Page 1

LEC-BASE

(SMARC Baseboard)

Technical Reference

P/N 50-1Z157-1010

Rev1.01

Advance Technologies. Automate the World.

Page 2

Disclaimer

Information in this document is provided in connection with ADLINK products. No license,

express or implied, by estoppel or otherwise, to any intellectual property rights is granted by

this document. Except as provided in ADLINK´s Terms and Conditions of Sale for such products, ADLINK assumes no liability whatsoever, and ADLINK disclaims any express or implied

warranty , relating to sale and/or use of ADLINK products including liability or warranties relating to fitness for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual property right. If you intend to use ADLINK products in or as medical

devices, you are solely responsible for all required regulatory compliance, including, without

limitation, Title 21 of the CFR (US), Directive 2007/47/EC (EU), and ISO 13485 & 14971, if

any . ADL INK may make changes to specifications and pr oduct descriptio ns at any time, with out notice.

Trademarks

MS-DOS, Windows, Windows 95, Windows 98, Windows NT and Windows XP are trademarks of Microsoft Corporation. PS/2 is a trademark of International Business Machines, Inc.

Intel and Solid State Drive are trademarks of Intel Corporation. PC/104 is a registered trademark of the PC/104 Consortium. All other trademarks appearing in this document are the

property of their respective owners. CoreModule is a registered trademark, and ADLINK, Little Board, LittleBoard, MightyBoard, MightySystem, MilSystem, MiniModule, ReadyBoard,

ReadyBox, ReadyPanel, RuffSystem, and ReadySystem are trademarks of ADLINK Technology, Inc. All other marks are the property of their respective companies.

Revision History

Revision Reason for Change Date

1000 Initial Release Dec/13

Revised board interface layout; updated interface pinout

1.01

tables; changed this document’s revision number from

1000 to 1.01

Apr/15

© Copyright 2013, 2014, 2015 ADLINK Technology, Incorporated

This document contains proprietary information protected by copyright. All rights are reserved.

No part of this manual may be reproduced by an y mechanical , electronic, or other means in any

form without prior written permission of the manufacturer

Audience

This manual provides reference only for computer design engineers, including but not limited

to hardware and software designers and applications engineers. ADLINK Technology, Inc.

assumes you are qualified to design and implement prototype computer equipment.

ii

Page 3

LEC-BASE

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global environmental preservation

through compliance with the European Union's Restriction of Hazardou s Subst ances (RoHS)

directive and Waste Electrical and Electronic Equipment (WEEE) directive. Environmental

protection is a top priority for ADLINK. We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as litt le impact on the

environment as possible. When products are at their end of life, our customers are encouraged to dispose of them in accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Important Safety Instructions

For user safety, please read and follow all Instructions, WARNINGs, CAUTIONs, and

NOTEs marked in this manual and on the associated equipment before handling/operating

the equipment.

Read these safety instructions carefully.

Keep this manual for future reference.

Read the specifications section of this manual for detailed information on the operating

environment of this equipment.

Turn off power and unplug any power cords/cables when installing/mounting or un-install-

ing/removing equipment.

To avoid electrical shock and/or damage to equipment:

Keep equipment away from water or liquid sources;

Keep equipment away from high heat or high humidity;

Keep equipment properly ventilated (do not block or cover ventilation openings) ;

Make sure to use recommended voltage and power source settings;

Always install and operate equipment near an easily accessible electrical socket-

outlet;

Secure the power cord (do not place any object on/over the power cord);

Only install/attach and operate equipment on stable surfaces and/or recommended

mountings; and,

If the equipment will not be used for long periods of time, turn off the power source and unplug

the equipment.

iii

Page 4

iv

Page 5

LEC-BASE

Table of Contents

1 Overview ........................................................................................................................... 1

1.1 Block Diagram........................................................................................................................ 1

1.2 Major Components (ICs)........................................................................................................ 2

1.3 Interface Headers, Jumper Headers, Switches, LEDs, and Connectors............................... 4

1.4 Specifications......................................................................................................................... 8

1.4.1 Physical Specifications ......................................................................................................8

1.4.2 Mechanical Specifications .................................................................................................8

2 Interface Signals...............................................................................................................9

2.1.1 SD/eMMC (AFB2) Interface ...... ... ................................................................................... 9

2.1.2 Camera 0 (CAM0)..................................... .... ... ... ... .... ... ... ... ....................................... ...10

2.1.3 Camera 1 (CAM1)..................................... .... ... ... ... .... ... ... ... ....................................... ...11

2.1.4 Camera 3 (CAM3)..................................... .... ... ... ... .... ... ... ... ....................................... ...11

2.1.5 Controller Area Network (CAN1)...................... ... ... .... ...................................... ... .... ... ...12

2.1.6 Cell Charger/Battery Supply (CN4) ...............................................................................12

2.1.7 GPIO1 ...........................................................................................................................13

2.1.8 Smart Battery (H25) ......... ... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ... .... ... ...13

2.1.9 I2S1...............................................................................................................................14

2.1.10 I2S2...............................................................................................................................14

2.1.11 I2S3...............................................................................................................................14

2.1.12 Alternate Function Block 1 (J9) .....................................................................................15

2.1.13 I2C (J10)................. ... ... .... ... ... ... ... .... ... ... ... .... ... ....................................... ... ... ... ... ..........16

2.1.14 Battery (J12)..................................................................................................................16

2.1.15 LVDS Control (J14) ................................... .... ... ... ... .... ... ... ... ....................................... ...16

2.1.16 TTL Panel Control (PC1)...............................................................................................16

2.1.17 Power Management (PW1)....................... .... ... ... ... .... ... ... ... ... .......................................17

2.1.18 SPI0...............................................................................................................................17

2.1.19 SPI1...............................................................................................................................17

2.1.20 LVDS.............................................................................................................................18

2.1.21 TTL................................................................................................................................19

Appendix A Technical Support ......................................................................................... 21

v

Page 6

vi

Page 7

1 Overview

USB1_B

USB1_A

HDMI-J6

HDMI-R GB

SI L9022

Codec

TLV320AI

C23BPW

LAN

Transformer

314-pin Connector

USB0

USB2

USB1

USB 2.0

SPI1

Level Shift

buffers

HDMI

RGB 18/24-bit

Header

18/24-bit RGB TTL

GbE

RJ45

10/100/1000

SATA1

SATA Connector

eMMC/SD/SDIO 8-bit

Line OUT

Line IN

SPDIF

Header

SPI0

UART1 (4-pin)

UART3

(2

-pin)

UART4(2

-pin

)

DB9

Camera Input Control Signals

CAM3

I2C LCD

USB 2.0 OTG

PCIE_

A (x1

)

HDMI / (or DP)

Header

24-bit LVDS

SDMMC

SD/SDIO 4-bit

SDIO

CSI1 Camera Input

I

2

2

C CAM

I2S1

I2S1

I C GP

I2S2 / HDA

I2S3

SPDIF

Management Pins

MIC

DB9

UART2 (4-pin)

CAN1 (2-pin)

CSI0 Camera Input

LVDS 18/24-bit

Header

I2C HDMI_CTRL

USB 2.0

(4 ports)

PC1

Header

Vdd, BKL_EN, BKL_CTRL

Boot Select / Force Recovery

DIP switch (4)

Test point

Header

Watchdog Time Out

GPIO (12-pin)

miniPCIe x1

A Slot

PCIe x1 Slot

PCIE_WAKE#

Power ena ble /

disable jumper

DB9

DB9

Header

Header

USB HUB

SMSC

USB2514i

USB

1

_C

miniPCIe x1

B Slot

DB9 (Dual)

GPS

Neo6

USB1_D

G Sensor

MMA7660FCT

EEPROM 4K

RTC

VRTC

I2C_HDMI

LEC_BASE_blkDiag_b

CAM0

CAM1

This initial manual version presents a general overview of the LEC-BASE baseboard including

the signal definitions of the non-standard user interfaces on the board. After reviewing this document you should understand the following features of the LEC-BASE.

