Page 1

®

Total Access OPTI-3 CPE Wallmount Cabinet

Installation and Maintenance Practice

CONTENTS

1. General .................................................................... 1

2. Installation............................................................... 3

3. System Power Turn-Up........................................... 6

4. Maintenance ............................................................ 7

5. Specifications .......................................................... 7

6. Warranty and Customer Service ............................. 7

FIGURES

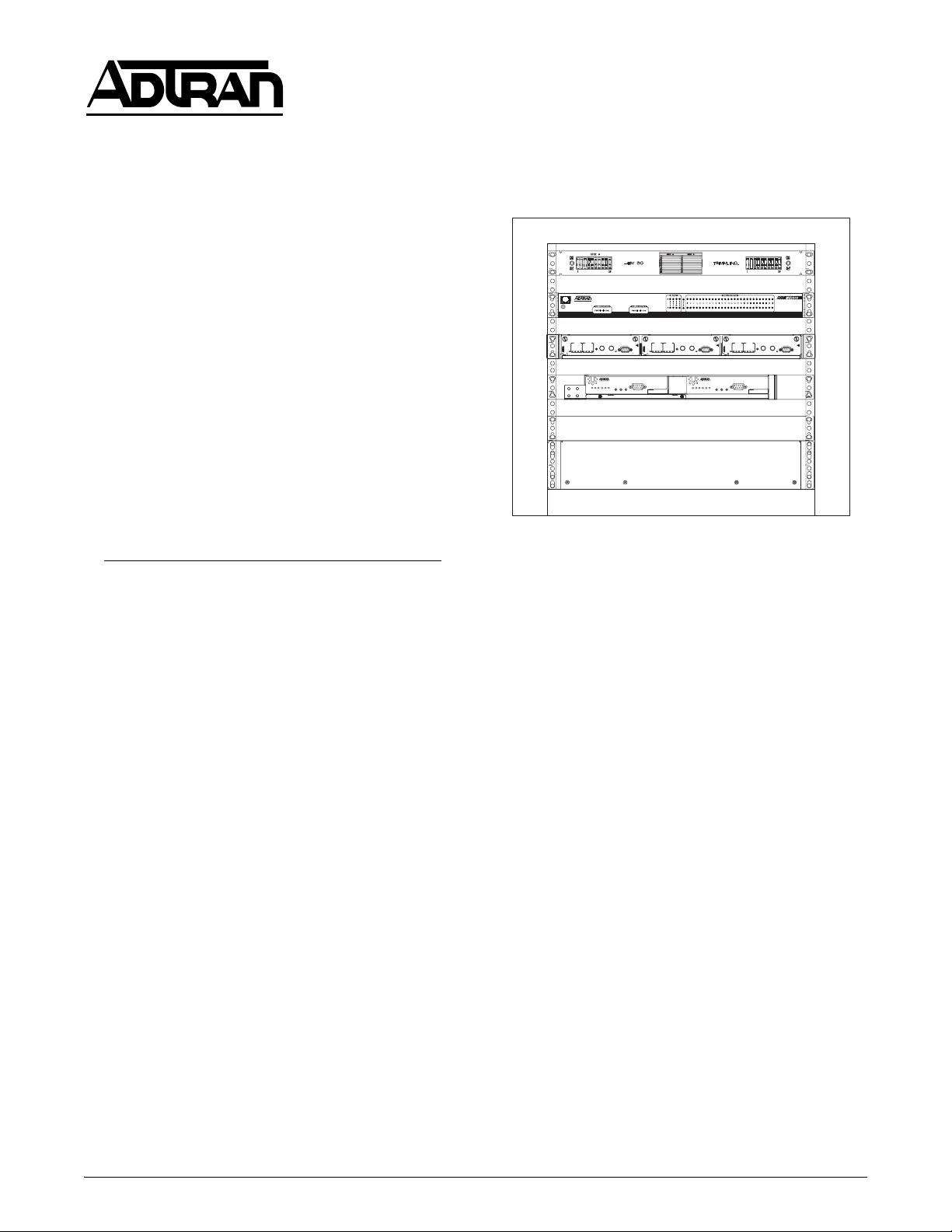

Figure 1. Wallmount Cabinet...................................... 1

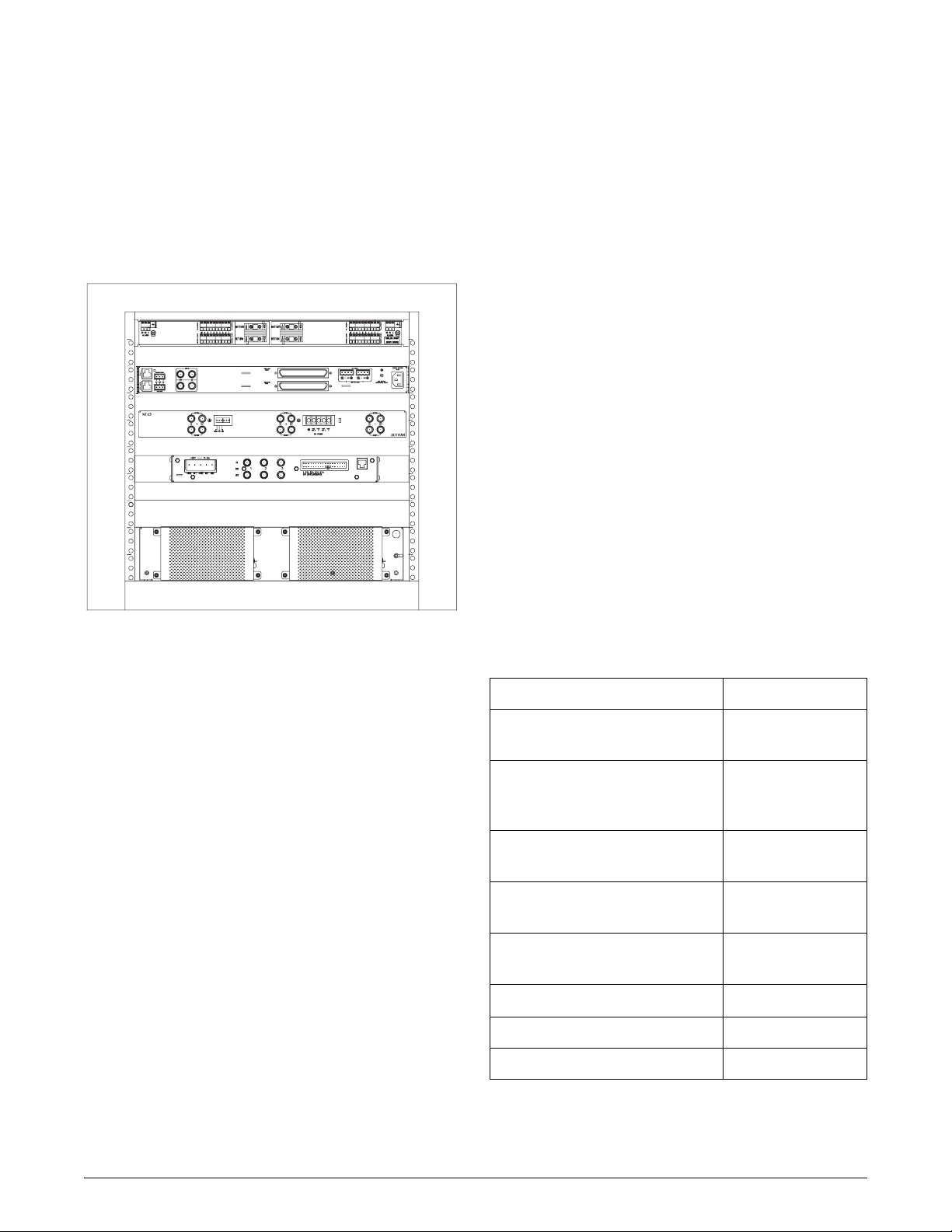

Figure 2. Wallmount Cabinet Rear View.................... 2

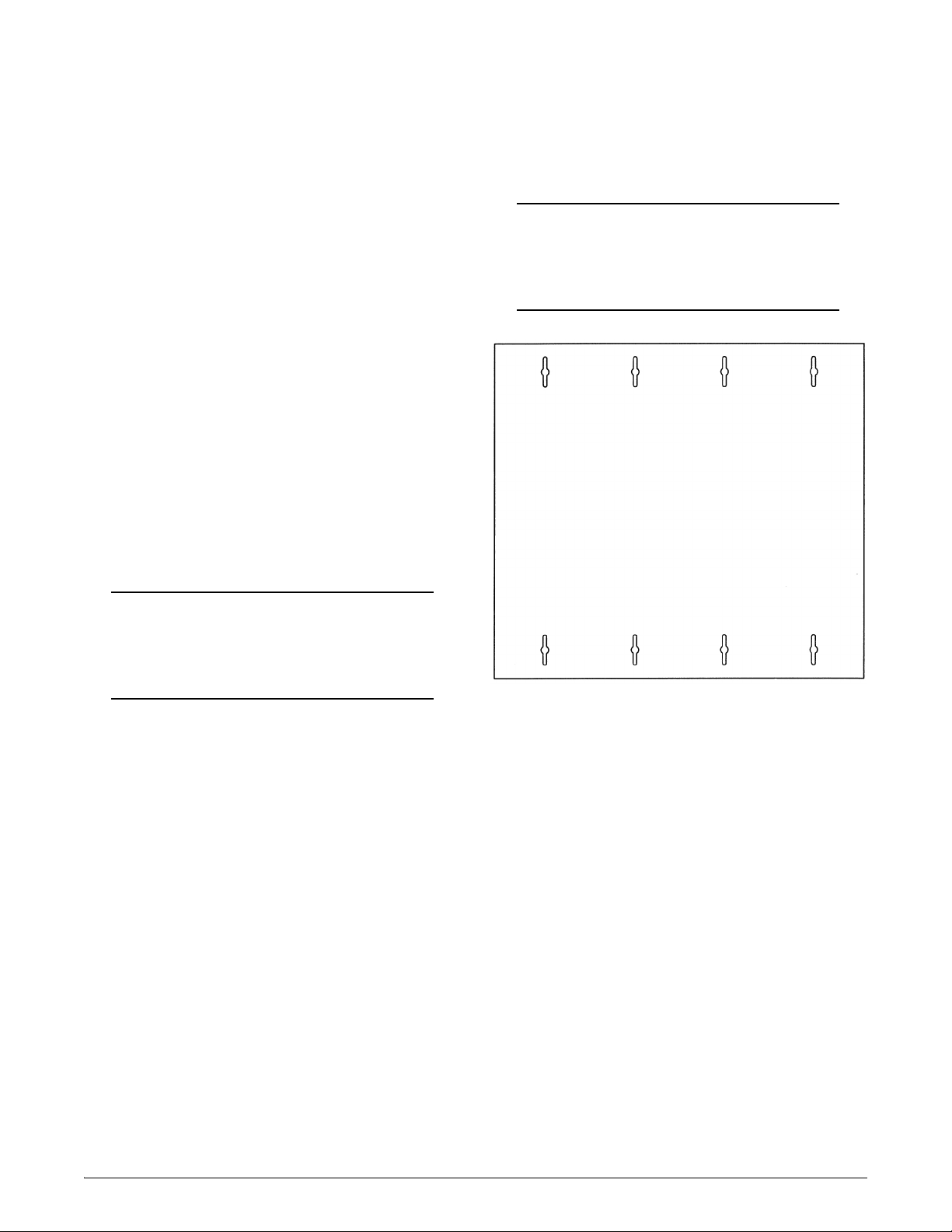

Figure 3. Cabinet Mounting Holes.............................. 3

Figure 4. Wiring Block Diagram................................. 4

Figure 5. Circuit Connections ..................................... 5

TABL ES

Table 1. Associated Documentation............................ 2

Table 2. Specifications ................................................ 7

Section 64150WALO3L7-5A

Issue 1, June 2004

T

T

T

T

S

N

KCU

W

NTWK MON

CUST MON

LBK SEL:

