Page 1

February 2001

61202156L1-1B

TDU 120e

User Man u al

Part Numbers

1202156L1

1202155L1

Page 2

Trademarks:

Windows is a registered trademark of Microsoft Corp.

T- Watch is a trademark of ADTRAN, Inc.

OpenView

R

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

Phone: (256) 963-8000

© 2001 ADTRAN, Inc.

All rights reserved.

Printed in USA.

Page 3

The following conventions are used in this manual.

Notes provide additional useful information.

Cautions signify information that could prevent service interruption.

Warnings provide information that could prevent damage to

the equipment or endangerment to human life.

Important Safety Instructions

When using your telephone equipment, please follow these basic safety precautions to reduce the risk of fire, electrical shock, or personal injury:

1. Do not use this product near water, such as near a bathtub, wash bowl,

kitchen sink, laundry tub, in a wet basement, or near a swimming pool.

2. Avoid using a telephone (other than a cordless-type) during an electrical

storm. There is a remote risk of shock from lightning.

3. Do not use the telephone to report a gas leak in the vicinity of the leak.

4. Use only the power cord, power supply, and/or batteries indicated in the

manual. Do not dispose of batteries in a fire. They may explode. Check with

local codes for special disposal instructions.

Save These Important Safety Instructions

iii

Page 4

FCC regulations require that the following information be provided to the customer in this manual.

1. This equipment complies with Part 68 of the FCC rules. The required label is

attached to the bottom of the chassis.

2. An FCC compliant telephone cord and modular plug is provided with this

equipment. This equipment is designed to be connected to the telephone network or premises wiring using a c ompatible modular jack which is Part 68

compliant. See installation instructions for details.

3. If your TDU 120e causes harm to the telephone network, the Telephone Company may discont inu e your service temporarily. If possible, they will notify

you in advance. If advance notice is not practical, you will be notified as soon

as possible. You will be advised of your right to file a complaint with the FCC.

4. Your telephone comp any may make change s in its facilities, equi pment, operations, or procedures that could affect the proper operation of your equipment. If they do , you w ill be given advance not ice so as to give you an

opportunity to maintain uninterrupted service.

5. If you experience trouble with the equipment TDU 120e, please contact ADTRAN at (256) 963-8000 for repair/warrant y in formation. The telephone company may ask you to disconnect this equipment from the network until the

problem has been corrected, or until you are sure the equipment is not malfunctioning.

6. This unit c on tains no user serviceabl e parts.

7. The following information may be required when app lying to your local telephone compa ny for leased line facilities .

Service Type REN/SOC FIC USOC

1.544 Mbps -SF 6.0N 04DU9-BN RJ-48C

1.544 Mbps - SF and B8ZS 6.0N 04DU9-DN RJ-48C

1.544 Mbps - ESF 6.0N 04DU9-1KN RJ-48C

1.544 Mbps - ESF and B8Z S 6.0N 04DU9-1SN RJ-48C

8. The FCC recommends that the AC outle t t o which e qui pment r equir in g AC

power is to be in st alle d is provided with an AC surge ar rester.

iv

Page 5

Affidavit Requirements for Connection to Digital Services

• An affidavit is required to be given to the telephone company whenever

digital terminal equip ment without encoded analog content and billing protection is used to transmit digital signals containing encoded analog content

which are intended for eventual convers ion into voice band analog signal

and transmitted on the network.

• The affidavit shall affirm that either no encoded analog content or billing

information is be ing transmitted or that the output of the device meets Part

68 encoded analog conte nt or billing protection spe c ificat ion .

• End use/cus tomer will be responsibl e to file a n affidavit with the local

exchange carrier when connecting unprotected CPE to a 1.544 Mbps or subrate digital servic e .

• Until such time as subrate digital termin al equipment is registered for voice

applications, the affidavit requirements for subrate services are waived.

v

Page 6

Affidavit for Connection of Customer Premises Equipment to 1.544 MBPS

and/or Subrate Dig i tal Se rvices

For the work to be performed in the certified territory of ______________ (telco

name)

State of ________________________________

County of ______________________________

I, _______________________ (name), ____________________ (business address),

_____________________ (telephone number) being duly sworn, state:

I have the responsibility for the operation and maintenance of the terminal equipment to be connected to 1.544 Mbps and/or __________________ subrate digital

services. The terminal equipment to be connected complies with Part 68 of the

FCC rules except for the encode d analog conten t a nd b illing protection specifi c ation. With respect to encoded analo g co nten t and billing protectio n:

( ) I attest that all operations asso ci ated with the e stablishment, maintenance and

adjustment of the digital CPE with respect to encoded analog content and billing

protection information continuously complies with Part 68 of the FCC rules and

Regulations.

( ) The digi tal CPE does not transmit digita l signal s co nta ining encod e d analog

content or billing informati on whic h is i n ten ded to b e decod ed wi thin the t elecomm u ni ca tions n e t work.

( ) The encoded analog content and billing protection is factory set and is not

under the control of the customer.

I attest that the operator(s) maintainer(s) of the digital CPE responsible for the

establishment, maintenance and adjustment of the encoded analog content and

billing information has (have) been trained to perform these functions by successfully having complet e d one o f th e f ollowing (check appropriate blocks):

( ) A. A training course provid ed by the m anu fa cturer/gran te e of the equi p ment

used to encode analog signals; or

( ) B. A training course provided by the customer or authorized representative,

using training materials and instructions provided by the manufacturer/grantee

of the equipment used to encode analog signals; or

( ) C. An independent tr aining course (e.g., tra de school or technical institution)

vi

Page 7

recognized by the manufacturer/grantee of the equipment used to encode analog signals; or

( ) D. In lieu of the proceeding training requirements, the operator(s)/maintainer(S) is (are) under the control of a supervisor trained in accordance with

_______________ (circle one) above.

I agree to provide ____________________ (telco’s name) with proper documentation to demonstrate compliance with the information in the preceding paragraph, if so requested.

_____________________ Signature

_____________________ Title

_____________________ Date

Subscribed and sworn to before me

This _________ day of ___________________, 20__

_______________________________________

Notary Public

My commission expires: _________________________

vii

Page 8

Federal Communications Commission Radio Frequency

Interference Statement

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, an d

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio frequencies.

Operation of this equipment in a resident ia l area is li kely t o c ause harm ful i nte rference in which c a se the us e r will be requ ired to correct the interference at his

own expense.

Shielded cable s must be used with t his u nit to ensure compliance wi th Clas s A

FCC limits.

Change or modifications to this unit not expressly approved by the party respons ible fo r complia nce cou ld void the u ser’s auth ority to operat e

the equipment.

Canadian Emissions Requ irements

This digital apparatus does not exceed the Class A l imits for radio noise emiss ions

from digital apparatus as set out in the interference-causing equipment standard

entitled “Digital Apparatus," ICES-003 of the Department of Communications.

Cet appareil nu erique respecte les limites de bru its r a dio ele ctri qu es a pp lic abl es

aux appareils numeriques de Class A prescrites dans la norme sur le materiel

brouilleur: "Appareils Numeriques," NMB-003 edictee par le ministre des Communications.

viii

Page 9

Canad i an Equipment Limitations

Notice: The Canadian Industry and Science Canada label identifies cert ified

equipment. This certification means that the equipment meets certain telecommunicati ons network protective, operational, and safety requir e ments. The

Depa rt ment doe s not g u a ra ntee th e eq u i pment w ill operate to the u s er’s sat i s faction.

Before installing this e quipment, us e rs should ensure that it is permissible to be

connected to the facilities of the local telecommunications company. The equipment must al so be inst alle d usin g an acceptab le me thod s of conn ect ion . In some

cases, the company’s inside wiring associated with a single line individual service may be extended by means of a certified connector assembly (telephone

extension cord). The customer should be aware that compliance with the above

limitations may not prevent de gradation of service in some situ a tions.

Repairs to certified equipment should be made by an authorized Canadian

maintenance facility designated by the supplier . Any repairs or alterations made

by the user to this equipment, or equipment malfunctions, may give the telecomm un ications company cau s e t o re qu e s t the u s er to disconn e ct t he equ i pment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephon e lines and internal metallic water pipe system, if present, are connected together. This precaution may be particularly

important in rura l areas.

Users should not attempt to make such connections themselves,

but should contract t he appropriate electric inspection authority, or an electrician, as appropriate.