Functional Block Diagram

Major Component (IC) Locations and Descriptions

Connector Locations and Descripti on s

Specifications

Non-Standard User Interface Signal Definitions (support is dependent on the specific

SMARC module; refer to the specific SMARC module manual for details)

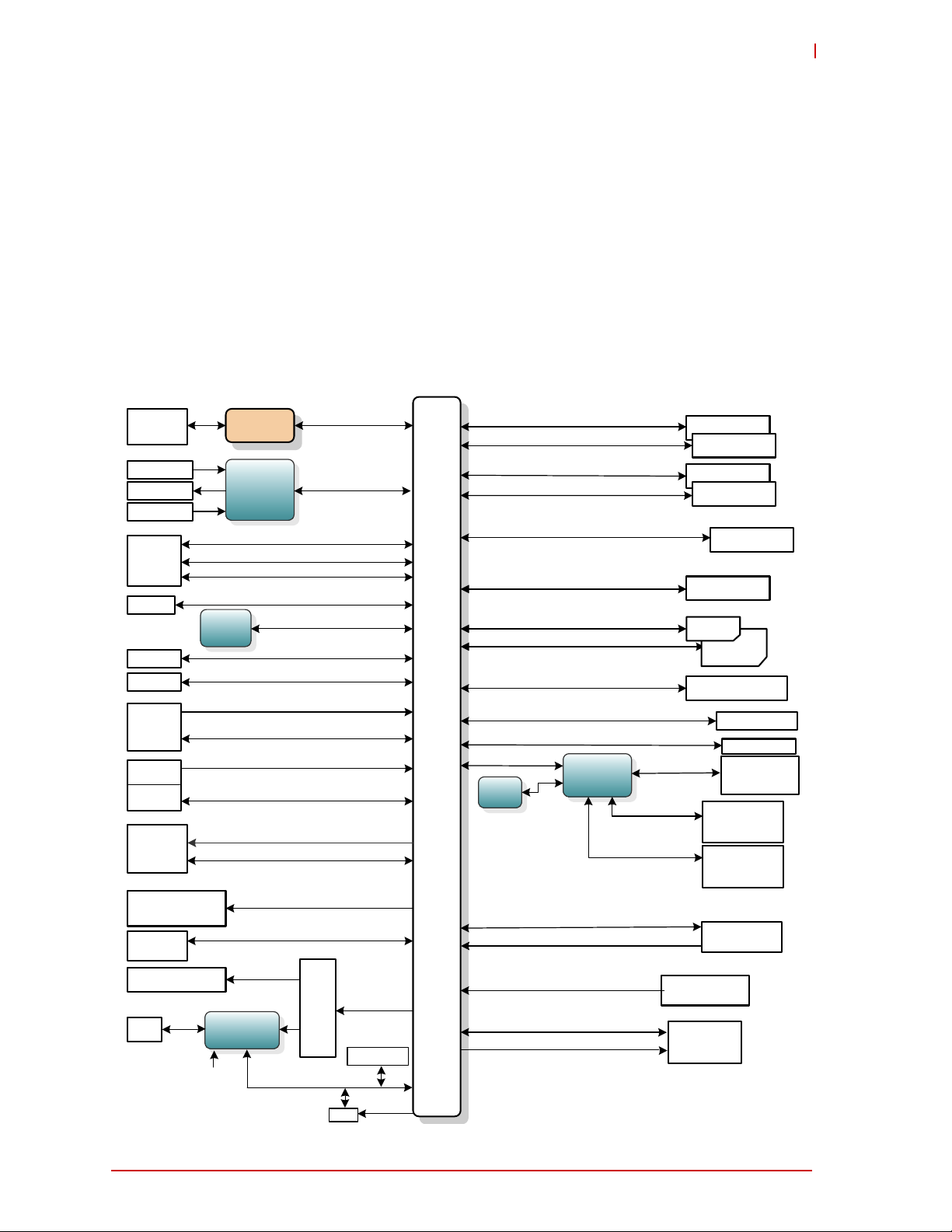

1.1 Block Diagram

Figure 1-1 presents a functional representation of the baseboard.

LEC-BASE

Overview 1

Figure 1-1: Functional Block Diagram

Page 8

1.2 Major Components (ICs)

Table 1-1 lists the major integrated circuits on the LEC-BASE, including a brief description of

each IC. Figure 1-2 shows the locations of the major ICs.

Table 1-1: Major Integrated Circuit Descriptions and Functions

Chip Type Mfg. Model Description Function

G-Sensor (U4) Freescale

Semicondu

ctor

Touch Panel

Controller

(U18)

I2C, 2-wire

EEPROM

(U19)

CAN

Transceiver

(U25, U26)

I2S Audio

CODEC (U27)

Real Time

Clock (U36)

GPS Module

(U136)

Texas

Instruments

Atmel AT24C08C 2-wire, 8Kb serial

Texas

Instruments

Texas

Instruments

Maxim DS1337S I2C Serial Real-Time

u-blox NEO-Q-0 GPS Receiver,

MMA7660FC 3-axis Orientation/

Motion Detection

Sensor, connected to

the I2C GP interface at

pins S48 and S49 of

the SMARC connector.

The I2C address is

0x4C/0x4D.

TSC2046 Low-Voltage Touch

Controller, connected

to the SPIO interface

at pins P43, P44, P45,

and P46 of the

SMARC connector.

EEPROM, connected

to the I2C LCD

interface at pins S139

and S140 of the

SMARC connector.

The I2C address is

0xA8/0xA9.

SN65HVDA540QDR Transceiver for

Controller Area

Network, connected to

the CAN0 and CAN1

interfaces at pins

P143, P144, P145,

and P146 of the

SMARC connector.

TLV320AIC23B I2S Stereo Audio

CODEC, connected to

the I2S0 interface at

pins S39, S40, S41,

S42 of the SMARC

connector.

Clock, connected to

the I2C LCD interface

at pins S139 and S140

of the SMARC

connector. The I2C

address is 0xD0/0xD1.

connected over the

USB hub to the

SMARC connector at

pins P65 and P66.

Senses data

changes, product

orientation, and

gestures through

an interrupt (INT)

pin.

Senses 4-wire

resistive touch

screen.

Provides storage

for baseboard

parameters

through the I

LCD pins, S139

and S140, on the

SMARC module.

Provides up to 1

Mbps of

differential

transmit and

receive

capabilities for the

CAN controller in

the CPU.

Supports

data-transfer word

lengths of 16, 20,

24, and 32 bits

with sample rates

from 8kHz to

96kHz.

