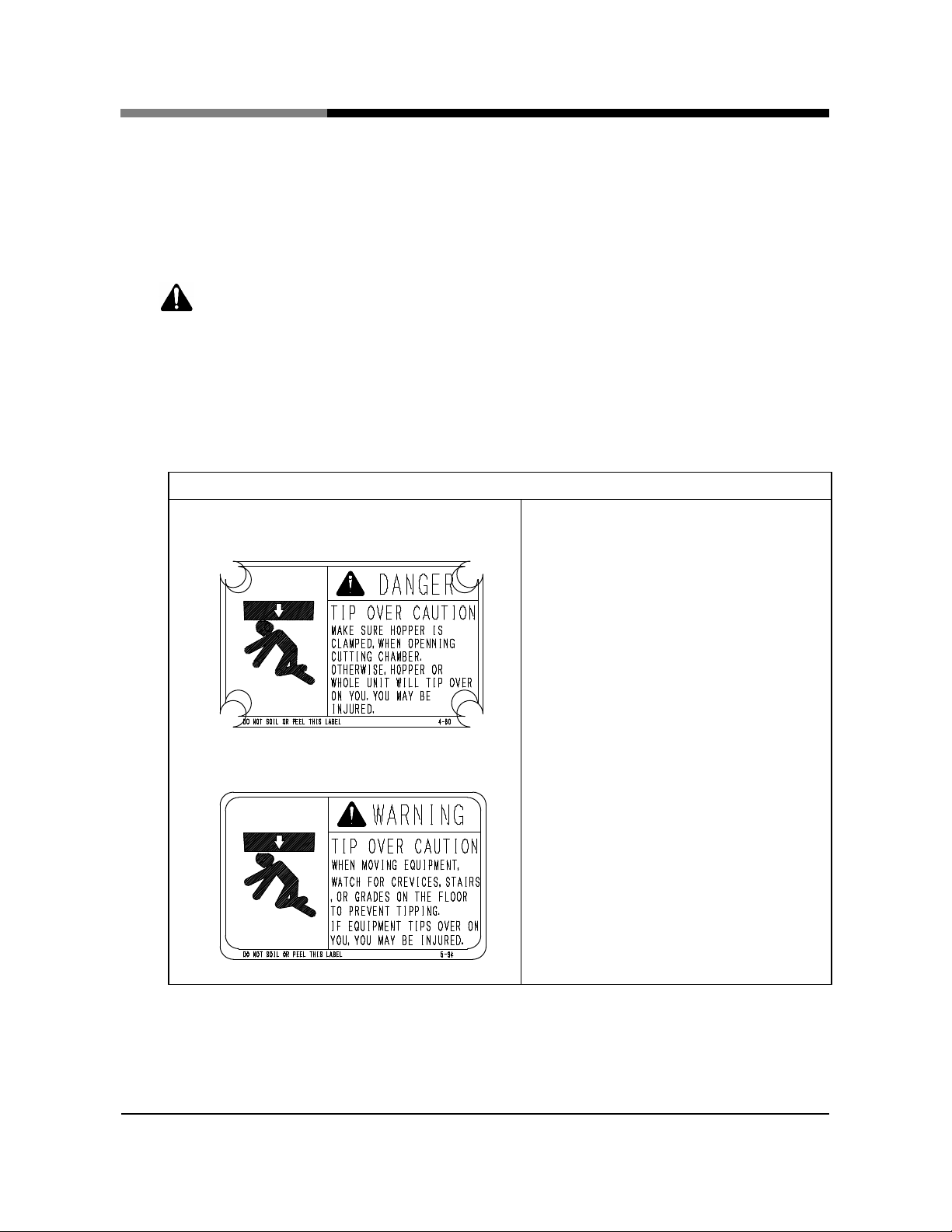

3. About labels

Maintenance of the labels

●Keep the labels legible until you dispose of this unit.

●If the labels become dirty, wipe with the soft cloth that was soaked in water or hot water

under 40℃ and wring well. Do not use petroleum solvent and thinner in any case.

3-1. Contents of the labels

1. Caution of openning the cutting chamber of

guranulator.

Chapter 1 For safe use

Labels are attached to this product at position where particular

attention is required by degree of danger. Before starting the operation

be sure to fully understand the instructions with the WARNINGs and

CAUTIONs.

Caution of tip over

Don't tip over granulator for heavy weight.

Damage such as a fracture is suffered when

caught under the equipment.

◇

chamber of guranulator.

◇

tipping. Then, be fully careful.

2. Coution of the transfer and movement.

[WO-3531;ET 4]

- 4 -

Page 10

at high

d hopper

and the lower part of granulator during the

The rotating cutters are made sharply. Don't

Don't peep into the inside of feed hopper during

is

1. Caution of the part of feed hopper during operation

2. Caution of the lower part of granulator during the

operation.

Chapter 1 For safe use

Caution of hands and fingers cutting

The rotating cutters of guranulator rotate

speed.

Don't insert a hand to the inside of fee

operation.

touch it during the stop as well.

Caution of keep face away

- 5 -

the operation.

Plastic material scatters, and has danger that

hit to the face.

