Page 1

)

)

(R

(G

M

N

R

E

O

TEST

T

M

)

)

(Y

(G

D

G

N

N

E

E

LBK

N

F

K

B

L

DS1 4

T

C

E

L

E

S

DS1 3

H

C

QDFR

1

DS1 2

DS1 1

7

L

OPTICS

7

30

1

8

1

®

Quad Fiber Remote (QDFR) Unit

Installation and Maintenance Practice

Document Number: 61181307L7-5E

CLEI: M3M1100B _ _

July 2006

Page 2

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Front Matter

Trademarks

Any brand names and product names included in this document are trademarks, registered

trademarks, or trade names of their respective holders.

To the Holder of the Document

The contents of this document are current as of the date of publication. ADTRAN® reserves the

right to change the contents without prior notice.

In no event will ADTRAN be liable for any special, incidental, or consequential damages or

for commercial losses even if ADTRAN has been advised thereof as a result of issue of this

document.

®

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

(256) 963-8000

©2006 ADTRAN, Inc.

All Rights Reserved.

ii 61181307L7-5E

Page 3

Revision History

Revision Date Description of Changes

A July 2005 Initial release

B December 2004 Added front panel LED information in Table 2.

C April 2005 Added QDFR Provisioning menu defaults in Table 3.

D June 2006 Changed connector designation from RJ-45 to RJ-48C.

Changed Transmit Level values to Output Optical Power

values in Table 5. Updated document format.

E July 2006 Updated CLEI.

Conventions

The following typographical conventions are used in this document:

This font indicates a cross-reference link. First-time references to tables and figures are

shown in this font.

This font indicates screen menus, fields, and parameters.

T

HIS FONT indicates keyboard keys (ENTER, ESC, ALT). Keys that are to be pressed simulta-

neously are shown with a plus sign (A

pressed at the same time).

LT+X indicates that the ALT key and X key should be

This font indicates references to other documentation and is also used for emphasis.

This font indicates on-screen messages and prompts.

This font indicates text to be typed exactly as shown.

This font indicates silkscreen labels or other system label items.

This font is used for strong emphasis.

NOTE

Notes inform the user of additional, but essential, information or

features.

CAUTION

Cautions inform the user of potential damage, malfunction, or disruption to equipment, software, or environment.

WARNING

Warnings inform the user of potential bodily pain, injury, or death.

61181307L7-5E iii

Page 4

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Training

ADTRAN offers training courses on our products. These courses include overviews on product

features and functions while covering applications of ADTRAN product lines. ADTRAN

provides a variety of training options, including customized training and courses taught at our

facilities or at customer sites.

For inquiries concerning training, contact ADTRAN:

Training Phone: 800-615-1176, ext. 7500

Training Fax: 256-963-6700

Training Email: training@adtran.com

iv 61181307L7-5E

Page 5

Contents

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Shipping Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing the QDFR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Panel Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Loop Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Provisioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Menu Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Menu Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Menu Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

QDF Unit Information Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Provisioning Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Auto In Service Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loopback and Test Commands Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Loopback Control Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Test Jack Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

BERT Test Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Self-Tests Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Performance History Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Performance History Channel # Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Performance History Fiber Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Scratch Pad, Circuit ID Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Alarm History Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

T1 Alarm History Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

61181307L7-5E v

Page 6

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Channel T1 Threshold Alarm History Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Event History Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting Guidance Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Clear PM and Alarm Histories Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

System PM/Screen Report Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Download QDFR via Y-Modem Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Virtual Terminal Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Appendix A

QDFR Loopbacks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Fiber Line Unit Maintenance Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Loopback Process Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Loopback Control Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B

Rear Panel DS1 Test Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Monitor Tx to Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Monitor Rx from Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Terminate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Intrusive Tx to Customer and Rx from Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Intrusive Tx to Network and Rx from Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Appendix C

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Warranty and Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

ADTRAN Sales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

ADTRAN Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

ADTRAN Repair/CAPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Repair and Return Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

vi 61181307L7-5E

Page 7

Contents

Figures

Figure 1. QDFR Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. QDFR Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 3. RJ-48C Pinout Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. ADTRAN QDF Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. QDF Unit Information Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. Provisioning Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 8. Auto In Service Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9. Loopback and Test Commands Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. Loopback Control Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 11. Test Jack Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 12. BERT Test Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 13. Network Pattern Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 14. Network Timeout Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 15. BERT Inject Errors Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 16. Self-Test Complete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 17. Performance History Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 18. Performance History Channel # Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 19. Performance History Fiber Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 20. Channel Performance History Screen, from Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 21. Channel Performance History Screen, from Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 22. Scratch Pad, Circuit ID Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 23. Alarm History Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 24. T1 Alarm History Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 25. Channel T1 Threshold Alarm History Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 26. Event History Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 27. Troubleshooting Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 28. Troubleshooting Guidance Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 29. Clear PM and Alarm Histories Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 30. System PM/Screen Report Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 31. Download QDFR via Y-Modem Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 32. Flash Upgrade, Y-Modem in Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 33. Virtual Terminal Control Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure B-1. DSX MON, Tx to Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Figure B-2. DSX MON, Rx from Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Figure B-3. Terminate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

61181307L7-5E vii

Page 8

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Tables

Table 1. Compliance Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2. Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 3. QDFR Provisioning Menu Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4. ADTRAN QDF Main Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table A-1. Loopback and Control Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

viii 61181307L7-5E

Page 9

Quad Fiber Remote Unit

GENERAL

This practice is an installation and maintenance guide for the ADTRAN Quad Fiber Remote

(QDFR) unit. The QDFR (P/N 1181307L7) front panel is illustrated in Figure 1. The QDFR rear

panel is illustrated in Figure 2.

QDFR

1181307L7

OPTICS

DS1 1

DS1 2

DS1 3

DS1 4

CH SELECT LBK

LBK

NEND(Y)

FENG(G)

TEST

TERM(R)

MON(G)

Figure 1. QDFR Front Panel

BATTERY

FIBER

OPTICS

24V-48V

DS1

4

DS1

3

DS1 2DS1

1

TX RX

Complies with 21CFR, SubchapterJ,

Parts 1010 and 1040.

ADTRAN, Huntsville Al. 35814 USA

CRAFT

Figure 2. QDFR Rear Panel

Description

The QDFR is a customer premise fiber optic access unit. The QDFR is designed to provide four

T1 interfaces that can be multiplexed together over a single mode fiber optic cable to a Total

Access 3000 Quad Fiber Central Office (QDFC) Module (P/N 1181308L7).

The QDFR is specifically designed to provide a high degree of resistance to damage typically

caused by Ground Potential Rises (GPRs). This is accomplished by having the network

interface optically isolated from the customer side and the DS-1 interfaces having over 6

kilovolts of isolation with respect to ground. The QDFR is virtually immune to the effects of

GPRs compared to other network interface equipment.

