Page 1

NuDAM-6011/ NuDAM-6014D

NuDAM-6012/D NuDAM-6017

NuDAM-6013/ NuDAM-6018

Analog Input Modules

User’s Guide

Page 2

Page 3

©Copyright 1996~2001 ADLINK Technology Inc.

All Rights Reserved.

Manual Rev. 5.15: October 2, 2001

The information in this document is subject to change without prior

notice in order to improve reliability, design and function and does not

represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special,

incidental, or consequential damages arising out of the use or inability

to use the product or documentation, even if advised of the possibility of

such damages.

This document contains proprietary information protected by copyright.

All rights are reserved. No part of this manual may be reproduced by

any mechanical, electronic, or other means in any form without prior

written permission of the manufacturer.

Trademarks

NuDAM

Other product names mentioned herein are used for identification

purposes only and may be trademarks and/or registered trademarks of

their respective companies.

is registered trademarks of ADLINK Technology Inc.,

Page 4

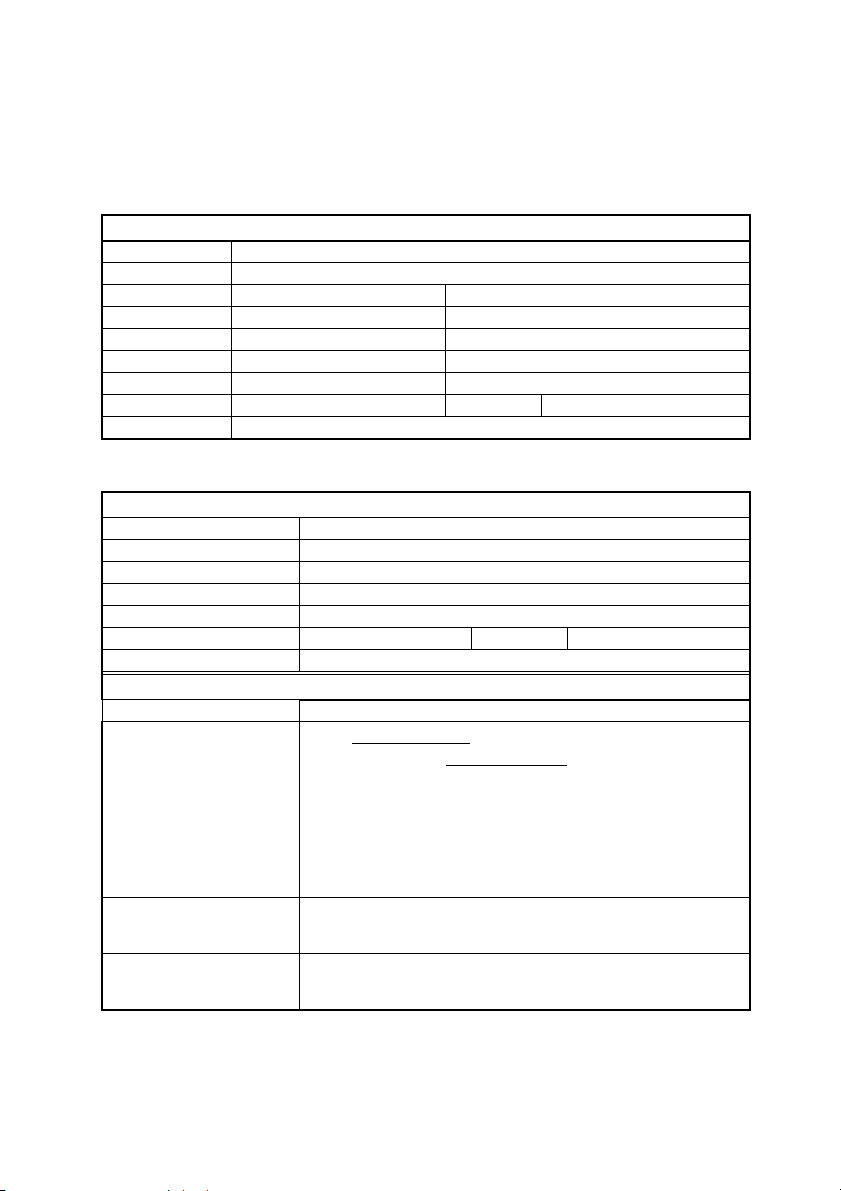

Getting service from ADLINK

♦ Customer Satisfaction is always the most important thing for ADLINK

Tech Inc. If you need any help or service, please contact us and get it.

ADLINK Technology Inc.

Web Site http://www.adlink.com.tw

Sales & Service service@adlink.com.tw

Technical NuDAQ nudaq@adlink.com.tw

Support NuDAM nudam@adlink.com.tw

NuIPC nuipc@adlink.com.tw

NuPRO nupro@adlink.com.tw

Software sw@adlink.com.tw

TEL +886-2-82265877 FAX +886-2-82265717

Address 9F, No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan, R.O.C.

♦ Please inform or FAX us of your detailed information for a prompt,

satisfactory and constant service.

Detailed Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX

Web Site

Questions

Product Model

Environment to Use

O

Computer

M/B: CPU:

Chipset: BIOS:

Video Card:

Network Interface Card:

Other:

Challenge Description

Suggestions for ADLINK

Page 5

Table of Contents

Chapter 1 Introduction .....................................................1

1.1 About the NuDAM Analog Input Modules ..............................1

1.2 Overview of NuDAM-6011/D.................................................. 1

What is NuDAM-6011/D ?................................................................1

Features of NuDAM-6011/D.............................................................2

Specifications of NuDAM-6011/D.....................................................2

Pin Definitions of ND-6011/D ...........................................................4

Functional Block Diagram of ND-6011/D .........................................4

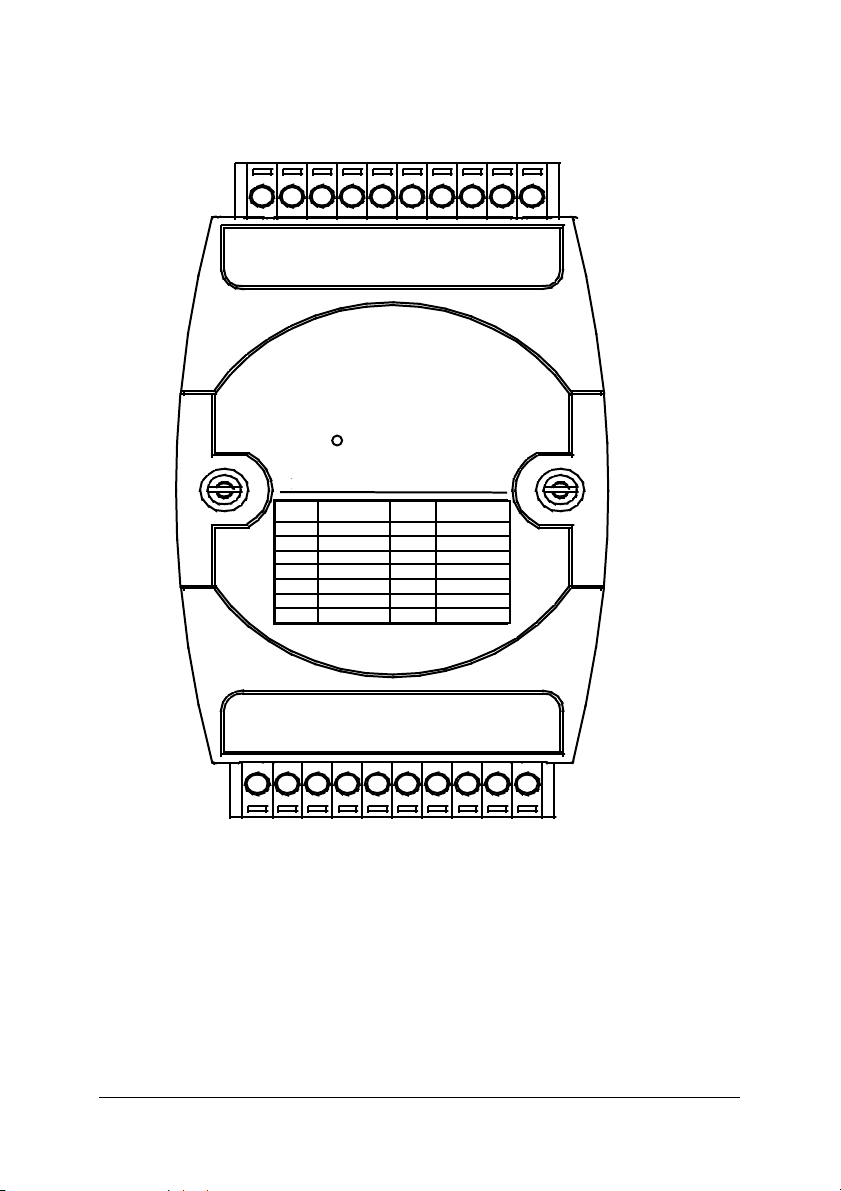

A Look at ND-6011/D & Pin Assignment..........................................5

1.3 Overview of NuDAM-6012/D.................................................. 6

What is NuDAM-6012/D?.................................................................6

Features of NuDAM-6012/D.............................................................6

Specifications of NuDAM-6012/D.....................................................6

Pin Definitions of ND-6012/D ...........................................................8

Functional Block Diagram of ND-6012/D .........................................8

A Look at ND-6012/D & Pin Assignment..........................................9

1.4 Overview of NuDAM-6013 ...................................................10

What is NuDAM-6013 ? ................................................................ 10

Features of NuDAM-6013 ............................................................. 10

Specifications of NuDAM-6013 ..................................................... 10

Pin Definitions of ND-6013............................................................ 11

Functional Block Diagram of ND-6013 .......................................... 11

A Look at ND-6013 & Pin Assignment .......................................... 12

1.5 Overview of NuDAM-6014D................................................. 13

What is NuDAM-6014D ?.............................................................. 13

Features of NuDAM-6014D........................................................... 13

Specifications of NuDAM-6014D................................................... 13

Pin Definitions of ND-6014D ......................................................... 15

Functional Block Diagram of ND-6014D ....................................... 15

A Look at ND-6014D & Pin Assignment........................................ 16

1.6 Overview of NuDAM-6017 ...................................................17

What is NuDAM-6017 ? ................................................................ 17

Features of NuDAM-6017 ............................................................. 17

Specifications of NuDAM-6017 ..................................................... 17

Pin Definitions of ND-6017............................................................ 18

Functional Block Diagram of ND-6017 .......................................... 18

A Look at ND-6017 & Pin Assignment .......................................... 19

1.7 Overview of NuDAM-6018 ...................................................20

What is NuDAM-6018 ? ................................................................ 20

Features of NuDAM-6018 ............................................................. 20

Specifications of NuDAM-6018 ..................................................... 20

Table of Contents • i

Page 6

Pin Definitions of ND-6018............................................................ 21

Functional Block Diagram of ND-6018 .......................................... 21

A Look at ND-6018 & Pin Assignment .......................................... 22

Chapter 2 Initialization & Installation............................ 23

2.1 Software Installation.............................................................23

2.2 Initializing a Brand-New Module ..........................................23

Objective of Initializing a Brand-New NuDAM ............................... 23

Default State ................................................................................. 24

Initialization Equipments ............................................................... 24

Initialization Procedure.................................................................. 24

Initialization Wiring ........................................................................ 25

2.3 Install a New NuDAM to a Existing Network........................ 25

Equipments for Install a New Module............................................ 25

Installing Procedures..................................................................... 25

2.4 Application Wiring for NuDAM-601X....................................26

Differential Voltage Input............................................................... 26

Single Ended Voltage Input........................................................... 26

Current Measurement ................................................................... 26

Digital Input Connect with TTL Signal ........................................... 27

Digital Input Used as an Event Counter ........................................ 27

Digital Output Connect with Power Loading.................................. 27

RTD Input (NuDAM-6013)............................................................. 28

Application Wiring for NuDAM-6014D ........................................... 29

Transmitter wiring for NuDAM-6014D ........................................... 30

Chapter 3 Command Set................................................ 31

3.1 Command and Response ....................................................31

Introduction ................................................................................... 31

Document Conventions................................................................. 31

Format of NuDAM Commands...................................................... 32