NTWK: 1X & HOLD

CUST: 2X & HOLD

DUAL: 3X & HOLD

STATUS

LOS = RED

AIS = AMBER

C-BIT = GRN

IDLE = AMBER

M13 = GRN

IDLE = AMBER

LBK

FUSE ALARM

LOS = RED

AIS = AMBER

C-BIT

M13

LBK

1212075

NIU3

TESTAPS ACO

ACO

DS3-3

DS3-1

DS3-2

ENABLE

OPTICS

STATUS

T

S

N

KCU

W

NTWK MON

CUST MON

LBK SEL:

NTWK: 1X & HOLD

CUST: 2X & HOLD

DUAL: 3X & HOLD

STATUS

LOS = RED

AIS = AMBER

C-BIT = GRN

IDLE = AMBER

M13 = GRN

IDLE = AMBER

LBK

FUSE ALARM

LOS = RED

AIS = AMBER

C-BIT

M13

LBK

1212075

NIU3

OPTI-3

1184002L1

DS3-1

DS3-2

DS3-3

OPTICS

STATUS

T

S

N

KCU

W

NTWK MON

CUST MON

LBK SEL:

NTWK: 1X & HOLD

CUST: 2X & HOLD

DUAL: 3X & HOLD

STATUS

LOS = RED

AIS = AMBER

C-BIT = GRN

IDLE = AMBER

M13 = GRN

IDLE = AMBER

LBK

FUSE ALARM

LOS = RED

AIS = AMBER

C-BIT

M13

LBK

1212075

NIU3

OPTI-3

1184002L1

TESTAPS ACO

ACO

ENABLE

1 RMU Fiber Management Shelf

Battery Backup

Figure 1. Wallmount Cabinet

1. GENERAL

This practice provides installation, wiring, and power

turn-up instructions for the ADTRAN

®

Total Access®

OPTI-3 CPE Wallmount Cabinet (Wallmount Cabinet).

The OPTI-3 deploys fiber-fed DS3s from an OC-3 feed.

The MX2800 converts one of the DS3s into 28 T1s. The

Wallmount Cabinet is intended for indoor use at the

customer premises. Figure 1 illustrates the Wallmount

Cabinet (P/N 4150WALO3L7).

Document Review

This document contains important pre-installation

information. Craft personnel should review the entire

document as part of installation planning.

Revision History

This is the initial release of this document. Future

revisions will be explained in this paragraph.

Description

The Wallmount Cabinet installation includes the

following components:

• Dual hinged 10U wallmount cabinet

• Mounting brackets

• Fiber management shelf

• Fiber splice tray

• six-port fiber connector module

• OPTI-3 rackmount chassis

• MX2800 rackmount chassis

• Two OPTI-3 controllers or lightwave controllers

• SC type optical connectors

• Coax cables and optical jumpers

• NIU3 3-slot shelf

• Three DS3 NIU3 MTC (MPOP) modules

• Two 1.9 amp power supply/battery chargers

• 10x10 fuse and alarm panel

• 7Ah battery backup

Cabinet Arrangement

All Wallmount Cabinet components are factory

mounted and wired for power, ground, and alarms.

Power wiring is complete with the exception of

connecting the keyed plug from the backup battery to

the power supply/battery charger (PS/BC). This wiring

is identified and labeled ready for craft connection after

the unit is securely mounted. Coaxial cables between

the OPTI-3, NIU3, and MX2800 are factory connected.

Optical jumper cables (3 meter) are provided for

customer connection described later in this document.

The Wallmount Cabinet has 10U of vertical rack space

and externally measures approximately 14-1/2-inches

high by 24-inches wide by 17-1/4-inches deep, and

weighs about 140 pounds equipped.

64150WALO3L7-5A PRELIMINARY 1

Trademarks: Any brand names and product names included in this document are

trademarks, registered trademarks, or trade names of their respective holders.

Page 2

The cabinet equipment access door has a full-view

safety-glass window. The swing out equipment housing

section has vent louvers on the top. The wallmount

support frame has cable access openings on the bottom.

A ground bus bar is mounted to the bottom inside of the

cabinet. Vertical equipment racks are sized for 19-inch

chassis components.

See Figure 2 for a rear view of cabinet arrangement.

