367

Spezialnähmaschine

Bedienanleitung

Operating Instructions

Instructions de maniement

D

GB

F

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 5 21/ 9 25-00 • Telefax +49 (0) 5 21/ 9 25 24 35 • www.duerkopp-adler.com

Ausg./Edition: 12/04 Printed in Federal Republic of Germany Teile-/Part-No.: 0791 367741

Content page:

Preface and general safety instructions

Part 1: Operating Instructions Class 367

1. Product description ............................................ 5

2. Designated use ............................................... 5

3 Subclasses .................................................. 6

4 Optional equipment ............................................ 6

5 Technical data ................................................ 7

6. Operation

6.1 Threading the needle thread ........................................ 9

6.2 Adjusting the needle-thread tension ................................... 11

6.3 Opening the needle-thread tensioner ................................... 11

6.4 Adjusting the thread regulator ....................................... 12

6.5 Winding on the looper thread ........................................ 13

6.6 Changing the looper-thread bobbin .................................... 14

6.7 Setting the looper-thread tension ..................................... 15

6.8 Changing the needle ............................................. 16

6.9 Liftingthesewingfoot............................................ 17

6.10 Lockingthesewingfeetintheupposition................................ 18

6.11 Settingthesewing-footpressure ..................................... 18

6.12 Settingthesewing-footstroke....................................... 19

6.13 Setting the stitch length ........................................... 20

6.14 Machine-arm keypad (subclass-170115; -170315; -180115; -180315) ............... 21

7. Direct-current positioning actuator

7.1 General ..................................................... 22

7.2 V810 operating panel ............................................ 22

7.2.1 Operating and display elements on the V810 operating panel .................... 22

7.2.2 Key functions on the V810 operating panel ............................... 23

7.2.3 Meaning of symbols on the V810 operating panel ........................... 23

7.2.4 Changing operator-level parameter values ............................... 24

7.2.5 Reducing the maximum rotation speed .................................. 24

7.2.6 Enteringthetechnician-levelcode .................................... 24

7.3 V820 operating panel ............................................ 25

7.3.1 Operating and display elements on the V820 operating panel .................... 25

7.3.2 Key functions on the V820 operating panel ............................... 25

7.3.3 Meaning of symbols on the V820 operating panel ........................... 27

Content page:

7.3.4 Changing operator-level parameter values ............................... 27

7.3.5 Reducing the maximum rotation speed .................................. 28

7.3.6 Fastinformationdisplayandsettingsentry(HIT)............................ 28

7.3.7 Enteringthetechnician-levelcodenumber ............................... 28

7.3.8 Seam programming with the V820 operating panel........................... 28

7.4 EFKAcontrolsparameterlist........................................ 29

7.5 Status and error messages on the V810 and V820 operating panels ................ 30

8. Coupling-positioning actuator

8.1 General ..................................................... 31

8.2 Operationofthe6F82FAsewing-drivecontrol ............................. 32

8.2.1 Operatingelementsinthe6F82FAsewing-drivecontrol ....................... 32

8.2.2 Keyfunctionsinthe6F82FAsewing-drivecontrol ........................... 32

8.2.3 Changing operator-level parameter values ............................... 32

8.2.4 Reducing the maximum rotation speed .................................. 33

8.2.5 Enteringthetechnician-levelcodenumber ............................... 33

8.3 6F82FA control operator-level parameter list .............................. 33

8.4 Status and error messages on the V810 and V820 operating panels ................ 33

9. Operation

9.1 Subclass 367-170010; -180010 ...................................... 34

9.2 Subclass -170115; -170315; -180115; -180315 ............................. 35

10. Maintenance

10.1 Cleaning and testing ............................................. 37

10.2 Lubrication ................................................... 39

4

1. Product description

2. Designated use

The Dürkopp Adler 367 is a special sewing machine for first-class

single-needle decorative seams in light to medium-heavy material.

It is a single-needle flatbed double-backstitch machine with lower

·

conveyor, needle transport and alternating upper foot conveyor.

A safety coupling prevents the shuttle from being displaced or

·

damaged if the thread jams in the shuttle track.

Large horizontal shuttle (bobbin as classes 767, 291, 8967).

·

Automatic wick lubrication with sight-glasses for the oil level.

·

Integral bobbin winder.

·

The 367 is a sewing machine designed for sewing light to medium-heavy

material. Such material is generally made of textile fibres, but it may also

be leather. It is used in the clothing industry and for domestic and

motor-vehicle upholstery.

This special sewing machine can also be used to produce so-called

technical seams. In this case, however, the operator must assess the

possible dangers which may arise (with which DÜRKOPP ADLER AG

would be happy to assist), since such applications are on the one hand

relatively unusual and, on the other, so varied that no single set of criteria

can cover them all. The outcome of this assessment may require

appropriate safety measures to be taken.

Generally only dry material may be sewn with this machine. The

material may be no thicker than 10 mm when compressed by the

lowered sewing feet. The material may not contain any hard objects,

since if it does the machine may not be operated without an

eye-protection device. No such device is currently available.

The seam is generally produced with textile-fibre sewing thread of gauge

up to 15/3 NeB (cotton), 20/3 Nm (synthetic) or 25/4 Nm (covering yarn).

Before using any other thread the possible dangers arising must be

assessed and appropriate safety measures taken if necessary.

This special sewing machine may be set up and operated only in dry,

well-maintained premises. If the sewing machine is used in premises which

are not dry and well-maintained it may be necessary to take further

precautions (which should be agreed in advance - see EN 60204-31:1999).

As manufacturers of industrial sewing machines we proceed on the

assumption that personnel who w ork on our products will have

received training at least s ufficient to acquaint them with all normal

operations and with any hazards that these may involve.

5

3. Subclasses

367-170010: single-needle flatbed-double-backstitch machine

with lower conveyor, needle transport and

alternating upper foot conveyor.

Needle thickness 100-150.

367-170115: like class 367-170010, but with

electromagnetic thread cutter,

electro-pneumatic bar-tacking and sewing-foot

lift. Needle thickness 100-150.

367-170315: like class 367-170115, but with electro-pneumatic

quick stroke adjustment, 2nd stitch-length

and 2nd thread tension. Pneumatic

residual-thread reduction to approx. 8 mm

after thread trimming.

Needle thickness 100-150.

367-180010: single-needle flatbed-double-backstitch machine

with lower conveyor, needle transport and

alternating upper foot conveyor.

Needle thickness 130-180.

367-180115: like class 367-180010, but with

electromagnetic thread cutter,

electro-pneumatic bar-tacking and sewing-foot

lift. Needle thickness 130-180.

367-180315: like class 367-180115, but with electro-pneumatic

quick stroke adjustment, 2nd stitch-length

and 2nd thread tension. Pneumatic

residual-thread reduction to approx. 8 mm

after thread trimming.

Needle thickness 130-180.

4. Optional equipment

Item no. Optional equipment

9780 000108 WE-8 maintenance unit

For pneumatic optional equipment

9822 510001 Sewing lamp (halogen) with 12V/20W bulb, fits on the upper part

of the machine

0907 487519 Sewing-lamp attachment set for 9822 510001

0798 500088 Sewing-light transformer

For 230V, with mains cable, without switch,

for sewing lamps 9822 510001 and 9822 510129

0797 003031 Pneumatic connection pack

9400 367001 Service set

9880 002001 Knee switch for automatic bartacking (Cl. 367-170115; 367-180115)

6

5. Technical data

Noise Workplace-related emission value in accordance with DIN 45635-48-A-1-KL2

Class 367-170010; -180010 LC = 82 dB (A)

367-170115; -180115

367-170315; -180315 Stitch length: 6,4 mm

Altern. sewing feet stroke.: 1,5 mm

Stitch rate: 2.800 rpm

Material: G1 DIN 23328 4-ply

Class 367-170010; -180010 LC = 82 dB (A)

367-170115; -180115

367-170315; -180315 Stitch length: 6,4 mm

Altern. sewing feet stroke.: 5,6 mm

Stitch rate: 2.800 rpm

Material: 2-ply Skai 1,6 mm 900g/m

2

DIN 53352

Stitch type

Needle system:

Class 367 Subclass

Needle thickness (depending on E no.:) max. [Nm]

Max. sewing-thread thicknesses: [Nm]

Max. sewing-foot stroke: Stitch length range

1-3mm

3-5mm

5-6,5mm 0-6mm

6,5-8mm

*) 9 mm

1-6,5mm

6,5-8mm 6-8mm

*) 9 mm

Max. clearance under sewing feet:

- sewing [mm]

- raised [mm]

double-backstitch

134-35

-170010 -180010

-170115 -180115

-170315 -180315

150 180

15/3 10/3

Max. Stitch rate: [min-1]

*)

-170010 -170115 -170315

-180010 -180115 -180315

2800 3000 3000

2300 2300 2300

2000 2000 2000

1800 1800 1800

- - 1800

2000 2000 2000

1800 1800 1800

- - 1800

10

20

Operating pressure: [bar]

Air consumption per working cycle: ca. [Nl]

Rated voltage:

Dimensions (H x W x D) [mm]

Working height (Factory settings): [mm]

6

0.7

depends on the drive fitted

630 x 220 x 420

790

7

Notes:

8

6. Operation

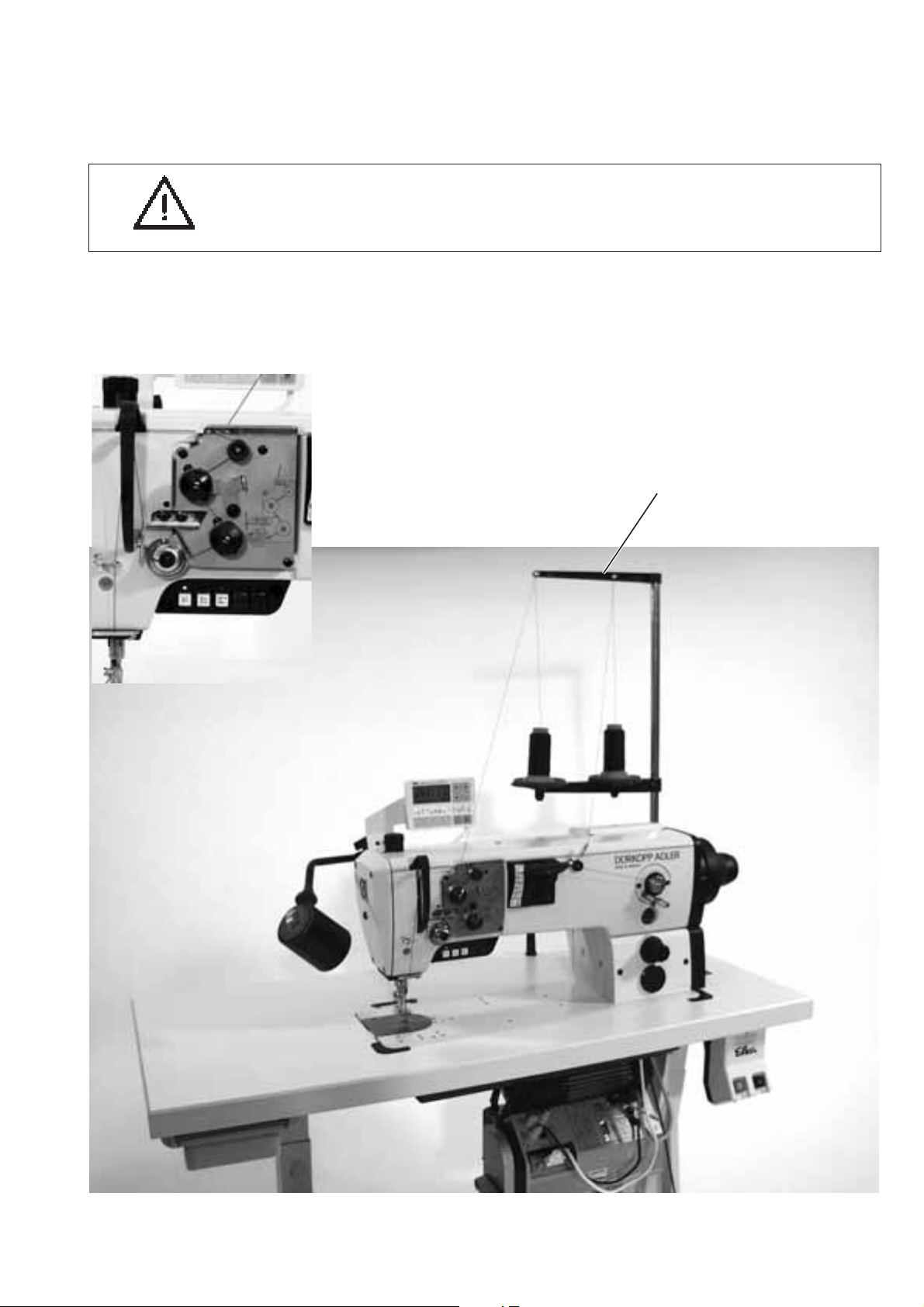

6.1 Threading the needle thread

Caution: danger of injury

Turn off the main switch.

The needle thread may only be threaded with the sewing machine

switched off.

–

–

Place the yarn reels on the reel stand and pass the needle and

looper threads through the unwinding arms.

Unwinding arm 1 must be vertically above the yarn reels.

Thread the needle thread as shown in the following illustration.

