Page 1

Operation and Installation Manual

ACOA Series Air-Cooled

Central Chillers

Important! Read Carefully before Attempting to Install or Operate Equipment

$30.00

Part No. A0537576 Bulletin No. AE3-620

Page 2

Page 3

Performance figures stated in this manual are based on a standard atmosphere of 59°F

(15°C) at 29.92” Hg (1,014 millibars) at sea level, using 60 hz power. Ambient air

temperature is an important consideration when specifying an air-cooled central chiller.

AEC/Application Engineering can advise you on proper selection and sizing of systems

for your operating environment.

AEC/Application Engineering is committed

to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual

are subject to change without notice.

© Copyright AEC/Application Engineering and AEC, Inc. 2004

All rights reserved. Effective 7/23/2004

Part No. A0537576 Bulletin No. AE3-620.2

Page 2

ACOA Series Air-Cooled Central Chillers

Page 4

Safety Considerations

AEC, Inc. ACOA air-cooled central chillers are designed to provide safe and reliable operation

when installed and operated within design specifications, following national and local safety

codes.

To avoid possible personnel injury or equipment damage when installing, operating or

maintaining this equipment, use good judgment and follow these safe practices:

Follow all SAFETY CODES.

Wear SAFETY GLASSES and WORK GLOVES.

Use care when LOADING, UNLOADING, RIGGING or MOVING this equipment.

Operate this equipment within design specifications.

OPEN, TAG AND LOCK ALL DISCONNECTS before working on equipment. It is a

good idea to remove the fuses and carry them with you.

Make sure the chiller is properly GROUNDED before switching power on.

When welding or brazing in or around this equipment be sure VENTILATION is

ADEQUATE. PROTECT adjacent materials from flame or sparks by shielding with sheet

metal. An approved FIRE EXTINGUISHER should be close at hand and ready for use if

needed.

The refrigeration system can develop refrigerant pressures in excess of 500 PSI. DO NOT

CUT into the system without first relieving pressure.

Do not jump or bypass any electrical safety control.

Do not restore power until all tools, test equipment etc. have been removed and the panels

replaced.

Only PROPERLY TRAINED personnel familiar with the information within this manual

should work on this equipment.

ACOA Series Air-Cooled Central Chillers Page 3

Page 5

Table of Contents

1 General Information ................................................. 7

1-1 Introduction

1-2 Necessary Documents

1-3 Models Covered

1-4 ACOA Physical Specifications

2 Shipping Information.............................................. 19

2-1 Unpacking and Inspection

2-2 In the Event of Shipping Damages

2-3 If the Shipment is Not Complete

2-4 If the Shipment is Not Correct

2-5 Returns

2-6 Uncrating Your Chiller

3 Installation...............................................................21

3-1 Installation Location Considerations

3-2 Process Water Piping Considerations

3-3 Galvanic Corrosion Considerations

3-4 Water Treatment Considerations

3-5 Making Process Water Connections

3-6 Refrigerant Charge Considerations

3-7 Making Electrical Connections

3-8 Checking Motor Rotation Direction

4 Sequence of Operation ..........................................25

4-1 General Information

4-2 Circuit Operation

5 Startup and Operation............................................ 33

5-1 Introduction

5-2 Pre-Startup Checklist

5-3 Starting the Chiller

5-4 Lubricating the Compressor

5-5 System Flow Rate

5-6 Capacity Control

Page 4

ACOA Series Air-Cooled Central Chillers

Page 6

Table of Contents

6 Electrical Devices ...................................................41

6-1 Control Circuit Power Switch - S1

6-2 Compressor Switch - S2, S3, S4, S5

6-3 Flow Switch - FLS

6-4 Chilled Water Pump Interlock - CWP

6-5 High Pressure Safety Switch - 1PS

6-6 Pumpdown Switch - 4PS

6-7 Compressor Oil Failure Switch - 3PS

6-8 Low Pressure Switch - 9PS, 5TR, 3TAS

6-9 Fan Pressure Switch - 10PS, 11PS

6-10 Compressor Cycle Timer - 1TR

6-11 Timer - 4TR

6-12 Contactors - M

6-13 Relays - CR

6-14 Crankcase Heater - HTR

6-15 Operating Thermostat - 4TAS

6-16 Liquid Line Solenoid Valve - SOL

6-17 Unloading Solenoid Valve

6-18 Motor Overload Protection - 1TAS

6-19 Undervoltage Relay - UVR

6-20 Fan Speed Control - SCR

7 Maintenance............................................................45

7-1 Making Periodic Inspections

7-2 Making Monthly Inspections

7-3 Maintaining the Evaporator and Condenser

7-4 Cleaning the Evaporator

7-5 Cleaning Air Cooled Condensers

7-6 Protections Against Electrical Malfunctions

7-7 Maintaining Compressors

7-8 The Refrigerant Charge

7-9 Preventive Maintenance Service

8 Troubleshooting.....................................................49

ACOA Series Air-Cooled Central Chillers Page 5

Page 7

Charts and Figures

1

ACOA Specifications 9

2

ACOA15, ACOA20, and ACOA25 Outline Drawing 10

3

ACOA30 and ACOA35 Outline Drawing 11

4

ACOA45 Outline Drawings 12

5

ACOA55 Outline Drawing 13

6

ACOA70 Outline Drawing 14

7

ACOA80 Outline Drawing 15

8

ACOA90 and ACOA100 Outline Drawing 16

9

ACOA110 Outline Drawing 17

10

11

12

13

14

15

16

17

18

19

20

21

ACOA125 and ACOA135 Outline Drawing 18

ACOA Control Settings and Set Points (Unit is Off) 28

Typical ACOA Wiring Diagram 29

Typical ACOA Option Wiring Details 30

One Circuit ACOA Refrigerant Piping Schematic 31

Two Circuit ACOA Refrigerant Piping Schematic 31

Three Circuit ACOA Refrigerant Piping Schematic 32

Four Circuit ACOA Refrigerant Piping Schematic 32

ACOA Evaporator Pressure Drop Curves 36

ACOA Capacity Control 38

ACOA Fan Cycling Control Chart 39

ACOA Load Points 50

22

23

Page 6

ACOA Isolator Specifications 51

R-22 Refrigerant Pressure/Temperature Properties 53

ACOA Series Air-Cooled Central Chillers

Page 8

1 General Information

1-1 Introduction

This manual provides all necessary information for installation, operation and maintenance of

AEC/Application Engineering ACOA Series air-cooled water chillers.

To use this manual effectively, you must first determine your unit model number from the unit

nameplate. Since this manual is comprehensive for a wide variety of units, you should be careful

to use only those sections which apply to your model. Note that each section is clearly marked as

to the applicable models.

Your AEC/Application Engineering chiller has been manufactured under a careful quality

control system. If the package is installed, operated, and maintained with care and attention to

these instructions, your chiller should give many years of satisfactory service.

You should have a basic understanding of the principles of air conditioning, refrigeration, and

electrical controls for installing, operating, and maintaining this equipment.

1-2 Necessary Documents

These documents are necessary for the operation, installation, and maintenance of AEC/

Application Engineering ACOA chillers. Additional copies are available from AEC, Inc. Make

sure that the appropriate personnel are familiar with these documents:

• This manual.

• The schematic and connection diagram in the control enclosure.

• The operation and installation manuals for accessories and options selected by the

customer.

• The Customer Parts List included in the information packet.

1-3 Models Covered

The chiller serial tag lists model numbers. A -Q following the model number indicates a

specially constructed unit; not all information in this manual may apply. You should know the

model number, serial number, and operating voltage of your chiller if you need to contact AEC.

ACOA chiller models are designated by the total compressor horsepower of all circuits (15 to

135). For example, an ACOA chiller with two 45 hp compressors has a model designation of

ACOA90.

ACOA Series Air-Cooled Central Chillers Page 7

Page 9

1-4 ACOA Physical Specifications

These air cooled units include semi-hermetic compressor(s), direct expansion internal finned

evaporator, copper tube/aluminum fin condenser coil with integral subcooling coil, and heavy

duty fan motors.

ACOA units are designed for operation down to -20ºF (-29ºC) ambient air temperature by

cycling condenser fans in response to refrigerant condensing pressure. Cylinder unloading, a fan

cycling switch, and heaters on the evaporator are standard.

All systems have pre-piped refrigeration circuits(s) and are pre-wired with a 115-volt control

transformer. Outside installation is possible with controls mounted in a weatherproof, galvanized

steel enclosure.

Page 8

ACOA Series Air-Cooled Central Chillers

Page 10

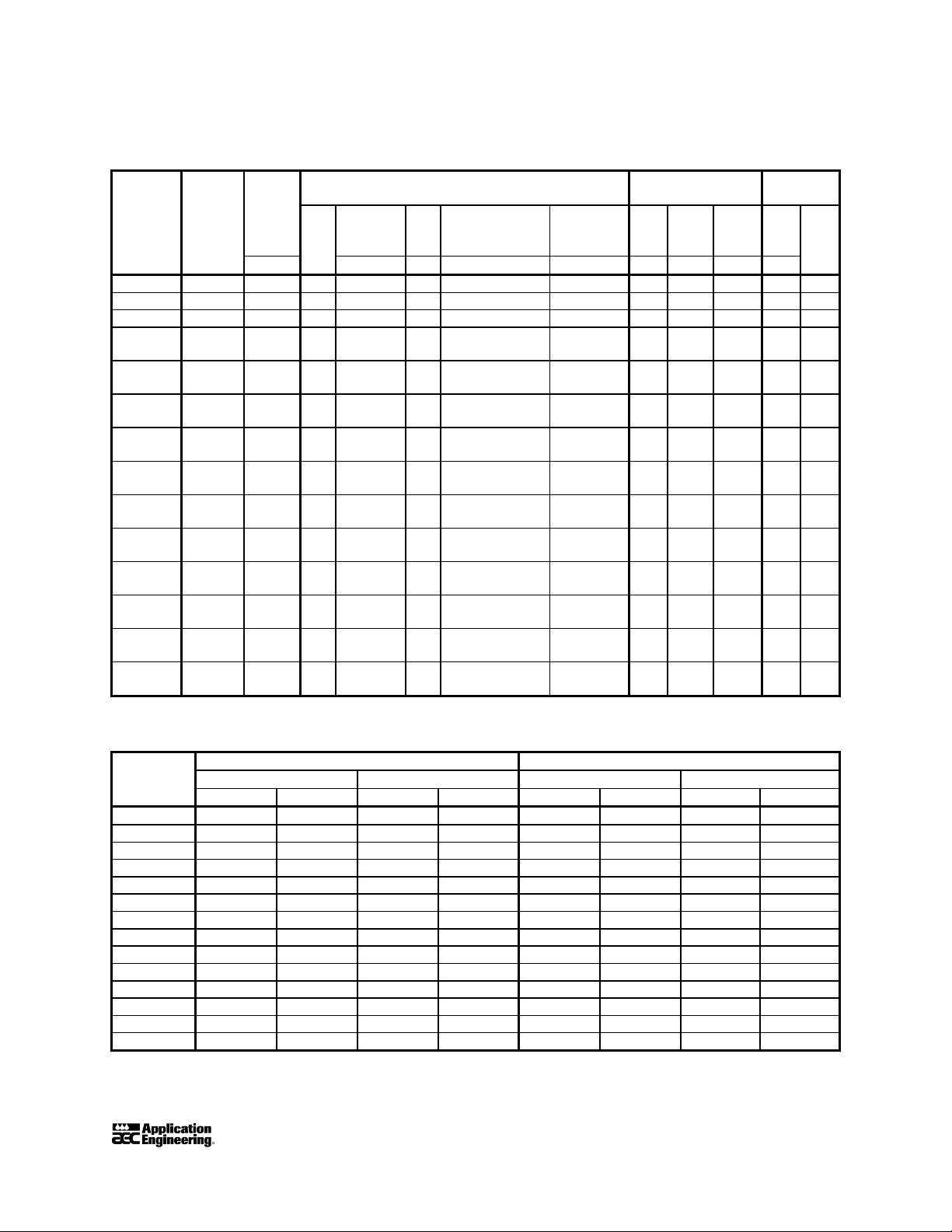

Figure 1

ACOA Specifications

Model

number Circuits Lbs. Qty cfm qts. % watts in. in. in. qty. kW

ACOA15 1 30 1 35.3 4.5 0, 50, 100 65 5 60 1 5/8 2 2.0

ACOA20 1 50 1 60.1 4.1 0, 50, 100 100 6 60 3 2 2.7

ACOA25 1 50 1 60.1 4.4 0, HGP, 50, 100 100 7 60 3 2 2.7

ACOA30 1 60 1 75.5 5

ACOA35 1 60 1 90.1 7.5

ACOA45 2 90 2 100.6 8.5

ACOA55 2 110 1 135.5 9.8

ACOA70 2 140 2 180.2 15

ACOA80 2 150 2 214.3 16.2

ACOA90 3 180 3 226.5 15

ACOA100 3 180 3 270.2 22.5

ACOA110 4 210 4 271 19.5

ACOA125 4 225 4 360 30

ACOA135 4 225 4 360 30

refrig-

Total

erant

charge

Displace-

ment

Compressor(s)

