Adler 367 Service Manual

367

Spezialnähmaschine

Serviceanleitung

Service Instructions

Instructions de service

Instrucciones de servicio

Instruções de serviço

Istruzioni per il servizio

D

GB

F

E

P

I

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Strasse 190, D-33719 Bielefeld

Telefon +49 (0) 5 21/ 9 25-00 • Telefax +49 (0) 5 21/ 9 25 24 35 • www.duerkopp-adler.com

Ausg./Edition: 07/2006 Printed in Federal Republic of Germany Teile-/Part-No.: 0791 367641

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot,

instruction book and operated by persons with appropriate

training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time

as the entire sewing unit is found to comply with EC directives.

Index Page:

Service instructions class 367

1. General notes ............................................... 3

1.1 Gauges .................................................... 3

1.2 Descriptionofthelockingpositions................................... 4

2. Sewing machine.............................................. 5

2.1 Positionofthearmshaftcrankonthearmshaft........................... 5

2.2 Upper and lower toothed belt wheel/ Toothed belt .......................... 6

2.2.1 Position of the upper toothed belt wheel ................................ 6

2.2.2 Position of the lower toothed belt wheel ................................ 7

2.2.3 Change the toothed belt.......................................... 8

2.3 Bottom feed and stitch regulator gear ................................. 9

2.3.1 Basic adjustment of stitch adjustment (subclass 367-170115; -170315 and

subclass 367-180115; -180315) ..................................... 9

2.3.2 Adjust the 2nd stitch length (subclass 367-170315 and 367-180315) .............. 10

2.3.3 Stitch r egulator gear ............................................ 11

2.3.4 Lifting motion of the feed-dog ...................................... 13

2.3.5 Feeding motion of the feed-dog ..................................... 14

2.3.6 Feed-dog height .............................................. 15

2.4 Needle bar linkage ............................................. 16

2.4.1 Alignment of the needle bar linkage................................... 16

2.4.2 Needle penetration in the feed-dog ................................... 18

2.5 Hook, looping stroke and needle bar height .............................. 19

2.5.1 Looping stroke, distance between hook tip and needle ....................... 19

2.5.2 Needle bar height ............................................. 21

2.6 Bobbin case holder ............................................ 22

2.7 Feeding foot and presser foot ...................................... 23

2.7.1 Stroke of feeding foot and presser foot ................................. 23

2.7.2 Lifting motion of the feeding foot .................................... 24

2.7.3 Sewingfootpressure ........................................... 25

2.8 Stitch length limitation ........................................... 26

2.8.1 Stitch length limitation in case of subclass 367-170115; -170315 and

subclass 367-180115; -180315 ..................................... 26

2.8.2 Stitch length limitation in case of subclass 367-170010 and 367-180010 ............ 27

2.8.3 Equal stitch lengths in case of subclass 367-170115; -170315 and subclass 367-180115; -180315 28

2.9 Settingtheshort-trimming ........................................ 29

2.10 Sewingfootliftandthreadtensionlift ................................. 31

2.10.1 Mechanical sewing foot lift ........................................ 31

2.10.2 Heightoftheliftedsewingfeetandliftlimitation........................... 32

2.10.3 Thread tension lift (subclass 367-170010 and 367-180010) .................... 33

2.11 Thread-guiding parts............................................ 34

2.11.1 Thread regulator .............................................. 34

2.11.2 Threadcontrollerspring.......................................... 35

2.12 Bobbin winder ................................................ 36

GB

Index Page:

2.13 Threadtrimmer............................................... 38

2.13.1 Positionofthecontrolcam........................................ 38

2.13.2 Position of the hook knife ......................................... 39

2.13.3 Armature of the thread trimmer magnet ................................ 40

2.13.4 Cuttingpressure.............................................. 41

2.14 Potentiometerinthearm......................................... 42

2.14.1 Basic adjustment without control panel................................. 42

2.14.2 Basic adjustment with control panel V810 or V820 .......................... 43

2.14.3 Checkadjustmentofpotentiometer................................... 44

2.15 Oillubrication................................................ 45

2.15.1 Hooklubrication .............................................. 46

2.16 Maintenance ................................................ 47

1. General notes

The service instructions on hand describe the adjustment of the

special sewing machine 367.

ATTENTION !

The operations described in the service instructions must only be

executed by qualified staff or correspondingly instructed persons

respectively!

Caution: Danger of injury !

In case of repair, alteration or maintenance work switch off main switch

and disconnect the machine from the pneumatic supply system.

Carry out adjusting operations and functional tests of the running

machine only under observation of all safety measures and with utmost

caution.