Response of NuDAM Commands ................................................. 33

3.2 Summary of Command Set.................................................. 33

3.3 Set Configuration .................................................................37

3.4 Read Configuration ..............................................................41

3.5 Read Module Name .............................................................42

3.6 Read Firmware Version .......................................................43

3.7 Software Reset.....................................................................44

3.8 Synchronized Sampling .......................................................45

3.9 Read Synchronized Data .....................................................46

3.10 Read Analog Data................................................................ 47

3.11 Span Calibration ..................................................................48

3.12 Span Calibration to each Channel .......................................49

ii • Table of Contents

Page 7

3.13 Offset Calibration .................................................................50

3.14 Offset Calibration to each Channel......................................51

3.15 Read Analog Data From Channel N ....................................52

3.16 Read All Analog Data Channel ............................................53

3.17 Enable/Disable channels for Multiplexing............................ 54

3.18 Read Channel Status...........................................................55

3.19 Read CJC Status .................................................................56

3.20 Enable/Disable CJC.............................................................57

3.21 Read enable/disable CJC Status.........................................58

3.22 Read Source High/Low Values for Linear Mapping............. 59

3.23 Read Target High/Low Values for Linear Mapping.............. 60

3.24 Write Source High/Low Values for Linear Mapping.............61

3.25 Write Target High/Low Values for Linear Mapping.............. 62

3.26 Enable/Disable Linear Mapping...........................................63

3.27 Read enable/Disable Linear Mapping Status .....................64

3.28 CJC Offset Calibration ......................................................... 65

3.29 Clear Latched Alarm ............................................................ 66

3.30 Clear Event Counter ............................................................67

3.31 Disable Alarm....................................................................... 68

3.32 Read Digital I/O and Alarm Status......................................69

3.33 Set Digital Output.................................................................71

3.34 Enable Alarm........................................................................72

3.35 Set High Alarm..................................................................... 73

3.36 Set Low Alarm...................................................................... 74

3.37 Read Event Counter ............................................................75

3.38 Read High Alarm Limit .........................................................76

3.39 Read Low Alarm Limit..........................................................77

3.40 Read Leading Code Setting.................................................78

3.41 Change Leading Code Setting............................................. 80

3.42 Set Host Watchdog Timer & Safety Value..........................82

3.43 Read Host Watchdog Timer & Safety Value.......................84

3.44 Host is OK ............................................................................ 85

Chapter 4 Data Format and Input Range ...................... 86

4.1 Data Format of Analog Input Modules ................................. 86

Engineering Units.......................................................................... 86

Percent of FSR (Full Scale Range) ............................................... 87

Two’s Complement Hexadecimal.................................................. 88

Ohm .............................................................................................. 89

4.2 Analog Input Range .............................................................90

Table of Contents • iii

Page 8

Chapter 5 Calibration ..................................................... 93

5.1 How to Calibrate the Analog Input Modules ? .....................93

What do you need to do calibration ?............................................ 93

Calibration Procedure for ND-6011/D, 6012/D,6014D, 6017 ........ 93

Calibration Procedure for ND-6013 (F/W version A3.05) .............. 94

Calibration Procedure for ND-6013 Firmware Rev C4.60 ............. 94

Calibration Procedure for ND-6018 Firmware Rev B1.10 ............. 95

Calibration Procedure for ND-6018 Firmware Rev E1.00

and e1.00 ...................................................................................... 95

CJC Calibration Procedure ........................................................... 96

Analog Input Module‘s Calibration Voltages.................................. 97

Product Warranty/Service.............................................. 99

iv • Table of Contents

Page 9

1

Introduction

1.1 About the NuDAM Analog Input Modules

The NuDAM provides a series of analog input modules which can sense

the analog signal or to control the remote devices. The basic features of

each module are shown here.

• NuDAM-6011/D: multi-functions high gain analog input module

• NuDAM-6012/D: multi-functions analog input module

• NuDAM-6013: 3 channels RTD input module

• NuDAM-6014D:Analog (Transmitter) input module with LED

display

• NuDAM-6017: 8 channels analog input module

• NuDAM-6018: 8 channels thermocouple input module

The models with an extended D have the same command set and

specification as without D, except the D version has a 5 1/2 LED

Display.

1.2 Overview of NuDAM-6011/D

What is NuDAM-6011/D ?

NuDAM-6011/D is a multi-functions analog input module with cold

junction compensation (CJC). The maximum input voltage range of

analog input channel is ±2.5V. The high gain feature allows very small

full range of ±15mV. To measure temperature by directly connect the

thermocouple is possible because of using the CJC inside and the high

gain feature. The voltage range of the ADC can be set according to

different types of thermocouple. The ADC can be calibrated by

Introduction • 1

Page 10

programming without handy adjustment. This features insure the best

performance under different environment.

The module provides the analog signal monitor or the alarm function.

The high and low bound of the alarm limit is programmable. The alarm

status can be sent to digital output channels if this function is ON. The

supervisor of a factory can ‘see’ or ‘hear’ the alarm if the digital output

channel control a real alarm device. The two digital output channels can

be set for general-purpose use if the alarm is disabled.

For example, connecting relay devices to DO channels, the

NuDAM-6011/D can be used to control the high power devices.

The module provides another one digital input channel. This can be

used for general purpose such as monitor digital signal, or be used as

input of the event counter.

Features of NuDAM-6011/D

• 1 analog input channel with differential input

• Programmable voltage range with high gain amplifier

• On board CJC for temperature measurement

• 5000 Vrms isolation voltage for AD channel (2500 Vrms for

NuDAM-6011/D)

• 2 digital output channels of open collector type

• Alarm function with high / low alarm output

• 1 digital input channel / event counter

• Programmable host watchdog timer for host failure protection

• Internal watchdog timer for device failure protection

• Easy programming by software

• Easy installation and wiring

• 5 1/2 digital LED Display (NuDAM-6011/D)

Specifications of NuDAM-6011/D

Interface

• Interface: RS-485, 2 wires

• Speed (bps): 1200, 2400, 4800, 9600, 19.2K, 38.4K,115.2K

(115.2K only for firmware reversion above A4.00)

Analog Input

• Input type: Differential input

• Resolution: 16 bits

• Unit Convertion: Thermocouple, mV, V, or mA

• Thermocouple Type: J, K, T, E, R, S, B, N, C

J: 0°C~760°C K: 0°C~1370°C

T: -100°C~400°C E: 0°C~1000°C

R: 500°C~1750°C S: 500°C~1750°C

B: 500°C~1800°C N: -270°C~1300°C

2 • Introduction

(1)

Page 11

C: 0°C~2320°C

• Voltage Range: Programmable 6 levels

±2.5V, ±1V, ±500mV, ±100mV, ±50mV, ±15mV

• Current Measurement: ±20mA (with external 125Ω resistor)

• Accuracy: ±0.4%

(1)

Note

: F/W version above A4.60 support K-type for 0~1370°C. Lower version

supports K-type for 0~1000°C.

Digital Output

• Channel numbers: 2

• Output characteristic: open collector transistor

• Maximum current sink: 50mA

• Max. power dissipation: 300mW

Digital Input

• Channel numbers: 1

• Logical level 0: +1V maximum

• Logical level 1: +2.0V~ +30V

• Pull up resister: 10KΩ

• Maximum current: 0.5mA

Watchdog Function

• Module internal watchdog timer: 150 ms

• Power failure threshold: 4.65 V

• Safety value: 2 digital output channels

• Host programmable watchdog: 100 ms ~ 25.500 sec

Power

• Power supply: +10V to +30V

• Current consumption: 0.76W(1.68W for NuDAM-6011/D)

