ADC EWH-25, EWS-80 M2, EWS-80 MP2 Installation Instructions

ECOWASH

INSTALLATION MANUAL

EWH-25 / EWH-30 / EWH-40 / EWH-60

EWR-25 / EWR-30 / EWR-40 / EWR-60

EWS-25 / EWS-30 / EWS40 / EWS-60 / EWS-80

M2 and MP2 Models

Part No. 113586 -4

1. INTRODUCTION

Dear customer,

Thank you for the confidence you have placed in our product. We hope it meets your needs.

ADC products embody advanced concepts in engineering, design, and safety. If this product is properly maintained, it will provide many years of safe, efficient, and trouble free operation.

This washer is warranted against defects in manufacturing and workmanship per the warranty sheet included with the washer.

The warranty does not cover damage to glass components, or consumables (seals, bulbs, etc.) nor damage due to the incorrect installation of the appliance, or to inappropriate use, inadequate maintenance or poor repair processes.

This appliance is subject to changes and modifications for its technical progress.

RETAIN THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation manual included with the washer.

The following “FOR YOUR SAFETY” caution must be posted near the washer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence ni d’autres vapeurs ou liquides inflammables à proximité de cet appareil ou de tout autre appareil.

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to make changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to change or discontinue models. The illustrations included in this manual may not depict your particular washer exactly.

IMPORTANT

For your convenience, log the following information:

DATE OF PURCHASE _____________________________________________ MODEL NO. _______________

RESELLER’S NAME _________________________________________________________________________

Serial Number(s) ____________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Replacement parts can be obtained from your reseller or the ADC factory. When ordering replacement parts from the factory, you can FAX your order to ADC at (508) 678-9447 or telephone your order directly to the ADC Parts Department at (508) 678-9000. Please specify the washer model number and serial number in addition to the description and part number, so that your order is processed accurately and promptly.

2 |

113586 -4 |

2. CONTENTS

1. |

INTRODUCTION ................................................................................................................................................. |

2 |

||

2. |

CONTENTS ......................................................................................................................................................... |

3 |

||

3. |

MAIN SPECIFICATIONS ..................................................................................................................................... |

4 |

||

4. |

MAIN DIMENSIONS ............................................................................................................................................ |

6 |

||

5. |

IMPORTANT INSTRUCTIONS REGARDING SAFETY AND USE ...................................................................... |

8 |

||

6. |

STANDARDS ..................................................................................................................................................... |

10 |

||

7. |

TRANSPORT ..................................................................................................................................................... |

10 |

||

8. |

CHARACTERISTICS OF THE PLACE OF INSTALLATION .............................................................................. |

10 |

||

9. |

HANDLING ........................................................................................................................................................ |

10 |

||

10. INSTALLATION (ALL MODELS) ........................................................................................................................ |

11 |

|||

10.1 |

Water Connection ....................................................................................................................................... |

11 |

||

10.2 |

Steam Connection ....................................................................................................................................... |

11 |

||

10.3 |

Drainage ...................................................................................................................................................... |

11 |

||

10.4 |

Electrical Connection................................................................................................................................... |

12 |

||

10.5 |

Auxiliary Connections .................................................................................................................................. |

14 |

||

10.6 |

Dispenser Inlet Connections ....................................................................................................................... |

14 |

||

11. |

INSTALLATION OF GROUPS H-R-S ................................................................................................................ |

15 |

||

11.1 |

Soft Washer Mounting Dimensions ............................................................................................................. |

15 |

||

11.2 |

Rigid Washer Mounting Dimensions ........................................................................................................... |

16 |

||

11.3 |

Group (H) Washers ..................................................................................................................................... |

17 |

||

11.4 |

Using a Steel Base ...................................................................................................................................... |

18 |

||

11.5 |

Using an Elevated Concrete Pad ................................................................................................................ |

18 |

||

|

11.5.1 |

Using Expansion Bolts .......................................................................................................................... |

19 |

|

|

11.5.2 |

Using J-bolts ......................................................................................................................................... |