The instruction manual on hand describes the adjustment of the

sewing machine in an appropriate sequence. Please observe in this

connection that various setting positions are interdependent. Therefore

it is absolutely necessary to do the adjustment following the described

order.

For all setting operations of parts involved in the stitch formation a new

needle without damage has to be inserted.

Machine covers having to be screwed off and on again for checking

and adjusting operations are not mentioned in the text.

GB

1.1 Gauges

Hint:

Some of the shafts of the special sewing machine 367 are provided

with flat spots. This facilitates the adjustment considerably.

In case of all adjustments on flat spots the first screw in rotation

direction is put on such a flat spot.

1

The locking peg 1 required for adjusting the machine belongs to the

standard accessories. It is located at the bottom side of the oil pan.

–

Tilt machine head to the back.

–

Take the locking peg 1 out of the fixture.

–

Tilt machine head back.

3

1.2 Description of the locking positions

1

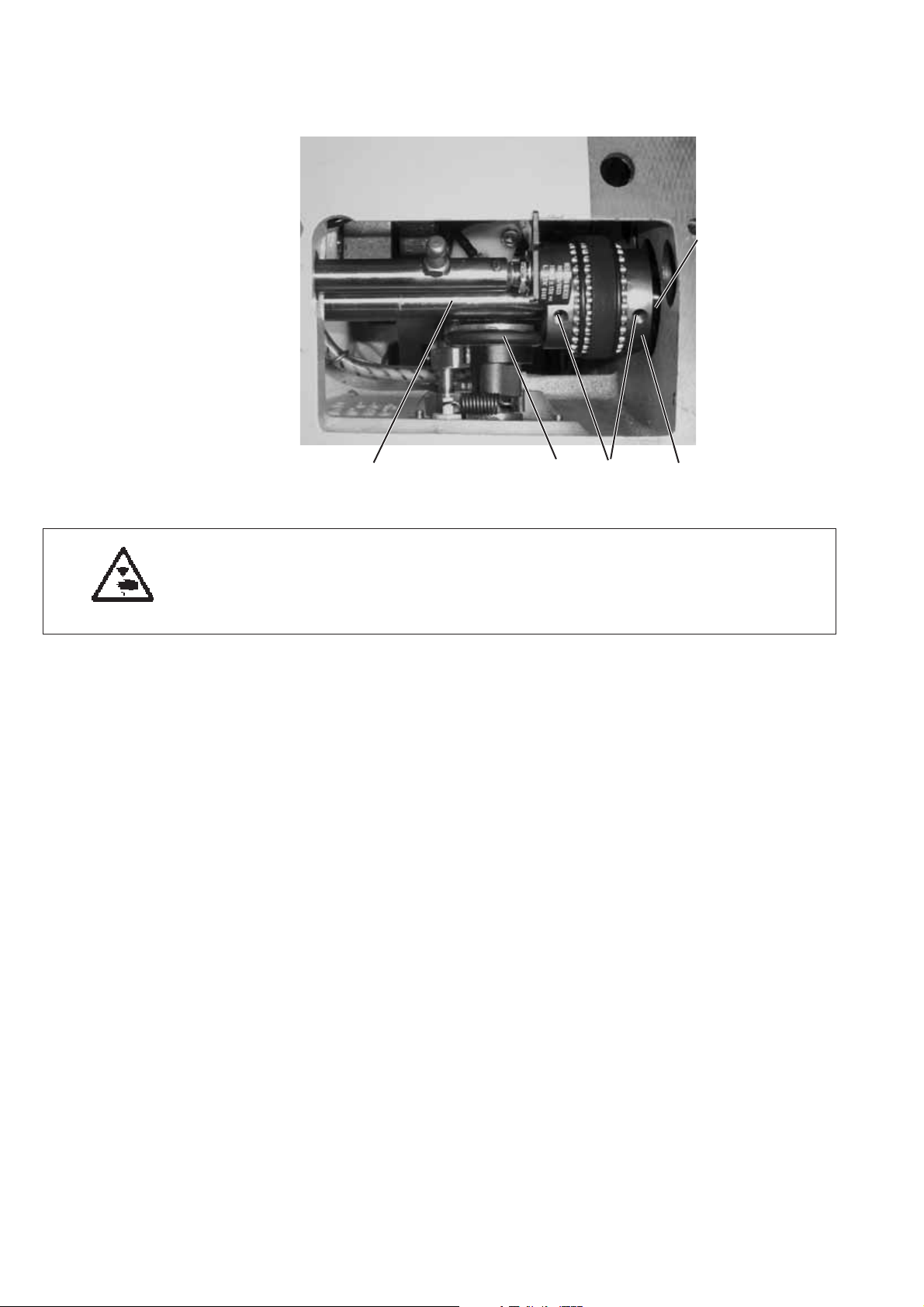

With the locking peg 1 and the arresting grooves 2 and 3 in the arm

shaft crank 4 the sewing machine can be arrested in two adjusting

positions.

