Page 1

TOTAL ACCESS 544R

System Manual

4200704L2#ATM Total Access 544R ATM

1200704L3 Total Access 544R without Power Cord

4200704L8 Total Access 544R with Euro Power Cord

4200704L9 Total Access 544R Total Access 544R with UK Power Cord

4200704L10 Total Access 544R with Australian Power Cord

4200704L11 Total Access 544R with US Power Cord

61200704L2-1B

July 2003

Page 2

Trademarks Total Access 544R System Manual

Trademarks

Any brand names and product names included in this manual are trademarks, registered trademarks, or

trade names of their respective holders.

To the Holder of the Manual

The contents of this manual are current as of the date of publication. ADTRAN reserves the right to change

the contents without prior notice.

In no event will ADTRAN be liable for any special, incidental, or consequential damages or for

commercial losses even if ADTRAN has been advised thereof as a result of issue of this publication.

About this Manual

This manual provides a complete description of the Total Access 544R system and system software. The

purpose of this manual is to provide the technician, system administrator, and manager with general and

specific information related to the planning, installation, operation, and maintenance of the Total Access

544R. This manual is arranged so that needed information can be quickly and easily found.

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

Phone: (256) 963-8000

© 2003 ADTRAN, Inc.

All Rights Reserved.

Printed in U.S.A.

2 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 3

Total Access 544R System Manual Revision History

Revision History

This is the second issue of this manual.

Conventions

Notes provide additional useful information.

Cautions signify information that could prevent service interruption.

Warnings provide information that could prevent damage to the equipment or

endangerment to human life.

61200704L2-1B © 2003 ADTRAN, Inc. 3

Page 4

Safety Instructions Total Access 544R System Manual

Safety Instructions

When using your telephone equipment, please follow these basic safety precautions to reduce the risk of

fire, electrical shock, or personal injury:

1. Do not use this product near water, such as a bathtub, wash bowl, kitchen sink, laundry tub, in a

wet basement, or near a swimming pool.

2. Avoid using a telephone (other than a cordless-type) during an electrical storm. There is a remote

risk of shock from lightning.

3. Do not use the telephone to report a gas leak in the vicinity of the leak.

4. Use only the power cord, power supply, and/or batteries indicated in the manual. Do not dispose of

batteries in a fire. They may explode. Check with local codes for special disposal instructions.

Save These Important Safety Instructions

4 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 5

Total Access 544R System Manual Save These Important Safety Instructions

Federal Communications Commission Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio frequencies. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with Class A FCC limits.

Changes or modifications to this unit not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

61200704L2-1B © 2003 ADTRAN, Inc. 5

Page 6

Affidavit Requirements for Connection to Digital Services Total Access 544R System Manual

Affidavit Requirements for Connection to Digital Services

• An affidavit is required to be given to the telephone company whenever digital terminal equipment

without encoded analog content and billing protection is used to transmit digital signals containing

encoded analog content which are intended for eventual conversion into voiceband analog signals and

transmitted on the network.

• The affidavit shall affirm that either no encoded analog content or billing information is being

transmitted or that the output of the device meets Part 68 encoded analog content or billing protection

specifications.

• End user/customer will be responsible for filing an affidavit with the local exchange carrier when

connecting unprotected customer premise equipment (CPE) to 1.544 Mbps or subrate digital services.

• Until such time as subrate digital terminal equipment is registered for voice applications, the affidavit

requirement for subrate services is waived.

6 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 7

Total Access 544R System Manual Affidavit Requirements for Connection to Digital Services

Affidavit for Connection of Customer Premises Equipment to 1.544 Mbps and/or Subrate Digital

Services

For the work to be performed in the certified territory of ___________________ (telco name)

State of ________________

County of ________________

I, _______________________ (name), ____________________________________ (business address),

____________________ (telephone number) being duly sworn, state:

I have responsibility for the operation and maintenance of the terminal equipment to be connected

to 1.544 Mbps and/or ________ subrate digital services. The terminal equipment to be connected

complies with Part 68 of the FCC rules except for the encoded analog content and billing protection

specifications. With respect to encoded analog content and billing protection:

I attest that all operations associated with the establishment, maintenance, and adjustment of the

digital CPE with respect to analog content and encoded billing protection information continuously

complies with Part 68 of the FCC Rules and Regulations.

The digital CPE does not transmit digital signals containing encoded analog content or billing

information which is intended to be decoded within the telecommunications network.

The encoded analog content and billing protection is factory set and is not under the control of the

customer.

I attest that the operator(s)/maintainer(s) of the digital CPE responsible for the establishment,

maintenance, and adjustment of the encoded analog content and billing information has (have) been

trained to perform these functions by successfully having completed one of the following (check

appropriate blocks):

A training course provided by the manufacturer/grantee of the equipment used to encode analog

signals; or

A training course provided by the customer or authorized representative, using training materials

and instructions provided by the manufacturer/grantee of the equipment used to encode analog

signals; or

An independent training course (e.g., trade school or technical institution) recognized by the

manufacturer/grantee of the equipment used to encode analog signals; or

In lieu of the preceding training requirements, the operator(s)/maintainer(s) is (are) under the

control of a supervisor trained in accordance with _________ (circle one) above.

I agree to provide ______________________ (telco’s name) with proper documentation to

demonstrate compliance with the information as provided in the preceding paragraph, if so

requested.

_________________________________Signature

_________________________________Title

_________________________________ Date

Transcribed and sworn to before me

61200704L2-1B © 2003 ADTRAN, Inc. 7

Page 8

Affidavit Requirements for Connection to Digital Services Total Access 544R System Manual

This ________ day of _______________, _______

_________________________________

Notary Public

My commission expires:

_________________________________

8 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 9

Total Access 544R System Manual Industry Canada Compliance Information

Industry Canada Compliance Information

Notice: The Industry Canada label applied to the product (identified by the Industry Canada logo or the

“IC:” in front of the certification/registration number) signifies that the Industry Canada technical

specifications were met.

Notice: The Ringer Equivalence Number (REN) for this terminal equipment is supplied in the

documentation or on the product labeling/markings. The REN assigned to each terminal device indicates

the maximum number of terminals that can be connected to a telephone interface. The termination on an

interface may consist of any combination of devices subject only to the requirement that the sum of the

RENs of all the devices should not exceed five (5).

Canadian Emissions Requirements

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus

as set out in the interference-causing equipment standard entitled “Digital Apparatus,” ICES-003 of the

Department of Communications.

Cet appareil numérique respecte les limites de bruits radioelectriques applicables aux appareils numériques

de Class A prescrites dans la norme sur le materiel brouilleur: “Appareils Numériques,” NMB-003 edictee

par le ministre des Communications.

61200704L2-1B © 2003 ADTRAN, Inc. 9

Page 10

Product Warranty Total Access 544R System Manual

Product Warranty

ADTRAN will replace or repair this product within the warranty period if it does not meet its published

specifications or fails while in service. Warranty information can be found at www.adtran.com/warranty.

Product Registration

Registering your product helps ensure complete customer satisfaction. Please take time to register your

products on line at www.adtran.com

. Click Service and Support on the top of the page, and then click

Product Registration under Support.

Customer Service, Product Support Information, and Training

ADTRAN will replace or repair this product within the warranty period if it does not meet its published

specifications or fails while in service. Warranty information can be found at www.adtran.com/warranty.

A return material authorization (RMA) is required prior to returning equipment to ADTRAN. For service,

RMA requests, training, or more information, use the contact information given below.

Repair and Return

If you determine that a repair is needed, please contact our Customer and Product Service (CAPS)

department to have an RMA number issued. CAPS should also be contacted to obtain information

regarding equipment currently in house or possible fees associated with repair.

CaPS Department (256) 963-8722

Identify the RMA number clearly on the package (below address), and return to the following address:

ADTRAN Customer and Product Service

901 Explorer Blvd. (East Tower)

Huntsville, Alabama 35806

RMA # _____________

Pre-Sales Inquiries and Applications Support

Your reseller should serve as the first point of contact for support. If additional pre-sales support is needed,

the ADTRAN Support web site provides a variety of support services such as a searchable knowledge

base, latest product documentation, application briefs, case studies, and a link to submit a question to an

Applications Engineer. All of this, and more, is available at:

http://support.adtran.com

When needed, further pre-sales assistance is available by calling our Applications Engineering

Department.

Applications Engineering (800) 615-1176

10 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 11

Total Access 544R System Manual Customer Service, Product Support Information, and Training

Post-Sale Support

Your reseller should serve as the first point of contact for support. If additional support is needed, the

ADTRAN Support web site provides a variety of support services such as a searchable knowledge base,

updated firmware releases, latest product documentation, service request ticket generation and

trouble-shooting tools. All of this, and more, is available at:

http://support.adtran.com

When needed, further post-sales assistance is available by calling our Technical Support Center. Please

have your unit serial number available when you call.

Technical Support (888) 4ADTRAN

Installation and Maintenance Support

The ADTRAN Custom Extended Services (ACES) program offers multiple types and levels of installation

and maintenance services which allow you to choose the kind of assistance you need. This support is

available at:

http://www.adtran.com/aces

For questions, call the ACES Help Desk.

ACES Help Desk (888) 874-ACES (2237)

Training

The Enterprise Network (EN) Technical Training Department offers training on our most popular products.

These courses include overviews on product features and functions while covering applications of

ADTRAN's product lines. ADTRAN provides a variety of training options, including customized training

and courses taught at our facilities or at your site. For more information about training, please contact your

Territory Manager or the Enterprise Training Coordinator.

