Page 1

ADAM-5000 Series

RS-485 Based Data Acquisition

and Control System

User's Manual

Page 2

Copyright Notice

This document is copyrighted, 2000, by Advantech Co., Ltd. All

rights are reserved. Advantech Co., Ltd., reserves the right to make

improvements to the products described in this manual at any time

without notice.

No part of this manual may be reproduced, copied, translated or

transmitted in any form or by any means without the prior written

permission of Advantech Co., Ltd. Information provided in this

manual is intended to be accurate and reliable. However, Advantech Co., Ltd. assumes no responsibility for its use, nor for any

infringements upon the rights of third parties which may result from

its use.

Acknowledgments

ADAM is a trademark of Advantech Co., Ltd.

IBM and PC are trademarks of International Business Machines

Corporation.

CE Notification

The ADAM-5000/485 series developed by Advantech Co., Ltd. has

passed the CE test for environmental specifications. Test conditions for passing included the equipment being operated within an

industrial enclosure, using shielded twisted-pair RS-485 cables and

having SFC-6 sleeve core clamps added to the power cable and the

RS-485 cable. In order to protect the ADAM-5000/485 system from

being damaged by ESD (Electrostatic Discharge) and EMI leakage,

we strongly recommend the use of CE-compliant industrial enclosure products, shielded twisted-pair RS-485 cables, and core

clamps.

FM Notification

Advantech’s ADAM-5000 series has passed the FM certification.

According to National Fire Protection Association, work sites are

classified into different classes, divisions and groups based on

hazard considerations. ADAM-5000 series is compliant with the

specifications of Class I, Division 2, Groups A, B, C, and D indoor

hazardous. The FM approval report Job ID is 3000008.

Part No.2000500031 4th Edition

Printed in T aiwan. April 2000

Page 3

A Message to the Customer...

Advantech Customer Services

Each and every Advantech product is built to the most exacting

specifications to ensure reliable performance in the unusual and

demanding conditions typical of industrial environments. Whether

your new Advantech equipment is destined for the laboratory or

the factory floor, you can be assured that your product will provide

the reliability and ease of operation for which the name Advantech

has come to be known.

Your satisfaction is our number one concern. Here is a guide to

Advantech’s customer services. To ensure you get the full benefit

of our services, please follow the instructions below carefully .

Technical Support

W e want you to get the maximum performance from your products.

So if you run into technical difficulties, we are here to help. For

most frequently asked questions you can easily find answers in

your product documentation. These answers are normally a lot

more detailed than the ones we can give over the phone.

So please consult this manual first. If you still can’t find the answer,

gather all the information or questions that apply to your problem

and, with the product close at hand, call your dealer. Our dealers

are well trained and ready to give you the support you need to get

the most from your Advantech products. In fact, most problems

reported are minor and are able to be easily solved over the phone.

In addition, free technical support is available from Advantech

engineers every business day. We are always ready to give advice

on application requirements or specific information on the installation and operation of any of our products.

Page 4

Product Warranty

Advantech warrants to you, the original purchaser, that each of its

products will be free from defects in materials and workmanship for

one year from the date of purchase.

This warranty does not apply to any products which have been

repaired or altered by other than repair personnel authorized by

Advantech, or which have been subject to misuse, abuse, accident

or improper installation. Advantech assumes no liability as a

consequence of such events under the terms of this Warranty.

Because of Advantech’s high quality-control standards and

rigorous testing, most of our customers never need to use our

repair service. If an Advantech product ever does prove defective,

it will be repaired or replaced at no charge during the warranty

period. For out-of-warranty repairs, you will be billed according to

the cost of replacement materials, service time and freight. Please

consult your dealer for more details.

If you think you have a defective product, follow these steps:

1 . Collect all the information about the problem encountered (e.g.

type of PC, CPU speed, Advantech products used, other

hardware and software used etc.). Note anything abnormal and

list any on-screen messages you get when the problem occurs.

2 . Call your dealer and describe the problem. Please have your

manual, product, and any helpful information readily available.

3. If your product is diagnosed as defective, you have to request

an RAM number. When requesting an RMA (Return Material

Authorization) number, please access ADVANTECH's RMA

website: http://www .advantech.com.tw/rma. If the web sever is

shut down, please contact our office directly . You should fill in

the "Problem Repair Form", describing in detail the application

environment, configuration, and problems encountered. Note

that error descriptions such as "does not work" and "failure"

are so general that we are then required to apply our internal

standard repair process.

Page 5

4 . Carefully pack the defective product, a completely filled-out

Repair and Replacement Order Card and a photocopy of dated

proof of purchase (such as your sales receipt) in a shippable

container. A product returned without dated proof of purchase

is not eligible for warranty service.

5. Write the RMA number visibly on the outside of the package

and ship it prepaid to your dealer.

Page 6

Contents

Chapter 1 Introduction ............................................................ 1-1

1.1 Overview.................................................................. 1-2

1.2 System Configuration ............................................... 1-3

1.3 A Few Steps to a Successful System ...................... 1-4

Chapter 2 Installation Guideline ........................................... 2-1

2.1 General ..................................................................... 2-2

2.2 Module Installation ................................................... 2- 6

2.3 I/O Slots and I/O Channel Numbering ..................... 2-6

2.4 Mounting................................................................... 2- 7

2.5 Wiring and Connections............................................ 2-9

Chapter 3 ADAM-5000 System ................................................ 3-1

3.1 Overview.................................................................. 3-2

3.2 Major Features of the ADAM-5000

System...................................................................... 3-2

3.3 System Setup............................................................ 3-6

3.4 T echnical Specifications of the

ADAM-5000 ............................................................ 3-7

Chapter 4 I/O Modules ............................................................ 4-1

4.1 RTD Input Module ................................................... 4- 2

4.2 ADAM-5013 RTD Input Resistance

Calibration ................................................................ 4-5

4.3 Analog Input Modules .............................................. 4-7

4.4 Analog Output Modules ......................................... 4-15

Page 7

4.5 Analog I/O Modules Calibration............................. 4-18

4.6 Digital Input/Output Modules ................................. 4-24

4.7 Relay Output Modules............................................ 4-38

4.8 Counter/Frequency Module.................................... 4-41

Chapter 5 Software Utilities ...................................................5-1

5.1 ADAM Utility Software........................................... 5-2

5.2 DLL (Dynamic Link Library) Driver ....................... 5-8

5.3 DDE (Dynamic Data Exchange) Server ................. 5-9

5.4 ADAM-4000 and ADAM-5000

Windows Utility ...................................................... 5-10

5.4.1 Overview ........................................................................ 5-10

5.4.2 Save Function ................................................................. 5-11

5.4.3 COM Port Settings ........................................................ 5-12

5.4.4 Search Connected modules ............................................. 5-13

5.4.5 Terminal Emulation ........................................................ 5-14

5.4.6 Data Scope ..................................................................... 5-16

5.4.7 Saving a Module’ s Configuration to File ........................ 5-17

5.4.8 Load Module’s Configuration File ................................. 5-19

5.4.9 Module Configuration .................................................... 5-21

5.4.10 Module Calibration ........................................................ 5-23

5.4.11 Data Input and Output .................................................. 5-25

5.4.12 Alarm Settings ................................................................ 5-27

5.4.13 Download Procedure ...................................................... 5-28

Chapter 6 Command Set ........................................................ 6-1

6.1 Introduction .............................................................. 6-2

6.2 Syntax....................................................................... 6-2

6.3 CPU Command Set.................................................. 6-4

6.4 ADAM-5013 RTD Input Command Set................ 6-19

6.5 Analog Input Command Set ................................... 6-37

6.6 ADAM-5017H Analog Input Command Set ......... 6-57

6.7 Analog Input Alarm Command Set ........................ 6-71

Page 8

6.8 Analog Output Command Set ................................ 6-90

6.9 Digital Input/Output Command Set ...................... 6-107

6.10 ADAM-5080 Counter/Frequency

Command Set ........................................................6-115

Chapter 7 Troubleshooting .....................................................7-1

7.1 Hardware Diagnosis ................................................. 7-2

7.2 Software Diagnosis .................................................. 7-2

7.3 System Indicators ..................................................... 7-3

7.4 Communication Problems......................................... 7-5

7.5 I/O Module Troubleshooting..................................... 7-6

Chapter A Quick Start Example ............................................ A-1

A.1 System Requirements to Setup an

ADAM-5000 System .............................................. A-2

A.2 Basic Configuration Hook-up .................................. A-5

A.3 Baud Rate and Checksum........................................ A-8

A.4 A Distributed ADAM-5000 Network

System Hook-up .................................................... A-1 1

Chapter B Data Formats and

I/O Ranges ............................................................ B-1

B.1 Analog Input Formats.............................................. B-2

B.2 Analog Input Ranges - ADAM-5017 and 5018 ...... B-4

B.3 Analog Input Ranges of ADAM-5017H................. B-7

B.4 Analog Output Formats ........................................... B-8

B.5 Analog Output Ranges ............................................ B-8

B.6 ADAM-5013 RTD Input Format and Ranges ........ B-9

Chapter C RS-485 Network .................................................... C-1

C.1 Basic Network Layout ............................................ C-3

Page 9

C.2 Line T ermination...................................................... C-6

C.3 RS-485 Data Flow Control...................................... C-9

Chapter D How to Use the

Checksum Feature ............................................... D-1

D.1 Checksum Enable/Disable....................................... D-2

Chapter E ADAM-4000/5000 System

Grounding Installation ......................................... E-1

E. 1 Power Supplies For relevant wiring issues,

please refer to the following scheme :......................E-2

E.2 Grounding Installation ............................................... E-2

E.3 External DI, DO, AI, AO Wiring Reference ...........E-3

E.4 Requirements for RS-485 signal wires .....................E-3

E.5 Grounding reference (Ground bar for the factory

environment should have a standard resistance

below 5 W)...............................................................E-5

E.6 Some Suggestions on W iring Layout ........................E-6

Chapter F Grounding Reference .......................................... F-1

F.1 Grounding .................................................................F-3

F.2 Shielding ...................................................................F-9

F .3 Noise Reduction T echniques.................................. F-14

F.4 Check Point List ..................................................... F-15

Page 10

Figures

Figure 1-1: ADAM-5000 System Configurations ................................. 1-3

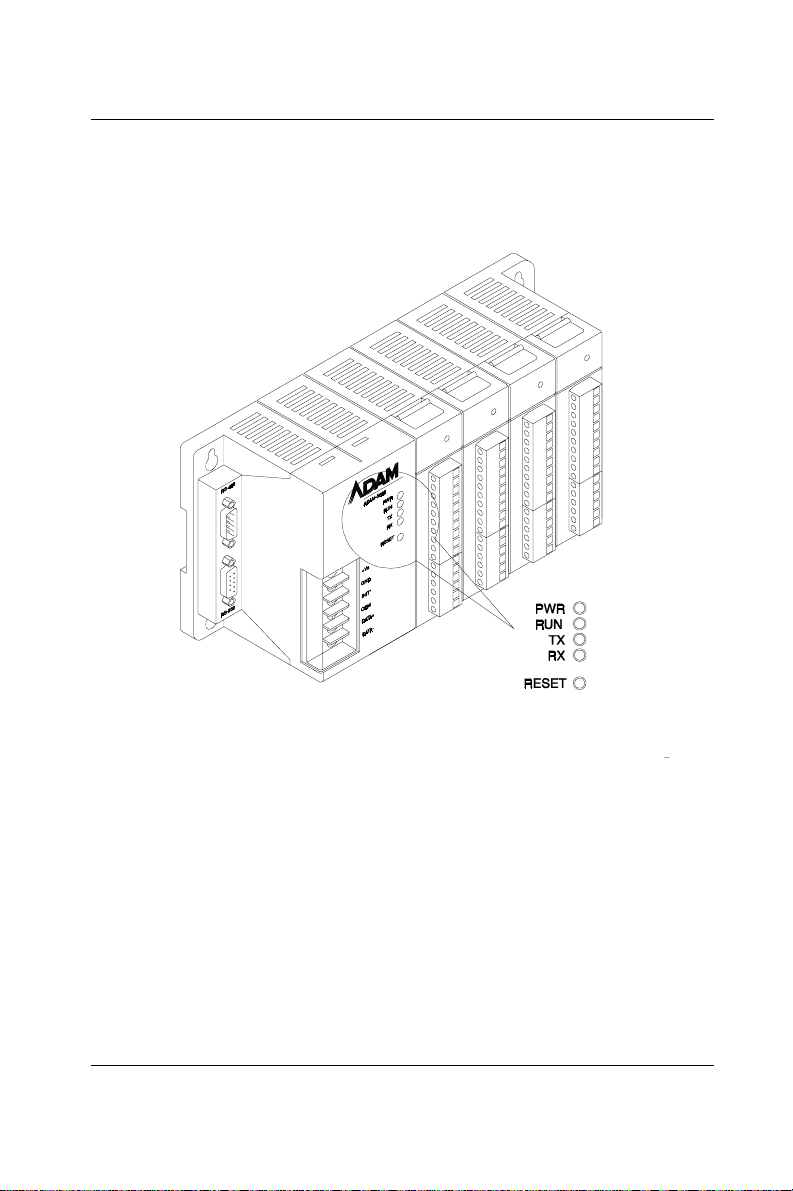

Figure 2-1: ADAM-5000 Diagnostic indicators .................................... 2-3