The Load Number (LN) assigned to each terminal device denotes the percentage of the total load to be connected to a telephone loop which is used by the

device, to prevent o ver loa ding. T he te rmination on a loop may con sist o f an y

combination of devices subject only to the requirement that the total of the Load

Numbers of all devices does not exceed 100.

ix

Page 10

Limited Prod uct War ranty

ADTRAN warrants that for five (5) years from the date of shipment to Customer,

all products manufactured by ADTRAN will be free from defects in materials and

workmanship. ADTRAN also warrants that products will conform to the applicable specifications and drawings for such products, as contained in the Product

Manual or in ADTRAN's internal specifications and drawings for such products

(which may or may not be reflected in the Product Manual). This warranty only

applies if Cus tomer giv es ADTR AN writ ten noti ce of d efe cts du ri ng the war ra nty

period. Upon such notice, ADTRAN will, at its option, either repair or replace the

defective item. If ADTRAN is unable, in a reasonable time, to repair or replace

any equipment to a condition as warranted, Customer is entitled to a full refund

of the purchase price upon return of the equipment to ADTRAN. This warranty

applies only to the origina l purchaser an d is not transfer abl e with out ADTRAN's

express written permission. T his w a rr anty becom e s null and void if Custom e r

modifies or alters the equipment in any way, other than as specifically authorized

by ADTRAN.

EXCEPT FOR THE LIMITED WARRANTY DESCRIBED ABOVE, THE FOREGOING CONSTITUTES THE SOLE AND EXCLUSIVE REMEDY OF THE CUSTOMER AND THE EXCLUSIVE LIABILITY OF ADTRAN AND IS I N LIEU OF

ANY AND ALL OTHER WARRANTIES (EXPRESSED OR IMPLIED). ADTR AN

SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING (W ITH OUT LIMITATION), ALL WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PAR T ICULAR PURPOSE. SOME STATES DO NOT ALLOW THE

EXCLUSION OF IMPLIED WARRANTIES, SO THIS EXCLUSION MAY NOT

APPLY TO CUSTOMER.

In no event will ADTRAN or its suppliers be liable to Customer for any incidental, special, punitive, exemplary or consequential damages experienced by either

Customer or a third party (including, but not limited to, loss of data or information, loss of profits, or loss of use). ADTRAN is not liable for damages for any

cause whatsoever (whether based in contract, tort, or otherwise) in excess of the

amount paid for the item. So m e states do no t allo w the lim ita tion or exclu sion of

liability for incidental or consequential damages, so the above limitation or exclusion may not apply to Customer.

x

Page 11

Customer Service, Product Support Information , and Tra ining

ADTRAN will replace or repair this product w ithin fiv e yea r s from the d ate of

shipment if the product does not meet its published specification, or if it fails

while in serv ice.

A return material authorizatio n (RMA) is req uired prior to returning equipment

to ADTRAN. For service, RMA requests, training, or more information, see the

toll-free contact numbers given below.

Presales Inquiries an d Applications Support

Please contact your local distributor, ADTRAN Applications Engineering, or

ADTRAN Sales:

Applications Engineering (800) 615-1176

Sales (800) 827-0807

Post-Sale Support

Please contact your local distributor first. If your local distributor cannot help,

please contact ADTRAN Technical Support and have the unit serial number

available.

Technical Support (888) 4ADTRAN

The Custom Extended Services (ACES) program offers multiple types and levels

of service plans which allow you to choose the kind of assistance you need. For

questions, call the ACES Help Desk.

ACES Help Desk (888) 874-2237

xi

Page 12

Repair and Return

If ADTRAN Technical Support determines that a repair is needed, T echn i cal Support will coordinate wit h the Custom and Product Service (CAPS) department to

issue an RMA number. For information regarding equipment currently in house

or possible fees associa te d with repair, c o ntac t CAPS di rectly at the following

number:

CAPS Department (256) 963-8722

Identify the RMA number clearly on the package (below address), and return to

the followin g a ddress:

ADTRAN Customer and Product Service

901 Explorer Blvd.

Huntsville, Alabama 35806

RMA # _____________

Training

The Enterprise Network (EN) Technical Training offers training on our most popular products. These courses include overviews on product features and functions

while covering app licat ions of ADTRAN's product lines. ADTRAN provides a variety of training options, including customized tra ining and courses taug ht at our facilities or at your site. For more information about training, please contact your

Territory Manager or the Enterprise Training Coordinator.

Training - phone (800) 615-1176, ext. 7500

Training - fax (256) 963 7941

Training - email training@adtran.com

xii

Page 13

Table of Contents

List of Figu re s ............ .. .......... .. .......... .. ... .......... .. .......... .. .......... .. ... ......... ... .......... .. ... xxi

List of Tab l es .......... ... ......... ... .......... .. .......... .. ... ......... ... ......... ... .......... .. .......... .. ... ...xxiii

Chap ter 1. Introduction ......................................... ................................................. 1-1

TDU120e Overview ..................................................................................................1-1

Standard Features in the TDU 120e.................................................................1-2

TDU O ption Modules............... ........................................... .............................. 1 -3

Optio n Module A rchitecture ........................... ............................................ ..... 1-4

TDU 120e Configuration Applicati ons .................................................................. 1-5

Router, PBX, Video C on f er e n c i ng Ap p lication.. .. .......... .. .......... .. .......... ........ 1-5

Chap ter 2. Installation ............................................................ ................................ 2-1

Unpack, Inspect, Power Up ....................................................................................2-1

Receip t I n s p e c ti o n ........... .......... .. .......... ......... ... .......... ......... ... ......... .......... ... ..... 2-1

ADTRAN Shipments Include........................................................................... 2-1

Customer Provides............................................................................................. 2-1

Power Connection.............................................................................................. 2-2

Groun ding Instruct ions ............. .......................... ............................................ ........ 2-2

Rear Panel Layout .................................................................................................... 2-4

TDU 120e Interfaces...........................................................................................2-5

Network Inte rface ... ............................................ ....................................... 2-5

Nx56/ 6 4 Se ri a l Inte r f ac e .............. .. ... ......... ... ......... ... .......... .. .......... .. ... ..... 2-5

DS-1 ( PBX) In terface .................. ........................... .......... ......... .......... ........ 2-5

Control Port Input .................................................................... .................. 2-5

Craft Port ........... ......... ... ......... .......... ... ......... ... ......... .......... ... ......... .......... .. . 2-6

Chain Port Output ..................................................................................... 2-6

10BaseT Interface ....................................................................................... 2-6

External Alarm Connector ........................................................................ 2-6

Power Up Testing .....................................................................................................2-7

Self-Test ............................................................................................................... 2-7

Board Level Tests ................................................................................ 2-7

RAM and EPROM Tests ....................................................................2-7

61202156L1-1 TDU 120e User Manual xiii

Page 14

Table of Contents

Unit Leve l Tes ts ....... .. .......... .. .......... ... ......... ... .. .......... .. .......... .. .......... . 2-7

Board-to-Board Interface Test ...........................................................2-7

Initialization ........................................................................................................ 2-8

Set Use r P as s co de ...... .. ... .......... .. .......... .. .......... .. .......... .. ... .......... .. .......... .. . 2 -8

Set Unit I d e n t if i ca t ion ...... .......... .. .......... ... ......... ... ......... ... .......... .. .......... .. . 2 -8

Set Cont rol Port ....... .. .. .......... ... ......... ... ......... ... .. .......... .. .......... ... ......... ... .. . 2 -8

Chain In (PC) ..............................................................................................2-8

Chain In/Chain Out .................................................................................. 2-9

Normal Power-Up Procedure.........................................................................2-10

Chap ter 3. Operation...............................................................................................3-1

Menu Fe atures ....... ........................................... ........................... ..............................3-1

Sample Terminal Screen with TDU 120e Menu .....................................3-2

General Menu Operation ..................................................................... .............3 -2

Select a n d Activat e a Menu It e m .. .......... .. .......... ......... ... .......... ......... ... ...3 -2

Exit Any Menu Field Operation Or Display ..........................................3-4

Data Port Identifica tion ........... ... ......... .......... .......... .......... ......... ... ......... .......... . 3 -5

Menu Structure ............. ............................................ ........................... ...............3-6

Telnet/Terminal Main Menu ...................................................................3-6

Menu O ptions .. .......... ............................................ .....................................3-7

Status . .... ........ ....... ....... ..... ....... ........ ....... ..... ....... ....... ........ ..... ....... ....... .3 -7

Config (Configuration ) ............................................................ ...........3-7

Util (Utilities) .......................................................................... .............3-7

Test ........................................................................................................ 3-7

Remote Menu Access ........................... .......... .......................... ...........3 -7

Manag e m e n t Configu ration ..... .......... .. .......... .......... .. .......... .......... .. . 3 -7

Flash Download ........................................ ..........................................3-7

Quit Se ss i o n . .. ... ......... ... ......... ... .......... .. .......... .. .......... .. .......... .. ... ........3-7

Front P a nel ............. ......... ... ......... ... .......... ......... ... ......... .......... ... ......... .......... .. .......... . 3 -8

ACO Switch......................................................................................................... 3-8

Remote LED .............................. .......... ........................... ......... ........................... . 3 -8

Craft Port ......... ......... ... ......... .......... ... ......... .......... .. .......... ... ......... .......... .. .......... . 3 -8