Steps of

Oil

chg

capacity

reduction

0, HGB, 30,

67, 100

0, HGB, 30,

67, 100

0, HGB, 25,

50,75, 100

0, HGB, 21,

42, 78, 100

0, HGB, 34,

50, 84, 100

0, HGB, 25,

50, 75, 100

0, HGB, 22, 33,

56, 67, 89, 100

0, HGB, 22, 33,

56, 67, 89, 100

0, HGB, 21,

42, 71, 100

0, HGB, 25,

50, 75, 100

0, HGB, 25,

50, 75, 100

Evaporator

Crankcase

heater

200 7 60 3 3 4.4

200 8 60 3 3 4.4

200 10 60 4 4 5.4

300 11 60 4 5 7.1

400 12 60 4 6 10.2

400 13 60 4 8 13.6

600 12 102 4 9 15.3

600 14 92 4 9 15.3

600 14 102 5 10 17

800 14 102 5 12 20.4

800 16 122 6 12 20.4

Shell

dia.

Tube

length

Conn.

size

Air-cooled

condenser

Fans

Total

Cooling Capacity, Unit Weights

Cooling capacity Weights

Model 100% water 50% H2O, 50% glycol Shipping weight Operating weight

no. tons Kcal/hr. tons Kcal/hr. lbs. kg lbs. kg

ACOA15 14.7 44,453 14.1 42,683 1,835 834 1,865 847

ACOA20 19.0 57,456 18.1 54,734 1,967 894 2,017 916

ACOA25 24.9 75,298 23.9 72,274 2,158 980 2,208 1,003

ACOA30 32.7 98,885 31.0 93,744 2,687 1,220 2,747 1,248

ACOA35 36.4 110,074 34.8 105,235 2,835 1,288 2,895 1,315

ACOA45 43.1 130,334 41.5 125,496 3,939 1,789 4,029 1,830

ACOA55 57.4 173,578 54.9 166,018 4,631 2,106 4,741 2,153

ACOA70 71.9 217,426 69.1 208,958 5,252 2,385 5,392 2,444

ACOA80 87.0 263,088 83.3 251,899 6,998 3,173 7,138 3,241

ACOA90 98.0 296,352 95.3 288,187 8,220 3,732 8,437 3,831

ACOA100 107.6 325,382 102.1 308,750 8,582 3,897 8,807 3,999

ACOA110 115.0 347,760 107.9 326,290 9,397 4,267 9,647 4,380

ACOA125 131.0 396,144 120.9 365,602 10,160 4,613 10,410 4,727

ACOA135 147.1 444,830 142.1 429,710 11,087 5,034 11,472 5,209

Based on 60ºF (16ºC) return from process, 50ºF (10ºC) chilled water supply temperature, and 95ºF (35ºC)

ambient. Consult factory for requirements below 40ºF (4ºC).

fan

ACOA Series Air-Cooled Central Chillers Page 9

Page 11

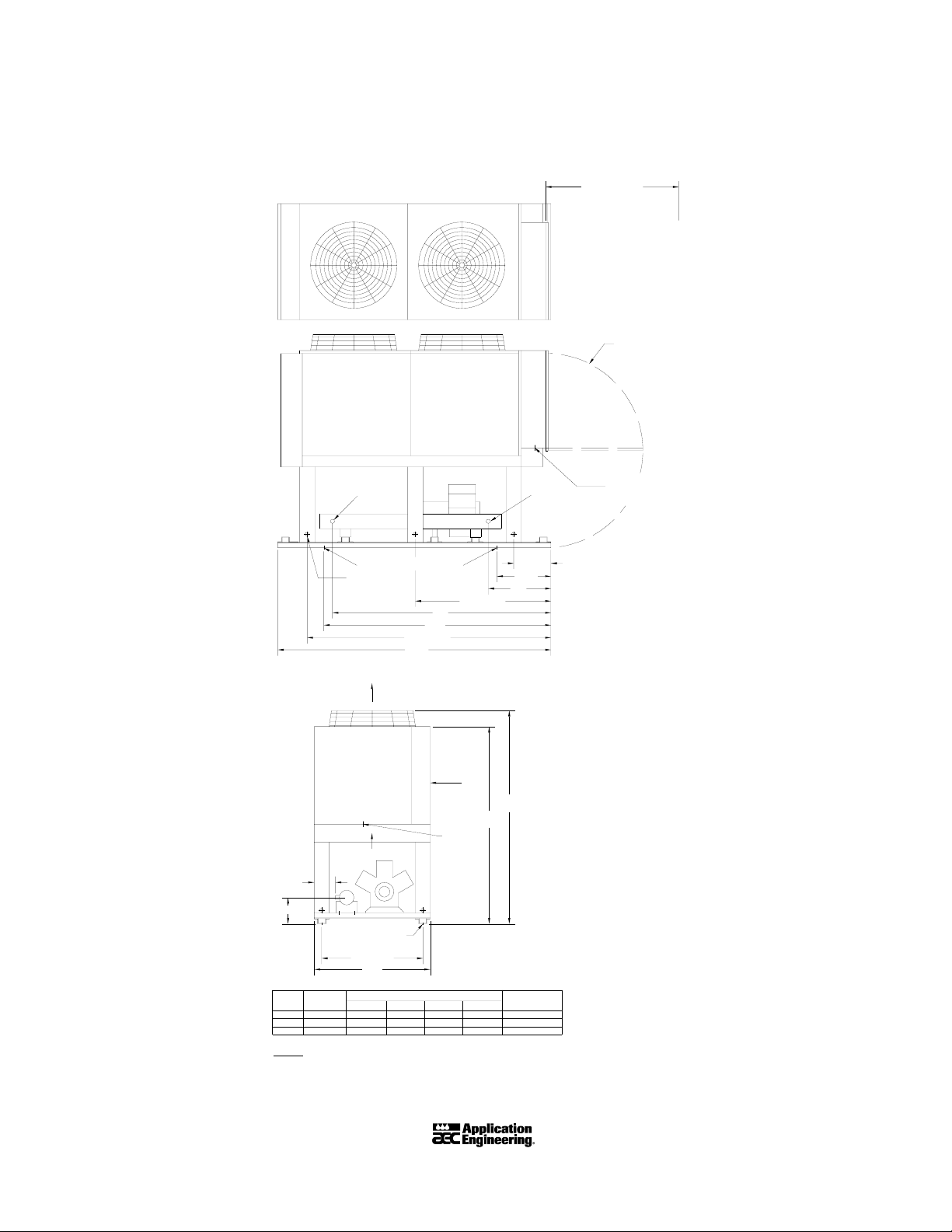

Figure 2

ACOA15, ACOA20, and ACOA25 Outline Drawing

ALLOW 60" FOR

SERVICE ACCESS

DOOR SWING

WATER

OUT

MOUNTING LOCATIONS

LIFTING

HOLE

90-3/16"

101"

50-3/16"

B

84"

AIR FLOW

CONTROL

BOX

AIR FLOW

`D'

`C'

MOUNTING

LOCATION

37-5/16

43"

MODEL

MODEL

ACOA

EVAP.

15

CHS00560

CHS00660

CHS00760

23-3/16" 80-13/16"

23-15/16"

20

25

NOTES:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTIONS PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT

NOTICE.

DIMENSIONS

'A'

80"

24"

80-1/16"

AIR

FLOW

POWER

ENTRY

'B'

'C'

5-1/16"

9-3/4"

5-7/16"

10-3/16"

2-3/4"

10-15/16"

73"

'D'

WATER

20"

A

79"

WATER

CONNECTION

1-1/2" N.P.T.

3" N.P.T.

3" N.P.T.

POWER ENTRY

IN

(SEE NOTE 4)

13-13/16"

Page 10

ACOA Series Air-Cooled Central Chillers

Page 12

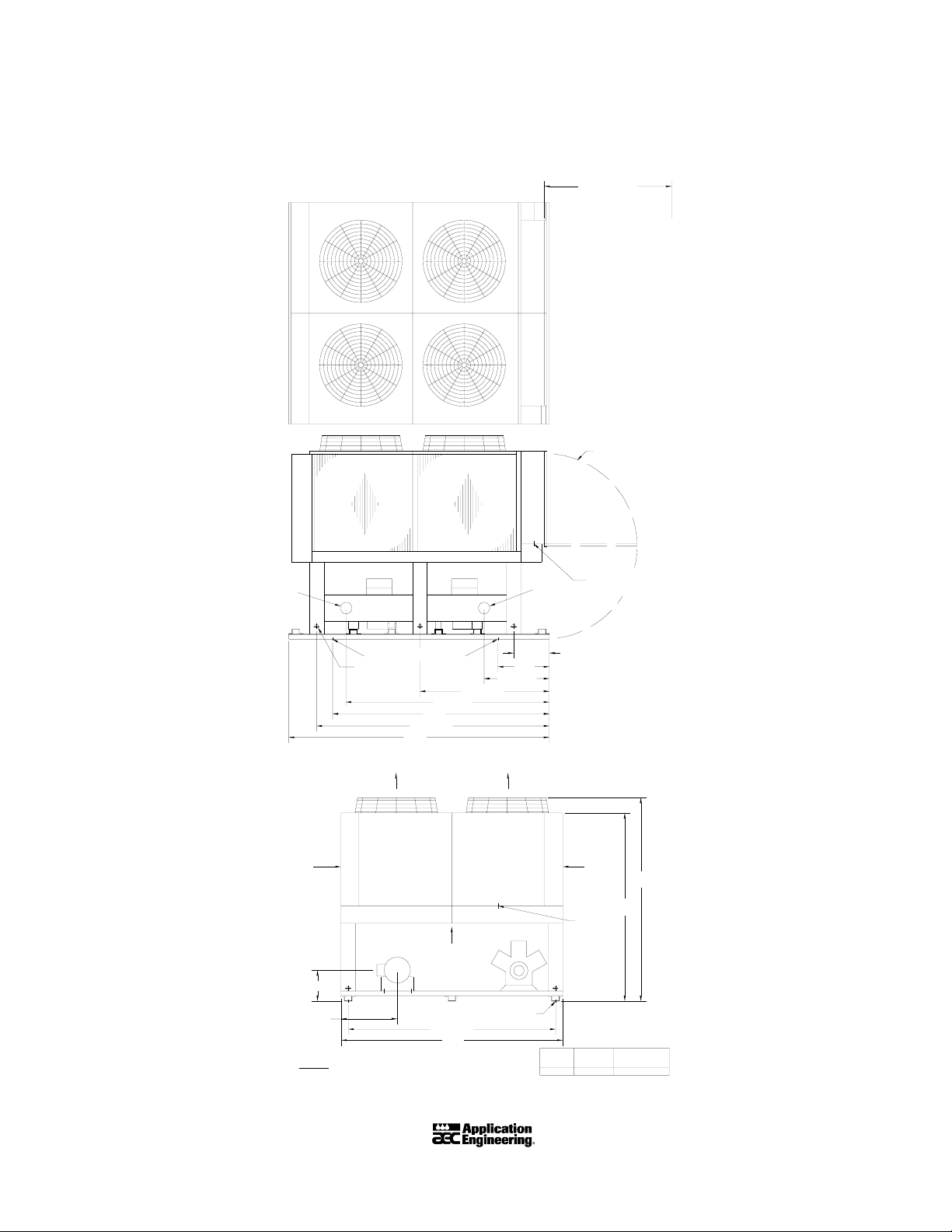

Figure 3

ACOA30 and ACOA35 Outline Drawing

ALLOW 60" FOR

SERVICE ACCESS

DOOR SWING

LIFTING

HOLE

WATER

OUT

MOUNTING LOCATIONS

120"