Training Phone (800) 615-1176, ext. 7500

Training Fax (256) 963-6700

Training Email training@adtran.com

61200704L2-1B © 2003 ADTRAN, Inc. 11

Page 12

Customer Service, Product Support Information, and Training Total Access 544R System Manual

12 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 13

Table of Contents

Section 1 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

This section of ADTRAN’s Product System Manual is designed for use by network engineers,

planners, and designers for overview information about the Product.

It contains general information and describes the L2 protocol support, routing capability, security, and testing features. This section should be used in conjunction with Section 2, Engineering

Guidelines, of this System Manual.

Section 2 Engineering Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Provides equipment dimensions, power requirements, front panel design, rear panel design,

LEDs, and at-a-glance specifications.

Section 3 Network Turnup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Provides shipment contents list, grounding instructions, mounting options, and specifics of supplying power to the unit.

Section 4 SHDSL RCU ATM User Interface Guide . . . . . . . . . . . . . . . . . . . . . . . . 29

The SHDSL RCU ATM User Interface Guide is designed for use by network administrators and

others who will configure and provision the system. This section provides details unique to the

SHDSL RCU ATM firmware. It contains an overview, application details, configuration information, and menu

Section 5 Detail Level Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

DLP-1 Connecting the Terminal or PC to the CRAFT Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

DLP-2 Logging in to the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

DLP-3 Adding/Removing Telnet Users and Changing Password Security Levels . . . . . . . . 105

DLP-4 Setting Ethernet IP Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

DLP-5 Verifying Communications Over an IP LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

DLP-6 Telnetting to the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

DLP-7 Upgrading the Firmware Using XMODEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

DLP-8 Upgrading the Firmware Using TFTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

DLP-9 Saving the Current Configuration Using TFTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

DLP-10 Loading the Current Configuration Using TFTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

DLP-11 Saving the Current Configuration Using XMODEM . . . . . . . . . . . . . . . . . . . . . . . . . 133

DLP-12 Loading the Current Configuration Using XMODEM . . . . . . . . . . . . . . . . . . . . . . . . 135

DLP-13 Saving and Loading Text Configuration Using the Terminal Command Line. . . . . . 137

DLP-14 Unit Installation Using The Auto-Config Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

DLP-15 A.03 to A.04 Firmware Upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Section 6 ADTRAN Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Provides instructions for configuring and using the ADTRAN Utilities software programs including Telnet, VT100, Syslog, and TFTP.

Section 7 MIBs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Provides a listing of SNMP Management Information Bases (MIBs) supported by the Total Access 544R. Traps supported for each MIB are also listed.

61200704L2-1B © 2003 ADTRAN, Inc. 13

Page 14

Table of Contents Total Access 544R System Manual

14 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 15

SYSTEM DESCRIPTION

This section of ADTRAN’s Product System Manual is designed for use by network engineers, planners,

and designers for overview information about the Product.

It contains general information and describes the L2 protocol support, routing capability, security, and

testing features. This section should be used in conjunction with Section 2, Engineering Guidelines, of this

System Manual.

CONTENTS

Firmware Updates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Terminal Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configuration and Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Software Upgradeable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Network Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LAN Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Protocol Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ATM Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PPP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Routing Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Integrated Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

61200704L2-1B © 2003 ADTRAN, Inc. 15

Page 16

Section 1 System Description Total Access 544R System Manual

1. SYSTEM OVERVIEW

The Total Access 544R is a cost-effective SHDSL access router designed for small and medium

businesses, branch offices and campuses. The unit provides up to 2312 kbps for dedicated Internet access

or remote office connectivity. With its integrated CSU/DSU, the Total Access 544R provides wide area

network access over a standard SHDSL or fractional SHDSL circuit.

Multiple users can share network access over a single SHDSL connection. For simultaneous access to

both a corporate network and the public Internet, the unit offers the ability to configure multiple PVCs. In

addition, the unit includes NAT/NAPT and IP filtering which provides security from unauthorized access

to the user's network.

The Total Access 544R also provides a cost-effective campus connectivity solution. When used with

private dry copper, the unit delivers up to 2.3 Mbps to cross-campus network elements. This solution is

ideal for extending LAN segments to other buildings.

Other features include a DHCP server, TELNET support, SNMP support, ping utility, and software

upgrades via TFTP and XMODEM.

Until now, the Total Access 544R unit has been running firmware version A.00.XX. Recently, D.04.XX

has been released. The development of D.04.XX code is a significant step in the evolution of the Total

Access product line, as it allows all Total Access family members to share the same base code. This means

that features and fixes are more easily implemented and are propagated across the product line. Section 4,

SHDSL ATM User Interface Guide, of this manual represents the D.04 firmware.

Firmware Updates

Firmware can be updated by using XMODEM transfer protocol via the unit’s CRAFT port or by using

TFTP from a network server.

Terminal Menu

The terminal menu is the access point to all other operations. Each terminal menu item has several

functions and submenus that identify and provide access to specific operations and parameters. These

menu selections are described later in this System Manual.

2. FEATURES AND BENEFITS

Below is a list of unit features and benefits.

Configuration and Management

• VT100 emulation via the CRAFT port

•Telnet

•SNMP

• LAN and WAN status LEDs

• Text-based configuration file support

• Syslog client

16 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 17

Total Access 544R System Manual Section 1 System Description

• ICMP Ping utility

• Trace route utility

Software Upgradeable

• TFTP download

• XMODEM via CRAFT port

Network Interface

G.shdsl: (ITU G.991.2 Compliant)

• Line Rate: 200- 2312 kbps (3-36 DS0s)

• Physical Interface: RJ-48C

• Rate Adaptive

• Improved Spectral Compatibility

• Echo Cancellation

LAN Interface

• 10/100 BaseT

• Half or Full Duplex

•RJ-45

• Secondary IP address

• DHCP server

• IEEE 802.3

Protocol Support

•IP

• DNS

•TCP

• RIP V1, V2 and static routes

• UDP, UDP Relay

•ICMP

•ARP

•PPP

•Frame Relay

61200704L2-1B © 2003 ADTRAN, Inc. 17

Page 18

Section 1 System Description Total Access 544R System Manual

ATM Support

•6 PVCs

• IP over ATM (RFC 1483)

• RFC 1483 (Multiprotocol Encapsulation over ATM), PPPoA (RFC 2364)

• Full Traffic Shaping and QoS Support

• VBR-rt and UBR Support

• F5 OAM Loopback Capability

PPP

• LCP, IPCP, BCP, CCP

• Van Jacobson (VJ) header compression

Routing Capability

• Ethernet: 10/100BaseT (RJ-45)

• IEEE 802.3 and 802.1D (MAC Bridging)

• IP Support: TCP, RIP V1, RIP V2, UDP, ICMP, ARP, UDP Relay, SYSLOG

• PPP Support: LCP, IPCP, BCP

• DHCP Server to LAN, DHCP from network (NAT)

Security

• PAP, CHAP, EAP, and Radius

• NAT/NAPT

• Packet filtering by source and destination IP address, source and destination port number, MAC

address, protocol or pattern

• Multi-layer Password protection

• Telnet security: Access list and password protection

Integrated Components

•IP router

• Network connection

• 10/100BaseT connection

• CRAFT port

18 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 19

ENGINEERING GUIDELINES

Provides equipment dimensions, power requirements, front panel design, rear panel design, LEDs, and

at-a-glance specifications.

CONTENTS

Reviewing the Front Panel Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Reviewing the Rear Panel Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

NTWK Connection (RJ-48C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CRAFT Port (RJ-48C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10/100BASET Connection (RJ-48C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC Power Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DB-9 to RJ Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FIGURES

Figure 1. Total Access 544R Front Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2. Total Access 544R Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TABLES

Table 1. Total Access 544R Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 2. SHDSL NTWK Connection Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 3. CRAFT Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 4. 10/100BASET Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Table 5. DB-9 to RJ Adapter Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

EQUIPMENT DIMENSIONS

The Total Access 544R measures 11.25” W, 7.5” D, and 2” H and comes equipped for table top or wall

mount use.

61200704L2-1B © 2003 ADTRAN, Inc. 19

Page 20

Section 2 Engineering Guidelines Total Access 544R System Manual

1. POWER REQUIREMENTS

The Total Access 544R operates with 240 VAC, 50 Hz and a maximum current drain of 300 mA. The Total

Access 544R maximum power consumption shall not exceed 10 Watts.