[WO-3531;ET 5]

Page 11

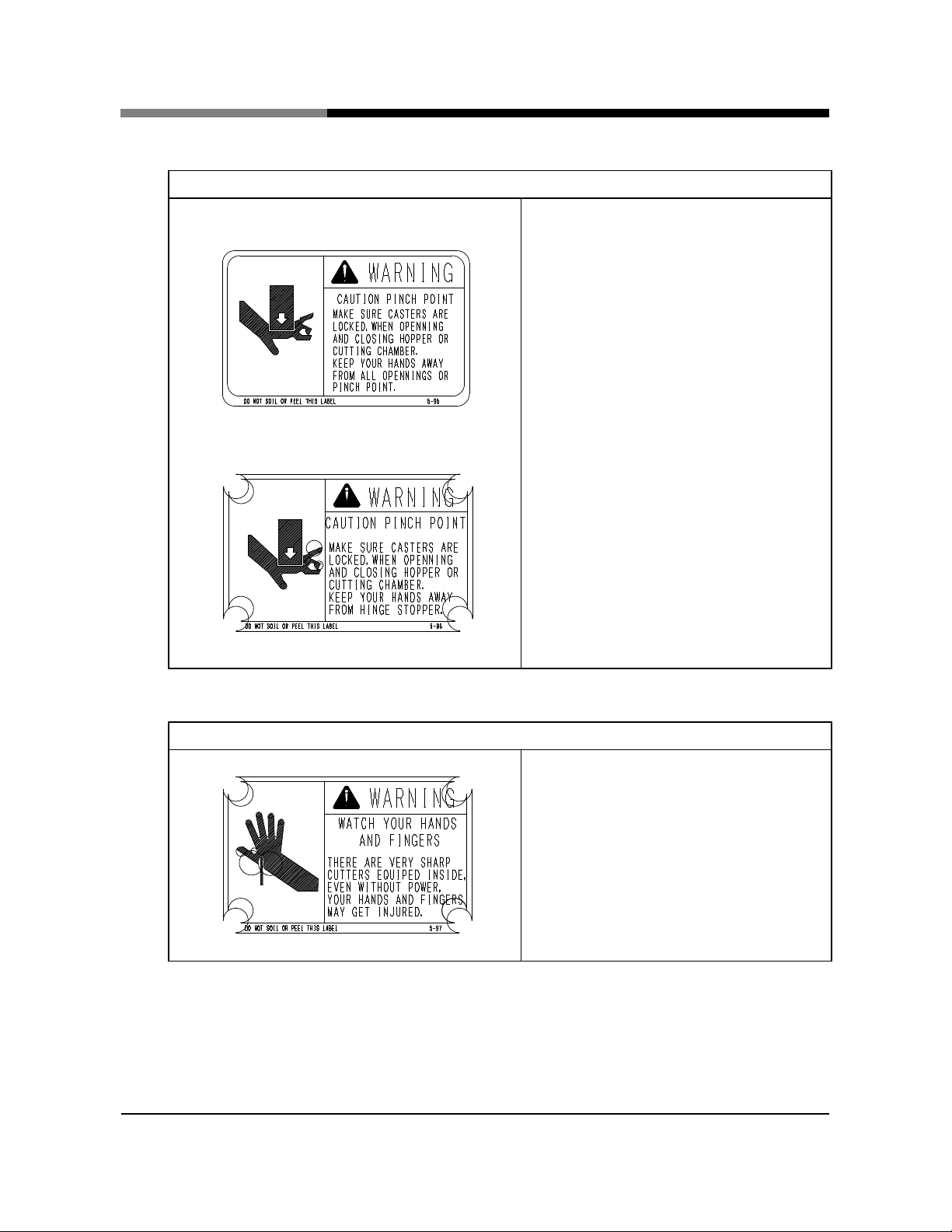

1. Caution of closing the feed hopper and cutting

2) for the

movement when feed hopper, cutting chamber

Lift feed hopper slowly, and don't insert a hand,

a finger into pinch point imprudently when you

Don't insert a hand into stopper of the hinge of

When hand and fingers are inserted into pinch

point, you suffer the damage of lacerations and

equiped

without power, your hands and

Caution which hands and fingers are pinch

chember

2. Caution of opening the feed hopper and cutting

chember

Chapter 1 For safe use

Be sure to lock wheels (caster ×

opens and closes.

close it.

feed hopper and granulator when you open it.

fracture.

Caut ion of hands and fingers may get injured

- 6 -

Don't touch the cutter carelessly.

There are very sharp rotating cutter

inside, even

fingers may get injured.

[WO-3531;ET 6]

