ADLINK PCI-8134A User Manual

PCI-8134/ PCI-8134A

4-Axis Servo / Stepper

Motion Control Card

User’s Guide

Manual Rev.: |

3.00 |

Revision Date: |

Sept 7, 2012 |

Part No: |

50-11173-1000 |

Recycled Paper

© Copyright 2012 ADLINK Technology, Inc.

All Rights Reserved.

The information in this document is subject to change without prior notice in order to improve reliability, design and function and does not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or inability to use the product or documentation, even if advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form without prior written permission of the manufacturer.

Trademarks

NuDAQ and PCI-8134/PCI-8134A are registered trademarks of ADLINK Technology Inc, MS-DOS & Windows 95 are registered trademarks of Microsoft Corporation., Borland C++ is a registered trademark of Borland International, Inc. Other product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks of their respective companies.

Getting service from ADLINK

♦Customer Satisfaction is always the most important thing for ADLINK Tech Inc. If you need any help or service, please contact us and get it.

ADLINK Technology Inc.

Web Site |

http://www.adlinktech.com |

|

|

Sales & Service |

service@adlinktech.com |

|

|

Technical |

NuDAQ |

nudaq@adlinktech.com |

|

Support |

Automation |

automation@adlinktech.com |

|

|

NuIPC |

nuipc@adlinktech.com |

|

|

NuPRO/EBC |

nupro@adlinktech.com |

|

TEL |

+886-2-82265877 |

FAX |

+886-2-82265717 |

Address |

9F, No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan |

||

♦Please inform or FAX us of your detailed information for a prompt, satisfactory and constant service.

Detailed Company Information

Company/Organization |

|

|

|

|

|

|

Contact Person |

|

|

|

|

|

|

E-mail Address |

|

|

|

|

|

|

Address |

|

|

|

|

|

|

Country |

|

|

|

|

|

|

TEL |

|

|

|

FAX |

|

|

Web Site |

|

|

|

|

|

|

|

|

Questions |

|

|

|

|

Product Model |

|

|

|

|

|

|

Environment to Use |

OS |

|

|

|

|

|

|

|

|

|

|

||

|

Computer Brand |

|

|

|

|

|

|

|

|

|

|

||

|

M/B: |

CPU: |

||||

|

Chipset: |

Bios: |

||||

|

Video Card: |

|

|

|

||

|

Network Interface Card: |

|||||

|

Other: |

|

|

|

||

|

|

|

|

|

|

|

Challenge Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

Suggestions for ADLINK

Table of Contents

Introduction.................................................................... |

1 |

||

1.1 |

Features................................................................................. |

4 |

|

1.2 |

Specifications......................................................................... |

4 |

|

1.3 |

Software Support ................................................................... |

6 |

|

1.3.1 |

Programming Library ............................................................... |

6 |

|

1.3.2 |

Motion Creator ......................................................................... |

6 |

|

1.4 |

Compatible Terminal Boards ................................................. |

6 |

|

Installation...................................................................... |

7 |

||

2.1 |

Package Contents ................................................................. |

7 |

|

2.2 |

PCI-8134/PCI-8134A Outline Drawing .................................. |

8 |

|

2.3 |

Hardware Installation............................................................. |

9 |

|

2.3.1 |

Hardware configuration............................................................ |

9 |

|

2.3.2 |

PCI slot selection ..................................................................... |

9 |

|

2.3.3 |

Installation Procedures .......................................................... |

10 |

|

2.3.4 |

Troubleshooting: .................................................................... |

10 |

|

2.4 |

Software Driver Installation.................................................. |

10 |

|

2.5 |

Programming Guide Installation .......................................... |

11 |

|

2.6 |

CN1 Pin Assignments: External Power Input ...................... |

11 |

|

2.7 |

CN2 Pin Assignments: Main connector ............................... |

12 |

|

2.8 |

CN3 Pin Assignments: Manual Pulser Input ....................... |

13 |

|

2.9 |

CN4 Pin Assignments: Simultaneous Start/Stop................. |

14 |

|

2.10 |

Jumper Setting..................................................................... |

14 |

|

2.11 |

Switch Setting ...................................................................... |

15 |

|

Signal Connections ..................................................... |

17 |

||

3.1 |

Pulse Output Signals OUT and DIR .................................... |

18 |

|

3.2 |

Encoder Feedback Signals EA, EB and EZ ........................ |

20 |

|

3.3 |

Origin Signal ORG ............................................................... |

22 |

|

3.4 |

End-Limit Signals PEL and MEL ......................................... |

23 |

|

3.5 |

Ramping-down Signals PSD and MSD ............................... |

24 |

|

3.6 |

In-position Signal INP .......................................................... |

24 |

|

3.7 |

Alarm Signal ALM ................................................................ |