Position I = Locking peg Ø 5 mm for large groove

Position II = Locking peg Ø 3 mm for small groove

2

4

3

Adjustments to be done in these two positions:

Position I Looping stroke, needle bar height

Position II Standstill of the feed-dog when moving the

stitch regulator linkage (zero position of gear)

4

2. Sewing machine

2.1 Position of the arm shaft crank on the arm shaft

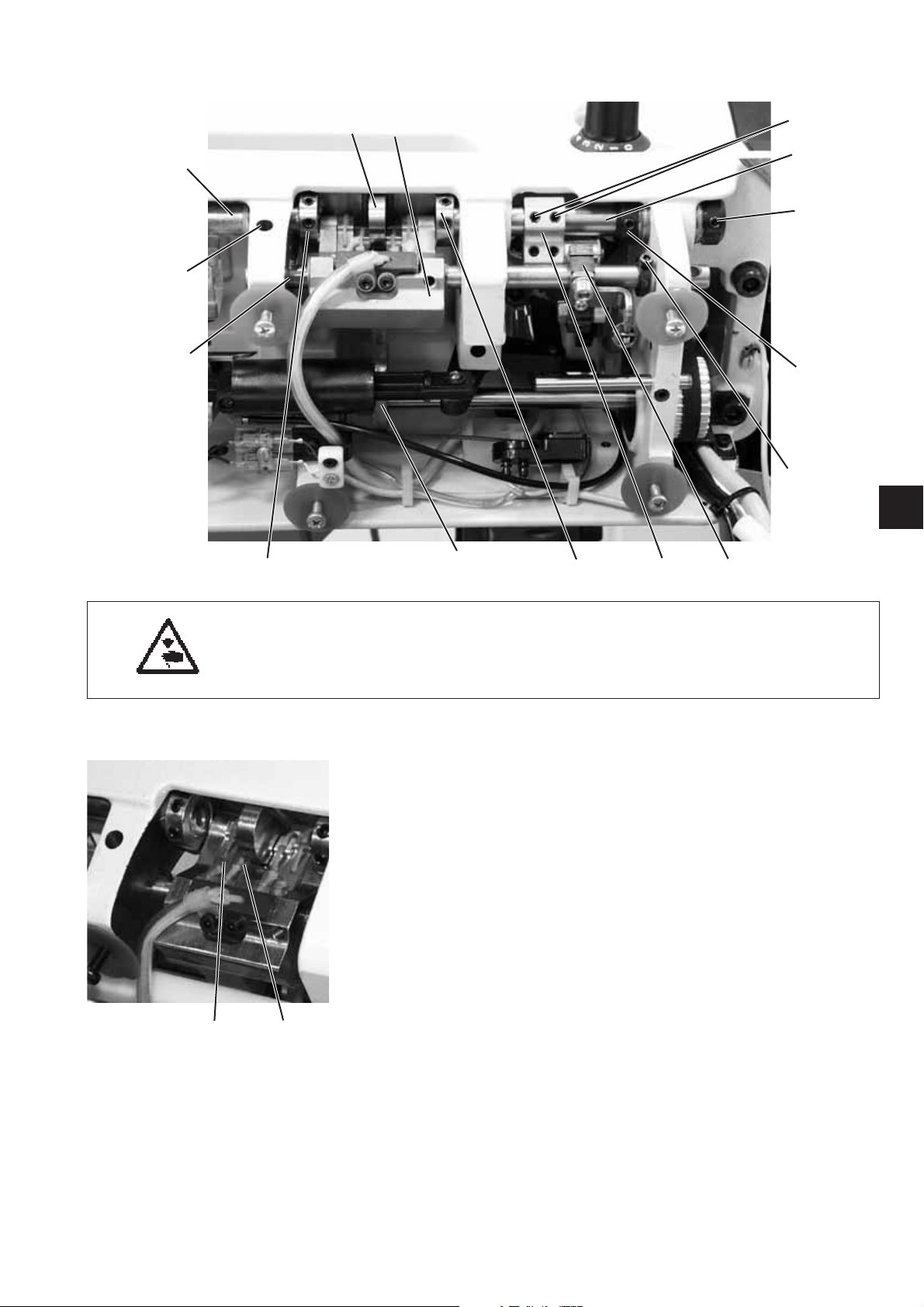

2

4

3

1

21

Caution: Danger of injury !

Switch off main switch.

Check and set the position of the arm shaft crank only when the

machine is switched off.