19 |

|

12. INSTALLATION OF SELF-SERVICE WASHING MACHINES (GROUP H-R-S) ............................................... |

20 |

|||

12.1 |

Central Pay .................................................................................................................................................. |

20 |

||

12.2 |

Card Reader ................................................................................................................................................ |

20 |

||

12.3 |

Coin ............................................................................................................................................................. |

20 |

||

13. WASHING MACHINE INSTALLATION AND MAINTENANCE........................................................................... |

21 |

|||

113586 -4 |

3 |

3. MAIN SPECIFICATIONS

Ambient conditions

Ambient operating temperature |

°C |

+5 / +41 |

|

°F |

+41 / + 106 |

||

|

|||

|

|

|

|

Storage temperature |

°C |

+1 / +55 |

|

°F |

+34 / +131 |

||

|

|||

|

|

|

|

Maximum relative humidity |

% |

90 |

|

|

|

|

|

Maximum altitude |

m |

1000 |

|

ft |

3280 |

||

|

|||

|

|

|

GROUP H (High spin soft mount washing machines)

MODEL |

|

EWH-25 |

EWH-30 |

EWH-40 |

EWH-60 |

|

|

|

|

|

|

|

|

Drum Volume |

L |

94 |

130 |

181 |

247 |

|

CuFt |

3.3 |

4.6 |

6.4 |

8.7 |

||

|

||||||

Maximum Load |

Kg |

10 |

13 |

18 |

25 |

|

Lb |

25 |

30 |

40 |

60 |

||

|

||||||

Washer Dry Weight |

Kg |

212 |

254 |

348 |

5002 |

|

Lb |

467 |

560 |

767 |

1107 |

||

|

||||||

Motor Power |

kW |

0.75 |

1.1 |

2.2 |

3.0 |

|

Hp |

1 |

1.5 |

3.0 |

4.0 |

||

|

||||||

Drain Diameter |

mm |

76 |

76 |

76 |

76 |

|

Inch |

3 |

3 |

3 |

3 |

||

|

||||||

|

|

|

|

|

|

|

Water Input Diameter |

GHT & |

3/4” |

3/4” |

3/4” |

3/4” |

|

BSPP |

||||||

|

|

|

|

|

||

Optional Steam Input Diameter |

BSPP |

1/2” |

1/2” |

1/2” |

3/4” |

|

|

|

|

|

|

|

|

Optional Steam Consumption |

Kg/h |

7 |

8.5 |

12 |

15 |

|

Lb/h |

15.5 |

17.7 |

26.5 |

33.1 |

||

|

||||||

|

|

|

|

|

|

|

Static Floor Load |

KN |

2.08 |

2.49 |

3.41 |

4.92 |

|

Lb |

467 |

560 |

767 |

1107 |

||

|

||||||

|

|

|

|

|

|

|

Maximum Dynamic Floor Load |

KN |

0.75 |

1.05 |

1.40 |

1.75 |

|

Lb |

169 |

236 |

315 |

393 |

||

|

||||||

Maximum Vertical Load |

KN |

2.83 |

3.54 |

4.81 |

6.67 |

|

Lb |

636 |

796 |

1082 |

1465 |

||

|

||||||

Dynamic Load Frequency |

Hz |

16.67 |

16.67 |

15.83 |

15.00 |

|

|

|

|

|

|

|

|

Maximum G Force |

|

450 |

450 |

450 |

350 |

|

|

|

|

|

|

|

|

Maximum Noise Level |

db |

<70 |

<70 |

<70 |

<70 |

|

|

|

|

|

|

|

4 |

113586 -4 |

GROUP R (Rapid spin rigid mount washing machines)