130-3/16"

141"

90-3/16"

WATER

IN

20"

A

50-3/16"

70"

B

13-13/16"

POWER ENTRY

(SEE NOTE 4)

AIR FLOW

CONTROL

BOX

AIR FLOW

`D'

`C'

MOUNTING

LOCATION

37-5/16"

43"

AIR

FLOW

POWER

ENTRY

79"

73"

MODEL

MODEL

ACOA

EVAP

30 CHS00760

ACOA Series Air-Cooled Central Chillers Page 11

23-15/16" 80-1/16"

25-1/4" 78-3/4" 11-1/2"

CHS0086035

NOTES:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTIONS PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

DIMENSIONS

'C'

B'

`A'

10-15/16"

2-3/4"

1-5/8"

'D'

WATER

CONNECTION

3" N.P.T.

3" N.P.T.

Page 13

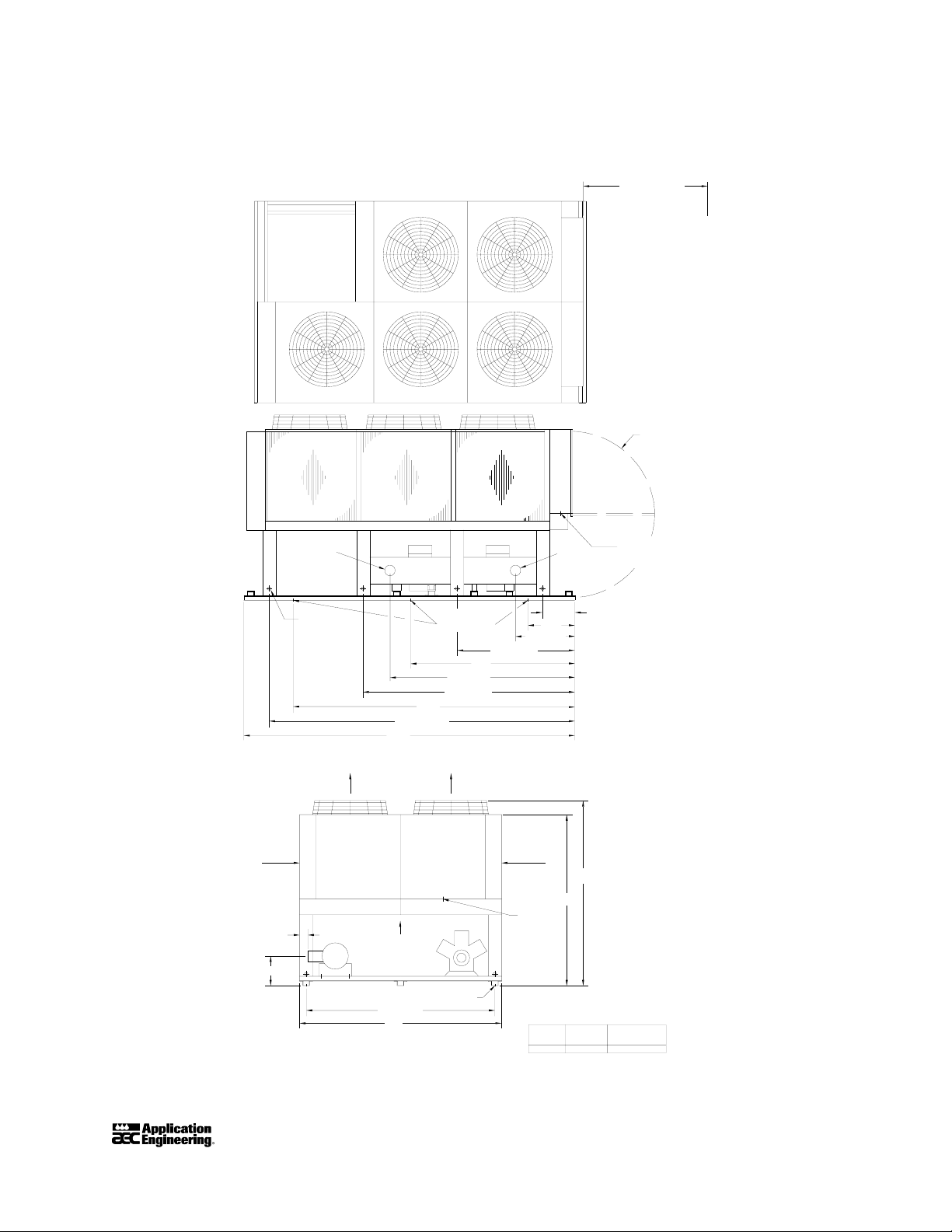

Figure 4

ACOA45 Outline Drawing

ALLOW 60" FOR

SERVICE ACCESS

DOOR SWING

WATER

OUT IN

MOUNTING LOCATIONS

LIFTING

HOLES

50-3/16"

78-3/4"

84"

90-3/16"

101"

AIR

FLOW

12-1/16"

4-11/16"

NOTES:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTIONS PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

CONTROL

BOX

AIR FLOW

MOUNTING LOCATIONS

80-5/16"

86"

25-1/4"

AIR FLOWAIR FLOW

CONTROL

BOX

20"

WATER

MODEL

ACOA

45

13-13/16"

AIR

FLOW

POWER

ENTRY

CHD01060

POWER ENTRY

(SEE NOTE 4)

MODEL

EVAP.

79"

73"

WATER

CONNECTION

4" N.P.T.

Page 12

ACOA Series Air-Cooled Central Chillers

Page 14

Figure 5

ACOA55 Outline Drawing

ALLOW 60" FOR

SERVICE ACCESS

DOOR SWING

FLOW

3-9/16"

12-5/8"

AIR

WATER

OUT

LIFTING

HOLES

CONTROL

BOX

130-3/16"

141"

AIR FLOW

120"

AIR FLOWAIR FLOW

CONTROL

MOUNTING

LOCATIONS

78-3/4"

90-3/16"

BOX

13-13/16"

POWER ENTRY

(SEE NOTE 4)

WATER

IN

20"

25-1/4"

50-3/16"

70"

AIR

FLOW

POWER

ENTRY

79"

73"

MOUNTING LOCATION

80-5/16"

86"

NOTES:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTIONS PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

ACOA Series Air-Cooled Central Chillers Page 13

MODEL

MODEL

EVAP.

ACOA

55 CHD01160 4" N.P.T.

WATER

CONNECTION

Page 15

Figure 6

ACOA70 Outline Drawing

AIR FLOW

AIR FLOW

ALLOW 60" FOR

SERVICE ACCESS

DOOR SWING

2-5/16"

13-3/16"

WATER

LIFTING

HOLES

OUT

CONTROL

BOX

POWER ENTRY

MOUNTING LOCATIONS

120"

130-3/16"

141"

AIR FLOW

CONTROL

BOX

AIR FLOW

MOUNTING LOCATION

80-5/16"

86"

90-3/16"

78-3/4"

13-13/16"

WATER

CONNECTION

4" N.P.T.

POWER ENTRY

(SEE NOTE 4)

WATER

IN

20"

25-1/4"

50-3/16"

70"

79"

73"

MODEL

MODEL

EVAP.

ACOA

CHD01260

70

Page 14

NOTES:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTIONS PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE.

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

ACOA Series Air-Cooled Central Chillers

Page 16

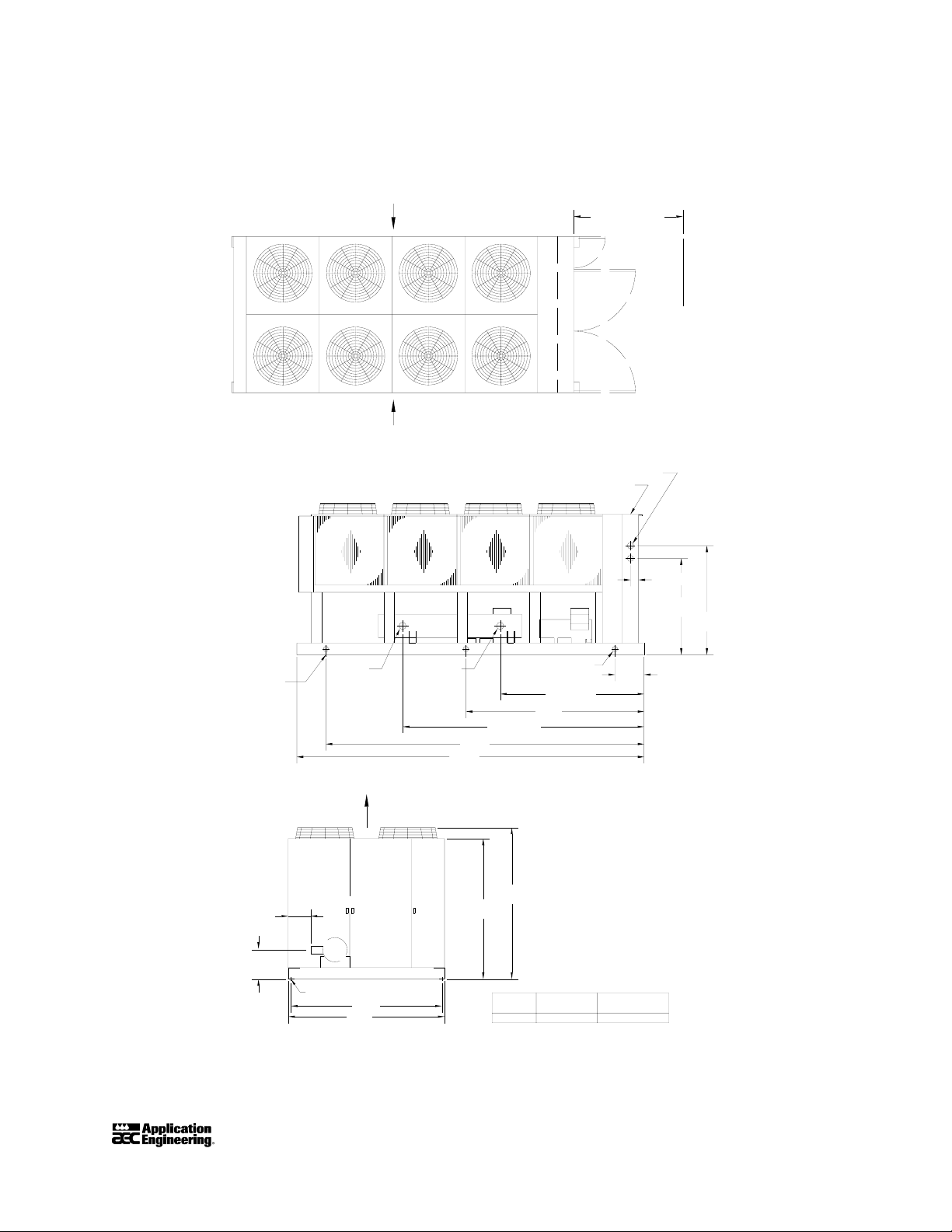

Figure 7

ACOA80 Outline Drawing

AIR FLOW

SIDE & BOTTOM

AIR FLOW

SIDE & BOTTOM

ALLOW 60" FOR

SERVICE ACCESS

MOUNTING

LOCATION

12-3/8"

WATER WATER IN

OUT

AIR FLOW

CONTROL BOX

POWER ENTRY (SEE NOTE #4)

132-3/4"

175"

191"

83-3/8"

77-3/8"

CONTROL BOX

LIFTING HOLE

79-1/4"

98"

4-1/2"

52-5/8"

59-5/8"

16"

16-1/8"

MOUNTING LOCATION

NOTE:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTIONS PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE.