Standard checking

The arm shaft crank 1 is fastened on the arm shaft 4 with the three

screws 2. The screws must sit on the flat spot 3.

Correction

–

Loosen screws 2 at the arm shaft crank.

–

Twist arm shaft crank 1 on the shaft in such a way that

the screws 2 sit on the flat spot 3.

–

Push arm shaft crank 1 axially to the right as far as it will go.

–

Tighten screws 2.

GB

5

2.2 Upper and lower toothed belt wheel/ Toothed belt

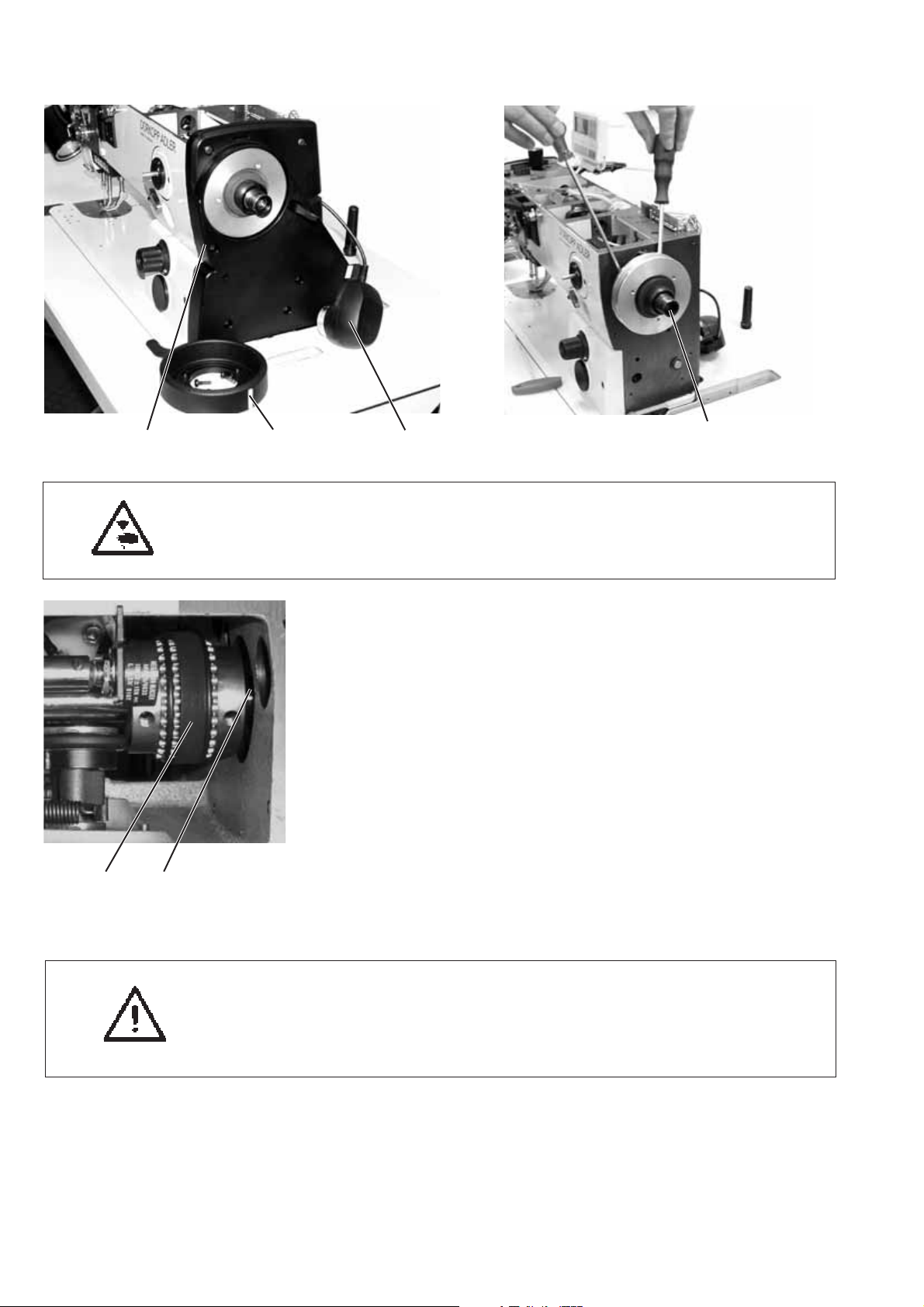

2.2.1 Position of the upper toothed belt wheel

4352

1

Caution: Danger of injury !

Switch off main switch.

Check and set the position of the upper toothed belt wheel only when

the machine is switched off.

Standard checking

The toothed belt wheel 2 is fastened on the arm shaft 4 with two

screws. The screws must sit on the flat spot 1.