1 RMU Fiber Management Shelf

The Trimm 10x10 fuse and alarm (F&A) panel is

mounted topmost in the cabinet. It receives primary and

secondary (redundant) power from the two PS/BCs. The

F&A panel has terminals and fuse protection capability

for primary and secondary power for a fully populated

cabinet plus spare capability for customer use.

Features

The Wallmount Cabinet supports the following features

and functions:

• 19-inch rackmount design

• Key lock security access

• Redundant power capability

• Independent frame ground connections

• Compact configuration

• Convenient access to front and back of chassis

• Factory wired for quick installation and turn-up

• FCC and UL compliant

• Meets NEBS Level 3 (all GR-63-CORE and

GR-1089-CORE requirements)

Figure 2. Wallmount Cabinet Rear View

The cabinet is configured with the two PS/BCs mounted

to a panel installed bottommost in the cabinet. Viewed

from the front, the left side PS/BC is the primary A-unit

and the right side is the redundant B-unit.

Mounted above the power supplies is the fiber

management shelf. It has a swing out door that gives

access to the 6-position fiber termination panel. It is

designed to accommodate fiber cable management for

two OPTI-3 controller modules.

The OPTI-3 chassis is mounted above the fiber

management shelf. It has slots for two OPTI-3 circuit

boards: the in-service unit and an optional redundant

unit if installed. Each OPTI-3 can feed three DS3 NIU3

circuit cards. The design is intended for 1-to-1

protection.

The DS3 NIU3 3-Slot chassis is mounted next above the

OPTI-3. The NIU3 chassis has slots for three NIU3

circuit cards. Three test cards are provided for this

installation: the DS3 Monitor and Test Card

(DS3 MTC), P/N 1212071L1.

Associated Unit Documentation

Individual unit documentation with detailed information exists for each element of the Wallmount

Cabinet solution (see Tabl e 1 ).

Table 1. Associated Documentation

Document ADTRAN P/N

OPTI-3 Rackmount Chassis

61184003L1-22

Job Aid

Total Access OPTI-3

61184002L1-5

Controller Module Installation

and Maintenance Practice

AC/DC Power Supply and

61175043L3-22

Battery Charger Job Aid

DS3 NIU3 3-Slot Shelf Unit

61212073L1-22

Job Aid

DS3 Monitor and Test Card

61212071L1-22

Job Aid

MX2800 Chassis Job Aid

Fiber splice tray Vendor provided

F&A panel guide Vendor provided

61200290L1-22

The MX2800 is mounted above the NIU shelf. It

converts one DS3 into 28 DSX-1s.

2 PRELIMINARY Issue 1, June 2004 64150WALO3L7-5A

Page 3

2. INSTALLATION

The Wallmount Cabinet installs at the customer

premises in a limited access controlled environment

location.

Inspection

After unpacking the Wallmount Cabinet inspect for

damage or missing components. If damage or missing

components are noted, file a claim with the carrier, then

notify ADTRAN. Refer to Warranty and Customer

Service section for more information.

Shipping Protection

Foam material may be installed to protect cabinet

components from shifting during transportation. Ensure

cabling is not damaged during foam removal.

Preparation

The system is shipped as an assembled and wired unit

with the exception of connecting the PS/BC to the

backup battery keyed plugs. Installation includes these

main steps:

I. Mounting the cabinet

II. Making wiring connections

Minimum Front Clearance

The Wallmount Cabinet extends 18 inches from the

mounting surface and requires 40 inches front clearance

from the mounting surface to fully open the door, and

28 inches to fully open the main housing.

NOTE

Craft should double check all dimensions in

this practice to actual dimensions on the

cabinet mounting area.

CAUTION

The cabinet with installed equipment weighs

140 pounds and will require two personnel to

safely lift and hang the cabinet.

The Wallmount Cabinet is designed to mount to a

minimum 3/4-inch plywood surface that is securely

fastened to support frames, studs, wall, or an

arrangement of equivalent strength. The Wallmount

Cabinet installs with standard hand tools; special tools

are not required.

The double hinged cabinet is comprised of three main

elements:

• Front door with full-size transparent window.