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

ACOA Series Air-Cooled Central Chillers Page 15

83"

86"

MODEL

ACOA

80

MODEL

EVAP.

CHD01360 4" NPT

WATER

CONNECTION

Page 17

Figure 8

ACOA90 and ACOA100 Outline Drawing

AIR FLOW

SIDE & BOTTOM

AIR FLOW

SIDE & BOTTOM

ALLOW 60" FOR

SERVICE ACCESS

WATER OUT WATER IN

MOUNTING

LOCATION

AIR FLOW

CONTROL BOX

271"

255"

77-3/8"

229-3/16"

83-3/8"

POWER ENTRY (SEE NOTE #4)

148-3/16"

175"

CONTROL BOX

LIFTING HOLE

98"

4-1/2"

52-5/8"

59-5/8"

16"

Page 16

16-3/8"

MODEL

MOUNTING

86"

LOCATION

83"

45-7/16"

NOTES:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTIONS PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE.

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

ACO

090 & 100

ACOA Series Air-Cooled Central Chillers

EXT14092

MODEL

EVAP.

WATER

CONNECTION

5" VICTAULIC

Page 18

Figure 9

ACOA110 Outline Drawing

AIR FLOW

SIDE & BOTTOM

AIR FLOW

SIDE & BOTTOM

ALLOW 60" FOR

SERVICE ACCESS

WATER OUT WATER IN

MOUNTING

LOCATION

238-3/8"

255"

271"

AIR FLOW

CONTROL BOX

83-3/8"

77-3/8"

POWER ENTRY (SEE NOTE #4)

LIFTING HOLE

147-3/4"

175"

CONTROL BOX

4-1/2"

52-5/8"

59-5/8"

16"

98"

16-3/8"

MOUNTING LOCATION

45-7/16"

83"

86"

NOTE:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTION PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE.

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

ACOA Series Air-Cooled Central Chillers Page 17

MODEL

ACO EVAP.

110

MODEL

EXF14102

WATER

CONNECTION

5" VICTAULIC

Page 19

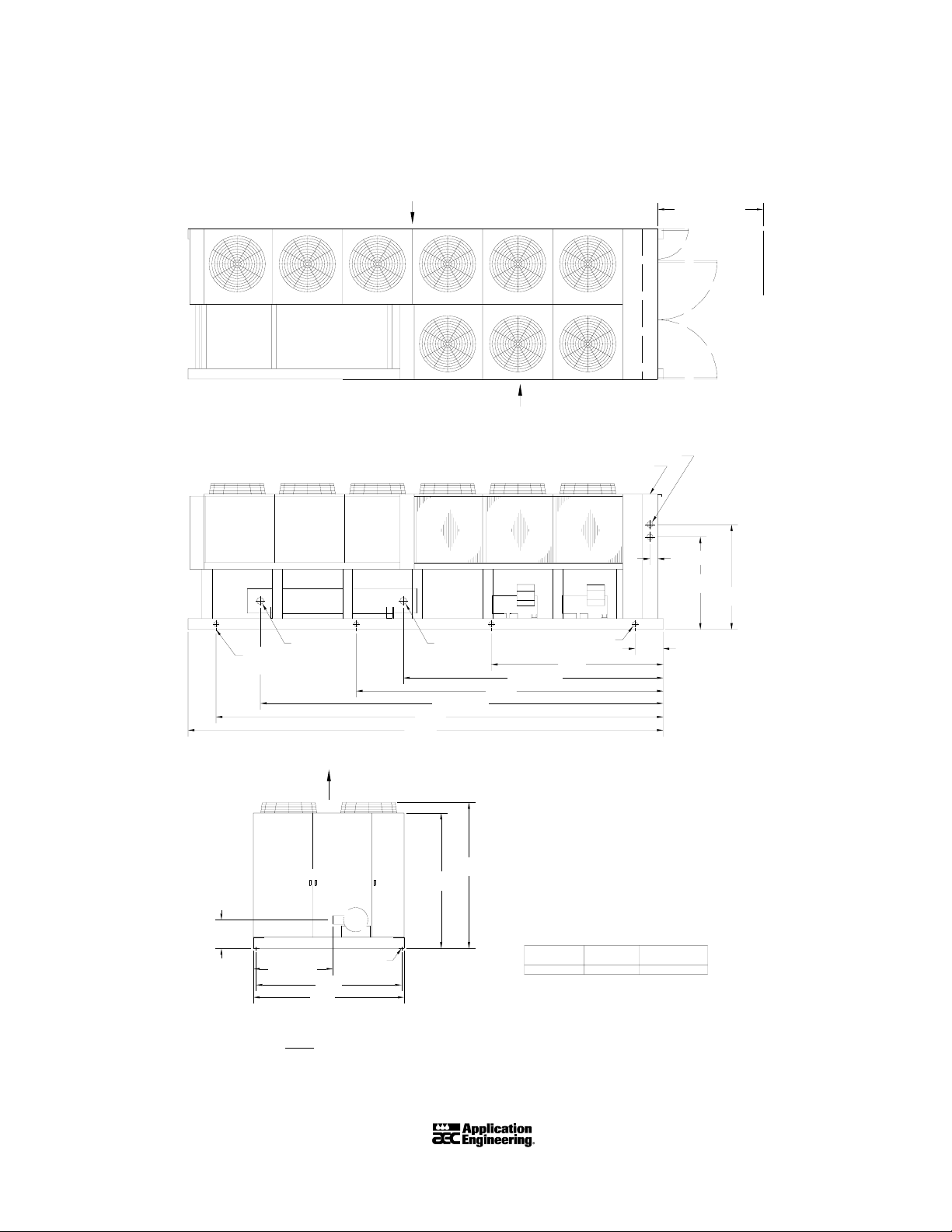

Figure 10

ACOA125 and ACOA135 Outline Drawing

AIR FLOW

SIDE & BOTTOM

AIR FLOW

SIDE & BOTTOM

ALLOW 60" FOR

SERVICE ACCESS

WATER OUT WATER IN

MOUNTING

LOCATION

AIR FLOW

271"

255"

POWER ENTRY (SEE NOTE #4)

175"

B

CONTROL BOX

LIFTING HOLE

98"

A

4-1/2"

52-5/8"

59-5/8"

16"

C

Page 18

CONTROL BOX

D

83"

86"

MOUNTING

LOCATION

77-3/8"

83-3/8"

NOTES:

1 - ALL DIMENSIONS IN INCHES.

2 - VENT AND DRAIN CONNECTIONS PROVIDED ON COOLER.

3 - ALLOW 60" CLEARANCE AT CONTROL PANEL END OF UNIT FOR SERVICE.

4 - USE MINIMUM 36" FLEXIBLE CONDUIT TO CONTROL BOX TO ISOLATE UNIT.

5 - WATER PIPING TO BE SUPPORTED TO MINIMIZE LOAD ON UNIT.

6 - ALL DIMENSIONS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

MODEL

MODEL

ACO

EVAP.

EXF14102 147-3/4" 238-3/8"

125

DIMENSIONS

A

ACOA Series Air-Cooled Central Chillers

B

C

16-3/8"D25-3/4"

WATER

CONNECTION

5" VICTAULIC

6" VICTAULIC27-7/8"17-3/8"241-13/16"132-1/16"EXF16122135

Page 20

2 Shipping Information

2-1 Unpacking and Inspection

You should inspect your AEC/Application Automation ACOA Series air-cooled central chiller

for possible shipping damage. If the container and packing materials are in re-usable condition,

save them for reshipment if necessary.

Thoroughly check the equipment for any damage that might have occurred in transit, such as

broken or loose wiring and components, loose hardware and mounting screws, etc. In case of

breakage, damage, shortage, or incorrect shipment, refer to the following sections.

2-2 In the Event of Shipping Damages

Important!

According to the contract terms and conditions of the Carrier,

the responsibility of the Shipper ends at the time and place of shipment.

The Carrier then assumes full responsibility of the shipment.

Notify the transportation company’s local agent if you discover damage.

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods to AEC, Inc. before the transportation company inspection and

authorization.

File a claim against the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise AEC, Inc. regarding your wish for replacement and to obtain an RMA (return

material authorization) number.

2-3 If the Shipment is Not Complete

Check the packing list. The apparent shortage may be intentional. Back-ordered items are noted

on the packing list.

ACOA Series Air-Cooled Central Chillers Page 19

Page 21

You should have:

ACOA Series central chiller.

Bill of Lading.

Packing list.

Operating and Installation packet.

Electrical schematic and panel layout drawings.

Component instruction manuals.

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking. Determine that the item was not inadvertently taken from the area before you

checked in the shipment. Notify AEC, Inc. immediately of the shortage.

2-4 If the Shipment is Not Correct

If the shipment is not what you ordered, contact AEC, Inc. immediately. Include the order

number and item. Hold the items until you receive shipping instructions.

2-5 Returns

Important!

Do not return any damaged or incorrect items

until you receive shipping instructions from AEC, Inc.

2-6 Uncrating Your Chiller

Caution!

Due to the size and weight of ACOA chillers,

AEC, Inc. recommends using bonded professional millwrights

to unload and move ACOA chillers.

Rig the chiller from the frame only and use spreader bars to prevent load transfer to any chiller

components. Rig the frame from at least four points and balance the load before lifting to clear

the skid.

Page 20

ACOA Series Air-Cooled Central Chillers

Page 22

3 Installation

3-1 Installation Location Considerations

• Consult a structural engineer to assure that the floor, mounting pad, or structural steel

support is of adequate strength.

• Provide a level foundation for proper operation.

• Put the air-cooled condenser(s) where plenty of ambient air can flow to the condenser and

can also remove the heated air from the area.

• Keep the condenser away from steam, hot air, or fume exhausts.

• Put chiller/condensers where sound levels and vibration can not be a problem.

• Support the chiller/condenser to avoid vibration and noise transmission into the building.

• ACOA chiller/condensers feature rubber shear vibration isolators.

• Mount rooftop condensers over corridors, utility areas, rest rooms, etc., or consult with

sound/structural specialists on critical installations.

• Locate the unit close to your process to reduce piping expense.

• Locate the unit adjacent to drain and city water sources.