The distance between the toothed wheel 2 and the bobbin winder

wheel 3 must amount to 0.8 mm when the bobbin winder is switched

off.

–

Check distance between toothed belt wheel 2 and bobbin winder

wheel 3 by means of a feeler gauge.

Correction

–

Loosen core pins 5 in the toothed belt wheel 2.

–

Turn toothed belt w heel 2 until the screws sit on the flat spot 1 of

the arm shaft 4.

–

Set lateral distance of 0.8 mm between toothed belt wheel 2 and

bobbin winder wheel 3 by a feeler gauge.

–

Tighten core pins 5 in the toothed belt wheel 2.

6

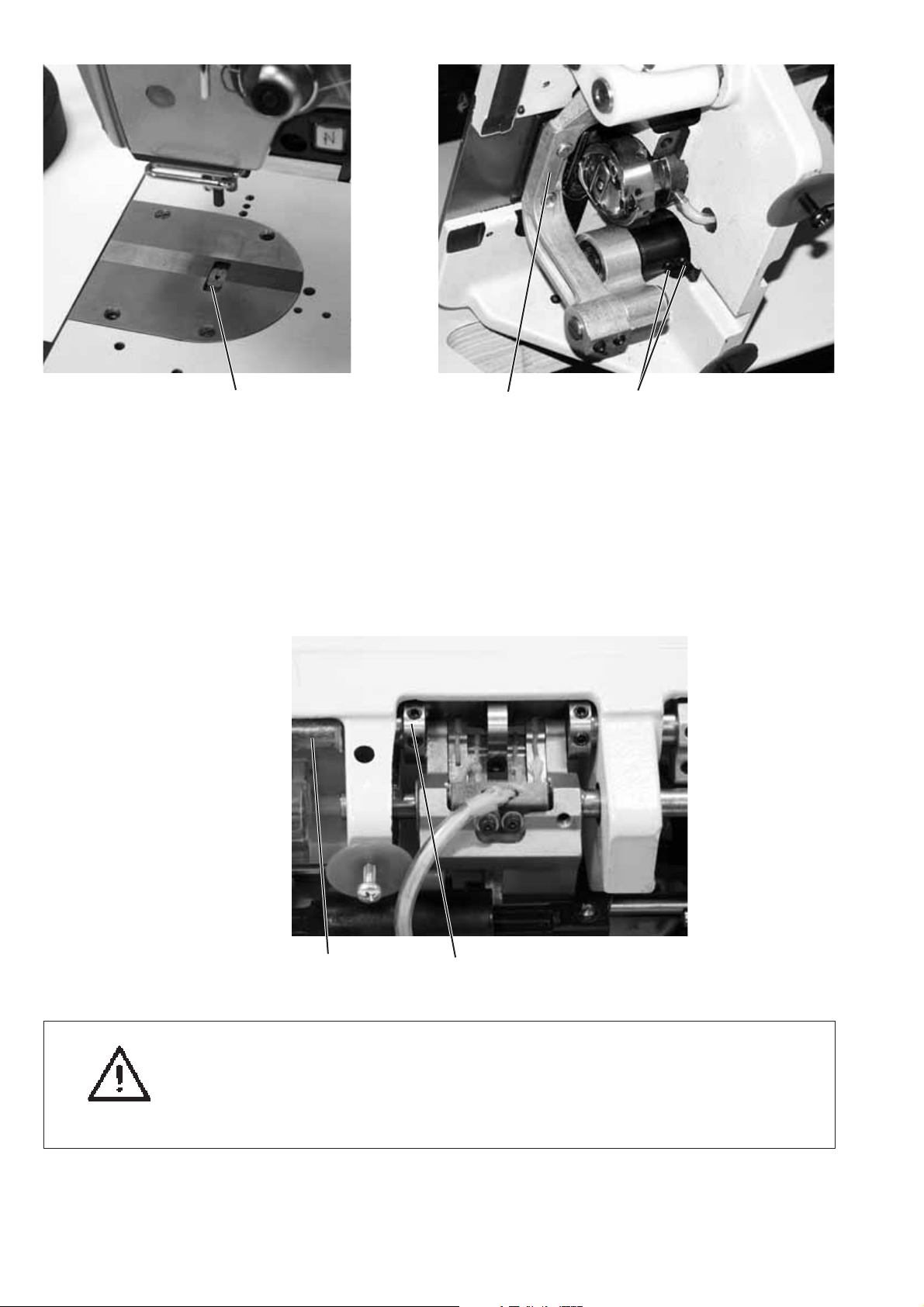

2.2.2 Position of the lower toothed belt wheel

43521

Caution: Danger of injury !