Network Mo nitor Jack ....................... ............................................ ....................3-8

DS1 Monitor Jac k..... .................... ......... .......... .......... .......... ......... .......... .......... ...3 -9

Network Sta tus LEDs................................................. ........................................3-9

Port S t at u s LEDs.............. ......... ... ......... .......... ... ......... .......... .. .......... .......... ......3-10

Port 1 .1 Op tion Ca rd Monito r Jac k s ............... ......... .......... .. .......... .......... ......3-10

Alternate Methods Of Control ...................................... ........................... .............3-11

T-Watch Pro (ADTRAN PC Program) ........... ........................................... ....3- 11

Settin g up the TDU 120e to Work O ver a LAN ................................... 3 -11

Setting up the TDU 120e to Work Over an EIA-232 Connection ......3-12

SNMP ....................................................................................................................... 3-12

xiv TDU 120e User Manual 61202156L1-1

Page 15

Table of Contents

Chapter 4. Status Menu................................................ .......................................... 4-1

Netw ork Performanc e Reports.................... .................................................... 4-2

Network Inte rface Errors ................................... ............................................ ... 4-3

Activ e Alarms ........ .......... ............................................ .......................... ............. 4-3

View History ....................................................................................................... 4-4

Port S t at u s .. .. .......... ... ......... .......... .. .......... .......... .. .......... .......... .. .......... .......... .. ... 4-4

Nx/DBU (0.1) Menu Items ....................................... ................................ 4-4

DTE Data/Clock ................................................................................. 4-4

DTE Status ........................................................................................... 4-5

DTE Port Rate ...................................................................................... 4-5

DBU Data/CNTRL ............................................................................. 4-5

DBU Control ........................................................................................ 4-5

DBU Status ........................................................................................... 4-5

DS-1 ( 0 .2 ) Menu Ite ms (DS-1 Er ro rs ) ...... .. .......... .. ... .......... .. .......... .. ........ 4 -6

Remote Port............... ......... .......... .......... ......... ........................... ......................... 4-6

Clear Port Alarm ................................................................................................ 4-6

Ethern e t St a tu s.. ... ......... ... .. .......... .. .......... ... ......... ... ......... ... .. .......... .. .......... ... ..... 4 -7

Chap ter 5. Configuration Menu ........................................................................... 5-1

Network (NI) .... ............................................ ........................................... .................. 5-3

Network (NI) Menu Items ................... .......................... ................................... 5-3

FORM AT ...... ....... .......... .......... ......... ........ ......... .......... ....... .......... ........ 5-3

CODE .. ..... ....... ........ ....... ..... ....... ....... ........ ..... ....... ....... ....... ..... ........ ..... 5-3

YELLOW ALARM .............................................................................. 5-3

TRANSMIT PRMS .............................................................................. 5-3

TIMING M O D E .. .......... .. .......... ... ......... ... .. .......... .. .......... .. .......... ... .. ... 5-3

TDU 120e Clock Source s ......... ............................................................. ..... 5-4

Network Tim ed .......................................................... ......................... 5-4

Based DS-1 ........................................................................................... 5-5

Base DTE Timing .. ......... .......... .......... .......... ......... ........................... ... 5-5

Internal Timing .................................................................................. . 5-6

Second ary Timing . ........................................... ................................... 5-6

Normal (CSU) Timing ........... ............................................................. 5-7

U-BR1T E ....... .......... ......... .......... ....... .......... .......... .......... ......... ........ ..... 5 -7

Set Line Bui ldout .......... .. .......... ... .. .......... .. .......... .. ... ......... ... .......... .. .. . 5-7

Inband Loopback ................................................................................ 5-8

Bit St uf f i ng . ......... .......... .. .......... .......... .. .......... .. .......... .......... .. .......... ...5-8

Unit Me nu ......... ... .. .......... .. .......... .. .......... ... ......... ... .. .......... .. .......... .. .......... ... ..... 5 -8

Control Port Rate ......................................... ....................................... 5-8

Traps ..................................................................................................... 5-8

Access ................................................................................................... 5-8

Init Modem ......... ... ......... .......... ... ......... ... ......... .......... ... ......... .......... .. . 5-9

61202156L1-1 TDU 120e User Manual xv

Page 16

Table of Contents

Control Port .........................................................................................5-9

IP Address ...................................... ......................................................5-9

Subne t M a s k .......... .......... ... ......... .......... .. .......... .......... .. .......... .......... .. . 5-9

Defau lt R outer ........... ... ......... ... .......... .. .......... .. .......... .. .......... .. .......... . 5-9

SLIP Rate ....................... ........................................... ............................5-9

SLIP Flow CTL ......... ........................... .......................... .....................5-10

Proxy Traps .................................... ........................................... ......... 5-10

Map E xchange............. .......................... ........................... ........................... ......5-10

OFF . .......... .......... ......... ........ ......... .......... .......... ....... .......... ......... ......... 5 -10

AUTO .. .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... .... 5- 10

Map In Use ...... .......................... ........................... ........................... ......... .........5-11

DS0 Ma ps ......... ................... .......... ......... .......... .......... .......... ......... .......... .......... . 5- 11

DS0 Ma p s Conf i gu ration Me n u .... .......... ......... ... ......... .......... .......... ......5-11

Creating a DSO Map ................................................................................5-12

Initializing the Temp Ma p ...... ......... ............................................ ...........5-12

Editing the T emp M ap ..................................... ........................... .............5-13

Applying the Temp Map ....................... ........................... .......................5-13

Copying Map ...... .......................... ............................................ ................5-14

Reviewing Map s .............................. ............................................ .............5 -14

Copy Map A (B) to Temp Map ....................................... ................ 5-14

Create Temp Map ............... .......... ......... .......... .......... .......................5-14

Review Map A(B) ..............................................................................5-15

Review Temp Map ............................................................................5-15

Edit Tem p M a p ........ .. .......... .. ... .......... .. .......... .. ... ......... ... ......... ... ......5 - 15

Apply Te mp to Map A(B) ............................... ................................. 5-15

Port Configu ra tion (Po rt Config ) ..... .......... ......... ... .......... .. .......... ......... ... ......5-15

Nx/DBU (0.1) Menu Items ........................ ............................................ . 5-15

Nx/DBU (0.1) .......... ............................................ ..............................5-15

DSO Rate ............................................................................................5-16

TX CLK CNTRL . .......... .. .......... .. .......... .......... .. .......... .. .......... .......... .5-16

Data ..................................................................................................... 5-16

CTS ........... .............. ............... ...................... .............. ...................... .... 5-16

DCD ....................................................................................................5-16

DSR . ... ......... ... ......... ... .. .......... .. .......... ... ......... ... ......... ... .. .......... .. ......... 5- 16

“O” INH I B ......... ......... .......... .......... ......... .................... .......... ......... ....5 - 17

INBAND MODE .................................. ............................................ . 5 -17

TX CLK SOURCE .... .......... ......... ... ......... ... .......... ......... ... ......... ... ......5-17

Dial Backup Configuration .....................................................................5-18

Backup Mode . .......... .......... ......... .......... ........................... ......... ......... 5- 18

Backup On ......... .......................... .......... ........................... ......... ......... 5- 18

NET FAIL ........................................................................................... 5-18

NET/DATA FAIL ................................................................ .............5-18

xvi TDU 120e User Manual 61202156L1-1

Page 17

Table of Contents

Pattern Verify .................................................................................... 5-18

Backup Delay ................ ........................... ......... ........................... ...... 5-18

Restore Del ay ...... .......... .......... .......................... ................................. 5-19

Retry Delay ................................................... ..................................... 5- 19

Num Ret ries ...... .. ... ......... ... .......... .. .. .......... ... .. .......... .. .......... .. ... ........ 5-19

Backu p Testing ... .......... .......... .......................... ........................... ...... 5- 19

WKEN D Locko ut .... ........................... ........................... .................... 5- 19

DS-1 ( 0.2) Menu Items......... ......... .......... .......... .......... ......... .......... .......... ........ 5-20

Format ................................................................................................5-20

Code .... ............ .......... ............ ............ ............. ............ ......... ............. ... 5 -20

Yellow A la rm ................. ... .. .......... .. ... .......... .. .. .......... ... ......... ... .. ...... 5 - 20

Line Le ngth (ft) ............. .......... ......... .......... .......... .......... ....................5-20

Inband Loopback (INBANK LPBACK) ......................................... 5-21

Robbed Bit Signaling ........................................................................ 5-21

RBS Start ......... .......... .......... .......... ......... .......... .......... ......... ................ 5-21

RBS E n d ........ .......... ................... .......... .......... ......... .......... .......... ........ 5 -21

Chapter 6. Utility Menu.........................................................................................6 -1

Time/Date........................................................................................................... 6-2

Facto r y Restor e ............. ........................... ........................................................... 6-2