Provides

low-power clock/

calendar with two

programmable

time-of-day

alarms and a

programmable

square-wave

output

Provides

6-positioning

engine for parallel

time/frequency

space searches

2

C

2 Overview

Page 9

LEC-BASE_Top_Comp_b

U18

U4

U19

U36

U26

U25

U27

U136

Key:

U4 - G-Sensor

U18 - Touch Panel Controller

U19 - I2C EEPROM

U25, U26 - CAN Transceivers

U27 - Audio CODEC

U36 - Real Time Clock

U136 - GPS Module

LEC-BASE

Figure 1-2: Component Locations (Top Side)

Overview 3

Page 10

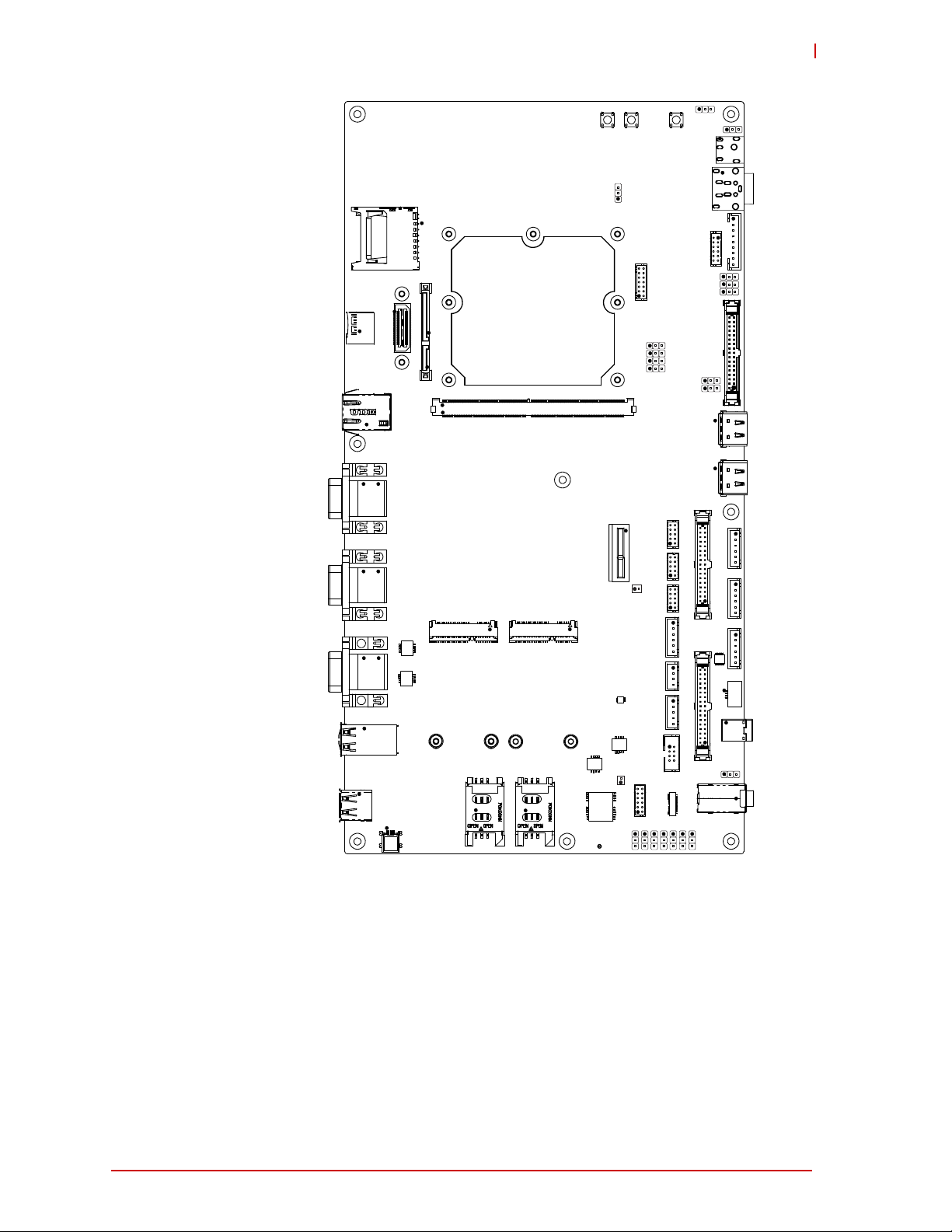

1.3 Interface Headers, Jumper Headers, Switches, LEDs, and Connectors

Table 1-2 describes the headers, switches, LEDs, and connectors for the LEC-BASE baseboard

shown in Figure 1-3.

Table 1-2: Header, Switch, LED, and Connector Descriptions

Header /

Connector#

AFB2 SD/eMMC Card 60-pin terminal for eMMC card

AJ1 Audio Jack 32-pin standard audio jack for three audio interfaces: Line

ANT1 GPS Antenna 3-pin, radio frequency, 50 ohm antenna for receiving GPS

CAM0 Camera 10-pin header for MIPI CSI1 camera

CAM1 Camera 10-pin header for MIPI CSI0 camera

CAM3 Camera Control 10-pin header for I2C clock/data signals on MIPI CSI

CAN1 (two

ports)

CN1 Touch Screen 4-pin, standard connector for 4-wire resistive touch

CN2 microSD 12-pin, standard socket for microSD memory cards

CN4 Cell Charger/Battery

CN5 MiniDin DC Jack 4-pin, female connector for additional power input for

COM1 (two

ports)

COM2 (two

ports)

GPIO1 GPIO 12-pin header for General Purpose IO

H25 Battery2 9-pin header for smart battery connection

I2S1 I2S Devices 6-pin header for I2S devices such as audio CODECs,

I2S2 I2S Devices 6-pin header for I2S devices such as audio CODECs,

I2S3 I2S Devices 6-pin header for I2S devices such as audio CODECs,

J1 SMARC Interface 314-pin, MXM socket for Memory, Video, and I/O functions

J3 TTL 34-pin header for VGA LCD flat panel output

J6 HDMI1 19-pin, standard HDMI micro connector

J8 LVDS 34-pin header for LVDS output

J9 (AFB1) Auxiliary Devices 34-pin header for differential pair and data bit signals

J10 I2C 2-pin header for general purpose, level-shifted 3.3V, I2C

J11 HDMI2 19-pin, standard HDMI micro connector

J12 Battery 2-pin header for RTC external battery

J14 LVDS Control 8-pin head er for LVDS panel and backlight control

JACK1 DC Power 6-pin, standard, right-angle 19V center-pin, DC power jack

JP2 LCD Power Select 3-pin, jumper header for LCD 3.3V (1-2) or 5V (2-3) power

JP3 I2C Select 3-pin, jumper header to select I2C_LCD (clock/data pair)

Signal / Device Description

In (Blue), Line Out (Green), and MIC In (Pink)

signals

camera

CAN Bus Dual, 9-pin standard DB9 connectors for transmitting and

receiving Controller Area Network signals

controller (not for TTL USB-based touch screen controller

in Starter Kit)