Page 12

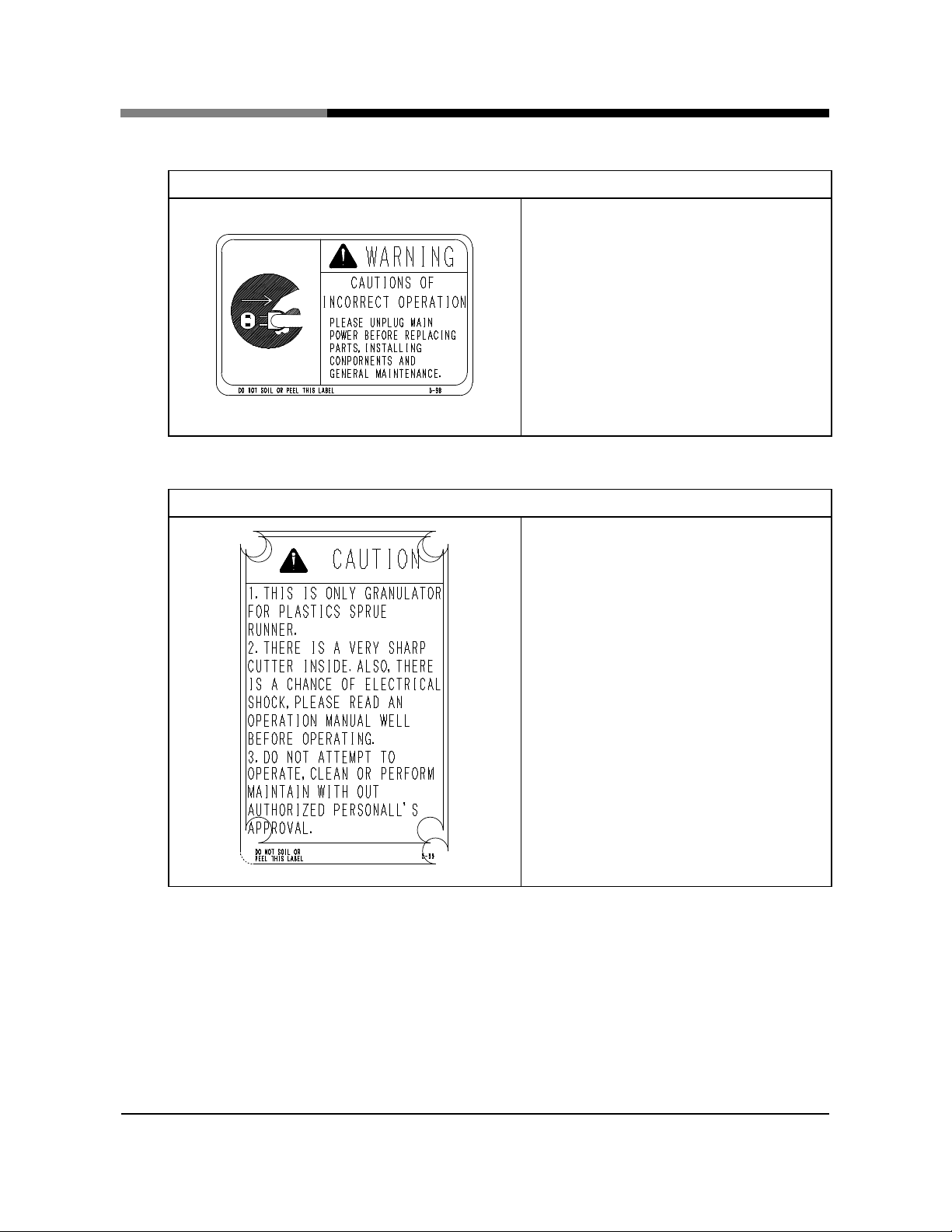

Before maintenance checking and exchange,

the

Don't granulate material except for plastics

Don't touch carelessness because sharp

Be sure to put off primary power supply

t use it except for the authorized

Chapter 1 For safe use

Cauti ons of incorrect operation

make sure to stop operation and put “OFF“

primary power supply.

Cautions for use

◇

sprue and runner.

◇

rotating cutters is being used.

◇

because it has the danger of electrical shock.

◇ Don'

personall's approval.

[WO-3531;ET 7]