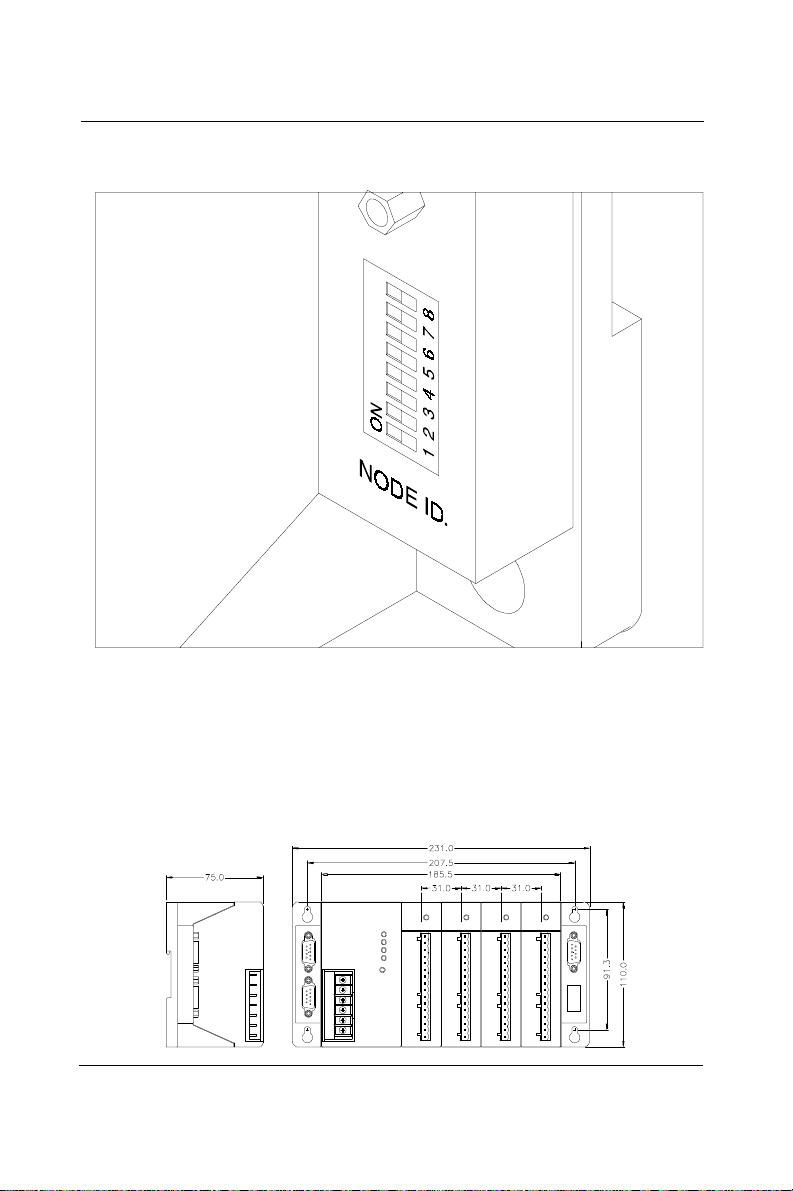

Figure 2-2: ADAM-5000 Network address DIP switch ........................ 2-4

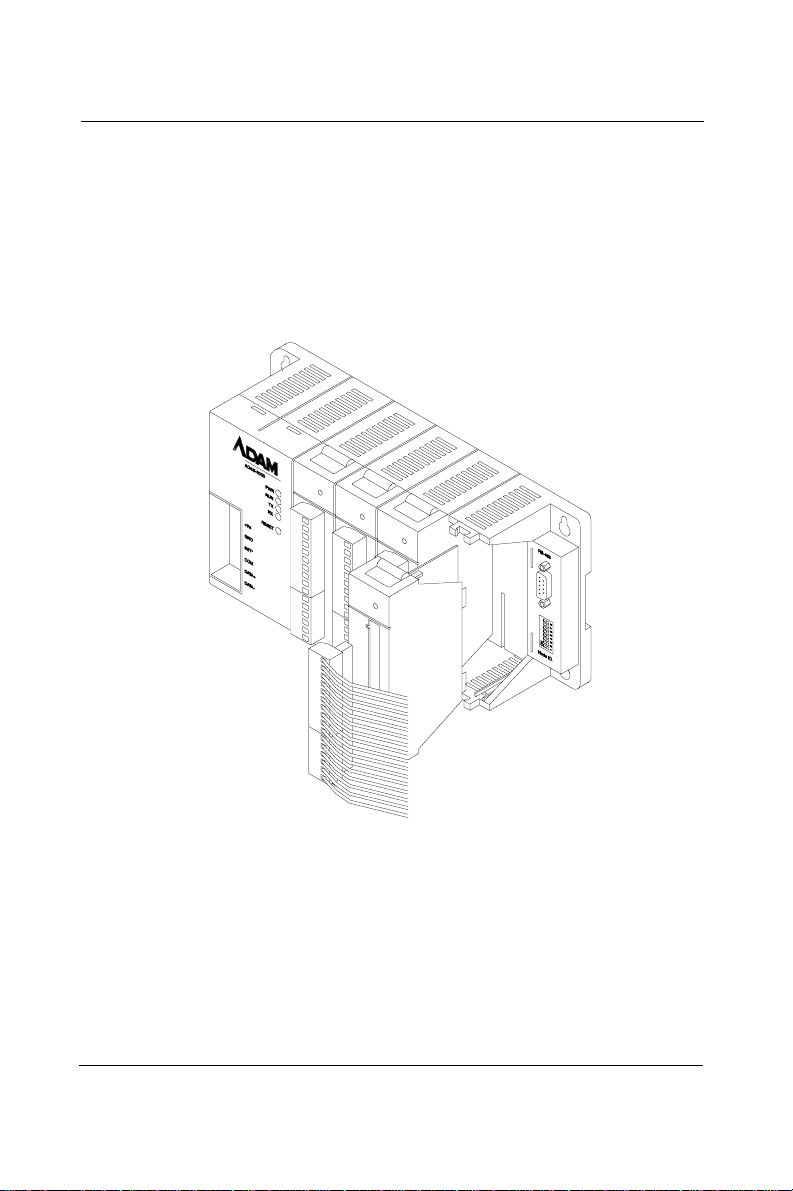

Figure 2-3: Module alignment and installation ................................... 2-6

Figure 2-4: ADAM-5000 Panel mounting ............................................ 2-7

Figure 2-5: ADAM-5000 Rail mounting ............................................... 2-8

Figure 2-6: ADAM-5000E Rail mounting ............................................. 2-9

Figure 2-7: ADAM-5000 Wiring and connections .............................. 2-10

Figure 2-8: Built-in Communication Ports for Diagnostic

Connection ...................................................................... 2-13

Figure 2-9: Flexible Communication Port Function Connection ....... 2-14

Figure 3-1: Function block diagram .................................................... 3-8

Figure 4-1: ADAM-5013 module frontal view ....................................... 4-2

Figure 4-2: RTD inputs ........................................................................ 4-3

Figure 4-3: Applying calibration resistance ........................................ 4-5

Figure 4-4: ADAM-5017 module frontal view ....................................... 4-7

Figure 4-5: Millivolt and volt input ........................................................ 4-8

Figure 4-6: Process current input ....................................................... 4-8

Figure 4-7: ADAM-5017H module frontal view ..................................4-10

Figure 4-8: Millivolt and volt input ...................................................... 4-11

Figure 4-9: Process current input ..................................................... 4-11

Figure 4-10: ADAM-5018 module frontal view ..................................... 4-14

Figure 4-11: Thermocouple input ........................................................ 4-14

Figure 4-12: ADAM-5024 module frontal view ..................................... 4-16

Figure 4-13: Analog output .................................................................. 4-17

Figure 4-14: Applying calibration voltage ............................................ 4-18

Figure 4-15: Zero calibration ...............................................................4-19

Figure 4-16: Span calibration .............................................................. 4-19

Figure 4-17: Cold junction calibration ................................................. 4-20

Figure 4-18: Output module calibration ..............................................4-23

Figure 4-19: Dip switch setting for digital I/O channel ........................ 4-25

Figure 4-20: ADAM-5050 module frontal view ..................................... 4-25

Page 11

Figure 4-21: Dry contact signal input (ADAM-5050) ............................ 4-25

Figure 4-22: Wet contact signal input (ADAM-5050) ........................... 4-26

Figure 4-23: Digital output used with SSR (ADAM-5050/5056) .......... 4-26

Figure 4-24: ADAM-5051 module frontal view ..................................... 4-27

Figure 4-25: TTL input (ADAM-5051) ...................................................4-28

Figure 4-26: Contact closure input (ADAM-5051) ............................... 4-28

Figure 4-27: ADAM-5051D Module ...................................................... 4-29

Figure 4-28: TTL Input (ADAM-5051D) ................................................ 4-30

Figure 4-29: Contact Closure Input (ADAM-5051D) ............................ 4-30

Figure 4-30: ADAM-5052 module frontal view ..................................... 4-31

Figure 4-31: Isolated digital input (ADAM-5052) ................................. 4-31

Figure 4-32: ADAM-5056 module frontal view ..................................... 4-32

Figure 4-33: Digital output used with SSR (ADAM-5050/5056) .......... 4-33

Figure 4-34: ADAM-5056D Module ...................................................... 4-34

Figure 4-35: ADAM-5056D Application Wiring .................................... 4-35

Figure 4-36: ADAM-5060 module frontal view ..................................... 4-38

Figure 4-37: Relay output .................................................................... 4-38

Figure 4-38: ADAM-5068 module frontal view ..................................... 4-39

Figure 4-39: Relay output .................................................................... 4-40

Figure 4-40: ADAM-5080 Module ........................................................ 4-42

Figure 4-41: Isolated Input Level .........................................................4-42

Figure 4-42: TTL Input Level ................................................................ 4-43

Figure 4-43: Counter / Frequency Mode .............................................. 4-43

Figure 4-44: Wiring for Up/Down Counting ......................................... 4-44

Figure 4-45: Wiring for Bi-direction Counting ...................................... 4-45

Figure 4-46: Wiring for Frequency Mode ............................................. 4-45

Figure 4-47: Setting Alarm Limit .......................................................... 4-46

Figure 4-48: Sending Alarm Signal (recommended settings) ........... 4-47

Figure 4-49: Sending Alarm Signal (settings not recommended) ..... 4-47

Figure 4-50: Digital Output Mapping ................................................... 4-49

Figure 4-51: Jumper Location on the ADAM-5080 Module ................. 4-50

Figure 4-52: TTL/Isolated Input Level Selectting ................................ 4-50

Figure 5-1: Main screen ...................................................................... 5-3

Figure 5-2: Setup options .................................................................... 5-4

Figure 5-3: Zero Calibration ................................................................ 5-6

Figure 5-4: Terminal emulation ........................................................... 5-7

Figure 5-5: Display the connected module ....................................... 5-11

Page 12

Figure 5-6: Save the information of connected modules to txt file .... 5-12

Figure 5-7: Setup options .................................................................. 5-12

Figure 5-8: Checksum function enabled ..........................................5-15

Figure 5-9: The connection for the Data Scope function .................. 5-16

Figure 5-10: Monitor the issuing commands from PC#1 ................... 5-17

Figure 6-1: Baud rate codes ................................................................ 6-6

Figure 6-2: Analog module error codes ............................................ 6-18

Figure 6-3: Data format for 8-bit parameters ....................................6-38

Figure 6-4: Data format of 8-bit parameters ..................................... 6-92

Figure A-1: Power supply connections ............................................... A-4

Figure A-2: ADAM-5000 system hook-up and configuration ............... A-6

Figure A-3: Grounding the INIT* terminal .......................................... A-10

Figure A-4: ADAM-5000 network system hook-up ............................ A-11

Figure C-1: Daisychaining .................................................................. C-3