Set Pass code . .......... ... ......... ... ......... ... .......... .. .......... .. .......... .. ... ......... ... .......... .. ... 6-3

Chang e /S e t a Pa s sc ode ...... .......... .. .......... .. .......... .. ... .......... .. .......... .. ........ 6-3

Lost Pa ss co de ........... .. .......... .. ... .......... .. .......... .. .......... .. .......... .. ... .......... .. ... 6-3

No Pass co de D e s i re d ... .. .......... .......... .. .......... ......... .......... ... ......... .......... .. . 6-3

Unit ID . ......... ... .. .......... .. .......... ... ......... ... ......... ... .. .......... .. .......... ... ......... ... ......... . 6-3

To Set the Unit Identification ................................................................... 6-4

No Unit ID Desired ........ .......... .. .......... .. .......... .......... .. .......... .......... .. ........ 6-4

Softw are Revision.. .......... .......... ......... ........................... .......... .......................... . 6-4

Port Utility..................................................... ................. ............ ............ ............. 6-4

Ethern e t Ad d re s s. .. ... ......... ... .. .......... .. .......... .. .......... ... .. .......... .. .......... .. .......... .. . 6-4

Chap ter 7. Test Menu.............................................................................................. 7-1

Network Tests ......................... ............................................................. ............... 7 -2

Loopb ack Tests ................................... ........................................... ............. 7-2

Network Inte rface Loopbacks .................................................................. 7-2

Line ....................................................................................................... 7-2

Paylo ad ....... ......... .......... .......... ....... .......... ......... .......... .......... ....... ........ 7-3

Local Loopbck ............................................................................................ 7-3

Line On .............. .......... ......... .......... .......... .......................... .......... ........ 7-3

Payload On .......................................................................................... 7-3

No Loopback ...... .......... .......... .. .......... .......... .. .......... ......... ... .......... ..... 7 -3

Remote Loopback .............. ......... ........................... .......... .......................... . 7-3

61202156L1-1 TDU 120e User Manual xvii

Page 18

Table of Contents

ATT In-Band LLB ................................................................................ 7-4

ANSI FDL PLB ......... ........................... .......................... .......................7-4

ANSI FDL LLB .......................... ........................................................... 7-4

ANSI FT1 LL B ................. ............................................ ......................... 7-4

No Loopback .. ... ......... .......... .. .......... .......... .. .......... .......... .. .......... ........ 7-4

Test Patt e rn ...... ... .. .......... .. .......... .. .......... ... .. .......... .. .......... .. .......... .. .......... . 7-4

All Ones ...................................................... .......................................... 7-4

All Zeros ............................................................................................... 7-4

QRSS Pattern ................. ......... .......... .......... .......... ......... .......... .......... ...7 -5

Pattern Result ..............................................................................................7-6

ES ....... ......... ............ ............. ............ ......... ............. ............ ............ ........ 7-6

BES ........................................................................................................ 7-6

SES ..... ....... .......... ......... .......... ....... .......... .......... ......... ........ ......... .......... . 7-6

*SYNC ............. ...................... ............... .............. ............ ............... ........ 7-6

Run Self-Test ............................. ............................................................. .............7-7

Port T e sts ........... .. .......... .......... .. .......... .......... .. .......... .......... .. .......... ......... ... ........ 7-8

Port T e st Menu It e ms Nx/DB U (0. 1) ..... ......... .......... .. .......... ... ......... ......7-9

DTE LOOPBACK ....................................................................................... 7-9

PORT/LOCAL ....................................................................................7-9

REMOTE ....... ......... ... .. .......... .. .......... ... ......... ... ......... ... .......... .. .. .......... . 7 -9

OFF . .......... .......... ......... ........ ......... .......... .......... ....... .......... ......... .......... . 7 -9

REM V.5 4 Cont. .............................................. .....................................7-9

511 PAT T R N .. .......... .......... ......... .......... .......... ......... .......... .......... ......7-10

511 RES U LTS .... ......... .......... .......... ......... .......... .......... .......... ......... ....7 - 10

DBU LOOPBACK .............................................................................7-10

DBU TEST .......................................................................................... 7-10

DBU DATA/CNTRL ........................................................................7-11

DBU TST RESULT ............................................................................. 7-11

DS-1 ( 0-2) Option Ports ............... ........................... .......... .......... ......... ....7- 11

Loopback ............................................................................................ 7-11

Cance l Tests.......................................................................................................7-11

Chapter 8. Remote/Management Menus.............................................................8-1

Remote Menu Access ............ ........................................... ........................... .............8-1

Manag e m e n t Config uration ..... .......... ... ......... .......... .. .......... ... ......... .......... .. .......... . 8-1

Unit Acc e ss Table ............... ... ......... ... ......... .......... ... ......... ... ......... .......... ... ......... ... ...8-1

SNMP Read Community.. .......... .......................... ........................... .................. 8 -4

SNMP Read/Write Community . .......... ........................... .......................... ......8-4

SNMP Trap Commun i ty ............ ......... ........................... ........................... ........ 8-4

Host 1 T ra p IP Ad dr e ss .... .. .......... .. ... ......... ... ......... ... .. .......... .. .......... . 8-4

Host 2 T ra p IP Ad dr e ss .... .. .......... .. ... ......... ... ......... ... .. .......... .. .......... . 8-5

Host 3 T ra p IP Ad dr e ss .... .. .......... .. ... ......... ... ......... ... .. .......... .. .......... . 8-5

xviii TDU 120e User Manual 61202156L1-1

Page 19

Table of Contents

Host 4 T ra p IP Ad dress .... .. .......... .. ... .......... .. .. ... .......... .. .. .......... ... .. ... 8-5

System Name ....................................................................................... 8-5

System Contact .................................................................................... 8-5

System Location .................................................................................. 8-5

Auth. Fa il Traps Se nt .... ... .. .......... .. .......... ... ......... ... ......... ... .......... .. ... 8-5

Poll Li nk Sta t u s Tr aps Sent ... .. .......... .. .......... .. .......... ... .. .......... .. ........ 8-5

Ping IP Host ......................................................... ................................ 8 -5

Telnet/Terminal Timeout .................................................................. 8-6

Telnet/Terminal Password ............................................................... 8-6

Exit ........................................................................................................ 8-6

Flash Download....................................... ........................................................... 8-6

XMODEM ............................................................................................ 8-6

Trivi al File Transfer Protocol (TFTP) ....................................... ........ 8-6

TFTP Server IP Address: 0.0.0.0. ........................................ ............... 8 -6

TFTP Server File name: T120e.biz ...................................... ..............8-7

Begin Firmware update. .................................................................... 8-7

Quit Se ss i o n....... ... .. .......... .. .......... .. .......... ... ......... ... ......... ... .......... .. .......... .. ........ 8-7

Append i x A. SNMP ... ... .. .......... .. ... ......... ... ......... ... .......... .. .. .......... ... ......... ... ........ A-1

Append i x B . Con ne ct o r Pin o ut s ................ ... .. .......... .. ... ......... ... ......... ... .. .......... .. B-1

Appendix C. System Messa ge s. .......... .......... .. .......... .. .......... .. .......... .......... .. ...... C-1

Append i x D . Spe ci fi ca t i ons..... .. .......... .. .......... .. ... .......... .. .......... .. ... ......... ... ........ D-1

Index ................................................................................................................ Index-1

61202156L1-1 TDU 120e User Manual xix

Page 20

Table of Contents

xx TDU 120e User Manual 61202156L1-1

Page 21

List of Figures

Figure 1 -1. TDU 120e Op tion Modules ......... ......... .......... .......... ......... .................. 1-4

Figure 1-2. Bridge, PBX, Video Conferencing Application Set Up.................... 1-5

Figure 2-1. TDU 120e Rear Panels........ .......... ......... .......... ........................... ..........2-4

Figure 2 -2. TDU 120e In terface s ......................... ........................... ......................... 2-5

Figure 2 -3. Example of Chain-in............................ ........................... ...................... 2-9

Figure 3 -1. Sample Terminal Screen with TDU 12 0e M enu.. .......... .......... .......... 3-2

Figure 3-2. Exampl e of Bas i c Menu Travel.... ......... .......... .......... .......................... . 3-3

Figure 3 -3. Telnet/Termina l Main M e n u .............................. ........................... ..... 3-6

Figure 3 -4. TDU 120e Fron t Panel Layout.............. .......... .......... ......... .......... ........ 3-8

Figure 4-1. Status Menu Tree ............................ ........................... .......................... . 4-1

Figure 4-2. Networ k I nterface Perform ance Rep ort ............................. ............... 4-2

Figure 5 -1. Configuration Menu Tree ....................... ......... ........................... ........ 5-2

Figure 5-2. Network Timed Clock Source.................................... ......................... 5-4

Figure 5 -3. DS-1 Timed C l ock Source .............. .......... ......... .......... ......................... 5-5