2. REVIEWING THE FRONT PANEL DESIGN

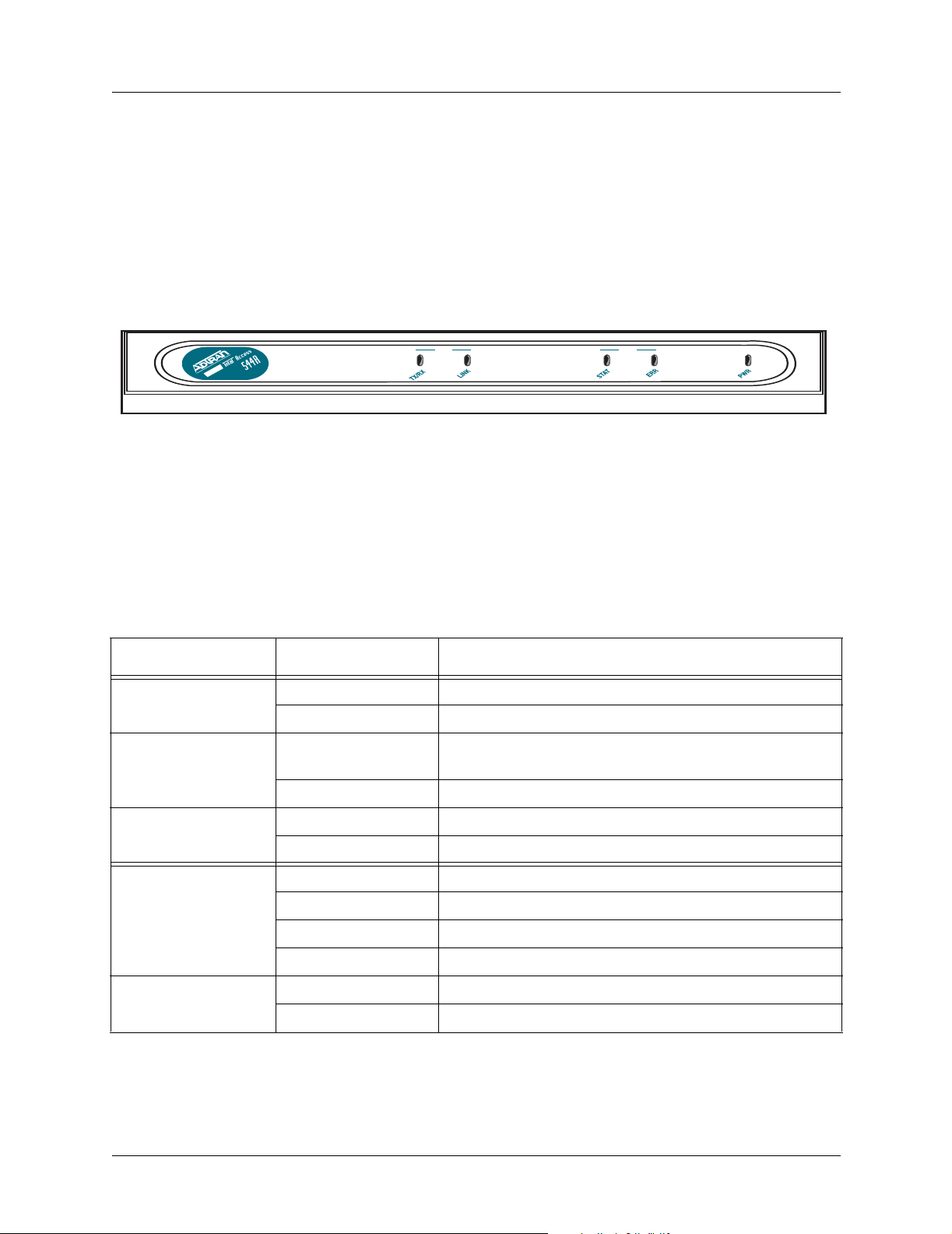

Figure 1. shows the front panel of the Total Access 544R which contains the LAN, WAN, and power

LEDs. These LEDs and their functions are described in Table 1.

.

LAN WAN

Figure 1. Total Access 544R Front Panel Layout

Front Panel LEDs

The front panel provides five status LEDs to monitor operation and activity. The following table provides

LED activity explanations.

Table 1. Total Access 544R Front Panel LEDs

For these LEDs... This color light... Indicates that...

LAN TX/RX Off there is no data traffic on the LAN.

Green (blinking) there is data traffic on the LAN.

LAN LINK

Off

Green (solid) there is link integrity on the LAN (physical link is up).

WAN STAT Red (solid) the SHDSL is shut down.

Green (solid) the SHDSL is up.

WAN ERR Red (flashing) the SHDSL is down.

Yellow (solid) errors are present on the WAN link.

Red (solid) severe errors are present on the WAN link.

Off the WAN link is up and error-free.

PWR Green (solid) power is supplied to the unit.

the physical link is down; there is no Ethernet

connection.

Off power is not supplied to the unit.

20 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 21

Total Access 544R System Manual Section 2 Engineering Guidelines

3. REVIEWING THE REAR PANEL DESIGN

The Total Access 544R rear panel is shown in Figure 2..

Figure 2. Total Access 544R Rear Panel

NTWK Connection (RJ-48C)

The NTWK connection pinout is an SHDSL connection. Table 1 shows the pinout for this connection.

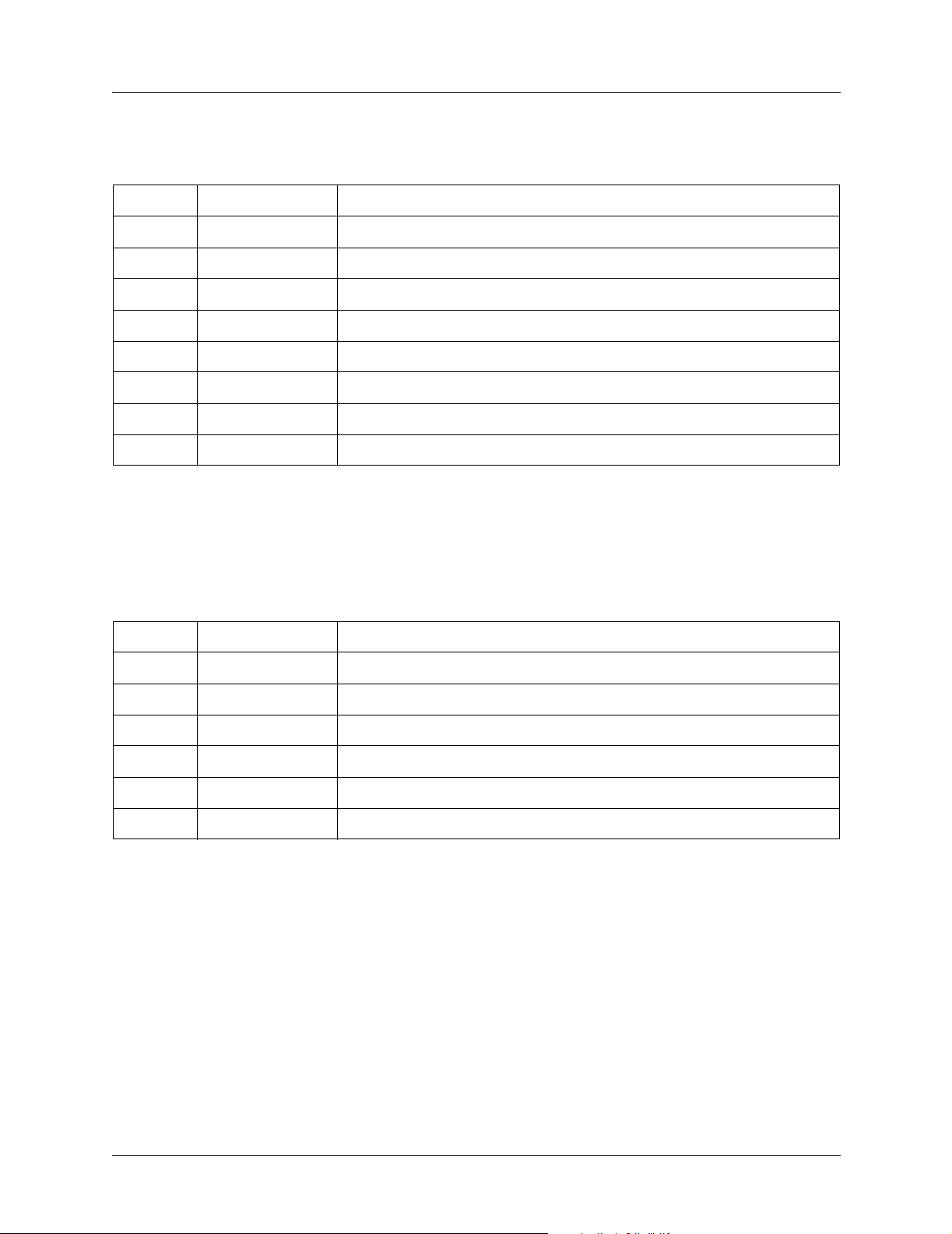

Connector type RJ-48C

Table 2. SHDSL NTWK Connection Pinout

PIN DESCRIPTION

1-3 Not Used

4 Ring

5 Tip

6-8 Not Used

CRAFT Port (RJ-48C)

The CRAFT port connects to a computer or modem. The CRAFT port input provides the following

functions:

• Accepts input from a PC or a modem for controlling the unit.

• Operates at 300, 1200, 2400, 4800, 9600, 19200, 38400, 57600, and 115200 bps.

• Acts as input for either VT100 or PC control.

• Acts as an interface for flash memory software downloads using XMODEM.

Table 3 shows the

CRAFT port pinout.

61200704L2-1B © 2003 ADTRAN, Inc. 21

Page 22

Section 2 Engineering Guidelines Total Access 544R System Manual

Table 3. CRAFT Pinout

PIN NAME DESCRIPTION

1 GND Ground - connected to unit chassis

2 RTS Request to send - flow control

3 RXDATA Data received by the unit.

4 DTR Data terminal ready

5 TXDATA Data transmitted by the unit.

6 CD Carrier detect

7 UNUSED —

8 CTS Clear to send - flow control

10/100BASET Connection (RJ-48C)

The 10/100BASET port (RJ-48C) provides a 10/100BaseT Ethernet LAN connection, which is used for IP

Routing, TFTP, SNMP, and Telnet connections. Table 4 shows the

Table 4. 10/100BASET Pinout

PIN NAME DESCRIPTION

1 TX1 Transmit Positive

2 TX2 Transmit Negative

3 RX1 Receive Positive

4, 5 UNUSED —

6 RX2 Receive Negative

7, 8 UNUSED —

10/100BASET port pinout.