- 7 -

Page 13

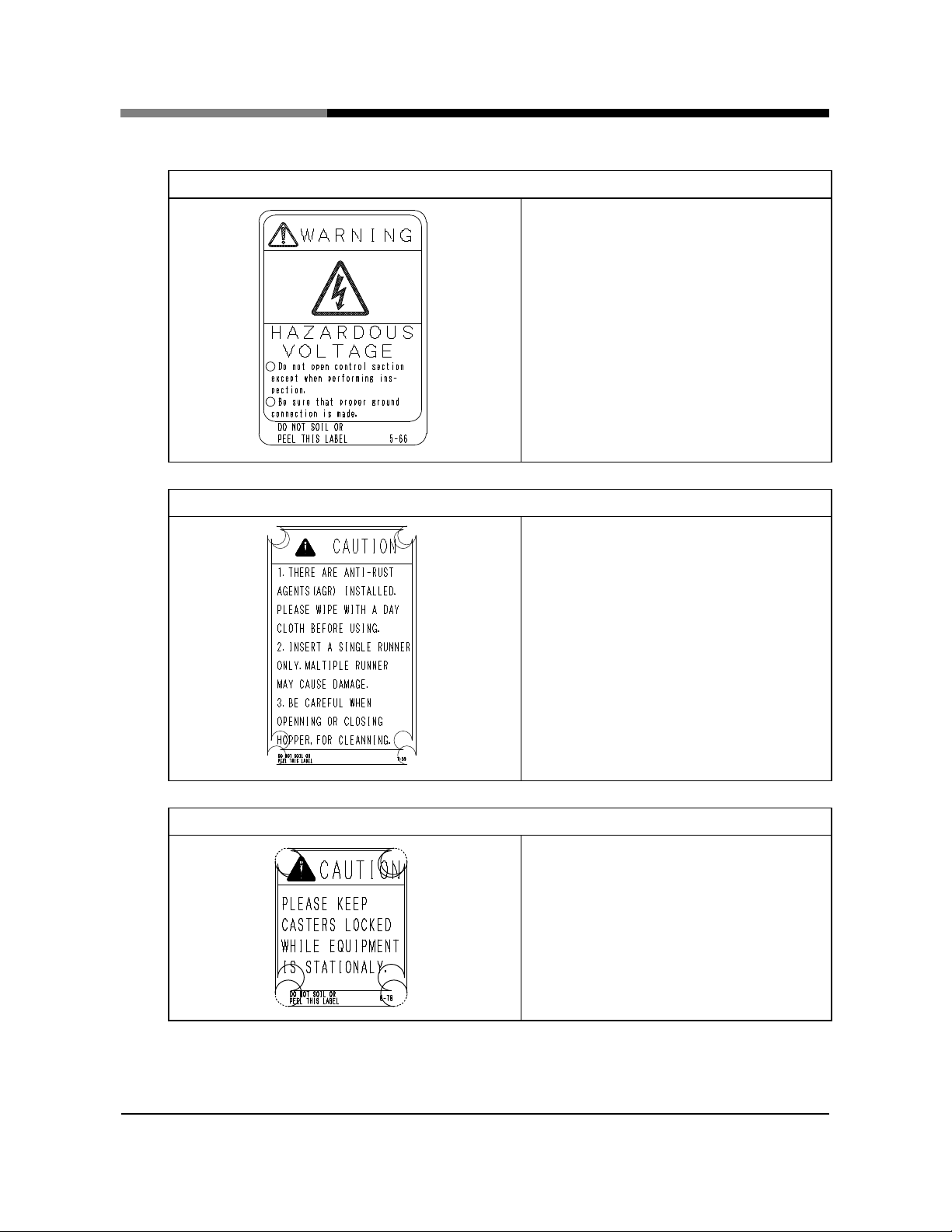

Before operation, confirm that the earth is

Be fully careful of what the tip over of the

equipment and pinch of the hand and the

close feed

Be sure to do two locks of caster except that you

Cautions to the authorized personall's approval

Chapter 1 For safe use

Cautions of electrical shock.

◇Don't open control box except for the check.

◇

provided perfectly.

◇There are ANTI-RUST AGENTS (AGR)

installed. Please wipe with a day cloth before

using.

◇Insert a single runner only.

◇

finger do when you open and

hopper and cutting chamber.

[WO-3531;ET 8]

Cation of casters locked

move granulator.

- 8 -

Page 14

Chapter 2 Precautions for use

This chapter explains precautions specific to the product.

To orevent the occurrence of danger, precautions are described with

headings (Refer to Chapter 1, section 1) from the most important items.

1. Precautions for the operator

Heading Item Precautions

WARNING

WARNING

About the use material

Operator and wear in

the operation

This equipment is only granulator for plastic sprue and runner.

Causes an accident occurrence, trouble and damaging because it

doesn't fit for other materials (Product granulation, wood chip,

iron, nonferrous metals, etc.).

Be careful because it can't be warranty about trouble that other

material was used for.

Don't do overhaul, wiping and operating except for the

authorized personall's approval.

Don't wear the clothes, which is often entangled in the

equipment.

Then, wear gloves so that you may avoid damage.

2. Precaution of movement and installation

Heading Item Precautions

Transfer, Movement Don't tip over granulator for heavy weight.

WARNING

Earth Before operation, confirm that the earth is provided perfectly.

WARNING

Damage such as a fracture is suffered when it is caught under

the equipment.

When moving guranulator, watch for crevices, stairs, or grades

on the floor to prevent tipping. Then, be fully careful.

Without it, there are fears that electric shocks take place.

- 9 -

[WO-3531;ET 9]

Page 15

3. Precautions of preparations for operation

Heading Item Precautions

WARNING

CAUTION

CAUTION

ANTI-RUST AGENTS

(AGR)

Caster Be sure to do two locks of caster except that you move

Reusing crushed

material

Only in delivery, after glove wears, wipes up AGR (Oil) that is

applied inside the unit by drying cloth after confirming the

blocking-off of your primary power.

※Be sure to wears a glove so as not to cut a hand with cutter.

granulator.

When using the crushed material after delivery in first, there is

possibility that the foreign material of AGR (oil) and the fine

particle, etc. is mixing.

As for the crushed material in initial and in set changes, surely,

reuses after check if AGR (oil) and the foreign material are

mixing in the crushed material.

Chapter 2 Precautions for use

4. Precations for operating

Heading Item Precautions

Don't insert a hand to the inside of feed hopper and the

lower part of granulator during the operation.

The rotating cutters are made sharply. Don't touch it during the

stop as well.

Don't peep into the inside of feed hopper during the operation.

Plastic material scatters, and has danger that is hit to the face.

Insert a single runner only.

It causes cutter damaging and trouble when many runners are

inserted.

It has the danger of electric shock, and causes trouble and

accident.

Then, don't add a strong shock, and don't shower water.

These acts become the cause of trouble and fire.

DANGER

DANGER

WARNING

WARNING

Feed hopper

lower part of granulator

Feed hopper

Feed runner

Control box Don't open control box except for the necessity.

- 10 -

[WO-3531;ET 10]

Page 16

Chapter 2 Precautions for use

5. Precautions for maintenance check and parts exchange

Heading Item Precautions

DANGER

WARNING

WARNING

WARNING

Cutting chamber of

guranulator

Feed hopper, cutting

chamber opens and

closes

Put off the power

supply.

Rotating cutter Don't touch the cutter carelessly.

Support the feed hopper firmly, and open it slowly when you

open the open cutting chamber of guranulator.

Don't tip over granulator for heavy weight.

Damage such as a fracture is suffered when it is caught under

the equipment.

Be sure to lock wheels (caster×2) for the movement when feed

hopper, cutting chamber opens and closes.