Figure 5-4. Base D TE Timing Clock Source ........... ........................... .................... 5-5

Figure 5-5. Internal Clock Source.... .......... .......................... ........................... ........ 5-6

Figure 5-6. Secondary Clock Source ......... .......................... ........................... ........ 5-6

Figure 5 -7. Normal (CSU) Timing .......... .......... .......... .......................... .................. 5-7

Figure 5 -8. DS0 Temp Map..... .......... .......... ......... .......... .......... .......... ......... .......... . 5-11

Figure 5 -9. DS0 Ma p D esignations.. .......... ......... .......... .......... .......... ......... ........... 5-14

Figure 6-1. Utility Menu Tree.................................................................................. 6-1

Figure 7-1. Test M enu Tree .................................. ........................... ......................... 7-1

Figure 7-2. Network Loopback Tests ............... ............................................ .......... 7-3

Figure 8- 1 . Unit A c ce s s Table.... .. .......... .. .......... .. ... .......... .. .......... .. .......... .. .......... .. . 8-2

61202156L1-1 TDU 120e User Manual xxi

Page 22

List of Figures

xxii TDU 120e User Manual 61202156L1-1

Page 23

List of Tables

Table 1-1. TDU 120e Optio n M odules ......................... .......... ........................... ..... 1-3

Table 3-1. Activa ting Alarm List from Statu s Men u ....................... .......... .......... 3-3

Table 3-2. Editin g a Data Fi e l d . ......... .......... .......... .......... ......... .......... .......... ......... . 3-4

Table 4-1. NI Error Typ es............ .......... ........................... .......................... ............. 4 -3

Table 4-2. Alarm Messa g e Display ...... ........................... .......................... ............. 4-3

Table 5-1. Norm al Mode of Operation.............. .......... .......... .......... .................... 5- 17

Table 8-1. Unit Access Comma n d s ... ........................... .......... ........................... ..... 8-3

Table B-1. Network Pinout of the 8 -Pin Modular Conn ector ... .......... .......... ..... B-1

Table B- 2. Network P i n out of the M ale 15-Pin D-Connector.. ......... ..................B-2

Table B-3. Control In/Chain In Pin out..................................................................B-2

Table B- 4. Chain-Out Pino u t.. .......... .......... ......... ........................... .......... ...............B-3

Table B- 5. Craft Po rt Pinou t . ........................... ......... ........................... .......... ..........B -3

Table B- 6 . V.3 5 Pinout f or Nx56/64 DTE. ......... .......... .......... .......... ......... .......... ...B -4

Table B-7. Base DS-1 Pinou t of the 8- P i n out Modular Conne ctor........... ......... .B -5

Table B-8. Base DS-1 Pinou t of the 15 -Pin Female D-Conn ector............... ........B-5

Table B- 9. 10BaseT Ethernet Conn ector ........ ......... .......... .......... ......... .......... ........B-6

Table B-10. Extern al Alarm Device Connect or...... .......... .......... ......... .......... ........B-6

Table B-11. Power Connector (for DC powered units) .......................................B-6

Table C- 1. Network Interfa ce (NI) Alarms ....... .......... ........................... .............. C-2

Table C-2. Nx/DBU In terface A l arms ... ........................... .......... ......... .......... ....... C-2

Table C- 3 . DS -1 (PBX) Interf ace Alarms............ .......... .......... .......... ......... .......... .. C-3

Table C- 4. Network Interfa ce (NI) Status Messages................. .......................... C-3

Table C-5. Nx/DBU In terface Status Me ssages ............ ......... .......... .......... ......... C-4

Table C- 6 . DS -1 (PBX) Interface Status Messag e s ........... .......... ......... .......... ....... C-4

Table D-1. T1/FT1 I nterface........... ......... .......... .......... ......... .......... .......... .......... ....D-1

Table D-2. Nx/DBU Interface - Port 0.1-Nx56/64 (V.35 Interface).................. D-2

61202156L1-1 TDU 120e User Manual xxiii

Page 24

List of Tables

Table D-3. D S-1 Interface - P ort 0.2 ... ........................... .......... ......... ......................D -3

Table D-4. Chain In/Out Ports & Craft Port .......................................................D-4

Table D-5. 10BaseT Interface.... .......... .......... .......... .......................... ......................D-4

Table D - 6. O p ti on Slot I nterface............................................... ........................... .. D -4

xxiv TDU 120e User Manual 61202156L1-1

Page 25

Chapter 1

Introduction

TDU120e OVERVIEW

The TDU 120e is a T1/FT1 multiplexer with the fo llo wing

features:

• Nx56/64 V.35 data port

• DS-1 (PBX) interface

• option slot

• embed ded SNMP management

The TDU 120e’s option slot accepts one of many available

option modul e s for voice and data applications.

The TDU 120e serves as the link between user data sources

such as:

• local area networ k (LAN) bri dges and routers

•computers

•CAD systems

• teleconferencing equipment

•PBXs.

Through the use of multiple data ports, the TDU 120e can

simultaneously connect one or more of these devices to a T1

circuit. The amount of bandwidth allocated to each port is

custom- programmable. You can manually allocate

bandwidth or set the bandwidth to change automatically at

predetermined times to use the available bandwidth most

advantageously. Changes in the configuration do no t disrupt

data flow in channels that are not being reconfigured. The

unique architecture and the availability of option modu les

provides a path for growth to accommodate future

requirements.

61202156L1-1 TDU 120e User Manual 1-1

Page 26

The TDU 120e offers a wide variety of network management

options. You can manage via SNMP through the 10BaseT or

chain-in ports. If you are using T-Watch Pro, a Microsoft

Windows® program, you can manage the TDU 120e via the

same 10BaseT or chain-in ports. An enhanced VT-100

terminal interface is also provided.

Standard Feat ures in the TDU 120e

The following list describes the standard features the

enhanced TDU 120e.

• A single T1 interface.

• A Nx/DBU V.35 port and DS-1 (PBX) interface.

• An inband communication channel requiring only 8k of

bandwidth from a single DS0.

• One o p tion slot to house o p t ion modul es with up to four

additional ports, including voice and data.

• Allows mix of port types to meet the data interface

requirements.

• Easy configuration cap abilities using simplistic menus

displayed on a terminal or computer connected to the

control port or the Craft Jack on front of the unit.

• Two programmable configuration maps that define the

bandwidth allocation between data ports.

• Data drop and insert, as well as full drop and insert.

• Flash memory for software updates.

• Timing is selectable from the network, from the Nx56/64

or DS-1 ports, internally, or fr om a secondary interface.

• QRSS; 51 1 test patterns using Nx option.

• Extensive self-testing and monitori ng provides assurance

of proper operation.