Figure C-2: Star structure .................................................................... C-4

Figure C-3: Random structure ............................................................ C-5

Figure C-4: ADAM-4000 and ADAM-5000 in a network ...................... C-6

Figure C-5: Signal distortion ............................................................... C-7

Figure C-6: Termination resistor locations ......................................... C-8

Figure C-7: RS-485 data flow control with RTS .................................. C-9

Figure E-1: Grounding Scheme ......................................................... E-2

Figure E-2: External Terminal Block and Fan ..................................... E-3

Figure E-3: Grounding for on-site facilities and ADAM-5000/4000

Systems ........................................................................... E-4

Figure E-4: Grounding for signal wires .............................................. E-4

Figure E-5 : Grounding Reference ...................................................... E-5

Figure F-1: Think the EARTH as GROUND......................................... F-3

Figure F-2: Grounding Bar. .................................................................. F-4

Figure F-3: Normal mode and Common mode. ................................. F-5

Figure F-4: Normal mode and Common mode. ................................. F-6

Figure F-5: The purpose of high voltage transmission ...................... F-7

Figure F-6: wire impedance. ............................................................... F-7

Figure F-7: Single point groundinF. (1) ............................................... F-8

Figure F-8: Single point groundinF. (2) ............................................... F-9

Figure F-9: Single isolated cable ........................................................ F-9

Figure F-10: Double isolated cable ..................................................... F-10

Page 13

Figure F-11: System Shielding ............................................................ F-11

Figure F-12: The characteristic of the cable ........................................ F-12

Figure F-13: System Shielding (1) ...................................................... F-13

Figure F-14: System Shielding (2) ...................................................... F-13

Figure F-15: Noise Reduction Techniques ......................................... F-15

Page 14

Tables

Table 4-1: Technical specifications of ADAM-5013 ............................. 4-4

Table 4-2: Calibration resistances of ADAM-5013 .............................. 4-6

Table 4-3: Technical specifications of ADAM-5017 ............................. 4-9

Table 4-4: Technical specifications of ADAM-5017H ........................ 4-12

Table 4-5: ADAM-5017H input signal ranges .................................... 4-13

Table 4-6: Technical specifications of ADAM-5018 ........................... 4-15

Table 4-7: Technical specifications of ADAM-5024 ........................... 4-17

Table 4-8: Calibration voltage of ADAM-5017/5018 .......................... 4-21

Table 4-9: Calibration voltage of ADAM-5017H ................................. 4-22

Table 4-10: Technical specifications of ADAM-5050 ........................... 4-27

Table 4-11: Technical specifications of ADAM-5051 ........................... 4-28

Table 4-12: Comparison between ADAM-5051 and ADAM-5051D .... 4-30

Table 4-13: Technical specifications of ADAM-5052 ........................... 4-32

Table 4-14: Technical specifications of ADAM-5056 ........................... 4-33

Table 4-15: Main Units Supporting Digital Output Holding Funciton .. 4-36

Table 4-16: Comparison between ADAM-5056 and ADAM-5056D .... 4-37

Table 4-17: Technical specifications of ADAM-5060 ........................... 4-39

Table 4-18: Technical specifications of ADAM-5068 ........................... 4-40

Table 4-19: ADAM-5080 technical specifications ................................4-51

Page 15

1

Introduction

Page 16

Introduction

1.1 Overview

The ADAM-5000 series is a complete product line that provides a wide

variety of features in a data acquisition and control application. It

includes 4 I/O-slots ADAM-5000/485 and 8 I/O-slots ADAM-5000E.

They are remotely controlled by the host computer through a set of

commands and transmitted in a RS-485 network. The system kernel is

small, but offers many good features to the users. The modular

design also provides more flexibility in the system configuration. The

following is a summary of the major ADAM-5000 system components.

ADAM-5000 System Kernel

The ADAM-5000/485 system kernel includes a CPU card, a power

regulator, a 4-slot base, a built-in RS-232 communication port and one

built-in RS-485 communication port. The 5000E system includes all of

the above components, except it has an 8-slot base. Details of the

system kernel features and more are covered in Chapter 3.

I/O Configuration

The ADAM-5000/485 CPU can support up to 64 I/O points with the 4slot base currently available.The ADAM-5000E CPU can support up to

128 I/O points with the 8-slot base currently available. These points

can be assigned as input or output points.

I/O Modules

The ADAM-5000 series has a complete range of I/O modules for your

applications. A full range of digital modules which support 10 to

30 VDC and relay outputs are offered. The analog modules provide

16-bit resolution and programmable input and output signal ranges

(including bipolar).

Software Utilities

There are some software utilities available to the ADAM-5000

systems. The DOS and Windows utility software helps you to

configure your ADAM-5000. The DLL (Dynamic Link Library) is

provided to write W indows applications, and the DDE (Dynamic Data

Exchange) server provides links to popular Windows packages such

as Intouch, FIX DMACS, Advantech GeniDAQ, etc.

1-2 ADAM-5000

Page 17

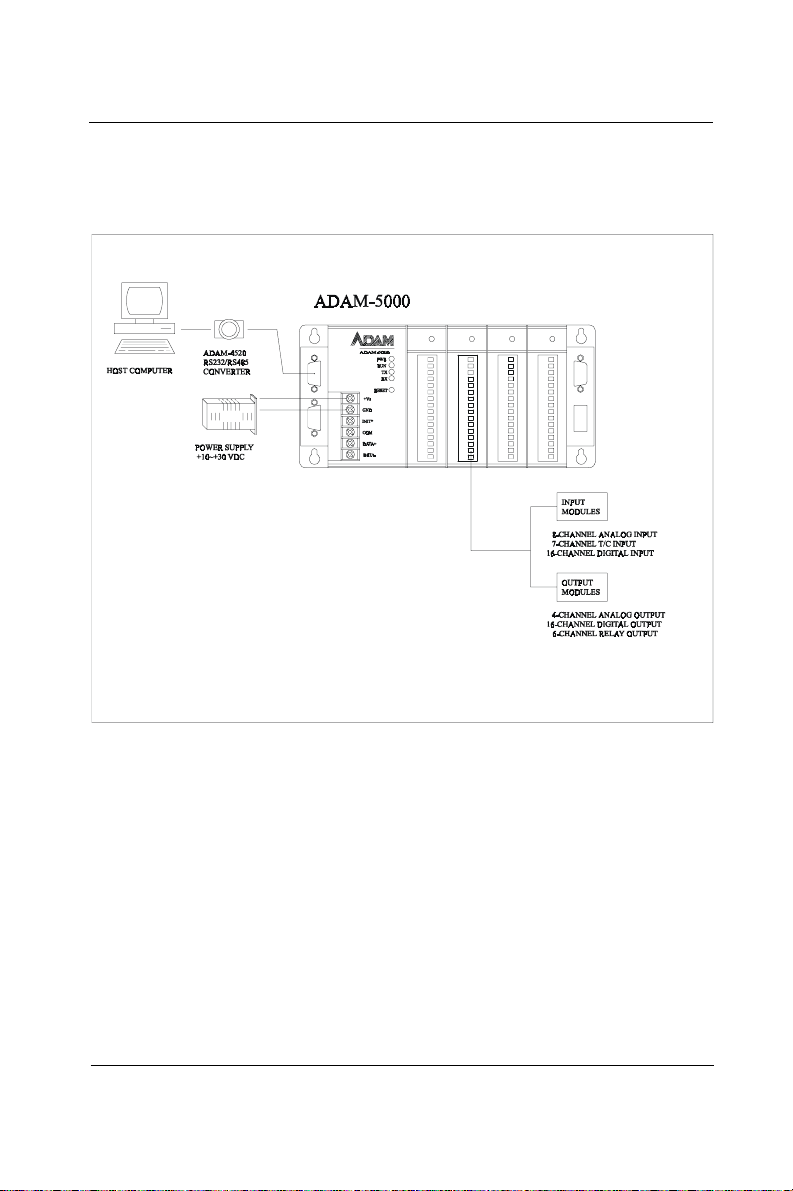

1.2 System Configuration

The following diagram shows the system configurations possible with

the ADAM-5000.

Chapter 1

Figure 1-1 ADAM-5000 System Configurations

Note: To avoid system over heating, only f our ADAM-5024

are allowed to be installed on AD AM-5000E.

ADAM-5000 1-3

Page 18

Introduction

1.3 A Few Steps to a Successful System

Step 1: Review the Installation Guideline

You should always make safety your first priority in any system

application. Chapter 2 provides several guidelines that will help

provide a safer, more reliable system.

Step 2: Understand the System Kernel

The system module is the heart of ADAM-5000 system. Make sure

you take time to understand the various features and setup requirements.

Step 3: Understand the I/O System Configurations

It is important to understand how your I/O modules can be configured.

It is also important to understand how the system power budget is

calculated. This can affect your I/O configuration.

Step 4: Understand the Utility Software

Before you begin to link your applications in your host computer with

the ADAM-5000 systems, it is very helpful to understand how the

DOS and Windows utility software helps you configure your

ADAM-5000.

Step 5: Review the Programming Concepts

All control systems differ in some areas. The ADAM-5000 system

allows you to develop your applications in DOS or Windows. It

provides an ASCII command set, DLL (Dynamic Library Link) and DDE

(Dynamic Data Exchange) server to you.

Step 6: Understand the Troubleshooting Procedures

Many things can be happened on the factory floor: switches fail, the

power supply is incorrect, etc. In most cases, the majority of the

troubleshooting time is spent trying to locate the problems. The

ADAM-5000 system has some built-in features that help you quickly

identify problems.

1-4 ADAM-5000

Page 19

2

Installation Guideline

Page 20

Installation Guideline

2.1 General

Environmental Specifications

The following table lists the environmental specifications that generally apply to the ADAM-5000 system (System kernel and

I/O modules).

Specification Rating

Storage temperature -13 to 185°F (-25 to 85°C)

Ambient operating

temperature

Ambient humidity* 5 to 95%, non-condensing

Atmosphere No corrosive gases

14 to 158°F (-10 to 70°C)

* Equipment will operate below 30% humidity . However , static

electricity problems occur much more frequently at lower humidity

levels. Make sure you take adequate precautions before you touch

the equipment. Consider using ground straps, antistatic floor coverings, etc. if you use the equipment in low humidity environments.

Power Requirements

Although the ADAM-5000 systems are designed for standard

industrial unregulated 24 VDC power supply, they accept any power

unit that supplies within the range of +10 to +30VDC. The power supply

ripple must be limited to 100 mV peak-to-peak, and the immediate ripple

voltage should be maintained between +10 and +30 VDC.

Diagnostic Indicators

Diagnostic indicators are located on the front panel of the ADAM

system. They show both normal operation and system status in your

remote I/O system. The indicators are:

• System status (PWR, RUN)

• Communication status (TX, RX)

• I/O module status

2-2 ADAM-5000

Page 21

Chapter 2

A complete description of the diagnostic indicators and how to use

them for troubleshooting is explained in Chapter 7.

Figure 2-1 ADAM-5000 Diagnostic indicators

Setting the Network Address Switch

Set the network address using the 8-pin DIP switch. Valid settings

range from 0 to 255 (00h to FFh) where ON in any of the 8 DIP switch

positions equates to a binary 1, and OFF equates to a binary 0.