1

9

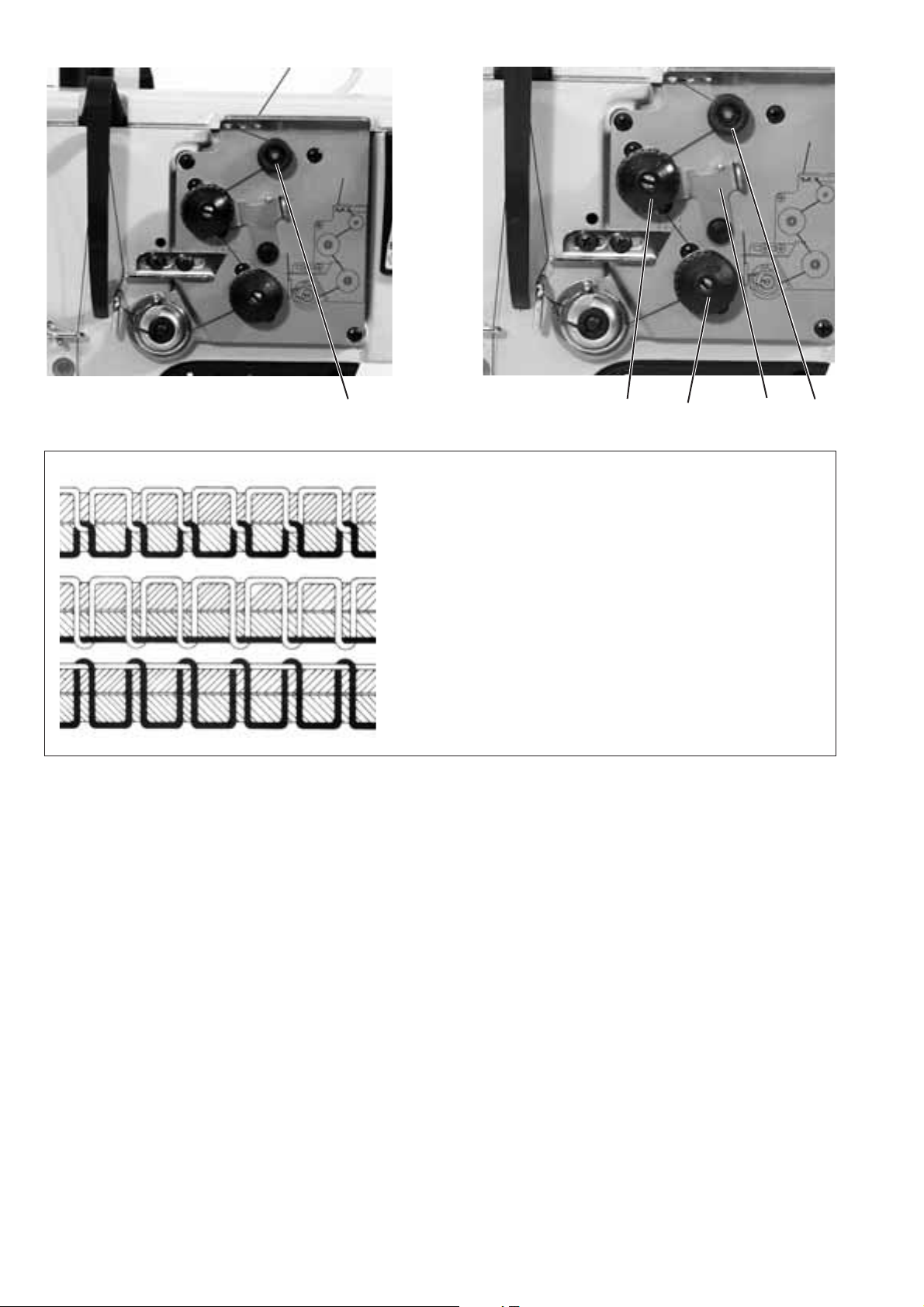

1 43

Fig. A: Correct thread loop in the centre of the

material

Fig. B: Needle-thread tension too low

or

Looper-thread tension too high

Fig. C: Needle-thread tension too high

or

Looper-thread tension too low

5

2

10

6.2 Adjusting the needle-thread tension

Pre-tensioner

When the main tensioner 4 and supplementary tensioner 5 are open

(e.g. when the sewing feet are raised) the needle thread must be

under slight residual tension. This residual tension is produced by the

pre-tensioner 2.

The pre-tensioner 2 simultaneously affects the length of the end of the

severed needle thread (the starting thread for the next seam).

–

Basic setting:

Turn knurled nut 2 until its front is flush with the bolt 1.

–

To shorten the starting thread:

Turn knurled nut 2 clockwise.

–

To lengthen the starting thread:

Turn knurled nut 2 anticlockwise.

Main tensioner

The main tensioner 4 should be set to the minimum possible tension.

The looping of the threads must be in the centre of the material.

With thin material excessive thread tension can cause unwanted

gathering and thread breakage.

–

Adjust the main tensioner 4 so that the stitches are uniform.

To increase tension - turn the knurled nut clockwise

To decrease tension - turn the knurled nut anti-clockwise

Supplementary tensioner

The supplementary tensioner 5 can be switched in to effect a rapid

change in needle-thread tension during operation (e.g. with thickened

seams).

–

Set the supplementary tensioner 5 lower than the main tensioner 4.

–

The supplementary tensioner 5 is switched on and off with the lever 3.

Lever 3 turned to the left = supplementary tensioner is switched

off.

Lever 3 turned to the right = supplementary tensioner is switched

on.

6.3 Opening the needle-thread tensioner

Subclass -170010; -180010

When the sewing feet are raised the main and supplementary

tensioners are also opened automatically.

Subclass -170115; -180115

The needle-thread tensioner is automatically opened when the thread

is severed.

Hint !

(subclass -170115; -180115 only)

The time when the thread-tensioner is opened can be set with

parameters F-191 and F-192 (technician level).

11

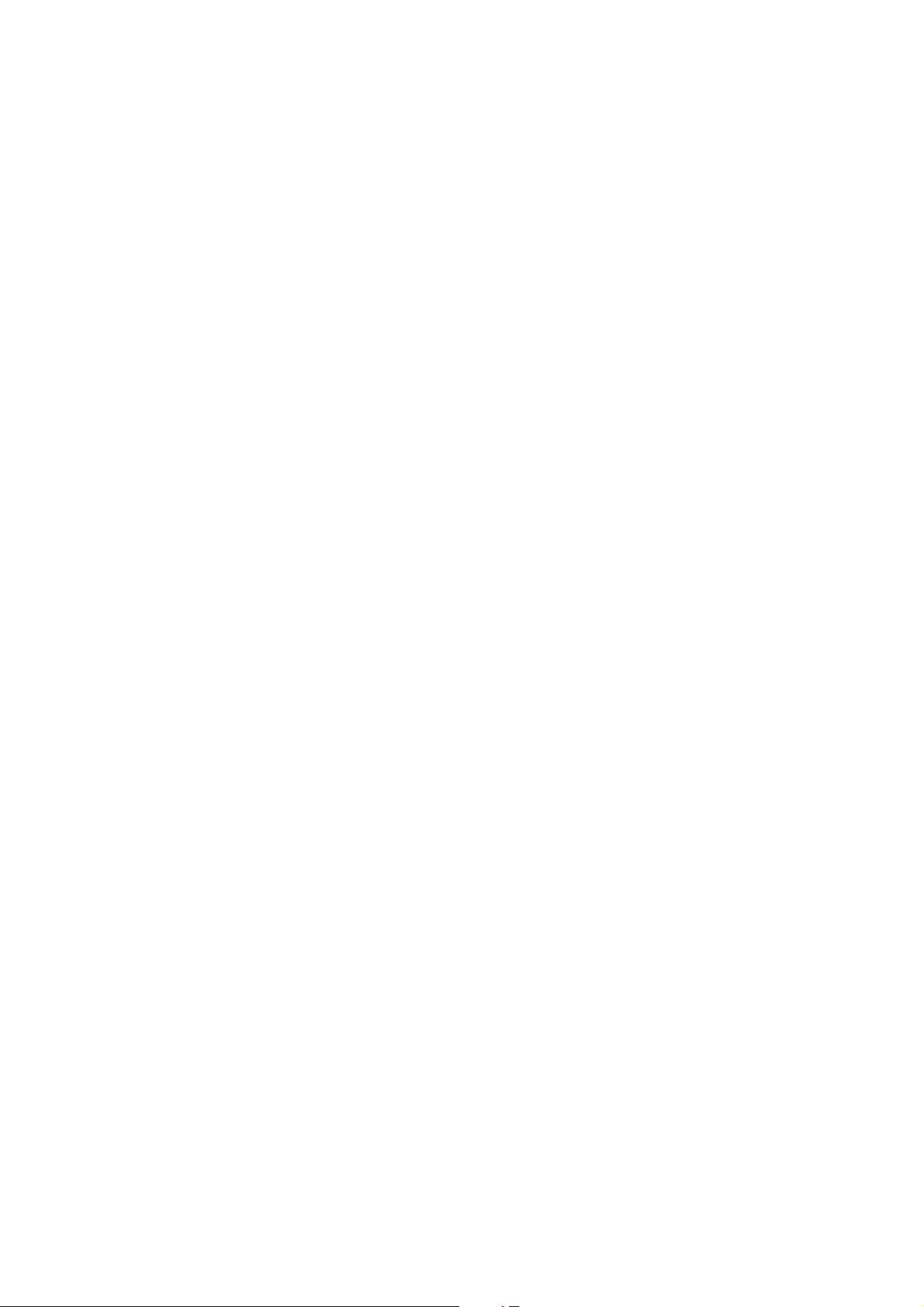

6.4 Adjusting the thread regulator

4

Caution: danger of injury

Turn off the main switch.

The thread regulator may only be adjusted with the sewing machine

switched off.

The thread regulator 3 controls the quantity of needle thread required

for stitch formation.

The thread regulator must be precisely adjusted for an optimum result.

The thread-regulator setting depends on the following factors:

–

Stitch length

–

Material thickness

–

Characteristics of the sewing yarn in use.

At the correct setting the needle-thread loop must slide at low tension

over the thickest point of the s huttle.

–

Undo screws 1 and 2.

–

Adjust the thread regulator 3.

–

Tighten screws 1 and 2.

Adjustment hint:

If the maximum quantity of thread is required the thread-tensioning

spring 4 must be pulled upwards about 0.5 mm from its lower limit

position. This is the case when the needle-thread loop passes the

maximum shuttle diameter.

1

23

12

Adjusting the thread regulator

–

Undo screws 1 and 2.