61181307L7-5E 1

Page 10

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Features

The QDFR provides the following features:

• Software provisionable via menu access (no onboard switches)

• Front panel indicators for the following:

– Optical port status

– T1 status for all channels

– Loopback status

–Test port operation

• Operation over extended temperature range of –40°C to +65°C

• Optical interface consisting of a single mode transceiver module comprised of a single fiber

transmitter and an SC receptacle

• Optical interface port support for flat SC-type optical connectors

• Single fiber optical interface

• Operating wavelengths:

– 1310 nm for the receiver

– 1550 nm for the transmitter

Compliance

The QDFR is NRTL listed to UL 60950. The QDFR is compliant to IEC-60825 Class 1 and is

also compliant with 21CFR 1040.10 and 1040.11 except for deviations pursuant to Laser

Notice No. 50, dated July 26, 2001. The QDFR is intended for use in restricted access

locations only.

Table 1 provides compliance codes for the QDFR.

Table 1. Compliance Codes

Code Input Output

Power Code (PC) F C

Telecommunication Code (TC) – –

Installation Code (IC) A –

The DS1 interfaces for the QDFR are to be connected to intra-building wiring only.

CAUTION

Per GR-1089-CORE October 2002, Section 9, this system is

designed and intended only for installation in a DC-C (common)

Bonding and Grounding system. It is not intended or designed for

installation in a DC-I (isolated) Bonding and Grounding system.

2 61181307L7-5E

Page 11

Installation

INSTALLATION

C A U T I O N !

SUBJECT TO ELECTROSTATIC DAMAGE

OR DECREASE IN RELIABILITY.

HANDLING PRECAUTIONS REQUIRED.

After unpacking the QDFR, inspect it for damage. If damage has occurred, file a claim with the

carrier then contact ADTRAN Customer Service. Refer to “Appendix C, Warranty” for further

information. If possible, keep the original shipping container for returning the QDFR for repair

or for verification of shipping damage.

SHIPPING CONTENTS

The contents include the following items:

•QDFR Unit

• Quad Fiber Remote (QDFR) Unit Job Aid (P/N 61181307L7-22)

CAUTION

Electronic modules can be damaged by ESD. When handling modules, wear an antistatic discharge wrist strap to prevent damage to

electronic components. Place modules in antistatic packing material when transporting or storing. When working on modules,

always place them on an approved antistatic mat that is electrically

grounded.

Installing the QDFR

To install the QDFR, perform the following steps:

1. Place the unit in a location where a DC power source is available. This unit operates

within a voltage range of –24 VDC to –48 VDC.

2. Using the hex nut and lock washer supplied with the QDFR, attach a grounding strap to

the grounding lug on the left side of the QDFR chassis. Finger-tighten only.

3. Conned power to the QDFR by connecting the plus (+), minus (–), and ground wires to a

three-position terminal block located at the left of the backplane (Figure 2). The DS1 loop

connections are made through four RJ-48C type connectors. Single-mode fiber is

connected to the SC-type connector located at the right of the backplane.

When the QDFR first powers up, the unit initializes a self test that lasts for approximately 30

seconds. After the self test is completed, the LEDs reflect the current status of the unit.

Front Panel LEDs

The QDFR provides front panel LEDs to display status information for the unit. Table 2 lists

the front panel LEDs and their indications.

61181307L7-5E 3

Page 12

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Table 2. Front Panel LEDs

Label Indications Description

OPT

DS1 (1-4)

LBK

NEND/FEND

TERM/MON

z

z

/

{

z

z

z

/

5

{

z

z

z

z

Green

Red

Flashing (Red/Green)

Off

Green

Yellow

Red

Flashing (Red/Green)

Flashing

Off

Green

Yellow

Green

Red

Front Panel Pushbuttons

Signal present

Loss of signal

Errored second

Port Service state set to Out of Service: Unassigned

Good signal present

Near-end or Far-end loopback present

Loss of signal

Errored second

Port selected for loopback switches and test access;

flashing state times out 1 minute after channel

selection is made

No loopback present on selected channel

Far-end loopback present on selected channel

Near-end loopback present on selected channel

Test jack in Monitor mode on selected channel

Test jack enabled for Terminate mode (intrusive

access) on selected channel

The QDFR has two pushbuttons located on the front panel:

• Channel Select (

•Loopback (

To initiate a channel loopback at the QDFR, press

flashing, then press

CH SELECT)

LBK)

CH SELECT until the desired channel LED is

LBK to initiate the loopback.

NOTE

This selection only pertains to the test jack and the pushbuttons.

The user may continue to initiate or terminate any loopback on any

channel via the craft port.

• To initiate a loopback at the QDFC, press the

• To terminate active loopback(s), press the

LBK pushbutton for at least 3 seconds.

LBK switch while any loopback is active.

NOTE

All loopbacks initiated by the QDFR pushbuttons are bilateral.

Data from the port input is sent to the port output, and data from

the network (fiber) is sent back to the fiber.

4 61181307L7-5E

Page 13

Loop Connections

T

LOOP CONNECTIONS

The T1 loop connections are made through four RJ-48C type connectors. For each connector,

transmit tip and ring are on pins 5 and 4, and receive tip and ring are on pins 2 and 1, respectively. The single-mode fiber is connected to the SC connector located on the back panel of the

unit.