AC Power Connection

Each unit includes an auto ranging 100-250 VAC, 50/60 Hz power supply with a 3-prong removable cable.

Connect the power supply to a standard 120 VAC, 60 Hz electrical outlet for proper operation.

22 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 23

Total Access 544R System Manual Section 2 Engineering Guidelines

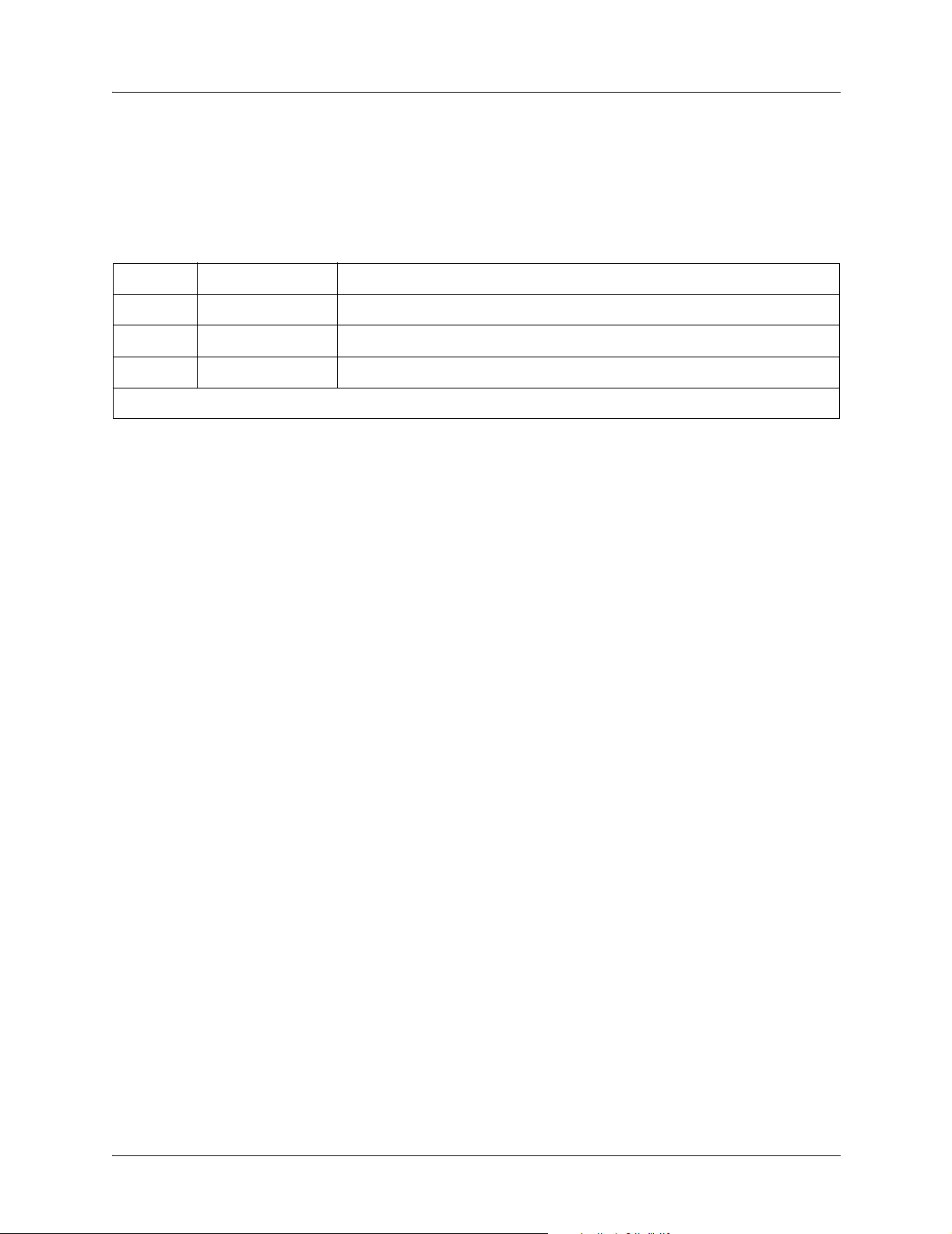

4. DB-9 TO RJ ADAPTER

The DB-9 to RJ adapter is used to connect a PC or VT100 terminal to the CRAFT port. The adapter pinout

is shown in Table 5.

Table 5. DB-9 to RJ Adapter Pinout

DB-9 RJ-45 DESCRIPTION

25 TX Data

33 RX Data

51 GND

Note: All other pins are unused.

61200704L2-1B © 2003 ADTRAN, Inc. 23

Page 24

Section 2 Engineering Guidelines Total Access 544R System Manual

24 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 25

NETWORK TURNUP PROCEDURE

Provides shipment contents list, grounding instructions, mounting options, and specifics of supplying

power to the unit.

CONTENTS

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unpack and Inspect the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Contents of ADTRAN Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Supplying Power to the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

61200704L2-1B © 2003 ADTRAN, Inc. 25

Page 26

Section 3 Network Turnup Procedure Total Access 544R System Manual

1. INTRODUCTION

This section discusses the unit installation process.

2. TOOLS REQUIRED

The tools required for unit installation are:

• Screws (customer-provided for wallmount installation)

• Screwdriver (for wall or rackmount installation)

To prevent electrical shock, do not install equipment in a wet location or during a

lightning storm.

During installation, power should be the last connection made.

Electronic modules can be damaged by static electrical discharge. Before handling

modules, wear an antistatic discharge wrist strap to prevent damage to electrical

components. Place modules in antistatic packing material when transporting or storing.

When working on modules, always place them on an approved antistatic mat that is

electrically grounded.

3. UNPACK AND INSPECT THE SYSTEM

Each unit is shipped in its own cardboard shipping carton. Open each carton carefully and avoid deep

penetration into the carton with sharp objects.

After unpacking the unit, inspect it for possible shipping damage. If the equipment has been damaged in

transit, immediately file a claim with the carrier, and then contact ADTRAN Customer Service (see the

contact information in the front of this manual).

Contents of ADTRAN Shipment

Your ADTRAN shipment of the Total Access 544R includes the following items:

• Mounting Instructions (P/N 64200600L1#T-19A)

•CD

• Cable Tie (P/N 3292032)

• Silver Satin Cable (P/N 3127004)

• Four Rubber Feet (P/N 3270BF003)

• Power Cord (P/N 3127009)

• 2 Mounting Brackets (P/N 3265421@C)

26 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 27

Total Access 544R System Manual Section 3 Network Turnup Procedure

• 4 Screws (P/N 3276003003)

• RJ-45 to DB-9 Adapter (P/N 3196ADPT001)

• The Total Access 544R base unit

Customers must supply the Ethernet cable.

4. GROUNDING INSTRUCTIONS

The following provides grounding instruction information from the Underwriters’ Laboratory UL60950

Standard for Safety of Information Technology Equipment Including Electrical Business Equipment, Third

Edition, of December 1, 2000.

An equipment grounding conductor that is not smaller in size than the ungrounded branch-circuit supply

conductors is to be installed as part of the circuit that supplies the product or system. Bare, covered, or

insulated grounding conductors are acceptable. Individually covered or insulated equipment grounding

conductors shall have a continuous outer finish that is either green, or green with one or more yellow

stripes. The equipment grounding conductor is to be connected to ground at the service equipment.

The attachment-plug receptacles in the vicinity of the product or system are all to be of a grounding type,

and the equipment grounding conductors serving these receptacles are to be connected to earth ground at

the service equipment.

A supplementary equipment grounding conductor shall be installed between the product or system and

ground that is in addition to the equipment grounding conductor in the power supply cord.

The supplementary equipment grounding conductor shall not be smaller in size than the ungrounded

branch-circuit supply conductors. The supplementary equipment grounding conductor shall be connected

to the product at the terminal provided, and shall be connected to ground in a manner that will retain the

ground connection when the product is unplugged from the receptacle. The connection to ground of the

supplementary equipment grounding conductor shall be in compliance with the rules for terminating

bonding jumpers at Part K or Article 250 of the National Electrical Code, ANSI/NFPA 70. Termination of

the supplementary equipment grounding conductor is permitted to be made to building steel, to a metal

electrical raceway system, or to any grounded item that is permanently and reliably connected to the

electrical service equipment ground.

The supplemental grounding conductor shall be connected to the equipment using a number 8 ring terminal

and should be fastened to the grounding lug provided on the rear panel of the equipment. The ring terminal

should be installed using the appropriate crimping tool (AMP P/N 59250 T-EAD Crimping Tool or

equivalent).

• This unit shall be installed in accordance with Article 400 and 364.8 of the NEC NFPA

70 when installed outside of a Restricted Access Location (i.e., central office, behind a

locked door, service personnel only area).

• Power to the unit’s AC system must be from a grounded 100-250 VAC, 50/60 Hz source.

• The power receptacle uses double-pole, neutral fusing.

• Maximum recommended ambient operating temperature is 45 ºC.