–

Move the thread regulator 3:

to the left for more thread,

to the left for less thread.

–

Tighten screws 1 and 2.

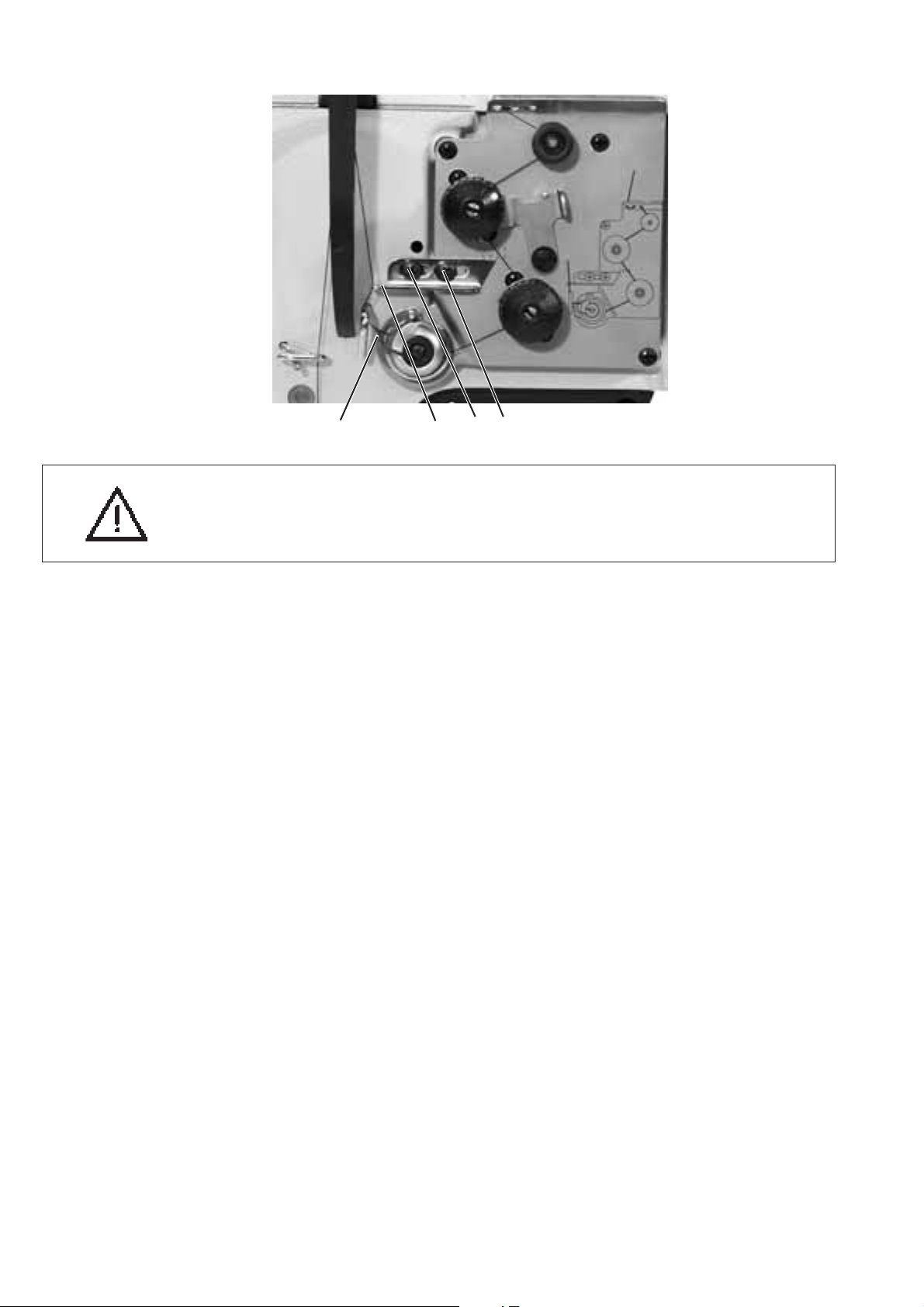

6.5 Winding on the looper thread

4321

–

Pull the thread through the guide 3 and the tensioner 4.

–

Place the thread behind the blade 5 and sever it.

–

Fit the bobbin 1 onto the bobbin winder.

Hint

There is no need to wind the thread onto the bobbin by hand.

–

Press the bobbin-winder lever 2 into the bobbin.

–

Sewing

The bobbin-winder lever terminates the process as soon as the

bobbin is full.

The bobbin winder always stops in such a position that the blade 5

is in the insertion position (see right-hand illustration).

–

Remove the full bobbin 1, place the thread behind the blade 5 and

sever it.

–

Fit empty bobbin onto the bobbin winder for the next winding

process and press the bobbin-winder lever 2 into the bobbin.

CAUTION !

If the thread is not to be wound on during sewing, it is essential

for the sewing foot to be locked in the raised position and the

sewing-foot stroke set to the smallest value.

5

13

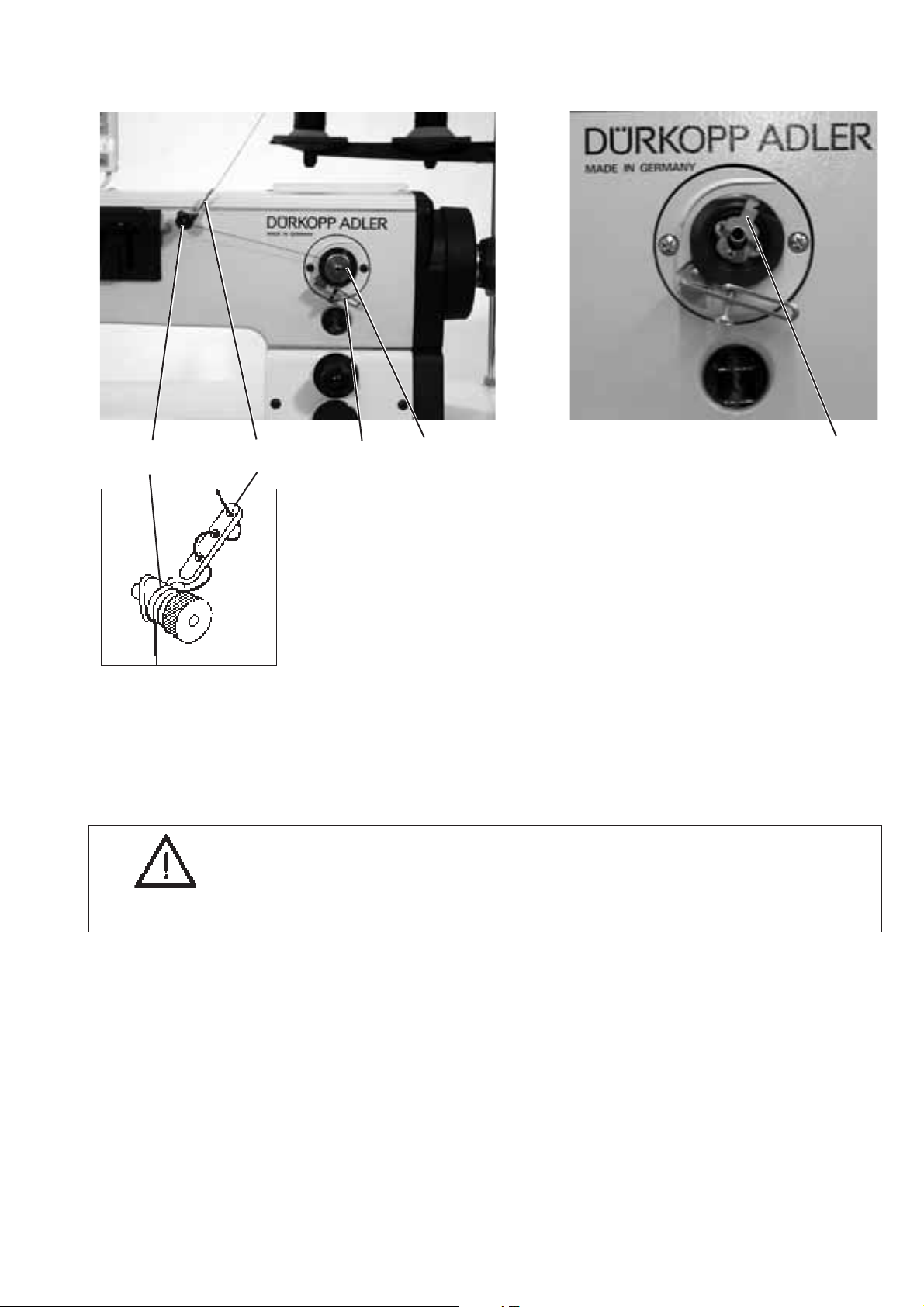

6.6 Changing the looper-thread bobbin

5

1

6

4

3

2

1

Caution: danger of injury

Turn off the main switch.