25 |

|

3.8 |

Deviation Counter Clear Signal ERC................................... |

26 |

|

3.9 |

General-purpose Signal SVON ........................................... |

27 |

|

3.10 |

General-purpose Signal RDY .............................................. |

27 |

|

Table of Contents • i

3.11 Pulser Input Signals PA and PB .......................................... |

28 |

||

3.12 |

Simultaneously Start/Stop Signals STA and STP .............. |

29 |

|

Operations.................................................................... |

31 |

||

4.1 |

Motion Control Modes.......................................................... |

31 |

|

4.1.1 |

Pulse Command Output......................................................... |

32 |

|

4.1.2 |

Constant Velocity Motion ....................................................... |

33 |

|

4.1.3 |

Trapezoidal Motion ................................................................ |

34 |

|

4.1.4 |

S-curve Profile Motion............................................................ |

37 |

|

4.1.5 |

Linear Interpolated Motion ..................................................... |

40 |

|

4.1.6 |

Home Return Mode................................................................ |

41 |

|

4.1.7 |

Manual Pulser Mode.............................................................. |

52 |

|

4.2 |

Motor Drive Interface ........................................................... |

53 |

|

4.2.1 |

INP......................................................................................... |

53 |

|

4.2.2 |

ALM ....................................................................................... |

53 |

|

4.2.3 |

ERC ....................................................................................... |

54 |

|

4.3 |

The Limit Switch Interface and I/O Status ........................... |

55 |

|

4.3.1 |

SD.......................................................................................... |

55 |

|

4.3.2 |

EL .......................................................................................... |

55 |

|

4.3.3 |

ORG....................................................................................... |

57 |

|

4.3.4 |

SVON and RDY ..................................................................... |

57 |

|

4.4 |

The Encoder Feedback Signals (EA, EB, EZ)..................... |

58 |

|

4.5 |

Multiple PCI-8134/PCI-8134A Cards Operation.................. |

59 |

|

4.6 |

Change Speed on the Fly.................................................... |

60 |

|

4.7 |

Interrupt Control................................................................... |

62 |

|

Motion Creator ............................................................. |

63 |

||

5.1 |

Main Menu ........................................................................... |

64 |

|

5.2 |

Axis Configuration Window.................................................. |

65 |

|

5.3 |

Axis Operation Windows ..................................................... |

69 |

|

5.3.1 |

Motion Status Display ............................................................ |

69 |

|

5.3.2 |

Axis Status Display ................................................................ |

69 |

|

5.3.3 |

I/O Status Display .................................................................. |

69 |

|

5.3.4 |

Set Position Control ............................................................... |

71 |

|

5.3.5 |

Operation Mode Control......................................................... |

71 |

|

5.3.6 |

Motion Parameters Control .................................................... |

73 |

|

5.3.7 |

Play Key Control .................................................................... |

73 |

|

5.3.8 |

Velocity Profile Selection ....................................................... |

74 |

|

5.3.9 |

Repeat Mode ......................................................................... |

74 |

|

Function Library (8134.DLL) ....................................... |

75 |

||

6.1 |

List of Functions................................................................... |

75 |

|

ii • Table of Contents

6.2 |

C/C++ Programming Library................................................ |

78 |

6.3 |

Initialization .......................................................................... |

79 |

6.4 |

Pulse Input / Output Configuration ...................................... |

80 |

6.5 |

Continuously Motion Move .................................................. |

82 |

6.6 |

Trapezoidal Motion Mode .................................................... |

84 |

6.7 |

S-Curve Profile Motion......................................................... |

87 |

6.8 |

Multiple Axes Point to Point Motion ..................................... |

89 |

6.9 |

Linear Interpolated Motion................................................... |

91 |

6.10 |

Interpolation Parameters Configuring.................................. |

92 |

6.11 |

Home Return ....................................................................... |

93 |

6.12 |

Manual Pulser Motion.......................................................... |

94 |

6.13 |

Motion Status....................................................................... |

95 |

6.14 |

Servo Drive Interface........................................................... |

96 |

6.15 |

I/O Control and Monitoring .................................................. |

97 |

6.16 |

Position Control ................................................................... |

98 |

6.17 |

Interrupt Control................................................................. |

100 |

Additional Function Library (8134A.DLL) ................ |

104 |

|

7.1 |

List of Functions................................................................. |

104 |

7.2 |

C/C++ Programming Library.............................................. |

106 |

7.3 |

Initialization ........................................................................ |

107 |

7.4 |

Pulse Input / Output Configuration .................................... |

108 |

7.5 |

Continuously Motion Move ................................................ |

110 |

7.6 |

Trapezoidal Motion Mode .................................................. |

112 |

7.7 |

S-Curve Profile Motion....................................................... |

113 |

7.8 |

Multiple Axes Point to Point Motion ................................... |

114 |

7.9 |

Linear Interpolated Motion ................................................. |

116 |

7.10 |

Home Return ..................................................................... |

118 |

7.11 |

Manual Pulser Motion ........................................................ |

120 |

7.12 |

Motion Status..................................................................... |