61200704L2-1B © 2003 ADTRAN, Inc. 27

Page 28

Section 3 Network Turnup Procedure Total Access 544R System Manual

5. SUPPLYING POWER TO THE UNIT

The AC powered unit comes equipped with a detachable power cord with a 3-prong plug for connecting to

a grounded power receptacle. As shipped, the unit is set to factory default conditions. After installing the

chassis, the unit is ready for power-up. To power-up the unit, ensure that the unit is properly connected to

an appropriate power source.

6. MOUNTING OPTIONS

The Total Access 544R comes equipped for table top or wallmount use. The unit is shipped with two

wall-mount brackets (P/N 326542@C) and four screws (P/N 3276003003) which the customer must attach

to the base unit for wallmount use.

If wallmounted, the Total Access 544R must be mounted with the LEDs pointing

down or sideways as shown in the mounting instructions (P/N 64200600L1#T-19A).

28 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 29

SHDSL RCU ATM USER INTERFACE GUIDE

The SHDSL RCU ATM User Interface Guide is designed for use by network administrators and others who

will configure and provision the system. This section provides details unique to the SHDSL RCU ATM

firmware. It contains an overview, application details, configuration information, and menu

CONTENTS

System Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

System Config. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

System Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Interfaces (SHDSL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Interfaces (ETH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

L2 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

L2 Protocol (SHDSL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

L2 Protocol (ETH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

FIGURES

Figure 1. System Info Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2. System Config Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 3. System Utility Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 4. Interfaces Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 5. L2 Protocol Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 6. Bridge Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 7. Router Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 8. Security Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 9. Application Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

TABLES

Table 1. Instructions for Changing Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 2. Telnet Security Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

61200704L2-1B © 2003 ADTRAN, Inc. 29

Page 30

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

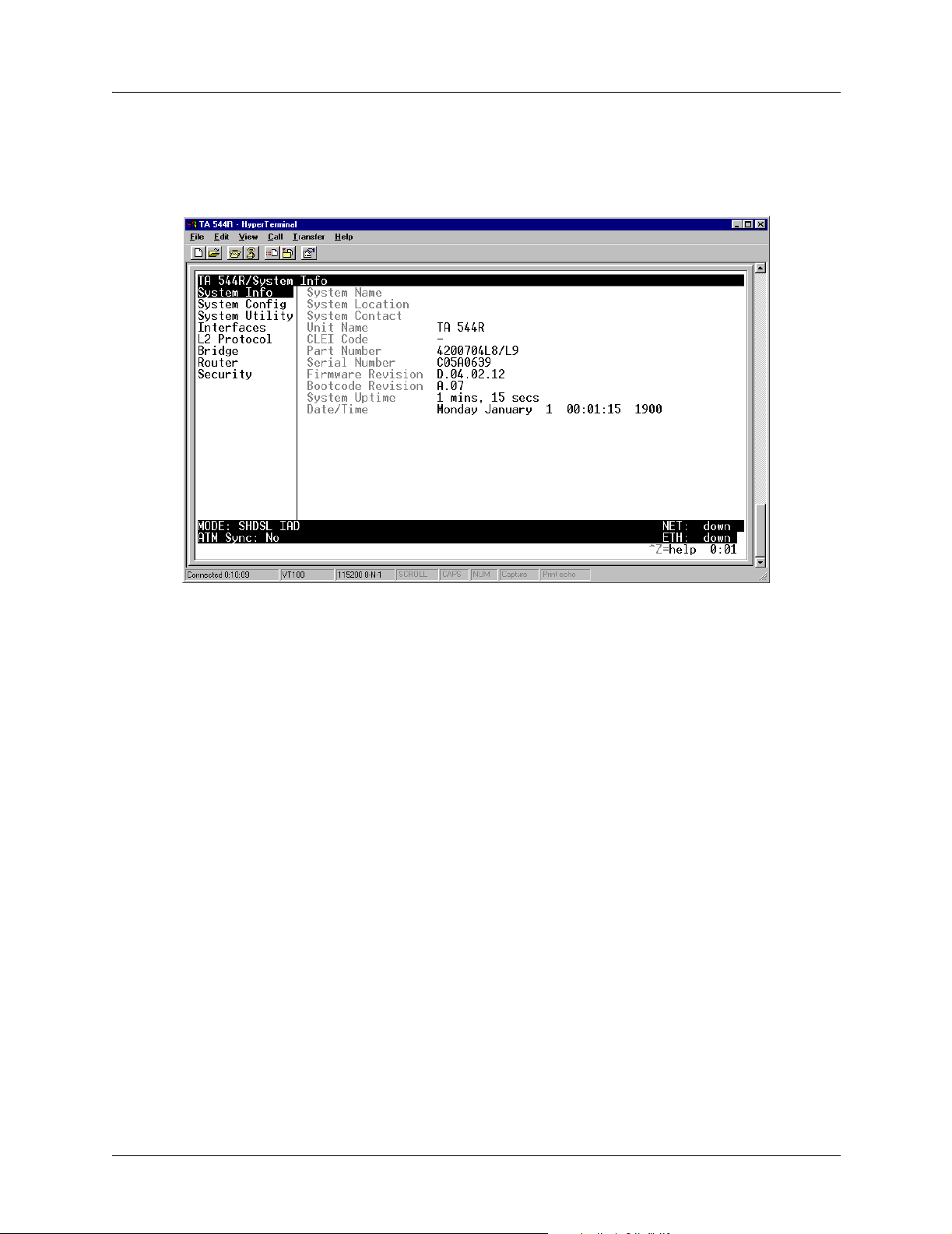

1. SYSTEM INFO

The System Info menu provides basic information about the unit as well as data fields for editing

information. Figure 1 displays the submenus that are available when you select this menu item.

Figure 1. System Info Menu

SYSTEM INFO > SYSTEM NAME

Provides a user-configurable text string for the name of the unit. This name can help you distinguish

between different installations. You can enter up to 31 alpha-numeric characters in this field, including

spaces and special characters (such as an underscore). This name will appear on the top line of all screens.

This field is blank by default.

SYSTEM INFO > SYSTEM LOCATION

Provides a user-configurable text string for the location of the unit. This field is to help you keep track of

the actual physical location of the unit. You can enter up to 31 alphanumeric characters in this field,

including spaces and special characters (such as an underscore). This field is blank by default.

SYSTEM INFO > SYSTEM CONTACT

Provides a user-configurable text string for a contact name. You can use this field to enter the name, phone

number, or E-mail address of a person responsible for the unit. You can enter up to 31 alpha-numeric

characters in this field, including spaces and special characters (such as an underscore). The factory default

is to have no entry in the system contact field

30 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 31

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

SYSTEM INFO > UNIT NAME

Product-specific name for the unit.

SYSTEM INFO > CLEI CODE

The CLEI code for the unit.

SYSTEM INFO > PART NUMBER

ADTRAN part number for the unit.

SYSTEM INFO > SERIAL NUMBER

The serial number field will reflect serial number located on bottom of the unit’s chassis.

SYSTEM INFO > FIRMWARE REVISION

Displays the current firmware revision level of the unit.

SYSTEM INFO > BOOTCODE REVISION

Displays the bootcode revision.

SYSTEM INFO > SYSTEM UPTIME

Displays the length of time since the last reboot of the unit.

Each time you reset the system, this value resets to 0 days, 0 hours, 0 min. and 0 secs.

SYSTEM INFO > DATE/TIME

Displays the current date and time, including seconds. This field can be edited. Enter the time in 24-hour

format (such as 23:00:00 for 11:00 pm). Enter the date in mm-dd-yyyy format (for example, 10-30-1998).

61200704L2-1B © 2003 ADTRAN, Inc. 31

Page 32

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM CONFIG

Set up the unit’s operational configuration from the SYSTEM CONFIG menu. Figure 3 shows the items

included in this menu.

Figure 2. System Config Menu

SYSTEM CONFIG > MANAGEMENT

Set up the CRAFT PORT, TELNET ACCESS, SNMP MANAGEMENT, and FDL MANAGEMENT from this menu.

SYSTEM CONFIG > MANAGEMENT > CRAFT PORT

Set up the CRAFT PORT parameters from this menu.

SYSTEM CONFIG > MANAGEMENT > CRAFT PORT > PASSWORD PROTECT

The unit’s VT100 CRAFT port can be accessed via an RJ-48C connector located on the rear of the unit, or

the DB-9 connector on the front of the unit.

PASSWORD PROTECT is set to NO, the CRAFT port is not password protected. When YES (def), the

When

unit will prompt for a password upon startup.

SYSTEM CONFIG > MANAGEMENT > CRAFT PORT > PASSWORD

This is the text string that is used for comparison when password protecting the CRAFT port. By default,

no password is entered. You can enter up to 30 characters in this field. Table 1 provides instructions for

changing the password.

32 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 33

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

The security level for the CRAFT port is always set to FULL. This gives full access to all

menus.

Passwords are case-sensitive and can contain up to 30 alphanumeric characters

(including spaces and special characters).

Table 1. Instructions for Changing Passwords

Step Action

1

2 Type the new password in the ENTER field.

3 Type the new password again in the CONFIRM field.

Select the PASSWORD field—a new PASSWORD field displays.

SYSTEM CONFIG > MANAGEMENT > CRAFT PORT > IDLE TIME

This option defines the amount of time in minutes user may stay connected without any activity on the

CRAFT port before the user is automatically logged out of the system. A value of 0 disables this inactivity

timer function enabling users to stay connected until manually logged out. The value range is

255 (min).