The looper-thread bobbin may only be changed with the machine

switched off.

Removing the empty bobbin

–

Raise the needle bar.

–

Lift the bobbin-housing flap 1.

–

Extract the upper part of the bobbin housing 2 together with the

bobbin 6.

–

Remove the empty bobbin from the upper part of the bobbin

housing 2.

Inserting the full bobbin

–

Insert the full bobbin in the upper part of the bobbin housing 2.

Check the bobbin’s direction of rotation.

This is correct if the bobbin rotates in the opposite direction to that

in which the thread is drawn off.

–

Pull the looper thread through the slit 4, under the tension spring 3

and into the hole 5.

–

Pull about 5 cm of looper thread out of the bobbin housing 2.

When the thread is drawn off the bobbin must turn in the direction

of the arrow.

–

Replace the bobbin housing 2.

–

Close the bobbin-housing flap 1.

14

Danger of breakage !

Press firmly on the bobbin housing and make sure it is properly locked

into position.

6.7 Pre-setting the looper-thread tension

1

2

4

3

Caution: danger of injury

Turn off the main switch.

The looper-thread tension may only be adjusted with the machine

switched off.

Braking spring

The braking spring 1 prevents the bobbin from running on when the

machine halts and when the looper thread is severed and cannot be

adjusted!

Setting the tension spring

–

When the bobbin is full the top of the bobbin housing 2 should

gradually descend under its own weight (see right-hand

illustration).

–

Adjust the tension spring 4 with the regulating screw 3 until the

required tension is reached.

15

6.8 Changing the needle

1

2

3

Caution: danger of injury

Turn off the main switch.

The needle may only be c hanged with the sewing machine switched off.

–

Undo screw 2.

–

Push the new needle as far as it will go into the hole in the needle

bar 1.

CAUTION !

The throat 3 of the needle must face towards the shuttle tip.

–

Tighten screw 2.

CAUTION !

After changing to a needle of a different thickness the distance

between the shuttle and the needle must be corrected (see servicing

instructions).

Failure to carry out this adjustment may lead to the following errors:

–

Changing to a thinner needle:

- faulty stitches

- damage to thread

–

Changing to a thicker needle:

- damage to the shuttle tip and needle

16

6.9 Lifting the sewing foot

1

2

Subclass -170010; -180010

The sewing foot can be raised mechanically by operating the knee

lever 1.

Subclass -170115; -180115

The sewing foot can be raised electro-pneumatically by operating the

foot pedal 2 or the knee lever 1.

Raising the sewing foot mechanically (knee lever)

–

To adjust the position of the material (e.g. for corrective purposes),

push the knee lever 1 to the right or press the pedal 2 half-way

back.

The sewing foot stays in the up position as long as pressure is

maintained on the knee lever 1.

Raising the sewing foot electro-pneumatically (pedal)

–

Press the pedal 2 half-way back.

The sewing feet are raised with the machine at a halt.

–

Press the pedal 2 all the way back.

The thread is severed and the sewing foot raised.

17

6.10 Locking the sewing feet in the up position

1

Once they have been mechanically or pneumatically raised the sewing

feet can be locked in the up position with button 1 (e.g. to wind on the

looper thread).

–

With the machine at a standstill press the knee lever to the right or

push the pedal half-way back.

The sewing feet are r aised.

–

Press button 1 and release the knee lever or pedal.

The raised sewing feet are locked in the up position.

–

Operate the knee lever or push the pedal half-way back once

again.

The sewing feet are no longer locked.

6.11 Setting the sewing-foot pressure

The required sewing-foot pressure is set with the knurled screw 2.

CAUTION !

The material must not “swim”.

Do not set a higher pressure than is necessary.

2

18

–

To increase the sewing-foot pressure = turn screw 2 clockwise.

–

To decrease the sewing-foot pressure = turn screw 2 anti-clockwise.

6.12 Setting the sewing-foot stroke

5

CAUTION !

Subclass -170010; -180010 has no automatic speed restriction.

It is essential to r educe the speed when working with a large

sewing-foot stroke (see the plaque on the sewing-foot-stroke lever).

Excessive speed makes sewing noticeably noisy and causes damage

to the machine.

The required sewing-foot-stroke height is adjusted with the

sewing-foot-stroke lever 5.

If you have to s ew with a s ewing foot stroke larger than 5 mm, the

slide 6 must be shifted to the right.

With the slide 6 actuated, sewn may only be done with reduced

speed.

The knurled nuts 3 and 4 integral to the sewing-foot-stroke lever can

be used to set stop screws for the minimum and maximum sewing-foot

stroke.

–

Sewing-foot-stroke lever fully up = minimum sewing-foot-stroke

–

Sewing-foot-stroke lever fully down = maximum sewing-foot-stroke

436

height.

height.

19

6.13 Setting the stitch length

321

Subclass -170010; -180010

The required forwards-stitch length is set with the knurled nut 1 in the

manual stitch-setting lever 2.

The required backwards-stitch length is set with the knurled nut 3 in

the manual stitch-setting lever 2.

Changing stitch length during sewing:

The stitch length can be infinitely varied during sewing with the manual

stitch-setting lever 2, within the limits of the stitch lengths set for

forwards and backwards sewing.

–

Fully raise the manual stitch-setting lever

to sew forwards with the stitch length set.

–

Fully lower the manual stitch-setting lever

to sew backwards with the stitch length set.

Subclass -170115; -180115

4

20

The required stitch length is set with adjustment wheel 4.

It has the same value for both forward and backward sewing.

Changing the stitch length while sewing:

The stitch length can be infinitely varied during sewing with the

adjustment wheel 4.

–

Turn the adjustment wheel fully to the right for minimum stitch

length.

–

Turn the adjustment wheel fully to the left for maximum stitch

length.

6.14 Machine-arm keypad (subclass -170115; -170315; 180115; 180315*))

LED Key Function

2

Position the needle in the up or down position.

The function of key 2 can be determined with the F-140 parameter.

1 = needle up, 2 = needle up/down, 3 = single stitch

4 = single stitch with 2nd stitch length / short stitch

5 = needle up if out of position 2.

The factory setting is 1 = needle up.

6789*)10

123 4*)5

*)

*)

10

1

Manual backwards sewing.

The machine sews backwards while key 1 is held down.

3

Trigger or suppress starting or ending bar tack.

If starting or ending bar tacks are generally switched on, pressing this key

switches the next one off.

If starting or ending bar tacks are generally switched off, pressing this key

switches the next one on.

*)

4

*)

5

6

7

8

*)

9

2nd Stitch length

2nd Thread length

LED display “mains on”

LED display: no function

LED display for key 3

LED display on = 1st (upper) Stitch length active

LED display off = 2nd (lower) Stitch length active

*)

LED display on = 2nd Thread tension active

LED display off = 2nd Thread tension off

21

7. EFKA DC1600/DA82GA direct-current positioning actuator

7.1 General

Operation

The DC1600/DA82GA sewing drive must be commissioned and

operated with the V810 or V820 operating panel.

Operating instructions

These operating instructions give the key functions and the meaning of

the operating-panel symbols, and describe how operator-level

parameter values are changed by the operator.

For a detailed description of the control please consult the “EFKA

DA82GA” operating manual.