123 |

7.13 |

Servo Drive Interface......................................................... |

124 |

7.14 |

I/O Control and Monitoring................................................. |

125 |

7.15 |

Position Counter Control.................................................... |

126 |

7.16 |

Interrupt Control................................................................. |

128 |

Connection Example ................................................. |

128 |

|

8.1 |

General Description of Wiring............................................ |

128 |

8.2 |

Connection Example with Servo Drive .............................. |

130 |

Appendix A: Auto Home Return Modes............... |

147 |

|

|

Table of Contents • iii |

|

Appendix B: 8134.DLL vs. 8134A.DLL ..................... |

157 |

Warranty Policy ......................................................... |

166 |

iv • Table of Contents

About This Guide

The PCI-8134 was EOL in May, 2011. ADLINK offers the new PCI8134A as a line replacement. While most PCI-8134A functions are fully compatible with legacy PCI-8134 functions, certain differences require changes in application, as outlined in this document.

Chapter1, "Introduction", gives an overview of the product features, applications, and specifications.

Chapter2, "Installation", describes how to install the PCI-8134/PCI- 8134A.

Chapter3, "Signal Connection", describes the connectors' pin assignment and how to connect the outside signal and devices with the PCI-8134/PCI-8134A.

Chapter4, "Operation Theorem", describes detail operations of the PCI- 8134/PCI-8134A.

Chapter5, “Motion Creator & Motion Creator Pro”, describe how to utilize a Microsoft Windows based utility program to configure and test running the PCI-8134/PCI-8134A.

Chapter6, "C/C++ Function Library", describes high-level programming interface in C/C++ language. It helps programmer to control PCI-8134/PCI-8134A in high level language style.

Chapter7, "Another Function Library (8134A.lib) ", describes highlevel programming interface. It helps programmer to control PCI-

8134 in high level language style.

Chapter8, “Connection Example” shows some typical connection examples between PCI-8134/PCI-8134A and servo driver and stepping driver.

About This Guide • v

1

Introduction

The PCI-8134/PCI-8134A is a 4-axis motion control card with PCI interface. It can generate high frequency pulses to drive stepping motors and servo motors. Multiple PCI-8134/PCI-8134A cards can be used in one system. Incremental encoder interface on all four axes provide the ability to correct for positioning errors generated by inaccurate mechanical transmissions. In addition, mechanical sensor interface, servo motor interface and general purpose I/O signals are provided for system integration.

Figure 1.1 shows the function block diagram of PCI-8134/PCI-8134A card. PCI-8134/PCI-8134A uses motion ASIC to perform 4-axis motion control. These ASICs are incorporate Nippon Pulse Motor. The motion control functions include linear and S-curve acceleration/deceleration, interpolation between two axes, continuous motion, in positioning and home return are done by the ASIC. Since these functions needing complex computations are done internally on the ASIC, the PC’s CPU is free to supervise and perform other tasks.

Motion Creator a Microsoft Windows-based application included with the PCI- 8134/PCI-8134A card for supporting application development. Motion Creator is very helpful for debugging a motion control system during the design phase of a project. The on-screen monitor shows all installed axis information and I/O signals status of PCI-8134/PCI-8134A cards. In addition to Motion Creator, both DOS and Windows version function library are included for programmers using C++ and Visual Basic language. Several sample programs are given to illustrate how to use the function library.

The following flowcharts show recommending processes for using this manual to develop an application. Please also refer to the relative chapters for details of each step.

Introduction • 1

PCI Bus

PCI Bus

Controller

PCL 5023 |

|

PCL 5023 |

|||

for axes |

|

for axes |

|||

|

X & Y |

|

Z & U |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Isolation

Pulse I/O |

Mechanical |

Servo |

General |

|

Driver |

Purpose |

|||

Interface |

||||

|

Interface |

I/O |

||

|

|

|||

OUT, DIR, |

+EL, -EL, |

INP, ALM |

SVON |

|

+SD,-SD, |

||||

EA, EB, EZ |

ERC |

RDY |

||

ORG |

||||

|

|

|

CN3

Pulser .

Input: PA,PB

CN4

Simultaneousl

y

Ext+24V Input

CN1

DC/DC

Ext +5V out

CN2

Figure 1.1 Block Diagram of PCI-8134

2 • Introduction

Figure 1.2 Block Diagram of PCI-8134A

Introduction • 3

1.1Features

The following lists summarize the main features of the PCI-8134 motion control system.

•32-bit PCI-Bus, plug and play.

•4 axes of step and direction pulse output for controlling stepping or servomotor.

•Maximum output frequency of 2.4 Mpps

•Pulse output options: OUT/DIR, CE/CCW

•Pulse input options: CW/CCW, AB phase x1, x2, x4

•2-axis linear interpolation.

•28-bit up/down counter for incremental encoder feedback.