• Allow sufficient space for maintenance and easy access to all components.

3-2 Process Water Piping Considerations

• Constant process water flow through the evaporator is critical for proper operation.

• Minimum external pressure drop is critical for proper operation.

• Run all properly-sized external chilled water connections for the process.

• Provide the largest possible openings and passages for the flow of chilled water through

platens, dies, molds, or other pieces of equipment.

• If process piping is exposed to temperatures below 32ºF (0ºC), use heater tape and/or

insulation to protect it from freezing. Main power is required to keep the tape, sump

heaters, and evaporator heaters on. Addition of anti-freeze is highly recommended for this

unit(s).

• Install water pressure gages before and after the evaporator (if not factory installed) to

make sure water pressure and flow rate are constant.

ACOA Series Air-Cooled Central Chillers Page 21

Page 23

3-3 Galvanic Corrosion Considerations

Water circuit piping components are primarily ferrous (iron) and react electro-chemically with

non-ferrous metallic materials such as copper. Some water has dissolved minerals that greatly

accelerate the reaction between dissimilar metals.

Use PVC or ferrous piping to reduce galvanic action. If piping must be copper, use dielectric

unions at the chiller.

3-4 Water Treatment Considerations

Water treatment is important in any piping system. In some locations, raw water can be used in

the system without problem; in other locations, it may result in large deposits of scale and

corrosion. Water that is corrosive, high in mineral content, or contains entrained solids can

reduce chiller efficiency and destroy evaporators.

AEC, Inc. offers a complete line of water treatment equipment. Contact your AEC, Inc. Sales

Representative for water testing and treatment options.

3-5 Making Process Water Connections

ACOA chillers have two chilled water connections per circuit:

TO PROCESS

The

TO PROCESS water connection is the chilled water supply outlet (located closest to the

expansion valve) leading to the process being controlled.

FROM PROCESS

The

FROM PROCESS water connection is the chilled water return inlet for water returning back

to the chiller from the process to be cooled and recirculated.

3-6 ACOA Refrigerant Charge Considerations

ACOA chillers are charged at the factory with the refrigerant for which they were designed. The

type and amount is listed on the serial tag.

Page 22

ACOA Series Air-Cooled Central Chillers

Page 24

3-7 Making Electrical Connections

Check the serial tag voltage and amperage requirements and make sure your electrical service

conforms.

Bring properly-sized power leads and ground from a fused disconnect (installed by your

electrician) to the unit. Use fuses in the disconnect switch, sized according to the National

Electrical Code recommendations listed on the electrical schematic in the control enclosure.

Caution!

Electrical connections must comply with all applicable electrical codes.

The chiller must be grounded in accordance with NEC Article 250.

Voltage must be within plus or minus ten percent (±10%) of the nameplate

rating.

Phase imbalance must be less than two percent (2%) in accordance with

NEMA MG1-14.32.

ACOA chillers must have properly sized disconnects conforming with all

local codes.

Check all wiring for damage and all terminal connections for tightness.

Shipping can loosen connections.

Use copper conductors when connecting to the ACOA terminal blocks.

3-8 Checking Motor Rotation Direction

Compressor

The compressor(s) operate(s) properly in either direction.

Condenser Fan

The condenser fan draws air through the condenser and discharges it up from the condenser.

To change fan rotation direction:

1. Disconnect and lock out power at the fused disconnect.

2. If all fans are going backwards, reverse any two main power leads.

3. If only some of the fans are going backwards, switch any two of the respective motor

leads.

ACOA Series Air-Cooled Central Chillers Page 23

Page 25

- Notes -

Page 24

ACOA Series Air-Cooled Central Chillers

Page 26

4 Sequence of Operation

4-1 General Information

The operating thermostat (opstat) labeled 4TAS monitors return chilled water/air temperature

and activates various steps of capacity control to maintain controlled leaving chilled water

temperature or return air temperature.

Each model has similar control logic. Refer to your wiring diagram located on the inside control

panel door for your control layout for more information.

4-2 Circuit Operation

Typical 2 compressor control sequence of operation 4 step capacity control, continuous

pumpdown. Refer to the typical wiring diagrams.

1. Unit on Standby

• Main field disconnect switch closed

• 115 VAC control power on

•

S1 control switch on

•

4TAS-1 through 4TAS-4 opstat contacts open or customer control contacts open

•

2TAS freezestat closed

• FLS flow switch closed

•

CWP chiller pump auxiliary contacts closed

• Water flow rates nominal

• Compressor control switches closed

• All safety switches closed

• Pumpdown during standby

Any one of the compressors may come on for a short time and pump down if any low side

pressure buildup occurs during the standby period. The 1TR cycle timer locks out for five (5)

minutes after a pumpdown before the compressor can restart. Pumpdowns can be expected

immediately following a normal

the

4PS pumpdown switch to close momentarily.

ON cycle as residual liquid in the low side vaporizes, causing

ACOA Series Air-Cooled Central Chillers Page 25

Page 27

2. Run Cycle Sequence (Increasing Load)

• Customer contacts close

Step 1

1. Opstat

bypasses pumpdown switch

4TAS-1 closes as return chilled water temperature starts to rise. Relay 8CR

4PS-1 to remove it from the control circuit.

Note: Go to Step 4 if Compressor 1 is off for more than five (5) minutes.

2. Cycle timer

1TR times out and closes (up to a five (5) minute delay).

3. Compressor 1 starts. Contactor auxiliary switch energizes liquid line solenoid 1SOL and

Circuit 1 refrigerant flow starts. Compressor 1 unload solenoid

4TAS-NC2 and NC4. Compressor 1 unloads one bank of cylinders.

3SOL energizes through

4. Oil failure switch 3PS-1 starts to time open (120 sec. delay). Low pressure switch 9PS-1

starts to time open (120 to 240 sec. delay).

Note: If oil pressure or suction pressure is not established at a normal level within the above-

listed delay times, Circuit 1 shuts down.

5. Circuit 1 oil and suction pressure rise to normal levels, and

3PS-1 and 9PS-1 terminate

the time open sequence.

First stage capacity is now on line.

Step 2

6. Opstat 4TAS-2 closes as water temperature continues to rise. Compressor 1 unload

solenoid

1SOL de-energizes as 4TAS-NC2 opens. Compressor 1 loads up to 100%.

Second stage capacity is now on line.

Step 3

7. Opstat 4TAS-3 closes as water temperature continues to rise. Relay 9CR bypasses

pumpdown switch

4PS-2 to remove it from the control circuit. Staging timer 4TR-2

delays Compressor 2 start (10 to 30 seconds).

8. Staging timer

loaded. Contactor auxiliary switch energizes liquid line solenoid

refrigerant flow starts. Oil Failure switch

pressure switch

4TR-2 closes. If cycle timer 1TR-2 times out, Compressor 2 starts 100%

2SOL and circuit 2

3PS-2 starts to time open (120 sec. delay). Low

9PS-2 starts to time open (120 to 240 sec. delay).

Note: If oil pressure or suction pressure is not established at a normal level within previously-

listed delay times, Circuit 2 shuts down.

Page 26

ACOA Series Air-Cooled Central Chillers

Page 28

9. Compressor 1 unload solenoid 3SOL re-energizes through 4TAS-2 and 4.

10. Compressor 1 unloads one bank of cylinders.

11. Circuit 2 oil and suction pressures rise to normal levels, and

3PS-2 and 9PS-2 terminate

the time open sequence.

Third stage capacity is now on line.

Step 4

12. Opstat 4TAS-4 closes as water temperature continues to rise. Compressor 1 unload

solenoid

3SOL de-energizes by 4TAS-NC4 open. Compressor 1 loads to 100%.

13. 100% unit capacity is not on line.

Run Cycle Sequence (Decreasing Load)

Step 4

1. Opstat 4TAS-4 opens as leaving water temperature starts to drop. Compressor 1 unload

solenoid

2. Compressor 1 unloads one bank of cylinders.

Third stage capacity is now on line (Compressor 1 at part load; Compressor 2 at 100%).

Step 3

3SOL energizes through 4TAS-NC4 closed and N02 closed.

1. Opstat 4TAS-3 opens as water temperature continues to drop. Relay 9CR de-energizes,

removing

de-energizes through

solenoid

2. When suction pressure drops to the pumpdown limit,

4PS-2 bypass (4PS-2 now controls pumpdown). Compressor 1 unload solenoid

4TAS-N02 open. Compressor 1 loads back up to 100%. Liquid line

2SOL de-energizes and Circuit 2 refrigerant flow stops.

4PS-2 opens and Compressor 2

stops. Circuit 2 pumpdown and off sequence is now complete, and all Circuit 2 controls

are back to standby status.

Second stage capacity is now on line (Compressor 1 at 100%).

Step 2

3. Opstat 4TAS-2 opens as water temperature continues to drop. Compressor 1 unload

solenoid

3SOL is energized through 4TAS-NC2 and NC4 closed. Compressor 1 unloads

one bank of cylinders.

First stage capacity is now on-line.

ACOA Series Air-Cooled Central Chillers Page 27

Page 29

Step 1

4. Opstat

solenoid

energizes, removing

4TAS-1 opens as water temperature reaches minimum set point. Liquid line

1SOL de-energizes and Circuit 1 refrigerant flow stops. Relay 8CR de-

4PS-1 bypass (4PS-1 now controls pumpdown). Compressor 1

remains running and Circuit 1 pumpdown begins.

5. When suction pressure drops to the pumpdown limit,

4PS-1 opens and Compressor 1

stops. Circuit 1 pumpdown and unload sequence is now complete, and all Circuit 1

controls are back to standby status.

Figure 11

ACOA Control Settings and Set Points (Unit is Off)

ACOA Control Settings

Time Delay

1TR-1 & 2 5 Min.

3PS-1 & 2 120 Sec.

9PS-1 & 2 120 Sec.

4TR-2 10 Sec.

5TR-1 & 2 2 Min.

Pressure (PSIG) Open Close

1PS-1 & 2 360

10, 11PS-1 140 190

10, 11PS-2 160 21-0

10, 11PS-3 170 230

Temperature Open Close

4TAS-1 LWT + .40R LWT + .55R

4TAS-2 LWT + .55R LWT + .70R

4TAS-3 LWT + .70R LWT + .85R

4TAS-4 LWT + .85R LWT + R

Percentage

of ethylene

glycol ºF ºC psig kPa psig kPa psig kPa ºF ºC

0% 32ºF 0ºC 55 psig 379 kPa 45 psig 310 kPa 70 psig 483 kPa 38ºF 3ºC

10% 27ºF -3ºC 49 psig 338 kPa 39 psig 269 kPa 64 psig 441 kPa 33ºF 1ºC

20% 18ºF -8ºC 39 psig 269 kPa 29 psig 200 kPa 54 psig 372 kPa 24ºF -4ºC

30% 3ºF -16ºC 33 psig 228 kPa 23 psig 159 kPa 48 psig 331 kPa 9ºF -13ºC

40% -13ºF -25ºC 33 psig 228 kPa 23 psig 159 kPa 48 psig 331 kPa -7ºF -22ºC

50% -20ºF -29ºC 33 psig 228 kPa 23 psig 159 kPa 48 psig 331 kPa -14ºF -26ºC

3TAS 40ºF 43ºF

ACOA Set Points

Minimum

ambient

Minimum

9PS open

4PS

open

4PS

close

Minimum

2TAS open

Caution!

Do not set 9PS, 4PS, or 2TAS lower than indicated for your glycol concentration—

the AEC, Inc. warranty is voided! The AEC, Inc. warranty does not cover freeze-up!