Functions of the DA82GA sewing-drive control

The functions of the DA82GA sewing-drive control are determined by

the program and the parameter settings. When parameter values are

correct the c ontrol is properly set for the relevant class and subclass.

Actuator parameter values are pre-set by EFKA prior to delivery.

Certain parameters must be altered for each class and subclass: see

the set-up instructions. All parameters are correctly set on delivery.

Access authorisation for command entry

To prevent the unwanted alteration of pre-set functions there are three

levels of command entry. These are as follows:

-themanufacturer has access to the highest level and all

subordinate levels with a code number. “manufacturer level”

-thetechnician has access to the two lower

levels with a code number. “technician level”

-theoperator has access to the lowest level with no code number.

“operator level”

7.2 V810 operating panel

7.2.1 Operating and display elements on the V810 operating panel

22

7.2.2 Key functions on the V810 operating panel

Functions can be turned on and off by briefly pressing the keys on the

operating panel. The functions are effective on the machine only if the

relevant devices (e.g. magnetic or electro-pneumatic sewing-foot lift)

are present.

Key Function Display

1 Double starting bar tack on

Starting bar tack off

Ssingle starting bar tack on

2 Double ending bar tack on

Ending bar tack off

Single ending bar tack on

3 Auto foot-lift on halt in seam on

Auto foot-lift on halt in seam off

Auto foot-lift after thread cut on

Auto foot-lift after thread cut off

4 Basic needle position = down

Basic needle position = up

A Suppress or trigger bar tack

If the starting or ending bar tack is switched on,

pressing the key switches the next bar tack off.

If the starting or ending bar tack is switched off,

pressing the key switches the next bar tack on.

B Needle up/down

or shift function in programming mode.

Pressing this key executes a needle movement

that can be programmed with parameter 140.

See the parameter list in the set-up instructions.

In programming mode this key has a different

function:

see set-up instructions.

P Programming mode on/off

for description see set-up instructions.

E Switch from parameter number to parameter

value.

Confirm parameter value and switch to next

paramet er.

For description see set-up instructions.

+ Increase the value displayed in programming

mode

- Decrease the value displayed in programming

mode

Right arrow above the key on

Both arrows off

Left arrow above the key on

Right arrow above the key on

Both arrows off

Left arrow above the key on

Left arrow above the key on

Left arrow above the key off

Right arrow above the key on

Right arrow above the key off

Left arrow above the key on

Right arrow above the key on

No display

No display

Parameter number/standard display

Parameter number/parameter value

Displayed value is increased

Displayed value is decreased

7.2.3 Meaning of symbols on the V810 operating panel

Symbol Function Display

C Automatic rotation speed active

Symbol on

Only seam sectors processed automatically.

D Light barrier switched on

E Sewing drive switched on

F Rotation-speed limit active

G Bobbin-thread monitor switched on

Symbol on

Symbol on

Symbol on

Symbol flashes when bobbin is running

out

23

7.2.4 Changing operator-level parameter values

The operator-level parameters are in the parameter list (see

section 7.4).

–

Turn on the main switch.

–

Press the “P” key. The first operator-level parameter F-000 is

displayed.

–

Press the “+”or“-” keys to move to the next or preceding

paramet er.

–

Press the “E” key. The value of the selected parameter is

displayed.

–

The parameter value can be changed with the “+” and “-”keys.

–

Press the “E” key to save the change and display the next

paramet er,

or press the “P” key twice to save the change and leave

programming level.

CAUTION:

The changed parameter values are not saved unless a complete

seam is sewn a fter leaving programming level, i.e. the pedal is

pushed forw ards and then all the way back. If the drive is

switched off straight after leaving programming level, the changes

are lost.

7.2.5 Reducing the maximum rotation speed

The maximum speed can be reduced to adapt it to particular

applications.

The current maximum speed is shown in the display after each seam

has been completed. This value can now be directly changed with the

“+” and “-” keys. The adjustment range lies between the values of

parameters F-111 (maximum value) and

F-121 (minimum value).

Caution:

Reducing the maximum rotation speed also reduces the rpm for

starting and ending bar tacks and for counted seam sections

executed automatically.

7.2.6 Entering the technician-level code number:

(see set-up instructions)

24

7.3 V820 operating panel

7.3.1 Operating and display elements on the V820 operating panel

7.3.2 Key functions on the V820 operating panel

Functions can be turned on and off by briefly pressing the keys on the

operating panel. The functions are effective on the machine only if the

relevant devices (e.g. magnetic or electropneumatic sewing-foot lift)

are present.

Key Function Display

1 Double starting bar tack on

Starting bar tack off

Single starting bar tack on

2 Stitch count, backwards seam

Stitch count off

Stitch count, forwards seam

3 Light-barrier function “light - dark”

= change from: “no material present” to

“material present”.

Light barrier off

Light-barrier function “dark - light”

= change from: “material present” to “no

material present”.

4 Double ending bar tack on

Ending bar tack off

Single ending bar tack on

5 Thread cutter on

Thread retractor on

Thread cutter and thread retractor on

Thread cutter and thread retractor off

6 Auto. foot lift on halt in seam on

Auto. foot lift on halt in seam off

Auto. foot lift after thread cut on

Auto. foot lift after thread cut off

7 Basic needle position = down

Basic needle position = up

8 Residual-thread monitor on

The function of the r esidual-thread monitor can

be altered with parameter 195

(see parameter list in the set-up instructions).

Right arrow above the key on

Bboth arrows off

Left arrow above the key on

Right arrow above the key on

Both arrows off

Left arrow above the key on

Right arrow above the key on

Both arrows off

Left arrow above the key on

Right arrow above the key on

Both arrows off

Right arrow above the key on

Left arrow above the key on

Right arrow above the key on

Both arrows on

Both arrows off

Left arrow above the key on

Left arrow above the key off

Right arrow above the key on

Right arrow above the key off

Left arrow above the key on

Right arrow above the key on

xxxx - - II--

25

Key Function Display

9

Function key

The function of the k ey can be altered with

parameter F-008 (see parameter list in section

1.4)

1 = Softs tar t ON /O FF

2 = ornamental-stitch bar tack ON/OFF

3 = stroke adjustment

Function of the knee-switch or key:

“press and release” = ON / “press and hold” =

OFF

4 = needle cooling ON/OFF

5 = handwheel reverse ON/OFF

0 Tteachinor

Sew stored sewing program

see programming instructions in the EFKA

DA82GA 3301 operating manual

A Suppress or trigger bar tacks

If the starting or ending bar tack is switched on,

pressing the key switches the next bar tack off.

If the starting or ending bar tack is switched off,

pressing the key switches the next bar tack on.

B Needle up/down

or shift function in programming mode.

Pressing this key executes a needle movement

that can be programmed with parameter 140.

See the parameter list in the set-up

instructions.

In programming mode this key has a different

function:

see set-up instructions.

P Programming mode on/off

for description see set-up instructions.

E Switch from parameter number to parameter

value.

Confirm parameter value and switch to next

paramet er.

For description see set-up instructions.

+ Increase the value displayed in programming

mode

- Decrease the value displayed in programming

mode

SSt ON*/OFF < - > SSc xxx

SrS ON*/OFF

hPr ON*/OFF

nh ON*/OFF

rd ON*/OFF

* when ON the left arrow above

the key is switched on.

Program number

Seam-section number

Seam-section stitch number

Number of stitches after light-barrier

detection

No display

No display

Parameter number/standard display

Parameter number/standard display

Displayed value is increased

Displayed value is decreased

26

7.3.3 Meaning of symbols on the V820 operating panel

Symbol Function Display

C Abbreviation C for the code number

D Abbreviation F for the parameter number

E Program number in teach-in mode

F Seam-section number in teach-in mode

G Cut-out active

H Entry via keys blocked

I Error message

J Stitch-rate entry in teach-in mode

K Bobbin-thread monitor on

L Speed limit effective

M Right needle switched off

N Equalising stitches for light barrier

O Machine running

P Automatic rpm effective

Q Left needle switched off

Symbol on when a code is displayed, e.g.