Switch off main switch.

Check and adjust position of the lower toothed belt wheel only when

the sewing machine is switched off.

Standard checking

The lower toothed belt wheel 1 must abut on the bearing 3.

The core pins 5 in the toothed belt wheel 1 must sit on the flat spot of

the lower shaft 4.

–

Check whether the toothed belt wheel abuts on the bearing.

Correction

–

Pull off toothed belt from the lower toothed belt wheel 1.

–

Loosen core pins in the toothed belt wheel.

–

Turn toothed belt w heel 1 until the screws sit on the flat spot of the

lower shaft 4.

–

Hold lower shaft 4 and push toothed belt wheel 1 to the left as far

as it will go.

–

Screw core pins 5 tight in the toothed belt wheel 1.

–

Put the toothed belt 2 on the toothed belt wheel 1 again.

GB

ATTENTION Danger of breakage !

After changing or removing the toothed belt check the following:

Hook adjustment (see chapter 2.5), feeding motion of the feed-dog

(see chapter 2.3.3) and lifting motion of the feed-dog

(see chapter 2.3.4).

7

2.2.3 Change the toothed belt

321

Caution: Danger of injury !

Switch off main switch.

Change the toothed belt only when the machine is switched off.

Remove toothed belt

–

Take off synchronizer 1.

–

Screw off handwheel 2.

–

Screw off belt protection 3.

–

Loosen screws at the handwheel flange 4.

–

Pull out flange 4 together with the bearing by means of two

screwdrivers.

–

Tilt machine head to the back.

–

Pull off toothed belt 6 from the lower toothed belt wheel.

–

Tilt machine head to the front again.

–

Pull toothed belt 6 out through the opening 5.

65

Mount toothed belt

–

Reinsert toothed belt in reverse order.

4

ATTENTION: Danger of breakage !

After changing or removing the toothed belt check the following:

Hook adjustment (see chapter 2.5), feeding motion of the feed-dog

(see chapter 2.3.3) and lifting motion of the feed-dog

(see chapter 2.3.4).