Introduction • 3

Page 12

Pin Definitions of ND-6011/D

g

r

g

g

g

g

Pin # Signal Name Description

1 IN+ Analog Input Positive Terminal

2 IN- Analog Input Negative Terminal

3 DO 1/ HI Digital Output Channel 1

or High alarm status output

4 DI 0 / EV Digital Input Channel 0

or event counter input

5 DO 0 / LO Digital Output Channel 0

or Low alarm output

6 DEFAULT* Initial state setting

7 (Y) DATA+ RS-485 series signal, positive

8 (G) DATA- RS-485 series signal, negative

9 (R) +Vs Power supply, +10V~+30V

10 (B) GND Ground

11 TC(+) Thermocouple Input positive Terminal

12 TC(-) Thermocouple Input negative Terminal

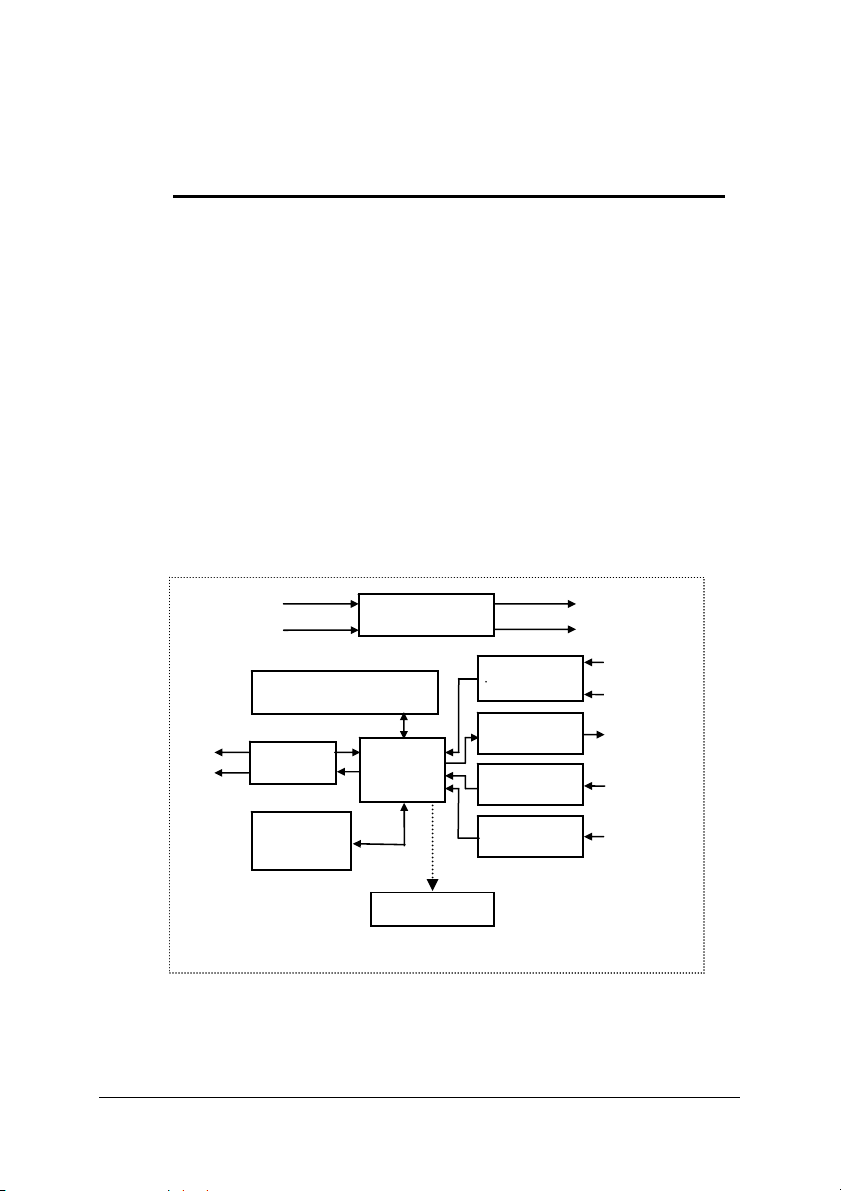

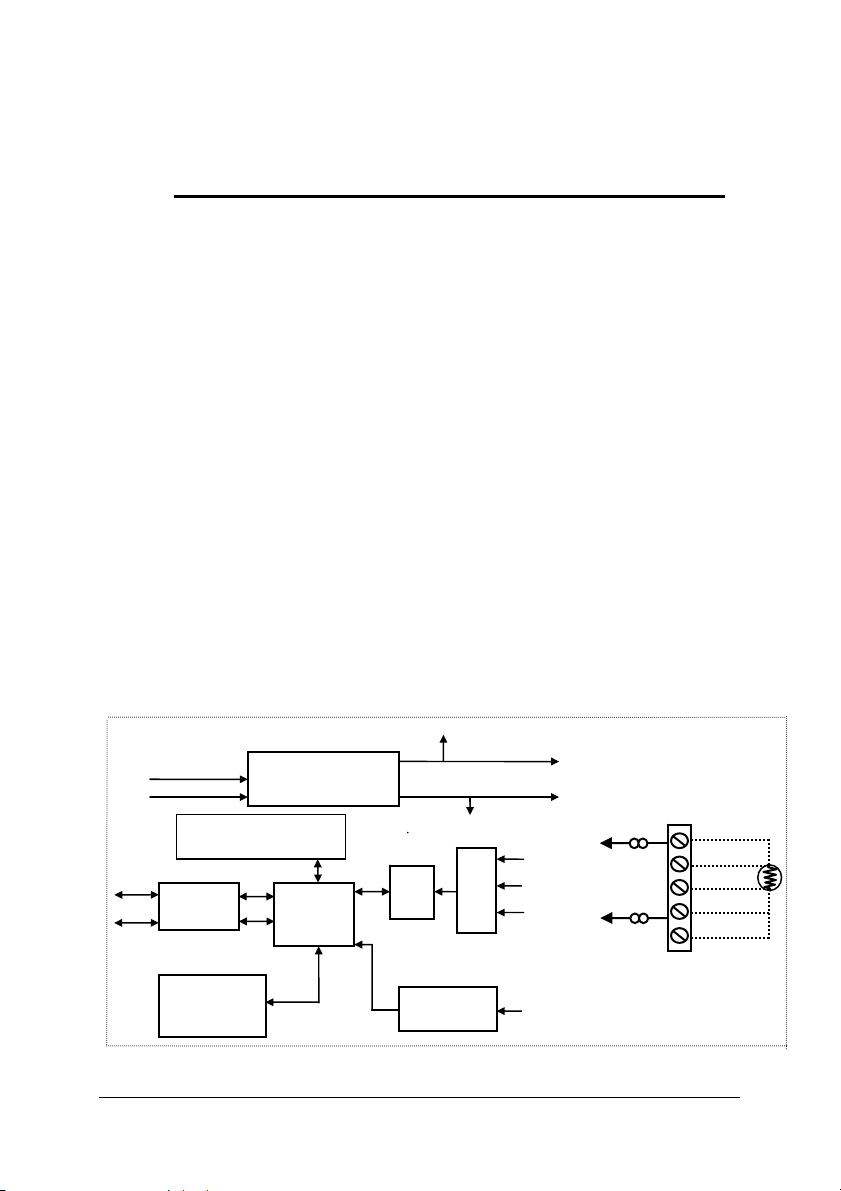

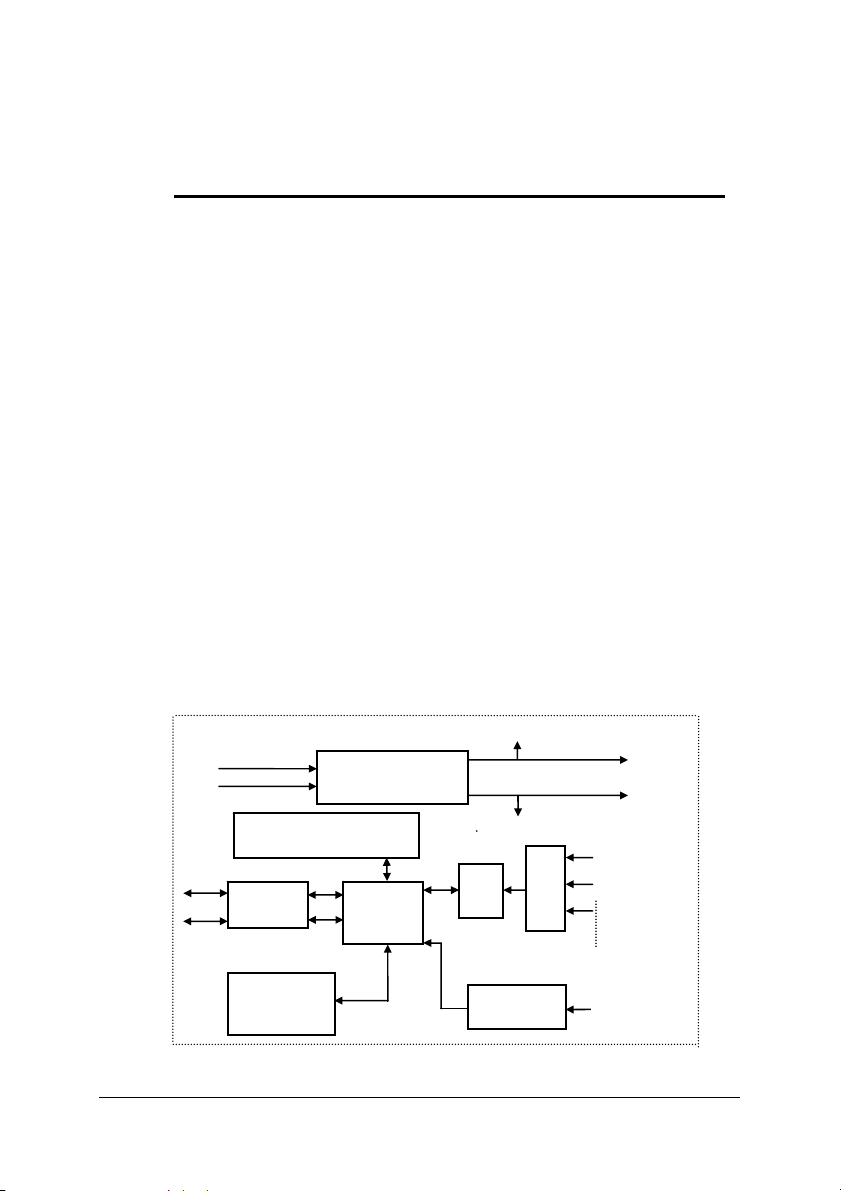

Functional Block Diagram of ND-6011/D

Power Input

+10V ~ +30V

Data +

Data -

4 • Introduction

Power

ulator & Filter

Re

Watchdog/Power Failure

Superviso

RS-485

Rec/Drv

EEPROM

Config Data

Safe Value

Micro

Processor

LED Display

(only ND-6011/D)

+ 5V

GND

ADC

2-bits

ital Output

Di

1-bit

ital Input

Di

1-bit

ital Input

Di

Analog

nal

Si

CJC

DO0

DI0

Default*

Pin

Page 13

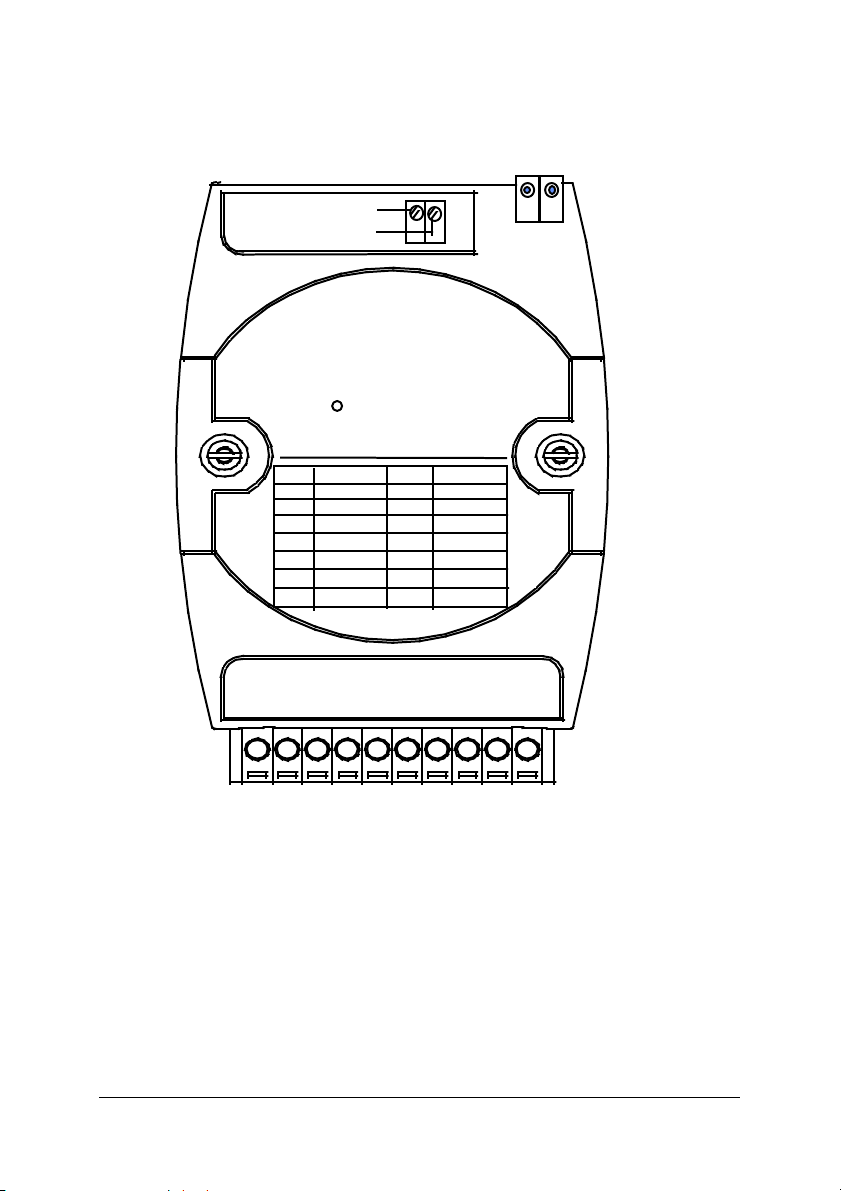

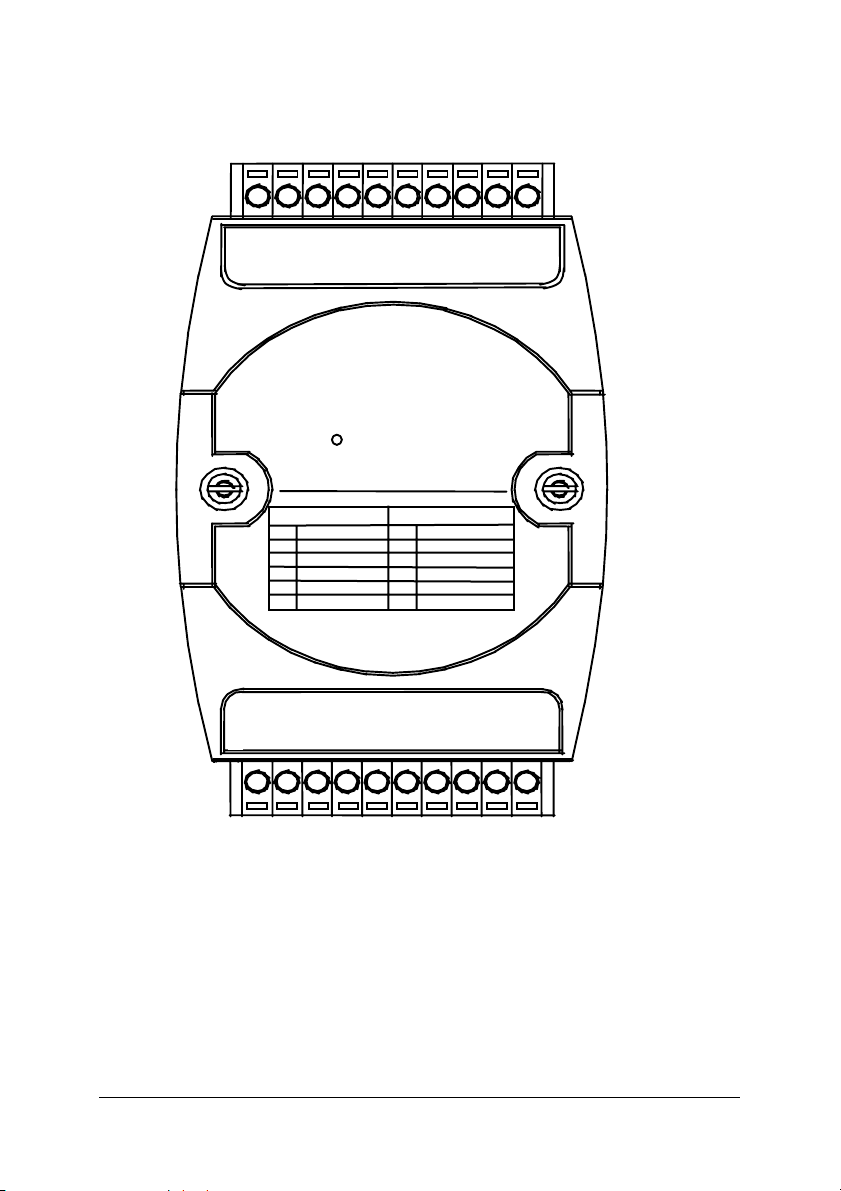

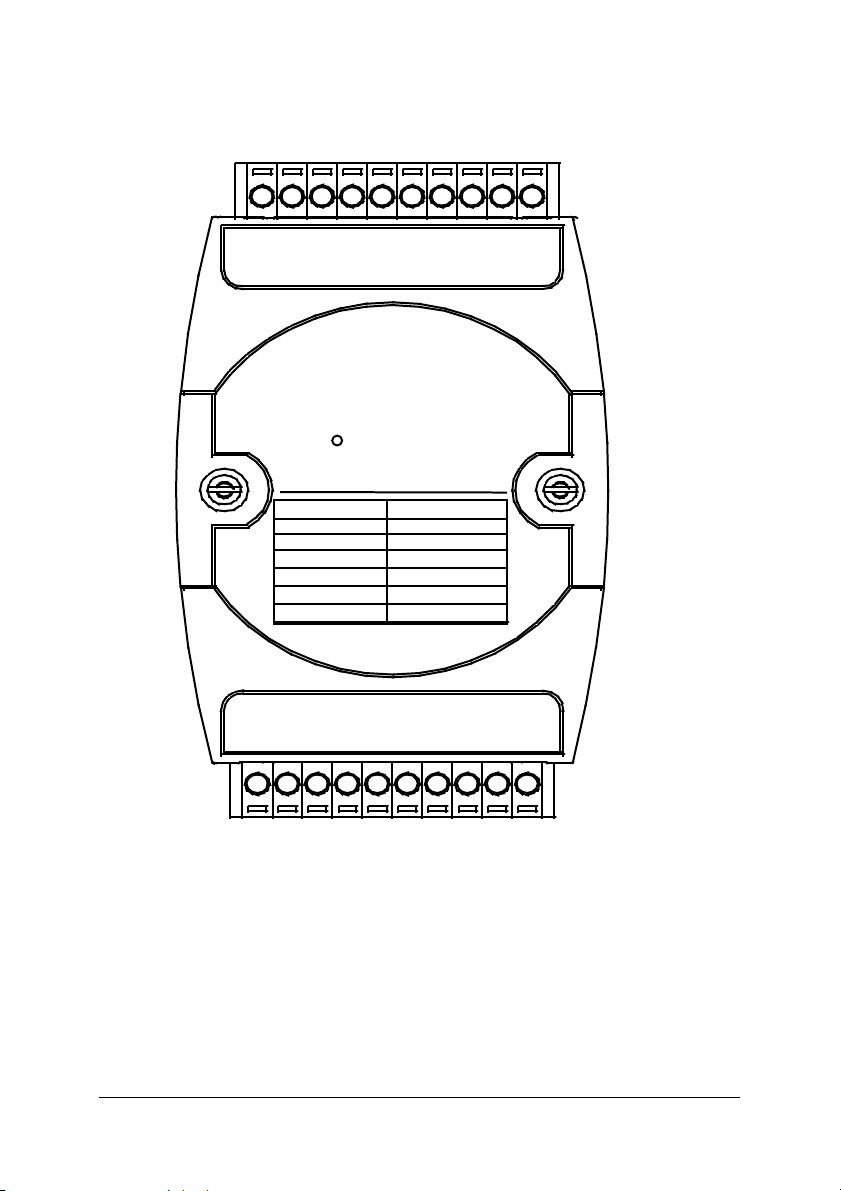

A Look at ND-6011/D & Pin Assignment

T/C (-)

T/C (+)

High Gain Analog

ND-6011

Code mV/mA Code T/C

15 mV

00

01

50 mV

02

100 mV

03

500 mV

04

1 V

2.5 V

05

20 mA

06

5 V

Input

0E

0F

10

11

12

13

14

J Type

K Type

T Type

E Type

R Type

S Type

B Type

1

IN (-)

IN (+)

DI0/EV

DO 1/HI

DO 0/LO

DEFAULT*

(Y)DATA+

(G)DATA-

10

(R)+Vs

(B)GND

Introduction • 5

Page 14

1.3 Overview of NuDAM-6012/D

What is NuDAM-6012/D?