• SNMP, Telnet, and T-Watch Pro management via SLIP or

10-BaseT

• Ability to proxy for “agentless” u nits

• Enhanced terminal mode

Chapter 1. Introduction

1-2 TDU 120e User Manual 61202156L1-1

Page 27

• Fractional T1 loopbacks as defined in annex B of ANSI

T1.403-1995

• Software configurable long-hau l or short -haul DS-1 port

• External alarm connector

TDU Option Modules

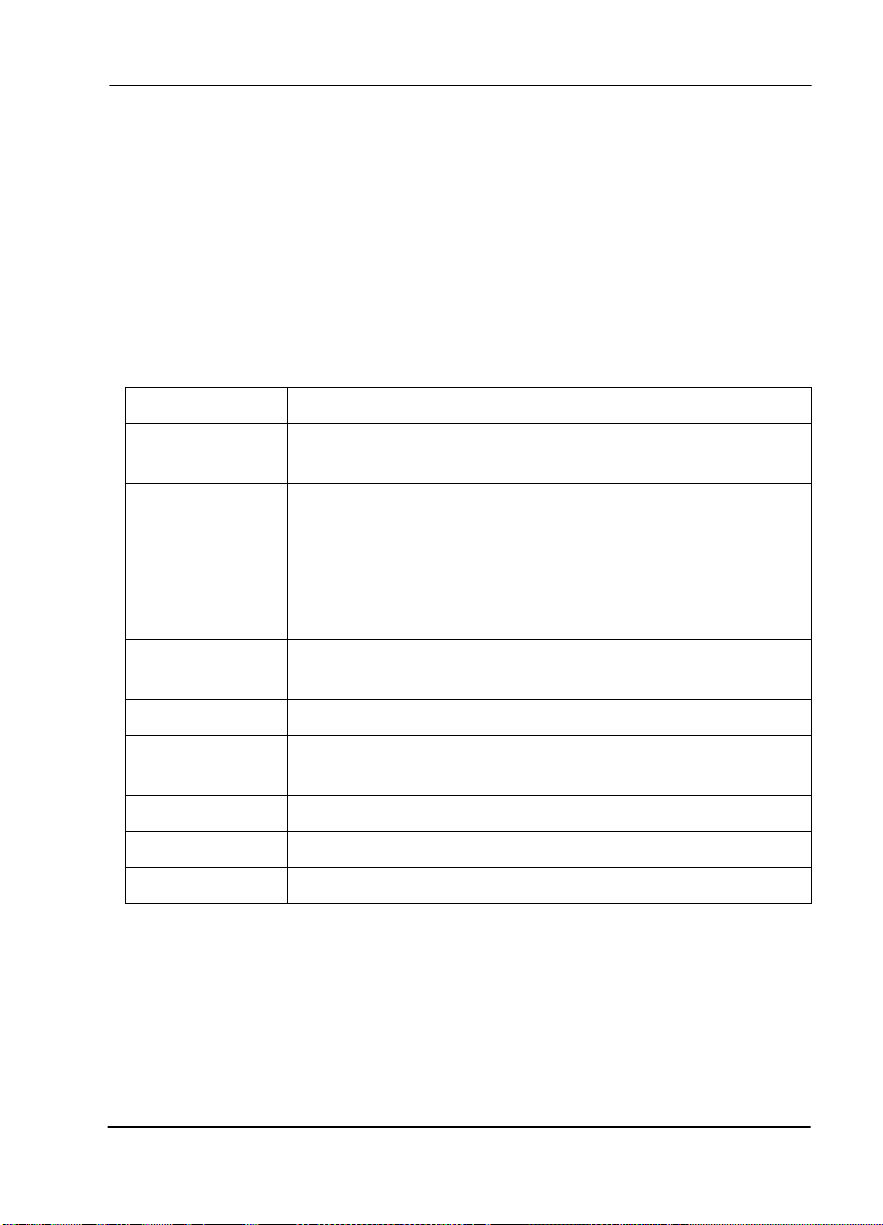

Table 1-1 shows a list of option modules and their

descriptions for the TDU 120e.

Module Description

Chapte r 1. Introduction

Table 1-1. TDU 120e Option Modules

DSX-1

Full Dr op an d

Insert

Nx56/64 serial

interface

Voice interface

OCU DP

DSU DP

Dial backup

U-BR1TE

Short haul T1 inte r face for operation with a PBX (Terminal

Interface)

Permits the dropping of data and insertion of new data into

the same DS0 time slot

This module includes a long haul DS-1 interface. It can

also be used as a second DS1 interface to provide an up

to 3 MB aggregate throughput

Provides a V.35 serial interface in either single or dual versions

2/4 channel FXS/FX0/E &M

Interfaces to DDS or 4-wire Switched 56, dual or single

versions

Provides two sync or async ports (EIA-232 or V.35)

Allows for backup of data upon network T1 failure

Allows I SDN l ines to b e extended over a T1 line

61202156L1-1 TDU 120e User Manual 1-3

Page 28

Option Module Architecture

The TDU 120e features a unique architecture that allows the

addition of one option module and plug-on board providing

an opportunity for growth to accommodate another

application. See Figure 1-1.

Chapter 1. Introduction

TDU 120e

R

E

M

O

T

E

A

C

C

C

E

R

S

S

A

N

F

E

T

T

W

O

R

K

M

O

N

P

O

R

T

0

.

2

M

I

N

O

N

O

U

T

I

N

A

O

C

O

U

T

O

K

I

N

O

U

T

R

E

I

N

D

O

U

T

T

E

S

T

Y

E

L

O

K

A

L

A

R

M

E

R

R

O

R

N

E

TW

O

R

K

ST

A

TU

S

T

D

U

1

T

2

E

S

0

T

e

A

C

A

L

A

R

M

P

O

R

T

1

.

1

0

.

1

M

O

N

0

.2

1

.1

1

.

2

1

.