Do not open the feed hopper and the cutting chamber of

granulator at same time.

In opened condition, don't touch a hand and lean on the feed

hopper.

Lift feed hopper slowly, and don't insert a hand, a finger into

pinch point imprudently when you close it.

Don't insert a hand into stopper of the hinge of feed hopper and

granulator when you open it.

When hand and fingers are inserted into pinch point, you suffer

the damage of lacerations and fracture.

Before maintenance checking and exchange, make sure to stop

operation and put “OFF“the primary power supply.

Then, avoid danger by incorrect operation.

There are very sharp rotating cutter equiped inside, even without

power, your hands and fingers may get injured.

- 11 -

[WO-3531;ET 11]

Page 17

Page 18

Page 19

Page 20

Page 21

Chapter 4 Installation

Damage such as a fracture is suffered when it is caught under the

This chapter describes the method of installing the product step by

step.

Step

Installation of the

1

equipment

Cas t ers l oc ked

2

Preparation for the

3

primary power supply

Item Description

Install the equipment on a stable level floor.

Secure an installation place for maintenance to be made in consideration of the

space where feed hopper can be opened.

DANGER

Don't tip over granulator for heavy weight.

equipment.

When moving equipment, watch for crevices, stairs, or grades on the

floor to prevent tipping, then, be fully careful.

And, do the disposal of set up an iron plate when there are ditch and

hole in the movement passage.

Be sure to do two locks of caster as shown in Fig.4-1.

Figure 4-1

CAUTION

Be sure to do two locks of caster except that you move equipment.

Confirm a use standard voltage to indicate in nameplate of the equipment.

Then, prepare an outlet for the standard voltage or power supply box.

- 16 -

[WO-3531;ET 16]

Page 22

Connect the power cord of equipment with the primary power supply after you

confirm whether the switch of control box changes on the "STOP

Step 4 working is dangerous. Therefore, perform to work with full-time

person.

Step

Confirmation of the

4

Item Description

Remove feed hopper clamp, and open feed hopper.

rotating cutter condition

Confirm whether there is looseness in each fixed bolts of fixed cutter and guide

plate.

Remove axis cover on the reverse side of the motor.

Then, take the part of the width of 2 area of keeper plate with spanner or

monkey wrench, and confirm whether a shaft rotates smoothly.

Adjust the installation position of fixed cutter and guide plate when rotation

isn't smooth. (Refer to Chapter 7. Maintenance and check

point of the granulating cutters)

◎It is pushed down slowly with keep feed hopper from the down side

when feed hopper is opened.

Don't insert a hand and a finger into stopper.

When feed hopper is closed, it is lifted slowly.

At that time, be careful to insert a hand and a finger into pinch point.

When a hand and a finger are inserted into pinch point, it has the

danger of lacerations and fracture.

Chapter 4 Installation

DANGER

, 7-5 Exchange

WARNING

Connection of the

5

power supply

◎Don't touch granulating cutter imprudently. Sharp granulating cutter

has the danger that a hand and a finger have lacerations.

Put off the primary power supply.

position"("0"indicated) side.

◇When the primary power supply is an outlet ;

Insert the power supply plug of equipment in the outlet.

Continue to the next page.

- 17 -

[WO-3531;ET 17]

Page 23

to the direction of

hase

condition when it look into the hole of shaft cover of the motor and shaft

change 2

phase (R phase, T phase) on the secondary side of control box or power supply

, confirm whether the direction of

Step

Connection of the

5

Item Description

power supply

Check of positive

6

phase or negative

phase

Chapter 4 Installation

◇When electric supply panel is a switchboard, ;

Connect the power supply cord of equipment with electric supply panel.

R phase … Red

Power supply cord … S phase … White … Primary power supply

T phase … Black

E phase … Green …… For earth

CAUTION

◎Be sure to change switch of control box on the "STOP

position"("0"indicated) side before you connect power supply cord.

◎Fasten it securely so that looseness may not be shown in the

connection part.

When connction part has looseness, it becomes an abnormal cause

such as the operation of single phase.

◎Be sure to connect the earth

Put “ON” the primary power supply.

Turn the emergency stop push button on operation box

arrow. Then, reset the emergency stop.

Press the operation push button on operation box and starts granulator.

.

[WO-3531;ET 18]

The connection of power supply is completion because it is positive p

rotates in clockwise direction.

It is negative phase when shaft turns in the reverse direction of clockwise.

Primary power supply is put "OFF "in such a case. Then, connect and

panel.

Again, put "ON" primary power supply. Then

the rotation is positive phase.

- 18 -

Page 24

Chapter 5 Preparations for operation

This chapter describes preparatpry operations necessary for starting

the equipment.

WARNING

When confirmation work is started, primary power supply is surely put

off first, and you must avoid danger by incorrect operation.

1. Confirmation inside granulator

Step

Lock confirmation of

1

caster

Open feed hopper

2

Confirmation inside

3

granulator

Close feed hopper

4

Item Description

Confirm whether caster with lock×2 of the installation base is locked

securely.

CAUTION

Be sure to do two locks of caster except that you move granulator.

Remove feed hopper clamp, and open feed hopper.

WARNING

It is pushed down slowly with keep feed hopper from the down side

when feed hopper is opened.

Don't insert a hand and a finger into stopper.

When a hand and a finger are inserted into pinch point, it has the

danger of lacerations and fracture.