• Swing open main housing with heavy-duty hinges

and 19-inch equipment rack.

• Wallmount support frame with mounting brackets,

ground bus bar, and cable entry openings.

Mounting Features and Dimensions

The Wallmount Cabinet occupies a nominal area 24

inches wide by 20.25 inches high and requires an

additional 9 inches on the hinge side so the cabinet main

housing can swing fully open, and 6 inches below for

wire access.

Figure 3. Cabinet Mounting Holes

Pilot Hole Location

The Wallmount Cabinet mounts to the wall using eight

1-1/2 by 1/4-inch lag screws with washers. Pilot holes

must be drilled into the mounting surface at the eight lag

screw positions. Locate and mark pilot holes per the

following directions:

Within the designated area for Wallmount Cabinet

mounting, mark a point for the upper left mounting lag

screw.

1. Exactly 16 inches horizontally to the right from

that point mark the spot for the upper right

mounting lag screw. Ensure a level measurement.

2. The Wallmount Cabinet can be mounted and then

the rest of the mounting screw locations can be

drilled from within the cabinet. Refer to I.

Mounting the Cabinet on page 4.

64150WALO3L7-5A Issue 1, June 2004 PRELIMINARY 3

Page 4

I. Mounting the Cabinet

The following procedure describes Wallmount Cabinet

mounting:

1. Assemble required hand tools and mounting

hardware.

2. Check the mounting position to ensure the

Wallmount Cabinet will hang plumb and that

adequate space exists on the hinge side to open the

equipment rack main housing, then drill the two

pilot holes at the marked point locations.

3. Partially insert the outside two top mounting

screws including washers, leaving about a 1/2-inch

gap between the washer and the mounting surface.

4. Ensure the door and main housing are securely

closed then, with two craft personnel, lift and

maneuver the cabinet so as to capture the two

mounting screws on the bracket keyhole notches,

ensure the washers are on the cabinet side of the

notches. Allow the cabinet to slide down so the

screw heads are at the top end of the slots.

5. With the Wallmount Cabinet thus suspended, hold

firm against the mounting surface and firmly

tighten the two lag screws.

6. Drill the holes for the other six lag screws.

7. Insert and tighten the six lag screws

This completes the Wallmount Cabinet mounting

procedure.

II. Making Wiring Connections

Wallmount Cabinet wiring is labeled and cut to length

with the appropriate terminals or keyed connectors

factory assembled and connected. See Figure 4 for

wiring block diagram identification and arrangement.

See Figure 5 for circuit connections.

A

AC Power to PS/BC A

B

AC Power to PS/BC B

C

Primary Power to F&A Panel

D

Redundant Power to F&A Panel

E

Primary Power to OPTI-3

F

Primary Power to NIU3

G

Primary Power to MX2800

H

Secondary Power to OPTI-3

I

Secondary Power to NIU3

J

Secondary Power to MX2800

PRI SEC

F&A

J

G

MX2800

I

Alarms

NIU3

F

H

E

OPTI-3

PS/BC A

A

C

Alarms

PS/BC B

B

D

Alarms

Figure 4. Wiring Block Diagram

CAUTION

Do not connect AC power until instructed to do

so later in this procedure.

4 PRELIMINARY Issue 1, June 2004 64150WALO3L7-5A

Page 5

A

Network OC-3 Feed to OPTI-3

B

DS3 Signal to NIU3

C

DS3 Signal to Field

D

DS3 Signal IN to MX2800

E

DS3 Signal OUT from MX2800

Alarms

The PS/BCs have an alarm output jack (AC ALARM

OUTPUT). The alarm outputs are joined and are factory

wire-wrapped on terminal posts AUX-1 on the OPTI-3

chassis backplane.

The F&A panel has a fuse fail alarm output that is

factory wire wrapped to AUX-2 on the OPTI-3 chassis

backplane.

MX2800

1 DS3

D

3 DS3s

B

C

Network

A

E

NIU3

Field

OPTI-3

Figure 5. Circuit Connections

A cable access plate on the Wallmount Cabinet bottom

panel provides the entry point for office ground, AC

power, network coax/fiber connections, and other

associated wiring.