OPERATION

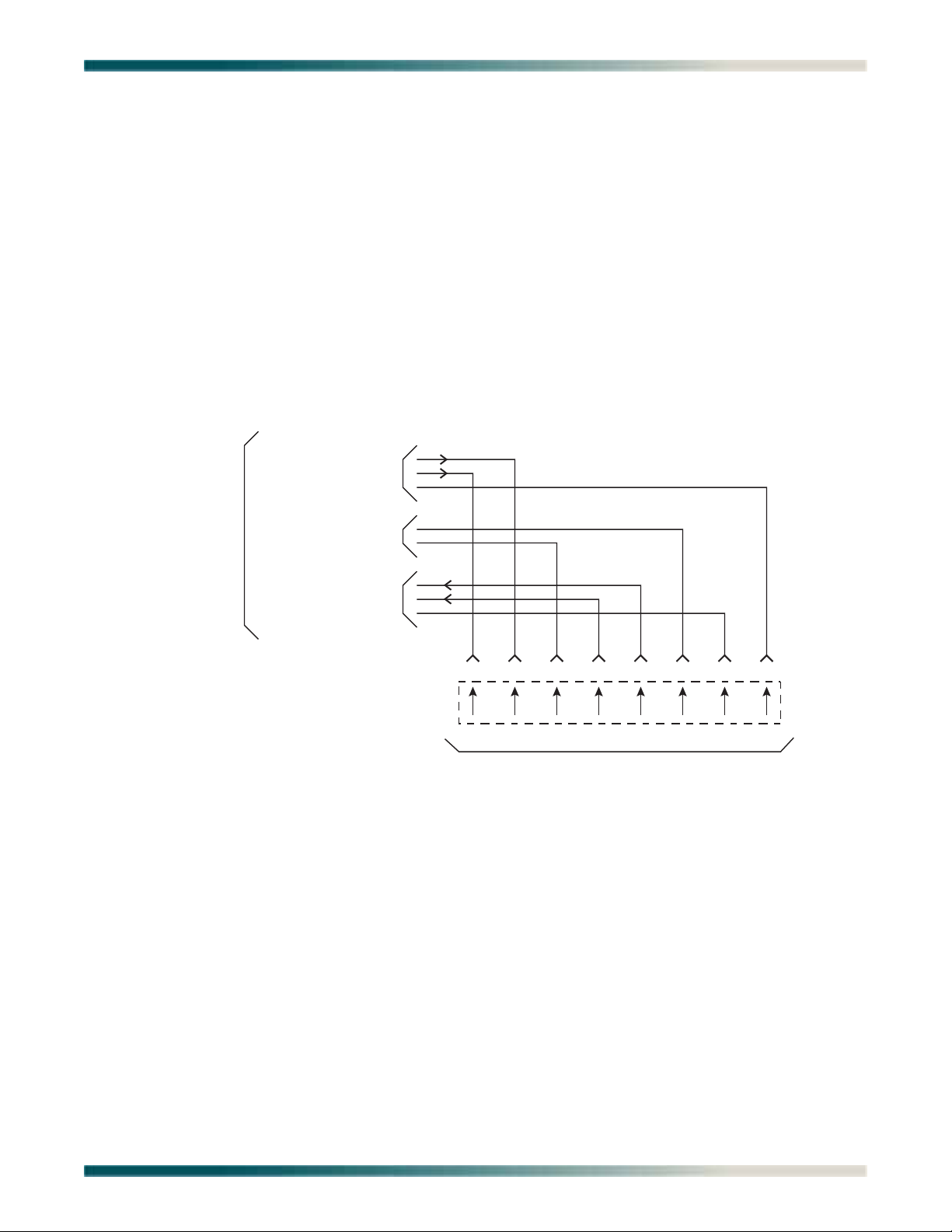

The Quad Fiber Remote (QDFR) Unit provides a platform to exchange data between four Tls

and an optical fiber interface. The customer data connection is via the RJ-48C connectors on

the unit. An optical fiber interface is provided for communication with the loop. The Quad

Fiber Remote (QDFR) Unit operates with a QDFC module at the other end of the fiber optic

cable. The figure below illustrates the pin-out configuration for the RJ-48C connectors.

T

Receive from Network

R

o Network

Reserved for Future Use

Transmit to Network

Miniature 8-Position Plug

T1

R1

12345678

R T R1 T1

To Registered Terminal Equipment

Figure 3. RJ-48C Pinout Configuration

Power Interface

The power for the QDFR can be supplied through a –48 VDC supply connected to the back of

the QDFR. The QDFR can be powered from –24 VDC to –48 VDC.

Diagnostics

There are several options available for diagnostics:

• Front panel LEDs (see Table 2 on page 4)

• “Loopback and Test Commands Menu” on page 12

• “Performance History Menu” on page 16

• “Troubleshooting Menu” on page 22

61181307L7-5E 5

Page 14

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

PROVISIONING

The QDFR provides the ability to change provisioning options. Table 3 lists the valid settings

and defaults for the provisioning options. Provisioning options are set independently for each

of the DS1s.

Table 3. QDFR

Option Settings (Default in BOLD)

Provisioning – Channel Options

DSX-1 Line Buildout 0-133 Feet

DSX-1/DS1 Line Code AMI;

NIU Loopback Disabled

Loopback Timeout None

DS1 TX Level 0 dB

Customer Loss Indicator AIS

Provisioning Menu Defaults

133-266 Feet

266-399 Feet

399-533 Feet

533-655 Feet

B8ZS

Enabled

120 Min

–7.5 dB

–15 dB

Loopback

6 61181307L7-5E

Page 15

Menu Structure

MENU STRUCTURE

The menu structure for the QDFR is a layered menu tree. Each layer of the menu tree is

displayed as a menu or a screen.

Menu

A menu is a display that provides numbered selections that are used to navigate to related

menus, modify provisioning information, or display information screens. A menu can contain

the following objects:

• Menu Option: A menu option is indicated by a number, which when selected navigates the

display to another menu layer or is used to change the option setting.

• Read-only Field: A read-only field displays information that cannot be changed. The

information displayed in a read-only field can be static or can be automatically updated by

the QDFR.

• Read-write Field: A read-write field displays information that when selected can be

modified.

• Hot Key: A hot key is a key or combination of keys that are assigned to a function. Hot keys

are indicated by the required key(s) and a brief description (i.e., N - Next Channel).

Screen

A screen is a display that usually indicates the end of a menu tree path. A screen can contain

the following objects:

• Read-only Field: A read-only field displays information that cannot be changed. The

information displayed in a read-only field can be static or can be automatically updated by

the QDFR.

• Read-write Field: A read-write field displays information that when selected can be

modified.

• Hot Key: A hot key is a key or combination of keys that are assigned to a function. Hot keys

are indicated by the required key(s) and a brief description (i.e., N - Next Channel).

MENU NAVIGATION

Basic menu navigation is accomplished by selecting the desired option number and then

pressing

ENTER. To return to the previous menu, press the ESC (escape) key.

61181307L7-5E 7

Page 16

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

MENU DESCRIPTIONS

The QDFR Main Menu (Figure 4) is the access point to all other operations. The Main Menu

options have several functions and submenus that identify and provide access to specific

operations and parameters.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

ADTRAN QDF Main Menu

1. QDF Unit Information

2. Provisioning

3. Status

4. Auto In Service

5. Loopbacks and Test

6. Performance History

7. Scratch Pad, Ckt ID

8. Alarm History

9. Event History

10. Troubleshooting

11. Clear PM and Alarm Histories

12. System PM/Screen Report

13. Flash Upgrade

14. Virtual Terminal Control

Selection:

Figure 4. ADTRAN QDF Main Menu

The Main Menu options are shown in Table 4.

Table 4. ADTRAN QDF Main Menu Options

Option Description Function

1 QDF Unit Information This option displays the “QDF Unit Information

Screen” on page 9.

2 Provisioning This option displays the “Provisioning Menu” on

page 10.

3 Status This option displays the “Status Screen” on page 11.

4 Auto In Service This option displays the “Auto In Service Screen” on

page 11.

5 Loopbacks and Test This option displays the “Loopback and Test

Commands Menu” on page 12.

6 Performance History This option displays the “Performance History Menu”

on page 16.

7 Scratch Pad, Ckt ID This option displays the “Scratch Pad, Circuit ID

Menu” on page 19.

8 61181307L7-5E

Page 17

Menu Descriptions

Table 4. ADTRAN QDF Main Menu Options (Continued)

Option Description Function

8 Alarm History This option displays the “Alarm History Menu” on

page 20.

9 Event History This option displays the “Event History Screen” on

page 21.

10 Troubleshooting This option displays the “Troubleshooting Menu” on

page 22.

11 Clear PM and Alarm Histories This option displays the “Clear PM and Alarm

Histories Option” on page 23.

12 System PM/Screen Report This option displays the “System PM/Screen Report

Menu” on page 24.

13 Flash Upgrade This option displays the “Download QDFR via Y-

Modem Menu” on page 25.

14 Virtual Terminal Control This option displays the “Virtual Terminal Control”

on page 26.