◇Confirm whether there is a mixing of the different material inside the

equipment.

◇Confirm whether there is looseness in each fixed bolts of fixed cutter and

guide plate.

Strangle a clamp securely, and fix it after you close feed hopper.

WARNING

When feed hopper is closed, it is lifted slowly.

At that time, be careful to insert a hand and a finger into pinch point.

When a hand and a finger are inserted into pinch point, it has the

danger of lacerations and fracture.

- 19 -

[WO-3531;ET 19]

Page 25

2. Confirmation of each unit condition

Confirmation unit Contents of confirmation

Feed hopper

Cutting chamber of the

granulator

Suction box (KKB)

or suction box (SKB)

or

receive box

Confirm whether feed hopper is closed securely.

(Confirm the fastening condition of the feed hopper clamp)

When feed hopper is open and when it isn't securely close.

The granulator can't start when either of two limit switch for the

closing confirmation is off.

Confirm whether cutting chamber of the granulator is closed securely.

(Confirm the fastening condition of the cutting chamber clamp)

When cutting chamber of the granulator is open and when it isn't

securely close.

The granulator can't start when either of two limit switch for the

closing confirmation is off.

Confirm whether suction box (KKB)(or suction box (SKB) or receive box)

is being installed in discharge port of granulator lower part.

Confirm whether the hinge bolt for the fixation is fastened.

Chapter 5 Preparations for operation

NOTE

NOTE

NOTE

[WO-3531;ET 20]

- 20 -

Page 26

Chapter 6 Operation

Turn the emergency stop push button on operation box to the

ion

Don't insert a hand and fingers to the inside of feed

hopper and the lower part of granulator during the

ated with the

Don't peep into the inside of feed hopper during the

is hit to the

When the cutting chamber of granulator or the feed

, a equipment doesn't

clamp of

, the equipment

doesn't start when it is in a limit switch for the close

a

tion

This chapter explains about operation of equipment and stop operation

in order.

NOTE

Before operation starts, do the mentioned work of Chapter 5.

Preparations for operation.

Step

1

Operation

Operation Contents of operation

direction of arrow. Then, reset the emergency stop.

Press the operation push button on operation box.

The granulator starts at the same time when the operat

indication (Green indicated) of the operation box is turn on.

◎

operation.

A hand and a finger are likely to be amput

sharp rotation cutter.

◎

operation.

Plastic material scatters, and has danger that

face.

Insert a single runner only.

It causes a trouble when many runners are inserted.

DANGER

CAUTION

[WO-3531;ET 21]

NOTE

◎

hopper isn't completely close. And

start when a limit switch for the close confirmation off.

◎ When fastening of the cutting chamber

granulator or feed hopper are loose. And

confirmation closing.

Then, the equipment stops as soon as possible when

limit switch for the close confirmation off by the vibra

in the start.

- 21 -

Page 27

The granulator stops at the same time when the operation

When pushing the emergency stop push button (In case of

cy stop), even if it pushes the operation push button, the

The equipment is stopping, don't insert a hand and a finger

into the feed hopper and the lower part of granulator

are likely to have lacerations with the

Step

2

Stop operation

Operation Contents of operation

Chapter 6 Operation

Press the emergency stop push button on operation box.

indication (Green indicated) of the operation box is put off.

※

emergen

unit doesn't start up. (Impossible to operate)

WARNING

imprudently.

A hand and a finger

sharp cutter.

[WO-3531;ET 22]

- 22 -

Page 28

Chapter 7 Maintenance and check

d the cause of the

If abnormal vibration is identified, stop operation immediately and fine the

temperature,stop operation immediately and find

Measure the load current value under the operation, and make sure that it is in

Exchange the new splash prevent curtain when you injure the deterioration

This chapter describes maintenance and check items and how to

perform it to maintain the unit in good condition per frequency.

WARNING

Performs to check with a full-time person of this unit.

1. Daily maintenance and check

Inspection items Contents of work

Geared motor

Check the noise (particularly metallic noise) occurring when operatong.

※If noise is identified, stop operation immediately and fin

nise.

CAUTION

Do not operate granulator when noise is identified.

Check the abnormal vibration ocuurring when operating.

※

cause of the vibration.

CAUTION

Do not operate granulator when vibration is identified.

Check the unit body and motor have abnormal hightemperature.

※If they get abnormally high-

the cause of the high heat

CAUTION

Do not operate granulator when they have high heat.

the rated value range.

The rated value is noted on the nameplate of the motor.

Splash prevent curtain inside

the feed hopper

[WO-3531;ET 23]

Check the deterioration conditions of the splash prevent curtain.

※

condition of the curtain firmly and cruel.

- 23 -

Page 29

gun or air

3. Remove the clamp of feed hopper, turns round the side the hopper is fallen,

the upper part of granulator, get rid of dust by the air

6. Remove the clamp of cutter chamber, turns round the side the feed hopper is

the upper hole of the axis of

10.As for the ditch of lower part of granulator and return cover (rotating part of

gun is to use a mask, because dust scatters in the

Inspection items Contents of work

Wiping and check inside the

feed hopper and granulator

Do the wiping and check in the following working order.

1. Put off the primary power supply.

2. Get rid of dust from the upper part of feed hopper with the aircleaner.

and opens slowly.

4. As for cleaning of

cleaner.

And, check the edge of blade condition of fixed cutter.

5.Close the feed hopper, and fixed with the clamp.

fallen, and opens slowly.