NuDAM-6012/D is a multi-functions analog input module. The

programmable input voltage range of analog input channel is from ±10V

maximum to ±150mV minimum.

The module also provides the alarm function and the event counter just

like NuDAM-6011/D. In fact, the NuDAM-6012/D provides almost all

functions that NuDAM-6011/D has except the CJC and temperature

measurement function.

Features of NuDAM-6012/D

• 1 analog input channel with differential input

• Programmable voltage range

• 5000 Vrms isolation voltage for AD channel (2500 Vrms for

ND-6012/D)

• 2 digital output channels of open collector type

• Alarm function with high / low alarm output

• 1 digital input channel / event counter

• Programmable host watchdog timer for host failure protection

• Internal watchdog timer for device failure protection

• Easy programming by software

• Easy installation and wiring

• 51/2 digital LED display (NuDAM-6012/D)

Specifications of NuDAM-6012/D

Interface

• Interface: RS-485, 2 wires

• Speed (bps): 1200, 2400, 4800, 9600, 19.2K, 38.4K ,115.2K

(115.2K only for firmware reversion above A4.00)

Analog Input

• Input type: Differential input

• Resolution: 16 bits

• Unit Convertion: mV, V, or mA

• Voltage Range: Programmable 5 levels

±10V, ±5V, ±1V, ±500mV, ±150mV

• Current Measurement: ±20mA (with external 125Ω resistor)

• Accuracy: ±0.05%

• Isolation Voltage: 5000 Vrms(2500 Vrms for NuDAM-6012/D)

6 • Introduction

Page 15

Digital Output

• Channel numbers: 2

• Output characteristic: open collector transistor

• Maximum current sink: 50mA

• Max. power dissipation: 300mW

Digital Input

• Channel numbers: 1

• Logical level 0: +1V maximum

• Logical level 1: +2.0V~30V

• Pull up resister: 10KΩ

• Maximum current: 0.5mA

Watchdog Function

• Module internal watchdog timer: 150 ms

• Power failure threshold: 4.65 V

• Host programmable watchdog: 100 ms ~ 25.500 sec

Power

• Power supply: +10V to +30V

• Current consumption: 1.1 W(2.0W for NuDAM-6012/D)

Introduction • 7

Page 16

Pin Definitions of ND-6012/D

g

r

g

g

g

g

Pin # Signal Name Description

1 IN+ Analog Input Positive Terminal

2 IN- Analog Input Negative Terminal

3 DO 1/ HI Digital Output Channel 1

or High alarm status output

4 DI 0 / EV Digital Input Channel 0

or event counter input

5 DO 0 / LO Digital Output Channel 0

or Low alarm output

6 DEFAULT* Initial state setting

7 (Y) DATA+ RS-485 series signal, positive

8 (G) DATA- RS-485 series signal, negative

9 (R) +Vs Power supply, +10V~+30V

10 (B) GND Ground

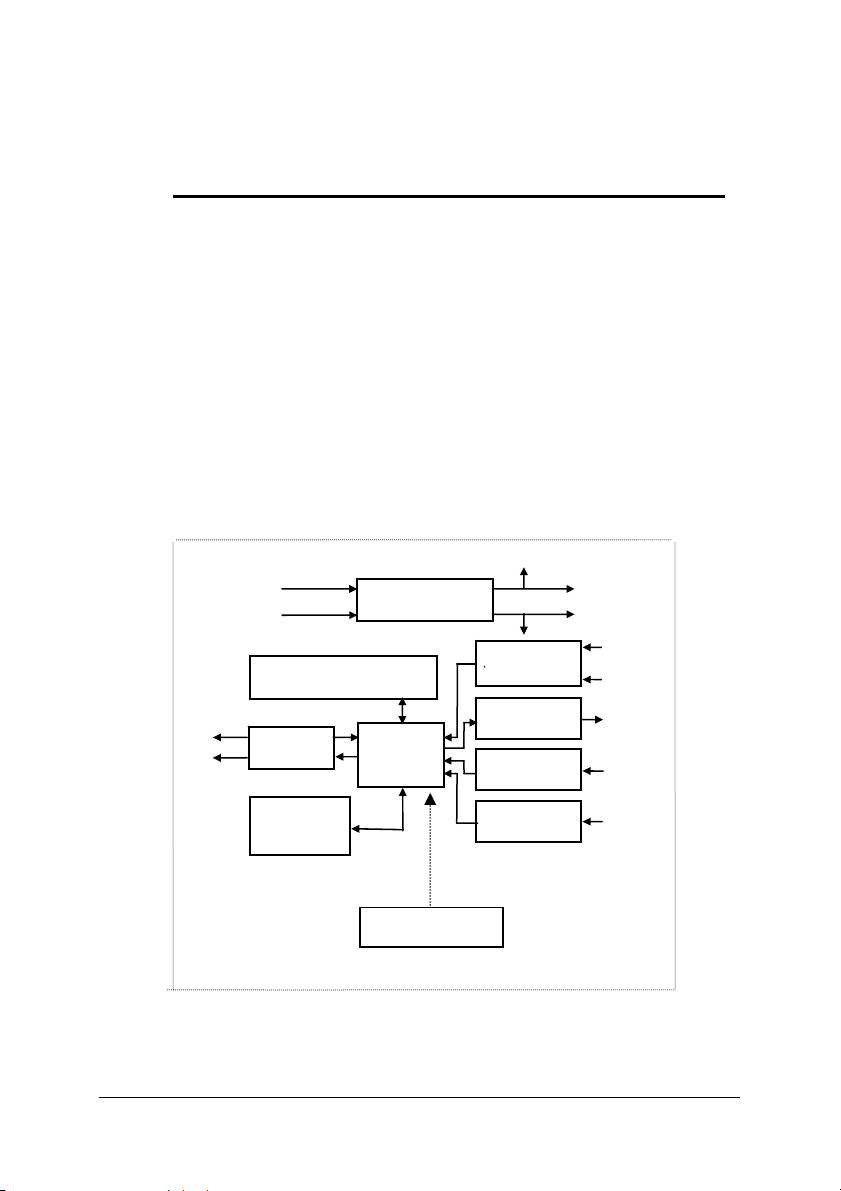

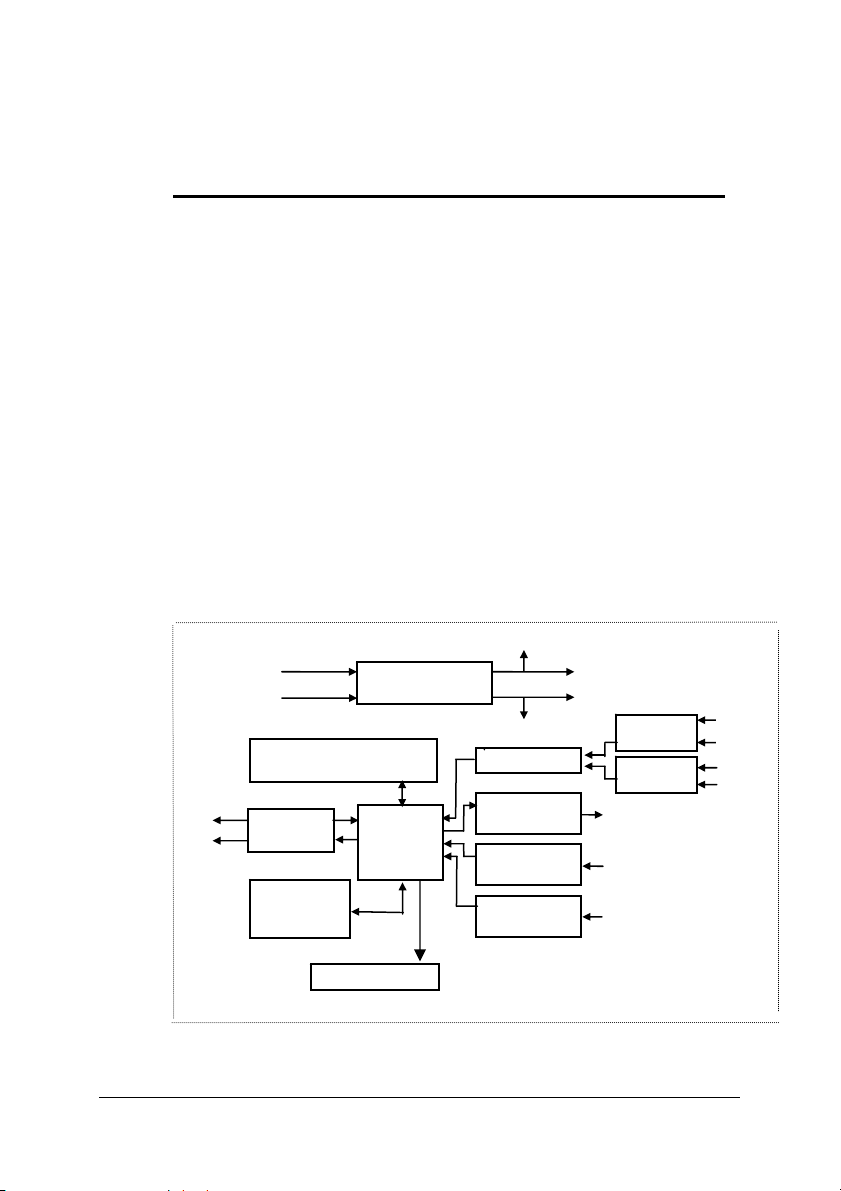

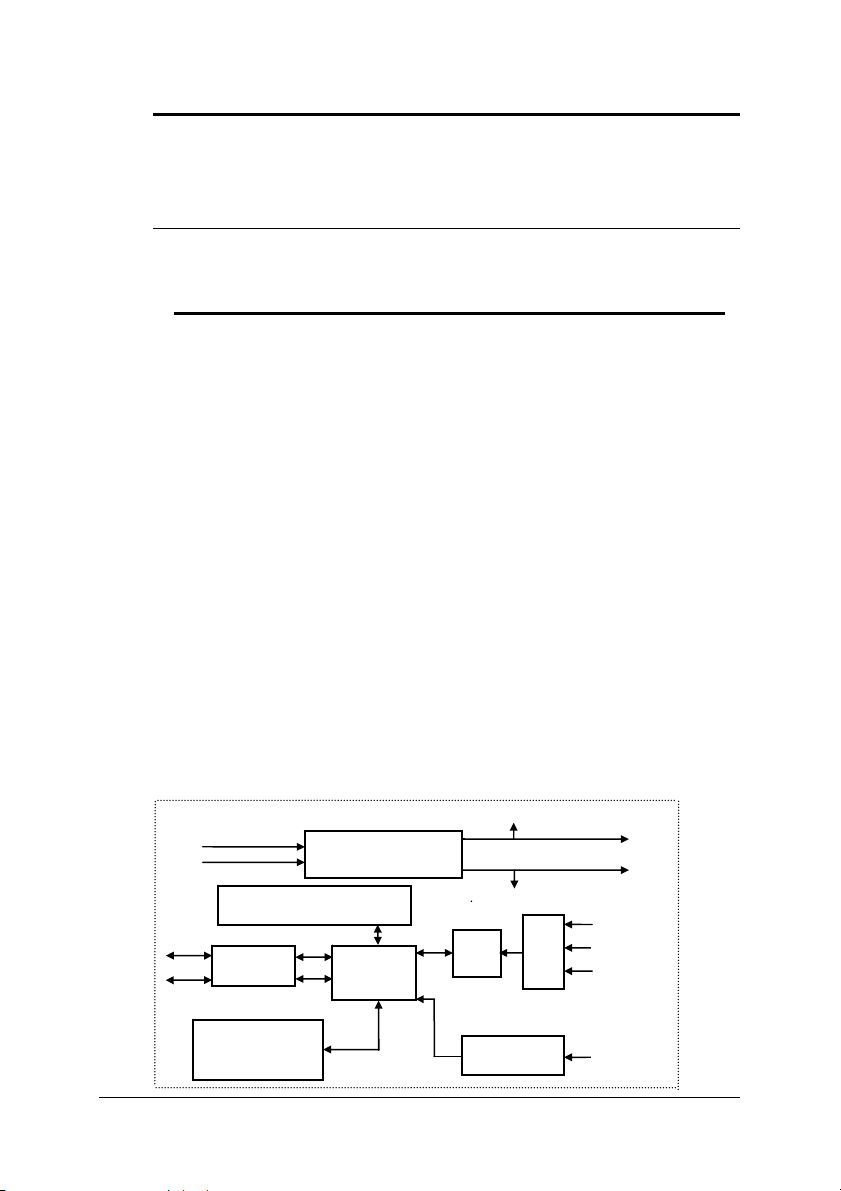

Functional Block Diagram of ND-6012/D

+ 5V

Power Input

+10V ~ +30V

Watchdog/Power Failure

Data +

Data -

RS-485

Rec/Drv

EEPROM

Config Data

Safe Value

Superviso

Power

ulator & Filter

Re

Micro

Processor

ADC

2-bits

ital Output

Di

1-bit

ital Input

Di

1-bit

ital Input

Di

GND

Analog

nal

Si

DO0

Default*

Pin

LED Display

( only ND-6012/D)