Figure 12

Page 28

ACOA Series Air-Cooled Central Chillers

Page 30

*

UNIT

FUSING

1TB

L1

L2

L3

SEE

NOTE 9

1M1

GND

CONTROL CIRCUIT 115/1/60

(CONTROL POWER)

Typical ACOA Wiring Diagram

200-230V/3/60

SEE NOTES 2, 3 & 4

321

3L1 3L3

3FM

15A

7M 4M

1MTR

COMPRESSOR MOTORS

SEE NOTE 5

(SEE NOTE 7)

2M1

2MTR

SEE BORDER

DGM. FOR

VAR. SPEED

OPTION

FUSE NO.

2M21M2

3M 5M

70 71 72 76 77 78

1FM

1M1-1

2M1-1

848382

5FM

FAN MOTORS

1HTR

2HTR

73 74 75

2FM

2

65

4

15A

4L1 4L3

8M6M

79 80 81

4FM

COMP NO. 1 OIL HEATER

COMP NO. 2 OIL HEATER

878685

6FM

5

8

J27

2UVR S3

8

J28

8

JJ

899

27

COMP

28

COMP

98 99

S21UVR

#1

18

#2

34

9

10 11

1TAS-1

SEE NOTE 8

MOTOR TEMP

SENSORS

1PS-2 3PS-2

1TAS-2

SEE NOTE 8

MOTOR TEMP

SENSORS

24H 24G

C1

C2

C3 NO3

+6.2

9PS-1

3PS-1

T1 M1 T2M2

S1

50 51 52 53

9PS-2

2019

S1

82

115VAC

24VAC

29 33

STEP 1

STEP 2

STEP 3

STEP 4

4TAS

12

S2S3C

21

S2

2T

NO1

NC1

NO2

NC2

NC3

NO4C4

NC4

ISA

8CR

13

4PS-1

BLK

9CR

22

4PS-2

M2 T2M1T1

C

S3

BLK

57565554

31

1TR-1

14

12

4

4CR-1

4TR-2

23

31

5CR-1

35

38

58

15

J15

15

59

24

25

J25

25

1M1-2

32

2M1-2

36

9CR

48

4CR

COMP NO. 1 START RELAY (10, 43)

COMP NO. 1 5 MIN. ANTI-CYCLE

TIMER

COMP NO. 1 CONTACTOR (1, 28)

1M2

HTR

HTR

5CR

2M1

2M2

HTR

HTR

1SOL

8CR

2SOL

9CR

3SOL

COMP NO. 1 CONTACTOR

COMP NO. 1 OIL FAIL

COMP NO. 1 LOW PRESSURE

COMP NO. 1 MOTOR TEMP

COMP NO. 2 START RELAY (19, 46)

COMP NO. 2 5 MIN. ANTI-CYCLE

TIMER

COMP NO. 2 CONTACTOR (2, 33)

COMP NO. 2 CONTACTOR

COMP NO. 2 OIL FAIL

COMP NO. 2 LOW PRESSURE

COMP NO. 2 MOTOR TEMP

COMP NO. 1 LIQ LINE SOLENOID

COMP NO. 1 LOCKIN RELAY (6)

COMP NO. 2 LIQ LINE SOLENOID

COMP NO. 2 LOCKIN RELAY (15, 37)

COMP NO. 1 UNLOAD SOLENOID

3PS-1

9PS-1

16

3PS-2

9PS-2

26

31

4CR-2

39

5CR-2

43

Typical schematic - See the drawings

provided with your ACOA chiller

ACOA Series Air-Cooled Central Chillers Page 29

10PS-1

11PS-1

CIRC 1

CIRC 2

40

10PS-2

CIRC 1

44

11PS-2

CIRC 2

41

42

10PS-3

CIRC 1

45

46

11PS-3

CIRC 2

5TB

3M

CONTACTOR-FAN 1

5M

CONTACTOR-FAN 3

7M

CONTACTOR-FAN 5

4M

CONTACTOR-FAN 2

6M

CONTACTOR-FAN 4

8M

CONTACTOR-FAN 6

CUSTOMER SUPPLIED 115VAC

POWER. MAXIMUM FUSE SIZE 15A.

102

CHILLER HEATER

T'STAT

101

CHR HTR

TRW

Page 31

Figure 13

Typical ACOA Option Wiring Details

Door Latch

Solenoid

Option

5SOL

2

1

6SOL

Hot Gas

Bypass

Option

4SOL

48

2

Transformer

Option

L1

L2

13FU 14FU

1T

115/1/60

13FU 14FU

VOLT

200

44

3 1/2230

3 1/2

Low Ambient Option

8

3TAS

5TR-1

15

16

3

1

3CR

REMOVE J15

VARIABLE SPEED

FAN MOTOR

~~

3M

66

5T

4A

1SCR

L1

64

24

VAC

M1

65

71

GND

70

1CPR

72

2

3

1

1FM

200-230/460V

3CR

17

1RES

10K

REMOVE J25

VARIABLE SPEED

FAN MOTOR

73

2

5TR-2

2625

3

1

3CR

~~

4M

6T

4A

L1

67

24

VAC

M1

68

2

3

1

200-230/460V

2FM

UVR

Option

3L1

3L2

3L3

ABC

1UVR 2UVR

827

1CR

REMOVE J27

1UVR

47 49

4L1

4L2

4L3

ABC

REMOVE J28

12

21

2UVR

1CR

69

74

2CPR

75

2CR

2SCR

GND

2RES

10K

2

288

2CR

Page 30

Pilot Light

Option

2LT

RR

910

6LT 7LT 8LT

18

19

CONTROL

POWER

52

1LT

W

3LT 4LT

R

12 13

11

RRR

2120

5LT

R

COMP 1

HIGH

MOTOR

TEMP

9LT

R

COMP 2

HIGH

MOTOR

22

TEMP

ACOA Series Air-Cooled Central Chillers

Page 32

Figure 14

One Circuit ACOA Refrigerant Piping Schematic

RELIEF

RELIEF

VALVE

VALVE

ANGLE

VALVE

ANGLE

VALVE

ANGLE

VALVE

COMP 1

MUFFLER

ANGLE

WATER

IN

SOLENOID

VALVE

EVAPORATOR

WATER

OUT

HOT GAS

REGULATORVALVE

ANGLE

VALVE

(HORIZ)

SC IN

SC OUT

EXPANSION

VALVE

COND

SIGHT

GLASS

COND

(VERT)

SOLENOID

VALVE

ANGLE

VALVE

FILTER

DRIER

Figure 15

Two Circuit ACOA Refrigerant Piping Schematic

RELIEF

RELIEF

VALVE

VALVE

ANGLE

VALVE

ANGLE

VALVE

COND

(VERT)

EXPANSION

VALVE

LH

SC OUT

GLASS

SC IN

SIGHT

RH

COND

(HORIZ)

ANGLE

VALVE

COND

(VERT)

VALVE

VALVE

RH

ANGLE

VALVE

FILTER

DRIER

HOT GAS

REGULATOR

SC OUT

SC IN

LH

COND

(HORIZ)

COMP 2

MUFFLER 2

COMP 1

MUFFLER 1

ANGLE

VALVE

WATER

IN

ACOA Series Air-Cooled Central Chillers Page 31

EVAPORATOR

SOLENOID

VALVE

WATER

OUT

CIRC 1

CIRC 2

Page 33

Figure 16

RELIEF

RELIEF

RELIEF

RELIEF

Three Circuit ACOA Refrigerant Piping Schematic

VALVE

VALVE

SCHRADER

VALVE

COMP 3

COMP 2

COMP 1

CIRC 1

CIRC 2

CIRC 3

WATER

MUFFLER 3

HG HG HG HG

LH LH

COND

MUFFLER 2

SC IN

SC OUT

MUFFLER 1

HOT GASANGLE

SOLENOID

VALVE

EVAPORATOR

IN

VALVE

WATER

OUT

REGULATOR

CIRC 1

CIRC 2

CIRC 3

COND

SC IN

TXV'S

SC OUT

SIGHT

GLASS

3 FANS 6 FANS

COND

RH

ANGLE

VALVE

SC IN

SC OUT

VALVE

VALVE

RH

COND

Figure 17

Four Circuit ACOA Refrigerant Piping Schematic

VALVE

VALVE

ANGLE

VALVES

FILTER

DRIER

Page 32

SCHRADER

VALVE

COMP 4

COMP 3

COMP 2

COMP 1

CIRC 1

CIRC 2

CIRC 3

CIRC 4

WATER

IN

MUFFLER 4

MUFFLER 3

MUFFLER 2

MUFFLER 1

ANGLE

VALVE

EVAPORATOR

SOLENOID

VALVE

WATER

OUT

HOT GAS

REGULATOR

CIRC 1

CIRC 2

CIRC 3

CIRC 4

HG

LH

COND COND

SC IN

SC OUT

HG

HG

LH

RHHGRH

COND

COND

SC IN

SC IN

SC IN

SC OUT

SIGHT

GLASS

ANGLE

VALVE

SC OUT

VALVE

VALVE

ANGLE

VALVES

FILTER

DRIER

SC OUT

TXV'S

ACOA Series Air-Cooled Central Chillers

Page 34

5 Startup and Operation

5-1 Introduction

Important!

AEC, Inc. includes factory startup for ACOA chillers.

• New chillers are started up by AEC, Inc.’s local qualified refrigeration service

representative.

• Installation must be completed before startup is requested. See Section 5-2

below.

• Have your own service and operating personnel present during startup to

assist the AEC representative and to be trained in ACOA operation and

maintenance.

• Upon arrival, the AEC representative inspects the installation to see if it

meets AEC, Inc. requirements, performs the initial startup, determines if the

system is in satisfactory operating condition, and instructs specified on-site

personnel in operation and maintenance for the length of time specified in

the purchase contract.

• Make sure the sump oil heaters are energized for at least 24 hours before the

AEC Service representative arrives for the startup.

• Call AEC/Application Engineering service at [800] 233-4819 to request

startup services.

5-2 Pre-Startup Checklist

An ACOA chiller is ready for initial start-up when:

Process water piping for the evaporator is installed and tested.

Electrical connections are made and properly fused.

The chiller transformer primary voltage connections are configured for the electrical power

you are using.

The voltage at the main power connection reads within plus or minus ten percent (±10%) of

the voltage listed on the serial tag and not have an imbalance exceeding two percent (2%).

The chiller has been leak tested, any leaks corrected, and refrigerant charge completed.

The compressor crankcase heater(s) have been energized for a minimum of 24 hours.

ACOA Series Air-Cooled Central Chillers Page 33

Page 35

Calibrated refrigerant gauges have been connected to the suction, discharge and oil pressure

ports.

The optional or field installed chilled water supply and return valves on the chiller are open.

The auxiliary reservoir tank and process water circuit piping are filled with a water/glycol

mixture. The water/glycol mix should provide freeze protection to 20° below the leaving

water temperature or anticipated ambient.

The chilled water pump rotation direction has been checked, and the water flow and pressure

through the evaporator has been adjusted to the specified flow rate.

The remote condenser fans have been manually energized and checked for proper rotation

direction. Fans should pull air through the condenser coil and discharge vertically upwards.

You can change rotation on three-phase motors by interchanging just two wires on the main

terminal block.

All refrigerant valves are open.

5-3 Starting the Chiller

1. Energize crankcase heaters for at least 24 hours before startup. Crankcase oil temperature

must be at least 100ºF (38ºC). This action vaporizes any refrigerant dissolved in the oil,

and assures that the oil is within normal operating temperature range.

2. Before starting the compressor(s), check all three phases of supply voltage of all legs of

the motor. They must be within plus or minus ten percent (±10%) of the nameplate

voltage and not have an imbalance exceeding two percent (2%).