For example, if the Node ID is 03h the DIP switch settings for switches

1 and 2 (representing bits 1 and 2) would both be ON while the rest of

the switches would be OFF . The default Node ID is 01h

ADAM-5000 2-3

Page 22

Installation Guideline

Figure 2-2 ADAM-5000 Network address DIP switch

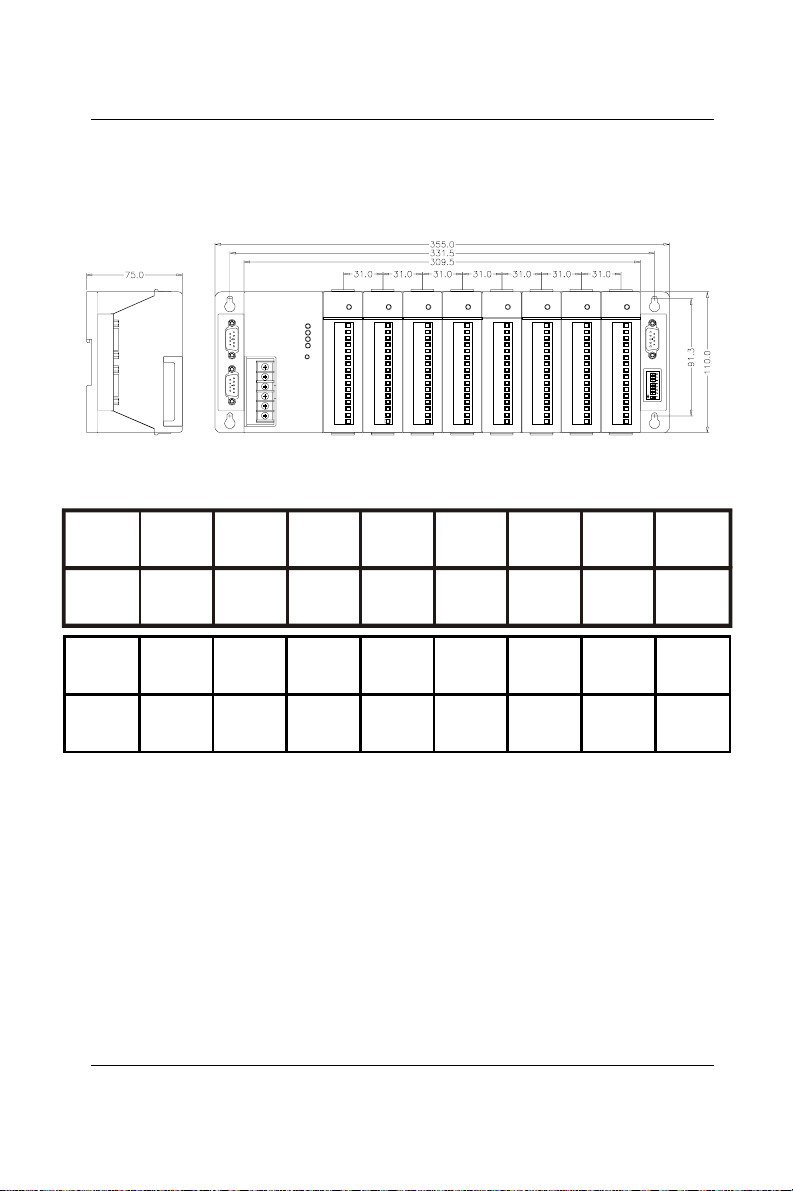

Dimensions and Weights (ADAM-5000)

The following diagrams show the dimensions of the system unit and

an I/O unit of the ADAM-5000. All dimensions are in millimeters.

2-4 ADAM-5000

Page 23

Chapter 2

Dimensions and Weights (ADAM-5000E)

The following diagrams show the dimensions of the system unit and

the I/O unit of the ADAM-5000E. All dimensions are in millimeters.

Module

Weight

Module

Weight

5000/485 5000E 5013 5017 5017H 5018 5024 5050

470g

5051 5051D 5052 5056 5056D 5060 5068 5080

65g 45g 68g 68g 45g 85g 65g 52g

ADAM-5000 2-5

45g525g 79g 45g 72g 75g 63g

Page 24

Installation Guideline

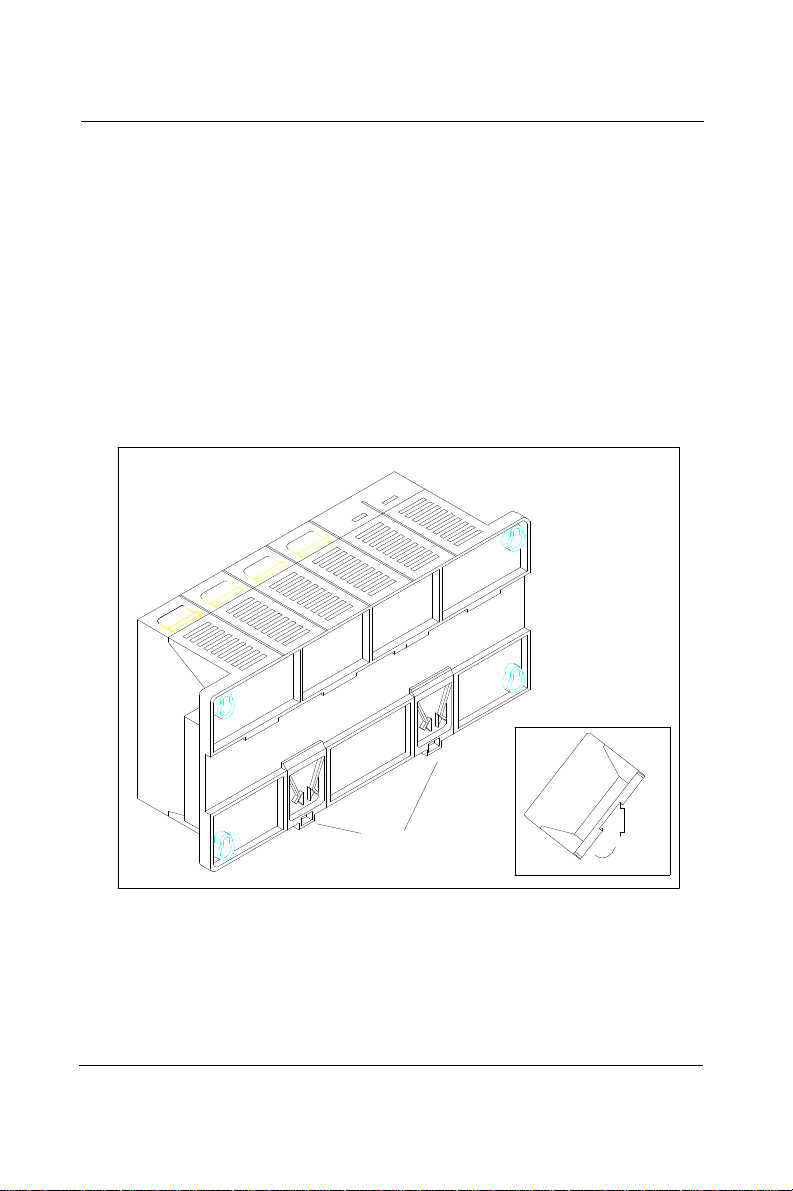

2.2 Module Installation

When inserting modules into the system, align the PC board of the

module with the grooves on the top and bottom of the system. Push

the module straight into the system until it is firmly seated in the

backplane connector. Once the module is inserted into the system,

push in the retaining clips (located at the top and bottom of the

module) to firmly secure the module to the system.

Figure 2-3 Module alignment and installation

2.3 I/O Slots and I/O Channel Numbering

The ADAM-5000/485 system each provides 4 slots for use with I/O

modules. The I/O slots are numbered 0 thru 3, and the channel

numbering of any I/O module in any slot starts from 0. The ADAM5000E system each provides 8 slots for use with I/O modules. The

slots are numbered 0 thru 7. For example, ADAM-5017 is a 8-channel

analog input module, its channel numbering is 0 through 7.

2-6 ADAM-5000

Page 25

2.4 Mounting

The ADAM-5000 system can be installed on a panel or DIN rail.

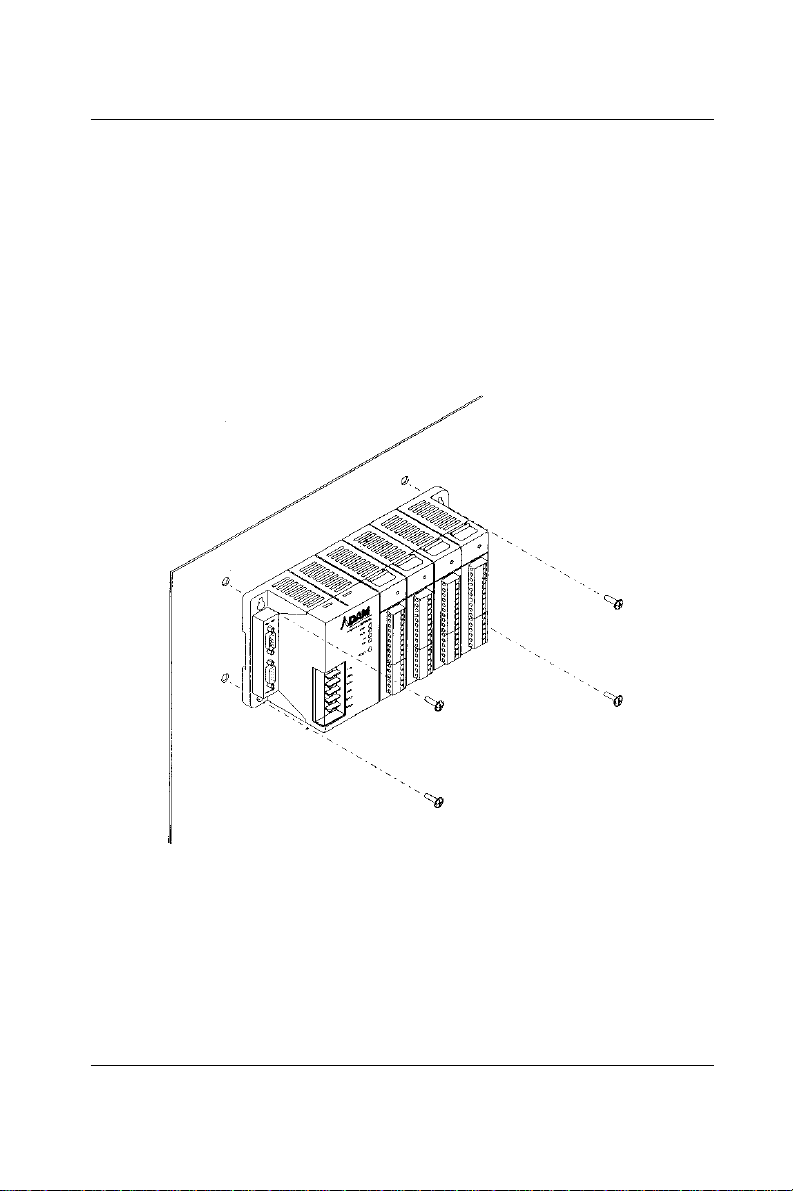

Panel Mounting

Mount the system on the panel horizontally to provide proper ventilation. You cannot mount the system vertically, upside down or on a flat

horizontal surface. A standard #7 tating screw (4mm diameter) should

be used.

Chapter 2

Figure 2-4 ADAM-5000 Panel mounting

ADAM-5000 2-7

Page 26

Installation Guideline

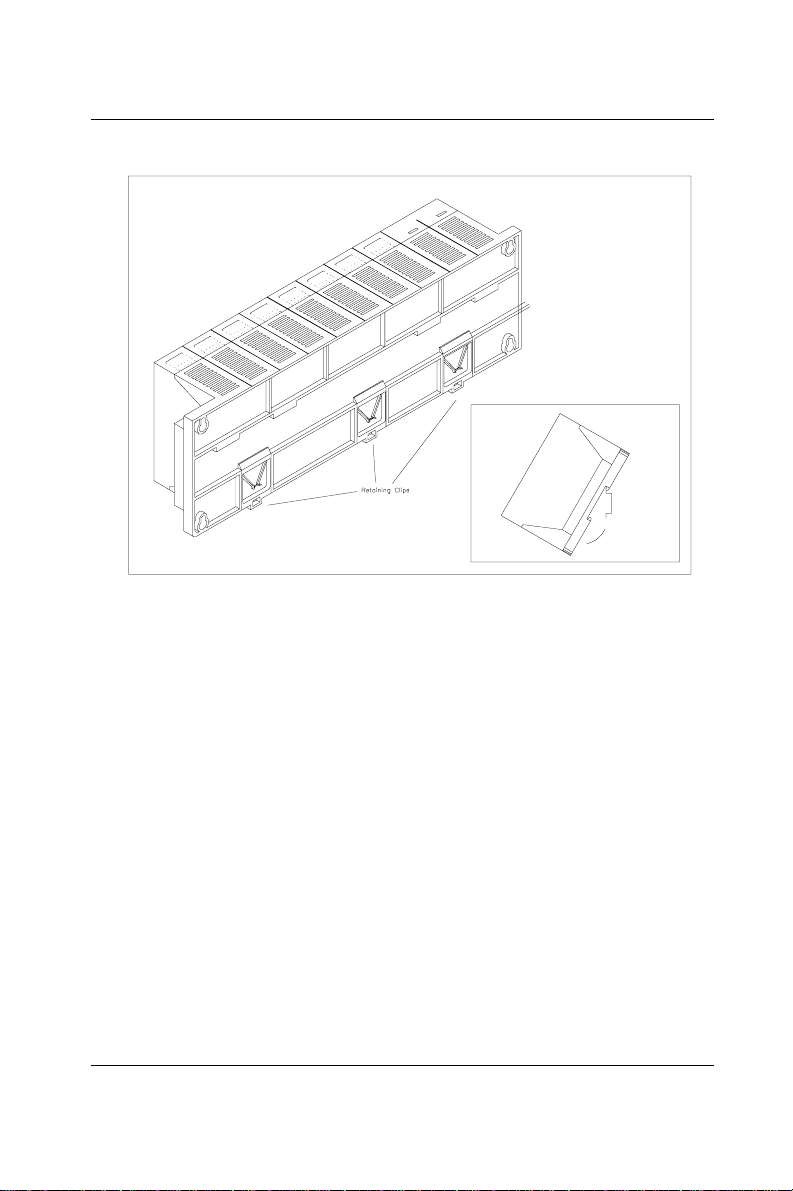

DIN Rail Mounting

The system can also be secured to the cabinet by using mounting

rails. If you mount the system on a rail, you should also consider

using end brackets on each end of the rail. The end brackets help

keep the system from sliding horizontally along the rail. This helps

minimize the possibility of accidentally pulling the wiring loose. If you

examine the bottom of the system, you will notice two small retaining

clips. To secure the system to a DIN rail, place the system onto the rail

and gently push up on the retaining clips. The clips lock the system

on the rail. T o remove the system, pull down on the retaining clips, lift

up on the base slightly, and pull it away from the rail.