8

2.3 Bottom feed and stitch regulator gear

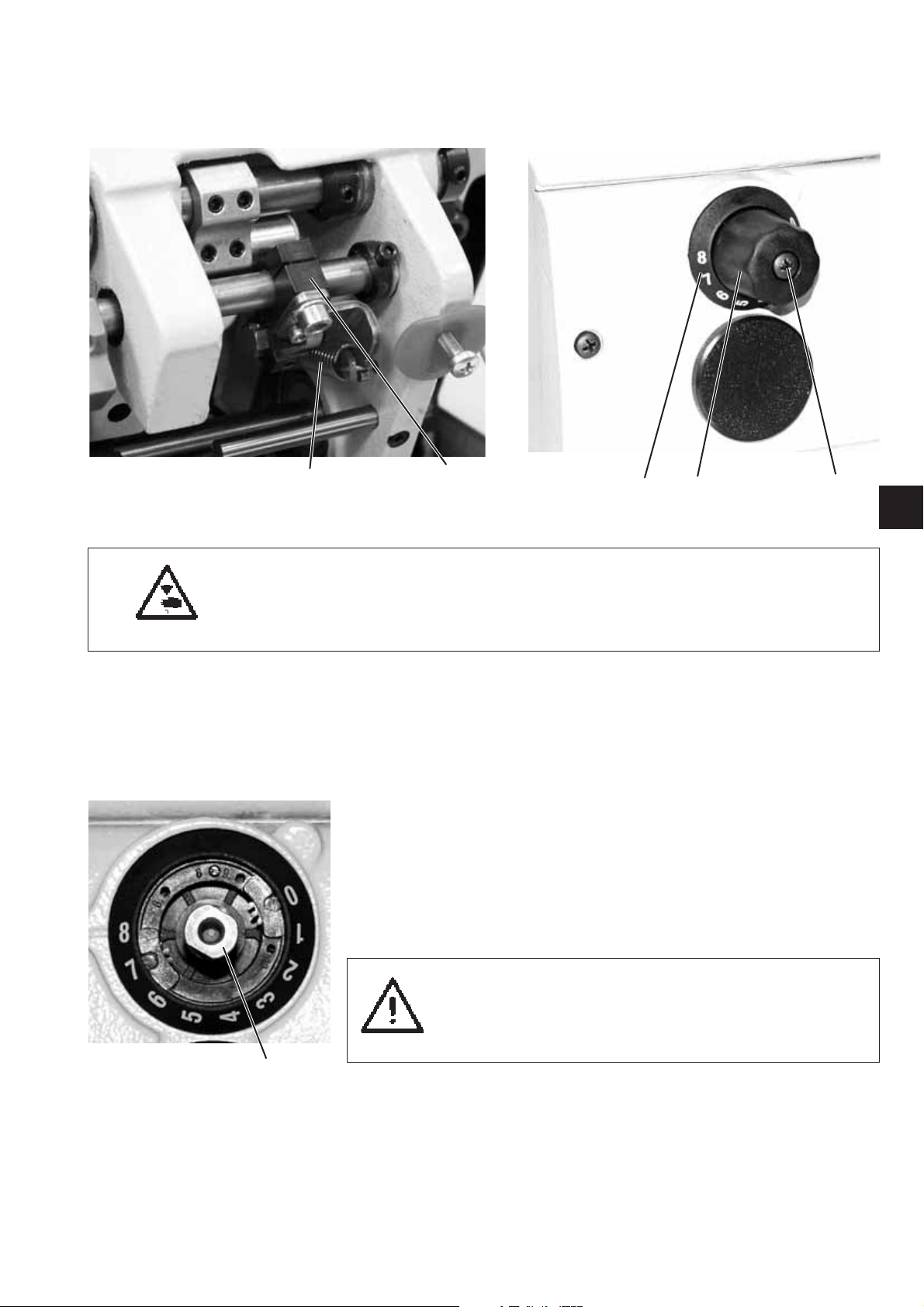

2.3.1 Basic adjustment of stitch adjustment (subclasses 367-170115; -170315 and 367-180115; -180315)

21

Caution: Danger of injury !

Switch off main switch.

Set basic adjustment of the stitch adjustment only when the sewing

machine is switched off.

Standard checking

When the setting wheel 4 is in zero position, the stitch regulator gear

should have the least possible clearance.

–

Set stitch length “0” at the setting wheel 4 (with the subclasses

367-170315 and 367-180315 use the upper setting wheel).

–

Check clearance of the stitch regulator gear at the stitch regulator

lever 1.

Correction

–

Unhook spring 2.

–

Unscrew screw 3 and pull off setting wheel 4.

–

Turn shaft 6 to the right by means of a 10 mm open-end wrench

until the stitch regulator lever 1 has the least possible clearance.

54 3

GB

ATTENTION: Danger of breakage !

Do not turn the shaft to the right too far.

The stitch regulator parts may jam and the

maximum stitch length of 8 mm and 6 mm respectively can

no longer be achieved.

6

–

Setscale5to“0”.

–

Put setting wheel 4 on again and tighten with screw 3.

–

Put spring 2 in again.

–

Check clearance of the stitch regulator lever 1.

9

7 10 9 8

Adjust eccentric

The eccentric 7 has to be adjusted in such a way that the axes of the

two markings 9 and 10 are on a similar level.

–

Loosen screw 8.

–

Turn eccentric in such a way that the axes of the two markings 9

and 10 are intersecting.

–

Tighten screw 8.