3. Start compressor(s), check the gauges and note if the pressures are within the prescribed

limits.

4. Check the refrigerant sight glass at the TX Valve to be sure it is free of bubbles. If not,

see Section 7-8 on Page 47.

5. Shut the compressor down and check the compressor crankcase sight glass for proper oil

level. It should be

1

/3 to 1/2 up on the sight glass. If not, add oil. See Section 5-4 on the

following page for more information.

6. Restart the compressor and put the process under load. After an hour, check the

expansion valve superheat setting. It should be between 8ºF and 12ºF (-13ºC and -11ºC)

at full load design conditions. You may need to lower the superheat setting for proper

distribution. Turn the TX valve adjustment stem clockwise to increase the superheat

setting and counterclockwise to decrease the setting. Allow ample time between

adjustments to let the system re-balance.

7. Check electrical control settings and, if necessary, reset to the settings on the wiring

diagram. Safety controls are factory set and must be maintained at settings indicated on

the wiring diagram.

8. Adjust the freezestat cut-out to 10º below the process temperature you want.

Page 34

ACOA Series Air-Cooled Central Chillers

Page 36

9. Set the controller to the entering temperature you want. Check the temperature of the

process water in and out to be sure the unit is operating within the desired temperatures

you have selected.

5-4 Lubricating the Compressor

Oil Pump

Note: Only a qualified service person should check oil pressure.

During operation, watch the oil through the sight glass to verify that the oil is being agitated,

which indicates that the oil pump is working. If you have any doubt about oil pump operation,

check oil pressure by installing a gauge in the ¼” tapped pump cover opening. Oil pressure

should be 30-45 psi (207-310 kPa) above suction pressure.

If oil pressure is insufficient:

1. Try reversing the rotation direction on the compressor. The compressor can operate in

either direction.

2. If reversing doesn’t work, check for a plugged oil strainer.

3. If the strainer is clean, replace the complete pump end plate assembly, not just the pump.

Oil Type

If the oil becomes discolored, indicating contamination, install a new filter-dryer in the liquid

line and change the oil. The amount of oil needed for each compressor is listed in Figure 1 on

Page 9.

Caution!

Use only Type 150SUS Calumet R015 or Texaco WF-32 refrigeration oil.

Do not use any other oil, or your warranty is voided!

5-5 System Flow Rate

You can estimate the quantity of chilled water being circulated by determining the water

pressure drop through the evaporator, and reading the flow rate in gallons (liters) per minute

from the appropriate pressure drop curve in Figure 18 on the following page.

An alternate method of determining flow rate is to measure pressure difference from pump inlet

to outlet and read the flow rate from the pump curve.

Water flow rates must not vary more than plus or minus ten percent (±10%) from design flow

rates.

ACOA Series Air-Cooled Central Chillers Page 35

Page 37

Figure 18

ACOA Evaporator Pressure Drop Curves

Chiller Curve Minimum flow rate Maximum flow rate

model number gpm lpm gpm lpm

ACOA15 1 27 103 70 265

ACOA20 2 29 110 97 367

ACOA25 3 37 140 104 393

ACOA30 4 50 190 168 635

ACOA35 5 70 265 232 878

ACOA45 6 78 296 315 1,192

ACOA55 6 86 326 315 1,192

ACOA70 7 94 356 377 1,426

ACOA80 9 101 383 420 1,589

ACOA90 11 158 598 444 1,680

ACOA100 12 155 587 444 1,680

ACOA110 13 174 659 553 2,093

ACOA125 13 174 659 553 2,093

ACOA135 15 236 894 693 2,623

Page 36

ACOA Series Air-Cooled Central Chillers

Page 38

5-6 Capacity Control

The standard AEC/Application Engineering ACOA chiller capacity control operates as follows:

• As the chiller load initially drops, the suction pressure of the compressor(s) start(s)

dropping proportionately, thus balancing minor load variations.

• Variation of unit capacity in response to system load requirements is controlled by an

operating thermostat which monitors the return water temperature.

• Single compressor packages are controlled by cylinder unloading or hot gas bypass. Up to

20 tons (60,480 Kcal/hr) nominal size cylinder unloading is achieved by blocking the

suction gas from entering the cylinders on one bank.

Hot gas bypass operates by imposing an artificial load on the evaporator. Discharge gas

from the compressor is introduced to the liquid-vapor mixture of refrigerant downstream of

the expansion valve. The discharge gas is cooled by the liquid refrigerant present in the

turbulence of the evaporator so that the final temperature does not rise. Hot gas bypass

does not offer any energy savings; it does allow the cooling capacity of the equipment to

vary precisely with the load requirements.

• On multiple compressor units, a combination of cylinder unloading and compressor staging

controls capacity.

Note: See Figure 19 on the following page to determine the capacity control scheme for your

specific unit.

ACOA Series Air-Cooled Central Chillers Page 37

Page 39

Figure 19

ACOA Capacity Control

Chiller

model

ACOA15 0 30 100

ACOA20 0 30 100

ACOA25 0 100

ACOA30 0 33 67 100

ACOA35 0 33 67 100 Opt.

ACOA45 0 25 50 75 100 first

ACOA55 0 21 42 78 100 capaACOA70 0 34 50 84 100 city

ACOA80 0 25 50 75 100 step

ACOA90 0 22 33 56 67 89 100

ACOA100 0 22 33 56 67 89 100

ACOA110 0 21 42 71 100

ACOA125 0 25 50 75 100

ACOA135 0 25 50 75 100

Modulates 100% to 30%

Hot gas bypass modulates to approximately half the capacity of the first step.

Comp.

off

Comp. 1

on 33%

Comp. 1

on 50%

Comp. 1

on 66%

Comp. 1

on 100%

Comp. 1

on 50%,

Comp. 2

on 100%

Comp. 1

on 67%,

Comp. 2

on 100%

Comp. 1

and

Comp. 2

on 100%

Comp. 1

on 67%,

Comp. 2 &

Comp. 3

on 100%

Comp. 1,

Comp. 2

& Comp.

3 on

100%

Comp. 1,

Comp. 2,

Comp. 3

& Comp.

4 on

100%

Hot

gas

by-

pass

Page 38

ACOA Series Air-Cooled Central Chillers

Page 40

Figure 20

ACOA Fan Cycling Control Chart

ACOA Refrig. Fan number “On” at each step

model circuit Step > 1 2 3 4 Remarks

ACOA15 1 OFF # 1 # 2

ACOA20 1 OFF # 1 # 2

ACOA25 1 OFF # 1 # 2 All fans in separate compartments.

ACOA30 1 OFF # 1 # 2 # 3

ACOA35 1 OFF # 1 # 2 # 3

ACOA45 1 OFF # 1 # 3

ACOA45 2 OFF # 2 # 4 2, 3, and 4 Compressor ACOAs have

ACOA55 1 OFF # 1 # 3 all fans in separate compartments.

ACOA55 2 OFF # 2 # 4 # 6

ACOA70 1 OFF # 1 # 3 # 5 Odd # Fans - Circuit 1

ACOA70 2 OFF # 2 # 4 # 6

ACOA80 1 OFF # 1 # 3 # 5 # 7 Even # Fans - Circuit 2

ACOA80 2 OFF # 2 # 4 # 6 # 8

ACOA90 1 OFF

ACOA90 2 OFF

ACOA90 3 OFF

ACOA100 1 OFF

ACOA100 2 OFF

ACOA100 3 OFF

ACOA110 1 OFF

ACOA110 2 OFF

ACOA110 3 OFF

ACOA110 4 OFF

ACOA125 1 OFF

ACOA125 2 OFF

ACOA125 3 OFF

ACOA125 4 OFF

ACOA135 1 OFF

ACOA135 2 OFF

ACOA135 3 OFF

ACOA135 4 OFF

Note: Refer to Figure 12 on Page 29 for fan pressure switch settings.

ACOA Series Air-Cooled Central Chillers Page 39

Page 41

- Notes -

Page 40

ACOA Series Air-Cooled Central Chillers

Page 42

6 Electrical Devices

6-1 Control Circuit Power Switch - S1

This switch energizes the 115 VAC control circuit. Keep it on at all times (except for temporary

control circuit service work) to allow off-cycle pumpdown and normal on-cycle operation. The

compressor crankcase heater(s) is/are not affected by this switch.

6-2 Compressor Switch - S2, S3, S4, S5

This switch disconnects power from the corresponding compressor control circuit. Use these

switches during service only, since pumpdown is disabled when the switch is off.

6-3 Flow Switch - FLS

The chilled water flow switch assures chilled water flow while the ACOA chiller runs.

6-4 Chilled Water Pump Interlock - CWP

AEC/Application Engineering recommends that you install an interlock between the accessory

chilled water pump and the ACOA chiller package to prevent the chiller from operating with the

chilled water pump off. Connect the interlock to the terminals shown on the wiring diagram.

6-5 High Pressure Safety Switch - 1PS

Manual Reset

This switch stops the compressor if discharge pressure is too high. This condition can be caused

by fan failure or coil blockage.

6-6 Pumpdown Switch - 4PS

Auto Reset

This low pressure switch provides automatic recycling pumpdown in standby mode. It is

bypassed when the operating thermostat (

4TAS) calls for the compressor to start.

ACOA Series Air-Cooled Central Chillers Page 41

Page 43

6-7 Compressor Oil Failure Switch - 3PS

Manual Reset, Time Delay

This differential pressure switch continuously compares oil pressure with suction pressure to

provide protection against low net oil pressure. It has a two (2) -minute delay to avoid nuisance

shutdowns due to momentary low fluctuations of oil pressure due to oil foaming, etc.

6-8 Low Pressure Switch - 9PS, 5TR, 3TAS

Manual Reset, Time Delay

This switch stops the compressor in the event of sustained low suction pressure, possibly caused

by inadequate refrigerant flow, chilled water flow, fan failure, coil blockage, or refrigerant loss

of charge. It has a two (2) -minute delay to avoid nuisance shutdowns during transient

conditions.

Low ambient option ACOA units have a two (2) -minute timer (

pressure time delay to four (4) minutes at the start of the compressor. This only occurs when the

3TAS thermostat senses ambient temperature below 40ºF (4ºC).

5TR) that extends the low

6-9 Fan Pressure Switch - 10PS, 11PS

Auto, Reverse Acting

This switch (in multiple) stages condenser fans on and off to maintain adequate high side

pressures for proper system operation by controlling net air flow across the condenser coils. See

Figure 20 on Page 39 for more information.

6-10 Compressor Cycle Timer - 1TR

This timer prevents rapid compressor recycling by providing a five (5) -minute compressor lockout immediately after any shutdown. The 12 restarts-per-hour limit protects the compressor

motor and bearings.

6-11 Timer - 4TR

This timer, used on multi-compressor units, provides staggered compressor starting. This feature

lets you avoid simultaneous compressor starts which can over-tax the main power supply.

Page 42

ACOA Series Air-Cooled Central Chillers

Page 44

6-12 Contactors - M

Contactors, operated by the control circuit, provide power individually to the compressor and fan

motors. Contactors are used either singly or in parallel pairs for across-the-line (simultaneous

operation) start. These devices are sized to handle rated load amps and locked rotor amps.

6-13 Relays - CR

These relays provide the necessary circuit logic for lock-in, lock-out, and transfer functions.

6-14 Crankcase Heater - HTR

The crankcase heater is continuously energized when main power is supplied to the chiller and

the compressor is off. It maintains crankcase temperature above the system temperature during

the Compressor Off cycle, preventing refrigerant migration into the crankcase and consequent

compressor damage.