C 1907

Symbol on when a parameter number is

displayed e.g. F - 111

Symbol on when a sewing-program

number is displayed

Symbol on when the seam-section

number of a sewing program is displayed

Symbol flashes on active cut-out.

Symbol on when entry via keys is

blocked.

Symbol on.

(See section 7.5 for fault list).

Symbol on when the number of stitches

in a seam section is displayed.

Symbol flashes when bobbin is running

out

Symbol on when one of the possible rpm

limits is effective.

Symbol on when the right needle bar is

switched off.

Only on machines with automatic

needle-bar switch-off.

Symbol on

Symbol on

Symbol on when a seam section in a

sewing program is being automatically

executed at constant rpm.

Symbol on when the left needle bar is

switched off.

Only on machines with automatic

needle-bar switch-off.

7.3.4 Changing operator-level parameter values

–

Turn on the main switch.

–

First press the “P” key, then the “E” key. The first operator-level

parameter value (Arv 002) is displayed.

–

Press the “+”or“-” key to change the value.

–

Press the “E” key. The next parameter value is displayed

or press the “P” key to save the change and leave programming

level.

27

7.3.5 Reducing the maximum rotation speed

The maximum speed can be reduced to adapt it to particular

applications.

After each completed seam the current value of the maximum speed is

shown in the display. This value can now be directly changed with the

“+” and “-” keys. The adjustment range lies between the values of

parameters F-111 (maximum value) and

F-121 (minimum value).

Caution !

Reducing the maximum rotation speed also reduces the rpm for

starting and ending bar tacks and for counted seam sections

executed automatically.

7.3.6 Fast information display and settings entry (HIT)

When functions are switched on with keys 1, 2, 3, 4 and 9 the

associated values are displayed to the operator for about 3 seconds.

During this period the value can be changed immediately with the “+”

or “-” keys.

CAUTION !

The changed parameter values are not saved unless a complete

seam is sewn a fter leaving programming level, i.e. the pedal is

pushed forwa rds and then all the w ay back.

If the drive is sw itched off straight after leaving programming

level, the changes are lost.

7.3.7 Entering the technician-level code number

See set-up instructions.

7.3.8 Seam programming with the V820 operating panel

A maximum of 8 programs with a total of up to 40 seam sections may

be saved.

The starting-bar-tack, ending-bar-tack, stitch-count, thread-cut and

foot-lift functions can be individually assigned to each seam.

For a description see the “EFKA DA82GA” operating manual.

28

7.4 Operator-level parameter list for EFKA controls DA82GA and 6F82FA-

The following pre-set values apply to class: 367

Parameter Name / Function Adj. range Pre-set

No. Abbr. Name / Function min max 100R

000 Arv starting-bar-tack stitches forwards

001 Arr starting-bar-tack stitches backwards

002 Err ending-bar-tack stitches backwards

003 Erv ending-bar-tack stitches forwards

004 LS number of light-barrier equalisation stitches

(large stitch length)

005 LSF number of light-barrier filter stitches for knits

006 LSn number of seams terminated with the light

barrier

007 Stc number of stitches in the

automatically-produced seam section

008 F assigning a function to key 9

1 = Softstart ON /O FF

2 = ornamental-stitch bar tack ON/OFF

3 = stroke adjustment

press and release = ON/ press and hold = OFF

4 = needle cooling ON/OFF

5 = handwheel reverse ON/OFF **

009 LS light barrier ON/OFF

010 cLS number of light-barrier equalising stitches

(small stitch length)

013 FA thread cutter ON/OFF

014 FW thread retractor ON/OFF

015 StS stitch count ON/OFF

080 Sav number of stitches, starting decorative-stitch

bar tack forwards

081 SAr number of stitches, starting decorative-stitch

bar tack backwards

082 SEr number of stitches, ending decorative-stitch

bar tack backwards

083 SEv number of stitches, ending decorative-stitch

bar tack forwards

085** cFW residual-thread-monitor stitch count

F-195 = 1-3

F-195 = 4

0 254 2

0 254 4

0 254 3

0 254 3

0 254 4

0 254 0

0151

0 254 10

152

OFF ON OFF

0 254 8

OFF ON ON

OFF ON ON

OFF ON ON

0 254 3

0 254 3

0 254 3

0 254 3

0 2540 0

0 9990 0

29

7.5 Status and error messages on the V810 and V820 operating panels

General information

V810 V820 Meaning

InF A1 InFo A1 The pedal is not in its zero position when the

sewing drive is switched on

StoP symbol “G”

flashes “cut-out”

flashes

InF A3 InFo A3 Reference position not stored.

InF A5 InFo A5 No valid Autoselect resistance

Programming error message

V810 V820 meaning

If InFo F1

jumps back

to 1st digit

Hardware and software error messages

V810 V820 meaning

InF E1 InFo E1

The cut-out is active

For programming see set-up instructions.

detected. For information see set-up

instructions

Incorrect code or parameter number

entered

After main sw itch on:

proximity or commutation switch

defective or connection lead wrongly connected.

During or after a sewing run:

proximity switch defective.

InF E2 InFo E2 Mains voltage too low or the time between

main switch OFF and main switch ON was

too short.

InF E3 InFo E3 Machine is blocked or not reaching the

required rotation speed

InF E4 InFo E4 Control disrupted by defective earthing

or defective plug connections

(contact error).

InF H1 InFo H1 Commutation-switch lead is defective or

the power electronics for the generation of the

rotating field is faulty.

InF H2 InFo H2 Processor faulty.

30

8. EFKA VD552KV/6F82FA coupling-positioning actuator

8.1 General

Operation

The VD552KV/6F82FA sewing-drive control contains an integral

“operating panel” with 5 k eys, 8 LEDs and a three-digit LED display. All

required adjustments to the sewing-drive control can be carried out

with this operating panel. The V810 or V820 operating panel can also

be connected to the control. In this case the integral operating

elements are ineffective.

Operating instructions

The functions of the operating elements of the 6F82FA sewing-drive

control are described below, together with the procedure for the

alteration by the operator of operator-level parameter values.

For a detailed description of the 6F82FA control please see the “EFKA

6F82FA” operating manual:

V810 operating panel - see section 7.2

V820 operating panel - see section 7.3.

Functions of the 6F82FA sewing-drive control

The functions of the 6F82FA sewing-drive control are determined by

the program and the parameter settings. When parameter values are

correct the c ontrol is properly set for the relevant class and subclass.

Actuator parameter values are pre-set by EFKA prior to delivery.

Certain parameters must be altered for each class and subclass: see

the set-up instructions. All parameters are correctly set on delivery.

Access authorisation for command entry

To prevent the unwanted alteration of pre-set functions there are three

levels of command entry. These are as follows:

-themanufacturer has access to the highest level and all

subordinate levels with a code number. “manufacturer level”

-thetechnician has access to the two lower

levels with a code number. “technician level”

-theoperator has access to the lowest level with no code number.

“operator level”

31

8.2 Operation of the 6F82FA sewing-drive control

8.2.1 Operating elements in the 6F82FA sewing-drive control

8.2.2 Key functions in the 6F82FA sewing-drive control

Functions can be turned on and off by briefly pressing the keys on the

operating panel. The functions are effective on the machine only if the

relevant devices (e.g. magnetic or electro-pneumatic sewing-foot lift)

are present.

Key Function Display

S1 programming mode on/off

S2 double starting bar tack

starting bar tack off

single starting bar tack

S3 double ending bar tack

ending bar tack off

single ending bar tack

S4 auto. foot lift on halt in seam

no auto. foot lift on halt in seam

auto. foot lift after thread cut

no auto. foot lift after thread cut

S5 basic needle position = down

basic needle position = up

LED 2 on, LED 1 off

both LEDs off

LED 1 on, LED 2 off

LED 4 on, LED 3 off

both LEDs off

LED 3 on, LED 4 off

LED 5 on

LED 5 off

LED 6 on

LED 6 off

LED 7 on, LED 8 off

LED 8 on, LED 7 off

8.2.3 Changing operator-level parameter values

The operator-level parameters are in the parameter list (see section

7.4).