0 (def) to

SYSTEM CONFIG > MANAGEMENT > CRAFT PORT > BAUD RATE

This is the asynchronous rate that the CRAFT port will run. The possible values are 300, 1200, 2400, 4800,

9600, 19200, 38400, 57600, and 115200. The default value is 9600.

SYSTEM CONFIG > MANAGEMENT > CRAFT PORT > DATA BITS

This is the asynchronous bit rate that the CRAFT port will run. The possible values are 7 or 8 (def) bits.

SYSTEM CONFIG > MANAGEMENT > CRAFT PORT > PARITY

This is the asynchronous parity that the CRAFT port will run. The possible values are NONE (def), ODD, or

EVEN.

SYSTEM CONFIG > MANAGEMENT > CRAFT PORT > STOP BITS

This is the number of stop bits used for the CRAFT port. The possible values are 1 (def), 1.5 or 2.

SYSTEM CONFIG > MANAGEMENT > TELNET ACCESS

Activate the Telnet access and set up the various telnet parameters from this menu.

61200704L2-1B © 2003 ADTRAN, Inc. 33

Page 34

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM CONFIG > MANAGEMENT > TELNET ACCESS > ACCESS

Sets ACCESS to ON or OFF. The factory default value for this parameter is ON.

SYSTEM CONFIG > MANAGEMENT > TELNET ACCESS > AUTHEN METHOD

Set up the telnet authentication method from this menu. The choices are PASSWORD, RADIUS,

PASSWORD/RADIUS, and RADIUS/PASSWORD. PASSWORD/RADIUS indicates that the unit will try Password

Authentication first and if that fails, it will try Radius Authentication.

RADIUS/PASSWORD indicates that the

unit will try Radius authentication first and if that fails, it will try Password authentication. The default is

PASSWORD.

SYSTEM CONFIG > MANAGEMENT > TELNET ACCESS > USER LIST

Add telnet users and control the telnet access conditions through this menu.

#

Display the index number of the telnet users. Up to four users can be configured for access to the

unit. Each user can be assigned a security level and idle time.

NAME

The name is a text string of the user name for this session. You can enter up to 15 characters in this

field. The factory default is no entry in the

PASSWORD

NAME field

When the authenticating method is password, or password radius, this text string is used for the

password. You can enter up to 30 characters in this field. The factory default is no entry in this field.

IDLE TIME (MINS)

This sets the amount of time in minutes you can be idle before you are automatically logged off. The

factory default is

LEVEL

10 MINUTES. The range is 1-255 minutes.

This is the security level granted to the user. Table 2 gives a brief description of each level. The

factory default is

FULL.

34 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 35

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

Table 2. Telnet Security Levels

Security

Description

Level

Full The user has all access to view and configure all menus (same as logging in to

the CRAFT port)

Support The user has read only access to view the SYSTEM INFO menu. The user has

privileges to view and change everything under the S

YSTEM CONFIG menu

except for the CRAFT port settings, telnet access lists, and the SNMP

management communities. The user has full access to the S

YSTEM UTILITY

menu, including the ability to upgrade firmware and reset the unit. The user has

full access to the I

The user does not have the ability to set R

S

ECURITY menu.

NTERFACES, L2 PROTOCOL, BRIDGE, ROUTER, and DS0 menus.

ADIUS SERVER settings under the

Config The same privileges as support, except that the user does not have privileges to

download firmware or configuration from the S

YSTEM UTILITY menu. The user

additionally does not have the privilege to reset the unit remotely, or enter the

terminal menu.

Router The user has read only privileges for the SYSTEM INFO menu. There is no access

to the S

the S

status from the I

R

YSTEM CONFIG menu. The user has PING and TRACEROUTE access from

YSTEM UTILITY menu. The user is limited to ethernet configuration and

NTERFACES menu. The user has full access to the BRIDGE and

OUTER menus. Access is limited to filters only from the SECURITY menu.

Voice The user has read only privileges for the SYSTEM INFO menu. The user has

access to the P

The user has full access to the FXS module from the I

ING and TRACEROUTE utilities from the SYSTEM UTILITIES menu.

NTERFACES menu.

Status The user has read access of all menus except for the following: SYSTEM

C

ONFIG/CRAFT PORT, SYSTEM CONFIG/TELNET ACCESS, SYSTEM CONFIG/SNMP

M

ANAGEMENT, and SECURITY/ RADIUS SERVER. The user does not have access

to U

PGRADE FIRMWARE, UPGRADE CONFIG, PING, or TRACEROUTE menus. The

user cannot reset the unit or enter terminal mode.

SYSTEM CONFIG > MANAGEMENT > TELNET ACCESS > IP ACCESS LIST

Set up the list of allowed telnet managers.

NETWORK ADDRESS AND MASK

Enter a network address and subnet mask from which telnet access to the unit is allowed. When a

remote unit requests telnet access to the unit, if the access list is empty or the remote’s IP address

matches a list entry, remote access is granted. A subnet mask of 0.0.0.0 will allow any host telnet

access, regardless of the network address. A network address of 0.0.0.0 with corresponding netmask

255.255.255.255 will not allow any host telnet access.

The factory default is

0.0.0.0. for both parameters, which will allow all users telnet IP access.

61200704L2-1B © 2003 ADTRAN, Inc. 35

Page 36

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM CONFIG > MANAGEMENT > SNMP MANAGEMENT

Access the SNMP management and configure the SNMP communities and traps from this menu.

SYSTEM CONFIG > MANAGEMENT > SNMP MANAGEMENT > ACCESS

When set to OFF, SNMP access is denied. When set to ON, the unit will respond to SNMP managers based

on the configuration. The factory default is

ON.

SYSTEM CONFIG > MANAGEMENT > SNMP MANAGEMENT >TRAP DELAY

Time in seconds that represents the delay inserted between the trap creation and trap transmission. The

range is 0 to 600 seconds. The factory default is

0 SEC.

SYSTEM CONFIG > MANAGEMENT > SNMP MANAGEMENT > COMMUNITIES

Set up the SNMP communities parameters from this menu.

#

Displays the index number of the SNMP Communities.

This list is used to set up to 8 SNMP communities that the unit will allow.

NAME

This is the text string used to identify the SNMP community. This field is blank by default.

PRIVILEGE

The access for this manager can be assigned three levels. The factory default is NONE.

NONE

GET

GET/SET

MANAGER IP

No access is allowed for this community or manager.

Manager can only read items.

Manager can read and set items.

This may be used in conjunction with the Netmask field to define a range of manager IPs. A netmask

of 255.255.255.255 defines a single IP as the manager host IP. The default value is

0.0.0.0.

36 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 37

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

NETMASK

The mask is used to determine which bits of the MANAGER IP are significant. A "0" bit means "don't

care." A "1" bit means that the corresponding address bits in the incoming SNMP packet must match

the address bit in the defined

the manager host IP. The default value is

MANAGER IP. The netmask of 255.255.255.255 defines a single IP as

0.0.0.0.

SYSTEM CONFIG > MANAGEMENT > SNMP MANAGEMENT > TRAPS

Sets up the trap manager name and IP from this menu.

#

Displays the index number in the SNMP traps table.

This list allows up to 20 managers to be listed to receive traps.

MANAGER NAME is the text string describing the name of the entry. It is intended for easy reference

and has no bearing on the SNMP trap function. You can enter up to 31 characters in this field. The

factory default is no entry in the manager name field.

MANAGER IP

This is the IP address of the manager that is to receive the traps. The factory default is 0.0.0.0.

SYSTEM CONFIG > MANAGEMENT > FDL MANAGEMENT

Enables the FDL management and configures mode and IP addresses from this menu.

SYSTEM CONFIG > MANAGEMENT > FDL MANAGEMENT > MODE

This enables the FDL (only in ESF mode) to be used for management. Learning mode can also be enabled

so the unit can "learn" its IP configuration to be used for its FDL management. Once it learns this

information from, for example a Total Access 4303, the configuration items populate. The factory default

is

ON.

SYSTEM CONFIG > MANAGEMENT > FDL MANAGEMENT > LINK IP ADDRESS

This is the local IP address used for FDL management. The FDL uses a separate IP network for

communication, distinct from the customer data that is configured under the Router menus. The factory

default is

0.0.0.0.

SYSTEM CONFIG > MANAGEMENT > FDL MANAGEMENT > IP NETMASK

This is the subnet mask defining the IP network used for FDL management. The factory default is 0.0.0.0.

61200704L2-1B © 2003 ADTRAN, Inc. 37

Page 38

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM CONFIG > MANAGEMENT > FDL MANAGEMENT > FAR-END IP ADDRESS

This is the far-end IP address used for the FDL management. The FDL is a separate IP network from the

customer data that is configured under the Router menus. The factory default is

0.0.0.0.

SYSTEM CONFIG > MANAGEMENT > FDL MANAGEMENT > LEARN ADDRESS

When set to ON, the destination address on each received packet is assumed to be the FDL interface

address. A 255.255.255.252 netmask is used, which determines the far-side address as well (since there can

be only two addresses on a subnet with that netmask). When set to

assigned to the FDL interface. Default is

ON.

OFF, the user must input the IP address

SYSTEM CONFIG > MANAGEMENT > FDL MANAGEMENT > ACCEPT ALL SNMP

When set to ON, SNMP gets/sets received over the FDL link are always accepted regardless of the

community table. When set to

SNMP traffic is rejected if a match is not found. Default is

OFF, the community table is searched for valid manager IP addresses and the

ON.