•Home switch, index signal, positive and negative limit switches interface provided for all axes

•Trapezoidal and S-curve velocity profiles for all modes

•Programmable interrupt sources

•Change Speed on the Fly.

•Simultaneous start/stop motion on multiple axes.

•Manual pulser input interface.

•Software supports maximum up to 12 PCI-8134/PCI-8134A cards (48 axes) operation.

•Compact, half size PCB.

•Motion Creator Microsoft Windows based application development software.

1.2Specifications

Applicable Motors:

Stepping motors.

AC or DC servomotors with pulse train input servo-drives.

Performance:

Number of controllable axes: 4

Maximum pulse output frequency: 2.4Mpps, linear, trapezoidal or S-Curve velocity profile drive.

Position pulse setting range: 0~268,435,455 pulses (28-bit).

Ramping-down point setting range: 0 to 16777215

Acceleration / deceleration rate setting range: 1 to 65535(16bit)

Up / down counter counting range: 0~268,435,455 (28-bit.) or – 134,217,728 to +134,217,727

4 • Introduction

Pulse rate setting steps: 0 to 2.4Mpps.

I/O Signals:

Input/Output Signals for each axis

All I/O signal are optically isolated with 2500Vrms isolation voltage

Command pulse output pins: OUT and DIR.

Incremental encoder signals input pins: EA and EB.

Encoder index signal input pin: EZ.

Mechanical limit/switch signal input pins: ±EL, SD and ORG.

Servomotor interface I/O pins: INP, ALM and ERC.

General purpose digital output pin: SVON.

General purpose digital input pin: RDY.

Pulser signal input pin: PA and PB.

Simultaneous Start/Stop signal I/O pins: STA and STP.

General Specifications

Connectors: 100-pin SCSI-type connector

Operating Temperature: 0° C ~ 50° C

Storage Temperature: -20° C ~ 80° C

Humidity: 5 ~ 85%, non-condensing

Power Consumption:

Slot power supply (input): +5V DC ±5%, 900mA max.

External power supply (input): +24V DC ±5%, 500mA max.

External power supply (output): +5V DC ±5%, 500mA, max.

PCI-8134 Dimensions: 164mm(L) X 98.4mm(W)

PCI-8134A Dimensions: 185mm(L) X 100mm(W)

Introduction • 5

1.3Software Support

1.3.1Programming Library

Windows® XP/7 DLLs are provided for the PCI-8134 and PCI-8134A. These function libraries are shipped with the board.

1.3.2Motion Creator

This Windows-based utility, also bundled with the product, is used to set up cards, motors, and systems, and can aid in debugging hardware and software. It allows users to set I/O logic parameters for their own programs.

1.4Compatible Terminal Boards

ADLINK provides servos & steppers with terminal boards for easy connection, specifically boards DIN-814M0, DIN-814M-J3A0, DIN-814Y0, DIN-814P-A40 for connection to dedicated servo drives. Steppers or other servo brands can be connected with general purpose terminal boards DIN- 814-GP and DIN-100S0. Compatible servos are as follows.

Servo |

Terminal Board |

Mitsubishi J2 Super |

DIN-814M0 |

|

|

Mitsubishi J3A |

DIN-814M-J3A0 |

|

|

Yaskawa Sigma II |

DIN-814Y0 |

|

|

Panasonic MINAS A4 |

DIN-814P-A40 |

|

|

Other Serovs and Steppers |

DIN-814-GP (specific for cable selection) |

|

DIN-100S0 |

|

|

6 • Introduction

2

Installation

This chapter describes how to install the PCI-8134/PCI-8134A, according to the following procedure.

•Check Package Contents (Section 2.1)

•Check the PCB (Section 2.2)

•Install the hardware (Section 2.3)

•Install the software driver (Section 2.4)

•Acquaint yourself with the I/O signal connections (Chapter 3) and their operation (Chapter 4)

•Check the connector pin assignments and wiring

2.1Package Contents

In addition to this User's Guide, the package includes the following items:

•PCI-8134/PCI-8134A 4-Axis Servo / Stepper Motion Control Card

•ADLINK All-in-one Compact Disc

•User’s Guide Manual

If any of these items are missing or damaged, contact the dealer from whom you purchased the product. Save the shipping materials and carton in case you want to ship or store the product in the future.