MODEL |

|

EWR-25 |

EWR-30 |

EWR-40 |

EWR-60 |

|

|

|

|

|

|

|

|

Drum Volume |

L |

100 |

130 |

181 |

247 |

|

CuFt |

3.5 |

4.6 |

6.4 |

8.7 |

||

|

||||||

|

|

|

|

|

|

|

Maximum Load |

Kg |

10 |

13 |

18 |

25 |

|

Lb |

25 |

30 |

40 |

60 |

||

|

||||||

Washer Dry Weight |

Kg |

212 |

241 |

282 |

404 |

|

Lb |

467 |

531 |

622 |

891 |

||

|

||||||

Motor Power |

kW |

0.7 |

1.1 |

1.5 |

2.2 |

|

Hp |

51 |

1.5 |

2.0 |

3.0 |

||

|

||||||

Drain Diameter |

mm |

76 |

76 |

76 |

76 |

|

Inch |

3 |

3 |

3 |

3 |

||

|

||||||

Water Input Diameter |

GHT & |

3/4” |

3/4” |

3/4” |

3/4” |

|

BSPP |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

Optional Steam Input Diameter |

BSPP |

1/2” |

1/2” |

1/2” |

3/4” |

|

|

|

|

|

|

|

|

Optional Steam Consumption |

Kg/h |

7 |

8.5 |

12 |

15 |

|

Lb/h |

15.5 |

17.7 |

26.5 |

33.1 |

||

|

||||||

Static Floor Load |

KN |

2.08 |

2.36 |

2.77 |

3.96 |

|

Lb |

467 |

531 |

622 |

891 |

||

|

||||||

Dynamic Floor Load |

KN |

5.0 |

6.0 |

8.0 |

10.0 |

|

Lb |

1124 |

1349 |

1798 |

2248 |

||

|

||||||

|

|

|

|

|

|

|

Maximum Vertical Load |

KN |

7.08 |

8.36 |

10.77 |

13.96 |

|

Lb |

1592 |

1880 |

2420 |

3139 |

||

|

||||||

Dynamic Load Frequency |

Hz |

12.67 |

12.67 |

12.00 |

11.50 |

|

|

|

|

|

|

|

|

Maximum G Force |

|

200 |

200 |

200 |

200 |

|

|

|

|

|

|

|

|

Maximum Noise Level |

db |

<70 |

<70 |

<70 |

<70 |

|

|

|

|

|

|

|

GROUP S (Standard spin rigid mount washing machines)