7. Get rid the dust that sticks to the inside of the granulator (rotating cutter)

with the air cleaner and the brush.

8. Insert an attached metal rod (with knob) into

rotating cutter, and, rotate the rotating cutter.

9. Check edge of blade condition with rotating the rotation cutter.

Chapter 7 Maintenance and check

large cutter), get rid of dust by air-gun.

11.If wiping is end, lift the feed hopperslowly, and close.

Then, fix the cutter chamber of granulator by the clamp.

WARNING

◎It is pushed down slowly with keep feed hopper from the down side

when feed hopper and cutting chamber is opened.

Don't insert a hand and a finger into stopper.

When feed hopper and cutting chamber is closed, feed hopper lifted

slowly.

At that time, be careful to insert a hand and a finger into pinch point.

When a hand and a finger are inserted into pinch point, it has the

danger of lacerations and fracture.

◎Don't touch the guranulator cutter imprudently. Because the cutter is

sharp, it has the danger that injures a hand and a finger.

NOTE

The wiping by the airair.

- 24 -

[WO-3531;ET 24]

Page 30

e switch of control box is changed to "OPERATION position"

("1"indicated) side under the condition that feed hopper is opened, and

When the granulator starts, the limit switch is a trouble, at once, do the

A hand and a finger are likely to be amputated by the sharp rotation

2. Every three months maintenance and check

Do the function check of each safety limit switch.

If, when the function doesn't operate normally, stop the operation, and

contact to the nearest our service division. (refer to the back cover)

DANGER

When the safety limit switch operates under the trouble condition,

because they become the cause of trouble and accident, never do it.

Inspection items Contents of work

Feed hopper and limit switch

×2 for closing confirmation of

cutting chamber

Th

confirms that the gaunulator doesn't start.

※

repair or exchange.

Chapter 7 Maintenance and check

DANGER

Don't insert a hand and fingers to the inside of granulator.

cutter.

- 25 -

[WO-3531;ET 25]

Page 31

ut

It is not necessary to exchange or add the grease. However, for more long life it

Chapter 7 Maintenance and check

3. Every six months maintenance and check

Inspection items Contents of work

Bolts and nuts of each part Check if there is any looseness of bolts and nuts.

Fasten them, if necessary.

4. Exchange of grease

Inspection items Contents of work

Bearing The oilless type is used. Therefore the exchange is not necessary for abo

30.000 hours operation.

Geared motor

(Hypoid motor)

is recommended to exchange after 20.000 hours operation.

[Recommended grease]

◇ Nihon Grease K.K.: Nigutait LYS NO.000

◇ Showa Shell K.K. : Albania EP grease R000

◇ Nihon Sekiyu K.K.: Buyknock Universal 000

※Face mount type Hollow shaft type

Motor output 0.75kW 1.5kW 2.2kW

Reduction ratio

Volume of grease 1.15kg 1.05kg 2.5kg

1/60~1/200 1/40~1/80 1/60~1/80

- 26 -

[WO-3531;ET 26]

Page 32

Remove the clamp of feed hopper, turns round the side the hopper

The fixed cutters and guide plate is removed and exchanged for the

5. Exchange point of the granulator cutters

Explains about the exchange work point of fixed cutter, guide plate and

rotating cutters (large and small) in order.

WARNING

Before exchange work, make sure to stop operation and put “OFF“ the

primary power supply.

Then, avoid danger by incorrect operation.

5-1. Exchage of the fixed cutters and guide plate

Hopper is opened, and the exchange work is done.

Step

1

2

Openning the feed

hopper

Exchang of the fixed

cutters and guide plate

Item Description

is fallen, and opens slowly.

It is pushed down slowly with keep feed hopper from the

down side when feed hopper is opened.

Don't insert a hand and a finger into stopper.

When feed hopper is closed, feed hopper lifted slowly.

At that time, be careful to insert a hand and a finger into

pinch point.

When a hand and a finger are inserted into pinch point, it

has the danger of lacerations and fracture.

new part. (refer to Fig. 7-1)

※Refer to 5-3 how to gap adjust of rotating cutters and fixed

cutters of this chapter for the adjustment of the installation

position.

Work carefully with wear the gloves, when touched the fixed

cutters and the guide plate.

For the sharp cutters, it has the danger that the hand and

the finger have the lacerations.

Chapter 7 Maintenance and check

WARNING

WARNING

[WO-3531;ET 27]

- 27 -

Page 33

Pullout the clamp and hinge bilts of feed hopper, and remove the

The cutting chamber of granulator is lifted slowly, and released,

Loosen fixed nuts of the bearings at both ends of rotating axis, and

5-2. Exchange of rotating cutters (large and small)

Feed Hopper is removed, and the exchange work is done.

Step

1

2

3

The removal of feed

hopper

The removal of geared

motor

Each part of overhaul

and exchange

Item Description

feed hopper.

and the geared motor is removed.

remove bolts.

With each rotating axis, pull up and remove the rotating cutters.

Stop ring⇒Collar⇒Bearing cover⇒Bearing⇒Side plate

(Labyrinth)⇒Small cutters⇒Large cutters

Pull out in order and exchange.

After exchange, assemble part reversely in order.

The exchange work is doing carefully with wear the gloves.

For the sharp cutters, it has the danger that the hand and

the finger have the lacerations.