Installation • 7

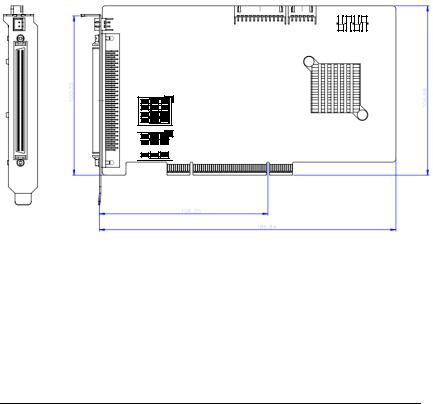

2.2PCI-8134/PCI-8134A Outline Drawing

Figure 2.1 PCB Layout of the PCI-8134

CN1: External Power Input Connector

CN2: Input / Output Signal Connector

CN3: Manual Pulser Signal Connector

CN4: Simultaneous Start / Stop Connector

8 • Installation

CN1 |

|

|

|

|

|

|

|

|

|

S1 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

CN3 CN4

CN2

J1

|

J8

Figure 2.2 PCB Layout of the PCI-8134A

CN1: External Power Input Connector

CN2: Input / Output Signal Connector

CN3: Manual Pulser Signal Connector

CN4: Simultaneous Start / Stop Connector

J1-J8: Pulse output type selection

S1: Polarity of end-limited switch selection

2.3Hardware Installation

2.3.1Hardware configuration

The PCI-8134/PCI-8134A has a plug and play PCI controller on board. The memory usage (I/O port locations) of the PCI card is assigned by system BIOS. The address assignment is done on a board-by-board basis for all PCI cards in the system.

2.3.2PCI slot selection

Your computer will probably have both PCI and ISA slots. Do not force the PCI card into a PC/AT slot. The PCI-8134/PCI-8134A can be used in any PCI slot.

Installation • 9

2.3.3Installation Procedures

Read through this manual, and setup the jumper according to your application

Turn off your computer, Turn off all accessories (printer, modem, monitor, etc.) connected to computer.

Remove the cover from your computer.

Select a 32-bit PCI expansion slot. PCI slots are short than ISA or EISA slots and are usually white or ivory.

Before handling the PCI-8134/PCI-8134A, discharge any static buildup on your body by touching the metal case of the computer. Hold the edge and do not touch the components.

Position the board into the PCI slot you selected.

Secure the card in place at the rear panel of the system unit using screw removed from the slot.

2.3.4Troubleshooting:

If your system won‘t boot or if you experience erratic operation with your PCI board in place, it’s likely caused by an interrupt conflict (perhaps because you incorrectly described the ISA setup). In general, the solution, once you determine it is not a simple oversight, is to consult the BIOS documentation that comes with your system.

2.4Software Driver Installation

Please refer to the ADLink All-in-one Compact Disc Manual to install it.

10 • Installation

2.5Programming Guide Installation

1)From the ADLINK All-In-One CD Choose Driver Installation>Motion Control>PCI-8134/PCI-8134A

2)Follow the procedures of the installer.

3)After installation is completed, restart Windows.

Note: Please download the latest software from the ADLINK website if necessary.

2.6CN1 Pin Assignments: External Power Input

CN1 Pin No |

Name |

Description |

1 |

EXGND |

Grounds of the external power. |

2 |

EX+24V |

External power supply of +24V DC ± 5% |

Note:

1.CN1 is a plug-in terminal board with no screw.

2.Be sure to use the external power supply. The +24V DC is used by external input/output signal circuit. The power circuit is configured as follows.

3.Wires for connection to CN1.

Solid wire: ϕ 0.32mm to ϕ 0.65mm (AWG28 to AWG22) Twisted wire: 0.08mm2 to 0.32mm2 (AWG28 to AWG22) Naked wire length: 10mm standard.

The following diagram shows the external power supply system of the PCI- 8134/PCI-8134A. The external +24V power must be provided, an on-board regulator generates +5V for both internal and external usage.

(External Power)

EX+24V

DC/DC

DC/DC

EXGND

EX+5V (OUTPUT)

I/O

SIGNALS

External Power Supply |

Internal Power Supply from PCI BUS |

Isolation

(Bus Power)

+5V

GND

I/O SIGNALS

Installation • 11

2.7CN2 Pin Assignments: Main connector

The CN2 is the major connector for the motion control I/O signals.