8 • Introduction

Page 17

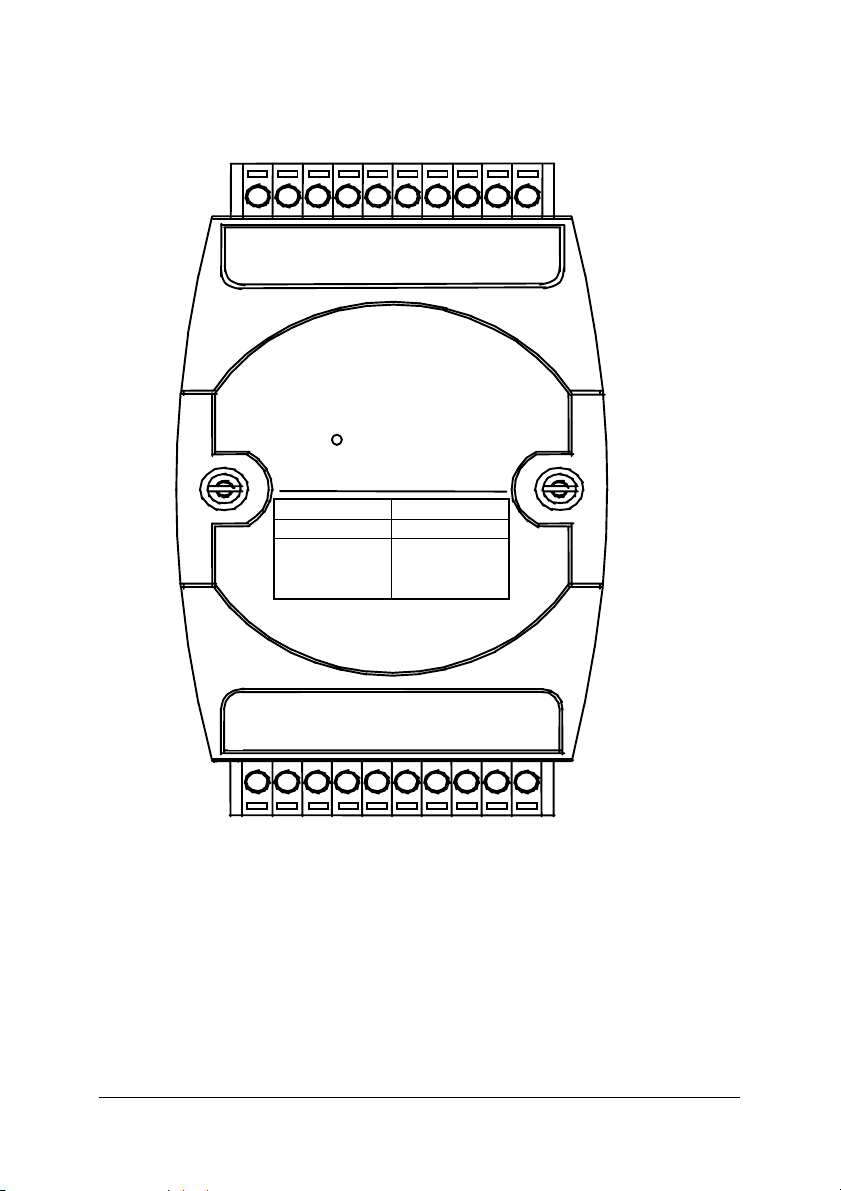

A Look at ND-6012/D & Pin Assignment

20

High Gain Analog

ND-6012

Code mV/mA

08

09

0A

0B

0C

0D

Input

10V

5 V

1 V

500 mV

150 mV

100 mV

0 - 20 mA

1

IN (-)

IN (+)

DI0/EV

DO 1/HI

DO 0/LO

DEFAULT*

(Y)DATA+

(G)DATA-

11

10

(R)+Vs

(B)GND

Introduction • 9

Page 18

1.4 Overview of NuDAM-6013

What is NuDAM-6013 ?

NuDAM-6013 is a RTD input module with 3 input channels. It supports

2, 3 or 4 wires RTD input device.

Features of NuDAM-6013

• 3 RTD input channels

• 2, 3 or 4 wire RTD input support

• Programmable RTD input range

• Internal watchdog timer for device failure protection

• Easy programming by software

• Easy installation and wiring

(2)

Note

: for H/W version C1.2 or above and F/W version C4.6 or above.

Specifications of NuDAM-6013

Interface

• Interface: RS-485, 2 wires

• Speed (bps): 1200, 2400, 4800, 9600, 19.2K, 38.4K ,115.2K

(115.2K only for firmware reversion above A4.00)

RTD Input

• Input type: Pt or Ni input, 2, 3 or 4 wires

• Channels Numbers: 3

• Resolution: 16 bits

• Unit Conversion: °C or Ohm

• Temperature Range: Programmable 5 levels, ±100°C, 0~100°C,

0~200°C, 0~600°C, 0~60 Ohms

• Accuracy: ±0.1%

(3)

Note

: Supported on F/W version C4.5 or above.

(3)

Power

• Power supply: +10V to +30V

• Current consumption: 0.65 W

10 • Introduction

Page 19

Pin Definitions of ND-6013

Pin # Signal Name Description

1 +IEXC0 Current source of CH0

2 +SENSE0 Differential positive input of CH0

3 -SENSE0 Differential negative input of CH0

4 -IEXC0 Current source of CH0

5 AGND0 Analog signal ground of CH0

6 DEFAULT* Initial state setting

7 (Y) DATA+ RS-485 series signal, positive

8 (G) DATA- RS-485 series signal, negative

9 (R) +Vs Power supply, +10V~+30V

10 (B) GND Ground

11 AGND2 Analog signal ground of CH2

12 -IEXC2 Current source of CH2

13 -SENSE2 Differential negative input of CH2

14 +SENSE2 Differential positive input of CH2

15 +IEXC2 Current source of CH2

16 AGND1 Analog signal ground of CH1

17 -IEXC1 Current source of CH1

18 -SENSE1 Differential negative input of CH1

19 +SENSE1 Differential positive input of CH1

20 +IEXC1 Current source of CH1

Functional Block Diagram of ND-6013

Power Input

+10V ~ +30V

Data +

RS-485

Rec/Drv

Data -

Config Data

Safe Value

Regulator & Filter

Watchdog/Power

Failure Supervisor

EEPROM

Power

Micro

Processor

+ 5V

ADC

1-bit

Digital Input

Mux

GND

3

RTD

Input

Channels

Default*

Pin

200µA

200µA

2, 3, 4

Wires

+IEXC

+SENSE

-SENSE

-IEXC

GND

Introduction • 11

Page 20

A Look at ND-6013 & Pin Assignment

N

20

IEXC 1+

SENSE 1+

SENSE 1-

IEXC 1-

AGND 1

IEXC 2+

3-CH RTD Input

D-6013

α=0.00385 α=0.003916

Code Input Range Code Input Range

20 Pt.-100°C~+100°C 24 Pt.-100°C~+100°C

21 Pt. 0°C~+100°C 25 Pt. 0°C~+100°C

22 Pt. 0°C~+200°C 26 Pt. 0°C~+200°C

23 Pt. 0°C~+100°C 27 Pt. 0°C~+100°C

28 Ni-1000°C~+100°C29Ni-

SENSE 0+

IEXC 0+

1

SENSE 0-

DEFAULT*

IEXC 0-

AGND 0

SENSE 2+

SENSE 2-

1200°C~+100°C

DATA +

DATA -

IEXC 2-

+Vs

11

AGND 2

GND

10

12 • Introduction

Page 21

1.5 Overview of NuDAM-6014D

What is NuDAM-6014D ?

NuDAM-6014D is a multi-functions analog(transmitter) input module

with LED display. The programmable input voltage range of analog

input channel is from ±10V maximum to ±150mV minimum.

The module also provides the alarm function and the event counter just

like NuDAM-6012/D. In fact, the NuDAM-6014D provides almost all

functions that NuDAM-6012/D has but there is more function with

transmitter.

Features of NuDAM-6014D

• 1 analog input channel with differential input

• Programmable voltage range

• 2500 Vrms isolation voltage for AD channel

• 2 digital output channels of open collector type

• Alarm function with high / low alarm output

• 1 digital input channel / event counter

• Programmable host watchdog timer for host failure protection

• Internal watchdog timer for device failure protection

• Easy programming by software

• Easy installation and wiring

• 51/2 digital LED Display

Specifications of NuDAM-6014D

Interface

• Interface: RS-485, 2 wires

• Speed (bps): 1200, 2400, 4800, 9600, 19.2K, 38.4K ,115.2K

(115.2K only for firmware reversion above A4.00)

Analog Input

• Input type: Differential input

• Resolution: 16 bits

• Unit Convertion: mV, V, or mA

• Voltage Range: Programmable 5 levels

±10V, ±5V, ±1V, ±500mV, ±150mV

• Current Measurement: ±20mA

• Accuracy: ±0.05%

• Isolation Voltage: 2500 Vrms

Introduction • 13

Page 22

Digital Output

• Channel numbers: 2

• Output characteristic: open collector transistor

• Maximum current sink: 50mA

• Max. power dissipation: 300mW

Digital Input

• Channel numbers: 1

• Logical level 0: +1V maximum

• Logical level 1: +2.0V~30V

• Pull up resister: 10KΩ

• Maximum current: 0.5mA

Watchdog Function

• Module internal watchdog timer: 150 ms

• Power failure threshold: 4.65 V

• Host programmable watchdog: 100 ms ~ 25.500 sec

Power

• Power supply: +10V to +30V

• Current consumption: 2.0 W

14 • Introduction

Page 23

Pin Definitions of ND-6014D

g

r

g

g

g

p

p

Pin # Signal Name Description

1 +15V External +15V

2 IIN+ Current Input Positive Terminal

3 IIN- Current Input Negative Terminal

6 DEFAULT* Initial state setting

7 (Y) DATA+ RS-485 series signal, positive

8 (G) DATA- RS-485 series signal, negative

9 (R) +Vs Power supply, +10V~+30V

10 (B) GND Ground

11 VIN- Analog Input Negative Terminal

12 VIN+ Analog Input Positive Terminal

13 +15V out External +15V Output

18 DO 0 / LO Digital Output Channel 0

or Low alarm output

19 DI 0 / EV Digital Input Channel 0

or event counter input

20 DO 1/ HI Digital Output Channel 1

or High alarm status output

Functional Block Diagram of ND-6014D

+ 5V

Power Input

+10V ~ +30V

Watchdog/Power Failure

Data +

Data -

Config Data

Superviso

RS-485

Rec/Drv

EEPROM

Safe Value

Power

ulator & Filter

Re

Micro

Processor

ADC

2-bits

ital Output

Di

1-bit

ital Input

Di

1-bit

ital Input

Di

GND

Voltage

In

Current

In

DO0

DO1

DI0

Default*

Pin

VIN+

VIN-

ut

ut

IIN+

IIN-

LED DISPLAY

Introduction • 15

Page 24

A Look at ND-6014D & Pin Assignment

)

N

)

±

1

20

DO1/HI

DI0/EV

DO0/LO

D-6014D

Code mV/mA

08/09/0A

0B/0C/0D

IIN+

+15V out

IIN-

Transmitter

Input Module

10V/25V/±1V

±

500mV/

±

150mV/

±

20mV

DEFAULT*

VIN-

+15V out

VIN+

GND

+Vs

B

R

(Y)DATA+

(G)DATA-

10

16 • Introduction

Page 25

1.6 Overview of NuDAM-6017

What is NuDAM-6017 ?

NuDAM-6017 is an analog input module with 8 input channels. Six of

the eight channels are differential type and the other two are single

ended type.