–

Turn on the main switch.

–

Press the “P” key. The first operator-level parameter 000 is

displayed.

–

Press the “+”or“-” keys to move to the next or preceding

paramet er.

–

Press the “E” key. The value of the selected parameter is

displayed.

–

The parameter value can be changed with the “+” and “-”keys.

–

Press the “E” key to save the change and display the next

paramet er,

or press the “P” key twice to save the change and leave

programming level.

32

CAUTION !

The changed parameter values are not saved unless a complete

seam is sewn a fter leaving programming level, i.e. the pedal is

pushed forw ards and then all the way back. If the drive is

switched off straight after leaving programming level, the changes

are lost.

8.2.4 Reducing the maximum rotation speed

The maximum speed can be reduced to adapt it to particular

applications.

The current maximum speed is constantly shown in the LED display

during sewing. The display shows a 3-digit figure that must be

multiplied by 10 to obtain the actual rotation speed. This value can be

changed during sewing or on a mid-seam halt with the “+” and “-”keys.

The adjustment range lies between the values of parameters F-111

(maximum value) and F-121 (minimum value).

8.2.5 Entering the technician-level code number:

See set-up instructions.

8.3 6F82FA control operator-level parameter list

See section 7.4.

8.4 Status and error messages on the V810 and V820 operating panels

See section 7.5.

33

9. Operation

9.1 Subclass 367-170010; -180010

Action Operation / Remarks

Before starting w ork

initial position

position material at start of seam

At the start of seam

starting bar tack and continue sewing

In mid-seam

interrupt

action

Continue

action

- Pedal in neutral position.

Sewing machine at a halt.

Needle up. Sewing foot down.

- Press knee lever.

The sewing foot rises.

- Position material.

- R elease knee lever.

The sewing feet descend onto the material.

- C arefully press pedal forwards.

The machine sews forwards.

- Pull down s titch-setting lever.

The machine sews backwards.

- R elease stitch-setting lever.

The machine sews forwards.

- R elease pedal (neutral position).

The machine halts.

The sewing feet are down.

- Push pedal forwards.

The machine sews at the speed

set by the pedal.

Sew intermediate

bar tack

Removing the material

at seam-end

- Press stitch-setting lever down.

The machine sews backwards.

- R elease stitch-setting lever.

The machine resumes forward sewing.

- R elease pedal (neutral position)

The machine halts.

- Manually rotate the needle to the up position.

- Operate the knee lever.

The sewing feet lift.

- Pull material forward and sever threads.

34

9.2 Subclass 367-170115; -170315; -180115; -180315

The description of operation is based on the following preconditions:

–

The following functions are set on the operating panel:

Starting bar tack: ON

Ending bar tack: ON

Sewing-foot position before

and after

cutting DOWN

needle position before

cutting: DOWN (position 1)

–

Main switch on.

–

The last action was concluded with an ending bar tack and

thread-cutting.

4

Operating and function sequence:

1234*)5

Action Operation / Remarks

Before starting w ork

Initial position

Position material at start of seam

At the start of seam

Starting bar tack and continue sewing

Do not sew start in g bar tac k

- Pedal in neutral position.

Sewing machine at a halt.

Needle up. Sewing foot down.

- Push pedal back.

The sewing feet rise.

- Position material.

- R elease pedal.

The sewing feet descend onto the material.

- Push pedal forwards and hold it there.

The starting bar tack is sewn.

The machine then continues sewing at the

speed set by the pedal.

- Press key 3 (bar-tack suppression).

- Push pedal forwards.

- The machine s ews at the speed

set by the pedal.

*)

35

4

Action Operation / Remarks

In mid-seam

1234*)5

*)

Interrupt

action

Continue

action

(after pedal is released)

Sew

intermediate bar tack

At the seam-end

Remove the material

Do not sew an ending bar tack

- R elease pedal (neutral position).

The machine halts in position 1 (needle down).

The sewing feet are down.

- Push pedal forwards.

The machine sews at the speed set by the

pedal.

The starting bar tack is not sewn.

- Press key 2 and hold the pedal down.

The machine sews backwards as long as key 2 is held down.

The speed is set by the pedal.

- Push pedal fully back and hold it there.

The ending bar tack is sewn.

The thread is severed.

The machine halts in position 2.

The sewing feet are r aised.

- Press key 3 (bar-tack suppression).

Push pedal fully back.

The ending bar tack is not sewn.

The thread is severed.

The machine halts in position 2.

Subclass 367-170315; -180315

36

The position of the sewing foot depends on key 4 on the

operating panel:

a) On: - sewing foot raised.

b) Off: - sewing foot down.

- The 2nd Stitch length key 4*)and

- The 2nd Thread tension key 5 *) can be at any time

switched on or off.

10. Maintenance

10.1 Cleaning and testing

Caution: danger of injury

Turn off the main switch.

Maintenance may only be carried out with the machine switched off.

Maintenance work must be carried out no less frequently than at the

intervals given in the tables (see “operating hours” column).

Maintenance intervals may need to be shorter when processing

heavy-shedding materials.

A clean machine is a trouble-free machine.

5

43 2 1

Maintenance work Explanation Operating

to be carried out hours

Upper part of machine

8

- Remove lint, pieces of thread

and other debris

(e.g. with a compressed-air pistol)

Places in special need of cleaning:

- underside of needle plate 4

- feeders

- area around shuttle 2

- bobbin housing 3

CAUTION !

Hold the compressed-air pistol so that the lint is

not blown into the oil collector 1.

- thread cutter

Clean the area under the thread clipper 1

especially thoroughly

(there may be problems with the

thread cutter 5)

- needle area

37

7

6

4

8

2

6

10

1

2

3

Maintenance work Explanation operating

to be carried out hours

Sewing drive

Cleanfangrille7.

(e.g. with a compressed-air pistol)

- Check condition and tension

of V-belt 6

Remove lint and pieces of thread from air-intake

openings.

It must be possible to depress the V-belt by about

10 mm by pressing it with a finger at its mid-point.

8

160

Pneumatic system

- Check water level in pressure

regulator.

- Clean filter cartridge.

- Check the system for leaks.

The water level must not rise to the level of the

filter cartridge 1.

- After screwing in the drain screw 3 blast water

under pressure out of the water separator 2.

Dirt and condensation are separated out by the

filter cartridge 1.

- Disconnect the machine from the

compressed-air supply.

- Unscrew the drain screw 3.

Theremustbenopressureinthe

machine’s pneumatic system.

- Unscrew water separator 2.

- Unscrew filter cartridge 1.

Wash the filter shell and cartridge

with cleaning fluid (not solvent)

and blast c lean.

- Re-assemble the maintenance unit.

40

500

500

38

10.2 Lubrication

1

Caution: danger of injury

Oil can cause skin eruptions.

Avoid protracted contact with the skin.

In the event of contact, thoroughly wash the affected area.

CAUTION:

The handling and disposal of mineral oils is subject to legal regulation.

Deliver used oil to an authorised collection point.

Protect your environment.

Take care not to spill oil.

To lubricate the special sewing machine use only DA-10 lubricating oil

or an equivalent oil of the following specification:

–

Viscosity at 40° C: 10 mm²/s

–

Flashpoint: 150° C

DA-10 is available from DÜRKOPP ADLER AG retail outlets under the

following part numbers:

250-ml container: 9047 000011

1-litre container: 9047 000012

2-litre container: 9047 000013

5-litre container: 9047 000014

23

Maintenance work Explanation Operating

to be carried out hours

Lubricating the upper part of

the machine

Lubricating the shuttle

The upper part of the machine is fitted with a

central oil-wick lubrication system. Except for the

shuttle all lubrication points are supplied from

the oil reservoir 1.

- The oil level must not fall below the“MIN”

mark.

- Top up through the holes in the sight glass to the

“MAX” mark.

- Turn back the upper part of the machine.

- Check oil supply through viewing window 3.

- Fill the oil reservoir through the nipple 2.

- The quantity of oil required to lubricate the

shuttle properly is factory-set.

40

8

39

Notes:

40

Loading...

Loading...