Retaining Clips

Figure 2-5 ADAM-5000 Rail mounting

2-8 ADAM-5000

Page 27

Figure 2-6 ADAM-5000E Rail mounting

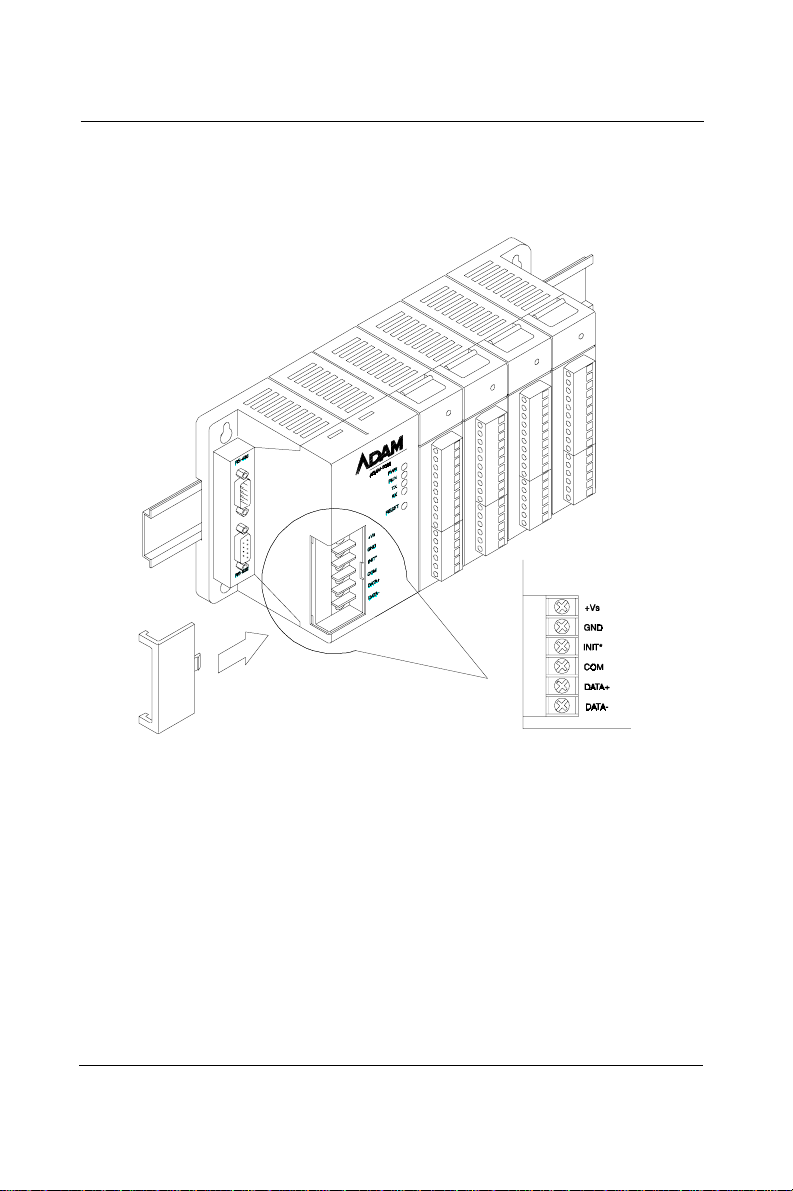

2.5 Wiring and Connections

Chapter 2

This section provides basic information on wiring the power supply

and I/O units, and on connecting the network.

DC Power Supply Unit Wiring

Be sure that the DC power supply voltage remains within the allowed

fluctuation range of between 10 to 30 VDC. T erminals +VS and GND are

for power supply wiring.

Note: The wire(s) used should be at least 2mm2.

ADAM-5000 2-9

Page 28

Installation Guideline

INIT* is used for changing baud rate and checksum. COM is provided

as reference to the RS-485 ground signal. DATA+ and DATA- are

provided for the RS-485 twisted pair connection.

Figure 2-7 ADAM-5000 Wiring and connections

I/O Modules Wiring

The system uses plug-in screw terminal blocks for the interface

between I/O module and field devices. The following information must

be considered when connecting electrical devices to I/O modules.

1 . The terminal block accepts 0.5 mm2 to 2.5 mm2 wires

2. Always use a continuous length of wire, do not combine

wires to attain needed length

3. Use the shortest possible wire length

4 . Use the wire trays for routing where possible

2-10 ADAM-5000

Page 29

Chapter 2

5 . Avoid running wires near high energy wiring

6 . A void running input wiring in close proximity to output

wiring where possible

7. Avoid creating sharp bends in the wires

RS-485 Port Connection

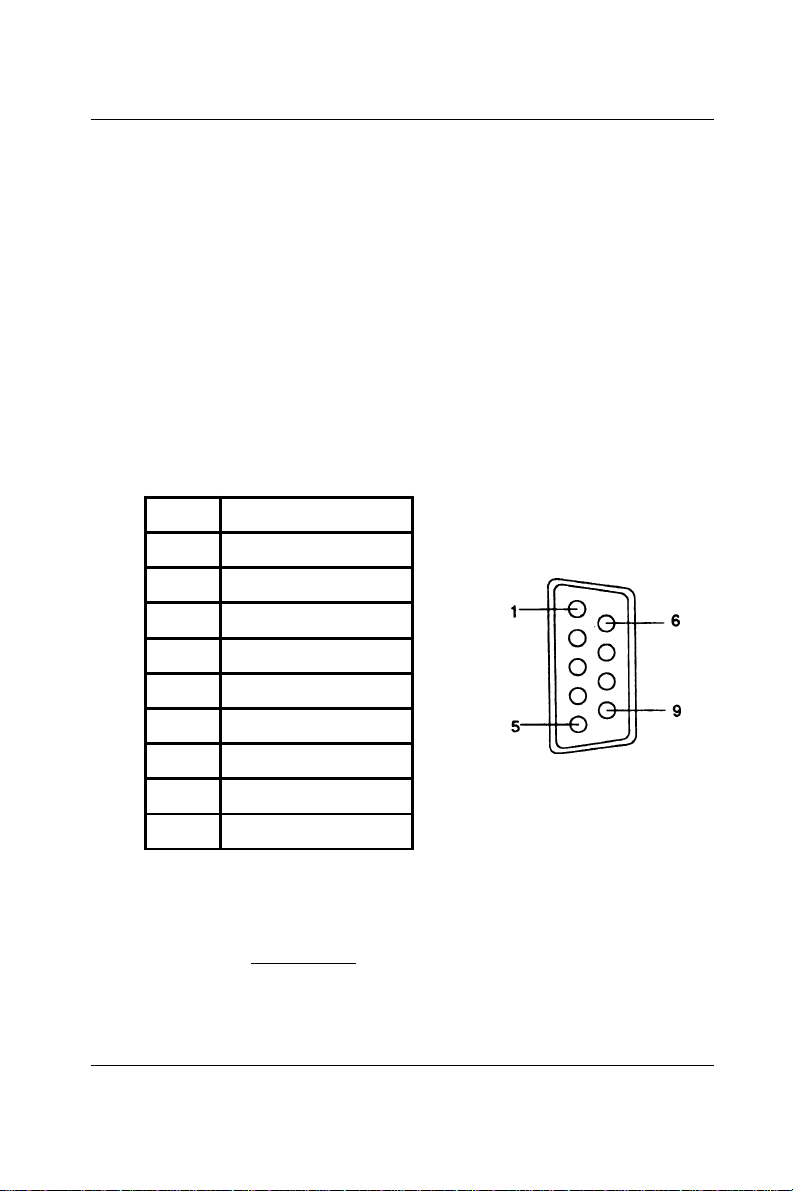

There is a pair of DB9 ports in the ADAM-5000 system. The ports are

designed to link the RS-485 through a cable to a network in a system.

The pin assignment of the port is as follows:

Pin No. Description

Pin 1 RS-485 Data -

Pin 2 RS-485 Data +

Pin 3 Not Used

Pin 4 Not Used

Pin 5 RS-485 Signal Ground

Pin 6 Not Used

Pin 7 Not Used

Pin 8 Not Used

Pin 9 Not Used

Note: The wiring of the RS-485 should be through a twisted

pair. To reduce electrical noise, it should be twisted

as tightly as possible

ADAM-5000 2-11

Page 30

Installation Guideline

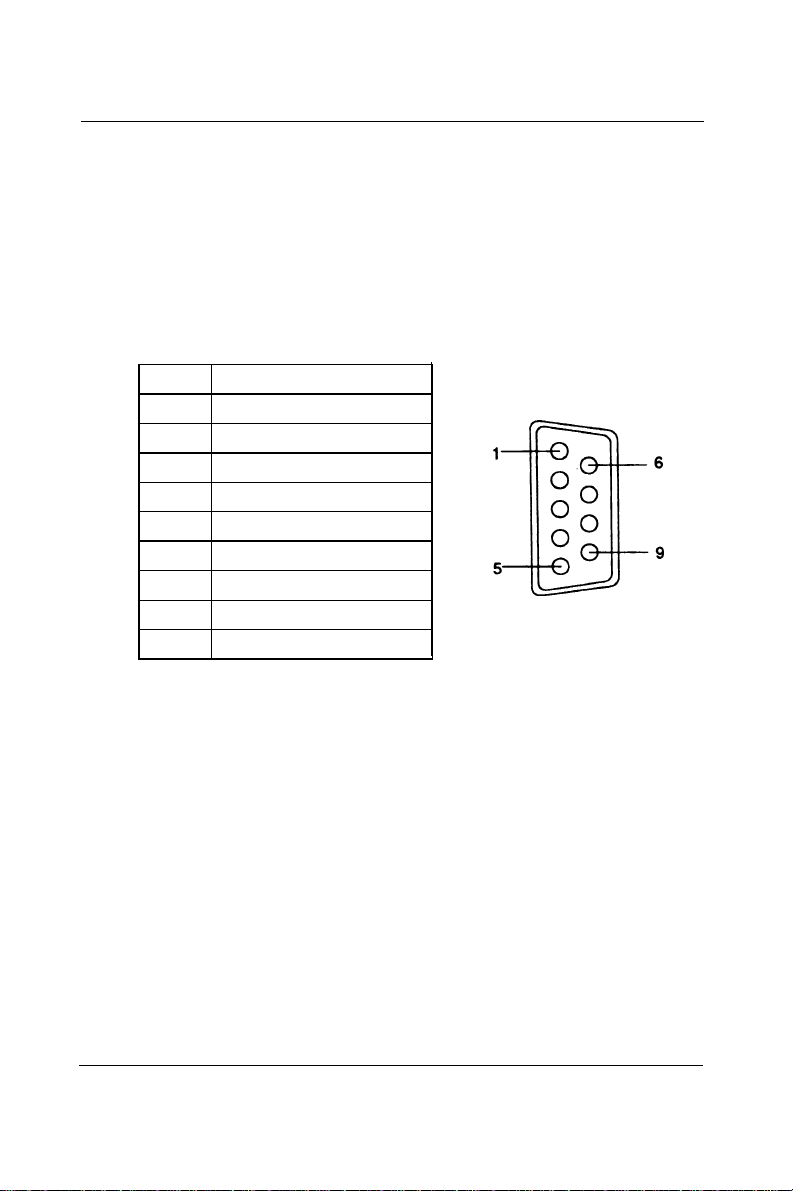

RS-232 Port Connection

The RS-232 port is designed for field configuration and diagnostics.