Features of NuDAM-6017

• 8 analog input channels

• 6 differential inputs and 2 single ended inputs

• Programmable input voltage range

• Programmable host watchdog timer for host failure protection

• 5000 Vrms isolation voltage

• Internal watchdog timer for device failure protection

• Easy programming by software

• Easy installation and wiring

Specifications of NuDAM-6017

Interface

• Interface: RS-485, 2 wires

• Speed (bps): 1200, 2400, 4800, 9600, 19.2K, 38.4K ,115.2K

(115.2K only for firmware reversion above A4.00)

Analog Input

• Input type: Differential input

• Channels Numbers: 8

• Resolution: 16 bits

• Unit Conversion: mV, V, or mA

• Voltage Range: Programmable 5 levels , ±10V, ±5V, ±1V,

±500mV, ±150mV

• Current Measurement: ±20mA (with external 125Ω resistor)

• Accuracy: ±0.1%

Power

• Power supply: +10V to +30V

• Current consumption: 1.2 W

(4)

Note

: The maximum input voltage shall not exceed to ±30V with reference to

AGND otherwise, they may cause an unrecoverable harm to the hardware

component.

(4)

Introduction • 17

Page 26

Pin Definitions of ND-6017

Pin # Signal Name Description

1 Vin5+ Differential positive input channel 5

2 Vin5- Differential negative input channel 5

3 Vin6+ Single-ended voltage input channel 6

4 AGND Analog signal ground of CH6 & 7

5 Vin7+ Single-ended voltage input channel 7

6 DEFAULT* Initial state setting

7 (Y) DATA+ RS-485 series signal, positive

8 (G) DATA- RS-485 series signal, negative

9 (R) +Vs Power supply, +10V~+30V

10 (B) GND Ground

11 Vin0+ Differential positive input channel 0

12 Vin0- Differential negative input channel 0

13 Vin1+ Differential positive input channel 1

14 Vin1- Differential negative input channel 1

15 Vin2+ Differential positive input channel 2

16 Vin2- Differential negative input channel 2

17 Vin3+ Differential positive input channel 3

18 Vin3- Differential negative input channel 3

19 Vin4+ Differential positive input channel 4

20 Vin4- Differential negative input channel 4

Functional Block Diagram of ND-6017

Power Input

+10V ~ +30V

Data +

Data -

18 • Introduction

Power

Regulator & Filter

Watchdog/Power Failure

Supervisor

RS-485

Rec/Drv

EEPROM

Config Data

Safe Value

Micro

Processor

ADC

1-bit

Digital Input

+ 5V

GND

Mux

8

Analog

Input

Channels

Default*

Pin

Page 27

A Look at ND-6017 & Pin Assignment

20

Vin 4+

Vin 4-

Vin 3+

Vin 3-

Vin 2-

Vin 2+

8-CH Analog Input

ND-6017

CODE

08

09

0A

0B

0C

0D

mV/mA

0 - 20 mA

10V

5 V

1 V

500 mV

150 mV

100 mV

Vin 1+

Vin 1-

11

Vin 0+

Vin 0-

1

Vin 5+

Vin 5-

Vin 6+

AGND

Vin 7+

DEFAULT*

(Y)DATA+

(G)DATA-

(R)+Vs

10

(B)GND

Introduction • 19

Page 28

1.7 Overview of NuDAM-6018

What is NuDAM-6018 ?

NuDAM-6018 is a thermocouple input module with 8 input channels.

Six of the eight channels are differential type and the other two are

single ended type.

Features of NuDAM-6018

• 8 analog input channels

• 6 differential inputs and 2 single ended inputs

• Programmable input voltage range

• Programmable host watchdog timer for host failure protection

• On board CJC for temperature measurement

• 2500 Vrms isolation voltage

• Internal watchdog timer for device failure protection

• Easy programming by software

• Easy installation and wiring

• Wiring open detection

Specifications of NuDAM-6018

Interface

• Interface: RS-485, 2 wires

• Speed (bps): 1200, 2400, 4800, 9600, 19.2K, 38.4K ,115.2K

(115.2K only for firmware reversion above A4.00)

Analog Input

• Input type: Differential input

• Channels Numbers: 8

• Resolution: 16 bits

• Unit Conversion: Thermocouple, mV, V or mA

• Thermocouple Type: J, K, T, E, R, S, B, N, C

J: 0°C~760°C K: 0°C~1370°C

T: -100°C~400°C E: 0°C~1000°C

R: 500°C~1750°C S: 500°C~1750°C

B: 500°C~1800°C N: -270°C~1300°C

C: 0°C~2320°C

• Voltage Range: Programmable 6 levels ±2.5V, ±1V, ±500mV,

±100mV, ±50mV, ±15mV

• Current Measurement: ±20mA (with external 125Ω resistor)

Power

• Power supply: +10V to +30V

• Current consumption: 0.9 W

(5)

Note

: For H/W version B4.0 or above and F/W version B1.31 or above.

(6)

(5)

(6)

20 • Introduction

Page 29

(6)

Note

: The maximum input voltage shall not exceed to ±30V with reference to

AGND otherwise, they may cause an unrecoverable harm to the hardware

component.

(7)

Note

: F/W version above C4.30 support K-type for 0~1370°C. Lower version

°

supports K-type for 0~1000

C.

Pin Definitions of ND-6018

Pin # Signal Name Description

1 Vin5+ Differential positive input channel 5

2 Vin5- Differential negative input channel 5

3 Vin6+ Single-ended voltage input channel 6

4 AGND Analog signal ground of CH6 & 7

5 Vin7+ Single-ended voltage input channel 7

6 DEFAULT* Initial state setting

7 (Y) DATA+ RS-485 series signal, positive

8 (G) DATA- RS-485 series signal, negative

9 (R) +Vs Power supply, +10V~+30V

10 (B) GND Ground

11 Vin0+ Differential positive input channel 0

12 Vin0- Differential negative input channel 0

13 Vin1+ Differential positive input channel 1

14 Vin1- Differential negative input channel 1

15 Vin2+ Differential positive input channel 2

16 Vin2- Differential negative input channel 2

17 Vin3+ Differential positive input channel 3

18 Vin3- Differential negative input channel 3

19 Vin4+ Differential positive input channel 4

20 Vin4- Differential negative input channel 4

Functional Block Diagram of ND-6018

Power Input

+10V ~ +30V

Data+

Data -

Watchdog/Power Failure

RS-485

Rec/Drv

EEPROM

Config Data

Safe Value

Power

Regulator & Filter

Micro

Processor

ADC

1-bit

+ 5V

GND

Mux

Thermo-

couple

Input

channels

Default*

Pin

Introduction • 21

8

Page 30

A Look at ND-6018 & Pin Assignment

N

20

Vin 4+

Vin 4-

ND-6017

Code mV/mA Code T/C

00 ±15mV 0E J Type

01 ±50mV 0F K Type

02 ±100mV 10 T Type

03 ±500mV 11 E Type

04 ±1V 12 R Type

05 ±2.5V 13 S Type

06 ±20mA 14 B Type

Vin 3-

D-6018

CODE

08

09

0A

0B

0C

0D

Vin 3+

Vin 2-

Vin 1-

Vin 2+

Multiple

Analog Input

8-CH Analog Input

mV/mA

10V

5 V

1 V

500 mV

100 mV

0 - 20 mA

11

Vin 0+

Vin 1+

Vin 0-

1

Vin 5+

Vin 5-

Vin 6+

AGND

Vin 7+

DEFAULT*

(Y)DATA+

(G)DATA-

(R)+Vs

10

(B)GND

22 • Introduction

Page 31

2

Initialization & Installation

2.1 Software Installation

1. If you have already installed “NuDAM Administration” then skip

other steps.

2. Backup your software diskette.

3. Insert “NuDAM Administration” disc into CD-ROM:

4. Change drive to the path of CD-ROM. For example, your drive of

CD-ROM is F:, then change the drive to F:

5. Find the setup of NuDAM Administration and run it.

6. Please follow the steps of setup program then you can successful

to install the nudism Administration.

2.2 Initializing a Brand-New Module

Objective of Initializing a Brand-New NuDAM

All NuDAM modules, except NuDAM-6520 and NuDAM-6510, in a

RS-485 network must have an unique address ID. Every brand-new

NuDAM has a factory default setting as following:

• Address ID is 01.

• Baud rate is 9600 bps

• Check-sum disable

• Host Watchdog timer is disable

Therefore, to configure the brand-new NuDAM before using is

necessary to avoid conflicting address. The baud rate may also be

changed according to user‘s requirements.

Initialization & Installation • 23

Page 32

The initialization procedures of a brand-new NuDAM are shown in the

following sections. The procedures are applicable for initializing

NuDAM-6011/D, NuDAM-6012/D, NuDAM-6013, NuDAM-6014D,

NuDAM-6017, and NuDAM-6018.

Default State

The NuDAM modules must be set at Default State when you want to

change the default settings, including the ID address, baud rate,

check-sum status etc. All NuDAM modules have an special pin labeled

as DEFAULT*. The module will be in Default State if the Default*1 pin

is shorted to ground when power ON. Under this state, the default

configuration is set as following:

• Address ID is 00.

• Baud rate is 9600 bps.

• Check-sum disable.

• Watchdog timer is disable.

Therefore, the configuration of the host and the module can be easily

set identically and initializing a module will be possible no matter what

configuration is set under operating state.

Initialization Equipments

• Host computer with an RS-232 port.

• An installed RS-485 module (NuDAM-6520) with 9600 baud rate.

• The brand new NuDAM module

• Power supply (+10 V

• Administration utility software

to +30 VDC) for NuDAM modules

DC

Note1: Never Connect the DRFAULT* pin to Vs or power source just left it

open or wired to GND.

Initialization Procedure

1. Power off the host computer and the installed NuDAM-6520. Be

sure of the baud rate of the NuDAM-6520 is 9600 bps.

2. Connect a brand new NuDAM module with the RS-485. Set the

module in Default State by shorting the DEFAULT* pin. Refer to

Figure 2.1 for detailed wiring.

3. Power on the host computer.

4. Power on the power supply for NuDAM modules.

5. Use the NuDAM Administration utility to configure the address ID,

Baud rate and check-sum status of the module.

24 • Initialization & Installation

Page 33

Initialization Wiring

Host

Computer

RS-232

Local Power Supply

+10 V to +30 V

+Vs GND

Figure 2-1 Layout for Initialization the NuDAM module

NuDAM-6520

RS-232/RS-485

Converter

DATA +

DATA -

New

NuDAM

module

DATA+

DATA -

Default*

+Vs GND +Vs GND

2.3 Install a New NuDAM to a Existing Network

Equipments for Install a New Module

• A existing NuDAM network

• New NuDAM modules

• Power supply (+10 to +30 V

Installing Procedures

1. Configure the new NuDAM module according to the initialization

procedures in section 2.2.

2. The baud rate and check-sum status of the new module must be

identity with the existing RS-485 network. The address ID must not

be conflict with other NuDAM modules on the network.

3. Power off the NuDAM power supply of the existing RS-485

network.

4. Power off the host computer.

5. Wire the power lines for the new NuDAM with the existing network.

Be careful about the signal polarity as wiring.

6. Wire the RS-485 data lines for the new NuDAM with the existing

network. Be careful about the signal polarity as wiring.

7. Wire to the input or output devices. Refer to section 2.4 for

illustrations.

8. Power on the host computer.

9. Power on the NuDAM local power supply.

10. Use the NuDAM administration utility to check entire network.

DC

)

Initialization & Installation • 25

Page 34

2.4 Application Wiring for NuDAM-601X

A

A

A

y

A

Differential Voltage Input

Differential

Signal

Source

Differential Analog Input Channel of

Differential Analog Input Channel of

NuDAM-6011/D/6012/D/6017/6018

NuDAM-6011/6012/6017/6018

IN(+)

DC

IN(-)

Single Ended Voltage Input

Ground

Signal

Source

Single Ended Input Channel of

NuDAM-6017/6018

Current Measurement

Current

Source

R=125 Ohm

%1 accurac

Differential Input Channel of

Differential Input Channel of

NuDAM-6011/D/6012/D/6017/6018

NuDAM-6011/6012/60176018

IN(+)

R

IN(-)

IN(+)

DC

GND

DC

26 • Initialization & Installation

Page 35

Digital Input Connect with TTL Signal

r

r

rSupply

NuDAM-6011D/6012D Digital Input Channel

+5V

TTL Buffer

TTL

Device

DI 0

GND

Digital Input Used as an Event Counter

NuDAM-6011D/ 6012D Digital Input Channel

+5V

TTL Buffer

Clock

Source

Digital Output Connect with Power Loading

NuDAM-601x Digital Output Channel

DI 0

GND

LED, SSR, Relay etc.