IN

3

O

U

T

1

.4

I

N

P

O

O

R

U

T

T

S

T

A

T

U

S

DSX-1

Module

OCU-DP

Module

V.35

Module

D&I

Module

DUAL

Voice

Plug on

V.35

Plug on

OCU DP

Plug on

Dual Voice

Figure 1-1. TDU 120e Option Modules

1-4 TDU 120e User Manual 61202156L1-1

Page 29

Chapte r 1. Introduction

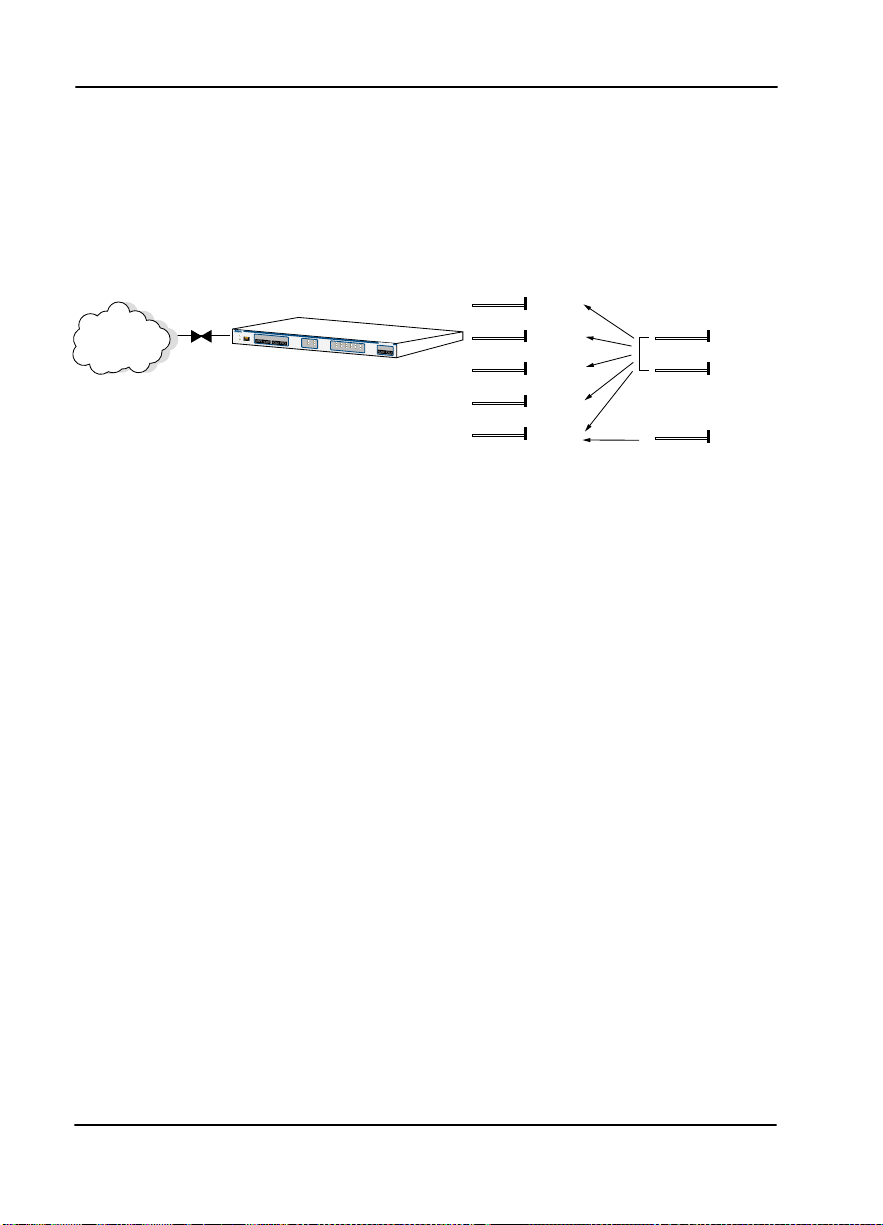

TDU 120e CONFIGURATION APPLICATIONS

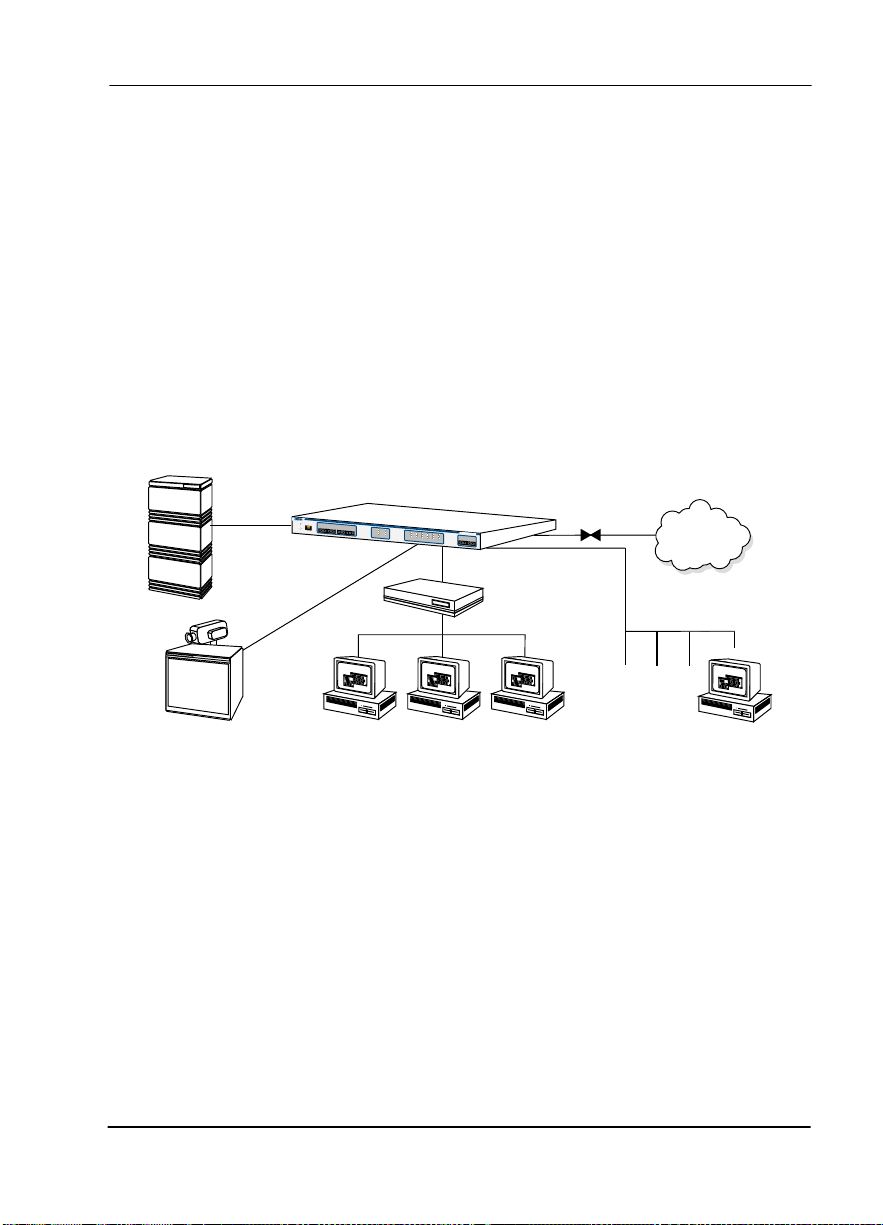

The follow ing e xamples illustrate possible configurations of

TDU 120e applications.

Router, PBX, Video Conferencing Application

In this application, the Base Nx/DBU provides a V.35

interface to a router. The PBX is interfaced to the TDU 120e

with the Base DS-1 interface. An OCU DP module and OCU

DP plug-on board provide two switched 56 circuits for video

conferencing. The 10BaseT port allows SNMP network

management over the LAN. See Figure 1-2.

PBX

VIDEO

CONFERENCING

TDU 120e

R

E

M

O

T

E

A

C

C

E

S

S

C

R

A

N

F

E

T

T

W

O

R

K

M

O

N

P

O

R

T

0

.

2

M

I

N

O

N

O

U

T

I

N

A

C

O

O

U

T

O

K

I

N

O

U

T

R

E

I

N

D

O

U

T

T

E

S

T

Y

E

L

O

K

A

L

A

R

M

E

R

R

O

R

N

E

T

W

O

R

K

ST

A

T

U

S

T

D

U

1

T

E

A

L

A

R

2

S

T

M

0

e

A

C

P

O

R

T

1

.

1

0

.

1

M

O

N

0

.

2

1

.

1

1

.

2

1

.

I

3

N

O

U

1

T

.

4

I

N

P

O

O

R

U

T

T

S

T

A

TU

S

ROUTER

10 BaseT LAN

SNMP NETWORK

MANAGEMENT WORKSTATION

Figure 1-2. Bridge, PBX, Video Conferencing Application Set Up

61202156L1-1 TDU 120e User Manual 1-5

Page 30

Chapter 1. Introduction

1-6 TDU 120e User Manual 61202156L1-1

Page 31

Chapter 2

Installation

UNPACK, INSPECT, P OWER UP

Receipt Inspection

Carefully inspect the TDU 120e for any shipping damages. If

you suspect damage, file a claim immediately with the

carrier and then contact ADTRAN Customer Service (see the

front section of this manual for contact information). If

possible, keep th e o riginal shipping c ontainer for use in

shipping the TDU 120e back for repair or for verification of

damag e during shipmen t.

ADTRAN Shipments Include

The following items are included in the ADTR AN shipment:

• The TDU 120e

• 2-line interface cables : A 15-foot, 8-position modular to 8-

position modular

• A DB-25 to modular adapter

• A 6-foot, 8 - position modu lar cable for connection to the

chain-in port

• The User Manual

Customer Provides

• Cables for any expansion modules to be used with the

TDU 120e

• 10BaseT cable for connection to a LAN or router (if you

plan to use remote management features)

61202156L1-1 TDU 120e User Manual 2-1

Page 32

Power Connection

AC powered units: Each TDU 120e AC is equipped with a

captive eight-foot power cord, terminated by a three-prong

plug which connects to a grounded power receptacle.

Power to the TDU 120e AC must be from a grounded 90-120

VAC, 50/60Hz source.

DC powere d un i ts: Each TDU 120e DC unit is provided with

a two-pin power receptacle and mating plug. Power to the

TDU 120e DC is +

48 VDC or +24 VDC.

GROUNDING INSTRUCTIONS

Grounding instructions from the Underwriters' Laboratory UL

1950 3rd Edition are provided in this section.

Chapter 2. Installation

An eq u i p m e n t g roundin g c onducto r th at is not sm a l le r in

size than the ungrounded branch-circuit supply conductors

is to be installed as part of the circuit that supplies the

product or system.

• Bare, covered, or insulated grounding conductors are

acceptable.

• Individually covered or insulated equipment grounding

conductors shall have a con tin uou s outer finish that is

either green, or green with one or more yellow stripes.

• The equipment grounding conductor is to be connected

to ground at the service equipment.

• The attachment-plug receptacles in the vicinity of the

product or system are all to be of a grounding type.

• The equipment grounding conductors serving these

receptacles are to be connected to earth ground at the

service equipment.

2-2 TDU 120e User Manual 61202156L1-1

Page 33

Chapter 2. Installation

• A supplementary equipment grounding conductor shall

be installed between the product or system and ground

that is in addition to the equipment grounding conductor

in the power supply cord.

• The supplementary equipment grounding conductor

shall not be smaller in size than the ungrounded branchcircuit supply conductors.

• The supplementary equipment grounding conductor

shall be connected to the product at the terminal

provided.

• It shall be connected to ground in a manner that will

retain the ground connection when the product is

unplugged from the receptacle.

• The connection to ground of the supplementary

equipment grounding conduc tor shall be in compli an ce

with the rules for terminating bonding jumpers at Part K

or Article 250 of the National Electrical Code, ANSI/

NFPA 70.

• T ermination of the supplementary equipment grounding

conductor is permitted to be made to building steel, to a

metal elec tri cal r ace way syst em, or to any g rou nde d item

that is permanently and reliably connected to the

electrical service equipment ground.

• The supplemental grounding conductor shall be

connected to he equipment using a number 8 ring

terminal.

• The terminal should be fastened to the grounding lug

provided on the rear panel of the equipment.

• The ring terminal should be in st a lle d us ing the

appropriate crimping tool (AMP P/N 59250 T-EAD

Crimping Tool or equivalent).

Do not use this product near water, such as in a wet basement.

For DC-powered devices, the supply power for the product

shall be inst alled near the equipm ent and shall be easily accessible.

61202156L1-1 TDU 120e User Manual 2-3

Page 34

REAR PANEL LAYOUT

Figure 2-1 shows the configuration of the TDU 120e rear

panels of the for both the AC powered unit and the DC

powered unit.

Chapter 2. Installation

Figure 2-1. TDU 120e Rear Panels

2-4 TDU 120e User Manual 61202156L1-1

Page 35

TDU 120e Interfaces

The TDU 120e is equipped with an Nx/DBU data port, a DS1 interface, an option slot, management interfaces, an

external alarm connector, and a T1 interface, in the rear panel.

See Figure 2-2.

PC or Modem

10BaseT

Control

Input

TSU 120e

NI

Chain

Output

Chapter 2. Installation

Chain

Chain

Input

Output

TSU 120e

NI

Network

Network Interface

The Network Interface (NI) port provides the connection to

the T1. This port complies with the applicable ANSI and

AT&T standards. For more information, see Wiring on page

B-1.

Nx56/64 Serial Interface

The Nx56/64 provides a serial V.35 port that operates from

56kbps to 1.536Mbps. This port provides 511 pattern

generation and detection and rem ote loopback capability.