Chapter 7 Maintenance and check

WARNING

[WO-3531;ET 28]

- 28 -

Page 34

Remove the clamp of feed hopper, turns round the side the hopper

The clamp is to do the part of upper and lower the cutting chamber

Hold and turned the width of 2 area of keeper plate with spanner or

using the thickness gauge (the gap) does the adjustment of

en the fixed cutters on a

5-3. How to gap adjust of rotating cutters and fixed cutters

Adjust the gap between the rotating cutters and fixed cutters to 0.2mm.

Step

1

2

3

Opening the feed hopper

Clamp of cutting

chamber

Adjustment of the gap

Item Description

is fallen, and opens slowly.

It is pushed down slowly with keep feed hopper from the

down side when feed hopper is opened.

Don't insert a hand and a finger into stopper.

When feed hopper is closed, feed hopper lifted slowly.

At that time, be careful to insert a hand and a finger into

pinch point.

When a hand and a finger are inserted into pinch point, it

has the danger of lacerations and fracture.

of granulator without gap.

(Tighten the clamp of citting chamber completely)

The removed bolts of fixed cutters are tightened temporarily.

Chapter 7 Maintenance and check

WARNING

monkey wrench.

Then,

interval.

Completing adjustment of the gap, tight

full scale.

The work is doing carefully with wear the gloves.

For the sharp cutters, it has the danger that the hand and

the finger have the lacerations.

WARNING

[WO-3531;ET 29]

- 29 -

Page 35

Ca p

End p lat e

Stop rin g

Moto r

Motor suppor t

& bearing cover

Side plate

Bearin g

Large cutter s

Small cutter s

Chapter 7 Maintenance and check

Fixed cutter s

Guide plat e

Side plate

※ Insert hole of

metal rod with kno b

Bearin g

Keeper plate

Ca p

[WO-3531;ET 30]

Figure 7-1

- 30 -

Page 36

Chapter 8 Troubleshooting

The cause of the failure in the equipment and how to manage the trouble

are explained in theis chapter.

WARNING

Stop the operation and put off the primary power supply before checking

woek.

The abnormal sound on the operation comes out.

Power down of granulating ability.

Check point Remedy Precaution

Check whether the feed hopper

and cutting chamber of

granulator are doing the clamp

securely.

Check mixing of the different

material in the feed hopper and

granulator.

Check whether the adjustment of

interval for rotating cutting and

fixed cutters is correct.

Check whether the edge of fixed

cutters and rotating cutters is

exhausted or it isn't lack.

Tighten the clamp of each part

securely.

Remove the different material.

Then, exchange it when there is a

damage part.

Adjust the interval of rotating

cutters and fixed cutters to

0.2mm.

Exchange the fixed cutters or

rotating cutters.

Do the work after the primary power

supply put off.

To purchase the parts or exchange, please

contact our service division.

Do the work after the primary power

supply put off.

Refer to Chapter 7. Maintenance and

check, 5-3 How to gap adjust of rotating

cutters and fixed cutters.

Refer to Chapter 7. Maintenance and

check, -1. Daily maintenance and check

item of Wiping and check inside the feed

hopper and granulator.

Refer to Chapter 7. Maintenance and

check, -5. Exchange point of the

granulator cutters.

[WO-3531;ET 31]

- 31 -

Page 37

the clamp of cutting

Check point Remedy Precaution

Check whether the feed hopper is

securely close.

And, check whether the different

material in the clamp part of feed

hopper isn't caught.

Check whether the cutting

chamber is securely close.

And, check whether the different

material in the clamp part of

cutting chamber isn't caught.

Check whether the two each limit

switch is functioning normally.

The granulator doesn't start.

Remove the different material.

And, tighten the clamp of feed

hopper securely.

Remove the different material.

And, tighten

chamber securely.

Do the repair of the switch or the

exchange.

The granulator doesn't start under the

"OFF" condition of the limit switch for

closing confirmation.

The granulator doesn't start under the

"OFF" condition of the limit switch for

closing confirmation.

Refer to Chapter 7. Maintenance and

check, -2. Every three maintenance and

check.

To repair or exchange the limit switch,

please contact our service division.

Chapter 8 Troubleshooting

- 32 -

[WO-3531;ET 32]

Page 38

Overload operation is given, motor breaker trips

Check point Remedy Precaution

Check whether many runners

aren't being inserted in the feed

hopper.

Check mixing of the different

material in the feed hopper and

granulator.

Check whether the granulating

ability doesn't down.

Check whether the bearing of

driving part is not over heating

condition.

Check whether the driving motor

starts normally.

Check whether the power supply

code of driving motor isn’t out.

Check whether there is looseness

in the connection part.

Chapter 8 Troubleshooting

Remove the runners inside the

feed hopper.

Do the work after the primary power

supply put off.

Insert a single runner only.

Remove the different material.

Then, exchange it when there is a

damage part.

Do the work after the primary power

supply put off.

To purchase the parts or exchange, please

contact our service division.

Repair the down cause of the

granulating ability.

Refer to this chapter. “The abnormal

sound on the operation comes out,

Power down of granulating ability.”

Exchange the bearing. Do the work after the primary power

supply put off.

To purchase the bearing or exchange,

please contact our service division.

Repair or exchange the driving

motor (geared motor).

To purchase the geared motor or exchange,

please contact our service division.

○Tighten the connection part of

the power supply.

○Exchange the power supply

Do the work after the primary power

supply put off.

code.

[WO-3531;ET 33]

- 33 -

Page 39

Page 40

Page 41

Page 42

Page 43

Loading...

Loading...