12-pin header for 2-cell, raw lithium ion battery interface to

Supply

UART Dual, 9-pin standard DB9 connectors for RS232 serial

UART Dual, 9-pin standard DB9 connectors for RS232 serial

power the baseboard

auxiliary circuitry

ports

ports

baseband modems, and touch controllers

baseband modems, and touch controllers

baseband modems, and touch controllers (designated also

for HD Audio CODECs)

clock and data signals for the module

selection

for HDMI controller (1-2 default)

4 Overview

Page 11

LEC-BASE

Table 1-2: Header, Switch, LED, and Connector Descriptions (Continued)

JP4 Battery Charger

Enable

JP5 Cell Charger Present 3-pin jumper header to accept charging (1-2 if cell present;

JP6 Cell Charger Voltage 3-pin jumper header for I2C voltage selection (pins 2-3 for

JP7 Cell Protection IC, I2C

Signal Pair

JP8 LCD/LVDS Select

(High = 1-2; Low = 2-3)

JP9 LCD/LVDS Select

(High = 1-2; Low = 2-3)

JP10 LVDS 3-pin jumper header for selecting strobe for LVDS

JP11 LVDS 3-pin jumper header for powering ON/OFF LVDS

JP12 LVDS Backlight

Control (for J14)

JP13 LVDS Panel Control

(for J14)

JP14 LVDS Backlight

Control (for J14)

JP15 I2C Select (related to

JP3)

JP16 Boot Select 0 3-pin jumper header for Boot Select Switch SW1 pins 1

JP17 Boot Select 1 3-pin jumper header for Boot Select Switch SW1 pins 1

JP18 Boot Select 2 3-pin jumper header for Boot Select Switch SW1 pins 1

JP19 Boot Select Force

Recovery

JP20 VIO Select (IO

Voltage)

JP21 DC-OUT 3-pin jumper header to override (1-2) or not override (2-3)

LAN1 Ethernet 8-pin, standard RJ45 jack for Gigabit Ethernet port

LED1 USB Green LED indicating USB is operational

LED2 Mini PCIE1 Green LED indicating WAN

LED3 Mini PCIE2 Green LED indicating WAN

LED4 nLID Green LED indicating active low LID signal is asserted

LED5 nSLEEP Green LED indicating active low SLEEP signal is asserted

LED6 nBATLOW Green LED indicating active low BATLOW signal is

LED7 SATA Green LED indicating SATA activity

LED8 SD Card Green LED indicating over current on SD card

LED9 USB Green LED indicating USB is operational

LED11 Cell Protection IC Green LED indicating battery pack conditions

3-pin jumper header for enabling the smart battery/cell

charger: ON (1-2) or OFF (2-3)

2-3 if cell not present)

2.5V or pins 1-2 for 3.3V) between cell and charger

3-pin header to allow Texas Instruments software to

communicate with the cell protection IC: 1=Data, 2=Clock,

and 3=GND

3-pin jumper header to make selection between LCD and

LVDS (JP9 Low and JP8 High = LVDS; JP9 High and JP8

Low = LCD; JP9 High and JP8 High = None)

3-pin jumper header to make selection between LCD and

LVDS (JP9 Low and JP8 High = LVDS; JP9 High and JP8

Low = LCD; JP9 High and JP8 High = None)

converter: rising edge 1-2, falling edge 2-3

controller: ON 1-2, OFF 2-3

3-pin jumper header for backlight power management to

select 3V (1-2) or 5V (2-3)

3-pin jumper header for panel power to select 3V (1-2) or

5V (2-3)

3-pin jumper header for backlight power management to

select 12V (1-2) or 5V (2-3)

3-pin jumper header tor selecting I2C_HDMI for HDMI

controller (2-3 Default)

and 8 (Pins 2-3 to ground boot_sel0; pins 1-2 to float

boot_sel0)

and 8 (Pins 2-3 to ground boot_sel1; pins 1-2 to float

boot_sel1)

and 8 (Pins 2-3 to ground boot_sel2; pins 1-2 to float

boot_sel2)

3-pin jumper header for Boot Select Switch SW1 pins 4

and 5 (Pins 2-3 to ground force_recover; pins 1-2 to float

force_recover)

3-pin jumper header for VIO 1.8V (1-2) [no other option is

valid, as defined by the SMARC specification]

power button (PWRON1) for automatic Power On testing

asserted

Overview 5

Page 12

Table 1-2: Header, Switch, LED, and Connector Descriptions (Continued )

LED12 Cell Protection IC Green LED indicating battery pack conditions

LED13 Cell Protection IC Green LED indicating battery pack conditions

LED14 Cell Protection IC Green LED indicating battery pack conditions

LED15 Cell Protection IC Green LED indicating battery pack conditions

LED16 Power Green LED indicating power asserted to baseboard

MINIPCIE1 PCIE Mini Card 52-pin, standard, right-angle socket for PCI Express Mini

Card

MINIPCIE2 PCIE Mini Card 52-pin, standard, right-angle socket for PCI Express Mini

Card

PC1 TTL Panel Control 6-pin header for control signals to flat panel display

PCIE1 PCI Express 36-pin, standard edge connector for x1 PCI Express

interface

PWM1 Power Management 14-pin header for Power Management signals

PWRON1 Power On 4-pin, push-button switch to turn on 12V to baseboard

PWRON2 Power On 4-pin, push-button switch to assert POWER_nBTN signal

for SMARC connector

SATA1 SATA 7-pin, standard Serial ATA connector with attached 15-pin

power connection

SD2 SD Card Slot Standard slot connector for Secure Digital memory card

SIM1 SIM Slot Standard slot connector for Subscriber Identity Module

SIM2 SIM Slot Standard slot connector for Subscriber Identity Module

SPDIF1 SPDIF-OUT Audio Standard connector for SPDIF digital audio interface

SPI0 System Packet

Interface

SPI1 System Packet

Interface

SW15 Reset Switch Push-button switch to warm reset the module

USBC1 USB 4-stack, standard USB 2.0 connector

USB1 Micro-USB Standard connector for micro-USB interface, OTG

USB2 USB Standard connector for single USB 2.0 interface

5-pin header for SPI interface

4-pin header for SPI interface

6 Overview

Page 13

JACK1

PWRON1

PWRON2

SD2

LED8

LED16

LED2

LED1

LED3

LED9

MINIPCIE1 MINIPCIE2

LED7

CN2

H25

CN4

LAN1

COM1

COM2

CAN1

USBC1

USB2

USB1

SIM1

SIM2

JP13

SPI0

SPI1

PC1

CAM3

CAM1

CAM0

PCIE1

J3

J10

J12

LED6

LED5

LED4

J8

J14

AJ1

SPDIF1

JP12

CN1

I2S3

I2S2

I2S1

J11

J1

S1

P1

J6

J9

(AFB1)

AFB2

SATA 1

JP2

JP14

JP8

JP9

CN5

JP4

JP20

JP15

JP7

JP6

JP5

JP3

LED15

LED14

LED13

LED12

LED11

PWM1

JP21

JP10

JP11

ANT1

GPIO1

SW15

LEC-BASE_Baseboard_Top_Conn_c

JP19

JP18

JP17

JP16

Key:

AFB2 - Alternate Function Block 2

AJ1 - Audio Jack

ANT1 - GPS Antenna

CAM0 - Camera 0

CAM1 - Camera 1

CAM3 - Camera 3

CAN1 - Controller Area Network (Dual Ports)