Users may connect a notebook PC to the RS-232 port to configure or

troubleshoot your system in the field. Further, the ADAM-5000

system can also be configured as the slave of the host computer

through this port connection. The pin assignment of the port is as

follows:

Pin No. Description

Pin 1 Not Used

Pin 2 Data Receive (RxD)

Pin 3 Data Send (TxD)

Pin 4 Not Used

Pin 5 RS-232 Signal Ground (GND)

Pin 6 Not Used

Pin 7 Not Used

Pin 8 Not Used

Pin 9 Not Used

Built-in Communication Ports for Diagnostic

Connection (ADAM-5000E only)

The Built-in Communication Ports for Diagnostic Function enables

users to perform a quick diagnostics to locate where the system is at

fault.

2-12 ADAM-5000

Page 31

Chapter 2

This Diagnostic Function requires the RS-485 port of ADAM-5000E to

be connected to COM1 of host PC, and the RS-232 port of

ADAM-5000E to COM2 of the previous host PC or other PCs. Then

you should install software such as ComWatch or Hyperterminal and

so on to monitor the commands that are being issued and the subsequent responses from connected modules.

Host PC

COM2

ComWatch

Hyper terminal

Software

COM1

Notebook

ADAM

ADAM-4520

RS-485

RS-232

ADAM-5000/E ADAM-5000/E

RS-485

ADAM

ADAM-4000

ADAM

ADAM-5000/485

A

DAM

ADAM-5000

PWR

RUN

COMM

BATT

RESET

+5V

GND

INT*

COM

DATA+

DATA-

Figure 2-8 Built-in Communication Ports for Diagnostic

Connection

Flexible Communication Port Function

Connection(ADAM-5000E only)

The Flexible Communication Port Function prevents ADAM-5000E

from system glitches due to communication line problems.

This function enables simultaneous connections via COM1 and COM2

port of your host PC to the RS-232 and RS-485 port of ADAM-5000E

specifically. While working in conjunction with specific HMI software

(e.g. AFX, FIX) that offers COM Port Backup Function, ADAM-5000E

can circumvent failed communication on one port by switching to

another available port to continue program execution.

ADAM-5000 2-13

Page 32

Installation Guideline

Host PC

COM2

AFX FIX

RS-232

COM1

ADAM

RS-485

ADAM-4520

ADAM-5000E

A

DAM

ADAM-5000 ADAM-5000

PWR PWR

RUN RUN

COMM COMM

BATT BATT

RESET RESET

+5V

GND

INT*

COM

DATA+

DATA-

A

DAM

+5V

GND

INT*

COM

DATA+

DATA-

ADAM-5000E

RS-485

ADAM

ADAM-4000

ADAM

ADAM-5000/485

A

DAM

ADAM-5000

PWR

RUN

COMM

BATT

RESET

+5V

GND

INT*

COM

DATA+

DATA-

Figure 2-9 Flexible Communication Port Function Connection

2-14 ADAM-5000

Page 33

3

ADAM-5000 System

Page 34

ADAM-5000 System

3.1 Overview

The ADAM-5000 series is a data acquisition and control system which

can control, monitor and acquire data through multichannel I/O

modules. Encased in rugged industrial grade plastic bases, the

systems provide intelligent signal conditioning, analog I/O, digital I/O,

RS-232 and RS-485 communication. The ADAM-5000/485 can handle

up to any 4 combinations of I/O modules (64 I/O points), while the

ADAM-5000E can handle up to 8 combinations of I/O modules (128 I/

O points). The systems communicate with their controlling host over a

multi-drop RS-485 network.

3.2 Major Features of the ADAM-5000 System

The ADAM-5000 system consists of two major parts: the system

kernel and I/O modules. The system kernel includes a CPU card, power

regulator, 4-slot base, 8-slot base, built-in RS-232 communication port,

and a pair of built-in RS-485 ports. It also offers the following major

features:

The CPU's Basic Functions

The CPU is the heart of the system and has the following basic

functions:

• Data acquisition and control for all I/O modules in the system

• Linearization of T/C (Thermocouple)

• Communication software and command set

• Calibration software and command set

• Alarm monitoring

• Management of the EEPROM device that holds the system

parameters

• Data transformation

• Diagnosis

3-2 ADAM-5000

Page 35

Chapter 3

Diagnosis

There are 4 LEDs (indicated as PWR, RUN, TX and RX) to provide

visual information on the general operation of the ADAM-5000

system. The LEDs also indicate the error status when the

ADAM-5000 system performs the self test. Besides the LED indicators, the system also offers software diagnosis via the RS-232 port.

For details, refer to Chapter 7.

3-Way Isolation and Watchdog Timer

Electrical noise can enter a system in many different ways. It may enter

through an I/O module, a power supply connection or the communication ground connection. The ADAM-5000 system provides isolation

for I/O modules (3000 VDC), communication connection (2500 VDC) and

communication power connection (3000 VDC). The 3-way isolation

design prevents ground loops and reduces the effect of electrical

noise to the system. It also offers better surge protection to prevent

dangerous voltages or spikes from harming your system. The system

also provides a W atchdog timer to monitor the microprocessor . It will

automatically reset the microprocessor in ADAM-5000 system if the

system fails.

Remote Software Configuration and Calibration

The ADAM-5000 system merely issues a command from the host

computer, you can change an analog input module to accept several

ranges of voltage input, current input, thermocouple input or RTD

input. With the exception of system node address, all the parameters

including speed, parity, HI and LO alarm, and calibration parameters

setting may be set remotely. Remote configuration can be done by

using either the provided menu-based software or the command set's

configuration and calibration commands. By storing configuration and

calibration parameters in a nonvolatile EEPROM, the systems are able

to retain these parameters in case of power failure.

Flexible Alarm Setting

The ADAM-5000 system provides a flexible alarm setting method via

an utility software (ADAM.EXE) between analog input modules and

digital output modules. The user may configure a point of any digital

output module plugged into any slot as the High alarm or Low alarm

ADAM-5000 3-3

Page 36

ADAM-5000 System

output of a channel of an analog input module. The relationship and

their High/Low alarm limits may be downloaded into the system‘s

EEPROM by the host computer.

The alarm functions can be enabled or disabled remotely. When the

alarm function is enabled, the user may select whether the digital

output is triggered. If the digital outputs are enabled, they are used to

indicate the High and Low Alarm state. The High and Low alarm

states can be read at any time by the host computer.

Every A/D conversion will be followed by a comparison with the High

and Low limit. When the input value is over the High limit or below

the Low limit, the High or Low alarm state is set to ON.

There are two alarm mode options: Momentary and Latching.

If the alarm is in Latching mode, the alarm will stay on even when the

input value returns within limits. An alarm in Latching mode can be

turned OFF by issuing a Clear Alarm command from the host computer.

A Latching alarm is cleared by the microprocessor when the opposite

alarm is set

For example, the alarm is in latching mode and the High alarm is turned

ON. When the module receives a value that is lower than the Low

alarm limit, the microprocessor will clear the High alarm and turn the

Low alarm ON.

When the alarm is in Momentary mode, the alarm will be turned ON

when the input value is outside of alarm limits and OFF while the input

value remains within alarm limits. The arrangement of coupling High

and Low alarm states with digital outputs may be utilized to build ON/

OFF controllers that can operate without host computer involvement.

Connectivity and Programming

ADAM-5000 systems can connect to and communicate with all

computers and terminals. They use either RS-232 or RS-485 transmission standards and communicate with ASCII format commands.

However, users can only select and use one communication port at

any time. All communications to and from the system are performed in

ASCII, which means that ADAM-5000 systems can be

3-4 ADAM-5000

Page 37

Chapter 3

programmed in virtually any high-level language. The details of all

commands will be covered in Chapter 6.

Flexible Communication Connection

ADAM-5000s built-in RS-232/485 conversion capability enables users

to freely choose either RS-232 port or RS-485 port to connect with host

PC. When user select either port to connect with their host PC, the

other port could be utilized according to their specific needs.

For example, if RS-232 port is selected for connection with host PC,

the RS-485 port can be used for connection with DA&C modules (such

as ADAM-5000/485, ADAM-5000, ADAM-4000 modules). Thus users

save extra costs for another RS-232/485 conversion device (e.g.

ADAM-4520).

Or if users select RS-485 port for host PC connection, the RS-232 port

can then have different usage such as described in the following

sections (see Built-in Communication Ports for Field Diagnostics and

Flexible Communication Port)

Built-in Communication Ports for Diagnostics

(ADAM-5000E only)

When users utilize application software to control their system,

ADAM-5000E can provide another port to let user monitor at any time

the communication quality and condition as a reference to mainte-

nance and test. When error occurs in the system, users can perform a

quick diagnostics to locate the fault. A considerable amount of

troubleshooting efforts can be saved. For example, using popular

ComWatch software, users can watch the current execution and

response of a certain command. It is very convenient to identify

whether it is communication or the hardware product that is causing

the problem.

Flexible Communication Port (ADAM-5000E only)

ADAM-5000E provides a further application. Users can simultaneous-

ly connect COM1 and COM2 of host PC to RS-232 and RS-485 port of

ADAM-5000E. When host PC issues a command through one of the

COM ports but receives no response (the other port will serve as

backup), the COM Port Backup Function of HMI software (e.g. AFX,

FIX) will automatically switch to another COM port to continue

ADAM-5000 3-5

Page 38

ADAM-5000 System

program execution without undue influence on your system. Probability of a system crash has thus minimized.

3.3 System Setup

A Single System Setup thru the RS-232 Port

If users would like to use a PC to locally control and monitor a simple

application, the ADAM-5000 system provides up to 64 points or 128

points and front-end wiring through the RS-232 port to the host

computer.

A Distributed I/O Setup thru the RS-485 Network

The RS-485 network provides lower-noise sensor readings as the

systems can be placed much closer to the source. Up to 256

ADAM-5000 systems may be connected to an RS-485

multi-drop network by using the ADAM-4510/4510S RS-485 repeaters,

extending the maximum communication distance to 4,000 ft. The host

computer is connected to the RS-485 network from one of its COM

ports through the ADAM-4520/4522 RS-232/RS-485 converter.

T o boost the network's throughput, the ADAM-4510/4510S RS-485

repeaters use a logical RTS signal to manage the repeater's direction.

Only two wires are needed for the RS-485 network: DA TA+ and

DA TA-. Inexpensive, shielded twisted-pair wiring is employed.

3-6 ADAM-5000

Page 39

Chapter 3

3.4 Technical Specifications of the ADAM-5000

Processor

CPU

RAM

ROM (Flash)

I/O Capacity

Watchdog Timer

Power Consumption

80188, 16-bit microprocessor

32 KB

128 KB

4 slots (ADAM-5000/485)

8 slots (ADAM-5000E)

Ye s

1.0 W (ADAM-5000/485)

4.0 W (ADAM-5000E)

Communication

RS-485 Ports 2, 1 each for input and output

Extended RS-232 Ports 1

Wiring RS-485, twisted pair

Speed 1200 bps to 115.2 Kbps

Max. Communication Distance 4000 ft. (1.2 Km)

Network Expansion Up to 256 ADAM-5000 systems

Protection Transient supression on RS-485

Protocol ASCII command/respones

per host serial port over twisted

pair wires

communication lines

Asynchoronous Data Format 1 start bit, 8 data bits, 1 stop bit,

Communication Error Check With checksum

no parity (1 start, 8-N-1)

ADAM-5000 3-7

Page 40

ADAM-5000 System

Isolation

Connection Power 3000 Vdc

Input/Output 3000 Vdc

Co mmunica ti on

2500 Vdc (ADAM-5000/485)

3000 Vdc (ADAM-5000E)

Diagnosis

Status Indicators

Self-Test

Software Diagnosis

- Power

- CPU

- Communication

- I/O modules

Yes, while on

Yes

Basic Function Block Diagram

Opto-Cou pled

GND

Isolation

Power

Isolation

WDT&

Reset

DATA+

COMM.

Controller

DATA-

+V

Rectifier

&

Filter

Memory

16 Bit

up

+5V GND

P. S.

Power

Converter

Bus

+10~

+30Vdc

Figure 3-1 Function block diagram

3-8 ADAM-5000

Page 41

4

I/O Modules

Page 42

I/O Modules

4.1 RTD Input Module

ADAM-5013 3-channel RTD input module

The ADAM-5013 is a 16-bit, 3-channel RTD input module that features

programmable input ranges on all channels. This module is an extremely cost-effective solution for industrial measurement and monitoring

applications. Its opto-isolated inputs provide 3,000 VDC of isolation

between the analog input and the module, protecting the module and

peripherals from damage due to high input line voltage.