Ground

WARNING

All grounds must terminate at an approved

ground source. Check metal to metal contact

on all ground connections. Do not combine or

stack connections. Verify ground circuit continuity.

At the inside bottom left of the wallmount support

frame is the cabinet ground bus bar. It has multiple

screw compression terminals for ground connections.

The ground bus is the primary cabinet ground source.

The bus bar is ground connected to the support frame

with a bolt arrangement. All shelf components are

factory connected to the ground bus bar.

Cabinet Office Ground

Connect a customer-supplied, 10 AWG minimum,

office ground wire to one of the unused compression

terminals on the ground bus bar. This is the primary

cabinet to office ground connection.

Power

The two PS/BC units (A and B) mount to the back side

of the battery. Each PS/BC power output originates at

the –54 VDC, 2A OUTPUT connection, and terminates

at a modular plug at the F&A panel. The F&A panel has

a mating connector for each PS/BC output plug. PS/BC

A supplies F&A panel A-side, PS/BC B supplies the Bside. F&A panel circuitry allows the PS/BC units to

power share with one unit picking up the entire load if

the other unit fails.

Power Distribution and Fuses

The F&A panel has 10 individually fused output

terminals on the A-side and an additional 10 on the

redundant B-side. Terminal sets

1A and 1B supply

primary and secondary power input to the OPTI-3. The

associated front panel GMT fuses are 3 amp. The

OPTI-3 power input and return is on power sharing

terminals labeled

RET.

F&A terminal sets

–48V A and RET, and –48V B and

2A and 2B supply primary and

secondary power input to the NIU3. The associated

front panel GMT fuses are 1.5 amp. The NIU3 power

input and return is on power sharing terminals labeled

–48V A and RET, and –48V B and RET.

F&A terminal sets

3A and 3B supply primary and

secondary power input to the MX2800. The associated

front panel GMT fuses are 3 amp. The MX2800 power

input and return is on power sharing terminals labeled

–48V A and RET, and –48V B and RET.

The remaining F&A output terminals are for customer

use.

NOTE

For a fully redundant system each PS/BC must

have an independent AC power source.

1. Connect PS/BC unit A power wire quick

disconnect to F&A panel A-side quick disconnect.

64150WALO3L7-5A Issue 1, June 2004 PRELIMINARY 5

Page 6

2. Connect PS/BC unit B power wire quick

disconnect to F&A panel B-side quick disconnect.

Refer to System Power Turn-Up below for the

remainder of applying power.

Fiber Optic Jumpers

Fiber optic jumper cables are provided. The 3-meter

cables connect the output of the fiber termination panel

inside the fiber management shelf to the SC style optic

connectors on the OPTI-3 circuit boards.

1. Open the fiber management shelf.

2. Partially insert an OPTI-3 card into the OPTI-3

chassis leaving the board mounted optical

connectors accessible.

3. Carefully route and connect an optic jumper cable

between the fiber termination panel and the

designated OPTI-3 connector. Make use of all

cable protection and management devices.

4. Insert the OPTI-3 card until firmly seated in the

backplane and lock with the lock/eject latch.

5. Repeat the procedure for the remaining OPTI-3

circuit boards.

Network and Field Wiring

The customer is responsible for providing both

network-side and field-side optical fiber and coaxial

cables and making the connections to the appropriate

termination. Refer to the applicable documentation

(Ta bl e 1 on page 2) for information and instructions for

identifying these connections.

Final

All factory installed wiring is dressed and laced during

installation. For those wires that were craft connected,

dress and lace to workmanship standards, take special

care with optical fiber cables. Allow slack for opening

the equipment housing. This completes the wiring

connections.

After all wiring connections are made and verified,

reinstall protective covers and shields that were

removed during the installation process. This step is

necessary to maintain NEBS, UL, FCC, and safety

certification.

3. SYSTEM POWER TURN-UP

System Power Turn-Up assumes that the OPTI-3 and

NIU3 chassis have been outfitted with appropriate

circuit cards, default options factory set, and wiring

connections verified in accordance with the applicable

documentation and this Installation and Maintenance

Practice. If such is not the case complete that task first.