QDF Unit Information Screen

The QDF Unit Information screen (see Figure 5) is a read-only display that identifies the QDFC

and QDFR. The QDFC and QDFR name, CLEI code, part number, serial number, date of

manufacturing, and software revision are included in this screen.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

ADTRAN

901 Explorer Boulevard

Huntsville, Alabama 35806-2807

--------------------- For Information or Technical Support -------------------- Support Hours ( Normal 7am - 7pm CST, Emergency 7 days x 24 hours )

Phone: 800.726.8663 / 888.873.HDSL Fax: 256.963.6217 Internet: www.adtran.com

--------------------------------------------------------------------------------

QDFC QDFR

P/N: 1181308L7 P/N: 1181307L7

S/N: LBADTN0426@12345678901234 S/N: LBADTN0426@12345678904321

CLEI: M3LIKHEAAA CLEI: M3M1400BRA

Manf: 12/01/2003 Manf: 07/01/2005

Ver: A03 Ver: A03

Figure 5. QDF Unit Information Screen

61181307L7-5E 9

Page 18

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Provisioning Menu

The Provisioning menu (Figure 6) is used to make provisioning changes to various options.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Provisioning

1. Channel Options

2. Fiber PM Threshold Options

3. T1 PM Threshold Options

4. Copy Settings

5. Restore Factory Defaults

Selection:

Figure 6. Provisioning Menu

The Provisioning menu contains the following submenus related to specific provisioning items:

• Channel Options

• Fiber PM Threshold Option

• T1 PM Threshold Options

•Copying Settings

• Restore Factory Defaults

Refer to Table 3 on page 6 for default channel provisioning options.

10 61181307L7-5E

Page 19

Menu Descriptions

Status Screen

The Status screen (Figure 7) provides information regarding the status of the QDFR.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Status Screen

______ ______

DSX-1 | QDFC | | QDFR | DS1

| | | |

Ports 1-4 | |--------------------------------------| | Ports 1-4

| | | |

|______| |______|

Net Cust

Test Port: CH 1,Mon Test Port: CH 1,Mon

Fiber

Rx Status Loopbacks Rx Status Rx Status Loopbacks

--------- --------- ----------- --------- --------CH 1: LOS NONE LOS CH 1: SF NONE

CH 2: LOS NONE CH 2: LOS NONE

CH 3: LOS NONE CH 3: LOS NONE

CH 4: LOS NONE CH 4: LOS NONE

Figure 7. Status Screen

Auto In Service Screen

The Auto In Service Status screen (Figure 8) displays the status of the equipment and

individual channels. The parameters are set through the QDFC, and are not provisionable

from the QDFR.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Auto In Service Status Screen

Current Auto In Service = ENABLED

Port State

---- --------- EQPT In-Service

CH 1 In-Service

CH 2 In-Service

CH 3 In-Service

CH 4 In-Service

--------------------------------------------------------------------------------

Auto In Service Parameters are controlled by the QDFC

Figure 8. Auto In Service Status Screen

61181307L7-5E 11

Page 20

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Loopback and Test Commands Menu

Loopback and Test Commands menu (Figure 9) provides several performance tests for the

QDFR.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Loopback and Test Commands

Loopback Status: QDFC QDFR

---------------- ------ ----- CH1: NONE NONE

CH2: NONE NONE

CH3: NONE NONE

CH4: NONE NONE

Test Port: CH 1,Mon CH 1,Mon

1. Loopbacks

2. Loopdown All

3. Test Port (Bantam Jack) Control

4. BERT Test Functions

5. Self Tests

Selection:

Figure 9. Loopback and Test Commands Menu

Loopback Control Menu

The Channel # Loopback Control menu (Figure 10) is used to perform loopback between the

QDFR and QDFC to the Network or Customer.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

CH 1 Circuit ID:

Channel 1 Loopback Control

1. Loopup QDFC to Network

2. Loopup QDFC to Customer

3. Loopup QDFR to Network

4. Loopup QDFR to Customer

'Sx'- Select Channel x 'N' - Next Channel 'P' - Previous Channel

Selection:

Figure 10. Loopback Control Menu

12 61181307L7-5E

Page 21

Menu Descriptions

Test Jack Configuration Screen

The Test Jack Configuration screen (Figure 11) controls the test jack, which is found on the

back of the QDFR unit. This jack can “look at” a chosen port, in either direction as chosen by

the user, as if it were a monitor jack (non-intrusive mode) or it can “break” a chosen port, in

either direction, as if it were a equipment jack (intrusive mode).

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Test Jack Configuration Screen

---------------------------------------------------- Test Jack Mode: Monitor

Active Port Number: Port 1

Intrusive Test Direction: Network

1. Toggle Test Jack Mode

2. Change Test Port Number

3. Toggle Intrusive Test Direction

Selection:

Figure 11. Test Jack Configuration Screen

The options on this screen are as follows:

• Toggle Test Jack Mode – Select Monitor (non-intrusive) or Terminate (intrusive)

• Change Test Port Number – Select an active port

• Toggle Inclusive Test Direction – This option has no effect on Monitor mode. Select Network

or Customer

Refer to “Appendix B”, “Rear Panel DS1 Test Access” for a full description of the function-

ality of the test jack.

61181307L7-5E 13

Page 22

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

BERT Test Screen

The Channel # BERT Test screen (Figure 12) performs a test with the following options:

• (Re)start Pattern – Use this option to (re)start a test.

• Stop Test – Use this option to manually stop a test.

• Select Data Pattern – Use this option to access the Current Pattern menu (Figure 13), which

is used to select the appropriate data test pattern for the desired results.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

CH 1 Circuit ID:

Channel 1 BERT Test Screen

Test Results

---------------------------------------------------- Test Direction: T1 Interface

Unframed Pattern Generation: OFF

Pattern: QRSS Pattern

Line Coding: AMI

Bit Errors: 0000000

Bit Error Rate: 0.0E-0

Pattern Sync: N/A

Pattern Sync Losses: 000

Test Length (HH:MM:SS): 01:00:00

Time Elapsed (HH:MM:SS): 00:00:00

-----------------------------------------------------

1. (Re)start Pattern 2. Stop Test

3. Select Data Pattern 4. Enter Test Timeout

5. Toggle Test Direction

'Sx'- Select Channel x 'N' - Next Channel 'P' - Previous Channel

Selection:

Figure 12. BERT Test Screen

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

NETWORK Pattern Screen

Current Pattern = QRSS Pattern

------------------------------------

1. 63 Pattern

2. 511 Pattern

3. 2047 Pattern

4. REV. 2047 Pattern

5. 2^15 Pattern

6. 2^20 Pattern

7. QRSS Pattern

8. 2^23 Pattern

Selection:

Figure 13. Network Pattern Screen

14 61181307L7-5E

Page 23

Menu Descriptions

• Enter Test Timeout – This option displays the Network Timeout screen (Figure 14). The

timeout can run for a specific duration by entering the hours and/or minutes, or can run

indefinitely by entering 00:00.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

NETWORK Timeout Screen

Test Timeout(Hr:Min) = 01:00

----------------------------

1. Change Timeout

*NOTE: When timeout is set to 00:00, the

test will run indefinitely.