CN1 - 4-wire Resistive Touch Controller

CN2 - microSD (8 bits)

CN4 - Cell Charger/Battery Supply

CN5 - MiniDin DC Jack

COM1 - UART (Dual Ports)

COM2 - UART (Dual Ports)

PC1 - TTL Panel Control

PCIE1 - PCI Express

PWM1 - Power Management

PWRON1 - Power On

PWRON2 - Power On

SATA1 - SATA

SD2 - SD Card Slot

SIM1 - SIM Slot

SIM2 - SIM Slot

SPDIF1 - SPDIF OUT

SPI0 - System Packet Interface

SPI1 - System Packet Interface

SW15 - Reset Switch

USBC1 - USB

USB1 - Micro USB

USB2 - USB

NOTE: The larger black pins

each represent pin 1

LAN1 - Ehternet

LED1 - USB

LED2 - Mini PCIE1

LED3 - Mini PCIE2

LED4 - nLID

LED5 - nSLEEP

LED6 - nBATLOW

LED7 - SATA

LED8 - SD Card (4 bits)

LED9 - USB

LED11 - Cell Protection IC

LED12 - Cell Protection IC

LED13 - Cell Protection IC

LED14 - Cell Protection IC

LED15 - Cell Protection IC

LED16 - Power

MINIPCIE1 - PCIe Mini Card

MINIPCIE2 - PCIe Mini Card

JP4 - Battery Charger Enable

JP5 - Cell Charger Present

JP6 - Cell Charger Voltage

JP7 - Cell Protection IC

JP8 - LCD/LVDS Select

JP9 - LCD/LVDS Select

JP10 - LVDS Strobe

JP11 - LVDS Controller

JP12 - LVDS Backlight Control

JP13 - LVDS Panel Control

JP14 - LVDS Backlight Control

JP15 - Select I2C_HDMI for J11

JP16 - Boot Select

JP17 - Boot Select

JP18 - Boot Select

JP19 - Boot Select Recovery

JP20 - VIO Select

JP21 - DC-OUT

GPIO1 - General Purpose IO

H25 - Smart Battery

I2S1 - I2S 1

I2S2 - I2S 2

I2S3 - I2S 3

J1 - SMARC Interface

J3 - TTL LCD

J6 - HDMI1

J8 - LVDS LCD

J9 - Alternate Function Block 1

J10 - I2C

J11 - HDMI2

J12 - External Battery (RTC backup)

J14 - LVDS Control

JACK1

- DC Power In

JP2 - LCD Power Select

JP3 - Select I2C_LCD for J11

Figure 1-3: Connector Locations (Top Side)

LEC-BASE

Overview 7

Page 14

1.4 Specifications

6.89" (175mm)

2.32" (59mm)

6.73" (171mm)

12.99" (330mm)

LEC-BASE_Top_MechDmn_b

1.4.1 Physical Specifications

Table 1-3 lists the physical dimensions of the baseboard.

Table 1-3: Weight and Footprint Dimensions

Item Dimension

Weight 0.42 kg (0.93 lb)

Height (overall) 33.02 mm (1.30 inches)

Board thickness 2.03 mm (0.08 inches)

Width 175.00 mm (6.89 inches)

Length 330.00 mm (12.99 inches)

1.4.2 Mechanical Specifications

Overall height is measured from the upper board

surface to the top of the highest permanent

component on the upper board surface. This

measurement does not include the cooling solution,

which can vary. The cooling solution will probably

increase this dimension.

Figure 1-4: Mechanical Dimensions (Top Side)

8 Overview

Page 15

2 Interface Signals

This section provides the pin signals for all the non-standard user interfaces on the LEC-BASE.

Signal definitions for standard interfaces such as SATA, USB, PCIe, and DB9 serial connectors

can be found in their respective specification data sheets.

NOTE: The tables in this section define pin sequence using the method in the following example: A 10-pin header with two rows of pins, using odd/even numbering, where pin 2 is directly

across from pin 1, is noted as 10 pins, 2 rows, odd/even pin sequence (1, 2).

2.1.1 SD/eMMC (AFB2) Interface

Table 2-4 lists the pin signals of the SD Card ground plane socket, which provides 60-pins, 2

rows, odd/even pin sequence (1, 2) with 0.02" (0.50mm) pitch. These signals are connected to

the SD/eMMC interface at pins S26 through S36 of the SMARC connector over a 3.3 volt level

shifter.

T able 2-4: SD/eMMC (AFB2) Interface Pin Signals

Pin # Signal

1

2 GND

3 MMC2_D0_3V

4

5

6 GND

7

8

9 MMC2_D1_3V

10

11

12 GND

13

14

15 MMC2_D2_3V

16

17

18

19

20

21 MMC2_D3_3V

22

23

24

25

26

27 MMC2_D4_3V

28

29

30 GND

31

32

33 MMC2_D5_3V

34

35

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

VDD_3V3

GND

GND

GND

GND

VDD_3V3

GND

GND

GND

GND

GND

LEC-BASE

Interface Signals 9

Page 16

Table 2-4: SD/eMMC (AFB2) Interface Pin Signals (Continued)

36 GND

37 GND

38

39 MMC2_D6_3V

40

41

42

43 GND

44

45 MMC2_D7_3V

46

47

48

49 GND

50

51 MMC2_CK_3V

52

53

54

55 GND

56

57 MMC2_CMDD_3V

58

59 GND

60

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

NOTE: The shaded table cells denote power or ground.

2.1.2 Camera 0 (CAM0)

Table 2-5 lists the pin signals of the Camera0 header, which provides 10-pins, 2 rows, odd/even

pin sequence (1, 2) with 0.079" (2.00mm) pitch. These signals are connected directly to the MIPI

CSI camera interface at the SMARC connector.

Table 2-5:Camera 0 Pin Signals (CAM0)

Pin # Signal

1 CSI1_CK+

2 CSI1_CK3 CSI1_D0+

4 CSI1_D05 CSI1_D1+

6 CSI1_D17 CSI1_D2+

8 CSI1_D29 CSI1_D3+

10 CSI1_D3-

10 Interface Signals

Page 17

LEC-BASE

2.1.3 Camera 1 (CAM1)

Table 2-6 lists the pin signals of the Camera1 header, which prov id es 1 0- pins, 2 rows , od d/even

pin sequence (1, 2) with 0.079" (2.00mm) pitc h. These signals are connected to the camera

control signals at the SMARC connector.

Table 2-6: Camera 1 Pin Signals (CAM1)

Pin # Signal

1 CSI0_CK+

2 CSI0_CK3 CSI0_D0+

4 CSI0_D05 CSI0_D1+

6 Not Connected

7 CSI0_D18 Not Connected

9

10

GND

GND

NOTE: The shaded table cells denote ground.

2.1.4 Camera 3 (CAM3)

Table 2-7 lists the pin signals of the Camera 3 header, which provides 10-pins, 2 rows, odd/even

pin sequence (1, 2) with 0.079" (2.00mm) pitc h. These signals are connected to the camera

control signals at the SMARC connector.