No. |

Name |

I/O |

Function(axis/) |

No. |

Name |

I/O |

Function(axis/) |

1 |

EX+5V |

O |

+5V power supply output |

51 |

EX+5V |

O |

+5V power supply output |

2 |

EXGND |

|

Ext. power ground |

52 |

EXGND |

|

Ext. power ground |

3 |

OUT1+ |

O |

Pulse signal (+), |

53 |

OUT3+ |

O |

Pulse signal (+), |

4 |

OUT1- |

O |

Pulse signal (-), |

54 |

OUT3- |

O |

Pulse signal (-), |

5 |

DIR1+ |

O |

Dir. signal (+), |

55 |

DIR3+ |

O |

Dir. signal (+), |

6 |

DIR1- |

O |

Dir. signal (-), |

56 |

DIR3- |

O |

Dir. signal (-), |

7 |

SVON1 |

O |

Multi-purpose signal, |

57 |

SVON3 |

O |

Multi-purpose signal, |

8 |

ERC1 |

O |

Dev. ctr, clr. signal, |

58 |

ERC3 |

O |

Dev. ctr, clr. signal, |

9 |

ALM1 |

I |

Alarm signal, |

59 |

ALM3 |

I |

Alarm signal, |

10 |

INP1 |

I |

In-position signal, |

60 |

INP3 |

I |

In-position signal, |

11 |

RDY1 |

I |

Multi-purpose signal, |

61 |

RDY3 |

I |

Multi-purpose signal, |

12 |

EXGND |

|

Ext. power ground |

62 |

EXGND |

|

Ext. power ground |

13 |

EA1+ |

I |

Encoder A-phase (+), |

63 |

EA3+ |

I |

Encoder A-phase (+), |

14 |

EA1- |

I |

Encoder A-phase (-), |

64 |

EA3- |

I |

Encoder A-phase (-), |

15 |

EB1+ |

I |

Encoder B-phase (+), |

65 |

EB3+ |

I |

Encoder B-phase (+), |

16 |

EB1- |

I |

Encoder B-phase (-), |

66 |

EB3- |

I |

Encoder B-phase (-), |

17 |

EZ1+ |

I |

Encoder Z-phase (+), |

67 |

EZ3+ |

I |

Encoder Z-phase (+), |

18 |

EZ1- |

I |

Encoder Z-phase (-), |

68 |

EZ3- |

I |

Encoder Z-phase (-), |

19 |

EX+5V |

O |

+5V power supply output |

69 |

EX+5V |

O |

+5V power supply output |

20 |

EXGND |

|

Ext. power ground |

70 |

EXGND |

|

Ext. power ground |

21 |

OUT2+ |

O |

Pulse signal (+), |

71 |

OUT4+ |

O |

Pulse signal (+), |

22 |

OUT2- |

O |

Pulse signal (-), |

72 |

OUT4- |

O |

Pulse signal (-), |

23 |

DIR2+ |

O |

Dir. signal (+), |

73 |

DIR4+ |

O |

Dir. signal (+), |

24 |

DIR2- |

O |

Dir. signal (-), |

74 |

DIR4- |

O |

Dir. signal (-), |

25 |

SVON2 |

O |

Multi-purpose signal, |

75 |

SVON4 |

O |

Multi-purpose signal, |

26 |

ERC2 |

O |

Dev. ctr, clr. signal, |

76 |

ERC4 |

O |

Dev. ctr, clr. signal, |

27 |

ALM2 |

I |

Alarm signal, |

77 |

ALM4 |

I |

Alarm signal, |

28 |

INP2 |

I |

In-position signal, |

78 |

INP4 |

I |

In-position signal, |

29 |

RDY2 |

I |

Multi-purpose signal, |

79 |

RDY4 |

I |

Multi-purpose signal, |

30 |

EXGND |

|

Ext. power ground |

80 |

EXGND |

|

Ext. power ground |

31 |

EA2+ |

I |

Encoder A-phase (+), |

81 |

EA4+ |

I |

Encoder A-phase (+), |

32 |

EA2- |

I |

Encoder A-phase (-), |

82 |

EA4- |

I |

Encoder A-phase (-), |

33 |

EB2+ |

I |

Encoder B-phase (+), |

83 |

EB4+ |

I |

Encoder B-phase (+), |

34 |

EB2- |

I |

Encoder B-phase (-), |

84 |

EB4- |

I |

Encoder B-phase (-), |

12 • Installation

35 |

EZ2+ |

I |

Encoder Z-phase (+), |

85 |

EZ4+ |

I |

Encoder Z-phase (+), |

36 |

EZ2- |

I |

Encoder Z-phase (-), |

86 |

EZ4- |

I |

Encoder Z-phase (-), |

37 |

PEL1 |

I |

End limit signal (+), |

87 |

PEL3 |

I |

End limit signal (+), |

38 |

MEL1 |

I |

End limit signal (-), |

88 |

MEL3 |

I |

End limit signal (-), |

39 |

PSD1 |

I |

Ramp-down signal (+), |

89 |

PSD3 |

I |

Ramp-down signal (+), |

40 |

MSD1 |

I |

Ramp-down signal (-), |

90 |

MSD3 |

I |

Ramp-down signal (-), |

41 |

ORG1 |

I |

Origin signal, |

91 |

ORG3 |

I |

Origin signal, |

42 |

EXGND |

|

Ext. power ground |

92 |

EXGND |

|

Ext. power ground |

43 |

PEL2 |

I |

End limit signal (+), |

93 |

PEL4 |

I |

End limit signal (+), |

44 |

MEL2 |

I |

End limit signal (-), |

94 |

MEL4 |

I |

End limit signal (-), |

45 |

PSD2 |

I |

Ramp-down signal (+), |

95 |

PSD4 |

I |

Ramp-down signal (+), |

46 |

MSD2 |

I |

Ramp-down signal (-), |

96 |

MSD4 |

I |

Ramp-down signal (-), |

47 |

ORG2 |

I |

Origin signal, |

97 |

ORG4 |

I |

Origin signal, |

48 |

EXGND |

|

Ext. power ground |

98 |

EXGND |

|

Ext. power ground |

49 |

EXGND |

|

Ext. power ground |

99 |

EX+24V |

I |

Ext. power supply, +24V |

50 |

EXGND |

|

Ext. power ground |

100 |

EX+24V |

I |

Ext. power supply, +24V |

2.8CN3 Pin Assignments: Manual Pulser Input

The signals on CN3 is for manual pulser input.