|

MODEL |

|

EWS-25 |

EWS-30 |

EWS-40 |

EWS-60 |

EWS-80 |

|

|

|

|

|

|

|

|

|

|

|

Drum Volume |

L |

100 |

130 |

181 |

247 |

350 |

|

|

CuFt |

3.5 |

4.6 |

6.4 |

8.7 |

12.3 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

Maximum Load |

Kg |

10 |

13 |

18 |

25 |

35 |

|

|

Lb |

25 |

30 |

40 |

60 |

80 |

|

|

|

|

|

||||||

|

Washer Dry Weight |

Kg |

2044 |

235 |

268 |

360 |

468 |

|

|

Lb |

50 |

518 |

591 |

794 |

1032 |

|

|

|

|

|

||||||

|

Motor Power |

kW |

0.75 |

1.1 |

1.5 |

2.2 |

3.0 |

|

|

Hp |

1 |

1.5 |

2.0 |

3.0 |

4.0 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

Drain Diameter |

mm |

76 |

76 |

76 |

76 |

76 |

|

|

Inch |

3 |

3 |

3 |

3 |

3 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

Water Input Diameter |

GHT & |

3/4” |

3/4” |

3/4” |

3/4” |

3/4” |

|

|

BSPP |

|

||||||

|

|

|

|

|

|

|

|

|

|

Optional Steam Input Diameter |

BSPP |

1/2” |

1/2” |

1/2” |

3/4” |

3/4” |

|

|

|

|

|

|

|

|

|

|

|

Optional Steam Consumption |

Kg/h |

7 |

8.5 |

12 |

15 |

18 |

|

|

Lb/h |

15.5 |

17.7 |

26.5 |

33.1 |

39.7 |

|

|

|

|

|

||||||

|

Static Floor Load |

KN |

2.00 |

2.31 |

2.63 |

3.53 |

4.59 |

|

|

Lb |

450 |

518 |

591 |

794 |

1032 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

Dynamic Floor Load |

KN |

3.00 |

4.00 |

5.00 |

6.00 |

8.00 |

|

|

Lb |

674 |

899 |

1124 |

1349 |

1798 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

Maximum Vertical Load |

KN |

5.00 |

6.31 |

7.63 |

9.53 |

12.59 |

|

|

Lb |

1124 |

1417 |

1715 |

2143 |

2831 |

|

|

|

|

|

||||||

|

Dynamic Load Frequency |

Hz |

8.93 |

8.93 |

8.42 |

8.02 |

7.58 |

|

|

|

|

|

|

|

|

|

|

|

Maximum G Force |

|

100 |

100 |

100 |

100 |

100 |

|

|

|

|

|

|

|

|

|

|

|

Maximum Noise Level |

db |

<70 |

<70 |

<70 |

<70 |

<70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

113586 -4 |

5 |

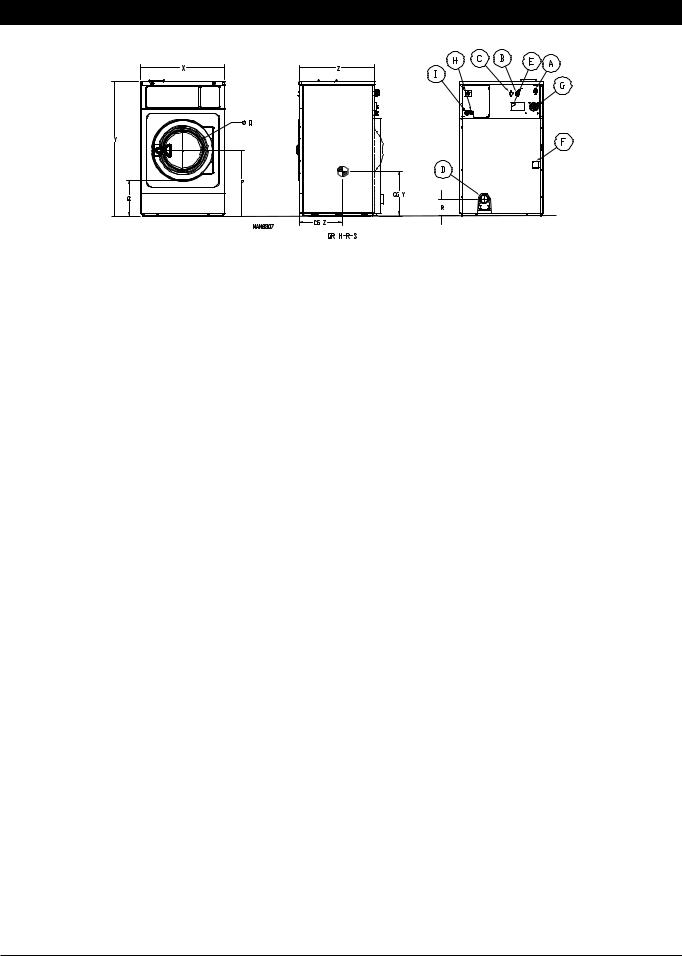

4. MAIN DIMENSIONS

A (Cold Water Inlet) |

29-58 psi (2-4 bar) |

|

|

B (Hot Water Inlet) |

29-58 psi (2-4 bar) |

|

|

C (Aux Water Inlet) |

29-58 psi (2-4 bar) |

|

|

D (Drainage) |

|

|

|

E (Tub Vent) |

|

|

|

F (Steam Inlet-Optional) |

29-58 psi (2-4 bar) |

|

|

G (Dispenser Inlets) |

(7) 10 mm (3/8”) Hose, (1) 1/2” BSPP |

|

|

H (Ext. Dispenser Cable Inlets) |

|

|

|

I (Main Power Cable Inlet) |

|

|

|

GROUP H (High spin soft mount washing machines)