Table 2-7: Camera 3 Pin Signals (CAM3)

Pin # Signal

1 CAM0_nPWR

2 I2C_CAM_CLK_1.8V

3 Not Connected

4 I2C_CAM_DATA_1.8V

5 Not Connected

6 Not Connected

7 CAM0_nRST_3V over the 3.3V level shifter

8 Not Connected

95 Volt

10 Not Connected

Interface Signals 11

Page 18

2.1.5 Controller Area Network (CAN1)

Table 2-8 and T able 2-9 list the pin signals of the Controller Area Network interface (CAN1A and

CAN1B), which provides standard dual DB9 connectors.

Table 2-8: Controller Area Network Signals (CAN1A)

Pin # Signal

1

2CAN1_H

3

4

5

6

7CAN1_L

8

9

NOTE: These pins are connected over the CAN transceiver to the CAN0 SMARC connector

interface (pins P143 and P144.)

Pin # Signal

1

2CAN2_H

3

4

5

6

7CAN2_L

8

9

Not Connected

Not Connected

Not Connected

GND

Not Connected

Not Connected

5 Volt

Table 2-9: Controller Area Network Signals (CAN1B)

Not Connected

Not Connected

Not Connected

GND

Not Connected

Not Connected

5 Volt

NOTE: These pins are connected over the CAN transceiver to the CAN1 SMARC connector

interface (pins P145 and P146.)

2.1.6 Cell Charger/Battery Supply (CN4)

Table 2-10 lists the pin signals of the Cell Charger/Battery Supply header, which provides 12

pins in 2 rows, odd/even pin sequence (1, 2), and 0.079" (2.00mm) pitch.

Table 2-10: Cell Charger/Battery Supply (CN4)

Pin # Signal

1

2+VE

3

4

5

6

7

8

9

10

11

12

Therm1

Cell_4 (positive terminal of); connected to pins 2, 4, 6

+VE

Cell_3 (positive terminal of)

+VE

Cell_2

(positive terminal of)

-VE

Cell_1 (positive terminal of)

-VE

-VE (negative terminal of); connected to pins 8, 10, 12

-VE

12 Interface Signals

Page 19

LEC-BASE

2.1.7 GPIO1

Table 2-11 lists the pin signals of the General Purpose IO header, which provides 12 pins in 2

rows, odd/even pin sequence (1, 2), and 0.079" (2.00mm) pitch. These pins are connected to

the SMARC connector over the 3.3 volt level shifter.

Ta bl e 2-11: General Purpose IO (GPIO1)

Pin # Signal

1

2

3

4

5

6

7

8

9

10

11

12

GPIO_28_3V (connected to SMARC pin P119)

CAM0_nPWREN_3V

(connected to SMARC pin P108)

GPIO_29_3V (connected to SMARC pin P112)

CAM1_nPWREN_3V

(connected to SMARC pin P109)

GPIO_177_3V (connected to SMARC pin P116)

CAM0_nRST_3V (connected to SMARC pin P110)

GPIO_54_3V (connected to SMARC pin P117)

CAM1_nRST_3V

(connected to SMARC pin P111)

GPIO_55_3V (connected to SMARC pin P113)

CAM_FLD_3V

(connected to SMARC pin P115)

GPIO_56_3V (connected to SMARC pin P114)

GPIO_27_3V (connected to SMARC pin P118)

NOTE: Signal names relative only to the LEC-3517 module.

2.1.8 Smart Battery (H25)

Table 2-12 lists the pin signals of the Smart Battery header, which provides 9 pins in a single row

with 0.079" (2.00mm) pitch. These signals are connected to and controlled by the onboard

LTC1760 smart battery charger controller.

Table 2-12: Smart Battery (H25)

Pin # Signal

1

2

3

4

5

6 TH1 (Thermistor Force/Sense connection to LTC1760 charger controller)

7

8 GND

9

NOTE: Shaded table cells denote ground.

+VE (battery and charging voltage)

+VE (battery and charging voltage)

+VE (battery and charging voltage)

1760_SCL1

(I2C bus from LTC1760 charger controller)

1760_SDA1 (I2C bus from LTC1760 charger controller)

GND

GND

Interface Signals 13

Page 20

2.1.9 I2S1

Table 2-13 lists the pin signals of the I2S1 header, which provides 6 pins in a single row with

0.098" (2.50mm) pitch. These pins are connected to the SMARC connector over the 3.3 volt

level shifter.

Table 2-13: I2S1 Signals (I2S1)

Pin # Signal

1

2

3

4

5

6

VDD_3V3

MCBSP1_FSX_3V (connected to SMARC pin S39)

MCBSP1_DX_3V (connected to SMARC pin S40)

MCBSP1_DR_3V (connected to SMARC pin S41)

MCBSP1_CLKX_3V (connected to SMARC pin S42)

GND

NOTE: Shaded table cells denote power or ground.

2.1.10 I2S2

Table 2-14 lists the pin signals of the I2S2 header, which provides 6 pins in a single row with

0.098" (2.50mm) pitch. These pins are connected to the SMARC connector over the 3.3 volt

level shifter.

Table 2-14: I2S2 Signals (I2S2)

Pin # Signal

1

2

3

4

5

6

VDD_3V3

MCBSP2_FSX_3V (connected to SMARC pin S43)

MCBSP2_DX_3V (connected to SMARC pin S44)

MCBSP2_DR_3V (connected to SMARC pin S45)

MCBSP2_CLKX_3V (connected to SMARC pin S46)

GND

NOTE: Shaded table cells denote power or ground.

2.1.11 I2S3

Table 2-15 lists the pin signals of the I2S3 header, which provides 6 pins in a single row with

0.098" (2.50mm) pitch. These pins are connected to the SMARC connector over the 3.3 volt

level shifter.

Table 2-15: I2S3 Signals (I2S3)

Pin # Signal

1

2

3

4

5

6

NOTE: Shaded table cells denote power or ground.

VDD_3V3

MCBSP3_FSX_3V (connected to SMARC pin S50)

MCBSP3_DX_3V (connected to SMARC pin S51)

MCBSP3_DR_3V (connected to SMARC pin S52)

MCBSP3_CLKX_3V (connected to SMARC pin S53)

GND

14 Interface Signals

Page 21

LEC-BASE

2.1.12 Alternate Function Block 1 (J9)

Table 2-16 lists the pin signals of the Alternate Function Block 1 header which provides 34-pins,

2 rows, odd/even pin sequence (1, 2) with 0.079" (2.0mm) pitch. These pins are connected

dirctly to the SMARC connector.

Table 2-16: Alternate Function Block 1 Interface Pin Signals (J9)

Pin # Signal

1

2 VDD_5V

3

4 GND

5

6

7

8

9

10 GND

11

12

13

14

15 GND

16 GND

17

18

19 GND

20

21

22 GND

23

24

25

26

27

28 GND

29 GND

30

31

32

33

34 GND

VDD_5V

AFB0_OUT (connected to SMARC pin S17)

GND

AFB_DIFF0+ (connected to SMARC pin S62)

AFB1_OUT

AFB_DIFF0AFB2_OUT

GND

AFB_DIFF1+ (connected to SMARC pin S65)

AFB3_IN

AFB_DIFF1-

AFB4_IN (connected to SMARC pin S21)

AFB_DIFF2+

AFB_DIFF2AFB5_IN

GND

AFB_DIFF3+

AFB6_PTIO

AFB_DIFF3AFB7_PTIO

AFB_DIFF4+

AFB8_PTIO

AFB_DIFF4AFB9_PTIO

(connected to SMARC pin S18)

(connected to SMARC pin S63)

(connected to SMARC pin S19)

(connected to SMARC pin S20)

(connected to SMARC pin S66)

(connected to SMARC pin S68)

(connected to SMARC pin S69)

(connected to SMARC pin S22)

(connected to SMARC pin S71)

(connected to SMARC pin S23)

(connected to SMARC pin S72)

(connected to SMARC pin S24)

(connected to SMARC pin S74)

(connected to SMARC pin S55)

(connected to SMARC pin S75)

(connected to SMARC pin S56)

NOTE: The shaded table cells denote ground or power.