NOTE

Power turn-up should be conducted prior to

connecting network and field data connections.

1. Insert both power supply AC plugs into a 120 VAC

source. The PS/BC LEDs will turn ON green.

The NIU3 status LEDs will turn ON green. The

OPTI-3 LEDs will go through various ON/OFF

sequences. The final OPTI-3 display will show the

STATUS LEDs ON green and the remaining LEDs

ON red or flashing red. Refer to specific unit

documentation for complete LED descriptions.

Test the power share and redundant functioning of

the PS/BCs:

2. Unplug PS/BC unit A AC source. Observe its LED

turning OFF. OPTI-3 and NIU3 LEDs should show

normal, indicating that PS/BC unit B picked up the

load.

3. Reinsert PS/BC unit A AC plug. The PS/BC LED

will turn ON green again indicating normal

operation.

4. Unplug the PS/BC unit B AC source. Observe its

LED turning OFF. OPTI-3 and NIU3 LEDs should

show normal, indicating that PS/BC unit A picked

up the load.

5. Reinsert PS/BC unit B AC plug. Observe its LED

turning ON green indicating normal operation.

For PS/BC LED details, refer to descriptions printed on

the PS/BC chassis, or Job Aid 61175043L3-22.

This completes system power turn-up. If LED indications are normal, operators can proceed with network

and field connections, and management and operation

turn-up functions.

6 PRELIMINARY Issue 1, June 2004 64150WALO3L7-5A

Page 7

4. MAINTENANCE

The OPTI-3 Wallmount Cabinet does not require

maintenance for normal operation.

Fuses

If a fuse fails replace with one of identical size, type,

and rating. Repeated failure indicates a circuit

malfunction.

6. WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within the

warranty period if it does not meet its published specifications or fails while in service. Warranty information

can be found at www.adtran.com/warranty

.

U.S. and Canada customers can also receive a copy of

the warranty via ADTRAN’s toll-free faxback server at

877-457-5007.

PS/BC

The PS/BCs have a 3-amp fuse adjacent to the AC wire.

F&A Panel

The F&A panel has 3 amp GMT fuses in positions 1A

and 1B supplying the OPTI-3, 1.5 amp GMT fuses in

positions 2A and 2B supplying the NIU3, and 3 amp

GMT fuses in positions 3A and 3B supplying the

MX2800.

5. SPECIFICATIONS

Specifications for the Wallmount Cabinet are detailed

in Tabl e 2 .

Table 2. Specifications

Power Supply/Battery Charger

AC Input:

Range:

DC Output:

Fuse Rating

MX2800:

NIU3:

OPTI-3:

Cabinet Physical

Dimensions:

Weig ht :

Environment/Temperature

Operating:

Storage:

Relative Humidity:

115 VAC Nominal

88 to 132 VAC

–54 Volts

3 amp

1.5 amp

3 amp

24 in. W × 14.5 in. H ×

17.25 in. D

140 lbs. fully equipped

–40°C to +50°C

–40°C to +85°C

95% noncondensing

• Request document 414 for the U.S. and Canada

Carrier Networks Equipment Warranty.

• Request document 901 for the U.S. and Canada

Enterprise Networks Equipment Warranty.

Refer to the following subsections for sales, support,

Customer and Product Service (CAPS) requests, or

further information.

ADTRAN Sales

Pricing/Availability:

800-827-0807

ADTRAN Technical Support

Pre-Sales Applications/Post-Sales Technical

Assistance:

800-726-8663

Standard hours: Monday - Friday, 7 a.m. - 7 p.m. CST

Emergency hours: 7 days/week, 24 hours/day

ADTRAN Repair/CAPS

Return for Repair/Upgrade:

(256) 963-8722

Repair and Return Address

Contact CAPS prior to returning equipment to

ADTRAN.

ADTRAN, Inc.

CAPS Department

901 Explorer Boulevard

Huntsville, Alabama 35806-2807

64150WALO3L7-5A Issue 1, June 2004 PRELIMINARY 7

Page 8

8 PRELIMINARY Issue 1, June 2004 64150WALO3L7-5A

®

Loading...

Loading...