MODEL |

Unit |

EWH-25 |

EWH-30 |

EWH-40 |

EWH-60 |

|

|

|

|

|

|

|

|

M (Drum Diameter) |

mm |

532 |

620 |

700 |

770 |

|

Inch |

21 |

24-3/8 |

27-1/2 |

30-3/8 |

||

|

||||||

N (Drum Depth) |

mm |

425 |

430 |

470 |

530 |

|

Inch |

16-3/4 |

16-7/8 |

18-1/2 |

20-7/8 |

||

|

||||||

|

|

|

|

|

|

|

O (Entrance Diameter) |

mm |

290 |

373 |

373 |

373 |

|

Inch |

11-3/8 |

14-5/8 |

14-5/8 |

14-5/8 |

||

|

||||||

P (Drum Center Height) |

mm |

632 |

689 |

737 |

853 |

|

Inch |

24-7/8 |

27-1/8 |

29 |

33-5/8 |

||

|

||||||

Q (Under Door Height) |

mm |

421 |

432 |

479 |

595 |

|

Inch |

16-5/8 |

17 |

18-7/8 |

23-3/8 |

||

|

||||||

|

|

|

|

|

|

|

R (Drain Height) |

mm |

121 |

126 |

99 |

130 |

|

Inch |

4-3/4 |

5 |

3-7/8 |

5-1/8 |

||

|

||||||

|

|

|

|

|

|

|

X (Cabinet Width) |

mm |

692 |

788 |

883 |

979 |

|

Inch |

27-1/4 |

31 |

34-3/4 |

38-1/2 |

||

|

||||||

Y (Cabinet Height) |

mm |

1162 |

1310 |

1410 |

1553 |

|

Inch |

45-3/4 |

51-5/8 |

55-1/2 |

61-1/8 |

||

|

||||||

Z (Cabinet Depth) |

mm |

791 |

800 |

845 |

973 |

|

Inch |

31-1/8 |

31-1/2 |

33-1/4 |

38-1/4 |

||

|

||||||

|

|

|

|

|

|

|

CG Y (Center of Gravity) |

mm |

424 |

398 |

464 |

773 |

|

Inch |

16-3/4 |

15-5/8 |

18-1/4 |

30-3/8 |

||

|

||||||

|

|

|

|

|

|

|

CG Z (Center of Gravity) |

mm |

577 |

651 |

702 |

503 |

|

Inch |

22-3/4 |

25-5/8 |

27-5/8 |

19-3/4 |

||

|

6 |

113586 -4 |

GROUP R (Rapid spin rigid mount washing machines)