Interface Signals 15

Page 22

2.1.13 I2C (J10)

Table 2-17 lists the pin signals of the I2C header, which provides 2 pins with 0.049" (1.25mm)

pitch. These pins are connected to the SMARC connector over the 3.3 volt level shifter.

Table 2-17: I2C Signals (J10)

Pin # Signal

1

2

I2C_GP_DAT_3V (connected to SMARC pin S48)

I2C_GP_CK_3V (connected to SMARC pin S49)

2.1.14 Battery (J12)

Table 2-18 lists the pin signals of the battery header, which provides 2 pins with 0.049"

(1.25mm) pitch.

Table 2-18: Battery Signals (J12)

Pin # Signal

1

2

V_RTC

GND

NOTE: Shaded table cells denote power or ground.

2.1.15 LVDS Con trol (J14)

Table 2-19 lists the pin signals of the Smart Battery header, which provides 8 pins in two rows

with odd/even pin sequence (1,2) and 0.01" (2.54mm) pitch.

Table 2-19: LVDS Control Signals (J14)

Pin # Signal

1

2

3

4 GND

5

6 GND

7

8

GND

PNLPWR (display supply voltage, selectable with JP13)

LVDS_BKL_CTRL (backlight control, selectable with JP12)

LCD_nEN (backlight enable)

Not Connected

BLPWR

(backlight supply voltage, selectable with JP14)

NOTE: Shaded table cells denote ground.

2.1.16 TTL Panel Control (PC1)

Table 2-20 lists the pin signals of the TTL Panel Control header, which provides 6 pins in a single row with 0.098" (2.50mm) pitch. These pins are connected directly to the display control pins

at the SMARC connector.

Table 2-20: LVDS Control Signals (PC1)

Pin # Signal

1

2

3

4 Not Connected

5 Not Connected

6 LCD_RESET (Active Low)

LCD_DE (connected over the 3.3 volt level shifter)

LCD_BKLT_PWM

LCD_VDD_EN

16 Interface Signals

Page 23

LEC-BASE

2.1.17 Power Management (PW1)

Table 2-21 lists the pin signals of the Power Management header, which provides 14 pins in 2

rows, odd/even pin sequence (1, 2), and 0.079" (2.00mm) pitch. These pins are connected

directly to the Power Management pins at the SMARC connector.

Table 2-21: Power Management Signals (PWM1)

Pin # Signal

1

2 VIN_PWR_nBAD

3

4 nCHARGING

5

6 CHARGE_nPRSNT

7

8 CHARGE_nSTBY

9

10 CARRIED_PWR_ON

11

12

13 GND

14

WDT_TIME

nLID

nSLEEP

nBATLOW

nTEST

Not Connected

Not Connected

GND

NOTE: Shaded table cells denote ground.

2.1.18 SPI0

Table 2-22 lists the pin signals of the System Packet Interface 0 header, which provides 5 pins in

a single row with 0.098" (2.50mm) pitch. These pins are connected to the SMARC connector

over the 3.3 volt level shifter.

Table 2-22: System Packet Interface 0 Signals (SPI0)

Pin # Signal

1

2

3

4

5

SPI2_CLK_3V (connected to SMARC pin P56)

SPI2_SOMI_3V (connected to SMARC pin P57)

SPI2_SIMO_3V (connected to SMARC pin P58)

SPI2_CS0_3V

SPI2_CS1_3V

(connected to SMARC pin P54)

(connected to SMARC pin P55)

NOTE: The signals for this header are defined by the module CPU as “SPI2”, but the header is

labelled “SPI0” on the board.

2.1.19 SPI1

Table 2-23 lists the pin signals of the System Packet Interface 1 header, which provides 4 pins in

a single row with 0.098" (2.50mm) pitch. These pins are connected to the SMARC connector

over the 3.3 volt level shifter.

Table 2-23: System Packet Interface 1 Signals (SPI1)

Pin # Signal

1

2

3

4

SPI1_CS0_3V (connected to SMARC pin P43)

SPI1_CLK_3V (connected to SMARC pin P44)

SPI1_SOMI_3V (connected to SMARC pin P45)

SPI1_SIMO_3V

(connected to SMARC pin P46)

Interface Signals 17

Page 24

2.1.20 LVDS

Table 2-24 lists the pin signals of the LVDS header which provides 34-pins, 2 rows, odd/even p in

sequence (1, 2) with 0.079" (2.0mm) pitch. These pins are connected directly to the LVDS interface at the SMARC connector.

Table 2-24: LVDS Interface Pin Signals (J8)

Pin # Signal Description

1 I2C_LCD_DAT System Management Data

2 I2C_LCD_CK System Management Clock

3

4

5 GND Ground

6 LVDS_A0N Data Negative Output

7 LVDS_A0P Data Positive Output

8 LCD_BLPWM_3V Backlight PWM(3.3V)

9 LVDS_A1N Data Negative Output

10 LVDS_A1P Data Positive Output

11 LVDS_BL_EN Backlight Enable, if supported

12 LVDS_A2P Data Positive Output

13 L VDS_A2N Data Negative Output

14 eDP_HPD Display Port Control

15 LVDS_CKN Clock Negative

16 LVDS_CKP Clock Positive

17

18 LVDS_A3P Data Positive Output

19 L VDS_A3N Data Negative Output

20

21 LCD_DUAL_PCK LCD Dual Display Pixel Clock

22 LCD_BKLTPWM_5V LCD Backlight Power Management (5V)

23

24 LCD_BKEN_5V LCD Backlight Enable (5V)

25 SEL68 Connected over 4.7 KOhm to GND

26

27 R/L Connected over 4.7 KOhm to 3.3V

28 NC Not Connected

29

30 VDD_3V3 3.3V Supply

31 U/D Connected over 4.7 KOhm to 3.3V

32

33 REV Connected over 4.7 KOhm to 3.3V

34

PNL_PWR Panel Power [JP2 (1-2) for 5V, (2-3) for 3.3V]

PNL_PWR Panel Power [JP2 (1-2) for 5V, (2-3) for 3.3V]

PNL_PWR Panel Power [JP2 (1-2) for 5V, (2-3) for 3.3V]

GND Ground

GND Ground

GND Ground

GND Ground

VDD_5V 5V Supply

GND Ground

NOTE: The shaded table cells denote power or ground.

18 Interface Signals

Page 25

LEC-BASE

2.1.21 TTL

Table 2-25 lists the pin signals of the TTL header which provides 34-pins, 2 rows, odd/even pin

sequence (1, 2) with 0.079" (2.0mm) pitch. These pins are connected directly to the LCD interface at the SMARC connector .