SYSTEM CONFIG > MANAGEMENT > FDL MANAGEMENT > MTU

Maximum Transmit Unit allows the user to set the largest acceptable IP packets that will be transmitted

before configuration takes place. The range is 64 to 256 kbps. The default is

256 KBPS.

SYSTEM CONFIG > SYSLOG

Configure the unit Syslog client for use with a Syslog server (supplied with ADTRAN Utilities or available

on most Unix platforms) from this menu.

For additional information, reference RFC3164: The BSD Syslog Protocol.

SYSTEM CONFIG > SYSLOG > SYSLOG IP

IP address of the syslog daemon to which log message should be sent. The values must be dotted decimal

notation.

SYSTEM CONFIG > SYSLOG > SYSLOG FORMAT

The SYSLOG FORMAT is the format of log messages. "ADTRAN" uses a format that is compatible with

Adtran Utilities and forces the Syslog Facility to LOCAL0.

reports at the configured facility level.

UNIX uses the traditional Unix format and

Adtran Utilities may malfunction if messages are received in the Unix format.

38 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 39

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

SYSTEM CONFIG > SYSLOG > SYSLOG FACILITY

The choices are: LOCAL0, LOCAL1, LOCAL2, LOCAL3, LOCAL4, LOCAL5, LOCAL6, LOCAL7. SYSLOG FACILITY

is the facility level for all messages forwarded from the unit to the syslog server. This allows all messages

received from the IAD to be filtered by facility level. See RFC3164: The BSD Syslog Protocol.

This does not have to correspond to the facility level shown in the terminal mode option.

See SYSLOG Facility using Terminal Mode on page 40.

The remaining Syslog parameters have the following level choices:

FATAL (Highest priority)

ALERT

CRITICAL

ERROR

WA R NI N G

NOTICE

INFO

DEBUG (Lowest priority)

Every log message generated by the IAD has a reporting level priority. If the message priority is lower than

the configured priority for the destination log, the message is not forwarded to the syslog daemon. See

RFC3164: The BSD Syslog Protocol. The lower the log level, the more messages that will be generated.

Setting reporting levels to DEBUG may negatively affect the performance of the IAD, including causing

the IAD to reset.

ADTRAN recommends using DEBUG for only short periods of time for debug purposes

only.

61200704L2-1B © 2003 ADTRAN, Inc. 39

Page 40

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSLOG using Terminal Mode

Another option for configuring syslog is using the terminal mode command log dump <logname>. The

logname must be all CAPS and be one of the following names:

FATAL

ALERT

CRITICAL

ERROR

WA R NI N G

NOTICE

INFO

DEBUG

The command will dump all messages for the indicated log (

the internal log buffer to the command line display.

ALL LEVEL shows all log messages) stored in

SYSTEM CONFIG > SYSLOG > ALL LEVEL

This entry allows setting the default reporting level for all log entries. If ALL LEVEL is a lower priority than

the individual log entry level,

ALL LEVEL overrides the individual log reporting level.

SYSTEM CONFIG > SYSLOG > KERNEL LEVEL

Minimum required level for sending KERNEL log messages.

SYSTEM CONFIG > SYSLOG > DHCP LEVEL

Minimum required level for sending DHCP log messages.

SYSTEM CONFIG > SYSLOG > NTP LEVEL

Minimum required level for sending NTP log messages.

SYSTEM CONFIG > SYSLOG > TFTP LEVEL

Minimum required level for sending TFTP log messages.

SYSTEM CONFIG > SYSLOG > TELNET LEVEL

Minimum required level for sending TELNET log messages.

SYSTEM CONFIG > SYSLOG > IP LEVEL

Minimum required level for sending IP log messages.

40 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 41

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

SYSTEM CONFIG > SYSLOG > PPP LEVEL

Minimum required level for sending PPP log messages.

SYSTEM CONFIG > SYSLOG > NAT LEVEL

Minimum required level for sending NAT log messages.

SYSTEM CONFIG > SYSLOG > ARP LEVEL

Minimum required level for sending ARP log messages.

SYSTEM CONFIG > SYSLOG > UDP LEVEL

Minimum required level for sending UDP log messages.

SYSTEM CONFIG > SYSLOG > NETWRITE LEVEL

This parameter is for ADTRAN internal use only.

SYSTEM CONFIG > SYSLOG > TCP LEVEL

Minimum required level for sending TCP log messages.

SYSTEM CONFIG > SYSLOG > COMPSYS LEVEL

This parameter is for ADTRAN internal use only.

SYSTEM CONFIG > SYSLOG > CONSOLE LEVEL

This parameter is for ADTRAN internal use only.

SYSTEM CONFIG > SYSLOG > CFGXFER LEVEL

Minimum required level for sending configuration transfer log messages.

SYSTEM CONFIG > SYSLOG > ROUTER LEVEL

Minimum required level for sending router log messages.

SYSTEM CONFIG > SYSLOG > NONVOL LEVEL

Minimum required level for sending nonvolatile memory log messages.

61200704L2-1B © 2003 ADTRAN, Inc. 41

Page 42

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM CONFIG > SYSLOG > NOKIA LEVEL

Minimum required level for sending log messages about communication with the Nokia DSLAM.

Messages are only generated for products with an SHDSL WAN interface.

SYSTEM CONFIG > SYSLOG > AUTOBAUD LEVEL

Minimum required level for sending log messages about communication with the Lucent Stinger DSLAM.

Messages are only generated for products with an SHDSL WAN interface.

SYSTEM CONFIG > SYSLOG > TOLLBRG LEVEL

Minimum required level for sending log messages about communication with the Tollbridge Voice

Gateway. Messages are only generated for ATM products.

SYSTEM CONFIG > SYSLOG > CMCP LEVEL

Minimum required level for sending log messages about communication with the CopperMountain

DSLAM. Messages are only generated for ATM products.

SYSTEM CONFIG > SYSLOG > SHDSL LEVEL

This parameter is for ADTRAN internal use only.

SYSTEM CONFIG > SYSLOG > L1 LEVEL

Minimum required level for sending log messages about WAN physical or Layer 1 connection.

SYSTEM CONFIG > SYSLOG > ETH LEVEL

Minimum required level for sending log messages about Ethernet physical connection.

SYSTEM CONFIG > SYSLOG > ICMP LEVEL

Minimum required level for sending ICMP log messages.

SYSTEM CONFIG > SYSLOG > CONFIG LEVEL

This parameter is for ADTRAN internal use only.

SYSTEM CONFIG > SYSLOG >DS0 LEVEL

Minimum required level for sending log messages about DSO mapping.

SYSTEM CONFIG > SYSLOG > SELFTEST LEVEL

Minimum required level for sending log messages about selftest.

42 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 43

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

SYSTEM CONFIG > SYSLOG > VOICE LEVEL

Minimum required level for sending log messages about AAL2 voices services.

Messages are only generated for ATM products.

SYSTEM CONFIG > SYSLOG > JETSTREAM LEVEL

Minimum required level for sending log messages about communication with the JetStream Voice

Gateway. Messages are only generated for ATM products.

SYSTEM CONFIG > SYSLOG > POTS LEVEL

Minimum required level for sending log messages about POTS line cards and services.

SYSTEM CONFIG > SYSLOG > LESCAS LEVEL

Minimum required level for sending messages about communication with LESCAS compatible Voice

Gateways. Messages are only generated for ATM products.

SYSTEM CONFIG > SYSLOG > ATM LEVEL

Minimum required level for sending ATM log messages. Messages are only generated for ATM products.

SYSTEM CONFIG > SYSLOG > COPPERCOM LEVEL

Minimum required level for sending log messages about communication with the CopperCom Voice

Gateway. Messages are only generated for ATM products.

SYSTEM CONFIG > SYSLOG > VOFR LEVEL

Minimum required level for sending voice-over-frame-relay log messages about communication with the

CopperMountain DSLAM. Messages are only generated for ATM products.

SYSTEM CONFIG > SYSLOG > XMODEM LEVEL

Minimum required level for sending XMODEM log messages for firmware and configuration transfers.

SYSTEM CONFIG > SYSLOG > EMWEB LEVEL

This parameter is for ADTRAN internal use only.

SYSTEM CONFIG > SYSLOG > FRELAY LEVEL

Minimum required level for sending frame relay log messages.

61200704L2-1B © 2003 ADTRAN, Inc. 43

Page 44

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM CONFIG > SYSLOG > BRIDGE LEVEL

Minimum required level for sending bridge mode log messages.

SYSTEM CONFIG > SYSLOG > MAINT LEVEL

Minimum required level for sending CRAFT port log messages.

SYSTEM CONFIG > SYSLOG > HDLC LEVEL

Minimum required level for sending low level HDLC log messages.

SYSTEM CONFIG > SYSLOG > VOATM LEVEL

Minimum required level for sending Voice-over-ATM log messages.

SYSTEM CONFIG > SYSLOG > PPPOA LEVEL

Minimum required level for sending PPP-over-ATM log messages.

SYSTEM CONFIG > SYSLOG > FDL LEVEL

Minimum required level for sending FDL log messages.

SYSTEM CONFIG > NETWORK TIME

Activate the network time and configure the server type, time zone and various other network time

parameters from this menu.

SYSTEM CONFIG > NETWORK TIME > SERVER TYPE

The unit time can be entered manually from the SYSTEM INFO menu, or the unit can receive time from an

NTP/SNTP server. The

communicates with the time server.