Selection:

Figure 14. Network Timeout Screen

• Toggle Test Direction – When a test is not running, this option is used to toggle the test

signal in the opposite direction (from customer to network and vice versa). When a test is

running, this option changes to Inject Bit Errors (Figure 15). This allows errors to be

generated from the test origination point to validate the test results.

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

CH 1 Circuit ID:

Channel 1 BERT Test Screen

Test Results

---------------------------------------------------- Test Direction: T1 Interface

Unframed Pattern Generation: ON

Pattern: 63 Pattern

Line Coding: B8ZS

Bit Errors: 0000000

Bit Error Rate: 0.0E-09

Pattern Sync: ACQUIRED

Pattern Sync Losses: 000

Test Length (HH:MM:SS): 01:01:00

Time Elapsed (HH:MM:SS): 00:01:30

-----------------------------------------------------

1. Number of Errors to Inject = 002 (Maximum=255)

2. Inject Bit Error

3. (Re)start

Selection:

Figure 15. BERT Inject Errors Screen

61181307L7-5E 15

Page 24

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Self-Tests Screen

Selecting Self-Tests performs tests of the QDFC and QDFR, with no additional user input. If

all functions pass, the “Self Test Complete” message appears (Figure 16).

Shelf: 1 Slot: 2 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

SELF TEST COMPLETE

QDFC : Passed

QDFR : Passed

Figure 16. Self-Test Complete

Performance History Menu

The Performance History menu (Figure 17) displays the performance of each individual end of

the circuit. A single channel can be viewed by selecting the option number for the channel of

choice.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Performance History

1. Channel 1

2. Channel 2

3. Channel 3

4. Channel 4

5. QDFC/QDFR Fiber

Selection:

Figure 17. Performance History Menu

16 61181307L7-5E

Page 25

Menu Descriptions

Performance History Channel # Menu

The Performance History Channel # menu (Figure 18) displays the performance of a specific

channel. From this screen, the network or customer receiver may be selected.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Performance History

Channel 1

Select the Receiver of Interest

1. Network Receiver (from Network)

2. Customer Receiver (from Customer)

Selection:

Figure 18. Performance History Channel # Menu

Performance History Fiber Menu

The Performance History Fiber menu (Figure 19) displays the performance of the QDFC and

QDFR.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Performance History - Fiber - 24 Hour Data

QDFC Data QDFR Data

ES-L SES-L UAS-L ES-L SES-L UAS-L

00000 00000 65535 00000 00000 00000

01/04 00000 00000 65535 01/04 00000 00000 00000

01/03 00000 00000 65535 01/03 00000 00000 00000

01/02 00000 00000 65535 01/02 00000 00000 00000

01/01 00000 00000 65535 01/01 00000 00000 00000

12/31 ----- ----- ----- 12/31 ----- ----- ---- 12/30 ----- ----- ----- 12/30 ----- ----- ---- 12/29 ----- ----- ----- 12/29 ----- ----- -----

1. Definitions 3. 15 Min Data

2. Reset Fiber Data

Selection:

Figure 19. Performance History Fiber Menu

61181307L7-5E 17

Page 26

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

The Channel Performance History of the DSX-1 Rx from the network is shown in Figure 20.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Channel 1 Performance History - DSX-1 Rx from Network - 24 Hour Data

Line Data Path Data

ES-L SES-L LOSS-L CV-L ES-P SES-P UAS-P CV-P

65535 65535 65535 0000000 00000 00000 00000 0000000

01/04 65535 65535 65535 0000000 01/04 00000 00000 00000 0000000

01/03 65535 65535 65535 0000000 01/03 00000 00000 00000 0000000

01/02 65535 65535 65535 0000000 01/02 00000 00000 00000 0000000

01/01 65535 65535 65535 0000000 01/01 00000 00000 00000 0000000

12/31 ----- ----- ----- ------- 12/31 ----- ----- ----- ------ 12/30 ----- ----- ----- ------- 12/30 ----- ----- ----- ------ 12/29 ----- ----- ----- ------- 12/29 ----- ----- ----- -------

1. Definitions 4. 15 Min Data

2. Reset CH 1 Data 5. View Next Channel

3. Toggle Network/Customer Data Selection:

Figure 20. Channel Performance History Screen, from Network

The Channel Performance History of the DSX-1 from the customer is illustrated in Figure 21.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Channel 1 Performance History - DS1 Rx from Customer - 24 Hour Data

Line Data Path Data

ES-L SES-L LOSS-L CV-L ES-P SES-P UAS-P CV-P

00000 00000 00000 0000000 00000 00000 00000 0000000

01/05 00000 00000 00000 0000000 01/05 00000 00000 00000 0000000

01/04 00000 00000 00000 0000000 01/04 00000 00000 00000 0000000

01/03 00000 00000 00000 0000000 01/03 00000 00000 00000 0000000

01/02 00000 00000 00000 0000000 01/02 00000 00000 00000 0000000

01/01 00000 00000 00000 0000000 01/01 00000 00000 00000 0000000

12/31 ----- ----- ----- ------- 12/31 ----- ----- ----- ------ 12/30 ----- ----- ----- ------- 12/30 ----- ----- ----- -------

1. Definitions 4. 15 Min Data

2. Reset CH 1 Data 5. View Next Channel

3. Toggle Network/Customer Data Selection:

Figure 21. Channel Performance History Screen, from Customer

18 61181307L7-5E

Page 27

Menu Descriptions

Scratch Pad, Circuit ID Menu

The Scratch Pad, Circuit ID menu (Figure 22) is used to give each circuit a circuit ID name,

number, or identity of the users choosing. The scratch pad can be used to make specific notes

or reminders.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Ch 1 Circuit ID =

Ch 2 Circuit ID =

Ch 3 Circuit ID =

Ch 4 Circuit ID =

Scratch Pad =

(1-4). Change Circuit ID

5. Change Scratch Pad

Selection:

Figure 22. Scratch Pad, Circuit ID Menu

61181307L7-5E 19

Page 28

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Alarm History Menu

The Alarm History menu (Figure 23) provides the options Red, Yellow, and Blue Alarms or PM

Threshold Crossing Alarms. A red alarm indicates a loss of signal or loss of framing, a yellow

alarm indicates a remote alarm indication, and a blue alarm is an alarm indication signal.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Alarm History

1. Alarm History - Red, Yellow, and Blue Alarms

2. Alarm History - PM Threshold Crossing Alarms

Selection:

Figure 23. Alarm History Menu

T1 Alarm History Screen

The T1 Alarm History screen (Figure 24) displays the alarm history, and the option to select a

specific channel.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

CH 1 Circuit ID:

T1 Alarm History

LOCATION ALARM FIRST LAST CURRENT COUNT

-------------------------------------------------------------------------------QDFC RED(LOS/LOF) 01/01/00 00:00:05 01/01/00 00:00:05 Alarm 001