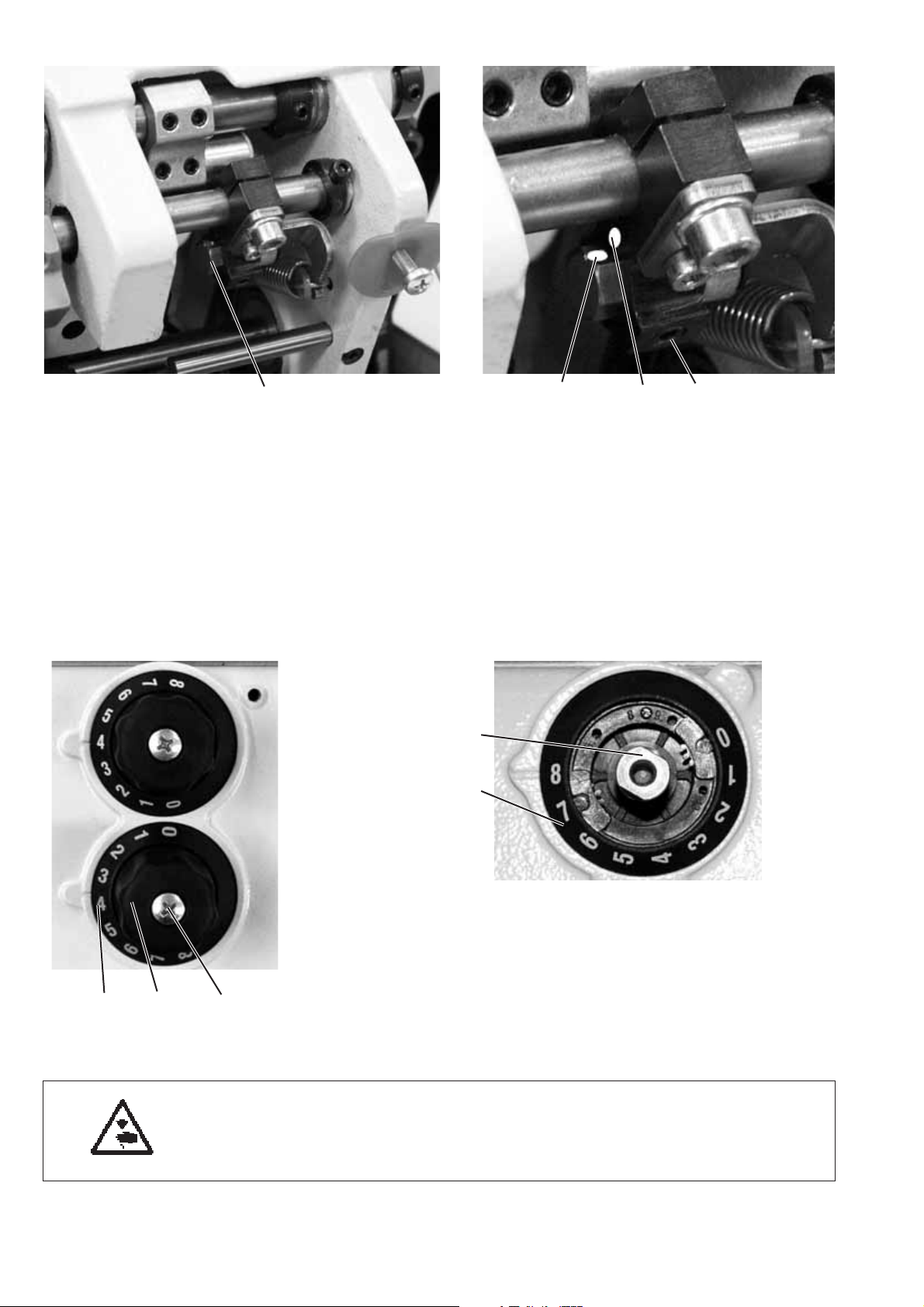

2.3.2 Adjust the 2nd stitch length (subclass 367-170315 and 367-180315)

14

11

11 12 13

10

Only adjust the 2nd stitch length after the stitch regulator gear has

been adjusted.

–

Turn the the upper setting wheel to “4”.

–

Loosen the screw 13 and remove the setting wheel 12.

–

Turn cautiously the shaft 14 clockwise as far as it will go using a

10 mm open-end wrench.

–

Twist the scale 11 to “4”.

–

Put the setting wheel 12 back again and fix it using the screw 13.

Caution: Danger of injury !

Switch off main switch.

Set the stitch adjustment basic setting only when the sewing machine

is switched off.

2.3.3 Stitch regulator gear

13

15

16 17

12

1

9

2

3

14

GB

87654

11 10

Caution: Danger of injury !

Switch off main switch.

Adjust bottom feed and stitch regulator gear only when the sewing

machine is switched off.

–

Set stitch regulator lever and setting wheel respectively on “0”.

–

Loosen all screws at the left sliding shaft 9 and the right sliding

shaft 1:

- at the adjusting rings 2,3 and 14

- screws 12 at lever 5

- at the shaft supports 6 and 8 of the gear linkage

–

Loosen screw at the stitch regulator block 4.

–

Loosen screws at the pusher eccentric 7.

–

Loosen screw 13 for bearing bolt 15.

–

Push right sliding shaft 1 into the shaft support 6 so far that there is

a distance of 0.1 mm from its left side.

–

Tighten screws at the shaft support 6.

–

Align gear frame 16 laterally in such a way that the gear linkage

with the two shaft supports 6 and 8 has equal clearance on the left

and on the right.

–

Tighten adjusting rings 2 and 3.

–

Set gear on “0”. This can be achieved by twisting the frame 17.

The connectors 10 and 11 must be in parallel position.

–

Tighten screws at the stitch regulator block 4.

–

Place frame 17 axially close to the bearing bolt 15 (tighten with

screw 13) and to the adjusting ring 14.

–

Tighten screws at the pusher eccentric 7.

11

14

13 12

–

Loosen screws 12.

–

Align feed-dog support 13 in such a w ay that the feed-dog 14 in the

throat plate has an equal lateral clearance.

In longitudinal direction it should stand approximately in the center.

–

Tighten screws at the left shaft support 8 of the gear linkage.

–

Tighten screw 12.

12

98

ATTENTION: Danger of breakage !

The shaft 9 must not project from the shaft support 8 of the gear

linkage.

If this is the case, the whole gear has to be shifted to the right.

Loading...

Loading...