Table 2-25: TTL Video Interface Pin/Signal Descriptions (J3)

Pin # Signal Description

1 FP0 Flat Panel 0 – data output, Blue0 (24-bit)

2 FP16 Flat Panel 16 – data output, Red0 (24-bit)

3 FP1 Flat Panel 1 – data output, Blue1 (24-bit)

4 FP17 Flat Panel 17 – data output, Red1 (24-bit)

5 FP2 Flat Panel 2 – data output, Blue0 (18-bit); Blue2 (24-bit)

6 FP18 Flat Panel 18 – data output, Red0 (18-bit), Red2 (24-bit)

7 FP3 Flat Panel 3 – data output, Blue1 (18-bit); Blue3 (24-bit)

8 FP19 Flat Panel 19 – data output, Red1 (18-bit), Red3 (24-bit)

9 FP4 Flat Panel 4 – data output, Blue2 (18-bit); Blue4 (24-bit)

10 FP20 Flat Panel 20 – data output, Red2 (18-bit), Red4 (24-bit)

11 FP5 Flat Panel 5 – data output, Blue3 (18-bit); Blue5 (24-bit)

12 FP21 Flat Panel 21 – data output, Red3 (18-bit), Red5 (24-bit)

13 FP6 Flat Panel 6 – data output, Blue4 (18-bit); Blue6 (24-bit)

14 FP22 Flat Panel 22 – data output, Red4 (18-bit), Red6 (24-bit)

15 FP7 Flat Panel 7 – data output, Blue5 (18-bit); Blue7 (24-bit)

16 FP23 Flat Panel 23 – data output, Red5 (18-bit), Red7 (24-bit)

17 FP8 Flat Panel 8 – data output, Green0 (24-bit)

18 VSYNC Vertical Sync

19 FP9 Flat Panel 9 – data output, Green1 (24-bit)

20 HSYNC Horizontal Sync

21 FP10 Flat Panel 10 – da ta output, Green0 (18-bit), Green2 (24-bit)

22 LCD_PCLK Pixel Clock – This signal provides the clock for transferri ng digital pixel data

23 FP11 Flat Panel 11 – data output, Green1 (18-bit), Green3 (24-bit)

24

25 FP12 Flat Panel 12 – da ta output, Green2 (18-bit), Green4 (24-bit)

26

27 FP13 Flat Panel 13 – da ta output, Green3 (18-bit), Green5 (24-bit)

28

29 FP14 Flat Panel 14 – da ta output, Green4 (18-bit), Green6 (24-bit)

30

31 FP15 Flat Panel 15 – da ta output, Green5 (18-bit), Green7 (24-bit)

32

33

34

VDD_5V 5 Volt Supply

VDD_5V 5 Volt Supply

VDD_5V 5 Volt Supply

LCD_3V3 3.3 Volt Supply

LCD_3V3 3.3 Volt Supply

GND Ground

GND Ground

NOTE: The shaded table cells denote power or ground.

Interface Signals 19

Page 26

20 Interface Signals

Page 27

Appendix A Technical Support

Contact us should you require any service or assistance.

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Zhonghe District

New Taipei City 235, Taiwan

ᄅקؑխࡉ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: Ϟ⍋Ꮦ⌺ϰᮄᓴ∳催⾥ᡔು㢇䏃 300 ো(201203)

300 Fang Chun Rd., Zhangjiang Hi-Tech Park,

Pudong New Area, Shanghai, 201203 China

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

ADLINK Technology, Inc. provides a number of methods for contacting Technical Support listed

in Table A-1 below. Requests for support through Ask an Expert are given the high est prior itie s,

and usually will be addressed within one working day.

ADLINK Ask an Expert – This is a comprehensive support center designed to meet all

your technical needs. This service is free and available 24 hours a day through the

ADLINK web site at http://www.adlinktech.com/AAE/

base of Frequently Asked Questions, which will help you with the common information

requested by most customers. This is a good source of information to look at first for your

technical solutions. However, you must register online if you wish to use the Ask a Question feature.

ADLINK strongly suggests that you register with the web site. By creating a profile on the

ADLINK web site, you will have a portal page called “My ADLINK”, unique to you with

access to exclusive services and account information.

Personal Assistance – You may also request personal assistance by creating an Ask an

Expert account and then going to the Ask a Question feature. Requests can be submitted 24 hours a day, 7 days a week. You will receive immediate confirmation that your

request has been entered. Once you have submitted your r equest, yo u m ust log in to go

to the My Question area where you can check status, update your request, and access

other features.

Download Service – This service is also free and available 24 hours a day at

http://www.adlinktech.com

. For certain downloads such as technical documents and sof t-

ware, you must register online before you can log in to this service.

. This includes a searchable data-

LEC-BASE

Table A-1: Technical Support Contact Information

Method Contact Information

Ask an Expert http://www.adlinktech.com/AAE/

Web Si te http://www.adlinktech.com

Standard Mail

21

Page 28

Table A-1: Technical Support Contact Information (Continued)

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ(100085)

Rm. 801, Power Creative E, No. 1 Shang Di East Rd.

Beijing, 100085 China

Tel: +86-10-5885-8666

Fax: +86-10-5885-8626

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

A1 2 ὐ C (518057)

2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7

High-Tech Industrial Park S., Shenzhen, 518054 China

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

LiPPERT ADLINK Technology GmbH

Address: Hans-Thoma-Strasse 11, D-68163

Mannheim, Germany

Tel: +49-621-43214-0

Fax: +49-621 43214-30

Email: emea@adlinktech.com

ADLINK Technology, Inc. (French Liaison Office)

Address: 6 allée de Londres, Immeuble Ceylan

91940 Les Ulis, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: ͱ101-0045 ᵅҀ䛑ҷ⬄⼲⬄䤯ފ⬎ 3-7-4

⼲⬄ 374 ɛɳ 4F

KANDA374 Bldg. 4F, 3-7-4 Kanda Kajicho,

Chiyoda-ku, Tokyo 101-0045, Japan

Tel: +81-3-4455-3722

Fax: +81-3-5209-6013

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 137-881 昢殾柢 昢爎割 昢爎堆嵢 326, 802 (昢爎壟, 微汾瘶捒娯)

802, Mointer B/D, 326 Seocho-daero, Seocho-Gu,

Seoul 137-881, Korea

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre

Singapore 349584

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: #50-56, First Floor, Spearhead Towers

Margosa Main Road (between 16th/17th Cross)

Malleswaram, Bangalore - 560 055, India

Tel: +91-80-65605817, +91-80-42246107

Fax: +91-80-23464606

Email: india@adlinktech.com

22

Page 29

Table A-1: Tec hnical Support Contact Information (Continued)

ADLINK Technology, Inc. (Israeli Liaison Office)

Address: 27 Maskit St., Corex Building

PO Box 12777

Herzliya 4673300, Israel

Tel: +972-54-632-5251

Fax: +972-77-208-0230

Email: israel@adlinktech.com

ADLINK Technology, Inc. (UK Liaison Office)

Tel: +44 774 010 59 65

Email: UK@adlinktech.com

LEC-BASE

23

Page 30

24

Loading...

Loading...