To

Micro Processor

To

Micro Processor

+Vs

From

Micro Processo

open

collector

DO n

GND

R : current limit resistor

Powe

Loading

Powe

Initialization & Installation • 27

Page 36

RTD Input (NuDAM-6013)

2 Wire

RTD

3 Wire

RTD

4 Wire

RTD

+IEXC 1

+SENSE

-SENSE

-IEXC

A.GND

+IEXC 1

+SENSE

-SENSE

-IEXC

A.GND

+IEXC 1

+SENSE

-SENSE

-IEXC

A.GND

28 • Initialization & Installation

Page 37

Application Wiring for NuDAM-6014D

Millivolt and Volt Input

Process Current Input

Initialization & Installation • 29

Page 38

Transmitter wiring for NuDAM-6014D

2-wire Transmitter Input

3-wire Transmitter Input

+15V out

IN+

-

30 • Initialization & Installation

Page 39

3

Command Set

3.1 Command and Response

Introduction

The NuDAM command is composed by numbers of characteristics,

including the leading code, address ID, the variables, the optional

check-sum bytes, and a carriage return to indicate the end of a

command. The host computer can only command only one NuDAM

module except those synchronized commands with wildcard address

“**”. The NuDAM may or may not give response to the command. The

host should check the response to handshake with the modules.

Document Conventions

The following syntax conventions describe the NuDAM commands in

this manual.

(Leading Code) Leading Code is the first characteristic of the NuDAM

(Addr) Module’s address ID, the value is in the range of 00 - FF

(Command

Variable)

[Data] Some commands need additional data.

[Checksum] Checksum in brackets indicate optional parameter, only

< > Identifies a control code character, such as <CR> for

command. All NuDAM commands need a command leading

code, such as %,$,#,@,...etc. 1- character

(Hex). 2- character

Command codes or value of variables.

Variable length

Variable length

checksum is enable then this field is required. 2- character

carriage return, its value is 0x0D.

1- character

Command Set • 31

Page 40

Format of NuDAM Commands

(Leading Code)(Addr)(Command)[Data][Checksum]<CR>

When checksum is enable then [Checksum] is needed, it is

2-character. Both command and response must append the checksum

characters.

How to calculate checksum value ?

[Checksum] =

0x100

Example 1: checksum is disable

User Command: $012<CR>

Response: !01400600<CR>

$

01

2

<CR>

Example 2: checksum is enable

User Command:

Response:

$

01

2

B7

<CR>

‘$’ = 0x24 ‘0’ = 0x30 ‘1’ = 0x31 ‘2’ = 0x32

B7 = ( 0x24 + 0x30 + 0x31 + 0x32 ) MOD 0x100

‘!’ = 0x24 ‘0’ = 0x30 ‘1’ = 0x31 ‘4’ = 0x34

‘6’ = 0x36

AC = ( 0x24 + 0x30 + 0x31 + 0x34 + 0x30 + 0x30 + 0x36 + 0x30

+ 0x30 ) MOD 0x100

((LeadingCode)+(Addr)+(Command)+[Data]) MOD

: LeadingCode

: Address

: Command (Read Configuration)

: Carriage return 0x0D

$012B7<CR>

!01400600AC<CR>

: LeadingCode

: Address

: Command (Read Configuration)

: Checksum value

: Carriage return 0x0D

32 • Command Set

Page 41

Note: 1. There is no spacing between the command words and

The checksum characters.

2. Every command follows a <CR> carriage return for

ending.

3. The checksum characters are optional.

Response of NuDAM Commands

The response message depends on versatile NuDAM command. The

response is composed with a few characteristics, including leading

code, variables, and carriage return for ending. There are two

categories of leading code for response message, ”!“ or ”>“ means valid

command and ”?“ means invalid. By checking the response message,

user can monitor the command is valid or not.

Note: Under the following conditions, there will have no response

message.

1. The specified address ID is not exist.

2. Syntax error.

3. Communication error.

4. Some special commands do not have response.

3.2 Summary of Command Set

There are three categories of NuDAM commands. The first is the

general commands, including set configuration command, read

configuration, reset, read module‘s name or firmware version, etc.

Every NuDAM can response to the general commands. The second is

the functional commands, which depends on functions of each

module. Not every module can execute all function commands. The

third is the special commands including functions about the

programmable watchdog timer, safe values, and the programmable

leading code. All the commands used in the NuDAM analog input

module are list in the following table.

Command Set of Analog Input Modules

Command Syntax

General Commands

%(OldAddr)(NewAddr)

Set Configuration

Read Configuration

Read Module Name

(InputRange)(BaudRate)

(DataFormat)

$(Addr)2

$(Addr)M

Module

ALL 3-7

ALL 3-11

ALL 3-12

s

Page

Command Set • 33

Page 42

Read Firmware Version

Software Reset

Functional Commands

Synchronized Sampling

Read Synchronized

Analog Data

Read Analog Data

Read Analog Data

Channel 0

Span Calibration

Span Calibration to each

Channel

Offset Calibration

Offset Calibration to each

Channel

Read Analog Data From

Channel N

Read All Analog Data

Enable/Disable Channel

for Multiplexing

Read Channel Status

Read CJC Status

Enable/Disable CJC

Read Enable/Disable

CJC Status

Read Source High/Low

Values for Linear

Mapping

$(Addr)F

$(Addr)RS

#**

$(Addr)4

#(Addr)

#(Addr)

$(Addr)0

$(Addr)0(Channel No)

$(Addr)1

#(Addr)1(Channel No)

#(Addr)(ChannelNo)

$(Addr)A

$(Addr)5(ChannelVal)

$(Addr)6

$(Addr)3

$(Addr)C(Status)

$(Addr)D

$(Addr)3

ALL 3-13

ALL(1) 3-14

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6013 3-17

ALL 3-18

6013(2) 3-19

ALL 3-20

6013(2) 3-21

6013,

6017,

6018

6013,

6017,

6018

6013,

6017,

6018

6013,

6017,

6018

6011/D,

6018

6011/D,

6018(3)

6011/D,

6018(3)

6014D 3-32

3-15

3-16

3-17

3-22

3-23

3-24

3-25

3-26

3-27

3-28

Read Target High/Low

Values for Linear

Mapping

34 • Command Set

$(Addr)5

6014D 3-33

Page 43

Write Source High/Low

Values for Linear

Mapping

$(Addr)6(Data_L)(Data_H)

6014D 3-34

Write Target High/Low

Values for Linear

Mapping

Enable/Disable Linear

Mapping

Read Enable/Disable

Linear Mapping Status

CJC Offset Calibration

Clear Latch Alarm

Clear Event Counter

Disable Alarm

Read Digital I/O and

Alarm Status

Set Digital Output

Enable Alarm

Set High Alarm

Set Low Alarm

Read Event Counter

Read High Alarm

Read Low Alarm

$(Addr)7(Data_L)(Data_H)

$(Addr)A(Status)

$(Addr)R

$(Addr)9(Counts)

@(Addr)CA

@(Addr)CE

@(Addr)DA

@(Addr)DI

@(Addr)DO(OutData)

@(Addr)EA(Mode)

@(Addr)HI(Data)

@(Addr)LO(Data)

@(Addr)RE

@(Addr)RH

@(Addr)RL

6014D 3-35

6014D 3-36

6014D 3-37

6011/D,

6018

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

6011/D,

6012/D,

6014D

3-38

3-39

3-40

3-41

3-42

3-44

3-45

3-46

3-47

3-48

3-49

3-50

Command Set • 35

Page 44

Special Commands

Read Command Leading

Code Setting

Change Command

Leading Code Setting

Set Host Watchdog /

Safety Value

Read Host WatchDog /

Safe Value

Host is OK

~(Addr)0

~(Addr)10(C1)(C2)(C3)

(C4)(C5)(C6)

~(Addr)2(Flag)

(TimeOut)(SafeValue)

~(Addr)3

~**

ALL 3-51

ALL 3-53

ALL 3-55

ALL 3-57

ALL 3-58

Note: “ALL” means for ND-6011/D, ND-6012/D, ND-6013, ND-6014D,

ND-6017 and ND-6018.

(1) This function only support on F/W version above A4.30.

(2)These two functions only support between F/W

versionA3.05 to A4.52.

(3)These two functions support on F/W version above B4.60

of ND-6018 and F/W version above A4.60 of ND-6011.

(4)These two functions support on F/W version above B1.31

of ND-6018 and F/W version above C4.60 of ND-6013.

36 • Command Set

Page 45

3.3 Set Configuration

@Description

Configure the basic setting of NuDAM, including the address ID, input

range, baud rate, and data format. The new configuration will be

available after executing the command.

@Syntax

%(OldAddr)(NewAddr)(InputRange)(BaudRate)(DataFormat)<CR

>

% Command leading code. (1-character)

(OldAddr)

(NewAddr)

(InputRange)

(BaudRate)

(DataFormat)

NuDAM module original address ID. The

default address ID of a brand new module is

01. The value range of address ID is 00 to FF

in hexadecimal.

(2-character)

New address ID, if you don’t want to change

address ID, let new address ID equals to the

old one. (2-character)

Define analog input range, refers to Table 3-1

for details. (2-character)

Define communication baud rate, refers to

Table 3-2 for details. (2-character)

Define checksum, integration time and output

data format, refers to Figure 3-1 for details.

(2-character)

(6011/D, 6012/D, 6013

6014D, 6017, 6018)

@Response

!(Addr)<CR>

or

?(Addr)<CR

>

(Addr)

!

?

Address ID.

Command is valid.

Command is invalid, parameter values are invalid, or

change the setting without grounding the DEFAULT*

pin.

Command Set • 37

Page 46

Note:

1. When you want to change the checksum or baud rate, the

DEFAULT* pin must be grounded at first.

2. Waiting a maximum of 7 seconds to perform auto calibration and

ranging after the analog input module is reconfigured. Please

don’t execute any other command during this time period.

@Example

User command: %0130050600<CR>

Response: !30<CR>

Item Meaning Description

% (Leading Code) Command leading code.

01 (OldAddr) Original address ID is 01(Hex).

30 (NewAddr) New address ID is 30(Hex).

05 (InputRange)

06 (BaudRate) Baud rate is 9600.

00 (DataFormat) 00 means data format is engineering

<CR> Carriage return 0x0D.

Analog input range is ±2.5V

units, checksum is disable and

integration time is 50 ms (60Hz).

38 • Command Set

Page 47

Code (Hex) Input Range Modules

00

01

02

03

04

05

06

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

15

16

20

21

22

23

24

25

26

27

28

29

2A 0~60 Ohms 6013

±15 mV

±50 mV

±100 mV

±500 mV

±1 V

±2.5 V

±20 mA

(Required 125Ω current conversion resistor.)

±10 V

±5 V

±1 V

±500 mV

±150 mV

±20 mA

(Required 125Ω current conversion resistor.)

Type J Thermocouple 0° to 760°C

Type K Thermocouple 0° to 1370°C

Type T Thermocouple -100° to 400°C

Type E Thermocouple 0° to 1000°C

Type R Thermocouple 500° to 1750°C

Type S Thermocouple 500° to 1750°C

Type B Thermocouple 500° to 1800°C

Type N Thermocouple -270° to 1300°C

Type C Thermocouple 0° to 2320°C

Pt-100, -100°C to +100°C, α=0.00385

Pt-100, 0°C to +100°C, α=0.00385

Pt-100, 0°C to +200°C, α=0.00385

Pt-100, 0°C to +600°C, α=0.00385

Pt-100, -100°C to +100°C, α=0.003916

Pt-100, 0°C to +100°C, α=0.003916

Pt-100, 0°C to +200°C, α=0.003916

Pt-100, 0°C to +600°C, α=0.003916

Ni-100, 0°C to +100°C

Ni-120, 0°C to +100°C

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6012/D,6017,

6014D

6012/D,6017,

6014D

6012/D,6017,

6014D

6012/D,6017,

6014D

6012/D,6017,

6014D

6012/D,6017,

6014D

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6011/D,6018

6013

6013

6013

6013

6013

6013

6013

6013

6013

6013

Table 3-1 AD Input Range Setting

Command Set • 39

Page 48

A

Code Baudrate

03 1200 bps

04 2400 bps

05 4800 bps

06 9600 bps

07 19200 bps

08 38400 bps

09 115200 bps

Table 3-2 Baud rate setting code

6

7

Checksum

0: disable

1: enable

Figure 3-1 Data Format Setting of Analog Input Modules

4 3 2 1 0

5

nalog Input Data Format

00: Engineering units

01: % of Full Scale Range

10: Two’s complement of hexadecimal

11: Ohms (6013 only)

Note:

6017/6018 only support engineering

units.

6013 supports engineering units and

ohms display.

Reserved

Must to be 0

40 • Command Set

Page 49

3.4 Read Configuration

@Description

Read the configuration of module on a specified address ID.

@Syntax

$(Addr)2<CR

>

$

(Addr)

2

@Response

!(Addr)(InputRange)(BaudRate)(DataFormat)<CR>

or

?(Addr)<CR

>

!

?

(Addr)

(InputRange)

(BaudRate)

(DataFormat)

Command leading code

Address ID.

Command code for reading configuration

Command is invalid.

Command is invalid.

Address ID.

Current setting of analog voltage input, refers

to Table 3-1 for details.

Current setting of communication baud rate,

refers to Table 3-2 for details.

Current settings of checksum, integration time

and output data format, refers to Figure 3-1 for

details.

(6011/D, 6012/D, 6013

6014D, 6017, 6018)

@Example

User command: $302<CR>

Response: !30050600<CR>

!

30

05

06

00

Command is valid.

Address ID.

Analog input range is ±2.5 V.

Baud rate is 9600 bps.

checksum is disable.

Command Set • 41

Page 50

3.5 Read Module Name

@Description

Read module name of NuDAM at specified address.