6-15 Operating Thermostat - 4TAS

This thermostat senses From Process chilled water temperature and cycles the compressor

on/off or unloads a compressor as the system load changes. A two-stage device is used on single

compressor units with one stage of cylinder unloading. A four-stage device is used on single

compressor units with two stages of cylinder unloading and on two compressor units.

6-16 Liquid Line Solenoid Valve - SOL

This valve closes when the compressor(s) is/are off to prevent any liquid refrigerant from

accumulating in the chiller during the off cycle.

6-17 Unloading Solenoid Valve

This solenoid is energized to unload a cylinder bank on the compressor.

ACOA Series Air-Cooled Central Chillers Page 43

Page 45

6-18 Motor Overload Protection - 1TAS

Automatic Reset

This solid-state device monitors the internal temperature of the compressor motor. If the

maximum motor temperature is exceeded, the compressor will shut down. To reset the

monitor, open the control switch for five (5) seconds.

1TAS

6-19 Undervoltage Relay - UVR

Optional

This optional device protects the ACOA chiller from damaging undervoltage, phase reversal and

single phasing conditions. If the UVR device trips, a control relay de-energizes and opens the

control circuit. An LED on the

UVR device indicates a normal power supply.

6-20 Fan Speed Control - SCR

The fan speed control varies the speed of the fan, depending on head pressure. When discharge

pressure is 140 psig (965 kPa/9.65 bars) or below, the fan is at minimum speed. As discharge

pressure rises, the fan speed increases proportionally until it reaches full speed at 200 psig (1,379

kPa/13.79 bars).

Page 44

ACOA Series Air-Cooled Central Chillers

Page 46

7 Maintenance

7-1 Making Periodic Inspections

A program of regular inspection, cleaning and preventive maintenance by trained personnel will

contribute greatly to the long satisfactory service life of your ACOA central chiller.

Read essential temperatures and pressures periodically to see that they indicate normal operation.

Record these readings on a log sheet. Refer to the sample log sheet on Page 52. If any abnormal

operation is observed, try to determine cause and remedy it. See Chapter 8 on Page 49 for more

information on troubleshooting.

7-2 Making Monthly Inspections

• Wipe down external surfaces on the unit.

• Shut down the unit, open the main disconnect, and inspect the control panel, checking for

loose wires, burned contacts, signs of overheated wires, etc.

• Restart the unit and check performance of controls.

• Check sight glasses for proper refrigerant charge.

7-3 Maintaining the Evaporator and Condenser

The efficient performance of evaporator and condenser heat transfer surfaces is essential for

efficient performance of your ACOA central chiller. If these surfaces accumulate a film of dirt,

scale or slime, performance efficiency degrades substantially. The refrigerant side of heat

transfer surfaces does not foul, since refrigerant is a good solvent and it is in a closed, filtered

cycle.

Water side surfaces can foul from the water system. A program of water treatment can slow the

rate of fouling on heat transfer surfaces, but not eliminate it.

7-4 Cleaning the Evaporator

You can detect the effects of fouling by recording full load performance data on the log sheet. If

the difference between leaving water from the evaporator and saturated suction temperature at

the compressor is 2º greater than the difference recorded at clean conditions, the tubes should be

cleaned. You should clean the evaporator water side surfaces at least annually, and more often

if you use severely fouled water. Do this cleaning with the appropriate cleaning chemicals.

ACOA Series Air-Cooled Central Chillers Page 45

Page 47

When using chemicals for cleaning, pump a caustic solution through the heat exchanger. The

chemicals attack dirt, slime, and mineral deposits and flushes them away. Water treatment

specialists can recommend appropriate chemicals.

Rinse the system thoroughly after cleaning to remove the chemicals before they attack the metal

surfaces. You cannot be physically clean the evaporator side because of the cross-flow baffle

construction.

7-5 Cleaning Air Cooled Condensers

Clean the face of the condenser at least once a month during operation. If conditions are bad

and condensers pick up dirt very quickly, clean them more frequently. If you allow the condenser

to get too dirty, the unit runs a high head pressure and does not provide satisfactory performance.

Clean dirty coils with a soft brush, by flushing with cool water, or by using commerciallyavailable coil cleaners. Do not use hot water or steam. Doing so causes excessive pressure in

the system. Clean the face of the condenser at the beginning of the season and periodically

thereafter as conditions require.

7-6 Protections Against Electrical Malfunctions

The unit has four devices designed to protect compressor motors and manual motor controllers

from electrical malfunction:

• Circuit breakers

• Starter overload relays

• Under voltage relay (optional)

• Motor over temperature protectors

If the undervoltage relay trips, it is a sign of trouble in incoming power. If it trips again after

resetting, call your electric utility to investigate the problem. If circuit breaker or motor overload

relay or motor overtemperature protectors trip, it is a sign of possible motor trouble. DO NOT

reset and try to run compressor again. Call an authorized service representative to check for

motor trouble. Resetting these safety devices and then starting the unit repeatedly could turn a

minor motor problem into a costly major motor burnout.

7-7 Maintaining Compressors

Discus compressors have four components you can replace: the suction strainer, oil pump,

cylinder heads, and valve plates.

Page 46

ACOA Series Air-Cooled Central Chillers

Page 48

If a component other than those listed fails, the compressor requires replacement. Return the

compressor to your local Copeland distributor for replacement.

Compressor bolt torque values

Component ft.-lbs. N•m

Bottom plate 33 ft.-lb. 45 N•m

Housing cover 33 ft.-lb. 45 N•m

Oil pump to housing cover 23 ft.-lb. 29 N•m

Cylinder head 42 to 50 ft.-lbs. 57 to 68 N•m

Oil screen cover 50 ft.-lb. 68 N•m

Crankcase heater plug 38 ft.-lb. 52 N•m

Discharge valve 42 ft.-lb. 57 N•m

Suction valve - 1/2” 42 ft.-lb. 57 N•m

Suction valve: 5/8” 80 ft.-lb. 109 N•m

Capacity control valve 42 ft.-lb. 48 N•m

Pipe plug, 1/4” 23 ft.-lb. 32 N•m

Pipe plug, 1/8” 17 ft.-lb. 23 N•m

Oil sight glass 3 ft.-lb. 4 N•m

To convert inches to millimeters, multiply by 25.4. If

applicable, customer is responsible to convert to

metric.

7-8 The Refrigerant Charge

All ACOA central chiller units are given a complete charge of refrigerant at the factory. The type

and amount of refrigerant required is in Figure 1 on Page 9. The total refrigerant listed is for the

entire system. Since these units have separate circuits, each circuit should be considered

separately for charging.

To check for proper refrigerant charge, look in each liquid line sight glass with the aid of a

flashlight during system operation. At all operating conditions, the sight glass should be clear. If

bubbles are visible at any operating condition, the circuit is short of charge or there may be a

restriction.

Be careful not to overcharge the chiller. Overcharging results in considerable liquid logging in

the condenser and excessive condensing pressure. Only a trained technician familiar with

refrigeration should perform this task.

To add refrigerant, connect a refrigerant vessel to the ¼” backseating port of the suction valve.

Purge the air from the tube with refrigerant gas before connecting. With the unit running, open

the refrigerant vessel vapor connection slightly. Refrigerant more readily flows from the vessel

into the unit if the refrigerant vessel is warmer than the cooler.

ACOA Series Air-Cooled Central Chillers Page 47

Page 49

To determine the proper refrigerant charge, check the amount of subcooling at design full load

conditions. The amount of subcooling at the liquid line (liquid line saturation temperature

corresponding to liquid line pressure minus liquid line temperature) should be between 15ºF and

20ºF (-9ºC and -6ºC).

Subcooling at the condenser out-subcooler inlet trap should not exceed 5ºF (-15ºC). The sight

glass should be clear with no bubbles.

7-9 Preventive Maintenance Service

Following a systematic preventive maintenance program helps you avoid costly down time. Call

the Application Engineering Service Department at AEC, Inc. to arrange a schedule of

inspections.

This service, described in AEC, Inc. Bulletin No. 10-106.3, is tailored to fit your maintenance

requirements. Inspections include:

Check refrigerant suction and discharge pressures.

Check safety and operating controls.

Check voltage and amperage of all motors.

Check all electrical connections.

Check quantity of refrigerant.

Check compressor oil level.

Check lubrication of motor and pump bearings.

Check circulating pump operation.

Check flow through heat exchangers.

Check compressor efficiency.

Check noise levels.

Check cleanliness of equipment area.

Page 48

ACOA Series Air-Cooled Central Chillers

Page 50

8 Troubleshooting

Symptom Possible cause Solution

Chiller does not start. Power off. Check main disconnect

switch.

Main line open. Check main fuses.

No control voltage. Check control terminal block

for 115 VAC.

Loose terminals. Tighten terminals.

Control circuit open. Check fuses, control

switches, and field-installed

interlocks, pressure and

temperature controls, and

readouts.

Incorrect phase sequence

(UVR option).

Compressor hums but does

not start.

No power on one phase of

Compressor cycles on low

pressure control.

No load on chiller. Check pump operation and

Restriction in liquid line. (a) Plugged filter-dryer. If

Head pressure too low. Fan cycle switches set too

Low voltage. Check at main entrance and

three-phase unit.

Refrigerant shortage. Check for leaks and add

Reverse incoming power

sequence.

at unit. Consult power

company if voltage is low,

and increase wire size to the

unit if voltage is normal at

main and low at unit. Voltage

must be within 10% of motor

nameplate rating.

Check fuses and wiring.

refrigerant.

water flow.

temperature drop exists

across the dryer, remove

and replace cores.

(b) Liquid line or suction

valve partially closed. Open

valves fully and close in one

full turn.

(c) Expansion valve clogged

or inoperative. Check

superheat setting. Check

charge and thermo bulb.

low. Check and reset.

ACOA Series Air-Cooled Central Chillers Page 49

Page 51

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Symptom Possible cause Solution

Compressor cycles on low

pressure control.

Improper water flow. Check pressure drop across

evaporator for proper flow.

Fouled evaporator. Backflush and/or clean.

Compressor cycles off on

high pressure control.

Compressor discharge valve

partially closed.

Open valve fully and close with

one turn.

Air in system. Purge condenser coils.

Overcharge of refrigerant. Reclaim system while in

operation until bubbles show in

sight glass. Close valve and

add small amount of

refrigerant until sight glass just

clears.

High pressure control

Adjust the control.

improperly set.

Condenser fan inoperative. Check, replace or repair set

screw (pulley), fan motor, or

inoperative fan control.

Dirty condenser. Clean condenser surfaces with

brush and/or vacuum.

Fan cycle switches

Check and readjust.

inoperative or set too high.

Fan motors not running. Check contactor, check motor,

check capacitor (if single

phase).

Fan motor reverse rotation. Reverse two fan motor leads

(three-phase only).

Figure 21

ACOA Load Points

ACOA Isolator weights Oper.

model Dimensions (inches) Load by position (lbs.)

number A B C D E #1 #2 #3 #4 #5 #6 #7 #8 lbs.

COA15 19.0” 83.0” 37.3 543 378 572 372 1,865

COA20 19.0” 83.0” 37.3 595 421 606 395 2,107

COA25 19.0” 83.0” 37.3 651 471 653 433 2,208

COA30 19.0” 69.0” 119.0” 37.3 597 487 298 608 476 281 2,747

COA35 19.0” 69.0” 119.0” 37.3 640 525 309 638 498 285 2,895

COA45 19.0” 83.0” 80.3” 1,025 867 1,140 997 4,029

COA55 19.0” 69.0” 119.0” 80.3” 974 780 341 1,045 1,047 554 4,741

COA70 19.7” 69.0” 119.0” 80.3” 1,024 952 593 1,112 1,103 608 5,392