Note: Owing to the conversion time required by the A/D

converter, the initialization time of each AD AM-5013

module is 5 seconds. Thus the total initialization

time will be about 20 seconds if all 4 I/O slots in an

ADAM-5510/P31 main unit contain AD AM-5013

modules.

ADAM-5013

3 RTD

ADAM-5013

1

EXC0+

SEN0+

SEN0-

EXC0+

A.GND

EXC1+

SEN1+

SEN1-

EXC1+

A.GND

EXC2+

SEN2+

SEN2-

EXC2-

A.GND

16

Figure 4-1: ADAM-5013 module frontal view

4-2 ADAM-5000

Page 43

Application wiring

EXC0+

SEN0+

SEN0-

EXC0-

A.GND

EXC0+

SEN0+

Chapter 4

2 Wire

RTD

SEN0-

EXC0-

A.GND

EXC0+

SEN0+

SEN0-

EXC0-

A.GND

3 Wire

RTD

4 Wire

RTD

Figure 4-2: RTD inputs

ADAM-5000 4-3

Page 44

I/O Modules

Technical specifications of ADAM-5013

Analog input channels

Input type

RTD type and temperature

range

Isolation voltage

Sampling rate

Input impedance

Bandwidth

three

Pt or Ni RTD

Pt -100 to 100° C a=0.00385

Pt 0 to 100° C a=0.00385

Pt 0 to 200° C a=0.00385

Pt 0 to 600° C a=0.00385

Pt -100 to 100° C a=0.00392

Pt 0 to 100° C a=0.00392

Pt 0 to 200° C a=0.00392

Pt 0 to 600° C a=0.00392

Ni -80 to 100° C

Ni 0 to 100° C

3000 V

DC

10 samples/sec (total)

2 MΩ

13.1 Hz @ 50 Hz,

15.72 Hz @ 60 Hz

Input connections

Accuracy

Zero drift

Span drift

CMR@50/60 Hz

NMR@50/60 Hz

Power consumption

2, 3 or 4 wire

± 0.1% or better

± 0.015 °C/°C

± 0.01 °C/°C

150 dB

100 dB

1.2 W

Table 4-1: Technical specifications of ADAM-5013

4-4 ADAM-5000

Page 45

Chapter 4

4.2 ADAM-5013 RTD Input Resistance Calibration

1 . Apply power to the ADAM-5510/P31 system that the R TD input

module is plugged into and let it warm up for about 30 minutes

2 . Make sure that the module is correctly installed and is properly

configured for the input range you want to calibrate. You can use

the ADAM utility software to help in this.

3. Connect the correct reference self resistance between the screw

terminals of the ADAM-5013 as shown in the following wiring

diagram. T able 4-2 below shows the correct values of the span and

zero calibration resistances to be connected. Reference resistances

used can be from a precision resistance decade box or from discrete

resistors with the values 60 Ω, 140 Ω, 200 Ω and 440 Ω.

Resistance

Decade Box

A.GND

EXC2-

SEN2-

SEN2+

EXC2+

Figure 4-3: Applying calibration resistance

4 . First, with the correct zero (offset) calibration resistance connected

as shown above, issue a Zero Calibration command to the module

using the Calibrate option in the ADAM utility software.

5. Second, with the correct span resistance connected as shown

above, issue a Span Calibration command to the module using the

Calibrate option in the ADAM utility software. Note that the

module zero calibration must be completed prior to the span

calibration.

ADAM-5000 4-5

Page 46

I/O Modules

Note: If the above procedure is ineffective, the user must

first issue an RTD Self Calibration command $aaSi2

to the module and then complete steps 4 and 5 after

self calibration is complete.

Calibration resistances (ADAM-5013)

Input Range

Code (Hex)

20 Pt, -100 to 100° C

21 Pt, 0 to 100° C

22 Pt, 0 to 200° C

23 Pt, 0 to 600° C

24 Pt, -100 to 100° C

25 Pt, 0 to 100° C

26 Pt, 0 to 200° C

27 Pt, 0 to 600° C

28 Ni, -80 to 100° C 200 Ohms 60 Ohms

Input Range Span

Calibration

Resistance

140 Ohms 60 Ohms

A = 0.00385

140 Ohms 60 Ohms

A = 0.00385

200 Ohms 60 Ohms

A = 0.00385

440 Ohms 60 Ohms

A = 0.00385

140 Ohms 60 Ohms

A = 0.00392

140 Ohms 60 Ohms

A = 0.00392

200 Ohms 60 Ohms

A = 0.00392

440 Ohms 60 Ohms

A = 0.00392

Zero

Calibration

Resistance

29 Ni, 0 to 100° C 200 Ohms 60 Ohms

Table 4-2: Calibration resistances of ADAM-5013

4-6 ADAM-5000

Page 47

Chapter 4

4.3 Analog Input Modules

ADAM-5017 8-channel analog input module

The ADAM-5017 is a 16-bit, 8-channel analog differential input module

that provides programmable input ranges on all channels. It accepts

millivolt inputs (±150mV , ±500mV), voltage inputs (±1V, ±5V and ±10V)

and current input (±20 mA, requires 125Ω resistor). The module

provides data to the host computer in engineering units (mV, V or mA).

This module is an extremely cost-effective solution for industrial

measurement and monitoring applications. Its opto-isolated inputs

provide 3,000 VDC of isolation between the analog input and the

module, protecting the module and peripherals from damage due to

high input line voltage. Additionally, the module uses analog multiplexers with active overvoltage protection. The active protection

circuitry assures that signal fidelity is maintained even under fault

conditions that would destroy other multiplexers. This module can

withstand an input voltage surge of 70 Vp-p with ±15 V supplies.

ADAM-5017

8 AI

ADAM-5017

1

V0+

V0-

V1+

V1-

V2+

V2-

V3+

V3-

V4+

V4-

V5+

V5-

V6+

V6-

V7+

V7-

16

Figure 4-4: ADAM-5017 module frontal view

ADAM-5000 4-7

Page 48

I/O Modules

Application wiring

1

V0+

V0-

V

+

mV/V

V1+

V1-

Figure 4-5: Millivolt and volt input

1

V0+

V0-

V1+

V1-

Figure 4-6: Process current input

125

0.1%

Ω

-

+

0 - 20 mA

-

in

I

Note: T o k eep measurement accuracy please short the

channels that are not in use.

4-8 ADAM-5000

Page 49

Technical specifications of ADAM-5017

Chapter 4

Analog input channels

Input type

Input range

Isolation voltage

Sampling rate

Analog input signal limit

Max. allowable voltage

difference between two

connectors in a module

Input impedance

Bandwidth

Accuracy

Zero drift

Span drift

CMR@50/60 Hz

Eight differential

mV, V, mA

± 150 mV, ± 500 mV, ± 1V,

±5V, ±10V and ±20 mA

3000 V

DC

10 samples/sec (total)

15 V max.

15 V max.

2 Mohms

13.1 Hz @ 50 Hz,

15.72 Hz @ 60 Hz

± 0.1%

± 1.5 µV/°C

± 25 PPM/°C

92 dB min.

Power requirements

Power consumption

+10 to +30 V

(non-regulated)

1.2 W

DC

Table 4-3: Technical specifications of ADAM-5017

ADAM-5000 4-9

Page 50

I/O Modules

ADAM-5017H 8-channel high speed analog input

module

The ADAM-5017H is a 12-bit plus sign bit, 8-channel analog differential input module that provides programmable input ranges on each

channel. It accepts millivolt inputs (± 500 mV , 0-500 mV), voltage

inputs (±1 V , 0-1 V, ±2.5 V , 0-2.5 V, ±5 V , 0-5 V, ±10 V and 0-10 V) and

current inputs (0-20 mA and 4-20 mA; requires a 125 ohms resistor).

The module provides data to the host microprocessor in engineering

units (mV , V or mA) or two’ s complement format. Its sampling rate

depends on the data format received: up to 1,000 Hz (total) in two’s

complement or 600 Hz (total) in engineering units. Space is reserved for

125-ohm, 0.1%, 10 ppm resistors (See Figure 4-10). Each input channel

has 3000 V

and the module, protecting the module and peripherals from high input

line voltages. Additionally, the module uses analog multiplexers with

active overvoltage protection. The active protection circuitry assures

that signal fidelity is maintained even under fault conditions that

would destroy other multiplexers. The analog inputs can withstand a

constant 70 Vp-p input with ±15 V supplies.

ADAM-5017H

of optical isolation between the outside analog input line

DC

8 AI

ADAM-5017H

1

V0+

V0V1+

V1V2+

V2V3+

V3V4+

V4V5+

V5V6+

V6V7+

V7-

16

Figure 4-7: ADAM-5017H module frontal view

4-10 ADAM-5000

Page 51

Application wiring

1

V0+

V0-

V1+

V1-

Figure 4-8: Millivolt and volt input

V

Chapter 4

+

mV/V

-

1

V0+

V0-

V1+

V1-

Figure 4-9: Process current input

ADAM-5000 4-11

125

0.1%

Ω

+

0 - 20 mA

-

I

in

Page 52

I/O Modules

Technical specifications of ADAM-5017H

Analog Input Channels 8 differential

ADC Resolution 12 bits, plus sign bit

Type of ADC Successive approximation

Isolation Voltage

Sampling Rate 1,000 Hz/module no. (total) in two's

Input Impedance 20 Mohms (voltage inputs);

Signal Input Bandwidth 1000 Hz for both voltage inputs and

Analog Signal Range ±15 V max.

3000 V

DC

complement data format;

600 Hz/module no. (total) in

engineering unit data format

125 ohms (current inputs)

current inputs

Analog Signal Range for

any two measured Pins

Power Requirements +10 to +30 V

Power Consumption 1.8 W

±15 V max.

(non-regulated)

DC

Table 4-4: Technical specifications of ADAM-5017H

4-12 ADAM-5000

Page 53

Chapter 4

Inp ut Ra ng e Wi th

Voltage

0 ~ 10 V 0 ~ 11 V ±1 LSB ±2 LSB ±1 LSB ±2 LSB 17 µV/°C 50

Inp uts

0 ~ 5 V 0 ~ 5.5 V ±1 LSB ±2 LSB ±1.5 LSB ±2 LSB 16 µV/°C 50

0 ~ 2.5 V 0 ~ 2.75 V ±1 LSB ±2 LSB ±1.5 LSB ±2 LSB 20 µV/°C 55

0 ~ 1 V 0 ~ 1.375 V ±1 LSB ±2.5 LSB ±2 LSB ±2.5 LSB 20 µV/°C 60

0 ~ 500 mV 0 ~ 687.5 mV - ±5 LSB ± 3 LSB ±3.5 LSB 20 µV/°C 67

± 10 V ±11 V ±1 LSB ±2 LSB ±1 LSB ±2 LSB 17 µV/°C 50

± 5 V ±0 ~ 5.5 V ±1 LSB ± 2 LSB ± 1.5 LSB ±2 LS B 17 µV/°C 50

± 2.5 V ±0 ~ 2.75 V ±1 LSB ±2 LSB ±1.5 LSB ±2 LSB 20 µV/°C 55

± 1 V ±0 ~ 1.375 V ±1 LSB ±2.5 LSB ±2 LSB ±2.5 LSB 20 µV/°C 60

± 500 mV ±0 ~ 687.5 mV - ±5 LSB ±3 LSB ±3.5 LSB 20 µV/°C 67

Current

0 ~ 20 mA 22 mA ±1 LSB ±1 LSB ±1.5 LSB ±2 LS B nA/°C ppm/°C

Inp uts

4 ~ 20 mA 22 mA ±1 LSB ±1 LSB ±1.5 LSB ±2 LSB nA/°C ppm/°C

Overranging

Offset

Error @

25° C

Offset

Error @

-10 to

+70° C

Error @

25° C

Gain

Gain

Error @

-10 to

+70° C

Table 4-5: ADAM-5017H input signal ranges

Offset

Drift

Gain

Drift

ppm/°C

ppm/°C

ppm/°C

ppm/°C

ppm/°C

ppm/°C

ppm/°C

ppm/°C

ppm/°C

ppm/°C

Display

Reso lution

2.7 mV

1.3 mV

0.67 mV

0.34 mV

0.16 mV

2.7 mV

1.3 mV

0.67 mV

0.34 mV

0.16 mV

5.3 µΑ

5.3 µΑ

ADAM-5018 7-channel thermocouple input module

The ADAM-5018 is a 16-bit, 7-channel thermocouple input module

that features programmable input ranges on all channels. It accepts

millivolt inputs (±15 mV , ±50 mV, ±100 mV , ±500 mV), voltage inputs (±1

V , ±2.5 V), current inputs (±20 mA, requires 125 Ω resistor) and

thermocouple inputs (J, K, T , R, S, E, B).