@Syntax

$(Addr)M<CR>

$

(Addr)

M

@Response

!(Addr)(ModuleName)

<CR>

or

?(Addr)<CR

>

Command leading code.

Address ID

Read module name

!

?

(Addr)

(ModuleName)

Command is invalid.

Command is invalid.

Address ID.

NuDAM module‘s name could be

‘6011’, ’6011/D‘, ‘6012’, ’6012/D‘, ‘6013’, ‘6017’

or ’6018‘.

4 or 5 characters

(6011/D, 6012/D, 6013

6014D, 6017, 6018)

@Example

User command: $30M<CR>

Response: !306011/D<CR>

!

30

6011/D

42 • Command Set

Command is valid.

Address

ND-6011/D (Analog Input Module)

Page 51

3.6 Read Firmware Version

@Description

Read firmware version of NuDAM at specified address.

@Syntax

$(Addr)F<CR>

$

(Addr)

F

@Response

!(Addr)(FirmRev) <CR>

or

?(Addr)<CR

>

Command leading code.

Address ID

Read module firmware version.

!

?

(Addr)

(FirmRev)

@Example

User command: $30F<CR>

Response: !30A2.10<CR>

!

30

A2.10

Command is valid.

Command is invalid.

Address ID.

NuDAM module‘s firmware version.

Command is valid.

Address

Firmware Version

(6011/D, 6012/D, 6013

6014D, 6017, 6018)

Command Set • 43

Page 52

3.7 Software Reset

@Description

To stop current operation , reset the module to initial power on state.

@Syntax

$(Addr)RS<CR>

$ Command leading code (1 character)

(Addr) Address ID (2 character)

RS Software Reset (2 character)

@Response

!(Addr)<CR>

or

?(Addr)<CR

>

!

?

(Addr

)

@Example

User

command:

Response: !06<CR>

To stop current operation , reset the module to initial power on state for

analog input module ND-6013 , address ID is 06H.

(6011/D, 6012/D, 6013

6014D, 6017, 6018)

Command is valid.

Command is invalid.

Address ID.

$060RS<CR>

44 • Command Set

Page 53

3.8 Synchronized Sampling

@Description

Synchronized all modules to sample analog input values and stored

the values in the module’s register at the same time. The sampled data

can be read by “Read Synchronized Data” command.

@Syntax

#**<CR

>

#

**

@Response

Note: Synchronized sampling command has NO response.

@Example

User command: #**<CR>

Command leading code.

Synchronized sampling command

(6011/D, 6012/D, 6014D)

Command Set • 45

Page 54

3.9 Read Synchronized Data

@Description

After a synchronized sampling command #** was issued, you can read

the sampled value that was stored in the register of the module at

specified address.

@Syntax

$(Addr)4<CR

>

$

(Addr)

4

@Response

>(Addr)(Status)(Data)<CR>

or

?(Addr)<CR

>

>

?

(Addr)

(Status)

(Data)

Command leading code.

Address ID

Read synchronized data.

Command is invalid.

Command is invalid or no synchronized sampling

command was issued.

Address ID.

0: Data has been sent at least once before.

1: Data has been sent for the first time since a

synchronized sampling command was

issued. (1-character)

There are four types of Data format, refers to

Chapter 4 for details.

(6011/D, 6012/D, 6014D)

@Examples

User command: $064<CR>

Response: >060+1.6888<CR>

Read synchronized data at address 06H, analog input module send its

analog input data +1.6888 (units). Status is 0 means it has sent the

same data at least once. The current units is set by the data format.

User command: $064<CR>

Response: >061+1.6888<CR>

Read synchronized data at address 06H, analog input module send its

analog input data +1.6888 (units). Status is 1 means it is the first time

that the data has been sent. The current units is set by the data format

46 • Command Set

Page 55

3.10 Read Analog Data

@Description

Read the analog input value from an analog input module at specified

address in a NuDAM network. While for ND-6013, it returns the channel

0 analog data.

@Syntax

#(Addr)<CR>

#

(Addr)

@Response

>(InputData)<CR>

Command leading code

Address ID

>

(InputData)

@Example

User command: #06<CR>

Response: >+1.6888<CR>

Read the analog input module data at address 06 (Hex). The analog

input module response data is +1.6888 units. The unit depends on the

data format.

Delimiter character

The input data represents the analog signal. The

unit of the digits depends on the data format used.

There are four types of data format. The format is

set by the set configuration command.

Delimiter character

(6011/D, 6012/D, 6013, 6014D)

Command Set • 47

Page 56

3.11 Span Calibration

@Description

To correct the gain errors of AD converter by using the span calibration.

@Syntax

$(Addr)0<CR>

$ Command leading code (1 character)

(Addr) Address ID (2 character)

0 Span calibration (1 character)

@Response

!(Addr)<CR>

or

?(Addr)<CR

>

!

?

(Addr)

@Example

User command: $060<CR>

Response: !06<CR>

To perform the span calibration for analog input module, address ID is

06H.

Command is valid.

Command is invalid.

Address ID.

(6011/D, 6012/D, 6013 C4.6

6014D, 6017, 6018)

Note: To perform the calibration, a proper input signal should be

connected to the analog input module. Different input range

have different input voltage, detail refer chapter 5 “Calibration”.

48 • Command Set

Page 57

3.12 Span Calibration to each Channel

A

@Description

To correct the gain errors of AD converter by using the span calibration.

@Syntax

$(Addr)0(Channel No)<CR>

$ Command leading code (1 character)

(Addr) Address ID (2 character)

0 Span calibration (1 character)

(Channel No) Channel for Calibration (1 character) 0~2

@Response

!(Addr)<CR>

or

?(Addr)<CR

>

!

?

(Addr)

@Example

User command: $0601<CR>

Response: !06<CR>

To perform the span calibration for analog input module ND-6013

channel 1, address ID is 06H.

Command is valid.

Command is invalid.

Address ID.

(for 6013 F/W version

3.05~A4.60)

Note: To perform the calibration, a proper input signal should be

connected to the analog input module. Different input range

have different input voltage, detail refer chapter 5

“Calibration” .

Command Set • 49

Page 58

3.13 Offset Calibration

@Description

To correct the offset errors of AD converter by using the offset

calibration.

@Syntax

$(Addr)1<CR>

$

(Addr)

1

@Response

!(Addr)<CR>

or

?(Addr)<CR

>

!

?

(Addr)

@Example

User command: $061<CR>

Response: !06<CR>

To perform the offset calibration for analog input module at specified

address 06 (Hex).

Command leading code

Address ID

Offset calibration.

Command is valid.

Command is invalid.

Address ID.

(6011/D, 6012/D, 6013 C4.6

and above, 6014D, 6017, 6018)

Note: To perform the calibration, a proper input signal should be

connected to the analog input module. Different input range

have different input voltage, detail refer chapter 5

“Calibration” .

50 • Command Set

Page 59

3.14 Offset Calibration to each Channel

A

(for 6013 F/W version

@Description

To correct the offset errors of AD converter by using the offset

calibration.

@Syntax

$(Addr)1(Channel No)<CR>

3.05~A4.60)

$

(Addr)

1

(Channel No) Channel for calibration.(1 character)0~2

@Response

!(Addr)<CR>

or

?(Addr)<CR

>

!

?

(Addr)

@Example

User command: $0612<CR>

Response: !06<CR>

To perform the offset calibration for analog input module ND-6013

channel 2 at specified address 06 (Hex).

Command leading code

Address ID

Offset calibration.

Command is valid.

Command is invalid.

Address ID.

(6013)

Note: To perform the calibration, a proper input signal should be

connected to the analog input module. Different input range

have different input voltage, detail refer chapter 5

“Calibration” .

Command Set • 51

Page 60

3.15 Read Analog Data From Channel N

@Description

Read the analog input value of a specified AD channel from an analog

input module at specified address in a NuDAM network.

@Syntax

#(Addr)(ChannelNo)<CR>

# Command leading code. (1-character)

(Addr) Address ID. (2-character)

(ChannelNo) Channel number, range (0 - 7). (1-character)

Range (0-2). For ND-6013

@Response

>(InputData)<CR>

>

(InputData)

@Example

User command: #061<CR>

Response: >+1.6888<CR>

Read the analog input channel 1 of AD module at address 06

(Hexadecimal) in the network. The analog input data is +1.6888 Volts

(Data format is engineering unit)

Delimiter character

Input value from a specified channel number, the

data format is a + or - sign with five decimal digits

and a fixed decimal point.

(6013, 6017, 6018)

52 • Command Set

Page 61

3.16 Read All Analog Data Channel

@Description

Read all the enable analog input channel value of a specified from an

analog input module at specified address in a NuDAM network.

@Syntax

#(Addr)A<CR>

# Command leading code. (1-character)

(Addr) Address ID. (2-character)

A

@Response

>(InputData)(InputData)(InputData)<CR>

All the enable channel

>

(InputData)

@Example

User command: #06A<CR>

Response: >+100.88+020.66+006.79<CR>

Read the analog input of AD module at address 06 (Hexadecimal) in the

network. The analog input data are +100.88 °C for channel 0, +020.66

°C for channel 1 and +006.79°C for channel 3. (Data format is

engineering unit).

Delimiter character

Input value from a specified channel number, the

data format is a + or - sign with five decimal digits

and a fixed decimal point.

(6013, 6017, 6018)

Command Set • 53

Page 62

3.17 Enable/Disable channels for Multiplexing

(6013, 6017, 6018)

@Description

Enable/Disable multiplexing simultaneously for individual channel.

@Syntax

$(Addr)5(ChannelVal)<CR>

$ Command leading code. (1-character)

(Addr) Address ID (2-character)

5 Enable/Disable channel. (1-character)

(ChannelVal)

@Response

!(Addr)<CR>

or

?(Addr)<CR

>

!

?

(Addr)

@Example

User command: $06548<CR>

Response: !06<CR>

$

06

5

48

bit 3~0 of 1st character: control channel 7 - 4.

bit 3~0 of 2nd character: control channel 3 - 0.

bit value 0: Disable channel

bit value 1: Enable channel (2-character)

Command is valid.

Command is invalid.

Address ID.

Command leading code.

Address ID.

Disable/Enable channel.

Channel Value is 0x48.

‘48’ is 01001000 that means enable channel 3 and

channel 6, the other channels are all disable.

54 • Command Set

Page 63

3.18 Read Channel Status

@Description

Read the enable/disable status the channels of ND-6013, ND-6017 or

6018.

@Syntax

$(Addr)6<CR>

$ Command leading code. (1-character)

(Addr) Address ID (2-character)

6 Read channel status. (1-character)

@Response

!(Addr)(ChannelVal)<CR>

or

?(Addr)<CR

>

!

?

(Addr)

(ChannelVal)

@Example

User command: $066<CR>

Response: !0648<CR>

4 is equals binary 0100 that means enable channel 6 and disable

channel 7, 5, 4.

8 is equals binary 1000 that means enable channel 3 and disable

channel 2, 1, 0.

Command is invalid.

Command is invalid.

Address ID.

bit 3~0 of 1st character: controlt channel 7 - 4.

bit 3~0 of 2nd character: control channel 3 - 0.

bit value 0: Disable channel

bit value 1: Enable channel (2-character)

(6013, 6017, 6018)

Command Set • 55

Page 64

3.19 Read CJC Status

@Description

Read the CJC (Cold Junction Compensation) sensors data.

@Syntax

$(Addr)3<CR>

$

(Addr)

3

@Response

>(Data)<CR>

or

?(Addr)<CR

>

>

(Data)

?

(Addr)

@Example

User command: $063<CR>

Response: >+0037.9<CR>

This command is to read analog input module CJC status at address

06H, return data is 37.9°C.

Command leading code.

Address ID

Read CJC status.

Command is invalid.

CJC sensor’s data.

Data format is engineering units. (an + or - sign with

five decimal digits and a decimal fixed point. The

resolution is 0.1°C

Command is invalid.

Address ID.

(6011/D, 6018)

56 • Command Set

Page 65

3.20 Enable/Disable CJC

@Description

To disable/enable CJC of ND-6011/D and ND-6018

@Syntax

$(Addr)C(Status)<CR>

$ Command leading code (1 character)

(Addr) Address ID (2 character)

C Disable/enable CJC command (1 character)

(Status)

@Response

!(Addr)<CR>

or

?(Addr)<CR

>

!

?

(Addr

))

@Example

User

command:

Response: !02<CR>

To enable CJC and module’s address is 02H.

Command is valid.

Command is invalid.

Address ID (2 character)

(6011/D, 6018)

0: Disable

1: Enable

$02C1<CR>

Command Set • 57

Page 66

3.21 Read enable/disable CJC Status

@Description

To read CJC disable/enable status of ND-6018

@Syntax

$(Addr)D<CR>

$ Command leading code (1 character)

(Addr) Address ID (2 character)

D Read CJC disable/enable staus command (1

character)

@Response

!(Addr)(Statu

s)<CR>

or

?(Addr)<CR

>

!

?

(Stat

us)

@Example

User

command:

Response: !021<CR>

To read CJC disable/enable status, and module’s address is 02H., the

CJC is enable.

Command is valid.

Command is invalid.

0: Disable

1: Enable

$02D<CR>

(6011/D, 6018)

58 • Command Set

Page 67

3.22 Read Source High/Low Values for Linear

Mapping

@Description