No. |

Name |

Function(Axis ) |

1 |

GND |

Bus power ground |

2 |

PB4 |

Pulser B-phase signal input, |

3 |

PA4 |

Pulser A-phase signal input, |

4 |

PB3 |

Pulser B-phase signal input, |

5 |

PA3 |

Pulser A-phase signal input, |

6 |

+5V |

Bus power, +5V |

7 |

GND |

Bus power ground |

8 |

PB2 |

Pulser B-phase signal input, |

9 |

PA2 |

Pulser A-phase signal input, |

10 |

PB1 |

Pulser B-phase signal input, |

11 |

PA1 |

Pulser A-phase signal input, |

12 |

+5V |

Bus power, +5V |

Note: +5V and GND pins are directly given by the PCI-Bus power. Therefore, these signals are not isolated.

Installation • 13

2.9CN4 Pin Assignments: Simultaneous Start/Stop

The signals on CN3 is for simultaneously start/stop signals for multiple axes and multiple cards.

No. |

Name |

Function(Axis ) |

1 |

GND |

Bus power ground |

2 |

STP |

Simultaneous stop signal input/output |

3 |

STA |

Simultaneous start signal input/output |

4 |

STP |

Simultaneous stop signal input/output |

5 |

STA |

Simultaneous start signal input/output |

6 |

+5V |

Bus power, +5V |

Note: +5V and GND pins are directly given by the PCI Bus power.

2.10 Jumper Setting

The J1~J8 is used to set the signal type of the pulse output signals (DIR and OUT). The output signal type could be differential line driver output or open collector output. Please refer to section 3.1 for details of the jumper setting. The default setting is the differential line driver mode.

Line Driver |

1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

||

Open Collector |

3 |

|

|

|

|

|

|

|

|

J1 |

J2 |

J3 |

J4 |

J5 |

J6 |

J7 |

J8 |

||

|

Figure 2.3 Illustration of PCI-8134 jumpers

14 • Installation

Line Driver

Open Collector

J4 |

|

|

J3 |

|

|

J8 |

|

|

J7 |

|

|

3 |

2 |

1 |

J6

J5

J2

J1

Figure 2.4 Illustration of PCI-8134A jumpers

2.11 Switch Setting

The switch S1 is used to set the EL limit switch’s type. The default setting of EL switch type is “normal open” type limit switch (or “A” contact type). The switch on is to use the “normal closed” type limit switch (or “B” contact type). The default setting is set as normal open type.

4 |

3 |

2 |

1 |

ON

Select ‘a’ Contact EL Switch (Normal Open)

Select ‘a’ Contact EL Switch (Normal Open)

Select ‘b’ Contact EL Switch (Normal Close)

Select ‘b’ Contact EL Switch (Normal Close)

Figure 2.5 Placement of S1 Switch on Board of PCI-8134

Installation • 15

ON |

|

|

|

1 |

2 |

3 |

4 |

Select ‘a’ Contact EL Switch (Normal Open)

Select ‘a’ Contact EL Switch (Normal Open)

Select ‘b’ Contact EL Switch (Normal Close)

Select ‘b’ Contact EL Switch (Normal Close)

Figure 2.6 Placement of S1 Switch on Board of PCI-8134A

16 • Installation

3

Signal Connections

The signal connections of all the I/O signals are described in this chapter. Please refer the contents of this chapter before wiring the cable between the PCI-8134/PCI-8134A and the motor drivers.

This chapter contains the following sections:

Section 3.1 Pulse output signals OUT and DIR Section 3.2 Encoder feedback signals EA, EB and EZ Section 3.3 Origin signal ORG

Section 3.4 End-Limit signals PEL and MEL Section 3.5 Ramping-down signals PSD and MSD Section 3.6 In-position signal INP

Section 3.7 Alarm signal ALM

Section 3.8 Deviation counter clear signal ERC Section 3.9 General-purpose signal SVON Section 3.10 General-purpose signal RDY Section 3.11 Pulser input signals PA and PB

Section 3.12 Simultaneous start/stop signals STA and STP

Signal Connections • 17

3.1Pulse Output Signals OUT and DIR

There are 4-axis pulse output signals on PCI-8134/PCI-8134A. For every axis, two pairs of OUT and DIR signals are used to send the pulse train and to indicate the direction. The OUT and DIR signals can also be programmed as CW and CCW signals pair, refer to section 4.1.1 for details of the logical characteristics of the OUT and DIR signals. In this section, the electronic characteristics of the OUT and DIR signals are shown. Each signal consists of a pair of differential signals. For example, the OUT2 is consisted of OUT2+ and OUT2signals. The following table shows all the pulse output signals on CN2.