The module forwards the data to the host computer in engineering

units (mV , V, mA or temperature °C). An external CJC on the plug-in

terminal is designed for accurate temperature measurement.

ADAM-5000 4-13

Page 54

I/O Modules

ADAM-5018

7 T/C

ADAM-5018

1

V0+

V0-

V1+

V1-

V2+

V2-

V3+

V3-

V4+

V4-

V5+

V5-

V6+

V6-

CJC+

CJC-

16

Figure 4-10: ADAM-5018 module frontal view

Application wiring

1

V0+

V0-

V1+

+

T/C

-

V1-

Figure 4-11: Thermocouple input

4-14 ADAM-5000

Page 55

Technical specifications of ADAM-5018

Analog Input Channels Seven differential

Input Type mV, V, mA, Thermocouple

Chapter 4

Input Range ± 15 mV, ± 50 mV,

T/C Type and

Temperature Range

Isolation Voltage 3000 V

Sampling Rate 10 samples/sec (total)

Input Impedance 2 Mohms

Bandwidth 13.1 Hz @ 50 Hz, 15.72 Hz

Accu racy ± 0.1% or better

Zero D rift ± 0.3 µV/°C

Span Drift ± 25 PPM/°C

CMR @ 50/60 Hz 92 dB min.

Power Consumption 1.2 W

± 100 mV, ± 500 mV, ± 1 V,

± 2.5 V and ± 20 mA

J 0 to 760 °C

K 0 to 1370 °C

T -100 to 400 °C

E 0 to 1400 °C

R 500 to 1750 °C

S 500 to 1750 °C

B 500 to 1800 °C

DC

@ 60 Hz

Table 4-6: Technical specifications of ADAM-5018

4.4 Analog Output Modules

ADAM-5024 4-channel analog output module

The ADAM-5024 is a 4-channel analog output module. It receives its

digital input from the host computer, via the RS-485 interface of the

ADAM-5510/P31 main unit. The format of the data is engineering

units. It then uses the D/A converter controlled by the main unit to

convert the digital data into output signals.

ADAM-5000 4-15

Page 56

I/O Modules

You can specify slew rates and start up currents through the configuration software. The analog output can also be configured as current

or voltage output through the software utility. The module protects

your equipment from ground loops and power surges by providing

opto-isolation of the D/A output and transformer based isolation up to

500 VDC.

Slew rate

The slew rate is defined as the slope (the ascending or descending rate

per second) of the analog output from the present to the required

value.

ADAM-5024

4 AO

ADAM-5024

1

I0+

I0-

I1+

I1-

I2+

I2-

I3+

I3-

V0+

V0-

V1+

V1-

V2+

V2-

V3+

V3-

16

Figure 4-12: ADAM-5024 module frontal view

4-16 ADAM-5000

Page 57

Application wiring

I3+

Chapter 4

I3-

mA Output

V0+

VO-

Figure 4-13: Analog output

V Output

Technical specifications of ADAM-5024

Analog Output

Channels

Output Type

Output Range

Isolation Voltage

Output Impedance

Accuracy

Zero Drift

Resolution

Span Temperature

Coefficient

Programmable Output

Slope

Current Load Resistor

Power Consumption

Table 4-7: Technical specifications of ADAM-5024

Four

V, mA

0-20mA, 4-20mA, 0-10V

3000 Vdc

0.5 Ohms

±0.1% of FSR for current

output

±0.2% of FSR for voltage

output

Voltage output: ±30 µV/ºC

Current output: ±0.2 µA/ºC

±0.015% of FSR

±25 PPM/ºC

0.125-128.0 mA/sec

0.0625-64.0 V/sec

0-500 Ohms (source)

2.5W (Max.)

ADAM-5000 4-17

Page 58

I/O Modules

4.5 Analog I/O Modules Calibration

Analog input/output modules are calibrated when you receive them.

However, calibration is sometimes required. No screwdriver is necessary because calibration is done in software with calibration parameters stored in the ADAM-5000 analog I/O module's onboard EEPROM.

The ADAM-5510/P31 system comes with the ADAM utility software

that supports calibration of analog input and analog output. Besides

the calibration that is carried out using the utility software, the

modules incorporate automatic Zero Calibration and automatic Span

Calibration at bootup or reset.

Analog input module calibration

Modules: ADAM-5017, 5017H, 5018

1 . Apply power to the ADAM-5510/P31 system that the analog input

module is plugged into and let it warm up for about 30 minutes

2. Assure that the module is correctly installed and is properly

configured for the input range you want to calibrate. You can do

this by using the ADAM utility software. (Refer to Chapter 5)

3. Use a precision voltage source to apply a span calibration voltage

to the module's V0+ and V0- terminals. (See T ables 4-8 and 4-9 for

reference voltages for each range.)

1

V0+

V0-

V1+

V1-

Figure 4-14: Applying calibration voltage

4-18 ADAM-5000

Voltage

Source

Page 59

Chapter 4

4 . Execute the Zero Calibration command (also called the Offset

Calibration command). This is also done with the ADAM utility

software. (See the “Zero Calibration” option in the Calibration submenu of the ADAM utility software.)

Figure 4-15: Zero calibration

5 . Execute the Span Calibration command. This can be done with

the ADAM utility software. (See the “Span Calibration” option in

the Calibration sub-menu of the ADAM utility software.)

Figure 4-16: Span calibration

ADAM-5000 4-19

Page 60

I/O Modules

6 . Only for ADAM-5018: Execute the CJC (cold junction sensor)

Calibration command. This can be done with the ADAM utility

software. (See the “CJC Calibration” option in the Calibration

submenu of the ADAM utility software.)

Figure 4-17: Cold junction calibration

* Note: Zero calibration and span calibration must be com-

pleted before CJC calibration. To calibrate CJC, the

thermocouple attached to ADAM-5018 and a standard thermometer should be used to measure a

standard known temperature, such as the freezing

point of pure water . The amount of offset between the

ADAM-5018 and the standard thermometer is then

used in the ADAM utility to complete CJC calibration.

4-20 ADAM-5000

Page 61

Calibration voltage (ADAM-5017/5018)

Chapter 4

Module Input Range

5018

5017

Code (Hex)

00h ±15 mV +15 mV

01h ±50 mV +50 mV

02h ±100 mV +100 mV

03h ±500 mV +500 mV

04h ±1V +1 V

05h ±2.5V +2.5 V

06h ±20 mA +20 mA (1)

0Eh J thermocouple

0Fh K thermocouple

10h T thermocouple

11h E thermocouple

12h R thermocouple

13h S thermocouple

14h B thermocouple

07h Not used

08h ±10 V +10 V

09h ±5 V +5 V

0Ah ±1 V +1 V

0Bh ±500 mV +500 mV

0Ch ±150 mV +150 mV

0Dh ±20 mA +20 mV (1)

Input Range Span Calibration

0 to 760 ºC

0 to 1000 ºC

-100 to 400 ºC

0 to 1000 ºC

500 to 1750 ºC

500 to 1750 ºC

500 to 1800 C

Voltage

+50 mV

+50 mV

+22 mV

+80 mV

+22 mV

+22 mV

+15 mV

ºC

Table 4-8: Calibration voltage of ADAM-5017/5018

ADAM-5000 4-21

Page 62

I/O Modules

Calibration voltage (ADAM-5017H)

Module Input Range

Code (Hex)

5017H 00h ±10 V +10 V

01h 0 ~ 10 V +10 V

02h ±5 V +5 V

03h 0 ~ 5 V +5 V

04h ±2.5 V +2.5 V

05h 0 ~ 2.5 V +2.5 V

06h ±1 V +1 V

07h 0 ~ 1 V +1 V

08h ±500 mV +500 mV

09h 0 ~ 500 mV +500 mV

0ah 4 ~ 20 mA *(1)

0bh 0 ~ 20 mA *(1)

Input Range Span Calibration

Voltage

Table 4-9: Calibration voltage of ADAM-5017H

(1) Note: You can substitute 2.5 V for 20 mA if y ou remove the

current conversion resistor for that channel. However, the calibr ation accuracy will be limited to 0.1%

due to the resistor's tolerance.

4-22 ADAM-5000

Page 63

Chapter 4

Analog output module calibration

The output current of analog output modules can be calibrated by

using a low calibration value and a high calibration value. The analog

output modules can be configured for one of two ranges: 0-20 mA and

4-20 mA. Since the low limit of the 0-20 mA range (0 mA) is internally

an absolute reference (no power or immeasurably small power), just

two levels are needed for calibration: 4 mA and 20 mA.

1 . Apply power to the ADAM-5510/P31 system including the analog

output module for about 30 minutes.

2. Assure that the module is correctly installed and that its

configuration is according to your specifications and that it

matches the output range you want to calibrate. You can do this

by using the ADAM utility software. (Refer to Chapter 5, Utility

Software)

3 . Connect either a 5-digit mA meter or voltmeter with a shunt resistor

(250 Ω, .01 % and 10 ppm) to the screw terminals of the module.

ammeter

Figure 4-18: Output module calibration

4. Issue the Analog Data Out command to the module with an output

ADAM-5000 4-23

Page 64

I/O Modules

value of 4 mA.

5 . Check the actual output value at the modules terminals. If this

does not equal 4 mA, use the "Trim" option in the "Calibrate"submenu to change the actual output. Trim the module until the mA

meter indicates exactly 4 mA, or in the case of the voltmeter with

shunt resistor, trim until the meter indicates exactly 1 V. (When

calibrating for 20 mA using a voltmeter and shunt resistor, the

correct voltage should be 5 V.)

6 . Issue the 4 mA Calibration command to indicate that the output is

calibrated and to store the calibration parameters in the module's

EEPROM.

7 . Execute an Analog Data Out command with an output value of

20 mA. The module's output will be approximately 20 mA.

8 . Execute the Trim Calibration command as often as necessary until

the output current is equal to exactly 20 mA.

9 . Execute the 20 mA Calibration command to indicate that the present

output is exactly 20 mA. The analog output module will store its

calibration parameters in the unit's EEPROM.

4.6 Digital Input/Output Modules

ADAM-5050 16-channel universal digital I/O module

The ADAM-5050 features sixteen digital input/output channels. Each

channel can be independently configured to be an input or an output

channel by the setting of its DIP switch. The digital outputs are opencollector transistor switches that can be controlled from the ADAM5510/P31. The switches can also be used to control solid-state relays,

which in turn can control heaters, pumps and power equipment. The

ADAM-5510/P31 can use the module’s digital inputs to determine the

state of limit or safety switches, or to receive remote digital signals.

Warning! A channel may be destroyed if it is subjected to an

input signal while it is configured to be an output

channel.

4-24 ADAM-5000

Page 65

Chapter 4

Dip Switch Key

ON = Digital Output

OFF = Digital Input

CH0 CH15

Figure 4-19: Dip switch setting for digital I/O channel

ADAM-5050

16 UDIO

ADAM-5050

1

V0

V1

V2

V3

V4

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

V15

16

Figure 4-20: ADAM-5050 module frontal view

Application wiring

Figure 4-21: Dry contact signal input (ADAM-5050)

ADAM-5000 4-25

Page 66

I/O Modules

Figure 4-22: Wet contact signal input (ADAM-5050)

-Vss

Power

Ground

Power

Ground

+Vss

limits current to 100 mA

Figure 4-23: Digital output used with SSR (ADAM-5050/5056)

4-26 ADAM-5000

Page 67

Chapter 4

Technical specifications of ADAM-5050

Points 16

Channel Setting Bitwise selectable by DIP

switch

Digital Input Dry Contact

Logic Level 0: close to GND

Logic Level 1: open

Wet Contact

Logic Level 0: +2 V max

Logic Level 1: +4 V to 30 V

Digital Output Open collector to 30 V,

100mA max load

Power Dissipation 450 mW

Power Consumption 0.4 W

Table 4-10: Technical specifications of ADAM-5050

ADAM-5051 16-channel digital input module

The ADAM-5051 provides sixteen digital input channels. The ADAM5510/P31 can use the module’s digital inputs to determine the state of

limit or safety switches or to receive remote digital signals.

ADAM-5051

16 DI

ADAM-5051

1

O

DI

1

DI

2

DI

3

DI

4

DI

5

DI

6

DI

7

DI

8

DI

9

DI

10

DI

11

DI

12

DI

13

DI

14

DI