The server type defines the port on which the unit will listen to receive timing information from the time

server. The choices are

server running SNTP software on its TIME port. When set to

an SNTP server. The factory default is

NETWORK TIME menu includes all parameters relating to how the unit

NT TIME and SNTP. When set to NT TIME, the unit will receive time from an NT

SNTP, the unit will receive time directly from

SNTP.

SYSTEM CONFIG > NETWORK TIME > ACTIVE

This network timing feature can be turned on and off. It determines whether the unit will request and

receive time from a time server. The factory default is

NO.

44 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 45

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

SYSTEM CONFIG > NETWORK TIME > TIME ZONE

All time zones are based off of Greenwich Mean Time (GMT). The choices are listed below

•GMT

• GMT -5 (E

• GMT -6 (C

• GMT -7 (M

• GMT -8 (P

• GMT -9 (A

• GMT -10 (H

ASTERN)

ENTRAL)

OUNTAIN)

ACIFIC)

LASKA)

AWAII)

The factory default is GMT-6 (CENTRAL).

SYSTEM CONFIG > NETWORK TIME > ADJUST FOR DAYLIGHT SAVING

Since some areas of the world use Daylight Savings Time, the unit is designed to adjust the time on the

first Sunday in April and the last Sunday in October accordingly if this option is turned on. The factory

default is

YES.

SYSTEM CONFIG > NETWORK TIME > HOST ADDRESS

This is the IP address of the time server that the unit will request and receive time from. The factory default

is no entry in the host address field.

SYSTEM CONFIG > NETWORK TIME > REFRESH

This is the interval of time between each request the unit sends out to the time server. A smaller refresh

time guarantees that the unit receives the correct time from the server and corrects possible errors more

quickly. This may be more taxing on the machine. A range of refresh times is available for the user to

decide which is best for their unit. Choices include

MINS, 40 MINS, 45 MINS, 50 MINS, 55 MINS, and 60 MINS. The factory default is 60 MINS.

5 MINS, 10 MINS, 15 MINS, 20 MINS, 25 MINS, 30 MINS, 35

SYSTEM CONFIG > NETWORK TIME > STATUS

This displays the current status of the time negotiation process. If an error is displayed, check all

connections and configurations to try to resolve the problem.

61200704L2-1B © 2003 ADTRAN, Inc. 45

Page 46

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM UTILITY

Use the SYSTEM UTILITY menu to view and set the system parameters shown in Figure 4.

Figure 3. System Utility Menu

SYSTEM UTILITY > UPGRADE FIRMWARE

Select the firmware upgrade method and perform upgrade from this menu.

SYSTEM UTILITY > UPGRADE FIRMWARE > TRANSFER METHOD

The customer can update firmware when unit enhancements are released.

The two methods for upgrading are

information.)

TFTP requires a TFTP server running on the network. The unit starts a TFTP client function

which gets the upgrade code from the TFTP server. Selecting

through the

TFTP.

CRAFT port using any PC terminal emulator with XMODEM capability. The factory default is

XMODEM and TFTP. (See the DLP section of this manual for more

XMODEM will load the upgrade code

SYSTEM UTILITY > UPGRADE FIRMWARE > TFTP SERVER ADDRESS

This is required when the transfer method is TFTP. It is the IP address or domain name (if DNS is

configured) of the TFTP server. The factory default is no entry in the TFTP server address field.

46 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 47

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

SYSTEM UTILITY > UPGRADE FIRMWARE > TFTP SERVER FILENAME

This is required when the transfer method is TFTP. It is the case-sensitive file name which contains the

upgrade code. The factory default is no entry in the

TFTP SERVER FILENAME field.

SYSTEM UTILITY > UPGRADE FIRMWARE > TRANSFER STATUS

This appears when TFTP is used. It displays the status of the transfer as it happens. Any error or success

message will be displayed here.

SYSTEM UTILITY > UPGRADE FIRMWARE > START TRANSFER

This activator is used when the configurable items in this menu are complete. This will initiate the transfer

for either TFTP or XMODEM upgrades.

Before using START TRANSFER, the unit should have a valid IP address, subnet mask, and

default gateway (if required). See DLP-2, Setting IP Parameters for the Total Access 544R

for more information.

SYSTEM UTILITY > UPGRADE FIRMWARE > ABORT TRANSFER

Use this activator to cancel any TFTP transfer in progress.

SYSTEM UTILITY > CONFIG TRANSFER

Select the config transfer method and perform the transfer from this menu.

SYSTEM UTILITY > CONFIG TRANSFER > TRANSFER METHOD

Sends a file containing the unit configuration to a PC connected to the CRAFT port using XMODEM

protocol or to a file on a TFTP server using the TFTP protocol.

CONFIG TRANSFER also lets you save the unit configuration as a backup file, so you can use the same

configuration with multiple units. In addition,

TFTP server.

To support these transfers, ADTRAN delivers a TFTP program with the unit called TFTP Server. You can

configure any PC running Microsoft Windows with this software, and store a configuration file.

Before using Start Transfer, the unit should have a valid IP address, subnet mask, and

default gateway (if required). See DLP-2, Setting IP Parameters for the Total Access 544R

for more information.

CONFIG TRANSFER can retrieve a configuration file from a

Only one configuration transfer session (upload or download) can be active at a time.

XMODEM and TFTP

are supported.

61200704L2-1B © 2003 ADTRAN, Inc. 47

Page 48

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM UTILITY > CONFIG TRANSFER > TFTP SERVER IP ADDRESS

Specifies the IP address of the TFTP server. Get this number from your system administrator. If using the

ADTRAN Utilities TFTP server, this number appears in the TFTP server status window. The factory

default value is

0.0.0.0.

SYSTEM UTILITY > CONFIG TRANSFER > TFTP SERVER FILENAME

Defines the name of the configuration file that you transfer to or retrieve from the TFTP server. The default

name is

ta_iad.cfg, but you can edit this name.

SYSTEM UTILITY > CONFIG TRANSFER > CURRENT TRANSFER STATUS

Indicates the current status of the update.

SYSTEM UTILITY > CONFIG TRANSFER > PREVIOUS TRANSFER STATUS

Indicates the status of the previous update.

SYSTEM UTILITY > CONFIG TRANSFER > LOAD AND USE CONFIG

Retrieves the configuration file specified in the TFTP Server Filename field from the server. To start this

command, enter

Y to begin or enter N to cancel.

If you execute this command, the unit retrieves the configuration file, reboots, then restarts

using the new configuration

SYSTEM UTILITY > CONFIG TRANSFER > SAVE CONFIG REMOTELY

Saves the configuration file specified in TFTP Server Filename to the server identified in TFTP Server IP

Address. To start this command, enter

Y to begin or enter N to cancel.

Before using this command, you must have identified a valid TFTP server in TFTP SERVER

IP A

DDRESS.

SYSTEM UTILITY > SYSTEM UTILIZATION

View the CPU utilization stats from this menu.

SYSTEM UTILITY > SYSTEM UTILIZATION > PERFORMANCE

Clear the system utilization stats and view the total and current CPU utilization stats from this menu.

48 © 2003 ADTRAN, Inc. 61200704L2-1B

Page 49

Total Access 544R System Manual Section 4 SHDSL RCU ATM User Interface Guide

SYSTEM UTILITY > SYSTEM UTILIZATION > PERFORMANCE > TOTAL AVG CPU UTILIZATION

TOTAL AVG CPU UTILIZATION is a running total of CPU utilization since the last reset.

SYSTEM UTILITY > SYSTEM UTILIZATION > PERFORMANCE > CURRENT AVG CPU UTILIZATION

CURRENT AVG CPU UTILIZATION is the running total of CPU utilization since the last clear.

SYSTEM UTILITY > SYSTEM UTILIZATION > PERFORMANCE >TOTAL AVG ISR UTILIZATION

The Total Avg ISR Utilization is a running total average of the ISR Utilization.

SYSTEM UTILITY > SYSTEM UTILIZATION > PERFORMANCE > CLEAR STATS

This activator will clear all the system utilization performance stats.

SYSTEM UTILITY > PING

Activate the ping test and define the ping packet characteristics from this menu.

SYSTEM UTILITY > PING > START/STOP

Activator to start and cancel a ping test.

Only one ping session can be active at a time.

Diagnostic features such as ping, extended ping, traceroute, extended traceroute, and

telnet client can also be performed via

TERMINAL MODE (see page 40).

SYSTEM UTILITY > PING > HOST ADDRESS

IP address or domain name (if DNS is configured) of device to receive the ping. This field is left blank by

default.

SYSTEM UTILITY > PING > SIZE (40-1500)

Total size of the ping to send. Range is 40 to 1500 bytes. The default is 64.

SYSTEM UTILITY > PING > # OF PACKETS

Total packets to send every 2 seconds. Setting this to 0 allows the client to ping continuously. The default is

5.

61200704L2-1B © 2003 ADTRAN, Inc. 49

Page 50

Section 4 SHDSL RCU ATM User Interface Guide Total Access 544R System Manual

SYSTEM UTILITY > PING > # TRANSMITS

Total packets sent (read only).

SYSTEM UTILITY > PING > # RECEIVES

Total packets received (read only).

SYSTEM UTILITY > PING > % LOSS

Percentage loss based on ping returned from host (read only).

SYSTEM UTILITY > TRACEROUTE

Utility program used to trace a data path to a final destination.

SYSTEM UTILITY > TRACEROUTE > TRACE TARGET