CN2 Pin No. |

Signal Name |

Description |

Axis # |

3 |

OUT1+ |

Pulse signals (+) |

|

4 |

OUT1- |

Pulse signals (-) |

|

5 |

DIR1+ |

Direction signal(+) |

|

6 |

DIR1- |

Direction signal(-) |

|

21 |

OUT2+ |

Pulse signals (+) |

|

22 |

OUT2- |

Pulse signals (-) |

|

23 |

DIR2+ |

Direction signal(+) |

|

24 |

DIR2- |

Direction signal(-) |

|

53 |

OUT3+ |

Pulse signals (+) |

|

54 |

OUT3- |

Pulse signals (-) |

|

55 |

DIR3+ |

Direction signal(+) |

|

56 |

DIR3- |

Direction signal(-) |

|

71 |

OUT4+ |

Pulse signals (+) |

|

72 |

OUT4- |

Pulse signals (-) |

|

73 |

DIR4+ |

Direction signal(+) |

|

74 |

DIR4- |

Direction signal(-) |

|

The output of the OUT or DIR signals can be configured by jumpers as either the differential line driver or open collector output. You can select the output mode either by closing breaks between 1 and 2 or 2 and 3 of jumpers J1~J8 as follows.

18 • Signal Connections

Output |

For differential line driver |

For open collector |

||

output, close a break |

output, close a break |

|||

Signal |

||||

between 1 and 2 of |

between 2 and 3 of: |

|||

|

||||

OUT1- |

J1 |

J1 |

|

|

DIR1- |

J2 |

J2 |

|

|

OUT2- |

J3 |

J3 |

|

|

DIR2- |

J4 |

J4 |

|

|

OUT3- |

J5 |

J5 |

|

|

DIR3- |

J6 |

J6 |

|

|

OUT4- |

J7 |

J7 |

|

|

DIR4- |

J8 |

J8 |

|

|

|

Inside PCI-8134/PCI-8134A |

EX+5V |

CN2 |

|

VCC |

|

|||

J1~J8 |

|

|||

|

|

|||

|

3 |

|

||

|

R |

2 |

OUT+, DIR+ |

|

|

|

1 |

|

|

OUT |

|

|

OUT-, DIR- |

|

|

|

|

||

DIR |

|

2631 |

EXGND |

|

from Motion ASIC

The default setting of OUT and DIR signals are the as differential line driver mode.

The following wiring diagram is for the OUT and DIR signals of the 4 axes.

NOTE: If the pulse output is set to the open collector output mode, the OUTand DIRare used to send out signals. Please take care that the current sink to OUTand DIRpins must not exceed 20mA. The current may provide by the EX+5V power source, however, please note that the maximum capacity of EX+5V power is 500mA.

Signal Connections • 19

3.2Encoder Feedback Signals EA, EB and EZ

The encoder feedback signals include the EA, EB, and EZ. Every axis has six pins for three differential pairs of phase-A (EA), phase-B (EB) and index (EZ) input. The EA and EB are used for position counting; the EZ is used for zero position index. The relative signal names, pin numbers and the axis number are shown in the following tables.

CN2 Pin No |

Signal Name |

Axis # |

CN2 Pin No |

Signal Name |

Axis # |

13 |

EA1+ |

|

63 |

EA3+ |

|

14 |

EA1- |

|

64 |

EA3- |

|

15 |

EB1+ |

|

65 |

EB3+ |

|

16 |

EB1- |

|

66 |

EB3- |

|

31 |

EA2+ |

|

81 |

EA4+ |

|

32 |

EA2- |

|

82 |

EA4- |

|

33 |

EB2+ |

|

83 |

EB4+ |

|

34 |

EB2- |

|

84 |

EB4- |

|

|

|

|

|

|

|

CN2 Pin No |

Signal Name |

Axis # |

CN2 Pin No |

Signal Name |

Axis # |

17 |

EZ1+ |

|

67 |

EZ3+ |

|

18 |

EZ1- |

|

68 |

EZ3- |

|

35 |

EZ2+ |

|

85 |

EZ4+ |

|

36 |

EZ2- |

|

86 |

EZ4- |

|

The input circuits of the EA, EB, EZ signals are shown as follows.

|

Inside PCI-8134/PCI-8134A |

|

CN2 |

Motion ASIC |

R |

EA+, EB+, |

|

EA, EB |

EZ+ |

|

|

EZ |

EA-, EB- |

|

EZ- |

Please note that the voltage across every differential pair of encoder input signals (EA+, EA-), (EB+, EB-) and (EZ+, EZ-) should be at least 3.5V or higher. Therefore, you have to take care of the driving capability when connecting with the encoder feedback or motor driver feedback. The

20 • Signal Connections

Loading...

Loading...