MODEL |

Unit |

EWR-25 |

EWR-30 |

EWR-40 |

EWR-60 |

|

|

|

|

|

|

|

|

M (Drum Diameter) |

mm |

620 |

620 |

700 |

770 |

|

Inch |

24-3/8 |

24-3/8 |

27-1/2 |

30-3/8 |

||

|

||||||

|

|

|

|

|

|

|

N (Drum Depth) |

mm |

330 |

430 |

470 |

530 |

|

Inch |

13 |

16-7/8 |

18-1/2 |

20-7/8 |

||

|

||||||

|

|

|

|

|

|

|

O (Entrance Diameter) |

mm |

373 |

373 |

373 |

373 |

|

Inch |

14-5/8 |

14-5/8 |

14-5/8 |

14-5/8 |

||

|

||||||

P (Drum Center Height) |

mm |

568 |

568 |

653 |

691 |

|

Inch |

22-3/8 |

22-3/8 |

25-3/4 |

27-1/4 |

||

|

||||||

Q (Under Door Height) |

mm |

310 |

310 |

395 |

433 |

|

Inch |

12-1/4 |

12-1/4 |

15-5/8 |

17 |

||

|

||||||

|

|

|

|

|

|

|

R (Drain Height) |

mm |

145 |

144 |

112 |

150 |

|

Inch |

5-3/4 |

5-5/8 |

4-3/8 |

5-7/8 |

||

|

||||||

X (Cabinet Width) |

mm |

719 |

719 |

788 |

884 |

|

Inch |

28-1/4 |

28-1/4 |

31 |

34-3/4 |

||

|

||||||

Y (Cabinet Height) |

mm |

1157 |

1157 |

1307 |

1319 |

|

Inch |

45-5/8 |

45-5/8 |

51-1/2 |

51-7/8 |

||

|

||||||

Z (Cabinet Depth) |

mm |

645 |

791 |

800 |

965 |

|

Inch |

25-3/8 |

31-1/8 |

31-1/2 |

38 |

||

|

||||||

|

|

|

|

|

|

|

CG Y (Center of Gravity) |

mm |

383 |

484 |

479 |

543 |

|

Inch |

15-1/8 |

19 |

18-7/8 |

21-3/8 |

||

|

||||||

|

|

|

|

|

|

|

CG Z (Center of Gravity) |

mm |

511 |

524 |

546 |

591 |

|

Inch |

20-1/8 |

20-5/8 |

21-1/2 |

23-1/4 |

||

|

GROUP S (Standard spin rigid mount washing machines)

MODEL |

Unit |

EWS-25 |

EWS-30 |

EWS-40 |

EWS-60 |

EWS-80 |

|

|

|

|

|

|

|

|

|

M (Drum Diameter) |

mm |

620 |

620 |

700 |

770 |

860 |

|

Inch |

24-3/8 |

24-3/8 |

27-1/2 |

30-3/8 |

33-7/8 |

||

|

|||||||

N (Drum Depth) |

mm |

330 |

430 |

470 |

530 |

602 |

|

Inch |

13 |

16-7/8 |

18-1/2 |

20-7/8 |

23-7/8 |

||

|

|||||||

O (Entrance Diameter) |

mm |

373 |

373 |

373 |

373 |

560 |

|

Inch |

14-5/8 |

14-5/8 |

14-5/8 |

14-5/8 |

22 |

||

|

|||||||

P (Drum Center Height) |

mm |

568 |

568 |

653 |

677 |

733 |

|

Inch |

22-3/8 |

22-3/8 |

25-3/4 |

26-5/8 |

28-7/8 |

||

|

|||||||

|

|

|

|

|

|

|

|

Q (Under Door Height) |

mm |

310 |

310 |

395 |

419 |

373 |

|

Inch |

12-1/4 |

12-1/4 |

15-5/8 |

16-1/2 |

14-5/8 |

||

|

|||||||

R (Drain Height) |

mm |

145 |

144 |

112 |

148 |

149 |

|

Inch |

5-3/4 |

5-5/8 |

4-3/8 |

5-7/8 |

5-7/8 |

||

|

|||||||

X (Cabinet Width) |

mm |

719 |

719 |

788 |

884 |

979 |

|

Inch |

28-1/4 |

28-1/4 |

31 |

34-3/4 |

38-1/2 |

||

|

|||||||

Y (Cabinet Height) |

mm |

1157 |

1157 |

1307 |

1307 |

1411 |

|

Inch |

45-5/8 |

45-5/8 |

51-1/2 |

51-1/2 |

55-1/2 |

||

|

|||||||

|

|

|

|

|

|

|

|

Z (Cabinet Depth) |

mm |

645 |

791 |

800 |

965 |

1057 |

|

Inch |

25-3/8 |

31-1/8 |

31-1/2 |

38 |

41-5/8 |

||

|

|||||||

CG Y (Center of Gravity Height) |

mm |

383 |

484 |

479 |

591 |

635 |

|

Inch |

15-1/8 |

19 |

18-7/8 |

23-1/4 |

25 |

||

|

|||||||

CG Z (Center of Gravity Depth) |

mm |

511 |

524 |

546 |

543 |

682 |

|

Inch |

20-1/8 |

20-5/8 |

21-1/2 |

21-3/8 |

26-7/8 |

||

|

113586 -4 |

7 |

Loading...

Loading...