(DSX-1) YELLOW(RAI) OK 000

BLUE(AIS) OK 000

QDFR RED(LOS/LOF) OK 000

(DS1) YELLOW(RAI) OK 000

BLUE(AIS) OK 000

--------------------------------------------------------------------------------

1. Channel 1 Alarms 5. Fiber Alarms

2. Channel 2 Alarms 6. Clear ALL Channel 1 Alarm Data

3. Channel 3 Alarms R. Clear ALL Alarm Data

4. Channel 4 Alarms

Selection:

Figure 24. T1 Alarm History Screen

20 61181307L7-5E

Page 29

Menu Descriptions

Channel T1 Threshold Alarm History Screen

An individual Channel T1 Threshold Alarm History screen (Figure 25) provides the errored

seconds, severely errored seconds, loss of signal seconds, code violation line, and code

violation path.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

CH 1 Circuit ID:

T1 Alarm History

LOCATION THRESH ALARM FIRST LAST CURRENT COUNT

-------------------------------------------------------------------------------QDFC ESL 15MIN OK 000

(DSX-1) SESL 15MIN OK 000

LOSSL 15MIN OK 000

CVL 15MIN OK 000

ESP 15MIN OK 000

SESP 15MIN OK 000

UASP 15MIN OK 000

CVP 15MIN OK 000

--------------------------------------------------------------------------------

1. Clear ALL CH 1 Data 4. View Next Channel

2. Toggle Network/Customer Data 5. View Fiber Alarms

3. 24 HOUR Data R. Clear ALL Alarm Data

Selection:

Figure 25. Channel T1 Threshold Alarm History Screen

Event History Screen

The Event History screen (Figure 26) displays various events that have taken place, including

changes to service states and alarms.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Num Description of Event Date Time Source Port

-----------------------------------------------------------------------------

1. QDFR Event Log Reset 08/04/04 08:39:54 QDFR SYS

Page Number: 1/ 1 Number of Events: 1

---------------------------------------------------------------------------- 'P' - Previous Page 'H' - Home 'R' - Reset Events

'N' - Next Page 'E' - End

Selection:

Figure 26. Event History Screen

61181307L7-5E 21

Page 30

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Troubleshooting Menu

The Troubleshooting menu (Figure 27) compiles information received from all facilities and

equipment in the circuit and presents them in both Real-Time and 7-Day historical format.

The Definitions option from this menu provides definitions of terms and acronyms.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Troubleshooting

Currently Active Previous 7 Days

CH 1 DSX-1 (Network) Rx OK OK

CH 1 DS1 (Customer) Rx LOS LOS

CH 2 DSX-1 (Network) Rx OK OK

CH 2 DS1 (Customer) Rx LOS LOS

CH 3 DSX-1 (Network) Rx OK OK

CH 3 DS1 (Customer) Rx LOS LOS

CH 4 DSX-1 (Network) Rx OK OK

CH 4 DS1 (Customer) Rx LOS LOS

QDFC Loop LOS LOS

QDFR Loop LOS LOS

1. Troubleshooting Guidance 4. Performance History

2. Definitions 5. Alarm History

3. Detailed Status R. Restart history for this screen

Selection:

Figure 27. Troubleshooting Menu

Troubleshooting Guidance Screen

The Troubleshooting Guidance screen (Figure 28) analyzes this information and makes repair

recommendations. The QDFR reads the operational status of the unit and returns Troubleshooting Guidance, or hints, as to the probable cause of the trouble.

Shelf: 1 Slot: 15 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Fiber Loss of Sync

- A Fiber Loss of Sync (FLOS) condition (OPT LED is solid Red) indicates that

end-to-end fiber synchronization does not exist between the fiber devices on a

given loop. The problem can exist for any number of reasons, but is most likely

related to some kind of loop fault.

- The condition could be related to a new installation where the field

equipment has not yet been installed (or it has been removed in error), but it

could also be related to a continuity problem due to facility trouble.

- If the condition is not due to the lack of termination, clear the office by

temporarily connecting an QDFR Remote at the network side of the loop. If

the open condition clears, i.e., the FLOS indication goes away (OPT LED is

extinguished), the problem is beyond that point.

Figure 28. Troubleshooting Guidance Screen

22 61181307L7-5E

Page 31

Menu Descriptions

Clear PM and Alarm Histories Option

Selecting the Clear PM and Alarm Histories option from the QDF Main menu, displays the

following prompt shown in Figure 29.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Adtran QDF Main Menu

1. QDF Unit Information

2. Provisioning

3. Status

4. Auto In Service

5. Loopbacks and Test

6. Performance History

7. Scratch Pad, Ckt ID

8. Alarm History

9. Event History

10. Troubleshooting

11. Clear PM and Alarm Histories

12. System PM/Screen Report

13. Flash Upgrade

14. Virtual Terminal Control

This will clear the PM data, Alarm History, and

Troubleshooting Histories for the QDFC and the QDFR.

Are you sure (Y/N)?

Selection: 11

Figure 29. Clear PM and Alarm Histories Prompt

Press

Y to clear historical data. The following line appears, to indicate that the PM and alarm

histories are being erased:

Clearing all Performance and Alarm History.

61181307L7-5E 23

Page 32

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

System PM/Screen Report Menu

System PM/Screen Report menu (Figure 30) is used to generate system reports.

6. Performance History

7. Scratch Pad, Ckt ID

8. Alarm History

9. Event History

10. Troubleshooting

11. Clear PM and Alarm Histories

12. System PM/Screen Report

13. Flash Upgrade

14. Virtual Terminal Control

Selection: 12

Enable data logging now.

Select Report Type or Press Escape to cancel:

1) Full System/History Report

2) Current Status Report

3) System Configuration Report

4) Alarm/Event History

Selection:

Figure 30. System PM/Screen Report Menu

24 61181307L7-5E

Page 33

Menu Descriptions

Download QDFR via Y-Modem Menu

The Download QDFR via Y-Modem menu (Figure 31) initiates a Y-Modem file transfer from the

computer connected to the craft access port to the QDFR. This file is downloaded to the

QDFR. The file downloaded to the QDFR should be of the “.bin” file type only and is only

provided for feature enhancements/additions and bug fixes.

Shelf: 1 Slot: 11 Total Access System mm/dd/yy hh:mm

Unacknowledged Alarms:

Download QDFR via Y-Modem

This utility programs the QDFR. The VT100 terminal emulation

program used must support Y-Modem file transfers and have access to

the software binary file (*.bin).

1. Start Transfer

2. Abort

Selection:

Figure 31. Download QDFR via Y-Modem Menu

Figure 32 shows a Flash upgrade session in progress.

Choose baud rate for Flash Download:on: 1

1. 9600

2. 19200

3. 38400

4. 57600

Choice: 1

Please change your terminal to 9600 and then press the space bar.BB0

Setup Instructions:

[Note: Your terminal program may differ slightly]

1. Select "Send File" from Transfer options.

2. Set "Transfer Protocol" to the following:

Xmodem(CRC) or Ymodem

3. Select appropriate binary file (*.BIN) to upload.

4. Upload File.

[Note: The screen will start displaying C's -- this is normal.]

=CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

Figure 32. Flash Upgrade, Y-Modem in Progress

61181307L7-5E 25

Page 34

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Virtual Terminal Control

The Virtual Control screen allows control of remote unit provisioning from a QDR module.

Select the Log into QDFR option from this screen and press

session with a the far-end unit. When the remote session is complete, press

ENTER to begin a user-initiated

CTRL+X to

terminate the session.

mm/dd/yy hh:mm

Press ESC to return to previous menu

Virtual Terminal Session: Inactive

Virtual Host: no

Virtual Terminal Control

1. Log into QDFC

Selection:

Figure 33. Virtual Terminal Control Screen

26 61181307L7-5E

Page 35

Maintenance

MAINTENANCE

The QDFR does not require routine maintenance for normal operation. In case of equipment

malfunction, use the rear panel bantam jack connectors to help locate the source of the

problem. ADTRAN does not recommend that repairs be attempted in the field. Repair services

may be obtained by returning the defective unit to ADTRAN. Refer to “Appendix C, Warranty”

for further information.

SPECIFICATIONS

Specifications for the QDFR are detailed in Table 5.

Specification Description

Operating Temperature:

Storage Temperature:

Input Voltage Range:

Maximum Power Dissipation:

Output Optical Power (P):

Table 5. Specifications

Environmental

Relative Humidity:

Power

Maximum Current:

Physical

Dimensions:

Weight:

Mounting:

Optical (QDFR)

Fiber Type:

Wave Length:

Optical Budget:

Receive Level:

Connector:

–40°C to +65°C

–40°C to +85°C

95 percent maximum @ 50°C, noncondensing

–24 VDC to –48 VDC input

90 mA –48 VDC

4.32 watts

Height: 1.8 inches

Width: 8.0 inches

Depth: 9.0 inches

2.5 pounds

Wallmount or Desktop

Single mode

1310 nm receive and 1550 nm transmit

17 ±1 dB

–14 dBm <

–31 ±1 dBm (worst case)

Single SC connector

P < –8 dBm

Connectors (QDFR)

T1 interface:

Fiber:

Compliance

Agency Approvals: UL 60950

Part Number

Quad Fiber Remote: 1181307L7

61181307L7-5E 27

RJ-48C

Flat SC adapter

Page 36

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

This page is intentionally blank.

28 61181307L7-5E

Page 37

Appendix A

QDFR Loopbacks

FIBER LINE UNIT MAINTENANCE MODES

This appendix describes operation of the optical fiber system with regard to detection of inband and ESF facility data link loopback codes.

Upon deactivation of a loopback, the T1 channel interface will synchronize automatically.

NOTE

Each T1 channel is independent of the others. The user can enable

loopbacks in either direction on any number of T1 channels.

Loopback Process Description

In general, the loopback process for the optical fiber system elements is modeled on the corresponding DS1 system process.

Specifically, the QDFC loopback is similar to an Intelligent Office Repeater loopback, and the

QDFR loopbacks are similar to an in-line T1 Repeater loopback.

The unit can detect the loopback activation or deactivation code sequence only if an error rate

-03

of 1E

or better is present.

61181307L7-5E A-1

Page 38

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

Loopback Control Codes

A summary of control sequences is given in Table A-1. All codes must be sent for a minimum

of 5 seconds to be detected and acted upon.

NOTE

In all control code sequences presented, the in-band codes are

shown left-most bit transmitted first, and the ESF data link codes

with right-most bit transmitted first.

Table A-1. Loopback and Control Codes

Pattern Description Source Arming

Required

1in3

3in7 QDFR DS1 loopback to network NET No

4in7 QDFC DS1 loopback to network NET No

5in7 QDFR DS1 loopback to customer CUST No

6in7 QDFC DS1 loopback to customer CUST No

3F1E QDFC DS1 loopback to customer CUST No

3F02 QDFR DS1 loopback to customer CUST No

3F02 QDFR DS1 loopback to customer NET Yes

FF1E QDFC loopback to network

FF02 QDFR loopback to network

2in5 Arm QDFC and QDFR. QDFR DS1 will loopup (toward Network only) if

3in5 Disarm and loopdown QDFC and QDFR

Loopdown QDFC and QDFR and disarm

Will not loopup QDFC if QDFC already in loopback to customer

Will not loopup QDFR if any unit already in loopback to customer

NIU LB is enabled

Restores Loopback Timeout Override after D5D6

NET

CUST

NET No

NET No

NET

CUST

NET

CUST

No

No

No

D3D3 QDFC DS1 loops up toward pattern: 2 seconds AIS, 5 seconds data,

then 231 bit errors toward pattern. 231 bit errors every 20 seconds as

long as the pattern is present

C742 QDFR DS1 loops up toward pattern: 2 seconds AIS, 5 seconds data,

and then 20 bit errors toward pattern. 20 errors every 20 seconds as

long as pattern present

A-2 61181307L7-5E

NET

CUST

NET

CUST

Yes

Yes

Page 39

Fiber Line Unit Maintenance Modes

Table A-1. Loopback and Control Codes (Continued)

Pattern Description Source Arming

Required

9393 Loopdown QDFC DS1 – either direction

Loopdown QDFR DS1 – customer loopback always; will only loopdown

QDFR network loopback if NIU is disabled

Does not disarm units if they are armed

D5D5 If unit is in loopback towards pattern, errors are periodically injected

toward pattern as long as pattern is present

QDFC: 231 errors every 20 seconds

QDFR: 20 errors every 20 seconds

D5D6 Loopback Timeout Override

Disables loopback timeout; restores original loopback timeout when

unit is disarmed

If unit is in loopback towards pattern, errors are periodically injected

toward pattern as long as pattern is present

QDFC: 231 errors every 20 seconds

QDFR (Network loopback): 20 errors every 10 seconds

QDFR (Customer loopback): 20 errors every 20 seconds

FF48 Arm QDFC and QDFR DS1

QDFR will Loopback (toward Network only) if NIU enabled

FF24 Loopdown and disarm QDFC and QDFR DS1

Restores Loopback Timeout Override after D5D6

NET

CUST

NET

CUST

NET

CUST

NET No

NET

CUST

No

No

Yes

No

1. Units must be armed with 11000b or FF48h before this code will work.

2. Loopback and error injection will only occur if the in-band code is received by the unit that is to go into loopback. If another loopback blocks the in-band code from being transmitted to the unit that is to go into loopback,

loopback and error injection will not occur.

NOTE

All codes listed above must be sent for a minimum of 5 seconds to

be detected and acted upon.

61181307L7-5E A-3

Page 40

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

This page is intentionally blank.

A-4 61181307L7-5E

Page 41

Appendix B

Rear Panel DS1 Test Access

GENERAL

Figure B-1 through Figure B-3 provides a graphical description of the test jack functionality

for the QDFR. The test jack can be provisioned to correspond to any of the four T1 channels.

There are two options for selecting the T1 channel to be “connected” to the test jack.

• The first is the front panel switch for channel selection (

channel will flash if that is the selected channel for the test jack.