DS-1 (PBX) Interface

The DS-1 Interface provides a T1 for a PBX or other

equipment. This port complies with ANSI T1.102. It can be

software configured for either long-haul or s h ort-h aul.

DS-1

Nx56/64 Nx56/64

Option Option

V.35

PBX

Figure 2-2. TDU 120e Interfaces

DS-1

DS-1

V.35

Control Port Input

The control port input provides an EIA-232 input from a PC

or a modem for contr ol of the TDU 120e. You can also use it

61202156L1-1 TDU 120e User Manual 2-5

Page 36

as a chain input fr om anot her TDU 1 20e or TSU 100 . Fo r more

information, see Wiring on page B-1.

Craft Port

The craft port provides the same functionality as the Control

Port Input. Both the craft port and the control port input may

be connected simultaneously, but only one port may be active

at a time. For more information, see Wiring on page B-1.

Chain Port Output

The chain port output provides an EIA-232 output to chain

control to other TDUs or to TSUs. For more information, see

Wiring on page B-1.

10BaseT Interface

The 10BaseT interface pro v ides the LAN interface for

managing the TDU 12 0e w ith SNMP or T-Watch Pro. For

more information, see Wiring on page B-1.

External Alarm Connector

The external alarm connector allows you to connect an

external alarm device to the TDU 120e. The alarm relay will

activate on any alarm. The relay will remain activated until

the ACO button on the front panel is pushed. For more

information, see Wiring on page B-1.

Chapter 2. Installation

2-6 TDU 120e User Manual 61202156L1-1

Page 37

Chapter 2. Installation

POWER UP TESTING

When shipped from the factory, the TDU 120e is set to factory

default conditions. At the first appl icat io n of power, the unit

automatically executes a memory self-test. A full self-test can

be run from the terminal. A passcode and unit ID may be set

using the UTIL menu.

Self-Test

When... Then...

Initiating a self-test The terminal displays System S elf-test Now

Testing and Memory Test Now Testing. The

test leds are illuminated.

The self-test is completed All LEDs go back to their normal state. The ter-

minal momentarily displays System Self-test

Tests passed.

A failure is detected A list of failures is displayed on the terminal.

The full self-test procedure (invoked from the terminal or TWatch PRO) consists of the following tests:

Board Level Tests

The TDU 120e contains an on-board processor which executes a series of tests checking the circuitry on the board.

RAM and EPROM Tests

Verify on-board circuitry

Unit Level Tests

Front panel LED verification.

Board-to-Board Interface Test

A test pattern is sent fro m the controll er throu gh a loopback

on all other boards and checked on the controller.

This verifies the data path, clocks, and control signals for the

entire chassis.

61202156L1-1 TDU 120e User Manual 2-7

Page 38

Initialization

Set User Passcode

The TDU 120e is designed to operate with or without the use

of a passcode. The default condition is without a passcode.

If the unit is to be remotely accessed using T-Watch PRO, you

must enter a passcode. When managing a number of units, the

passcode can be the sa me for all the units.

The passcode should be a number easily remembered. Once

entered, the passcode is required to acces s any operation

other than viewing. See Set Passcode on page 6-3 for details.

Set Unit Identification

The Unit ID sets the unit to respond to remote control

(controlled by a device other than the front panel or

terminal). If n o Unit ID is recorded, it is not possible to

operate from any remote control device, including the local

PC for T-Watch PRO or SNMP. See Unit ID on page 6-3 for

details.

Chapter 2. Installation

Set Control Port

The TDU 120e can be configured from the control port when

T- Watch PRO, SNMP, or the termina l interface ar e being

used. If the control port is to be used, the control port baud

rate must also be selected.

Chain In (PC)

The unit can be controlled from an external PC connected

directly or via modem to the Chain-In port. When using

Chain-In, the s ele ction of the Control Port baud rate from

9600 (factory default), 1200, 2400, or 4800, 19200, or 38400

must be made usin g the U

NIT CONFIGURATION

menu. See Unit

Menu on page 5-8 for details.

2-8 TDU 120e User Manual 61202156L1-1

Page 39

Chain In/Chain Out

TDU 120e units and other TDUs and TSUs can be linked

together to form a chain. Figure 2-3 sho ws an example of a

chain-in arrangement with a PC or a modem. The first TDU

120e in the chain receives controlling input from the PC or

modem.

PC or Modem

Chapter 2. Installation

Control

Input

TDU 120e

Chain

Out

ChainInChain

Out

TDU 120e /

TSU 100/TSU

ChainInChain

Out

TDU 120e /

TSU 100/TSU

Figure 2-3 . Example of Chain-in

Subsequent TDU/TSUs in the chain are in a position to

intake information from another TDU or TSU. This intaking

of information from another TDU in the chain is identified as

Chain In. The baud r a te for the chained units must match

that of the first unit.

Unless locked out externally, the front panel can also control

the unit.

At this point, the Un it Init ia liza ti on procedure is conclu ded .

If the unit is to be configured remotely, there are no

additional items necessary to complete prior to executing

remote configuration.

The Passcode, the Unit ID, and the Co ntrol Port settings are

stored in a nonvolatile memory. This ensures they are

operable for subsequent power-up sequences.

61202156L1-1 TDU 120e User Manual 2-9

Page 40

Normal Power-Up Procedure

After the unit has been put into operation with the initial

power-up and initialization, subsequent power -up procedure

includes only the Power-Up self-test followed by the request

for a passcode (password) if this option was selected during

initialization.

Chapter 2. Installation

Type the previously recorded passcode and press

Enter

.

2-10 TDU 120e User Manual 61202156L1-1

Page 41

Chapter 3

MENU FEATURES

The TDU 120e uses a VT 100 type terminal to display control

and monitor menus. Initiate this mode by key ing in <CTRL>

PTT on the terminal onc e it is connec ted to the Control In or

Craft port.

When you begin the telnet session, you will be prompted for

a password. The default password is ADTRAN. You can

change this password using the M

For detailed information on this method of control, see

Telnet/Terminal Main Menu on page 3-6.

You can also connect to the TDU 120e via telnet. Before

attempting to connect via telnet, first define the IP address,

the default gateway, and the subnet mask.

Operation

ANAGEMENT

submenu.

See D

EFAULT UNIT PASSCODE

details. The telnet sess ion w ill time-o ut after a predefine d

value that is a ls o set in the M

Only one tel net session can be a ctive at a time.

61202156L1-1 TDU 120e User Manual 3-1

in Table 8-1 on page 8-3 for

ANAGEMENT

menu.

Page 42

Sample Terminal Screen with TDU 120e M enu

An example of a PC screen with a TDU 120e menu is shown

in Figure 3-1.

Main Menu

1) Status

2) Config

3) Util

4) Test

5) Remote Menu Access

6) Management Config

7) Flash Download

8) Quit Session

Command:

Figure 3-1. Sample Terminal Screen with TDU 120e Menu

General Menu Operation

The TDU 120e uses a multilevel menu structure containing

both menu items and data f ie lds. All menu operations an d

data are displayed on the terminal.

Chapter 3. Operation

Select and Activate a Menu Item

T o choose a menu item, place the cursor on the desired menu

item by:

• pressing the number corresponding to the menu item, or

• using the up and down arrows.

Table 3-1 on page 3-3 describe how to activate the alarm list

option from the Status Menu.

Figure 3-2 on page 3-3 shows an example of basic menu

travel.

3-2 TDU 120e User Manual 61202156L1-1

Page 43

Chapter 3. Operation

Table 3-1. Activating Al arm List from Statu s Menu

Step Action Result

Activate the STATUS menu using the

1

arrow keys or by pressing 1.

The cursor will flash on the number next to the activated selection.

Press Enter. The status subme nus will dis -

2

play.

Use the arrow keys to view submenu

3

items.

Choose an item on the submenu

4

such as ACTIVE ALARMS.

The cursor will flash on the number next to the activated selection.

Press Enter. The active alarm list will display.

5

View the Alarm List.

6

.

1) NETWORK (NI) PERFORMANCE REPORTS

2) NETWORK (NI) ERRORS

3) ACTIVE ALARMS (ALARM LIST)

4)VIEW HISTORY END OF LIST

STATUS 5) PORT STATUS

6) REMOTE PORT

7) CLEAR PORT ALARM

8) ETHERNET STATUS

Figure 3-2. Example of Basic Menu Travel

61202156L1-1 TDU 120e User Manual 3-3

Page 44

Chapter 3. Operation

Y ou can edit data fields preceded by a colon (:). T o edit a data

field, perform the steps in Table 3-2:

,

Table 3-2. Editing a Data Field

Step Action Result

Position the cursor on the sub-

1

menu item number and press

.

Enter

Using the space bar, scroll to scan

2

the available value settings.

When the desired value is dis-

3

played in the data field position,

press

to set that value.

Enter

Another submenu field may be

selected, or press E

SCAPE

to return

to the submenu.