For example, if T1 channel 4 corresponds to the test jack, the LEDs for DS1 1, 2, and 3

remain solid while the LED for DS1 4 flashes.

To change the selected channel, momentarily press the

channel’s LED indicator flashes.

• The next option for selecting test jack channel operation is from the Loopbacks and

Test\Test Port (Bantam Jack) Control screen. The parameter for this option is Change Test

Port Number.

The test jacks can operate as either a terminate jack, also known as intrusive mode, or as a

monitor jack, also known as non-intrusive mode. The functionality of the test jack is

dependent on the provisioning of Test Jack Mode found under Loopbacks and Test\Test Port

(Bantam Jack) Control.

• If this parameter is set to “Monitor”, the test jack can be utilized to monitor the Tx data

from the network or from the customer.

• If the parameter is set to “Intrusive”, the test jack can be utilized to connect a test set to

allow transmitting and receiving data for troubleshooting purposes.

In Intrusive mode, the direction of the test jack must also be selected. This parameter is

set when Toggle Intrusive Test Direction is changed.

CH SELECT). The LED for the T1

CH SELECT switch until the desired

– If the test direction is “Network”, the Tx and Rx data is to and from the network

equipment.

– If the test direction is set to “Customer”, the Tx and Rx data is to and from the customer’s

equipment. Further description of each mode is found on the following pages.

61181307L7-5E B-1

Page 42

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

MONITOR MODE

Monitor Tx to Customer

The Rx of the monitor BERT receives data from the TX point of the test jack, Figure B-1. This

monitors the data that the customer’s equipment is receiving from the network equipment.

TX

432ohm

RX

TX

RX

T1 BERT

432ohm

Figure B-1. DSX MON, Tx to Customer

To set up the QDFR for this mode the following sequence must be performed:

1. Select the correct T1 channel to monitor.

This is accomplished by accessing the front panel switch or from the craft port interface.

2. After the correct T1 channel is selected, verify that the Test Jack Mode is set to “Monitor”.

If the Test Jack Mode is not set to “Monitor”, change this parameter via the Loopbacks and

Test\Test Port (Bantam Jack) Control\Test Jack Mode screen.

The Intrusive Test Direction parameter is not applicable for this mode. In this mode, the

data has a monitor jack impedance of 432 ohms. The BERT should be set to a monitor

mode. The BERT Tx is not used. This test is non-intrusive.

B-2 61181307L7-5E

Page 43

Monitor Mode

Monitor Rx from Customer

The Rx of the monitor BERT receives data from the RX point of the test jack, Figure B-2. This

monitors the data that the customer’s equipment is transmitting to the network equipment.

TX

RX

T1 BERT

432ohm

TX

RX

432ohm

Figure B-2. DSX MON, Rx from Customer

To set up the QDFR for this mode, the following sequence must be performed:

1. Select the correct T1 channel to monitor.

This selection is accomplished by accessing the front panel switch or from the craft port

interface.

2. After the correct port Is Selected, Verify That The Test Jack Mode is set to “Monitor”.

If the Test Jack Mode is not set to “Monitor”, change this parameter via the Loopbacks and

Test\Test Port (Bantam Jack) Control\Test Jack Mode screen.

The Intrusive Test Direction parameter is not applicable for this mode. In this mode the

data has a monitor jack impedance of 432 ohms. The BERT should be set to a monitor

mode. The BERT Tx is not used. This test is non-intrusive.

61181307L7-5E B-3

Page 44

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

TERMINATE MODE

Intrusive Tx to Customer and Rx from Customer

NOTE

This is an intrusive test and the original data path will be disrupted.

The Tx of the BERT connects to the Tx of the test jack. The Rx of the BERT connects to the Rx

of the test jack, Figure B-3. The Tx data of the test jack is transmitted to the customer’s

equipment while the Rx data from the customer is monitored. In this mode the monitor jack

impedance of 432 ohms is removed from the data path. The BERT should be set to terminate

mode.

TX

TX

RX

T1 BERT

RX

Figure B-3. Terminate Mode

To set up the QDFR for this mode the following sequence must be performed:

1. Select the correct T1 channel to monitor.

This selection is accomplished by accessing the front panel switch or from the craft port

interface.

2. After the correct T1 channel is selected, verify that the Test Jack Mode is set to “Intrusive”.

If the Test Jack Mode is not set to “Intrusive”, change this parameter via the Loopbacks

and Test\Test Port (Bantam Jack) Contro\Test Jack Mode screen.

3. Verify the Intrusive Test Direction parameter is set to “Customer”.

If the Intrusive Test Direction parameter is not set to “Customer”, change this parameter

via the Loopbacks and Test\Test Port (Bantam Jack) Control\Toggle Intrusive Test

Direction screen.

B-4 61181307L7-5E

Page 45

Terminate Mode

Intrusive Tx to Network and Rx from Network

NOTE

This is an intrusive test and the original data path will be disrupted.

The Tx of the BERT connects to the Tx of the test jack. The Rx of the BERT connects to the Rx

of the test jack, Figure B-3. The Tx data of the test jack is transmitted to the network

equipment while the Rx data from the network equipment is monitored. In this mode the

monitor jack impedance of 432 ohms is removed from the data path. The BERT should be set

to terminate mode.

To set up the QDFR for this mode the following sequence must be performed:

1. Select the correct T1 channel to monitor.

This selection is accomplished by accessing the front panel switch or from the craft port

interface.

2. After the correct T1 channel is selected, verify that the Test Jack Mode is set to “Intrusive”.

If the Test Jack Mode is not set to “Intrusive”, change this parameter via the Loopbacks

and Test\Test Port (Bantam Jack) Control\ Test Jack Mode screen.

3. Verify the Intrusive Test Direction parameter is set to “Network”.

If the Intrusive Test Direction parameter is not set to “Network”, change this parameter via

the Loopbacks and Test\Test Port (Bantam Jack) Control\Toggle Intrusive Test Direction

screen.

61181307L7-5E B-5

Page 46

Quad Fiber Remote (QDFR) Unit Installation and Maintenance Practice

This page is intentionally blank.

B-6 61181307L7-5E

Page 47

Appendix C

Warranty

WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within the warranty period if it does not meet its

published specifications or fails while in service. Warranty information can be found at

www.adtran.com/warranty

Refer to the following subsections for sales, support, Customer and Product Service (CAPS)

requests, or further information.

ADTRAN Sales

Pricing/Availability:

800-827-0807

.

ADTRAN Technical Support

Pre-Sales Applications/Post-Sales Technical Assistance:

800-726-8663

Standard hours: Monday - Friday, 7 a.m. - 7 p.m. CST

Emergency hours: 7 days/week, 24 hours/day

ADTRAN Repair/CAPS

Return for Repair/Upgrade:

(256) 963-8722

Repair and Return Address

Contact CAPS prior to returning equipment to ADTRAN.

ADTRAN, Inc.

CAPS Department

901 Explorer Boulevard

Huntsville, Alabama 35806-2807

61181307L7-5E C-1

Page 48

®

Carrier Networks Division

901 Explorer Blvd.

Huntsville, AL 35806

Loading...

Loading...